Patents

Literature

92results about How to "Increased cathodic polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

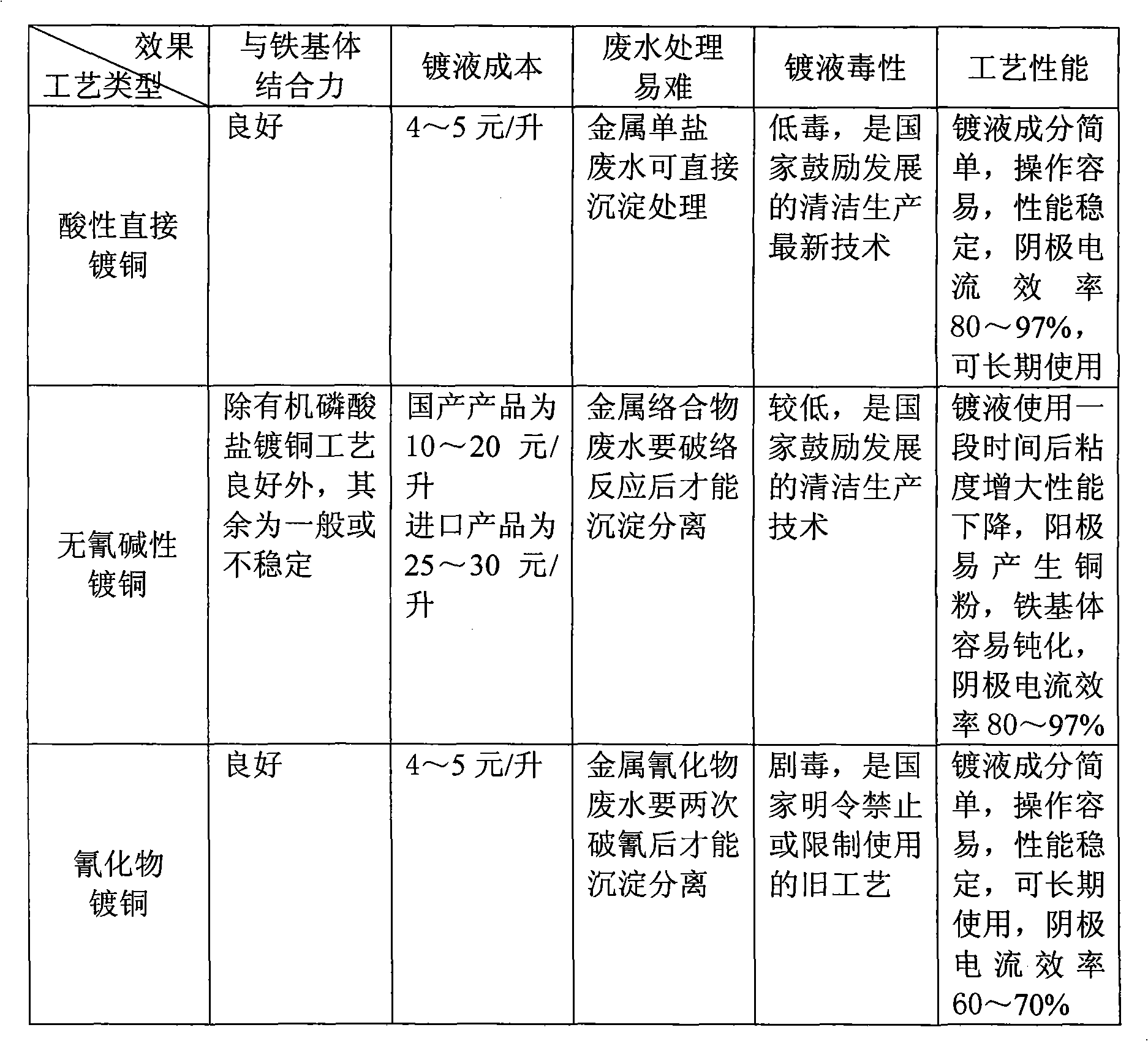

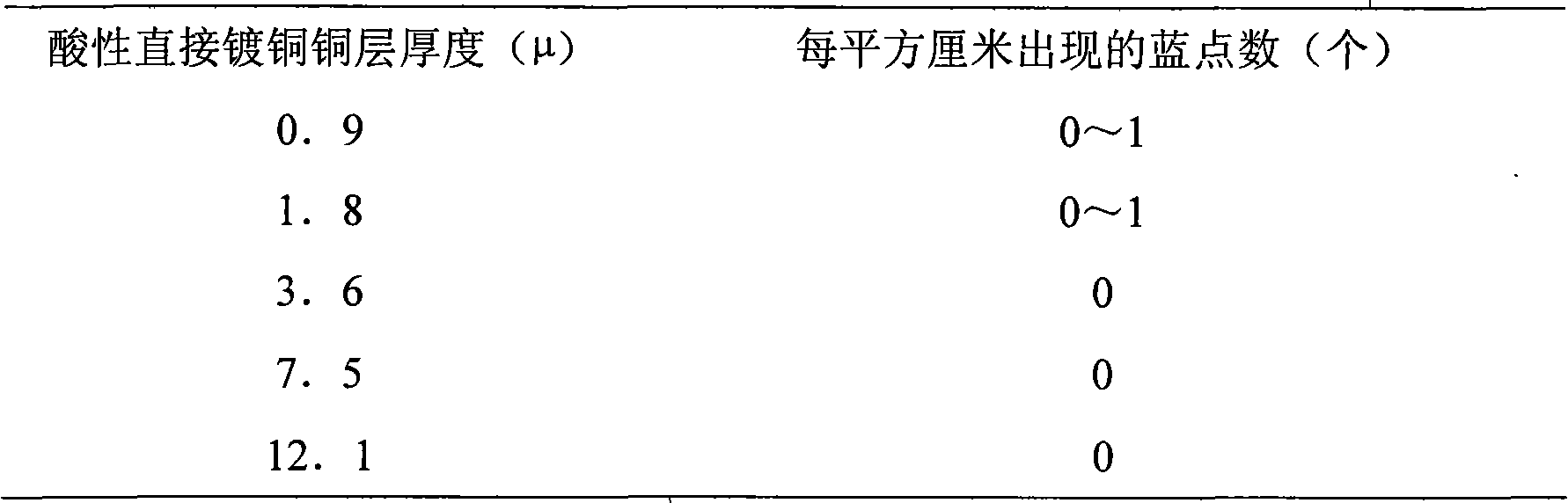

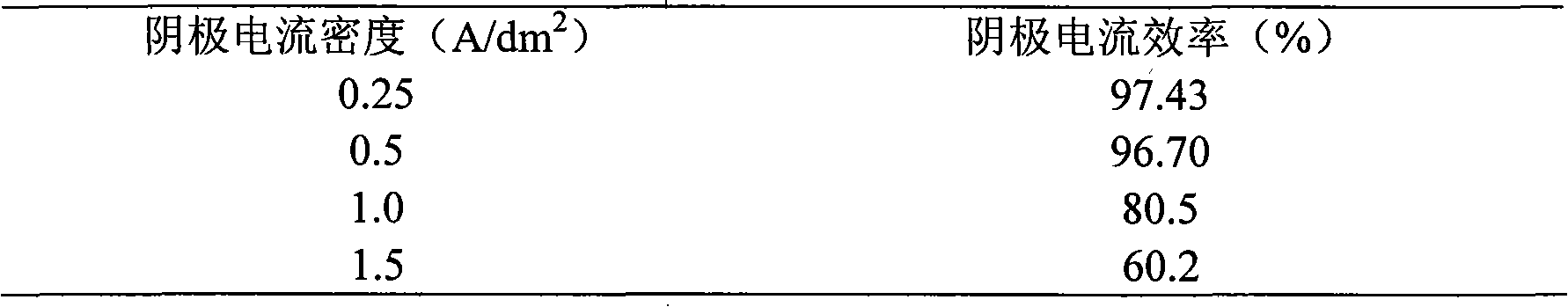

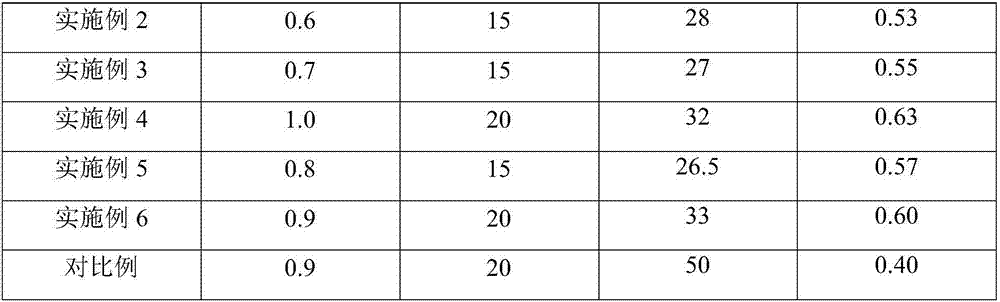

Steel member acidic electroplating additive for copper pre-plating and pre-plating process

The invention relates to a copper plating process pre-plating addition agent, comprising a key light agent and an auxiliary light agent, wherein the key light agent comprises (1) a nonionic surfactant, (2) a sulfur and nitrogen containing organic compound, (3) an alcohol compound, (4) an aldehyde compound, (5) a ketone compound, (6) dyes, (7) a metallic salt and (8) water; the auxiliary light agent comprises (1) a nonionic surfactant, (2) an aldehyde compound, (3) dyes, (4) chloride, (5) a metallic salt, (6) water and (7) an inorganic acid. Preplating is a process which directly carries out copper plating in an acidic solution, thereby overcoming the disadvantage that copper plating can not be directly carried out in a steel acidic solution and realizing direct copper preplating on a steel part; moreover, the copper plating process pre-plating addition agent solves the bonding force between a copper plating layer and an iron matrix and realizes the aims of environment protection and lower cost.

