Patents

Literature

203results about How to "Solving Manufacturing Challenges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

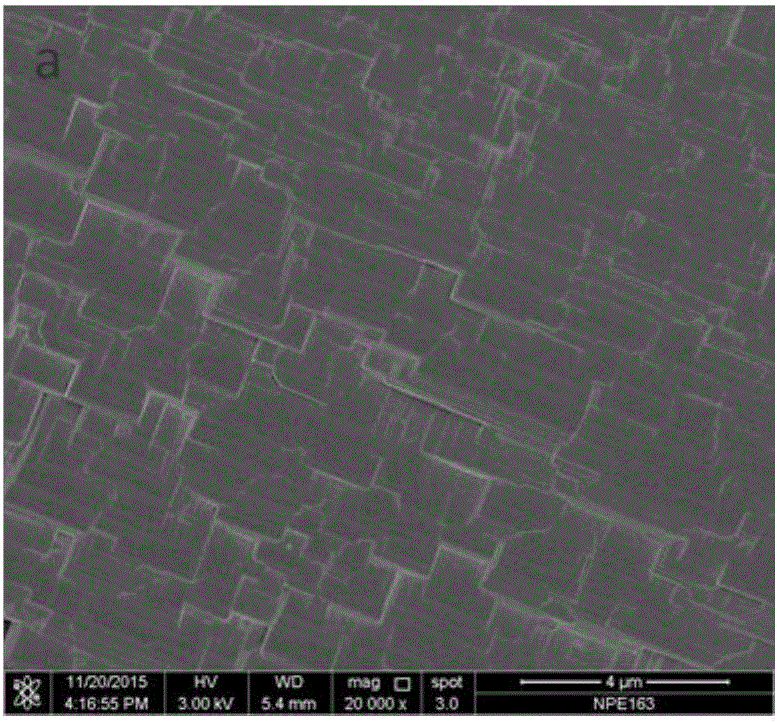

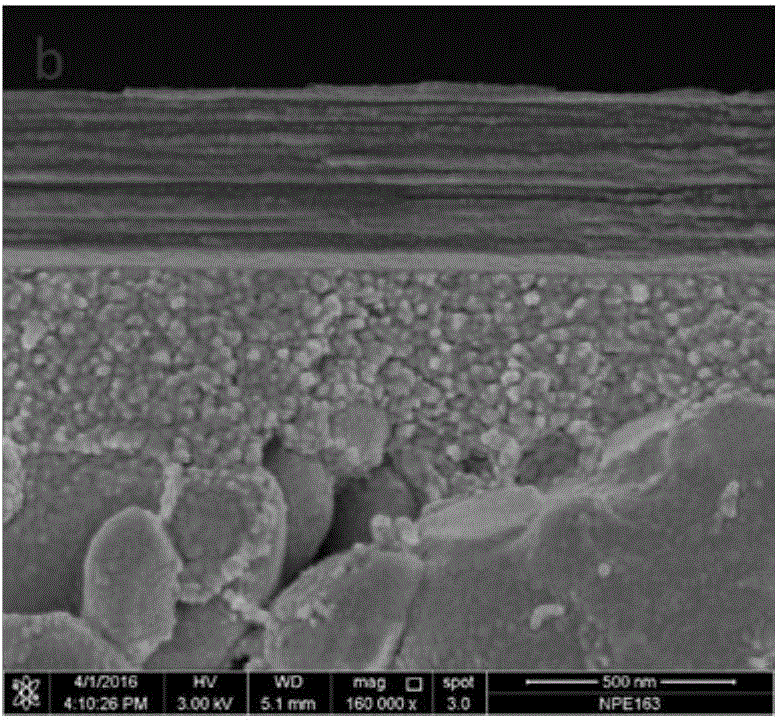

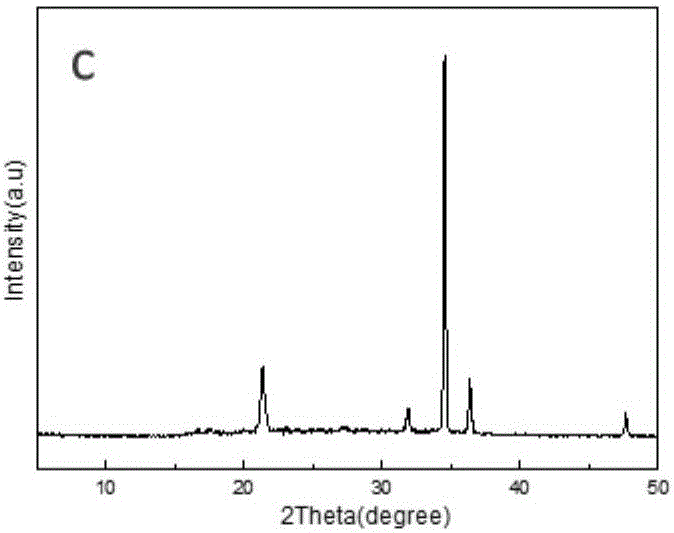

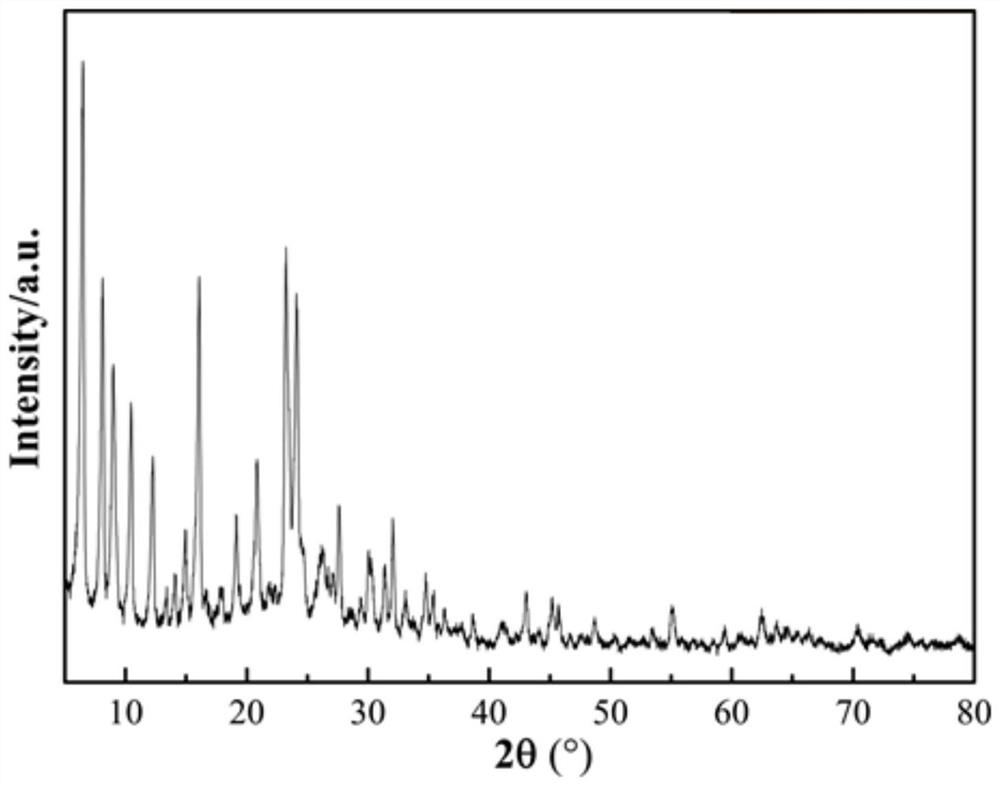

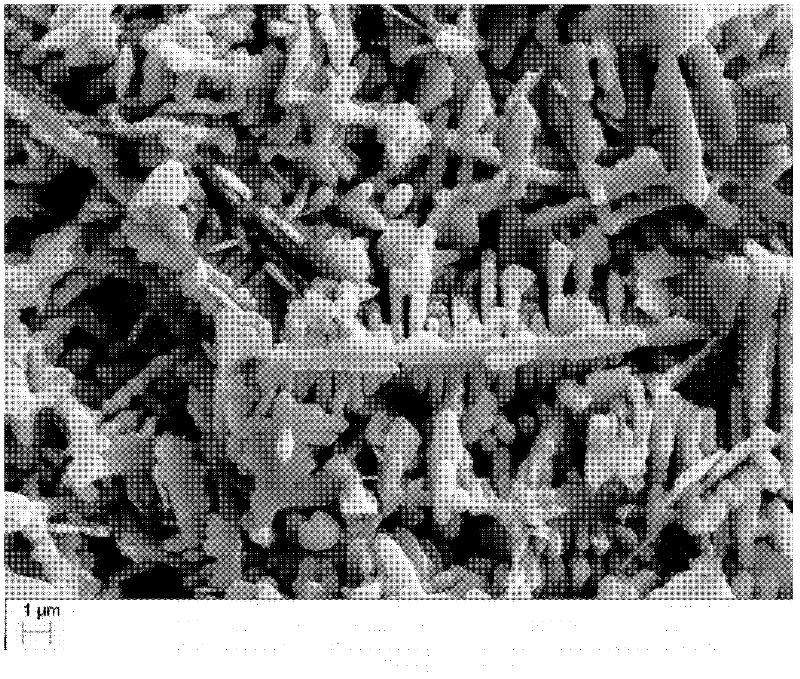

Simple solvothermal growth method for preparing oriented growing metal organic skeleton nanometer slice film

ActiveCN105797594ASolving Manufacturing ChallengesSolve preparation difficultiesSemi-permeable membranesMetal-organic frameworkActive point

The invention relates to a simple solvothermal growth method for preparing an oriented growing metal organic skeleton nanometer slice film. The method comprises the following steps: introducing a positioning active point for the oriented growth of the metal organic skeleton nanometer slice film on the surface of a carrier, namely, growing a layer of nanoscale zinc oxide as the positioning active point for metal central ion coordinate on the carrier surface through hydro-thermal synthesis, thereby acquiring a carrier with ZnO nanometer layer positioning active point; putting the carrier into a synthesis solution of the metal organic skeleton nanometer slice film and compounding through a solvothermal system; and controlling growth, thereby forming the continuous and uniform horizontal or vertical oriented metal organic skeleton nanometer slice film. The preparation method solves the problem of difficulty and complexity of preparation of a metal organic skeleton nanometer slice film and has the advantages of simpleness, convenience, capability of forming film on large-area carriers and excellent amplifying and application prospect.

Owner:DALIAN UNIV OF TECH

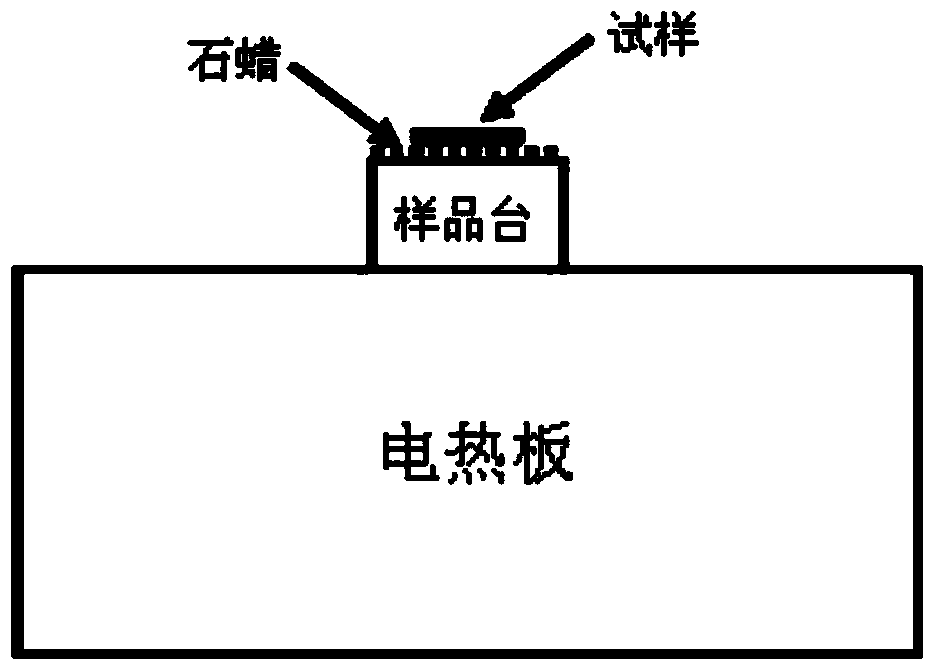

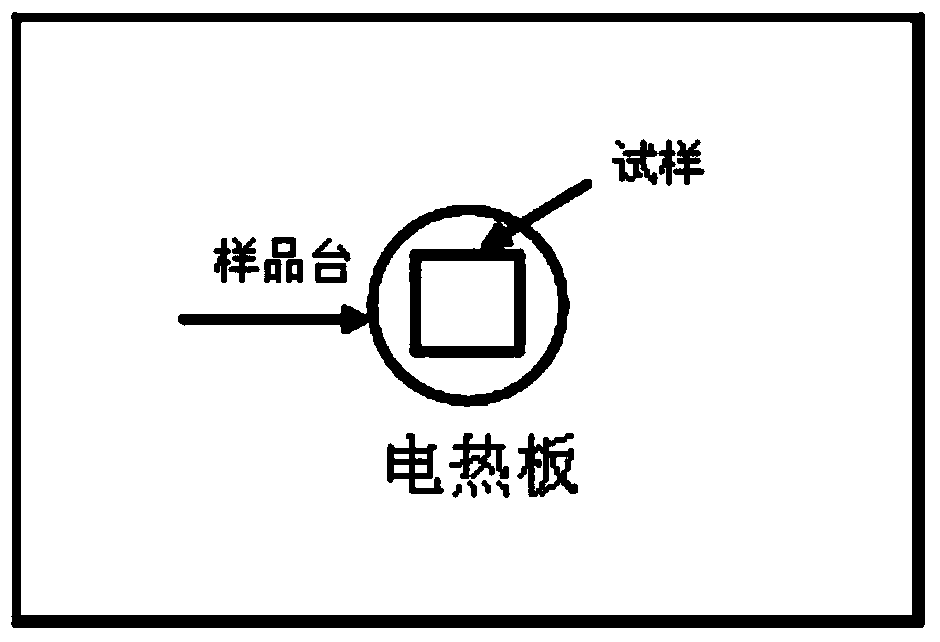

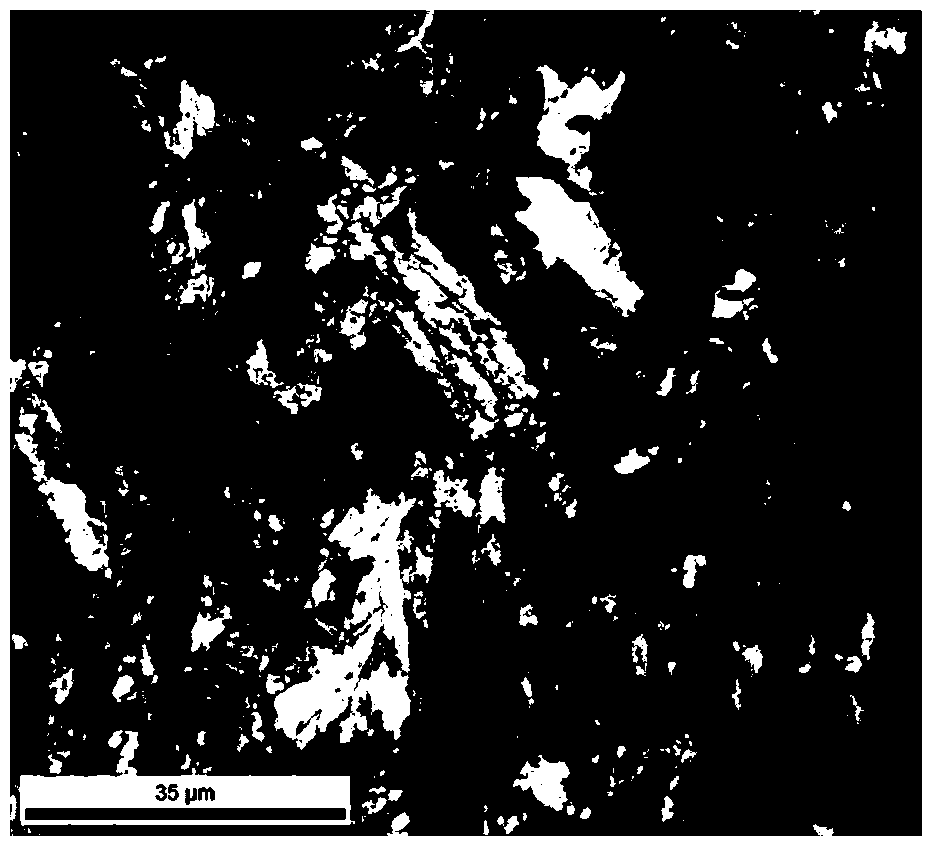

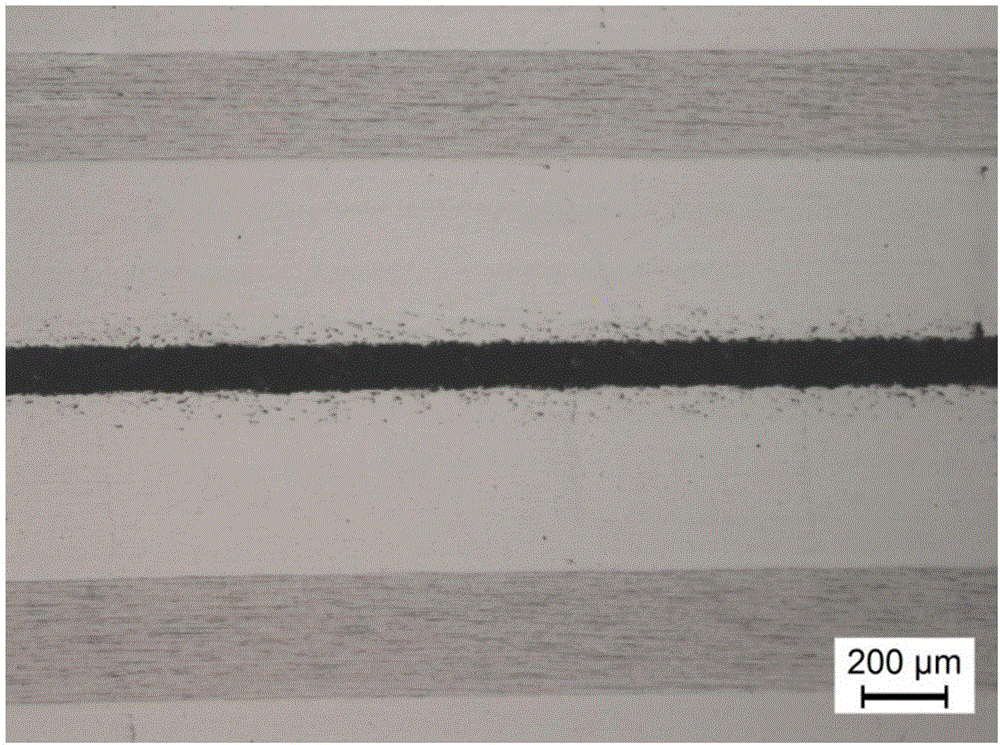

Sample preparation method for electron back scattering diffraction analysis of thin steel and iron material

InactiveCN103913364AQuality improvementImprove observation effectMaterial analysis using wave/particle radiationPreparing sample for investigationParaffin oilsSand-paper

The invention discloses a sample preparation method for electron back scattering diffraction analysis of a thin steel and iron material. The sample preparation method comprises the following steps: (1) taking a small plate surface of the thin steel and iron material as a sample, grinding one surface of the sample to be flat by using sand paper, and taking the flatly ground surface as a surface A; (2) selecting a cylindrical body as a sample table, uniformly melting a proper amount of paraffin on the sample table, and sticking the sample onto the molten paraffin until the paraffin is solidified and the sample is fixed to the sample table; (3) grinding and polishing the surface A of the sample fixed on the sample table; corroding the polished sample in natal for 3-15 seconds; and (4) observing and analyzing the sample processed through the steps (1) to (3) in electron back scattering diffraction equipment. The method is used for preparing a high-quality EBSD analysis sample without residual stress; the observation effect and quality are relatively high, so that the method is very suitable for preparing the EBSD analysis sample of the thin steel and iron material with the thickness not exceeding 0.5mm.

Owner:武钢集团有限公司

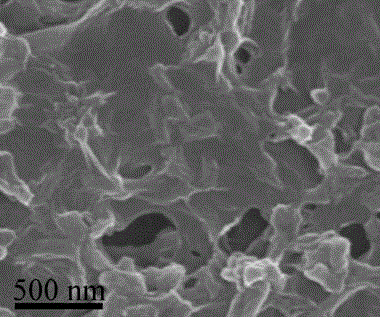

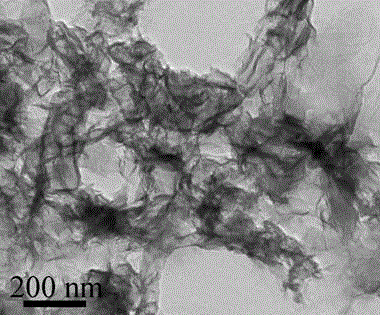

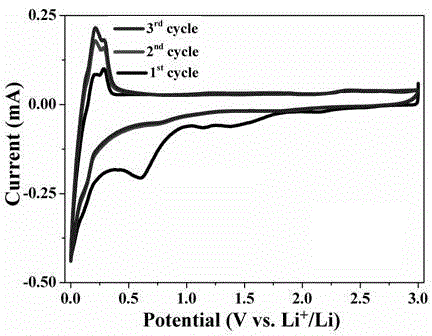

Preparation method of graphene coated silica nanotube composite negative electrode material for lithium ion battery

InactiveCN104157840APromote commercial applicationScalable productionCell electrodesSecondary cellsSilicic acidSilicon oxide

A preparation method of graphene coated silica nanotube composite negative electrode material for lithium ion batteries is as follows: (1) dispersing zinc oxide nanorods to an ethanol solution, sequentially adding water, ammonia water and a TEOS solution to obtain zinc oxide / silica core-shell nanorods; (2) dispersing the products from the step (1) in to an aqueous solution of sodium chloride, and adding PDDA for modification; (3) dispersing the products from the step (2) and the graphene oxide into an aqueous solution, dropwise adding sodium borohydride to obtain graphene coated zinc oxide / silica core-shell nanorods; and (4) dispersing the products obtained from the step (3) in an excessive amount of acid solution to dissolve zinc oxide nanorods, so as to obtain the composite negative electrode material. According to the invention, zinc oxide nanorods are used as templates, and coated by silicon dioxide and graphene, and then the template is removed, so as to prepare the graphene coated silica nanotube composite material. The prepared composite material has the performances of high discharge capacity, long cycle life and high rate capability.

