Hollow spherical cerium dioxide nano material and preparation method and application thereof

A technology of hollow spherical ceria, which is applied in secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problem of low specific capacity, rate performance and cycle stability, and difficult control of the specific surface area of hollow spherical ceria , unable to control the hollow spherical shell, etc., to achieve excellent circulation, easy process operation, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Dissolve 0.130 g of glucose in 20 mL of ultrapure water.

[0064] (2) Dissolve 0.376g of urea in 12mL of ultrapure water.

[0065] (3) 0.068g CeCl 3 ·7H 2 O was added to the solution obtained in step (2).

[0066] (4) Add the solution obtained in step (3) into the solution obtained in step (1) under constant stirring, and continue stirring for 30 min.

[0067] (5) Transfer the mixed solution obtained in step (4) to a 100 mL polytetrafluoroethylene-lined autoclave.

[0068] (6) Tighten the autoclave in step (5) and put it into an oven, keep it warm at 160° C. for 20 hours, and then cool it down to room temperature naturally.

[0069] (7) The precipitate obtained in step (6) was centrifuged, washed with distilled water and ethanol three times respectively, dried in a blast drying oven at 80° C. for 24 hours, and ground to collect the product.

[0070] (8) Keep the solid powder obtained in step (7) in a muffle furnace at 400° C. for 450 min, and calcinate to obtai...

Embodiment 2

[0073] (1) Dissolve 0.130 g of glucose in 32 mL of ultrapure water.

[0074] (2) 0.068g CeCl 3 ·7H 2 O was added to the solution obtained in step (1), and stirring was continued for 30 min.

[0075] (3) Transfer the mixed solution obtained in step (2) to a 100 mL polytetrafluoroethylene-lined autoclave.

[0076] (4) Tighten the autoclave in step (3) and put it into an oven, keep it warm at 160° C. for 20 hours, and then cool it down to room temperature naturally.

[0077] (5) The precipitate obtained in step (4) was centrifuged, washed three times with distilled water and ethanol, dried in a blast drying oven at 80° C. for 24 hours, and ground to collect the product.

[0078] (6) Keep the solid powder obtained in step (5) in a muffle furnace at 400° C. for 450 min, and calcinate to obtain a hollow spherical single-shell structure ceria nanomaterial.

