Patents

Literature

289results about How to "High silicon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

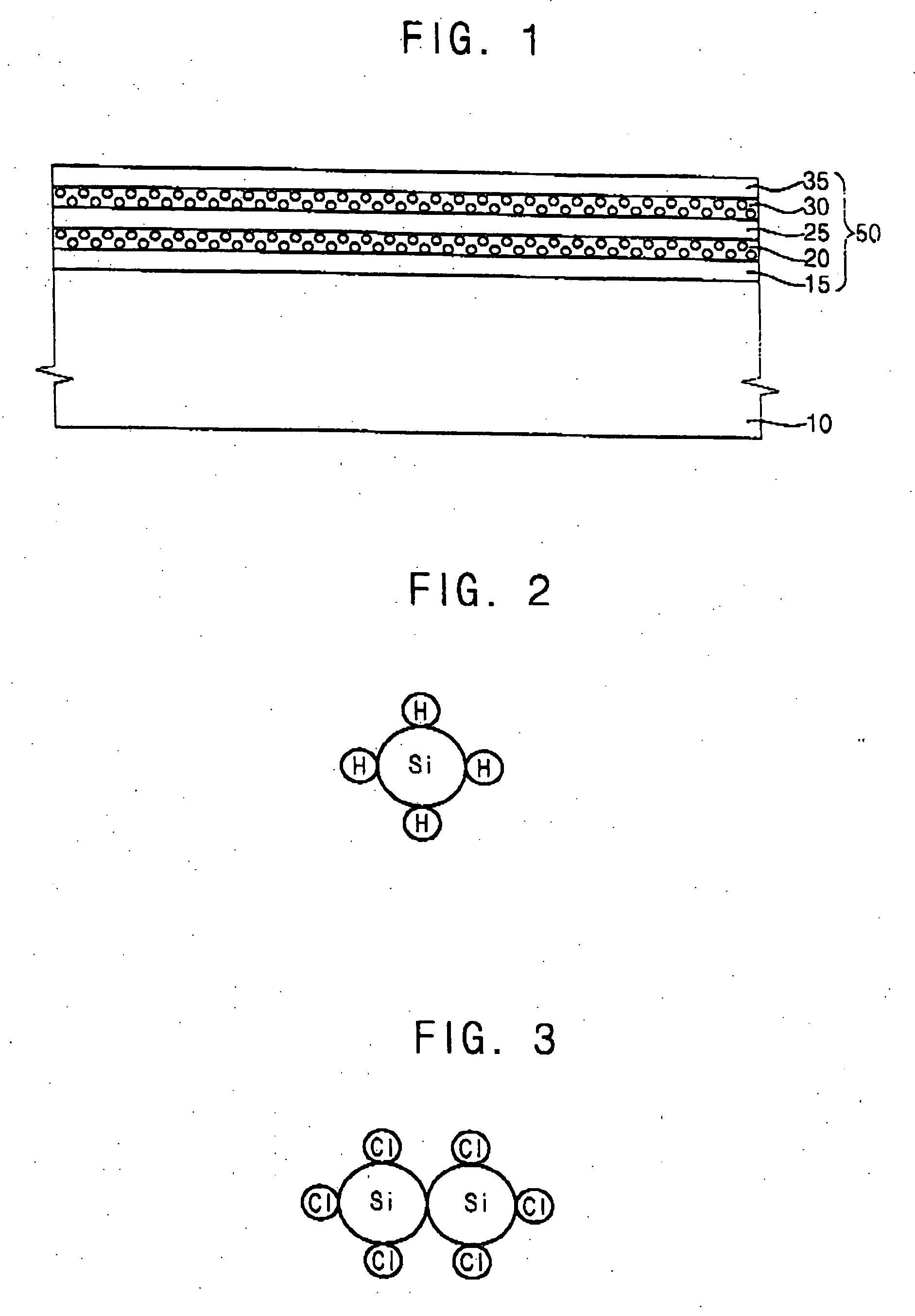

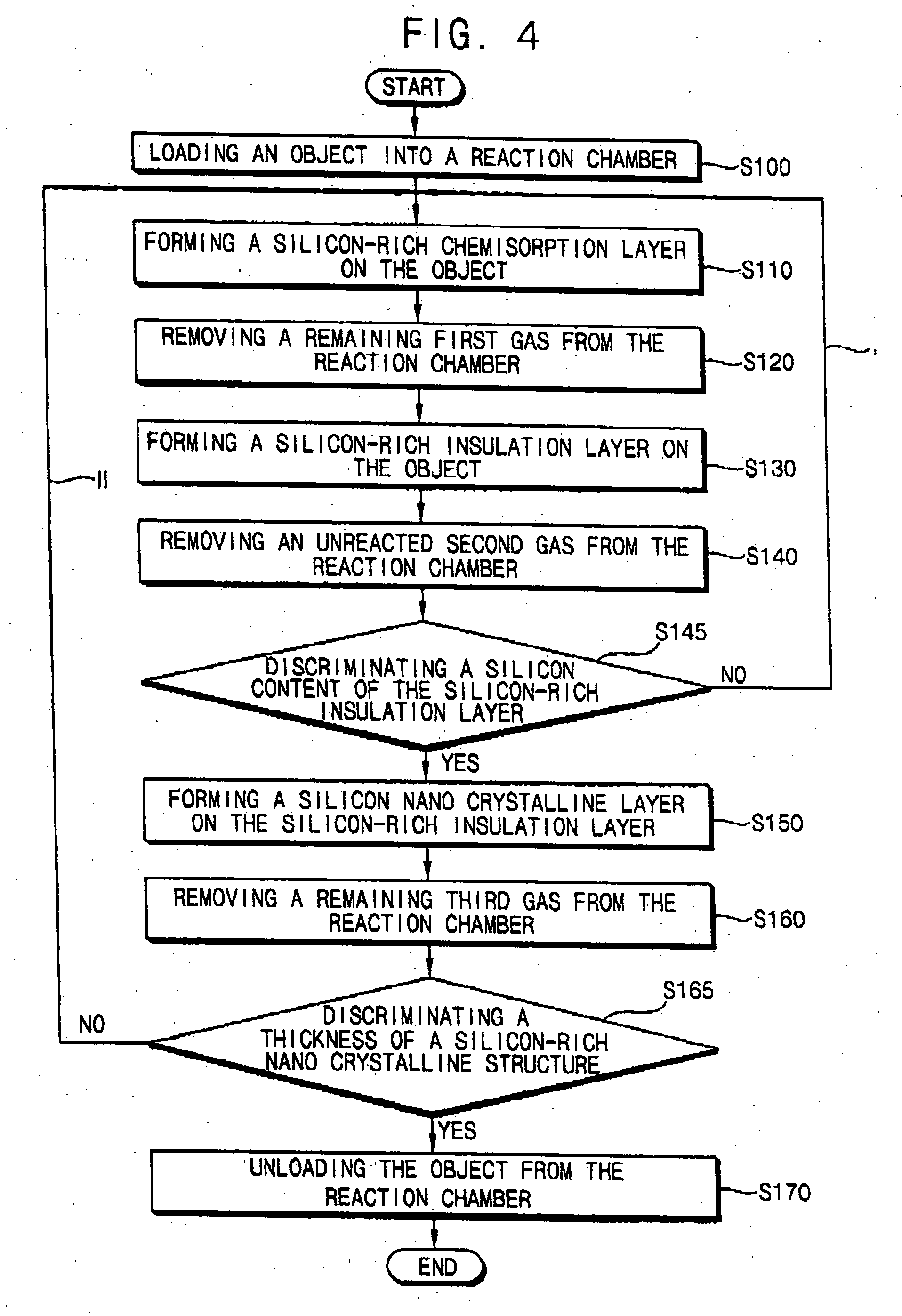

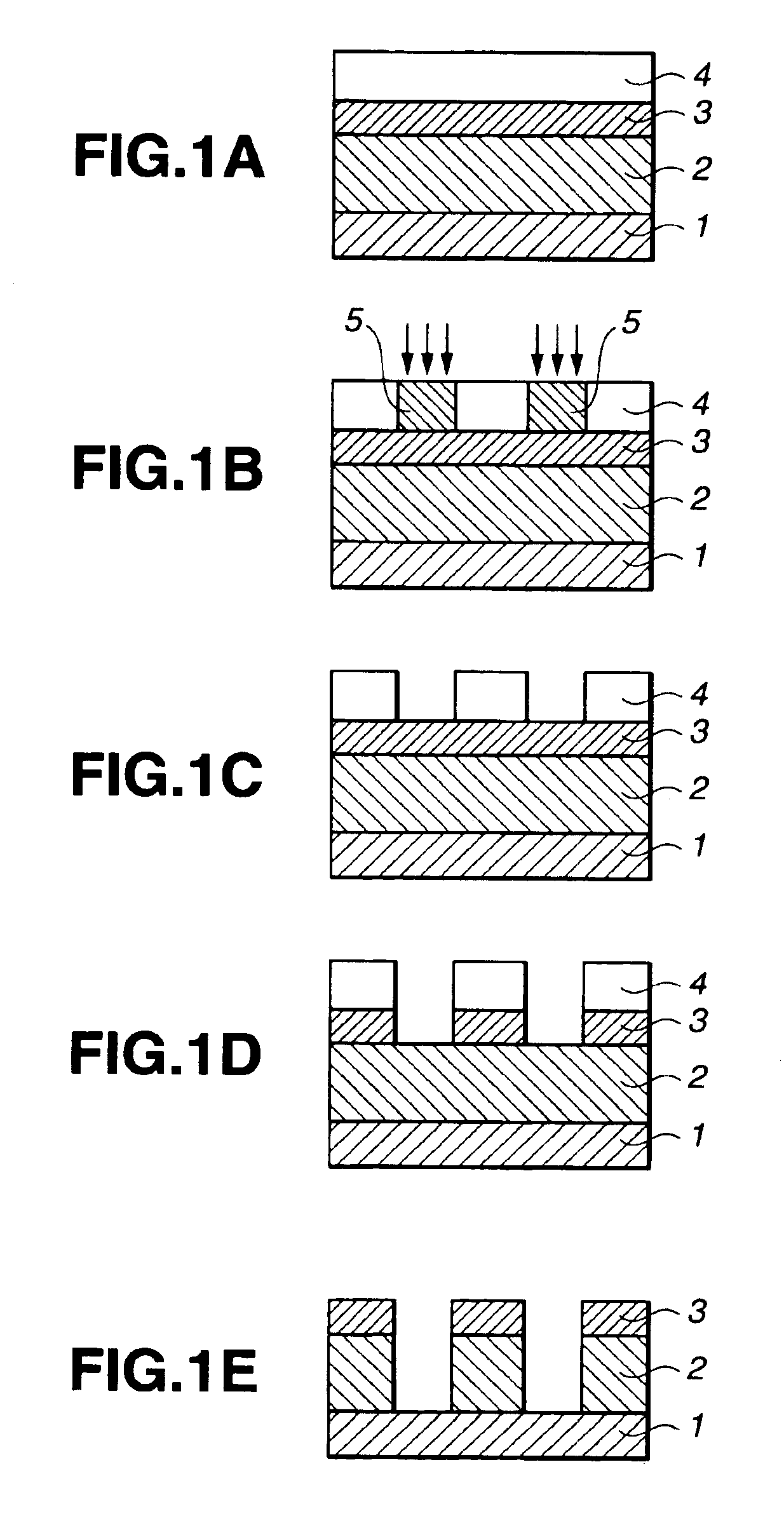

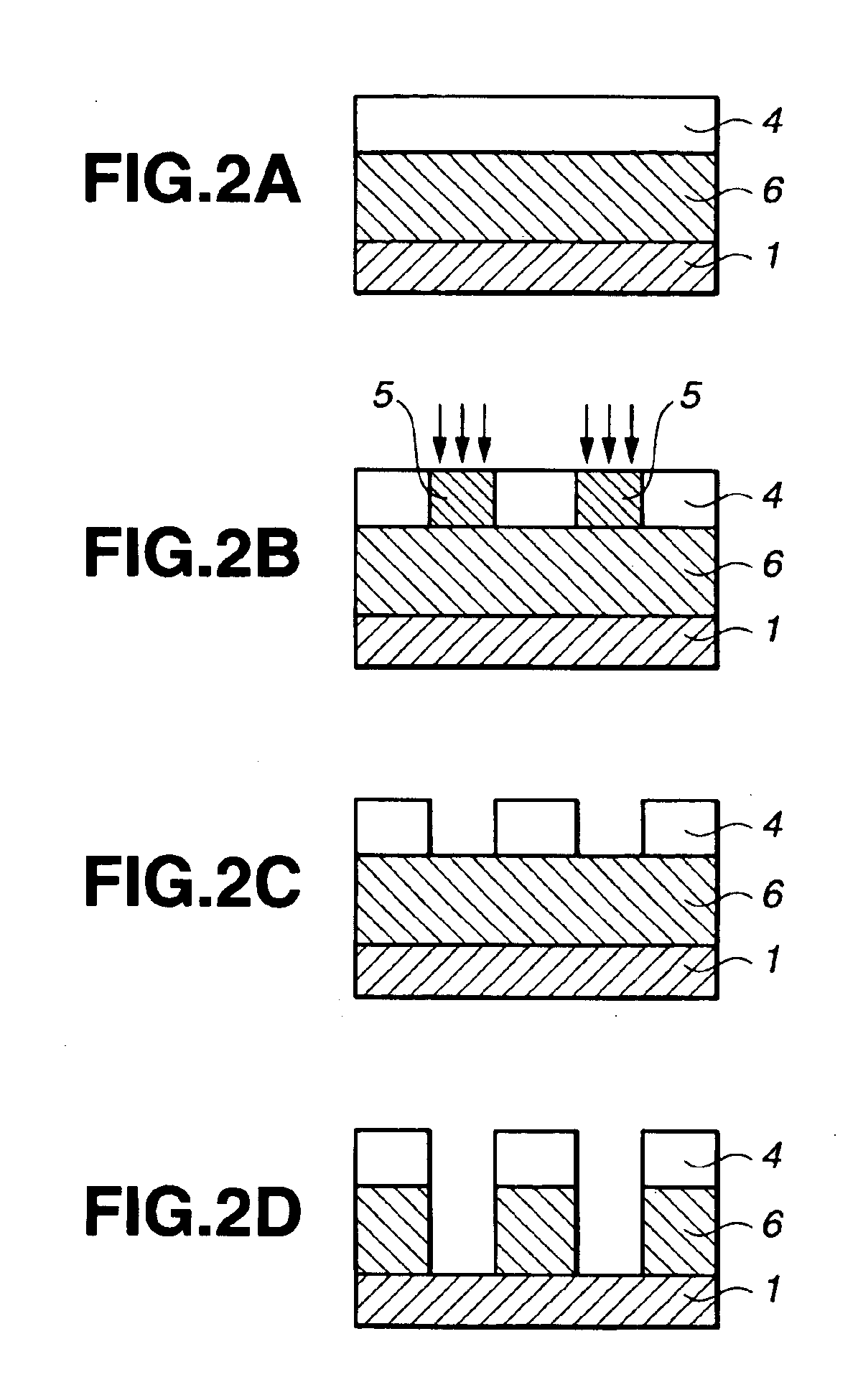

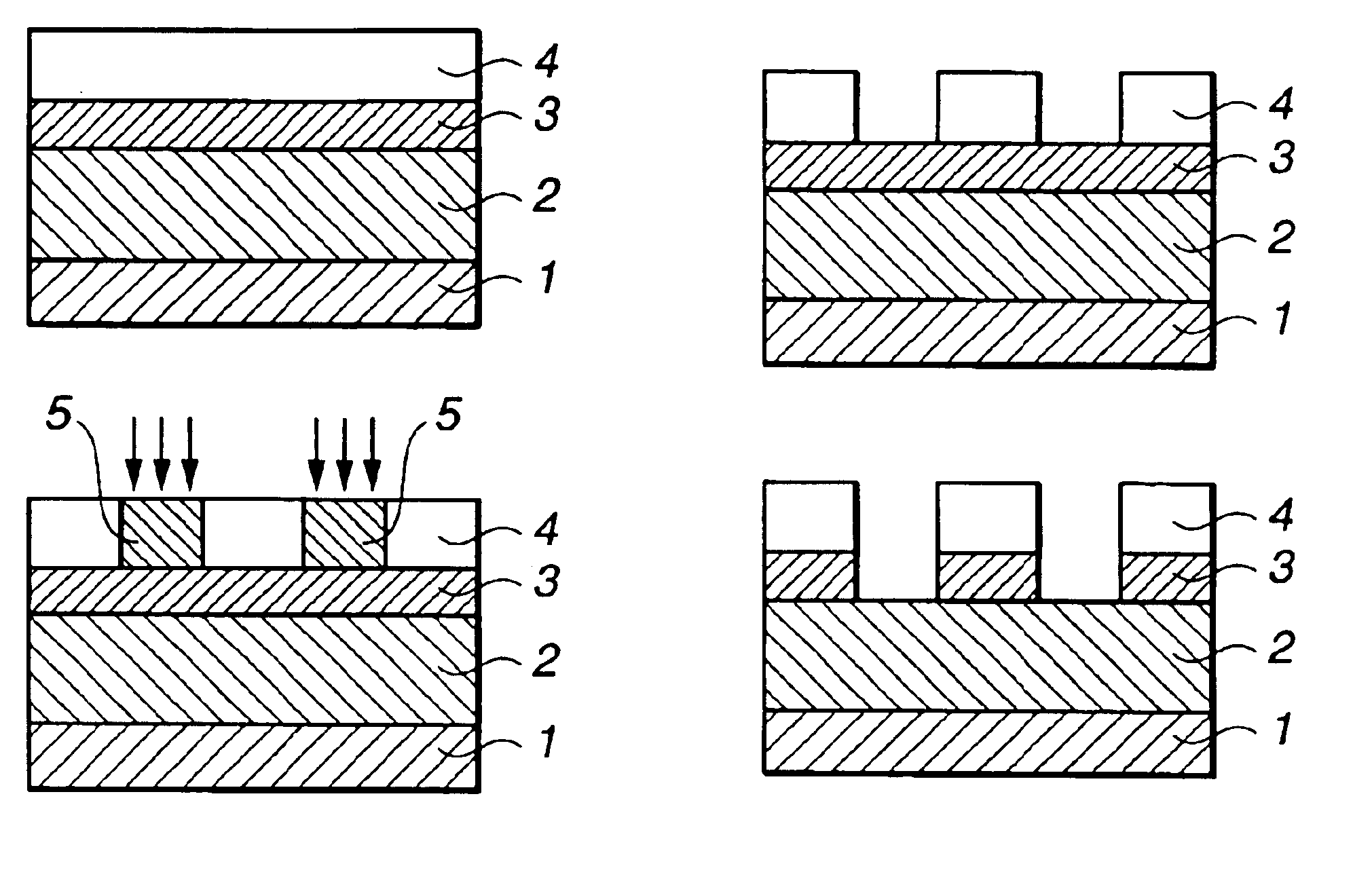

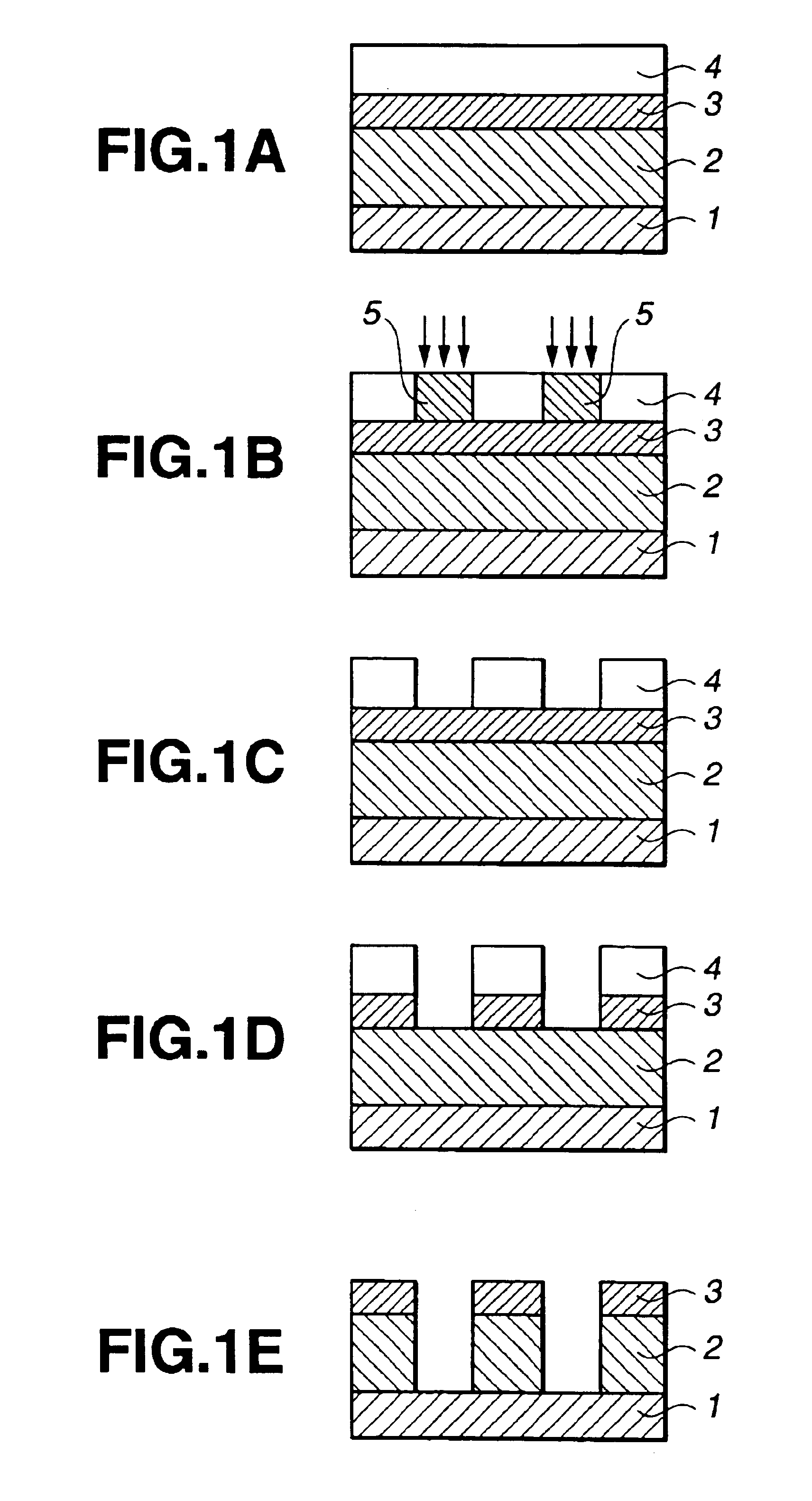

Method of forming a silicon-rich nanocrystalline structure by an atomic layer deposition process and method of manufacturing a non-volatile semiconductor device using the same

ActiveUS7419888B2Good step coverageImprove variationPolycrystalline material growthNanoinformaticsSilicon nanocrystalsInsulation layer

