Patents

Literature

51results about How to "Improve contact fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth and carbon co-infiltration method in continuous furnace for automobile gearbox gear

InactiveCN1654700AChange other functionsOsmoticSolid state diffusion coatingHigh concentrationCarbon potential

The continuous micro deformation RE-carbon co-penetrating process for gear of automobile gear box is realized via making the pre-treated workpiece enter the different regions with RE co-penetrant in continuous carbonizing furnace at 840-890 deg.c. The workpiece is made to enter successively region-I for preheating and pre-penetrating; region-II and region-III with carbon potential of 1.15-1.25 % for carbonizing; region-IV with carbon potential of 0.8-1.05 % for diffusion treatment; and region-V with carbon potential of 0.8-1.05 % for waiting for discharging and quenching. The present invention is one controllable low temperature RE high concentration gas carbonizing process capable of resulting in optimal metallurgical structure, and has the advantages of high carbonizing rate, high efficiency and low power consumption.

Owner:HARBIN INST OF TECH

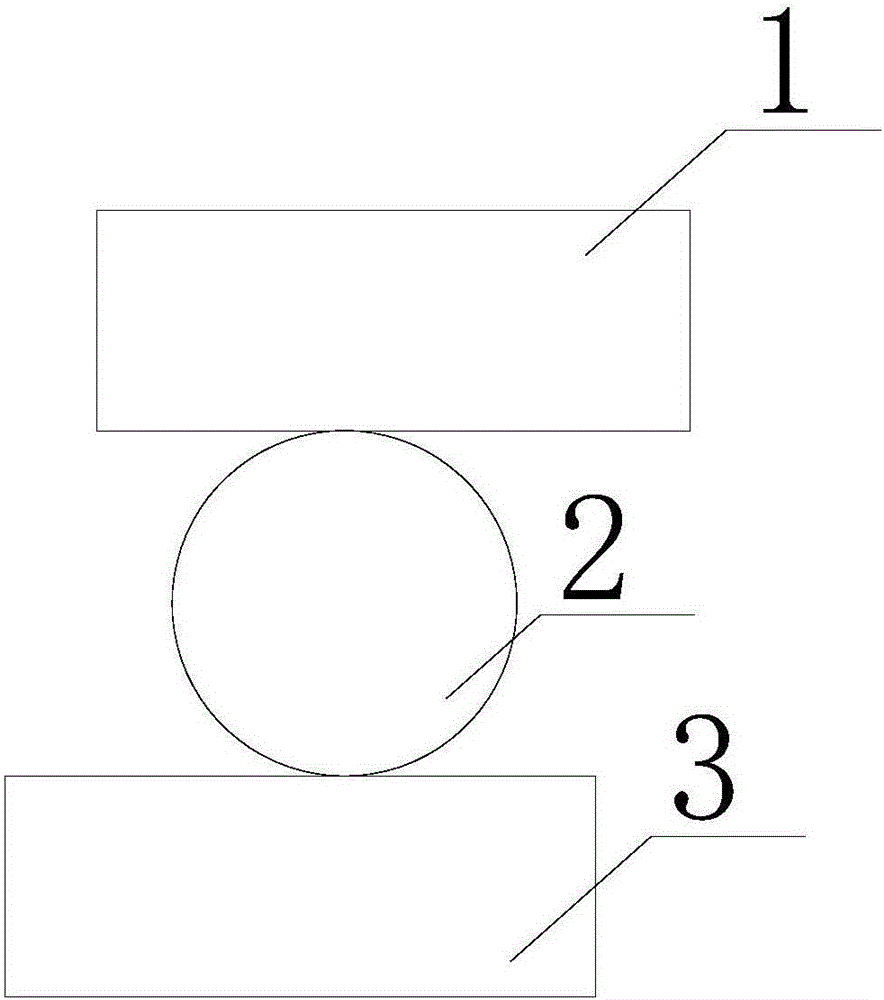

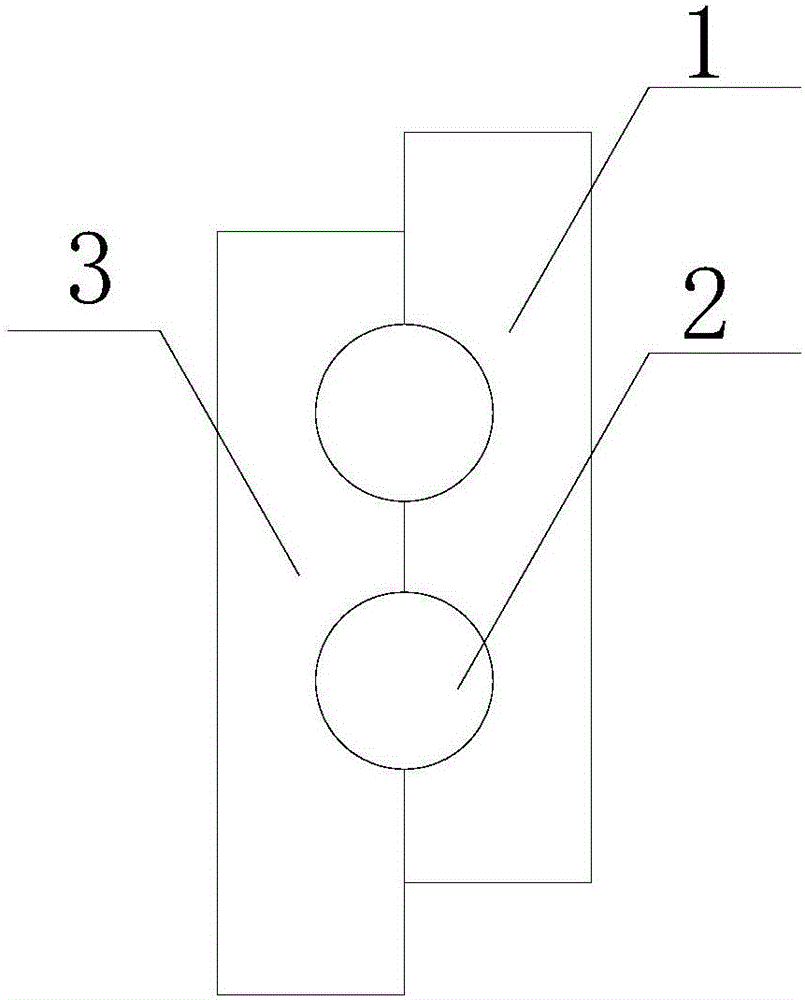

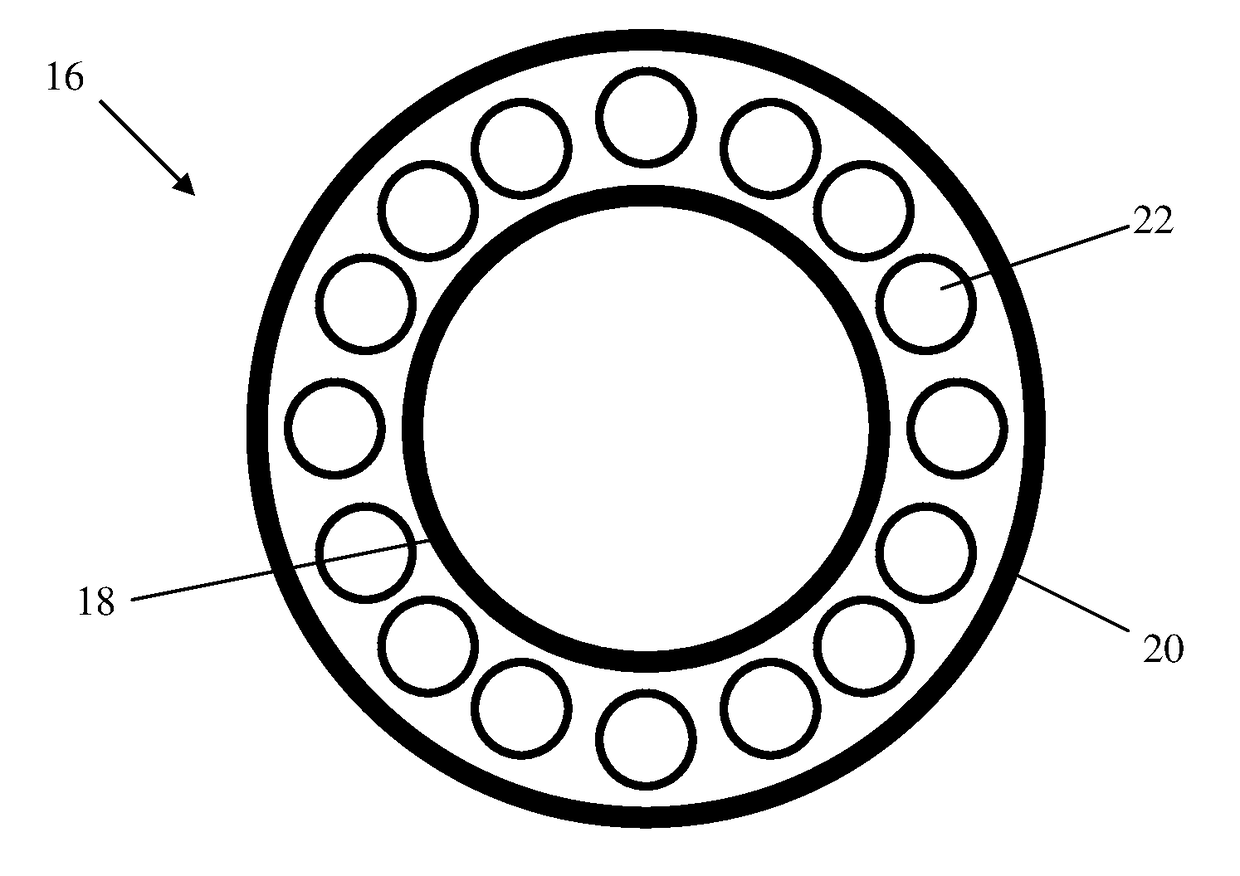

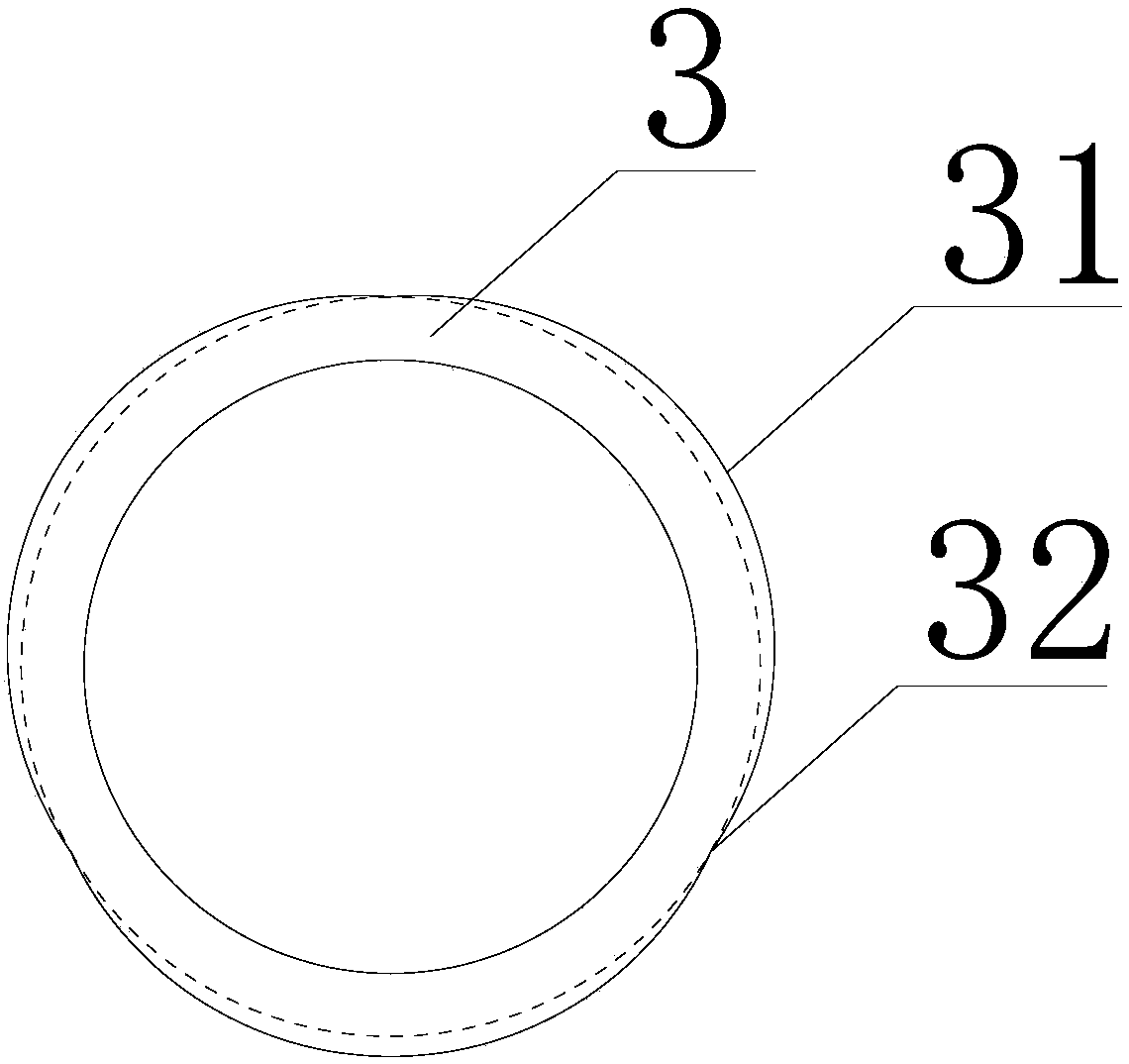

High-toughness and high-rigidity rolling bearing

ActiveCN105757124AEvenly distributedGrain refinementBearing componentsFurnace typesEngineeringToughness

The invention discloses a high-toughness and high-rigidity rolling bearing, comprising a bearing outer ring, a rolling body and a bearing inner ring; an outer raceway surface of the bearing inner ring comprises three bumps protruding towards the outer side of the bearing inner ring, the three bumps are sequentially connected, and a concave part is formed in a connecting part of every two adjacent bumps; both of the bumps and the concave parts are arcs; the three bumps are evenly distributed on the outer raceway surface along the circumferential direction of the bearing inner ring. The bearing inner ring is made from the following components by weight percent: 0.6-0.7% of C, 0.15-0.35% of Si, 0.4-0.5% of N, 0.09-0.12% of B, 0.3-0.4% of Mn, 0.1-0.2% of V, 0.1-0.15% of W, 0.18-0.22% of Mo, 0.12-0.15% of Nb, 0.22-0.26% of Al, 3-4% of Cr, 0.07-0.10% of Ce and the balance of Fe.

