Patents

Literature

110results about How to "Increase oil production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

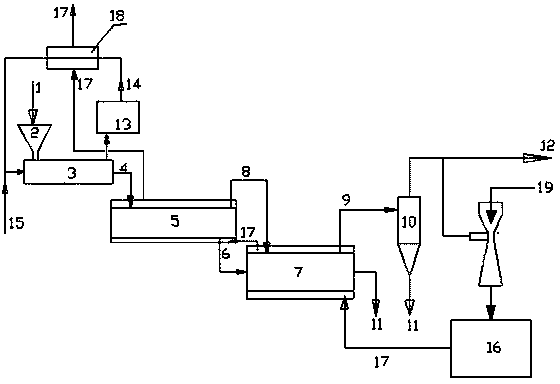

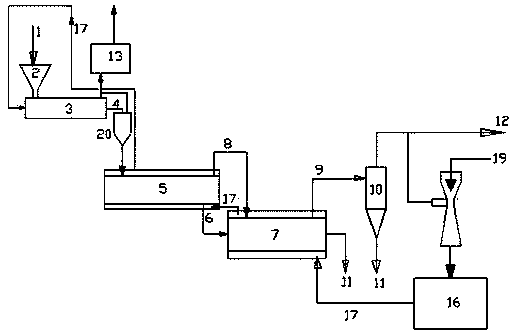

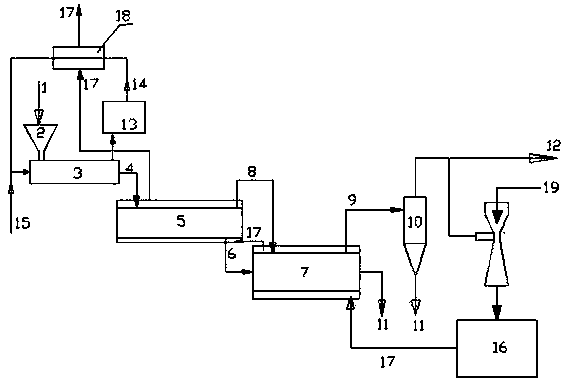

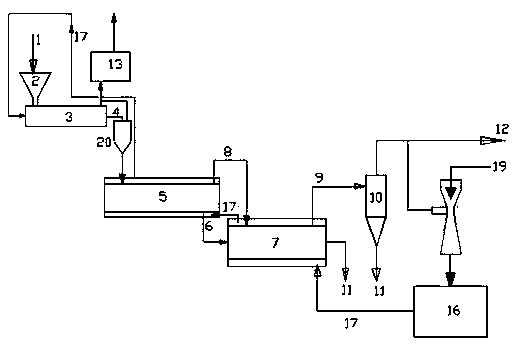

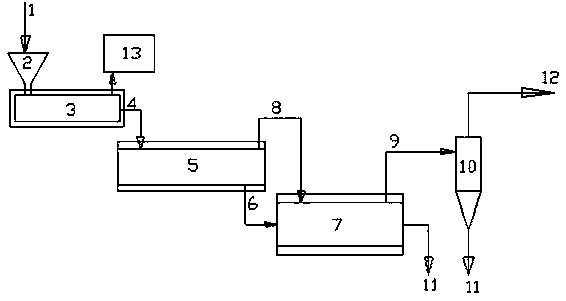

Waste pyrolysis system with adjustable oil, gas and carbon and method

ActiveCN104087340ALightweightLow viscositySolid waste disposalSludge treatment by pyrolysisThermodynamicsFlue gas

The invention relates to a waste pyrolysis system with adjustable oil, gas and carbon and a method. The system comprises a pre-reaction section, a main reactor, a conditioner and a particle separator. The front of the pre-reaction section is connected to a feeder and the tail of the pre-reaction section is connected to the main reactor. The conditioner is connected after the main reactor. The particle separator is connected after the conditioner. In specific, waste having a water content not more than 60% is fed into the pre-reaction section through the feeder, reacted waste is fed to the main reactor, residue coke generated after the reaction is finished is fed into the conditioner and a generated volatile material is discharged in a forced manner into the conditioner to be contacted, reacted and conditioned with the residue coke at the same time. The conditioner achieves conditioning of the residue coke and the volatile material at the same time. The volatile material after being conditioned is fed into the particle separator to output a clean volatile material. The residue coke after conditioning has a calorific value of 3.37-6.74 MJ / kg, and can be used as building raw materials or is conveyed to a sanitary landfill. The working temperature of the pre-reaction section is 105-298 DEG C and an inert gas or flue gas is fed into the pre-reaction section. The working temperature of the main reactor is 450-650 DEG C. The working temperature of the conditioner is 700-900 DEG C. The system and the method can obtain oil with better quality and more combustible gases and are adapt to changes of the water content of the waste.

Owner:上海济德能源环保技术有限公司

Culturing and method for picking rose flowers

A method for cultivating rose includes such steps as field planting by alternatively wide and narrow row spacings and staggered pits, forced dormancy, and conventional field management same as the method for tea trees. A method for picking up the rose flower is also disclosed. Its advantages are high output of rose flower, and high output rate of rose oil.

Owner:重庆雅香美源生态农业科技有限公司

Preparation method for high-temperature delay type organic zirconium cross-linking agent

InactiveCN102040995AIncrease oil production rateHigh temperature and shear resistanceDrilling compositionPrepolymerOrganic acid

The invention discloses a preparation method for a high-temperature delay type organic zirconium cross-linking agent. The preparation method comprises the following steps of: sufficiently dissolving inorganic zirconium salt in water and adding a proper amount of organic acid; under the catalytic action of NaOH, controlling the pH value of the system and raising the temperature and reacting to obtain organic acid-zirconium prepolymer; keeping the temperature constant, adding a ligand and a cross-linking shielding agent into the organic acid-zirconium-prepolymer to perform reaction; continuously keeping the temperature constant, adding polyalcohol and a high-temperature stabilizing agent, adjusting the pH value and reacting at constant temperature; removing the high-temperature stabilizing agent residue after reaction is finished so as to obtain the modified clarified transparent high-temperature delay type cross-linking agent. The aqueous fracturing fluid prepared by the invention has good shear resistance, good sand carrying property and wide application prospect, greatly enhances the heat resistance property, reduces the use cost and relieves damage to the stratum environment.

Owner:SHAANXI UNIV OF SCI & TECH

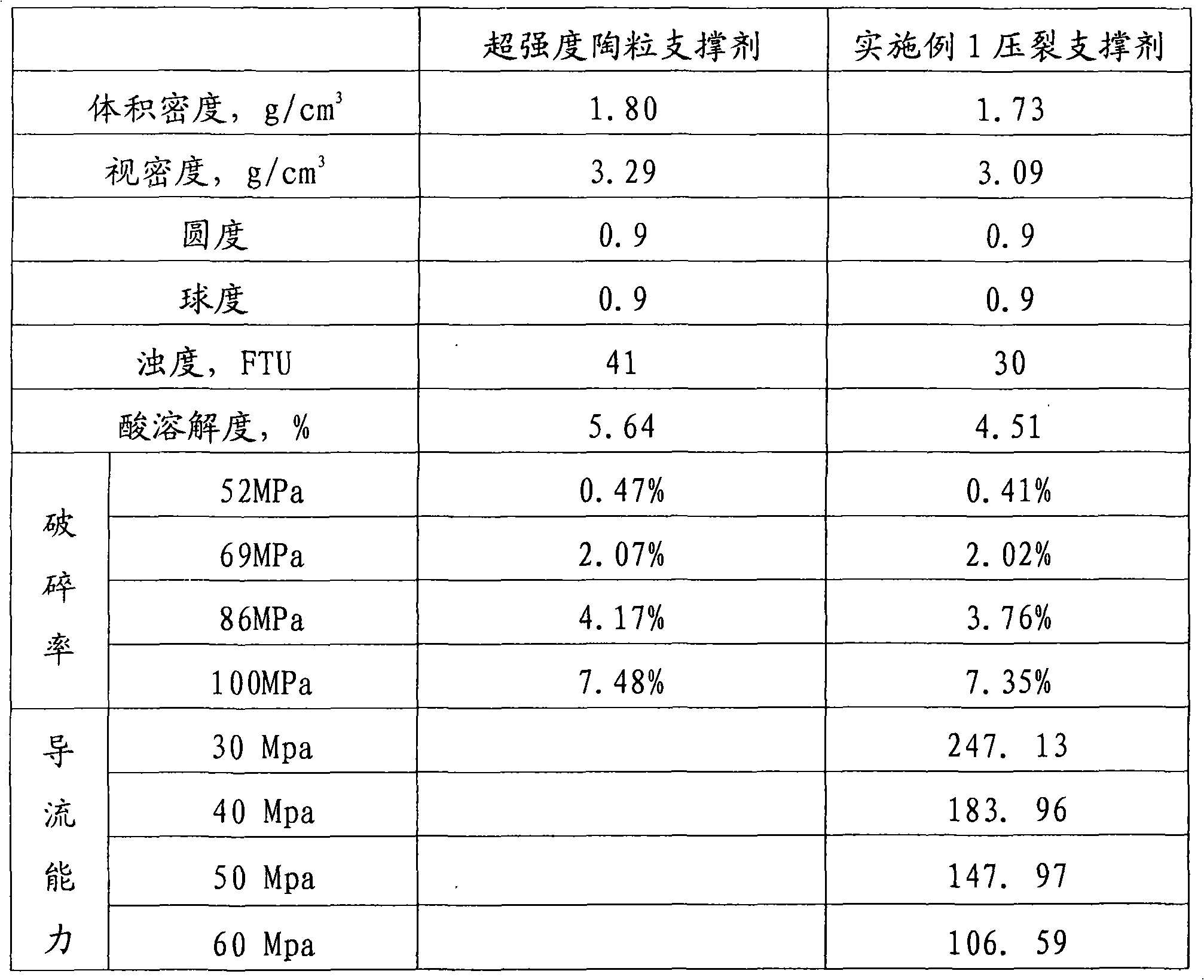

Fracturing propping agent for oil gas well and preparation method thereof

ActiveCN101270280AImprove product qualityHigh breakage resistanceFluid removalSoluble glassAcid corrosion

The invention relates to a fracturing proppant used for oil and gas wells, which is prepared with the following materials by weight: 80 to 88 portions of low content bauxite, 1 to 4 portions of manganese ore, 2 to 3 portions of potash feldspar, 2 to 4 portions of solid soluble glass, 1 to 5 portions of calcium mountain meal, and 1 to 5 portions of French chalk. The quality of the fracturing proppant is stable; the break resistance is high; the acid corrosion resistance is high; the volume density is low; the fracturing proppant can effectively prop up fracture, and significantly improve the permeability in the fracture so that oil and gas flow smoothly, and the oil productivity is improved. In addition, the raw materials and the preparation method are simple, and low requirements are proposed about the raw materials, and the fracturing proppant is prepared simply.

Owner:XINMI WANLI IND DEV

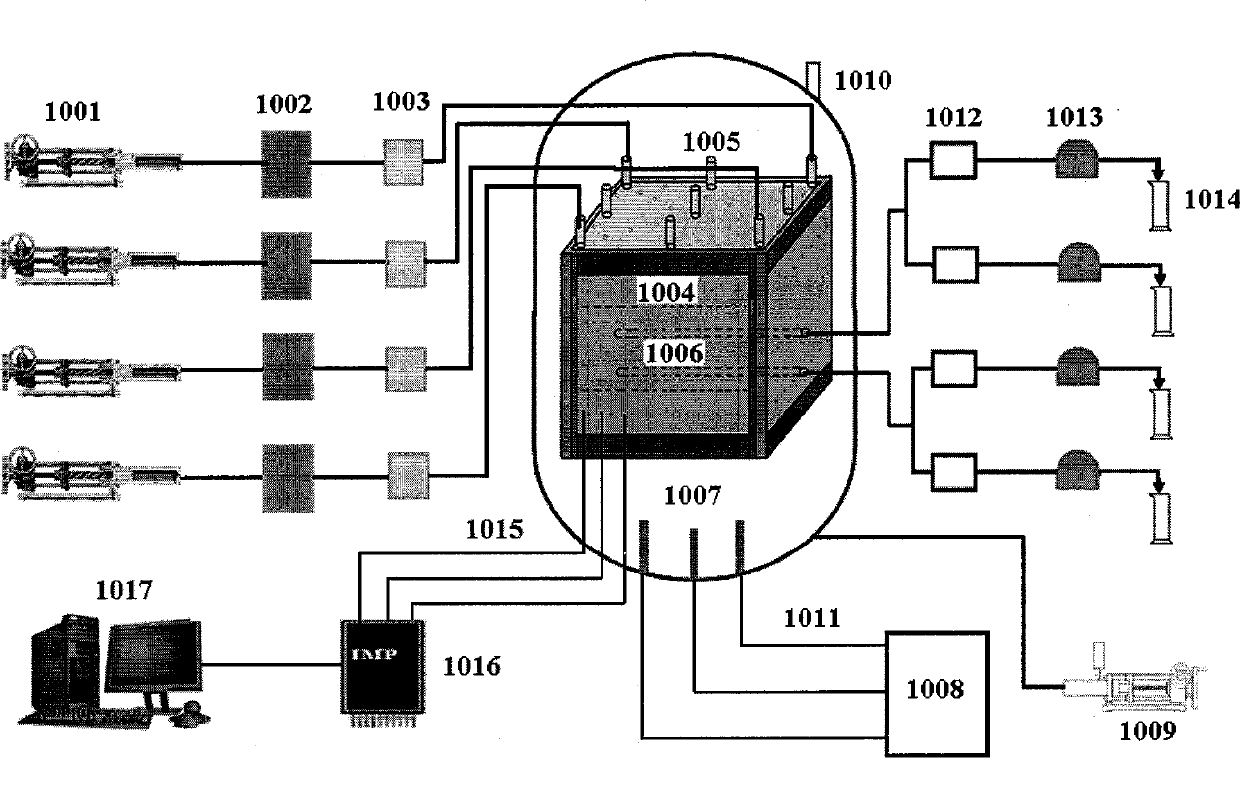

Oil reservoir development simulation system, upper-coated pressure system and data processing method thereof

ActiveCN101509367ASolve the simulationRealize high-precision simulationSurveyFluid removalData acquisitionEngineering

A multimode linkage three-dimensional proportion simulation system of steam injection for thermal recovery of an oil reservoir comprises a steam injection system, a reservoir model body, an overburden pressure system and a data acquisition and graphic system; wherein, the overburden pressure system consists of a spherical pressure tank, a triple pump, a relief valve, an electrical heating component and temperature control interfaces and various pipeline interfaces thereof as well as corresponding connecting pipelines and valves. The technical proposal solves simulation of steam throughput elastic energy and the unique design of a cap layer, a bottom layer and the overburden pressure system ensures transmission of heat to the cap layer and the bottom layer, simulation of mass transfer and control of the overburden pressure during steam injection for thermal recovery of an oil layer.

