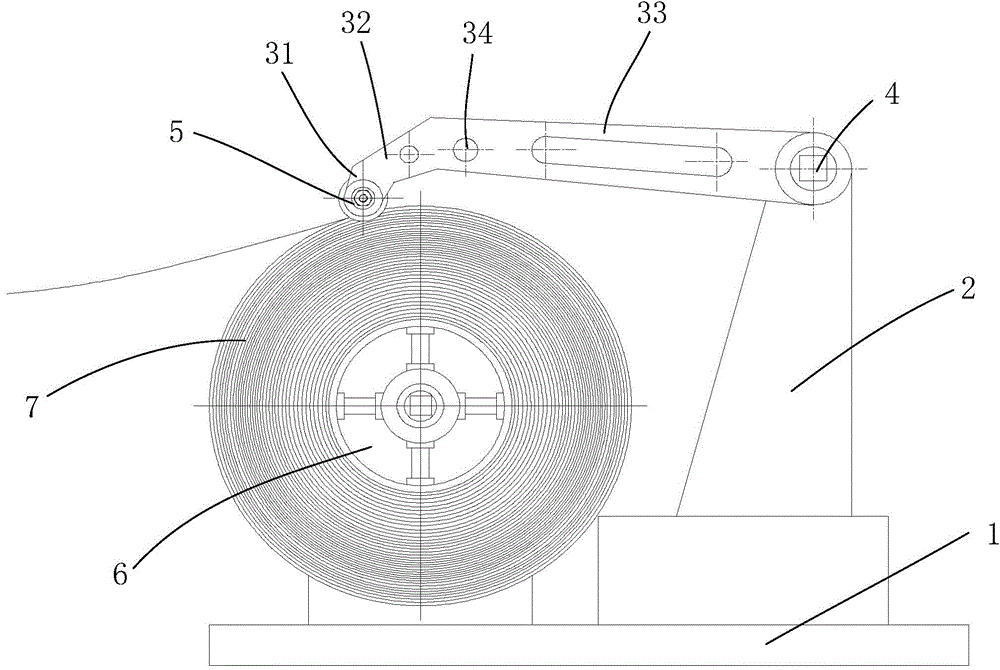

Belt pressing device of coiling machine

A technology of coiling machine and coiling mechanism, which is applied in the field of coiling steel strips, can solve the problems of inconvenient operation, inconvenient installation, and inability to ensure the compression of coiled steel strips in real time, so as to achieve the effect of ensuring the compression effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

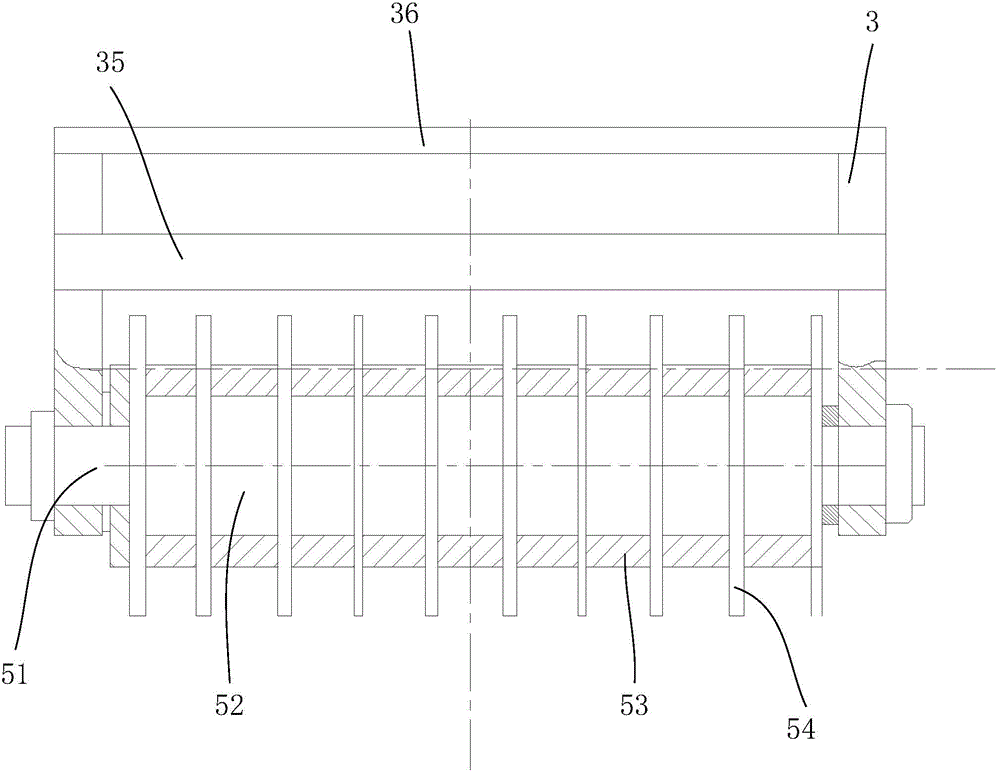

[0038] Such as figure 1 with figure 2 As shown, the present invention provides a crimping machine strapping device, including a mounting base 1 and a strap fixing frame 2 and a tape winding mechanism 6 installed on the mounting seat 1, and the strap fixing frame 2 is located at the side of the strap winding mechanism 6 At the rear, the upper end of the belt-pressing fixed frame 2 is rotatably installed with a belt-pressing movable frame 3 through the support shaft 4, and the front part of the belt-pressing movable frame 3 is provided with two groups of counterweight mechanism mounting holes 34, and the counterweight mechanism mounting holes 34 A counterweight 35 is installed inside, and the front end of the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com