Owner:安徽省宁国顺昌机械有限公司

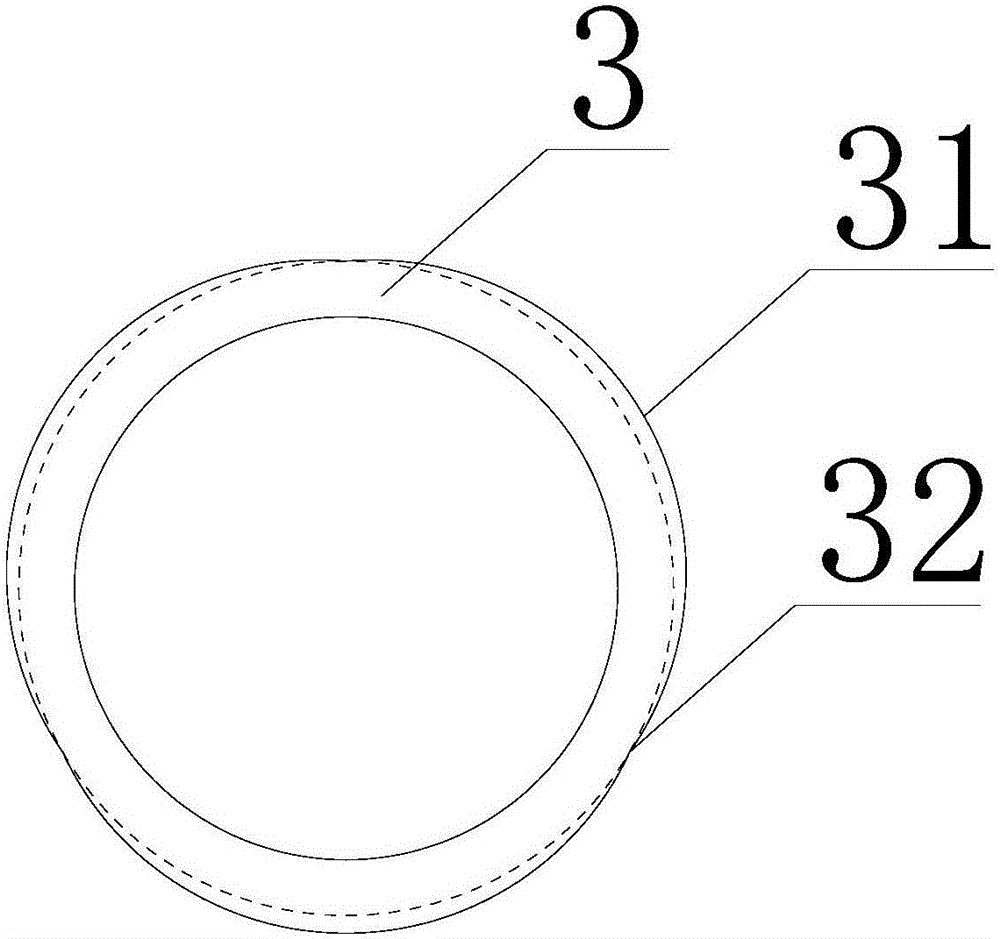

Wear-resistant and corrosion-resistant bearing

ActiveCN105673706AEvenly distributedImprove wear resistanceShaftsBearing componentsWear resistantEngineering

The invention discloses a wear-resistant and corrosion-resistant bearing which comprises a bearing outer ring, a rolling ball and a bearing inner ring, wherein the rollaway nest of the bearing outer ring and the rollaway nest of the bearing inner ring are in a double rollaway-nest structure; in a radial section, the distance between the centers of circles of the two rollaway nests is 84 mm; the radius of curvature of any one rollaway nest is 30.8 mm, the radius of the rolling ball is 29.6 mm, and the bearing contact angle is 50 degrees. The bearing inner ring comprises the following components in percentages by weight: 0.55-0.65% of C, 0.20-0.40% of Si, 0.15-0.25% of N, 0.10-0.20% of B, 0.30-0.45% of V, 0.10-0.20% of W, 0.20-0.23% of Mo, 0.08-0.12% of Nb, 0.25-0.35% ofAl, 3.00-3.50% of Cr, 0.12-0.15% of Y, less than or equal to 0.015% of S, less than or equal to 0.02% of P and the balance Fe.

Owner:河南联轴实业有限公司

Bearing long in service life

ActiveCN105587771AExtended service lifeDelay transitionBearing componentsEngineeringMechanical engineering

Owner:临清市万达轴承有限公司

Method for manufacturing quill roller for bearing

ActiveCN102501158AHigh precisionUniform qualityEdge grinding machinesPolishing machinesEngineeringQuenching

The invention relates to a method for manufacturing a quill roller for a bearing by adopting a roll-polishing way. The method comprises the following steps: A, roll polishing: cutting selected GCr15 steel to form a quill roller blank, and then, performing the roll polishing and grinding on the peripheries of both ends of the quill roller into spherical surfaces through a barrel polishing machine; B, heat treatment: grinding the roll-polished quill roller blank through a grinding machine, deburring through the barrel polishing machine, and then, performing quenching and tempering; and C, mechanical treatment: performing semi-coarse grinding, semi-accurate grinding and accurate grinding to obtain a finished product. The method for manufacturing the quill roller for the bearing by adopting the roll-polishing way is capable of treating a plurality of quill rollers at a time, and thereby, the production efficiency is greatly improved. The problems that uneven grinding and inhomogenous product quality often generated in the existing production are solved. The spherical surfaces of both ends of the obtained quill roller are ensured to be smooth, and the radian of each spherical surface meets the requirement, i.e. the spherical surfaces are neither too round nor too flat.

Owner:NINGBO ZHONGHE AUTO PATS

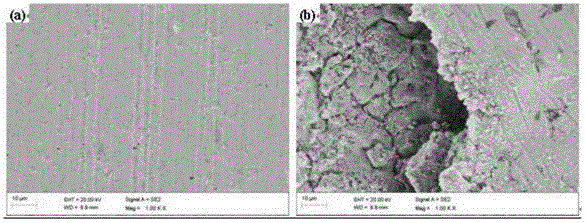

Coating material and coating with high contact fatigue strength based on 304 stainless steel base material

InactiveCN104862698AHigh contact fatigue strengthSimple preparation processMetallic material coating processesIron powderUltimate tensile strength

The invention discloses a coating material and coating with high contact fatigue strength based on a 304 stainless steel base material. The coating material comprises the following components in percentage by weight: 3-15% of Ni powder, 5-15% of Cr powder, 4-18% of Si powder, 20-40% of Mn powder, 0.1-2% of La2O3 powder, 0-3% of C powder, and the balance of reduced iron powder. The coating material is prepared through the following steps: mixing the powder, adding ball milling mediums and mixed powder into a ball milling pot for ball milling, and then performing vacuum drying and processing at 120 DEG C for 1 h so as to obtain the coating material. The coating is prepared through the following steps: grinding the surface of the 304 stainless steel base material level, paving the coating material on the surface of the 304 stainless steel base material, and performing fusion covering by using complete laser heat treatment equipment so as to obtain the coating with high contact fatigue strength. The coating material and the coating, disclosed by the invention, are higher in contact fatigue strength, simple in preparation technology, and low in building cost, and can be produced in batches.

Owner:GUIZHOU UNIV

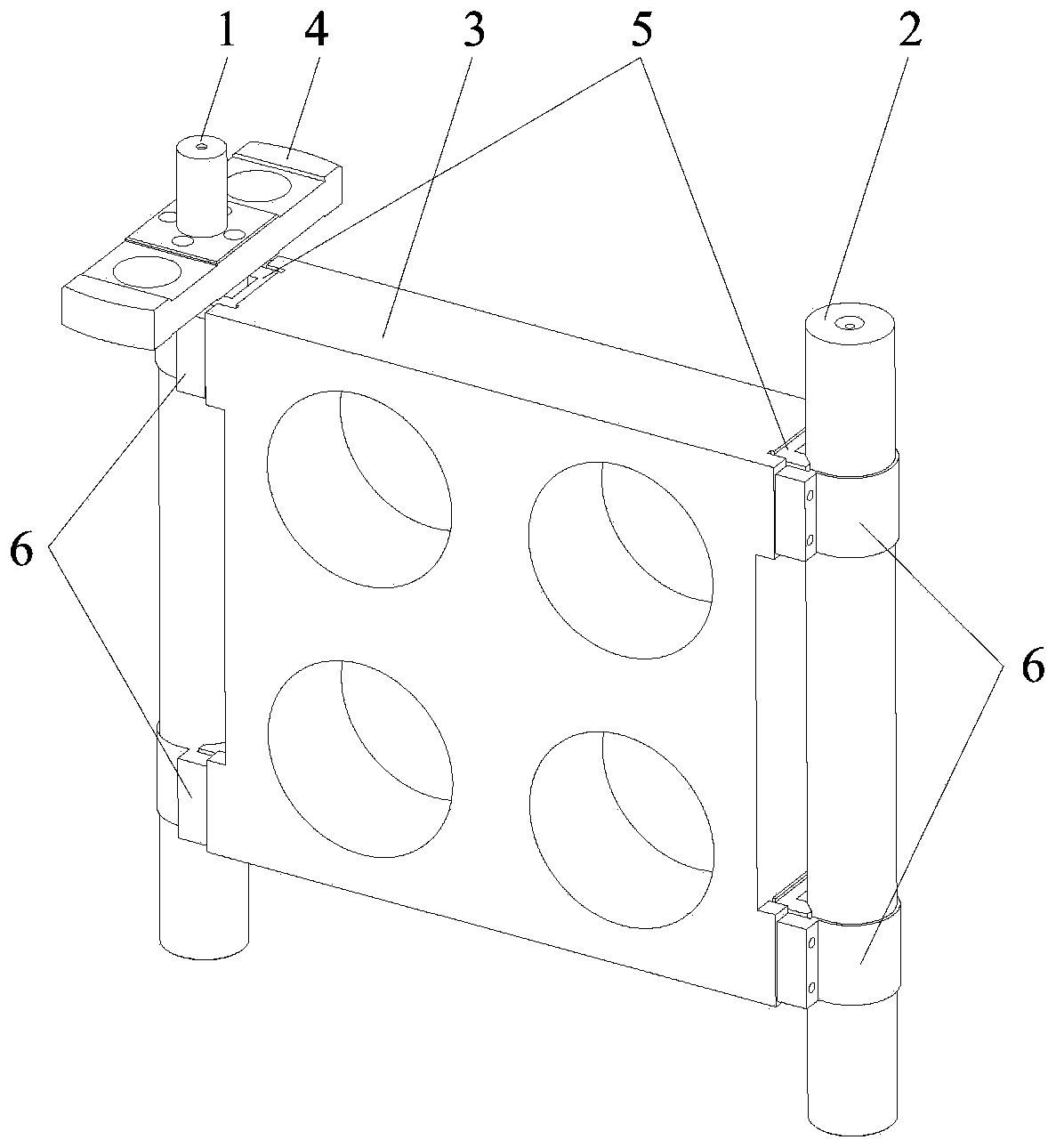

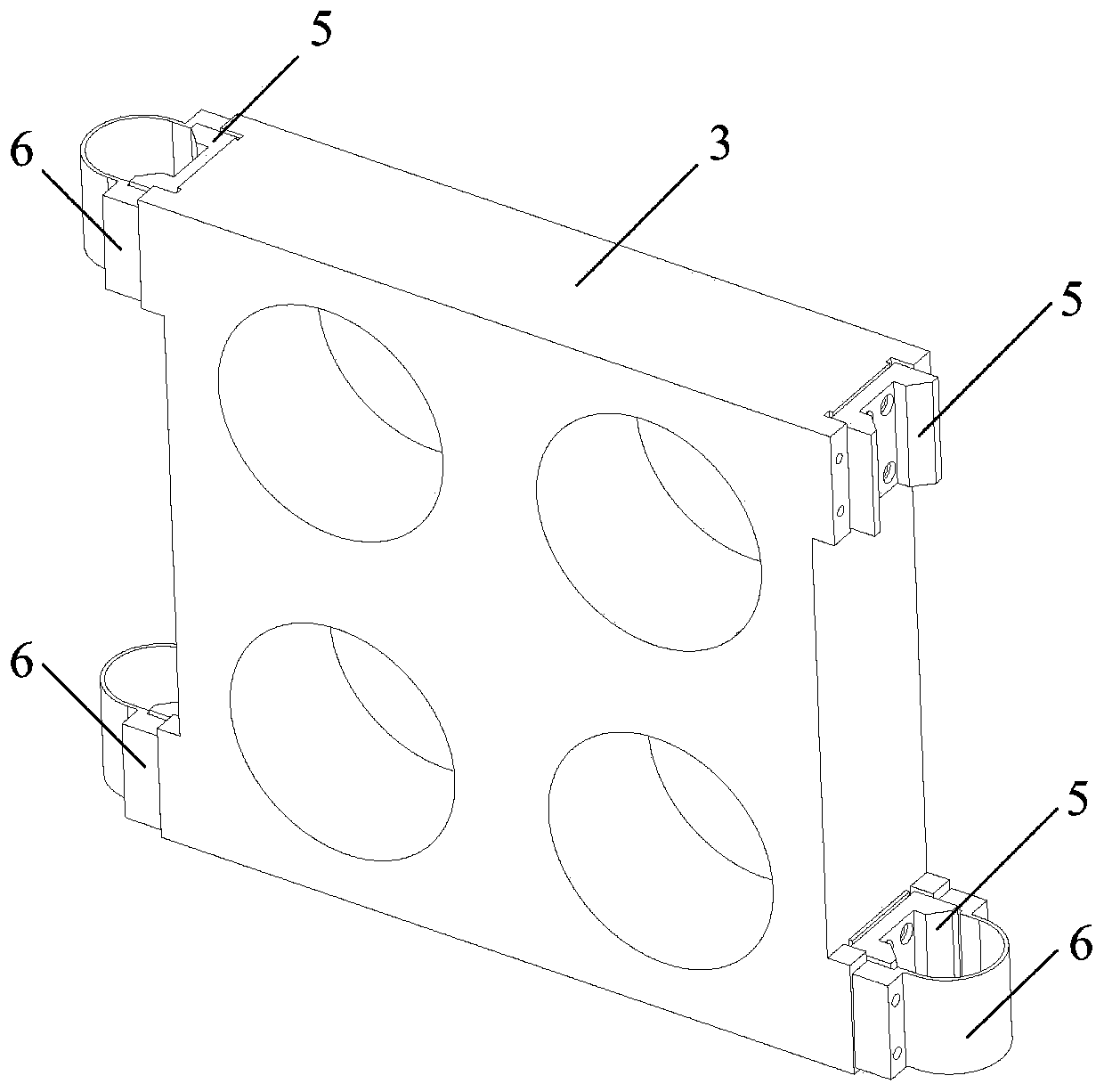

Dual-shaft, arc and large-size involute sample plate

InactiveCN110398188AHigh hardnessImprove contact fatigue performanceMeasuring wheelsMechanical counters/curvatures measurementsReference blockStructural rigidity

The invention discloses a dual-shaft, arc and large-size involute sample plate. The sample plate employs an approximate curve arc to substitute a large-gear standard theoretical involute, the influence of structural rigidity and temperature within size characteristic and large-size range of the large-size involute sample plate on accuracy is fully considered, and a dual-shaft arc structure foundation is proposed. The dual-shaft, arc and large-size involute sample plate comprises a measurement central shaft, a centering shaft, a framework, a reference block, a V-shaped block and a clamping hoop, wherein four stepped through holes are formed in the V-shaped block, a screw penetrates through the stepped through holes and is screwed into a threaded hold in the framework, and the V-shaped blockand the framework are fastened. By the dual-shaft, arc and large-size involute sample plate, a new idea is provided for building of a large-size gear involute value transfer system.

