Patents

Literature

35 results about "Cerium trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ternary denitration sulfur-resistant catalyst in-situ loaded compound filter material and preparation method thereof

ActiveCN106512552AImprove antisulfur activityHigh low temperature activityDispersed particle separationMembrane filtersFiberSulfide

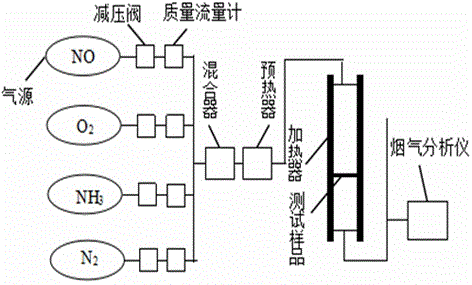

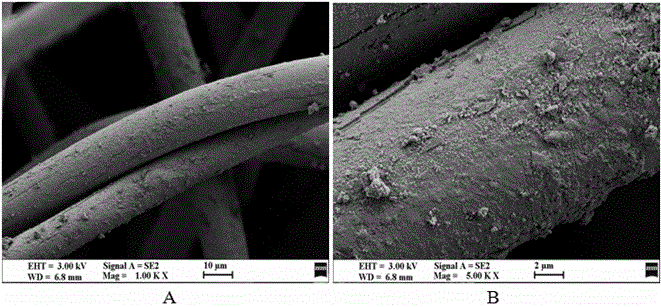

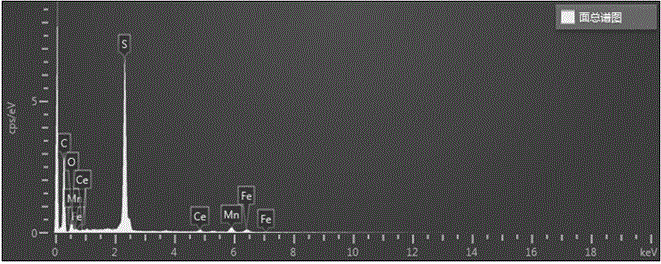

The invention discloses a ternary denitration sulfur-resistant catalyst in-situ loaded compound filter material and a preparation method thereof. The preparation method includes: taking a polyphenylene sulfide filter material as a catalyst carrier, and adopting lauryl sodium sulfate for surface modification of a polyphenylene sulfide needled felt to activate the polyphenylene sulfide filter material; taking potassium permanganate, anhydrous ferric chloride and cerium trichloride heptahydrate as catalyst precursors and taking deionized water as a solvent to realize one-step in-situ loading of a MnO2-Fe2O3-CeOx catalyst on the surface of the activated polyphenylene sulfide filter material. The compound filter material is firm in combination of the catalyst and polyphenylene sulfide fibers, excellent in low-temperature activity and denitration effect on nitric oxides in smoke and great in sulfur resistance, and defects of high cost, complexity and the like of a tail purification system in the prior art can be overcome. The ternary denitration sulfur-resistant catalyst in-situ loaded compound filter material and the preparation method thereof have advantages of technical simplicity in preparation, environment friendliness, low production cost and promising application prospect.

Owner:FUZHOU UNIV

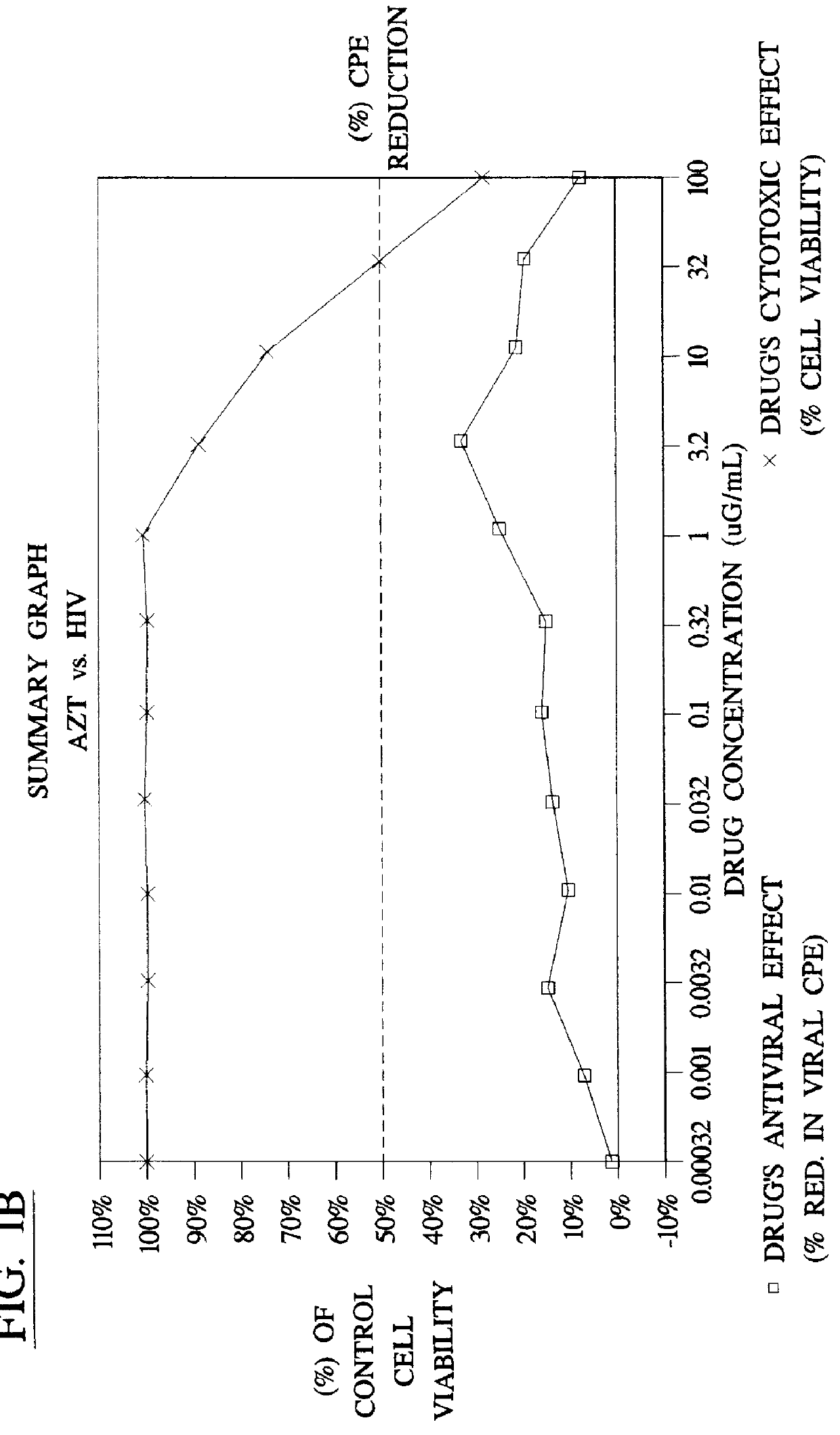

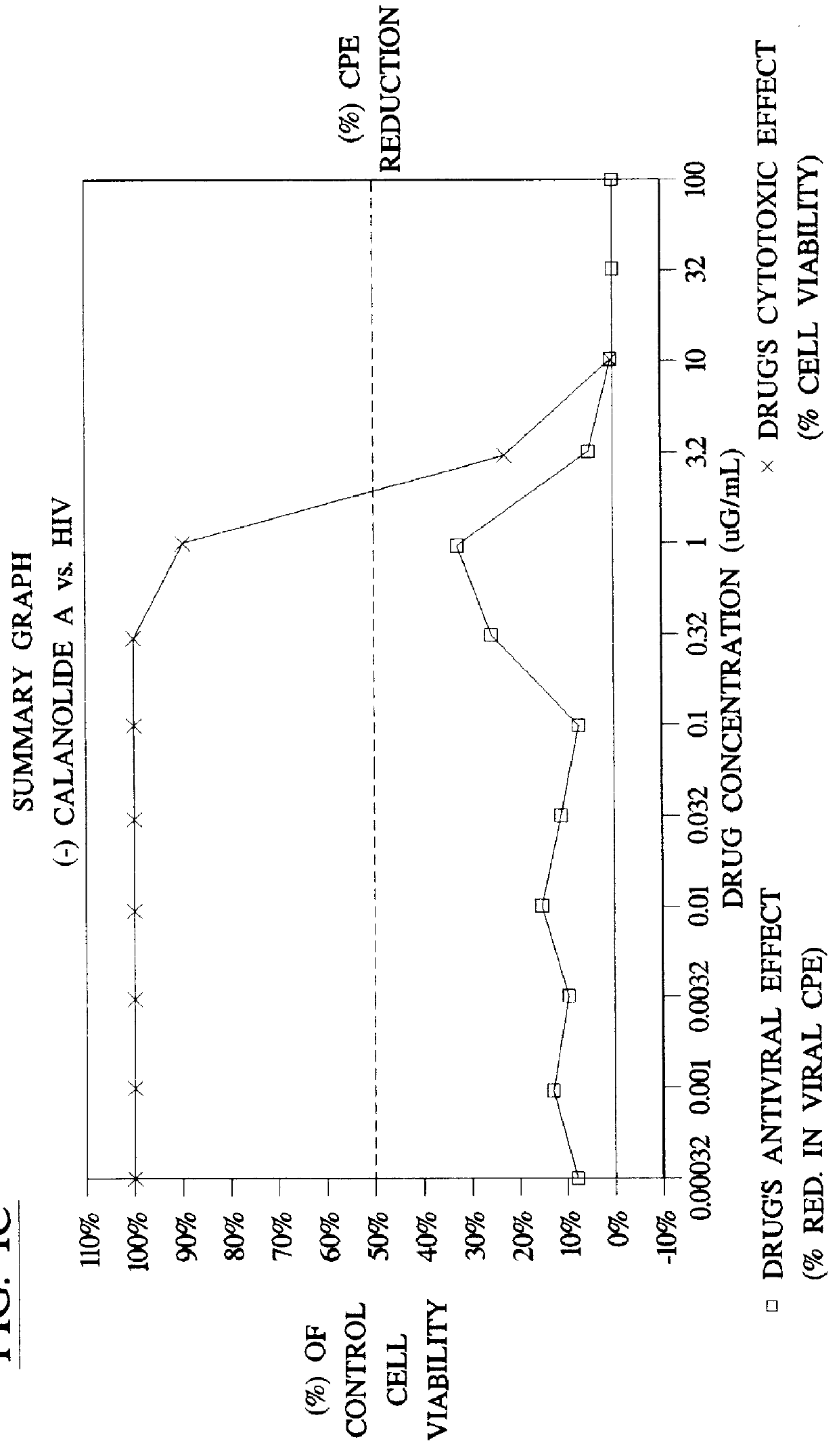

Method for the preparation of (+/-)-calanolide A and intermediates thereof

InactiveUS6043271APractical and convenientHigh yieldBiocideOrganic chemistryHydrolysisEnzyme inhibitor

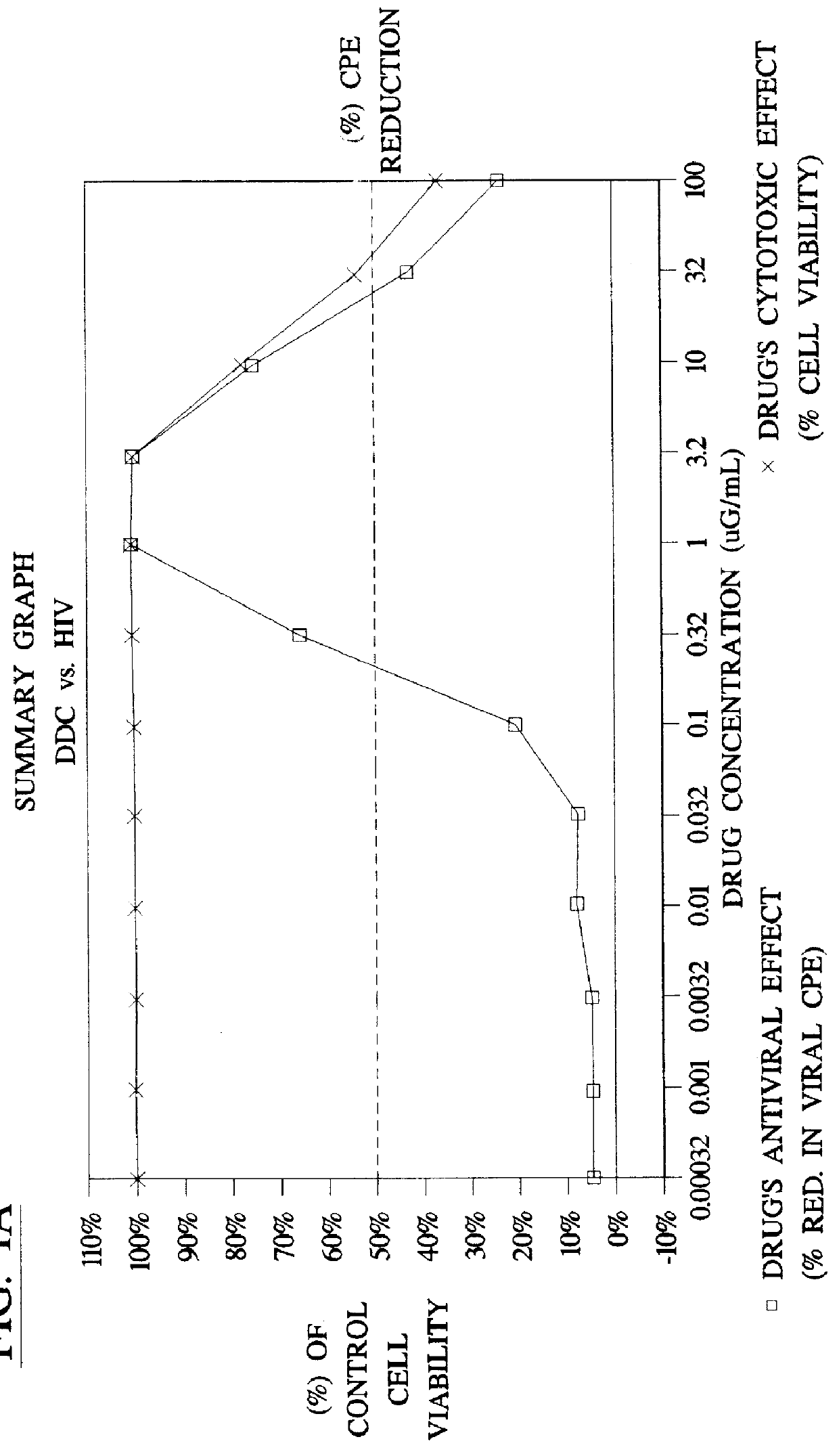

A method of preparing (+ / -)-calanolide A, 1, a potent HIV reverse transcriptase inhibitor, from chromene 4 is provided. Useful intermediates for preparing (+ / -)-calanolide A and its derivatives are also provided. According to the disclosed method, chromene 4 intermediate was reacted with acetaldehyde diethyl acetal or paraldehyde in the presence of an acid catalyst with heating, or a two-step reaction including an aldol reaction with acetaldehyde and cyclization either under acidic conditions or neutral Mitsunobu conditions, to produce chromanone 7. Reduction of chromanone 7 with sodium borohydride, in the presence of cerium trichloride, produced (+ / -)-calanolide A. A method for resolving (+ / -)-calanolide A into its optically active forms by a chiral HPLC system or by enzymatic acylation and hydrolysis is also disclosed. Finally, a method for treating or preventing a viral infections using (+ / -)-calanolide or (-)-calanolide is provided.

