High-purity AlSi14A alloy and preparation technique thereof

A preparation process and alloy technology, applied in the field of aluminum alloy materials, can solve the problems of melting of Si element, great influence on the internal structure of the product, unable to meet customer requirements, etc., to achieve the effect of ensuring uniformity and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

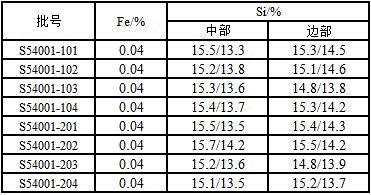

[0048]First spread 3.076 tons of 4N refined aluminum ingots evenly on the bottom of the furnace, heat up and melt, and when the temperature of the molten aluminum reaches 760°C, add 0.87 tons of preheated 2202 industrial silicon, spread it evenly on the surface of the molten aluminum, and wait until the silicon is completely melted Then add 2.051 tons of 4N refined aluminum liquid, stir for 15 minutes, control the refining temperature between 710-730 °C, the amount of refining agent is 5‰, and the refining time is 35 minutes. Set aside for 20 minutes to sample. The composition of the alloy liquid meets the requirements, the temperature in the furnace is controlled at about 730°C, and a 6kg ingot casting machine is used for casting; after the furnace hole is opened, the aluminum liquid is degassed and slag-removed through online refining and filtering equipment, and the aluminum melt after the online degassing is tested The hydrogen content is less than 0.12 (mL / 100gAl), the de...

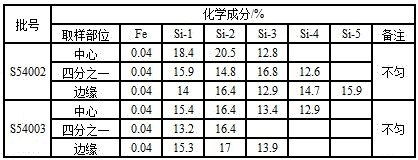

Embodiment 2

[0051] First spread 4.206 tons of 4N refined aluminum ingots evenly on the bottom of the furnace, heat up and melt, when the temperature of the molten aluminum reaches 800°C, add 1.18 tons of preheated 2202 industrial silicon, spread it evenly on the surface of the molten aluminum, and wait until the silicon is completely melted Then add 2.805 tons of 4N refined aluminum liquid, stir for 15 minutes, control the refining temperature between 710-730 °C, the amount of refining agent is 5‰, and the refining time is 35 minutes. Set aside for 20 minutes to sample. The composition of the alloy liquid meets the requirements, the temperature in the furnace is controlled at about 730°C, and a 6kg ingot casting machine is used for casting; after the furnace hole is opened, the aluminum liquid is degassed and slag-removed through online refining and filtering equipment, and the aluminum melt after the online degassing is tested The hydrogen content is less than 0.12 (mL / 100gAl), the degas...

Embodiment 3

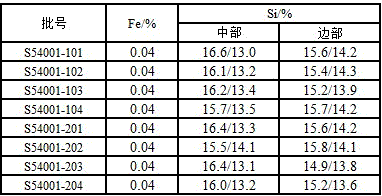

[0054] First spread 4.147 tons of 4N refined aluminum ingots evenly on the bottom of the furnace, heat up and melt, when the temperature of the molten aluminum reaches 800°C, add 1.16 tons of preheated 2202 industrial silicon, spread it evenly on the surface of the molten aluminum, and wait until the silicon is completely melted Then add 2.765 tons of 4N refined aluminum liquid, stir for 15 minutes, control the refining temperature between 710-730 °C, the amount of refining agent is 5‰, and the refining time is 35 minutes. Set aside for 20 minutes to sample. The composition of the alloy liquid meets the requirements, the temperature in the furnace is controlled at about 725°C, and a 6kg ingot casting machine is used to cast; The hydrogen content is less than 0.12 (mL / 100gAl), the degassing efficiency reaches 55%, and the filter specification is 50ppi; the casting temperature is controlled at 650-680°C during the entire casting process; the cooling water temperature is guarante...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com