Owner:BEIJING UNIV OF TECH

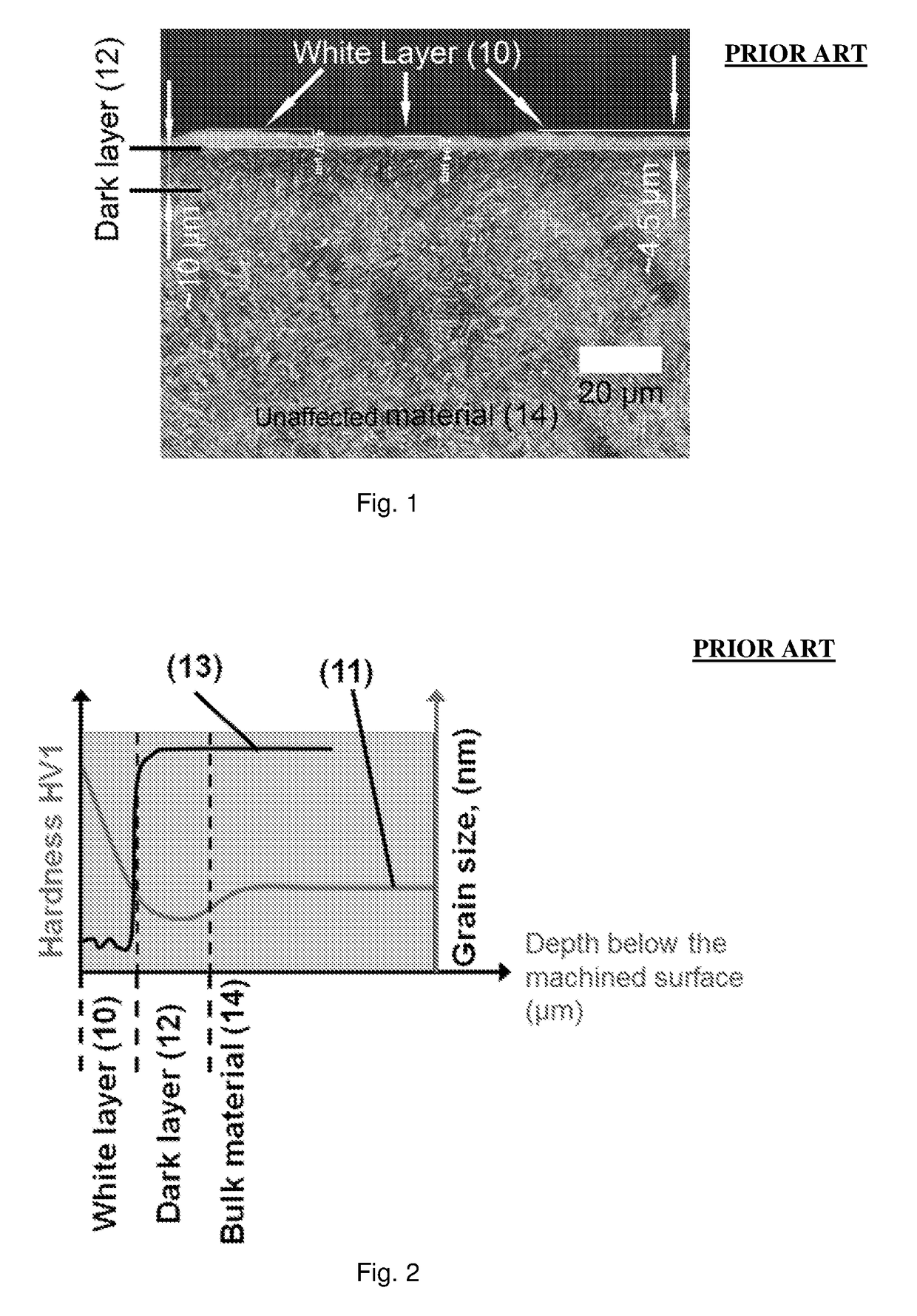

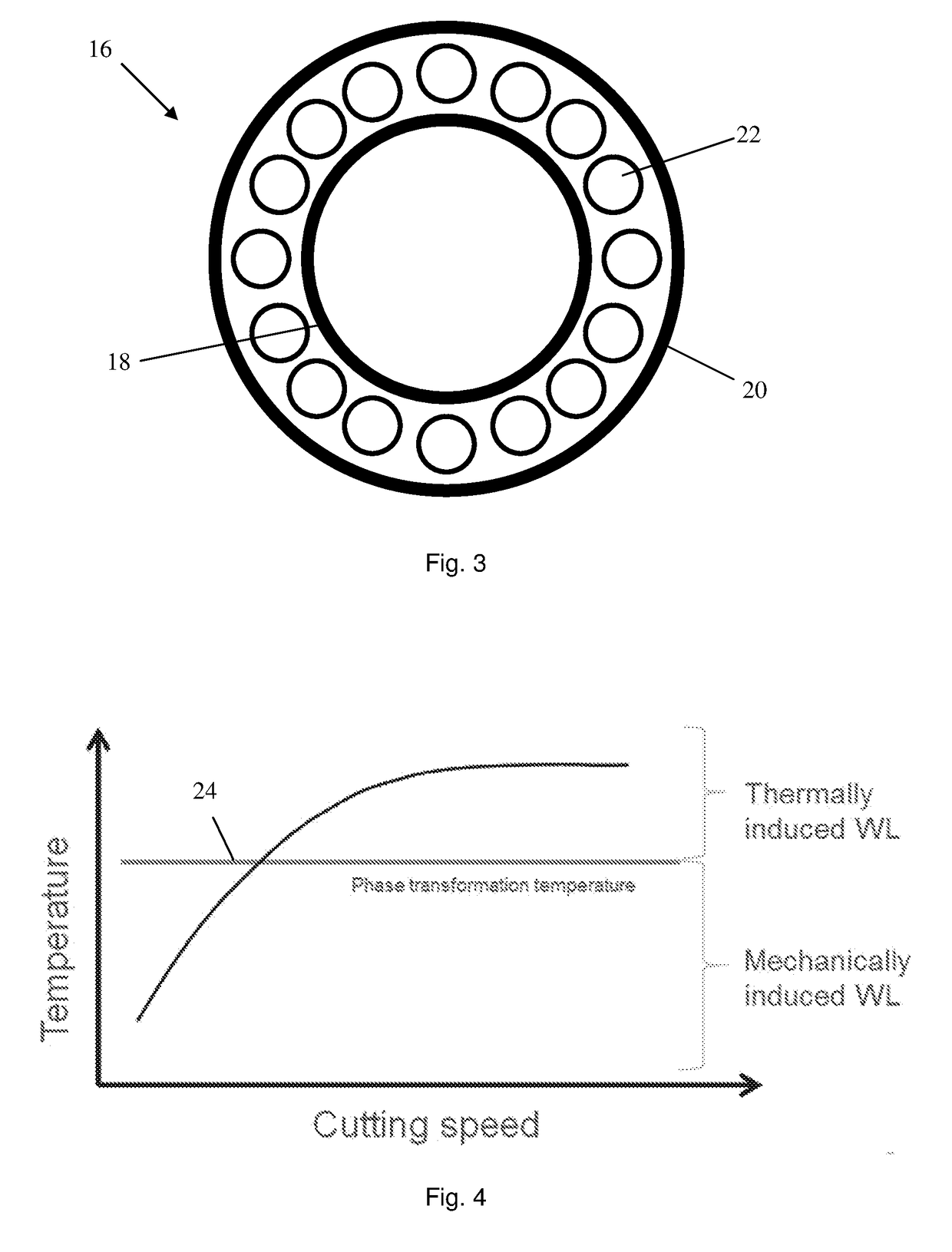

Bearing component & method

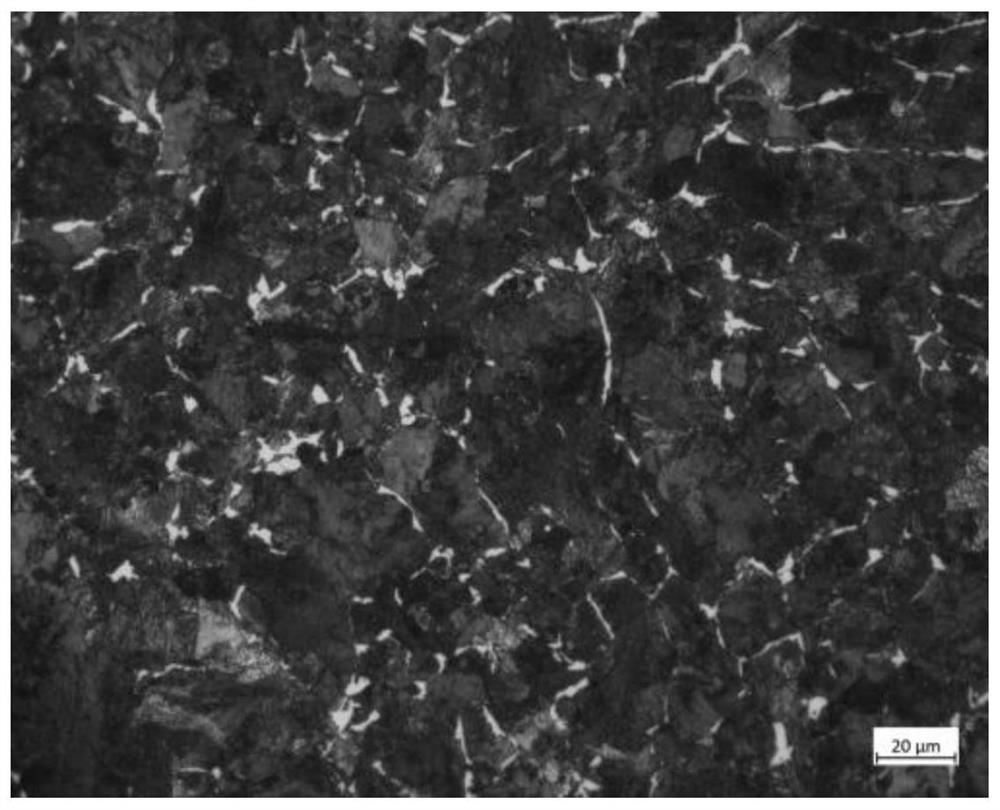

ActiveUS20170328408A1Improved rolling contact fatigue performanceImprove contact fatigue performanceRolling contact bearingsShaftsNano crystallineMachining process

Bearing component providing unaffected material that has a surface, which has been subjected to a hard machining process during where the temperature of the surface did not exceed the austenitizing temperature of the unaffected material. The surface of the bearing component includes a white layer formed during the hard machining process. The white layer has a nano-crystalline microstructure that includes grains having a maximum grain size up to 500 nm. The white layer is located directly adjacent to the unaffected material of the bearing component, where no dark layer is formed during the hard machining process.

Owner:AB SKF

Medium-carbon wheel steel and heat treatment method thereof as well as preparation method of wheel

InactiveCN110284069AHigh strengthImprove contact fatigue performanceFurnace typesHeat treatment furnacesChemical compositionRolling contact fatigue

The invention discloses a medium-carbon wheel steel and a heat treatment method thereof as well as a preparation method of a wheel. The medium-carbon wheel steel comprises the following chemical components: by weight, 0.48-0.52% of C, 0.20-0.40% of Si, 0.60-0.80% of Mn, <= 0.020% of P, <= 0.015% of S, 0.09-0.12% of Mo, 0.15-0.30% of Cr, and the remainder comprising Fe and inevitable impurity elements. Compared with the traditional ER7 wheel steel, the medium-carbon wheel steel of the invention can significantly improve the strength of a wheel rim, on the premise that the toughness of the wheel rim of a wheel made from the traditional ER7 wheel steel is basically equivalent to the toughness of the wheel rim of a wheel made from the medium-carbon wheel steel; and thus effectively improves the capacity of resistance to rolling contact fatigue, reduces the occurrence probability of out of circularity, and improves the running quality and safety of a vehicle.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparing method of brake pad friction block

The invention discloses a preparing method of a brake pad friction block. The preparing method comprises the steps that raw materials are subject to temperature rising in argon atmosphere to be in a molten state, and vacuum heat preservation is carried out, so that a first material is obtained; the first material is out of a furnace to be casted, the first material is cooled to 375 DEG C to 395 DEG C, and surface machining is carried out to obtain a second material; the second material is subject to temperature rising to reach Ta DEG C, austenitizing is carried out, heat preservation is carried out, the second material is taken out to be placed in a nitrate bath at he temperature of 200 DEG C to 220 DEG C, the material is subject to temperature rising to reach Tb DEG C, heat preservation is carried out, the material is subject to oil cooling to 100 DEG C to 120 DEG C, the material is subject to temperature rising to Tc DEG C to be tempered, heat preservation is carried out, and the second material is subject to air cooling to the room temperature to obtain the brake pad friction block; and Ta=1050+Ka*(nCo+nMo) / nNb, the value of Ka ranges from 60 to 70, Tb=355+Kb*(nCo+nMo) / nNb, the value of Kb ranges from 18 tp 20, Tc=200+Kc*100*(nNb+nCo+nMo), and the value of Kc ranges from 170 to 200.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