Owner:SARAWAK MEDICHEM PHARMA

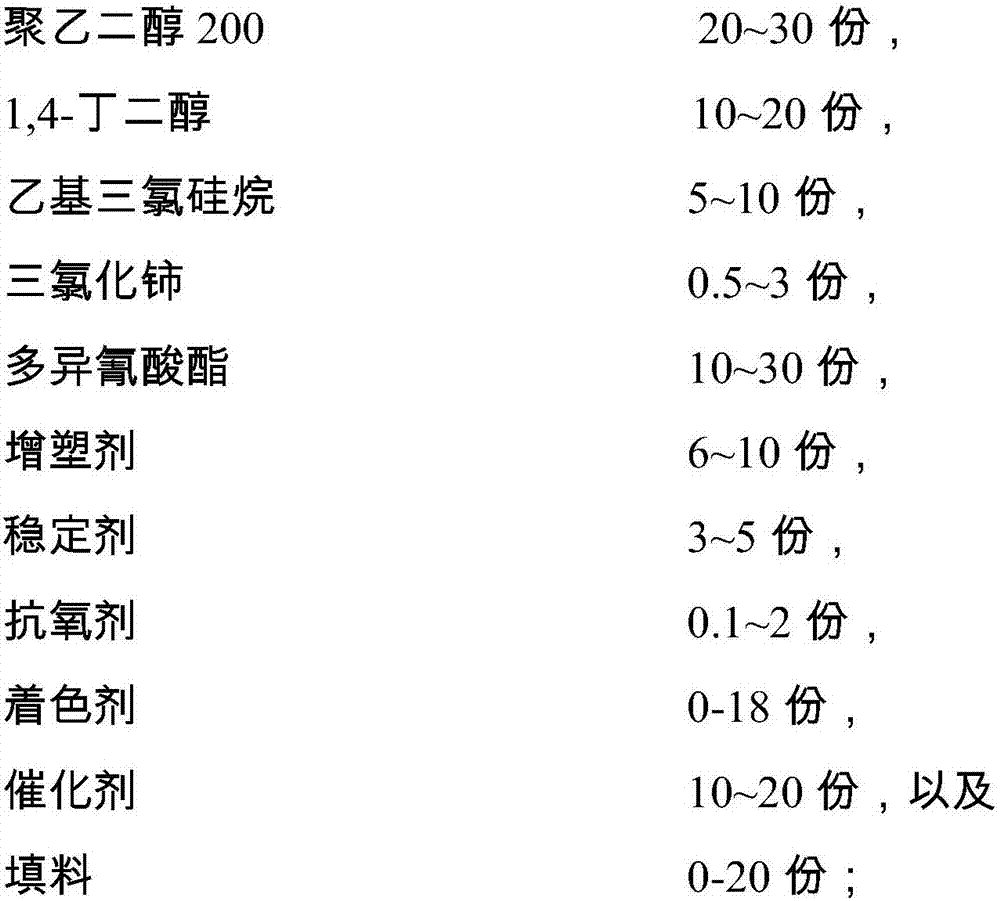

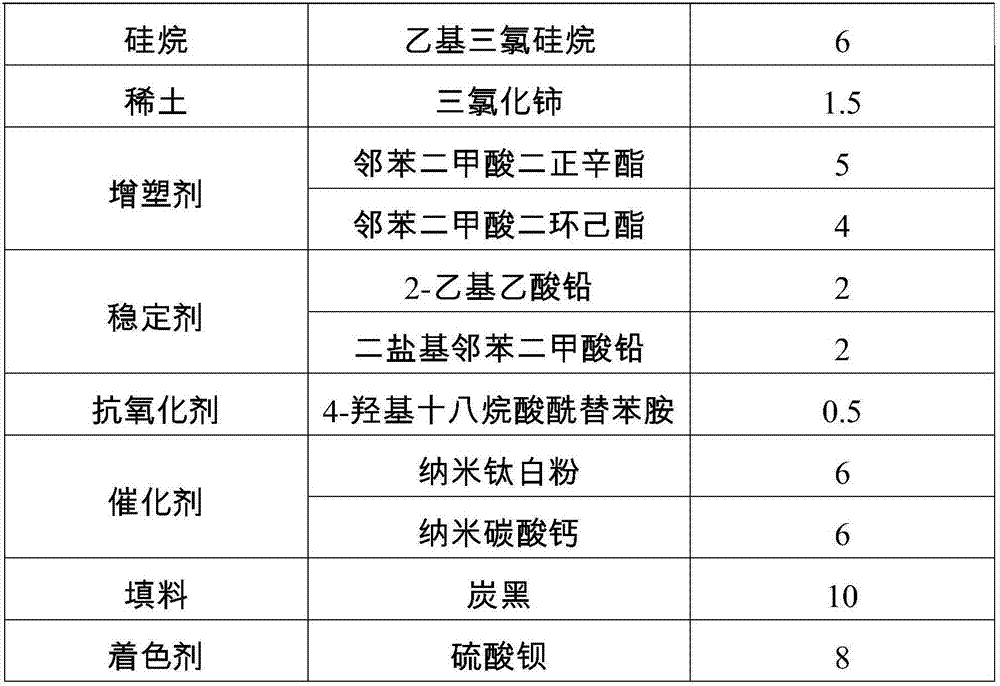

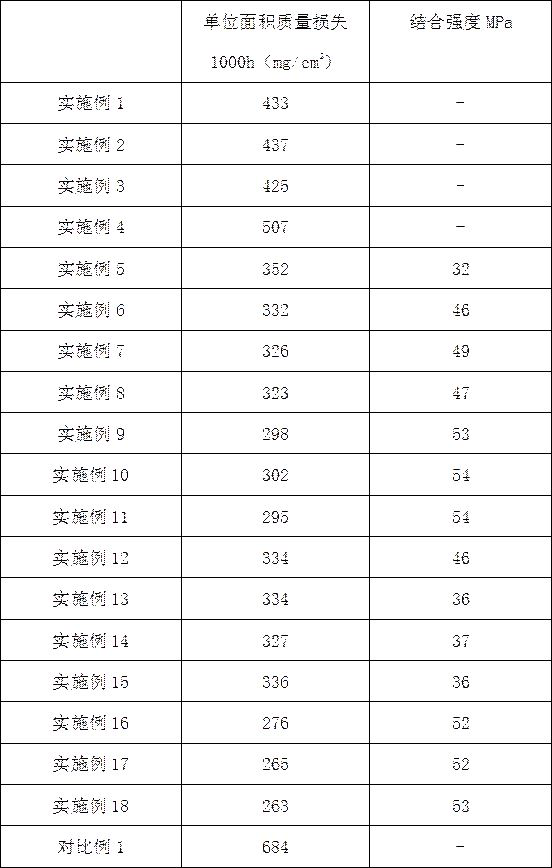

Moisture curing type polyurethane hot melt adhesive and preparation method thereof

ActiveCN107245317AImprove toughnessGood colorNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPolyethylene glycol

The invention relates to a moisture curing type polyurethane hot melt adhesive and a preparation method thereof. The moisture curing type polyurethane hot melt adhesive comprises the following raw materials in parts by weight: 20-30 parts of polyethylene glycol 200, 10-20 parts of 1,4-nutanediol, 10-30 parts of polyisocyanate, 5-10 parts of ethyltrichlorosilane, 0.5-3 parts of cerium trichloride, 5-12 parts of a plasticizer, 2-6 parts of a stabilizing agent, 0.1-2 parts of an antioxidant, 0-18 parts of a coloring agent, 10-20 parts of a catalyst and 0-20 parts of a filler, wherein the polyisocyanate is selected from MDI and / or HDI; the catalyst is selected from nano titanium dioxide and / or nano calcium carbonate. The moisture curing type polyurethane hot melt adhesive provided by the invention wholly has the characteristics of strong initial adhesion force, high bonding strength and good toughness, meanwhile has very strong permeability and affinity and can resist high temperature and be applicable to firm bonding of metals, plastics, glass and other base materials. The preparation method of the moisture curing type polyurethane hot melt adhesive, provided by the invention, is simple and reliable, and convenient in sizing.

Owner:GUANGZHOU QIANSHUN IND MATERIAL

Process for making montelukast and intermediates therefor

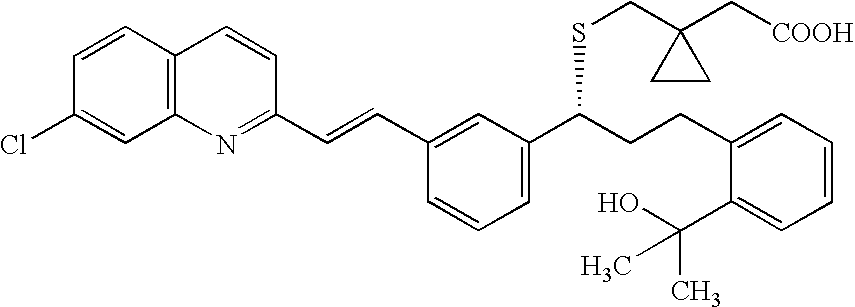

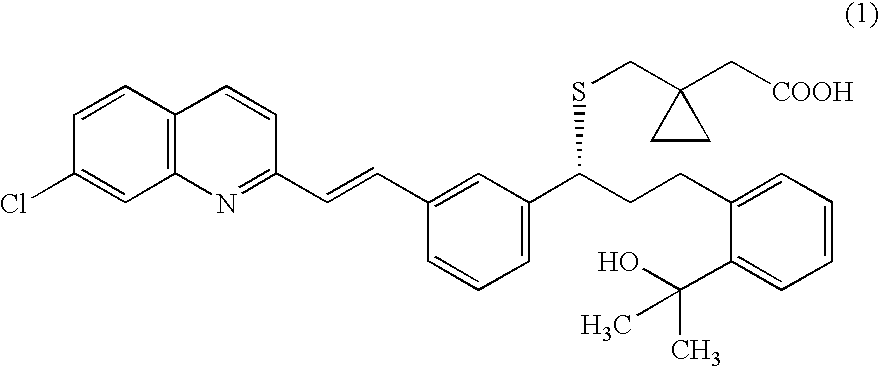

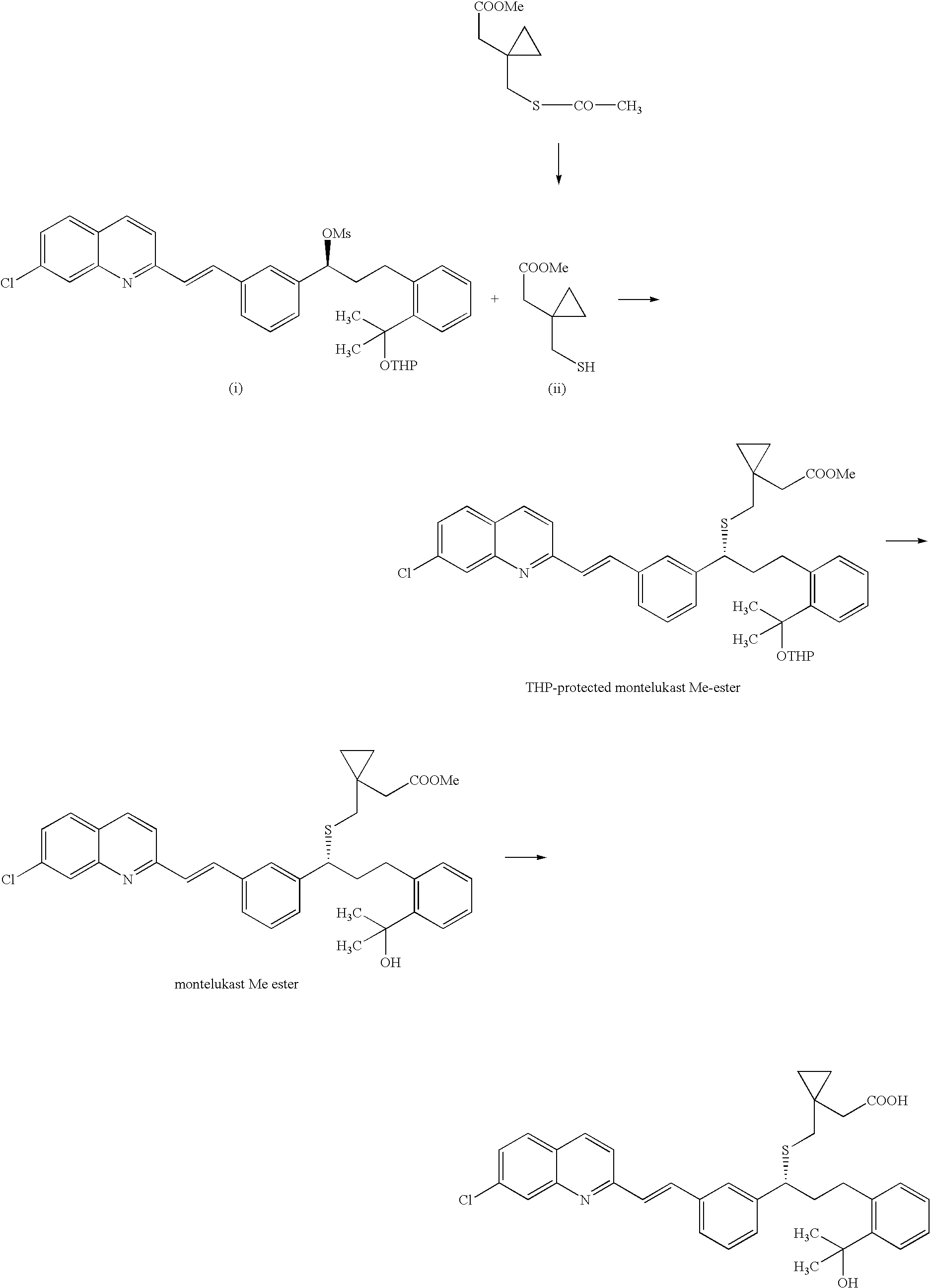

InactiveUS20070135643A1Lower Level RequirementsImprove the level ofBiocideOrganic chemistryMontelukastCe element

The reaction of methylmagnesium halide is improved by the presence of a cerium (III) salt such as cerium trichloride. The reactions are typically associated with the production of montelukast, a pharmaceutically useful compound of the following formula and salts thereof. Further enhancements can be derived from certain intermediates, salts thereof and / or purification thereof before and / or after the reaction involving methylmagnesium halide.

Owner:SYNTHON BV

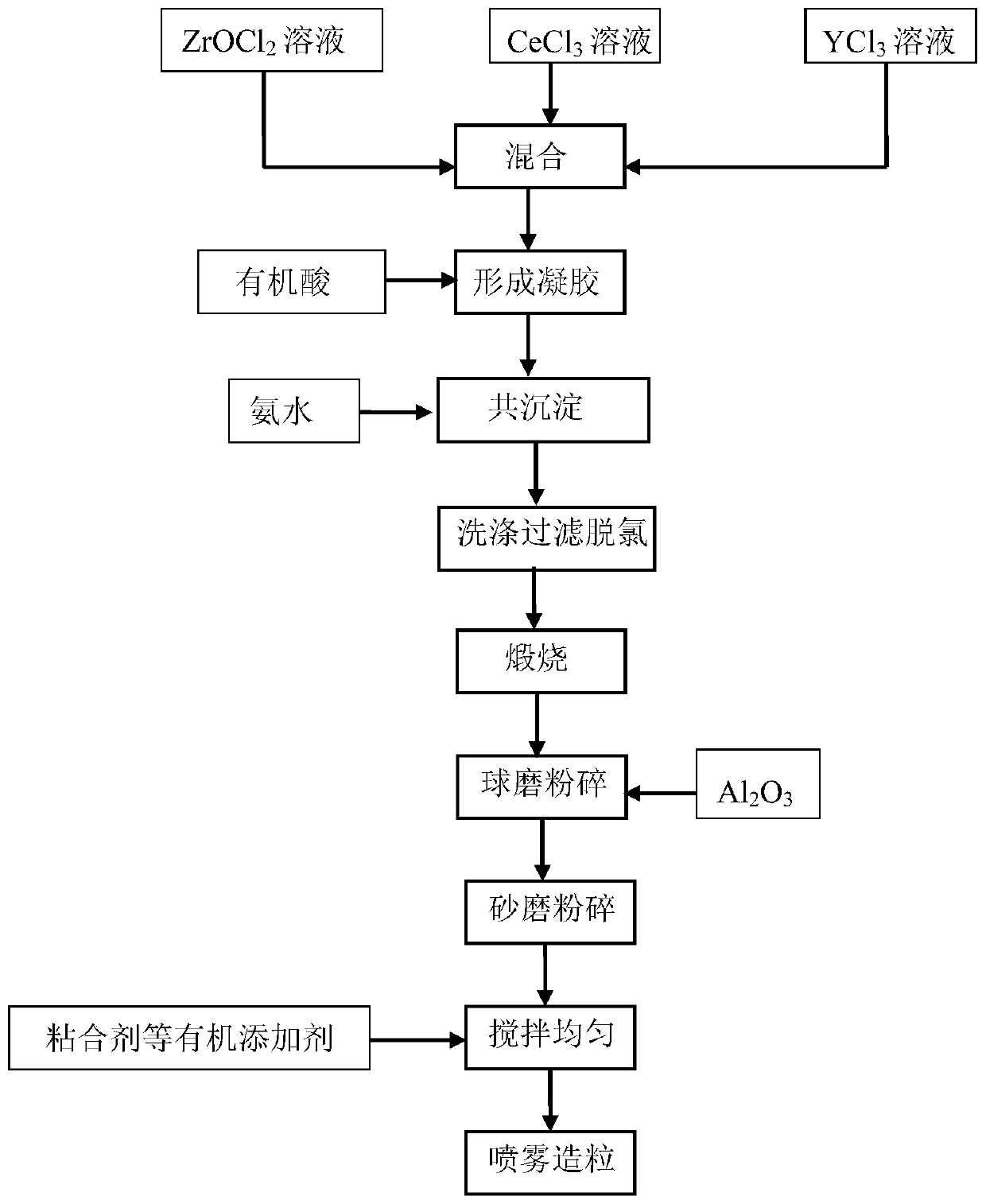

Preparation method of yttrium-stabilized zirconium powder for structural member

The invention belongs to the technical field of inorganic new materials, and particularly relates to a preparation method of yttrium-stabilized zirconium powder for a structural member. The preparation method comprises mixing a zirconium oxychloride solution, a cerium trichloride solution and a yttrium trichloride solution in proportion, adding organic acid to generate gel, adding an ammonia watersolution to neutralize and precipitate, carrying out washing, filtering and dechlorinating, calcining a filter cake to obtain precursor powder, adding Fe2O3, carrying out ball milling and sanding crushing, adding organic additives such as a binder, uniformly mixing, carrying out spray granulation, and drying to obtain the yttrium-stabilized zirconium powder for the structural member. The preparation method of the yttrium-stabilized zirconium powder for the structural part is simple and convenient in process and high in yield, the produced powder is uniform in particle size distribution, goodin fluidity, stable in shrinkage rate, easy to form and high in green body strength, and fine processing such as cutting, milling and punching can be conducted on green bodies and sintered finished products to produce ceramic products high in strength, good in stability and complex in structure.

