Patents

Literature

131results about How to "Good metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653AGood acid and alkali resistance and water resistanceGood metallic lusterCoatingsPigment treatment with organosilicon compoundsDouble bondChemistry

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps: by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

Preparation method for organic/inorganic hybridization cladding aluminum composite particle

InactiveCN102516831AStrong combinationGood dispersionPigment treatment with organosilicon compoundsAluminum compositesOrganosilicon

The invention discloses a preparation method for an organic / inorganic hybridization cladding aluminum composite particle, which includes mixing leafing aluminum powder and solvent alcohol evenly to be transferred to a reactor to be stirred for a period of time, then adding alcoholic solution containing an organic silicon source and an inorganic silicon source at a constant speed and mixed solution of catalyst, water and alcohol, reacting for a period of time at the constant temperature, and finally filtering, washing and vacuum drying to obtain the organic / inorganic hybridization cladding aluminum composite particle. The organic / inorganic hybridization cladding aluminum composite particle has the following advantages of being capable of scattering in hydrosolvent and the alcohol solvent well and good in compatibility with resin, keeping good metal glossy, and simultaneously having good performance for resisting acid and alkaline corrosion. The organic / inorganic hybridization cladding aluminum composite particle can be used as environment-friendly metallic pigment for water-based paint.

Owner:SUN YAT SEN UNIV

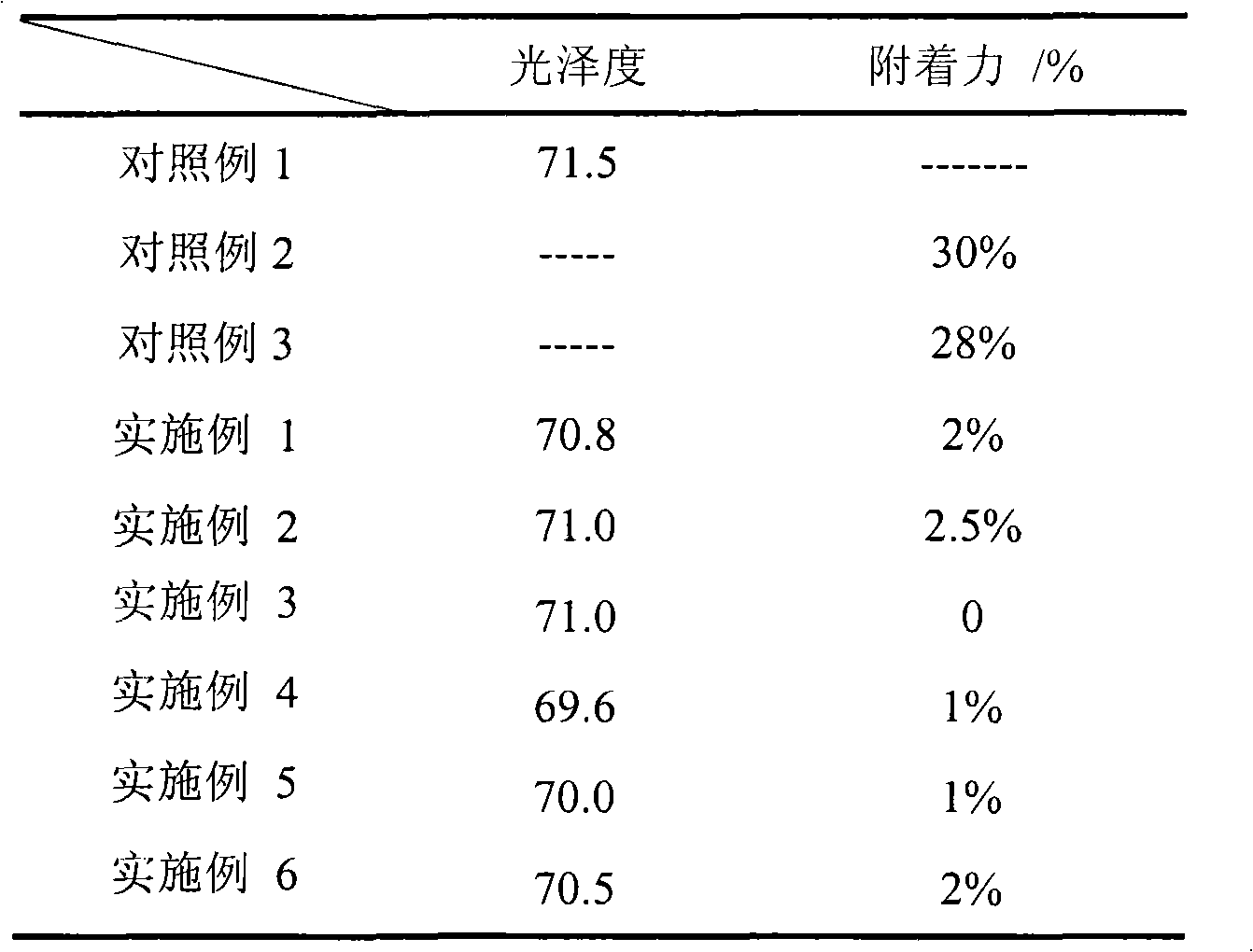

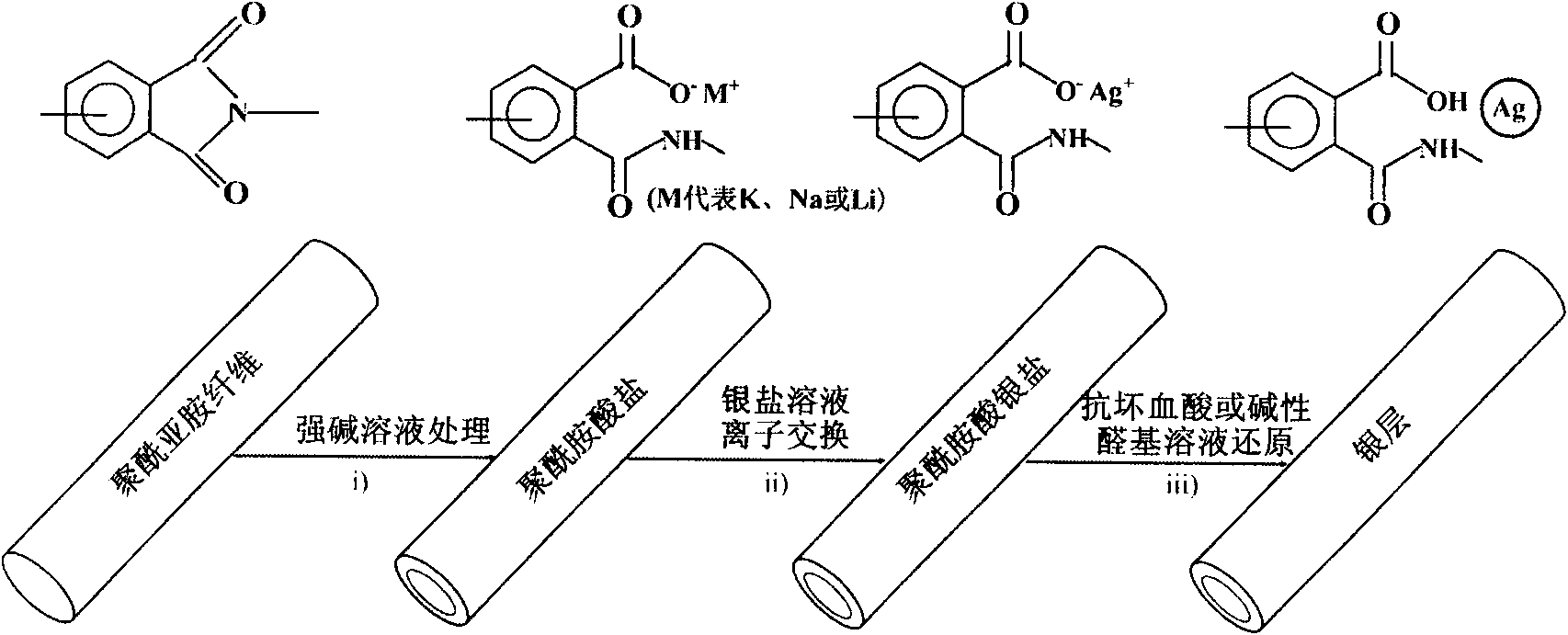

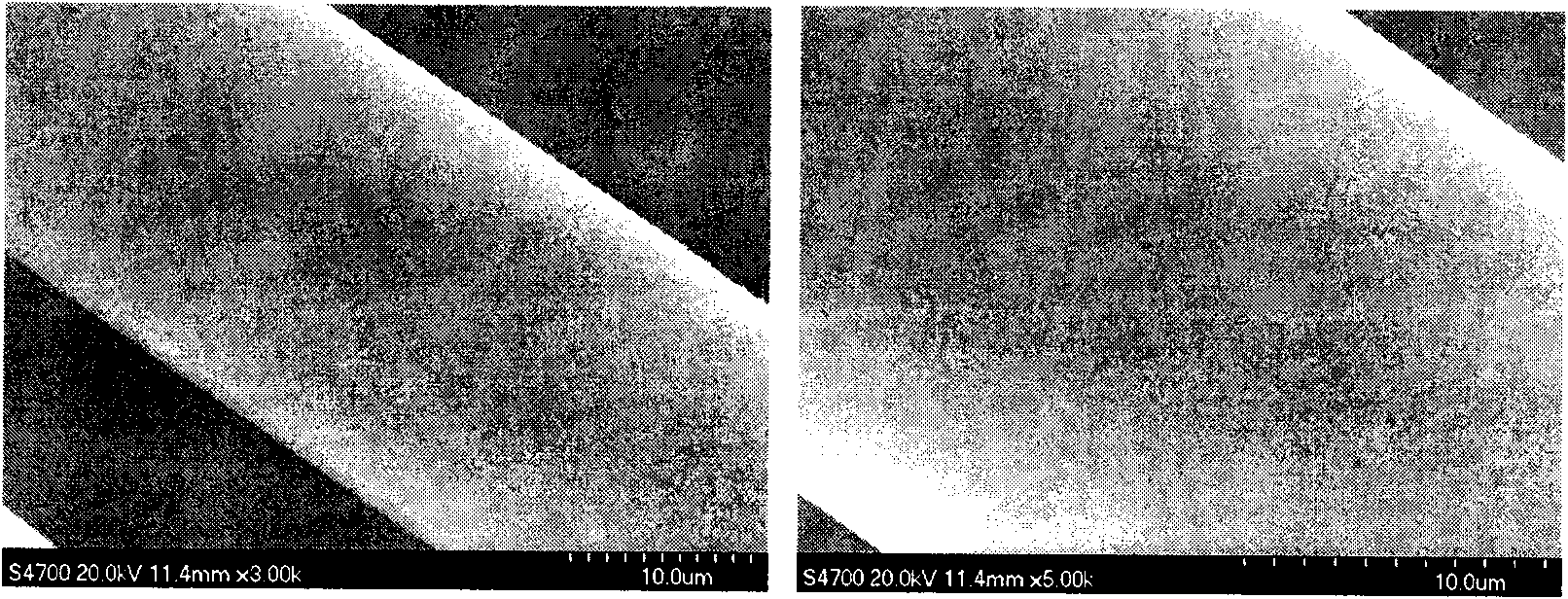

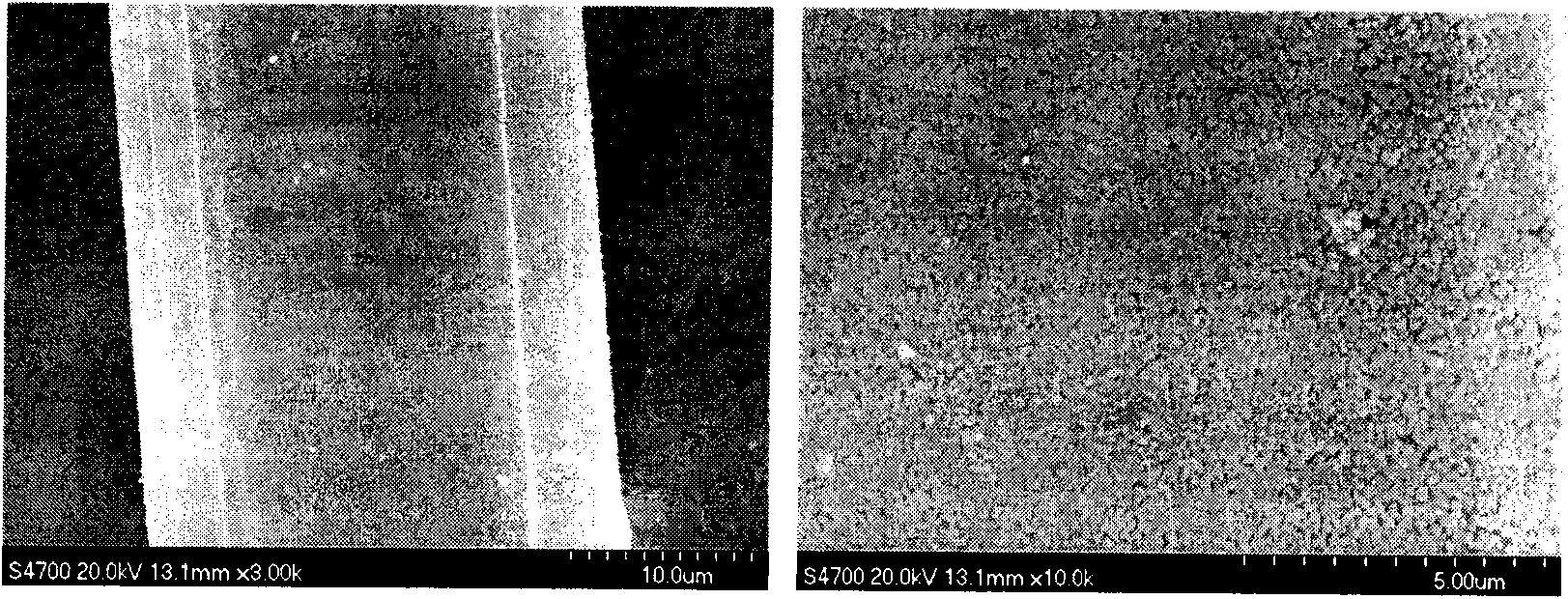

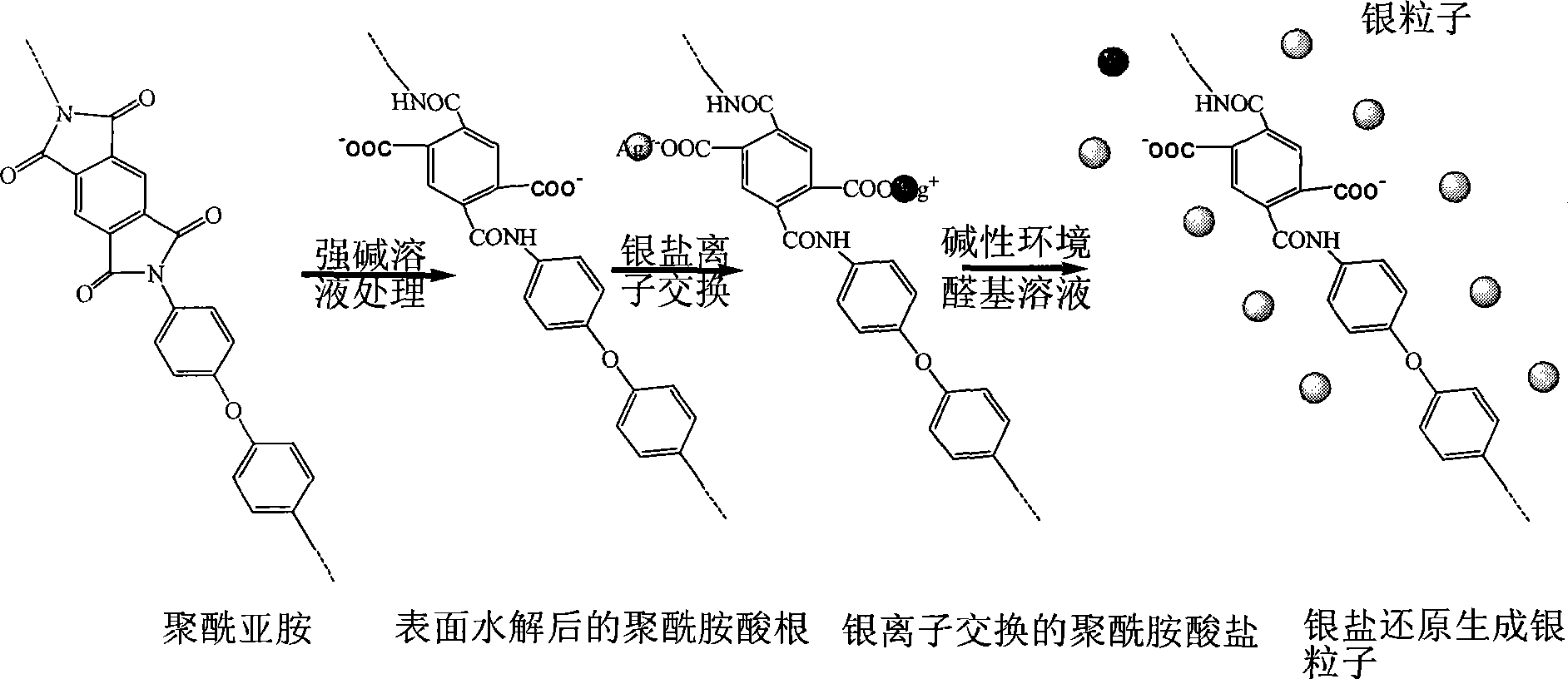

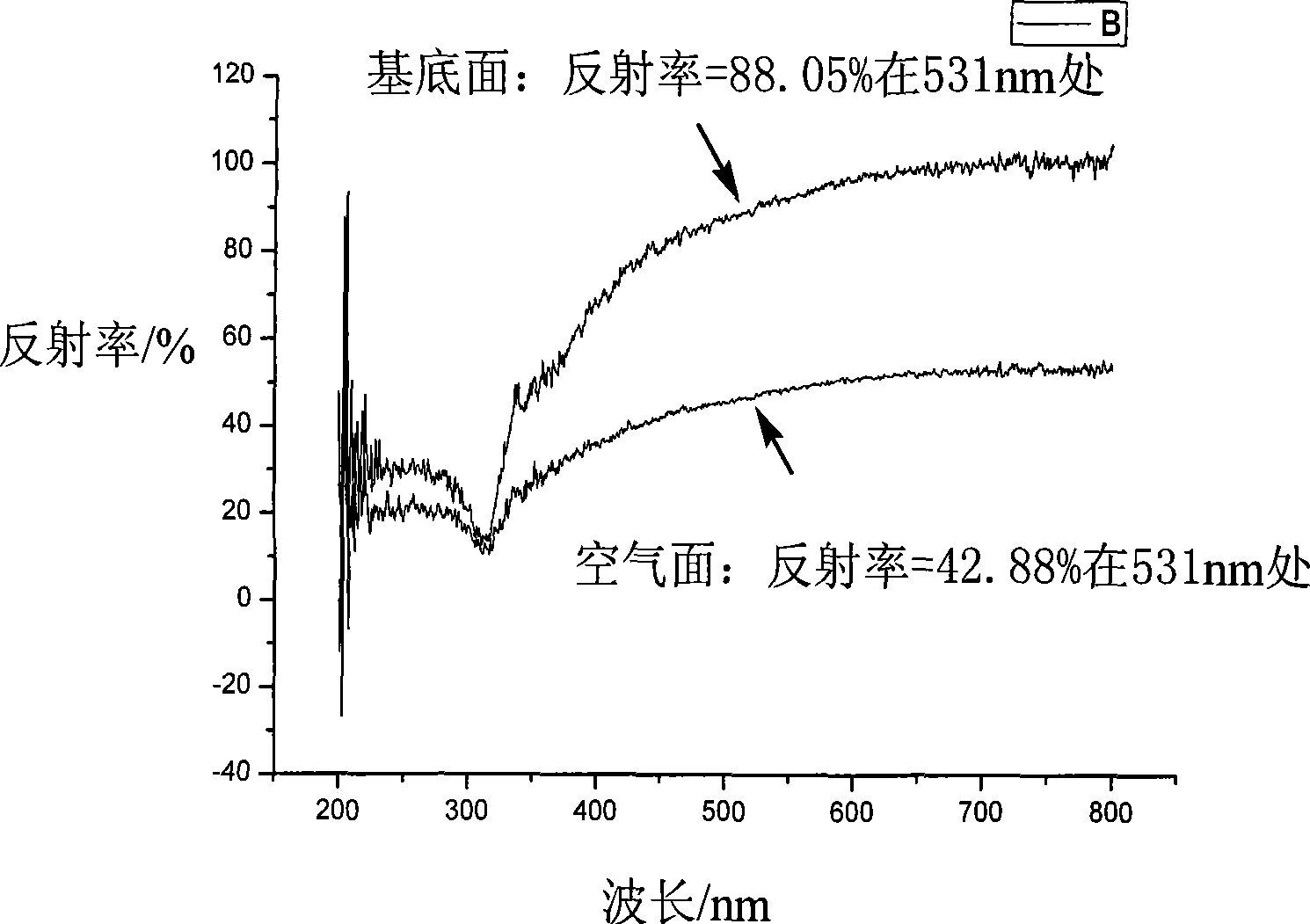

Method for preparing polyimide/silver composite conductive fiber