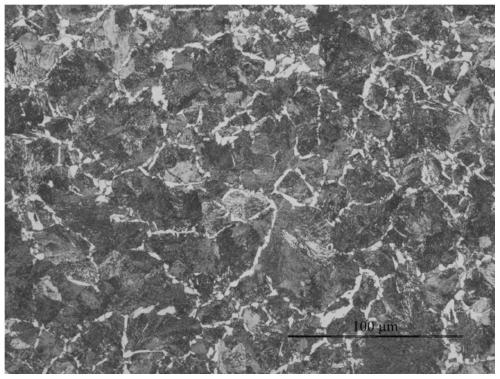

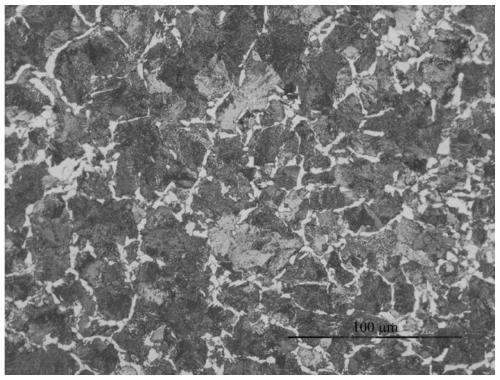

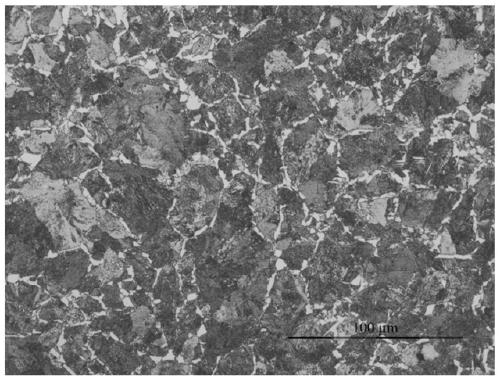

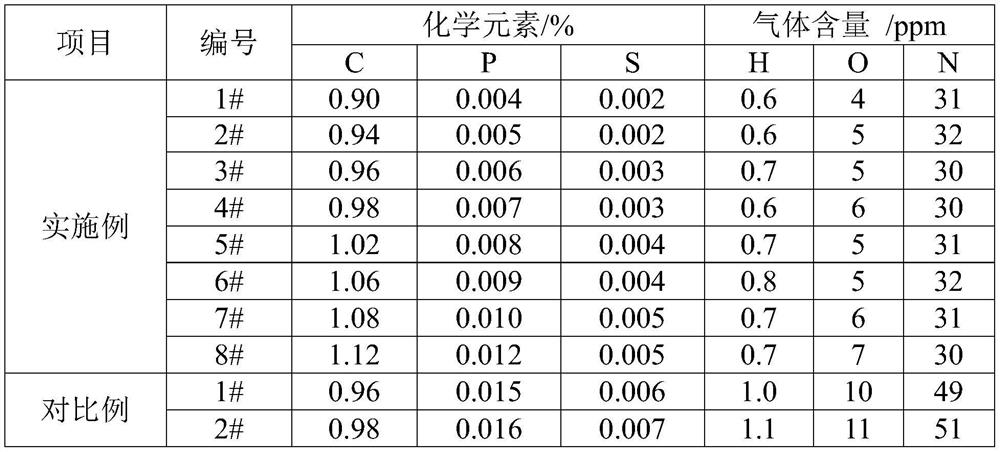

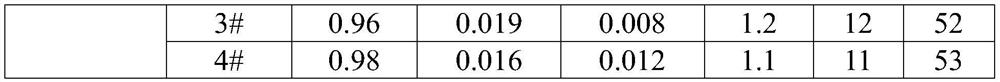

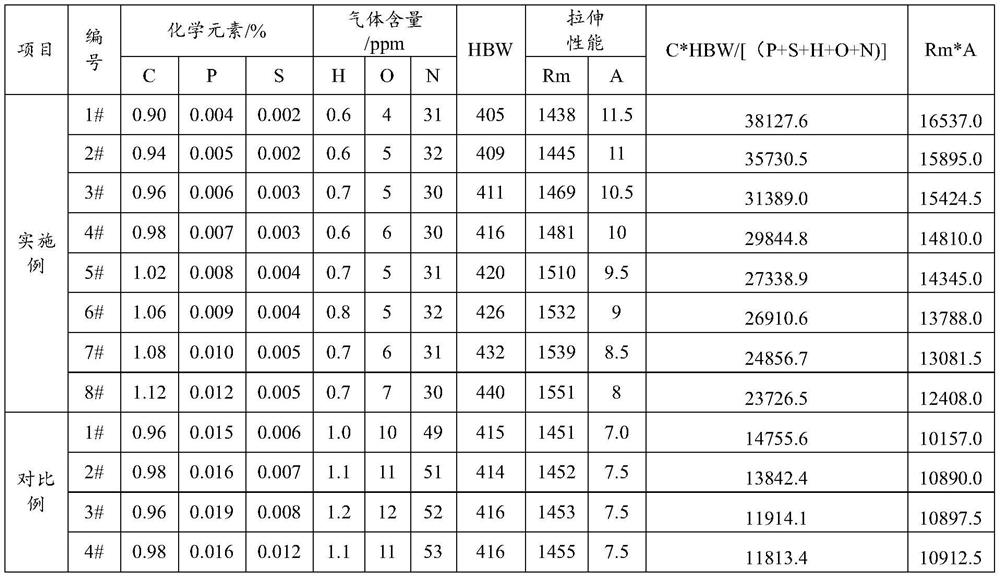

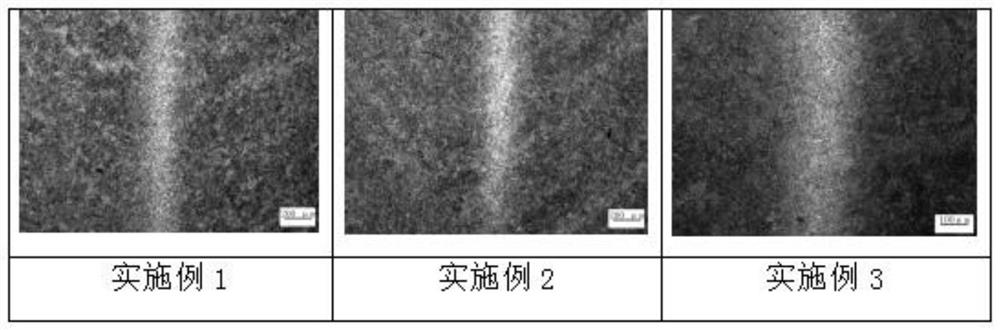

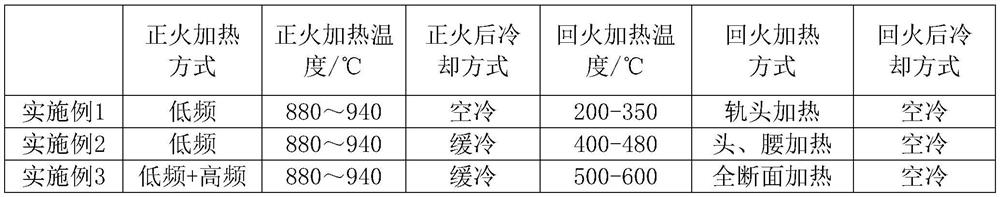

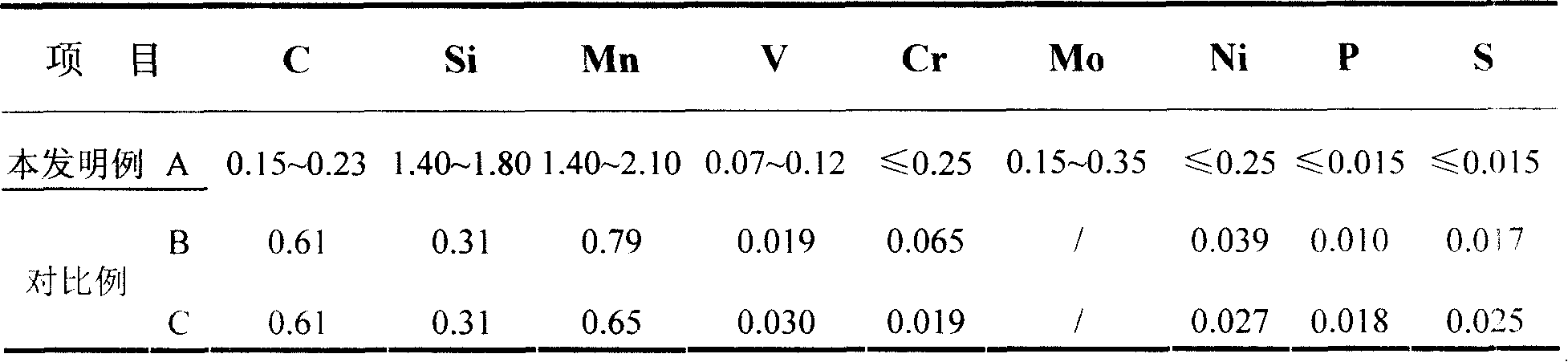

Method for producing anti-contact fatigue hypereutectoid steel rail

ActiveCN114045426AImprove contact fatigue performanceImprove purityFurnace typesMetal rolling arrangementsContinuous castingContact fatigue

The invention discloses a method for producing an anti-contact fatigue hypereutectoid steel rail. The method comprises the steps of molten iron desulfurization, converter smelting, LF refining, RH refining, continuous casting, billet heating, rolling and post-rolling heat treatment. The steel rail is obtained. The post-rolling heat treatment comprises the steps that accelerated cooling and air cooling are conducted on the rail head tread center, the two sides of a rail head and the rail bottom center of the steel rail obtained after rolling, the initial cooling temperature of accelerated cooling is 650-900 DEG C, the cooling speed is 1.0-5.0 DEG C / s, and the final cooling temperature is 400-550 DEG C; after the final cooling temperature is reached, accelerated cooling is stopped, and air cooling is performed to room temperature; based on the total mass of the steel rail, the steel rail comprises the following chemical components in percentage by mass: 0.9-1.2% of C. According to the hypereutectoid steel rail manufactured through the method for producing the anti-contact fatigue hypereutectoid steel rail, the tread hardness is larger than 420 HB, the laboratory abrasion loss of the steel rail is smaller than 0.2 g, and the contact fatigue performance is improved by 20%. The hypereutectoid steel rail is higher in purity, better in contact fatigue resistance and good in wear resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

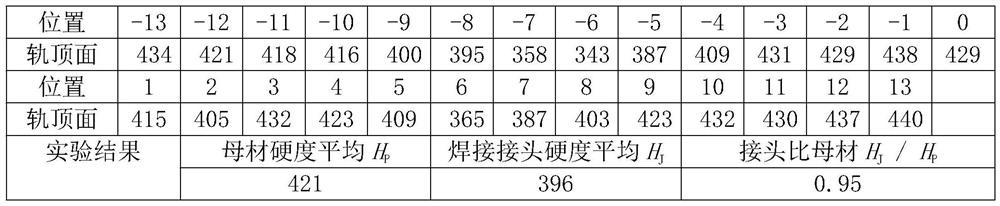

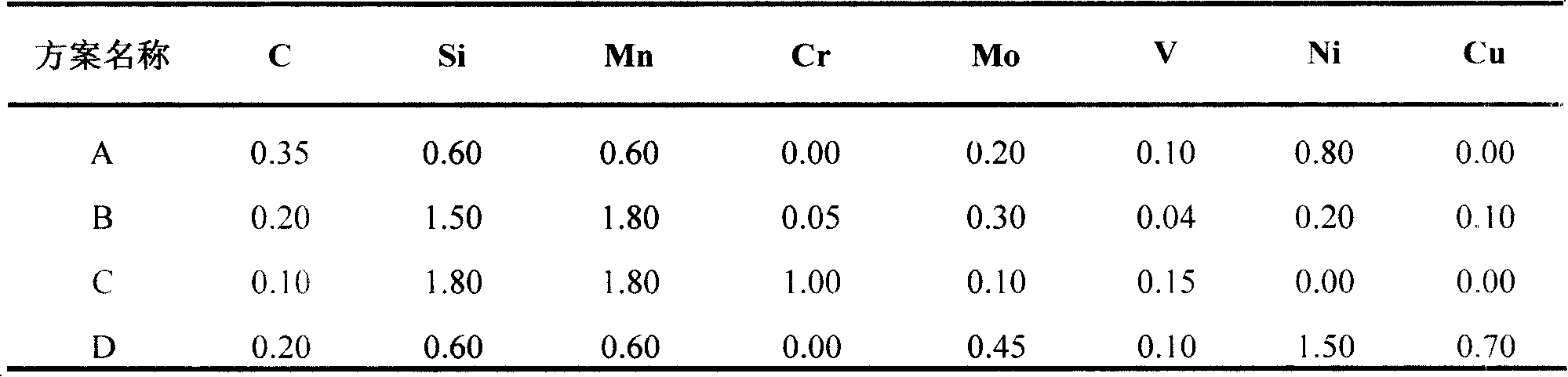

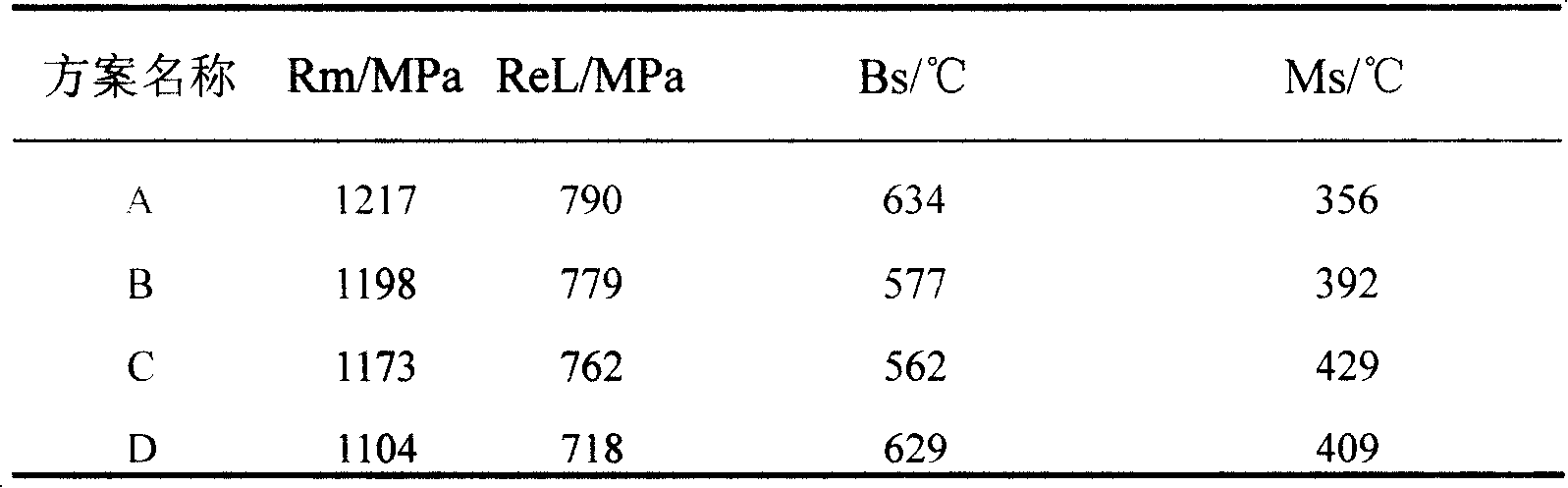

Heat treatment process for high-strength and high-toughness bainite steel rail welded joint for heavy haul railway

PendingCN114507772AReduce residual stressReduce distributionIncreasing energy efficiencyFurnace typesHeat-affected zoneTempering

The invention aims to provide a heat treatment process for a high-strength and high-toughness bainite steel rail welded joint for a heavy haul railway, which is characterized in that the joint is controlled within a bainite phase change interval as long as possible after the steel rail is normalized according to the structure transformation characteristic of the bainite steel rail by combining the process designed by changing each key temperature point in a steel rail CCT curve; a certain bainite structure proportion is guaranteed, and then low-carbon martensite structure transformation is conducted; and a tempering process is combined, so that the joint has a bainite and tempered martensite complex phase structure with excellent mechanical properties. After the joint heat treatment process is used, sufficient transformation of a metallographic structure of a welded joint can be guaranteed, residual stress of a welding seam and a heat affected zone is reduced, martensite segregation bands of part of the heat affected zone are relieved or eliminated, performance matching of the welding seam of the bainite steel rail and base metal can be effectively improved, and the welding quality of the bainite steel rail is improved. The comprehensive mechanical property and the contact fatigue property of the welding seam are improved, so that the service performance of the welding seam is effectively improved.

Owner:BAOTOU IRON & STEEL GRP

Bainite steel for railroad carriage wheel

ActiveCN100395366CImprove toughnessExtended service lifeFurnace typesHeat treatment furnacesNickelBainite

