63Ni radioactive source and preparation method thereof

A radioactive source and pH value technology, applied in the field of 63Ni radioactive source and its preparation, can solve the problems of low bonding degree of Ni radioactive source layer, low repeatability, poor stability of radioactive source layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

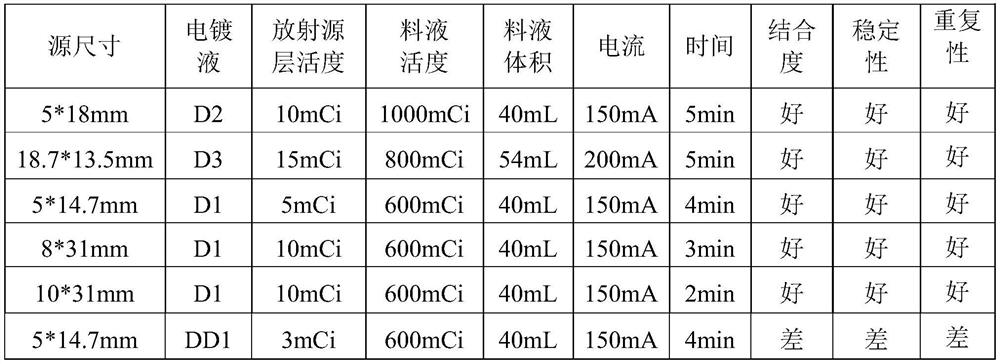

[0008] provided by the invention 63 The preparation method of the Ni radiation source comprises cleaning the surface of the substrate and placing it in the electroplating solution for electroplating to form on the substrate 63 Ni radiation source layer, the electroplating solution contains 63 NiCl 2 , cerium trichloride, pH buffer and conductive salt and the balance is water.

[0009] said 63 NiCl 2 as main salt. said 63 NiCl 2 Specifically, you can use 63 NiCl 2 used in the form of feed liquid, the 63 NiCl 2 Feed liquid is 63 NiCl 2 of hydrochloric acid solution. said 63 NiCl 2 The activity of the feed liquid is preferably 600-1000mCi. In the plating solution 63 NiCl 2 The concentration is preferably 0.5g / L~4g / L, for example, 0.5g / L, 1g / L, 1.5g / L, 2g / L, 2.5g / L, 3g / L, 3.5g / L, 4g / L Wait.

[0010] The cerium trichloride as an additive can improve the coating deposition speed and coating quality. The concentration of cerium trichloride in the electroplating s...

preparation example

[0019] In the following preparation examples, comparative preparation examples and examples:

[0020] (1) Electroplating equipment includes: 1 electroplating tank; 1 power supply, dual-channel DC stabilized power supply (0-30V, 0-10A); 1 platinum electrode; 1 radioactive source ionization current tester, GLZ-5.

[0021] (2) The main reagents include: boric acid, potassium chloride, hydrochloric acid, sodium hydroxide, cerium trichloride, A.R; 63 Ni liquid, 63 NiCl 2 Soluble in HCl, nuclear purity >99%, specific activity ~10Ci / g.

preparation example 1

[0023] This preparation example is used to illustrate the preparation method of the electroplating solution provided by the present invention.

[0024] Add 40 g of analytically pure H to 1 L of distilled water 3 BO 3 , stirred until completely dissolved, then added 20 grams of analytically pure KCl, stirred until completely dissolved, then added 0.8 g of cerium trichloride, stirred until dissolved, and obtained solution A. Take 40 ml of solution A, add to it 63 Ni liquid ( 63 NiCl 2 Hydrochloric acid solution, the same below) 600mCi, and finally adjust the pH value to 1.5-2 with 1mol / L HCl or 1mol / LNaOH solution to obtain the electroplating solution, which is recorded as D1. The plating solution D1 63 NiCl 2 The concentration of cerium trichloride is 1.5g / L, the concentration of cerium trichloride is 0.8g / L, H 3 BO 3 The concentration of KCl is 40g / L, the concentration of KCl is 20g / L, the balance is water, and the pH value is 1.5-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com