Wheel with high contact fatigue performance and production method thereof

A contact fatigue and production method technology, which is applied in the direction of wheels, wheels characterized by track running parts, vehicle parts, etc., can solve the problems such as the inability to quickly identify the key factors of the comprehensive performance of wheel steel, and achieve the wheel surface contact fatigue resistance. Performance improvement, ratio improvement, effect of increasing yield strength

Inactive Publication Date: 2021-09-17

MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this invention focuses on optimal design and adjustment of the composition of the wheel steel, and cannot quickly identify the key factors that affect the comprehensive performance of the wheel steel, and adopts the conventional tread intensive cooling process, and some parts of the wheel appear undesired non-pearlite structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 3

[0046] A wheel with high contact fatigue performance, including the following mass percentage components: the following Table 1, the balance not shown in Table 1 is Fe and unavoidable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Login to View More

Abstract

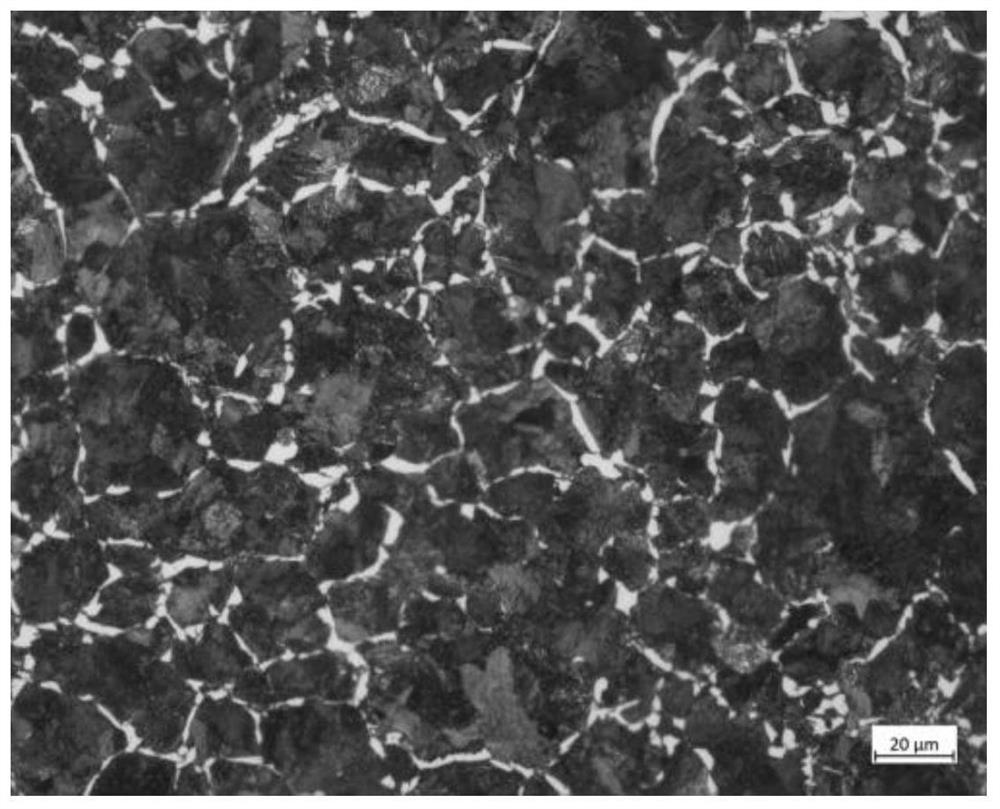

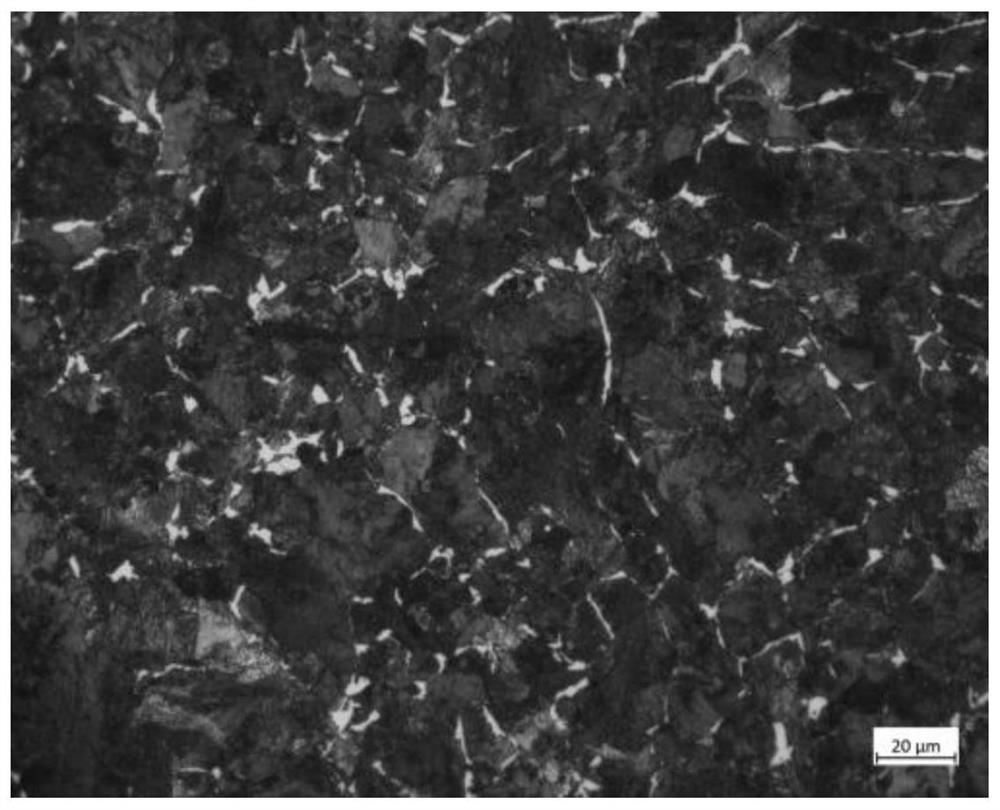

The invention provides a wheel with high contact fatigue performance and a production method thereof. The wheel comprises the following components of 0.55%-0.65% of C, 0.15%-0.30% of Si, 0.40%-1.2% of Mn, 0.10%-0.25% of Cr, 0.02%-0.03% of Al, less than or equal to 0.010% of P, 0.020%-0.035% of S, 0.10%-0.20% of V, less than or equal to 10 ppm of T.O, less than or equal to 1.5 ppm