Owner:梁国柱 +1

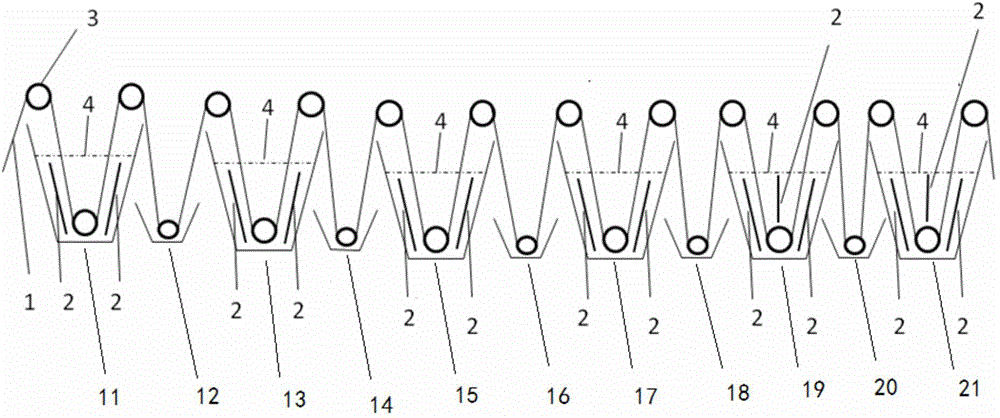

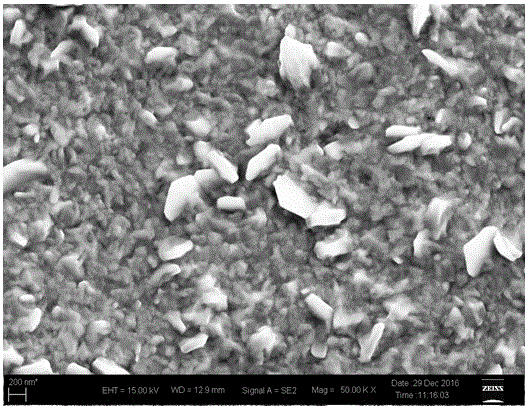

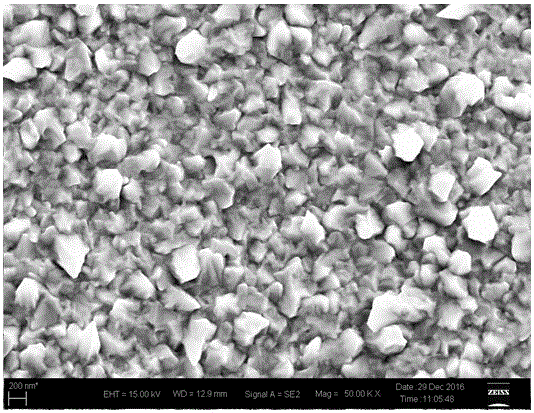

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

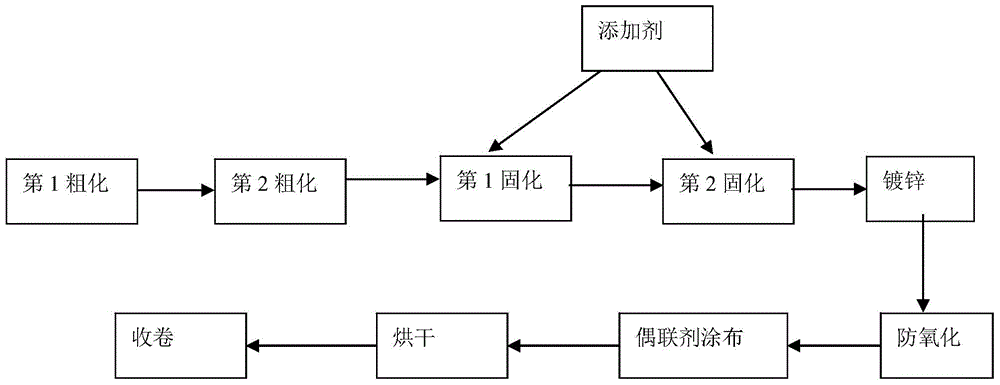

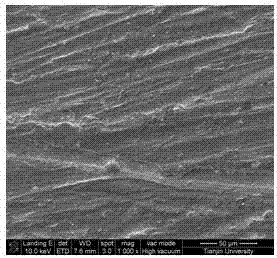

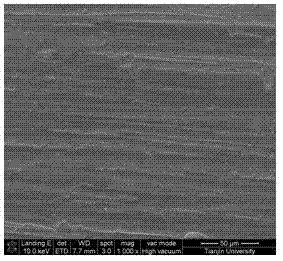

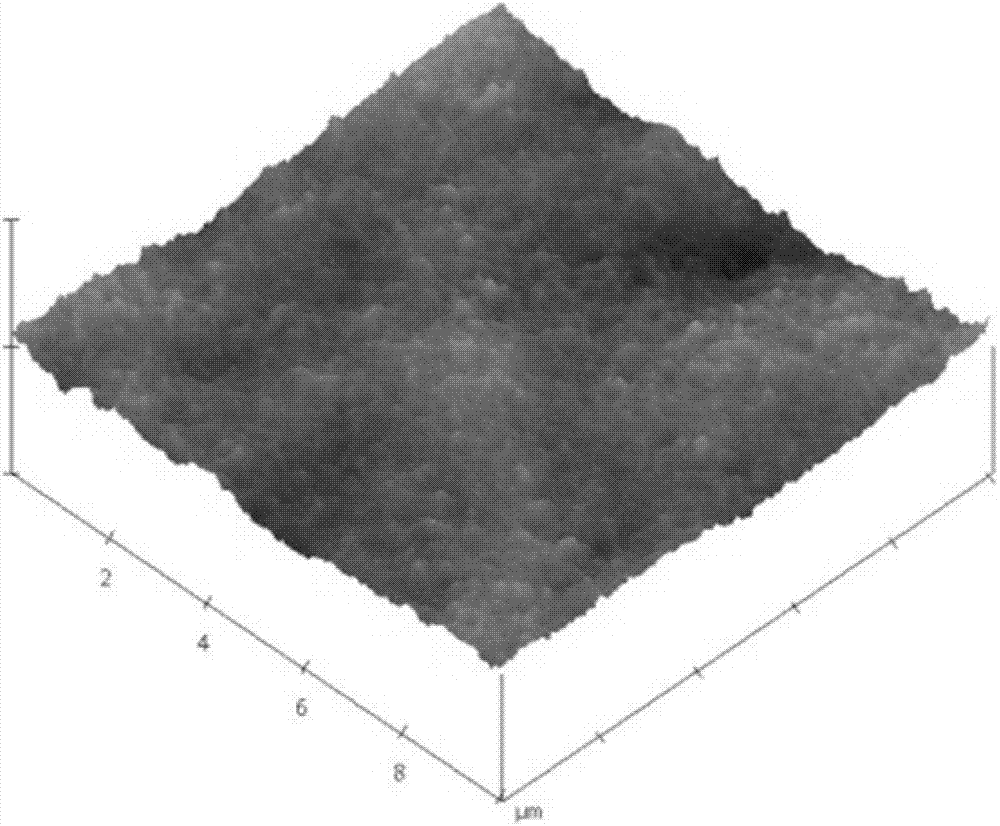

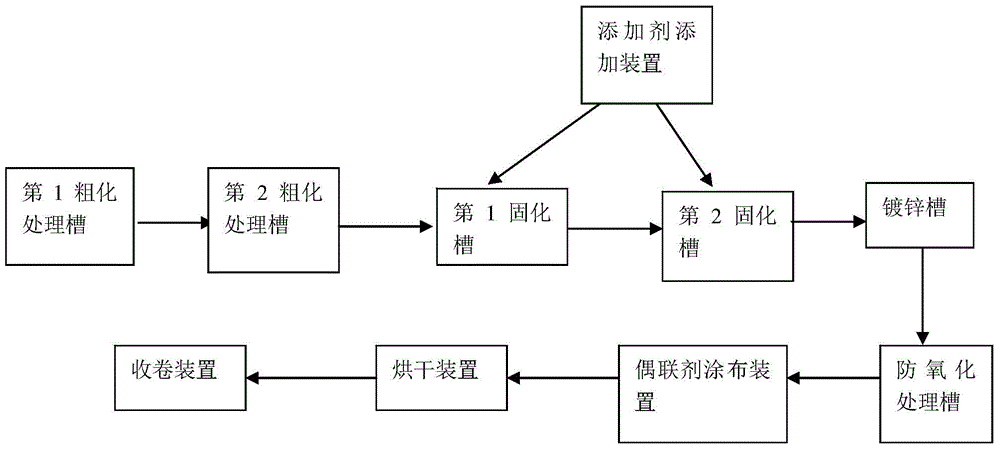

Surface treatment method for reducing copper powder on rough surface of copper foil

The invention provides a surface treatment method for reducing copper powder on the rough surface of copper foil. Coarse foil formed by electroplating raw foil is treated through the first coarsening process, the second coarsening process, the first solidifying process, the second solidifying process, the galvanizing process, the oxidation prevention process, the coupling agent coating process and the drying process. Through the treatment processes, the copper powder is greatly reduced, the number of the copper powder in a 10-square-centimeter copper foil sample does not exceed 10, the maximum diameter of the copper powder does not exceed 30 microns, and therefore the risk that short circuits are caused when the copper foil is used for making printed circuit boards is greatly reduced.

Owner:ANHUI TONGGUAN COPPER FOIL +1

Pyrophosphate copper plating used as grounding electroplate liquid for cyanogen-free copper plating

The invention discloses a strike bath solution with pyrophosphate plating copper as the cyanide-free copper, which contains a make-up agent and rehydration salt; the make-up agent contains the following raw materials: potassium pyrophosphate, copper pyrophosphate, ammonium citrate, sorbol, sulfosalt, phenyl carboxylate, dextrin, alkyl thiourea and nitrogen heterocyclic; the rehydration salt is as supplementation of all raw materials in the make-up agent during the plating process; the invention does not contain harmful substances, such as cyanidum, heavey metal, etc and is in compliance with EU RoHS Directive (2002 / 95 / EC) with stable bath solution and wide cathode current density range, and the plating layer prepared by the invention is fine, even and in a semi-bright state; and the make-up is conducted with original solution, supplementation is conducted with single rehydration salt, which is convenient in operation and simple in management; the plating layer is well adhesive to the matrix, with good straggling capability and covering capability. The invention is applicable in pre-plating of iron materials, zinc alloys, aluminum alloys and copper alloys, as well as barrel plating and suspension plating, with the waste water easy to dispose, which will not bring the secondary pollution.

Owner:江门市瑞期精细化学工程有限公司

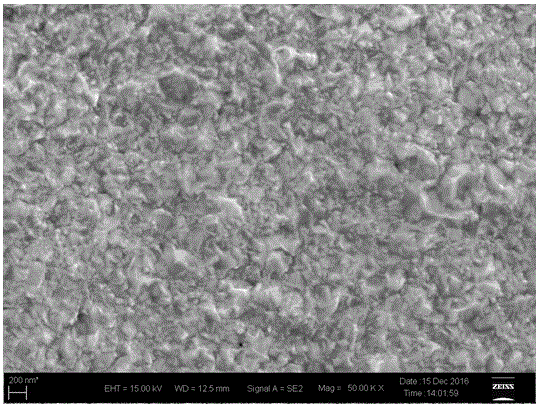

Preparation method of nano Sn/SiC composite plating

InactiveCN102051657AIncreased cathodic polarizationDense coatingElectrolytic coatingsCopper foilCorrosion

The invention discloses a preparation method of nano Sn / SiC composite plating, relating to a preparation method of Sn / SiC composite plating. The invention aims to solve the problems that the existing pure tin plating is easy to grow tin whisker and has poor mechanical property and codeposition of nano particles on a cathode can not be realized easily in the conventional nano composite plating technology. The preparation method comprises the following steps: 1, soaking SiC nano particles in methanesulfonic acid, then adding dispersant, stirring, and sequentially adding tin methanesulfonate, brightening agent, codeposition accelerant and main salt stabilizer to compose a plating solution; 2, parallelizing a cathode copper foil and a pure tin anode plate into the plating solution; and 3, adjusting the cathode current density, mechanically stirring and plating alternately, and keeping stirring under compressed nitrogen all the time, thus finishing preparing the nano Sn / SiC composite plating. The prepared nano Sn / SiC composite plating is obviously improved in inhibition of tin whisker growth, corrosion resistance, hardness and the like, and the preparation method can be applied to the field of weldable plating.

Owner:HARBIN INST OF TECH

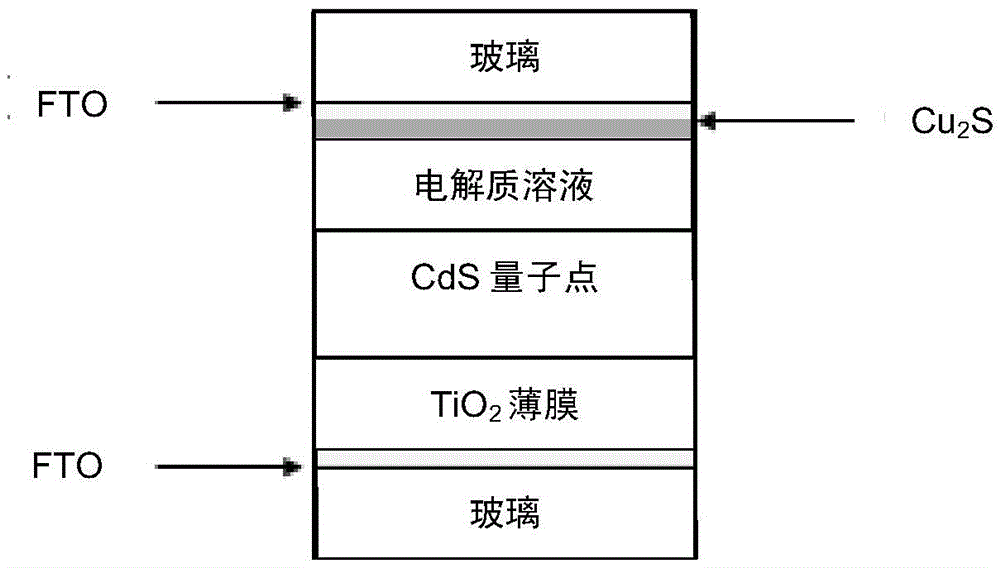

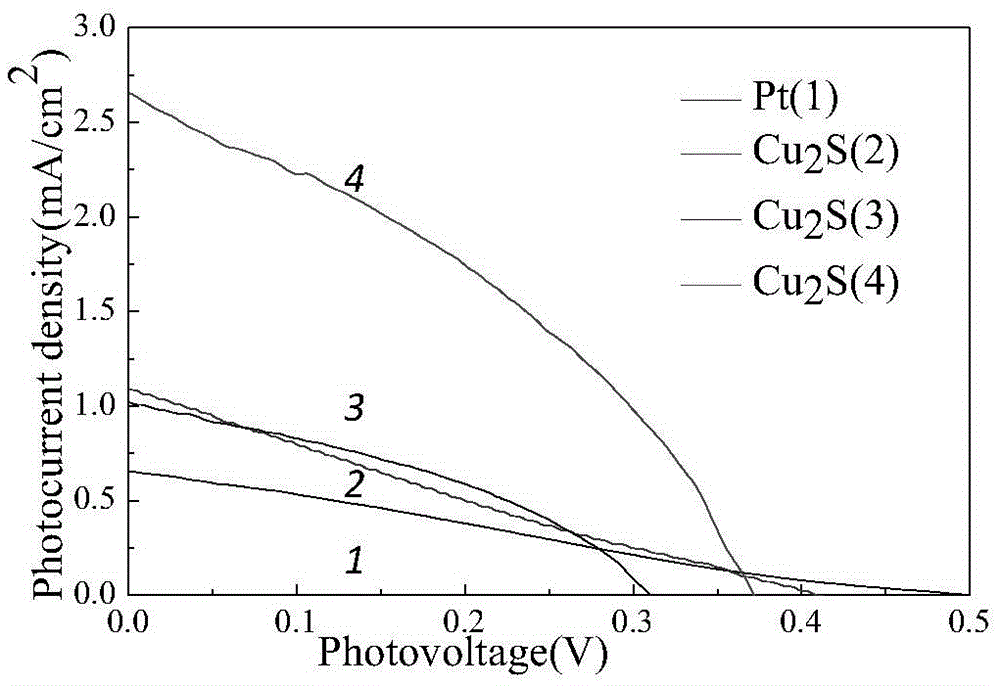

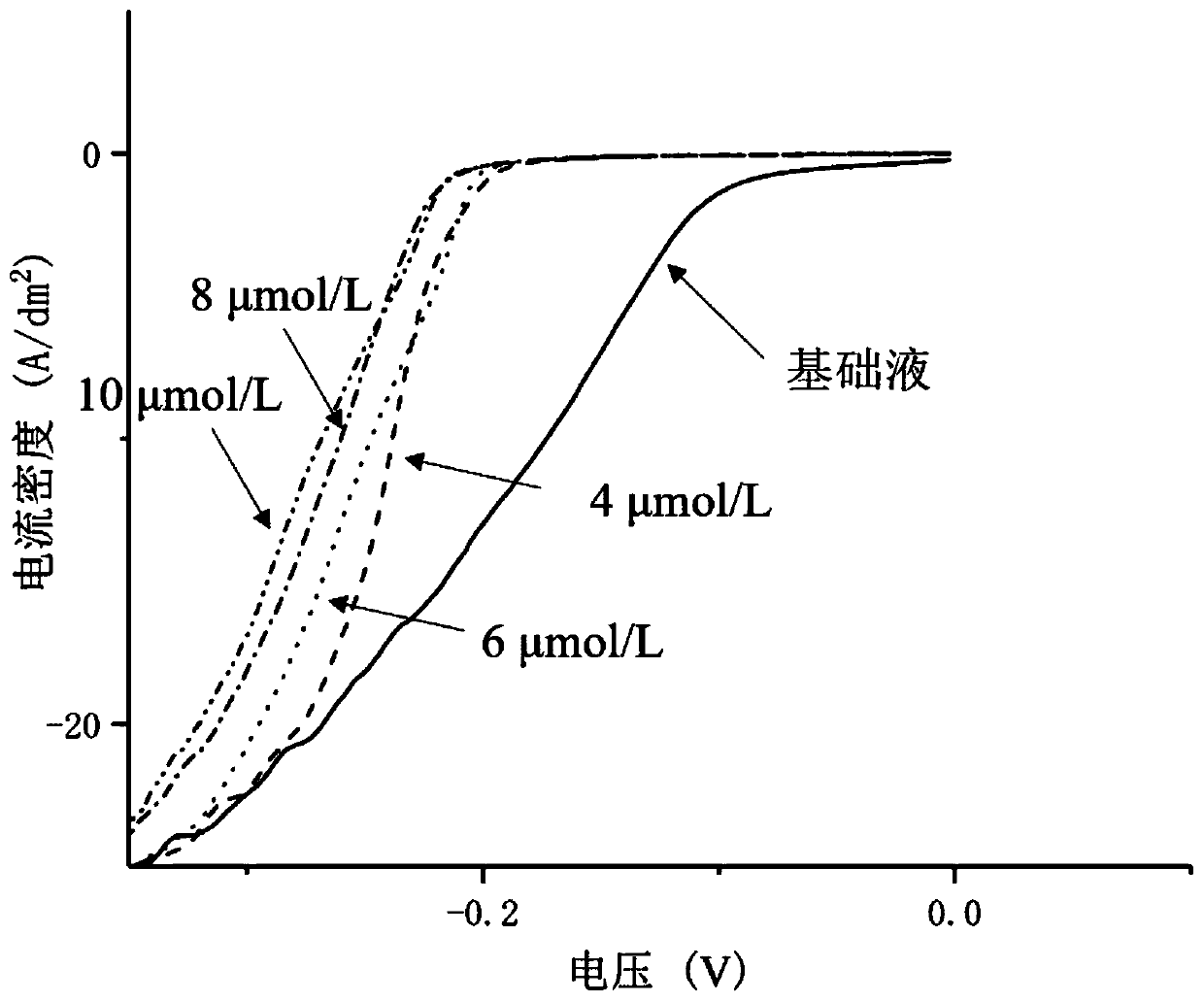

Solar cell Cu2S/FTO counter electrode and electrochemical deposition preparation method thereof