Owner:MAANSHAN IRON & STEEL CO LTD

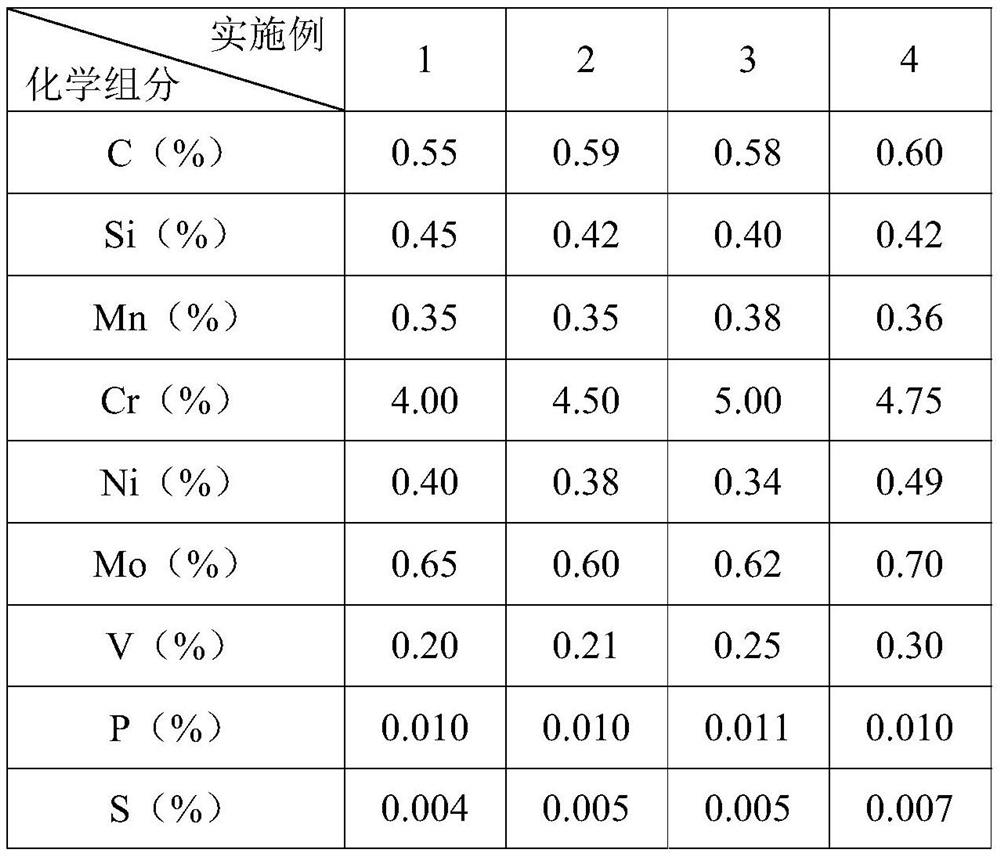

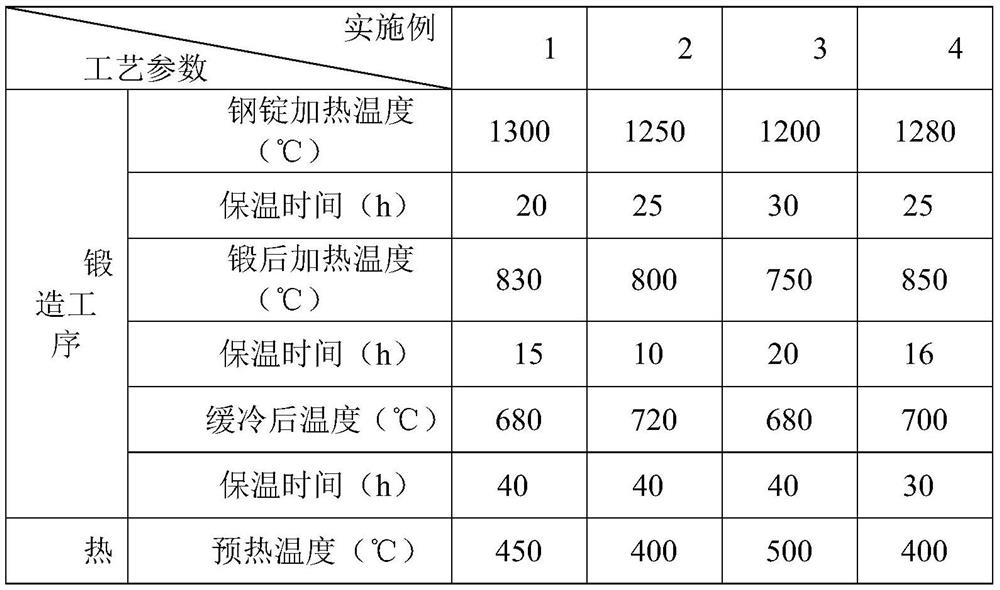

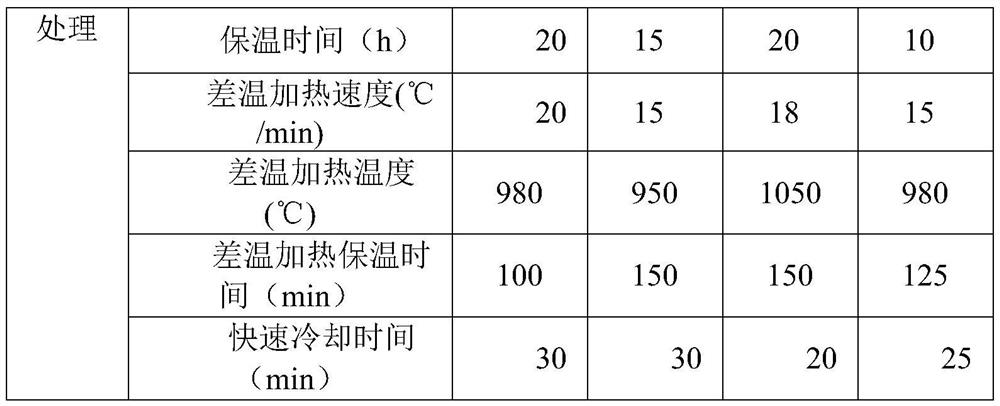

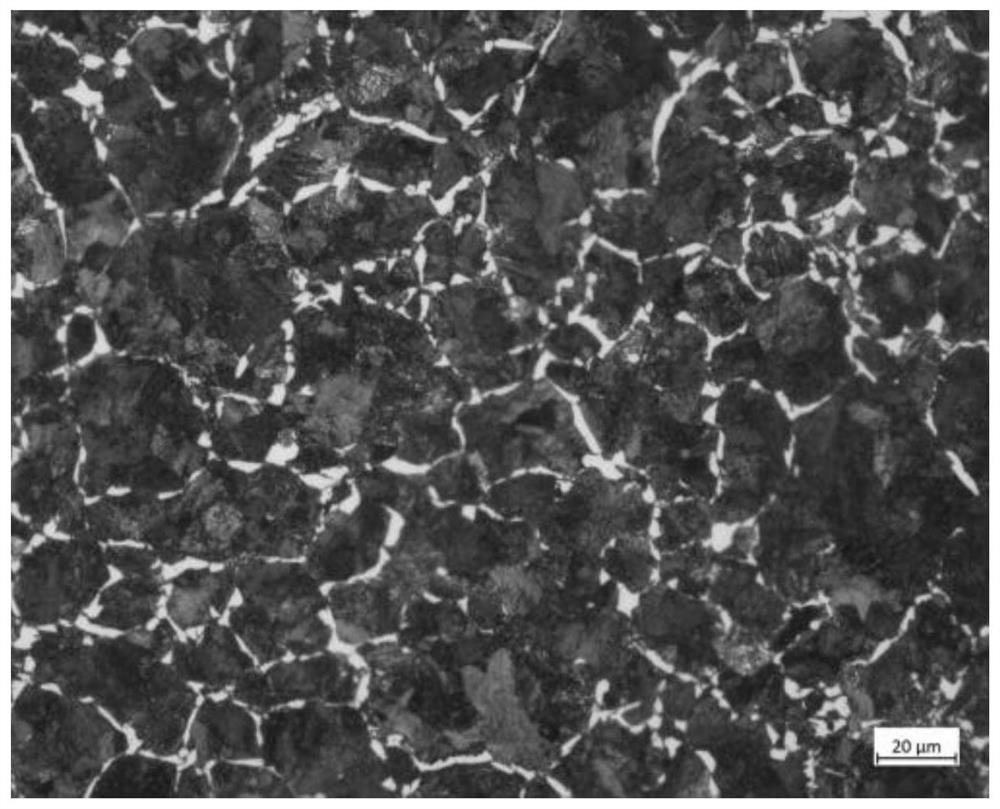

Manufacturing method of equal-hardness Cr5 supporting roller

The invention discloses a manufacturing method of an equal-hardness Cr5 supporting roller. The method comprises the following steps: 1) preparing steel raw materials according to chemical components and weight percentage contents in a Cr5 supporting roller material, and preparing a steel ingot according to a smelting procedure production process; 2) preparing a roller blank from the steel ingot according to a forging procedure production process; 3) conducting heat treatment on the roller blank; and 4) machining and detecting the roller blank to obtain the equal-hardness forged steel supporting roller. According to the manufacturing method, the problems that hardness, abrasion resistance and contact fatigue of a conventional forged steel supporting roller are rapidly reduced in the middle and later periods of use are solved, and the comprehensive use period and the service life of the supporting roller are prolonged.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Heavy-duty locomotive wheel steel resistant to surface contact fatigue and wheel production method

ActiveCN113528967AHigh yield strengthImproved resistance to surface contact fatigueFurnace typesHeat treatment furnacesMechanical engineeringMaterials science

The invention provides heavy-duty locomotive wheel steel resistant to surface contact fatigue and a wheel production method. Components of the wheel steel comprise 0.60%-0.67% of C, 0.15%-1.00% of Si, 0.60%-0.90% of Mn, 0.04%-0.15% of V, 0.10%-0.25% of Cr, not larger than 0.040% of Al, not larger than 0.015% of Als, (70-100) * 10 <-4 >% of N, not larger than 0.003% of Ti, not larger than 0.020% of P, not larger than 0.015% of S and the balance Fe and inevitable impurity elements. In wheel production, the austenitizing soaking temperature is 30-50 DEG C higher than the conventional heating temperature, and the holding time of the soaking section is not shorter than 1.5 h. Compared with the prior art, the surface contact fatigue resistance of the wheel is obviously superior to that of a traditional locomotive wheel, the non-planned turning repair frequency of the wheel is reduced, and the service life of the wheel is prolonged.

Owner:MAANSHAN IRON & STEEL CO LTD

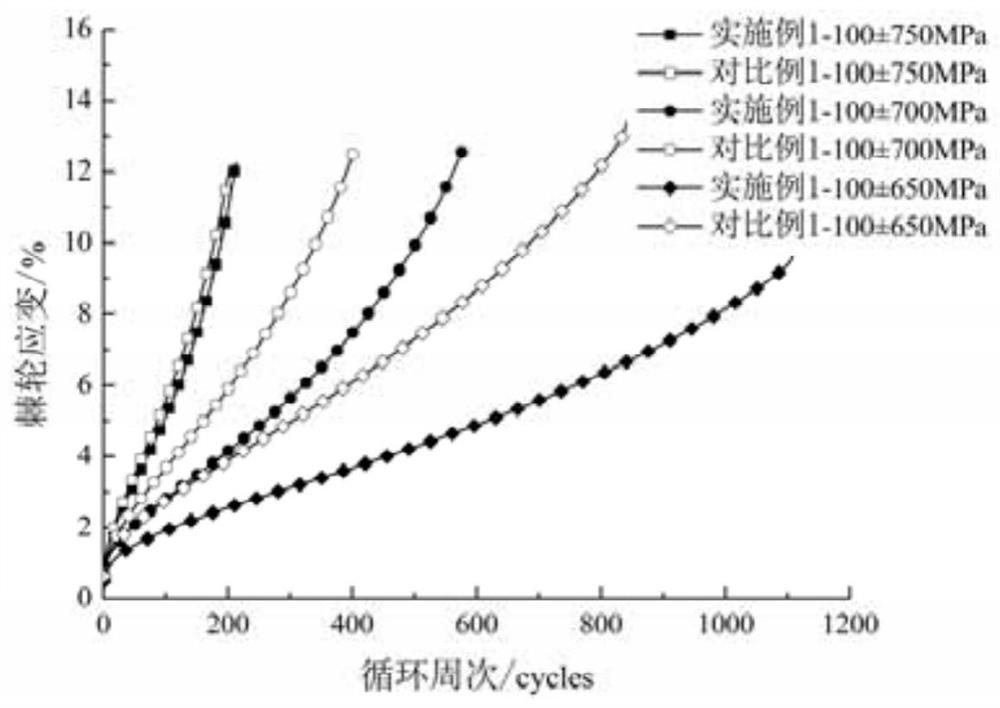

Wheel with high contact fatigue performance and production method thereof

InactiveCN113403538AEasy to segregateStrong dragRail-engaging wheelsFurnace typesContact fatigueHeat treating

The invention provides a wheel with high contact fatigue performance and a production method thereof. The wheel comprises the following components of 0.55%-0.65% of C, 0.15%-0.30% of Si, 0.40%-1.2% of Mn, 0.10%-0.25% of Cr, 0.02%-0.03% of Al, less than or equal to 0.010% of P, 0.020%-0.035% of S, 0.10%-0.20% of V, less than or equal to 10 ppm of T.O, less than or equal to 1.5 ppm of [H], 80-120 ppm of [N] and the balance Fe and inevitable impurity elements. Compared with the prior art, steel for the wheel with the high contact fatigue performance is produced by using specific components and a reasonable preparation method, and through a certain heat treatment process, it is ensured that the surface contact fatigue resistance of the prepared wheel is obviously improved.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

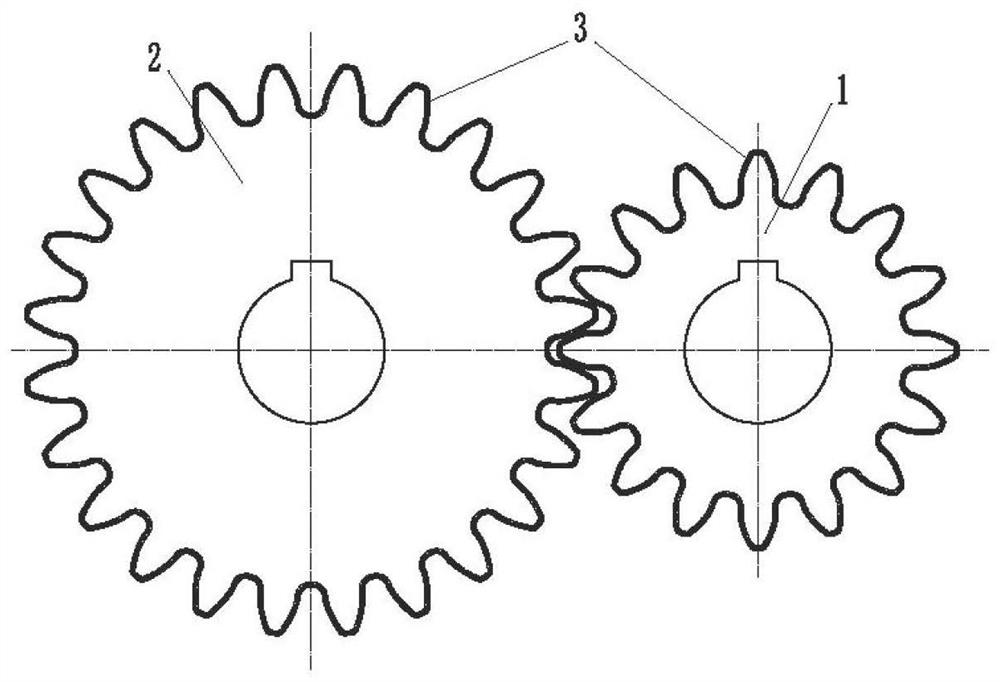

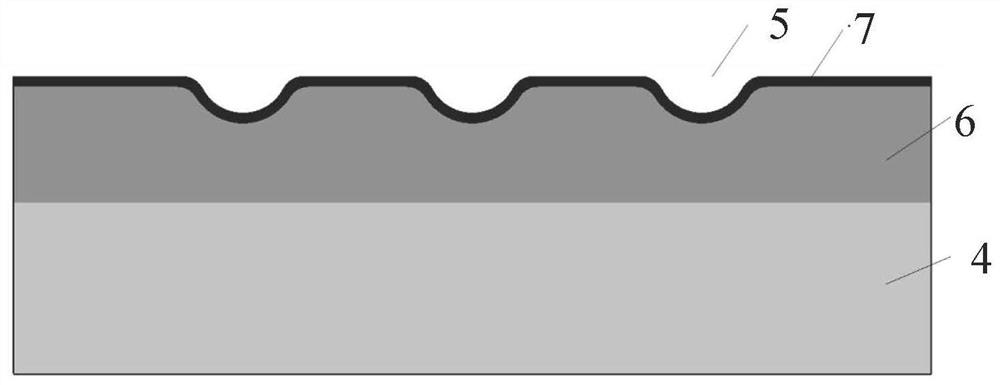

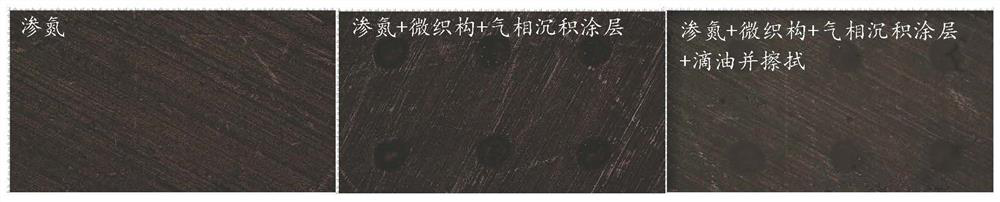

Aviation heavy-duty gear and preparation method thereof

PendingCN113774315AImprove macro oil storage capacityGood self-lubricating performanceVacuum evaporation coatingSputtering coatingAviationGear wheel

The invention belongs to the technical field of aviation part manufacturing, and particularly relates to an aviation heavy-duty gear and a preparation method thereof. According to the aviation heavy-duty gear and the preparation method thereof, the tooth surface of the heavy-duty gear is firstly subjected to laser micro-texture treatment, the macroscopic oil storage capacity and the self-lubricating performance of the working surface of the gear are improved, then the heavy-duty gear is subjected to carbonitriding, quenching and tempering heat treatment, a permeation strengthening layer is formed on the surface of a gear base body in a permeation mode, and the surface hardness of the gear is improved; good base body support is provided for vapor deposition plating of a gradient hard anti-friction coating on the surface of the gear base body in the next step, the eggshell effect of a soft base body and a hard coating is avoided, and the gradient hard anti-friction coating and the surface of the gear have good bonding performance; and the surface hardness, the contact fatigue performance and the self-lubricating performance of the gear are further improved by vapor deposition of the Cr layer, the CrN layer, the CrWCN layer and the WC-DLC layer gradient hard antifriction coating in sequence.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE +1