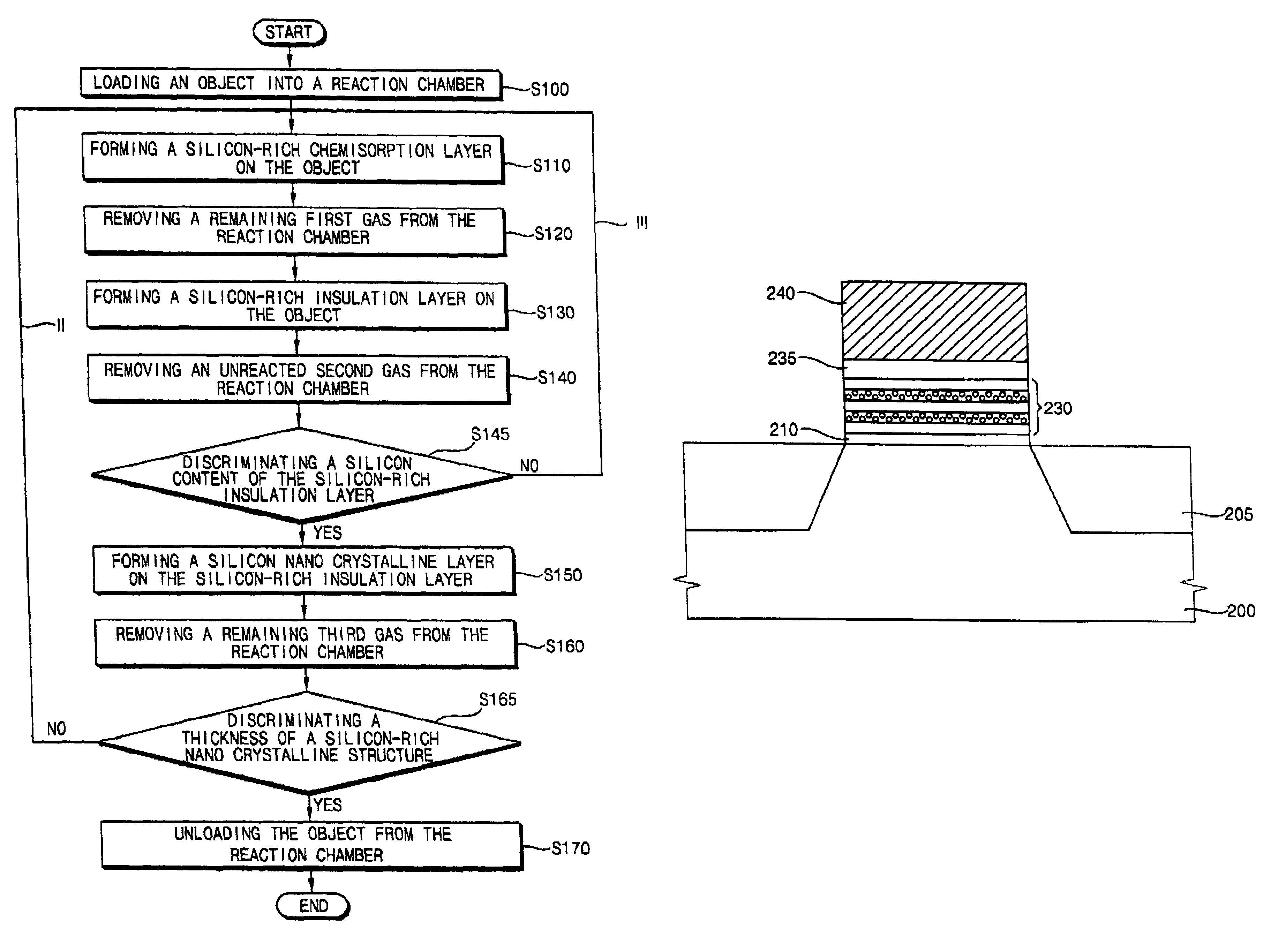

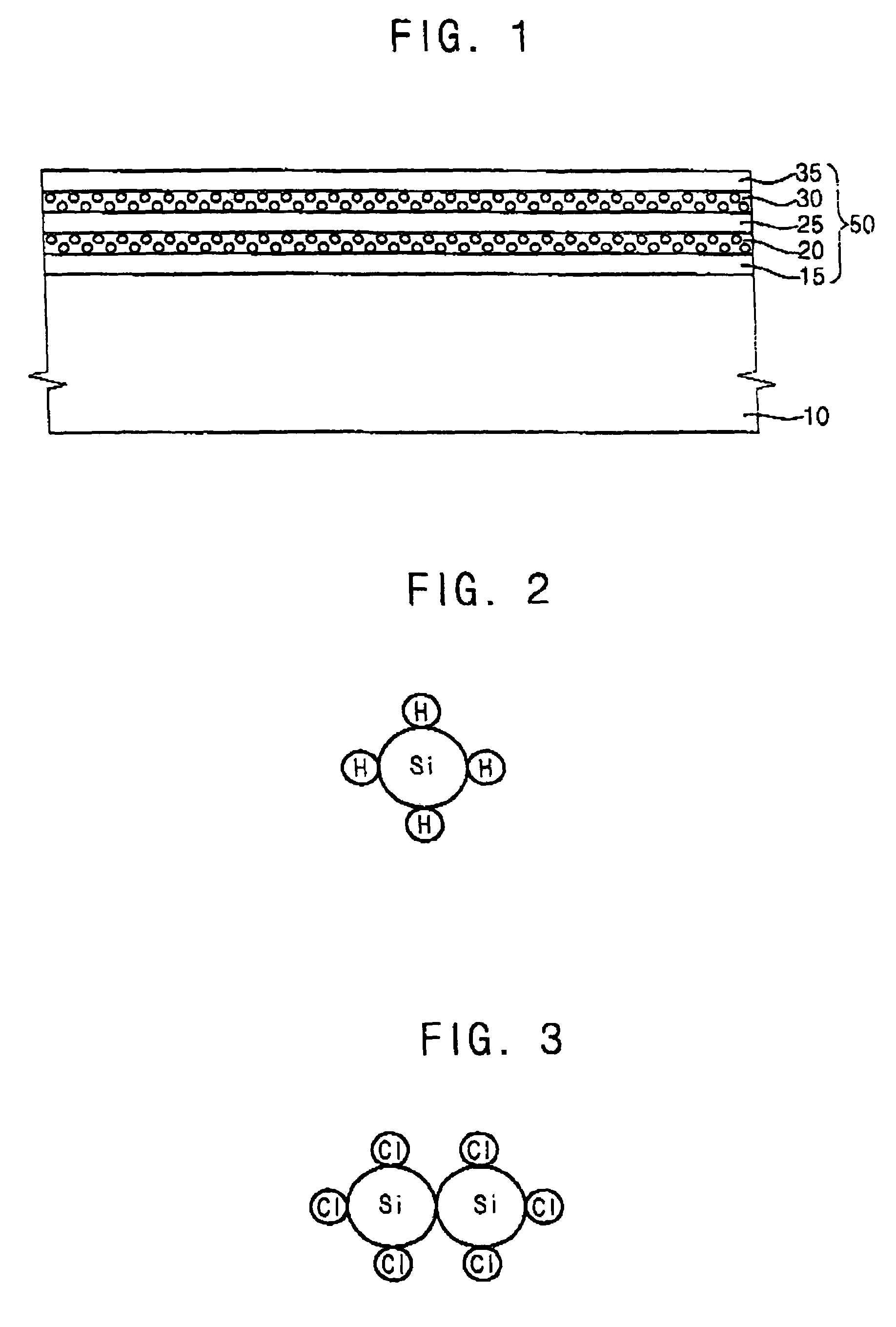

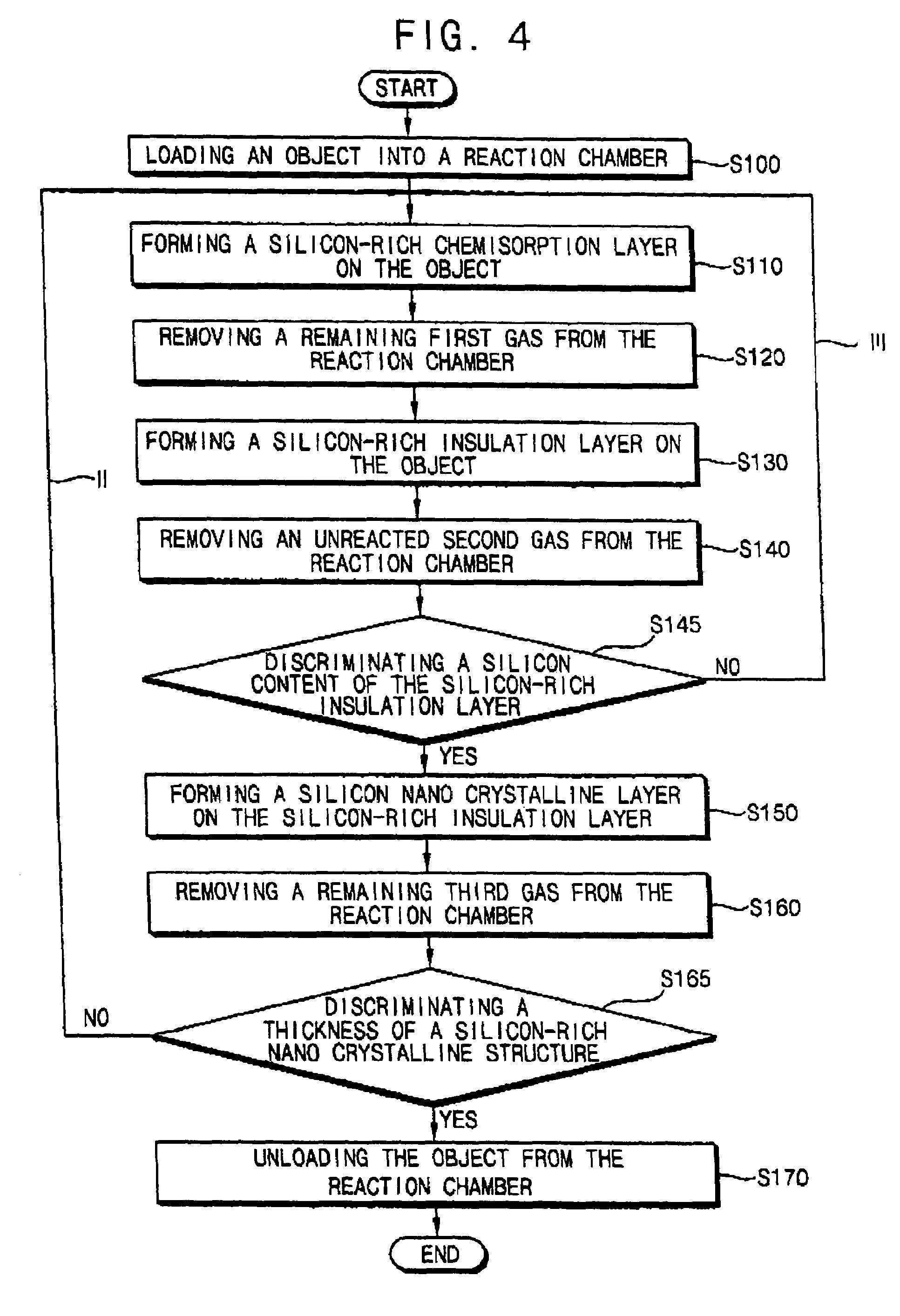

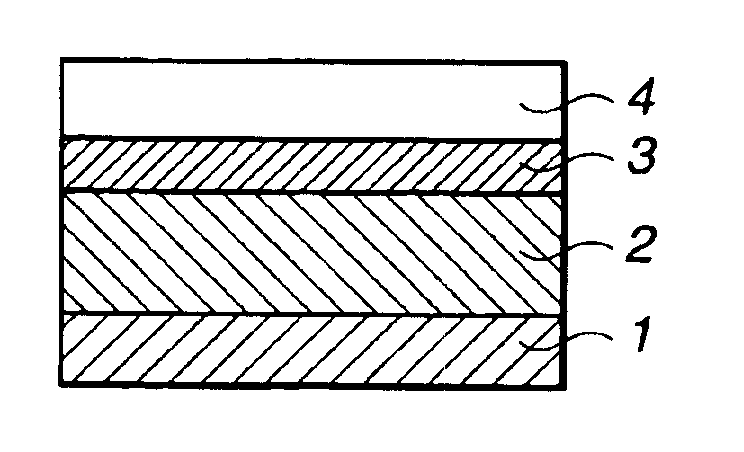

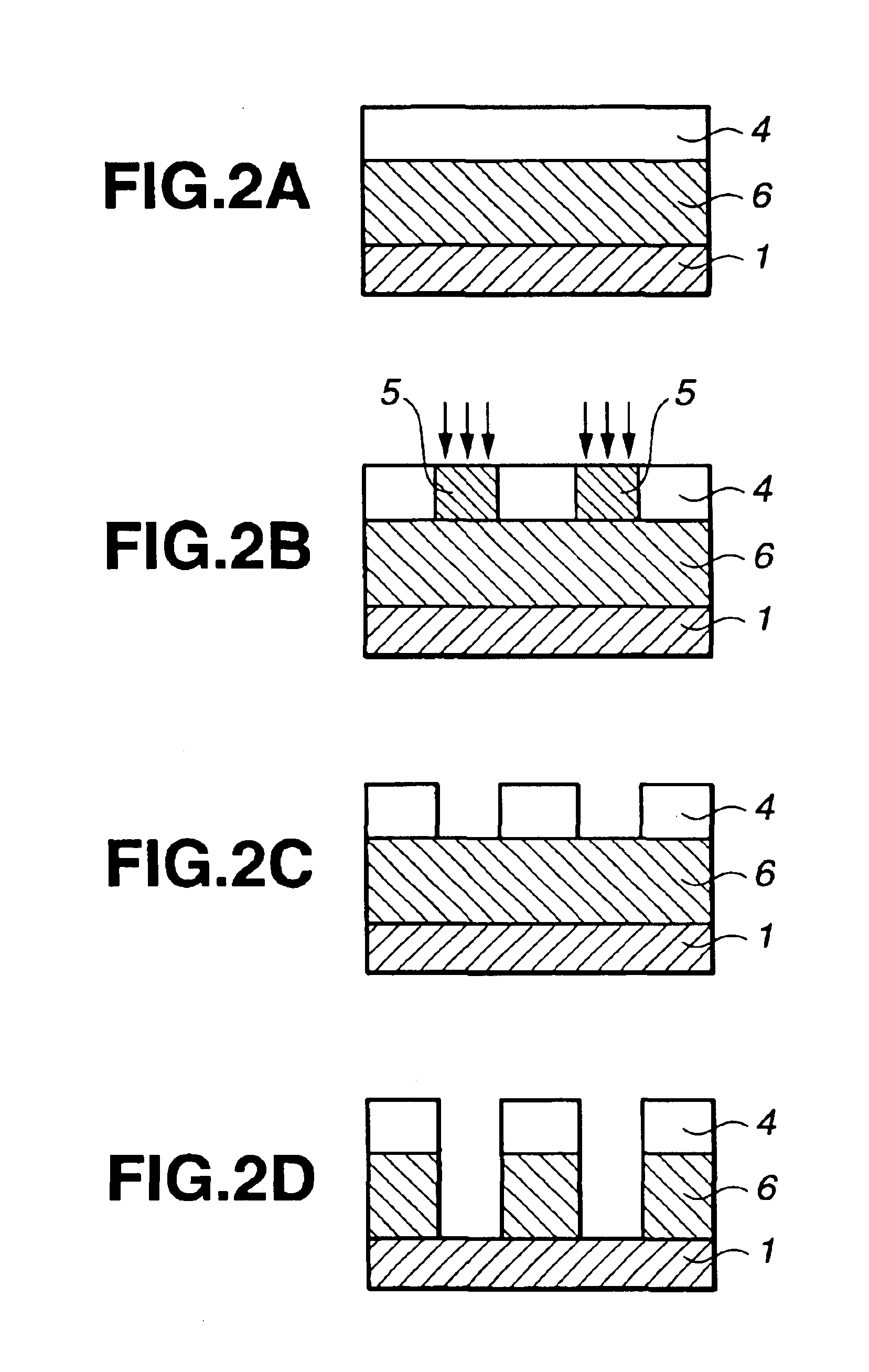

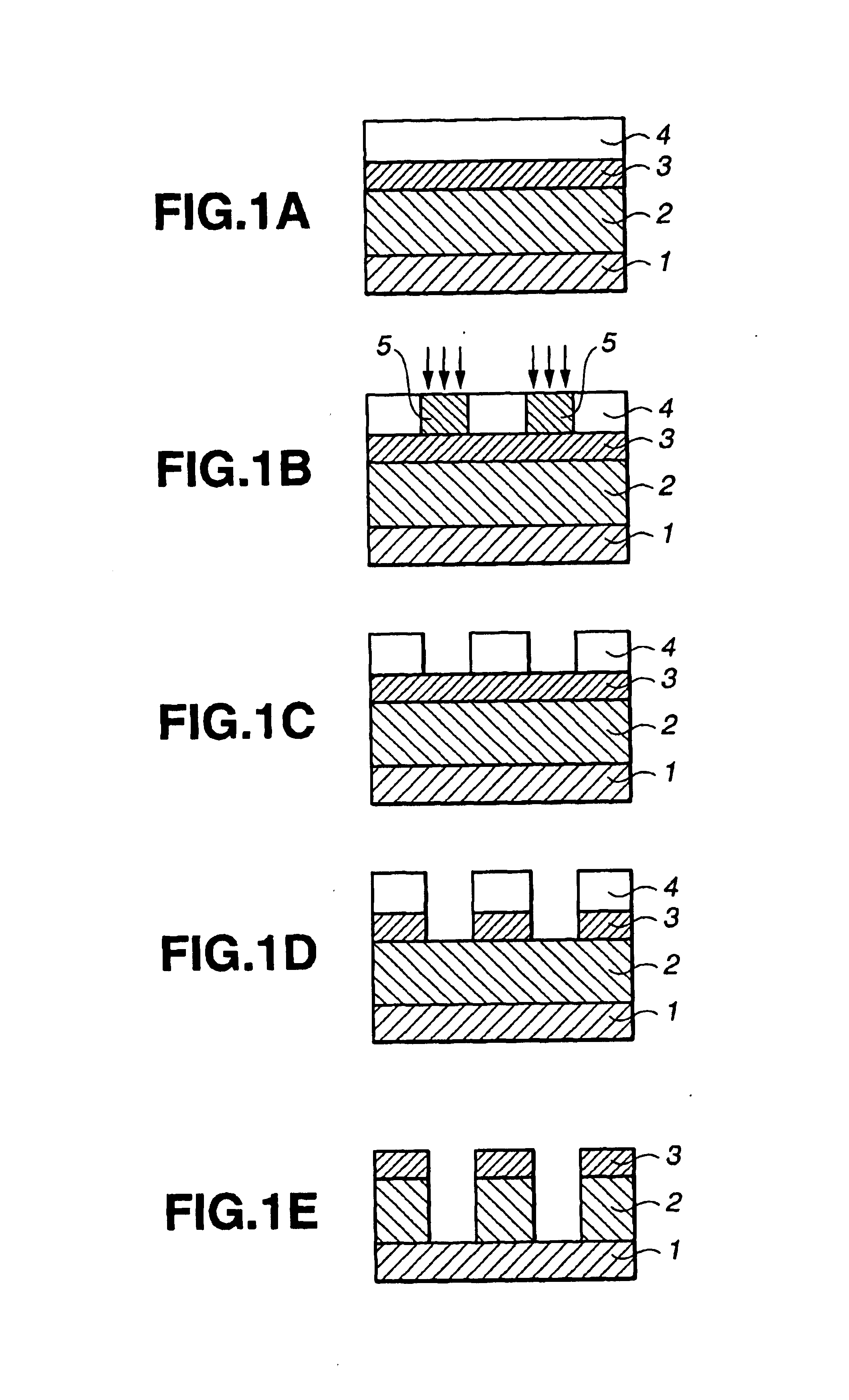

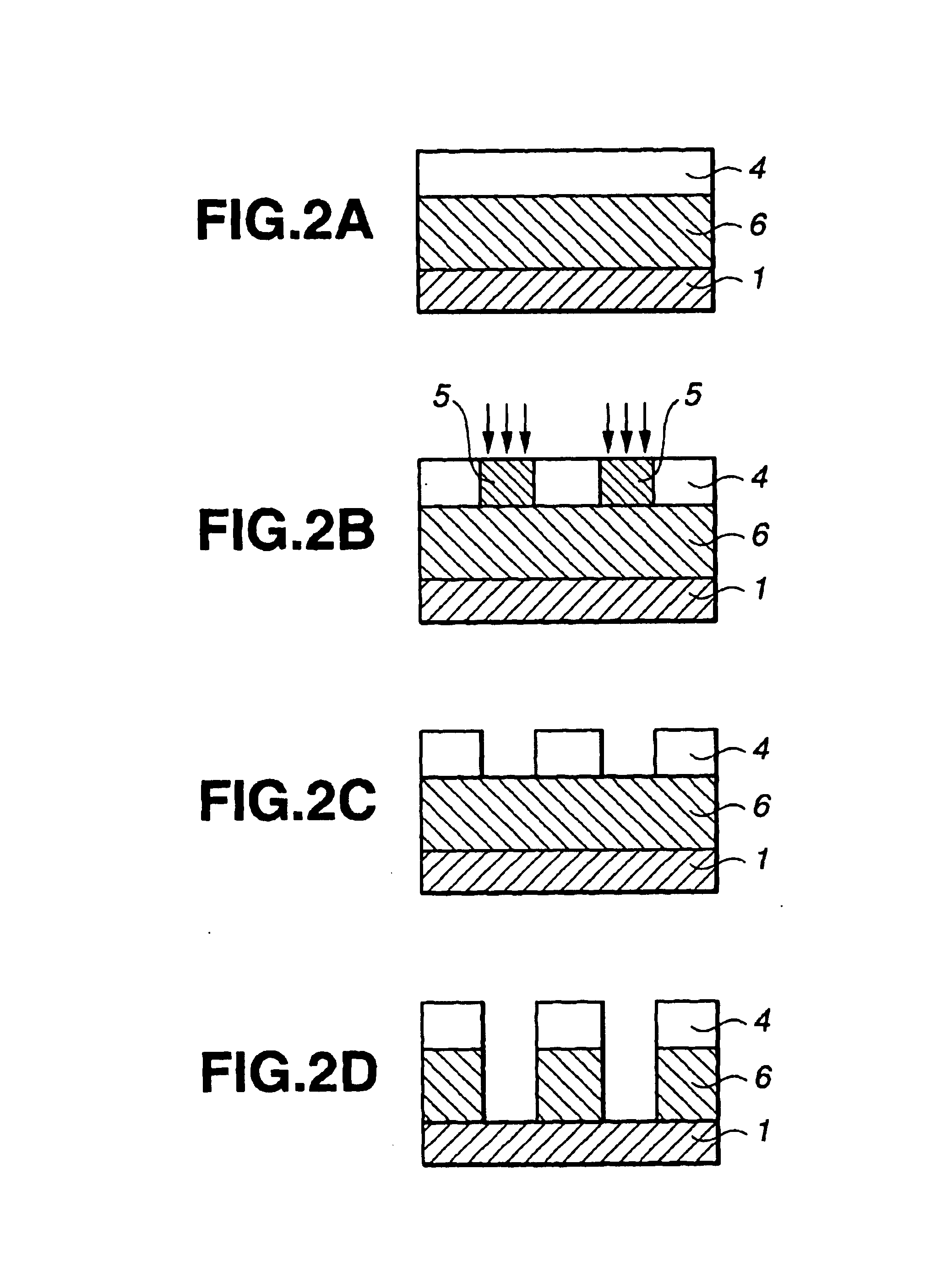

In a method of forming a silicon-rich nanocrystalline structure by an ALD process, a first gas including a first silicon compound is provided onto an object to form a silicon-rich chemisorption layer on the object. A second gas including oxygen is provided onto the silicon-rich chemisorption layer to form a silicon-rich insulation layer on the object. A third gas including a second silicon compound is provided onto the silicon-rich insulation layer to form a silicon nanocrystalline layer on the silicon-rich insulation layer. The first gas, the second gas and the third gas may be repeatedly provided to alternately form the silicon-rich nanocrystalline structure having a plurality of silicon-rich insulation layers and a plurality of silicon nanocrystalline layers on the object.