InactiveCN105655131ASimple preparation processLow costLight-sensitive devicesFinal product manufactureElectrolyte leakageThiourea

The invention provides a method for preparing a solar cell Cu2S / FTO counter electrode based on the electrochemical deposition process and belongs to the technical field of solar cells. According to the method, an electrolyte is prepared firstly and then a Cu2S / FTO counter electrode is obtained in a three-electrode system through electrochemically depositing the Cu material on an FTO according to the potentiostatic method and then sulfurizing the deposited Cu material in a polysulfide solution. The above electrolyte is composed of a buffer system comprising 0.03-0.05 mol / L of CuCl2, 6.6*10<-3>-1.3*10<-2> mol / L of thiourea and 0.3-0.5 mol / L of lactic acid, and the pH value of the buffer system is 5.0-7.0. The polysulfide solution is composed of a methanol solution comprising 0.5-1 M of Na2S*9H2O, 0.5-1 M of S and 0.05-0.1 M of KCl. The method is simple in preparation process and low in cost, which provides a reliable preparation scheme for the preparation of QDSCs counter electrodes. Meanwhile, the problems of the mechanical stability and the electrolyte leakage of Cu2S / FTO counter electrodes can be solved.

Owner:JILIN UNIV

Rare earth alloy, preparation technique and application thereof

The invention relates to a light rare earth base heavy rare earth alloy, a preparation technology and application thereof. The alloy contains 1-40wt% heavy rare earth, and is prepared by oxide fused salt electrolysis process in fluoride molten salt. The electrolyte is composed of rare earth fluoride, lithium fluoride and magnesium fluoride, the compositions are: 65 to 87wt% of base fluoride in rare earth fluoride, 5 to 25wt% of heavy rear earth fluoride, 5-12wt% of lithium fluoride and 0.5 to 3wt% of magnesium fluoride. Since the electric efficiency is larger than 75%, the metal recovery rate is large than 90%, the preparation technology is especially suitable for industrialized mass production.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

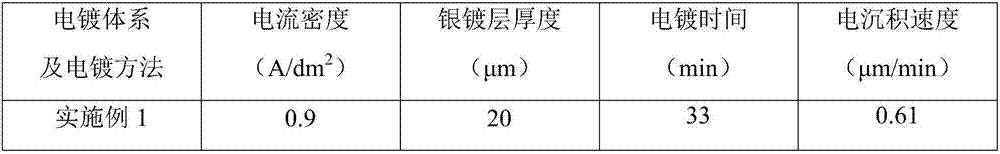

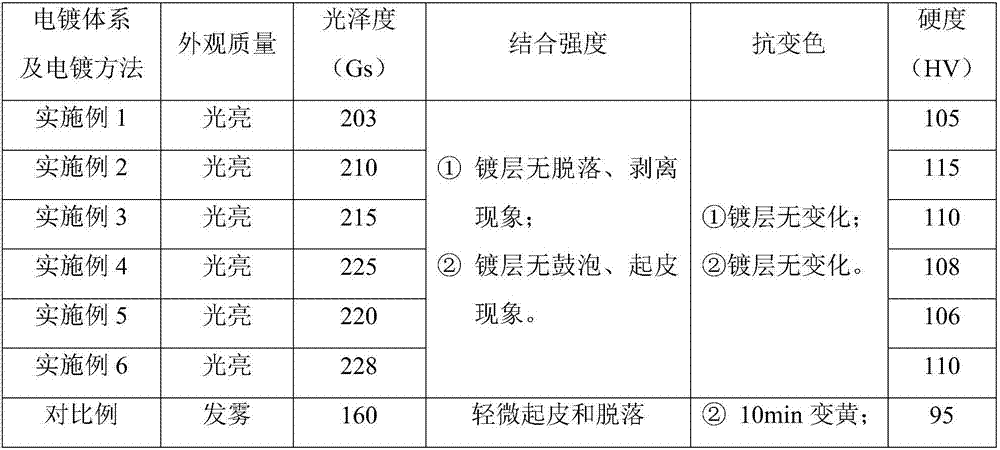

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

Neodymium-iron-boron magnet nickel electroplating solution and use method thereof

ActiveCN102978679AIncreased cathodic polarizationImprove dispersion ability and deep plating abilityElectrolytic coatingsNickel electroplatingYttrium

The present invention discloses a neodymium-iron-boron magnet nickel electroplating solution and a use method thereof, wherein a purpose of the present invention is to overcome defects of non-uniform thickness distribution and high porosity of the existing neodymium-iron-boron magnet nickel electroplating layer. The formula of the neodymium-iron-boron magnet nickel electroplating solution comprises 80-350 g / L of nickel sulfate, 20-80 g / L of nickel chloride, 30-55 g / L of boric acid, 0.1-5 g / L of yttrium sulfate, 0.04-2 g / L of nanometer silica, and the balance of water. According to the present invention, the nickel electroplating layer obtained by using the method has characteristics of uniform thickness distribution and lower porosity, and corrosion resistance of the neodymium-iron-boron magnet is improved.

Owner:浙江东阳东磁有限公司

High-leveling performance acid copper brightener for copper electroplating

The invention relates to the field of electroplating, in particular to a high-leveling performance acid copper brightener for copper electroplating. 1L of the high-leveling performance acid copper brightener for copper electroplating comprises the following raw materials in proportions by mass: 3-4g of a leveling agent, 1.5-2.5g of an accelerator, 7-15g of a carrier and the balance of water.

Owner:WINSTAR CHEM SHANGHAI

Tin plating electrolyte and preparation method and application thereof

The invention relates to a tin plating electrolyte which contains a solvent and the materials with following concentration: 10-20g / L of tin methane sulfonate, 30-60g / L of methanesulfonic acid, 0.4-5g / L of compound additive, and a proper amount of PH regulator; and the compound additive is formed by thiourea, hydroquinone, 2-mercapto benzimidazole and propylene glycol block polyether. For the tin plating electrolyte, by reasonably selecting types and use amount of additives, the problems of instable plating solution and high cost in the methanesulfonic acid system are solved, and by using the tin plating electrolyte, a high-mass plating layer is acquired beneficially.

Owner:GUANGDONG GUANGHUA SCI TECH

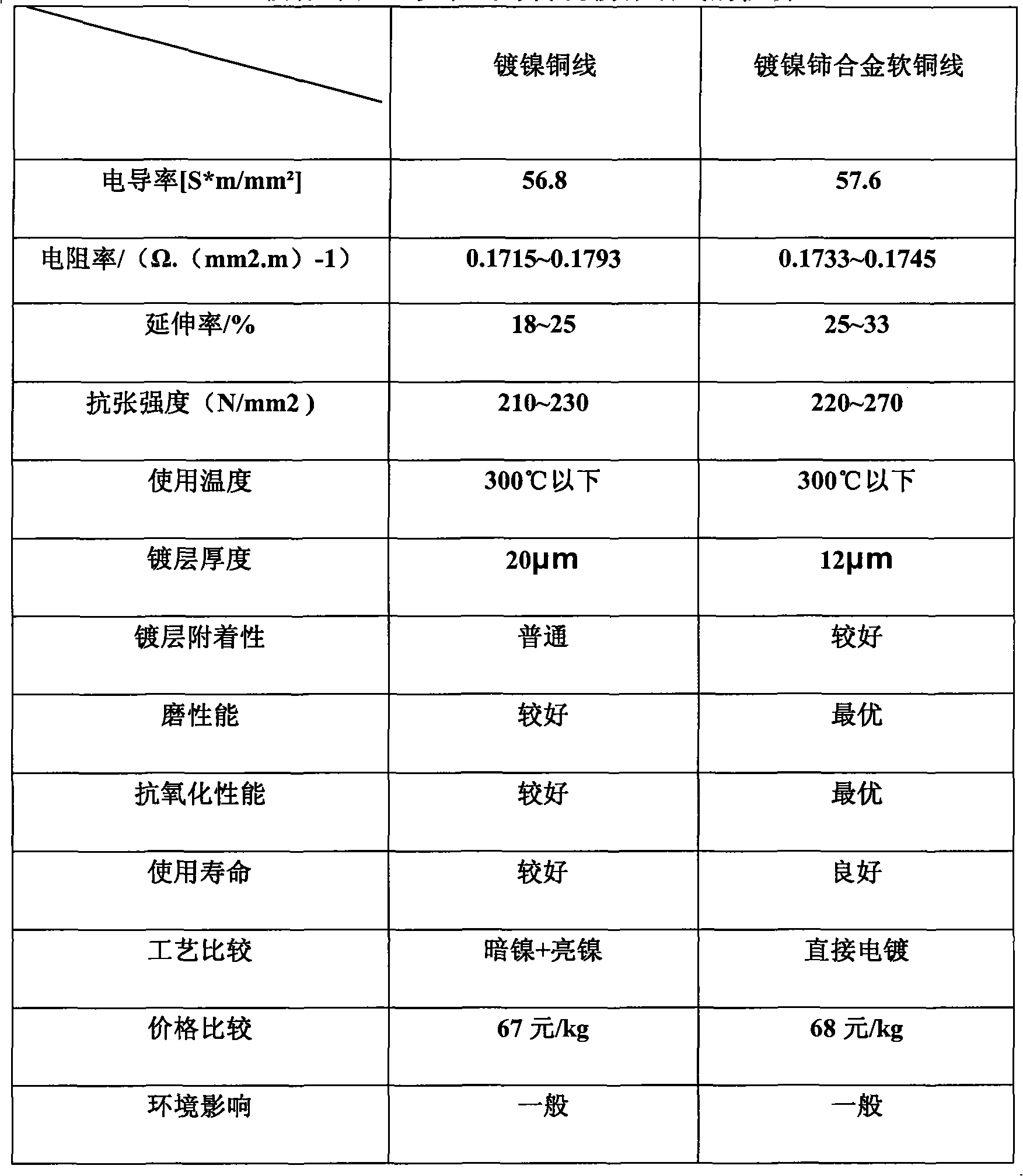

Technique for producing nickelplated mischmetal annealed copper wire

InactiveCN101556846AGood metallic lusterGood adhesionCable/conductor manufactureMischmetalCopper wire

The invention relates to a technique for producing a nickelplated mischmetal annealed copper wire, which comprises the working procedures such as drawing copper wire, removing oil, washing, acid cleaning, preplating, electroplating, hot water rinsing, ultrasonic washing, drying and wire collecting, quality testing and warehouse entry, and the like, wherein, the process of electroplating is the electrochemical process by taking nickel and cerium elements as plating additive. The nickelplated mischmetal annealed copper wire prepared by the technique has good metal luster on the surface of the plating layer and excellent adhesiveness, toughness and tractility, is difficult to find a pinhole and suitable for manufacturing aircraft wires and cables as well as special installation conductive core, and can be widely applied to the wires and cables used for installing and connecting electric appliances such as aerocraft, railway, automobile, streamship, etc.

Owner:丹凤县永鑫电子材料有限责任公司

Ionic liquid gold plating solution containing coordination agent and additive and gold plating method adopting ionic liquid gold plating solution

The invention discloses an ionic liquid gold plating solution containing a coordination agent and an additive and a gold plating method adopting the ionic liquid gold plating solution and belongs to the technical field of gold electroplating. The gold plating solution is prepared from a solvent [BMIm] [BF4], main salt chloroauric acid, the coordination agent and the additive. Gold electroplating mainly includes the steps of (1) a substrate pretreatment and nickel preplating process and (2) gold electroplating. The ionic liquid gold plating solution containing the coordination agent and the additive and the gold plating method adopting the ionic liquid gold plating solution have the advantages that the added coordination agent has a certain coordination relation to gold ions, the stability of a gold complex in the plating solution can be improved, cathodic polarization can be improved in the electroplating process, and the functions of refining grains and brightening plating coatings are achieved; the added additive cooperates with the coordination agent to a certain degree so that the grains can be further refined, the coatings can be more compact and the appearance can be brighter; and to sum up, the ionic liquid gold plating solution and the gold plating method have the best characteristic that by adding the coordination agent and the additive in an ionic liquid system, the stability of the gold complex in the gold plating solution and the stability of the gold plating solution are improved, and therefore the gold plating coatings and the gold plating solution which are good in properties are obtained.