Owner:NANJING NORMAL UNIVERSITY

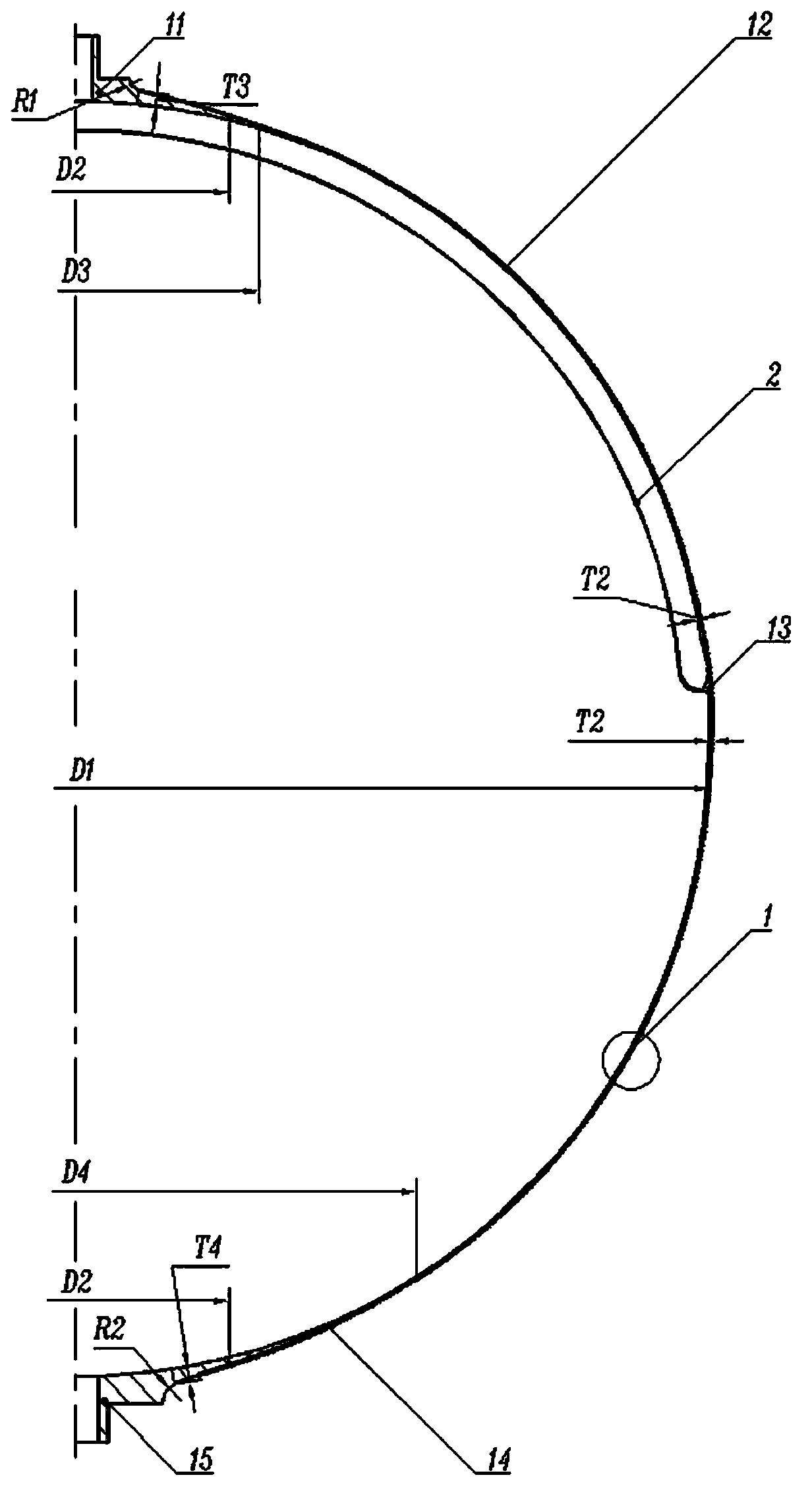

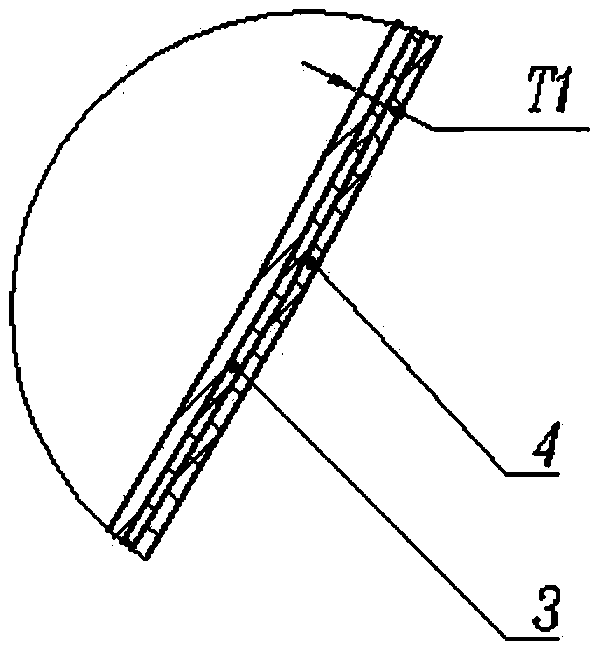

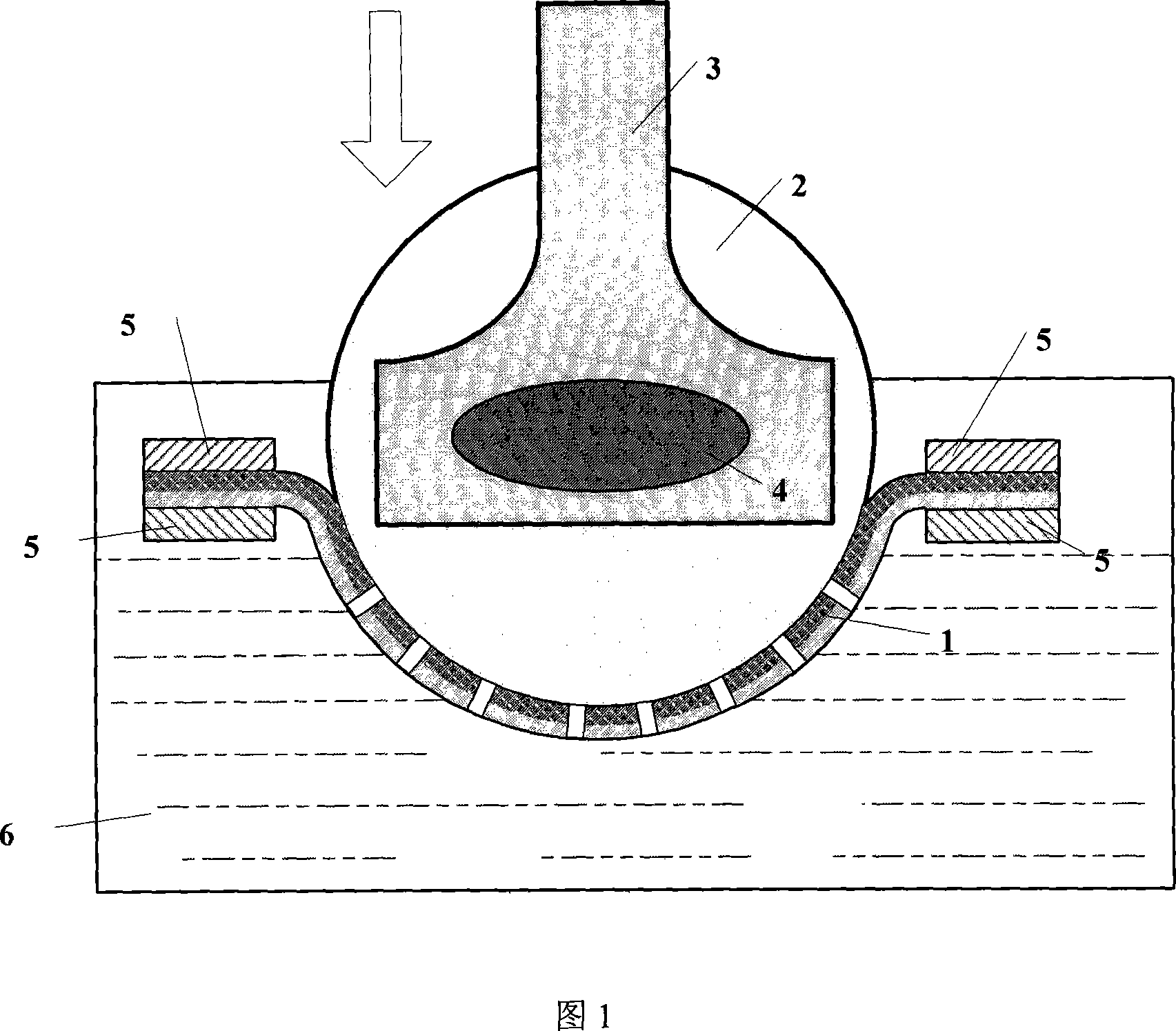

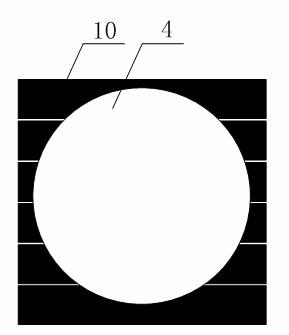

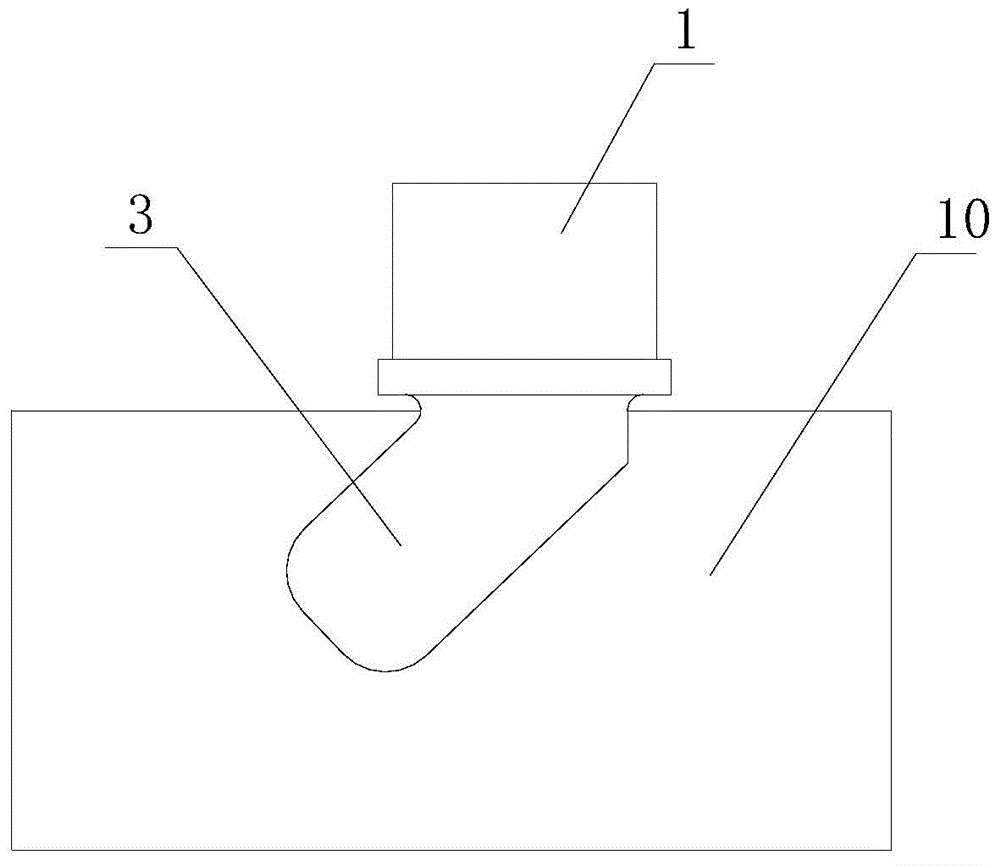

Metal diaphragm storage box made of carbon-fiber composite materials and manufacturing method thereof

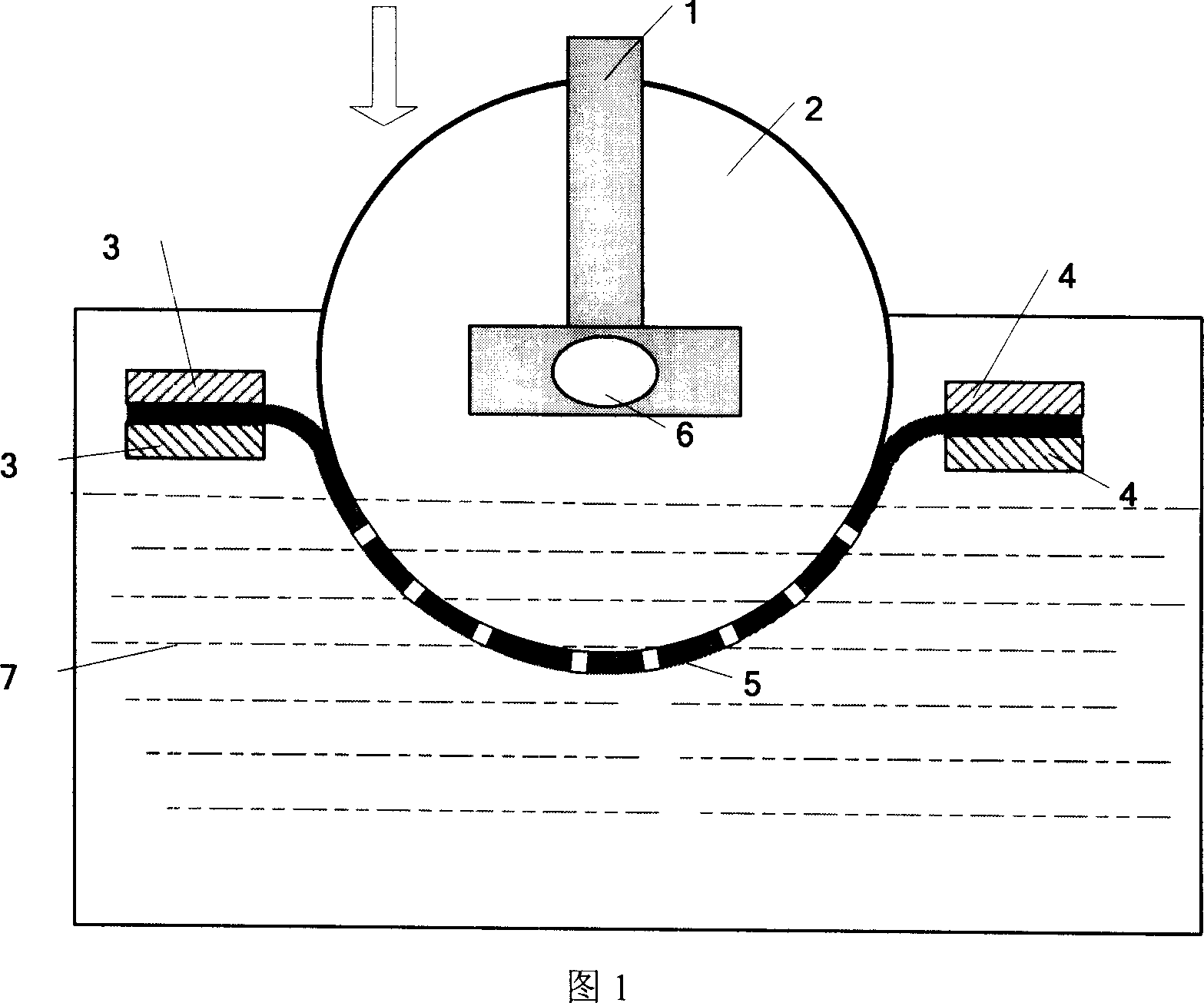

ActiveCN103437913ASimple structureGood manufacturing processRocket engine plantsCarbon fiber compositeFlange

The invention provides a metal diaphragm storage box made of carbon-fiber composite materials and a manufacturing method thereof. The metal diaphragm storage box comprises a liner 1 and a metal diaphragm 2 and also comprises an insulating layer 3 and a carbon-fiber composite material layer 4, wherein the liner 1 comprises an upper flange 11, an upper hemisphere 12, a connecting ring 13, a lower hemisphere 14 and a lower flange 15; the upper hemisphere 12 and the lower hemisphere 14 are connected by the connecting ring 13; the upper flange 11 is connected with the upper hemisphere 12; the lower flange 15 is connected with the lower hemisphere 14; the metal diaphragm 2 is butted with the connecting ring 13; the outer surface of the liner 1 is coated with the insulating layer 3; the outer surface of the insulating layer 3 is wound with the carbon-fiber composite material layer 4, and is connected with the carbon-fiber composite material layer 4 in a bonding manner. The metal diaphragm storage box provided by the invention has the advantages that the problems of large weight and low structure efficiency of the metal diaphragm storage box are solved, the light-weight design of the metal diaphragm storage box is realized, the cost is reduced and the performance of a product is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

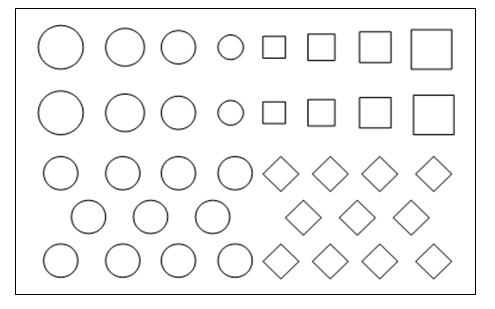

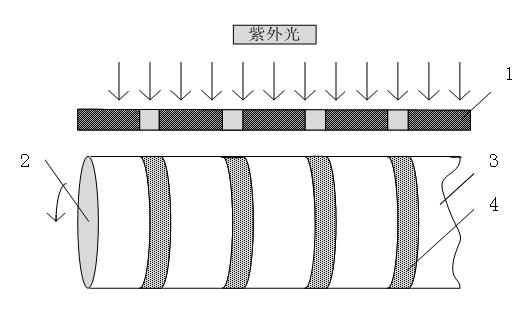

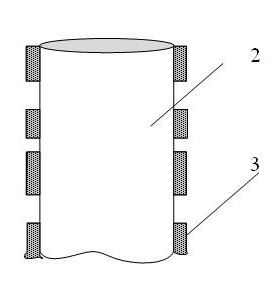

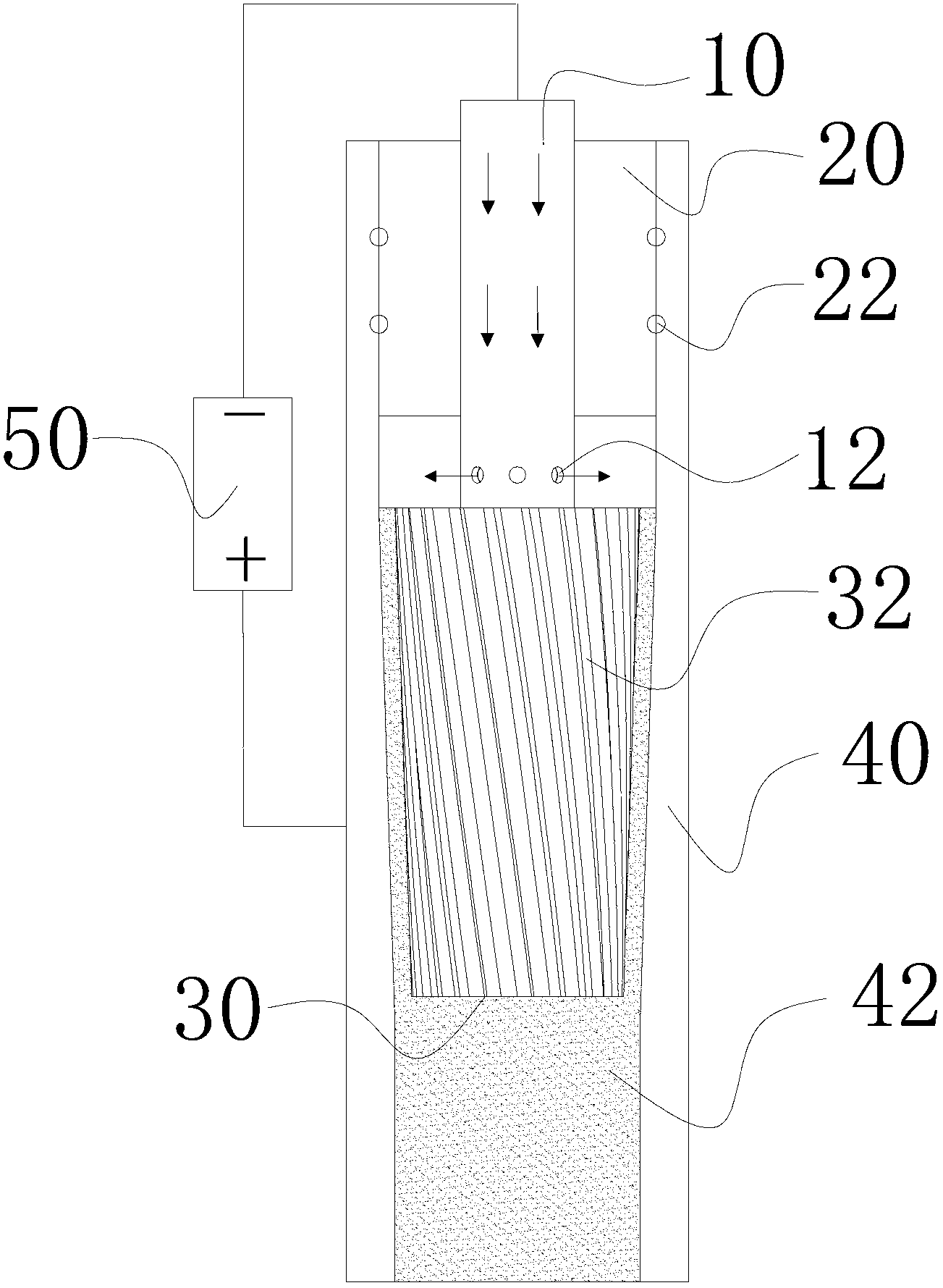

Processing method of cylindrical component with mask micro-structure on outer curved surface

