Patents

Literature

32 results about "Cryptocrystalline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

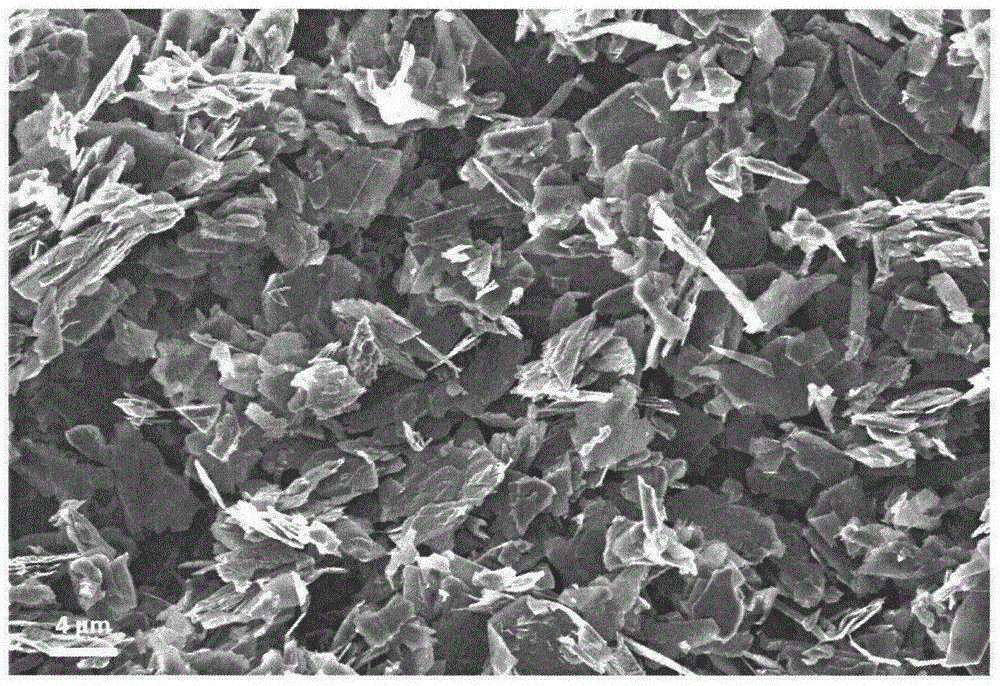

Cryptocrystalline is a rock texture made up of such minute crystals that its crystalline nature is only vaguely revealed even microscopically in thin section by transmitted polarized light. Among the sedimentary rocks, chert and flint are cryptocrystalline. Carbonado, a form of diamond, is also cryptocrystalline. Volcanic rocks, especially of the acidic type such as felsites and rhyolites, may have a cryptocrystalline groundmass as distinguished from pure obsidian (acidic) or tachylyte (basic), which are natural rock glasses. Onyx is also a cryptocrystalline. Agates such as the fairburn agate are also composed of cryptocrystalline silica.