Owner:SAMSUNG ELECTRONICS CO LTD

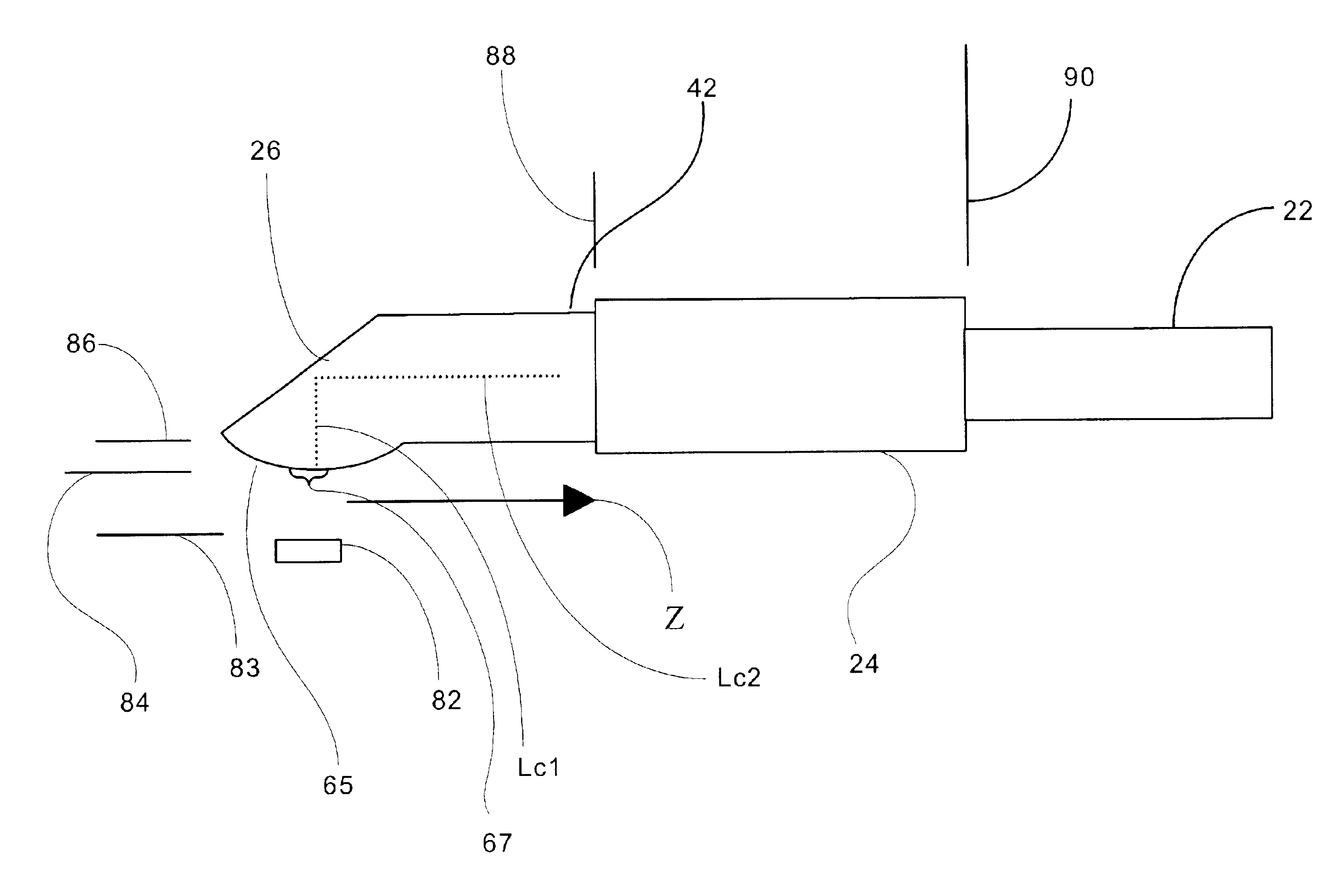

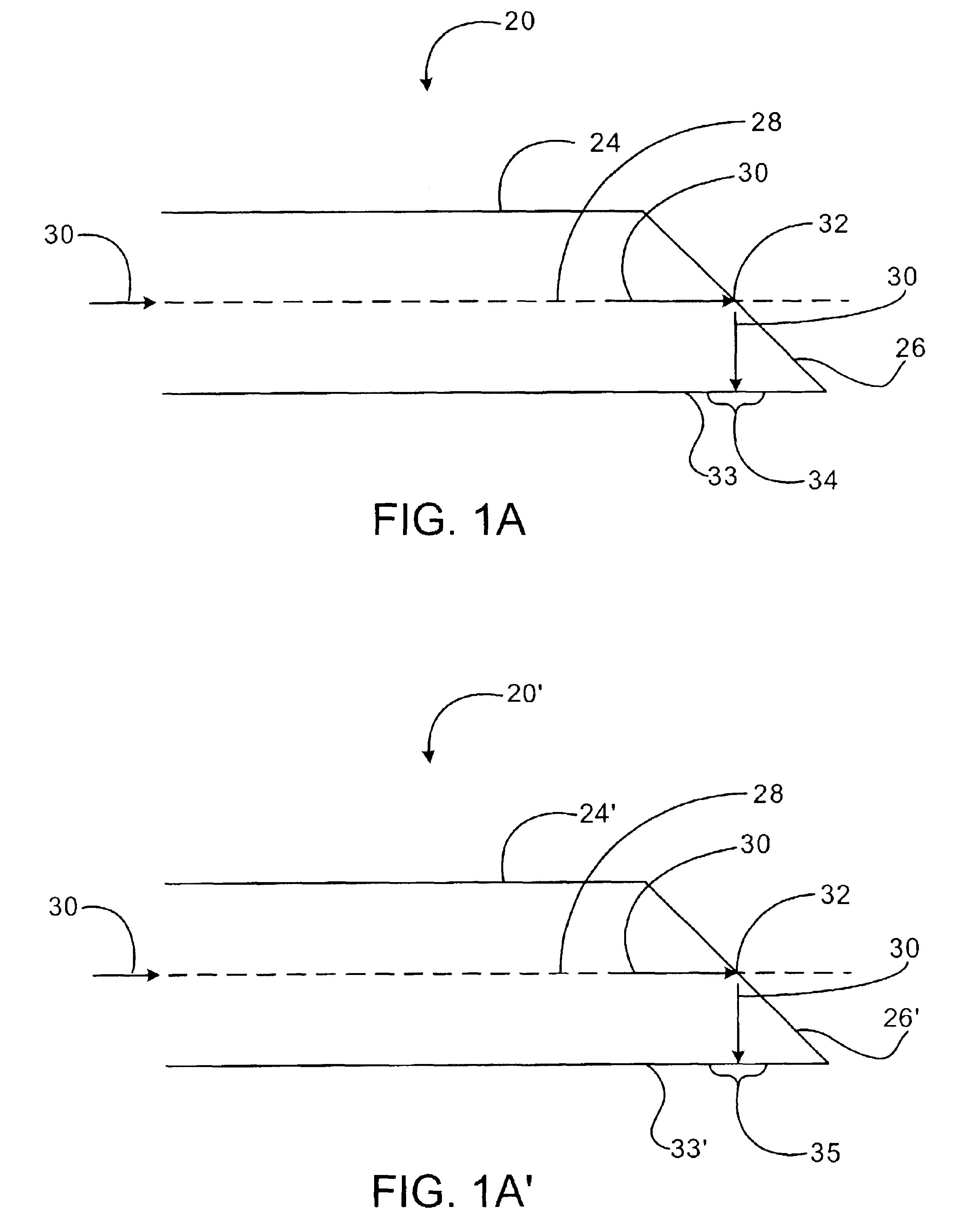

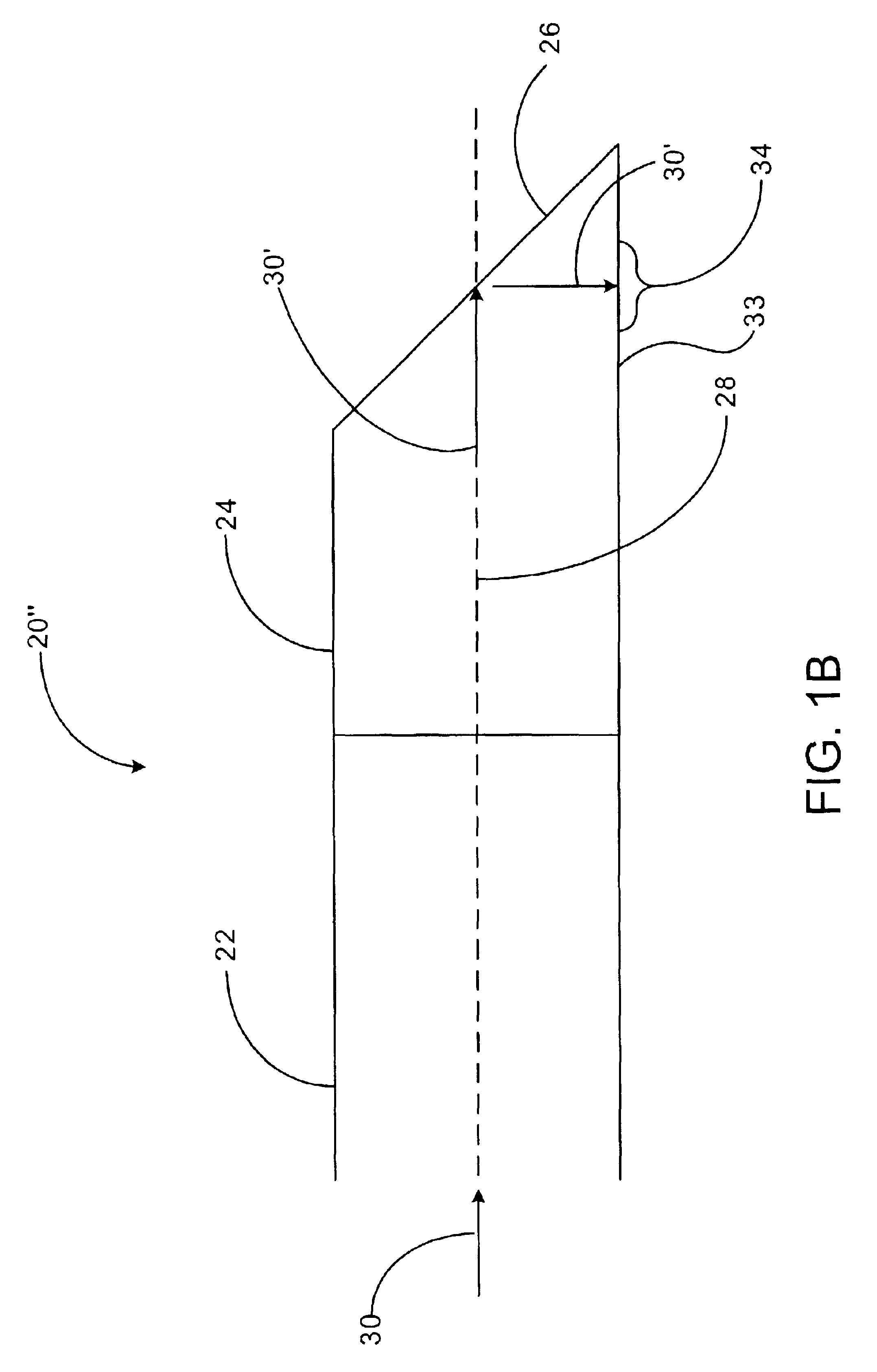

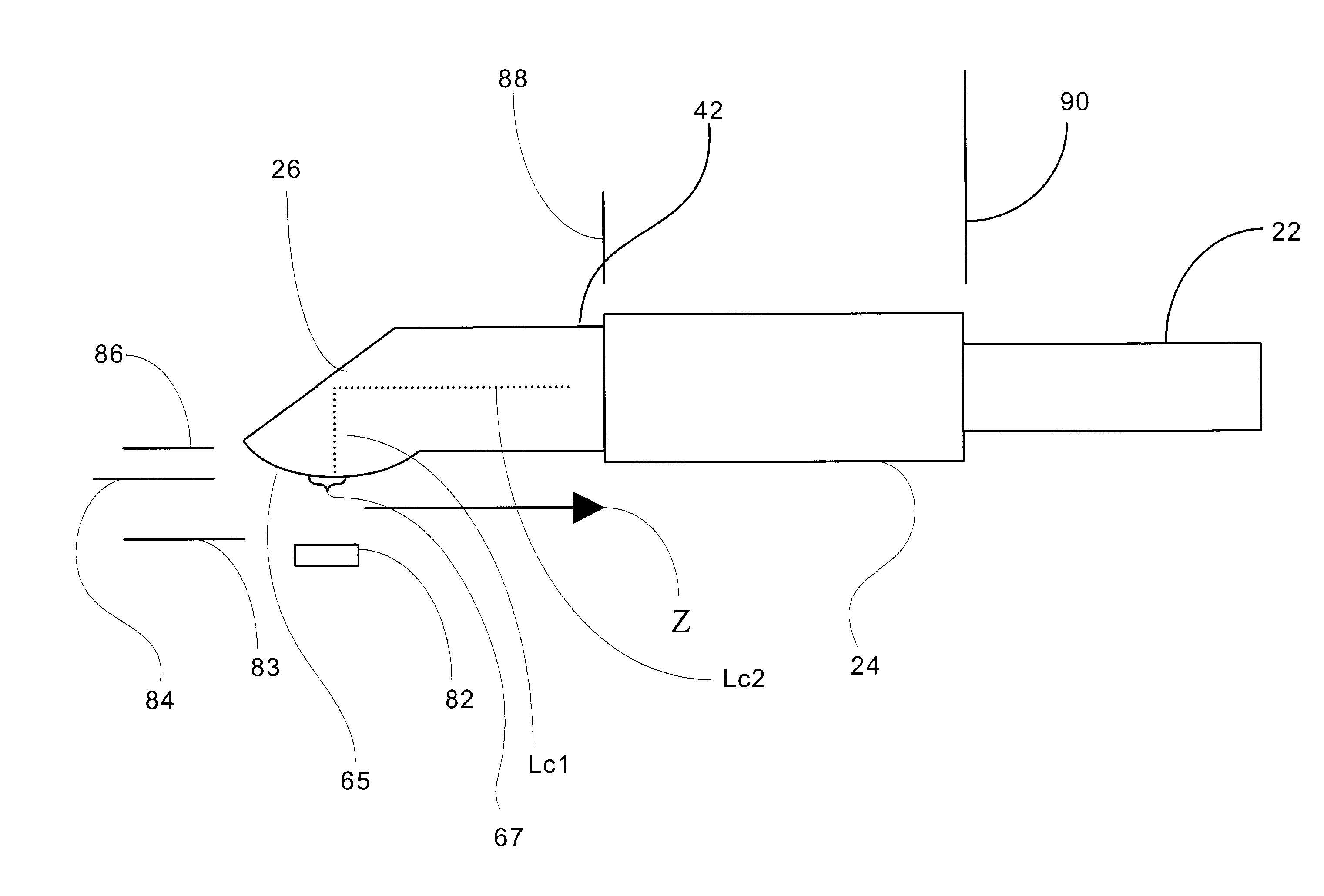

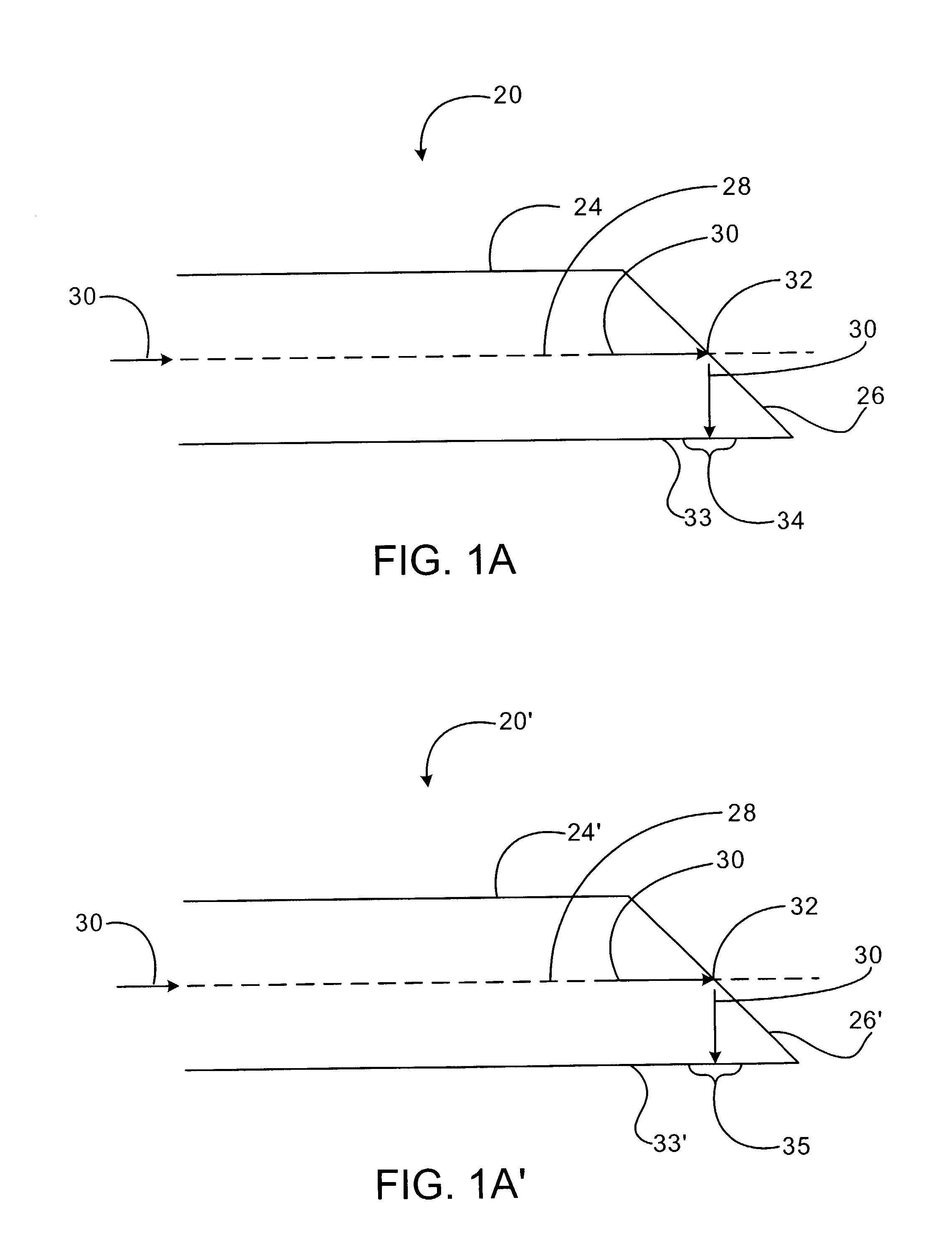

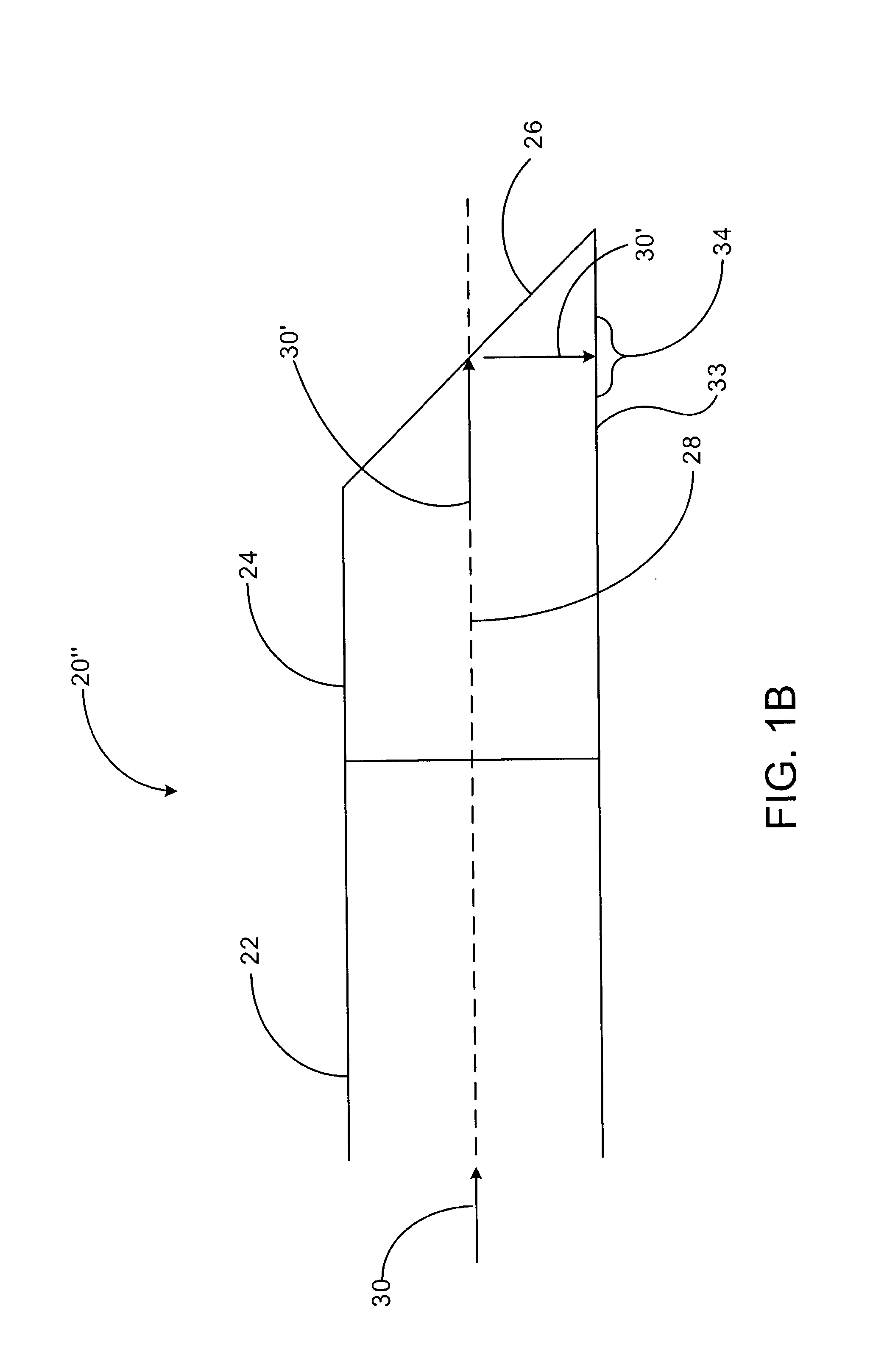

Beam bending apparatus and method of manufacture

An apparatus for altering the mode field of an optical signal is disclosed. The apparatus includes a GRIN-fiber lens and a reflective surface disposed at one end of the GRIN-fiber lens, the reflective surface configured to cooperate with the GRIN-fiber lens to redirect the path of the optical signal directed against the reflective surface. A method of manufacturing an apparatus for altering the mode field of an optical signal and an optical assembly are also disclosed.