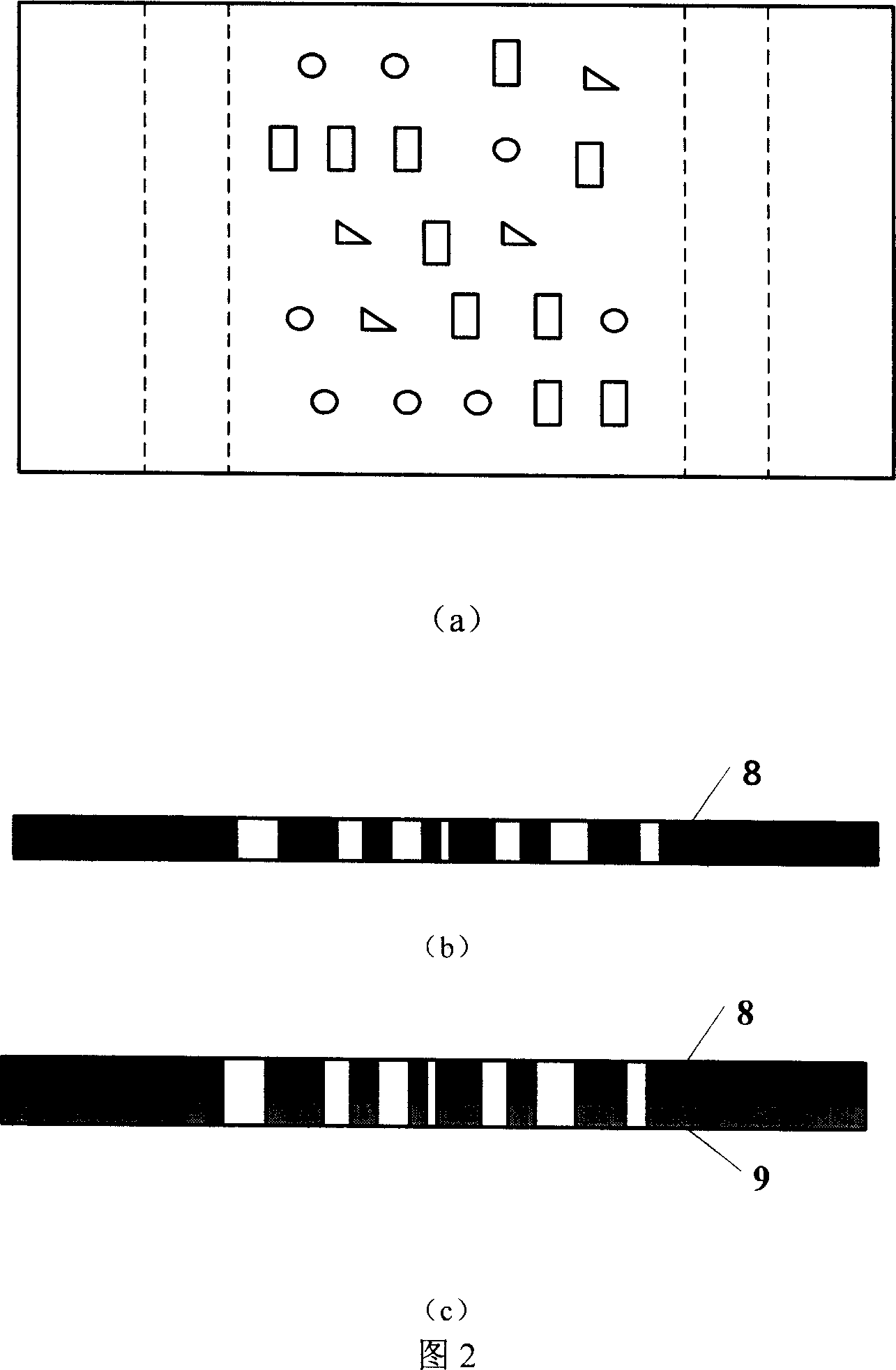

InactiveCN101791726ASolving Manufacturing ChallengesHigh coaxiality requirementsMachining electrodesMachining working mediaProcessing accuracyMicrostructure

The invention discloses a processing method of a cylindrical component with a mask micro-structure on the outer curved surface, which belongs to the field of electrochemical machining. The method comprises the following steps: imaging the surface of a curved-surface part through dipping, glue coating and rolling lithography or processing a planar flexible insulation shielding thin film with laser and fixing the thin film on the surface of the curved-surface part, and carrying out micro electrolytic machining with a cylindrical part as the anode and a sleeve as a cathode, thereby forming a micro structure on the curved surface. The method solves the manufacturing problem of the curved-surface part with the outer surface of a complex fine microstructure, and can be used for processing large-area curved-surface microstructures, in particular microstructures with complex patterns and small sizes. The curved-surface microstructures processed by the invention have the advantages of large processing area and high processing accuracy. The invention has the advantages of capability of processing microstructures with complex patterns and small sizes, simple operation, high efficiency and low processing cost.

Owner:XI AN JIAOTONG UNIV

One-way continuous fiber-reinforced resin-based composite prepreg and preparation method thereof

The invention discloses one-way continuous fiber-reinforced resin-based composite prepreg and a preparation method thereof and belongs to the technical field of resin-based composites. Particularly, a solvent is used for preparing a saturated solution containing soluble resin or one or more of active monomers of the soluble resin, a curing agent, a catalyst and a prepolymer, powder of another resin or filler is added, and a suspension with part of soluble components evenly formed on the surface of the powder is formed through a phase inversion method for dipping; fiber bundles are arranged after being dipped, rolling is carried out after the solvent is evaporated to dryness, and the prepreg is obtained. The prepreg has good laying performance and can be formed at low pressure, and low porosity is obtained. A first component is soluble resin or one or more of the active monomers of the soluble resin, the curing agent, the catalyst and the prepolymer. A second component is resin matrix powder or reinforcing and toughening filler powder.

Owner:JILIN PROVINCE HUAYU AUTO PARTS

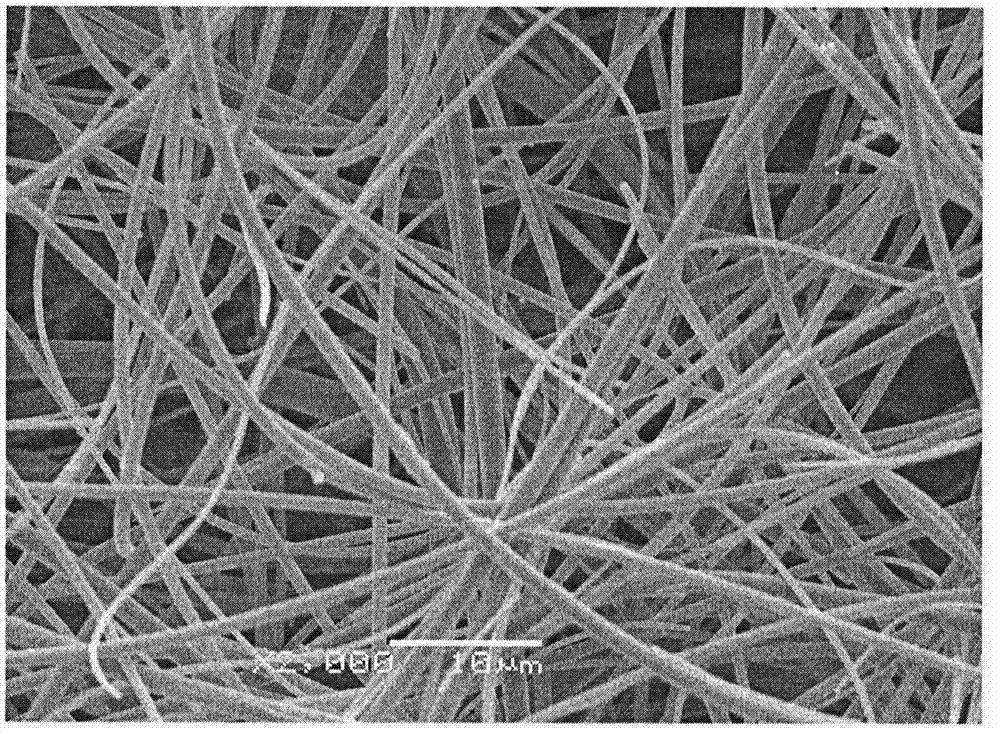

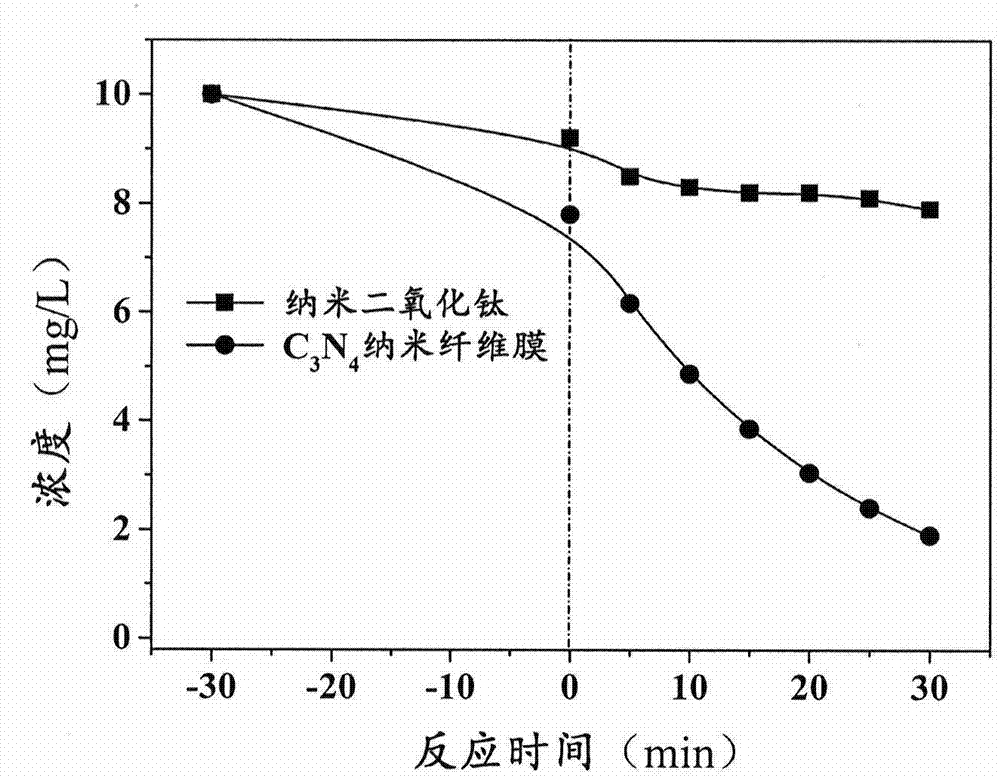

Carbon nitride photocatalytic activity nano fiber membrane and preparation method thereof

ActiveCN104772160ASolving Manufacturing ChallengesEasy to preparePhysical/chemical process catalystsWater/sewage treatment by irradiationDichloromethaneHigh pressure

The invention belongs to the technical field of photocatalytic water treatment, and particularly relates to a carbon nitride photocatalytic activity nano fiber membrane and a preparation method thereof. According to the carbon nitride photocatalytic activity nano fiber membrane, polypiperazine-amide acts as a spinning precursor, and a dichloromethane spinning solvent acts as a raw material, and a nano fiber membrane is prepared by electrostatic spinning in the high-voltage electrostatic field effect under oxygen insulation condition, and the nano fiber membrane is further subjected to in-situ high-temperature polycondensation. The nano fiber membrane has the advantages of small fiber diameter, high specific surface area, obvious quantum effect and the like, can obtain a relatively good degradation effect when being applied to pentachlorophenol visible light catalysis treatment, and still keeps the complete morphology and relatively high catalysis activity after being recycled for 10 times. The invention provides a novel utilizing mode of carbon nitride photocatalyst, which has a relatively good application prospect in the field of water pollution control.

Owner:BEIJING NORMAL UNIVERSITY

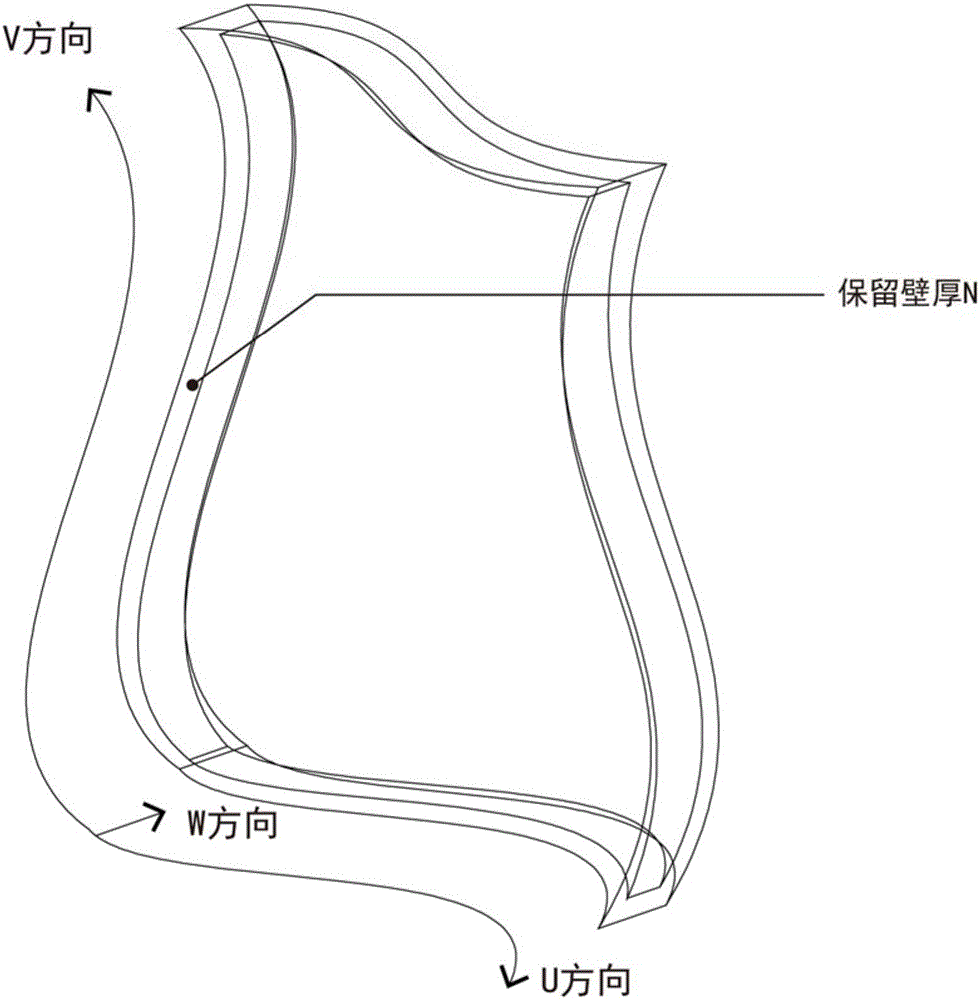

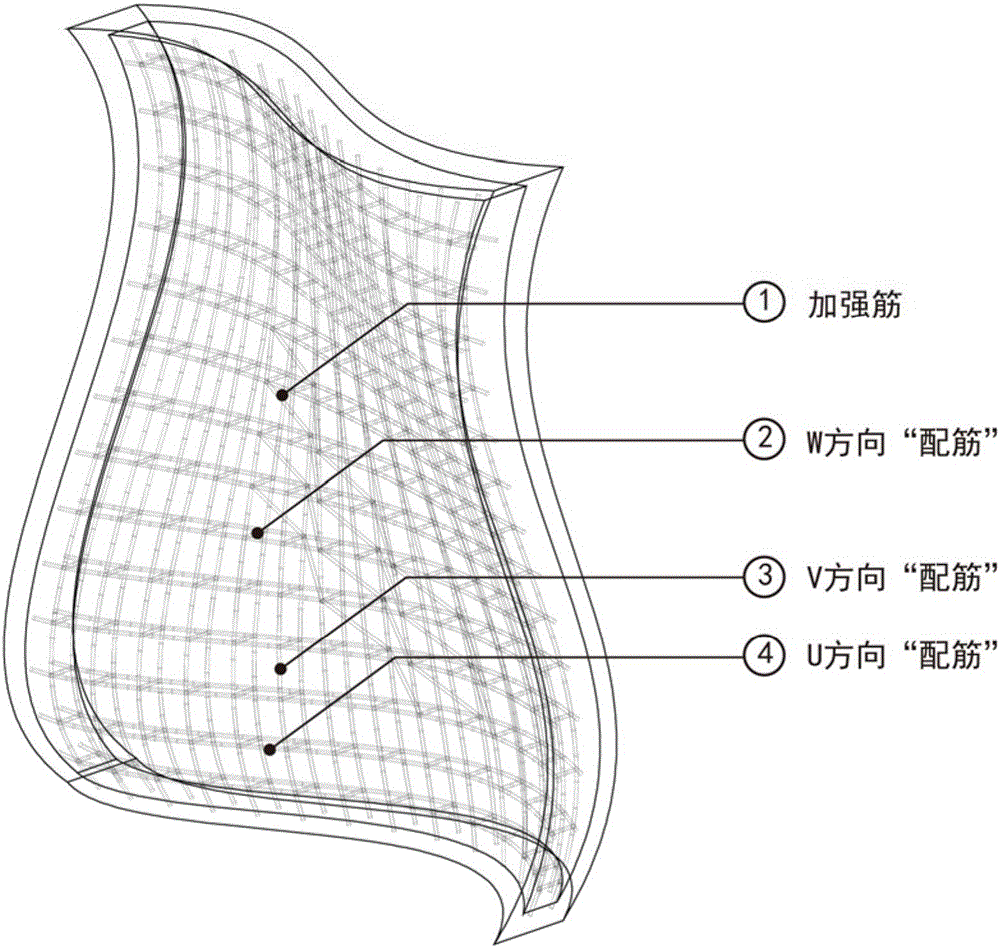

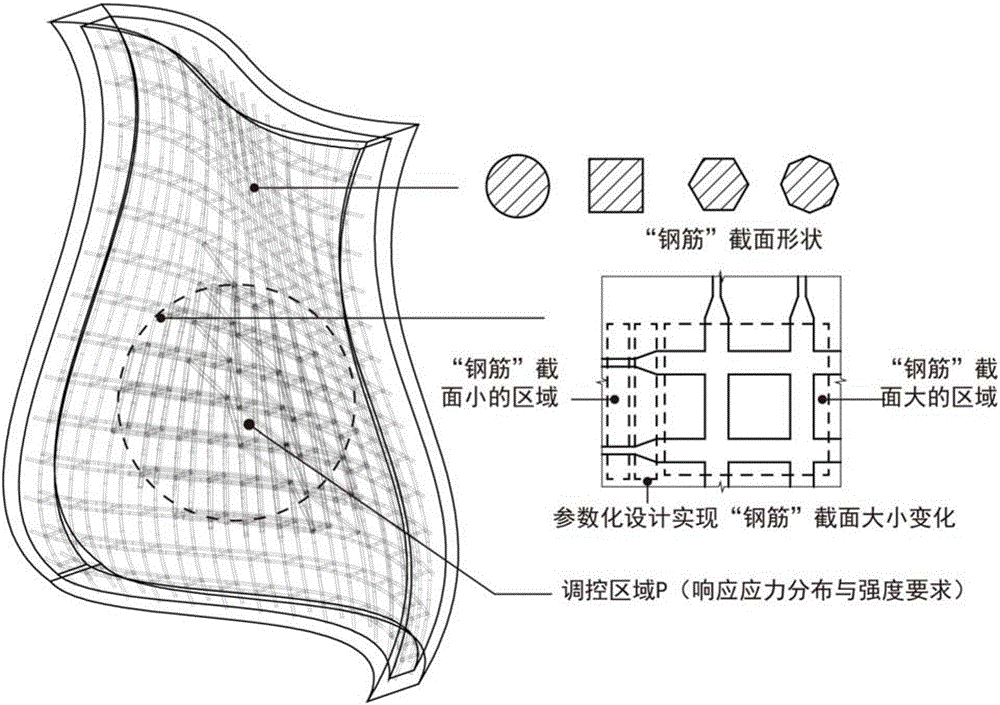

3d printing process and concrete combined building structure and construction method

The invention discloses a 3d (three-dimensional) printing process and concrete combined building structure and a construction method. The construction method comprises the following steps: 1) constructing a digital model of a shell and an internal structure of a building component; 2) performing 3d printing operation on the digital model; 3) pouring concrete to form an integrated structural component with the model which is printed in the step 2), and performing cooperative work; 4) after the building component in the step 3) is formed integrally, deciding whether to remove the shell of the 3d printing model according to engineering requirement, wherein the bare material of the concrete can be used as a model element. According to the 3d printing process and concrete combined building structure and the construction method, the problem that reinforcing steel bars are difficult to manufacture in special-shaped curved surface reinforced concrete construction can be effectively solved; force is transferred explicitly; construction components are reduced; construction processes are simplified; construction cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