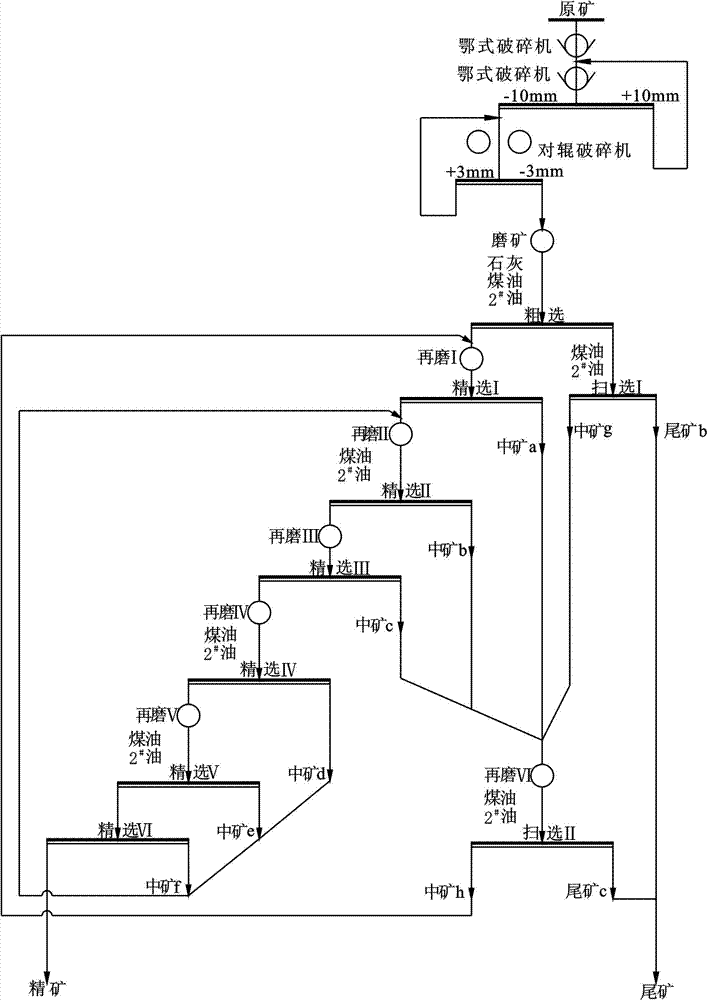

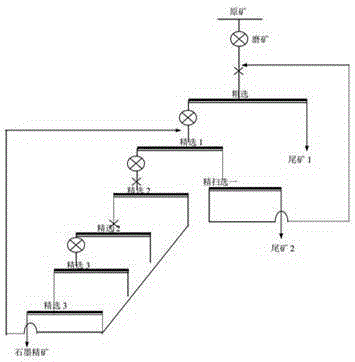

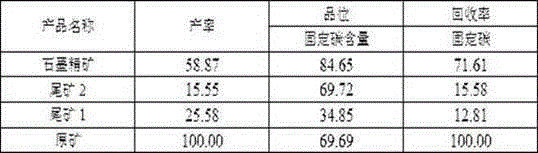

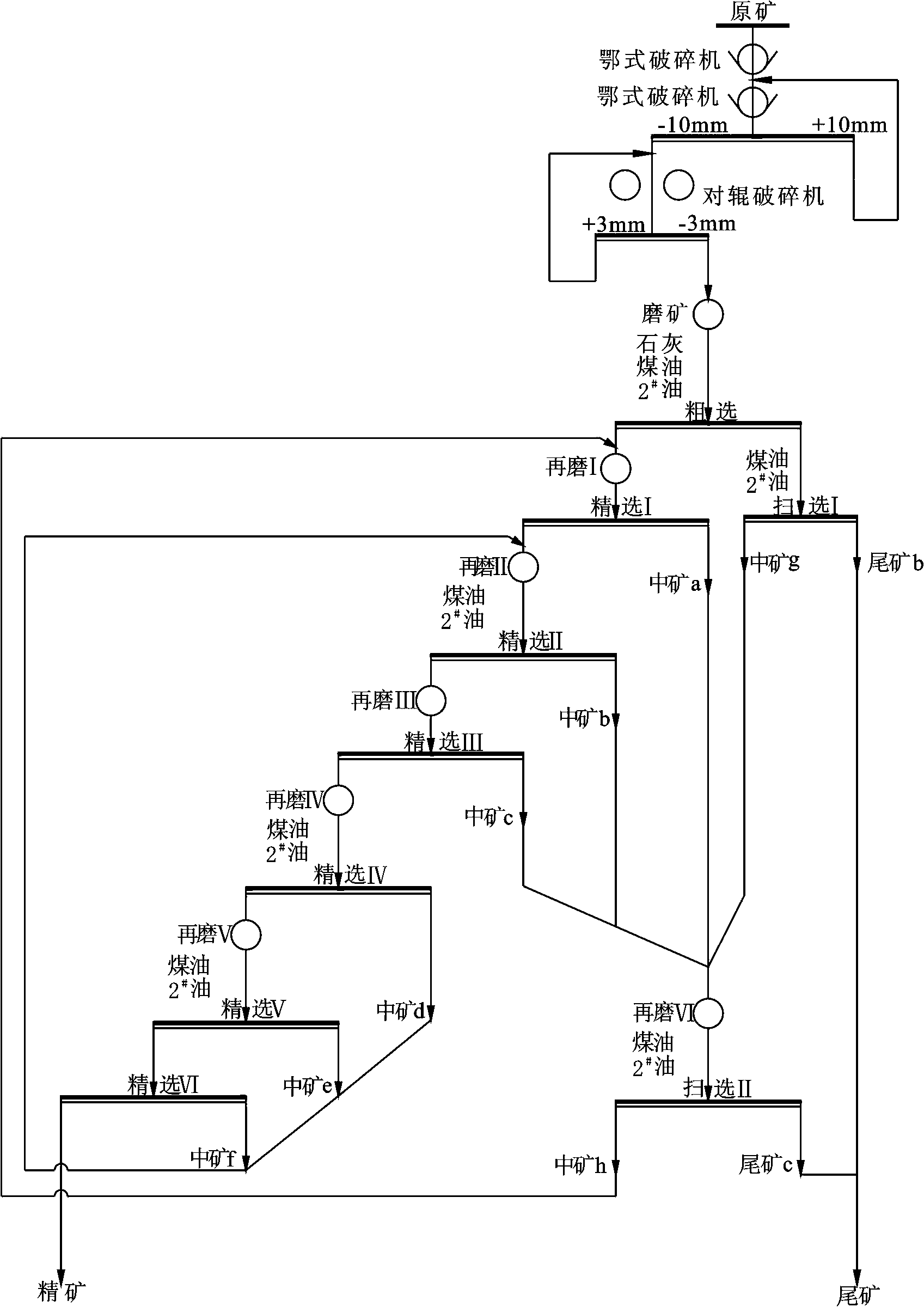

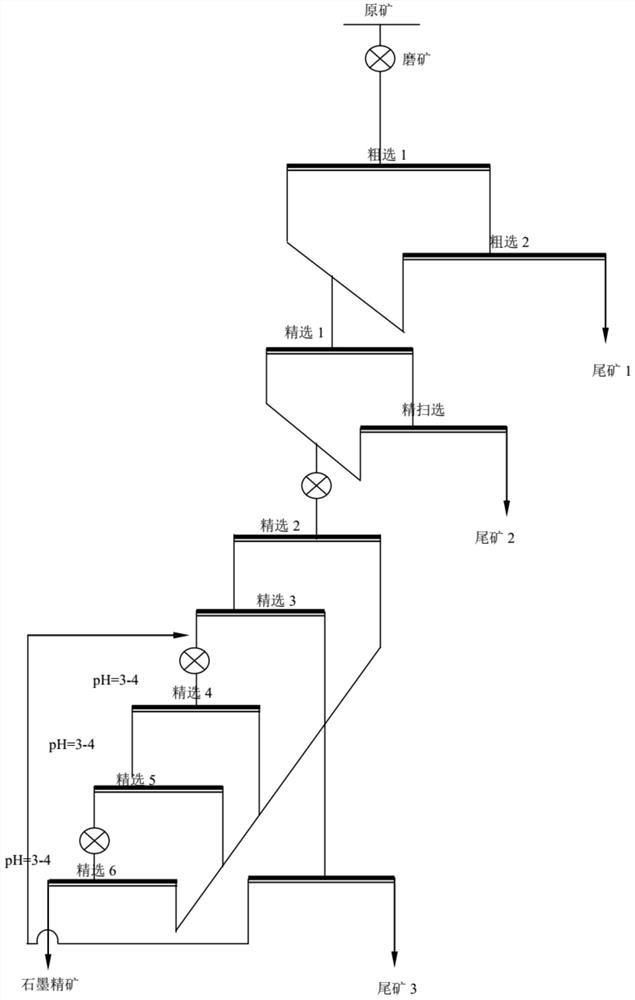

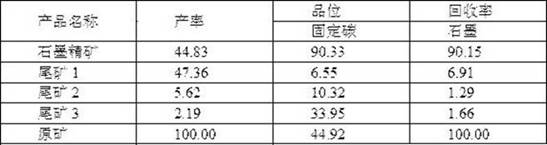

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

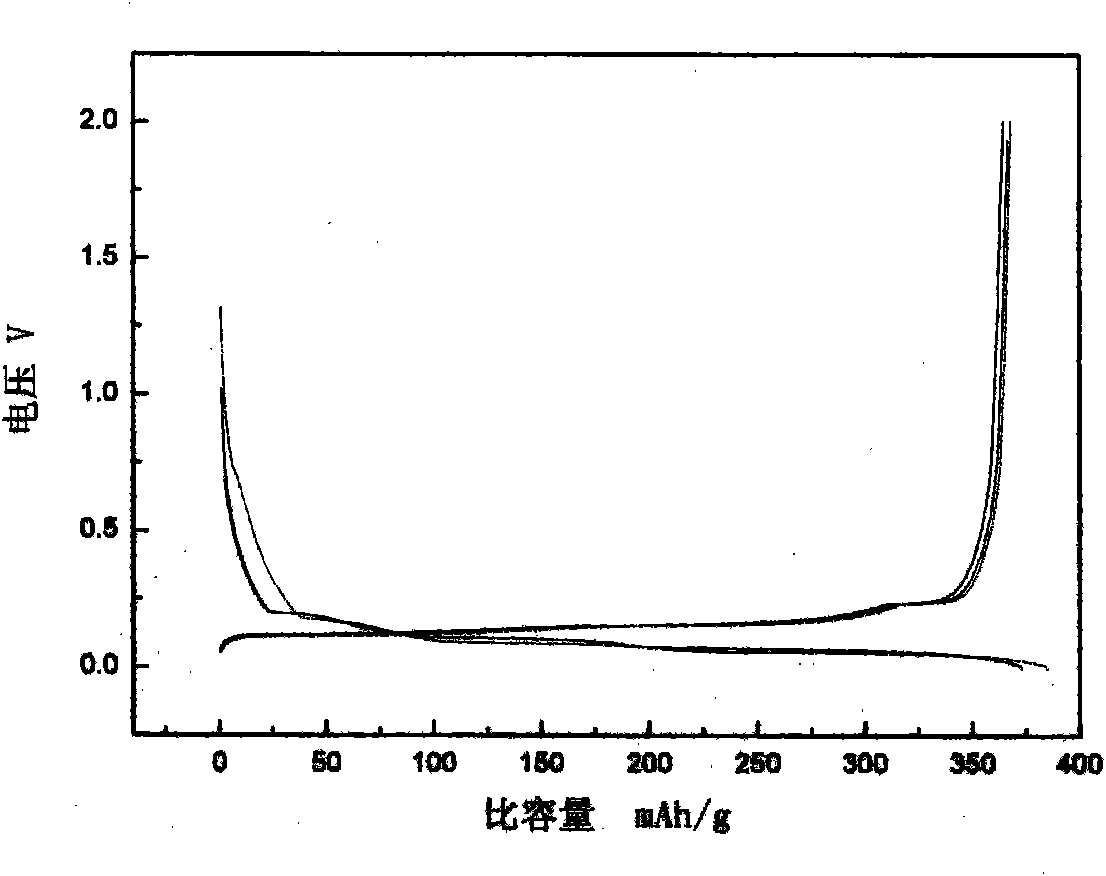

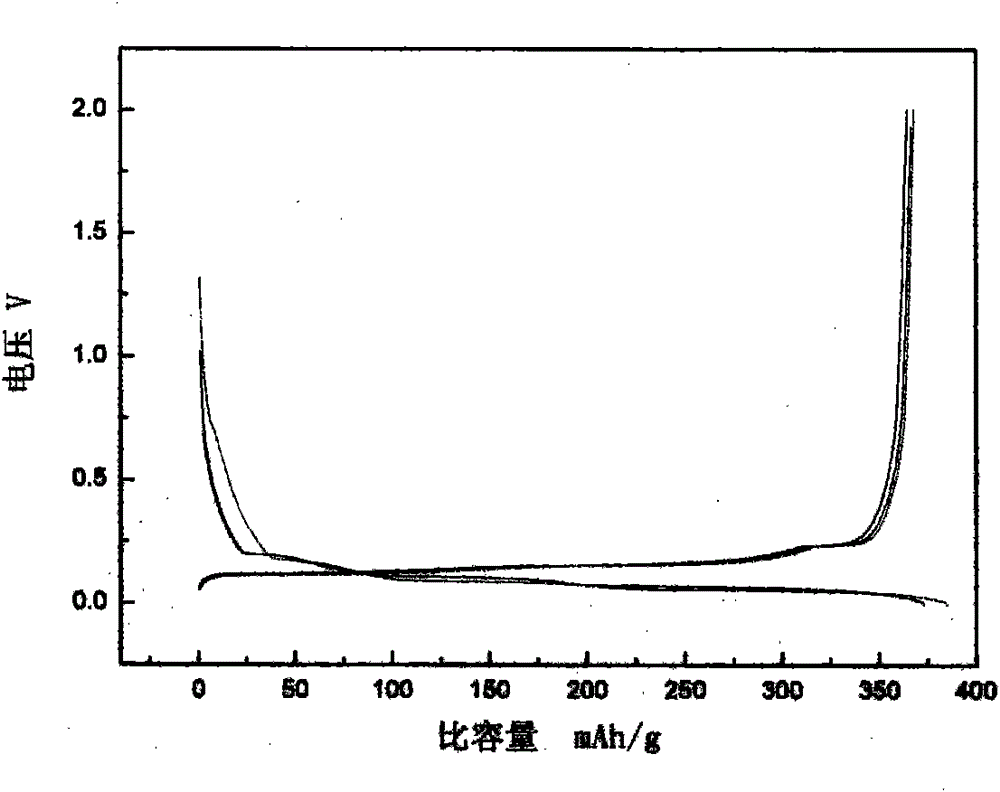

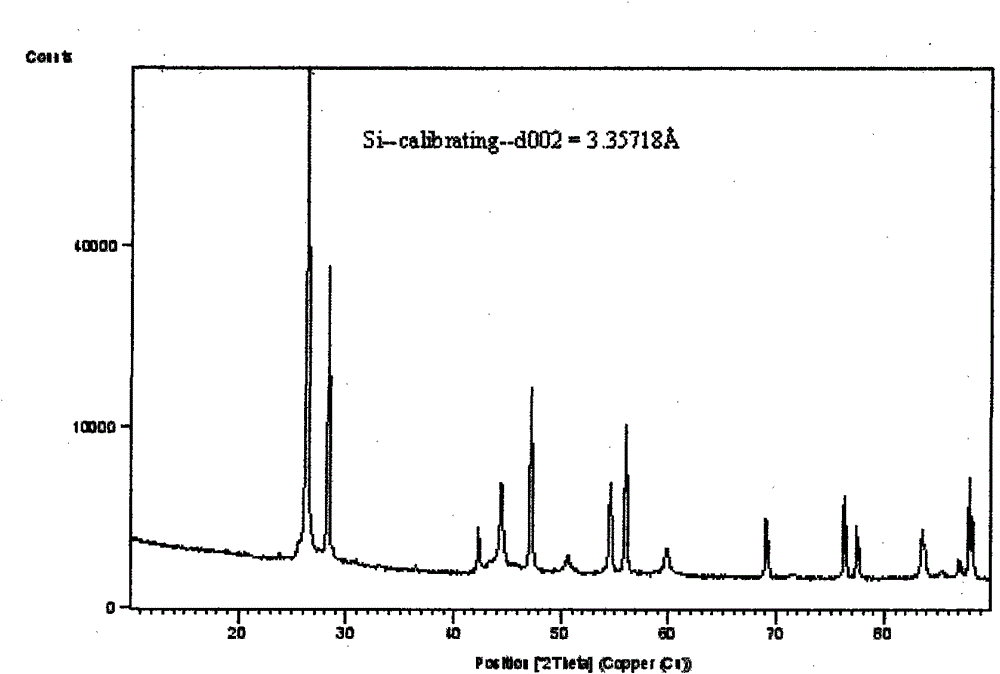

Lithium ion battery cathode material and preparation method thereof

The invention discloses a lithium ion battery cathode material and a preparation method thereof, which lower the cost of the lithium ion battery cathode material and improve the high-energy density thereof. The lithium ion battery cathode material takes more than one of natural crystalline graphite, natural cryptocrystalline graphite and natural crystalline vein graphite as matrixes, a non-graphitic carbon material is coated outside the matrixes, and the coated particles are compounded with a conductive material. The preparation method of the lithium ion battery cathode material comprises the following steps of mixing and drying a liquid phase, carbonizing, carrying out high-temperature treatment and compounding. Compared with the prior art, the graphite with lower carbon content is taken as a raw material to greatly reduce the raw material cost; by adopting a hot air drying mode, the preparation process is simplified and a coating layer is more solid and compact; and by adopting lower carburizing temperature and the temperature for high-temperature heat treatment, energy consumption is reduced, and product cost is further lowered.

Owner:BTR NEW MATERIAL GRP CO LTD

Ore dressing technique of microcrystal and cryptocrystal low grade collophanite ore

InactiveCN101352699AOvercome the shortcoming that the single positive flotation cannot obtain qualified phosphorous concentrateOvercome the shortcomings of less than qualified phosphorous concentrateFlotationHigh energyPhosphoric acid

The invention relates to a beneficiation technology of crystallite and cryptocrystalline collophanite with low grade. The technology comprises the following steps: (1) ores are crushed and wetly ground to fineness that the content of minus 200 mesh is 90%-92%; (2) flotation method is carried out to remove mud; (3) phosphate salt direct flotation method is carried out; (4) carbonate salt reversed-flotation is carried out, and after reversed-flotation scavenging operation, the product in a flume is phosphate concentrate which is the ultimate product. The method of the invention is used for beneficiating collophanite with low grade, and overcomes the defect that no qualified phosphate concentrate can be obtained only by direct flotation previously; the content of deleterious impurity MgO in the phosphate concentrate is lowered to 1.78%, which achieves the requirement of phosphoric acid third grade phosphate concentrate prepared by wet process. The technology of the invention overcomes low recovery rate of concentrate in calcination-digestion- spiral beneficiation and high energy consumption, and the recovery rate of P2O5 is improved from 47.08% to 74.66%-80.90%.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Jade-like Ru porcelain and preparation method thereof

The invention relates to a jade-like Ru porcelain and a preparation method thereof. The jade-like Ru porcelain comprises a body and a glaze, wherein the preparation raw material of the body is of kaolin, and the preparation raw materials of the glaze comprises the following components in percentage by weight: 55%-80% of feldspar, 10%-25% of calcite, 5%-15% of cryptocrystalline quartz, 2%-10% of alkaline stone, 1%-8% of bone ash and 1%-8% of plant ash. According to the jade-like Ru porcelain disclosed by the invention, the Ru porcelain glaze with jade quality is combined with the body with thejade quality, a traditional Ru porcelain firing process is adopted for enabling the porcelain body to show the jade-like translucent state, color and luster are elegant, pale and graceful, a brand new visual impact and an artistic effect can be further generated, and the millenary Ru porcelain can further realize the historic breakthrough. A new species is added in the family of the Ru porcelain,the cultural connotation of the Ru porcelain is enriched, and the added value and the market share of Ru porcelain products are further improved.