Owner:HARBIN INST OF TECH

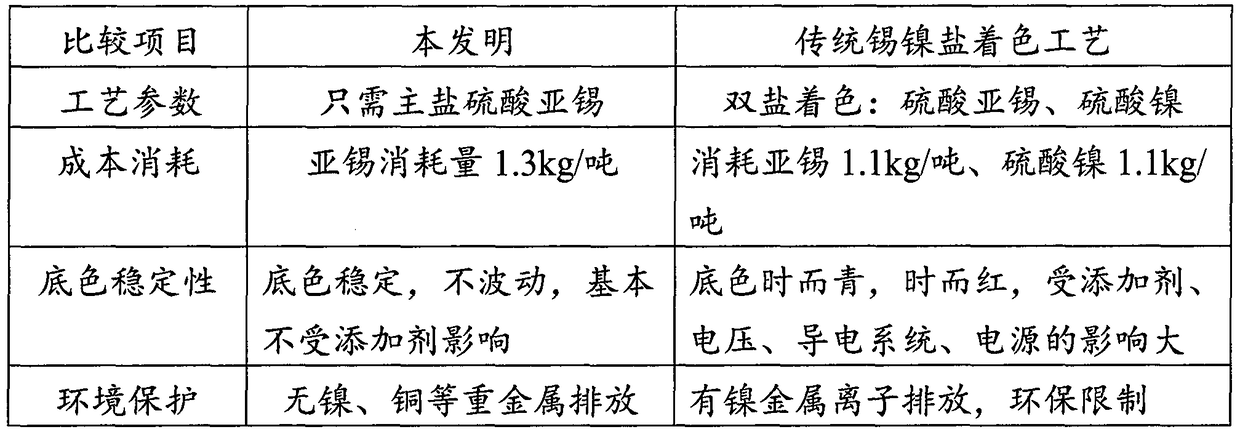

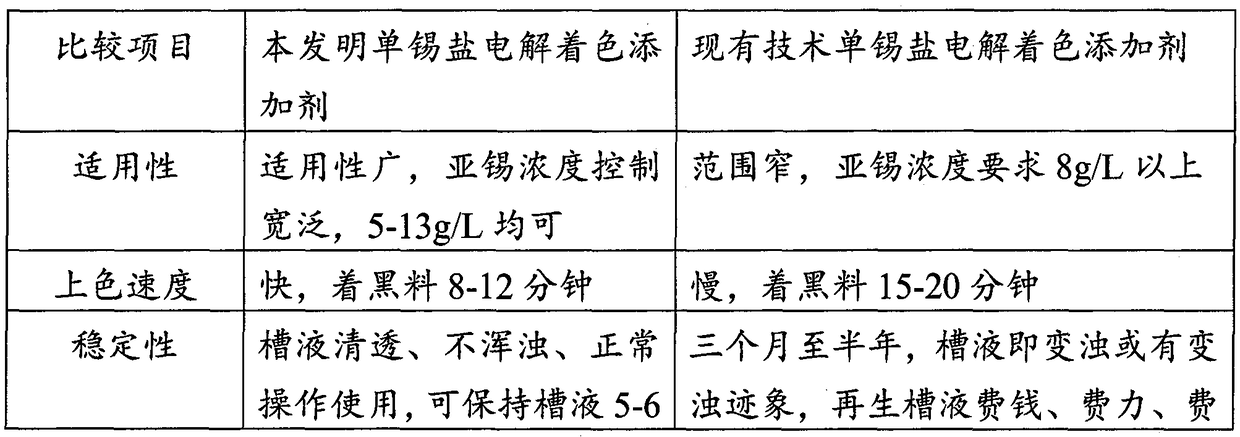

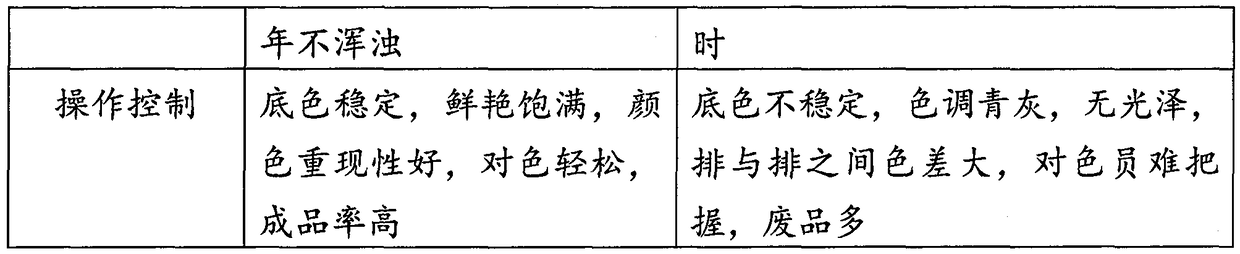

Single tin salt electrolytic coloring additive and application thereof

InactiveCN108342763AAntioxidantProtection stabilitySurface reaction electrolytic coatingZinc phosphateElectrolysis

The invention discloses a single tin salt electrolytic coloring additive. The single tin salt electrolytic coloring additive comprises a complexing agent, a buffer agent, an antioxidant and a surfactant, wherein the antioxidant comprises ferrous sulfate; the single tin salt electrolytic coloring additive also comprises an auxiliary agent containing ferrous sulfate; the auxiliary agent comprises modified amino amide zinc phosphate. The single tin salt electrolytic coloring additive disclosed by the invention has good comprehensive performances, solves the problem that nickel must take part in the reaction in an electrolytic coloring process, and is stable in groove liquid and quick and uniform to color, and the cost can be lowered effectively. Moreover, the single tin salt electrolytic coloring additive is low-carbon, energy-saving and green and environment-friendly, and process and product quality consistent to those of a double salt system can be obtained.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