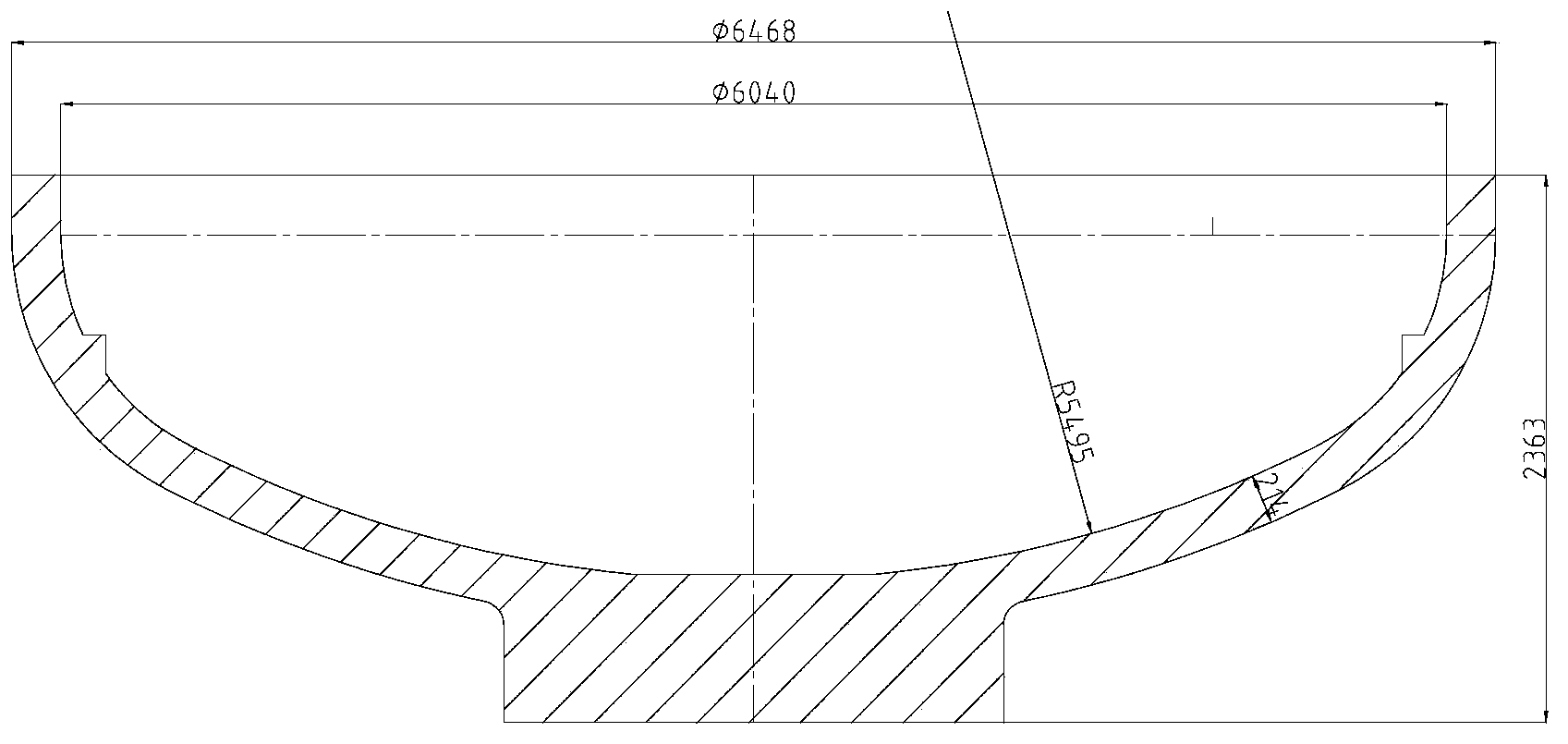

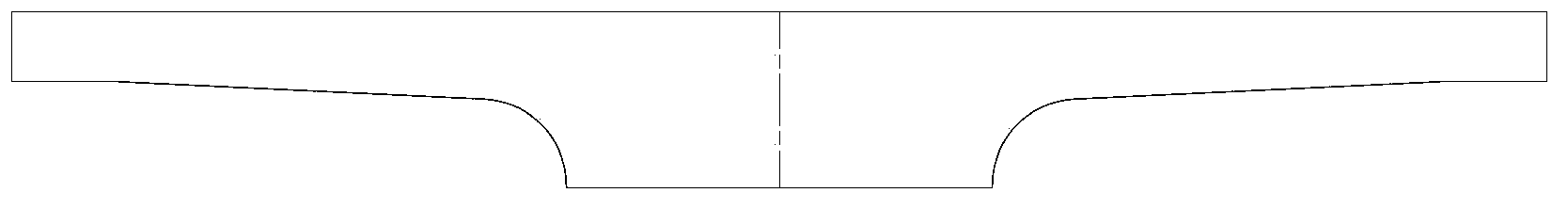

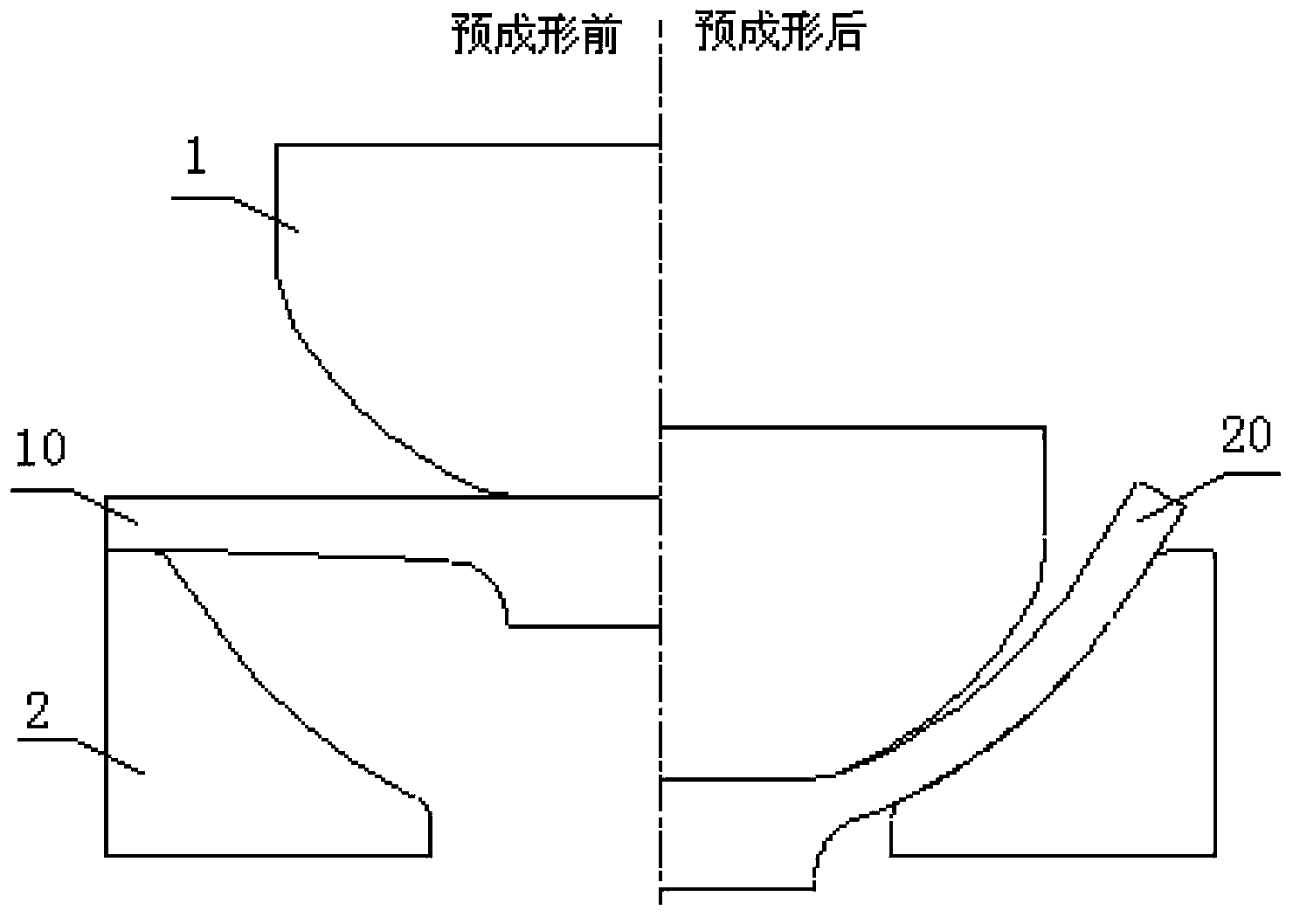

Forging method for elliptical seal head of CAP1400 steam generator

ActiveCN103567339ASolving Manufacturing ChallengesBloomMetal-working apparatusEngineeringMechanical engineering

The invention discloses a forging method for an elliptical seal head of a CAP1400 steam generator. The forging method comprises the steps of 1) manufacturing a blank; 2) heating; 3) assembling a die; 4) preforming; 5) stamping. By adopting the forging method, when the elliptical seal head with ultra-large size cannot be directly forged, firstly a circular plate blank with smaller diameter is preformed through a forging method of rotary drawing to increase the arc length of a workpiece and form an enough large circular-arc-shaped blank, and then the blank is stamped as a whole body to meet the requirement on the final size of the ultra-large size elliptical seal head. Therefore, the forging method for the elliptical seal head of the CAP1400 steam generator can effectively solve the problem that the large-sized and integrated forged piece of the elliptical seal head of the CAP1400 steam generator is difficult to manufacture.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

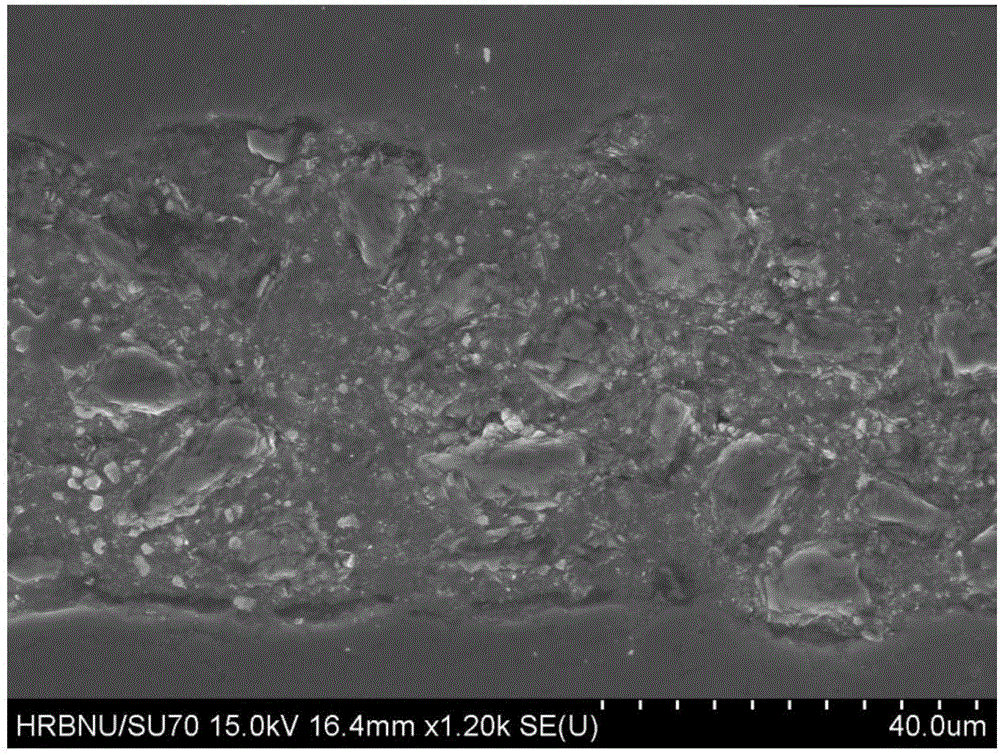

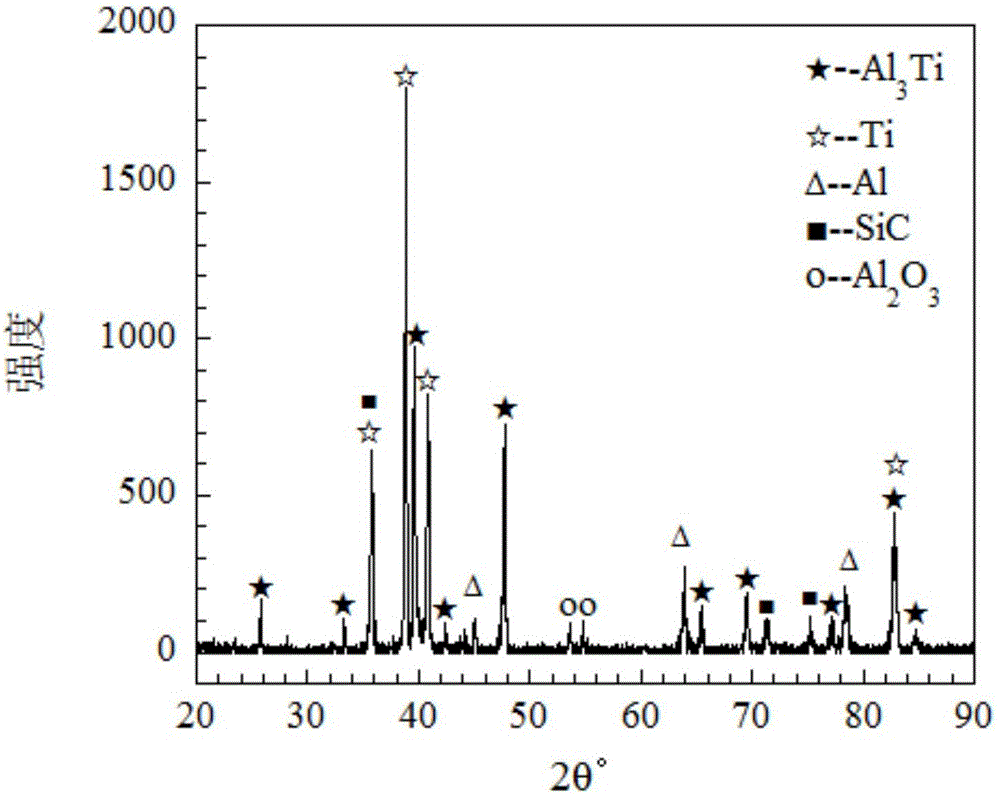

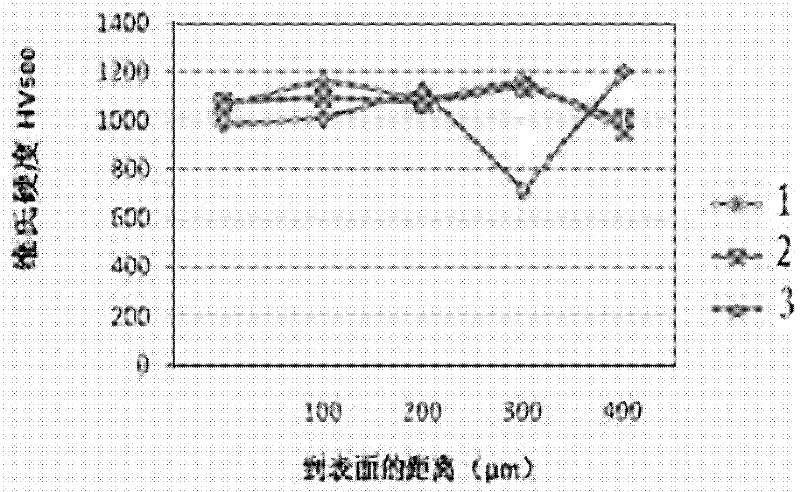

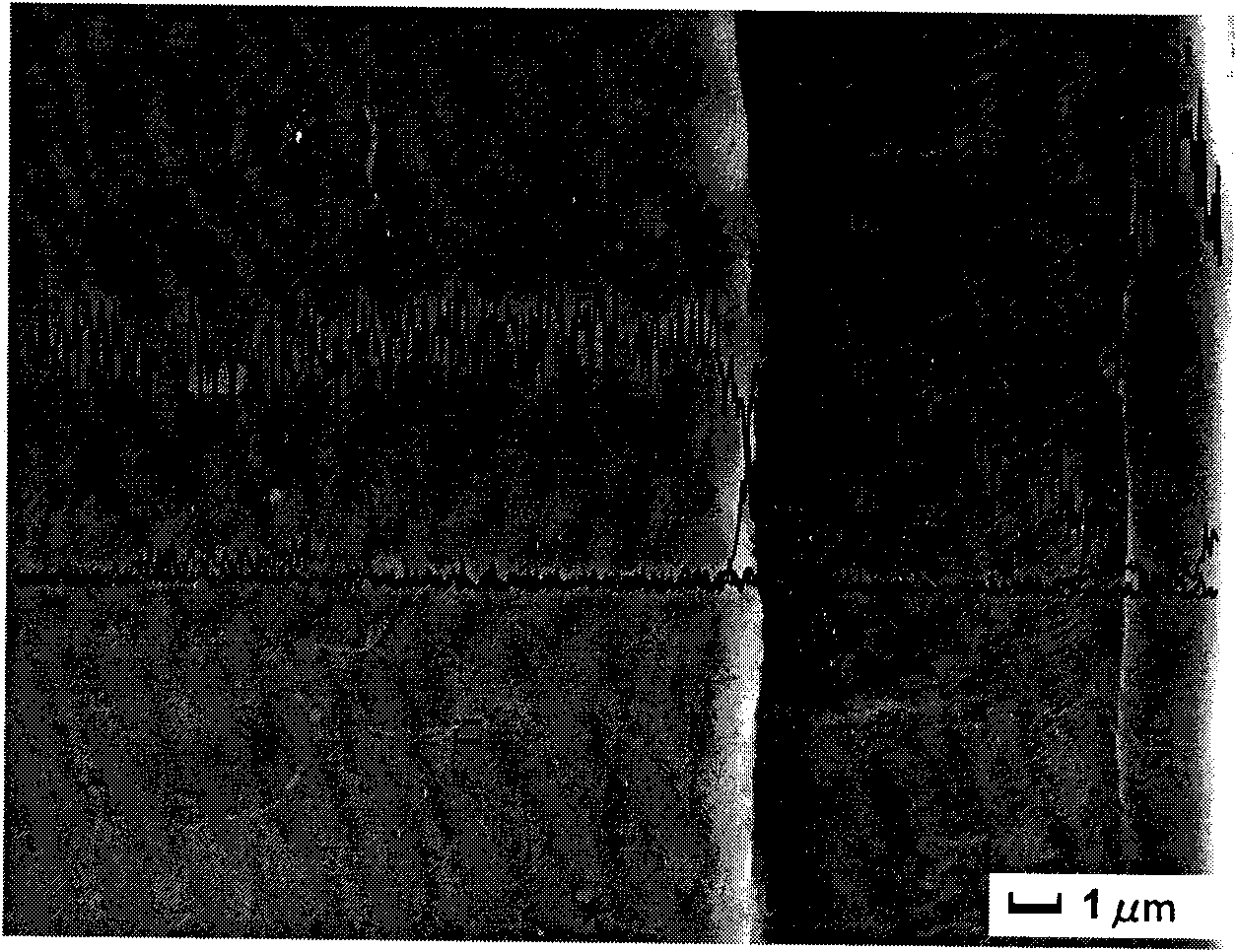

Preparation method of SiC particle enhanced intermetallic compound based laminated composite material Ti/Al3Ti

The invention provides a preparation method of a SiC particle enhanced intermetallic compound based laminated composite material Ti / Al3Ti. The preparation method comprises the following steps: (1) ball-milling gAl powder, SiC powder and stearic acid in a ball mill until the gAl powder, the SiC powder and the stearic acid are mixed uniformly; (2) adding ball-milled powder in a grinding tool and preparing into SiC particle enhanced aluminum-based composite materials by using a powder metallurgy method; (3) hot-rolling the SiC particle enhanced aluminum-based composite materials into foil plates at the temperature between 450 DEG C and 500 DEG C and then jointly cutting the foil plates and TC4 foil materials into materials with the same sizes; and (4) alternately arraying the TC4 foil materials and the SiC particle enhanced aluminum-based composite materials alternately; and (5) placing the materials in a vacuum hot pressing furnace and carrying out hot pressed sintering, vacuumizing at first until the pressure reaches 3*10<-2> Pa, then heating to the temperature of 675-680 DEG C step by step, insulating for 4 hours, then slowly heating to the temperature of 750 DEG C and insulating for 3 hours. The prepared composite material is excellent in comprehensive mechanical property and low in cost.