Owner:CORNING INC

Beam bending apparatus and method of manufacture

InactiveUS20030165291A1Minimize couplingReduce aberrationLaser detailsCladded optical fibreFiberOptics

An apparatus for altering the mode field of an optical signal is disclosed. The apparatus includes a GRIN-fiber lens and a reflective surface disposed at one end of the GRIN-fiber lens, the reflective surface configured to cooperate with the GRIN-fiber lens to redirect the path of the optical signal directed against the reflective surface. A method of manufacturing an apparatus for altering the mode field of an optical signal and an optical assembly are also disclosed.

Owner:CORNING INC

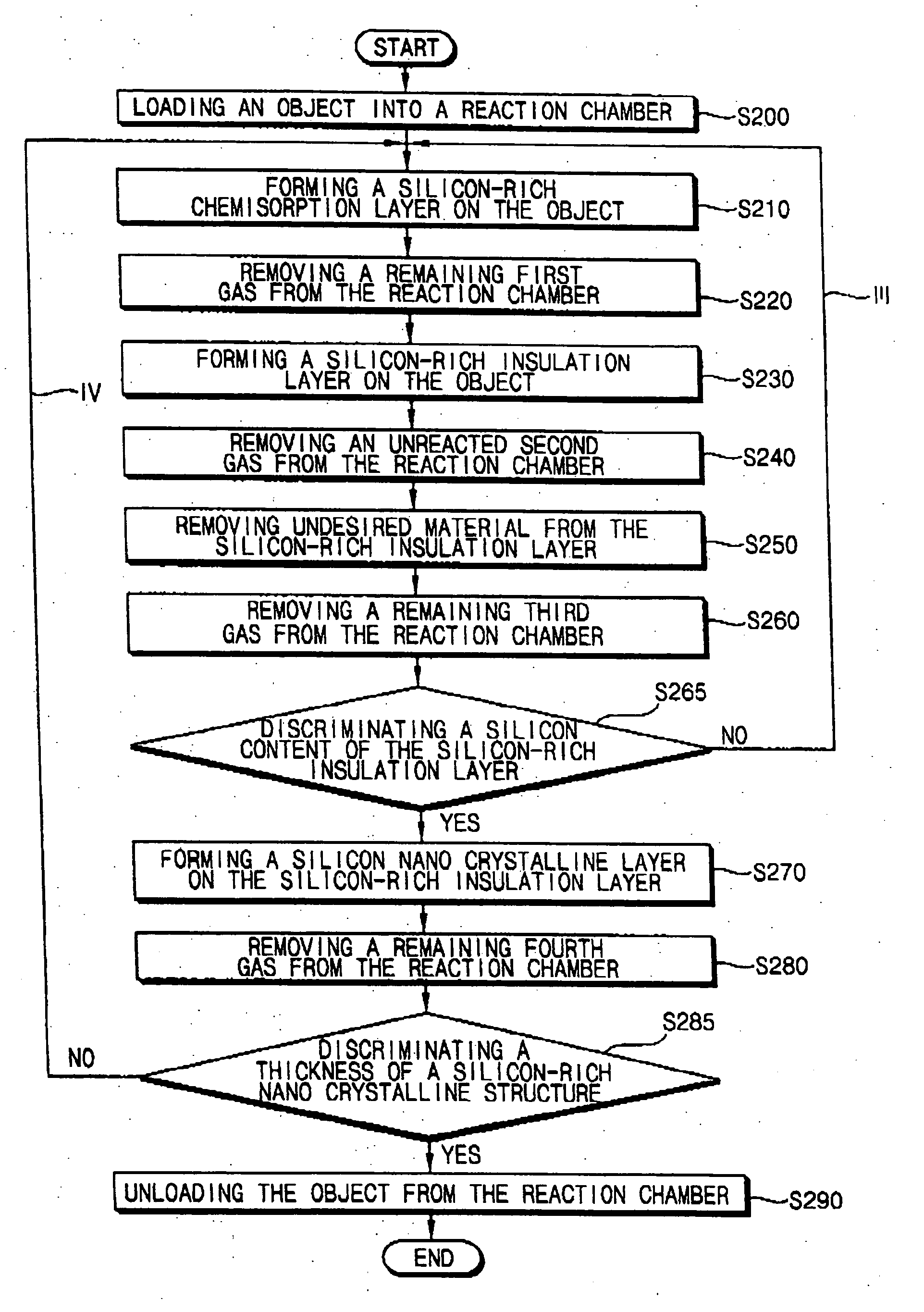

Method of forming a silicon-rich nanocrystalline structure by an atomic layer deposition process and method of manufacturing a non-volatile semiconductor device using the same

ActiveUS20070066083A1High silicon contentGood step coveragePolycrystalline material growthNanoinformaticsChemisorptionNanometre

In a method of forming a silicon-rich nanocrystalline structure by an ALD process, a first gas including a first silicon compound is provided onto an object to form a silicon-rich chemisorption layer on the object. A second gas including oxygen is provided onto the silicon-rich chemisorption layer to form a silicon-rich insulation layer on the object. A third gas including a second silicon compound is provided onto the silicon-rich insulation layer to form a silicon nanocrystalline layer on the silicon-rich insulation layer. The first gas, the second gas and the third gas may be repeatedly provided to alternately form the silicon-rich nanocrystalline structure having a plurality of silicon-rich insulation layers and a plurality of silicon nanocrystalline layers on the object.

Owner:SAMSUNG ELECTRONICS CO LTD

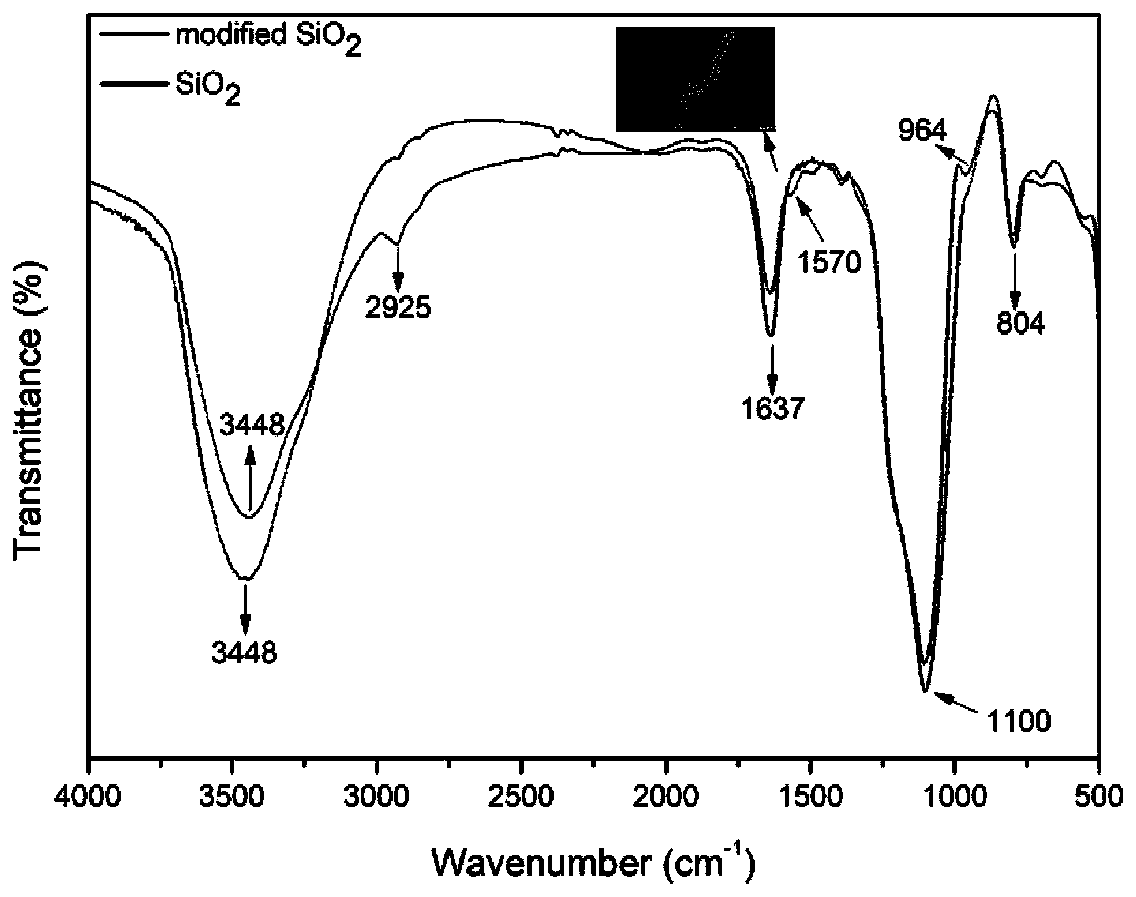

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

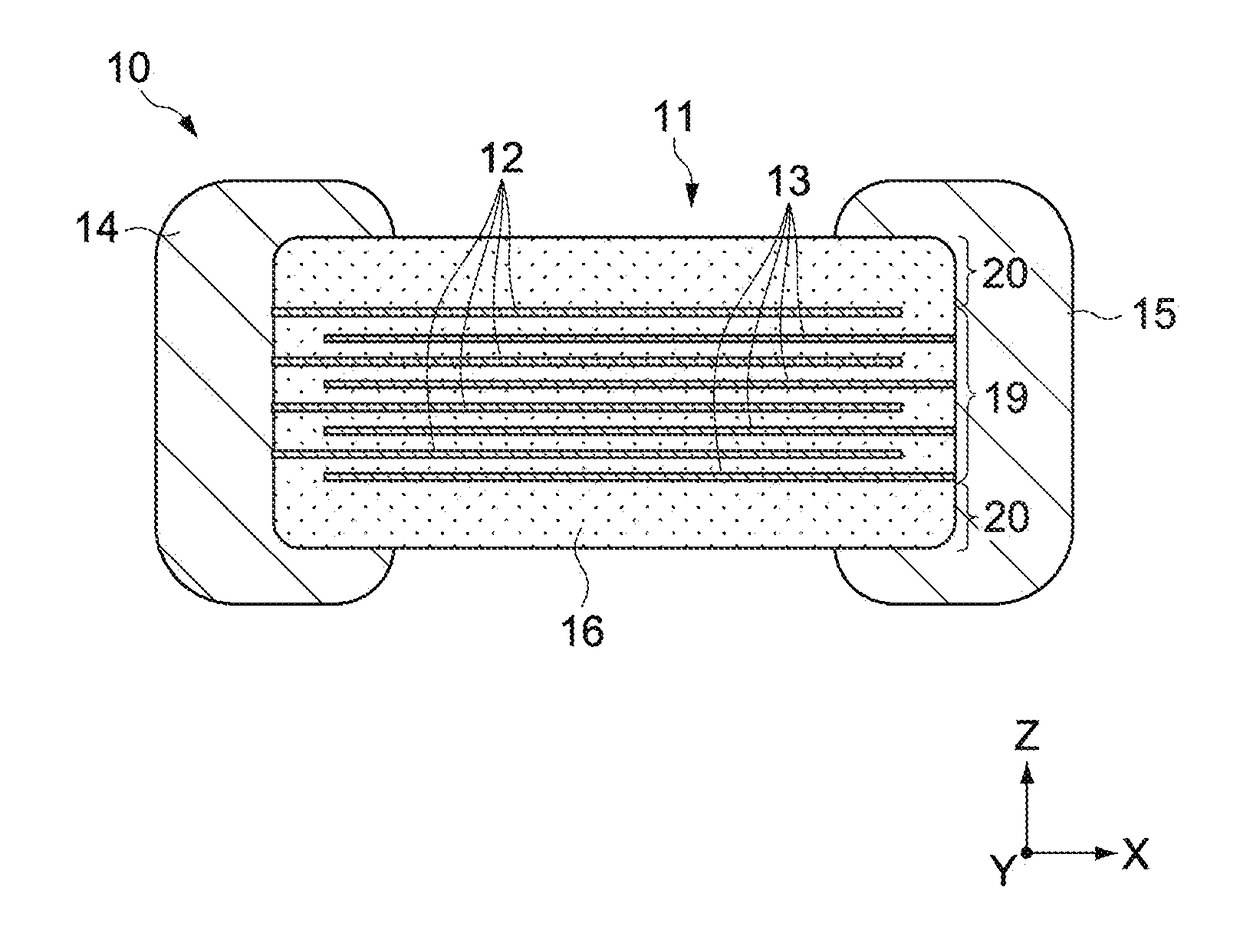

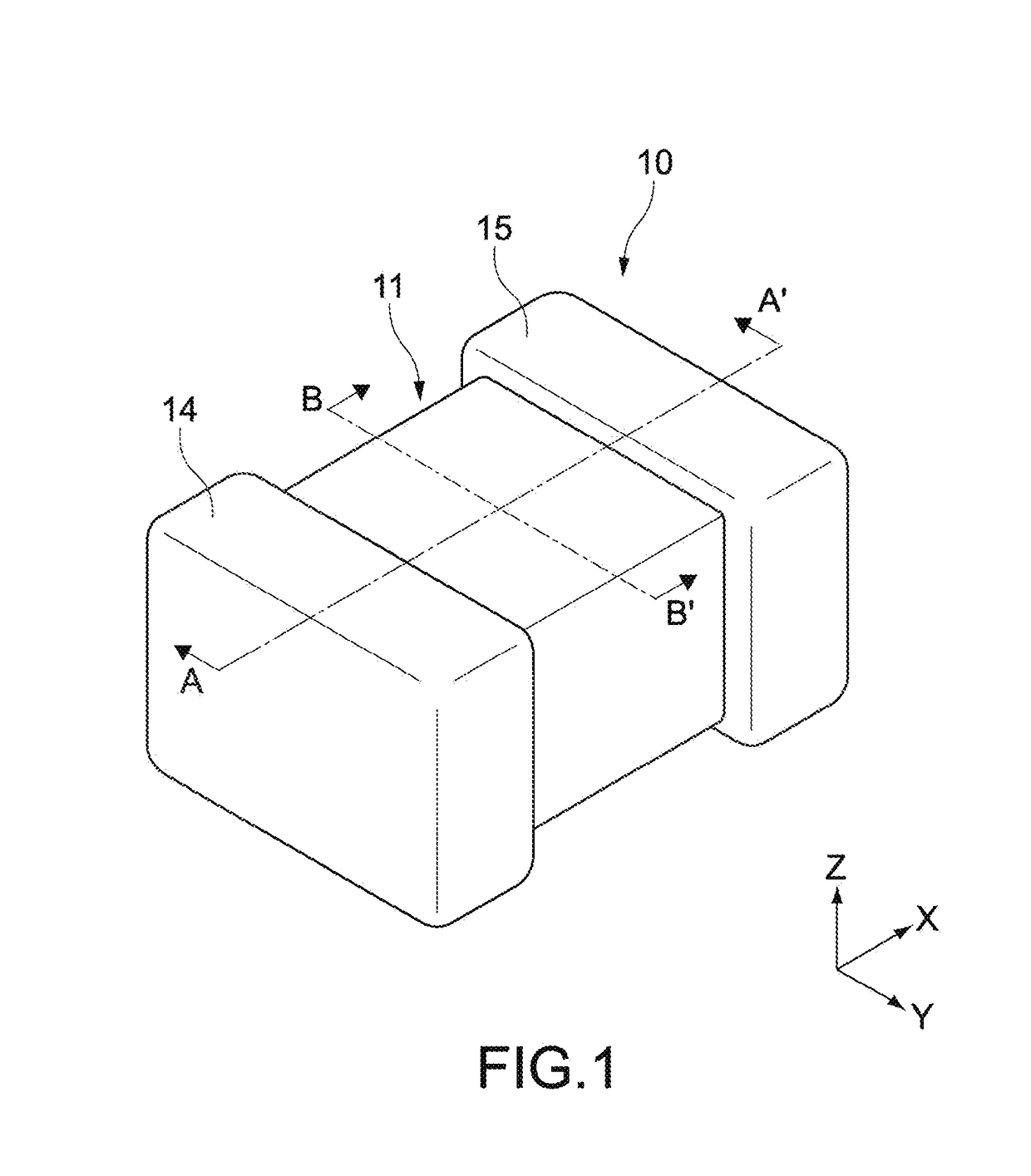

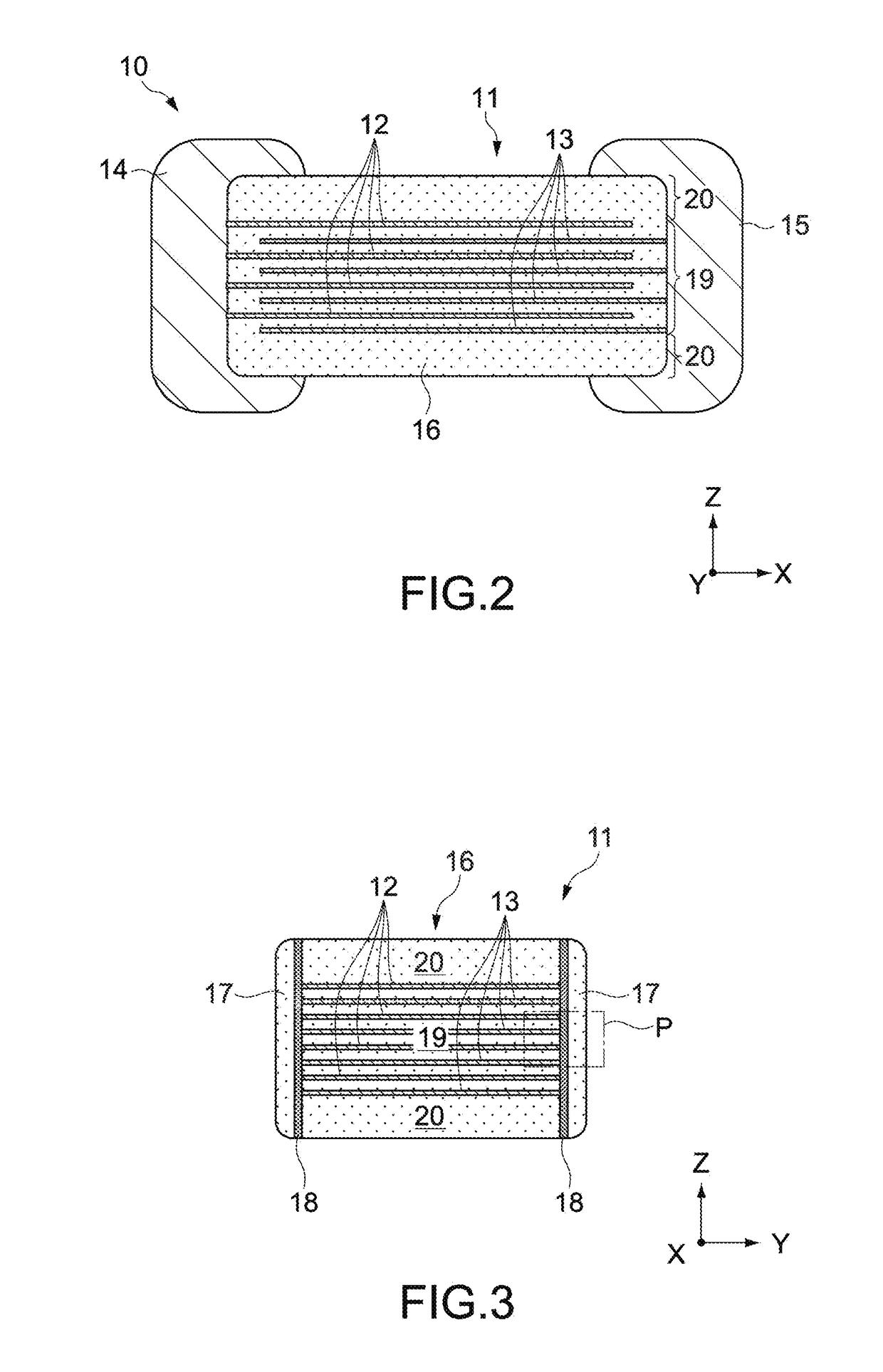

Multi-Layer Ceramic Capacitor and Method of Producing the Same

ActiveUS20170169952A1Improve adhesionHigh silicon contentFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorSilicon

A multi-layer ceramic capacitor includes a multi-layer unit, side margins, and bonding units. The multi-layer unit includes ceramic layers laminated in a first direction and internal electrodes disposed between the ceramic layers. The side margins cover the multi-layer unit from a second direction orthogonal to the first direction. The bonding units are each disposed between the multi-layer unit and each of the side margins and have higher silicon content than the ceramic layers and the side margins.

Owner:TAIYO YUDEN KK

Silicon-containing polymer, resist composition and patterning process

ActiveUS6994946B2High sensitivityHigh resolutionPhotosensitive materialsRadiation applicationsResistHigh energy

Novel silicon-containing polymers are provided comprising recurring units having a POSS pendant and units which improve alkali solubility under the action of an acid. Resist compositions comprising the polymers are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of up to 300 nm and improved resistance to oxygen plasma etching.

Owner:SHIN ETSU CHEM IND CO LTD

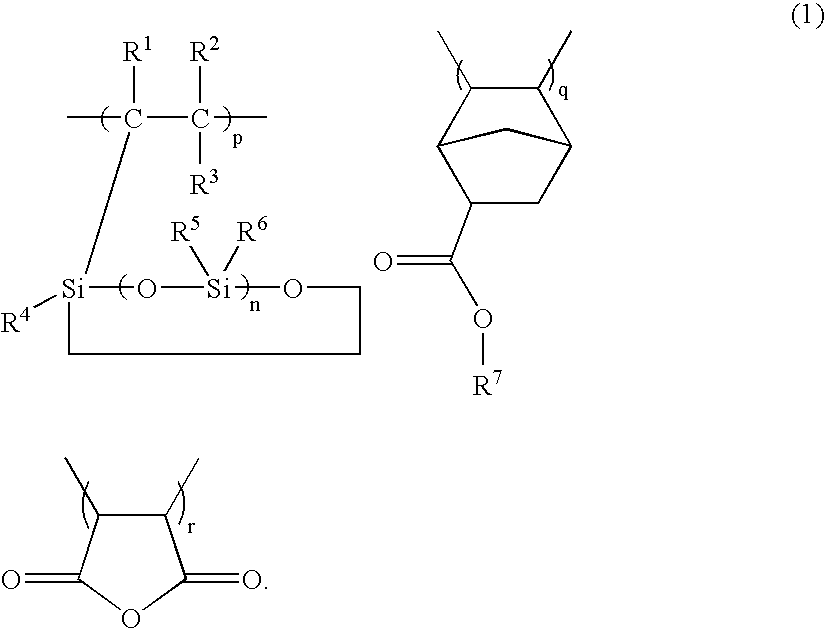

Silicon-containing polymer, resist composition and patterning process

InactiveUS6919161B2High sensitivityImprove heat resistancePhotosensitive materialsConductive materialResistAryl

Silicon-containing polymers comprising recurring units of formula (1) are novel wherein R1 is a single bond or alkylene, R2 is hydrogen or alkyl, R3, R4 and R5 are alkyl, haloalkyl, aryl or silicon-containing group, R6 is hydrogen, methyl, cyano or —C(═O)OR8 wherein R8 is hydrogen, alkyl or acid labile group, R7 is alkyl, —NR9R10 or —OR11 wherein R9, R10 and R11 are hydrogen or alkyl, a and b are positive numbers satisfying 0<a+b≦1. Resist compositions comprising the polymers are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of less than 300 nm and improved resistance to oxygen plasma etching.

Owner:SHIN ETSU CHEM IND CO LTD

Method for manufacturing a high-strength structural steel and a high-strength structural steel product

ActiveUS20140299237A1Increased austenite stabilityHigh silicon contentFurnace typesHeat treatment furnacesSheet steelRoom temperature

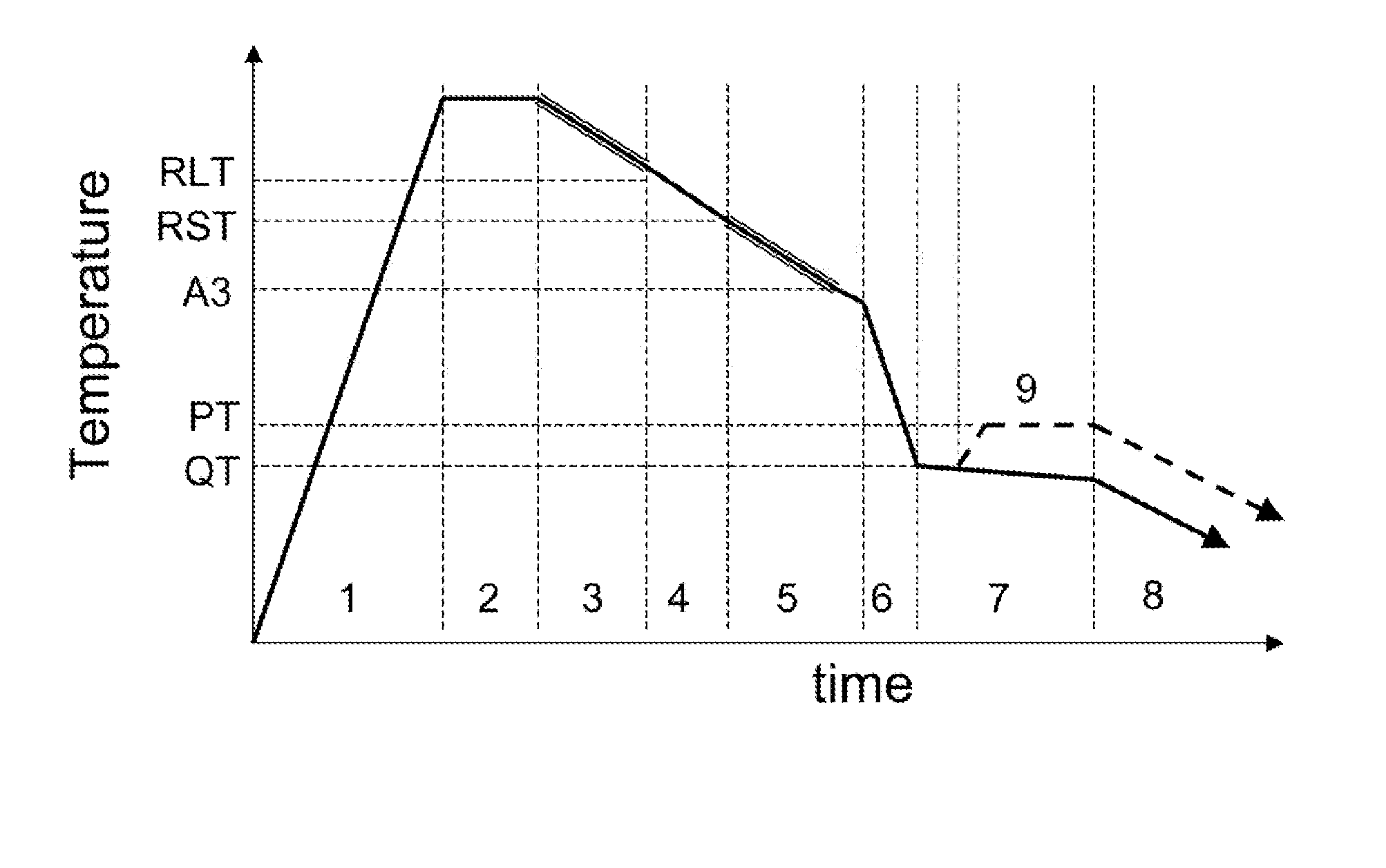

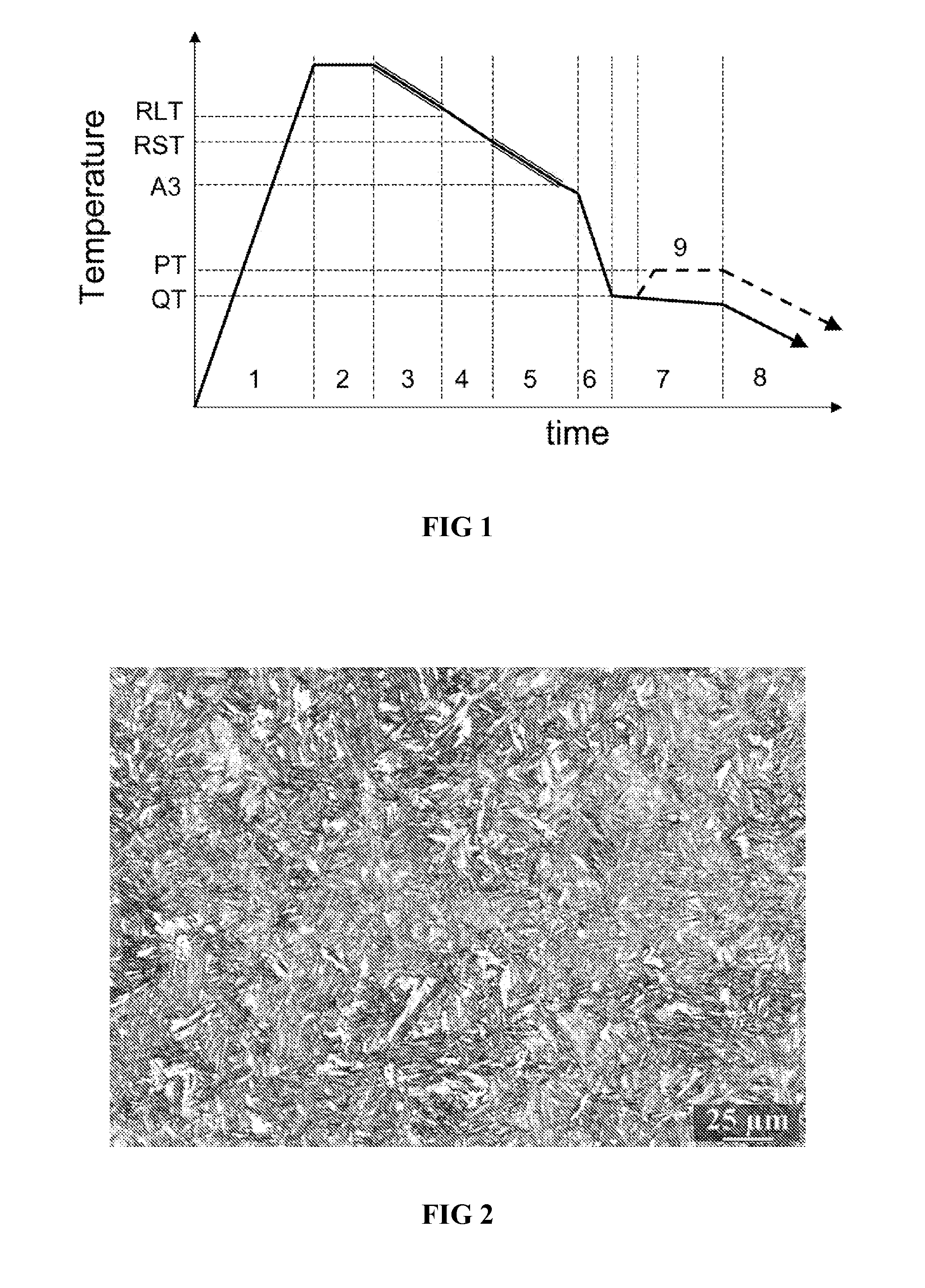

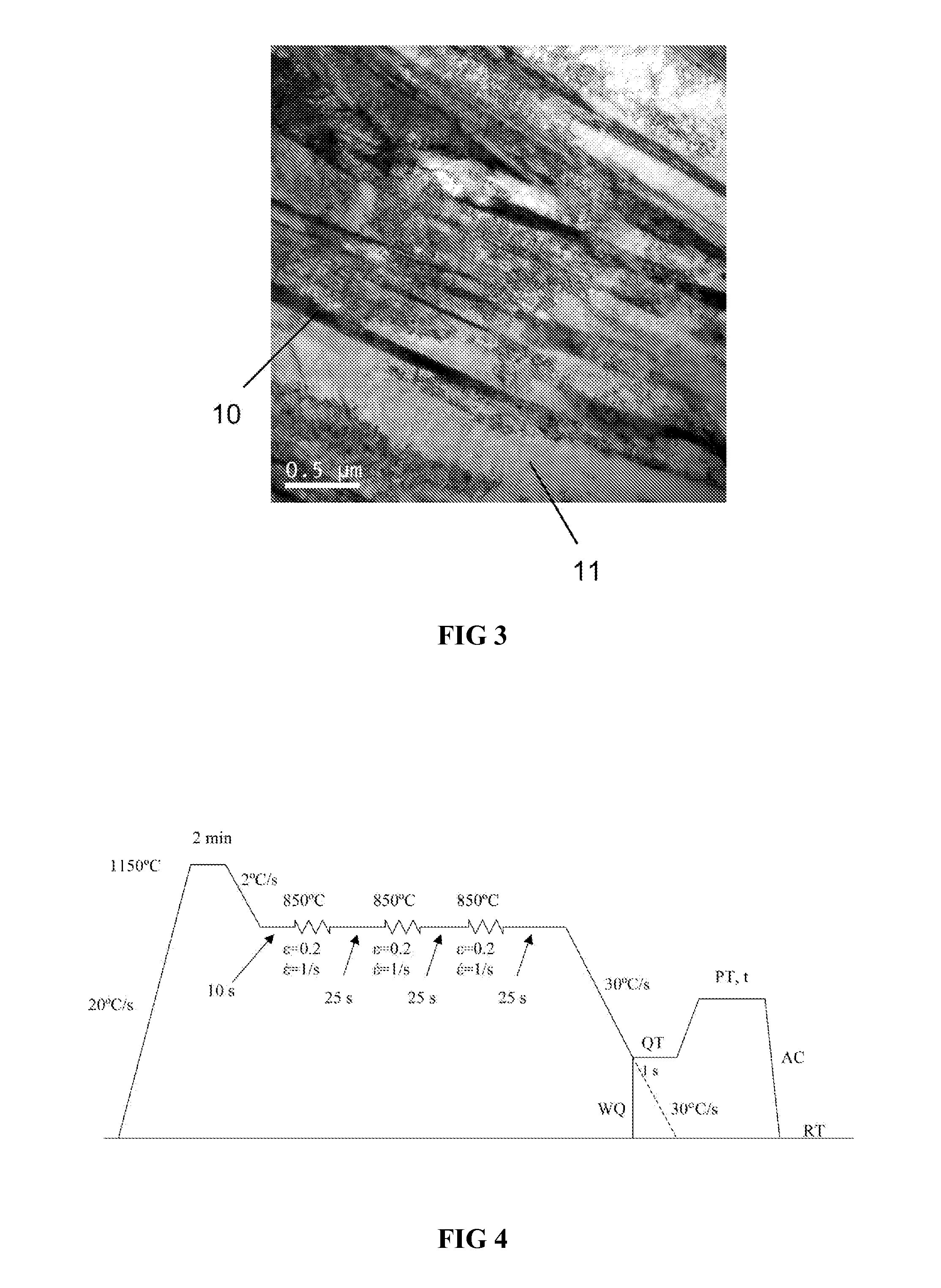

The invention relates to a method for manufacturing a high-strength structural steel and to a high-strength structural steel product. The method comprises a providing step for providing a steel slab, a heating step (1) for heating said steel slab to 950 to 1300 C, a temperature equalizing step (2) for equalizing the temperature of the steel slab, a hot rolling step including a hot rolling stage of type I (5) for hot rolling the steel slab in the no-recrystallization temperature range below the recrystallization stop temperature (RST) but above the ferrite formation temperature A3, a quenching step (6) for quenching said hot-rolled steel at cooling rate of at least 20 C / s to a quenching-stop temperature (QT) between Ms and Mf temperatures, a partitioning treatment step (7, 9) for partitioning said hot-rolled steel in order to transfer carbon from martensite to austenite, and a cooling step (8) for cooling said hot-rolled steel to room temperature.