Owner:河南弘宝汝瓷坊有限公司

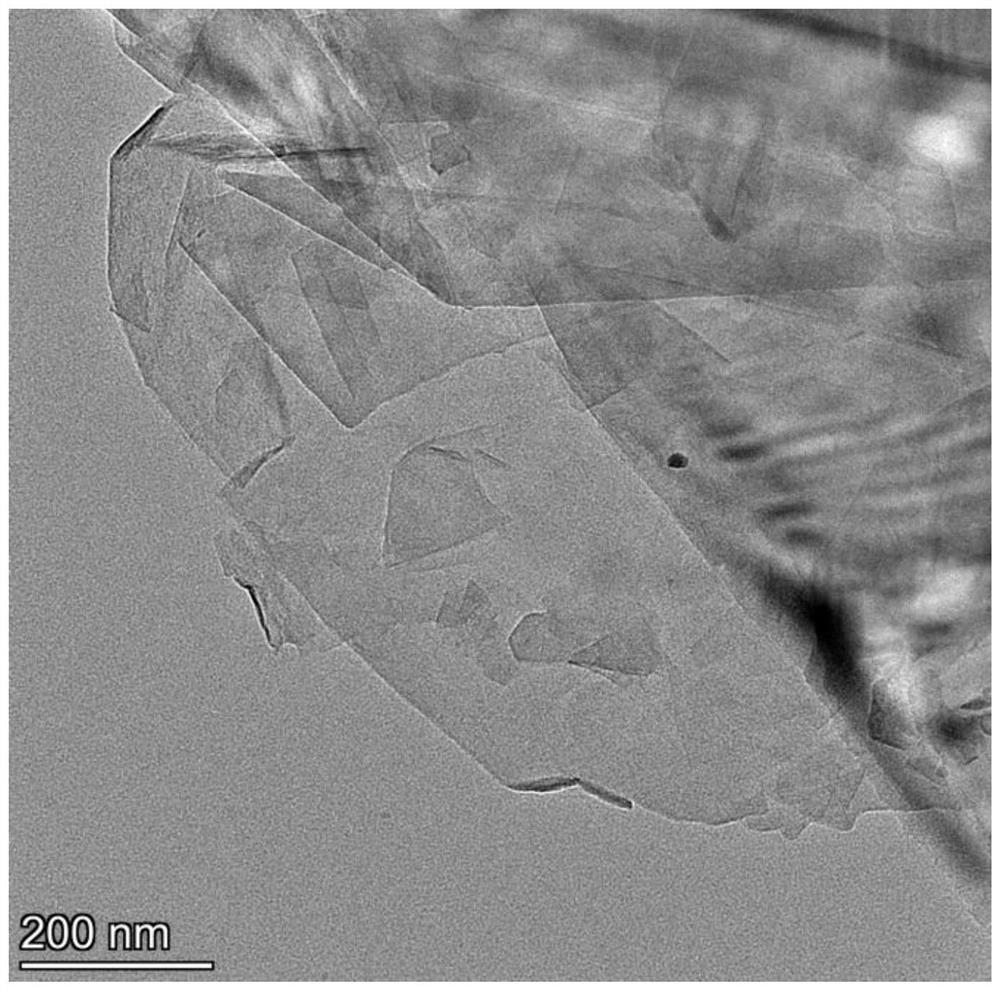

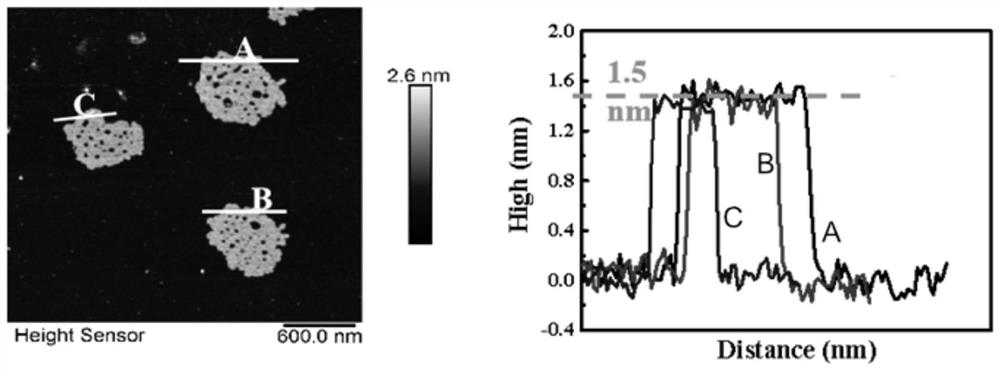

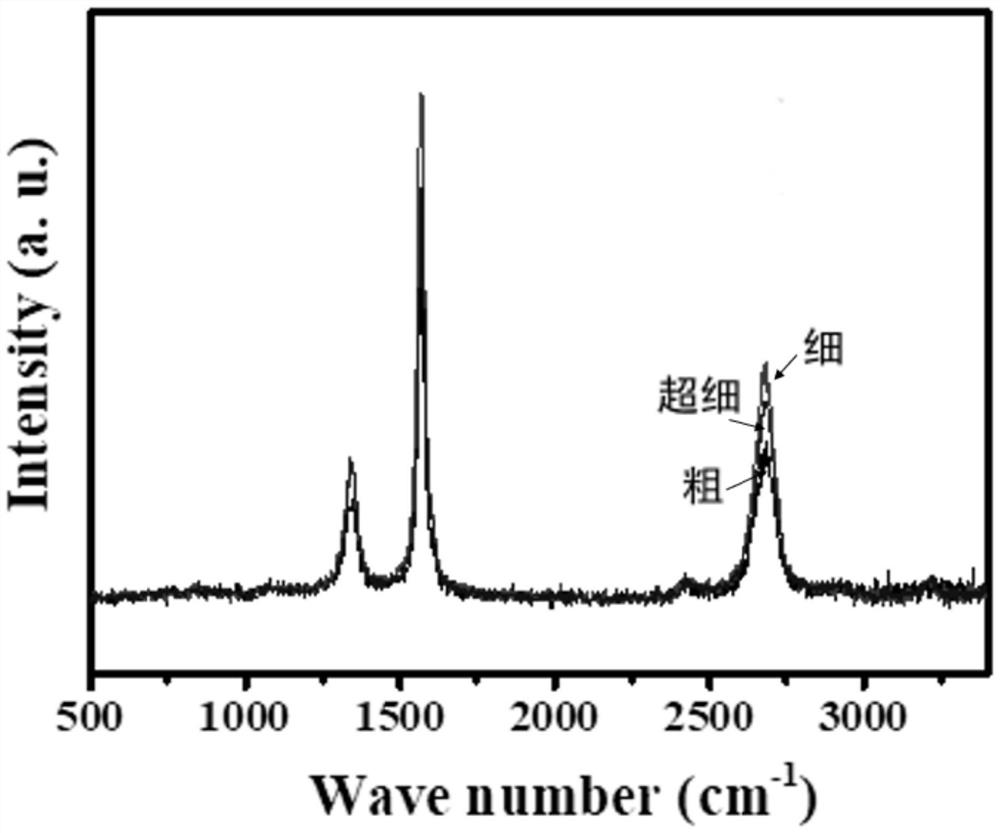

Method for preparing high-purity small oxidized graphene

The invention belongs to the technical field of oxidized graphene, and particularly relates to a method for preparing small oxidized graphene from cryptocrystalline graphite.The method mainly solves the problems of existing oxidized graphene preparing methods that purity is low, toxicity is high, technology is complicated and cost is high.According to the method, purified cryptocrystalline graphite, concentrated acid and strong oxidant are evenly mixed for reaction in an airtight environment at the temperature of 80-120 DEG C, a reaction mixture is slowly poured into an excessive amount of deionized water, uniform stirring is conducted, then an aqueous hydrogen peroxide solution with the mass concentration of 25% is added till turbid liquid becomes brown or luminous yellow, acid pickling and washing are conducted till pH value becomes 6-7, and then centrifugal separation is conducted to generate the small oxidized graphene.The ratio of the mass of purified cryptocrystalline graphite to the volume of concentrated acid is 1 : (20-80), and the mass ratio of purified cryptocrystalline graphite to purified cryptocrystalline graphite is 1 : (3-10).

Owner:SHANXI UNIV

Coating color for accurate core with high permeation and light coating layer

ActiveCN101176909APenetrative sexClear outlineFoundry mouldsFoundry coresSuspending AgentsDip-coating

The invention discloses a dip-coating coating for precision sand core with high permeability and thin coating, which is mainly composed of the following raw materials in terms of weight fraction: 35% to 45% of silicon micropowder, 5% to 10% of calcined talc %, cryptocrystalline graphite 3% to 5%, suspending agent 1% to 2%, composite binder 1.5% to 4%, deionized water 46% to 52%. The dip-coating coating of the present invention is suitable for mass production of resin sand for castings, especially for precision phenolic resin sand cores of coated sands. After the coating is applied to the sand cores, the coating has high strength and strong ability to withstand molten iron mechanical and thermal shocks ;The coating is thin, so that the poured castings have clear contours and high dimensional accuracy, which can meet the requirements of various complex precision castings produced in industries such as automobiles, diesel engines, and hydraulic parts.

Owner:赵溶

Steel for bearing ring of large-size shield tunneling machine and heat treatment method thereof

The invention discloses steel for a bearing ring of a large-size shield tunneling machine and a heat treatment method thereof. The steel consists of the following elements in percentage by weight: 0.41-0.45 percent of C, 0.17-0.37 percent of Si, 0.60-0.80 percent of Mn, 0.90-1.20 percent of Cr, 0.15-0.25 percent of Mo, 0.50-0.70 percent of Ni, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.00018 percent of H, less than or equal to 0.0015 percent of O and the balance of Fe and normal impurities. The experiment steel subjected to alloying design has good hardenability, the hardening layer depth can be over 40mm in the end quenching experiment and is 30mm higher than that of 42CrMo; the bearing ring of the large-size shield tunneling machine is wholly subjected to quenched-tempered heat treatment, and after the surface is subjected to induction hardening, the surface hardening layer texture is cryptocrystalline martensite, and the matrix structure is tempered sorbite; the surface has high hardness and has the average value of 58.5-60.3HRC; the core has good toughness, the impact toughness AKv value at the temperature of 20 DEG C below zero is over 106J; and the steel has proper hardness, and the average value of the hardness is 272-283HB. Meanwhile, a control process window of an actual production cooling medium is wide, and the cooling speed is over 10 DEG C per second. Therefore, the requirement on the comprehensive mechanical property of the steel for the bearing ring of the large-size shield tunneling machine can be met.

