Technique for producing nickelplated mischmetal annealed copper wire

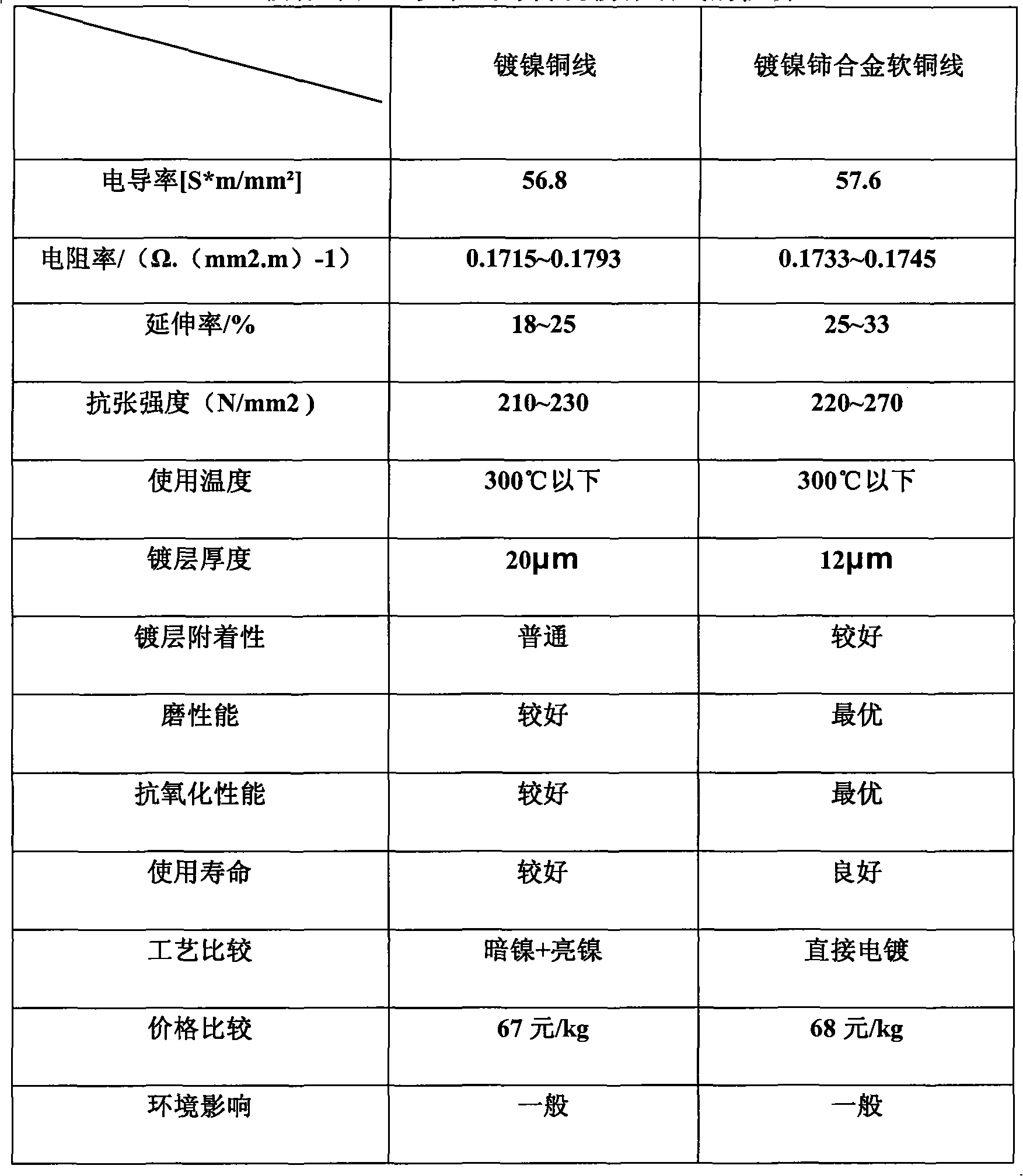

A production process, cerium alloy technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as easy peeling of the coating, insufficient bonding force of the coating, and uneven alloy layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The production process of the nickel-cerium alloy annealed copper wire of the present invention includes copper wire drawing, degreasing, water washing, pickling, pre-plating, electroplating, hot water washing, ultrasonic water washing, drying and taking-up, and quality inspection and warehousing in sequence. The conditions of each process are as follows.

[0045] 1. Copper wire drawing

[0046] The copper rod with a diameter of 8.00mm is first drawn to a diameter of 2.80mm to 3.00mm through a large drawing machine, and then drawn to a diameter of 0.40mm to 1.20mm through a middle drawing machine, and then annealed and induced in a bell-type annealing furnace After formula continuous annealing, a round copper wire with a diameter of 0.40 mm to 1.20 mm is obtained.

[0047] 2. Degreasing

[0048] During the drawing process of copper wire, lubricating oil will adhere to its surface. Oil stains on metal surfaces are almost unavoidable, mainly from cooling, lubrication, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com