The invention relates to a method for preparing polyimide / silver composite conductive fiber, comprising: after removing surface impurities by ultrasonic treatment, soaking finished product polyimide fiber into alkaline solution, and leading polyimide on the surface layer of the fiber to open ring and hydrolyze to generate polyamide salt; then, soaking the polyamide salt into soluble silver salt water solution for ion exchange to form polyamic acid silver salt; finally, soaking the fiber with the polyamic acid silver salt on the surface into ascorbic acid or alkaline water solution containing aldehyde group, leading silver ion in an etch layer to be reduced and gathered on the surface, and obtaining the polyimide / silver composite conductive fiber. The method provided by the invention is simple and convenient for operation, non-toxic, free from pollution, low in cost and easy for industrialization; furthermore, the prepared composite conductive fiber not only maintains the mechanical property of matrix polyimide, but also has good electric conduction property.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing coated aluminum powder pigment

InactiveCN106317969AImprove bindingIsolated contactPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsWater bathsAlcohol

The invention discloses a coated aluminum powder pigment and a preparation method thereof. The preparation method comprises the following steps: mixing the aluminum powder pigment with solvent alcohol; then adding organosiloxane, water and an acidic catalyst, carrying out heating in a water bath and carrying out a reaction so as to obtain aluminum powder pigment preliminarily coated by organosiloxane; then heating a reaction system to 65 to 120 DEG C, adding an initiator and one or a plurality of monomers containing polymerizable groups and carrying out a reaction to obtain the aluminum powder pigment coated by organosiloxane and polymer; and finally, carrying out cooling, filtering, washing and drying so as to obtain the coated aluminum powder pigment. According to the invention, organosiloxane forms a first coating layer on the surface of the aluminum powder pigment at first and then the polymer forms a second coating layer on the surface of the aluminum powder pigment, so the coated aluminum powder pigment has good acid and alkali resistance on the basis of maintenance of good metal luster and is applicable to a waterborne paint; and the method overcomes the problem of gas generation in the process of usage and storage of traditional aluminum powder pigments and lays a foundation for safe use of the aluminum powder pigment.