Owner:UNIV OF SCI & TECH BEIJING

Soil improvement agent suitable for grounding works in high soil resistivity environments

InactiveCN102226089AOrganic fertilisersSoil conditioning compositionsElectrical conductorSodium Bentonite

The invention discloses a soil improvement agent suitable for grounding works in high soil resistivity environments, which comprises the following components in percentage by weight: 14-18wt% of modified starch super absorbent resin with the molecular weight of 20,000-40,000, 42-52wt% of 150-200 meshed cryptocrystalline graphite powder, 26-38wt% of calcium-magnesium-based soil gelling agent (calcium-magnesium-based bentonite), 2-4wt% of calcium-aluminum-based soil affinity agent (calcium-aluminum hydroxide mixture), 1-3wt% of soil blowing agent (sodium silicate), 1-3wt% of zinc metal preservative, and 1-3wt% of lanthanide rare earth metal slag. The soil improvement agent disclosed by the invention utilizes the water absorption characteristic of the super absorbent resin to achieve the purpose of preservation of soil moisture, utilizes the electrical conductivity of the graphite material to reduce the contact resistance between the metal conductors and soil, adds a soil gelling agent and other components to result in a more compact and stable transition conducting layer, adds the lanthanide rare earth metal slag to enhance the electrical conductivity, and adds the zinc metal preservative to prolong the service life. The soil improvement agent is especially suitable for soil improvement in geological environments with high soil resistivity and extremely-droughty geological environments.

Owner:XIAN JSBOUND TECH CORP

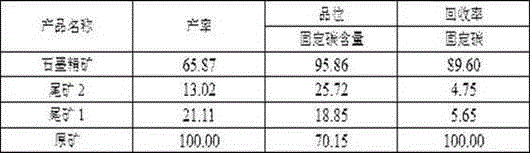

Combined collecting agent for flotation of cryptocrystalline graphite ore

InactiveCN105233993AEfficient development and utilizationImprove development and utilization valueFlotationMining engineeringEther

The invention relates to a collecting agent for flotation of cryptocrystalline graphite ore. The collecting agent is a combined collecting agent AM, wherein the combined collecting agent AM is composed of the following components in parts by weight: 60-70 parts of diesel oil, 20-30 parts of ether alcohol and 10-20 parts of C12H25-N(CH3)2CH2COO. The collecting agent has high collecting capacity for cryptocrystalline graphite and excellent selectivity and can obtain high-carbon graphite concentrate from low-grade cryptocrystalline graphite ore through beneficiation, wherein the fixed carbon content of the high-carbon graphite concentrate is 95%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Thermal treatment method for hinge pin shaft of hydraulic support

InactiveCN102634650AWear-resistantAnti-fatigueIncreasing energy efficiencyFurnace typesCryptocrystallineHardness

The invention discloses a thermal treatment method for a hinge pin shaft of a hydraulic support. The method comprises the following steps of: tempering the pin shaft to obtain a tempered sorbite; and performing surface quenching on the pin shaft at the temperature of between 80 and 150 DEG C above Ac3 to obtain a fine cryptocrystalline martensite. By utilizing the method, the surface of the part has certain hardness, the part has abrasion resistance and fatigue resistance, and the core has enough strength and toughness.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