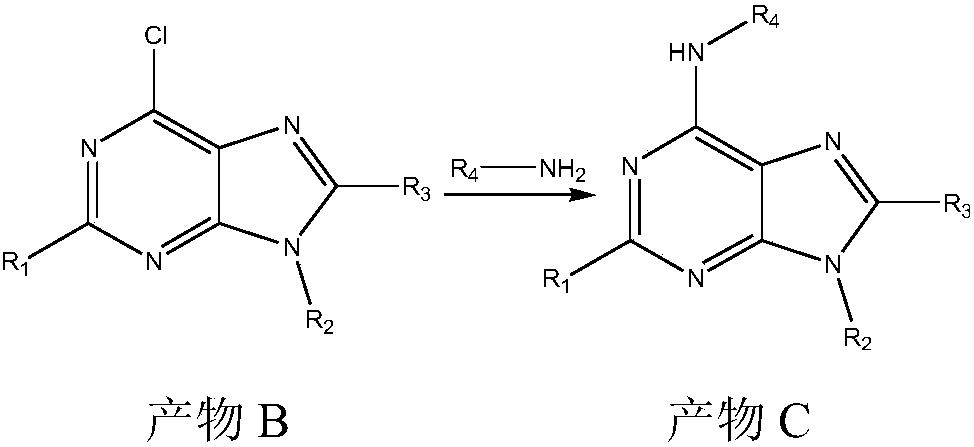

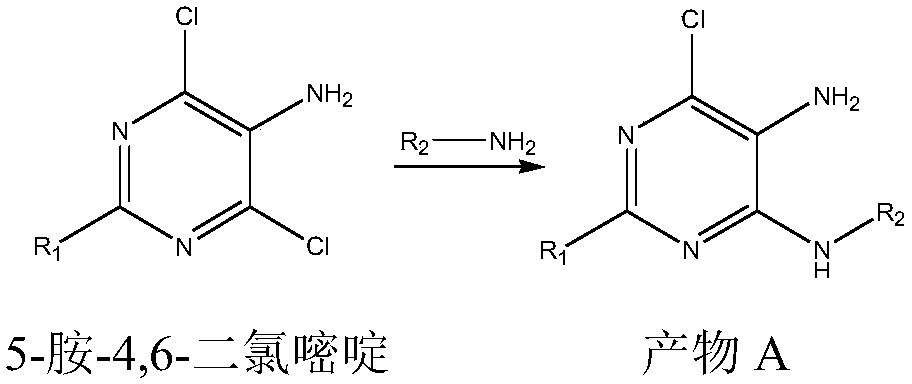

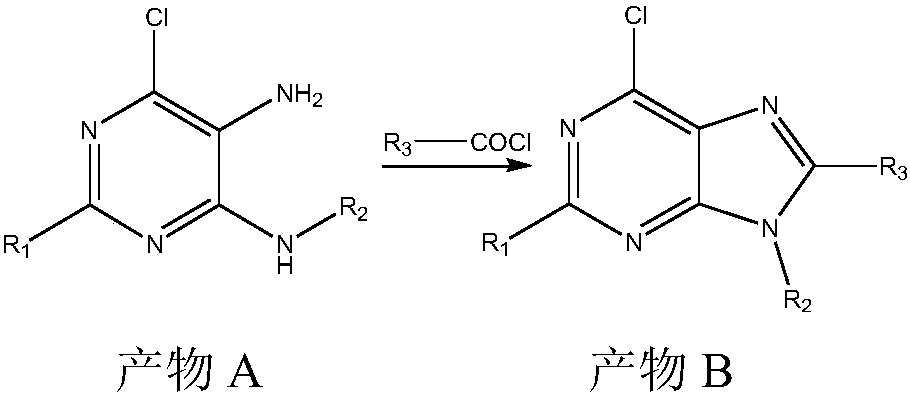

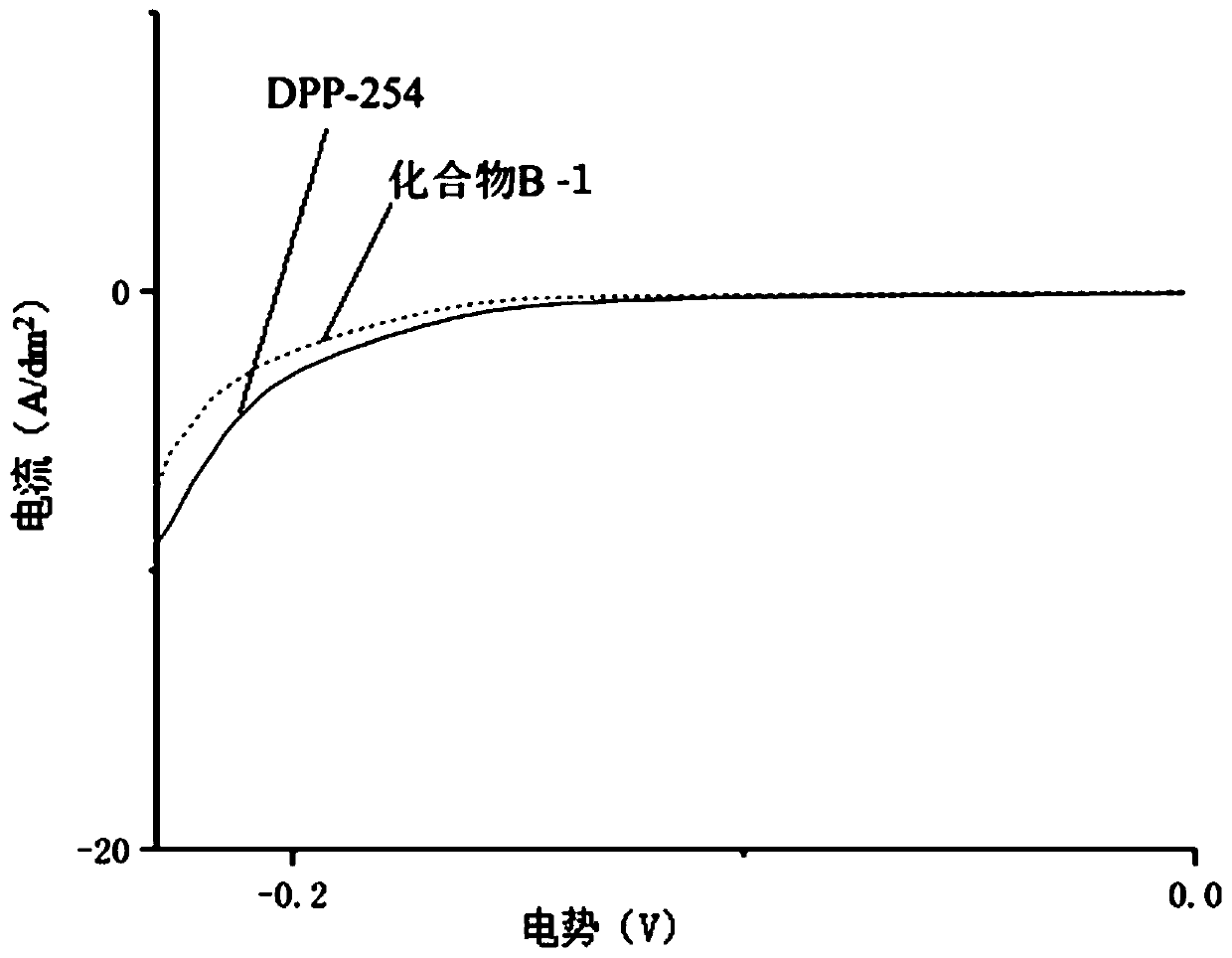

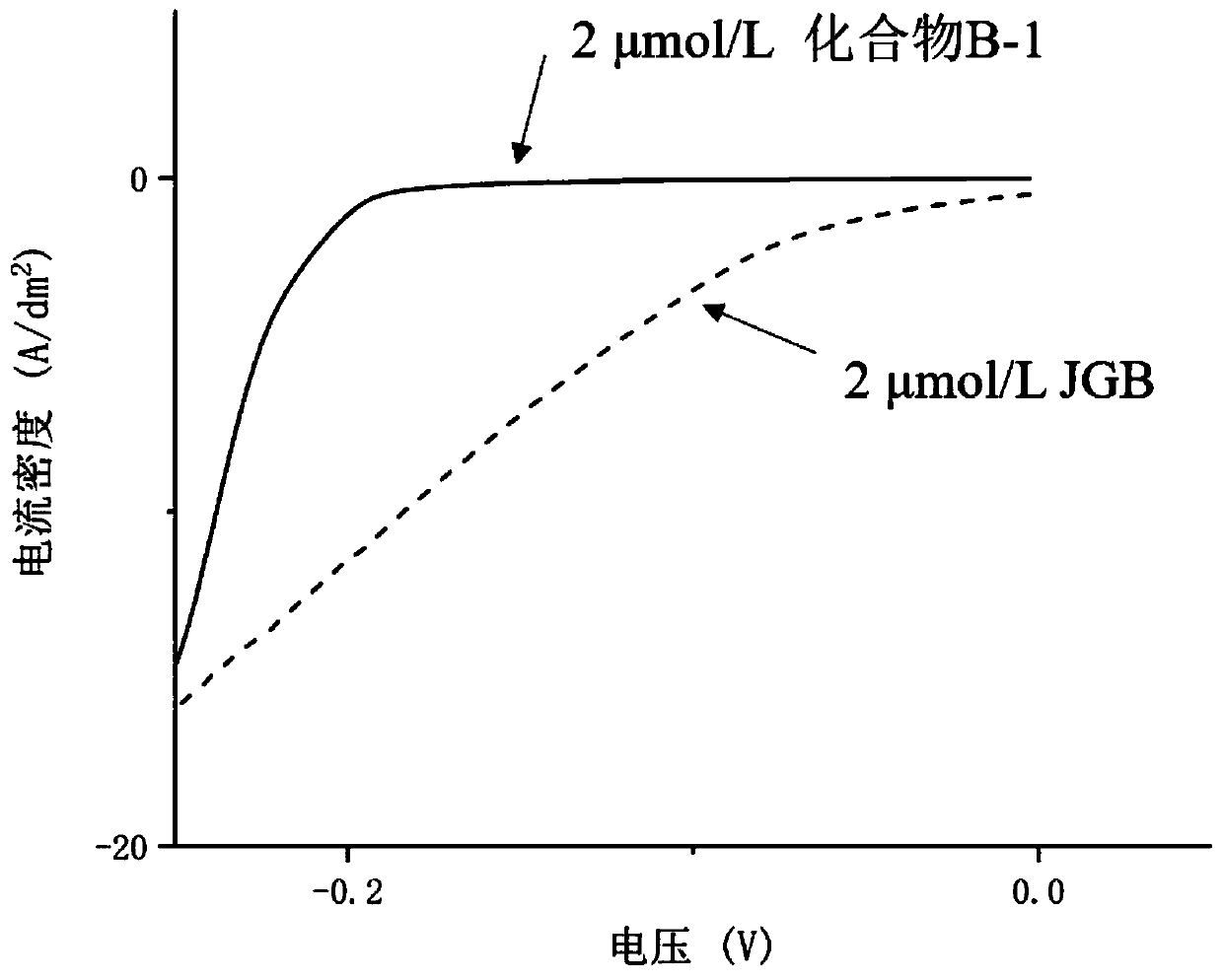

Heterocyclic diketopyrrolopyrrole (DPP) quaternary ammonium salt compounds and preparation method and applications thereof

ActiveCN109824674AImprove the plating effectAvoid depositionOrganic chemistryCopper platingStructural formula

The invention discloses heterocyclic diketopyrrolopyrrole (DPP) quaternary ammonium salt compounds. The structural formula of the compounds is represented by a formula B, and the definitions of all substituents are shown in the description. The provided heterocyclic diketopyrrolopyrrole (DPP) quaternary ammonium salt compounds have a good electroplating performance and can be used as a quaternaryammonium salt leveling agent for acidic copper plating.

Owner:EAST CHINA UNIV OF SCI & TECH +1

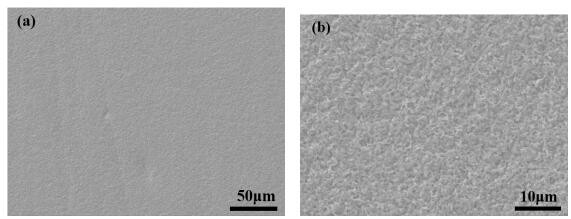

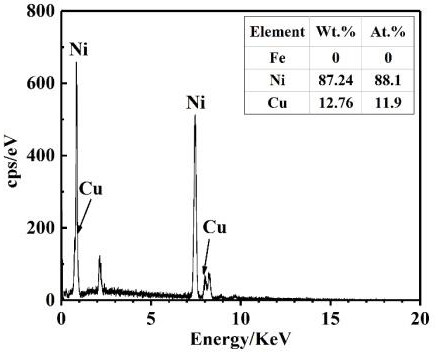

Method for preparing nickel-copper alloy plating layer on surface of carbon steel

The invention discloses a method for preparing a nickel-copper alloy plating layer on the surface of carbon steel. The method specifically comprises the following steps: (1) pretreatment, wherein a carbon steel workpiece is pretreated to obtain a carbon steel base material for later use; (2) preparation of an electroplating solution, wherein nickel sulfate, copper sulfate, trisodium citrate, boric acid, an additive and a brightener are dissolved in deionized water to prepare the electroplating solution for later use, and the concentrations of nickel sulfate, copper sulfate, trisodium citrate, boric acid, the additive and the brightener in the electroplating solution are 170-200 g / L, 5-20 g / L, 60-100 g / L, 10-25 g / L, 0.05-1 g / L and 0.1-1 g / L respectively; and (3) preparation of the nickel-copper alloy plating layer, wherein the carbon steel base material is immersed into the electroplating solution, the carbon steel base material serves as a cathode, one of monel alloy, pure nickel, graphite and pure copper serves as an anode, and electroplating deposition is conducted on the carbon steel base material to form the nickel-copper alloy plating layer. The nickel-copper alloy plating layer prepared through the method not only can effectively solve the problem of corrosion of a fluorine-making electrolytic cell made of carbon steel, but also has good thermal conductivity and strong binding force with the carbon steel base material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Chemical oxidation treatment solution for aluminum alloy

InactiveCN101892476AHas enhanced surface adsorptionReduce releaseMetallic material coating processesIron saltsCitrate salt

The invention relates to chemical oxidation treatment solution for aluminum alloy. The solution is aqueous solution formed by dissolving citrate, gluconate, tartrate, trivalent iron salt, chromite and inorganic acid in water, wherein one liter of the solution comprises 6 to 20 grams of citrate, 1 to 5 grams of gluconate, 1 to 3 grams of tartrate, 1 to 5 grams of trivalent iron salt, 3 to 5 grams of chromite and 10 to 30 grams of inorganic acid. The oxidation treatment solution has the advantages of simple preparation, low cost, relatively low control requirement on the technical conditions when used for oxidation treatment and simple and convenient operation; and an obtained oxide film layer is uniform and compact and is closely combined with a substrate. In addition, the oxidation treatment solution is used without being limited to the size and shape of a part and is suitable for surface treatment of various aluminum alloy workpieces.

Owner:SUZHOU NUCLEAR POWER RES INST +1

High-strength antibacterial wood preparation method and high-strength antibacterial wood

ActiveCN110253703AIncreased nanovoidsImprove adsorption capacityWood compressionElectric wood treatmentSulfite saltMildew

The invention discloses a high-strength antibacterial wood preparation method and a high-strength antibacterial wood. During the use, the mildew of wood is serious, such that the performances of the material are reduced, and the service life is shortened. According to the method, lignin and hemicellulose are removed from wood, the obtained wood is infiltrated with polyaniline, and the polyaniline-containing pretreated wood is placed in an electroplating solution and is electroplated to obtain a metal-plated wood complex; and the metal-plated wood complex is placed in a hot pressing machine, and is subjected to hot pressing. According to the present invention, lignin and hemicellulose are removed from wood by using a sodium sulfite solution so as to substantially increase the nanometer gaps inside the wood and improve the adsorption capacity of the wood; polyaniline is uniformly distributed inside the wood, such that the wood has electrical conductivity; and the hot pressing drying technology promotes the internal moisture of the wood to move to the outside.

Owner:HANGZHOU DIANZI UNIV

Method for electroplating zinc in neodymium iron boron magnet ionic liquid

The invention relates to a method for electroplating zinc in neodymium iron boron magnet ionic liquid. According to the method, a neodymium iron boron magnet treated before plating is used as a cathode, a zinc sheet is used as an anode, the ionic liquid is adopted as electroplating liquid, under the magnetic stirring condition, a power supply is conducted, the temperature, the current intensity and the electroplating time are controlled for electroplating, and then, bright dipping, passivation and aging treatment are carried out. The method is applied to the neodymium iron boron magnet electroplating, the process is simple, the price of medicine is low, the operation temperature is low, more importantly, the hydrogen evolution reaction is avoided, the obtained plating layer is bright and compact, the combination of the plating layer and a base body is firm, and the corrosion resistance performance is good.

Owner:TAIYUAN UNIV OF TECH

Preparation method of alkaline zincate zinc-plating brightener

The invention discloses a preparation method of an alkaline zincate zinc-plating brightener and relates to a preparation method of a brightener, and the preparation method is used for solving the problems that the existing zincate zinc-plating brightener is narrow in bright current density range, dark in plating layer and rough in surface. The preparation method comprises the following steps of: adding 12-15g of 33wt% dimethylamine into a four-neck bottle; then heating to 23 DEG C, completely dropwise adding 12-15g of epichlorohydrin into the four-neck bottle at the speed of 3-4s / drop; after dropwise adding is finished, heating to 25 DEG C-30 DEG C, reacting for 1.5-2.5 hours, and completely dropwise adding 0.1-1g of tetraethylenepentamine into the four-neck bottle; and after dropwise adding is finished, heating to 65 DEG C-75 DEG C, and reacting for 4-5 hours, so as to obtain the alkaline zincate zinc-plating brightener. The current density of the alkaline zincate zinc-plating brightener disclosed by the invention is 0.5-10.73A / dm<2>. The alkaline zincate zinc-plating brightener disclosed by the invention is applied to the field of zinc electroplating.

Owner:HARBIN UNIV OF SCI & TECH

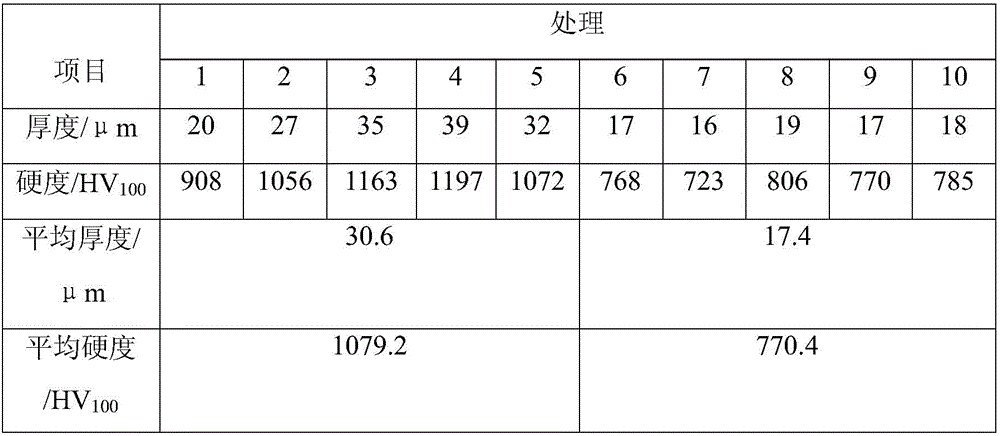

Chromium plating method of automobile stainless steel tail gas decorating part

InactiveCN106119907AIncreased cathodic polarizationImprove Chrome Plating QualityStrong acidsHardness

The invention discloses a chromium plating method of an automobile stainless steel tail gas decorating part. The chromium plating method includes the following steps that a chemical oil removal agent is used for removing oil for the automobile stainless steel tail gas decorating part; electrochemistry oil removal is carried out; the automobile stainless steel tail gas decorating part is immersed into strong acid liquid to be activated after cleaning is finished; and the automobile stainless steel tail gas decorating part is placed into a plating bath to be electroplated with current which is 1.5 times to 2 times of normal electroplating current in density for 3 minutes to 5 minutes and then electroplated with the normal electroplating current, and the automobile stainless steel tail gas decorating part is obtained. A plating layer obtained through the chromium plating method is even and smooth in surface, the structure of the plating layer is compact, the degree of finish of the surface of the decorating part is improved, and the appearance of the decorating part is more bright and clean; in addition, the properties including the hardness, the anti-corrosion property, the abrasive resistance, the bonding force, the corrosion resistance, the electrochemistry performance and the like of the plating layer are excellent; and compared with a plating layer obtained through a conventional method, the plating layer obtained through the method has the excellent comprehensive performance, can be suitable for various using environments, has remarkable advantages when being used under the hostile environment and has a wide application prospect.