Owner:刘从荡

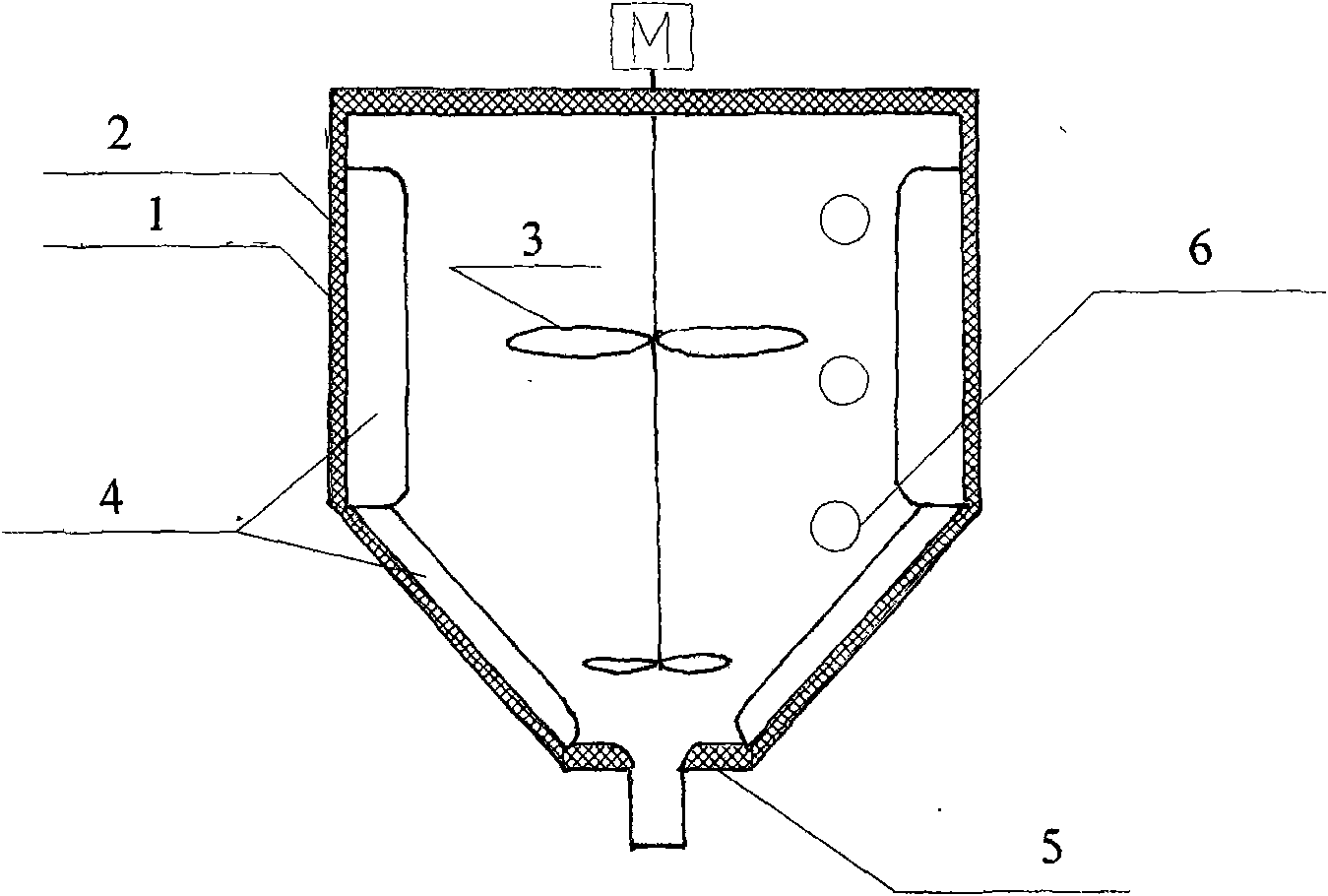

Iodine crystallizer

InactiveCN101670189APromote productionAvoid corrosionIodineSolution crystallizationFrequency conversionIodine

The invention relates to an iodine crystallizer which is characterized in that: (1) a steel net PO is take as a lining in the crystallizer; (2) a small platform is added at the cone bottom of the crystallizer; (3) the crystallizer is provided with a plurality of oxidant adding points; (4) a stirrer of the crystallizer is a frequency-conversion adjusting mode and the frequency of the mixer can be changed according to the characteristic during the formation process of the crystals; (5) the wall of the crystallizer is provided with a viewing hole; (6) the crystallizer is internally provided witha baffle plate so that the collision occurs between crystals or between the crystals and the wall, the stirrer and the like, thus generating minute crystals to induce the secondary nucleation, therebyleading the crystals forming the specified crystal shape. The steel net PO of the lining in the crystallizer has very good performances of iodine-resistance and oxidant-corrosion resistance, thus avoiding the phenomenon of blocking a liquid drain pipe in the crystallization; and adjusting the shapes of the crystals by adjusting the speed of the stirrer, thus obtaining the product with the good shape of the crystal and obvious metallic luster.

Owner:WENGFU (GRP) CO LTD

Metal surface treatment process

InactiveCN102392246AIncreasing the thicknessHigh hardnessVacuum evaporation coatingSputtering coatingSurface cleaningSprayer

The invention belongs to the technical field of metal surface treatment, and especially relates to a metal surface treatment process which comprises the following process steps of: (a) surface cleaning, that is, performing surface cleaning of a metal substrate to be treated, removing attachments on the surface of the metal substrate; (b) glaze layer spraying, that is, performing atomization spraying of glaze onto the surface of the metal substrate by a spray gun or a sprayer to form a glaze layer; (c) baking and curing, that is, baking the metal substrate with the sprayed glaze layer in a baking oven so as to cure the glaze layer; (d) secondary cleaning, that is, performing secondary cleaning of the metal substrate with the sprayed glaze layer; (e) PVD coating, that is, performing PVD coating of the metal substrate with the sprayed glaze layer to form a film layer on the surface of the glaze layer so as to obtain the metal substrate finished product. The metal substrate finished product of the invention has high thickness and hardness, and thus has strong wear resistance and scratching resistance; the PVD coating provides the metal substrate finished product with good temperature change resistance and corrosion resistance, and good metal luster.

Owner:东莞市泉硕五金加工有限公司

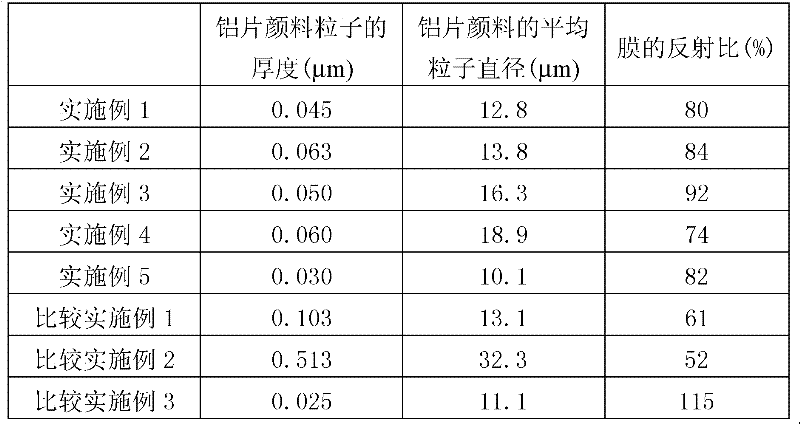

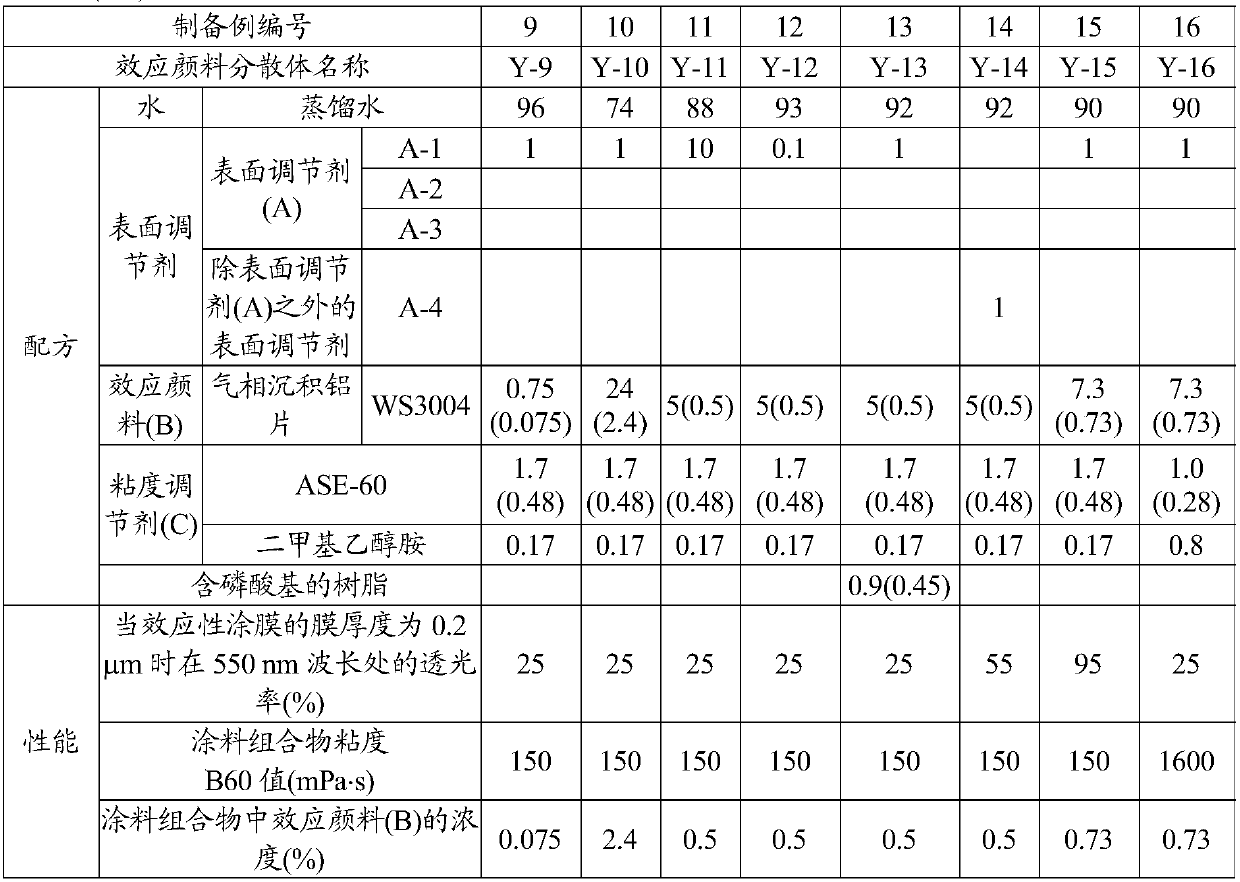

Aluminum sheet pigment, aluminum sheet pigment-contained coating composite, aluminum sheet pigment-contained printing ink composite and membranes obtained from aluminum sheet pigment

InactiveCN102389977AGood metallic lusterReduce manufacturing costPigmenting treatmentOrganic solventPrinting ink

In order to provide an aluminum sheet pigment which has excellent metallic luster and close grains and has similar coating appearance with silvery fashionable luster, the invention especially provides the aluminum sheet pigment which is obtained through grinding aluminum powder in an organic solvent and is 0.025-0.07mu m in average thickness (t) and 8-30mu m in average particle diameter (D50), an aluminum sheet pigment-contained coating composite, an aluminum sheet pigment-contained printing ink composite and membranes obtained from the aluminum sheet pigment. The aluminum powder is preferentially prepared through an atomization method. A grinding machine for performing the grinding is preferentially selected to serve as a ball mill.