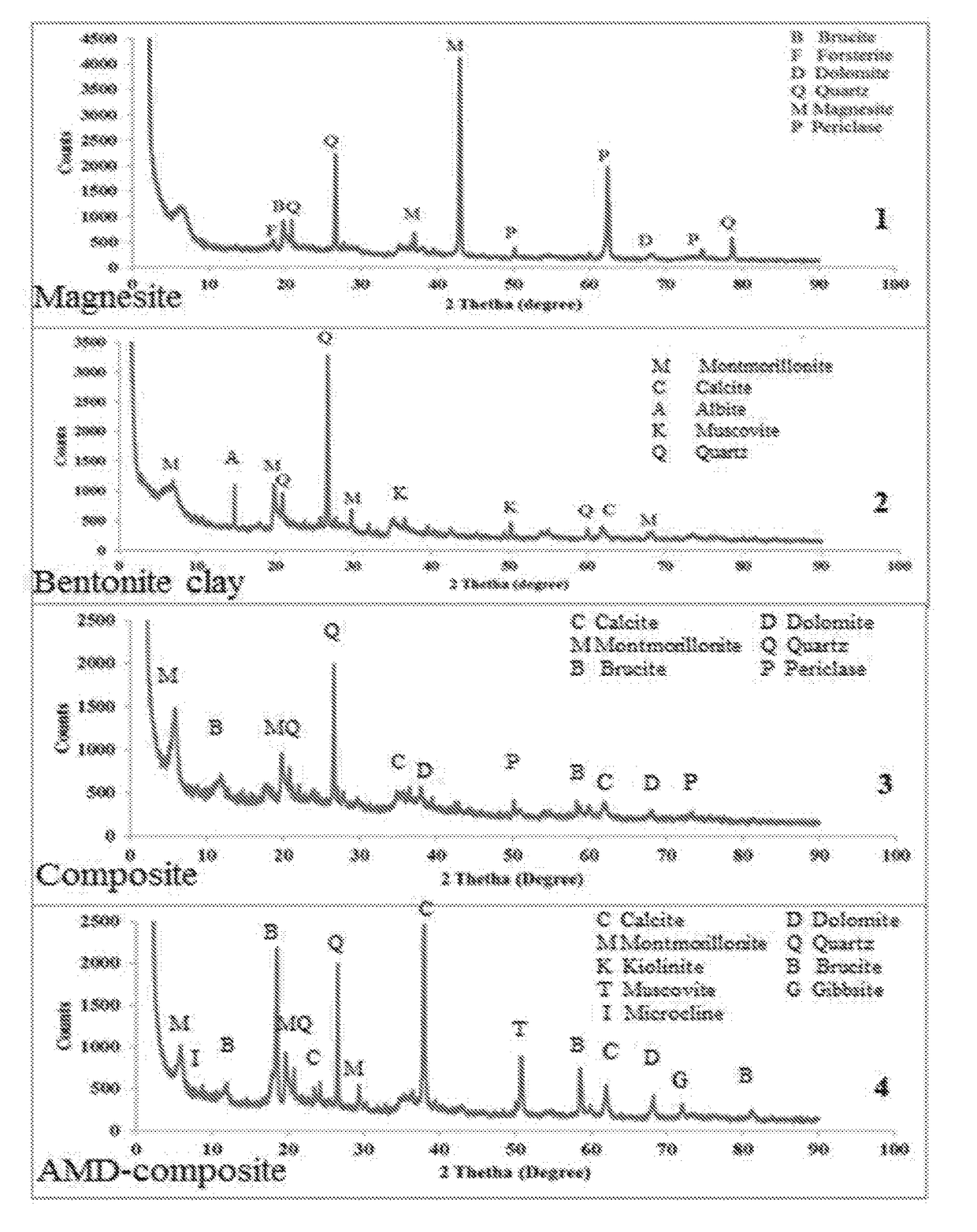

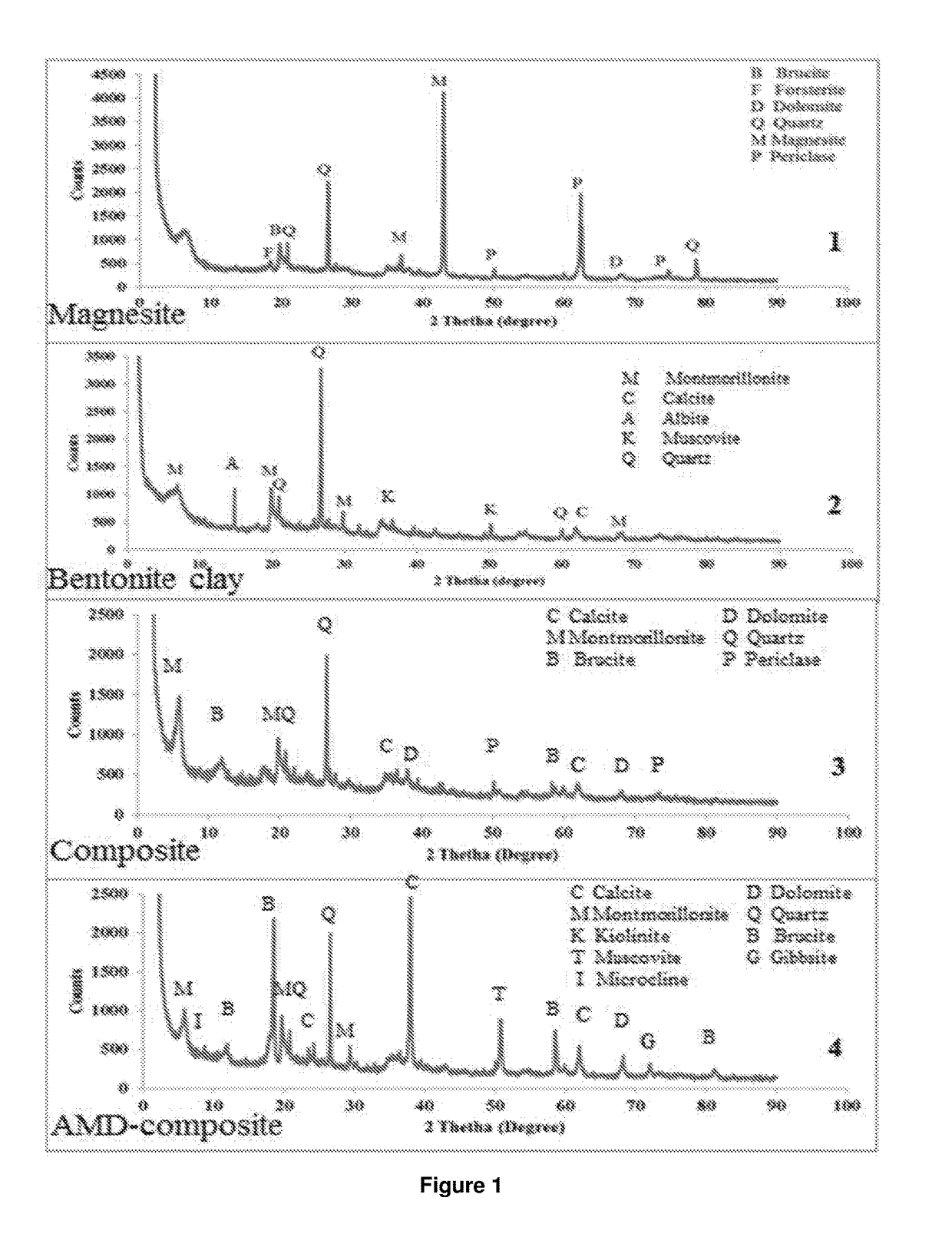

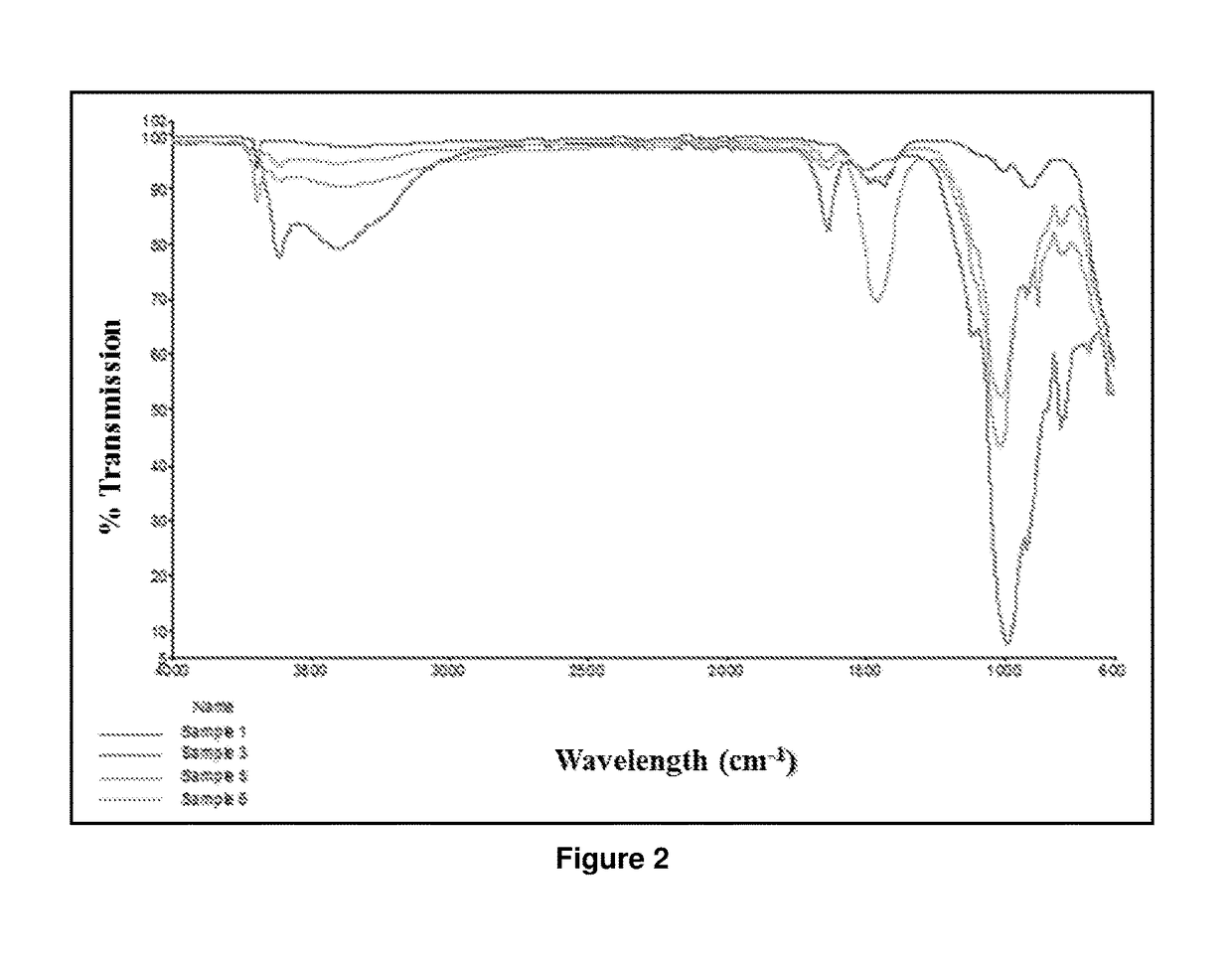

Water treatment using a cryptocrystalline magnesite - bentonite clay composite

InactiveUS20170341959A1Waste water treatment from quariesWater treatment parameter controlMulti pollutantCryptocrystalline

A process for the treatment of contaminated water includes contacting the contaminated water with a cryptocrystalline magnesite-bentonite clay composite thereby to remove one or more contaminants from the water. The invention extends to a method for the manufacture of a cryptocrystalline magnesite-bentonite clay composite wherein an admixture of cryptocrystalline magnesite and bentonite clay is milled to a desired particle size with amorphization of the magnesite and bentonite clay in the resultant cryptocrystalline magnesite-bentonite clay composite, and to a cryptocrystalline magnesite-bentonite clay composite.

Owner:CSIR

Ground strengthening agent

The invention discloses a ground strengthening agent, which is characterized by consisting of the following components in percentage by weight: a. 8.5-12WT% of modified starch super absorbent resin; b. 13-17WT% of polyethylene and high water swelling resin; c. 36-45WT% of cryptocrystalline graphite powder of 150-200 meshes; d. 28-35WT% of calcium-magnesium bentonite; and e. 6-10WT% of silicate cement. The ground strengthening agent disclosed by the invention is specifically applicable to electric system power transmission pole grounding engineering under a high earth resistivity geological environment and an extreme drought geological environment.

Owner:SHANGHAI KE DONG IND

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving the severe problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of low technical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

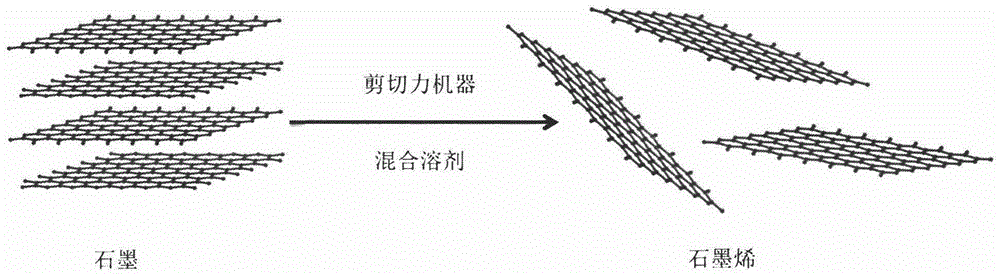

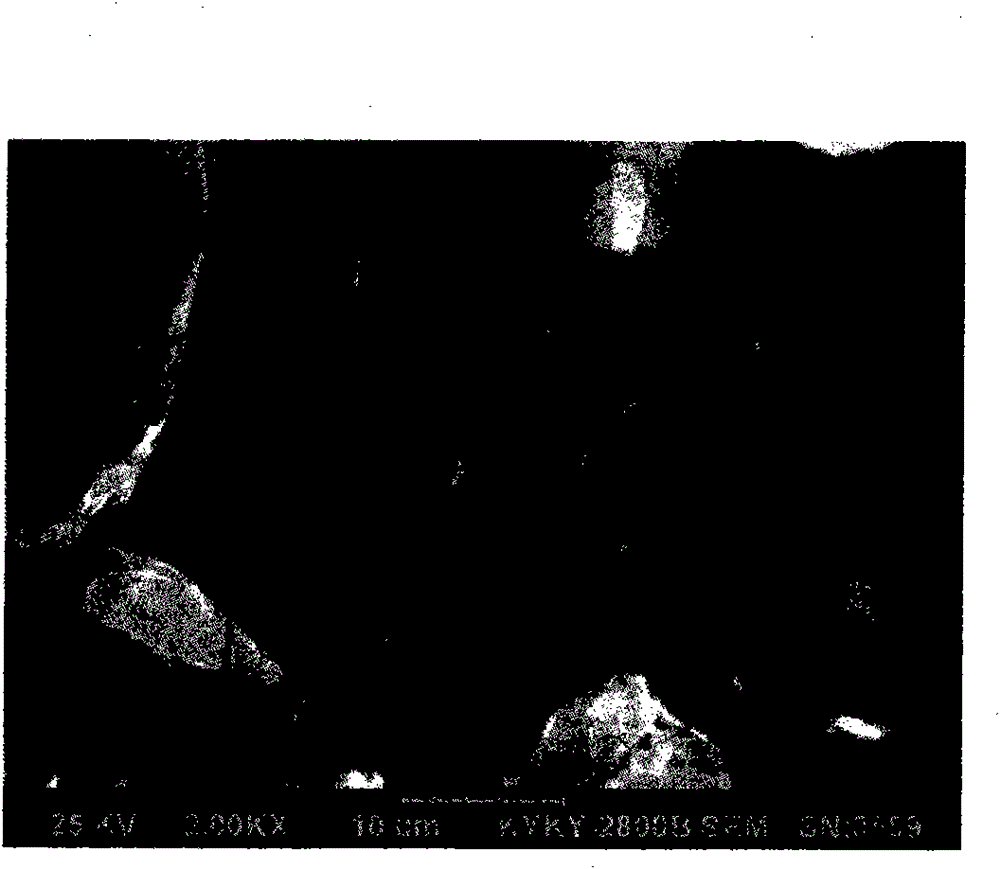

Method for peeling off graphite to obtain graphene based on shear force machine

The invention relates to the technical field of nanometer preparation, in particular to a method for peeling off graphite to obtain graphene based on a shear force machine. The method comprises the specific steps that 5-1*10<9> mg of one or more of massive crystalline graphite, crystalline flake graphite, cryptocrystalline graphite, expanded graphite and highly oriented pyrolytic graphite are weighed, 50-5*10<6> mL of water and a mixing solvent with 10 or smaller carbon atom alcohol are added, the uniformly-mixed solution is placed into the shear force machine for performing peeling for 0.3-120 h, standing is performed, the centrifuging speed is 100-10000 rpm / min, and post-treatment is performed, so that graphene is obtained. The preparation method is mild in condition, the reaction is green, adopted raw materials and solvents are simple, no liquid waste pollution exists, large-scale preparation can be performed, and the method has the application prospect for producing graphene.

Owner:苏州烯墨纳米科技有限公司

Method for processing thrust wheel axle

InactiveCN109128708AImprove quality levelImprove surface fatigue resistanceWater basedAustenite grain

The invention provides a method for processing a thrust wheel axle. Lathing of the outer round of a whole bar is achieved by using a bar centreless lathing technology, and the technology that lathingis carried out after existing bar segment cutting is replaced; a roller pressing process is used for enabling the axle surface to generate plastic deformation, metal flowing is used for eliminating surface defects such as machining knife lines and pits, the surface smoothness is improved, the compressive stress on the axle surface is increased, and the fatigue resistance of the surface of a finished product is improved; induction heating is carried out, so that rapid heating and short-time heat preservation are performed, austenite grains are refined, and scale on the surface of the workpieceis reduced; quenching is carried out with a water-based quenching agent, and fine cryptocrystalline martensite is obtained inside the workpiece; tempering at appropriate temperature is carried out toachieve the aim of replacing the hardening and tempering process, and the cost of heat treatment is significantly reduced.