Owner:PETROCHINA CO LTD

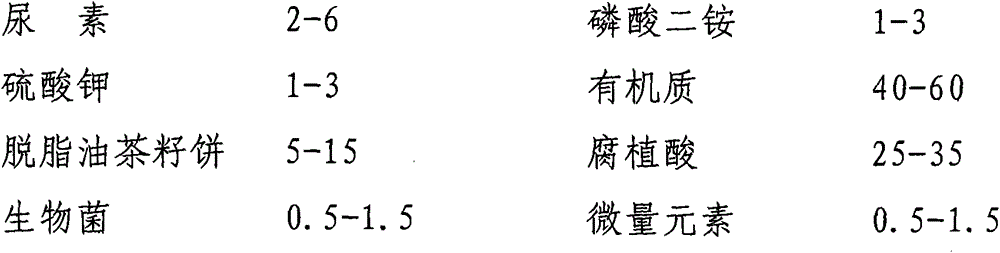

Camellia oleifera dedicated biological organic fertilizer and preparation method thereof

InactiveCN104892056AIncrease productionImprove mu yieldFertilizer mixturesCamellia oleiferaTrace element

The invention discloses a camellia oleifera dedicated biological organic fertilizer and a preparation method thereof, wherein the camellia oleifera dedicated biological organic fertilizer is prepared by mixing 2-6 parts by weight of urea, 1-3 parts by weight of diammonium phosphate, 1-3 parts by weight of potassium sulfate, 40-60 parts by weight of an organic matter, 5-15 parts by weight of a defatted camellia oleifera seed cake, 25-35 parts by weight of humic acid, 0.5-1.5 parts by weight of biological bacteria and 0.5-1.5 parts by weight of a trace element; the camellia oleifera dedicated biological organic fertilizer has the characteristics of strong specificity and high fertilizer efficiency, and can greatly improve the camellia oleifera yield, quality and oil production rate; under same nutrient conditions, with use of the product, the camellia oleifera seed yield per mu is increased by 10-20%, the oil production rate is increased by 5-10%, the quality is greatly improved, and the fertilizer efficiency is far superior to other common compound fertilizers; and the camellia oleifera dedicated biological organic fertilizer is especially suitable for camellia oleifera planting in areas of central south China and regions south of the Yangtze River, and has z quite significant effect.

Owner:HUNAN TIANJIN TECH

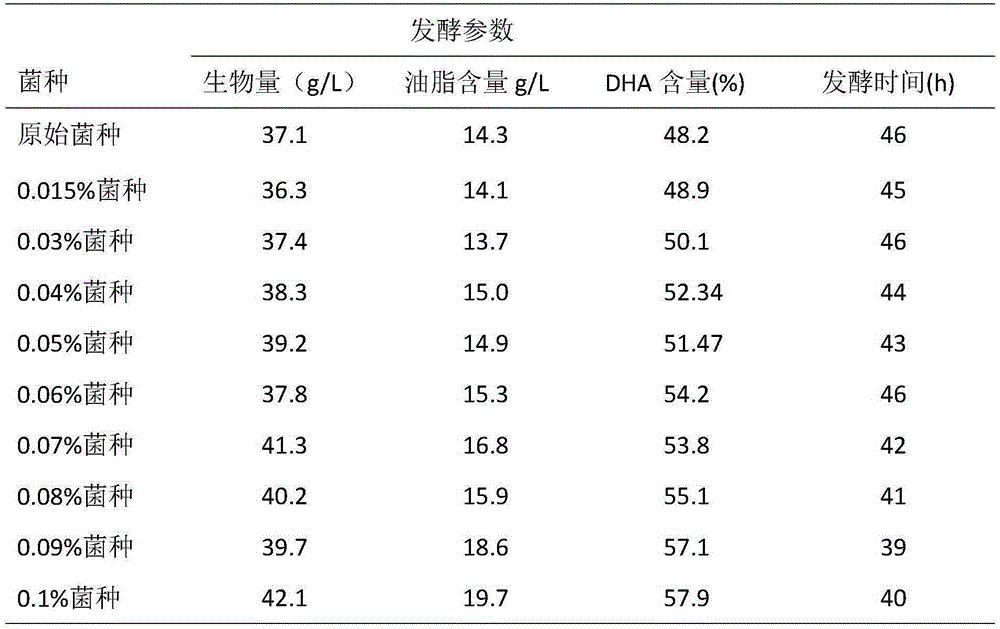

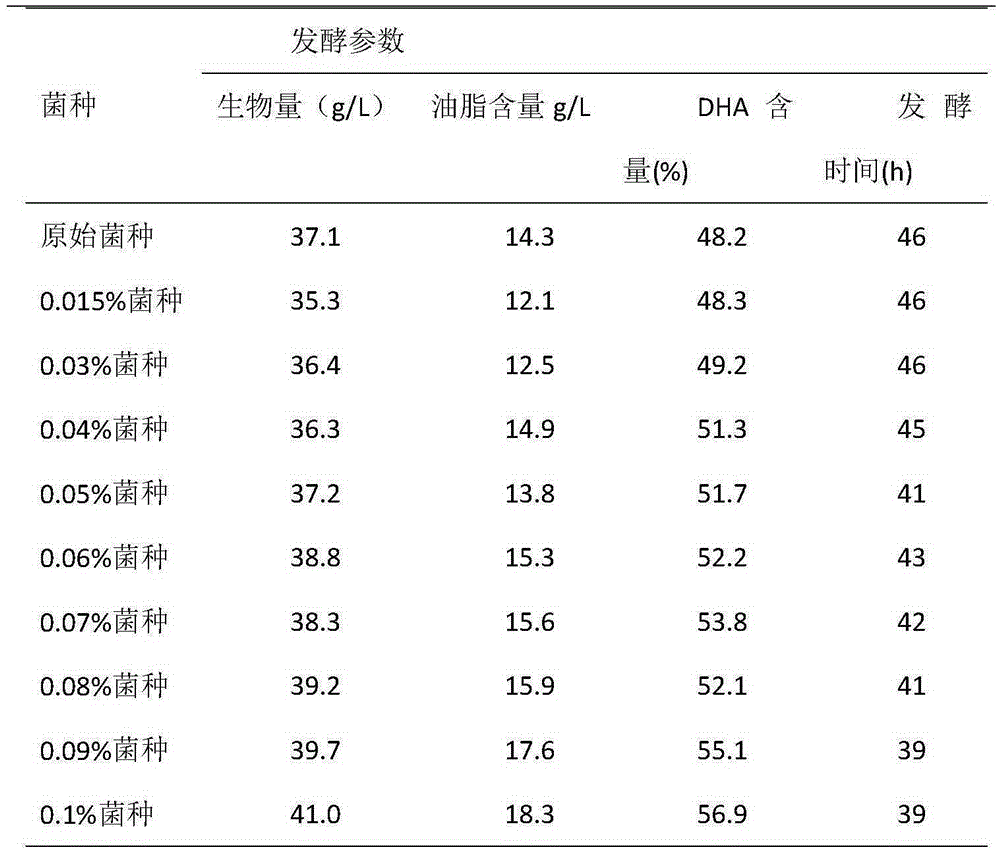

Docosahexaenoic acid-producing strain and mutation and screening method and application thereof

ActiveCN101591617AIncrease oil production rateImprove throughputMicrobiological testing/measurementUnicellular algaeBiotechnologyScreening method

The invention discloses a docosahexaenoic acid-producing bacterium and a mutation and screening method and application thereof. The strain is classified and named as Crypthecodinium cohnii HX-308, is preserved in China Center for Type Culture Collection, and has the preservation number M208246. The strain is a DHA-producing bacterium with high yield, has the DHA content 1.53 times of a starting strain, stable physiological-biochemical characteristic and stable heritability, and simultaneously can produce polyunsaturated fatty acid through liquid culture and fermentation; the content of unsaturated fatty acid reaches 20.4g / L, wherein the DHA content reaches 8.16g / L; and the strain is a good strain for producing natural DHA, and has excellent industrial production prospect.

Owner:NANJING TECH UNIV

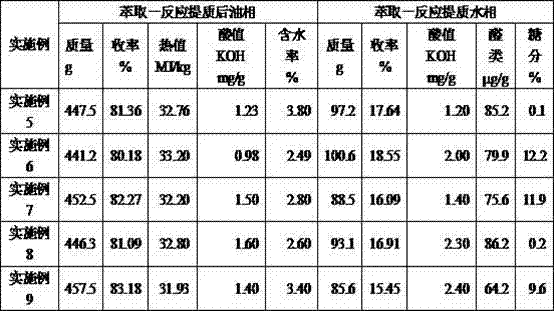

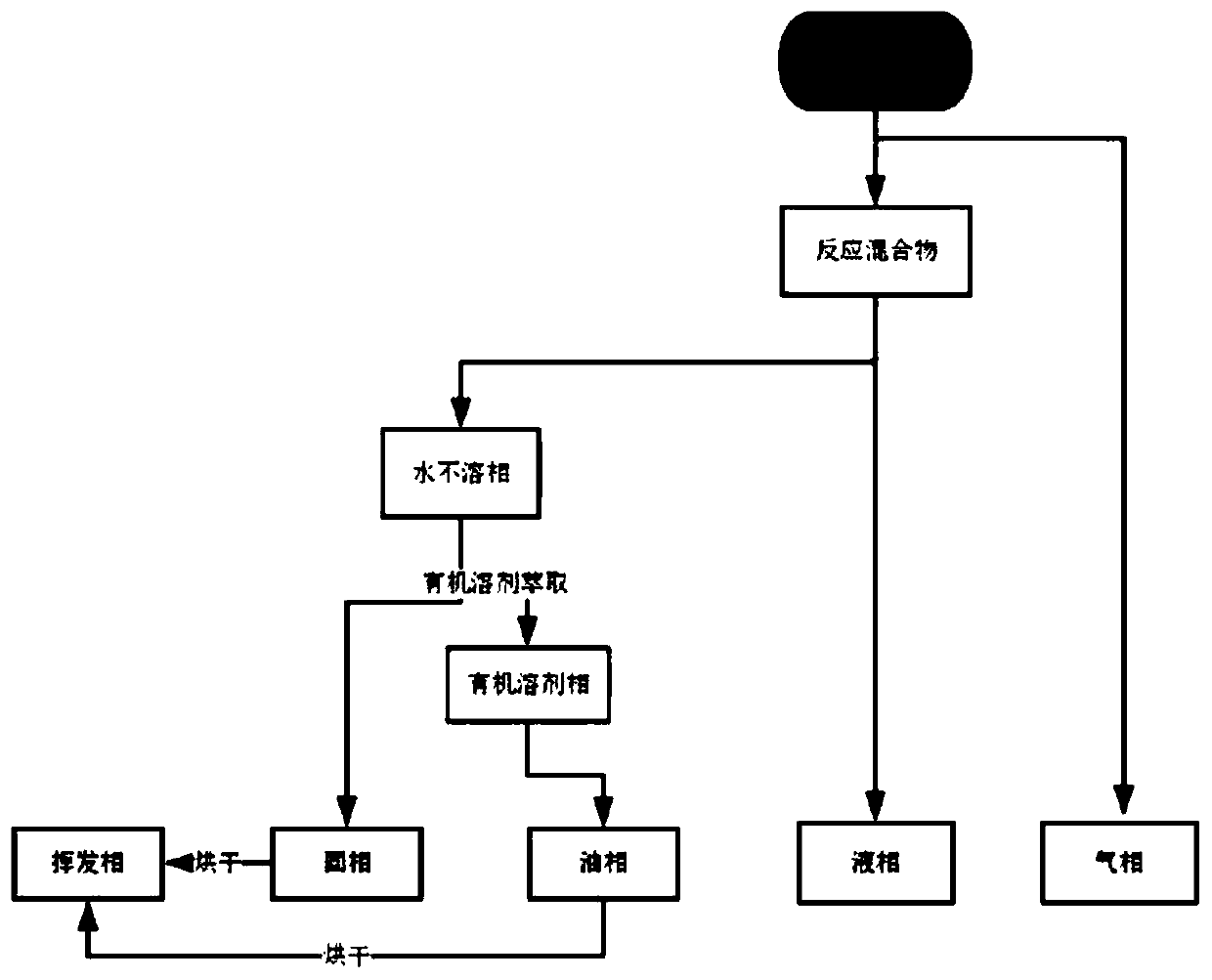

Biological oil phase-division upgrading method and device

ActiveCN103571535AInhibit or reduce side effectsInhibit cokingTreatment with hydrotreatment processesProcess engineeringAldehyde

The invention discloses a method for preparing fuel oil with a high calorific value by upgrading biological oil (high-speed thermally cracked biomass oil), and particularly relates to a method comprising the steps of firstly, adding water to divide the biological oil into a water soluble phase and an oil soluble phase, and then, upgrading the water soluble phase by using a chemical extracting-to-coupling conversion technology and upgrading the oil-soluble phase through hydrodeoxygenation. The method can be used for subjecting compounds such as acid, aldehyde and the like in the water soluble phase and fatty alcohol with 1-4 carbon atoms to esterification and acetalation to obtain ester, acetal, hemiacetal and the like with good combustibility, and the fuel oil with the high calorific valueis prepared after the oil soluble phase is subjected to hydrodeoxygenation. The method has the advantages that few cokes are generated in an upgrading process, and after being upgraded, an oil product is low in water content and acid value, high in calorific value and the like.

