Method for preparing high-purity flake graphite

A flake graphite, high-purity technology, applied in the field of purifying flake graphite, can solve problems such as difficulties, and achieve the effects of simple equipment, solving production and preparation problems, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

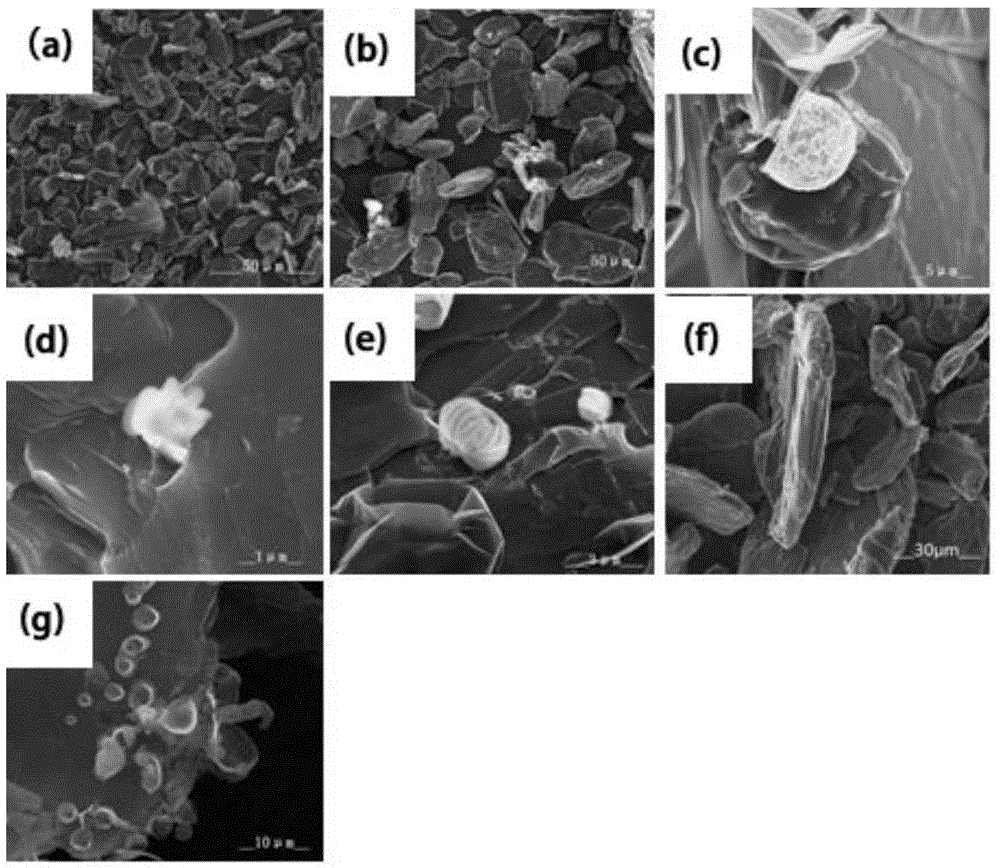

Image

Examples

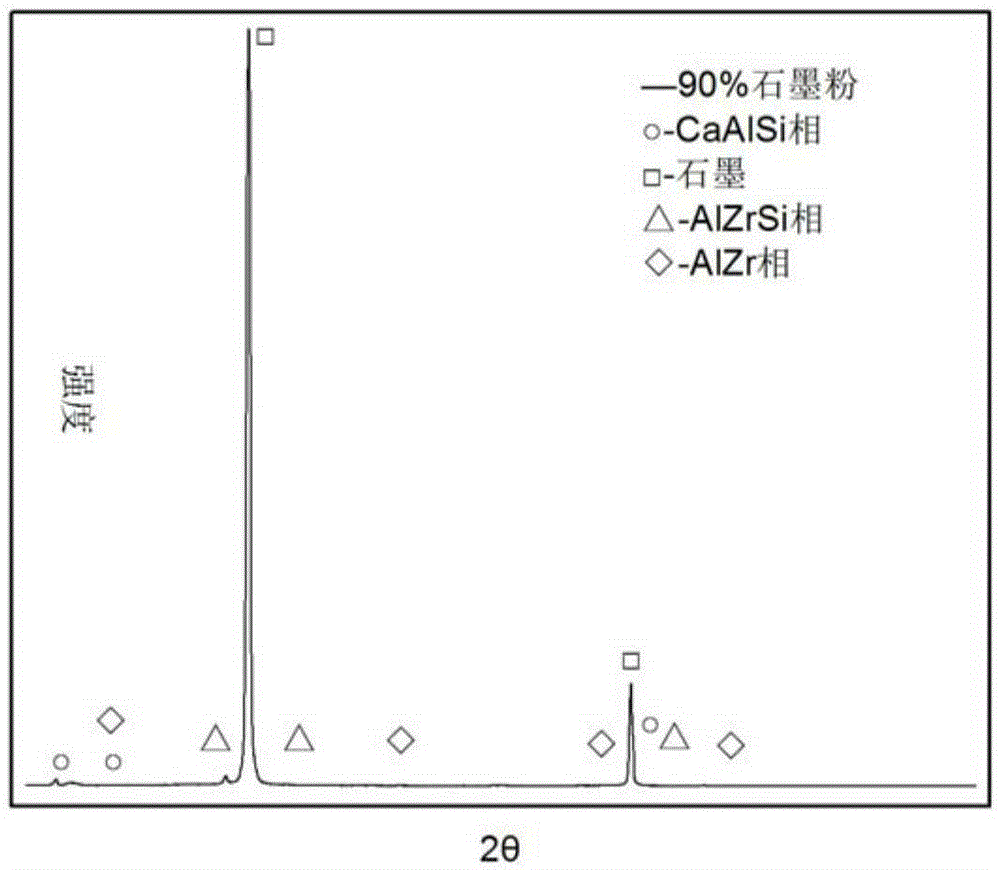

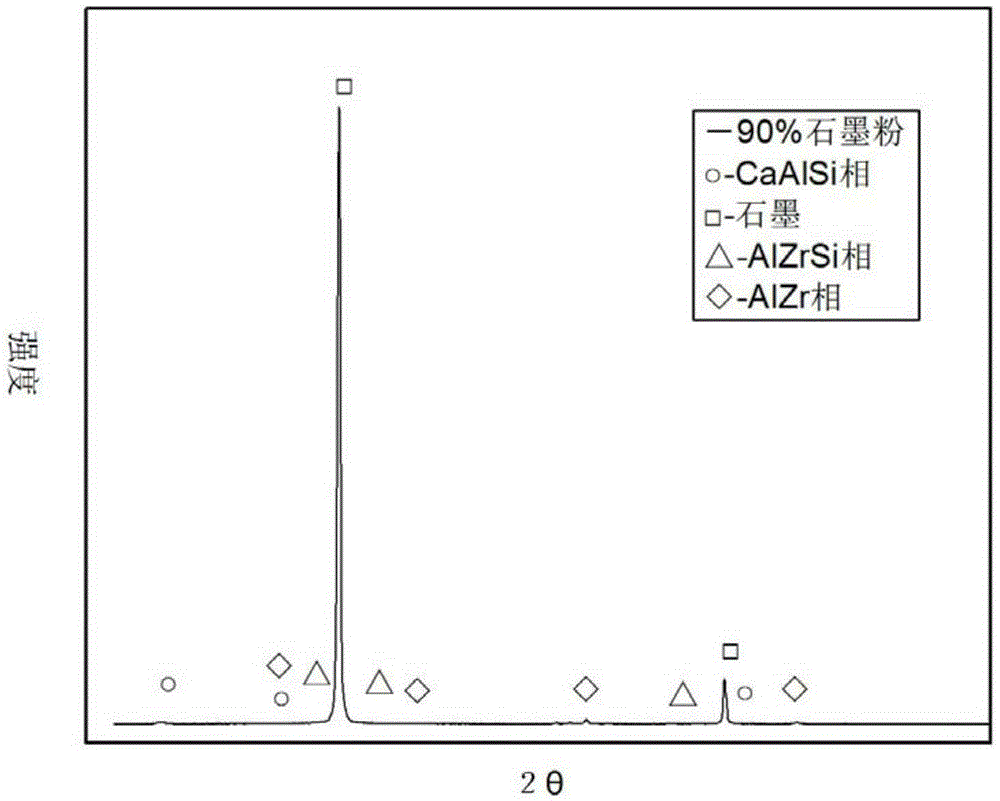

Embodiment 1

[0022] Put the flake graphite powder and dilute hydrochloric acid into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Put the crude product together with sodium hydroxide solution into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Mix the crude product with the sodium chloride aqueous solution at a ratio of 99:1, put it into a heat treatment reactor, the heating rate is 5°C / min, nitrogen is used as the protective gas, the system is heated to 1000°C, and kept for 1-3h, the sample Cool down to room temperature with the furnace and take it out; put the sample treated in the previous step into a continuous horizontal high-temperature graphitization furnace ...

Embodiment 2

[0024] Put the flake graphite powder and dilute hydrochloric acid into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Put the crude product together with sodium hydroxide solution into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Mix the crude product with the sodium chloride aqueous solution according to the ratio of 97:3, put it into the heat treatment reaction furnace, the heating rate is 5°C / min, nitrogen is used as the protective gas, the system is heated up to 1000°C, and kept for 1-3h, the sample Cool down to room temperature with the furnace and take it out; put the sample treated in the previous step into a continuous horizontal high-temperatu...

Embodiment 3

[0026] Add flake graphite powder and dilute hydrochloric acid into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Put the crude product together with sodium hydroxide solution into the reaction kettle, heat to 50-60°C, stir and impregnate for 2-3 hours at the same time. Use a centrifuge to separate the solid from the liquid, wash the filter cake with water until it is neutral, and dry it. Mix the crude product with the sodium chloride aqueous solution at a ratio of 95:5, put it into a heat treatment reaction furnace, the heating rate is 5°C / min, nitrogen is used as the protective gas, the system is heated to 1000°C, and kept for 1-3h, the sample Cool down to room temperature with the furnace and take it out; put the sample treated in the previous step into a continuous horizontal high-temperature graphitization fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com