Owner:长裕控股集团股份有限公司

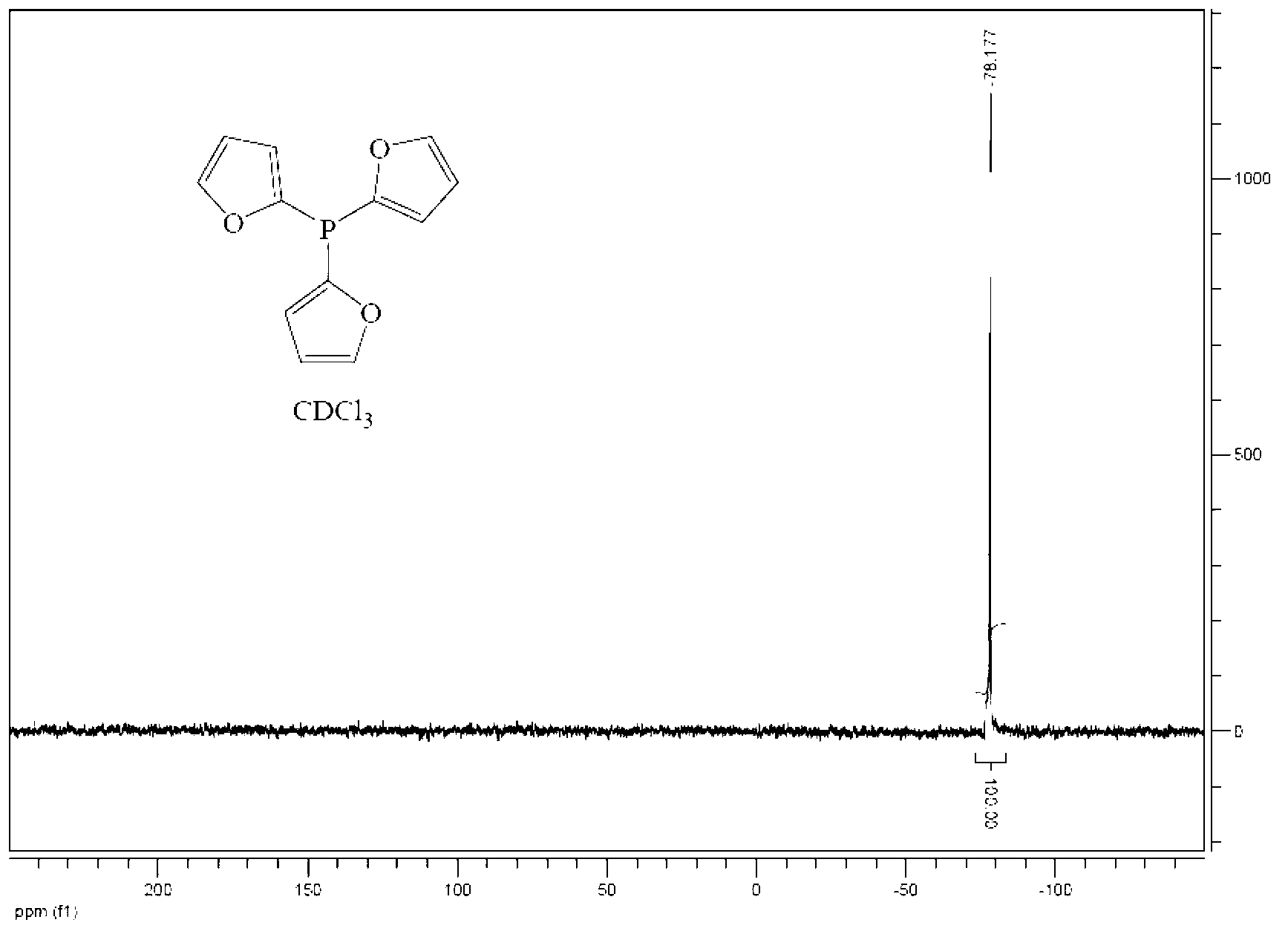

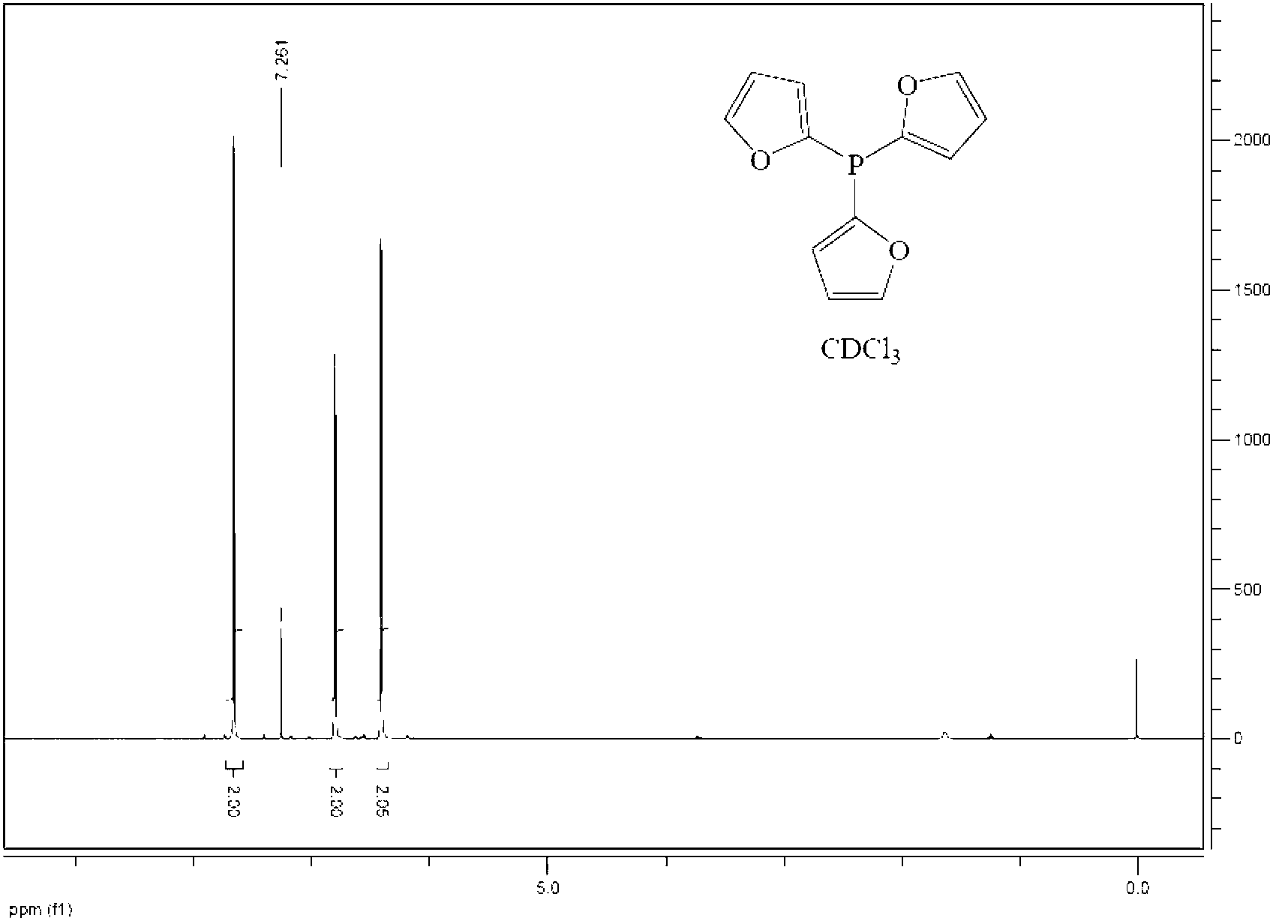

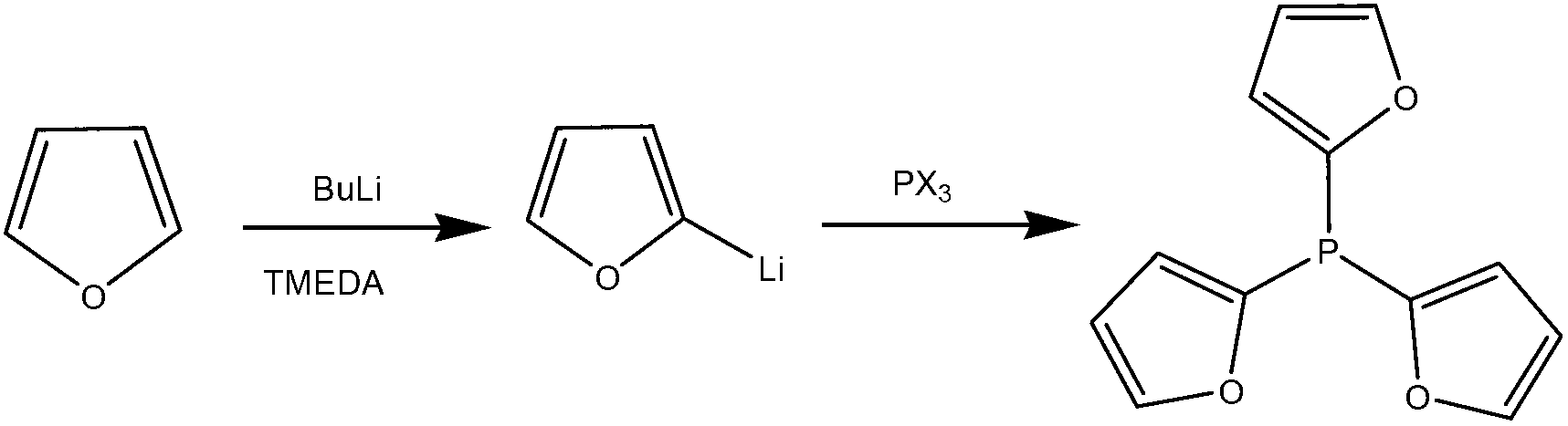

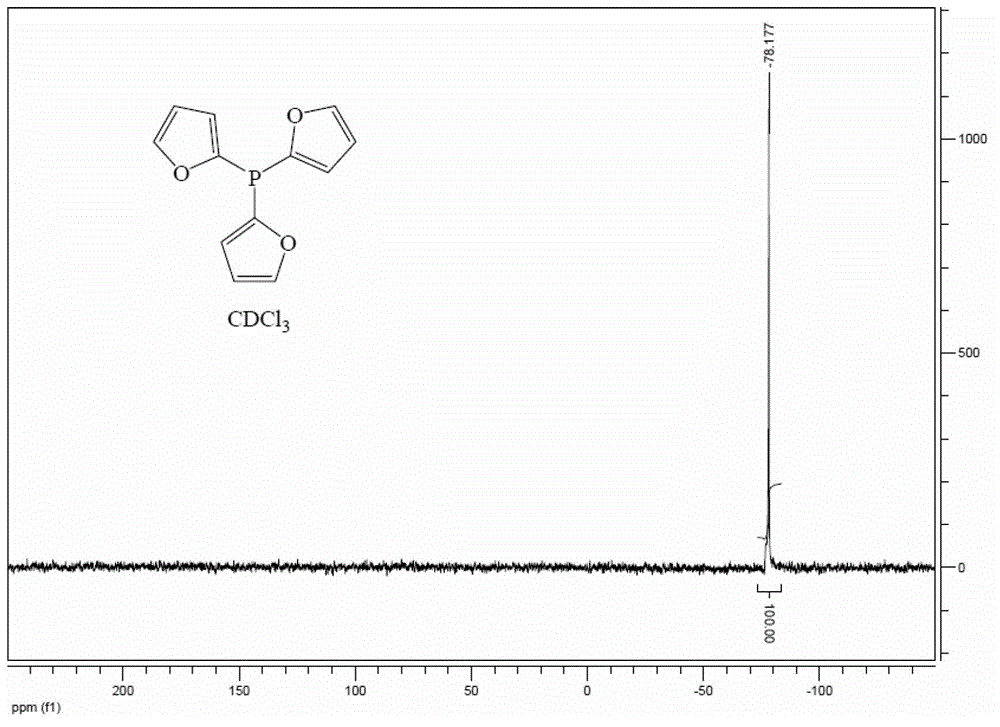

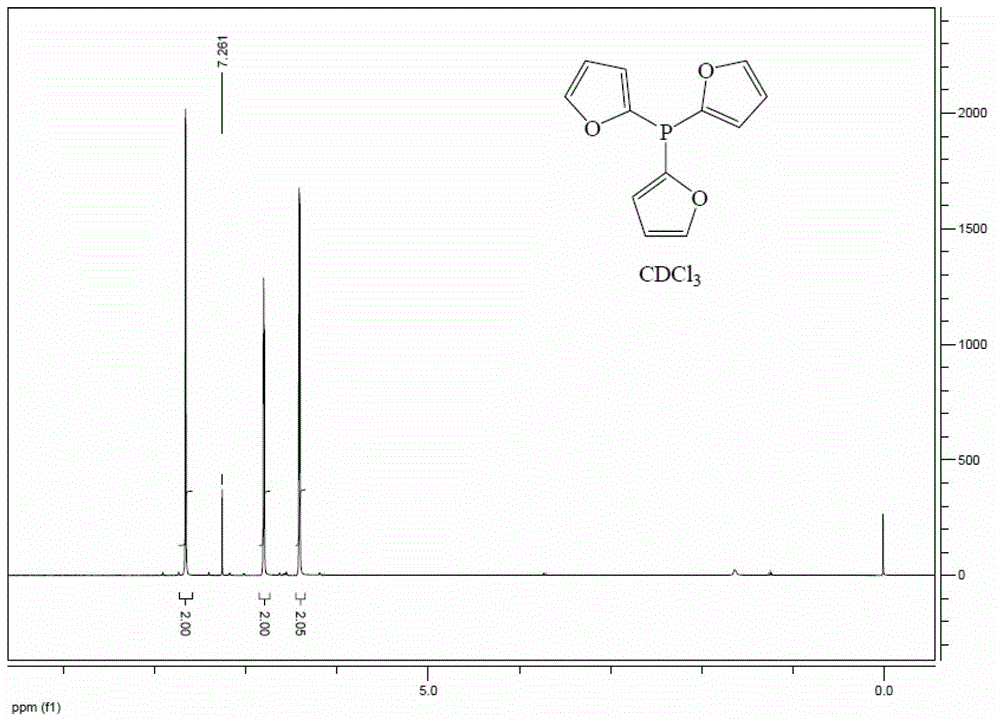

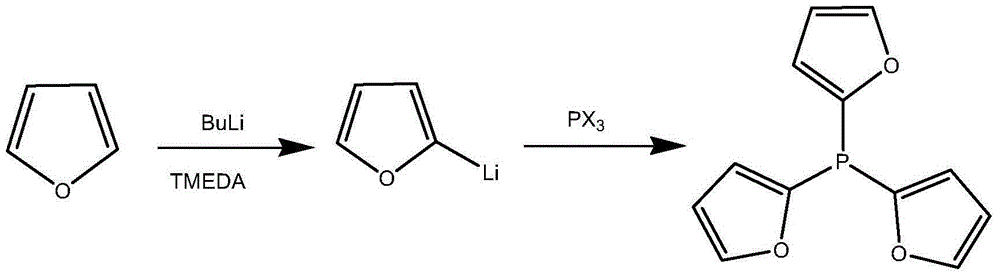

Preparation method of tris(2-furyl) phosphine

The invention relates to a preparation method of tris(2-furyl) phosphine, which comprises the following steps of: in the atmosphere of inert gas, at the room temperature, dripping a butyl lithium solution in a normal hexane solution containing furan and tetramethylethylenediamine, raising the temperature to 40-60 DEG C, and keeping for 0.5-3 hours to produce a furyl lithium reagent; dripping phosphorus halide in the normal hexane solution at the temperature of minus 10 to 0 DEG C, carrying out heat insulation for 0.5-2 hours, naturally raising the temperature to the room temperature, and stirring for 1-8 hours; and pouring a reaction solution into a saturated strong acidic-weak basic inorganic salt solution, concentrating an organic phase to obtain a crude product, and then recrystallizing with of petroleum ether to obtain tris(2-furyl) phosphine. With the adoption of the preparation method, the preparation cost is greatly lowered, the yield is greatly increased, and the product purity is high. In the embodiment of the invention, anhydrous cerium trichloride is added into produced furyl lithium to obtain an organic cerium reagent, and the organic cerium reagent is further reacted with phosphorus trihalide, so the yield can be further increased, and the by-products can be reduced.