Owner:SHANDONG UNIV OF TECH

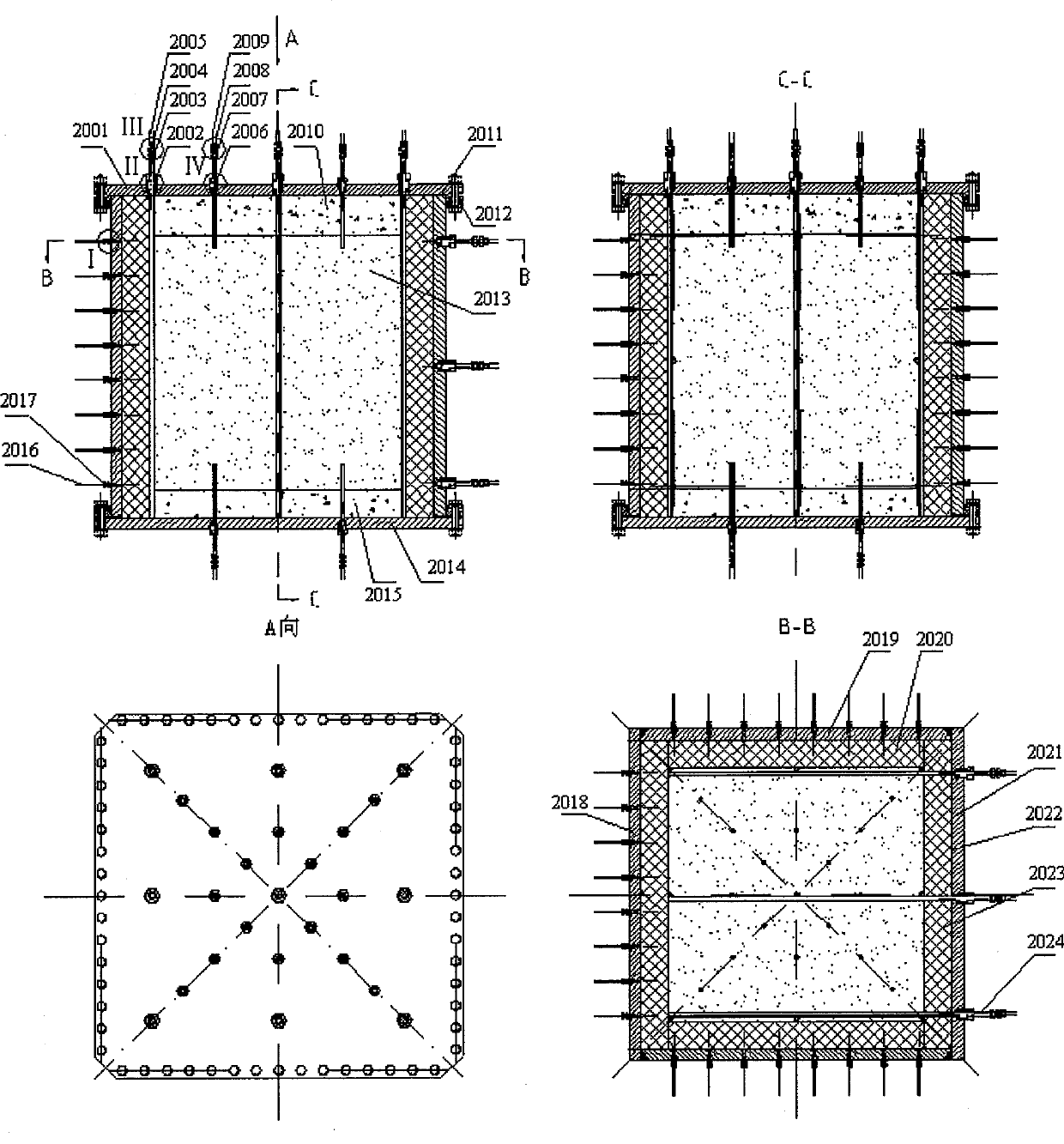

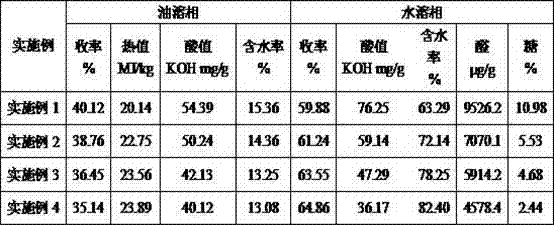

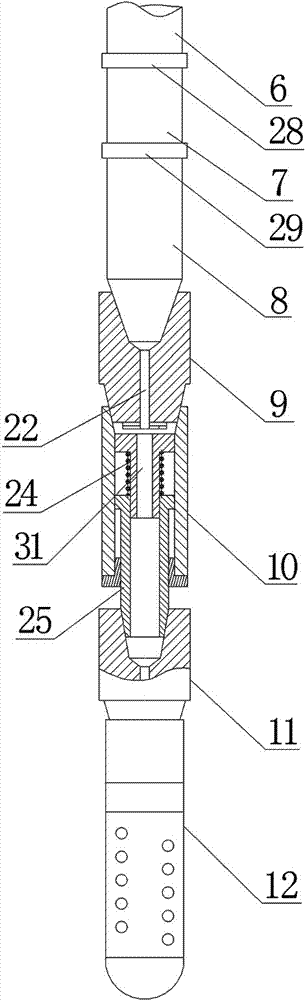

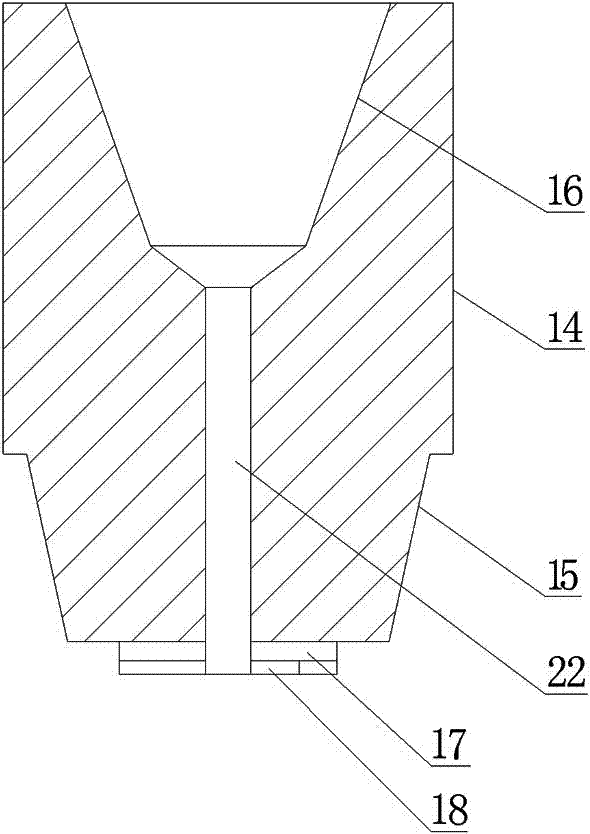

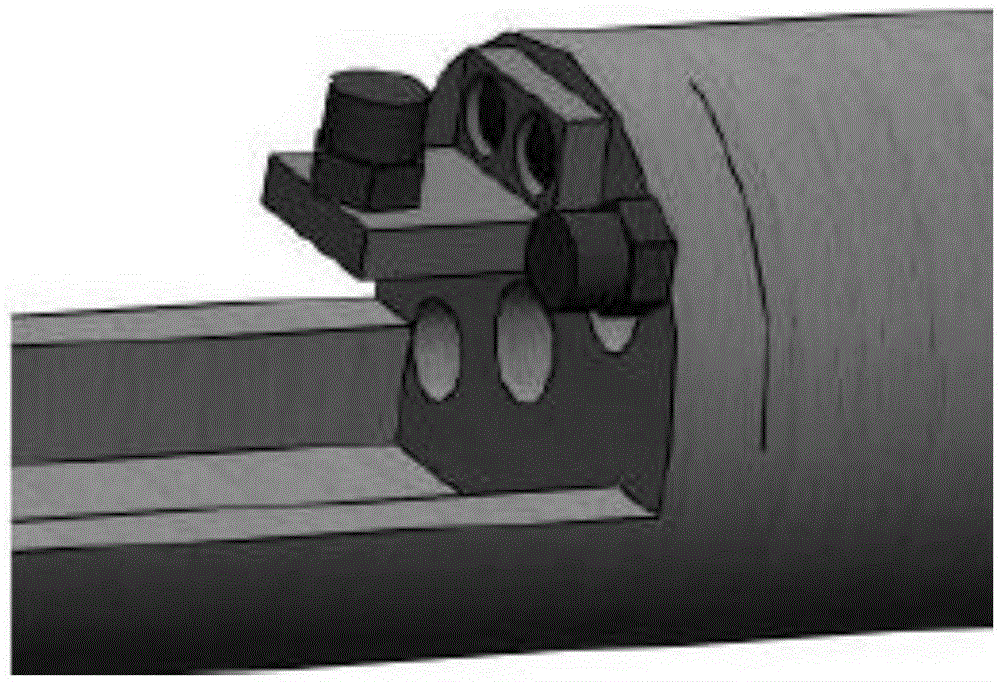

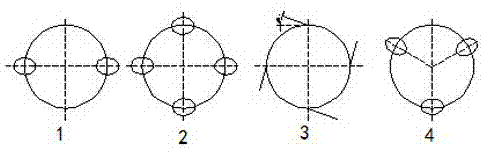

Mechanics experiment system and method for perforated string in underground perforating blasting of oil-gas well

ActiveCN106908339AGuaranteed Strength RequirementsAvoid accidentsSurveyFluid removalTime domainAudio power amplifier

The invention discloses a mechanics experiment system for a perforated string in underground perforating blasting of an oil-gas well. The system comprises an experiment water pool, a perforated string arranged in the experiment water pool, a signal amplifier, an A / D converter and a computer, wherein the signal amplifier, the A / D converter and the computer are arranged outside the experiment water pool and are sequentially electrically connected; the perforated string comprises an oil pipe, a packing tube, a sleeve, an acceleration testing short joint A, a damper, an acceleration testing short joint B and a perforating gun which are sequentially connected from top to bottom. The invention further discloses an experiment method. The system and the method have the beneficial effects that the dynamic data of an underground pressure field can be acquired during perforating, including an annulus pressure field, and the radial, axial and circumferential acceleration time domain variation value of the string during perforating, thus the analyzing basis is provided to analyze underground accident occurrence mechanism of perforating; the construction and work are guided to avoid accidents; the system and the method are of important significance in ensuring the string intensity demand and increasing the oil yield.

Owner:SOUTHWEST PETROLEUM UNIV

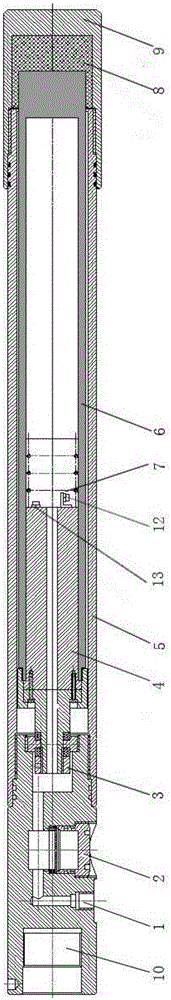

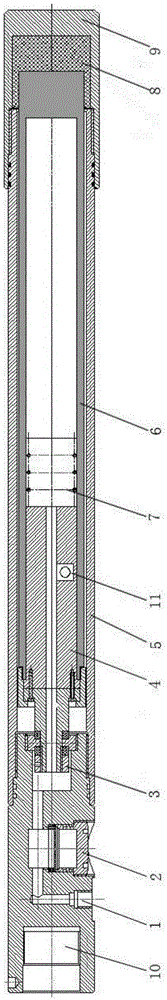

Downhole string dynamic response test system and test method under explosive blast

InactiveCN105352696ASimple structureThe test data is accurateShock testingShock waveThermal insulation

The invention discloses a downhole string dynamic response test system and test method under explosive blast, relates to an ultra-deep oil-gas well string dynamic response test system and test method, and belongs to the technical field of well logging in the process of development of oil and gas fields. The test system comprises an acceleration test mechanical system and an electronic circuit and support software subsystem. The acceleration test mechanical system comprises an acceleration sensor and a test system shell. The test system shell is mainly composed of an accelerometer head, a buffer connecting member, a thermal insulation sleeve connecting member, a thermal insulation sleeve, a circuit board support, an external sleeve and a rear cover component. The acceleration sensor is isolated from the external high temperature condition by protection of the thermal insulation sleeve and can normally work in extreme circumstances. The invention also discloses the test method realized based on the test system. Axial, radial and circumferential acceleration of a perforating gun in the extreme circumstances can be measured, and the law of shock wave loading and the law of string dynamic response can be researched by analyzing and processing the measured acceleration information.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