Owner:HARBIN ENG UNIV

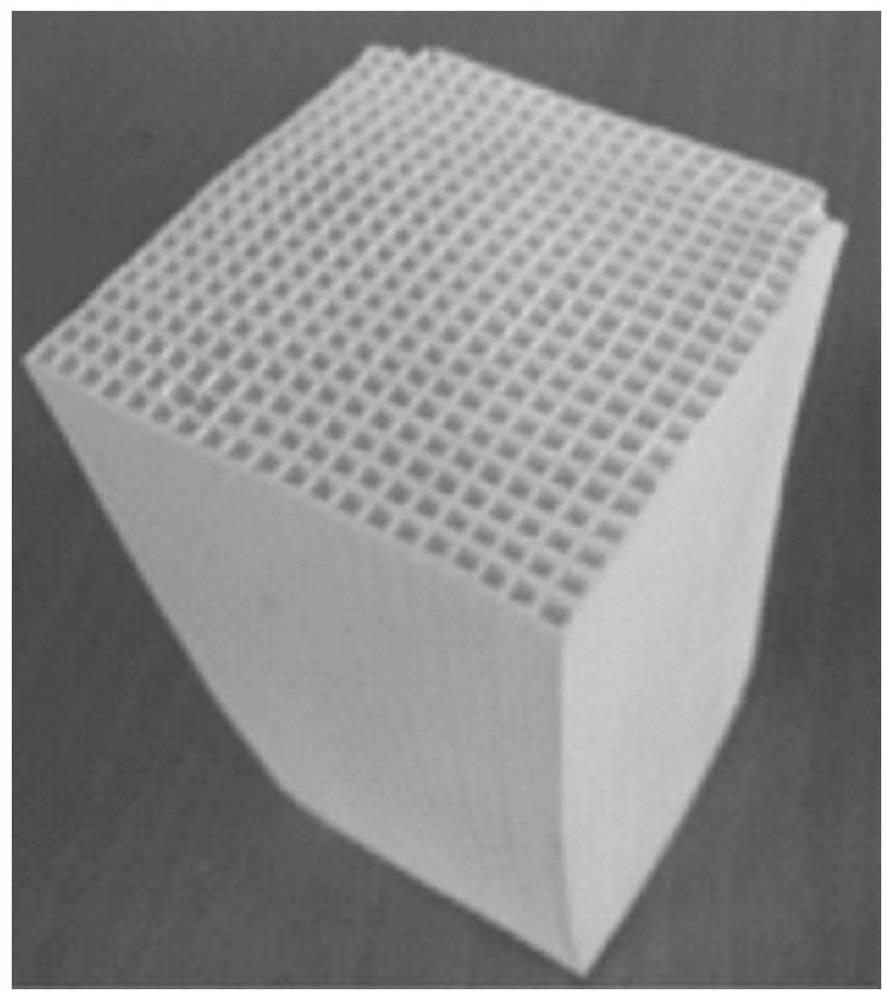

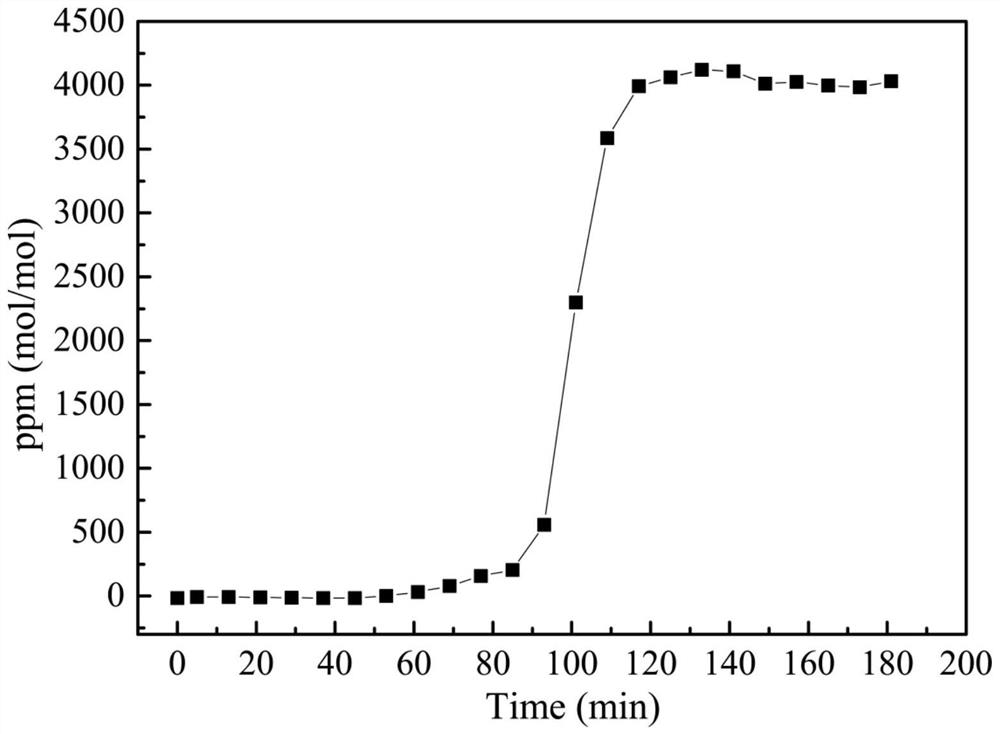

Integral honeycomb molecular sieve for purifying VOCs in zeolite adsorption runner and preparation

PendingCN112246217AGood removal effectImprove adsorption capacityGas treatmentOther chemical processesMolecular sievePlasticizer

The invention relates to an integral honeycomb molecular sieve for purifying VOCs in zeolite adsorption runner and preparation, the preparation method comprises the following steps: 1) powder pre-granulation: mixing a molecular sieve, an inorganic filler, an inorganic binder A and water to prepare slurry, and then carrying out granulation and high-temperature roasting to obtain particle powder; 2)mixing and pugging: uniformly mixing the particle powder, an inorganic reinforcing agent, an organic binder, a pore-forming agent, a plasticizer and a dispersing agent, adding a lubricant, an inorganic binder B and water, and kneading and pugging to obtain pug; and 3) extrusion molding and high-temperature roasting: carrying out vacuum extrusion molding on the pug, and then carrying out drying and high-temperature roasting. Compared with the prior art, the integral honeycomb molecular sieve with the pore density of more than or equal to 300 meshes and the wall thickness of less than or equalto 0.25 mm, which is suitable for purifying VOCs in a zeolite adsorption rotating wheel, is prepared, and when the integral honeycomb molecular sieve is applied to purification of low-concentration VOCs-containing waste gas, the filling volume is small, the adsorption rate and the desorption rate are high, and the thermal regeneration temperature is low.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

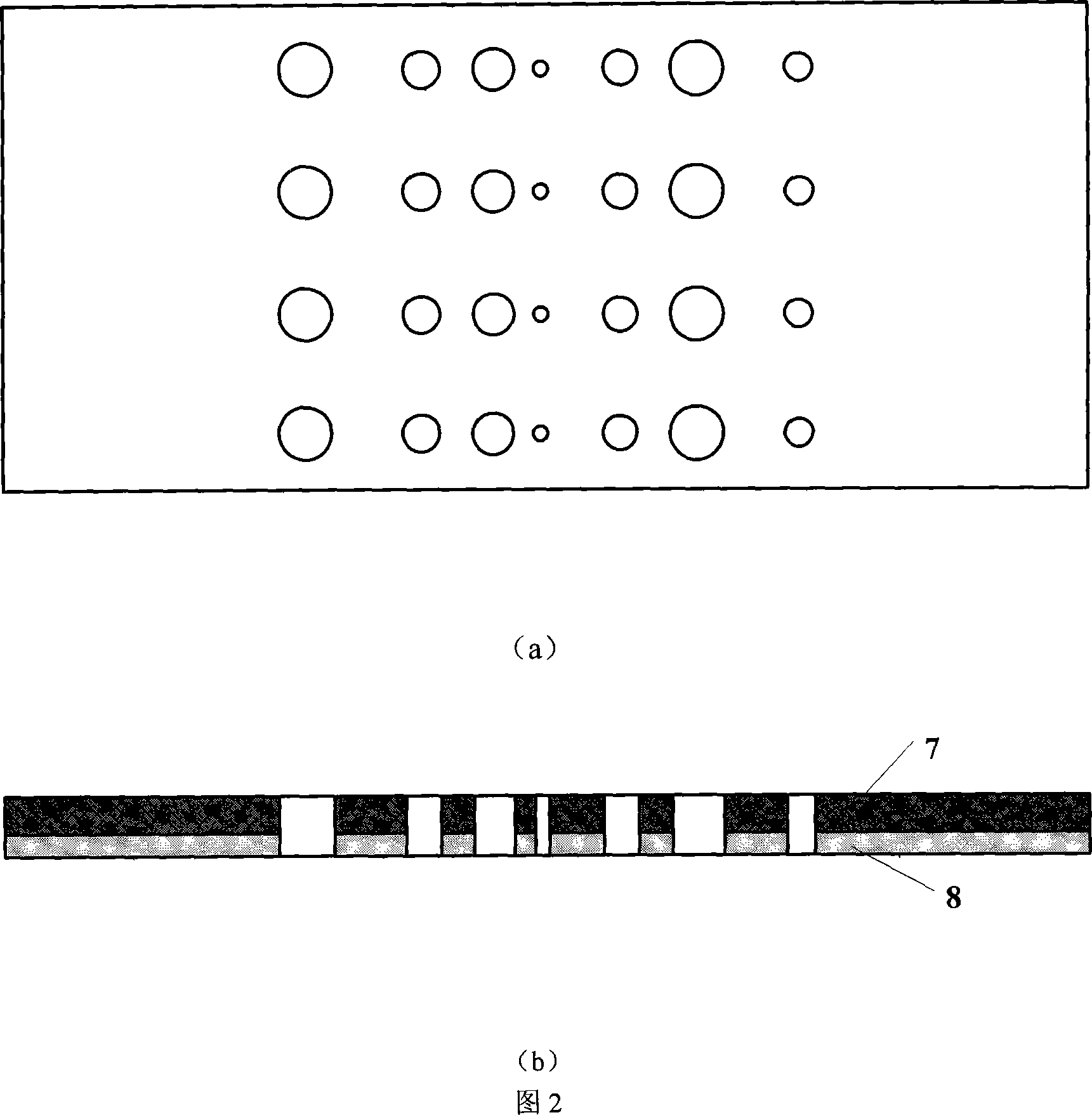

Column-shape revolving-body element external-surface micro-tissue electrolysic processing method

ActiveCN101070605AReduce processing costsImprove efficiencyElectrochemical machining apparatusElectrolysisMechanical engineering

The invention provides a method of electrochemical machining to minuteness texture of column aspect tumbling body part exteriority, which belongs to electrochemical machining domain. The characteristic of the method is that it adopts machinery extrusion method to closely fit column aspect tumbling body part and flexible screened film which has the structure of micro hiatus. Electrolyze with the part as anode, and minuteness texture will be formed in the exteriority of column aspect tumbling body part. Simultaneously if uses double layer flexible electrolytic screened film which contents insulating layer and metallic layer, its metallic layer can be directly utilized as the electrolysis cathode. If uses the electrochemical machining method of this invention, minuteness texture can be formed in the exteriority of column aspect tumbling body part. It has the characteristics of manufacture precision high, the speed quick and the cost low and so on.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

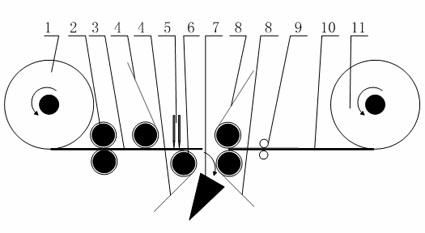

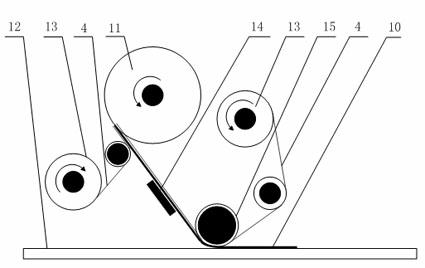

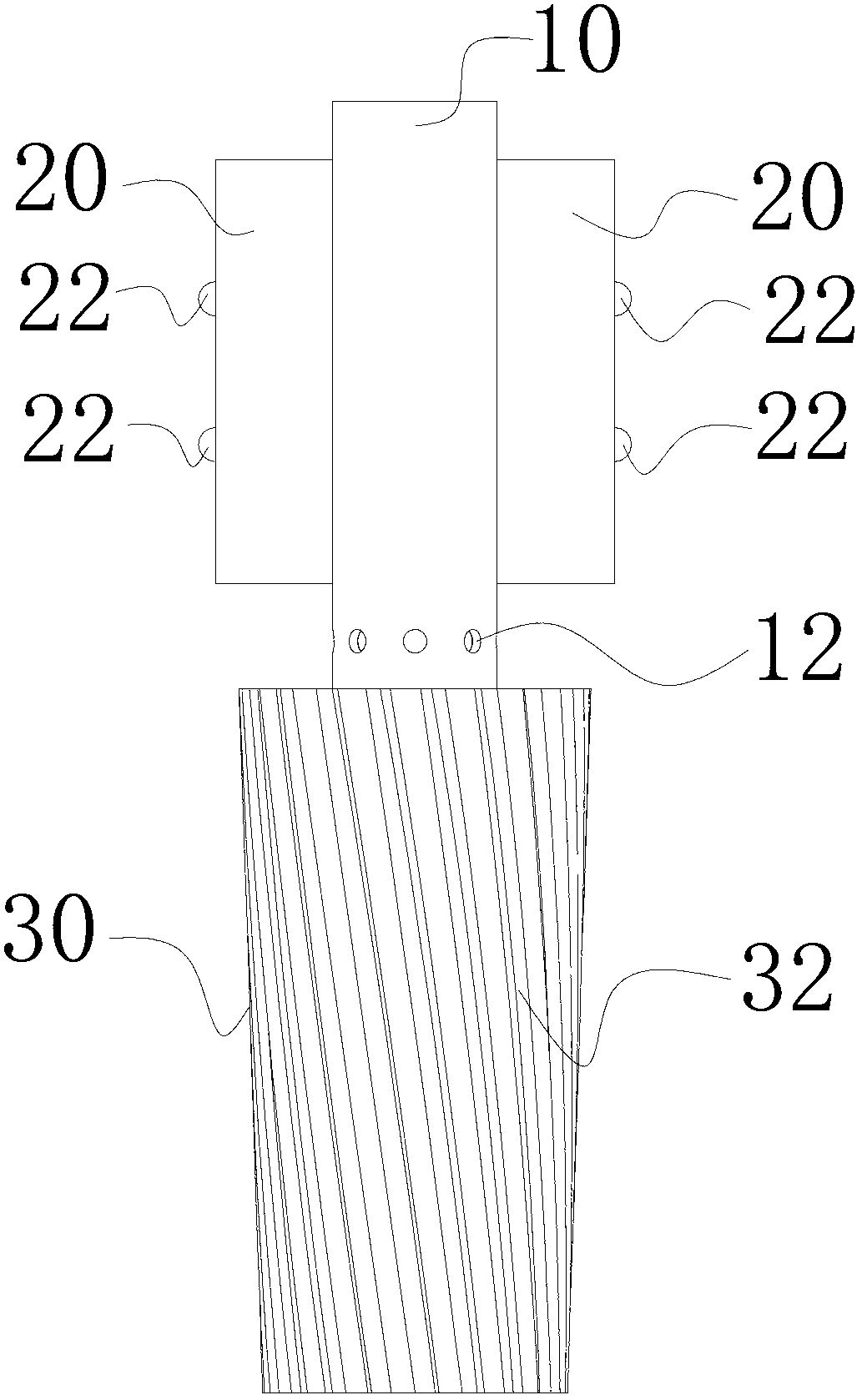

Automatic tape-laying forming method for composite material with hollowed-out structure

The invention relates to an automatic tape-laying forming method for a composite material with a hollowed-out structure, belonging to the field of laying and forming of composite materials. The invention is characterized by comprising the following processes: (1) designing the shape of a prepreg tape according to the shape and dimension of a product, the bandwidth of the prepreg tape and the direction of tape laying so as to further obtain a predetermined fold line path of a cutting knife; (2) precutting the prepreg tape, rolling up strip coils, wherein, the method of double layer back lining paper rolling or single layer back lining paper rolling can be employed to roll up the strip coils, and when one part of predetermined linear path of the predetermined fold line path is related to low-angle cutting, carrying out cutting by using the method of notching fold line cutting; (3) laying the cut prepreg tape on the surface of a die with the head of a laying tape so as to complete automatic tape-laying forming of the composite material with a hollowed-out structure. The invention enables basic functions of a tape-laying machine to be realized and fabrication difficulty of composite materials with a hollowed-out structure to be overcome.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

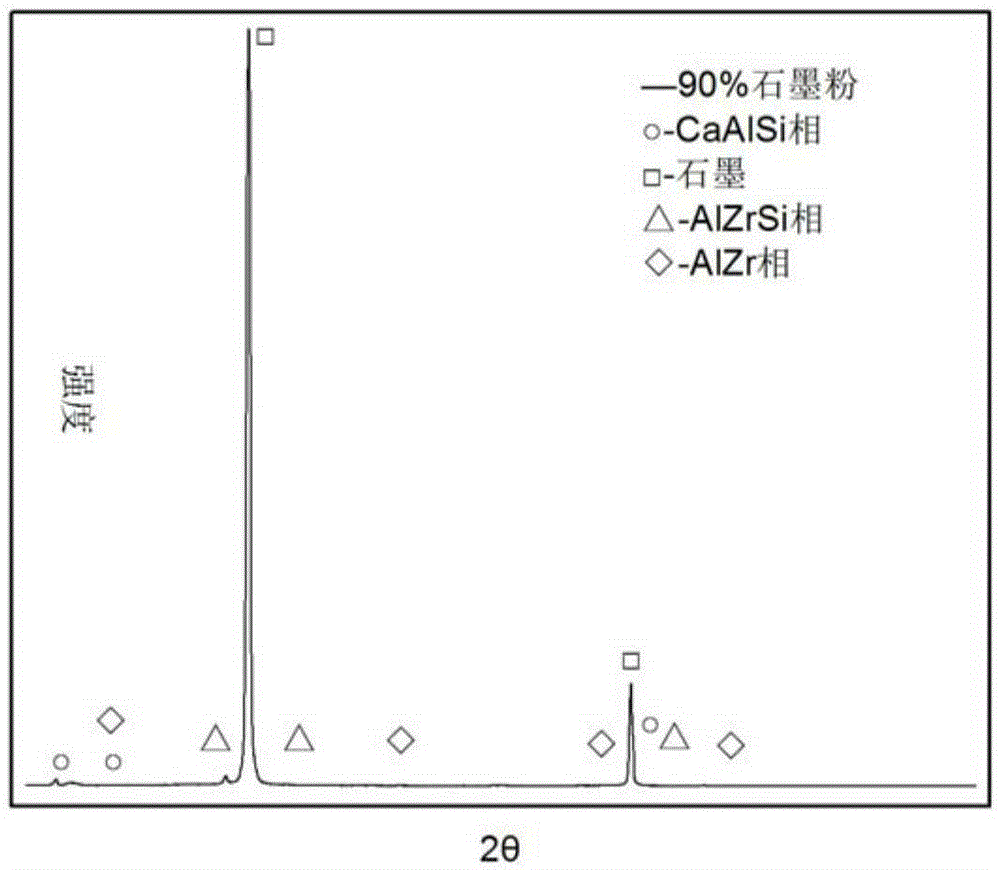

Powder material of high temperature erosion resistant cladding layer and preparation method of cladding layer

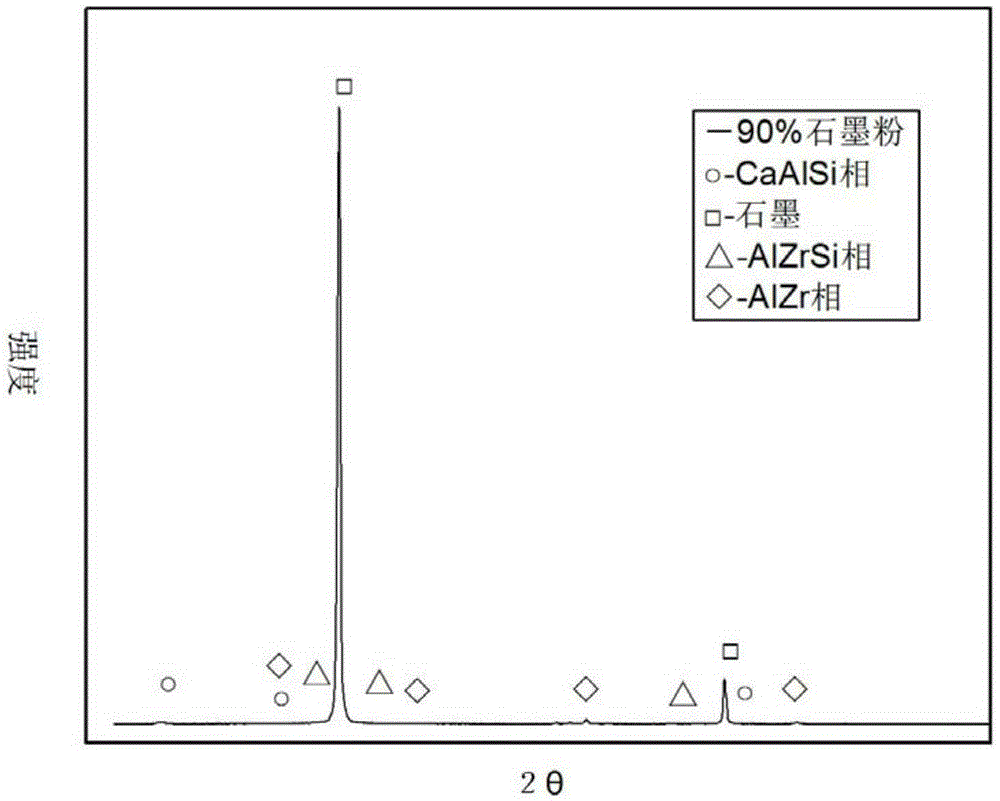

InactiveCN102268671AImprove bindingLow dilution rateMetallic material coating processesSurface engineeringGraphite

The invention relates to a powder material of a cladding layer with high temperature resistance and erosion resistance and a preparation method of the cladding layer, belonging to the technical field of surface engineering. The powder in the powder material comprises the following components by weight percent: 24-32% of pure titanium powder, 4.8-8% of graphite powder, 24-30% of chromium powder, 5-10% of molybdenum powder, 3-5% of titanium diboride powder, 1-3% of niobium carbide powder and the balance of nickel powder, wherein the weight ratio of pure titanium powder to graphite powder is 3.8-4. The preparation method of the cladding layer comprises the following steps: preparing mixed powder for cladding and preparing the cladding layer. The powder material has the advantages that the preparation cost is lower, the cladding layer has long life, the technology is easier and the powder material can be used to solve the preparation problem of the composite steel plate with high temperature erosion and corrosion resistance for the rocket launcher.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

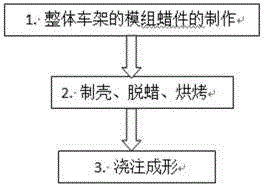

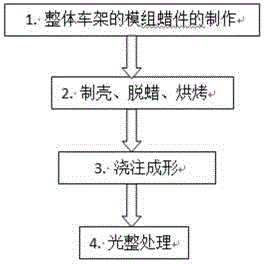

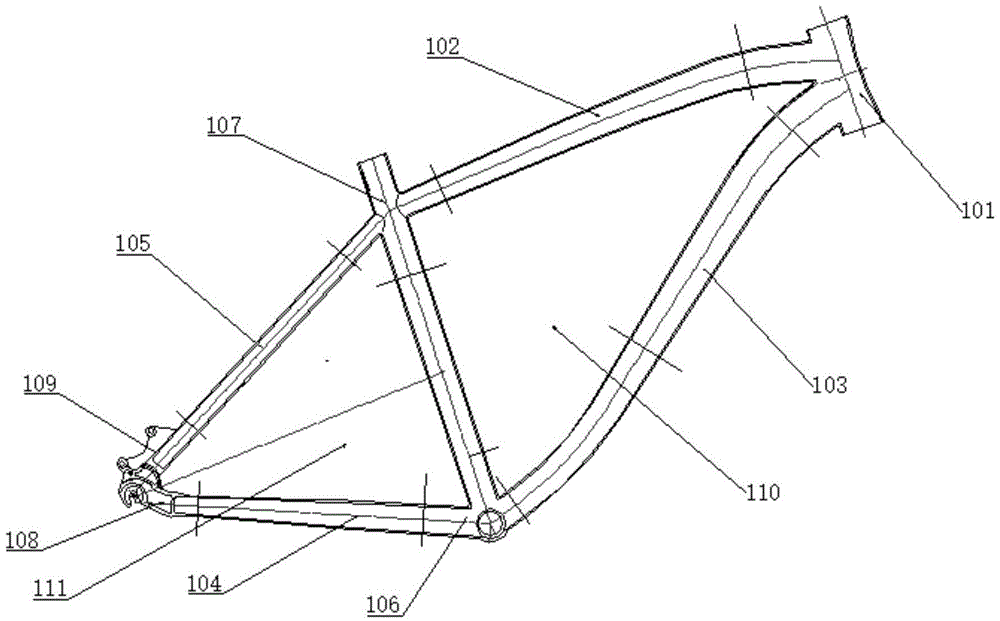

Making method of integrally formed bicycle frame

InactiveCN104815955AEasy to manufactureSolving Manufacturing ChallengesFoundry mouldsFoundry coresWaxChemical composition

The invention provides a making method of an integrally formed bicycle frame. The method comprises the following steps: making a frame wax member and a process wax member, welding the frame wax member and the process wax member to form an integral module wax member, making a shell, dewaxing, baking, carrying out casting formation, and carrying out cleaning and polishing to obtain the integrally formed bicycle frame. The frame is divided into a plurality of assemblies, so the making process of the frame wax member is simplified, and the method can be widely used in integral formation of various bicycle frames without restriction by the structure, the dimension, the weight and the chemical components of the frame; no welded joints exist among all parts of the whole frame, so the whole frame has beautiful and simple profile, and the fatigue rupture resistance is improved; and the integral forming method is adopted, so the production efficiency is effectively improved.

