Method for preparing special pulp moulding plate with convex part and mould

A raised part, pulp technology, applied in the direction of textiles and paper making, can solve problems such as fracture, uneven wall thickness of raised parts, unsuitable special-shaped pulp molded boards, etc., to reduce manufacturing costs, simplify structural forms, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

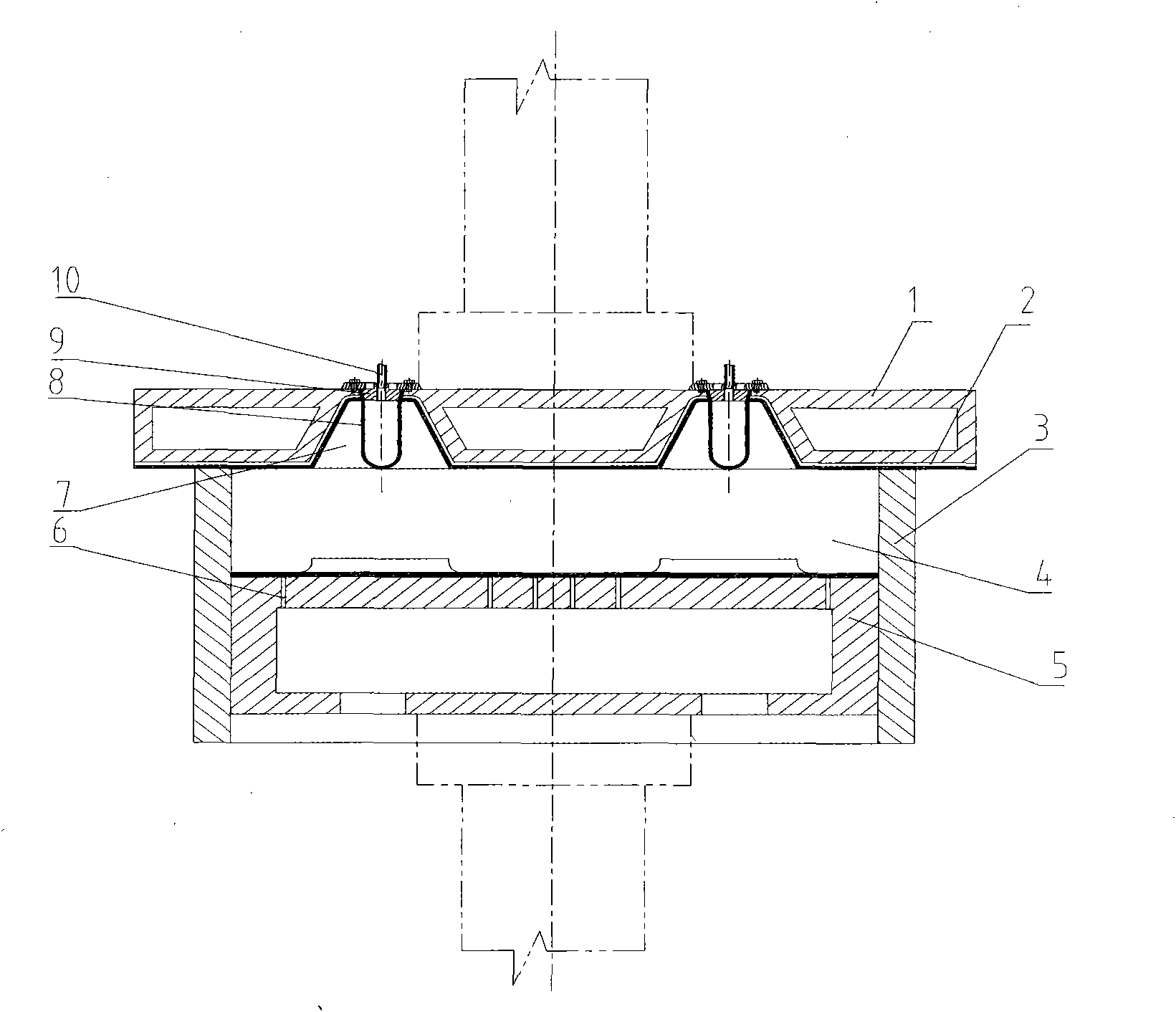

[0015] Combine now figure 1 The preparation method and the mold of the present invention are further specifically described: the surrounding frame 3 is fixed on the frame of the forming device, and the cover plate 1 can move up and down under the action of the pressing rod to open or close the upper opening of the surrounding frame 3; Under the action of the push rod, it moves up and down in the surrounding frame 3, and the dynamic seal between the pressing block 5 and the surrounding frame 3 has sufficient pressure resistance to ensure that the pulp will not leak from the sealing place during extrusion molding. When the cover plate 1 moves downward to close the upper opening of the enclosure frame 3, the enclosure frame 3, the cover plate 1 and the briquetting block 5 form a mold cavity 4 with variable space, wherein the molding surfaces of the cover plate 1 and the briquetting block 5 are covered with strainer.

[0016] When the cover plate 1 is opened and the briquetting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com