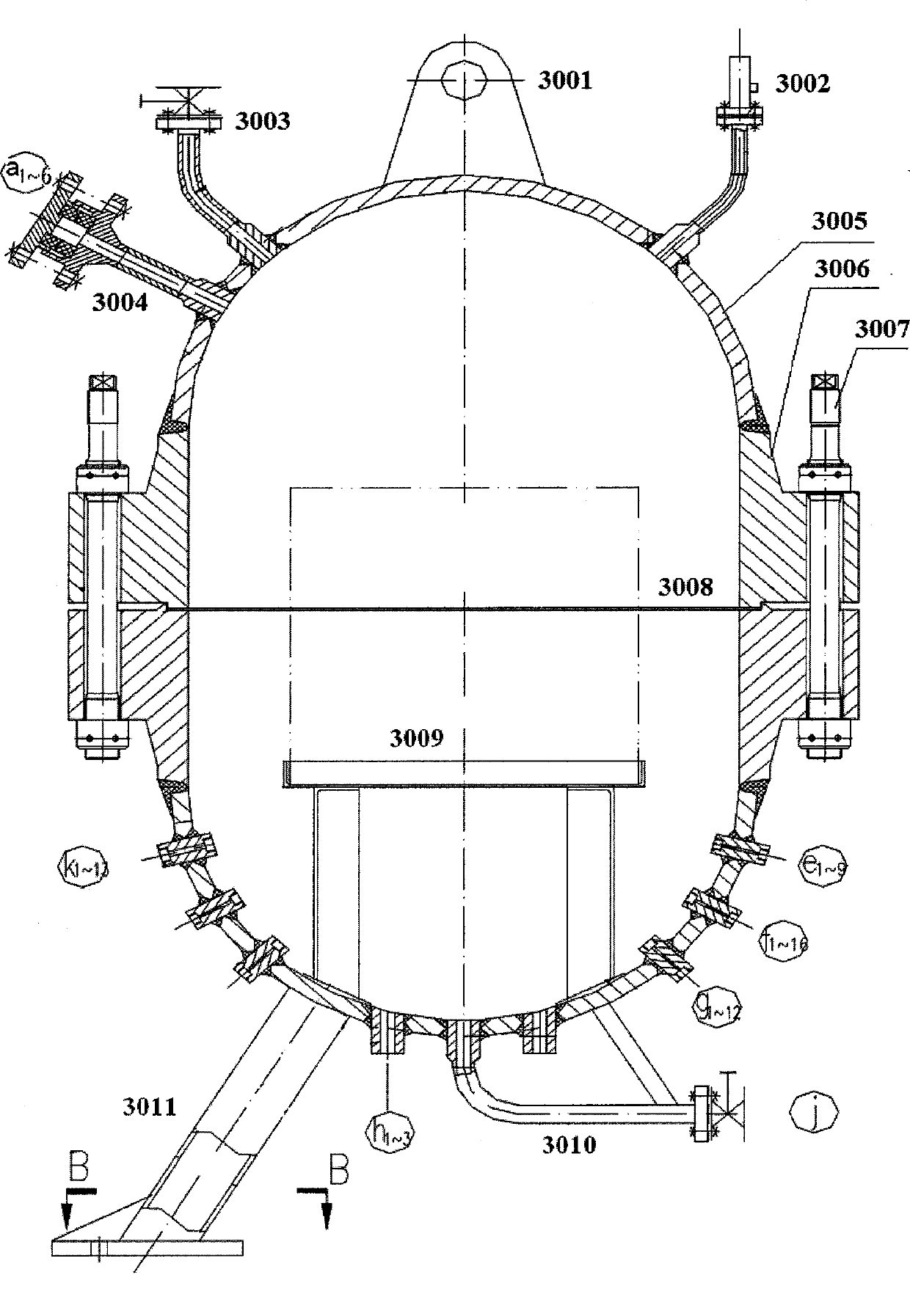

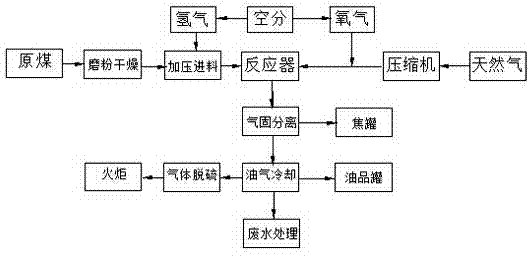

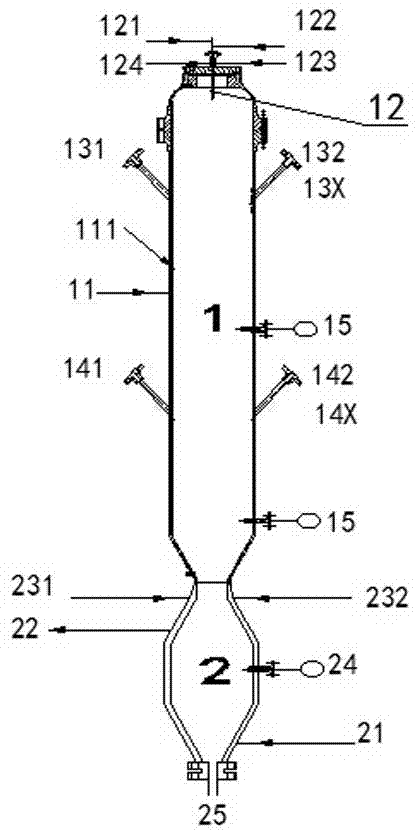

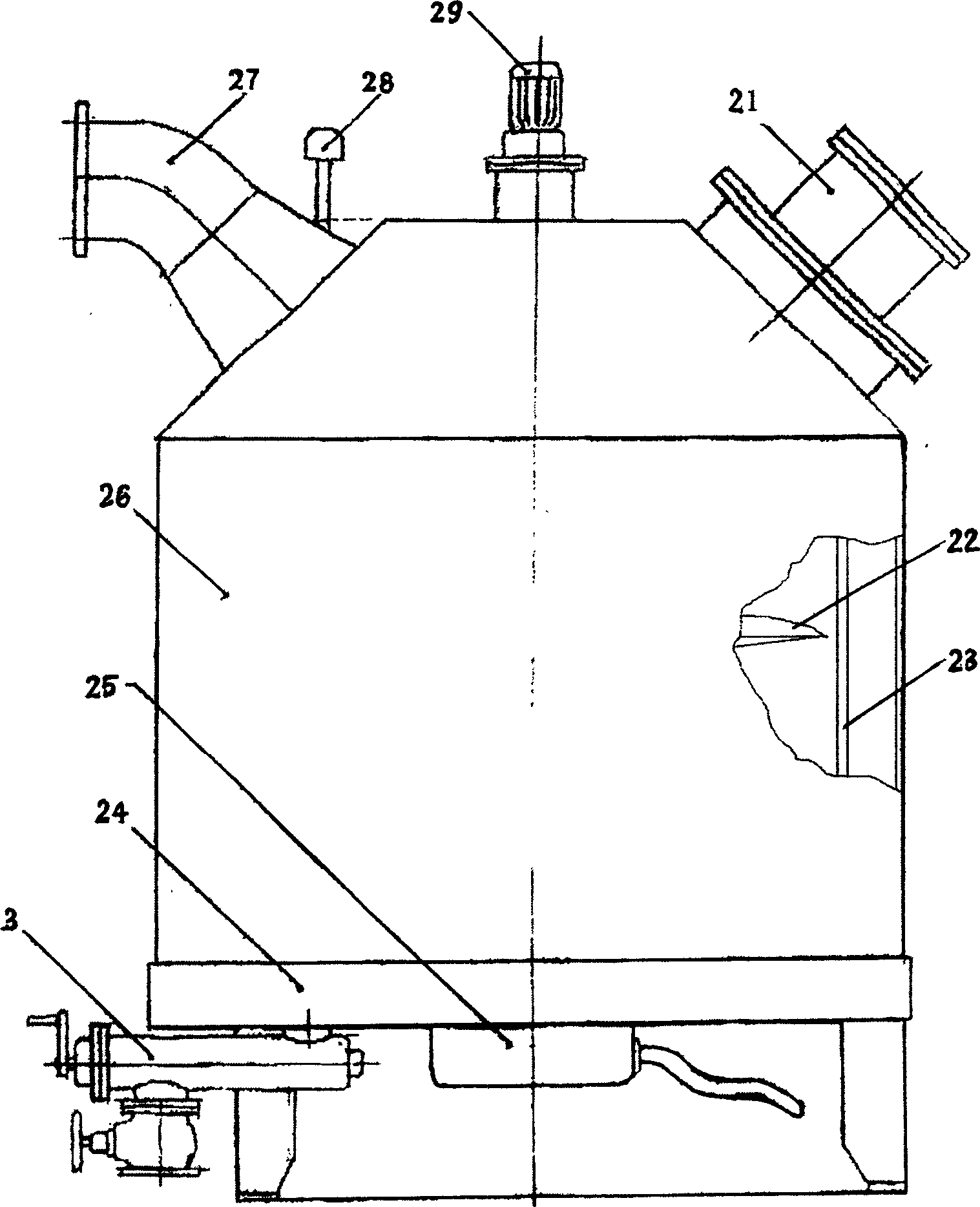

Novel pulverized coal pyrolytic hydrogenation reactor and pyrolytic hydrogenation reaction method

ActiveCN104877700AEasy to handleShort reaction timeLiquid hydrocarbon mixture productionSyngasHydrogenation reaction

The invention belongs to the technical field of pulverized coal pyrolytic hydrogenation reaction devices and processes, and particularly relates to a novel pulverized coal pyrolytic hydrogenation reactor and a pyrolytic hydrogenation reaction method. The novel pulverized coal pyrolytic hydrogenation reactor and the pyrolytic hydrogenation reaction method mainly solve the technical problems of high cost, low heat recycling rate, low utilization rate of raw materials, severe waste and severe pollution of existing coal-to-liquid equipment and strict requirements on reaction conditions and low oil yield of a coal-to-liquid method. The novel pulverized coal pyrolytic hydrogenation reactor adopts the technical scheme by comprising a reaction chamber, at least one conversion furnace, at least one syngas nozzle, a quick-cooling chamber, a first-stage separator, at least two constant-force hangers, a second-stage separator and a third-stage separator, wherein the reaction chamber is provided with a pulverized coal nozzle, the at least one conversion furnace is provided with a process burner, and the number of the syngas nozzle is the same as that of the conversion furnace. The novel pulverized coal pyrolytic hydrogenation reactor has the advantages of simple structure, energy conservation, environmental friendliness, low energy consumption, high heat recycling rate and high coal-to-liquid rate.

Owner:中美新能源技术研发(山西)有限公司

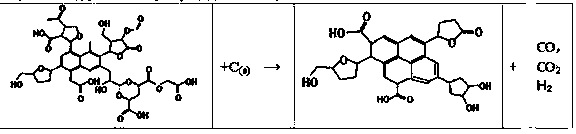

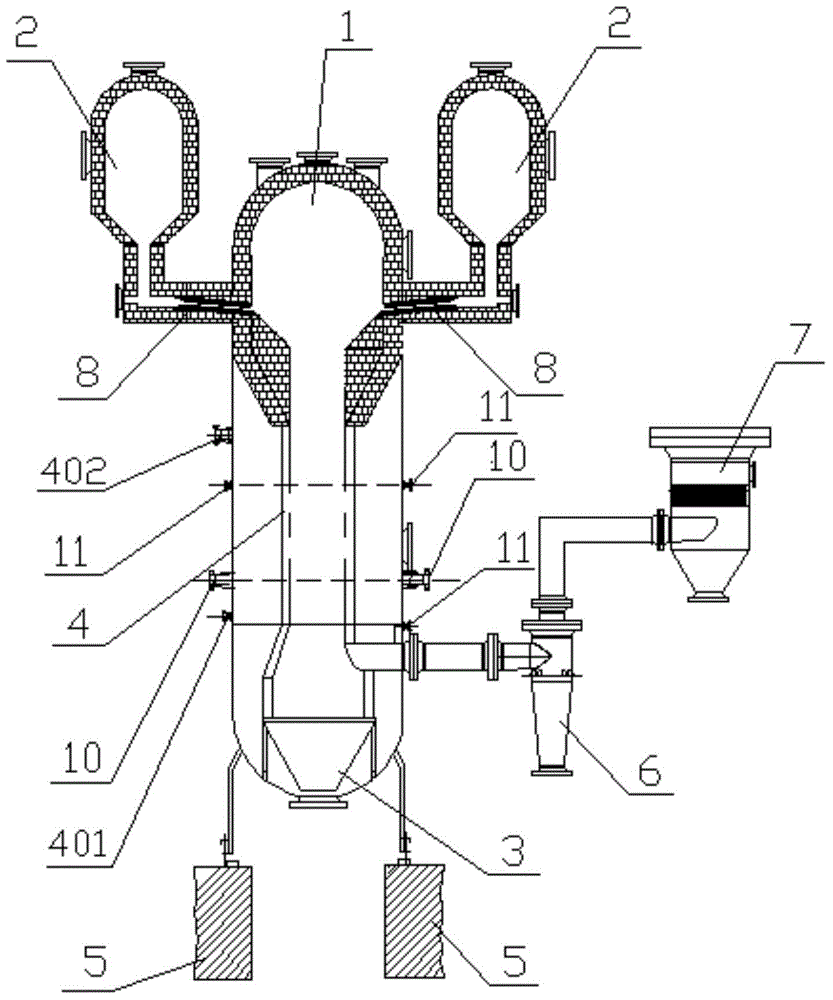

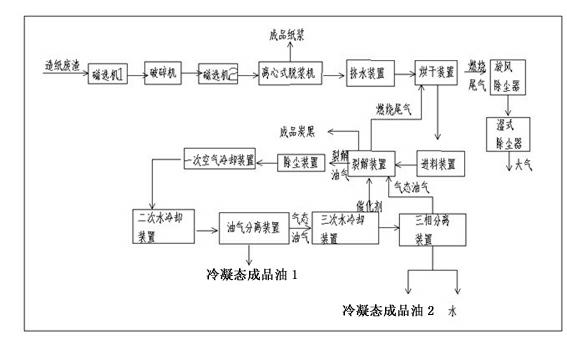

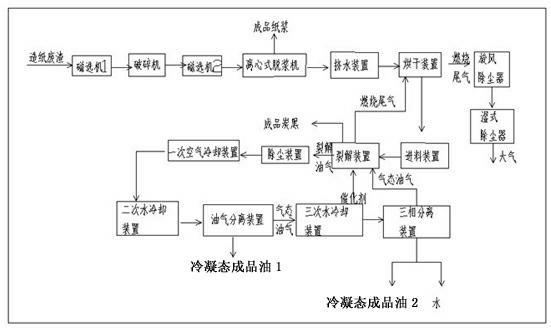

Method for recycling papermaking waste residues

InactiveCN102366756ASmall sizeAvoid destructionSolid waste disposalPaper recyclingPulp and paper industryCracking reaction

The invention discloses a method for recycling papermaking waste residues, belonging to the technical field of papermaking waste residue treatment. The method comprises the following steps: magnetic separation, stave processing, centrifugal deslurrying, squeezing water, drying, cracking and cracking oil-gas separation. The method fully utilized various ingredients of waste residues, can achieve the purpose of recycling the papermaking waste residues, and can eliminate the damage of papermaking waste residue to the environment.

Owner:仁精科技(昆山)有限公司

Complex plug removal water injection agent used for water injection well of sandstone reservoir and preparation method thereof

ActiveCN103421478AEasy to useReduce surface tensionFluid removalDrilling compositionBiopolymerDissolution

The invention provides a complex plug removal water injection agent used for a water injection well of a sandstone reservoir and a preparation method thereof, and discloses a self-synthesized organic cation low molecular weight polymer with well prevention of clay swelling and transport of clay particle, and excellent anti-erosion property. According to the invention, selected and used hydrofluoric acid, formic acid and acetic acid have well dissolution and corrosion properties for sandstone and retarding property, so that the action between the acid and the sandstone is slowed down, the depth of the entering of the acid is increased to be able to acidize deeply so as to effectively relieve the plug of rock particles and scales; a self-synthesized phosphinic acid group polyacrylic acid biopolymer anticrustator has well anti-calcium scale ability to retard the plug of scales, the added dyhydroxylpolyoxy propylene polyoxyethylene ether has excellent anti-emulsification and demulsification abilities for the emulsification caused by water injection and acidification of an oil field, and the using of the complex plug removal water injection agent makes innovative demonstration effect for improving the oil productivity.

Owner:XINJIANG KELI NEW TECH DEV +1

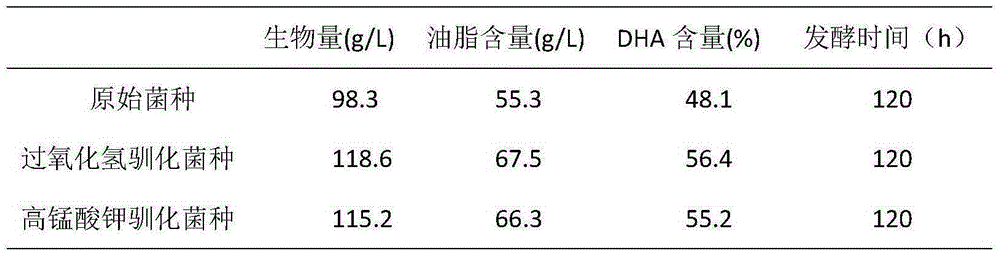

DHA fermenting high-yielding method

ActiveCN105331572AStrong growthShort fermentation cycleMicroorganism based processesFermentationEconomic benefitsMaterial resources

The invention provides a DHA fermenting high-yielding method. The DHA fermenting high-yielding method includes the steps that schizochytrium limacinum strains are domesticated through a culture medium with a strong oxidant, the domesticated strains are cultured through a fermenting culture medium, and fermenting high yielding of DHA can be achieved accordingly. After the domesticated strains are fermented, the DHA content is 57.9%, and oil-producing efficiency is 0.492 g / L / h; compared with a control group, the DHA content and the oil-producing efficiency are increased about 20% and 55% respectively. The domesticating method does not involve a genetic engineering method, does not harm the environment, does not increase manpower and material resources, is simple and convenient, and has economic benefits.

Owner:南京脂禾生物科技有限公司

Quick hydropyrolysis reactor and process thereof

ActiveCN104498075APromote formationReduce processLiquid hydrocarbon mixture productionChemical/physical processesHydrogen atmosphereCoal conversion

The invention discloses a quick hydropyrolysis reactor and a process thereof and relates to pyrolysis of coal, solving the problems that the exiting pyrolysis process is high in energy consumption and low in oil extraction rate. A reactor is provided with a synthesis gas nozzle, a hydrogen nozzle and a coal ash nozzle as well as temperature measuring points of the reactor, wherein the synthesis gas nozzle is communicated with a natural gas and oxygen inlet pipe and is further communicated with a cooling water inlet / outlet; a chilling tank is communicated with the bottom of the reactor, the chilling tank is connected with a water inlet and a water outlet, and the chilling tank is provided with a cooling water nozzle, temperature measuring points of the chilling tank and an outlet of a chilling room. The process comprises the following steps: firstly, feeding the synthesis gas into the reactor; conveying coal ash for quick pyrolysis reaction in a hydrogen atmosphere; and then quickly decreasing the temperature to terminate reaction. The reactor and process disclosed by the invention are used for the coal-to-oil field and have the advantages of simple structure, low energy consumption, high coal conversion rate and high oil product yield.

Owner:中美新能源技术研发(山西)有限公司

Method for manufacturing fuel through straw quick thermal cracking and fuel product thereof

InactiveCN101602954AEasy to operateStrong securityBiofuelsLiquid carbonaceous fuelsBoiling pointEngineering

The invention relates to a method for manufacturing fuel through straw quick thermal cracking and a fuel product thereof. The method comprises the following steps: crushing straw materials; drying the crushed materials; carrying out thermal cracking of the dried materials; completing gas-solid separation of the thermal cracking products; condensing gaseous biomass oil; collecting low-boiling point biomass oil; and mixing and grinding biomass carbon obtained after gas-solid separation, condensed biomass oil, water and surfactant. The fuel product comprises the following components in percentage: 30 to 60 percent of the biomass carbon, 2 to 15 percent of the heavy biomass oil, 0.2 to 1 percent of the surfactant, and the balance of water. The method converts straw through quick thermal cracking and makes straw into the novel fuel product of the biomass oil, the biological carbon and the water; moreover, the method has the advantages of lower production cost, higher yield of biomass fuel and better control of quick thermal cracking conditions. The fuel product has the advantages that the product has high thermal value and low sulphur content and does not block up pipelines and burner nozzles frequently during combustion; moreover, the product has stable performance and is convenient for transportation and storage. Therefore, the fuel product can be widely used in thermal power plants, heating boiler rooms, and the like.