Owner:XUZHOU XCMG CRAWLER CHASSIS CO LTD

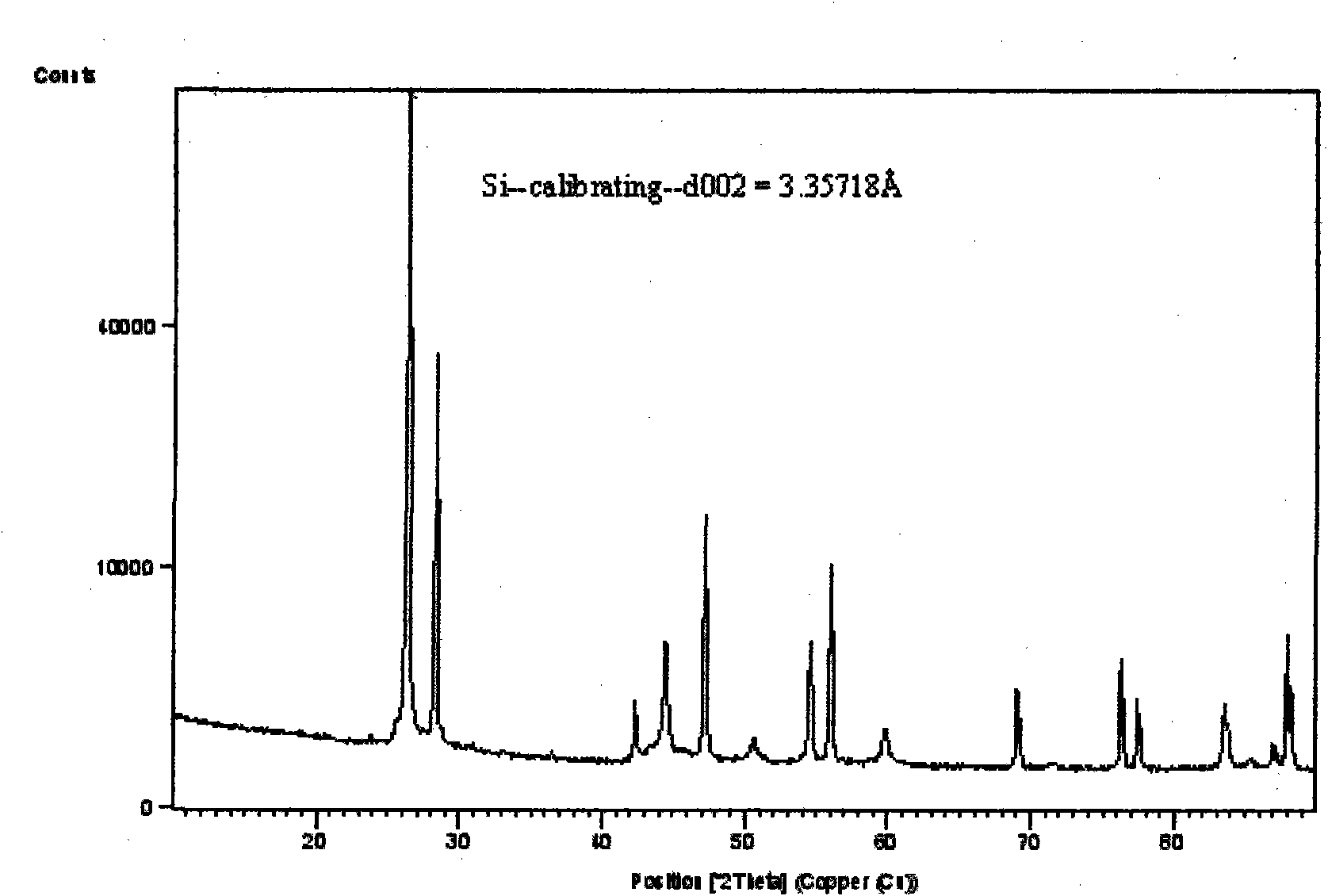

Purification method of natural cryptocrystalline graphite

InactiveCN104495797AReduce lossAchieve the effect of high temperature calcined alkali fusionSulfonatePurification methods

The invention provides a purification method of natural cryptocrystalline graphite. The method using natural cryptocrystalline graphite as a raw material comprises the following steps: adding a sodium hydroxide solid and an assistant to the raw material, adding water, heating, fully stirring the obtained solution for a reaction, separating the solution and graphite, washing, precipitating, filtering, and drying to prepare alkali washed graphite, wherein the assistant is composed of sodium metaborate and sodium diisobutyl naphthalene sulfonate; adding alkali washed graphite, a soluble fluoride salt and nitric acid into a reaction container, heating while carrying out a stirring and soaking reaction, and separating the obtained solution and graphite to prepare graphite; and washing acid-containing graphite, precipitating, filtering, and drying to prepare graphite with the carbon content of above 99.90%. The purification method has the advantages of low energy consumption, little environmental pollution and high purification efficiency.

Owner:林前锋

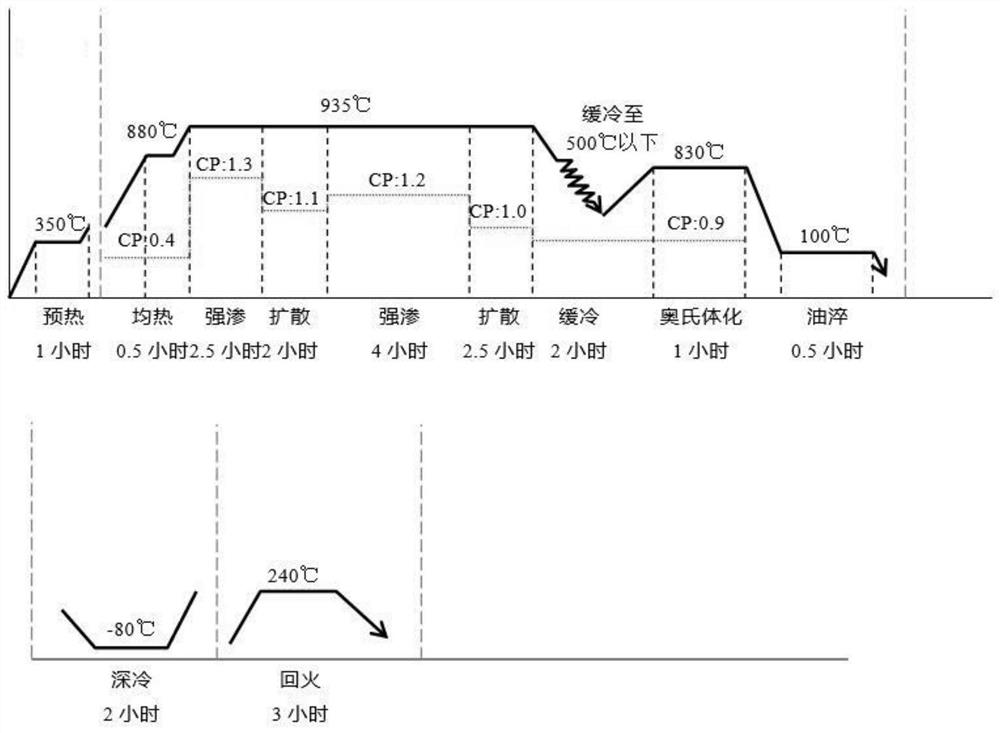

Carburizing heat treatment process for fatigue-resistant metal sliding block

PendingCN113337826AImprove contact fatigue performanceAvoid formingSolid state diffusion coatingFurnace typesCryptocrystallineCryogenic treatment

A carburizing heat treatment process for a fatigue-resistant metal sliding block comprises the steps that S1, the sliding block is preheated to 350 DEG C, and the preheating time is 1 h; S2, the sliding block is subjected to carburizing and quenching; S3, the sliding block is subjected to cryogenic cooling, wherein the temperature is minus 80 DEG C, and the time is 2 h; and S4, the sliding block is tempered, wherein the temperature is 240 DEG C, and the time is 3 h. According to the carburizing heat treatment process for the fatigue-resistant metal sliding block, controllable atmosphere carburization is adopted, multiple stages of strong carburization and diffusion are alternately carried out, it is avoided that carbon is gathered on the surface to form cementite, and meanwhile a carburized layer has a good and gentle hardness gradient; and then, in combination with the modes of conducting carburizing slow cooling and conducting two times of heating and quenching, extremely fine cryptocrystalline martensite is obtained, then the retained austenite is further reduced through cryogenic treatment, and therefore the contact fatigue resistance of the sliding block is improved.

Owner:KUNSHAN SUNMIN DRILUBE ELECTRONIC MATERIAL TECHNOLOGY CO LTD

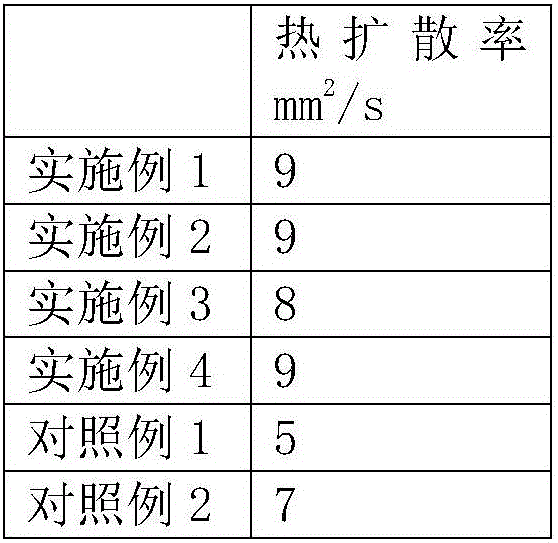

Preparation method of cryptocrystalline graphite/polyvinyl alcohol heat-conducting composite material

InactiveCN106751267AThermally conductiveIncrease the degree of aggregationChemical industryHeat-exchange elementsSodium bicarbonateHeat conducting

The invention discloses a preparation method of a cryptocrystalline graphite / polyvinyl alcohol heat-conducting composite material, and belongs to the field of composite materials. The method comprises the following steps: 1, mixing cryptocrystalline graphite, ammonium fluoride and a hydrochloric acid solution, heating, washing with deionized water until the pH value is 7, and drying; 2, mixing weighed sodium bicarbonate, corn starch and cryptocrystalline graphite, performing wet ball milling and drying; 3, dissolving polyvinyl alcohol into water, adding the treated cryptocrystalline graphite mixture, mixing uniformly and drying in a drying oven; 4, pulverizing and performing hot-press molding. The thermal diffusion rate is 8 to 9 mm<2> / s, because in the cryptocrystalline graphite granules subjected to purifying treatment, the aggregation degree is high, the density is increased, the heat-conducting effect is denser, and the heat transfer efficiency is improved.

Owner:NANJING JOOZ INFORMATION SCI & TECH

Local quenching process for link plate hole surface

InactiveCN101798619AHigh surface hardnessImprove surface wear resistanceFurnace typesHeat treatment furnacesUltra fineAlternating current

Owner:HUANGSHAN JINGRUI CONVEYING MACHINERY

Graphite purification method

InactiveCN108358201AImprove the purification effectFully dissociatedCarbon compoundsPurification methodsLower grade

The invention discloses a graphite purification method which comprises the following steps: 1) with low-grade cryptocrystalline graphite of which the cryptocrystalline graphite content is 65-73% as araw material, performing superfine crushing treatment till the particle size of the ore sample is 45 [mu]m or less; 2) putting the cryptocrystalline graphite subjected to superfine crushing treatmentin the step 1) into a reaction kettle, adding sodium hydroxide, sodium metaborate and water, performing a reaction for 2-3 hours at 150-260 DEG C, and performing alkali fusion treatment; and 3) performing acid soaking on the cryptocrystalline graphite after alkali fusion in the step 2), namely washing the cryptocrystalline graphite after alkali fusion in the step 2) with water till the pH value is7.5-7.8, adding an acid for a first time, uniformly stirring, and leaving to stand and settling down for 1-1.5 hours, wherein the volume concentration of the acid is 2-5%. According to the method, the low-grade cryptocrystalline graphite of which the cryptocrystalline graphite content is 65-73% as the raw material, through processes of superfine crushing and alkali fusion-acid soaking in the reaction kettle, high-grade cryptocrystalline graphite of which the cryptocrystalline graphite content is greater than or equal to 99.0% is prepared, and the cryptocrystalline graphite can be relatively wide in application range.