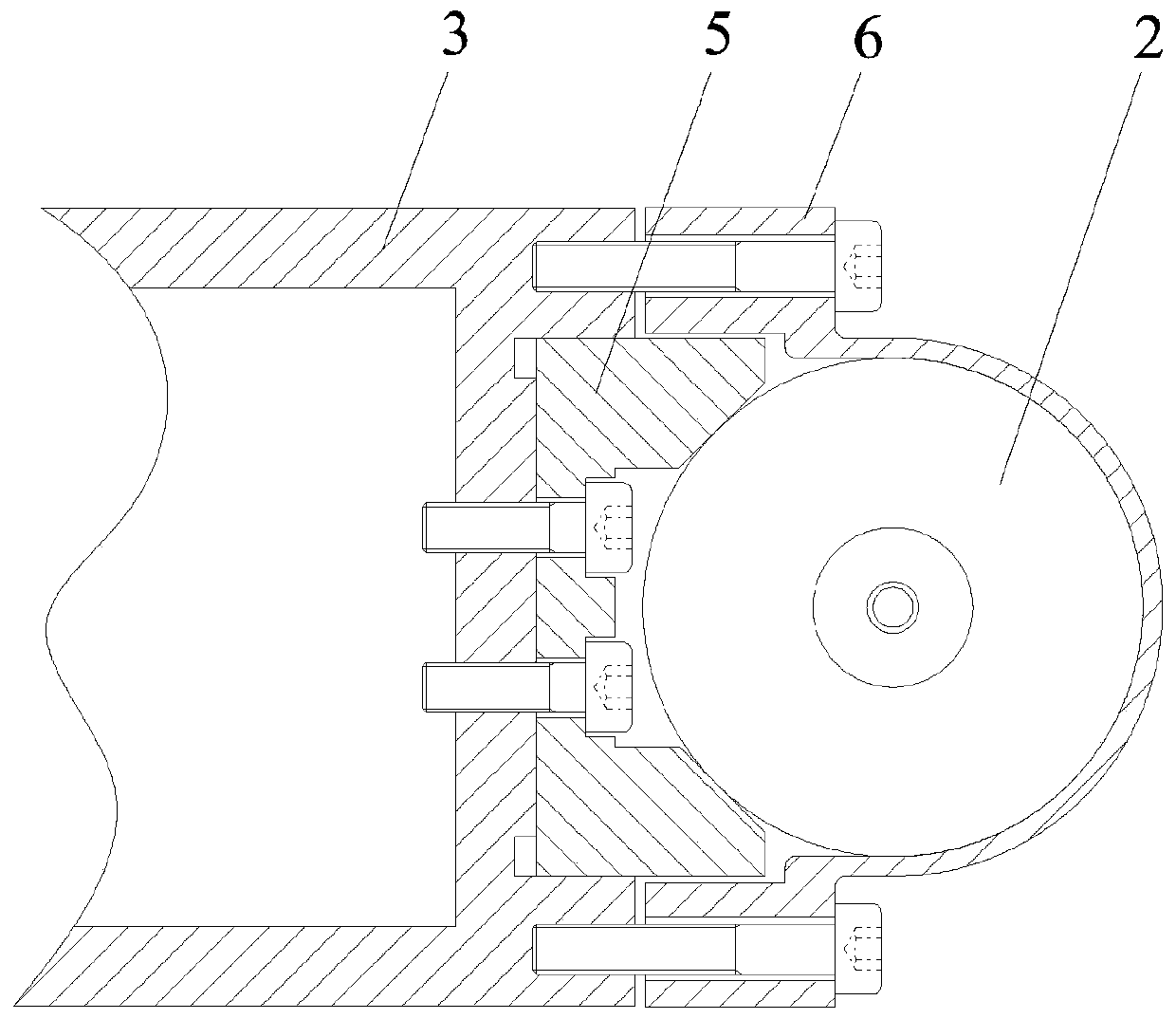

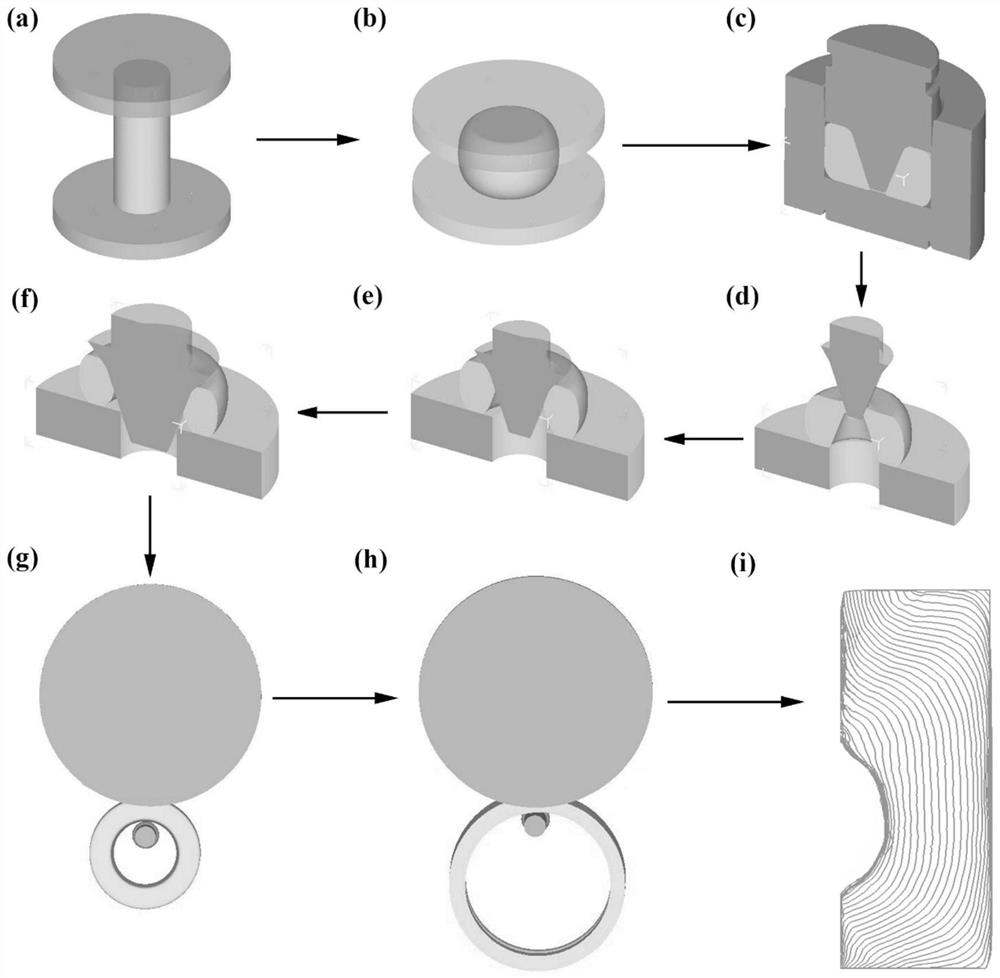

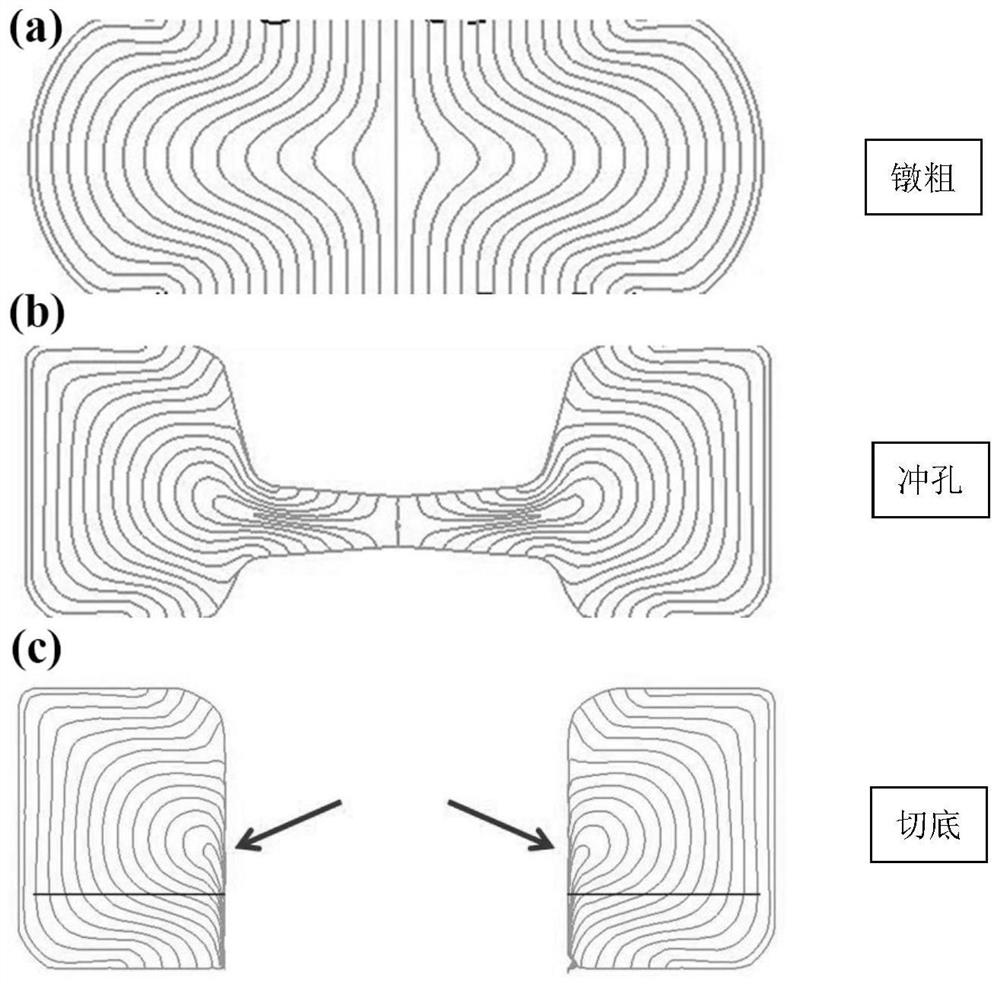

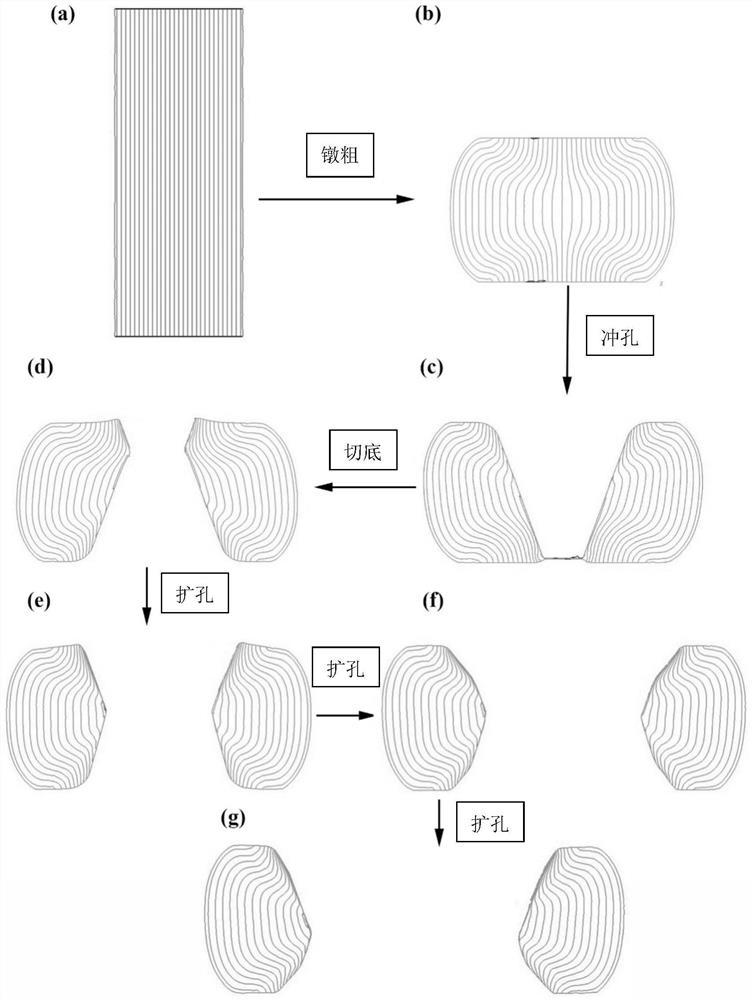

Eccentric ball bearing outer ring forming method for controlling distribution of metal flow lines along channels

PendingCN114406604AImprove performanceAvoid cutsMetal-working apparatusEngine componentsBall bearingCarbide

The invention relates to a forming method of an eccentric ball bearing outer ring, in particular to a forming method of an eccentric ball bearing outer ring for controlling metal streamlines to be distributed along a channel. The invention aims to solve the technical problems that the metal streamline of the ferrule is cut off and the contact fatigue performance of the surface of a raceway of the ferrule is seriously reduced due to the fact that the existing bearing ferrule forging adopts a process of firstly freely forging a blank, then rolling the blank into an annular piece and finally turning a channel. According to the method, the bearing outer ring is directly formed through the eccentric channel in a ring rolling mode, the procedure that the metal flow lines are distributed along the channel replaces the procedure that the outer ring channel is machined in a cutting mode, metal flow lines are effectively prevented from being cut off, and the contact fatigue performance and the material utilization rate of materials can be improved. Due to the fact that the large upsetting ratio is adopted, the strain in the deformation process is increased, meanwhile, refining of grains and primary carbides in materials is caused by ring rolling forming, and then the performance of the bearing ring is improved.

Owner:AVIC HARBIN BEARING

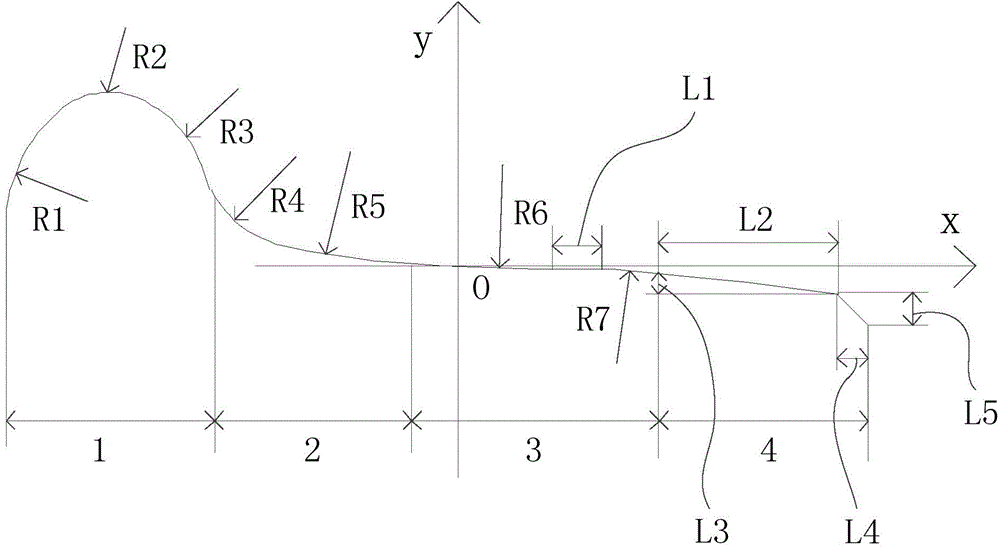

Wheel for railway vehicle

PendingCN106314020AImprove stabilityImprove contact fatigue performanceRail-engaging wheelsElectrical and Electronics engineeringContact fatigue

The invention discloses a wheel for a railway vehicle. The wheel for the railway vehicle comprises a rim, a rim root, a tread and a tread outer side which are connected in sequence. The tread comprises a first tread arc section, a tread straight line section and a second tread arc section which are sequentially connected head to tail. One end of the first tread arc section is connected with the rim root, one end of the second tread arc section is connected with the tread outer side, and the first tread arc section, the tread straight line section and the second tread arc section are matched with a track in appearance. A rim outer side and the tread of the wheel for the railway vehicle can be accurately matched with the track in appearance, and thus the wheel has good dynamics performance and contact fatigue performance.

Owner:SHANGHAI SHENTONG METRO +1

Preparation method of impact resistant and wear resistant pipe

InactiveCN105734439ASlow down the spreadDelay transitionFurnace typesHeat treatment furnacesMolten stateWear resistant

The invention discloses a preparation method of an impact resistant and wear resistant pipe. A raw material is heated to a molten state for insulation to obtain a material a; the material a is charged from a furnace for pouring, cooling to 450-480 DEG C and surface machining to obtain a material b; and the material b is heated to T1 DEG C for austenitizing and insulation by 3-4 h, is taken out to put in a nitrate bath with a temperature of 220-230 DEG C, is heated to T2 DEG C for insulation by 4-5 h, is cooled to 140-155 DEG C by air, is heated to T3 DEG C for tempering and insulation by t3 h, and is cooled to room temperature by air to obtain the impact resistant and wear resistant pipe, wherein T1 is 980-1040, t1 is 2-2.6, T2 is 280-295, t2 is 2.2-2.5, T3 is 175-190, t3 is 4.5-5, T1 / T2 is not more than 3.6 and not less than 3.4, (T2*t2) / (T3*t3) is not more than 0.93 and not less than 0.66, and t1 / t3 is not more than 0.55 and not less than 0.45.