Owner:TIANJIN JINLUN TIANDA NUMERICAL CONTROL MACHINE TOOL

Preparation method of high-strength high-conductivity copper-silver multi-core composite wire

ActiveCN103606422AMeet practical application needsSolving Manufacturing ChallengesCable/conductor manufactureSolution treatmentHigh intensity

The invention provides a preparation method of a high-strength high-conductivity copper-silver multi-core composite wire. The preparation method comprises the following steps: A, loading a Cu-24Ag alloy rod into a first copper tube, and carrying out solder sealing on two ends of the first copper tube; B, carrying out the solution treatment; C, squeezing; D, carrying out multi-pass drawing, and carrying out the aging treatment in the drawing process, thereby obtaining a copper-silver single-core composite wire; E, sequentially carrying out the sizing cutting, straightening and acid pickling treatment, loading 559 wire bundles into a second copper tube, and carrying out solder sealing on two ends of the second copper tube; F, squeezing; G, carrying out the multi-pass drawing, and carrying out the aging treatment and recrystallization treatment in the drawing process, thereby obtaining the IACS high-strength high-conductivity copper-silver multi-core composite wire with the tensile strength of more than or equal to 920MPa and the conductivity of more than or equal to 70 percent. The prepared copper-silver multi-core composite wire has high strength and high conductivity and can meet the real application requirement in the fields of pulse magnets, contact wires and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

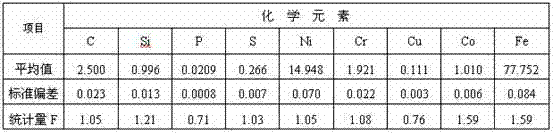

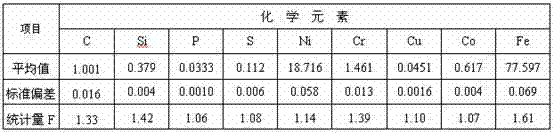

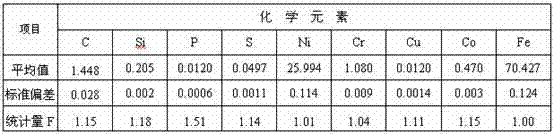

Nickel-iron spectrum standard sample and preparation method thereof

ActiveCN102776451AGood molding effectImprove the rate of successPreparing sample for investigationChemical elementCopper

The invention discloses a nickel-iron spectrum standard sample and a preparation method thereof. The nickel-iron spectrum standard sample is characterized by comprising the following chemical elements by weight: 14.9-50.0% of Ni, 0.03-2.50% of C, 0.2-4.5% of Si, 0.004-0.040% of P, 0.002-0.300% of S, 0.4-2.0% of Co, 0.01-0.25% of Cu, 0.1-2.0% of Cr and 40-80% of Fe. The method utilizes processes including intermediate-frequency furnace smelting, rain drench type pouring, water cooling copper mould casting, tundish bottom pouring and the like, so that uniform component tissue of the spectrum standard sample is ensured.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

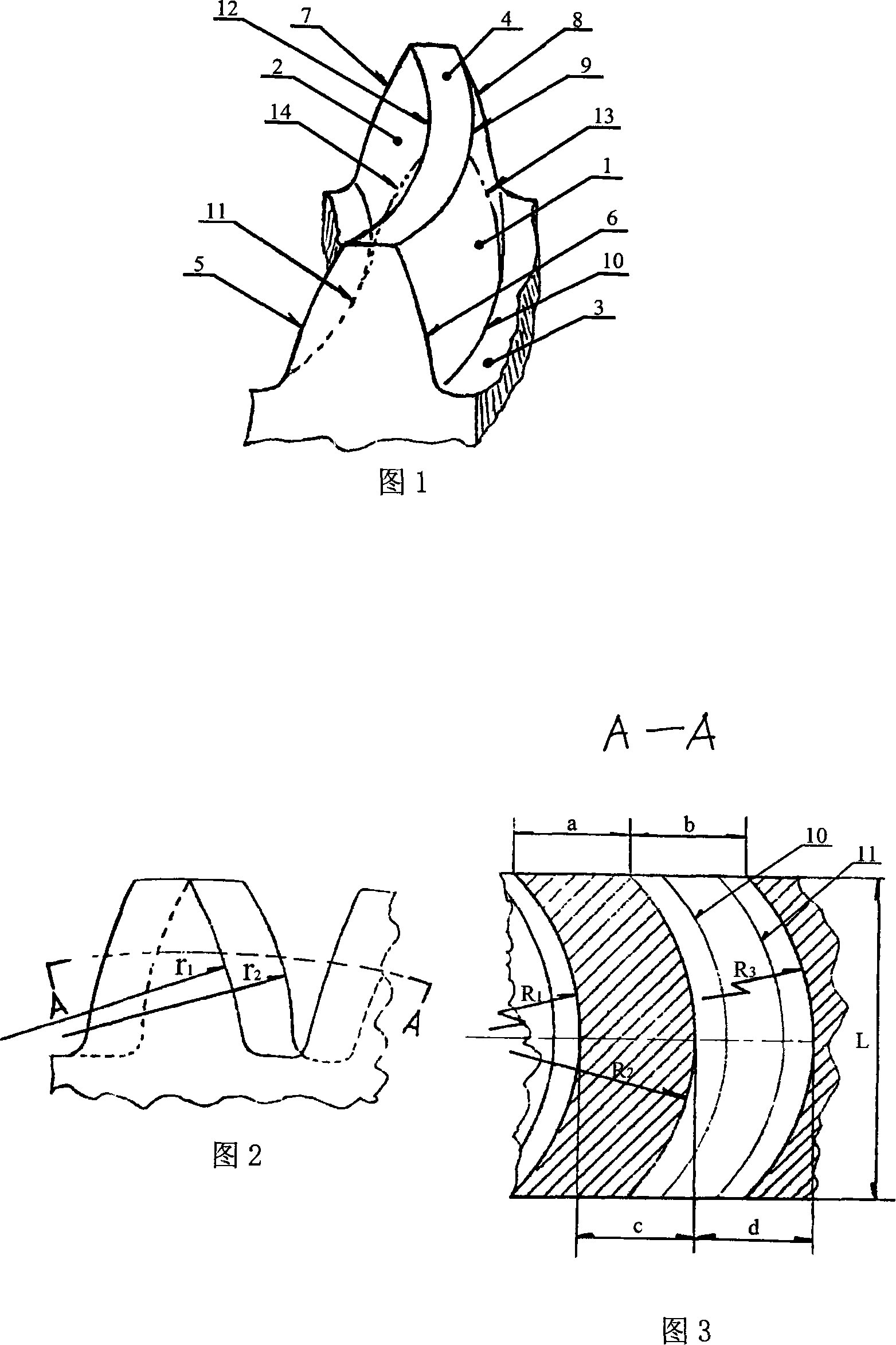

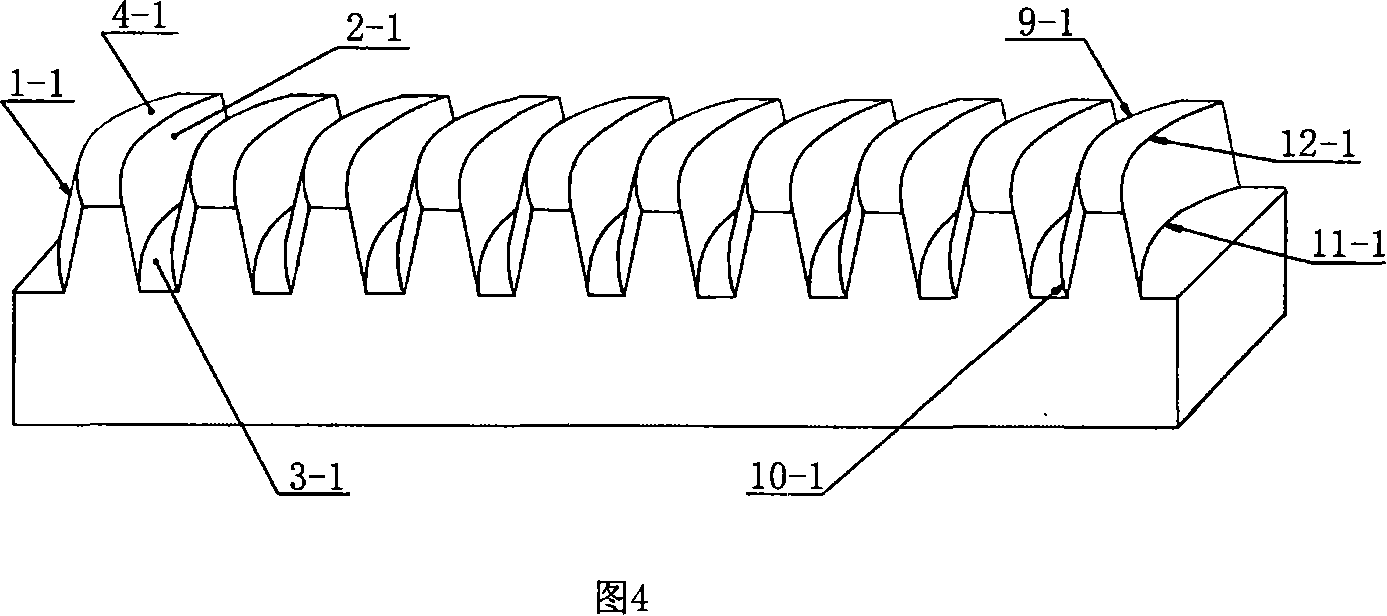

Arc helix cylindrical gear and arc rack

InactiveCN101149104AThe meshing track is tight and precisePerfect meshing theoryPortable liftingGearing elementsConvex sideEngineering

The present invention discloses one kind of curved teeth helical cylindrical gear and curved teeth helical rack. The curved teeth helical cylindrical gear has teeth comprising convex tooth face, concave tooth face, tooth root and tooth crest, and gear teeth cross section contour line comprises involutes, convex arc lines and concave arc lines to constitute bidirectional arc spiral line. The curved teeth helical rack has teeth comprising convex tooth face, concave tooth face, tooth root and tooth crest. The curved teeth helical cylindrical gear and the curved teeth helical rack have precise mesh path, 100 % contact surface, great bearing capacity and long service life.

Owner:完颜学明 +2

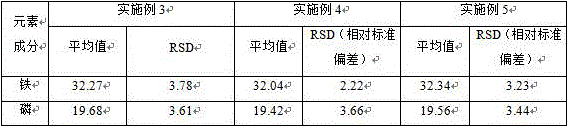

Fluorescence analysis method for measuring element content of lithium iron phosphate

InactiveCN105842266AFast detection methodEasy to operateMaterial analysis using wave/particle radiationEnvironmental resistanceX-ray

The invention discloses a fluorescence analysis method for measuring element content of lithium iron phosphate. The method comprises the following steps: equally dividing a lithium iron phosphate sample into three parts; processing a first part of the lithium iron phosphate sample by the use of hydrochloric acid, filtering and carrying out standard solution titration with potassium dichromate, and measuring content of iron element; processing the second part of the lithium iron phosphate sample by the use of hydrochloric acid, filtering and measuring content of phosphorus element by an ammonium phosphomolybdate volumetric method; preparing six standard samples with different contents from the third part of the lithium iron phosphate sample; respectively compressing into flaky pieces, and measuring fluorescence intensity of iron and phosphorus elements in each flaky standard sample by X-ray fluorescence spectrometry; drawing an XRF standard curve; compressing the lithium iron phosphate sample to be measured into flaky pieces, and measuring fluorescence intensity; and obtaining iron and phosphorus contents through the XRF standard curve. The method of combining a wet chemistry method and an X-ray fluorescent spectrometry is fast and high-speed, is simple to operate, has little error and long consumption time, and is environmentally friendly.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

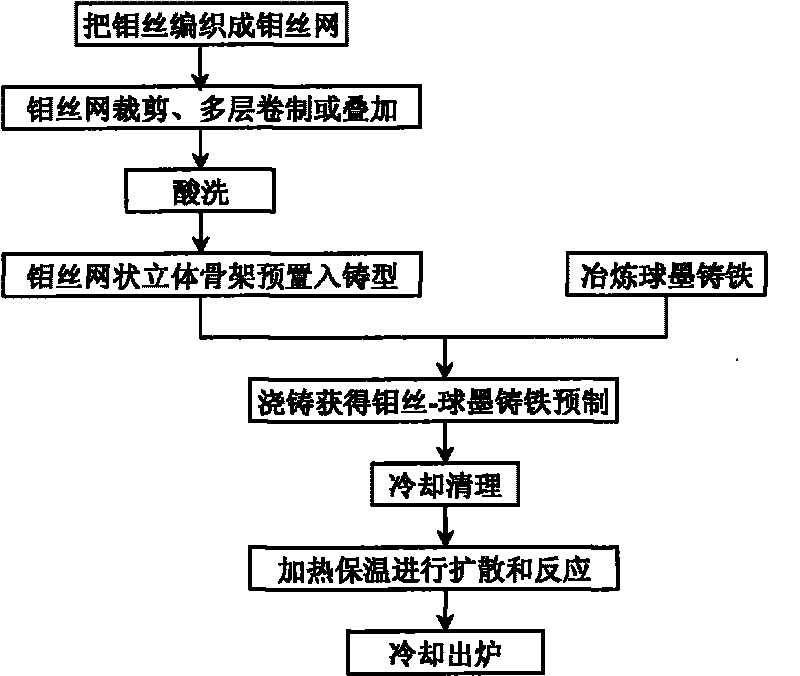

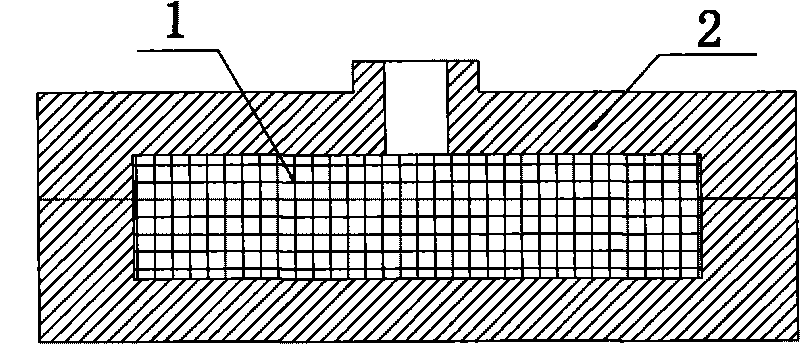

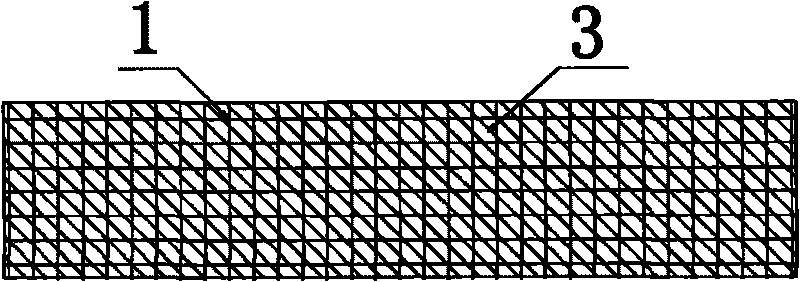

Process for preparing ductile cast iron-based composite

The invention discloses a process for preparing a ductile cast iron-based composite, which mainly comprises the following steps: weaving molybdenum nets with molybdenum wire, shearing the nets, and rolling a plurality of layers of molybdenum nets or overlapping the molybdenum nets to form a netty solid framework structure; manufacturing a casting mold according to the requirements of a manufacturing process, and pre-placing the molybdenum wire solid netty framework in the cavity of the casting mold; pouring smelted ductile cast iron into the casting mold and cooling and cleaning the ductile cast iron to obtain a molybdenum wire-ductile cast iron binary material prefabricated body; and placing the molybdenum wire-ductile cast iron binary material prefabricated body into a heat treatment furnace to heat the molybdenum wire-ductile cast iron binary material prefabricated body to a temperature at which carbides are formed and keeping the temperature to obtain the molybdenum carbide particle-reinforced ductile cast iron-based composite. The composite prepared by the method has the advantages that: the high-temperature wear resistance of a molybdenum carbide hard phase and the high toughness of the ductile cast iron are fully played; the regulation is convenient; the process is reliable; and the problems of incomplete reaction of the composite, the uneven particle distribution in the reinforced phase and the weak anti-pollution performance of the interface of the reinforced phase and the like are solved. The composite is widely used in mine, power, metallurgy, coal and building material wear-resistance fields and other wear-resistance fields.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

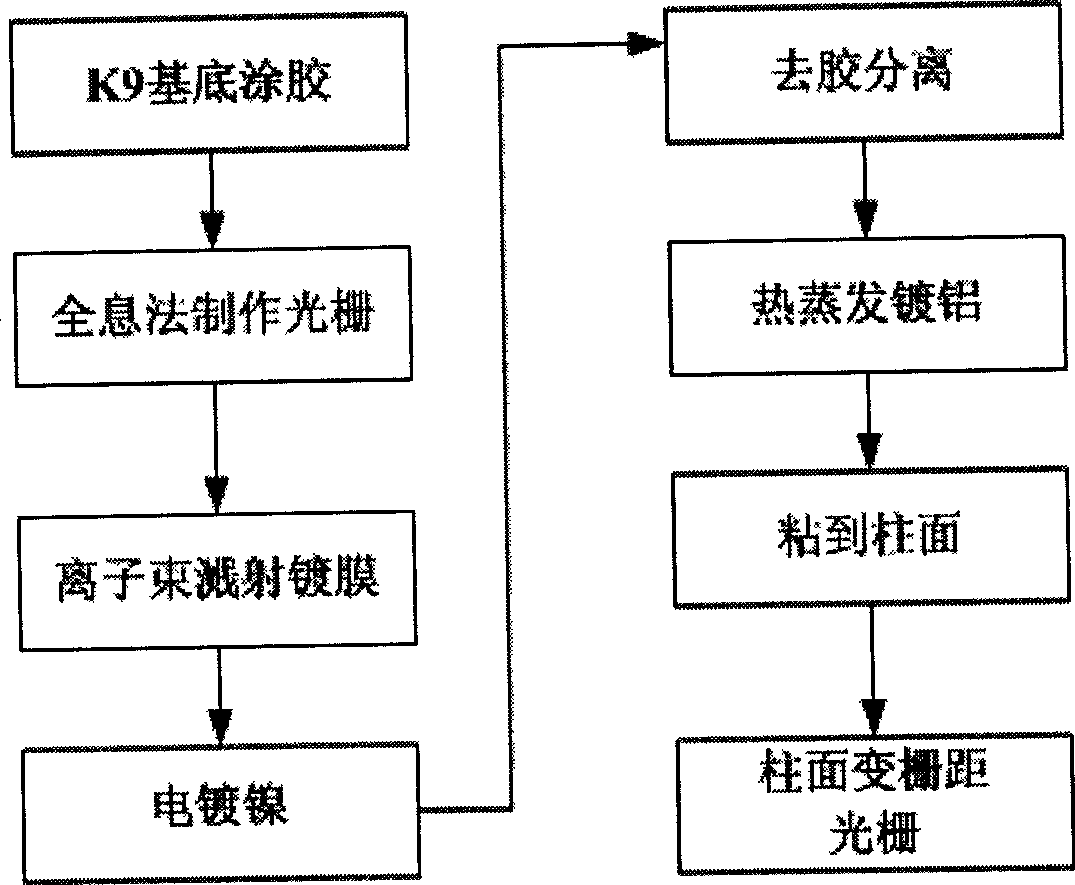

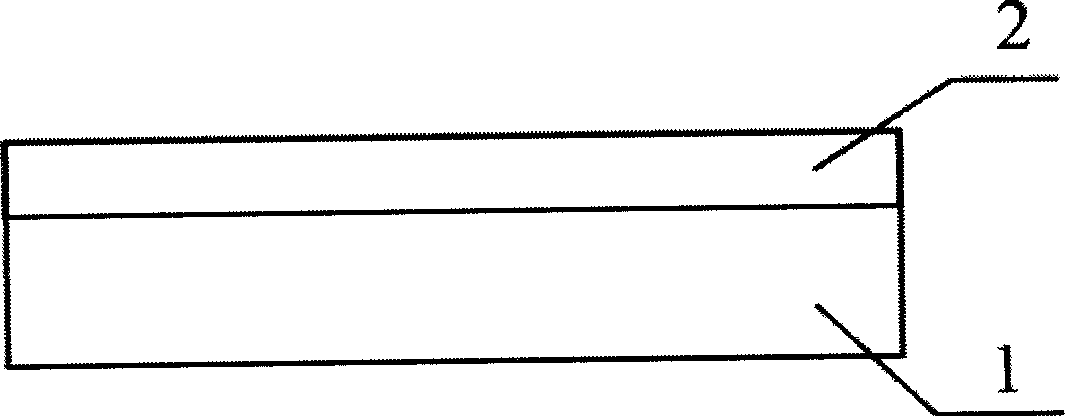

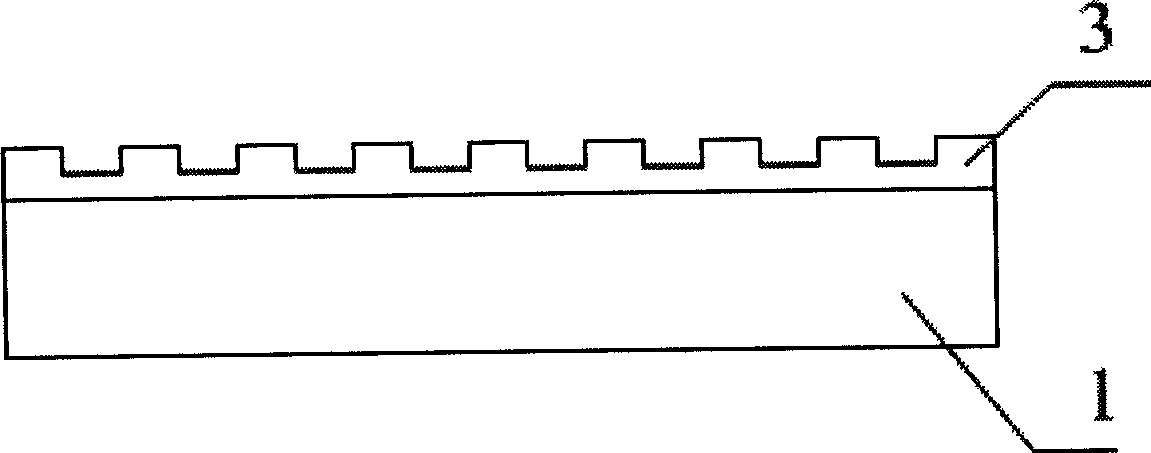

Method for producing cylinder grid pitch changing grating

InactiveCN101398315AHigh grating efficiencyLow costPhotomechanical apparatusConverting sensor output opticallyOptical glassPhotoresist

The invention relates to a preparation method used for a reflection-typed variable lattice spacing grating on a cylindrical surface, which solves the preparation difficulty of the cylindrical variable lattice spacing grating in the existing absolute-typed angle displacement sensor; the preparation method comprises the detailed steps as follows: photoresist is coated on an optical glass substrate; a holographic method is used to prepare the variable lattice spacing grating image on the photoresist; a sputtering method is used to plate chrome and gold on the variable lattice spacing grating image of relief structure; subsequently, nickel is electroplated so as to obtain the metal nickel variable lattice spacing grating; the photoresist layer is dissolved by acetone solution; subsequently, aluminium is plated to gain the a metal nickel variable lattice spacing grating substrate; finally, the metal nickel variable lattice spacing grating substrate is bent and bonded to the cylindrical surface; and after solidification, the cylindrical variable lattice spacing grating is obtained. The method needs no high machining accuracy to polish the metal substrate; the surface accuracy of the cylindrical variable lattice spacing metal grating is gained by copying the surface accuracy of the photoresist grating, therefore, the surface accuracy of nanometer-class can be achieved. The manufacture cost is low and the grating efficiency is higher.

