Flotation method of cryptocrystalline graphite

A cryptocrystalline graphite, flotation technology, applied in flotation, solid separation and other directions, can solve problems such as high cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

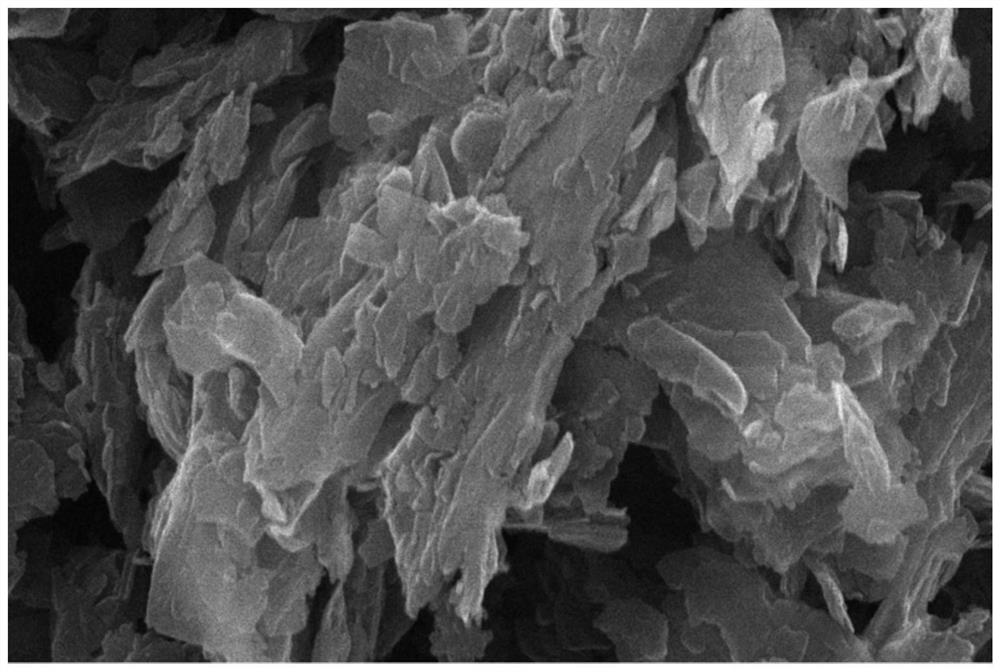

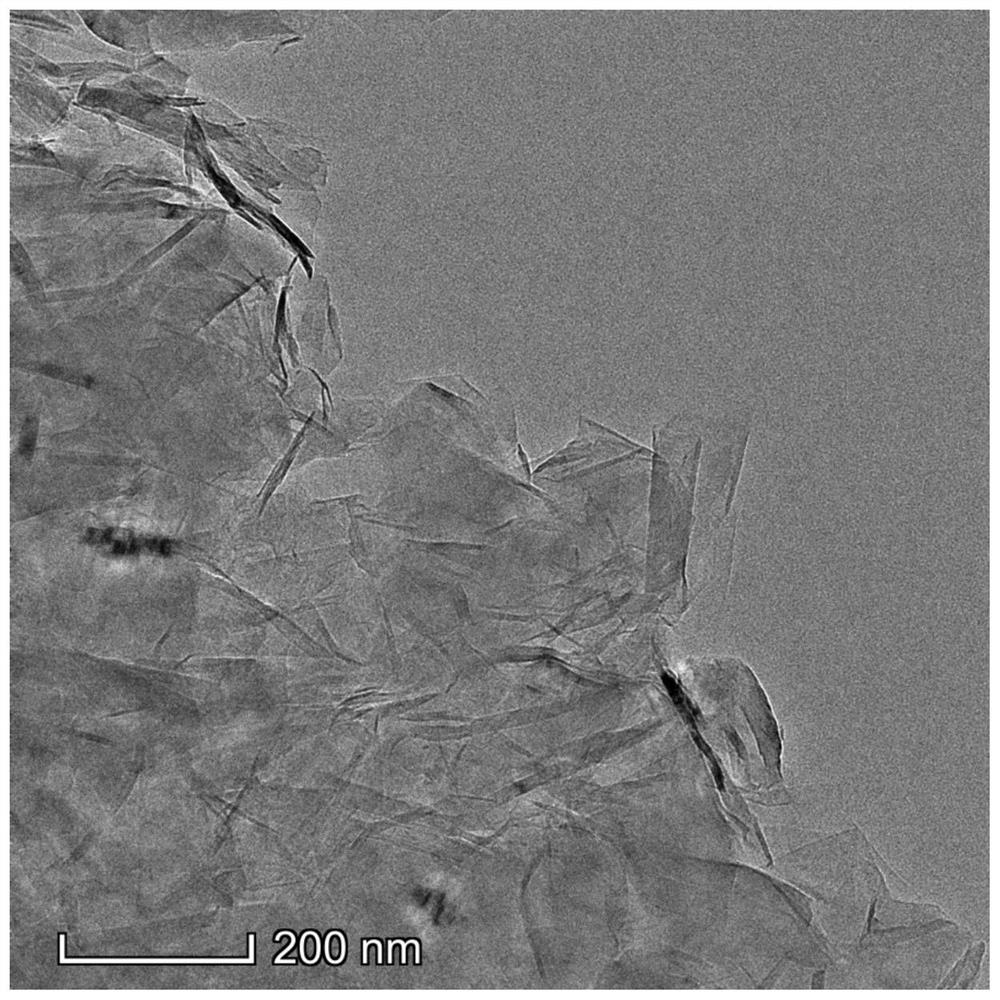

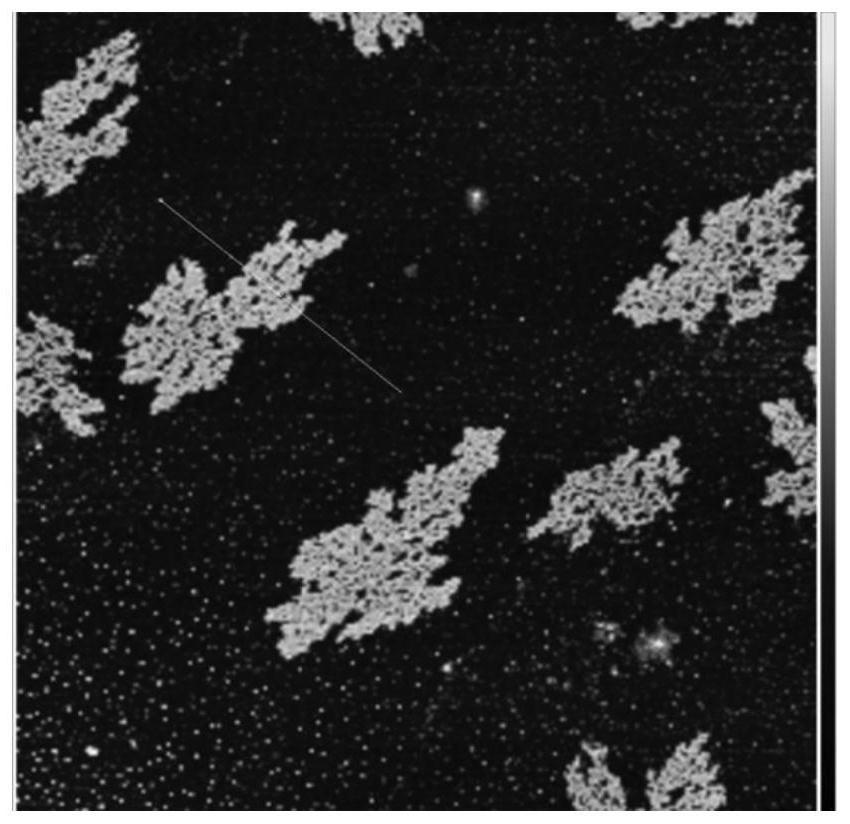

Image

Examples

Embodiment 1

[0047] S1 Adjust the powder of aphanitic graphite (D50≤2μm, fixed carbon≥90%) to a slurry with a concentration of 19wt%, and then add alumina with a particle size of 30 meshes accounting for 1% of the mass of aphanitic graphite, using Grinding is carried out in a vertical stirring mill. The vertical agitating mill adopted during ore grinding is a 1000-liter vertical agitating mill with a linear velocity of 10 m / s and a feed rate of 28 liters / minute. Then dilute the slurry to 15wt%, add alumina with a particle size of 30 meshes accounting for 0.5% of the mass of aphanitic graphite, and use a vertical stirring mill for grinding to obtain slurry I. The vertical agitating mill adopted during ore grinding is a 1000-liter vertical agitating mill with a linear velocity of 10 m / s and a feed rate of 28 liters / min.

[0048]S2 Dilute the slurry I with water to a concentration of 8wt%, and add 1kg of 2-octanol, 1kg of kerosene, 3kg of water glass, and 1.5kg of sodium hexametaphosphate fo...

Embodiment 2

[0056] S1 Adjust the powder of aphanitic graphite (D50≤2μm, fixed carbon≥90%) to a slurry with a concentration of 20wt%, and then add alumina with a particle size of 30 meshes accounting for 1% of the mass of aphanitic graphite. Grinding is carried out in a vertical stirring mill. The vertical agitating mill adopted during ore grinding is a 1000-liter vertical agitating mill with a linear velocity of 10 m / s and a feed rate of 28 liters / minute. Then dilute the slurry to 15wt%, add alumina with a particle size of 30 meshes accounting for 0.5% of the mass of aphanitic graphite, and use a vertical stirring mill for grinding to obtain slurry I. The vertical agitating mill adopted during ore grinding is a 1000-liter vertical agitating mill with a linear velocity of 10 m / s and a feed rate of 28 liters / minute.

[0057] S2 Dilute the slurry I with water to a concentration of 8wt%, and add 1kg of 2-octanol, 1kg of kerosene, 3kg of water glass, and 1.5kg of sodium hexametaphosphate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com