Owner:TOYO ALUMINIUM KK

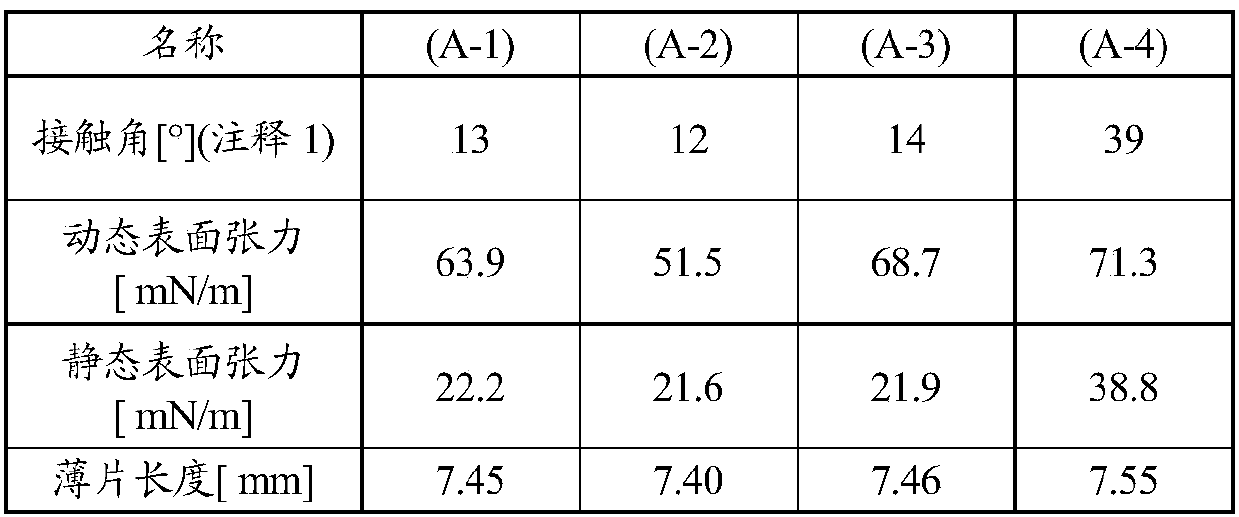

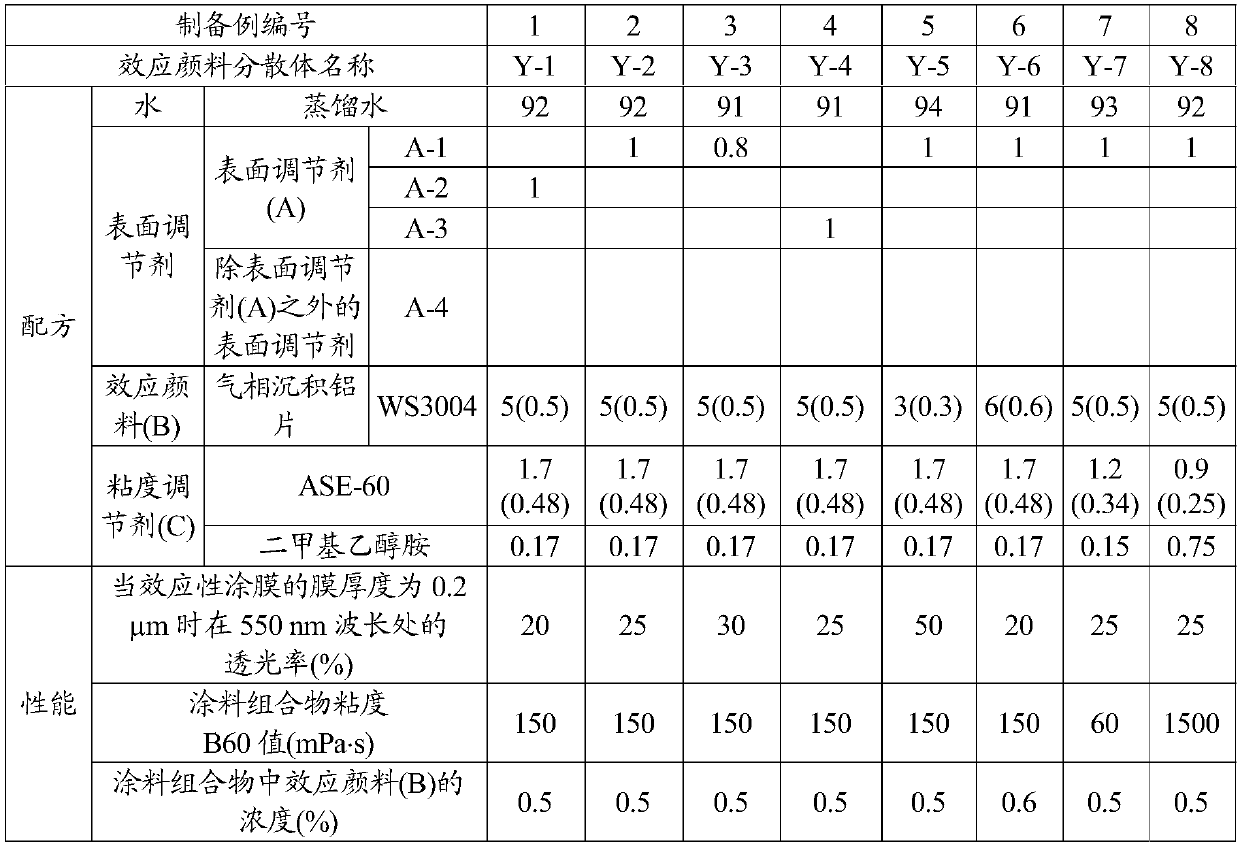

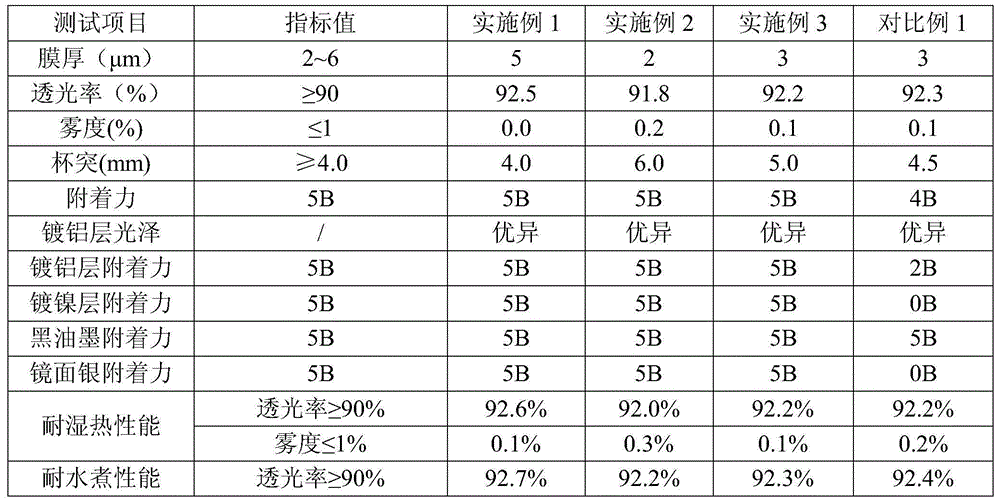

Multi-layer coating film formation method

ActiveCN107708878AGood metallic lusterGood lookingPretreated surfacesSpecial surfacesPigment dispersionTransmittance

A multi-layer coating film formation method comprises heating an uncured color coating film, an uncured glittering coating film and an uncured clear coating film which are respectively formed by coating a color coating material (X), a glittering pigment dispersion (Y) and a clear coating material (Z) in this order on a material of interest and then curing the three coating films simultaneously, wherein the glittering pigment dispersion (Y) comprises water, a surface modifier (A), a scale-like glittering pigment (B) and a viscosity modifier (C) and has such a property that a film produced by coating the glittering pigment dispersion (Y) in such a manner that a dried form of the film can have a thickness of 0.2 [mu]m has a transmittance of light having a wavelength of 550 nm of 10 to 50%.

Owner:KANSAI PAINT CO LTD

Ink jet recording method and record

ActiveUS20100187805A1Good metallic lusterOther printing matterMeasurement apparatus componentsGlass transitionPolymer chemistry

An ink jet recording method for recording an image having a metallic luster on a recording medium with an ink jet recording apparatus includes forming an underlayer on the recording medium by applying droplets of a first ink composition containing a first thermoplastic resin to the recording medium and also includes forming a metallic luster layer on the underlayer by applying droplets of a second ink composition containing a metal pigment and a second thermoplastic resin to the underlayer. The glass transition temperature of the first thermoplastic resin is lower than or equal to the glass transition temperature of the second thermoplastic resin. The underlayer is formed at a temperature higher than the glass transition temperature of the first thermoplastic resin.

Owner:SEIKO EPSON CORP

Vacuum plating under-coating paint as well as application and preparation method of vacuum platable hard thin film for IML prepared from vacuum plating under-coating paint

InactiveCN104387948AStrong adhesionGood metallic lusterPolyurea/polyurethane coatingsEpoxy resin coatingsChemistryPhotoinitiator

The invention discloses a vacuum plating under-coating paint as well as a preparation method and an application of a vacuum platable PET hard thin film for IML. The vacuum plating under-coating paint is prepared from the following components: 10-30 parts of polyurethane acrylate, 5-10 parts of epoxy acrylate, 5-10 parts of modified acrylate, 0.5-2 parts of flatting agent, 1-2 parts of photoinitiator and 50-70 parts of organic solvent. The vacuum plating under-coating paint for a PET substrate is produced by evenly mixing a reactive diluent, the flatting agent and the organic solvent together, next, adding the polyurethane acrylate, the epoxy acrylate and the modified acrylate and mixing evenly, and then adding the photoinitiator at the final stage for dispersing evenly; the vacuum plating under-coating paint is applicable to preparing the vacuum platable PET hard thin film for the IML; the cost can be effectively reduced; the obtained vacuum platable PET hard thin film for the IML has certain forming tensile properties, and the outer layer of the hard thin film has high hardness and high wear resistance, while the inner layer of the same has excellent adhesion to a metal coating and a screen printing ink layer, and furthermore, the metal coating is excellent in glossiness.

Owner:GUANGZHOU HUMAN ENG MATERIAL

Ink jet recording method and record

ActiveUS8215764B2Good metallic lusterMeasurement apparatus componentsDuplicating/marking methodsGlass transitionPolymer chemistry

Owner:SEIKO EPSON CORP

Pattern coating glass and preparation method thereof

ActiveCN102976624AWith arbitrary pattern selection featureApplicable to different needsMachiningMetal

The invention discloses a pattern coating glass and a preparation method thereof, and belongs to the technical field of glasses. The pattern coating glass is characterized in that coating layers are covered on partial surface of the glass, and patterns formed by the coating layers are arranged as arrays. The preparation method comprises the process routes of cutting, edging, coating colored glaze, coating, tempering and carrying out combined machining. The coating glass has the characteristic that the patterns can be selected at random, so that different demands can be met; and the coating glass can be used in a form of single glass and also can be processed into hollow sandwich composite glasses. LOW-E coating can be carried out based on pattern coating, thus the low radiation performance is brought to the glass as well as higher metal gloss, and the requirement on appearance in special environments is met.

Owner:TIANJIN SYP ENG GLASS CO LTD

Method for preparing two-sided polyimide / silver compound film

Owner:BEIJING UNIV OF CHEM TECH

Etch-cleaning method for high purity polycrystalline silicon briquette

InactiveCN101775662AHigh glossImprove surface qualityPolycrystalline material growthAfter-treatment detailsAcid etchingHydrofluoric acid

The invention discloses an etch-cleaning method for a high purity polycrystalline silicon briquette, which relates to a cleaning method for a high purity polycrystalline silicon briquette in the field of polycrystalline silicon production. In the method, hydrofluoric acid solution etching process is arranged after mixed acid etching and pure water (EW-I) rinsing processes; hydrofluoric acid solution is diluted from electronic grade hydrofluoric acid and pure water (EW-I) in a proportion of 1:2-5 (weight part), and the etching soaking time is determined according to the thickness of an oxygen layer on the surface of the silicon briquette and the concentration of the hydrofluoric acid solution; and after ultrasonic cleaning, the briquette is subjected to hot nitrogen water shearing and vacuum drying to obtain the high-purity disposable polycrystalline silicon briquette meeting the requirements of Czochralski single crystals. By adding the hydrofluoric acid solution etching process, the surface oxygen layer of the silicon briquette, which is generated when the polycrystalline silicon briquette is subjected to mixed acid etching and is contacted with air once again, can be removed so as to obtain the disposable high-purity polycrystalline silicon material with good metal glossiness of the surface and better surface quality.

