Bismuth oxychloride crystal and preparation method thereof

A technology of bismuth oxychloride and crystal, applied in the field of bismuth oxychloride crystal and its preparation, can solve the problems of limited application, influence on brightness, complicated preparation process, etc., and achieve the effect of ensuring speed and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of a kind of bismuth oxychloride crystal disclosed by the present invention is as follows:

[0031] The growth of described bismuth oxychloride crystal is carried out by following reaction:

[0032] Bi(NO 3 ) 3 + HCl + H 2 O → BiOCl(crystal) + 3HNO 3

[0033] The mixture of described bismuth nitrate and hydrochloric acid is bismuth salt, and wherein, the ratio of bismuth nitrate and hydrochloric acid is 1: 0.8~1.2, by adjusting the consumption of described bismuth salt solution, the size of bismuth oxychloride crystal is controlled, at pH≤1 The hydrolysis reaction is carried out under acidic conditions, and the directional growth of the crystal is controlled by AEO9, thereby preparing a regular tetragonal sheet-like bismuth oxychloride crystal.

[0034] In some embodiments, the preparation method also uses NaOH solution as an adjustment solution to adjust the pH of the solution, thereby preparing the bismuth oxychloride crystals. The specifi...

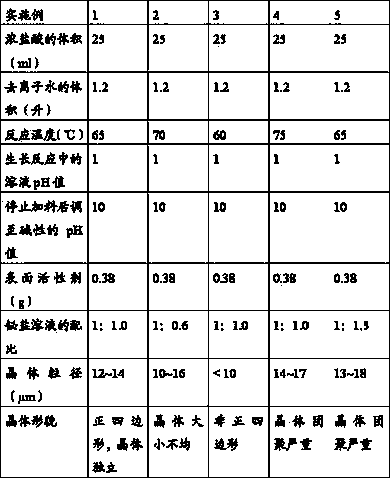

Embodiment 1

[0044] Add 25 mL of concentrated hydrochloric acid to 1.2 L of deionized water, stir and heat to 65 °C, then start to add 0.38 g of surfactant AEO9 dropwise, and at the same time add bismuth salt solution (bismuth nitrate The ratio of hydrochloric acid and hydrochloric acid is 1:1.0) and NaOH solution with a concentration of 20% is added to the system. After adding for 30 minutes, increase the dropping rate to 0.2 mL / min. After dropping for 120 minutes, stop adding the bismuth salt solution dropwise, continue adding NaOH until the pH is 10, and stop heating and stirring. After cooling to room temperature, the solution was allowed to stand until the layers were separated, and then the supernatant was removed. The resulting solid was washed with deionized water to obtain BiOCl crystals. Observation by microscope shows that the obtained product presents regular tetragonal flaky crystals with a particle size of 12-14 μm.

Embodiment 2

[0046] Add 25 mL of concentrated hydrochloric acid into 1.2 L of deionized water, stir and heat to 70 °C, then start to add 0.38 g of surfactant AEO9 dropwise, and at the same time add bismuth salt solution (bismuth nitrate The ratio of hydrochloric acid and hydrochloric acid is 1:0.6) and NaOH solution with a concentration of 20% is added to the system. After adding for 30 minutes, increase the dropping rate to 0.3 mL / min. After dropping for 120 minutes, stop adding the bismuth salt solution dropwise, continue adding NaOH until the pH is 10, and stop heating and stirring. After cooling to room temperature, the solution was allowed to stand until the layers were separated, and then the supernatant was removed. The resulting solid was washed with deionized water to obtain BiOCl crystals. Observation by microscope shows that the crystal size of the obtained product is uneven, and the particle diameter is 10-16 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com