Owner:UNIV OF SCI & TECH OF CHINA

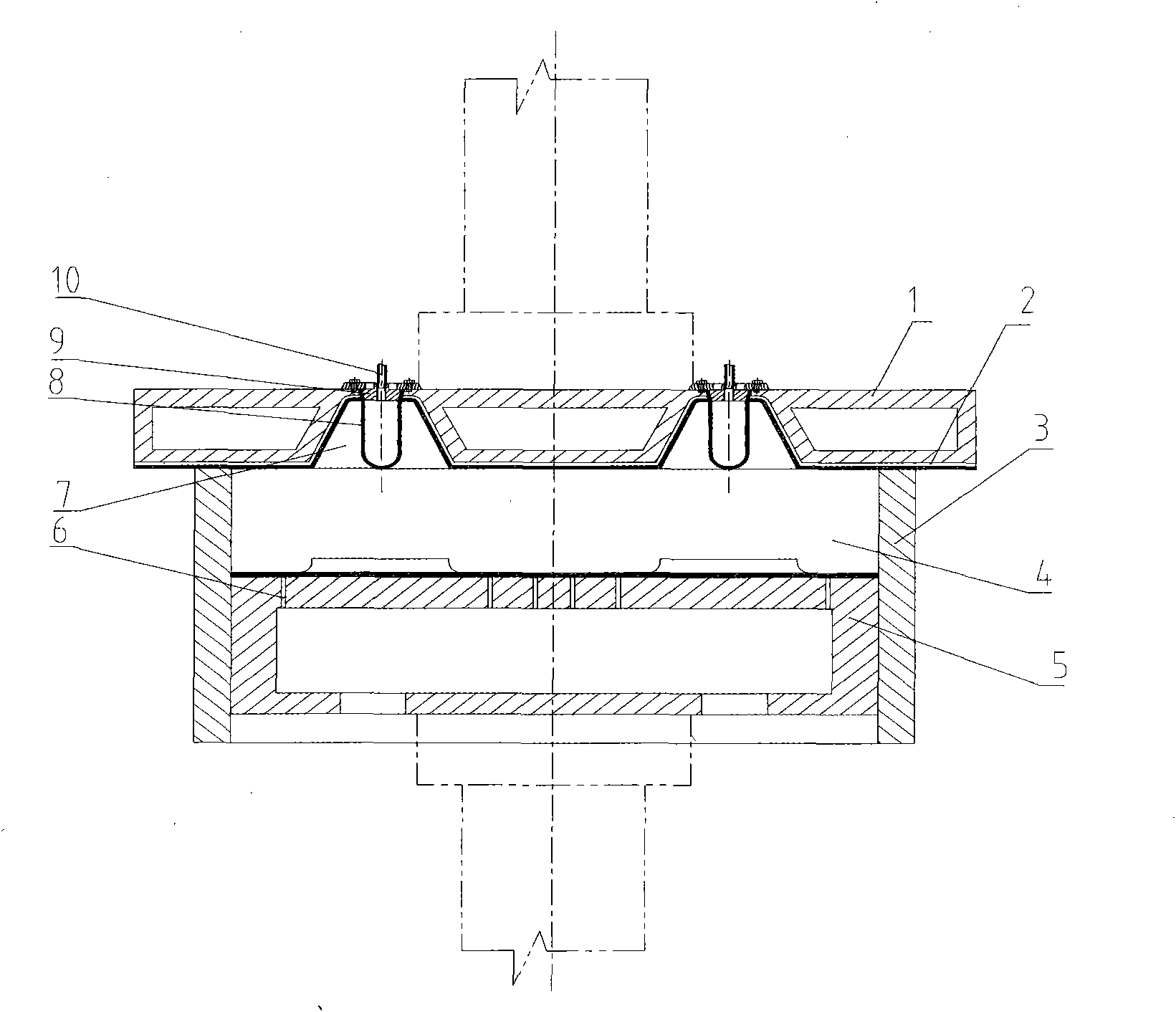

Method for preparing special pulp moulding plate with convex part and mould

InactiveCN101634124ASolving Manufacturing ChallengesSimplified structureTextiles and paperGramMarket potential

The invention discloses a method for preparing a special pulp moulding plate with a convex part and a mould. The preparation method is characterized in that the water squeezing moulding on the convex part of the special (non-flat) pulp moulding plate adopts a flexible mould method; the mould used is characterized in that: the mould is provided with a cavity according to the shape of the convex part of the special (non-flat) pulp moulding plate, and the center of the cavity is provided with a flexible punch device which has the minimum initial volume and applies pressure on peripheral pulp or paper fibers when the volume is expanded; the prepared pulp moulding plate is characterized in that: the plate has a non-flat and special shape, and is provided with at least one convex part; the ratio of the height of the convex part to the minimum caliber of the convex part is more than 0.3; and the weight per unit area of the plate is more than 0.30 gram per square centimeter, and the density of the plate is more than 0.6 gram per square centimeter. The method enables the manufacture of super-thick and high-density special pulp moulding products to be possible, simplifies process and reduces cost; and the products have good comprehensive usability. The special pulp moulding plate can be widely used in the fields such as industrial packaging, storage and transportation, buildings, decoration, office equipment and products and the like, and has great market potential.

Owner:郎旗

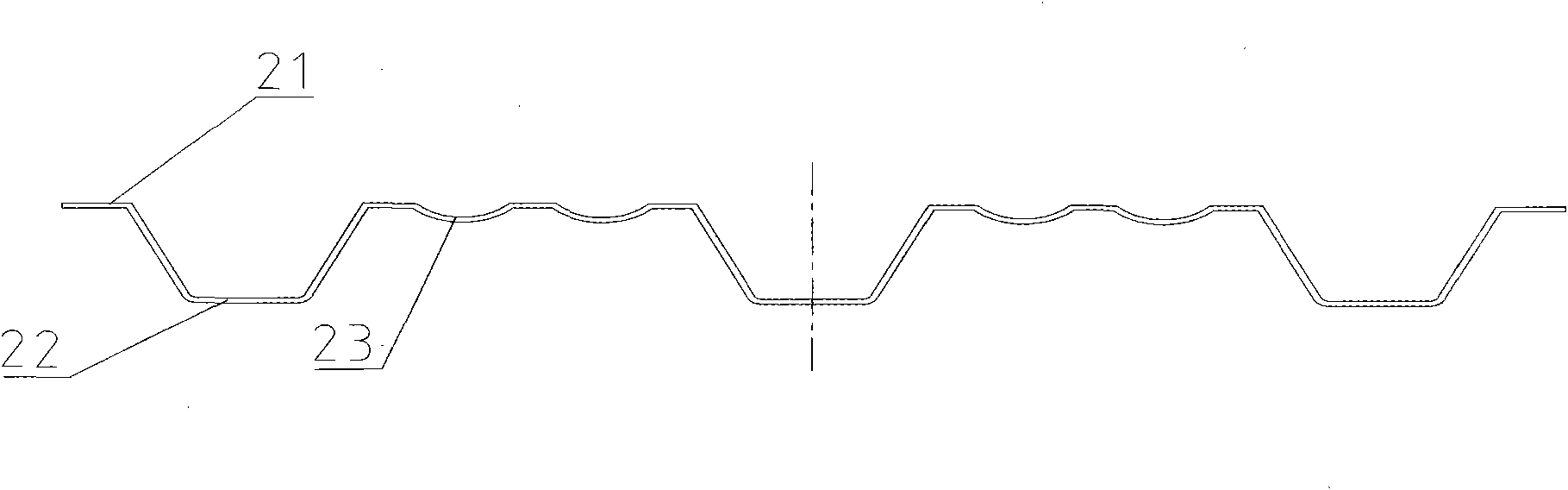

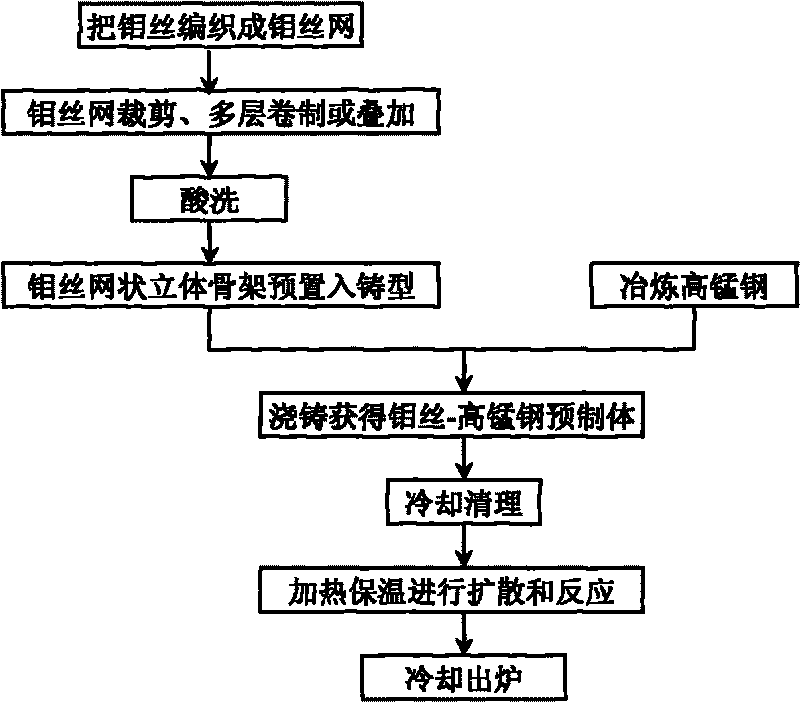

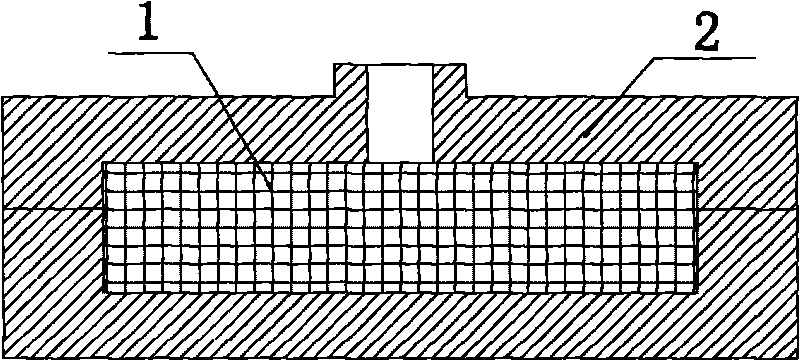

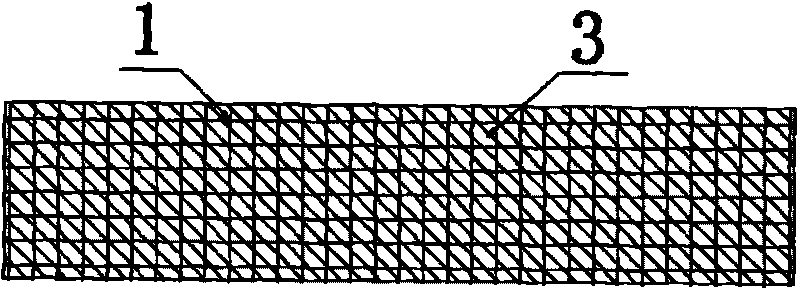

Preparation process of high manganese steel based composite material

InactiveCN101705444AAvoid floating and segregationThe interface is clean and pollution-freeBuilding materialCoal

The invention discloses a preparation process of a high manganese steel based composite material, which mainly includes the following steps: weaving a molybdenum wire mesh by using molybdenum wires, and manufacturing a reticular three-dimensional framework structure by cutting, multilayer rolling or superposing; manufacturing a casting mold according to casting process requirements, and pre-placing the molybdenum wire three-dimensional reticular framework into a cavity of the casting mold; smelting high manganese steel to obtain liquid high manganese steel which is poured into the casting mold, and obtaining molybdenum wire-high manganese steel binary material preform after cooling and clearing; and placing the molybdenum wire-high manganese steel binary material preform into a heat treatment furnace, heating to a temperature at which carbide is formed, preserving heat, and obtaining molybdenum carbide particle reinforced high manganese steel based composite material. The composite material prepared by using the method fully plays the high abrasion resistance of molybdenum carbide hard phase and the good toughness of the high manganese steel, the regulation and control are convenient, and the process is reliable, thus solving the problems of incomplete reaction of the composite material, the uneven distribution of reinforced phase particles, the pollution weakening of reinforced phase interfaces and the like; and the composite material can be widely applied in the fields of wear resistance such as mines, electric power, metallurgy, coal, building materials and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

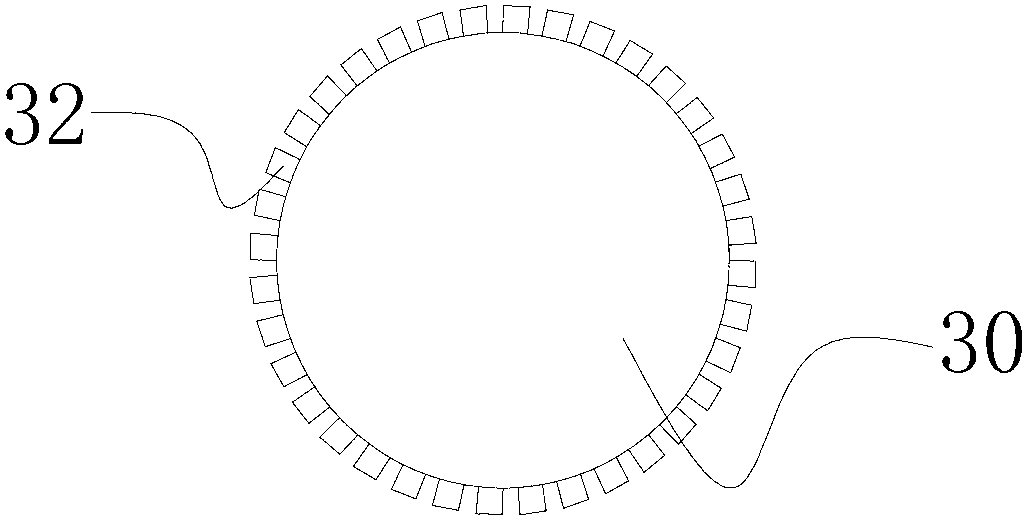

Electromoulding processing method for micro-structure on external surface of cylindrical revolving body element

InactiveCN101012568AReduce processing costsImprove efficiencyElectroforming processesMicro structureMetallic materials

The invention discloses a trace structural electric-cast manufacturing method on the external surface of column-shaped rotary bulk element in the electric cast manufacturing domain, which is characterized by the following: making flexible electric-cast screen film with micro-hole structure; attaching column-shaped rotary bulk element and flexible electric-cast screen film through mechanic squeezing pattern; casting element as cathode; forming trace projecting structure on the external surface of column-shaped rotary bulk element; making electric-cast screen film through insulating material; adding a layer of electrochemical insoluble metal material (platinum or titanium) to make the insulating material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Manufacture method of titanium or titanium alloy laryngotracheal interventional stent

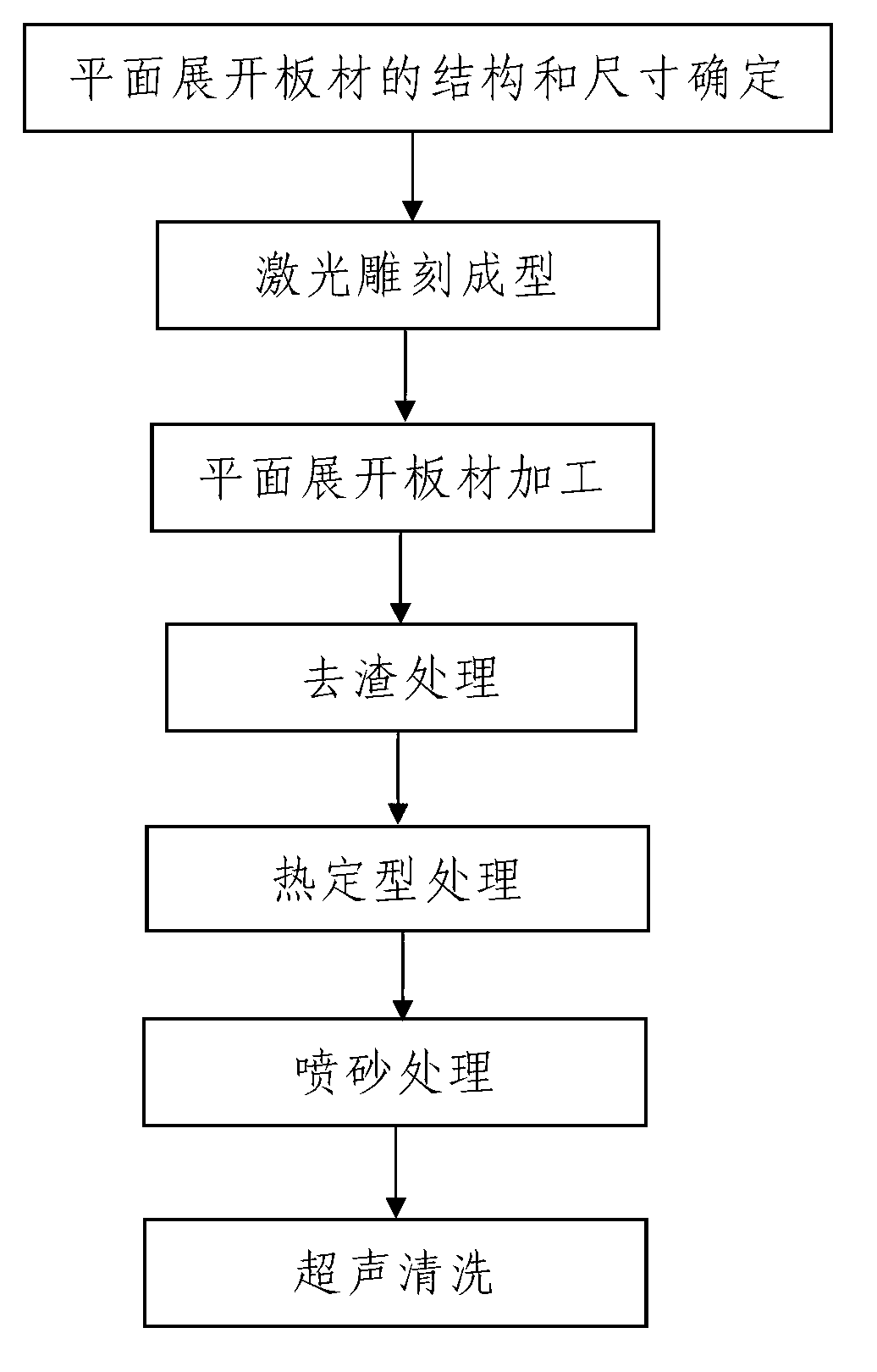

ActiveCN102988119AHigh dimensional accuracyThe preparation method is simple and easyTubular organ implantsTitanium alloyMechanical property

The invention discloses a manufacture method of a titanium or titanium alloy laryngotracheal interventional stent, comprising the following steps of: 1, determining the structure and the size of a plane spread plate; 2, forming by means of laser engraving: under the protection of inert gas, carrying out laser engraving on the plate to be treated by a laser engraving machine; 3, machining the plane spread plate; 4, deslagging; 5, carrying out heat setting, wherein the treatment process comprises the following steps of: 501, putting into a mould: putting the deslaged-plane plate into a forming cavity of the pre-machined thermal treatment mould; and 502: thermally treating; 6, blasting sand: blasting sand to the thermally-treated laryngotracheal interventional stent by a sand-blasting machine; and 7, ultrasonically cleaning. The manufacture method disclosed by the invention is simple in process step, reasonable to design, convenient to realize, and good in use effect, the oxidization of the stent in the process of machining can be effectively avoided, and the prepared interventional stent is high in dimensional accuracy and good in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