Owner:ANHUI ZHENGSHI NEW BUILDING MATERIAL

Steel for subway wheels and wheel production method

ActiveCN112322979AImprove contact fatigue performanceImprove running qualityFurnace typesProcess efficiency improvementSteelmakingRolling contact fatigue

The invention provides steel for subway wheels and a wheel production method. The steel comprises the following components of, in percentage by mass, 0.60%-0.64% of C, 0.20%-0.37% of Si, 0.60%-0.80% of Mn, P less than or equal to 0.015%, S less than or equal to 0.015%, 0.10%-0.15% of Cr, 0.10%-0.20% of Ni, 0.01%-0.03% of Al, 0.05%-0.15% of V, 50ppm-90ppm of N and the balance Fe and inevitable impurity elements. According to the steel for the subway wheels and the wheel production method, the use amount ratio of design elements is optimized and electric furnace steelmaking, blank hot forming rhythm and heat treatment are controlled, so that the wheel performance is improved; and compared with traditional CL60 wheel steel, on the premise that the toughness level of a rim is basically equal,the strength and toughness of the wheel rim can be remarkably improved, so that the rolling contact fatigue resistance is effectively improved, the probability of out-of-round and stripping is reduced, and the running quality and safety of a vehicle are improved.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Preparation method for high-hardness friction block for brake pad

The invention discloses a preparation method for a high-hardness friction block for a brake pad. The preparation method comprises the following steps of raising the temperature of raw materials in the argon atmosphere until a molten state, and then carrying out vacuum heat preservation to obtain a material a; discharging the material a, pouring, cooling to 400-500 DEG C, and carrying out surface machining to obtain a material b; raising the temperature of the material b to T1 DEG C, austenitizing, then carrying out heat preservation for 3-4h, taking out, putting in a nitrate bath with the temperature to be 220-230 DEG C, raising the temperature to T2 DEG C, and carrying out heat preservation for 4-5h to obtain the high-hardness friction block for the brake pad, wherein T1=1100+K1x240x110x(nC+nW+nZr) / 28.7, T2=345+K2x100x(nC+nW+nZr), a value of K1 is 5-8, a value of K2 is 28-30, and nC, nW and nZr express the weight percentages of carbon element, tungsten element and zirconium element occupied in the material a respectively.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

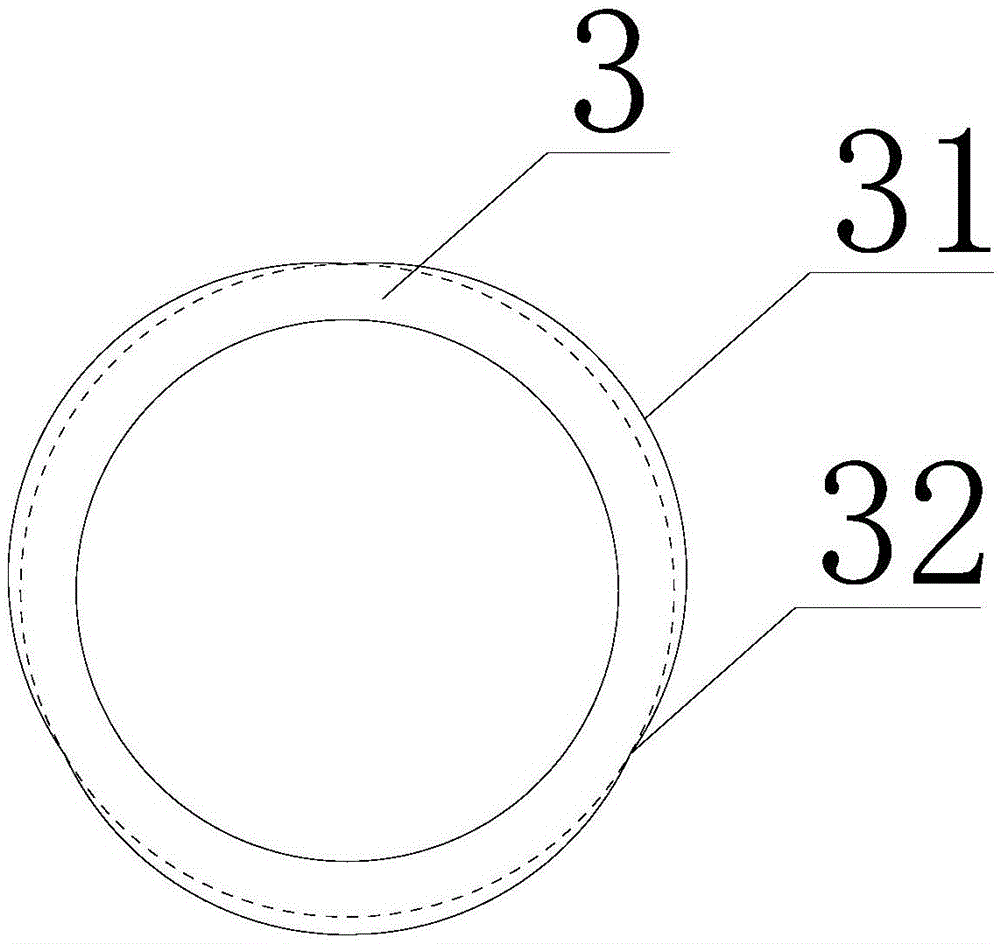

Long-life high-carbon bearing steel pipe and preparation method and application thereof

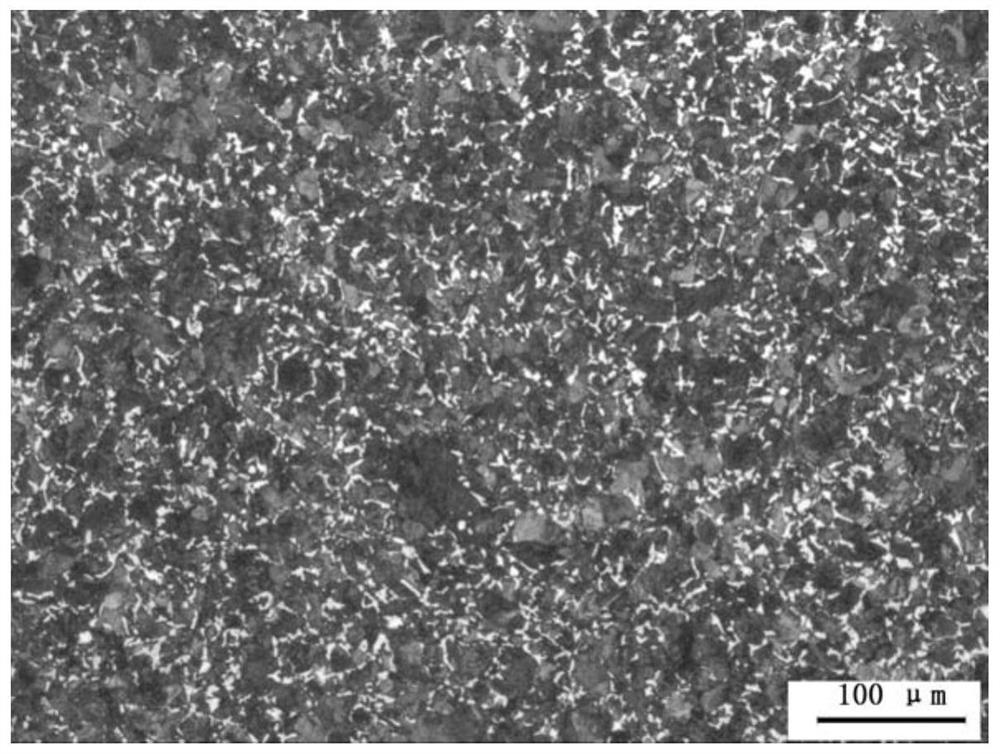

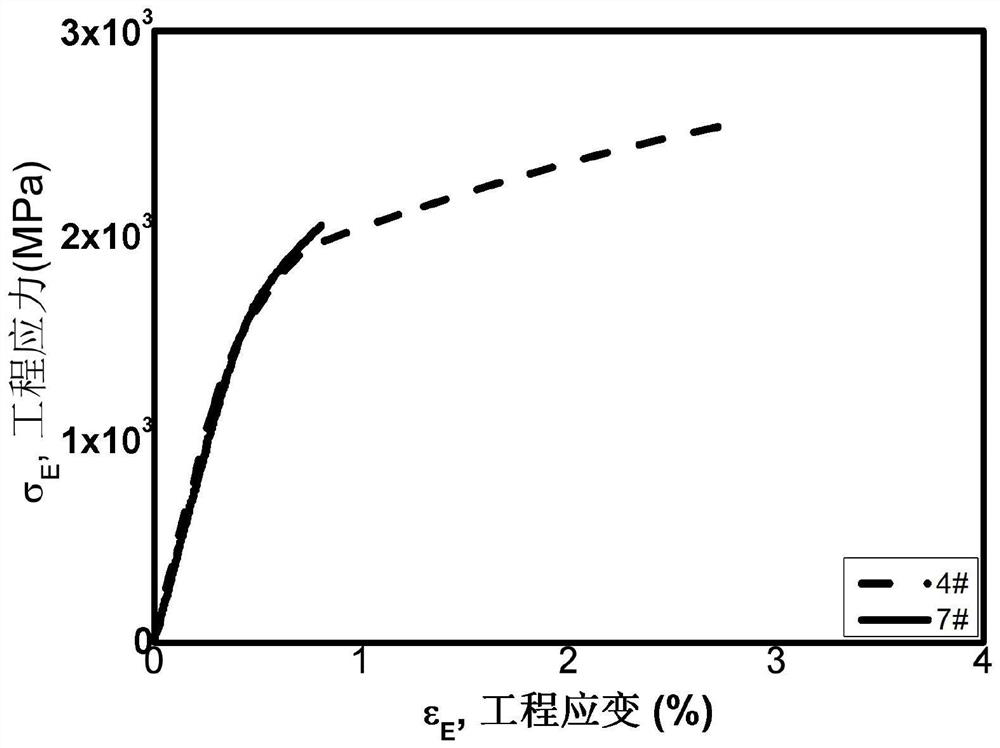

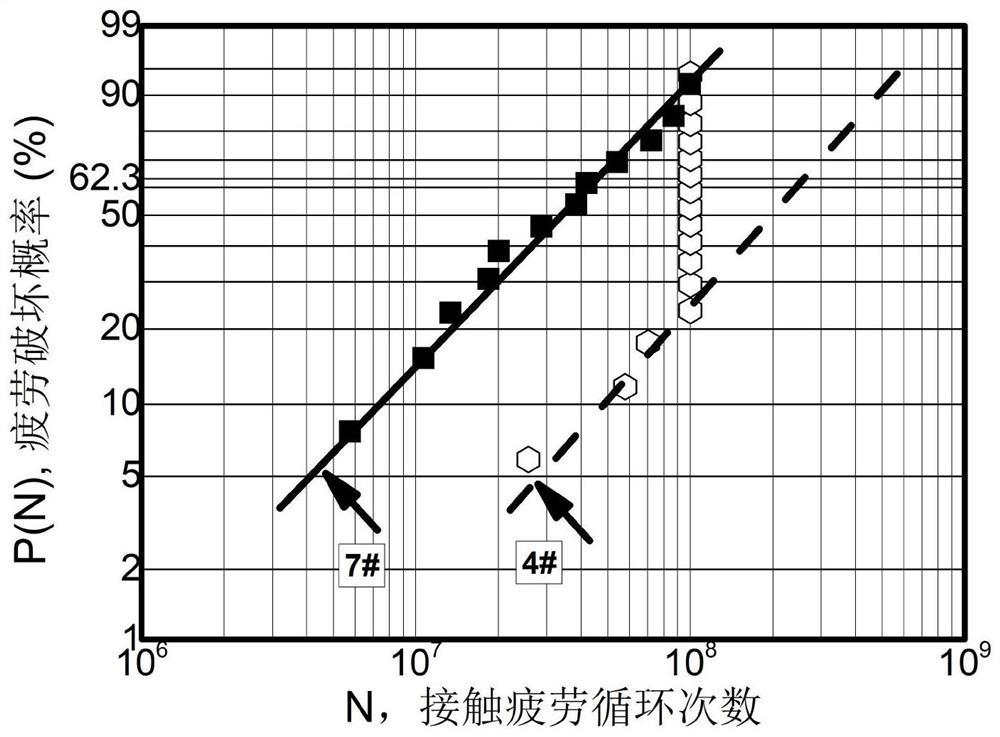

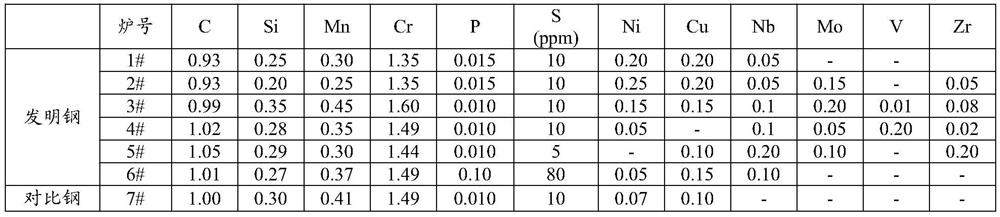

The invention provides a long-life high-carbon bearing steel pipe and a preparation method and application thereof, and belongs to the technical field of bearing steel. The long-life high-carbon bearing steel pipe is prepared from the following components in percentage by mass: 0.93-1.05wt% of C, 1.35-1.60wt% of Cr, 0.20-0.35wt% of Si, 0.25-0.45wt% of Mn, less than or equal to 0.015%wt% of P, less than or equal to 10ppm of S, 0.05-0.20wt% of Nb, 0-0.20wt% of Mo, 0-0.20wt% of V, 0-0.20wt% of Zr, 0-0.2wt% of Ni, 0-0.2wt% of Cu and the balance Fe. The prepared high-carbon bearing steel pipe has long contact fatigue life, and the problems that the service life of a traditional bearing steel pipe is short, and bearing inner and outer rings long in fatigue life cannot be manufactured through a direct turning technology can be solved.

Owner:CENT IRON & STEEL RES INST

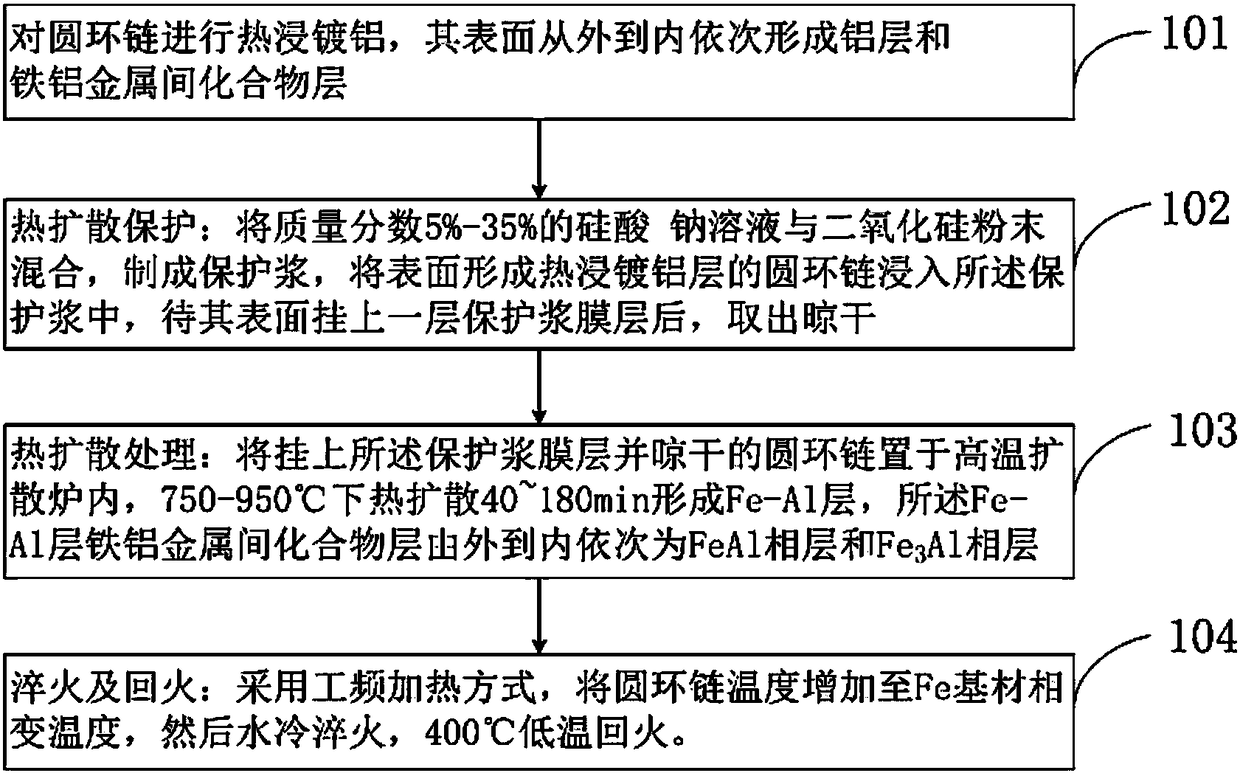

Aluminizing method of circular ring chain

ActiveCN108315684AEffective surface protectionEffective surface enhancementHot-dipping/immersion processesSlurrySODIUM SILICATE SOLN

The invention provides an aluminizing method of a circular ring chain, which can form an ultra-thick iron-aluminum compound layer under a high-temperature environment within relatively short time. Thealuminizing method comprises the following steps: firstly, carrying out hot dip aluminum plating on the circular ring chain to form an aluminum layer and an iron-aluminum intermetallic compound layeron the surface in sequence from outside to inside; carrying out thermal diffusion protection: mixing a sodium silicate solution with the mass percent to 5 to 35 percent and silicon dioxide powder toprepare protection slurry; immersing the circular ring chain with a hot dip aluminum plated layer on the surface into the protection slurry; after one protection slurry film layer is hung on the surface, taking out and airing; carrying out thermal diffusion treatment: putting the circular ring chain which is hung with the protection slurry film layer and is aired into a high-temperature diffusionfurnace and carrying out thermal diffusion at 750 to 950 DEG C for 40 to 180min to form an Fe-Al layer, wherein an Fe-Al phase layer and an Fe3Al phase layer are arranged in sequence from outside to inside; quenching and tempering: increasing the temperature of the circular ring chain to phase change temperature of an Fe substrate by adopting a power frequency heating manner; then carrying out water quenching and hardening and carrying out low-temperature tempering at 400 DEG C.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

Molding process of chrome steel ring piece

The invention provides a molding process of a chrome steel ring piece and relates to the technical field of molding of metal ring pieces. The molding process includes the five steps of blanking, pre-heating, pre-molding, ring formation and cutting. The molding process is optimized and combined with the special physicochemical properties of a steel material, so that the production cost is further lowered and the production efficiency is improved. The process is simple and high in adaptability.