Owner:PANJIN GELIN KAIMO TECH CO LTD

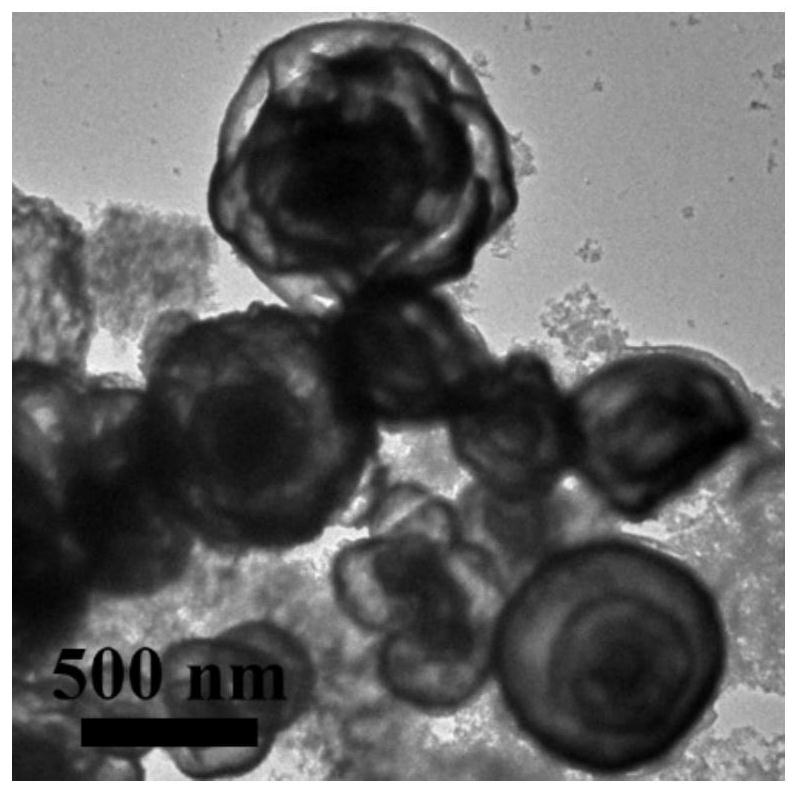

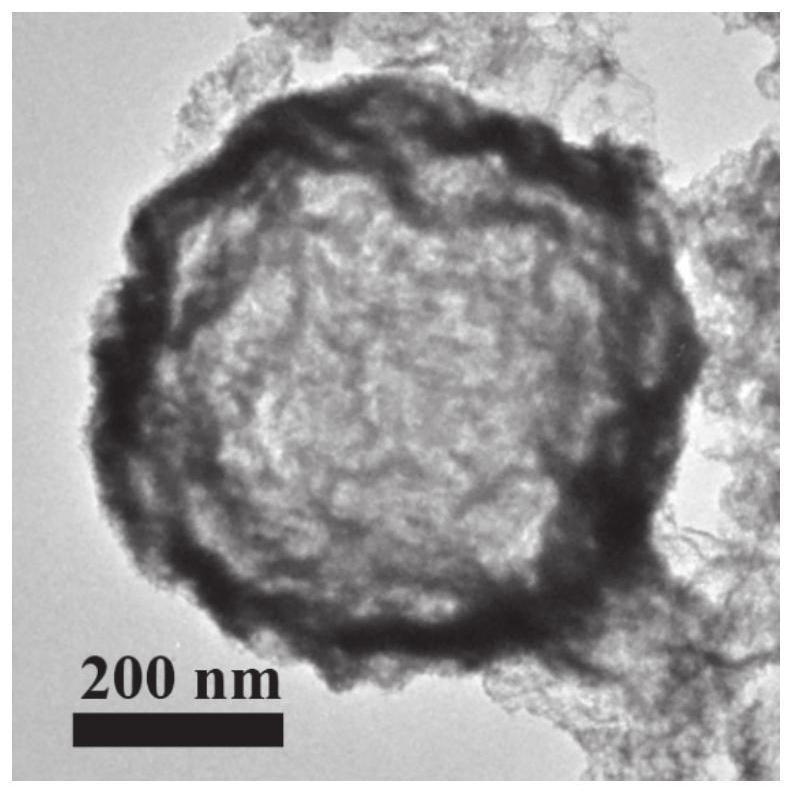

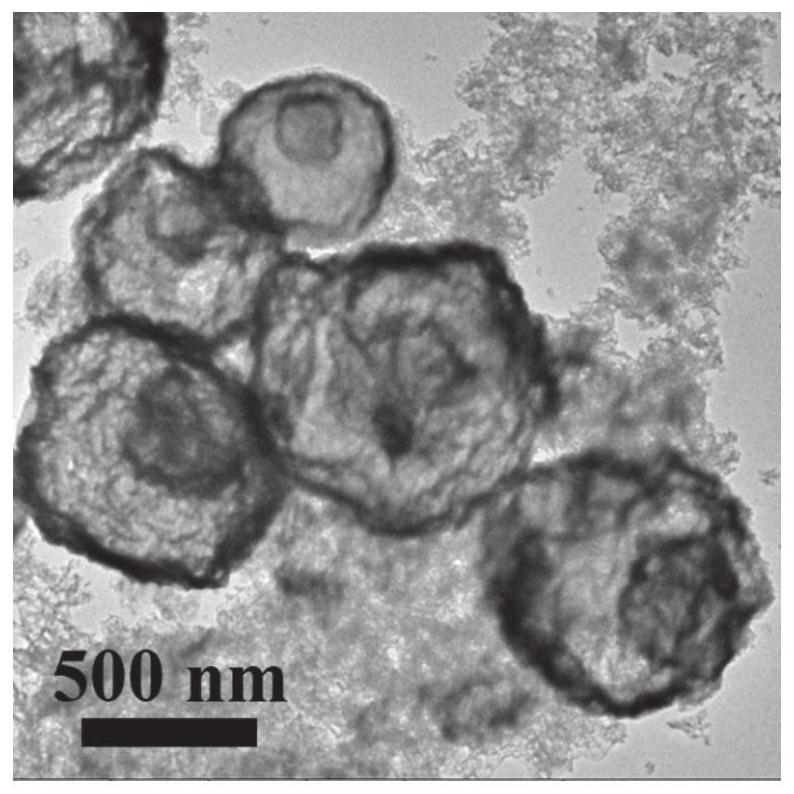

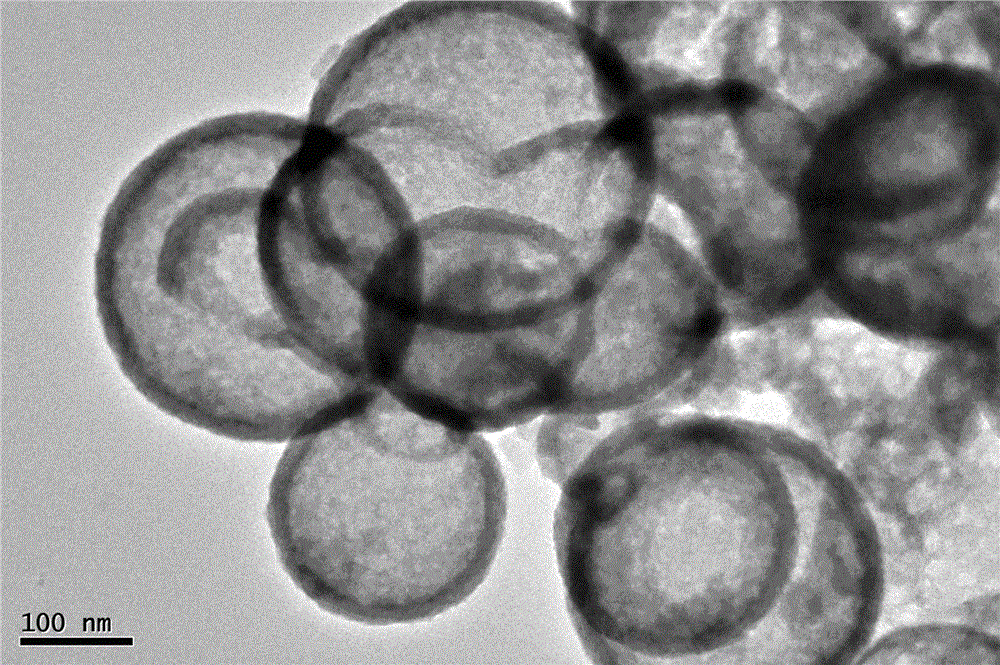

Hollow spherical cerium dioxide nano material and preparation method and application thereof

ActiveCN112909236AEasy to makeEasy to operateMaterial nanotechnologyCerium oxides/hydroxidesCarbon compositesElectrolytic agent

The invention discloses a hollow spherical cerium dioxide nano material and a preparation method and application thereof. The preparation method comprises: glucose serving as a carbon source, urea serving as a precipitator, cerium trichloride serving as a cerium source, water serving as a solvent, and preparing a cerium dioxide / carbon composite material through a hydrothermal method; and calcining in a muffle furnace to obtain the hollow spherical multi-shell structure cerium dioxide nano material. The number of shell layers of the material can be adjusted by adjusting the amount of urea and the calcination temperature. In the process, the preparation method is simple, the preparation process is safe, environment-friendly, low in energy consumption and high in operability. According to the cerium dioxide nano material with the hollow spherical structure prepared in the invention, the number of shell layers can be adjusted, the shell layer spacing is relatively large, the specific surface area can be increased, the contact area between the material and an electrolyte is increased, and the structure collapse caused by volume expansion of an electrode material in the charging and discharging process can be relieved. The electrochemical performance is effectively improved.

Owner:QILU UNIV OF TECH

Preparation method of magnetic loading cerium oxide for exhaust gas treatment

ActiveCN106076350AImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsWater bathsSalicylaldehyde

The invention discloses a preparation method of magnetic loading cerium oxide for exhaust gas treatment. The method sequentially comprises the following steps: adding hydrogen peroxide and a dilute NaOH solution to a FeCl2 solution in a dropwise manner under a thermostatic water bath condition, stirring the solutions, transferring the finally obtained solution to an autoclave, continuously carrying out a reaction, naturally cooling the obtained reaction product to room temperature to obtain a solid precipitate, and adding the solid precipitate to a sodium dodecyl benzene sulfonate solution to obtain magnetic organic hydrotalcite; preparing a formation solution from (3-aminopropyl)triethoxysilane, salicylaldehyde and cerium trichloride according to a molar ratio of 1:1:1, and adding magnetic organic hydrotalcite to form a cerium-containing organic complex pillared hydrotalcite; and adding the cerium-containing organic complex pillared hydrotalcite to a muffle furnace, roasting the cerium-containing organic complex pillared hydrotalcite at 400-550 DEG C for 6-8h to convert carbon and nitrogen elements into gas which overflows and form tunnels in order to obtain the magnetic synergistic cerium oxide catalyst. The above structure of the catalyst is in favor of adsorbing and catalyzing pollutants, and is also in favor of separating.