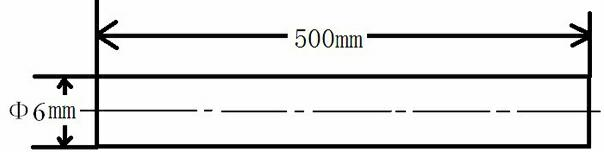

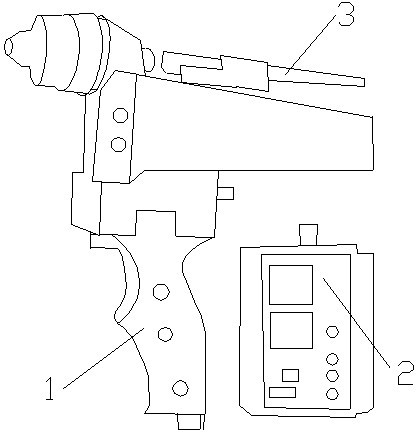

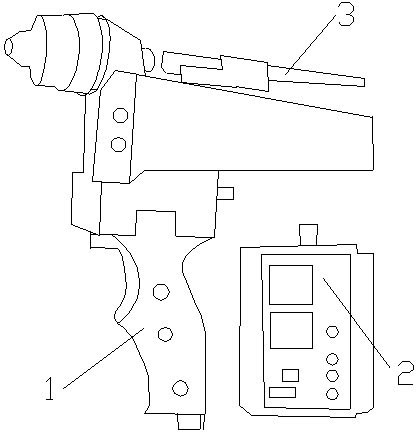

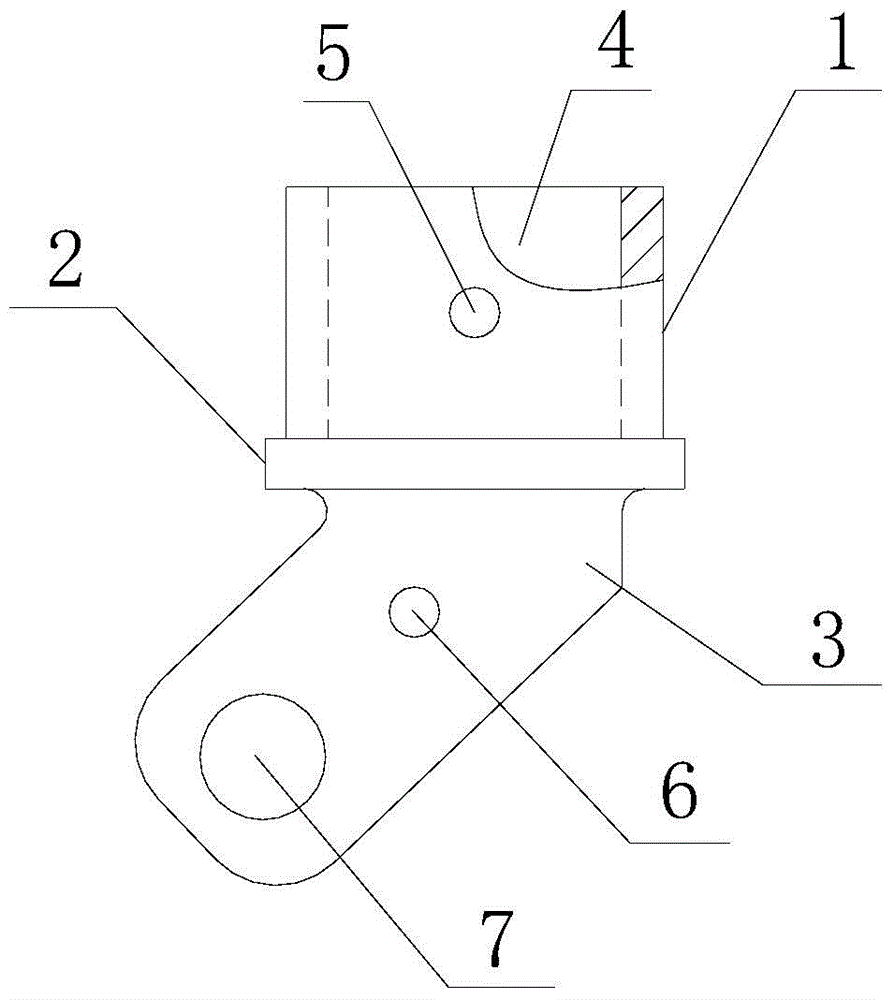

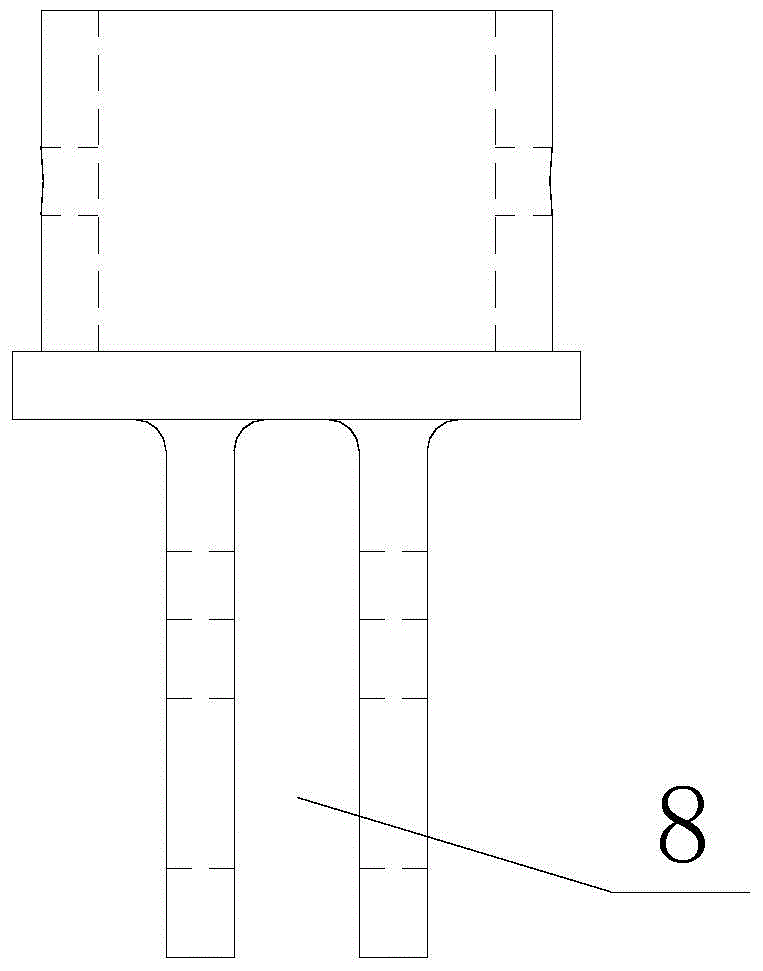

Micro electrochemical machining device and machining method for discontinuous microstructures on inner wall of micro heat pipe

InactiveCN102699456AEasy to operateSolving Manufacturing ChallengesMachining electrodesElectrical-based machining electrodesMicro-loop heat pipeElectrolysis

The invention discloses a micro electrochemical machining device for discontinuous microstructures on the inner wall of a micro heat pipe, which comprises an electric conducting and liquid conducting rod, a guide device and a working cone body, wherein the guide device surrounds the electric conducting and liquid conducting rod and can prevent the electric conducting and liquid conducting rod from horizontally jittering; the upper end of the working cone body is fixed at the lower end of the electric conducting and liquid conducting rod, and the central axis of the electric conducting and liquid conducting rod coincides with the working cone body; and the working cone body is a conical structure with narrow lower end and wide upper end, and a plurality of spiral line insulating tapes are coated on the outer surface of the working cone body. Meanwhile, the invention also discloses a micro electrochemical machining method for discontinuous microstructures on the inner wall of the micro heat pipe by using the electrochemical machining device. Different sizes and different shapes of complex discontinuous microstructures are formed on the inner surface of the micro heat pipe via electrolysis through two forward and backward rotary feeding of a variable cross-section multiline spiral electrode. The method is simple to operate, and the difficulty of making surface microstructures is effectively solved.

Owner:GUANGDONG UNIV OF TECH

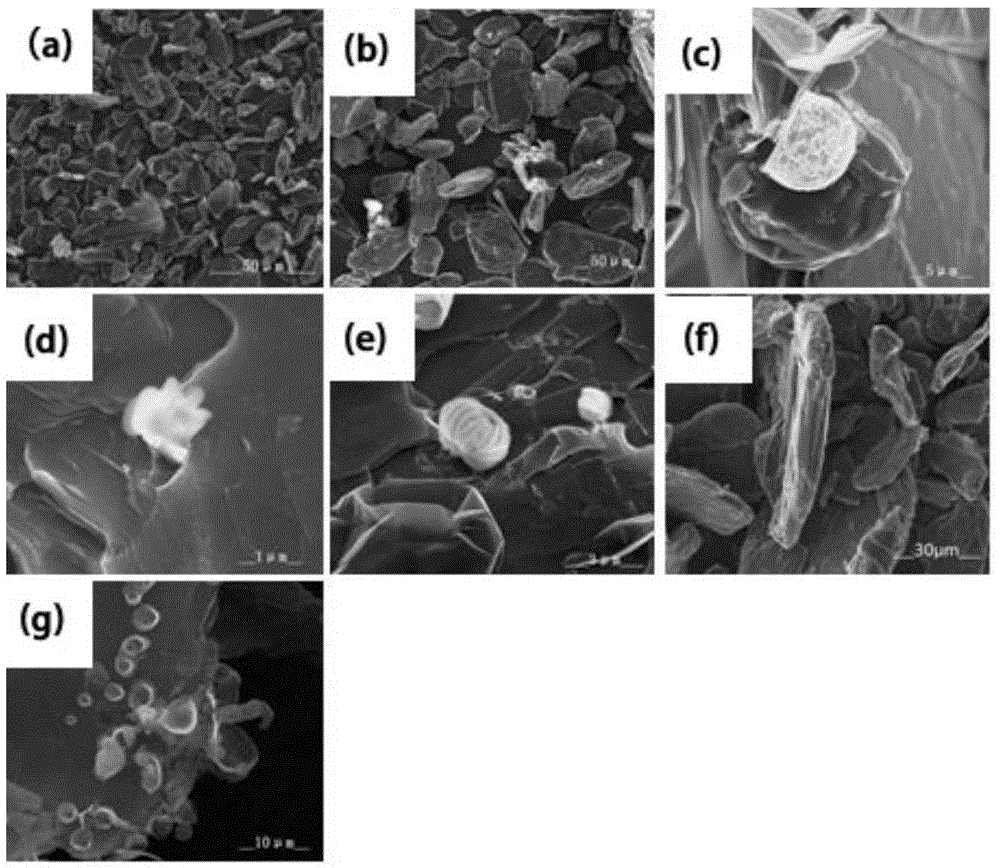

Method for preparing high-purity flake graphite

InactiveCN105883780AHigh puritySolve the problems of production preparationPositive pressureFree cooling

The invention discloses a method for purifying high-purity flake graphite. The method comprises the steps of adopting graphite powder with the carbon content being greater than 90% as raw material powder, adding the graphite powder into a reaction kettle together with diluted hydrochloric acid, conducting heating and stirring, conducting dipping for 2-3 hours, then adding the mixture into the reaction kettle together with a sodium hydroxide solution with the mass ratio being 1: (2.8-3), conducting heating, and meanwhile conducting stirring for a dipping reaction; then mixing a second crude product with sodium chloride according to the mass ratio of 100: (1-5), then conducting drying, transferring the materials into a graphite crucible, under the protection of micro-positive pressure nitrogen, raising the temperature to 1000-1200 DEG C, preserving the temperature for 1-3 hours, naturally cooling the materials to the room temperature, then raising the temperature to 2200-2600 DEG C, and preserving the temperature for 6-10 minutes, so that the high-purity flake graphite is finally obtained. By means of the purification process, flake graphite with the carbon content being 90% can be purified to the extent of approximate 99.9933-99.9955%, the technical content of the flake graphite is greatly raised, and the application scope of the flake graphite is greatly widened.

Owner:CENT SOUTH UNIV

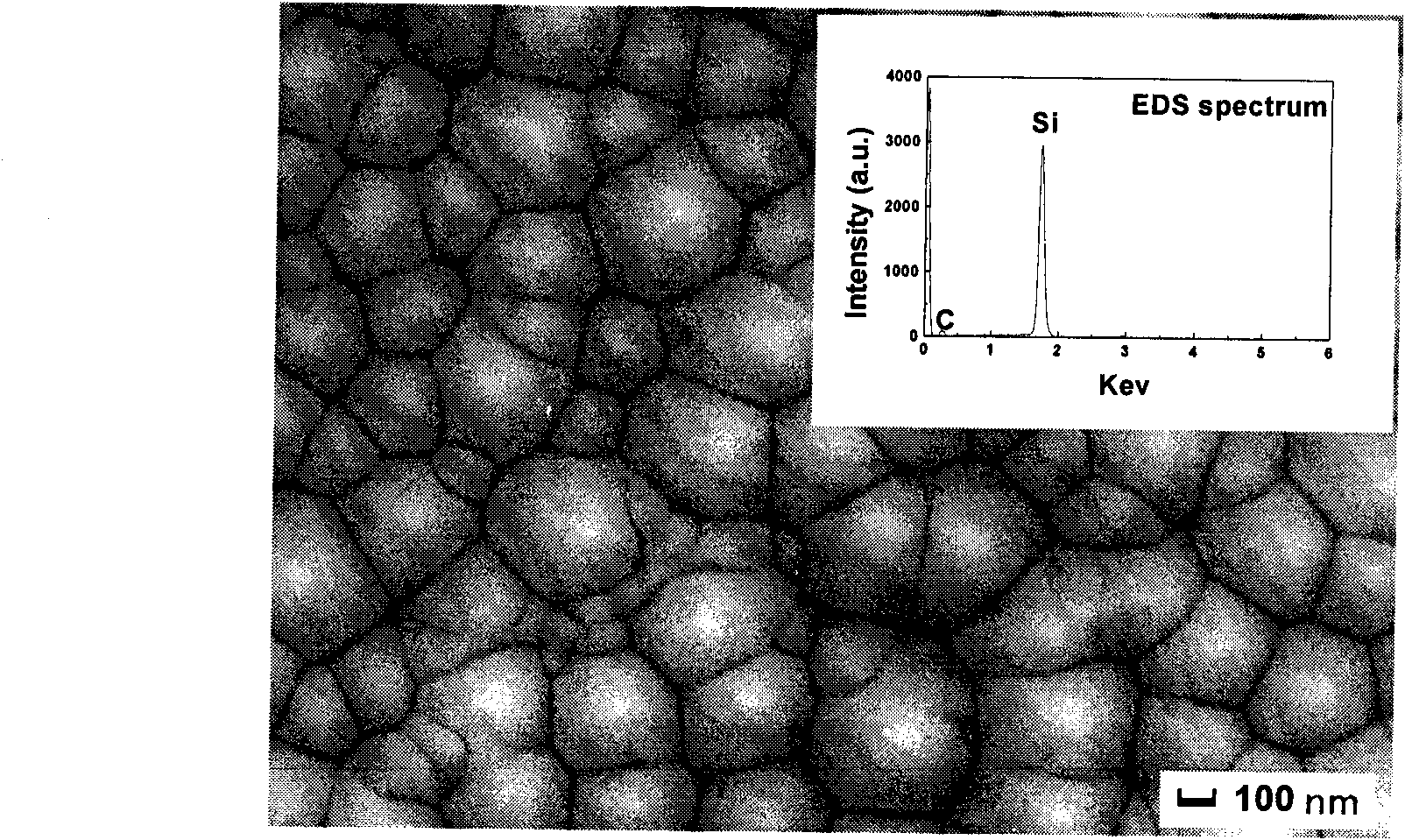

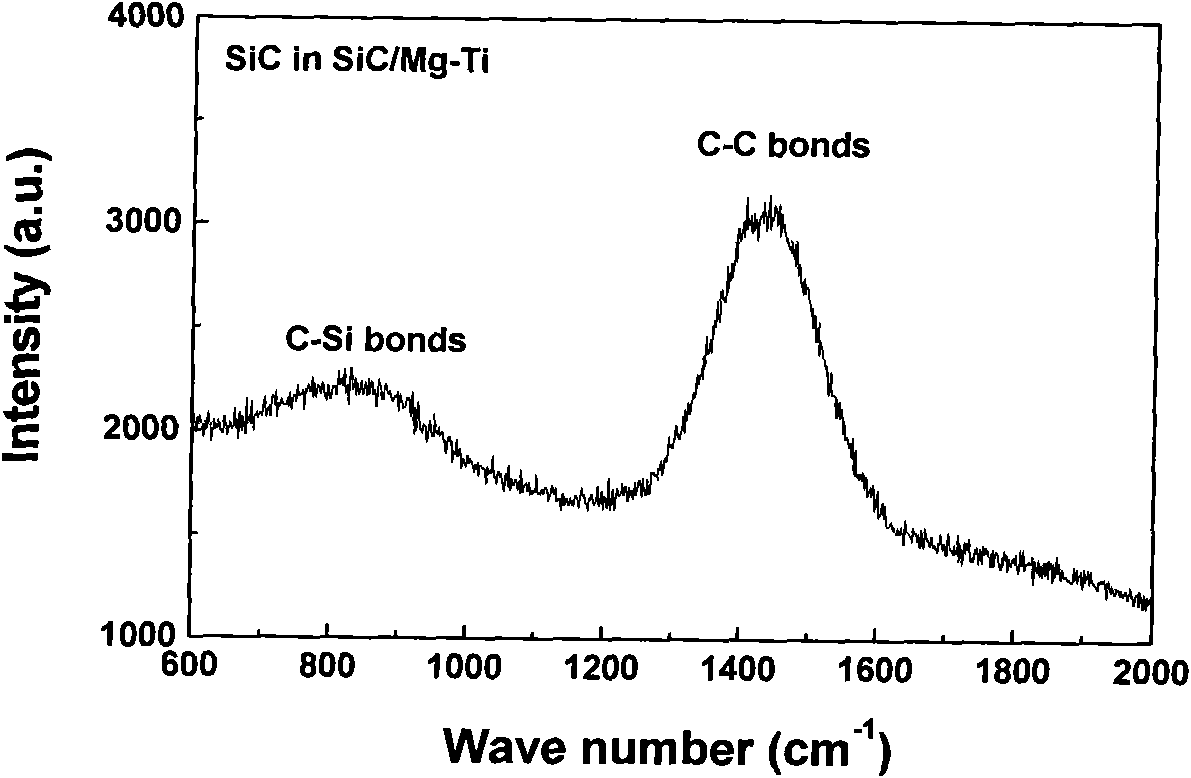

Method for preparing ultralow elasticity modulus high-wearing feature shell microstructural membrane on surface of titanium

InactiveCN101671808ASolving Elasticity ProblemsSolve the problem that the friction and wear performance cannot be balancedVacuum evaporation coatingSputtering coatingTitaniumRadio frequency

The invention discloses a method for preparing an ultralow elasticity modulus high-wearing feature shell microstructural membrane on the surface of titanium, which is characterized by comprising the following steps: firstly, evenly settling a layer of middle pure magnesium membrane playing the role of induction on the surface of the cleaned titanium base material in a direct current way by a magnetron sputtering technology by taking the titanium as a base material and pure magnesium as a target; secondly, promptly settling a carborundum membrane on a middle membrane in a radio-frequency way bythe magnetron sputtering technology after the settling of the middle membrane is finished and enabling the carborundum membrane to be the coalition of a plurality of shell structures of submicrons bythe diffusion effect of the magnesium so as to enable the spring modulus of the final surface membrane to be between 7 GPa and 30 GPa. The invention well solves the difficulty in preparing the membrane having ultralow elasticity modulus and high wearing feature and has simple technology procedure, thereby having wide application prospects in fields such as biology, medicine, and the like.

Owner:JIANGSU UNIV

Self-propagating reactive spraying method for cermet rods

InactiveCN102277549AIncrease melting energyEnergy savingMolten spray coatingExothermic reactionCeramic coating

The invention relates to a self-propagating reaction spraying method for cermet rods. The method includes the following process: the method comprises the following process: pressing self-propagating powder, which can generate metal through self-propagating reaction during the spraying process. The rod material of the ceramic rod is put into the ceramic rod spray gun, heated by the oxyacetylene flame to cause a self-propagating exothermic reaction, the reaction product is melted at high temperature, and the compressed air atomizes it into particles, which are sprayed onto the surface roughened and pretreated. A carbide cermet coating is formed on the surface of a hot metal substrate. By adopting the method of the invention, a carbide cermet coating with a higher melting point and more wear resistance can be prepared on the steel surface with a ceramic rod spraying gun.

Owner:江阴东大新材料研究院

Final drive positioner manufacturing process method

ActiveCN104589004APositioning and installation without deviationMeet Vertical Manufacturing RequirementsAircraft componentsNumerical controlManufacturing technology

The invention belongs to an aircraft tool manufacturing process and relates to a final drive positioner manufacturing process method. A vertex of a combined disc is used as a datum point for alignment, a grinding smooth surface of a positioning sleeve is used for positioning, a fork lug is processed on a molybdenum wire cutting machine tool, the shape of the fork lug and the center surface of a positioning groove are used as a benchmark, the positioning sleeve and the combined disc are processed by a digital controlled lathe, an alignment tool plate of which the boundary dimension is larger than that of the fork lug is mutually fixed with a final drive positioner, a method that each hole of the final drive positioner is processed in a computer numerical control boring and milling machine is adopted, an inner groove and an outer shallow of the fork lug of the final drive positioner meet the concentric manufacturing tolerance requirement, the thickness sizes of two flat lug sheets of the fork lug are identical, the thick surfaces are mutually parallel, and the center line of an inner hole of the positioning sleeve coincides with the center surface of the inner groove of the fork lug of a positioning joint. According to the final drive positioner manufacturing process method, the zero deflection of the positioning and mounting of an aircraft final drive joint product is ensured.

Owner:HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com