Owner:BEIJING YIMINBAO ENERGY TECH CO LTD

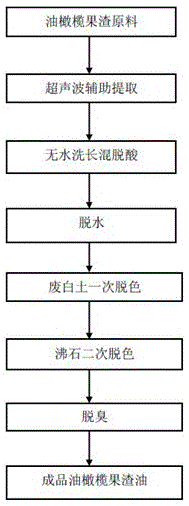

Method for ultrasonic-assisted extraction of olive pomace oil

InactiveCN105038943AEliminate the steps of deacidification and washingHigh yieldFatty-oils/fats refiningFatty-oils/fats productionUltrasonic assistedOil quality

The invention discloses a method for ultrasonic-assisted extraction of olive pomace oil. The method comprises the following steps: 1, preparing an olive pomace oil raw material; 2, adding n-hexane to the olive pomace oil raw material, and carrying out ultrasonic-assisted extraction to obtain crude olive pomace oil; 3, carrying out waterless washing long-mixing depickling treatment on the crude olive pomace oil to obtain depickled olive pomace oil; 4, dehydrating the depickled olive pomace oil to obtain dehydrated olive pomace oil; 5, respectively carrying out primary decoloring and secondary decoloring treatment on the dehydrated olive pomace oil to obtain double decolored olive pomace oil; and 6, deodorizing the double decolored olive pomace oil to obtain finished olive pomace oil. The method for ultrasonic-assisted extraction of olive pomace oil has the advantages of simple process, safety, environmental protection, high efficiency, fastness, good oil quality and high oil yield, and is suitable for small-lot production of the olive pomace oil.

Owner:WUHAN POLYTECHNIC UNIVERSITY

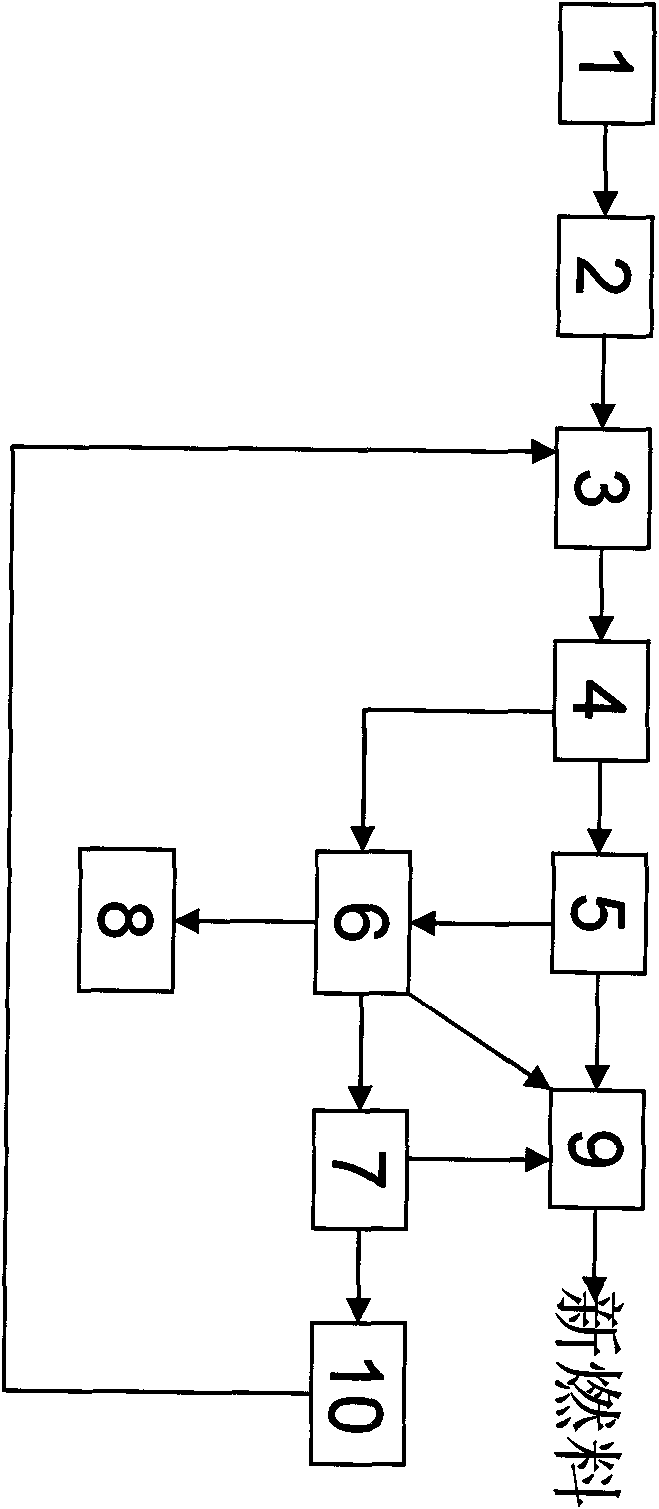

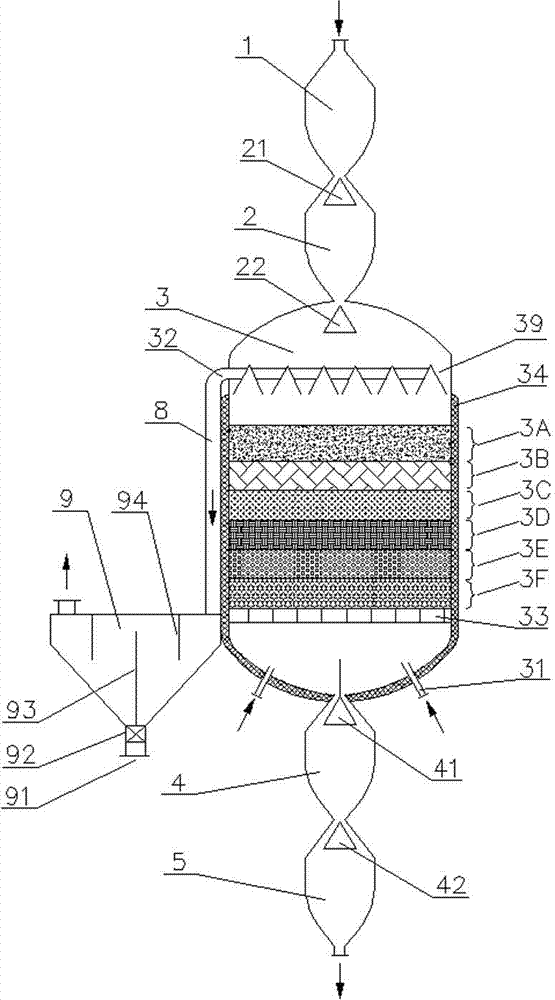

Oil preparation and gas production system and technology by conducting pressurization, hydrogenation and pyrolysis on large-sized seaweeds

ActiveCN105505429AImprove qualityHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenFiltration

The invention provides an oil preparation and gas production system and technology by conducting pressurization, hydrogenation and pyrolysis on large-sized seaweeds. The system comprises a rapid thermal cracking system and a secondary pyrolysis system; the rapid thermal cracking system comprises a pressurization feeding system, a rapid thermal cracking system, a particle separation device, a filtration device, a hydrogen material flow pipeline, a flammable gas tank, an oil-gas separator and an oil storage tank, the secondary pyrolysis system comprises a secondary pyrolysis furnace, a secondary pyrolysis fuel bin and a dreg falling opening, and the second pyrolysis furnace comprises two feed inlets. The whole system is simple in structure, the oil yield of seaweed biomass is high, the problems of solid waste semicocke losses and environmental pollution are avoided, and efficient and clean utilization of the large-sized seaweed biomass resource is finally achieved.

Owner:泰州市海创新能源研究院有限公司

Special novel blending fertilizer for rape, and preparation method thereof

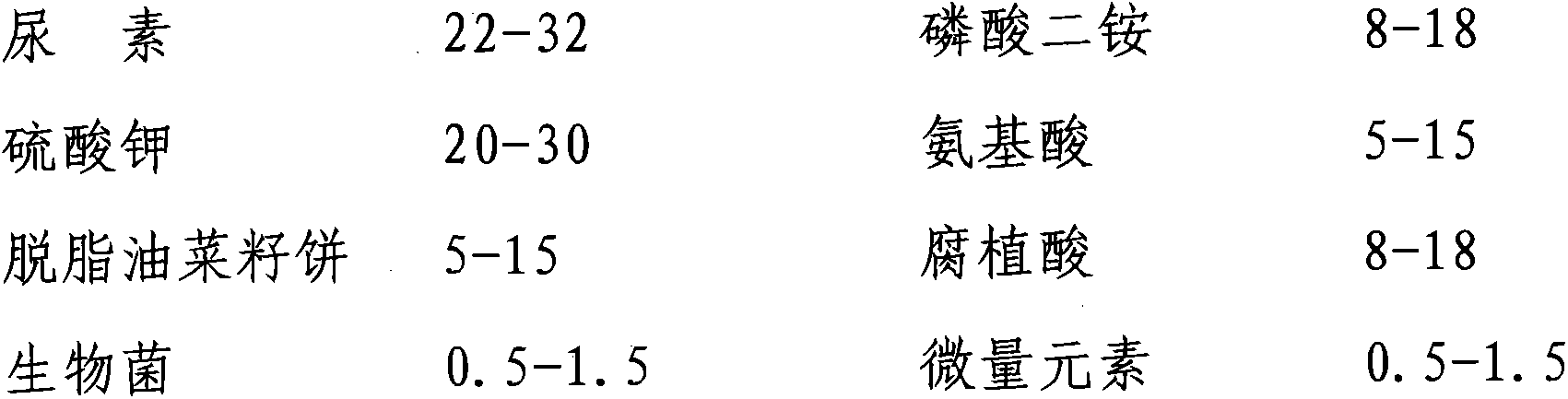

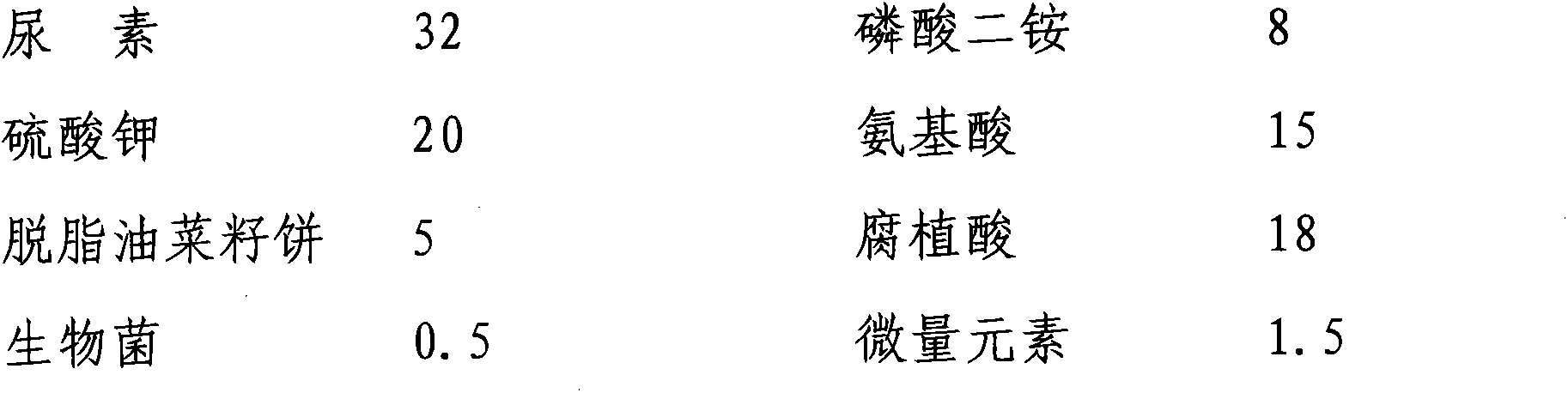

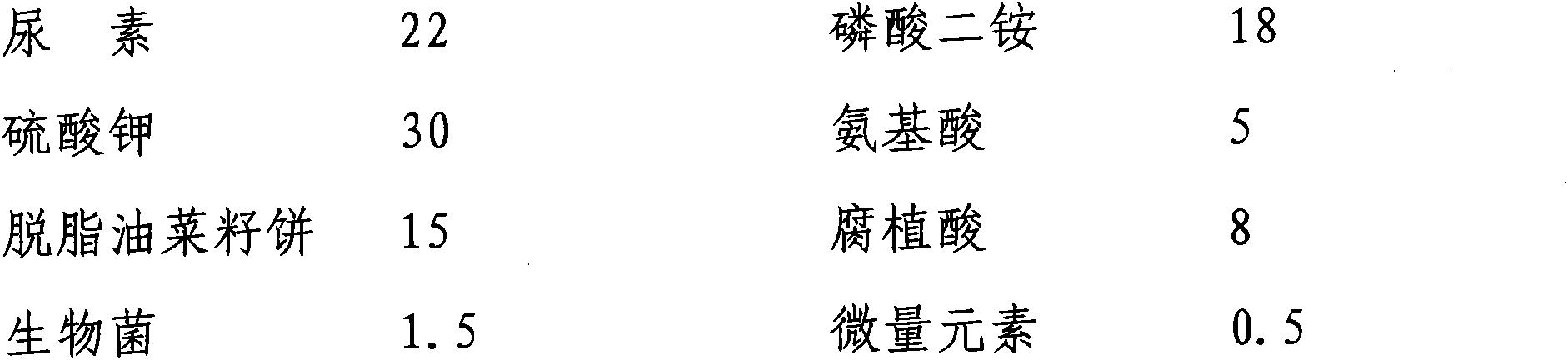

InactiveCN104045416AIncrease productionIncrease oil production rateFertilizer mixturesFruit treeTrace element

The invention discloses a special novel blending fertilizer for rape, and a preparation method thereof. The fertilizer is prepared by mixing the following raw materials, by weight, 22-32 parts of urea, 8-18 parts of diammonium phosphate, 20-30 parts of potassium sulfate, 5-15 parts of amino acids, 5-15 parts of degreased rapeseed cakes, 8-18 parts of humic acid, 0.5-1.5 parts of biological fungi and 0.5-1.5 parts of trace elements. The fertilizer has the advantages of strong specificity, high fertilizer efficiency, great improvement of the output, the quality and the oil productivity of rape, and the like, can improve the rapeseed output per 666.7m<2> by 10-20% and the oil productivity by 5-10%, and can greatly improve the quality. The fertilizer has better fertilizer efficiency than other common composite fertilizers, is especially suitable for the plantation of rapes in the regions of central south and south of the Yangtze River, and has very substantial effects. The fertilizer can be used for rapes, and can also be used for economic crops comprising grain and oil crops, fruit trees, vegetables and tea leaves. The fertilizer can be applied mainly through furrow application, can be broadcasted as an after fertilizer or is spread on the blade surfaces with water.