Owner:ANHUI TONGSHENG RING

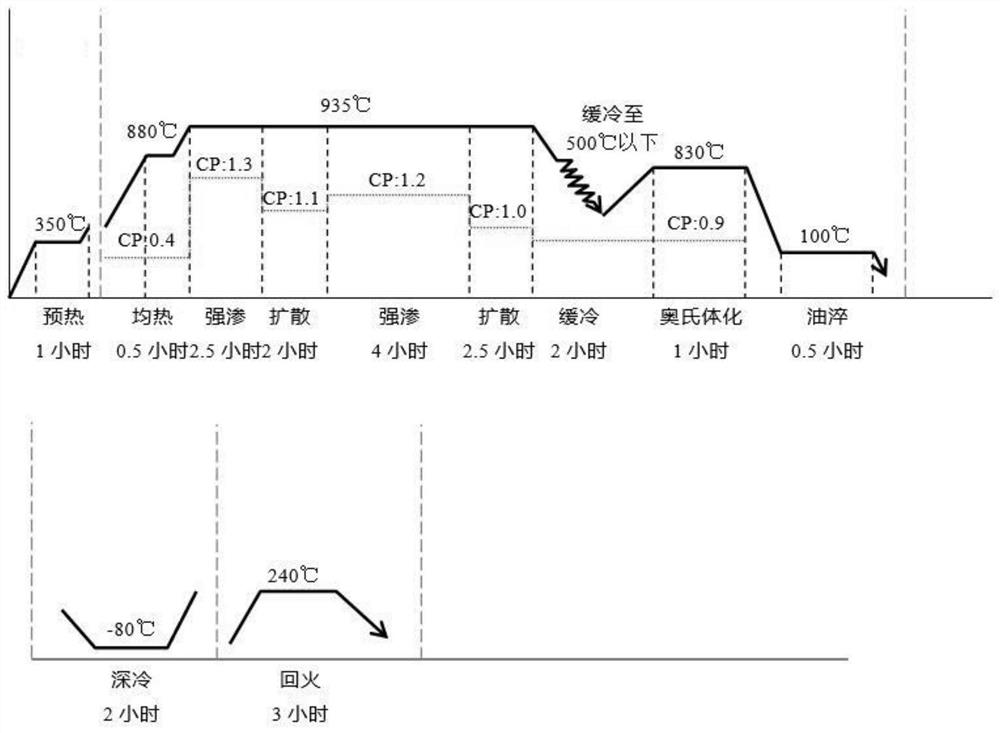

Carburizing heat treatment process for fatigue-resistant metal sliding block

PendingCN113337826AImprove contact fatigue performanceAvoid formingSolid state diffusion coatingFurnace typesCryptocrystallineCryogenic treatment

A carburizing heat treatment process for a fatigue-resistant metal sliding block comprises the steps that S1, the sliding block is preheated to 350 DEG C, and the preheating time is 1 h; S2, the sliding block is subjected to carburizing and quenching; S3, the sliding block is subjected to cryogenic cooling, wherein the temperature is minus 80 DEG C, and the time is 2 h; and S4, the sliding block is tempered, wherein the temperature is 240 DEG C, and the time is 3 h. According to the carburizing heat treatment process for the fatigue-resistant metal sliding block, controllable atmosphere carburization is adopted, multiple stages of strong carburization and diffusion are alternately carried out, it is avoided that carbon is gathered on the surface to form cementite, and meanwhile a carburized layer has a good and gentle hardness gradient; and then, in combination with the modes of conducting carburizing slow cooling and conducting two times of heating and quenching, extremely fine cryptocrystalline martensite is obtained, then the retained austenite is further reduced through cryogenic treatment, and therefore the contact fatigue resistance of the sliding block is improved.

Owner:KUNSHAN SUNMIN DRILUBE ELECTRONIC MATERIAL TECHNOLOGY CO LTD

Heat treatment process of high-nitrogen stainless bearings

ActiveCN106350647AImprove wear resistanceImprove contact fatigue performanceFurnace typesHeat treatment furnacesWear resistanceMaterials science

The invention relates to the technical field of heat treatment processes, and relates to a heat treatment process of high-nitrogen stainless bearings. The process comprises the following steps: S1, selecting high-nitrogen steel liquid as a basic raw material; S2, arranging a plurality of sand tanks, wherein the sand tanks are different in temperature; S3, annealing; S4, selecting the sand tanks with temperature of 350-400 DEG C, 250-300 DEG C, 150-200 DEG C, 50-100 DEG C and 15-40 DEG C respectively; S5, preparing a surface smearing agent; S6, preheating; S7, firing components produced in the step S6 by using a flame gun; S8, selecting an air cooler and cooling the components produced in the step S7 via the air cooler; and S9, cooling the components cooled in the step S8 via air. Through the process, the resource waste is reduced to a certain extent; the abrasion resistance, contact fatigue and flexibility of the bearing components can be improved; the service quality of the bearing components is greatly improved, and the service life of the bearing components is greatly prolonged.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

Self-lubricating alloy high-hardness bearing

The invention discloses a self-lubricating alloy high-hardness bearing which comprises a bearing outer ring, a ball and a bearing inner ring; polytetrafluoroethylene is used for coating an outer roller surface of the bearing inner ring; the ball is made of an iron alloy; and the iron alloy consists of the following components in percentage by weight: 0.2-0.5% of C, 0.3-0.6% of Si, 0.04-0.07% of B, 0.1-0.3% of V, 0.05-0.08% of Ni, 0.2-0.3% of Mo, 0.13-0.17% of Nb, 0.2-0.4% of Al, 3.2-4.0% of Cr, 0.07-0.1% of Zr, 0.05-0.08% of Sc, 0.07-0.1% of Y, less than or equal to 0.015% of S, less than or equal to 0.02% of P and the balance Fe. The self-lubricating alloy high-hardness bearing is small in friction force, is less in abrasion, is great in hardness, is excellent in toughness, is good in contact fatigue strength and is long in service life.

Owner:NINGBO DAER MACHINERY TECH CO LTD

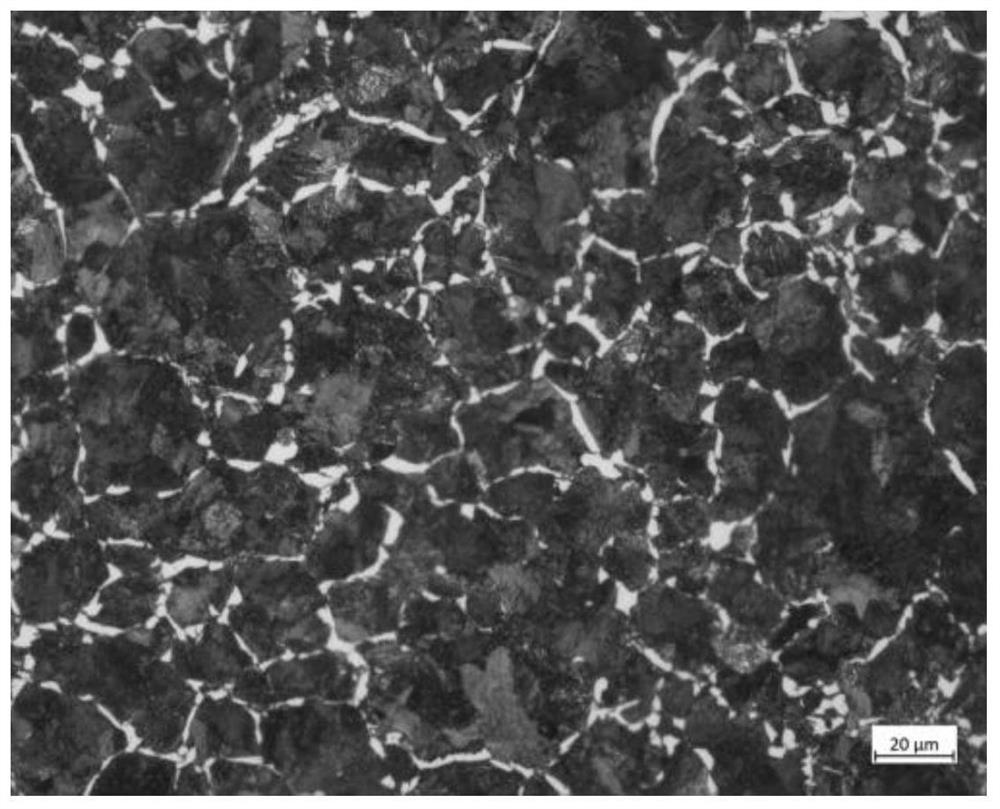

Long-service-life railway bearing steel and preparation method thereof

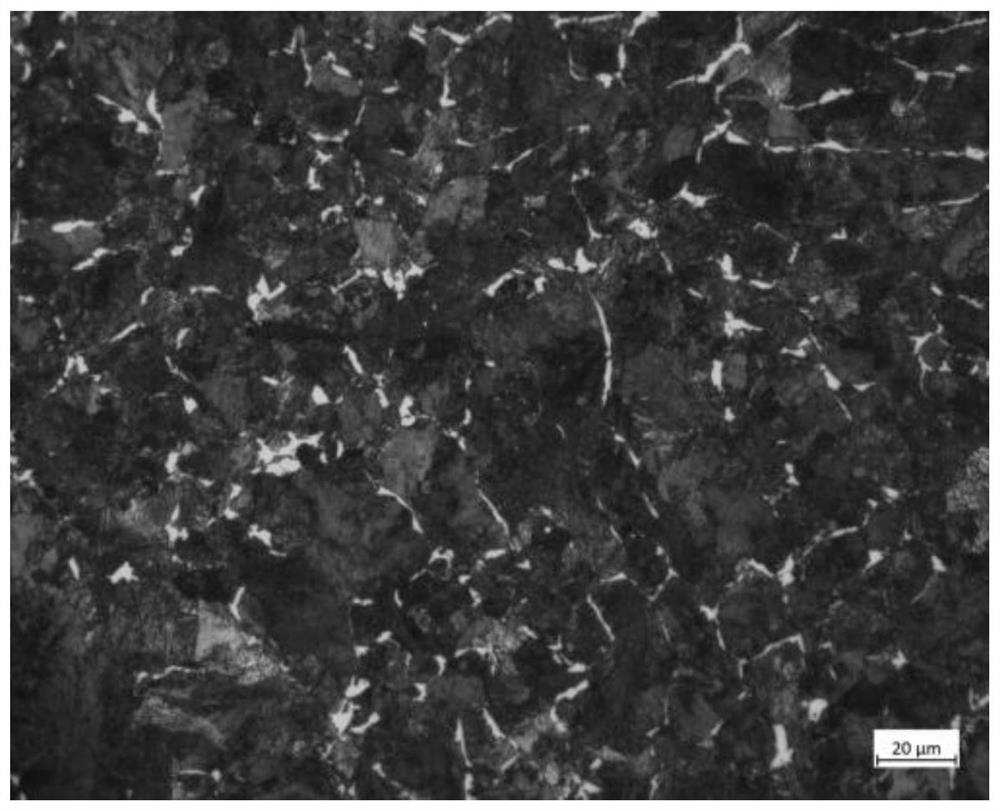

ActiveCN113564496AImprove contact fatigue performanceExtended service lifeSolid state diffusion coatingTemperingCarbide

The invention discloses long-service-life railway bearing steel. The steel comprises the following chemical components in percentage by weight: 0.17 to 0.23 percent of C, 0.15 to 0.40 percent of Si, 3.0 to 3.8 percent of Mn, 0.35 to 0.65 percent of Cr, 0.6 to 0.9 percent of Ni, 0.20 to 0.30 percent of Mo, less than or equal to 0.30 percent of Cu, 0.05 to 0.20 percent of V, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S and the balance of Fe and impurities. In addition, the invention further provides a preparation method of the long-service-life railway bearing steel, and the method mainly comprises the steps of forging, carburizing treatment, primary quenching and tempering and isothermal quenching. According to the long-service-life railway bearing steel and the preparation method thereof, the residual austenite and the grain structure are reasonably regulated and controlled, so that the surface structure of the steel is bainite, acicular martensite, nano austenite and acicular carbide. The steel has good obdurability matching and excellent contact fatigue performance.

Owner:铁科金化检测中心有限公司 +3

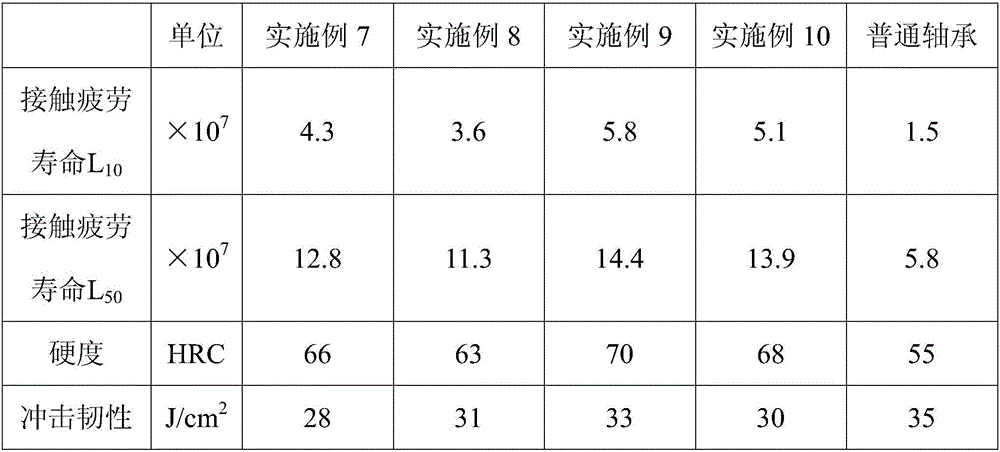

A rolling bearing with high toughness and high hardness

ActiveCN105757124BEvenly distributedGrain refinementBearing componentsFurnace typesMechanical engineeringToughness

The invention discloses a high-toughness and high-rigidity rolling bearing, comprising a bearing outer ring, a rolling body and a bearing inner ring; an outer raceway surface of the bearing inner ring comprises three bumps protruding towards the outer side of the bearing inner ring, the three bumps are sequentially connected, and a concave part is formed in a connecting part of every two adjacent bumps; both of the bumps and the concave parts are arcs; the three bumps are evenly distributed on the outer raceway surface along the circumferential direction of the bearing inner ring. The bearing inner ring is made from the following components by weight percent: 0.6-0.7% of C, 0.15-0.35% of Si, 0.4-0.5% of N, 0.09-0.12% of B, 0.3-0.4% of Mn, 0.1-0.2% of V, 0.1-0.15% of W, 0.18-0.22% of Mo, 0.12-0.15% of Nb, 0.22-0.26% of Al, 3-4% of Cr, 0.07-0.10% of Ce and the balance of Fe.

Owner:安徽省宁国顺昌机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com