Owner:YICHANG CSG POLYSILICON CO LTD

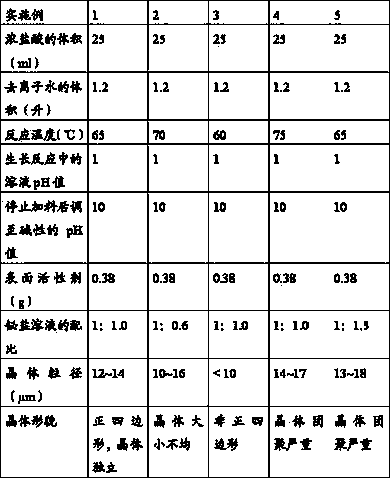

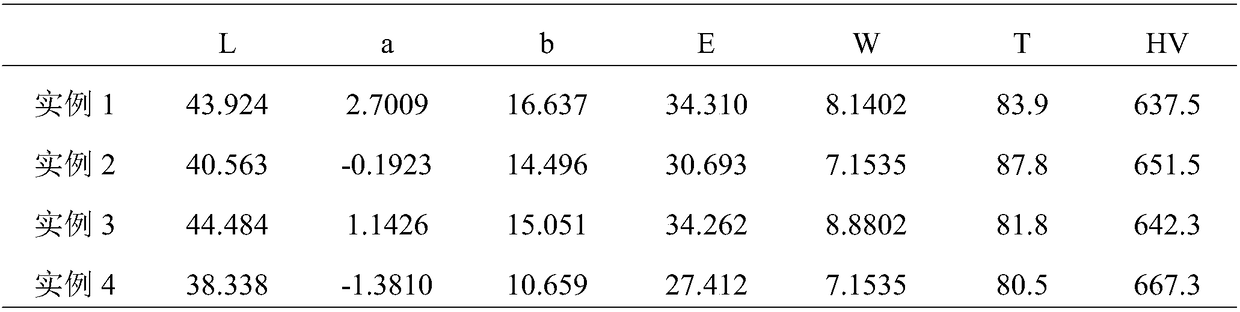

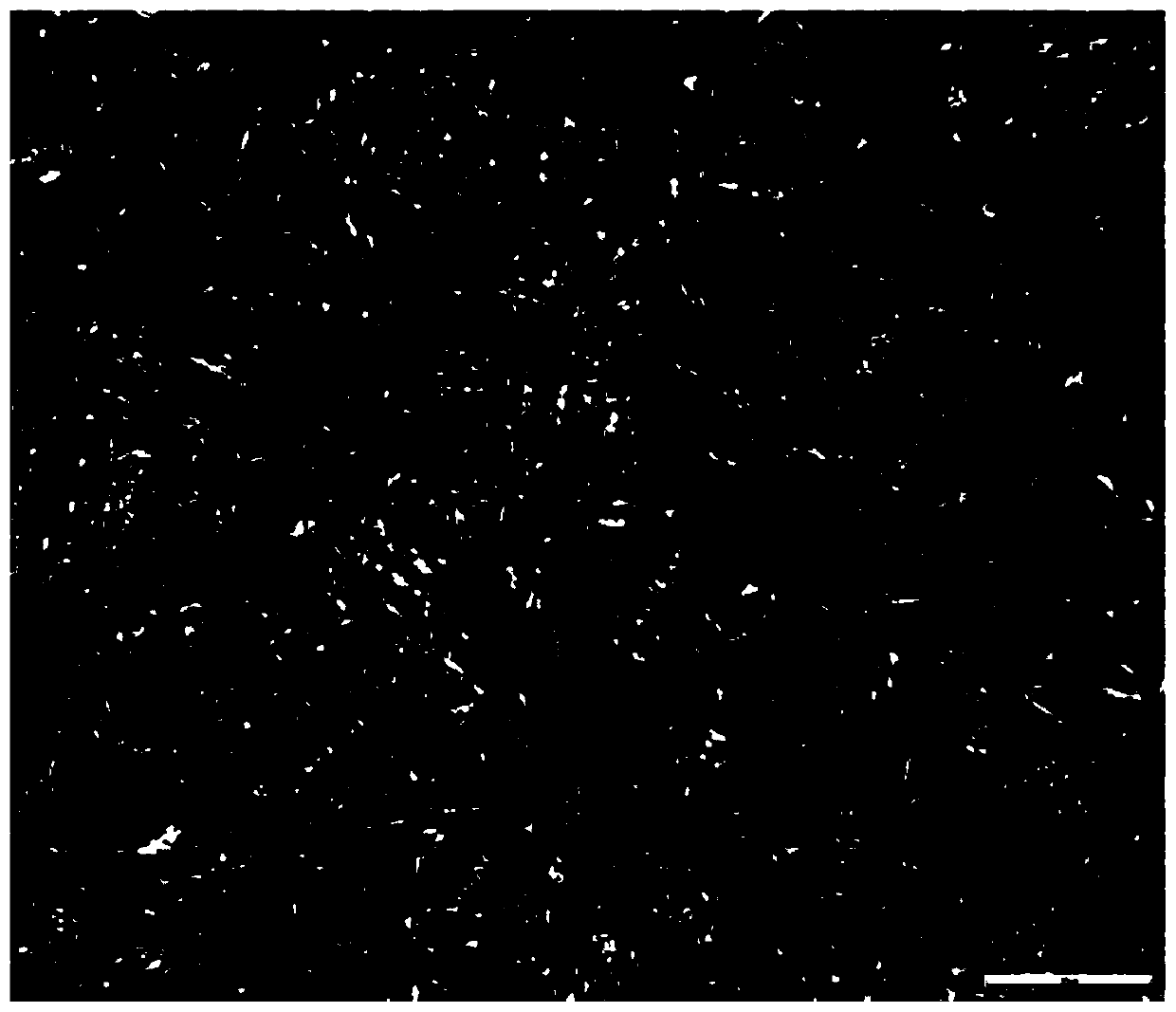

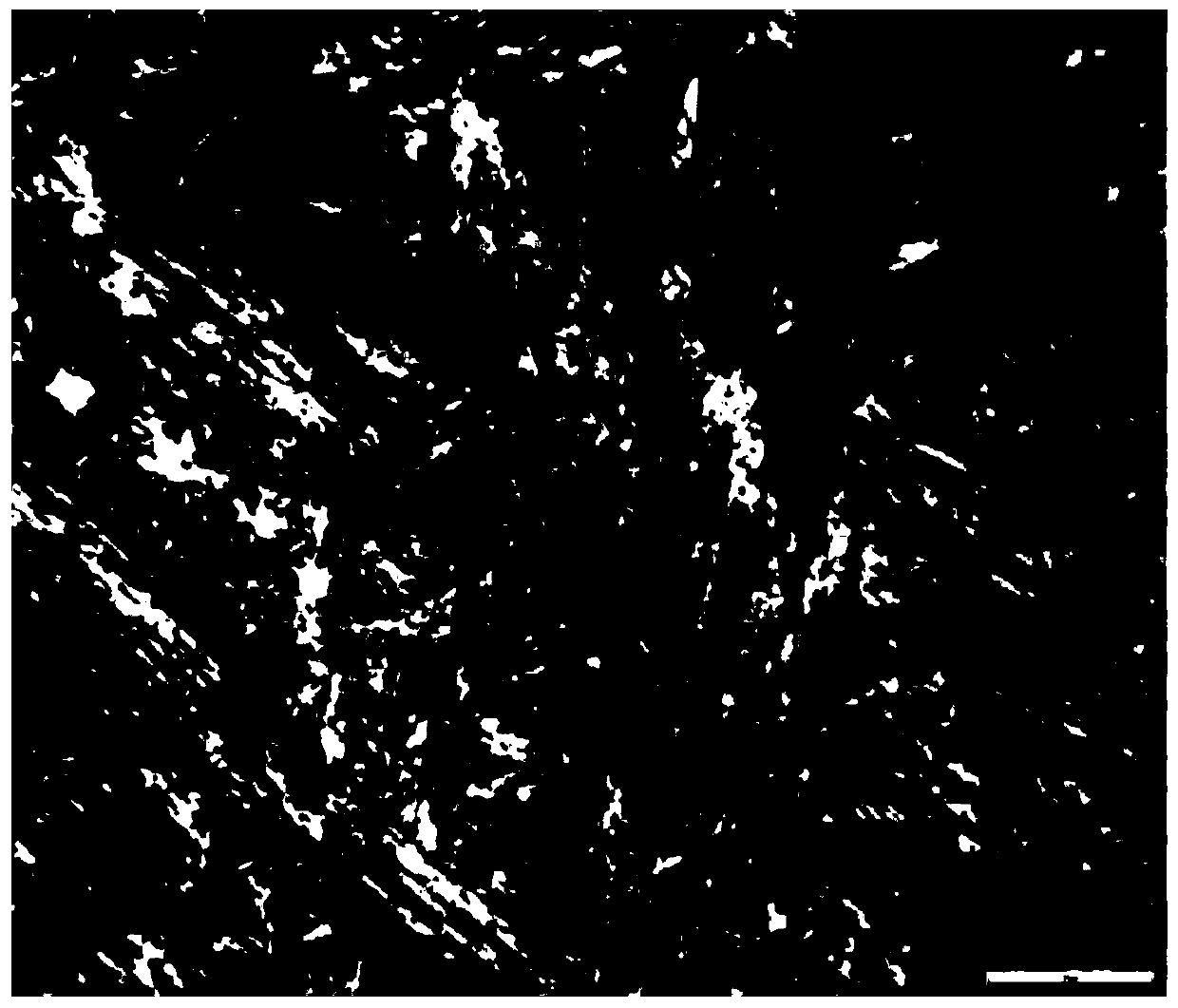

Bismuth oxychloride crystal and preparation method thereof

InactiveCN103663378AIncrease brightnessGood metallic lusterHalogen oxides/oxyacidsLamellar crystalsChemical industry

The invention discloses a bismuth oxychloride crystal and a preparation method thereof, and belongs to the technical field of chemical industry. The bismuth oxychloride crystal is a lamellar crystal which is controllable in size and is in a regular square quadrilateral shape, and the size ranges from 8 micrometers to 20 micrometers. The preparation method comprises the following steps: neutralizing redundant acid in a reaction process by adopting bismuth nitrate as a raw material, providing chloride ions which form bismuth oxychloride through hydrochloric acid and adding a sodium hydroxide solution with a proper concentration to keep the proper acidity of the growth of the bismuth oxychloride crystal; carrying out hydrolysis reaction under the acidic condition that the pH is less than or equal to 1; and controlling the orientated growth of the crystal through a surface active agent to prepare the lamellar bismuth oxychloride crystal in the square quadrilateral shape. The bismuth oxychloride crystal synthesized by the method disclosed by the invention has very good brightness, metal luster and hiding power and can be widely applied to the fields of cosmetics, plastics, printing ink, automobile baking paint, and the like by being prepared into pearly slurry.

Owner:MINJIANG UNIV

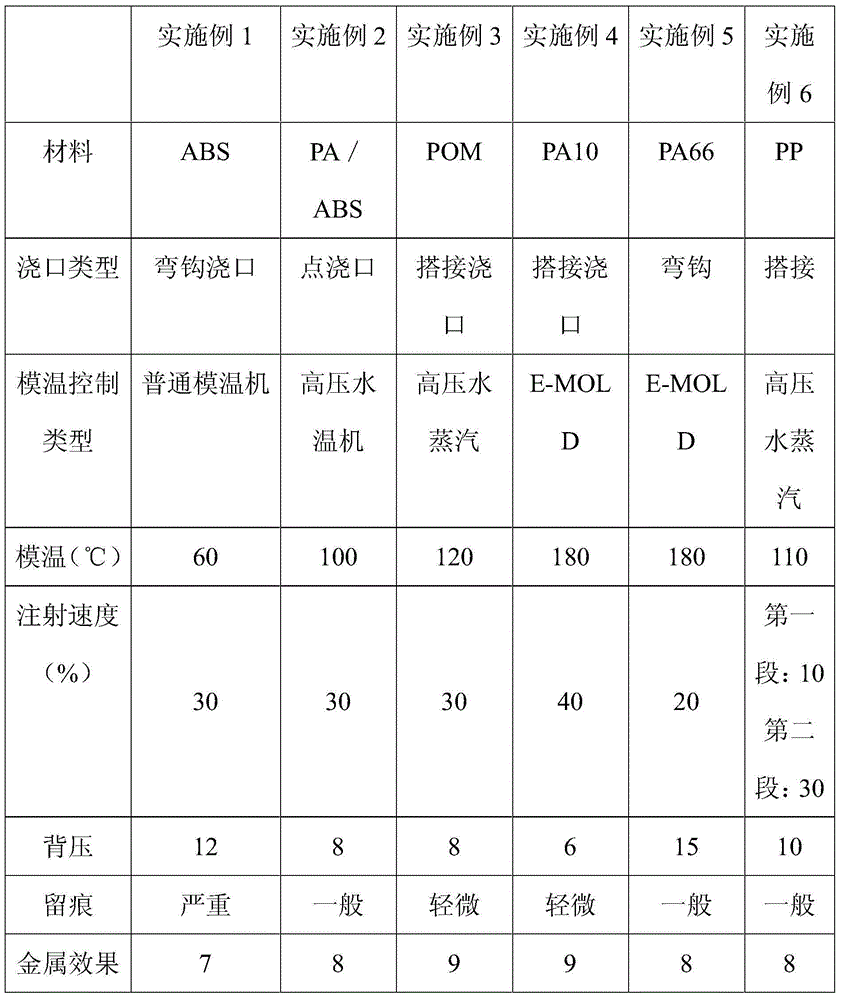

Free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts

The invention discloses a free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts. The free-spraying metallic-luster injection molding process comprises the following steps: adding metal powder into a raw material which is a plastic base material, and arranging a random water path close to a mould cavity of an injection mould with the high surface quality and the small thermal deformation to enable the surface temperature of the mould to be uniform; pouring the mould by adopting a hooked pouring gate, a pin-point gate and a side pouring gate; controlling the temperature of the surface of the mould in an injection-molding process; and pouring by adopting one or more pouring gates by adopting a high-pressure low-speed injection molding technique, a low-pressure high-speed injection molding technique or a normal-pressure normal-speed injection molding technique, and a sequential injection molding process, wherein the pouring gates adopt a needle valve type pouring gates. The parts produced by adopting the free-spraying metallic-luster injection molding process have no flow marks and solution marks on surfaces, have the good metallic luster and can be used for car interior trim parts and exterior parts.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