Owner:RAUTARUUKKI

3D printing photosensitive resin material

InactiveCN107868443ALow viscosityReduce the smellAdditive manufacturing apparatusOligomerReactive diluent

The invention discloses a 3D printing photosensitive resin material. The 3D printing photosensitive resin material comprises the following components in parts by weight: 10-50 parts of a low-viscosityphotosensitive resin oligomer, 10-50 parts of organosilicone modified epoxy acrylate, 30-50 parts of a reactive diluent, 1-5 parts of a photoinitiator, 1-5 parts of an auxiliary agent and 0.01-1 partof a pigment. The 3D printing photosensitive resin material is very low in viscosity and odor, high in curing rate, high in precision of a printed product and universal in universality; meanwhile, the organosilicone modified epoxy acrylate resin is obtained by grafting silicon onto a molecular chain of epoxy resin, so that the polarity of an organosilicone component is reduced and the compatibility thereof in the photosensitive resin material can be improved; in addition, the content of the organosilicone is high, and the organosilicone component in a branched-chain state contributes to movement of the molecular chain and can easily migrate to an interface between a 3D printing trough and the photosensitive resin material, so that the 3D printing photosensitive resin material shows excellent release capability.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

Core/shell type organosilicone-modified acrylate emulsion and preparation method and application thereof

InactiveCN105601799AUniform appearanceImprove stabilityLiquid repellent fibresEmulsionEmulsion polymerization

The invention relates to a core / shell type organosilicone-modified acrylate emulsion and a preparation method and application thereof. The core / shell type emulsion is prepared through polymerization based on the core / shell emulsion polymerization technology and is prepared from, by weight, 500-850 parts of acrylate mixed monomers, 150-500 parts of organosilicone monomers, 10-50 parts of an emulsifying agent, 5-12 parts of an initiating agent, 5-50 parts of a crosslinking agent and 1000-4000 parts of water, wherein acrylate mixed monomers are composed of methyl methacrylate, butyl acrylate and acrylic acid at the mass ratio of (1.0-3.5):(6.5-9.0):(0.15-0.75), and a seed emulsion in the core / shell emulsion polymerization technology is obtained through polymerization of the acrylate mixed monomers. The core / shell type emulsion is good in stability, the mean grain size is 170 nm or so, and an emulsion film has an excellent film-forming property, an excellent bonding property, low surface energy and good waterproofness.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Terylene fabric deepening agent copolymer emulsion and preparation method thereof

InactiveCN103255618AHigh silicon contentThe preparation method is simple and environmentally friendlyFibre typesEpoxideEmulsion

The invention discloses a terylene fabric deepening agent copolymer emulsion and preparation method thereof. Organic silsesquioxane is prepared, epoxy chloro alkyl compound of amino silicone oil is modified, and then the organic silsesquioxane and modified epoxy chloro alkyl compound of amino silicone oil are compound. The organic silsesquioxane with smaller molecular weight and particle size is prepared by using the emulsion polymerisation technology according to the invention, and the silicon content in the object is high, and the silicon one of the main component of the deepening agent, and the preparation method is environmental protection without pollution, and the epoxy chloro alkyl compound of amino silicone oil containing double-amino with suitable molecular weight is appropriately modified, and a epoxide group is introduced, and after the fabric is processed, the hydrophility keeps unchangeable. The invention has an obvious color increasing effect, and after the fabric is treated by the deepening agent, no residual harmful substances are on the fabric surface, so the product belongs to the green environmental protection finishing agent.

Owner:SUZHOU UNIV

Silicon-containing polymer, resist composition and patterning process

InactiveUS6902772B2High sensitivityImprove heat resistancePhotosensitive materialsPhotomechanical apparatusResistAryl

Silicon-containing polymers comprising recurring units of three components represented by the general formula (1) are novel wherein R1, R2 and R3 are hydrogen or C1-10 alkyl, R4, R5 and R6 are hydrogen, C1-20 alkyl or haloalkyl, or C6-20 aryl, R7 is C4-20 alkyl, n is 1 to 5, p, q and r are positive numbers. Resist compositions comprising the polymers are sensitive to high-energy radiation and have a high sensitivity and resolution at a wavelength of less than 300 nm and improved resistance to oxygen plasma etching

Owner:SHIN ETSU CHEM IND CO LTD

High-titanium and low-silicon titanium-silicon-iron alloy and preparation method thereof

The invention discloses a high-titanium and low-silicon titanium-silicon-iron alloy and a preparation method thereof, which belong to the technical fields of vanadium-titanium resource comprehensive utilization and iron alloy smelting. The titanium-silicon-iron alloy is characterized in that: the titanium content is higher than 40 percent by weight, and contains 40-70 percent by weight of Ti, 8-40 percent by weight of Si, 3-15 percent by weight of Fe and unavoidable impurities. In preparation method of the titanium-silicon-iron alloy, the high-titanium and low-silicon titanium-silicon-iron alloy is prepared by adding an admixture into high-titanium blast furnace slag and undergoing a melting thermal reduction reaction, wherein the weight proportion of the high-titanium blast furnace slag to the admixture is 1:(0.4-0.8); the admixture comprises 40-80 percent by weight of a reducing agent; and the major component of the reducing agent is metal aluminum. The titanium-silicon-iron alloy disclosed by the invention instead of titanium and iron can be taken as a titanium alloy agent, and the popularization and application of the titanium-silicon-iron alloy can be promoted; and according to the method disclosed by the invention, improvement on the environment is facilitated, and the resource utilization ratio is increased.

Owner:PANZHIHUA GANGCHENG GROUP

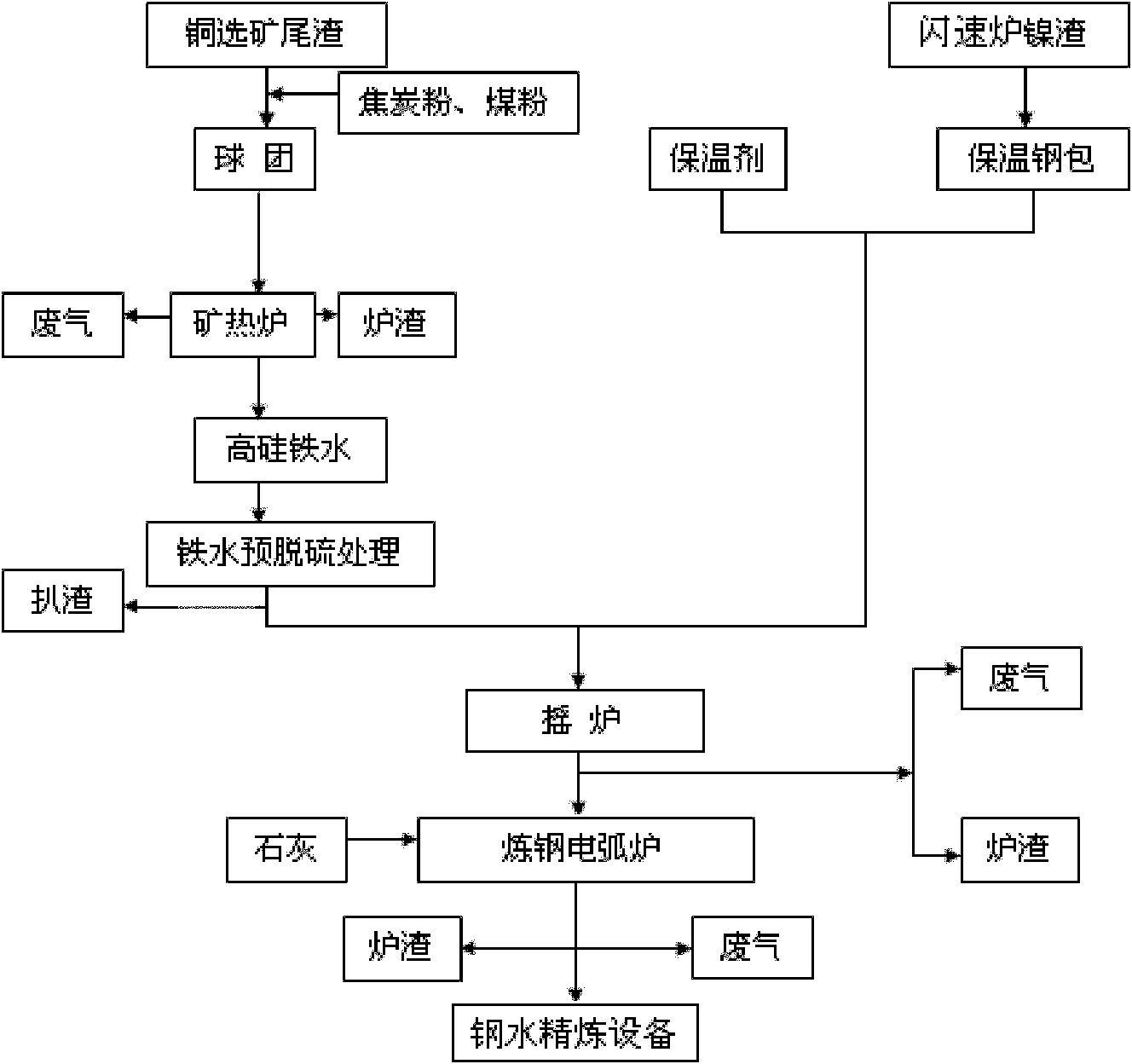

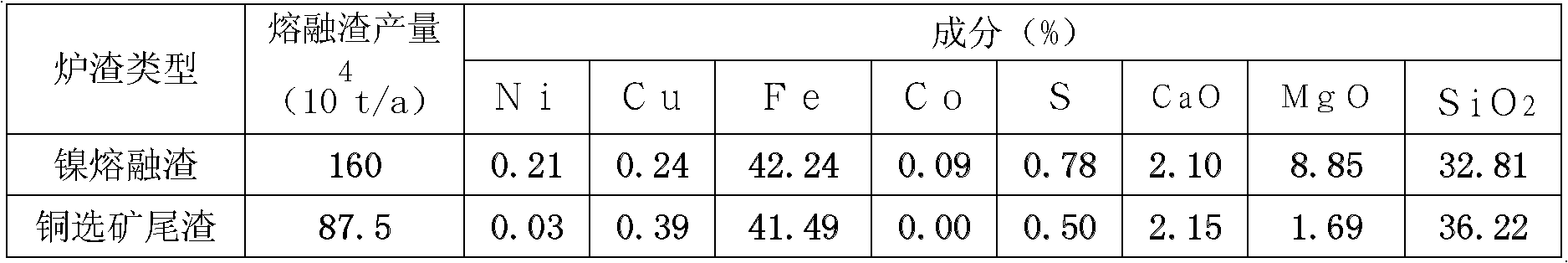

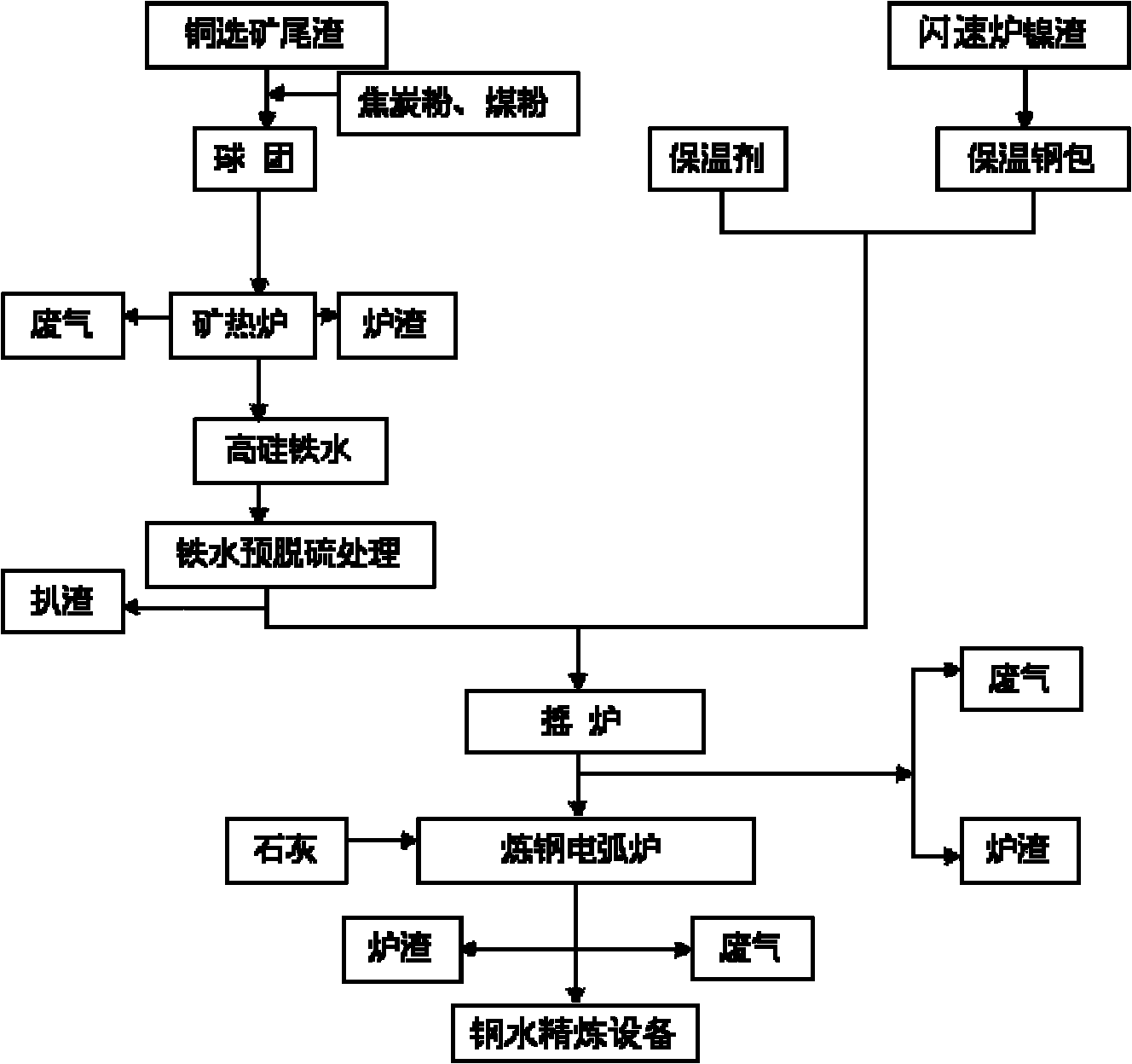

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of silicon modified double-component waterborne polyurethane composite coating for automobile varnish

ActiveCN109762454AImprove adhesionImprove water resistancePolyurea/polyurethane coatingsSilanesDouble bond

The invention discloses silicon modified double-component waterborne polyurethane composite coating for automobile varnish and a preparation method thereof. The composite coating is prepared from a component A and a component B, wherein the component A is silicon modified waterborne polyacrylate emulsion; the component B comprises a hydrophilic isocyanate curing agent, graphene and an auxiliary agent; the silicon modified waterborne polyacrylate emulsion contains methyl methacrylate, butyl acrylate, styrene, acrylic acid, a copolymer of beta-hydroxyethylmethacrylate and polysiloxane with double bonds, and silane modified silicon dioxide nanoparticles. According to the composite coating, the polysiloxane, silicon dioxide nanoparticles and the graphene are uniformly introduced into matrix resin, so that the attachment force and the water resistance of the composite coating are effectively improved; meanwhile, the hardness and the strength are increased and the composite coating is especially suitable for the automobile varnish.