Owner:CHANGZHOU UNIV

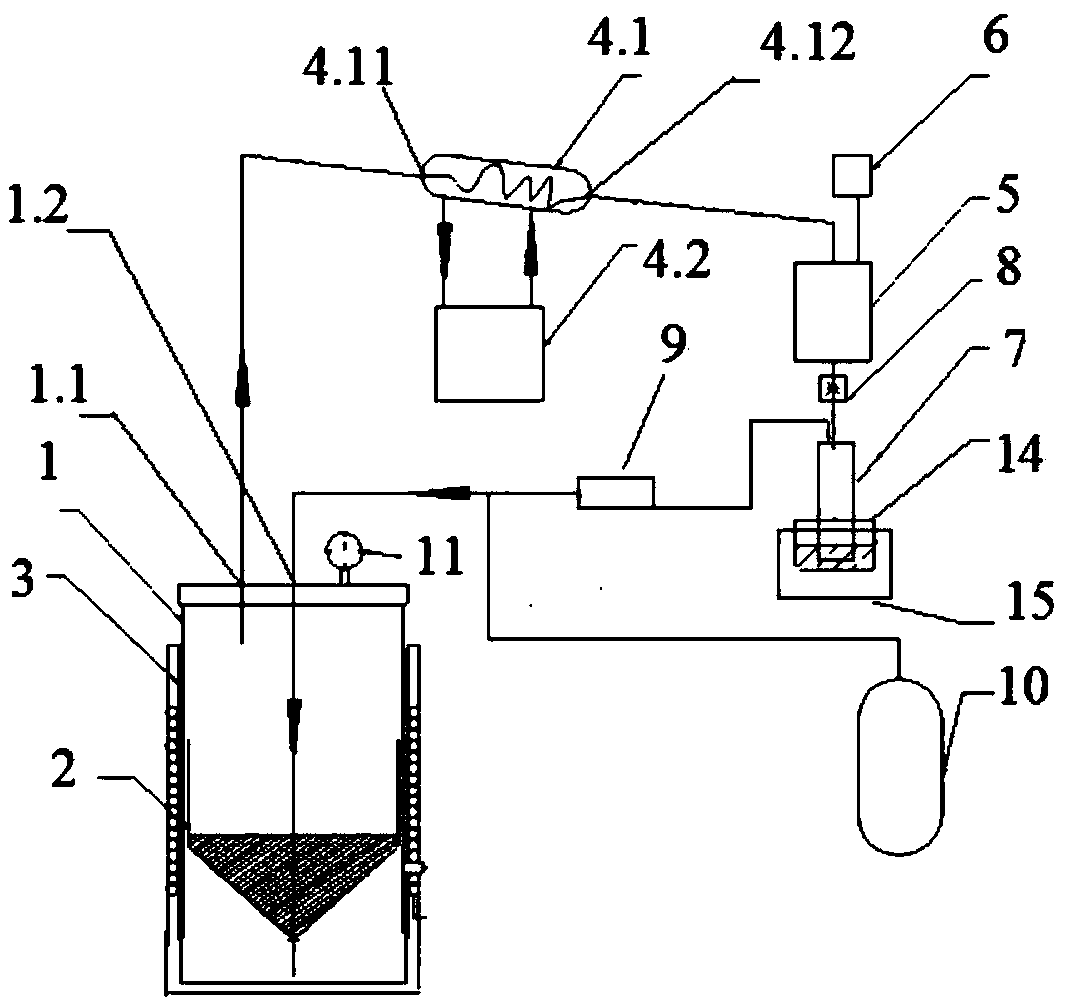

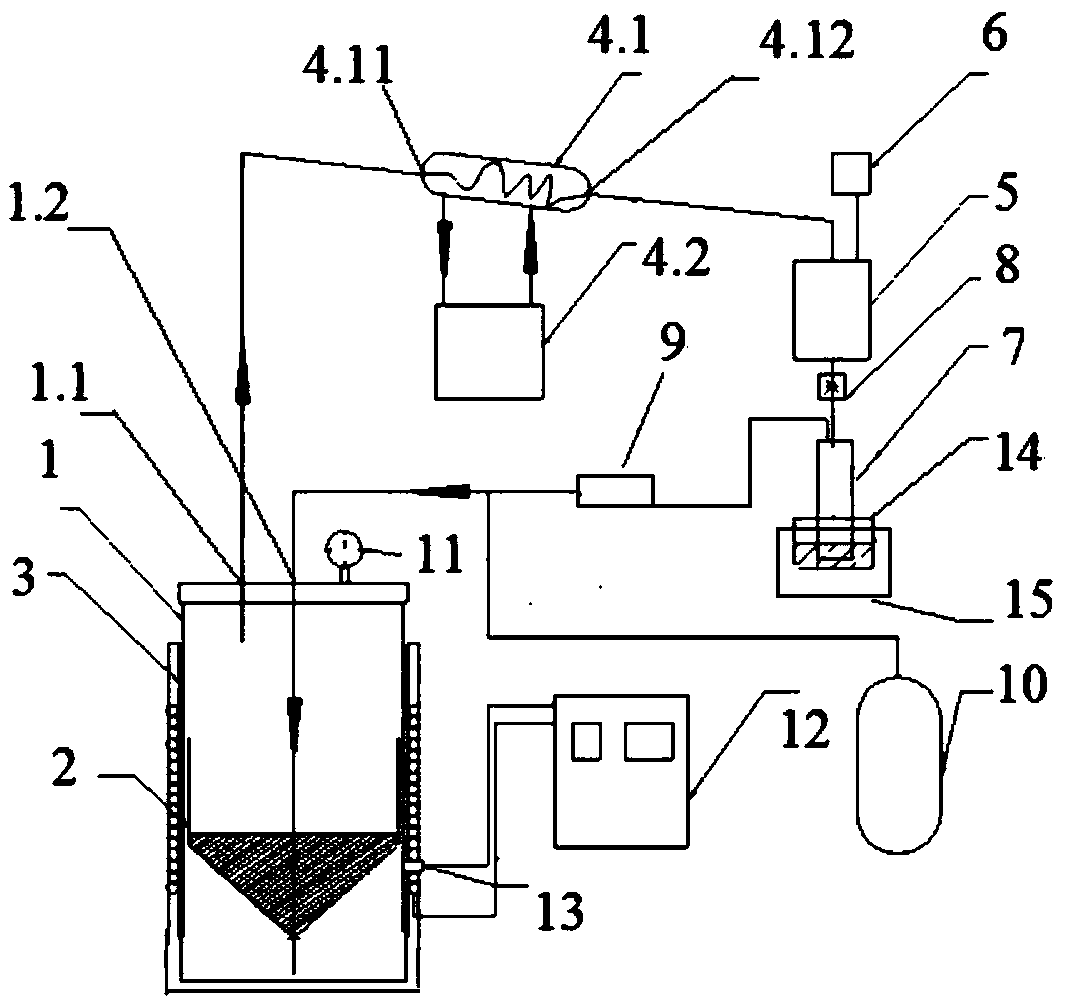

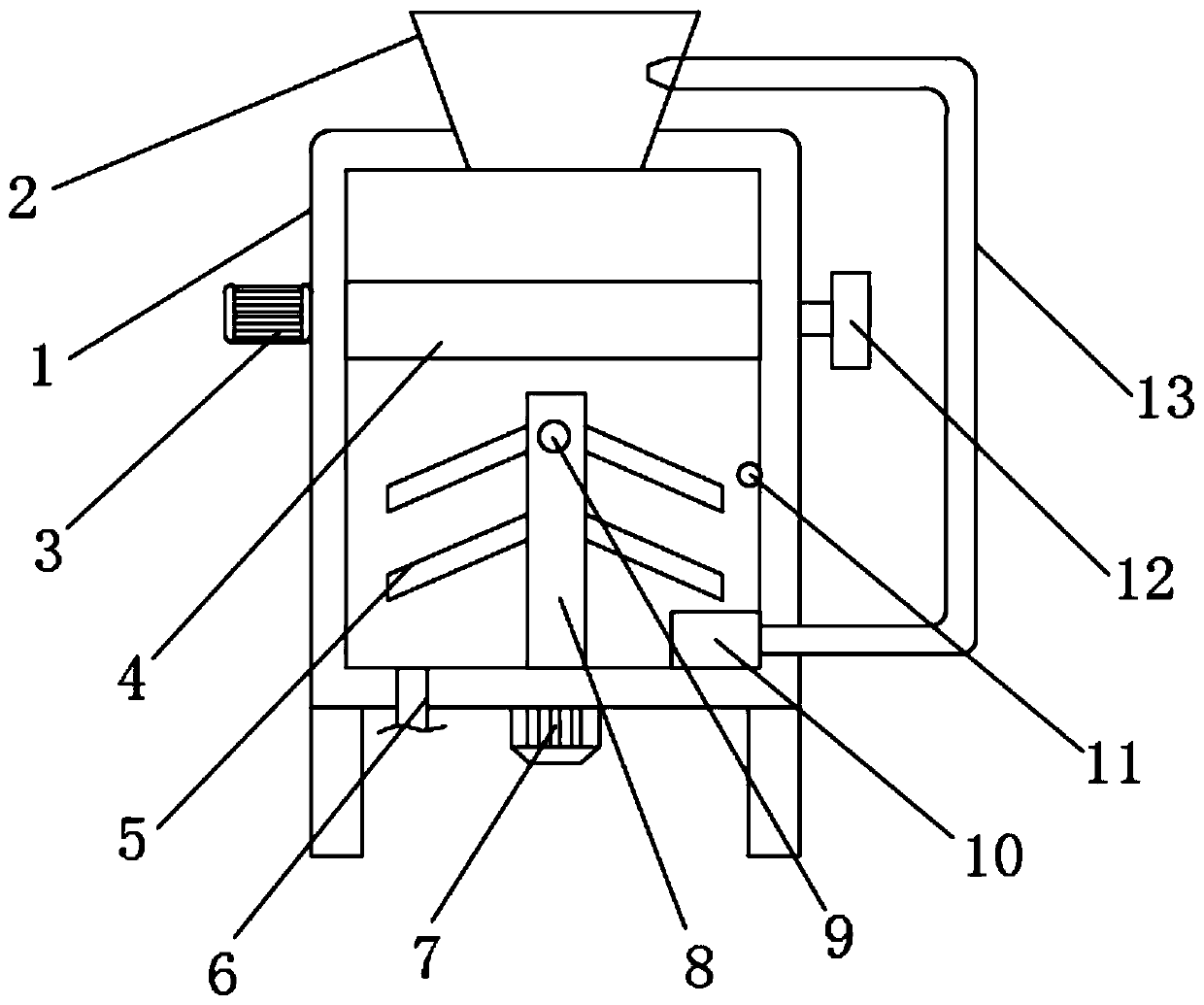

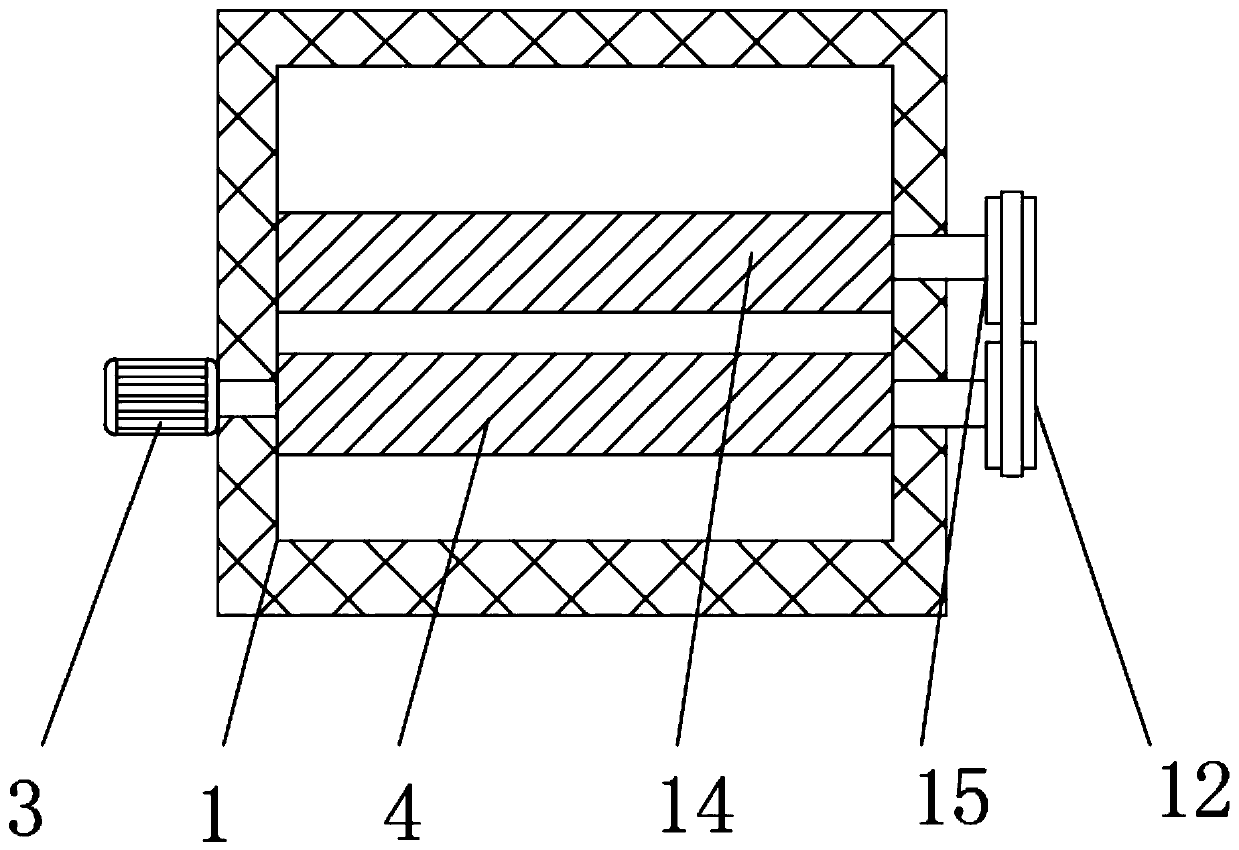

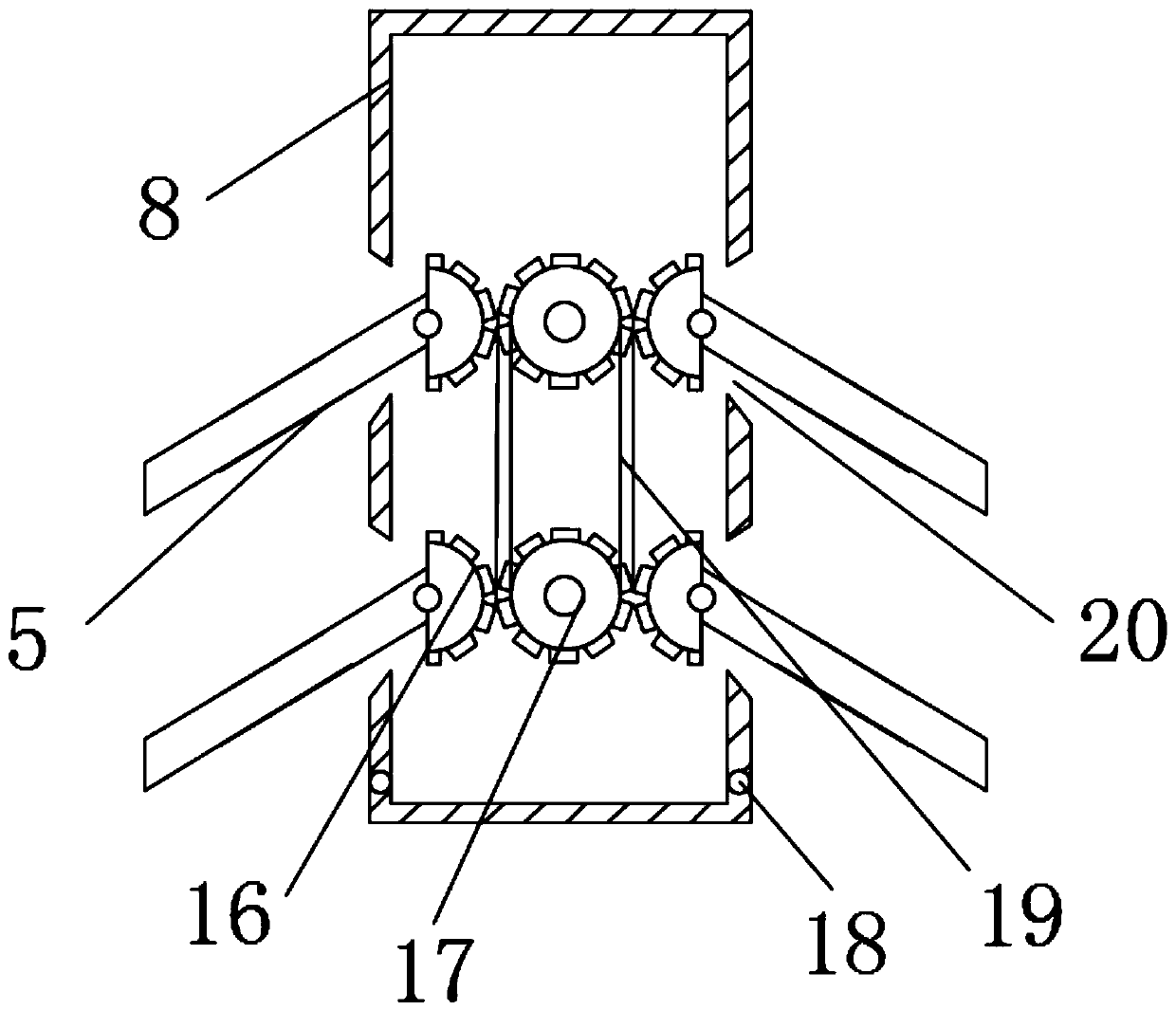

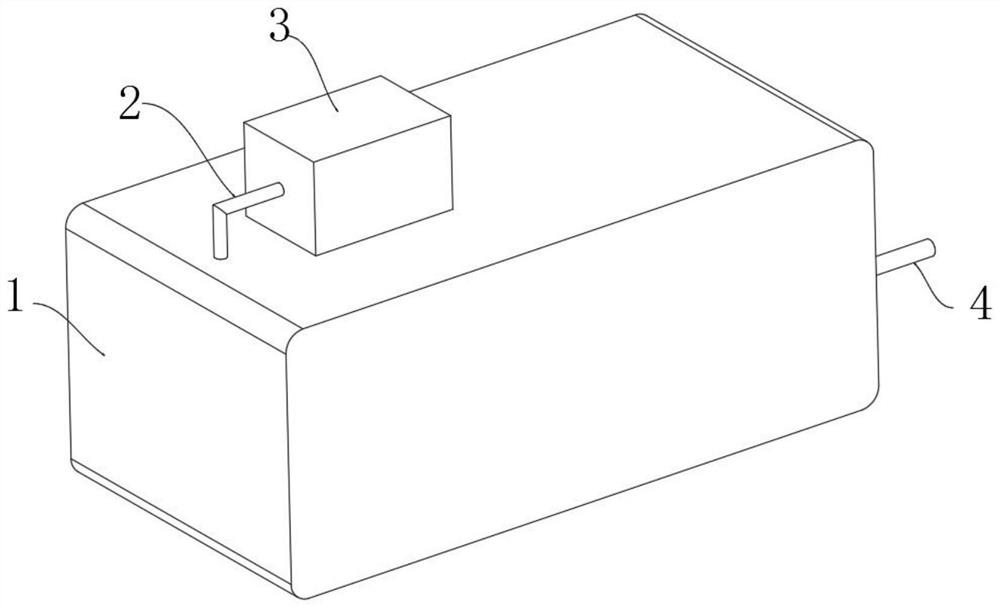

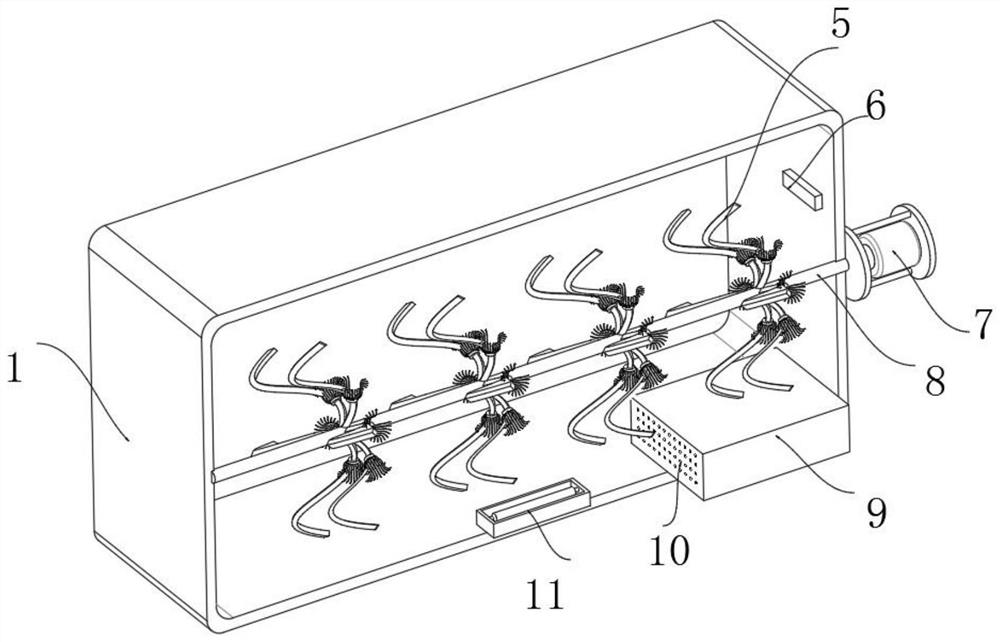

Cerium dioxide chlorination device

PendingCN109678194ALess corrosiveIncrease profitRare earth metal chloridesGas supplyCarbon tetrachloride

The invention discloses a cerium dioxide chlorination device which comprises a reactor, a heating unit, a condensing unit, a gas and liquid separation unit, a gas absorption unit, a CC14 liquid collection unit and a gas supply unit. The cerium dioxide chlorination device disclosed by the invention has the beneficial effects that cerium dioxide can be chlorinated into cerium trichloride to absorb toxic products C12 and COC12, carbon tetrachloride is fully recycled, and the separation of the cerium trichloride as a reaction product from the carbon tetrachloride as a chlorinating agent can be realized after reaction completion; not only does no waste exist, and can the stoichiometric reaction be achieved basically, but also no waste can be produced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Cooling fluid of wind turbine inverter and preparation method of cooling fluid