Owner:赵文渊

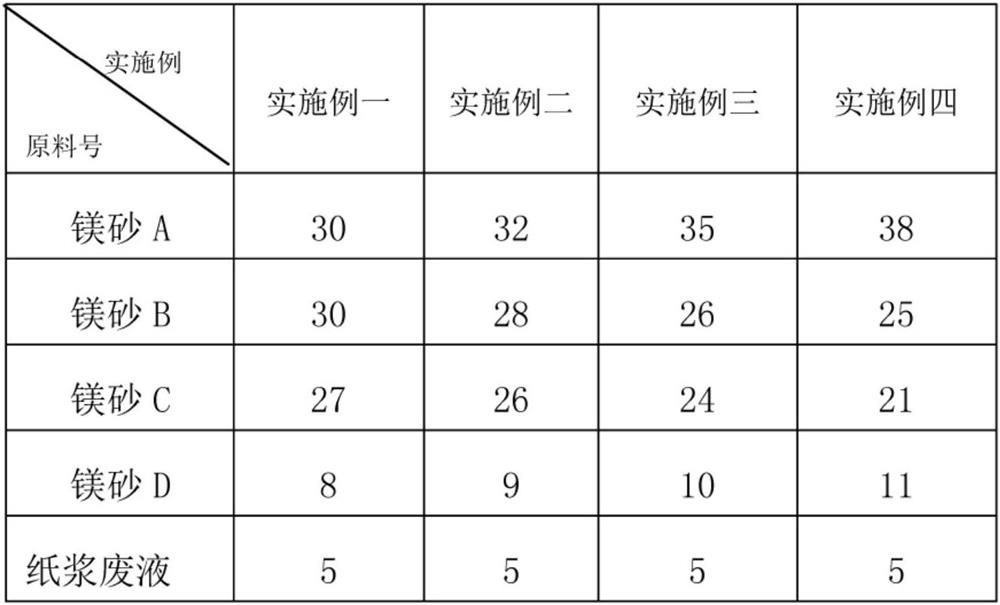

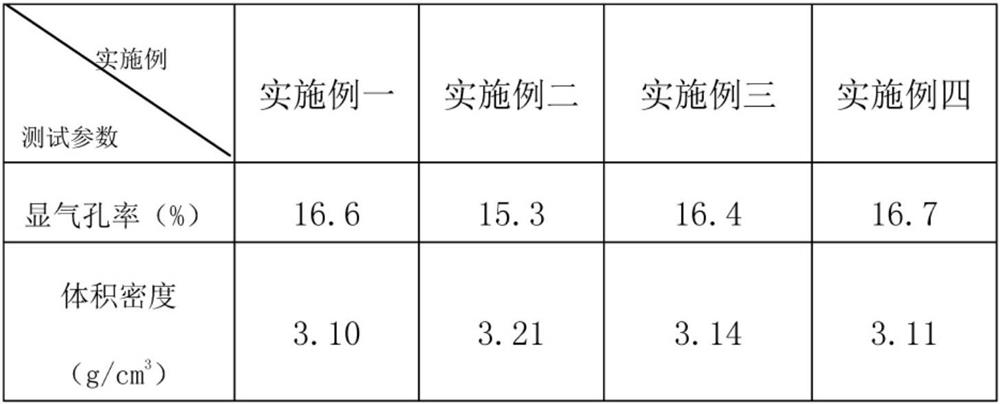

High-purity magnesite brick for ultrahigh-temperature shaft kiln with temperature greater than or equal to 2100 DEG C and manufacturing method of high-purity magnesite brick

The invention relates to a high-purity magnesite brick for an ultrahigh-temperature shaft kiln with a temperature larger than or equal to 2100 DEG C and a manufacturing method of the high-purity magnesite brick. The high-purity magnesite brick is prepared from magnesite A, magnesite B, magnesite C, magnesite D and paper pulp waste liquid. The manufacturing method of the high-purity magnesite brick comprises the steps of mixing, forming, drying and sintering. The raw material magnesite of the high-purity magnesite brick is prepared by crushing and screening large-crystal magnesite obtained by electrically melting high-purity cryptocrystalline magnesite produced in Kamaduo Village, Leiwuqi County, Tibetan, and an impurity content is extremely low; then multi-stage grain composition is adopted for batching, a large-tonnage press is adopted for green brick forming, and sintering is performed in a tunnel kiln at a high temperature of greater than or equal to 1810 DEG C; and thus, refractoriness under load and sinterability are improved, the strength of the product is improved, and the sintered magnesite brick can meet the requirement of an ultrahigh-temperature sintering shaft kiln of more than or equal to 2100 DEG C.

Owner:河北北方窑业工程有限公司

Flotation method of cryptocrystalline graphite

The invention provides a flotation method of cryptocrystalline graphite, which comprises the following steps: S1, carrying out first-stage ore grinding on the cryptocrystalline graphite to obtain slurry I; s2, the slurry I is subjected to first-stage flotation, and slurry II is obtained; s3, the slurry II is subjected to second-stage ore grinding, and slurry III is obtained; s4, the slurry III is subjected to second-stage flotation, and slurry IV is obtained; s5, an organic solvent capable of being mixed and dissolved with water is added into the slurry IV, then third-section flotation is conducted, and slurry V is obtained; and S6, carrying out filter pressing on the slurry V, and drying to obtain the nano-scale cryptocrystalline graphite. And a surfactant adopted in the third-stage flotation comprises polyethyleneimine.

Owner:湖南润众新材料科技有限公司

Method for preparing graphene through dry grinding and stripping

The invention provides a method for preparing graphene through dry grinding and stripping. According to the method for preparing the graphene through dry grinding and stripping, dense crystallized graphite, flake graphite and cryptocrystalline graphite are mixed according to a certain ratio; and because the dense crystallized graphite, the flake graphite and the cryptocrystalline graphite have different kinds of lubricity, hardness and plasticity, under the condition that polydimethylsiloxane is used as an assistant, graphite is rapidly stripped through dry direct grinding due to the different performances of the different kinds of graphite, and the stripping performance is high. Besides, through the dispersion lubricating feature of the polydimethylsiloxane, the structure of the obtained graphene layer is well preserved, and the grinding device can be a Raymond mill or a vertical mill or a ball mill.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