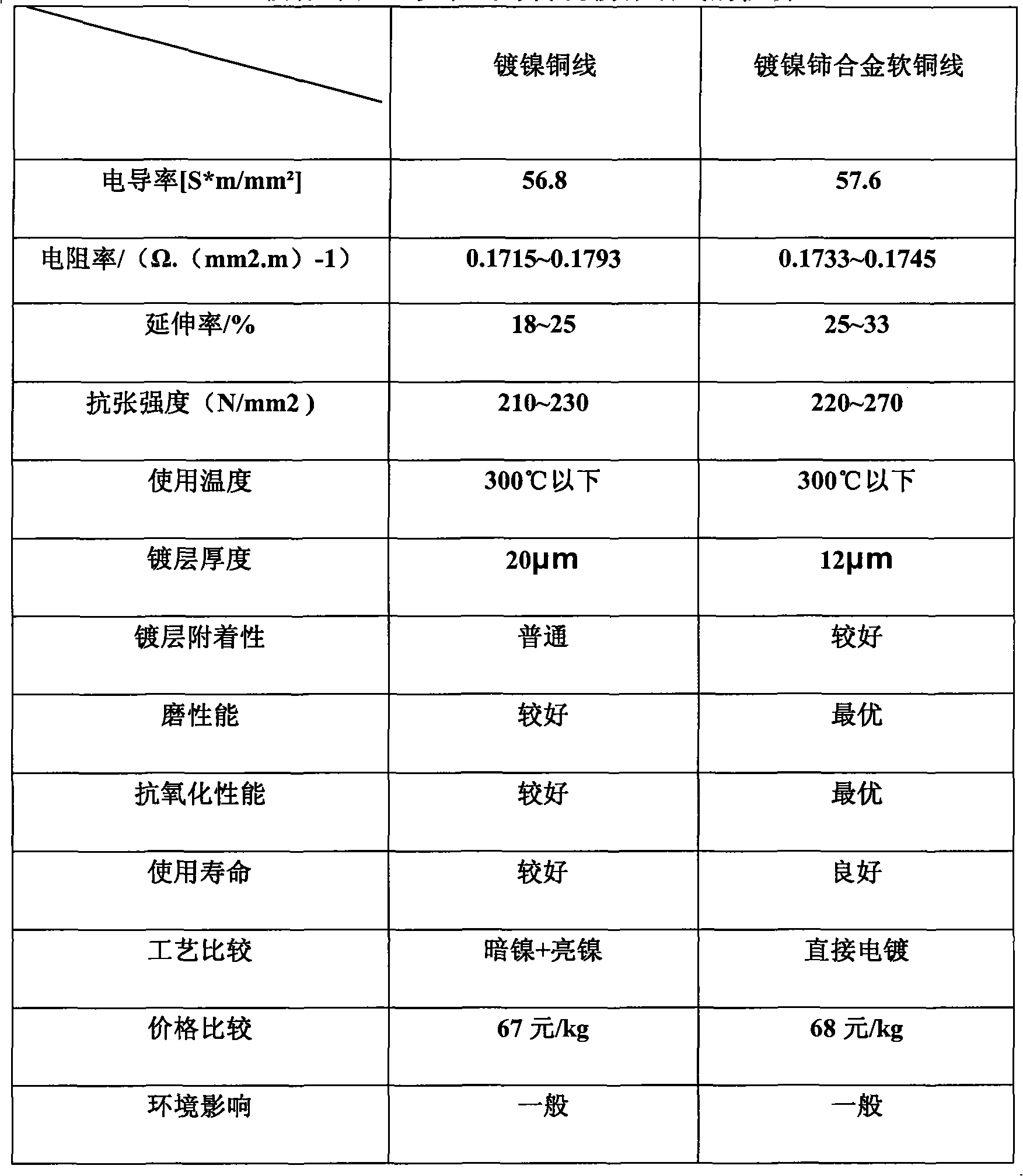

Technique for producing nickelplated mischmetal annealed copper wire

InactiveCN101556846AGood metallic lusterGood adhesionCable/conductor manufactureMischmetalCopper wire

The invention relates to a technique for producing a nickelplated mischmetal annealed copper wire, which comprises the working procedures such as drawing copper wire, removing oil, washing, acid cleaning, preplating, electroplating, hot water rinsing, ultrasonic washing, drying and wire collecting, quality testing and warehouse entry, and the like, wherein, the process of electroplating is the electrochemical process by taking nickel and cerium elements as plating additive. The nickelplated mischmetal annealed copper wire prepared by the technique has good metal luster on the surface of the plating layer and excellent adhesiveness, toughness and tractility, is difficult to find a pinhole and suitable for manufacturing aircraft wires and cables as well as special installation conductive core, and can be widely applied to the wires and cables used for installing and connecting electric appliances such as aerocraft, railway, automobile, streamship, etc.

Owner:丹凤县永鑫电子材料有限责任公司

Metal press-key

InactiveCN101425412AButton quality improvedGood metallic lusterWax adhesivesElectric switchesPowder metallurgyHardness

The invention provides a metal key-press which comprises key-press material and patterns or characters positioned on the key-press material, wherein the key-press material is made of metal powders through a powder metallurgy method, and the Rockwell hardness of the key-press material is HRC20-40. In the invention, as the key-press is metallically prepared by metal powders, the produced key-press has metal texture and is resistant in abrasion; besides, as the metallic coating step is not needed by the metal key-press, the preparation technology is simple.

Owner:BYD CO LTD

Method for preparing environmental-friendly waterborne ceramic coating

InactiveCN108395743AImprove stabilityReduce emission contentAlkali metal silicate coatingsAnti-corrosive paintsSelf-healingCeramic coating

The invention discloses a method for preparing an environmental-friendly waterborne ceramic coating. The environmental-friendly waterborne ceramic coating is prepared from a base stock, a filler, deionized water and an additive, wherein the base stock is mainly liquid silicate, the filler is mainly aluminium powder, and the aluminium powder is pretreated to improve the stability of the coating tothe great degree; and the additive is mainly prepared from a coupling agent, a corrosion inhibitor, a thixotropic agent, a surfactant, a defoaming agent and the like, and the environmental-friendly waterborne ceramic coating is prepared through the processes of stirring and sanding. The environmental-friendly waterborne ceramic coating has the characteristics of being environmental-friendly, non-toxic, free of pungent odour, low in VOC emission, simple in construction procedure, and widely applied in multiple fields. The environmental-friendly waterborne ceramic coating has high surface adaptability to the base stock, the adhesive force of the coating is strong, and the environmental-friendly waterborne ceramic coating has good metal luster and high performances of self repairing, high temperature resistance, salt fog resistance, abrasion resistance, corrosion resistance, thermal shock resistance, static electricity resistance, mildew resistance and water resistance, and the like.

Owner:ANHUI UNIVERSITY

Lead-free metal luster gold glaze and preparation method thereof

The invention discloses lead-free metal luster gold glaze and a preparation method thereof. The lead-free metal luster gold glaze is prepared from the following ingredients in percentage by mass: 65 to 75 percent of basic glass fused blocks, 10 to 20 percent of MnO2, 1 to 10 percent of CuO, 1 to 10 percent of TiO2 and 1 to 5 percent of NiO. The preparation method comprises the following steps thatbasic glass fused block powder and inorganic oxide powder are added into a ball mill tank; ball milling is performed to prepare black glaze slurry; the black glaze slurry is glazed on the blank bodysurface in a spraying, coating or glaze pouring mode; drying is performed; then, the glazed blank body is fired at high temperature under the oxidizing atmosphere; heat insulation is performed; a metal glaze building ceramic product with metal luster and gold decoration effect can be obtained. A traditional ceramic glaze preparation technology is used; the gold decoration ceramic glaze with good metal luster can be obtained; the characteristics of wide firming range, stable color appearance, high surface hardness, no lead pollution in the preparation process and the like are realized; the lead-free metal luster gold glaze can be safely used for surface glaze layer decoration of tableware ceramics.

Owner:WUHAN UNIV OF TECH

Preparation method for resin with spraying-free metal effect

Owner:SHANGHAI KUMHO SUNNY PLASTICS

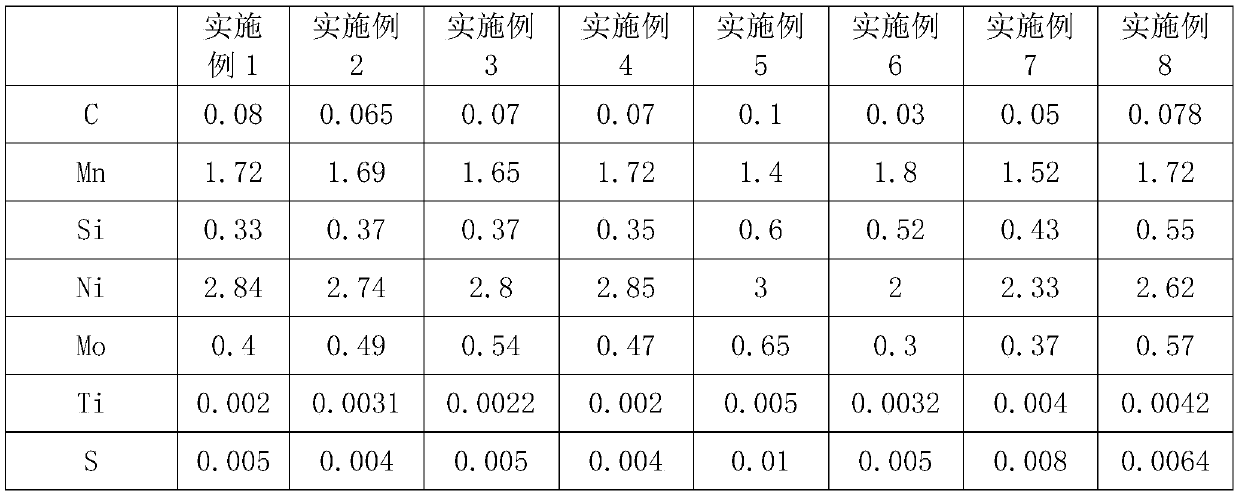

Gas shielded welding wire matched with weather-resistant bridge steel Q690qE and preparation method thereof

InactiveCN110549033ASimple welding processReduce splashWelding/cutting media/materialsSoldering mediaCopper platingGas protection

The invention discloses a gas shielded welding wire and a preparation method thereof. The welding wire comprises the following components of, in percentage by weight, 1.40% to 1.80% of Mn; 2.00% to 3.00% of Ni; 0.30% to 0.65% of Mo; greater than 0 and less than or equal to 0.10% of C; greater than 0 and less than or equal to 0.60% of Si; greater than 0 and less than or equal to 0.010% of S; greater than 0 and less than or equal to 0.010% of P; greater than 0 and less than or equal to 0.60% of Cr; greater than 0 and less than or equal to 0.35% of Cu; greater than 0 and less than or equal to 0.005% of Ti; greater than 0 and less than or equal to 0.005% of V; and the balance Fe and other impurities. The preparation method comprises the following steps of (a) preparing a disc strip according to the formula of the welding wire, and then drawing the disc strip roughly; (b) annealing the disc strip treated in the step (a) to remove an oxidation layer on the surface of the disc strip; (c) roughly drawing the disc strip treated in the step (b) again to a certain specification; and (d) finely drawing the disc strip treated in the step (c), plating copper on the surface of the disc strip, andwinding the disc strip. According to the gas shielded welding wire, through a reasonable welding process, the tensile strength of weld metal is greater than 810 MPa and the yield strength is larger than 755 MPa, which is close the mechanical property of a base material, and meets the mechanical property requirement of the bridge steel Q690qE.

Owner:SICHUAN XIYE NEW MATERIAL +1

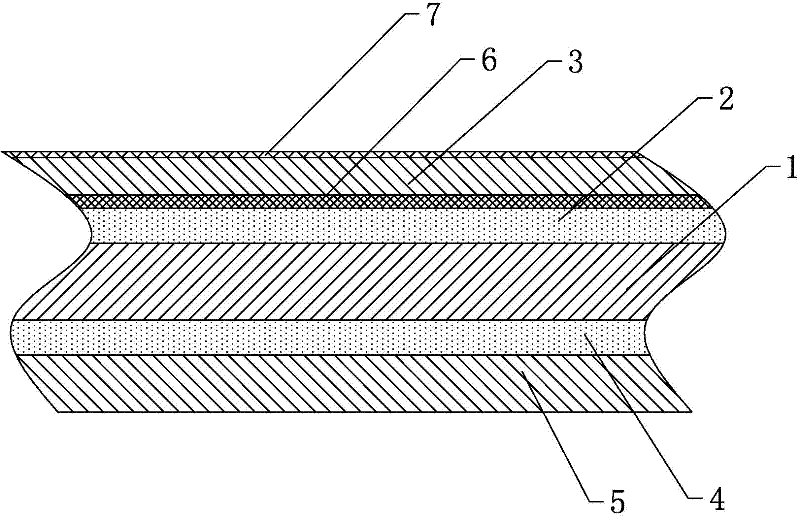

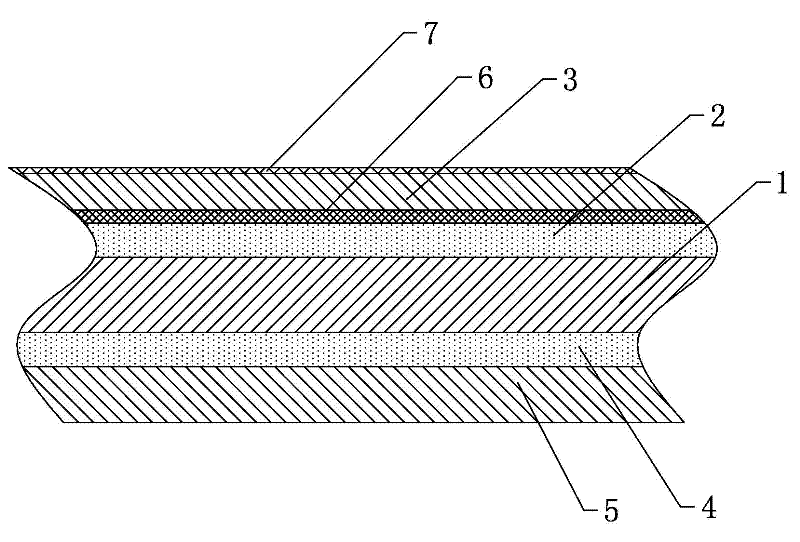

Stainless steel simulated composite film with wire drawing effect

InactiveCN102371726AHigh glossPrevent oxidationNatural patternsSynthetic resin layered productsPolyethylene terephthalate glycolMetallic aluminum

The invention discloses a stainless steel simulated composite film with a wire drawing effect, comprising a metal aluminium foil layer, a PET (Polyethylene terephthalate) film layer, a PVC (Poly Vinyl Chloride) film layer, a printing colouring layer and a protection layer, of which surfaces are implemented with a wire drawing treatment; the PET film layer and the PVC film layer are respectively bonded on the two surfaces of the metal aluminium foil layer through corresponding bonding layers, the printing colouring layer is arranged on the surface which is bonded by the PET film layer and the corresponding bonding layer; the protection layer is arranged on the another surface of the PET film layer. The stainless steel simulated composite film has a very strong stainless steel wire-drawing gloss, a high stainless steel simulation degree and a durable metal gloss; the stainless steel simulated composite film can be applied for home appliances and kitchen devices to make the home appliances and the kitchen devices be more beautiful, thereby product grades can be improved.