InactiveCN110699048AEffective protectionSlow consumptionChemical industryHeat-exchange elementsPhosphateHigh energy

The invention discloses a cooling fluid of a wind turbine inverter and a preparation method of the cooling fluid, and belongs to the field of operation and maintenance of the wind power industry. Thecooling fluid consists of the following components in parts by weight: 1,3-propanediol 40-60 parts, cerium trichloride heptahydrate 0.5-1 part, allocinnamic acid 0.2-0.5 part, ethylidene diamine tetramethylphosphonic acid 1-5 parts, sodium benzoate 0.5-1 part, potassium dihydrogen phosphate 1-5 parts, triethanolamine 1-5 parts, sodium hydroxide 0.1-0.3 part, deionized water 40-50 parts and water-based fluorescent blue dye 0.02-0.05 part. The cooling fluid does not freeze at -45 DEG C, and a compound of cerium trichloride heptahydrate and allocinnamic acid can form a conversion film on the surface of aluminum metal, so that corrosion of aluminum alloy can be effectively inhibited. The formula of the cooling fluid can be used to effectively avoid problems of performance instability and deposition of an inorganic corrosion inhibitor in high temperature environment, and has the properties of high energy efficiency, low cost and low pollution.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Anti-counterfeiting ink for plastic packaging

InactiveCN109852144AHigh fluorescence intensityGood natural environmental protection and antibacterial propertiesInksGrain treatmentsLanthanumHydroxy compound

The invention discloses anti-counterfeiting ink for plastic packaging. The anti-counterfeiting ink is prepared from the following raw materials in parts by weight: 80-120 parts of resin, 0.2-0.3 partof fluorescent powder, 8-12 parts of cerium trichloride, 16-24 parts of lanthanum trichloride, 24-36 parts of chitosan and 8-12 parts of pigment. According to the anti-counterfeiting ink, La<3+> is added, and fluorescence intensity of Ce<3+> can be enhanced by the La<3+>. In addition, the excessive chitosan reacts with the lanthanum trichloride and the cerium trichloride. Firstly hydroxyl in the chitosan is coordinated with the cerium trichloride, so that the fluorescence intensity is improved; through synergistic effect of the hydroxyl and the cerium trichloride, the fluorescence intensity isfurther improved; and through organic combination of the transition metal cerium and the fluorescent powder which is tertiary calcium phosphate fluorescent powder, the fluorescent intensity of the fluorescent powder in high-shielding-strength ink such as red ink, yellow ink, green ink, blue ink, white ink, black ink and the like can be enhanced, the fluorescent decay time of the fluorescent anti-counterfeiting ink is prolonged, and the characteristics of long concealing time, good anti-counterfeiting effect and the like of the fluorescent anti-counterfeiting ink are achieved.

Owner:广州铮讯信息科技有限公司

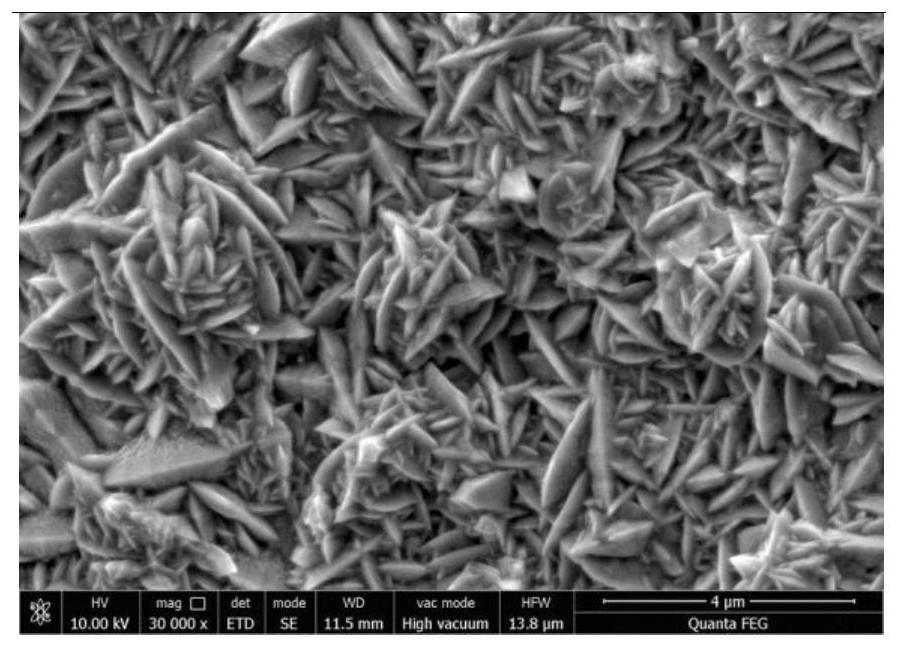

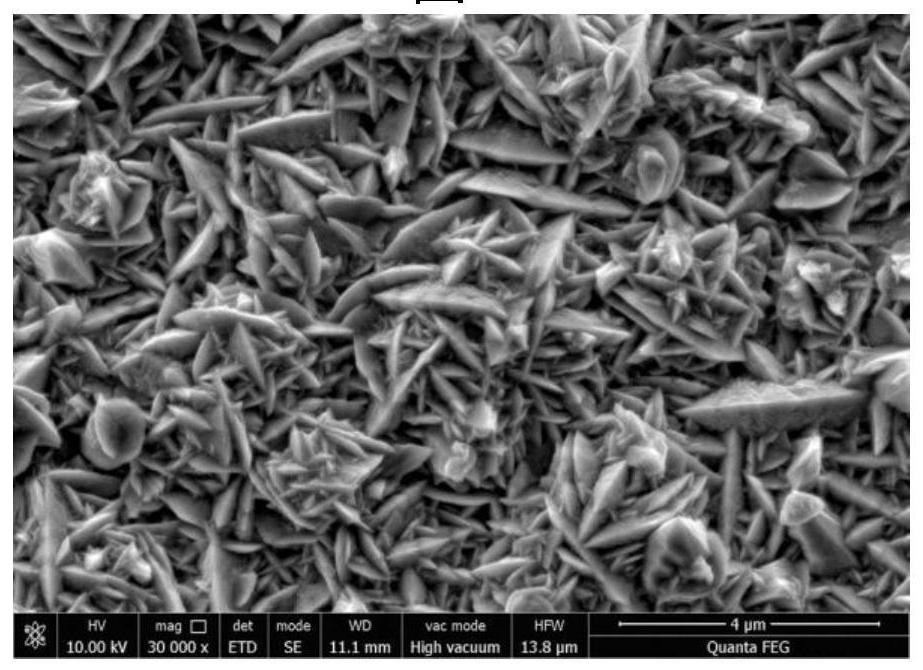

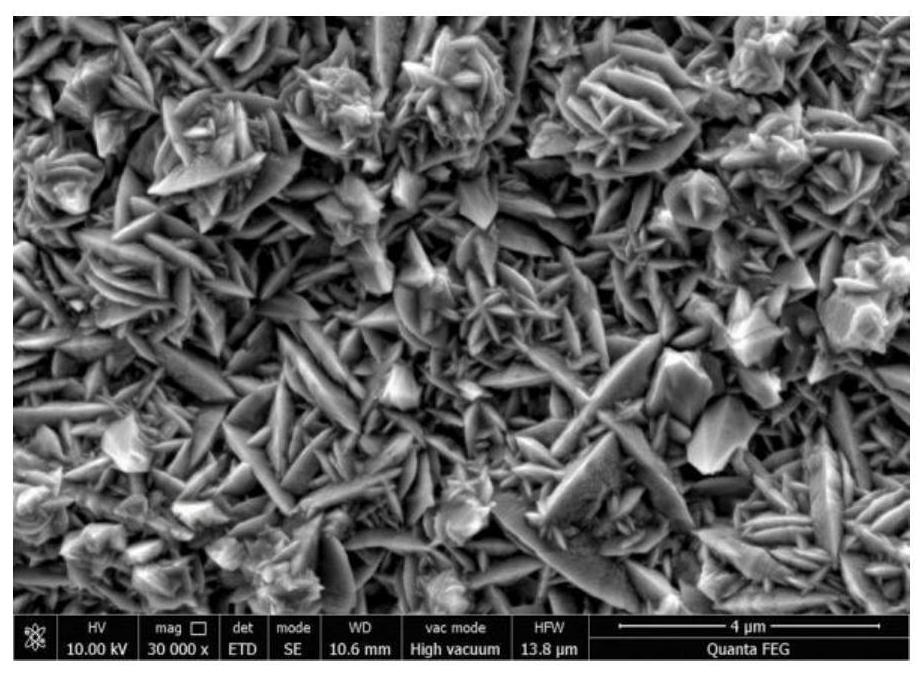

Method for refining electrodeposited nickel crystal grains through cerium trichloride

The invention discloses a method for refining electrodeposited nickel crystal grains through cerium trichloride, and relates to the technical field of electrodeposited nickel. The method comprises the following steps that S1, a deposition solution is prepared, wherein the cerium trichloride is added into an electrolyte and stirred and dissolved to prepare the deposition solution; S2, a cathode test piece is treated, wherein the polished surface of the cathode test piece is stripped off, ultrasonic washing, flushing, activating, flushing and blow-drying are conducted, and the treated cathode test piece is prepared; S3, electrodeposition is conducted, wherein the deposition solution is added into an electrodeposition tank, heating is conducted, the cathode test piece and an anode test piece are put in, a power supply is connected, electrifying is conducted for electrodeposition, and the cathode test piece after electrodeposition is prepared; and S4, post-treatment of the cathode test piece is conducted, wherein washing, blow-drying and sealing are conducted on the cathode test piece subjected to electrodeposition, and a nickel-plated cathode test piece is prepared. According to the method for refining the electrodeposited nickel grains through the cerium trichloride, the rare earth element Ce is added into the electrolyte, the grain refining effect is remarkable, and the minimum average grain size can reach 349.34 nm.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

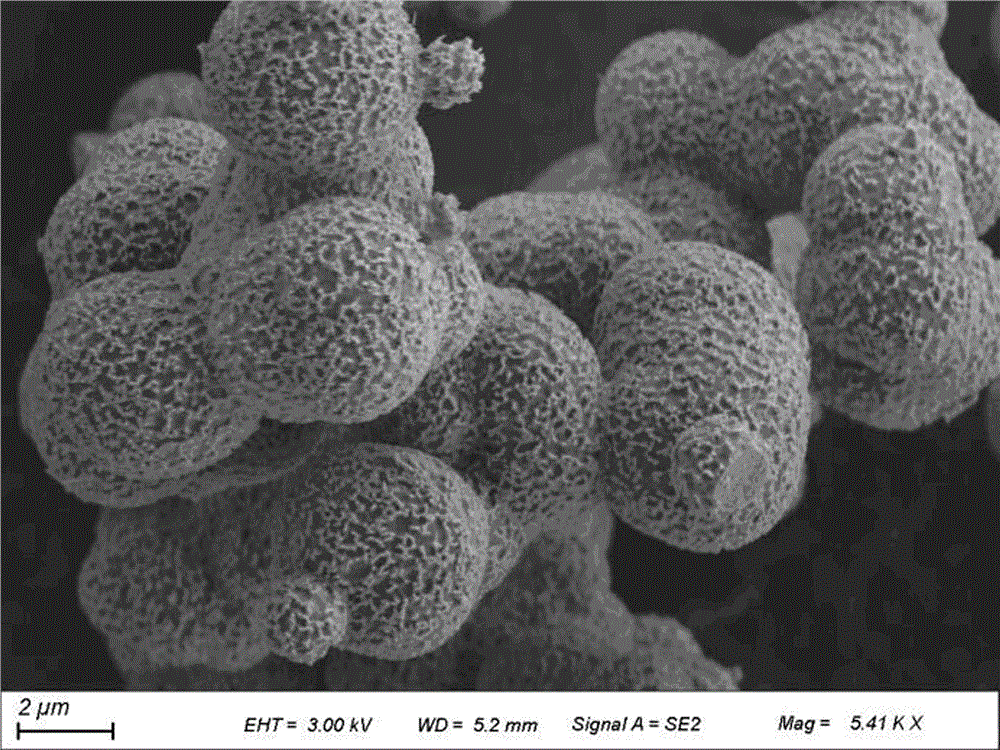

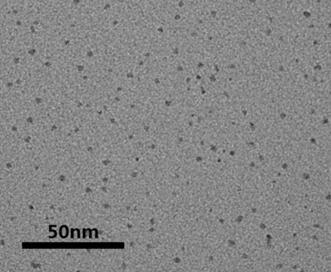

Simple preparation method of hollow cerium oxide nano-spheres

InactiveCN106745175AGood lookingReduce pollutionRare earth metal oxides/hydroxidesMaterial nanotechnologyHigh pressureVacuum drying

The invention discloses a simple preparation method of hollow cerium oxide nano-spheres. The preparation method comprises the following steps: (1) weighing cerium trichloride heptahydrate and L-cysteine respectively, mixing, adding the mixture into water or anhydrous ethanol, and stirring uniformly to obtain a suspension A; (2) pouring the suspension A stirred uniformly into an inner container of a hydrothermal kettle, tightening the high pressure kettle, putting the hydrothermal kettle into a vacuum drying box of 160-200 DEG C, and reacting for 3-24 hours to obtain a product in the inner container; and (3) after the reaction ends, centrifuging the product in the inner container to remove byproducts, continuously washing the product three times with deionized water and one time with anhydrous ethanol, and drying the product at 40 DEG C, thus obtaining the hollow cerium oxide nano-spheres. The agent prepared by the method only contains common chemical reagents such as cerium trichloride heptahydrate, L-cysteine and deionized water, so the method is relatively low in cost, relatively high in availability and relatively low in pollution to the environment and complies with the requirement of large-scale production.

Owner:NANJING INST OF TECH

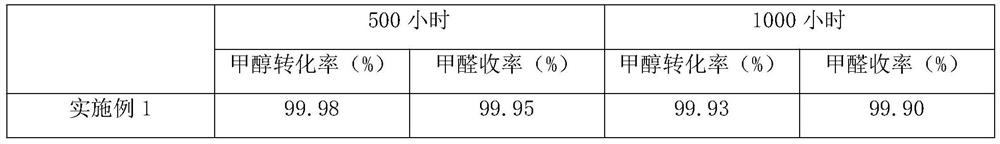

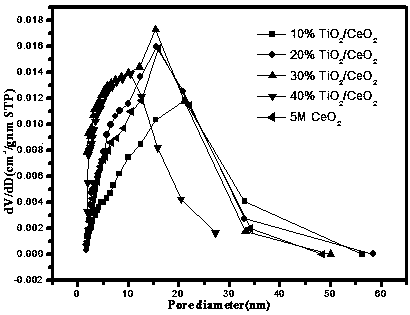

Manganese dioxide composite material and preparation method and application thereof

ActiveCN112191264AImprove conversion rateHigh yieldPhysical/chemical process catalystsOrganic compound preparationHalloysitePhosphate

The invention provides a manganese dioxide composite material as well as a preparation method and application thereof. The manganese dioxide composite material is prepared by taking manganese dihydrogen phosphate, cerium trichloride, melamine, halloysite and the like as raw materials. The manganese dioxide composite material can be used for a reaction for preparing formaldehyde through methanol oxidation, and the methanol conversion rate and the formaldehyde yield are greatly improved. Preparation of formaldehyde by methanol oxidation belongs to dehydrooxidation, so that the key of promoting the reaction is how to promote hydrogen removal. In the preparation process, rich pores are formed in a precursor calcining process, so that the composite material has a good adsorption effect on methanol, good contact between the composite material and reactant methanol is promoted, and a good foundation is provided for subsequent catalytic reaction.

Owner:ANHUI UNIVERSITY

Silver and lanthanum ion water purification composite ceramic membrane process

ActiveCN113546527ASimple preparation processLow toxicitySemi-permeable membranesWater contaminantsIridiumComposite ceramic

The invention discloses a silver and lanthanum ion water purification composite ceramic membrane process. The process comprises the following steps: step 1, reacting titanium dioxide powder with a concentrated sodium hydroxide solution to obtain sodium trititanate powder; step 2, soaking the sodium trititanate powder in a mixed aqueous solution of cerium trichloride and iridium trichloride, and then conducting calcining to obtain solid-phase powder A; step 3, pressing the solid-phase powder A into a sheet sample, and conducting calcining to obtain a ceramic sheet B; and step 4, putting the ceramic sheet B into a dopamine aqueous solution, then putting the dopamine aqueous solution into a vacuum box, vacuumizing the box, then taking out the ceramic sheet, putting the ceramic sheet into a Tris buffer solution, soaking the ceramic sheet for 18-20 hours, then taking out the ceramic sheet, washing the ceramic sheet with deionized water, and drying the ceramic sheet to obtain the composite ceramic membrane. The preparation technology of the ceramic membrane is optimized, the prepared ceramic membrane can intercept a large number of free silver ions and lanthanum ions in sewage, recycling of metal ions in wastewater is facilitated, and the toxicity of the sewage can be reduced.