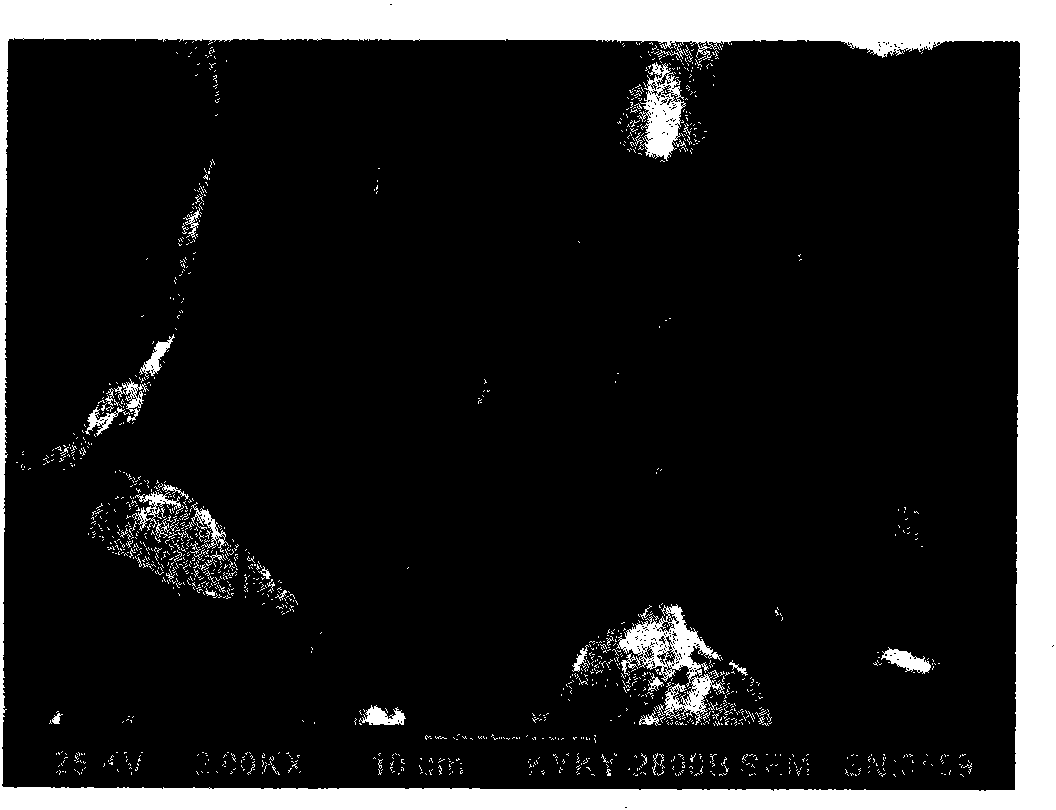

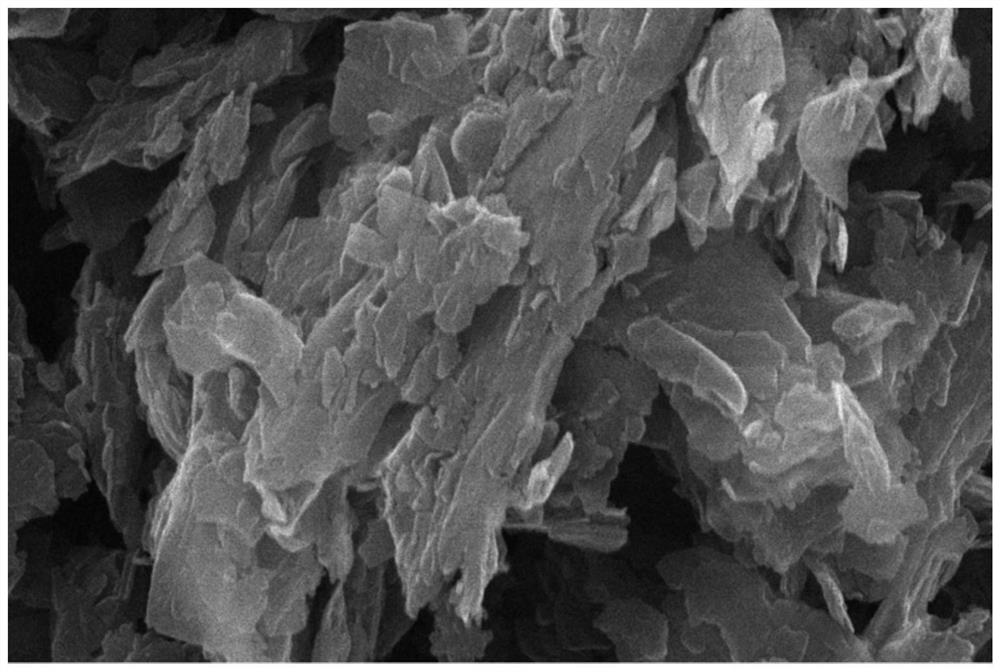

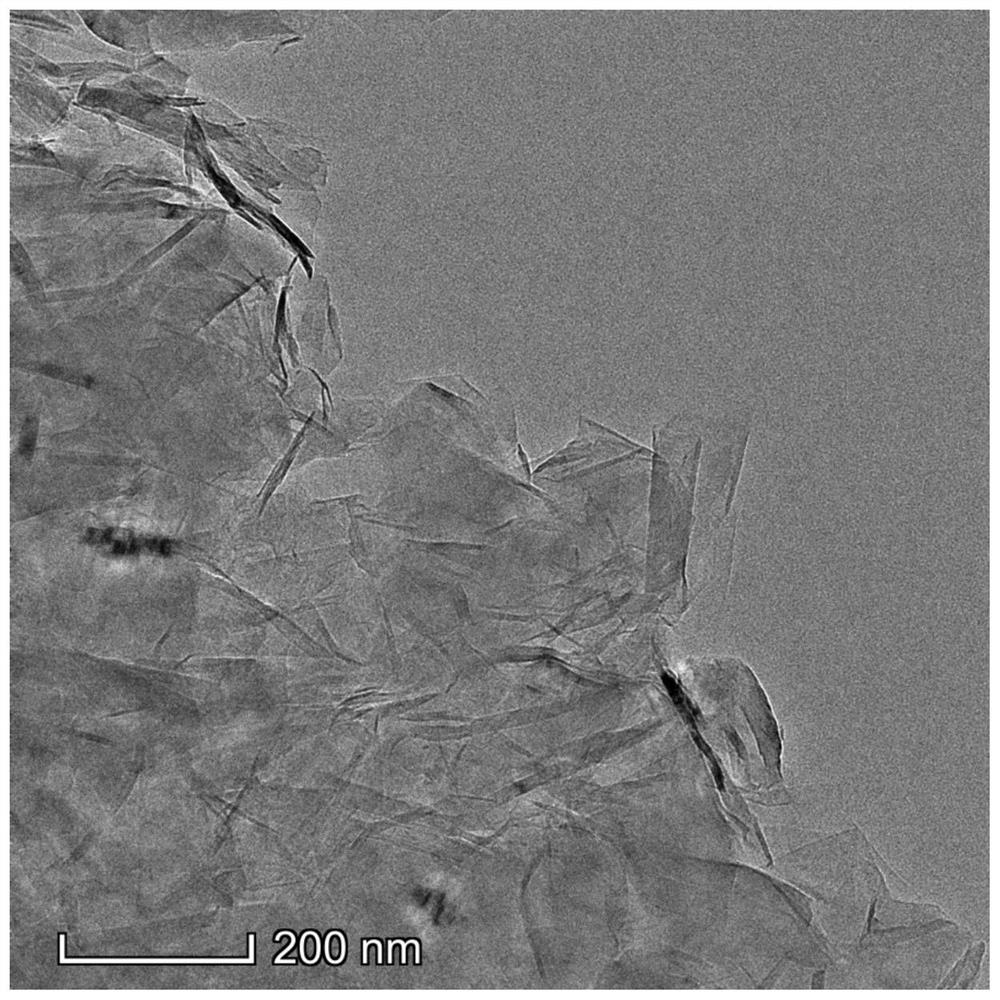

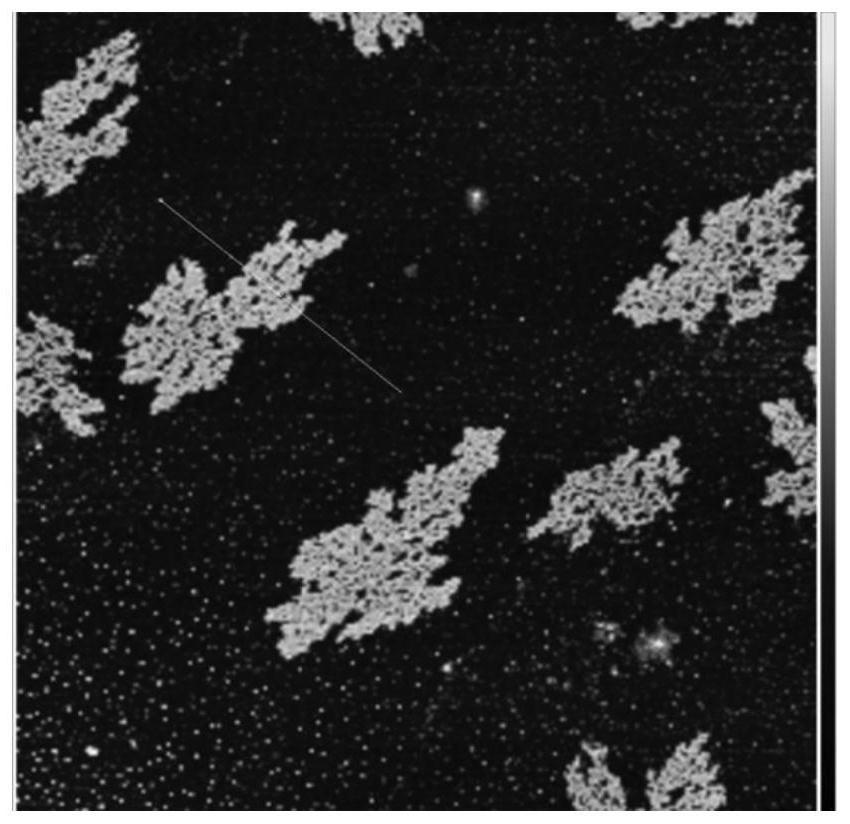

Preparation method of few-layer cryptocrystalline graphene

ActiveCN114014307AReduce manufacturing costGood discharge performance at low temperatureGrapheneCryptocrystallineGraphite

The invention provides a low-cost batch preparation method of few-layer cryptocrystalline graphene. Few-layer cryptocrystalline graphene with high carbon content is obtained through a brand new liquid phase stripping process.

Owner:湖南润众新材料科技有限公司

Lithium ion battery cathode material and preparation method thereof

Owner:BTR NEW MATERIAL GRP CO LTD

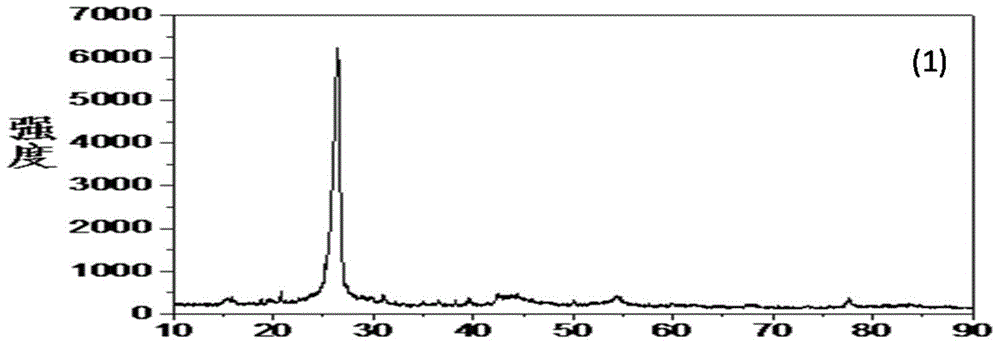

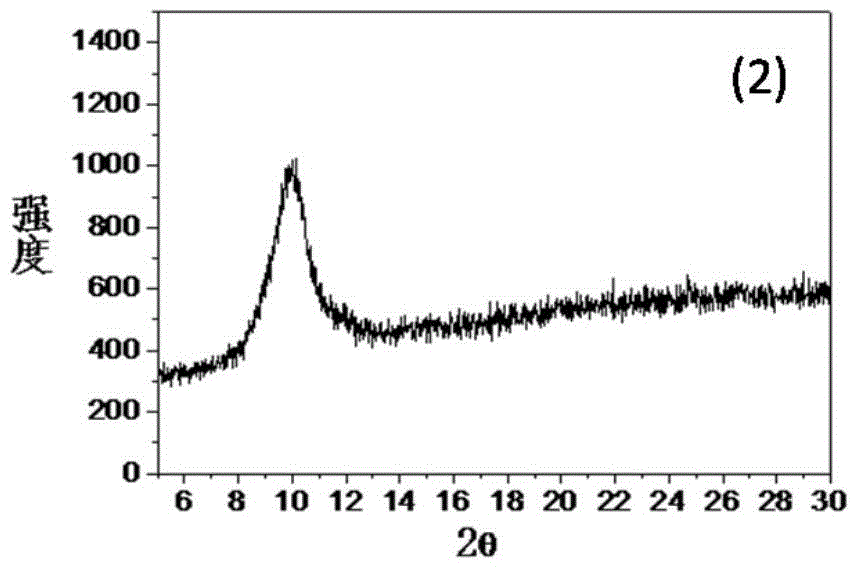

A kind of beneficiation and purification method of low-grade microcrystalline graphite

ActiveCN109607527BShort processHigh enrichment ratioCarbon compoundsFlotationFoaming agentProcess engineering

The invention relates to a method for beneficiation and purification of low-grade microcrystalline graphite. Firstly, the ore of microcrystalline graphite is sequentially crushed and ground, and a collector and a foaming agent are added to the ground pulp, stirred, and graphite flotation is carried out. Obtain graphite coarse concentrate and tailings 1; conduct a selection and a sweep of graphite coarse concentrate to obtain concentrated concentrate and tailings 2; conduct regrinding and selection on the selected concentrate to obtain a re-grinding Grinding concentrated concentrate and regrinding concentrated tailings; regrinding 1-2 times of regrinding concentrated ore, and then performing 2-4 times of beneficiation under acidic conditions to obtain high-grade graphite concentrate and regrinding Mill tailings. The mineral processing and purification method of the present invention has a short process flow and a high enrichment ratio, and solves the problems of low-grade aphanitic graphite mineral processing technical indicators, low graphite concentrate grade, low recovery rate, complicated process, and high cost, and makes low-grade microcrystalline Graphite ore is efficiently, economically and rationally utilized.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Soil improvement agent suitable for grounding works in high soil resistivity environments

InactiveCN102226089BOrganic fertilisersSoil conditioning compositionsSodium BentoniteElectrical conductor

Owner:XIAN JSBOUND TECH CORP

A kind of purification method of aphanitic graphite flotation concentrate

ActiveCN105692606BEnvironmentally friendly beneficiation methodEfficient beneficiation methodCarbon compoundsGranularityUltra fine

The invention discloses a method for purifying aphanitic graphite flotation concentrate. The method includes steps of (1), removing reagents by means of ultra-fine grinding; (2), carrying out two-section heating rinsing and concentrating on the aphanitic graphite flotation concentrate; (3), soaking the aphanitic graphite flotation concentrate in acid at the constant temperatures of 90 DEG C for 1 hour; (4), removing impurities by means of reverse flotation. The method has the advantages that the aphanitic graphite flotation concentrate with the carbon (C) content of 85-90% is used as a raw material and is treated by the aid of processes for 'removing the reagents by means of ultra-fine grinding, carrying out the two-section heating rinsing and concentrating, soaking the aphanitic graphite flotation concentrate at the constant temperatures of 90 DEG C for 1 hour and removing the impurities by means of reverse flotation' for characteristics of small particle sizes of graphite crystals in the aphanitic graphite flotation concentrate, stable properties at the normal temperatures, good inherent flotability, the residual flotation reagents on the surfaces of minerals and the like, and accordingly high-purity graphite concentrate with the carbon (C) content higher than 99% can be obtained.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Method for flotation of cryptocrystalline magnesite

PendingCN112742607AIncrease the content of MgOExcellent technical indicatorsFlotationMagnetic separationSocial benefitsMining engineering

The invention relates to a method for flotation of cryptocrystalline magnesite. According to the technical scheme, magnesite lean ore is smashed and then ground, the obtained magnesite lean ore powder is sequentially subjected to primary ore grinding, low intensity magnetic separation, high intensity magnetic separation, third-time reverse flotation, secondary ore grinding and fifth-time direct flotation, and finally the upper-layer foam material which is received is dried. By adopting the method disclosed by the invention, the content of MgO in the low-grade cryptocrystalline magnesite can be effectively increased, the impurity content can be reduced, and the existing cryptocrystalline magnesite resources can be effectively developed and utilized, so that not only is the energy saved, but also the resource environment is protected, and better economic benefits and social benefits are created.

Owner:辽宁省地质矿产研究院有限责任公司

Steel for bearing ring of large-size shield machine and heat treatment method thereof

InactiveCN104532140BMeet the requirements of comprehensive mechanical propertiesHigh hardnessInduction hardeningMartensite

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com