Owner:HUNAN ZHONGKE AGRI

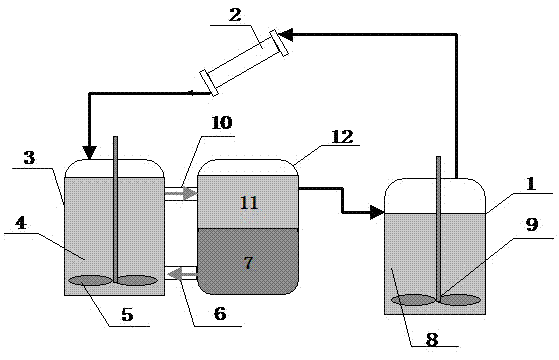

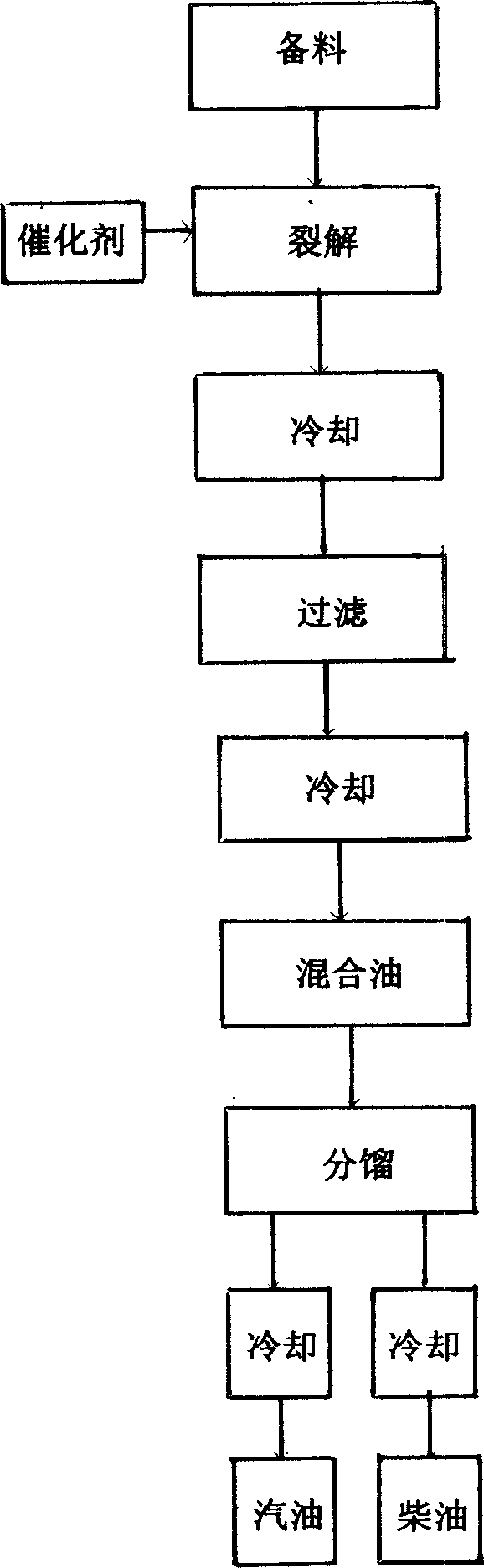

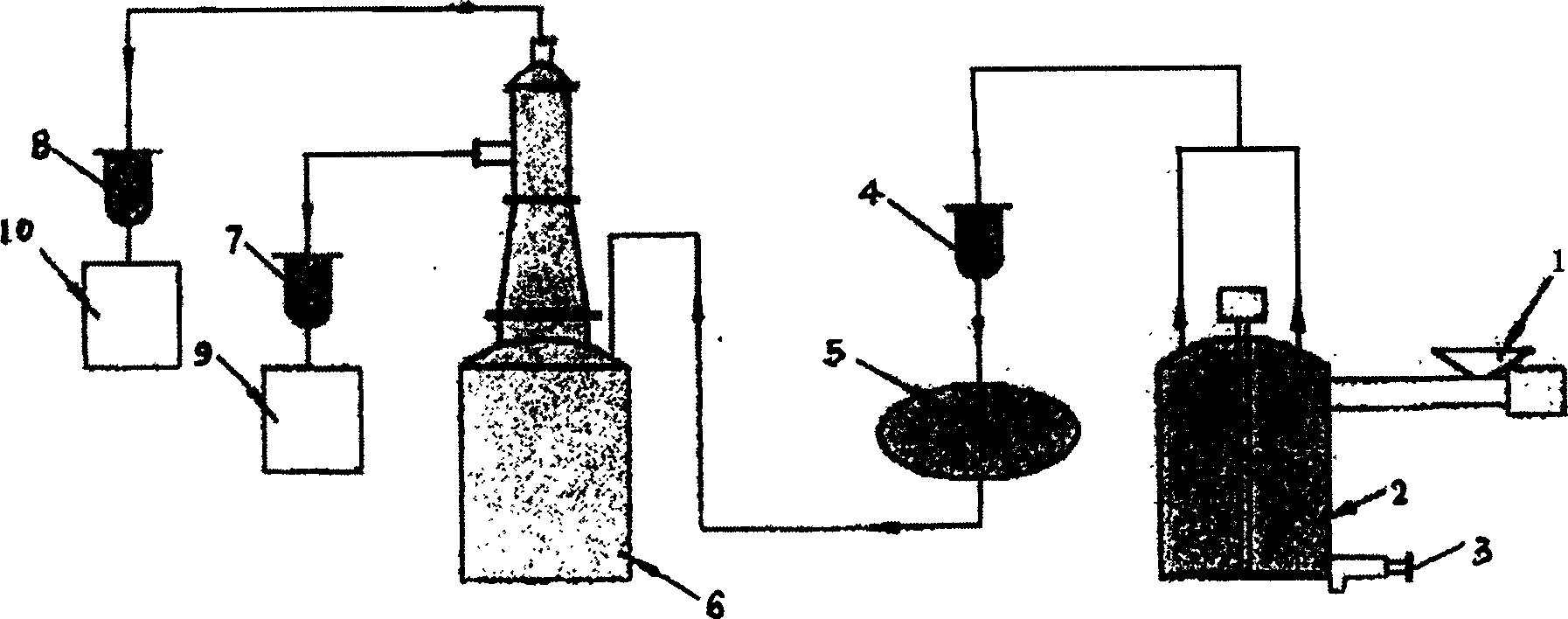

Method and device for producing fuel using waste plastics

InactiveCN1683473AIncrease oil production rateHeating up fastLiquid hydrocarbon mixture productionCatalytic pyrolysisEpoxy

A method and device for producing fuel using waste plastics is disclosed. The method contains heating, catalytic pyrolysis, fractionating, separation, filtering and so on. The characters of the method are that a mixture of activated kaoline (carclazyte) and natural bussokuseki is used for catalyst to increase oil rate of the material, medium frequency heating using medium frequency induction furnace to connect the copper pipe outside is used to make copper pipe generate electromagnetic radiation to heat the materials in the furnace with the characteristics of electricity-saving and quick heating. The device contains cracking furnace, fractionating furnace, condenser and electromagnetic heating device. The characters of the device are that the furnace pipe of the cracking furnace is 8 type so as to save material, increase capacity, save energy and increase efficiency, articulated chain is used to scrape the bottom and resulting in non-sticky, and vermiculite is used as heat insulator and epoxide resin is used as sheathing material.

Owner:伟驹有限公司

Moving bed self-heating type pressure gasification hydrogen-rich environment dry distillation furnace and dry distillation method thereof

ActiveCN104745222AHigh calorific valueTake advantage ofDirect heating destructive distillationLiquid hydrocarbon mixture productionInsulation layerDistillation

The invention discloses a moving bed self-heating type pressure gasification hydrogen-rich environment dry distillation furnace and a dry distillation method thereof. The dry distillation furnace comprises a storage bin, a material lock, a dry distillation furnace body, an ash lock and an ash bin, wherein the storage bin is arranged on the upper part of the material lock and connected with the material lock through a material lock upper valve; the material lock is arranged on and connected with the upper part of the dry distillation furnace body a material lock lower valve; a thermal-insulation layer or a cooling layer is arranged on the outer wall of the dry distillation furnace body; a gasifying agent inlet is formed in the lower part of the dry distillation furnace body, and an oil-gas outlet is formed in the upper part of the dry distillation furnace body and communicated with the inner part of the furnace body; a rotary furnace grate is arranged between the lower part of the inner wall of the dry distillation furnace body and the ash lock; the ash lock is arranged on and connected with the lower part of the dry distillation furnace body an ash lock upper valve; the ash bin is arranged on and connected with the lower part of the ash lock by an ash lock lower valve. The dry distillation method comprises steps of loading materials, performing pressurized distillation, and discharging ashes. The moving bed self-heating type pressure gasification hydrogen-rich environment dry distillation furnace has the characteristics of being simple in structure, high in oil yield rate, good in oil quality, high in heating efficiency, high in coal gas heat value, capable of sufficiently utilizing chemical latent heat of fixed carbon, less in carbon content in outlet ashes, good in activity, strong in raw material adaption and high in source utilization rate.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

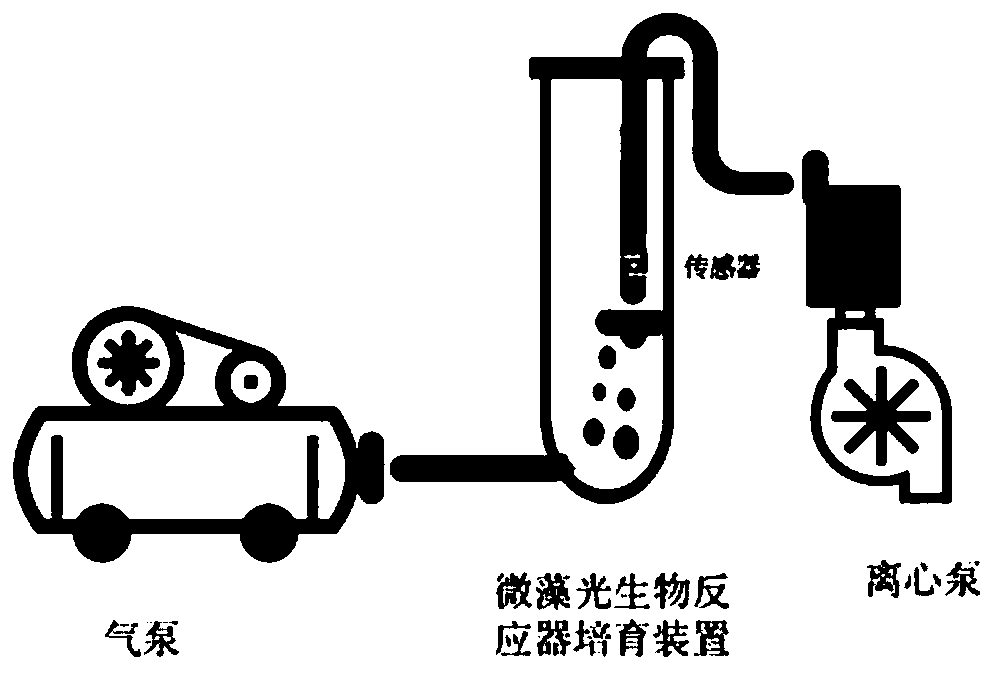

Integrated recycling system for co-hydrothermal preparation of oil with sludge and microalgae and culture of microalgae with waste liquid

InactiveCN110194981ARealize added valueOvercome the difficulty of purification standardsBiofuelsSolid fuelsLiquid wasteSocial benefits

The invention discloses an integrated recycling system for co-hydrothermal preparation of oil with sludge and microalgae and culture of microalgae with waste liquid. The system comprises a microalgaeculture device and a hydrothermal liquefaction reactor. The cultured microalgae are adopted as the raw material and are compounded with sludge in proportion, then the mixture is input into the hydrothermal liquefaction reactor, the liquid phase in the pyrolysis product of the hydrothermal liquefaction reactor is input into the microalgae culture device and mixed with sewage in proportion, then themixture is used as the microalgae culture raw material, thus purifying sewage and avoiding the discharge of carbon, nitrogen and phosphorus elements in the liquid phase. The system provided by the invention has high economic, environmental and social benefits, is effectively applicable to treatment of urban sludge treatment with growing industry and can produce considerable economic and environmental benefits.

Owner:JIANGSU UNIV

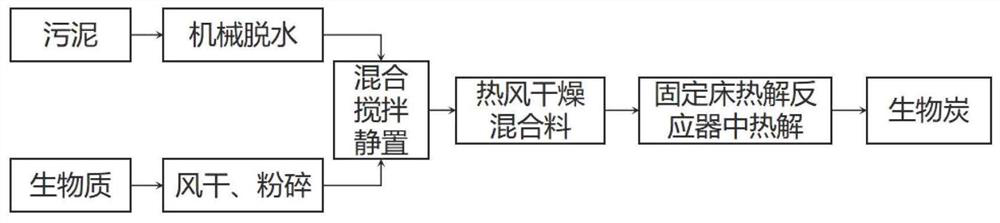

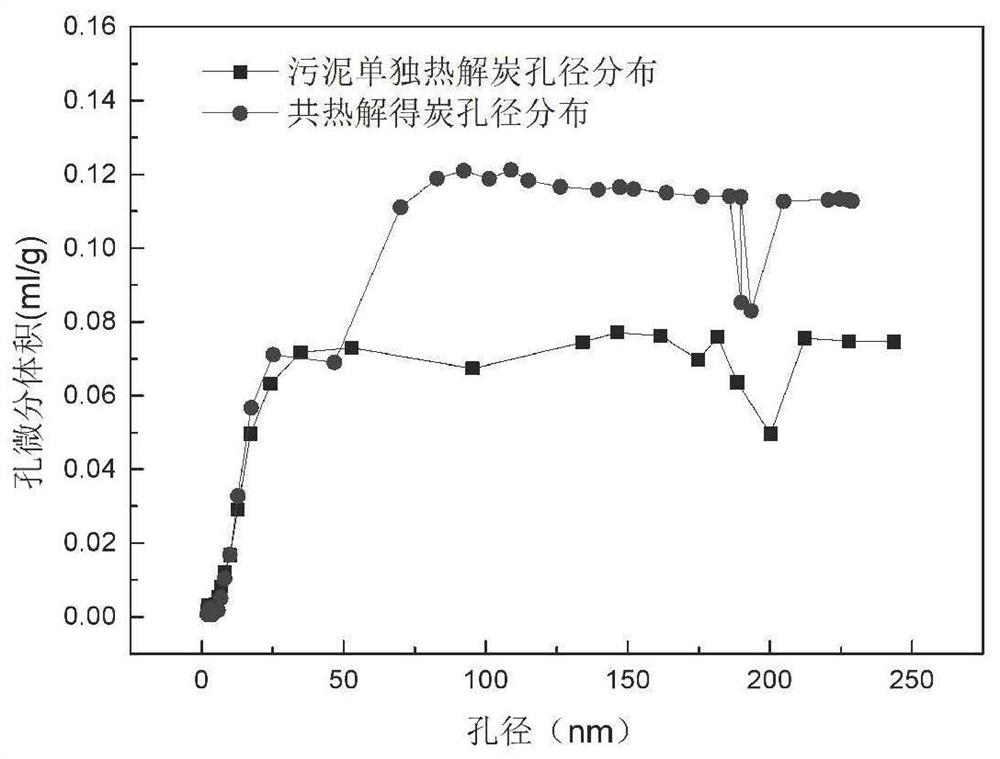

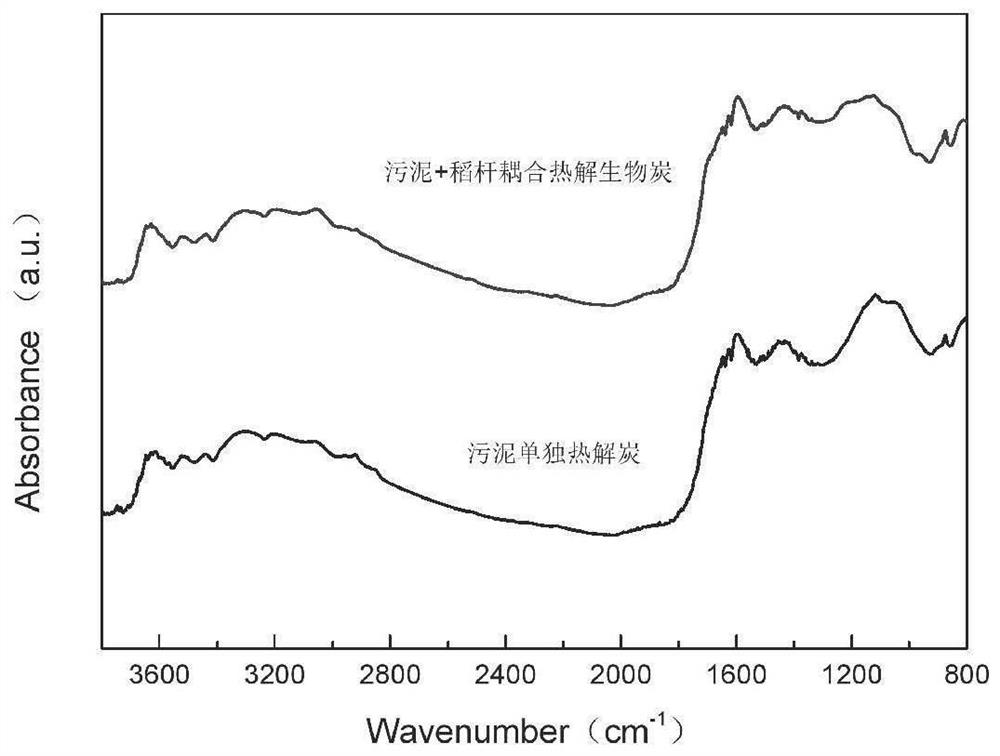

Method for preparing biochar and solidifying heavy metals through coupling sludge with biomass pyrolysis

ActiveCN112919754AHigh volatile contentIncrease oil production rateOther chemical processesWater contaminantsSludgeBiochar

The invention discloses a method for preparing biochar and solidifying heavy metals by coupling sludge with biomass pyrolysis, which comprises the following steps: 1) pretreating biomass, and mechanically dehydrating sludge; 2) fully and uniformly mixing the treated biomass and sludge, adding into a stirrer, stirring and standing to obtain a mixture; step 3) adding the mixture into a drying furnace for dewatering and drying to obtain a dried sludge-biomass mixture; and 4) adding the sludge-biomass mixture into a pyrolyzing furnace, pyrolyzing in an anaerobic or anoxic environment, and cooling solid residues after the pyrolysis is completed to obtain the biochar. According to the method for preparing the biochar and solidifying the heavy metal through sludge coupling biomass pyrolysis, the biochar can be prepared through sludge pyrolysis efficiently, meanwhile, the heavy metal in the biochar is solidified, and heavy metal pollution is greatly reduced.