of [H], 80-120 ppm of [N] and the balance Fe and inevitable impurity elements. Compared with the prior art, steel for the wheel with the high contact fatigue performance is produced by using specific components and a reasonable preparation method, and through a certain heat treatment process, it is ensured that the surface contact fatigue resistance of the prepared wheel is obviously improved.

Description

technical field [0001] The invention belongs to the technical field of railway wheel preparation, and in particular relates to a wheel with high contact fatigue performance and a production method thereof. Background technique [0002] The working environment of the wheel is complex and harsh, and the main failure forms are tread peeling, pitting peeling caused by contact fatigue, fatigue peeling, etc. It is usually required that the material has good strength, toughness and wear resistance, so the performance of the material can be reflected by the contact fatigue of the material. In view of the complex working environment of wheels, many scholars have also done related research on their contact fatigue: [0003] The patent application "Steel for Wheels" published by Nippon Steel & Sumitomo Metal Co., Ltd. in China on July 24, 2013, publication number: CN 103221561 A, discloses a steel with properties such as wear resistance, contact fatigue resistance and thermal damage. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/24C21D1/18C21D6/00C21D8/00C21D9/34B60B17/00

CPCC22C38/02C22C38/04C22C38/06C22C38/24C21D1/18C21D6/002C21D6/005C21D6/008C21D8/005C21D9/34B60B17/00C21D2211/009C21D2211/005C21D2211/002

Inventor 国新春陈刚张磊邓荣杰王翔宁珅

Owner MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com