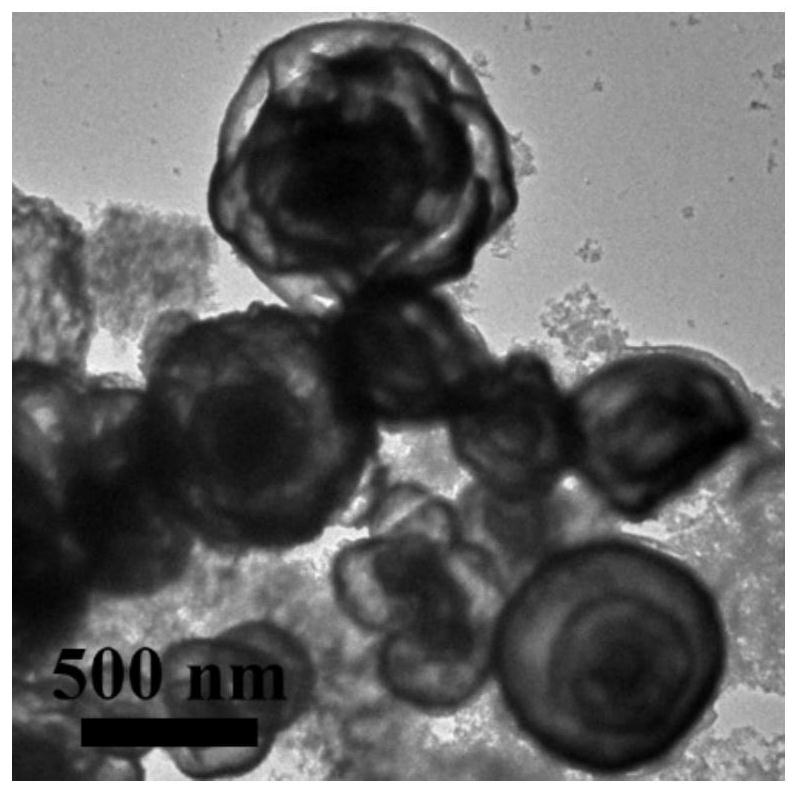

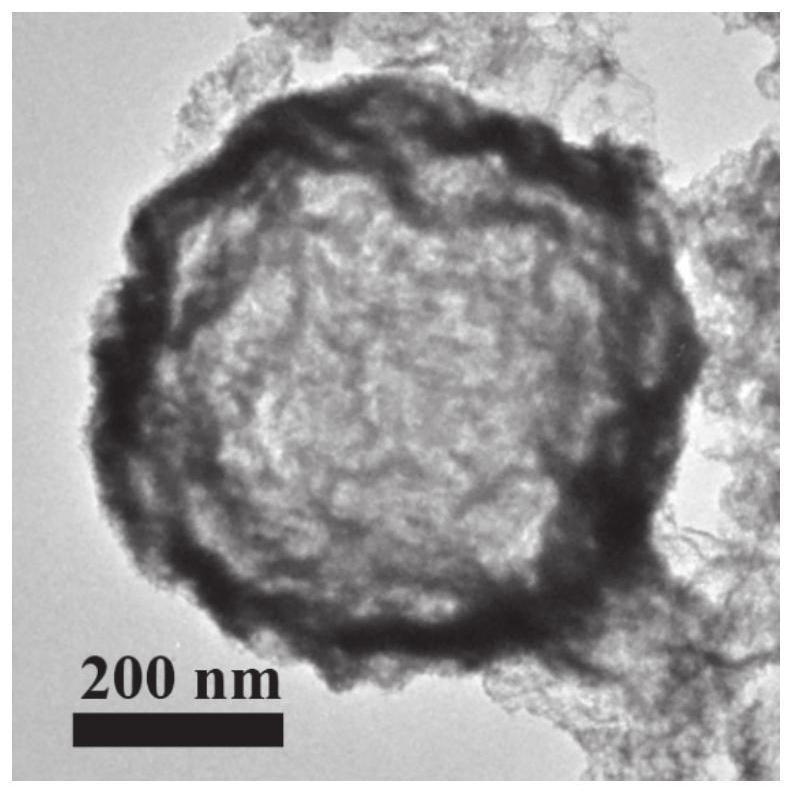

[0079] Observation by transmission electron microscope, such as figure 2 As shown, the ceria nanomaterial prepared by thi...

Embodiment 3

[0081] (1) Dissolve 0.260 g of glucose in 20 mL of ultrapure water.

[0082] (2) Dissolve 0.188g of urea in 12mL of ultrapure water.

[0083] (3) 0.067g CeCl 3 ·7H 2 O was added to the solution obtained in step (2).

[0084] (4) Add the solution obtained in step (3) into the solution obtained in step (1) under constant stirring, and continue stirring for 30 min.

[0085] (5) Transfer the mixed solution obtained in step (4) to a 100 mL polytetrafluoroethylene-lined autoclave.

[0086] (6) Tighten the autoclave in step (5) and put it into an oven, keep it warm at 160° C. for 20 hours, and then cool it down to room temperature naturally.

[0087] (7) The precipitate obtained in step (6) was centrifuged, washed with distilled water and ethanol three times respectively, dried in a blast drying oven at 80° C. for 24 hours, and ground to collect the product.

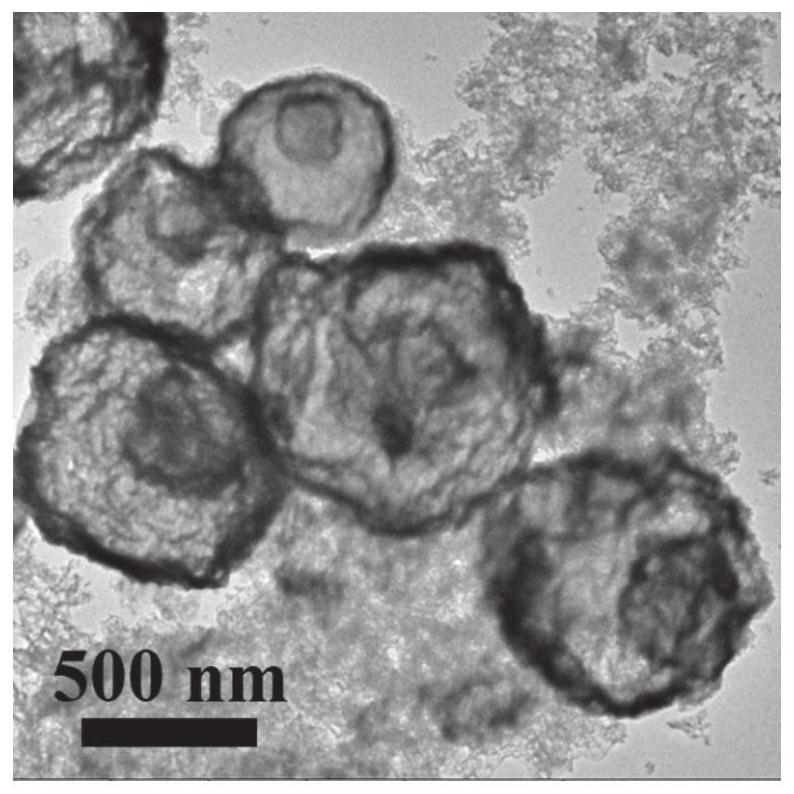

[0088] (8) Keep the solid powder obtained in step (7) in a muffle furnace at 400° C. for 450 min, and calcinate to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com