Owner:JIANGSU OBON PLASTIC

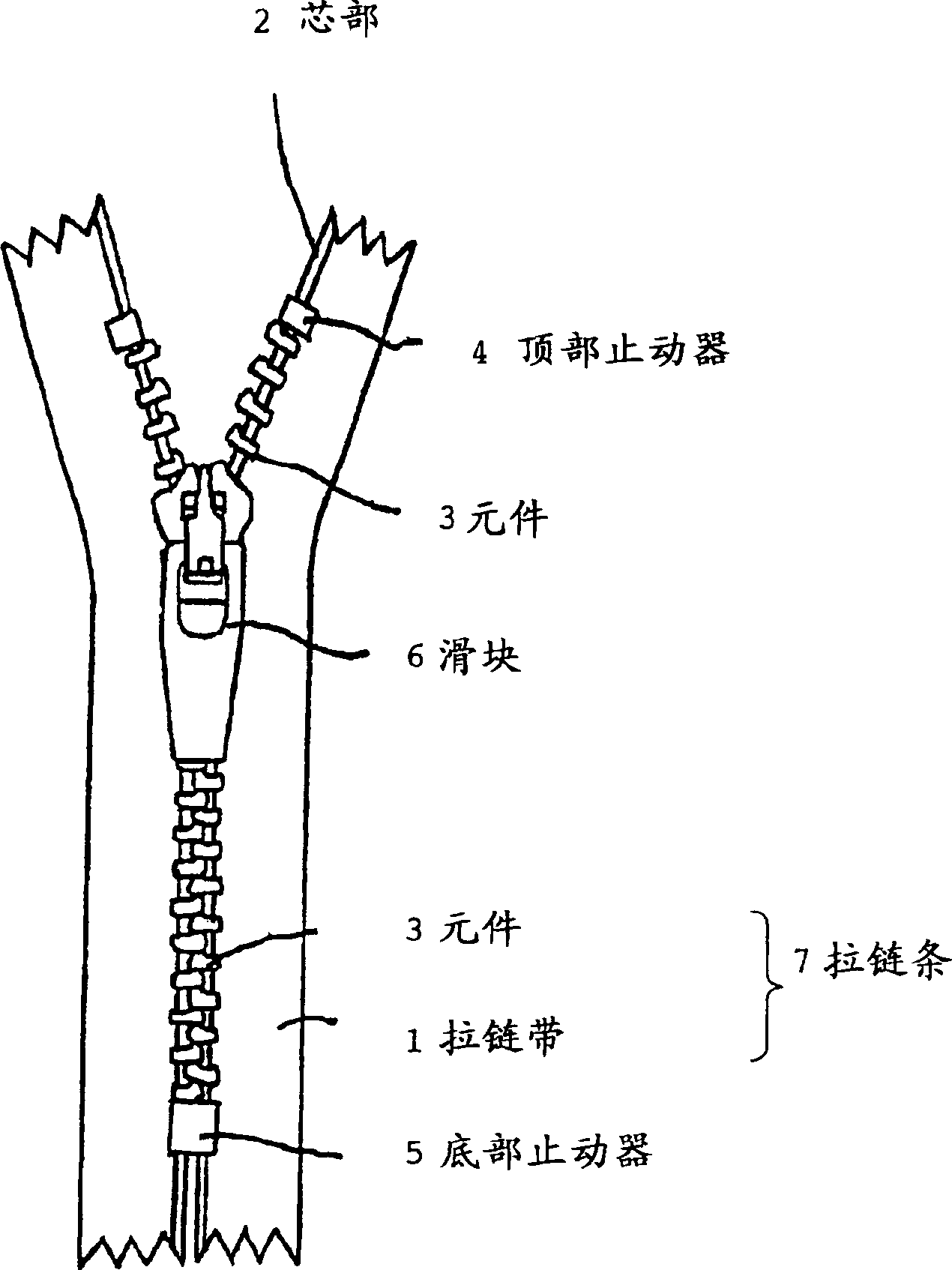

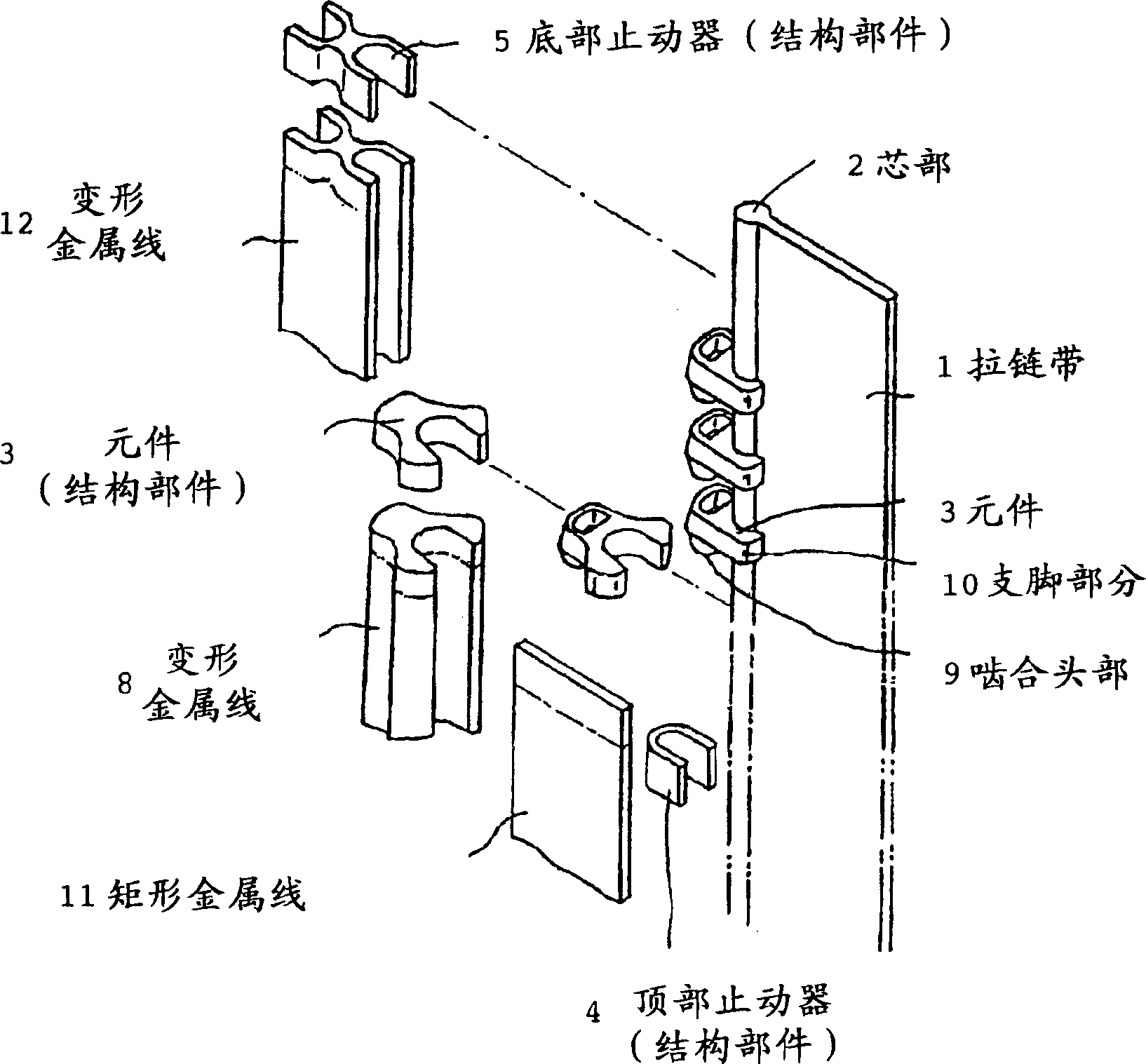

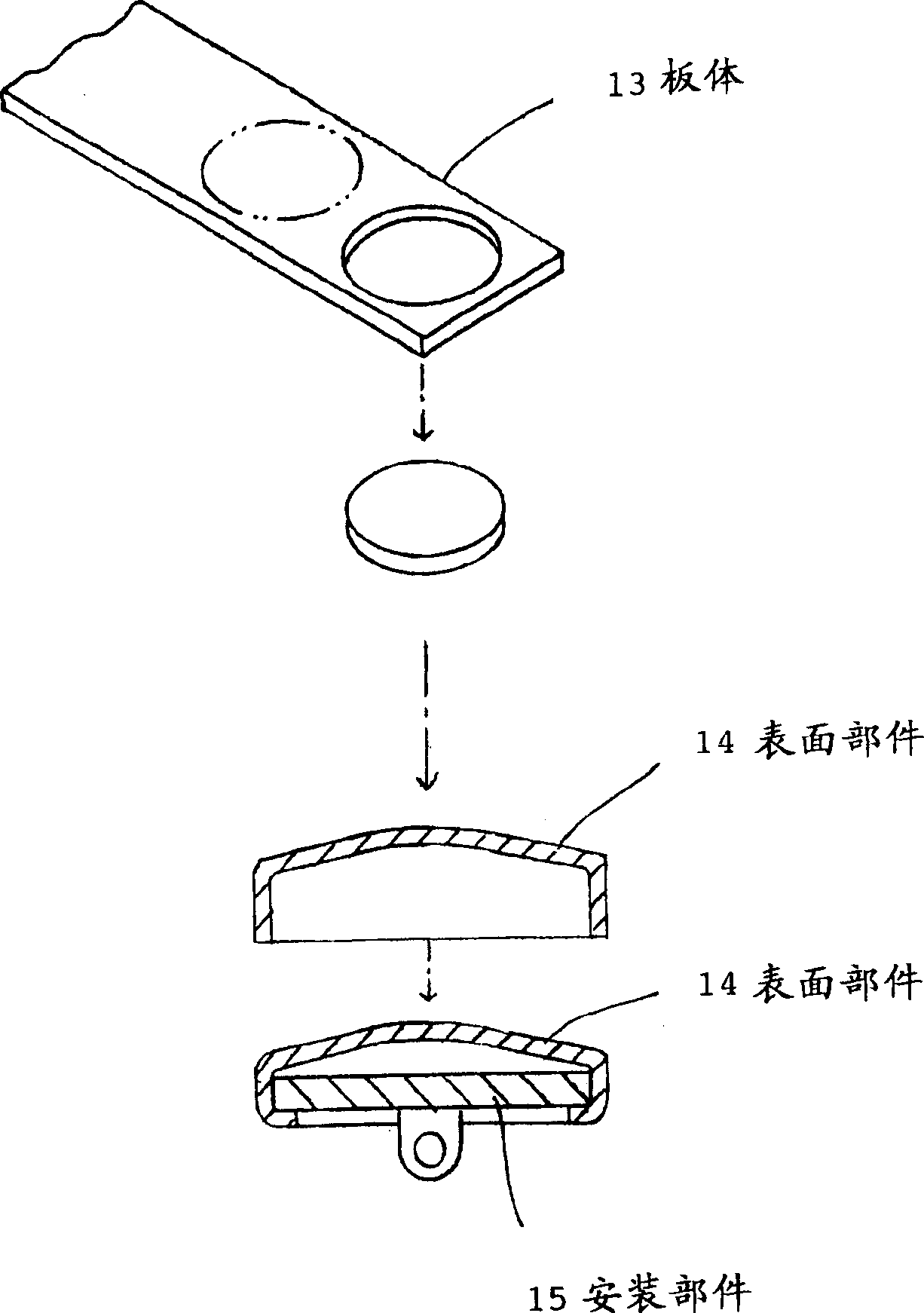

Aluminum alloy with excellent decorativeness

An aluminum alloy with excellent decorativeness, having a composition represented by the general formula AlaMgbMncCrd, wherein b, c, and d are, in mass percentage, 3.0<=b<=5.6, 0.05<=c<=1.0, 0.05<=d<=0.7, c+d>0.2, and a is the balance with unavoidable impurity elements possibly being contained, wherein a matrix of the aluminum alloy is a structure substantially composed of an aluminum solid solution, in which no beta-phase is present. This alloy has excellent decorativeness and decorativeness as well as superior strength, hardness and other such mechanical properties and is useful as materials for slide fastener constituent members, such as their elements, stops, and sliders, and / or in snap buttons, ordinary buttons, and clasps.