Owner:江西嘉陶无机材料有限公司

Polycarbonate film for bags and suitcases

ActiveCN114479411AGood mechanical propertiesImprove heat resistancePolycarbonateDodecylsulfonic acid

A preparation method of the polycarbonate film comprises the following steps: 1) adding sepiolite into an aqueous solution of sodium dodecyl sulfate, then adding an aqueous solution of ferric chloride, pyrrole and ferric citrate, washing, drying, carrying out ball milling, and sieving with a 1000-mesh sieve to obtain sieved powder; 2) soaking the sieved powder in an aqueous solution of cerium trichloride and nickel dichloride, adding octadecyl trimethyl ammonium bromide, and calcining to obtain calcined powder; 3) soaking the calcined powder in an N, N-dimethylformamide solution of lipoic acid to form a mixture, and performing sealed heating, solid-liquid separation, washing and drying to obtain modified powder; and 4) carrying out melt blending on polycarbonate and the modified powder, carrying out extrusion granulation, and then carrying out injection molding and film drawing to form the polycarbonate film. The polycarbonate material prepared by the invention has good mechanical properties and certain heat resistance, the use effect of the polycarbonate body is obviously improved, the durability of the material is improved, and the use range of the film is widened.

Owner:株洲地博光电材料有限公司

Preparation method of formaldehyde scavenger

InactiveCN109046015AGood photocatalytic effectLarge specific surface areaDispersed particle separationWater bathsEnvironmental resistance

The invention discloses a preparation method of a formaldehyde scavenger. The preparation method comprises the steps of: adding titanium alkoxide, zinc oxide and cerium trichloride heptahydrate in a certain mass concentration of hydrochloric acid and stirring for a period of time to obtain a compound A; adding molecular sieve SBA-15 to the compound A, ultrasonically dispersing for a period of time, performing reduced pressure distillation, and absorbing with a certain mass concentration of liquid alkali solution to obtain a filter cake; after drying, calcining, and natural cooling, thus obtaining a compound B; in a water bath condition, adding disodium hydrogen phosphate, polyethylene glycol and polyvinyl alcohol to a certain amount of water, stirring for a period of time, dropwise addinga silver nitrate solution, and ultrasonically reacting for a period of time to obtain a compound C; adding kieselguhr and the compound B to the compound C, stirring, grinding, filtering, and drying toobtain a formaldehyde scavenger D. The formaldehyde scavenger has the advantages of environmental protection and high efficiency in removing formaldehyde.

Owner:龚娟

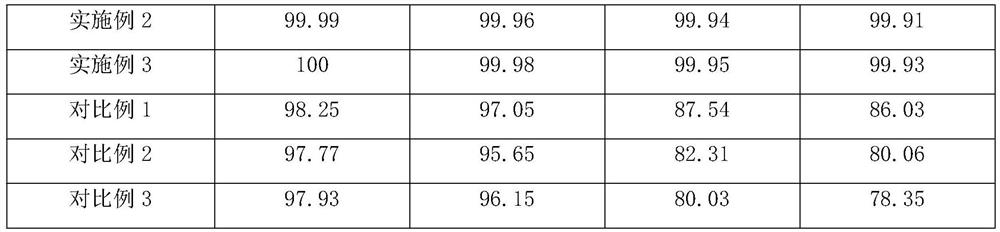

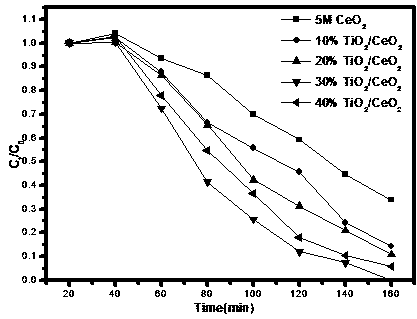

A preparation method of ceria nanorod doped titania nanoparticle photocatalyst

ActiveCN107243340BIncrease profitImprove photocatalytic abilityWater/sewage treatment by irradiationWater treatment compoundsPtru catalystCerium(IV) oxide

Owner:NANCHANG HANGKONG UNIVERSITY

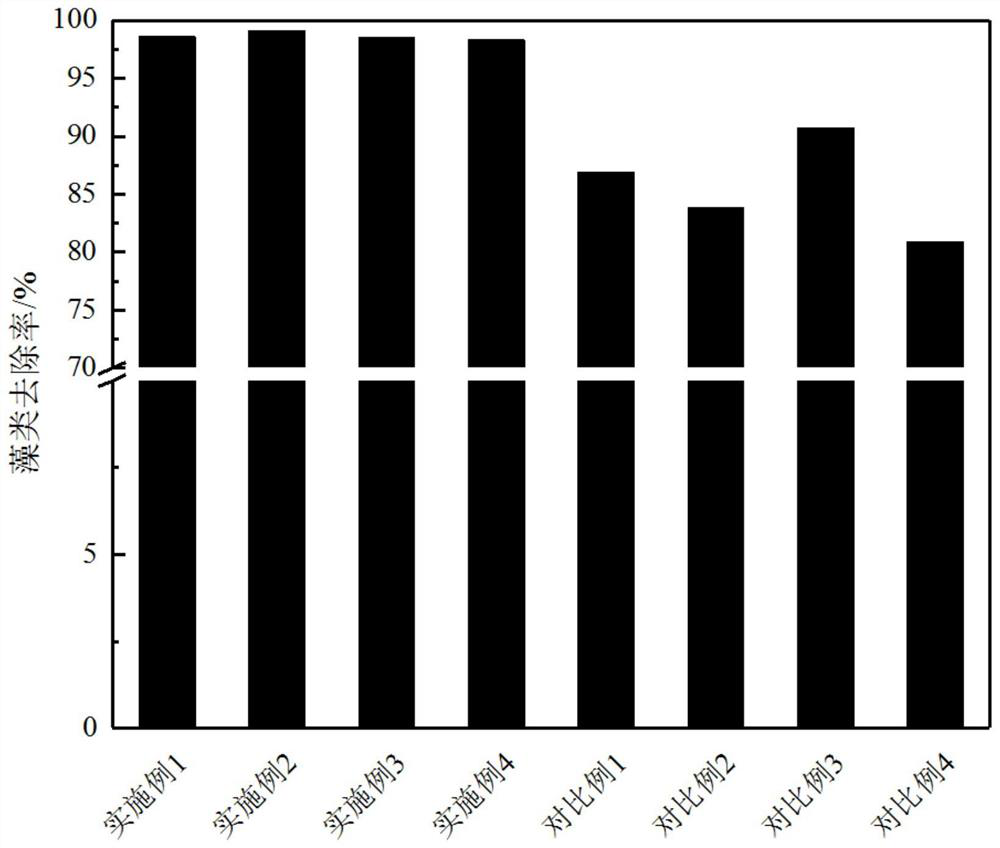

A kind of preparation method of environment-friendly algae-removing coagulant

ActiveCN113057176BGood effect on algae removalReduce pollutionBiocideAnimal repellantsAluminium chlorideWater chlorination

The invention discloses a preparation method of an environment-friendly algae-removing coagulant. The preparation method is as follows: (1) taking aluminum chloride hexahydrate, ferric chloride hexahydrate and cerium trichloride hexahydrate respectively after sieving Powder, mixed evenly, heated for one roasting, air cooling, mixed with iridium trichloride, second roasting, air cooling; (2) Add deionized water to the roasted powder to react until dark brown polymer is formed and air cool to room temperature Stop stirring to obtain the crude coagulant; (3) Configure an aqueous solution of sodium hydroxide, soak the crude coagulant in the aqueous solution of sodium hydroxide, stir rapidly, then add iron oxide powder and hydrogen peroxide sequentially therein, and the feeding is completed Then continue to stir, stand at room temperature for more than 20h, and freeze-dry to obtain the coagulant. The algae-removing coagulant prepared by the invention has good algae-removal effect, less water pollution, and is suitable for primary treatment of water body pollutants.

Owner:CHANGZHOU INST OF LIGHT IND TECH

A kind of preparation method of three (2-furyl) phosphine

The invention relates to a preparation method of tris(2-furyl) phosphine, which comprises the following steps of: in the atmosphere of inert gas, at the room temperature, dripping a butyl lithium solution in a normal hexane solution containing furan and tetramethylethylenediamine, raising the temperature to 40-60 DEG C, and keeping for 0.5-3 hours to produce a furyl lithium reagent; dripping phosphorus halide in the normal hexane solution at the temperature of minus 10 to 0 DEG C, carrying out heat insulation for 0.5-2 hours, naturally raising the temperature to the room temperature, and stirring for 1-8 hours; and pouring a reaction solution into a saturated strong acidic-weak basic inorganic salt solution, concentrating an organic phase to obtain a crude product, and then recrystallizing with of petroleum ether to obtain tris(2-furyl) phosphine. With the adoption of the preparation method, the preparation cost is greatly lowered, the yield is greatly increased, and the product purity is high. In the embodiment of the invention, anhydrous cerium trichloride is added into produced furyl lithium to obtain an organic cerium reagent, and the organic cerium reagent is further reacted with phosphorus trihalide, so the yield can be further increased, and the by-products can be reduced.

Owner:PANJIN GELIN KAIMO TECH CO LTD

A kind of preparation method of magnetic load cerium oxide for treating waste gas

ActiveCN106076350BImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsWater bathsSalicylaldehyde

The invention discloses a preparation method of magnetically supported cerium oxide for treating waste gas. It includes the following steps in sequence: under constant temperature water bath conditions, dropwise add hydrogen peroxide and NaOH dilute solution to the FeCl2 solution, stir and transfer to the autoclave, continue the reaction, naturally cool to room temperature, obtain a solid precipitate, and add it to dodecane In sodium benzene sulfonate solution, magnetic organic hydrotalcite is obtained. Prepare a solution of (3-aminopropyl)triethoxysilane, salicylaldehyde and cerium trichloride in an amount of 1:1:1 (molar ratio), add magnetic organic hydrotalcite to form a cerium-containing organic complex Pillared hydrotalcite; the cerium-containing organic complex pillared hydrotalcite is placed in a muffle furnace and roasted at 400-550°C for 6-8 hours. The carbon, nitrogen and other elements in it are converted into gases and overflow to form pores, thereby obtaining magnetic collaborative oxidation. Cerium catalyst. This structure is conducive to adsorbing and catalyzing pollutants, and is also conducive to separation.

Owner:CHANGZHOU UNIV

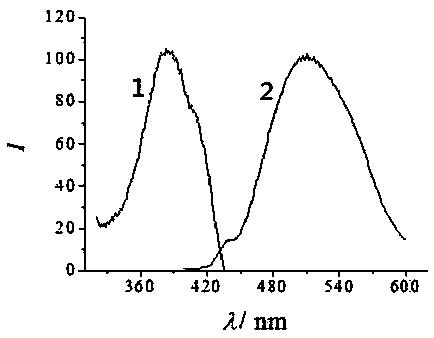

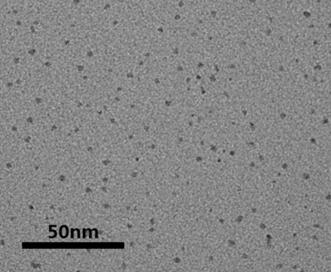

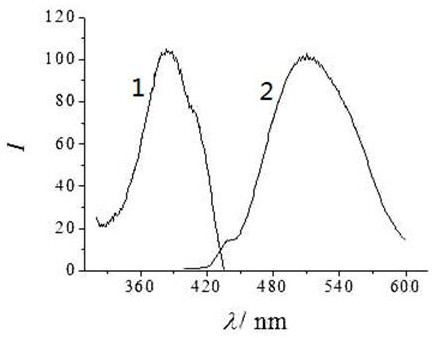

Method for preparing cerium sulfide doped carbon quantum dot nano fluorescent material

ActiveCN110437835AHigh stability of fluorescence performanceSmall and uniform in sizeMaterial nanotechnologyNanoopticsItaconic acidBiocompatibility Testing

The invention discloses a method for preparing a cerium sulfide doped carbon quantum dot nano fluorescent material. The method is characterized in that: the method includes preparing an A solution from deionized water, itaconic acid and cerium trichloride; preparing a B solution from deionized water and thioacetamide; adding the A solution into a reactor, and stirring the A solution; adding the Bsolution dropwise into the A solution, with the volume ratio of the A solution to the B solution being 5:1; stirring and reacting the mixture for 30 min after the dropwise addition is finished; transferring the mixture to a reaction kettle, covering the kettle with a sealing cover, and putting the kettle into a thermostat; reacting the mixture at a constant temperature of 180 + / -2 DEG C for 20-24h to obtain a red suspension liquid; performing solid liquid separation to obtain liquid that is a crude product of the cerium sulfide doped carbon quantum dot nano fluorescent material; and purifyingthe material through a dialysis manner. The method is green and simple to operate, and the material can have high fluorescence stability, a small and uniform size, good biocompatibility and other characteristics without the need of secondary modification.

Owner:UNIV OF JINAN

A silver, lanthanum ion water purification composite ceramic membrane technology

ActiveCN113546527BSimple preparation processLow toxicitySemi-permeable membranesWater contaminantsComposite ceramicEngineering

The invention discloses a silver and lanthanum ion water purification composite ceramic membrane process, comprising the following steps: step 1, reacting titanium dioxide powder and concentrated sodium hydroxide solution to obtain sodium trititanate powder; The mixed aqueous solution of iridium chloride is soaked in sodium trititanate powder, and then calcined to obtain solid phase powder A; step 3, the solid phase powder A is pressed into a tablet sample, and calcined to obtain ceramic sheet B; step 4, ceramic sheet B is obtained Put in dopamine aqueous solution, then put the dopamine aqueous solution in a vacuum box, fill the box with vacuum, then take out the ceramic sheet, put it in Tris buffer, soak for 18-20 hours, then take out the ceramic sheet, wash with deionized water , and dried to obtain the composite ceramic membrane. The invention optimizes the preparation process of the ceramic membrane, the prepared ceramic membrane can retain a large amount of free silver ions and lanthanum ions in the sewage, which is helpful for the recovery and utilization of metal ions in the waste water, and can reduce the toxicity of the sewage.

