Moisture curing type polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve the effect of strong permeability and affinity, good surface activity, and convenient sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

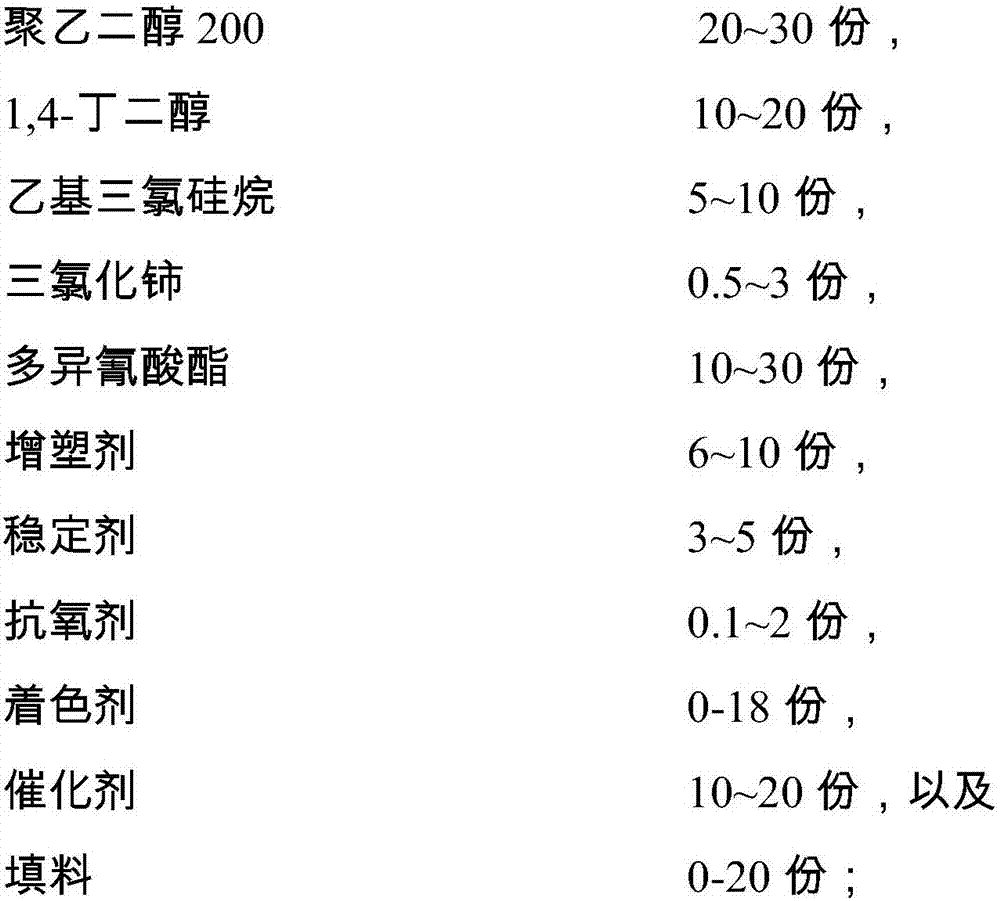

[0022] This embodiment provides a moisture-curable polyurethane hot melt adhesive, including the raw materials in Table 1 in parts by weight. The preparation method of the moisture-curable polyurethane hot-melt adhesive of the present embodiment comprises the following steps:

[0023] Each raw material was weighed according to the composition of the moisture-curable polyurethane hot melt adhesive in Table 1.

[0024] React polyethylene glycol 200, 1,4-butanediol, ethyltrichlorosilane, cerium trichloride and polyisocyanate at 40°C for 5 hours under the condition of protective gas to obtain molecular weights ranging from 10 to 20 Wan's Si-O-containing polyurethane, and then add plasticizers, stabilizers and antioxidants to mix and disperse evenly to form a semi-finished base material. Add catalyst, filler and colorant to semi-finished base material, evenly disperse, defoam, and obtain.

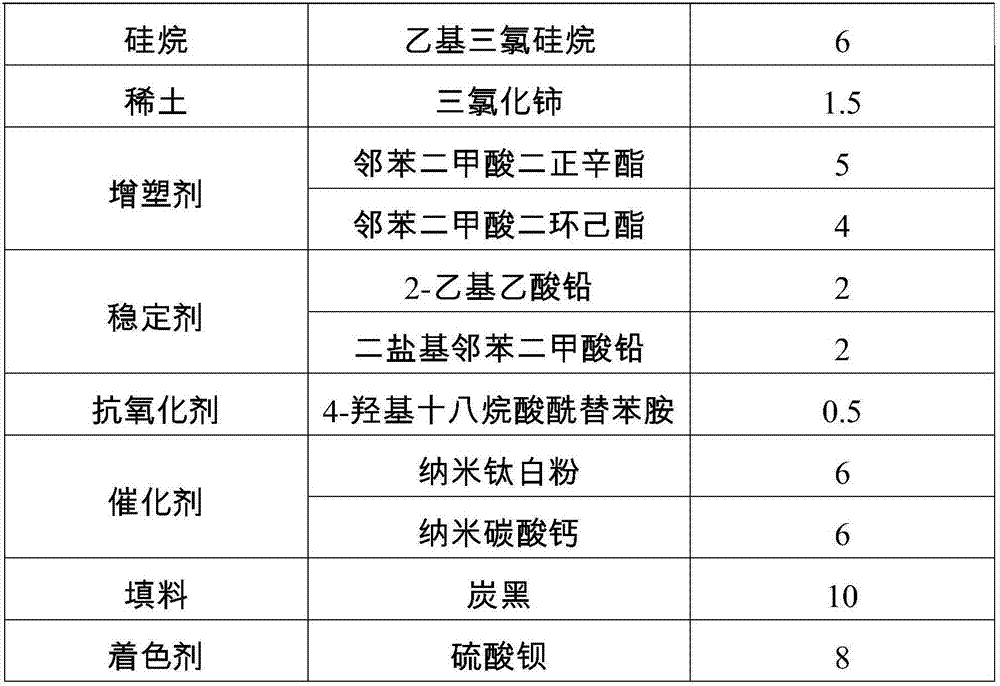

[0025] The composition of the moisture-curable polyurethane hot-melt adhesive of table 1 e...

Embodiment 2

[0029] This embodiment provides a moisture-curable polyurethane hot melt adhesive, including the raw materials in Table 2 in parts by weight. The method for preparing the moisture-curable polyurethane hot-melt adhesive of this embodiment is the same as that of Embodiment 1.

[0030] The composition of the moisture-curable polyurethane hot-melt adhesive of table 2 embodiment 2

[0031]

[0032]

Embodiment 3

[0034] This embodiment provides a moisture-curable polyurethane hot-melt adhesive, including the raw materials in Table 3 in parts by weight. The method for preparing the moisture-curable polyurethane hot-melt adhesive of this embodiment is the same as that of Embodiment 1.

[0035] The composition of the moisture-curable polyurethane hot-melt adhesive of table 3 embodiment 3

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com