Owner:LIUZHOU JINYUAN MACHINERY MFG

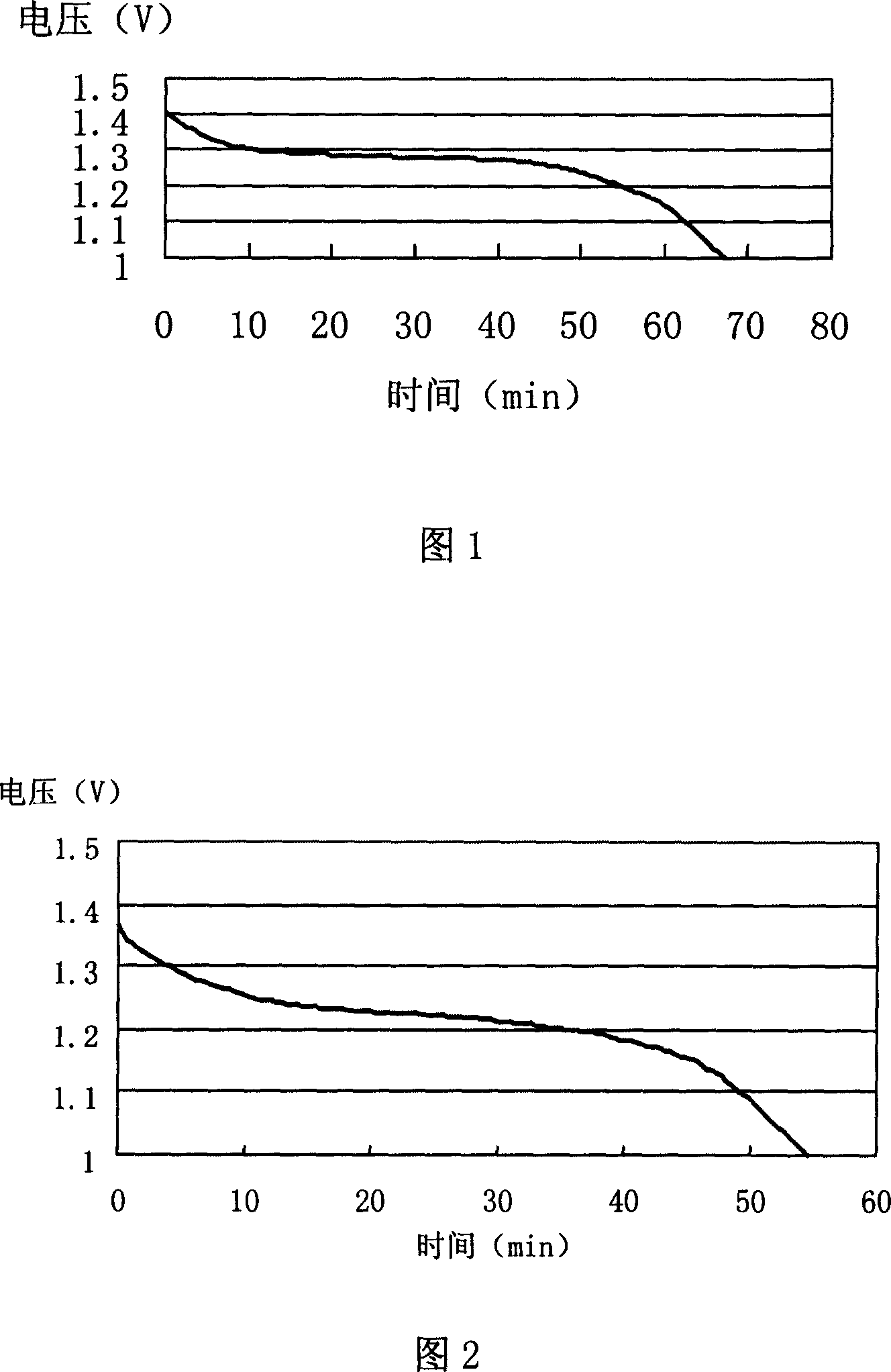

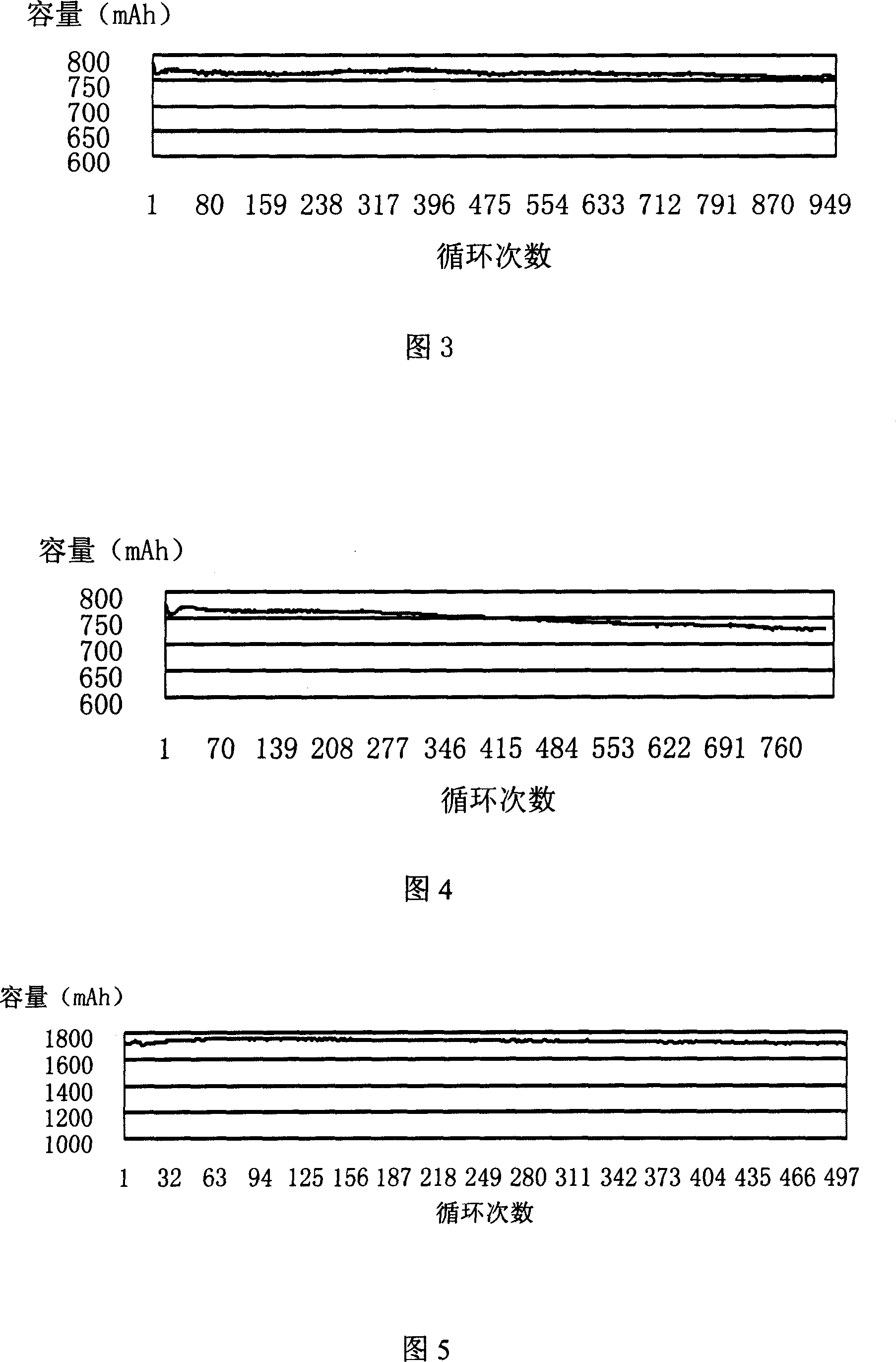

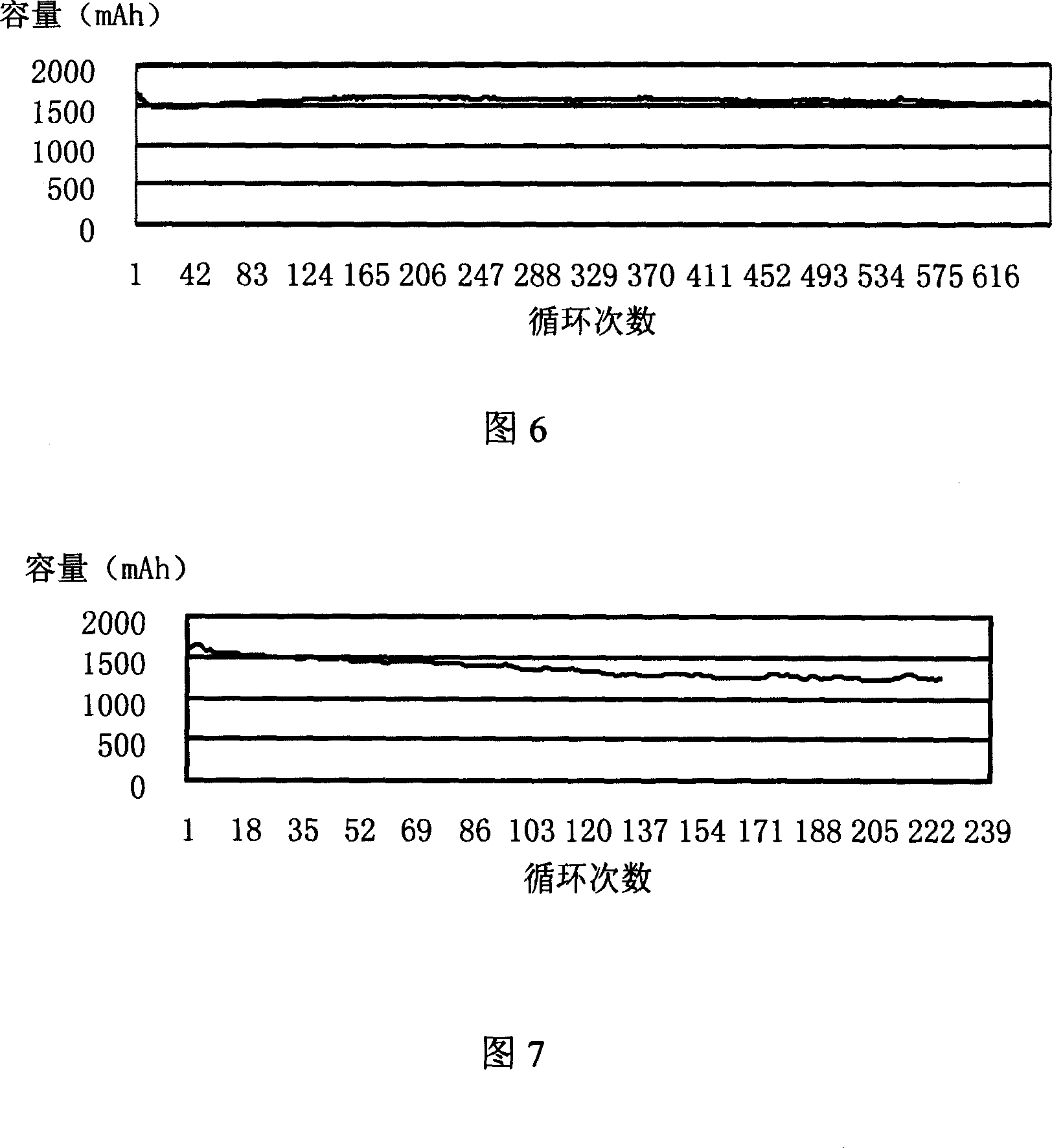

Electroplating liquid for nickel-cadmium battery negative pole and manufacturing method for nickel-cadmium battery negative pole

InactiveCN101082136AIncreased cathodic polarizationPlating bright and detailedAlkaline accumulator electrodesCadmium sulfateBinding force

The present invention relates to one kind of electroplating solution for preparing negative electrode of nickel-cadmium cell. The electroplating solution consists of cadmium sulfate and additives, including brightener, wetting agent and emulsifier stable under acid condition. Thus prepared negative electrode of nickel-cadmium cell has active compact cadmium coating with great binding force. The present invention also relates to the making process of negative electrode of nickel-cadmium cell with the electroplating solution. The nickel-cadmium cell with the negative electrode has high capacity, high discharge power, excellent fast charging capacity and high current efficiency.

Owner:BYD CO LTD

Zinc-nickel alloy electroplating solution

The invention discloses a zinc-nickel alloy electroplating solution. The zinc-nickel alloy electroplating solution comprises 2-20g / L of zinc oxide, 60-200g / L of sodium hydroxide, 5-40g / L of nickel sulfate, a complexing agent, a brightener and deionized water. When the solution is used, the current density is 2-4A / dm<2>, the solution is used at an anode, and the temperature is 10-30DEG C. The solution is characterized in that the solution also comprises triethanolamine, and the complexing agent is 50-70ml / L of sodium dodecyl benzene sulfonate; and the brightener is 4-6ml / L of an amine and epoxy compound condensate. The zinc-nickel alloy electroplating solution has the advantages of good stability and good coating performance.