Owner:SOUTHEAST UNIV

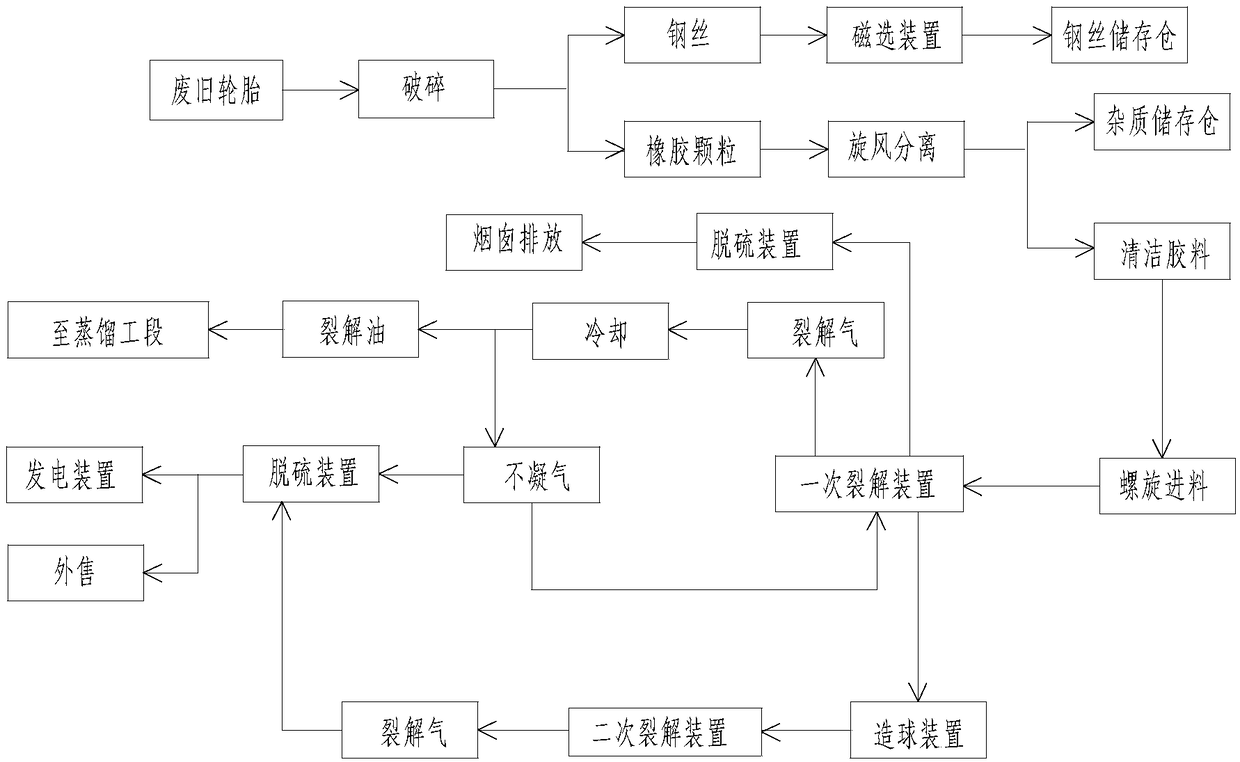

Method for catalytic cracking treatment of waste/used tires

InactiveCN108342215AFast heating rateSolve the problem of poor cracking efficiency aloneLiquid hydrocarbon mixture productionDistillationPre treatment

The invention discloses a method for catalytic cracking treatment of waste / used tires and belongs to the technical field of reutilization of the waste / used tires. The method is used for solving the problems in the prior art that the recovery rate is low, carbon black granules are large in size, and the pollution is heavy. The method for the catalytic cracking treatment of the waste / used tires comprises the procedures of raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization, wherein the secondary cracking means adding a solid-state cracked product produced from primary catalytic cracking into a secondary cracker for secondary cracking, subjecting produced cracked gas to dedusting and desulfurizing, and then, storing up the cracked gas. The method can be applied to the catalytic cracking treatment of the waste / used tires.

Owner:山东铂铠环保科技有限公司

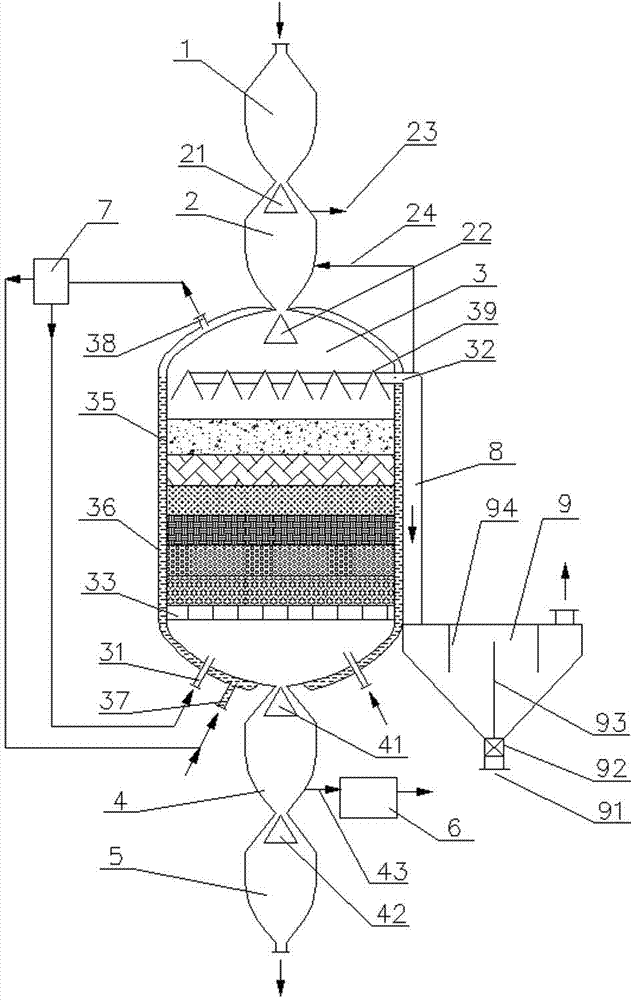

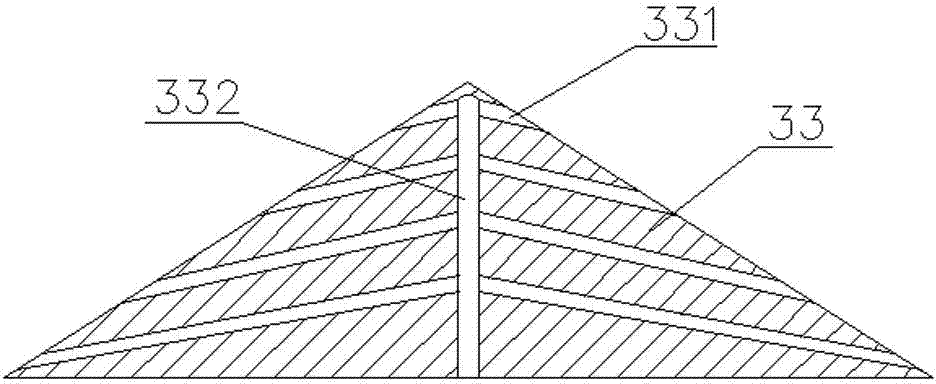

A system and method for waste pyrolysis with adjustable oil, gas and charcoal

ActiveCN104087340BSave the hassle of frequent replacementLightweightSolid waste disposalSludge treatment by pyrolysisFlue gasWorking temperature

The invention relates to a waste pyrolysis system with adjustable oil, gas and carbon and a method. The system comprises a pre-reaction section, a main reactor, a conditioner and a particle separator. The front of the pre-reaction section is connected to a feeder and the tail of the pre-reaction section is connected to the main reactor. The conditioner is connected after the main reactor. The particle separator is connected after the conditioner. In specific, waste having a water content not more than 60% is fed into the pre-reaction section through the feeder, reacted waste is fed to the main reactor, residue coke generated after the reaction is finished is fed into the conditioner and a generated volatile material is discharged in a forced manner into the conditioner to be contacted, reacted and conditioned with the residue coke at the same time. The conditioner achieves conditioning of the residue coke and the volatile material at the same time. The volatile material after being conditioned is fed into the particle separator to output a clean volatile material. The residue coke after conditioning has a calorific value of 3.37-6.74 MJ / kg, and can be used as building raw materials or is conveyed to a sanitary landfill. The working temperature of the pre-reaction section is 105-298 DEG C and an inert gas or flue gas is fed into the pre-reaction section. The working temperature of the main reactor is 450-650 DEG C. The working temperature of the conditioner is 700-900 DEG C. The system and the method can obtain oil with better quality and more combustible gases and are adapt to changes of the water content of the waste.

Owner:上海济德能源环保技术有限公司

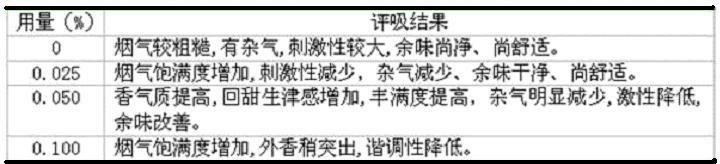

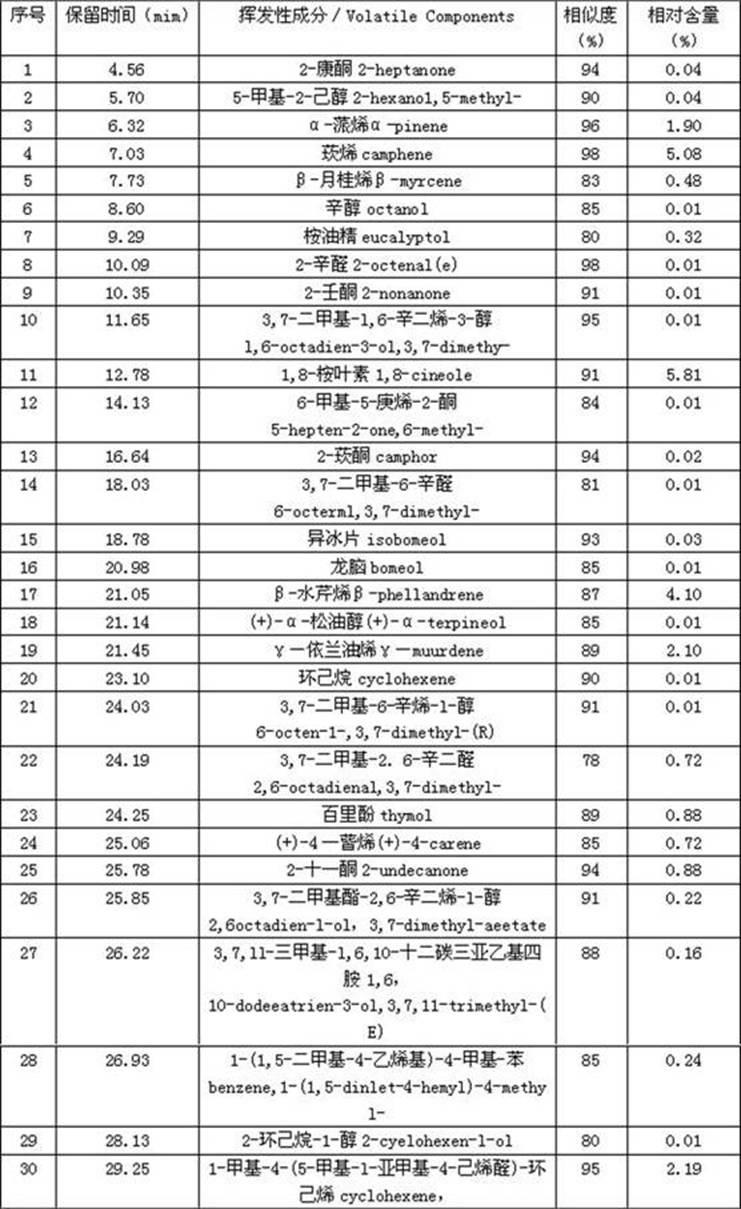

Perfume essential oil for tobacco and preparation method and application thereof

InactiveCN102604742AThe preparation method is simple and environmentally friendlyFast preparation methodTobacco treatmentEssential-oils/perfumesBiotechnologyNicotiana tabacum

The invention belongs to the technical field of perfumes for tobacco, specifically relating to perfume essential oil for tobacco and a preparation method and application thereof; the preparation method comprises the following steps: making ginger stems and leaves as raw materials, after removing sundries and drying the raw materials, crushing the raw materials into powder, then, processing carbon dioxide supercritical extraction to the steams and leaves powder. According to The invention, the ginger steams and leaves are used as the raw materials so as to prepare the perfume essential oil for the tobacco; a new tobacco perfume preparation way is provided, thus, the ginger steams and leaves turn waste into wealth; simultaneously, the preparation method is characterized by environmental protection, quick process, and high oil productivity.

Owner:CHINA TOBACCO HENAN IND

Extraction method of rose essential oil as well as rose essential oil

ActiveCN108676624AIncrease oil production rateQuality improvementEssential-oils/perfumesDistillationCooking process

The invention discloses an extraction method of rose essential oil as well as the rose essential oil, and belongs to the technical field of an extraction process of the rose essential oil. The extraction method comprises the following steps: A, treating raw materials: adding fresh rose flowers into a distillation kettle; B, performing steam billowing distillation: introducing steam in the distillation kettle, performing billowing distillation on the fresh rose flowers, controlling and adjusting the temperature of a water outlet of condensed water as well as controlling and adjusting distillation time, wherein the form that the steam enters the distillation kettle is vertical multi-layer interval distribution; and C, separating: enabling oil and water mixed steam generated in the distillation kettle to pass through a condenser and then enter a separator to perform separation, and collecting the rose essential oil. The technical problem of incomplete and non-uniform cooking caused by thefact that the rose flowers is liable to bond into layers in the cooking process in the prior art that can be solved, and the technical effects of increasing the oil yield of the rose essential oil and improving the quality of the essential oil can be achieved.