Owner:江西嘉陶无机材料有限公司

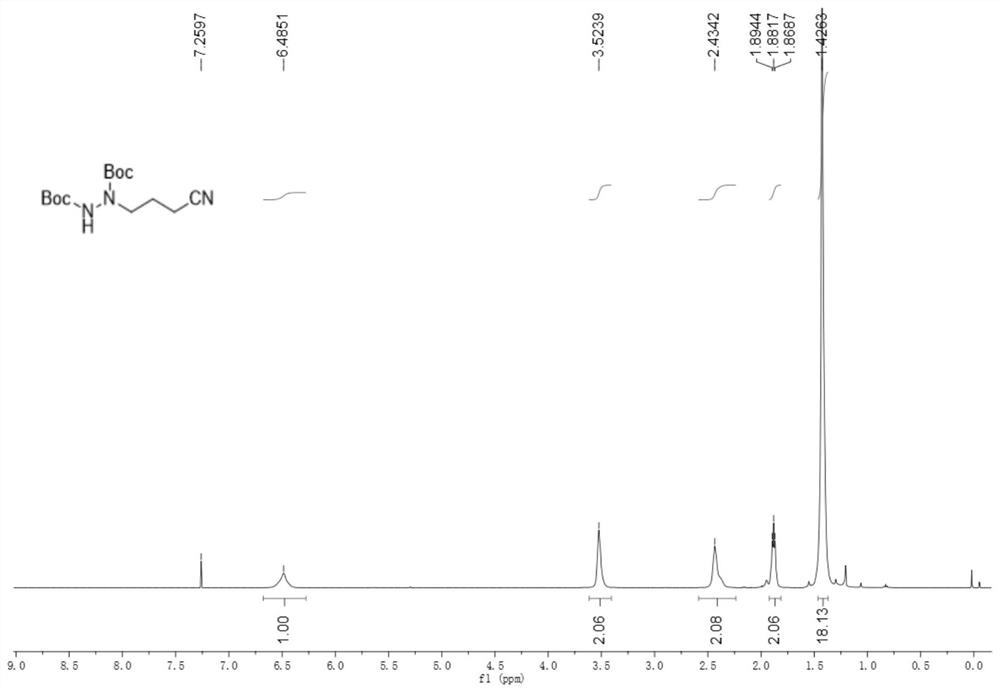

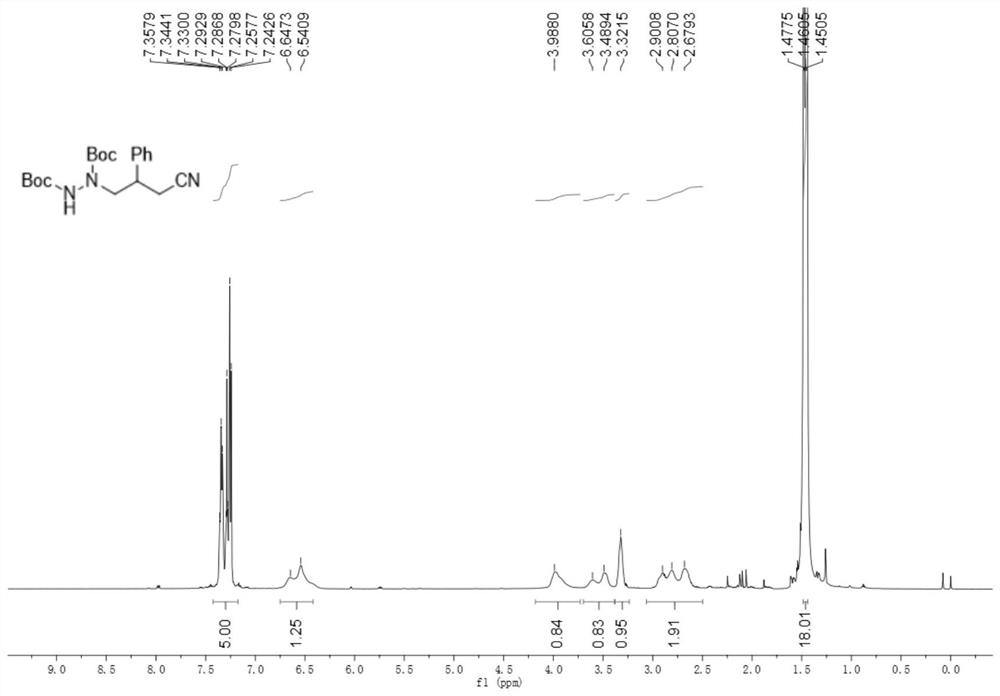

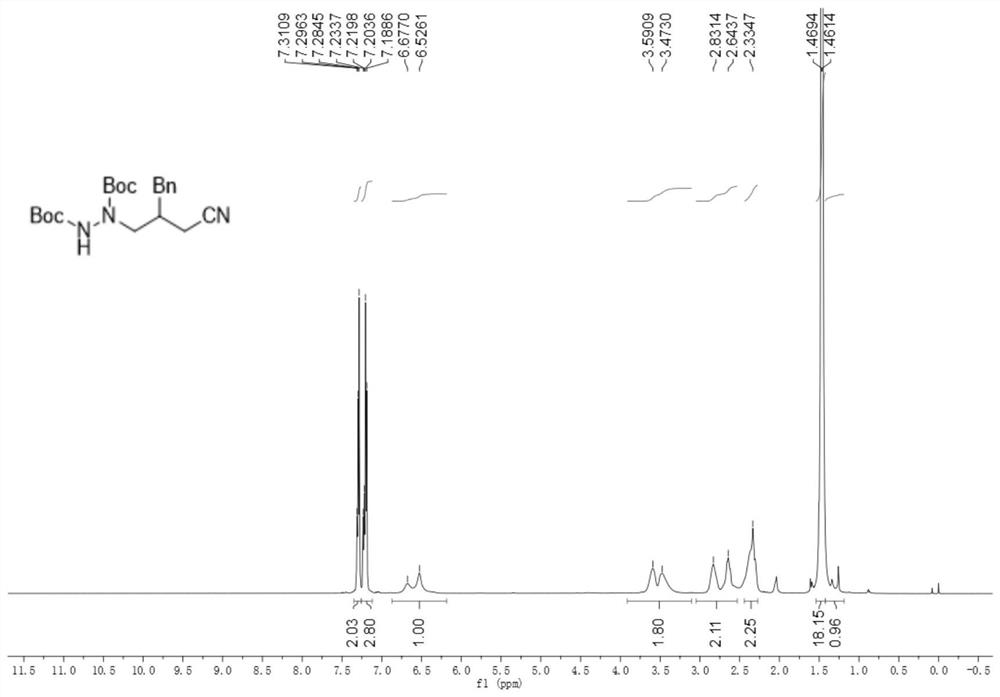

Gamma-hydrazino cyanide compound and synthesis method thereof

ActiveCN112457221AReduce usageImprove compatibilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCyanide compoundPtru catalyst

The invention relates to the technical field of organic synthesis, and discloses a gamma-hydrazino cyanide compound and a synthesis method thereof, aiming at the problem that the synthesis method of the gamma-hydrazino cyanide compound in the prior art is blank, and the synthesis method comprises the steps: (1) under the protection of inert gas, mixing azodicarboxylate and alpha-imino oxoacid, dissolving in a solvent, and reacting under the action of a catalyst and alkali, to obtain gamma-hydrazino cyanide with the structure shown in the formula I; and (2) carrying out post-treatment on the reaction product to obtain a finished product. The gamma-hydrazino cyanide compound and the synthesis method thereof have the beneficial effects that (1) cerium trichloride which is low in price and easy to obtain is used as a photocatalyst, so that other expensive photocatalysts are prevented from being used; (2) the reaction only needs a catalytic amount of alkali, the reaction conditions are mild, the operation is simple, and the compatibility of substrate functional groups is strong; and (3) a high-activity imine free radical intermediate is generated by utilizing an LMCT strategy, and a hydrazination reaction is developed, so that an efficient and simple method is provided for introducing a long-chain cyano functional group into an organic small molecular compound.

Owner:ZHEJIANG UNIV OF TECH

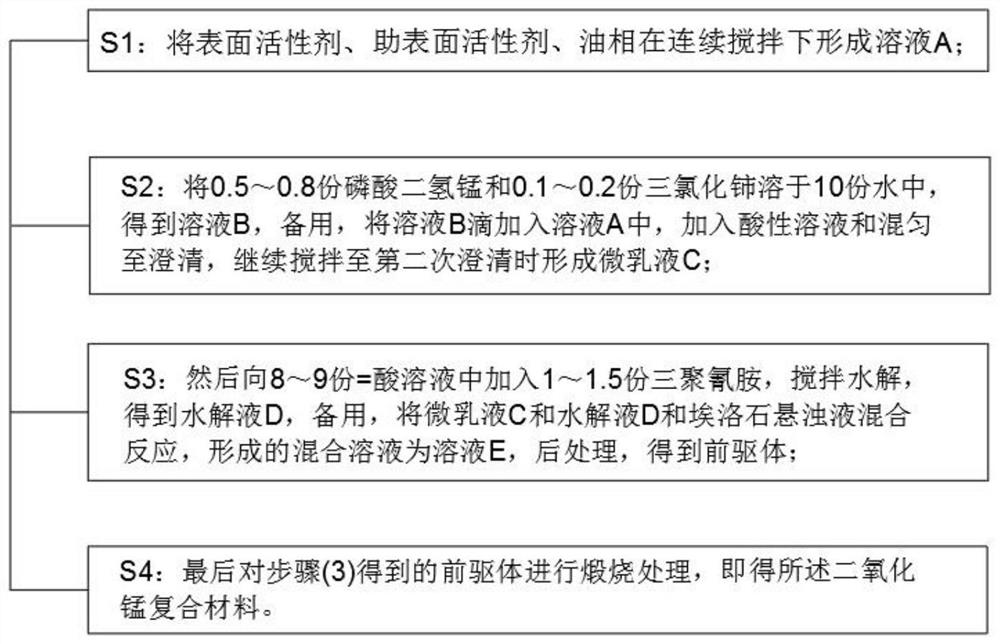

Preparation method of manganese dioxide composite material

PendingCN114849696AImprove conversion rateHigh yieldCombination devicesOrganic compound preparationHalloysiteHydrolysate

The invention discloses a preparation method of a manganese dioxide composite material. The preparation method specifically comprises the following steps: S1, continuously stirring a surfactant, a cosurfactant and an oil phase to form a solution A; s2, dissolving 0.5-0.8 part of manganese dihydrogen phosphate and 0.1-0.2 part of cerium trichloride in 10 parts of water to obtain a solution B for later use, dropwise adding the solution B into the solution A, adding an acidic solution, uniformly mixing until the solution is clear, and continuously stirring until the solution is clear for the second time to form a microemulsion C; s3, adding 1-1.5 parts of melamine into 8-9 parts of an acid solution, stirring and hydrolyzing to obtain a hydrolysate D for later use, mixing the microemulsion C, the hydrolysate D and the halloysite suspension for reaction to form a mixed solution which is a solution E, and performing post-treatment to obtain a precursor. The preparation method of the manganese dioxide composite material disclosed by the invention has the effects of being simple and convenient, relatively low in cost, short in reaction period and easy to quickly prepare in a large scale.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Process method for preparing bio-oil through pyrolysis of straw office -waste paper

InactiveCN112280579AIncrease oil production rateReduce processingBiofuelsWaste based fuelHydration reactionPtru catalyst

The invention relates to the technical field of biomass energy, in particular to a method for preparing bio-oil through pyrolysis of straw- office waste paper. The preparation method comprises the following steps: mixing TiC, fumaric acid and ferric chloride hexahydrate, carrying out a hydrothermal reaction, calcining to obtain a TiC / MOF skeleton Fe2O3 composite material, and mixing the TiC / MOF skeleton Fe2O3, cerium trichloride heptahydrate, an HSAPO-3 molecular sieve and an HZSM-5 molecular sieve to obtain a catalyst for later use; granulating straw, drying, mixing straw particles and wastepaper scraps, grinding into powder, uniformly adding a ZnCl2 solution into the mixed powder, standing, and mixing with the catalyst; and then feeding the material into a microwave reactor for pyrolysis, and filtering to obtain the bio-oil. The bio-oil preparation method disclosed by the invention is extremely high in bio-oil yield and heat value and low in viscosity.

Owner:泉州台商投资区海雅达新材料有限公司

A kind of preparation method of cerium sulfide doped carbon quantum dot nano fluorescent material

ActiveCN110437835BHigh stability of fluorescence performanceExcellent fluorescence performanceMaterial nanotechnologyNanoopticsThio-Sulfide

The invention discloses a preparation method of cerium sulfide-doped carbon quantum dot nano fluorescent material, which is characterized in that liquid A is prepared by using deionized water, itaconic acid and cerium trichloride; deionized water, thioethyl Amide, prepared to obtain liquid B; then, add liquid A to the reactor and stir, add liquid B dropwise to liquid A, the volume ratio of liquid A to liquid B is 5:1, after the dropwise addition, stir for 30 minutes, transfer Put it into the reaction kettle, cover the sealed cover, place it in a constant temperature box, keep the temperature at 180±2°C, and react for 20 to 24 hours to obtain a red suspension liquid, which is separated from the solid and liquid, and the liquid is crude cerium sulfide doped carbon quantum dot nano Fluorescent material; dialysis method is used to purify cerium sulfide doped carbon quantum dot nano fluorescent material. The preparation method has the advantages of green environmental protection, simple operation, and the cerium sulfide doped carbon quantum dot nano fluorescent material does not need secondary modification, and has the characteristics of high stability of fluorescence performance, small and uniform size, good biocompatibility and the like.

Owner:UNIV OF JINAN

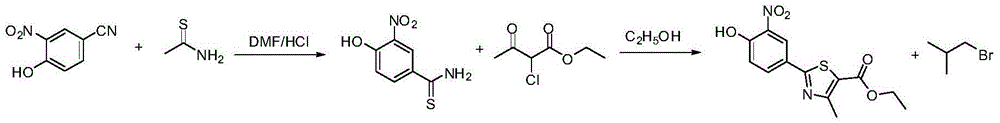

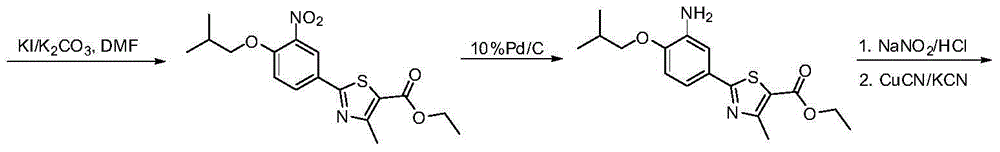

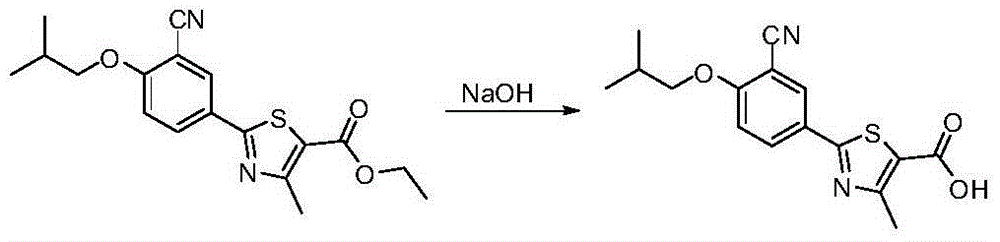

Preparation method of febuxostat intermediate

InactiveCN104418823ALess corrosiveLow toxicityOrganic chemistryHexamethylenetetramineFormylation reaction

The invention relates to a preparation method of a febuxostat intermediate. The preparation method comprises the following steps of in the presence of cerium trichloride, performing formylation reaction on 2-(4-hydroxyphenyl)-4-methyl-thiazole-5carboxylic ethyl ester and urotropine by taking acetic acid as a solvent. The preparation method disclosed by the invention is small in raw material corrosion, small in toxicity, gentle in reaction condition and more suitable for the industrial production needs.

Owner:上海龙翔生物医药开发有限公司

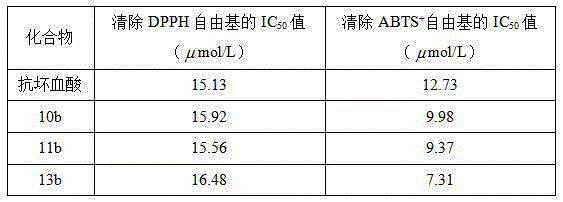

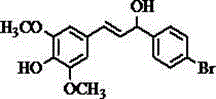

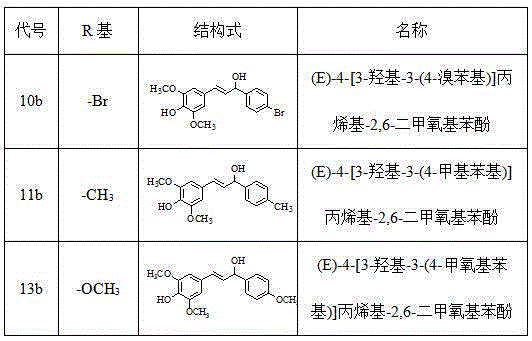

A kind of chalcone derivative and its application

InactiveCN104003853BStrong ability to scavenge free radicalsNervous disorderOrganic compound preparationNeuro-degenerative diseaseAcetophenone

The invention discloses a chalcone derivative with good anti-free radical oxidation damage activity, and its structural formula is as follows. The preparation method of the chalcone derivatives is as follows: syringaldehyde and p-substituted acetophenone react under conditions of piperidine and high temperature to generate corresponding substituted chalcones; the purified chalcone and sodium borohydride react in seven React under the condition of water cerium trichloride to generate crude chalcone derivatives, which can be obtained after purification. The ascorbic acid product of the invention has a low IC50 value for anti-DPPH free radicals and anti-ABTS+ free radicals, and has a strong ability to scavenge free radicals, and has broad application prospects in the preparation of drugs for treating neurodegenerative diseases.

Owner:SHANTOU UNIV MEDICAL COLLEGE

Surface treatment process for valve body casting part

PendingCN112899668AImprove corrosion resistanceInhibit associationAnti-corrosive paintsMetallic material coating processesEpoxyMeth-

The invention relates to the field of valve body surface treatment, and particularly discloses a surface treatment process of a valve body casting part. According to the surface treatment process of the valve body casting part, the valve body casting part is obtained through pretreatment, first-time surface treatment and second-time surface treatment; a first-time surface treatment method comprises the steps that the pretreated valve body casting part is soaked in a treatment agent prepared from bis (dimercapto-1, 3, 4-thiadiazole), cerium trichloride, dimethylformamide and 95 wt% ethyl alcohol, and the valve body casting part is fished out and aired; and a second-time surface treatment method comprises the step of coating the surface of the valve body casting part subjected to the first-time surface treatment with a corrosion-resistant coating, wherein raw materials of the corrosion-resistant coating comprise epoxy resin, acrylic resin, ethyl cellulose, citric acid, acetonitrile, dibutyltin dilaurate and methyl cyclopentadienyl zirconium trichloride. The valve body casting part obtained through the surface treatment process has good corrosion resistance, the surface bonding strength of the corrosion-resistant coating on the surface of the valve body casting part is good, and the corrosion-resistant coating is not prone to falling off.

Owner:WENZHOU WANHONG VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com