Aluminum alloy material capable of being molded by high-speed extrusion and preparation method thereof

An aluminum alloy material and extrusion molding technology, applied in the field of aluminum alloy, can solve the problems of high production cost and low production efficiency

Inactive Publication Date: 2010-12-29

深圳华加日铝业有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the brittle phase β-AlFeSi, coarse Mg 2 The presence of Si, excess Mg or Si, etc., causes the surface defects of various extrusion materials that are sensitive to speed to easily occur, such as pits, pockmarks, die marks, etc. Therefore, a lower extrusion speed has to be exchanged for Satisfactory extrusion surface

This makes the production efficiency very low and the production cost of the product is very high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0029] The preparation method of the aluminum alloy of the present invention includes melting and casting and high temperature homogenization treatment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

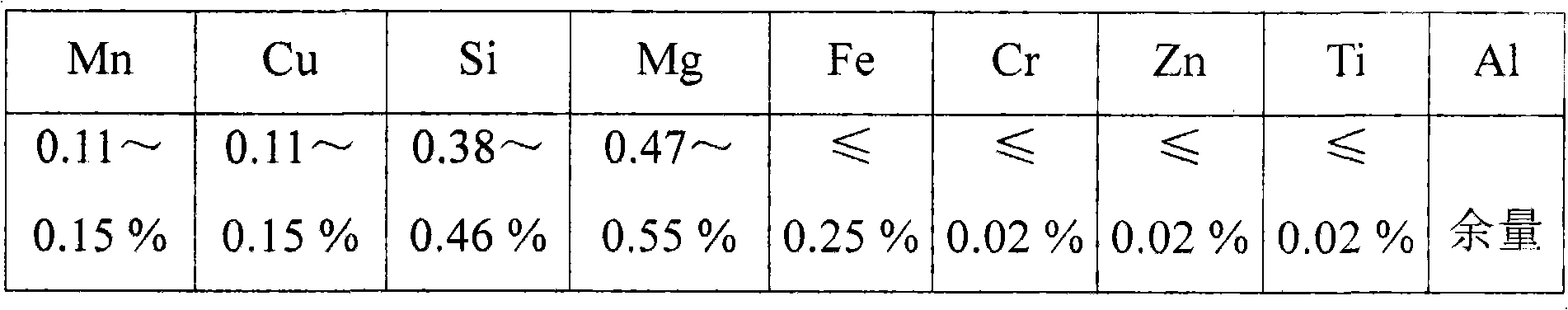

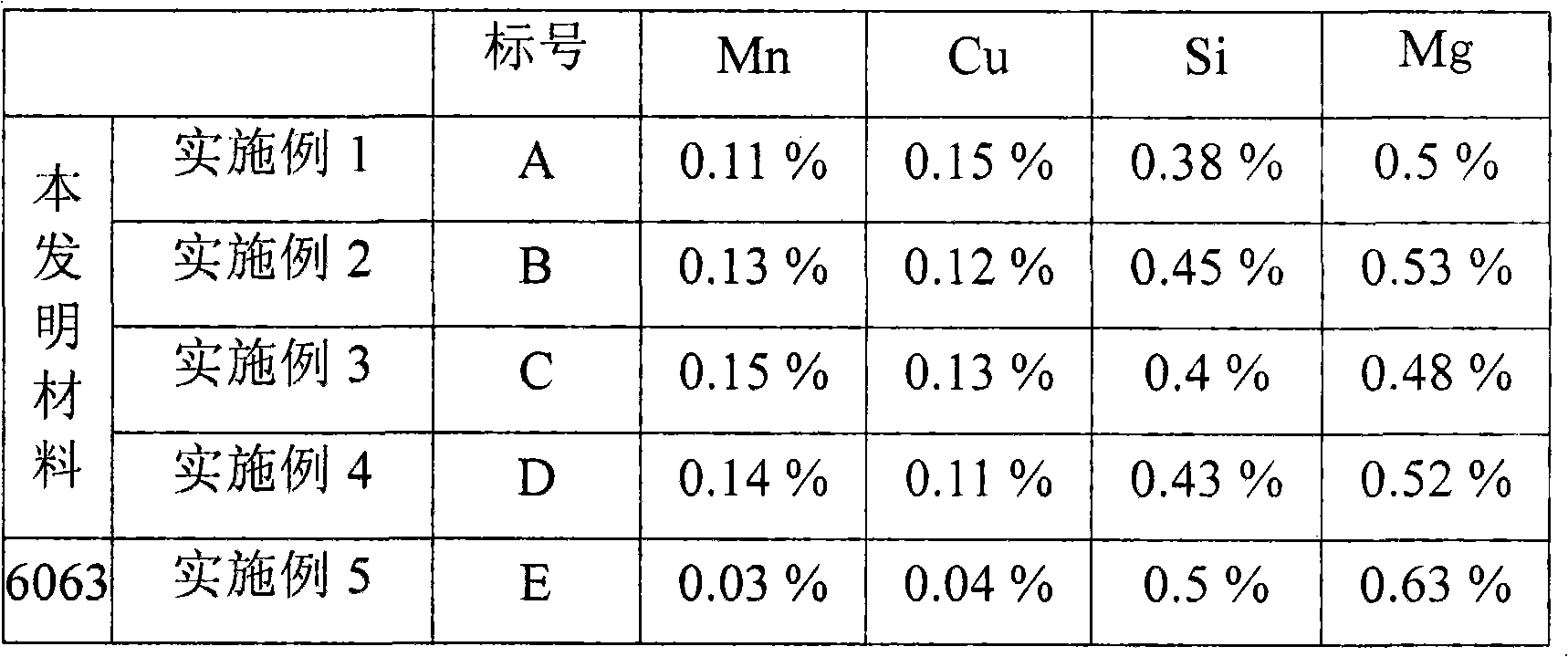

The invention discloses an aluminum alloy material capable of being molded by high-speed extrusion, which comprises the following components in percentage by weight: 0.11-0.15% of Mn, 0.11-0.15% of Cu, 0.38-0.46% of Si, 0.47-0.55% of Mg, 0-0.25% of Fe, 0-0.02% of Cr, 0-0.02% of Zn, 0-0.02% of Ti, and the balance of Al. The invention also discloses a preparation method of the aluminum alloy material capable of being molded by high-speed extrusion; and compared with traditional aluminum alloy 6063, the speed for extruding sectional materials by the aluminum alloy material can be improved greatly, and the production efficiency of the aluminum alloy sectional material can be enhanced remarkably.

Description

technical field [0001] The invention relates to an aluminum alloy, in particular to an aluminum alloy material suitable for high-speed extrusion and a preparation method. Background technique [0002] Among the aluminum alloys used for extrusion production, the most widely used is the 6063 alloy. However, due to the brittle phase β-AlFeSi, coarse Mg 2 The existence of Si, excess Mg or Si, etc. leads to the easy generation of surface defects of various types of extrusion materials that are sensitive to speed, such as pits, pockmarks, die marks, etc. Therefore, a lower extrusion speed has to be used in exchange for Satisfactory extrusion surface. This makes the production efficiency very low, and the production cost of the product is very high. SUMMARY OF THE INVENTION [0003] The purpose of the present invention is to aim at the above-mentioned defects existing in the existing 6063 aluminum alloy. On the basis of the existing 6063 aluminum alloy, by changing the element...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C21/08C22C1/03C22C1/06B22D1/00C22F1/047

Inventor 姚立群宋冰鞠岚

Owner 深圳华加日铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com