Owner:高延厅

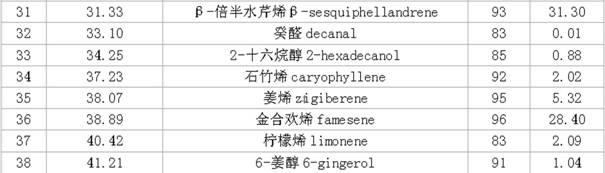

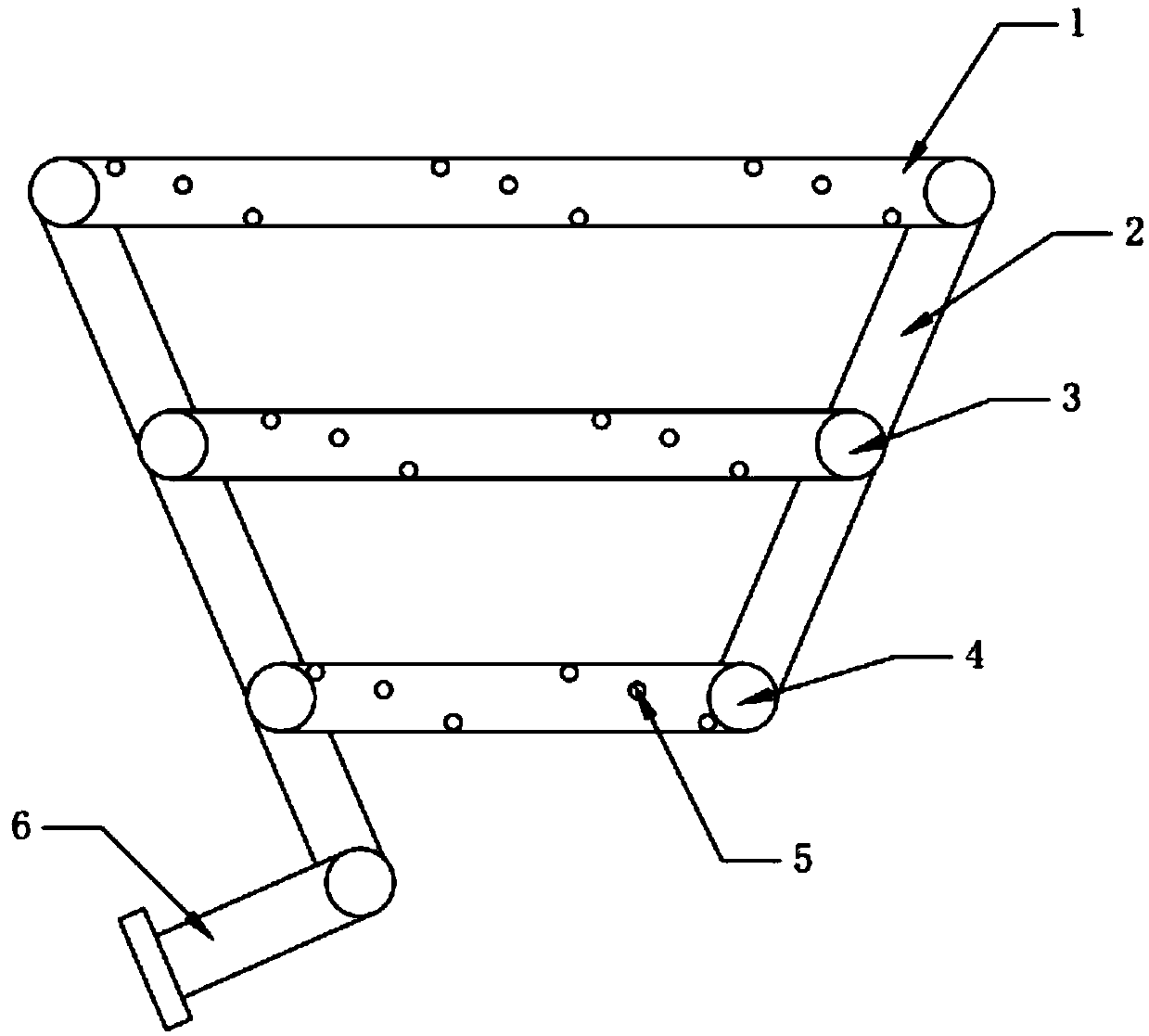

Method for preparing prickly ash seed oil through mechanical compression

InactiveCN105132141ASimple processIncrease oil production rateFatty-oils/fats refiningFatty-oils/fats productionFiltrationChemical constituents

The invention discloses a method for preparing prickly ash seed oil through mechanical compression. The method comprises the following steps: step 1, drying prickly ash seeds, that is, blowing cold wind to cool the prickly ash seeds to 15-40 DEG C and to lower the water content of the prickly ash seeds to 4-10%; step 2, conducting peeling treatment on the dried prickly ash seeds, so as to lower the mass percent of prickly ash seed peels in the dried prickly ash seeds to 10% or below; step 3, compressing the peeled prickly ash seeds to obtain crude oil, conducting settlement and filtration on the obtained crude oil, and feeding the treated crude oil into a hydration tank for hydration treatment, and carrying out dehydration and drying after the hydration treatment. Through adoption of the peeling and cold compression processes, the method is simple and under a low-temperature condition, most natural and active nutrients can be kept in a finished prickly ash seed oil product during compression; due to the mechanical compression process, the introduction of chemical constituent is avoided, and both the prickly ash seed oil and the method provided by the invention are more environmental-friendly.

Owner:罗春燕

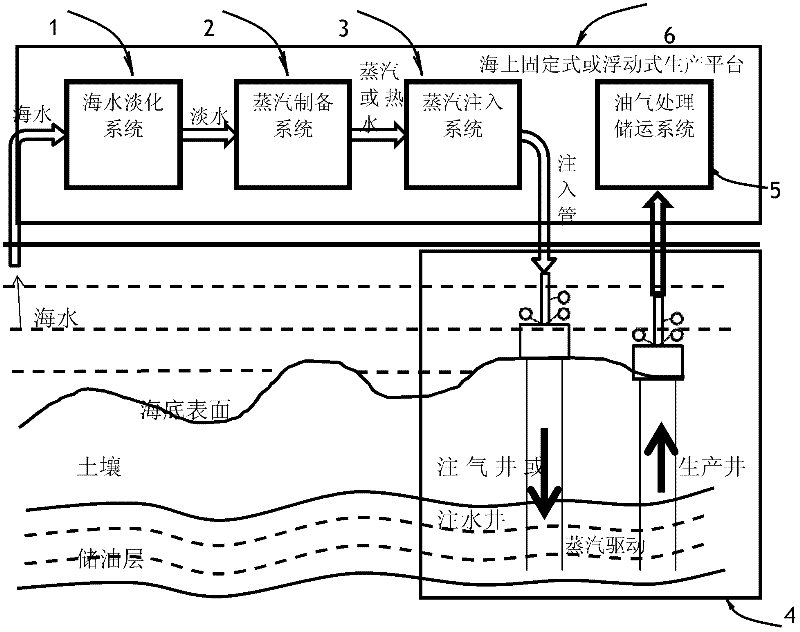

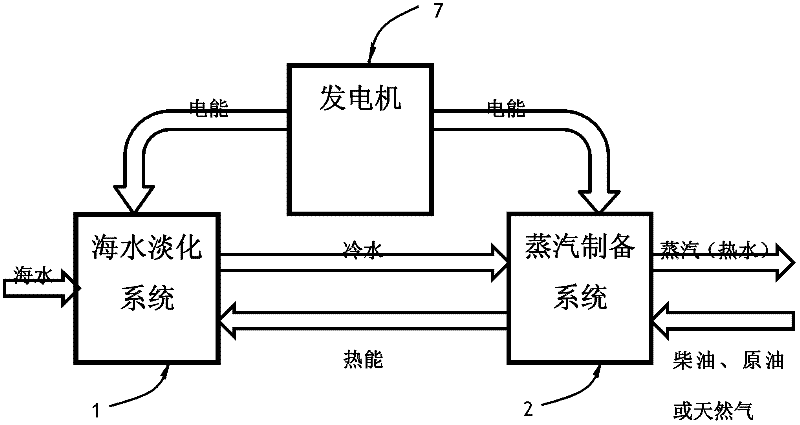

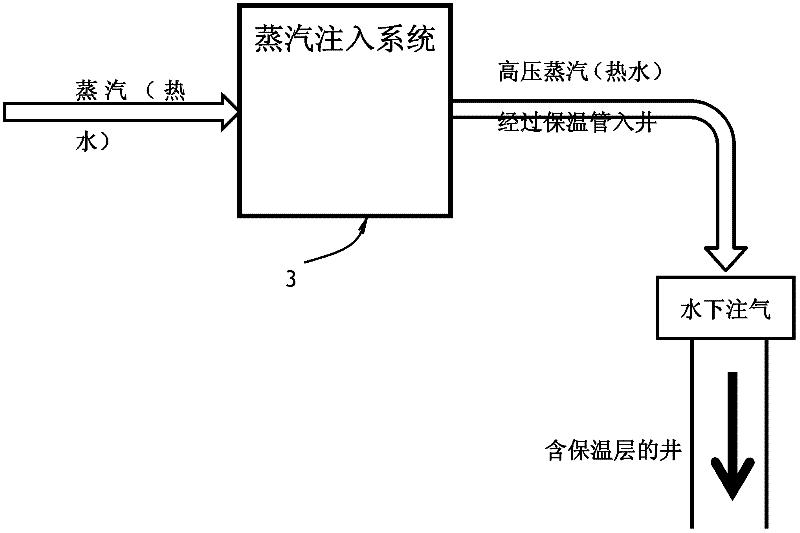

Thermal mining system of marine heavy oil field and mining method

InactiveCN102337876ASolving Manufacturing ChallengesSupply is variableFluid removalCombustorFresh water organism

The invention discloses a thermal mining system of a marine heavy oil field and a mining method. The system comprises a seawater desalination subsystem, a steam preparation subsystem, a steam injection subsystem and an oil / gas production subsystem, and the steam preparation subsystem, the steam injection subsystem and the seawater desalination subsystem are arranged on a fixed or floating marine production platform. The method comprises seawater desalination, steam preparation, steam injection and oil / gas production. By adopting the integrated system with the seawater desalination device, the marine steam preparation device, the steam injection device and a marine mining device, the problems of marine freshwater sources and steam preparation can be solved, and basic conditions can be provided for thermal mining of marine heavy oil and steam. Due to the adoption of the flexible fuel supply and a burner with a wide scope of application, convenience is provided for marine steam preparation. Moreover, the economic performance of thermal mining of marine heavy oil and steam can be greatly improved.

Owner:CHINA FIRST HEAVY IND

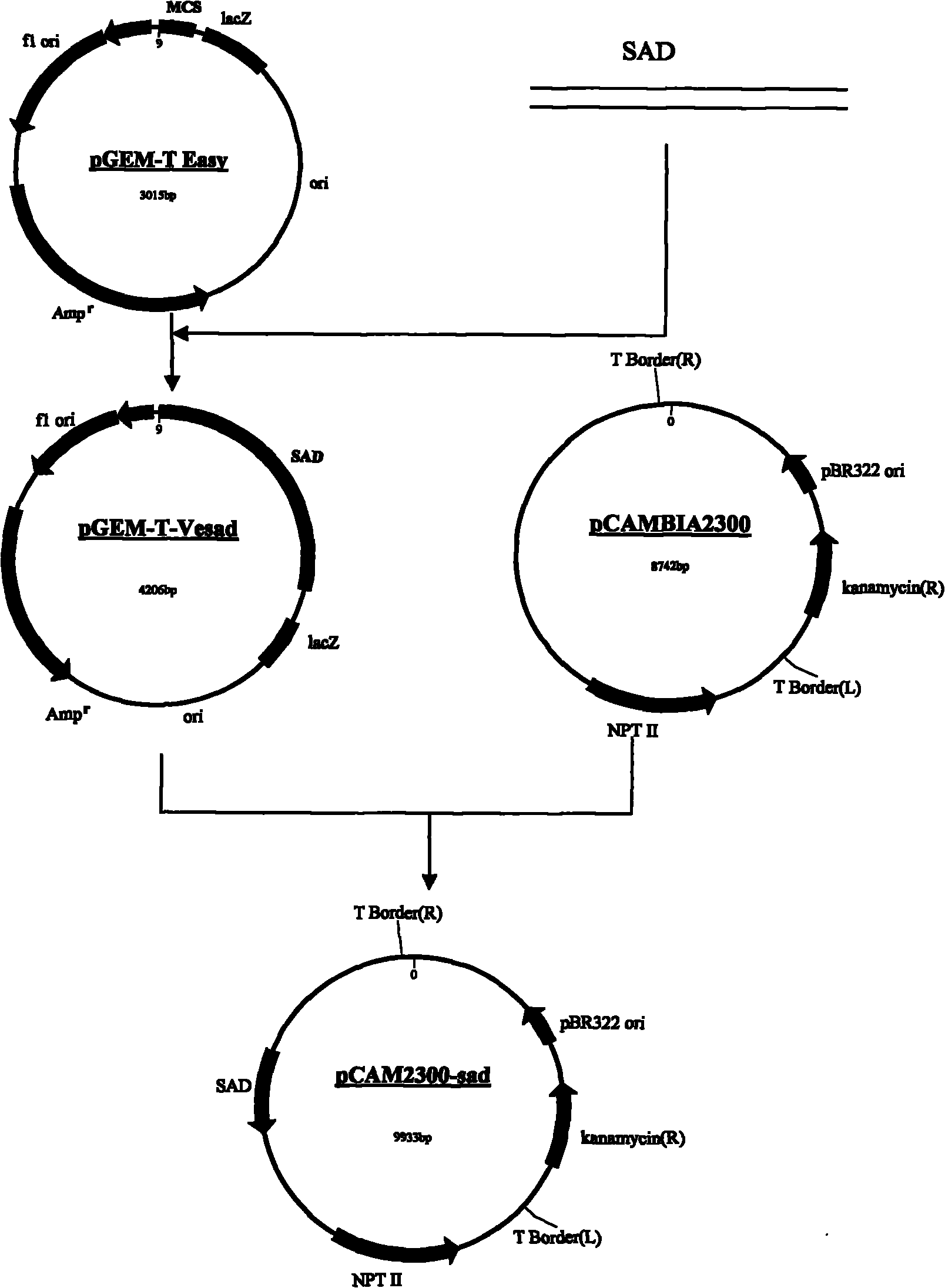

Method for constructing cryptococcus albidus engineering bacterial strain for producing oleic acid in high yield

InactiveCN101892250AIncrease oil production rateIncrease contentFungiMicroorganism based processesCryptococcus albidusTotal rna

The invention relates to a method for constructing a cryptococcus albidus engineering bacterial strain for producing oleic acid in high yield, and provides a yeast engineering bacterial strain for producing oleic acid in high yield. A vector uses pCAMBIA2300 as a basic framework, contains aleurites montana VeSAD genes, and can change an oil producing yeast fatty acid component so as to improve the oleic acid content. The method comprises the following steps of: (1) acquisition of a full-length sequence of a cDNA coding area of the enzyme cutting site-containing aleurites montana VeSAD gene; (2) construction of a VeSAD positive expression vector; (3) acquisition of a recombinant agrobacterium strain; and (4) acquisition of the cryptococcus albidus engineering bacterial strain. The method has the advantages that: the VeSAD genes separated from total RNA of aleurites montana seeds are constructed on the yeast expression vector pCAMBIA2300, and the VeSAD genes are guided into the cryptococcus albidus by adopting an agrobacterium-mediated method so that a synthetic gene of vegetable fatty acid is efficiently expressed in the yeast, the oil yield of the cryptococcus albidus is increased, and particularly the oleic acid content of the grease is improved.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com