Owner:CHONGQING WANGJIANG IND

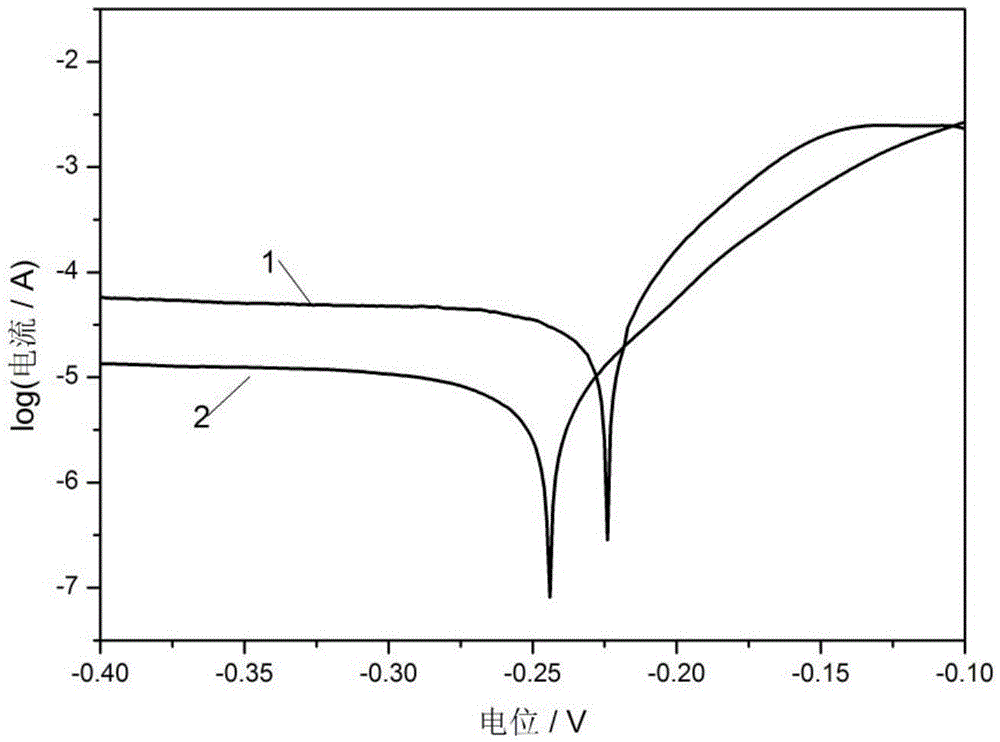

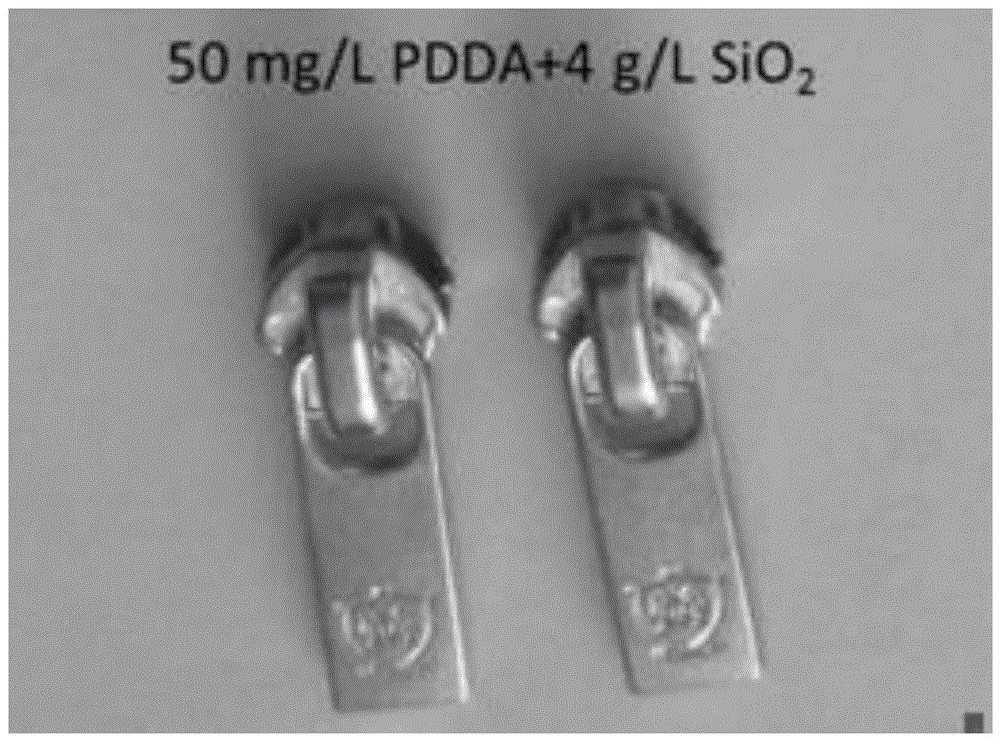

Nano-composite electroplating solution, preparing method of nano-composite electroplating solution and zinc alloy electroplated part

ActiveCN105463534AInhibit growthImprove corrosion resistanceSlide fastenersElectrolytic coatingsPorositySodium potassium tartrate tetrahydrate

The invention provides a nano-composite electroplating solution. The nano-composite electroplating solution is prepared from, by concentration, 23-26 g / L of cuprous cyanide, 10-12 g / L of zinc cyanide, 43-51 g / L of sodium cyanide, 25-35 g / L of sodium carbonate, 10-20 g / L of sodium potassium tartrate tetrahydrate, 4-8 g / L of ammonium chloride, 1-4 g / L of nano SiO2 and the balance water. By adding the nano SiO2, the degree of polarization of the cathode is increased, and growth of Cu-Zn alloy grains is prevented, so that a coating is more refined and compact, the porosity of a deposited layer is decreased, the particle-reinforced metal-based composite coating is formed, and accordingly the corrosion resistance of the coating is improved. It is indicated through test results that the corrosion current of the coating is greatly decreased, and it is proved that the corrosion resistance of the nano-composite coating is obviously improved compared with a Cu-Zn alloy coating. The invention further provides a preparing method of the nano-composite electroplating solution and a zinc alloy electroplated part.

Owner:ZHEJIANG WEIXING IND DEV

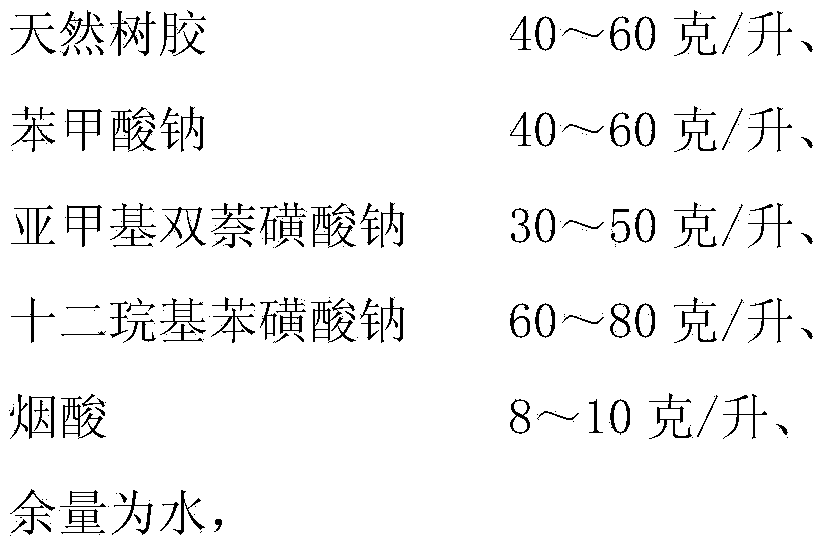

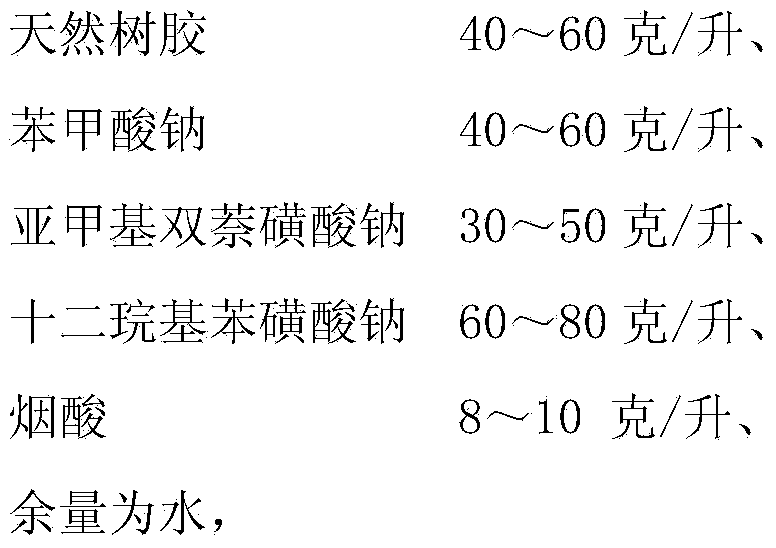

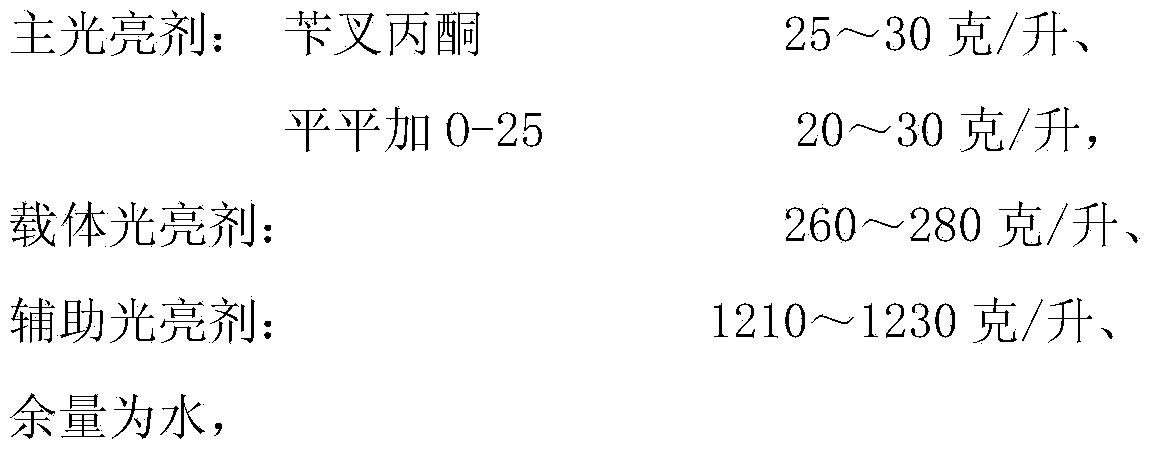

Auxiliary brightening agent for potassium chloride galvanizing and preparation method and use of auxiliary brightening agent

The invention provides an auxiliary brightening agent for potassium chloride galvanizing. The auxiliary brightening agent is combined with a main brightening agent and a carrier brightening agent for application, and is characterized in that the formula of the auxiliary brightening agent comprises natural gum, wherein the natural gum is crushed into powder, the powder is dissolved in hot water, impurities are filtered from the powder through a filter, and the powder is added into the auxiliary brightening agent for uniform stirring. According to the auxiliary brightening agent, the cathodic polarization of a high-current density area can be improved, the dispersion capability of a plating solution can be improved, and plated layer crystals are delicate and bright; the plating solution is high in covering power, and a plated layer is clear, smooth and high in deposition speed, the binding force of the plated layer can meet requirements, high current efficiency is ensured, and a plated part is prevented from being scorched and blackened; the auxiliary brightening agent is easy to prepare, stable, low in cost, pollution-free and environmentally friendly.

Owner:王维福

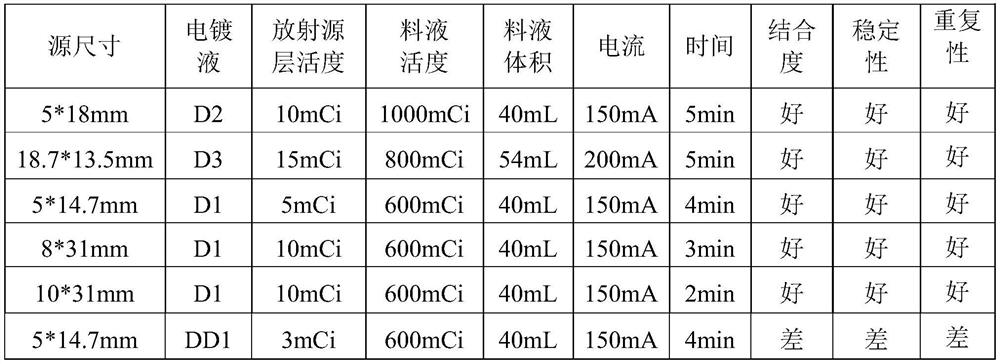

63Ni radioactive source and preparation method thereof

The invention belongs to the technical field of radioactive source preparation, and relates to a 63Ni radioactive source and a preparation method thereof. The preparation method of the 63Ni radioactive source comprises the following steps: thoroughly cleaning the surface of a substrate, and then placing the substrate into an electroplating solution and electroplating to form a 63Ni radioactive source layer on the substrate, wherein the electroplating solution contains 63NiCl2, cerous chloride, pH value buffer agent, conducting salt and the balance water. By adopting the method for preparing the 63Ni radioactive source, the combination degree of the substrate and the radioactive source layer can be increased and the stability of the radioactive source layer can be improved; and moreover, great repeatability is further achieved, the operation difficulty in an industrial production process can be lowered, batch production is facilitated, and the need of the society on 63Ni pure beta radioactive source is met.