Owner:YKK CORP

Hastelloy electrolytic polishing process

The invention provides a hastelloy electrolytic polishing process, and belongs to the technical field of a polishing process. The specific steps are as follows: carrying out drying and cleaning pretreatments on a hastelloy electrolytic polishing workpiece to ensure that no redundant moisture is left on the surface of the workpiece; directly carrying out an electrolytic polishing treatment on the dry and clean workpiece; hanging the dry workpiece on a titanium alloy fixture, putting the titanium alloy fixture in an electric polishing groove, immediately electrifying constant voltage direct current, carrying out electrolytic polishing for 60-120 seconds, and controlling the current density at 5-7 A / dm<2>; cleaning the electrolytically polished workpiece in hot water of 38-42 DEG C for 2 minutes and drying the workpiece. According to the invention, a universal electrolytic polishing liquid reagent is adopted, and the pretreatment manner and the control process are adjusted, so that the appearance of the electrolytically polished surface of the hastelloy workpiece is good, the surface brightness is increased, the hastelloy workpiece has obvious metallic luster and has no spot corrosion, and the processing quality is effectively guaranteed.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

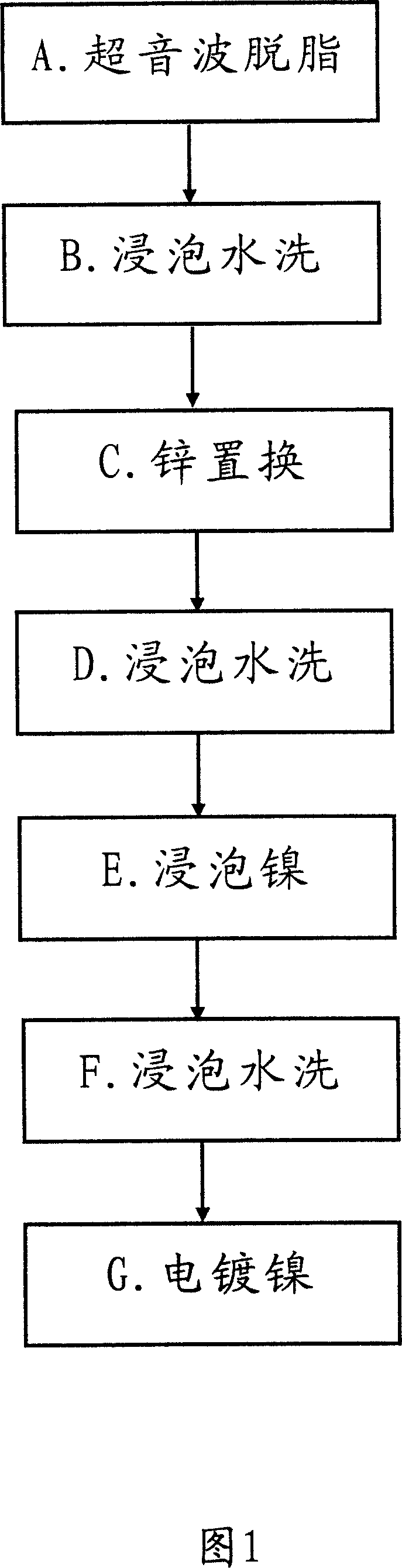

Electroplating method for aluminium product

The invention is an aluminum product plating method, comprising the steps of: A. supersonic degreasing; B. soaking and water washing; C. zinc replacement; D. soaking and water washing; E. soaking nickel; F. soaking and water washing; G. nickeling; and thus it can improve plating quality of aluminum products.

Owner:康顺发

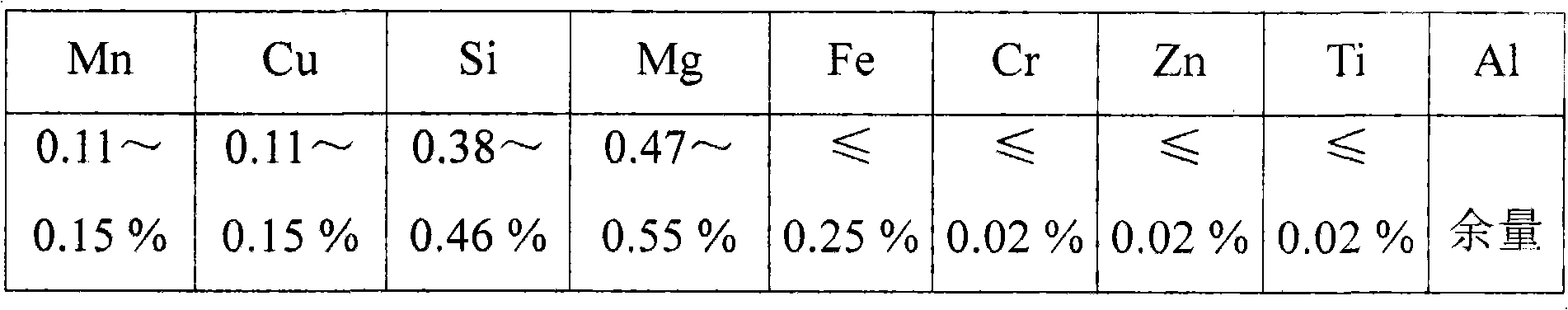

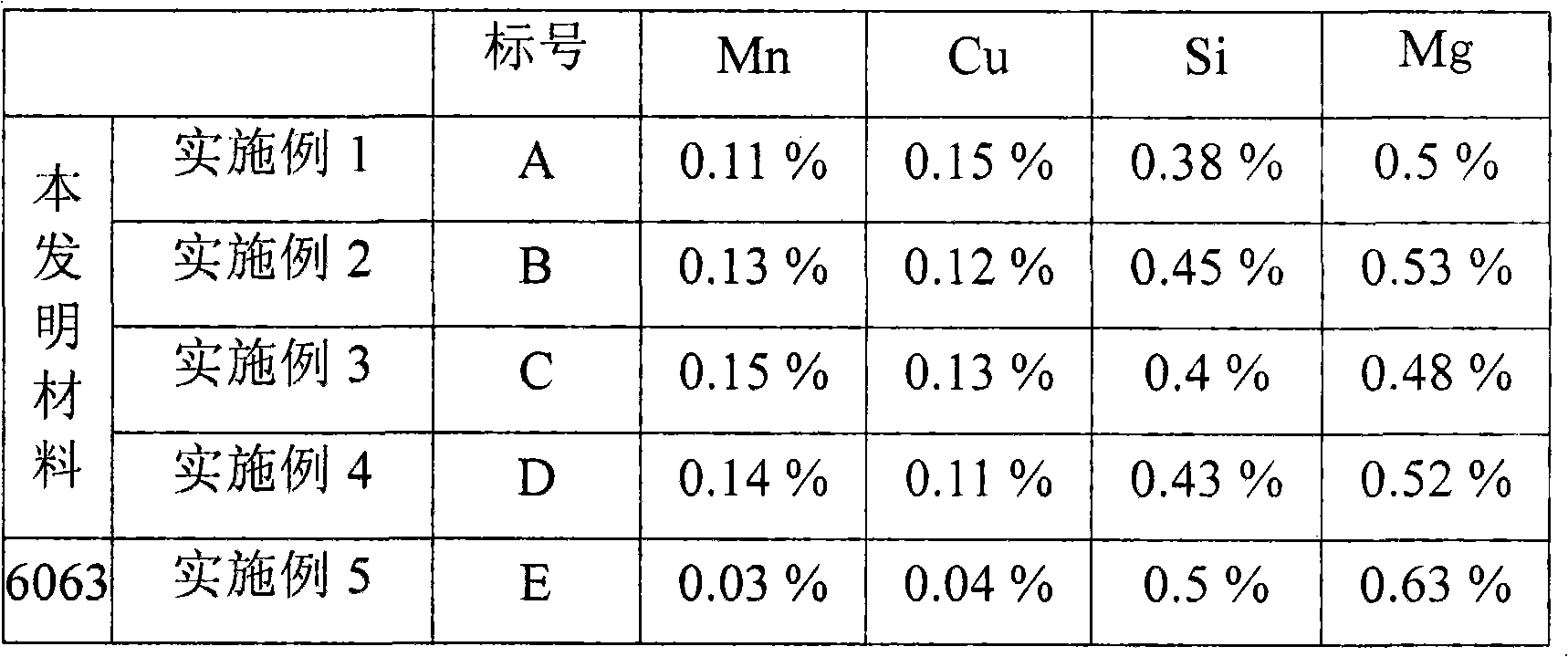

Aluminum alloy material capable of being molded by high-speed extrusion and preparation method thereof

The invention discloses an aluminum alloy material capable of being molded by high-speed extrusion, which comprises the following components in percentage by weight: 0.11-0.15% of Mn, 0.11-0.15% of Cu, 0.38-0.46% of Si, 0.47-0.55% of Mg, 0-0.25% of Fe, 0-0.02% of Cr, 0-0.02% of Zn, 0-0.02% of Ti, and the balance of Al. The invention also discloses a preparation method of the aluminum alloy material capable of being molded by high-speed extrusion; and compared with traditional aluminum alloy 6063, the speed for extruding sectional materials by the aluminum alloy material can be improved greatly, and the production efficiency of the aluminum alloy sectional material can be enhanced remarkably.

Owner:深圳华加日铝业有限公司

Plate drying process

InactiveCN102097621ABeautiful appearanceGood lookingLead-acid accumulator electrodesRinse waterEngineering

The invention discloses a plate drying process, which comprises the following steps of: when plates are grooved, uniformly loosening the negative plates piece by piece, directly placing the negative plates on a steel frame, and placing the whole steel frame in a pure water tank; after the grooving of the negative plates is finished, hoisting all the negative plates on the frame to a pool by using a traveling crane, and rinsing the negative plates from top down by using tap water, wherein supplied water and discharged water form counter current, and a pH value of the plate rinsing water is 5 to 7; after the rinsing is finished, feeding the plates into a boric acid pool, and impregnating the plates by using boric acid solution with the density of 1.025 to 1.045 g / cm<3> at 65 DEG C for 15 to 20 minutes; after the boric acid impregnation is finished, placing all the plates on the frame below an axial flow fan blowing air from top to down, and performing air blowing for 30 to 60 minutes in summer and 45 to 90 minutes in winter; and after the air-drying is finished, placing the plates into a Zhongnan drying kiln and performing drying for 40 minutes, wherein the temperatures of three drying stages are 160 DEG C, 150 DEG C and 120 DEG C respectively. The process provided by the invention is used for treating the negative plates, increases the lead metal content of the negative plates, avoids the pates being oxidized in storage and reduces the labor intensity of workers in the plate drying process.

Owner:JIANGSU LEOCH BATTERY

Millimeter wave radar thermal insulation wave transparent radome

InactiveCN108521015AMeet the needs of useGood metallic lusterRadiating element housingsThermal insulationRadar

The invention discloses a millimeter wave radar thermal insulation wave transparent radome. The radome includes a substrate. A colored layer, a nanometer metal level, an antioxidation layer, a paint inner protective layer and a base are inwardly arranged on the substrate in order. A wave transparent thermal insulation layer and a paint outer protective layer are outwardly arranged on the substratein order. The wave transparent thermal insulation layer is porous silicon nitride ceramic. The sign of the radar radome has good metallic luster, the wave transparent performance is excellent, the performance of sound and shock absorption, heat preservation, strength, rain corrosion resistance and ablation resistance is good, and usage requirements of customers can be met.

Owner:HEFEI HUMP ELECTRONICS TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com