Owner:HTA CO LTD

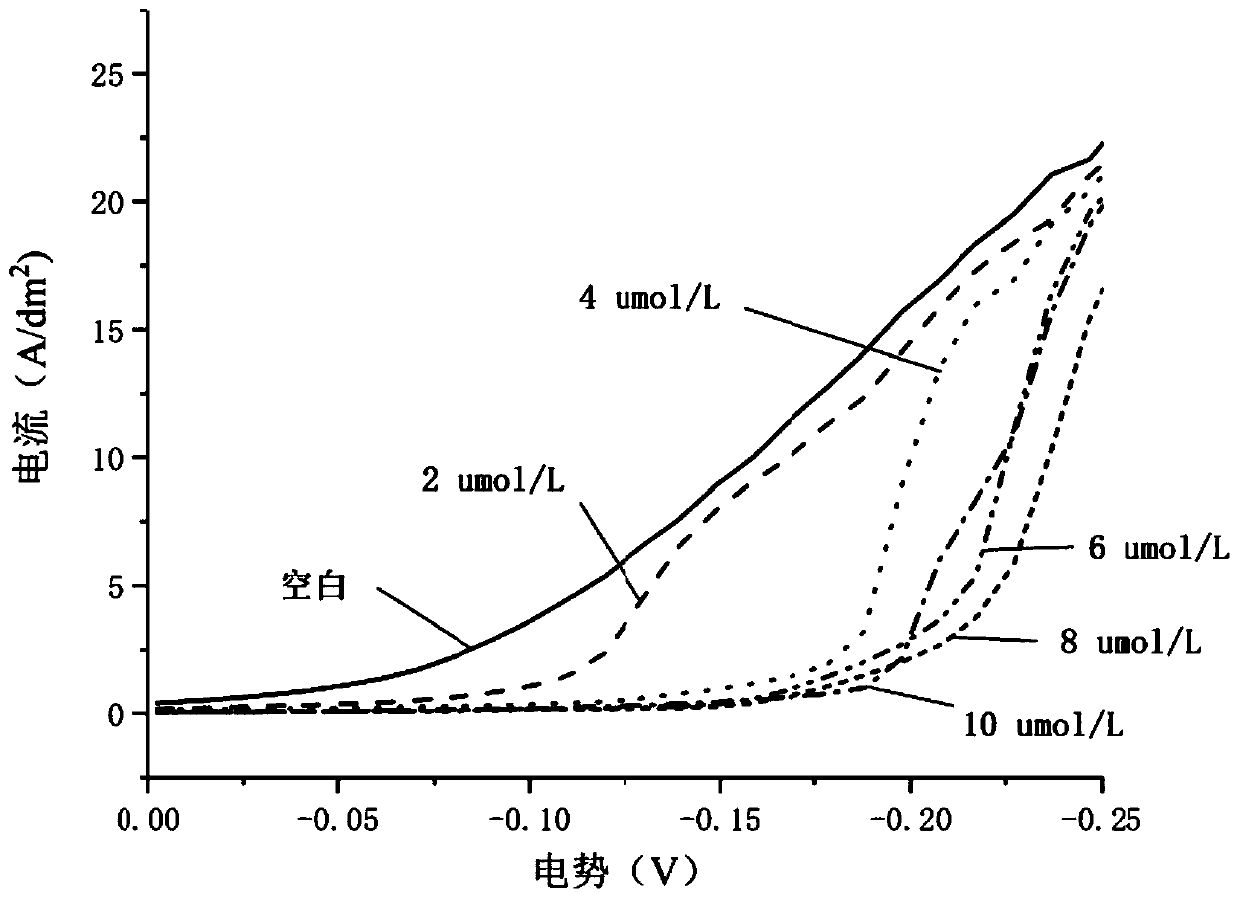

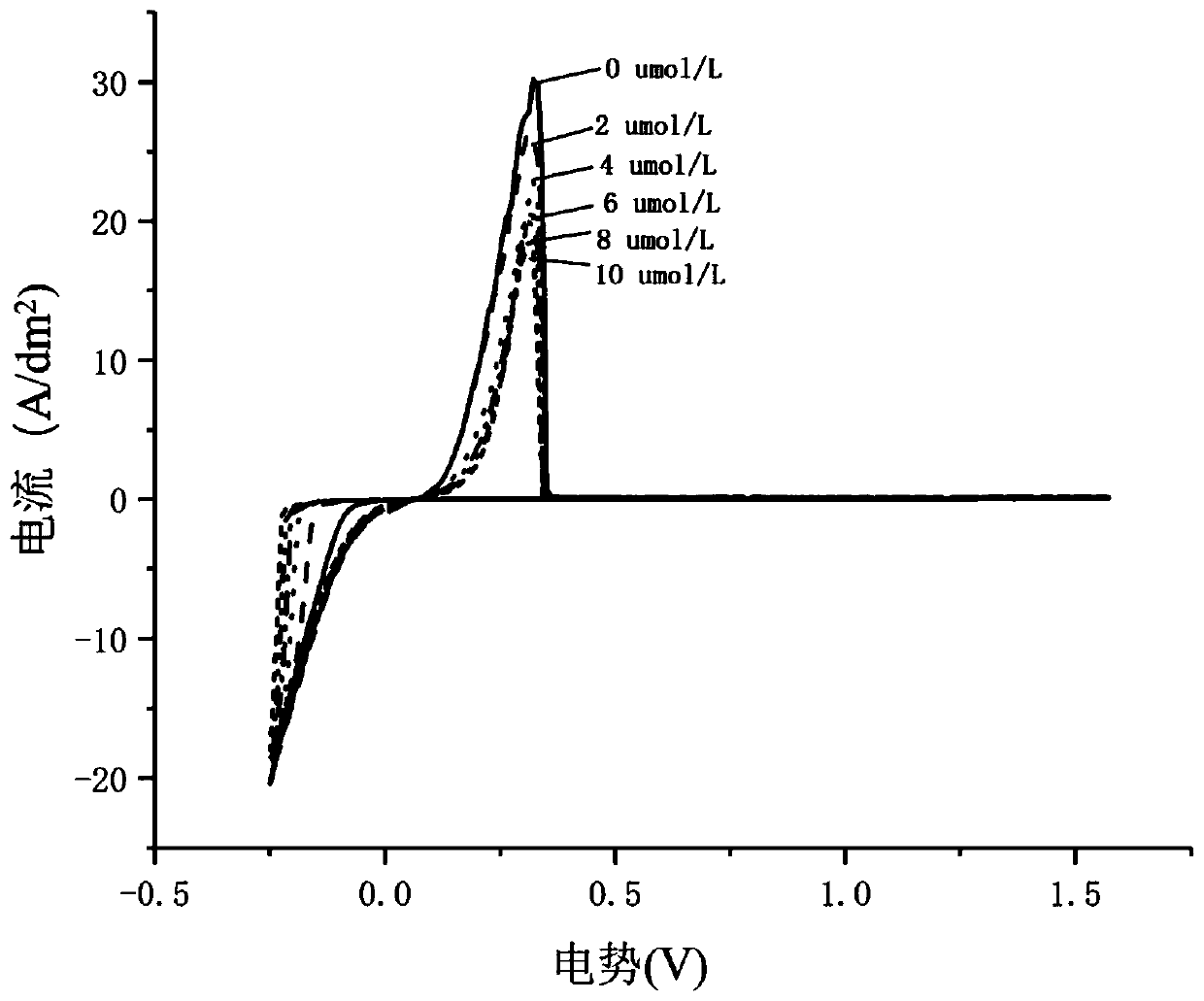

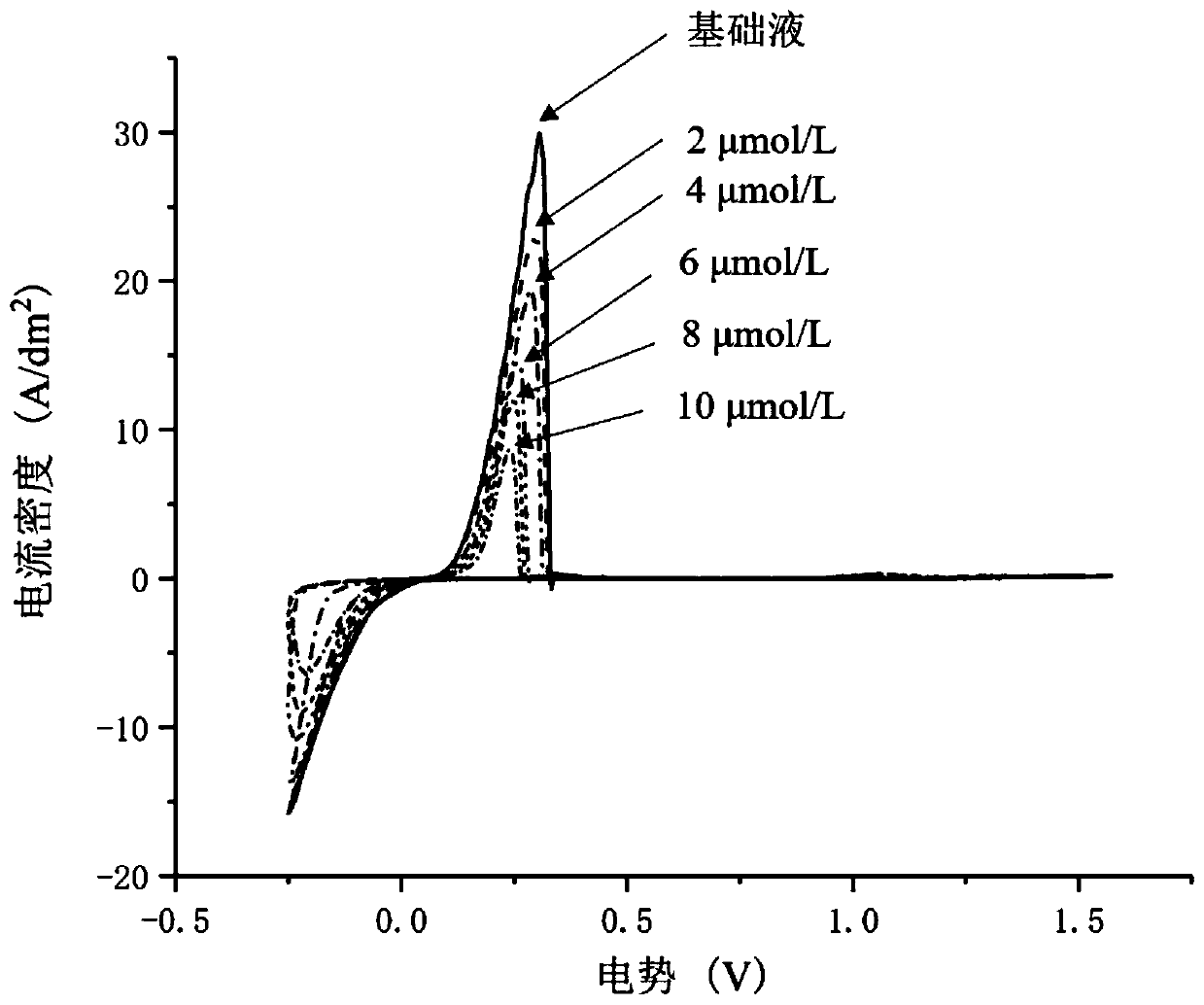

Quinacridone quaternary ammonium salt compound and preparation method and application thereof

ActiveCN110105357AImprove the plating effectAvoid depositionOrganic chemistryStructural formulaElectroplating

The invention discloses a quinacridone quaternary ammonium salt compound. A structural formula is shown as a general formula B, and the definition of each substituent is detailed in the description. The quinacridone quaternary ammonium salt compound has good electroplating performance and can produce a synergistic inhibition effect with other electroplating additives, and the electroplating performance of the quinacridone quaternary ammonium salt compound is verified through a cyclic voltammetry curve, a polarization curve and a continuous current timing addition curve.

Owner:EAST CHINA UNIV OF SCI & TECH

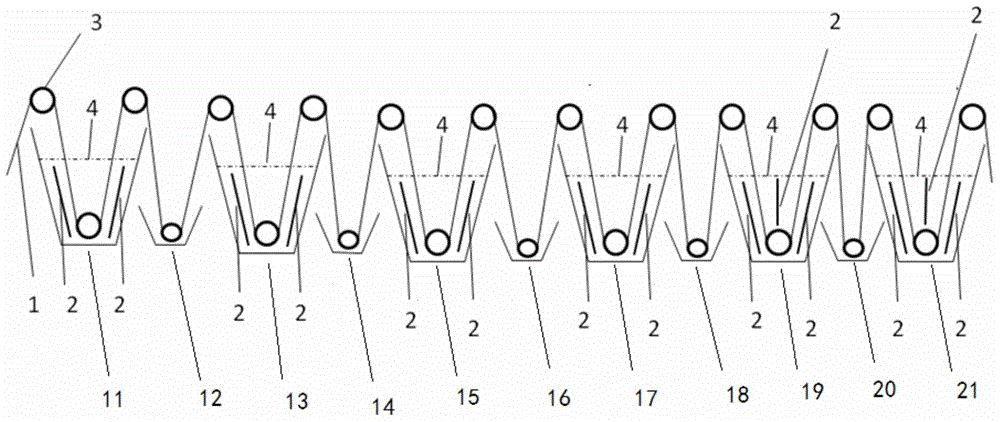

Surface treatment device capable of reducing copper powder on rough surface of copper foil

ActiveCN104911661AIncreased cathodic polarizationReduce generationChromatisationRough surfaceCopper foil

The invention provides a treatment device capable of reducing copper powder on a rough surface of copper foil. The device comprises a first roughing treating tank, a second roughing treating tank, a first solidifying tank, a second solidifying tank, a galvanizing tank, an oxidation resisting tank, a coupling agent coating device and a drying device. With the adoption of the device, the produced copper powder can be greatly reduced; a 10cm<2> copper foil sample contains not greater than 10 copper powder, and the diameter of the maximum copper powder does not exceed 30 microns; therefore, the risk of short circuit caused by being used for preparing a printed circuit board can be greatly reduced.

Owner:ANHUI TONGGUAN COPPER FOIL +1

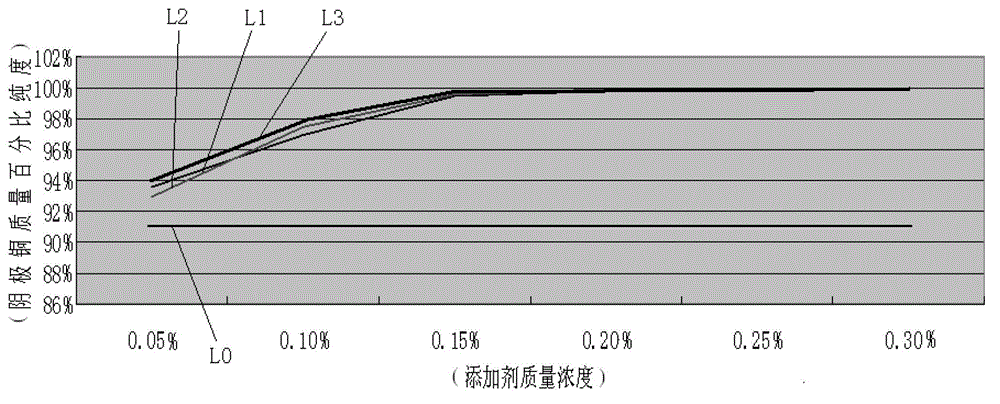

Additive of electrolytic acidic cupric chloride solution

ActiveCN102877067AIncreased cathodic polarizationCrystallizationElectrolysis componentsPhotography auxillary processesSulfonatePolyol

The invention discloses an additive of electrolytic acidic cupric chloride solution. The additive comprises, by weight, from 1% to 5% of polyether polyol, from 2% to 4% of amine compounds, from 1% to 3% of sulfonate and from 88% to 96% of solvents which are mixed. A catholic polarization effect of electrolytic copper can be strengthened under the action of hydroxyl in the polyether polyol, discharge of copper ions in cathodes can be suppressed, and crystallization of the cathode copper is refined; growth of crystals can be promoted under the interaction of amine functional groups in the amine compounds and the copper ions; and surface tension of the solution is reduced by the sulfonate, and the surface of the cathode copper is smooth. Accordingly, the additive of the electrolytic acidic cupric chloride solution can guarantee that the cathode copper of the electrolytic acidic cupric chloride solution is compact and smooth, and the effect of increasing the purity of the cathode copper is achieved. Besides, the additive is simple in preparation, low in cost, easy to store and suitable for industrial production and application, and is non-hazardous.

Owner:HUNAN ZHIHUI ENVIRONMENTAL PROTECTION CONSTR

Safe and environment-friendly additive for copper plating, and preparation method of additive

The invention relates to the field of electroplating, in particular to a safe and environment-friendly additive for copper plating, and a preparation method of the additive. The safe and environment-friendly additive, provided by the invention, for copper plating is prepared from 2-8g / L of fatty amine polyoxyethylene ether, 1-5g / L of heterocyclic compound containing sulfhydryl, 5-20g / L of polyethylene imine alkyl compound and 0.5-3g / L of a complexing agent, wherein the total amine value of fatty amine polyoxyethylene ether is 50-60mgKOH / g, and the polyethylene imine alkyl compound contains a heterocyclic ring group.

Owner:上海赛夫特半导体材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com