Owner:CENT SOUTH UNIV

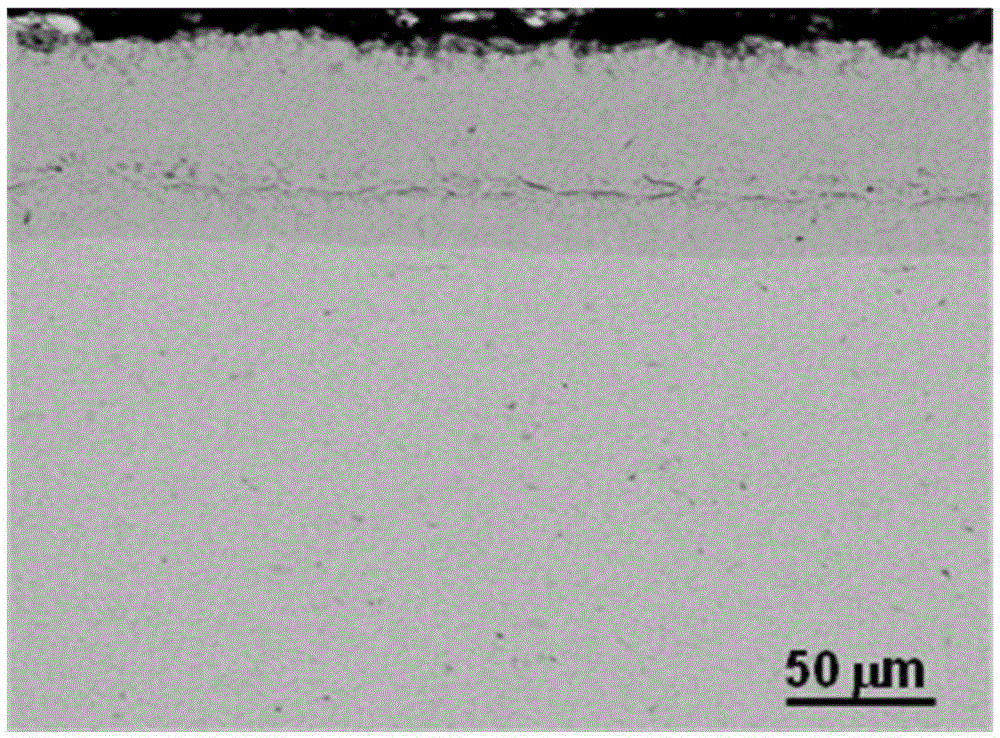

Method for preparing high-silicon steel from low-silicon steel

ActiveCN105296917AExcellent magnetic propertiesSuppression of eddy current lossSolid state diffusion coatingSuperimposed coating processIonCorrosion

The invention belongs to the field of material preparation, in particular to a method for preparing high-silicon steel from low-silicon steel. The method comprises the following steps: a, using a low-silicon steel hot-rolled plate with a smooth surface as a base material, and carrying out cold rolling so as to obtain a thin plate; b, carrying out acid pickling on the thin plate so as to remove oil stains and an oxide film on the surface; c, in a temperature range of 450-550DEG C, carrying out thermal insulation on the cold-rolled thin plate in a solid siliconizing agent for 20-30 minutes; d, in a temperature range of 750-820DEG C, carrying out solid siliconizing on the thermally insulated thin plate for 10-30 minutes in the solid siliconizing agent; e, rolling the thin plate at a temperature of 350-450DEG C; f, at a non-oxidization atmosphere, carrying out diffusion annealing on the siliconized thin plate at a temperature of 850-1100 DEG C for 30-480 minutes; and g, under nitrogen protection, rapidly cooling the thin plate subjected to diffusion annealing to a room temperature and coating a MgO coating. The method is characterized by low raw materials and simple processing and treating. The problems of steel band surface serious corrosion and Fe losses, caused by high Cl-ion concentration in the process of preparing the high-silicon steel by a vapor deposition process are solved.

Owner:NORTHEASTERN UNIV

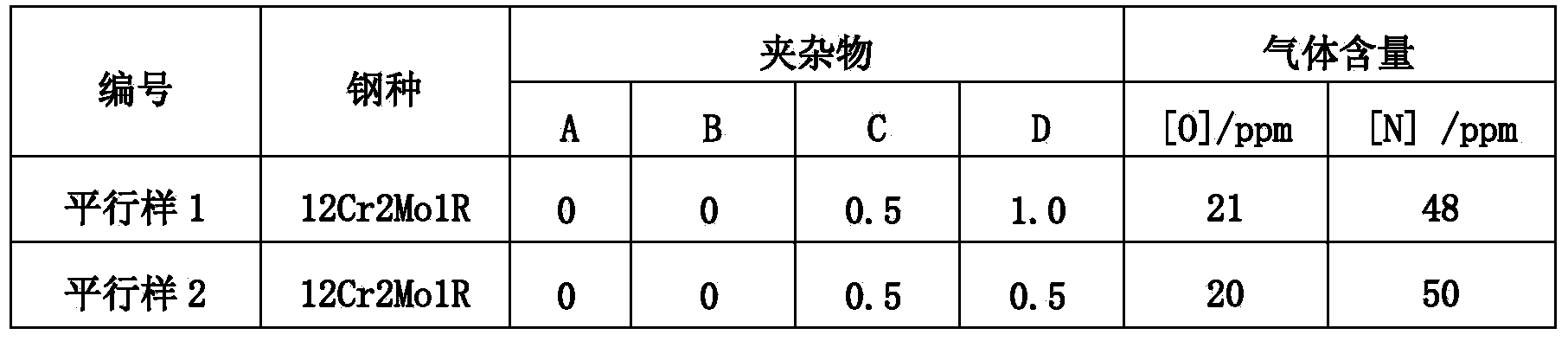

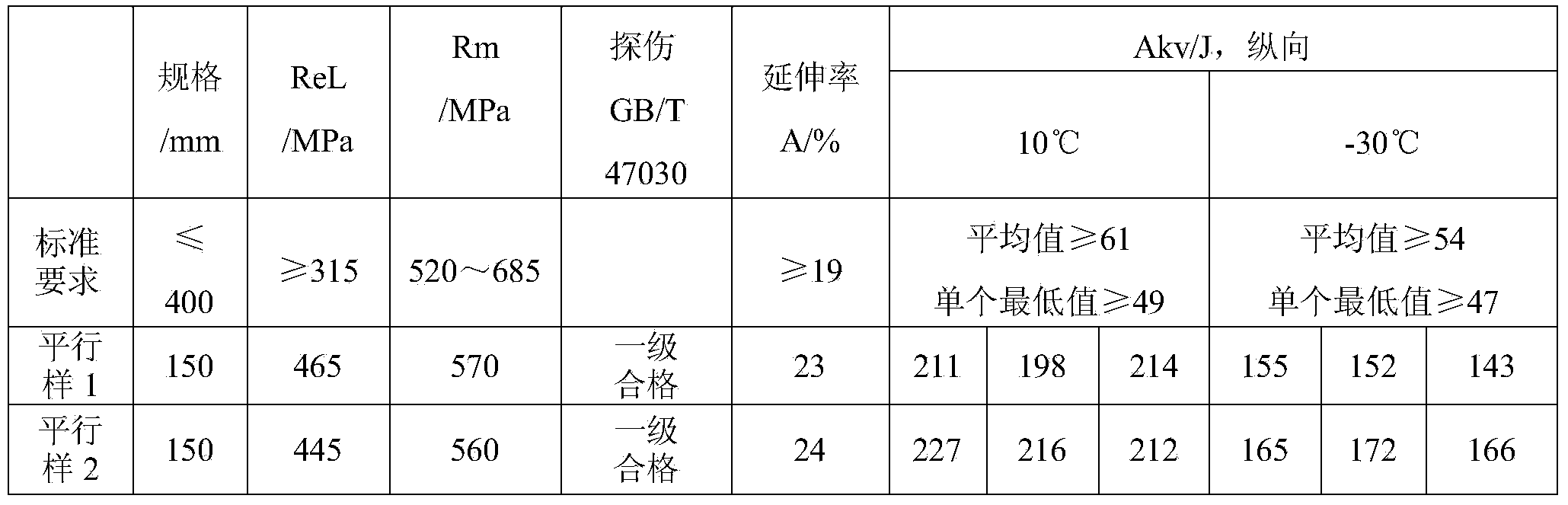

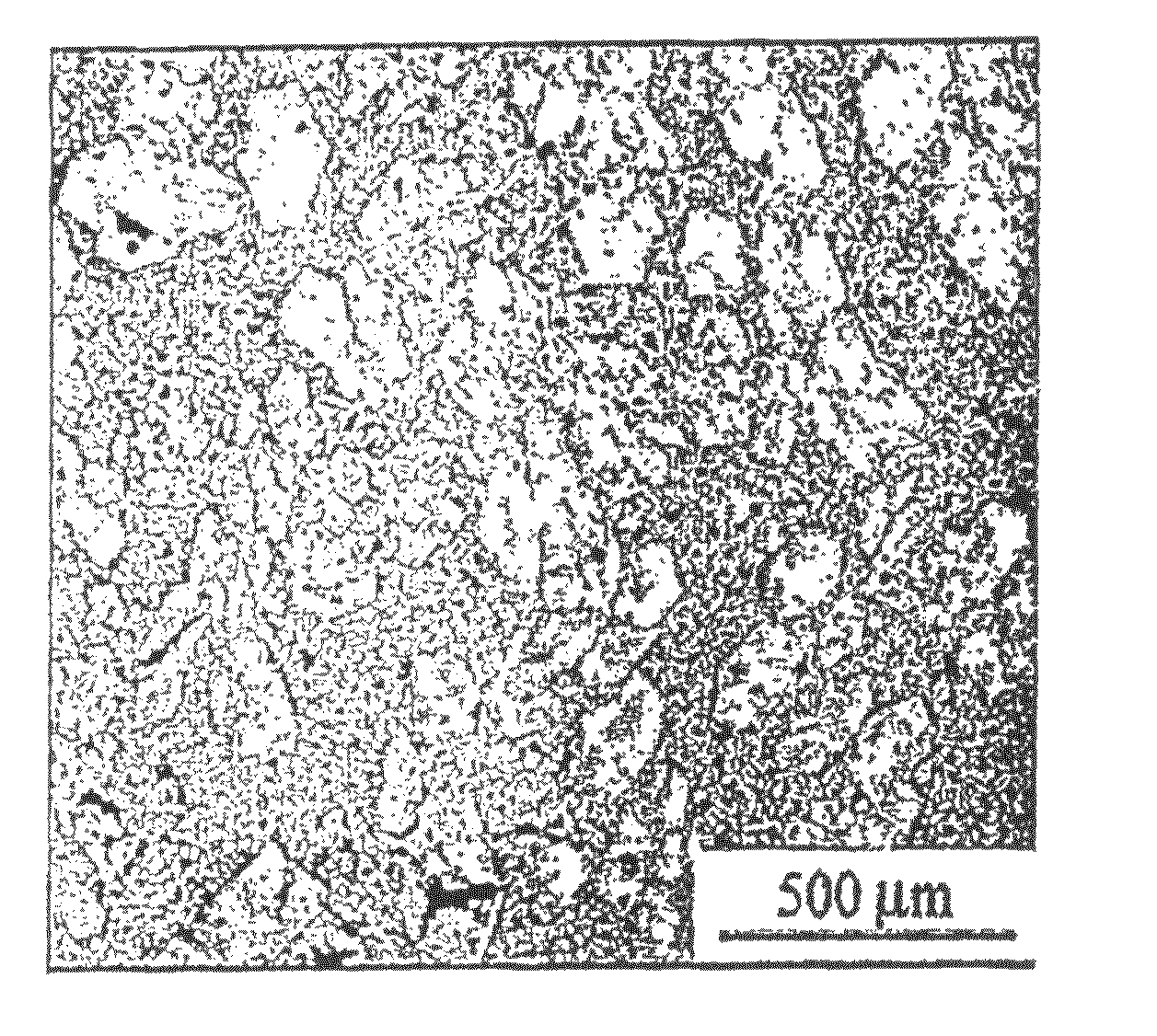

Premelting slag used for producing container steel of hydrogenation reactor and application thereof

The invention discloses a premelting slag used for producing a container steel of a hydrogenation reactor and an application thereof. The premelting slag comprises the following components by weight percentage: 45-55% of CaF2, 20-30% of Al2O3, 15-25% of CaO, 0-5% of SiO and 0-5% of MgO. The application of the premelting slag for production of the container steel comprises an electroslag remelting and smelting step and a steel plate rolling step, and normalizing heat treatment is carried out after steel plate rolling is completed. By aiming at component requirement of the low silicon of the container steel, the premelting slag employs five-membered slag, wherein content of SiO2 and CaF2 is low, silicon content increase of the container steel of the hydrogenation reactor can be avoided, CaF2 volatilization is reduced, and synergism of Al2O3, CaO and MgO can obviously reduce the conductivity of the premelting slag, power consumption is reduced, productivity is increased, and the premelting slag of the present invention can be used for producing high purity container steel plate.

Owner:武钢集团有限公司

Polymer and preparation method and application thereof

InactiveCN103554348AConducive to preservationStable storageWater-repelling agents additionPaper coatingSolubilityPolymer science

The invention discloses a copolymer. The copolymer is prepared through copolymerizing monomers (a, b and c), wherein the monomers a are mixed monomers of one or more than two kinds of slightly-water-soluble or water-insoluble polymerizable monomers of a1) alkenes or derivatives thereof, a2) esters or derivatives thereof and a3) nitriles or derivatives thereof; the monomers b are mixed monomers of one or more than two kinds of polymerizable monomers of alkenyl silanes, acryloxy silanes and acrylamide silanes; the monomers c are mixed monomers of one or more than two kinds of polymerizable monomers with cationic groups and polymerizable monomers with anionic groups. Compared with the traditional organosilane group modified copolymers, the copolymer disclosed by the invention has the advantages that the silicon content is high, the storability of organosilane groups is good, and the storage is stable; polymers are modified by ionic groups, so that the copolymer has water solubility.

Owner:广东喜洋洋纸业有限公司

Extraction for silicon-containing fertilizer from paper-making waste water using straw as raw material, producing technique and use thereof

The invention relates to the technical field of a fertilizer, in particular to a silicon fertilizer and the production technique and application thereof. The invention aims at utilizing straw as paper making raw materials to extract elements of silicon, humic acid, fulvic acid, cellulose, carbon, calcium, potassium, boron, magnesium, etc., which are beneficial to crops from waste liquid generated in paper making, and main active ingredients of extractive are utilized, a plurality of accessory ingredients are added, thereby generating a soluble fertilizer with high quality. The fertilizer parts by weight are that: 0.5 to 4 portions of soluble silicon, 0.8 to 6 portions of humic acid, 0.5 to 5 portions of fulvic acid, 0.5 to 4 portions of cellulose, 0.3 to 20 portions of phosphorus, potassium, calcium, boron and magnesium, 0.6 to 3 portions of surface active agent, 0.5 to 2 portions of synergistic agent, 1 to 3 portions of filmerformer, 2 portions of settling agent, 50 to 95 portions of pulverized fuel ash. The invention has the advantages that: raw material cost is not required by utilizing waste liquid of straw paper making as the raw materials; resources are saved, and produced fertilizer comprises a high content of silicon; the fertilizer can be completely absorbed by the crops, pertaining to an environment friendly fertilizer, which brings no secondary pollution to soil. The invention can be widely applied to paddy rice and other gramineous crops, oil crops, cash crops, fruits, sugar cane and grapes, and is endowed with a huge market potential.

Owner:王左邦

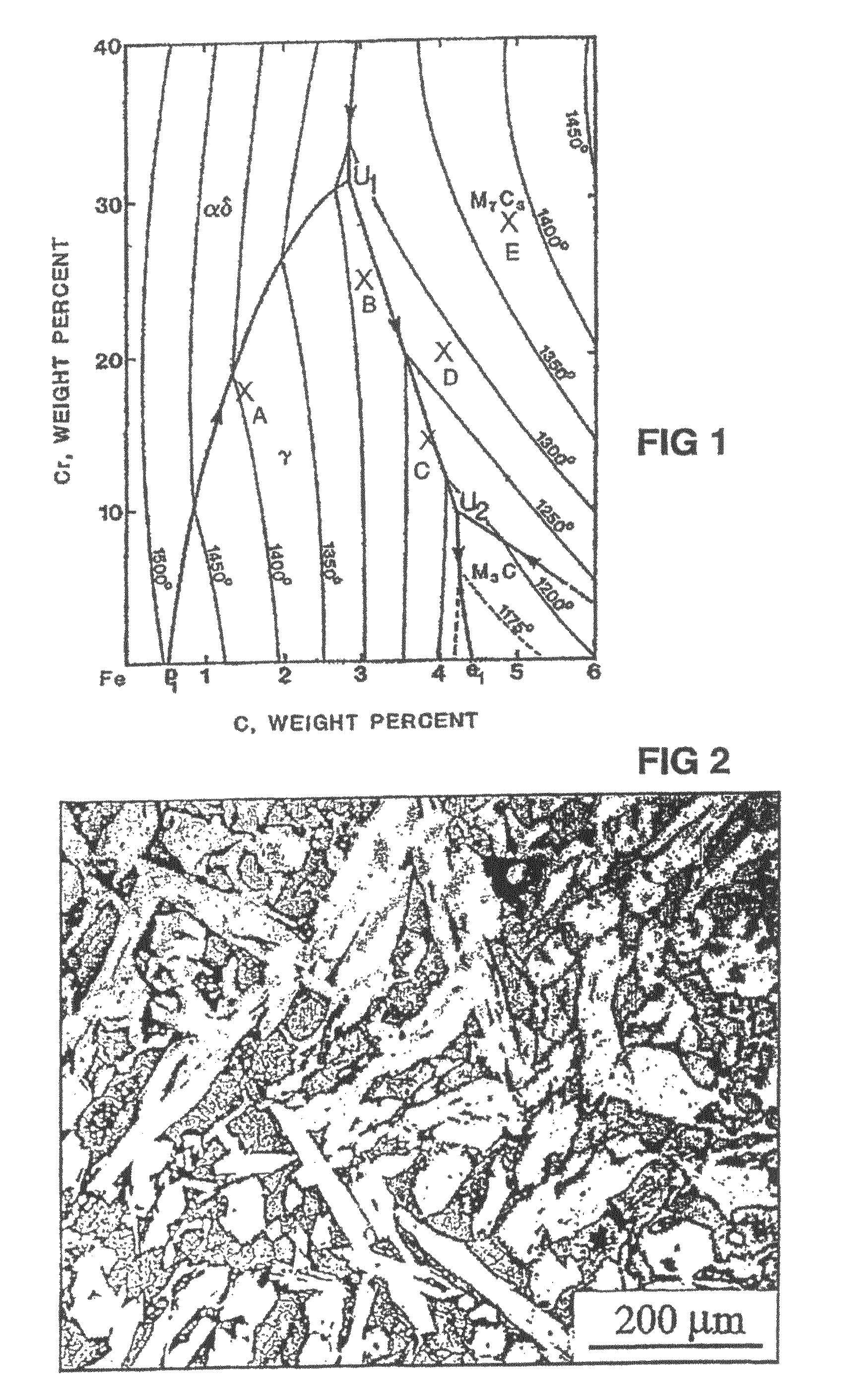

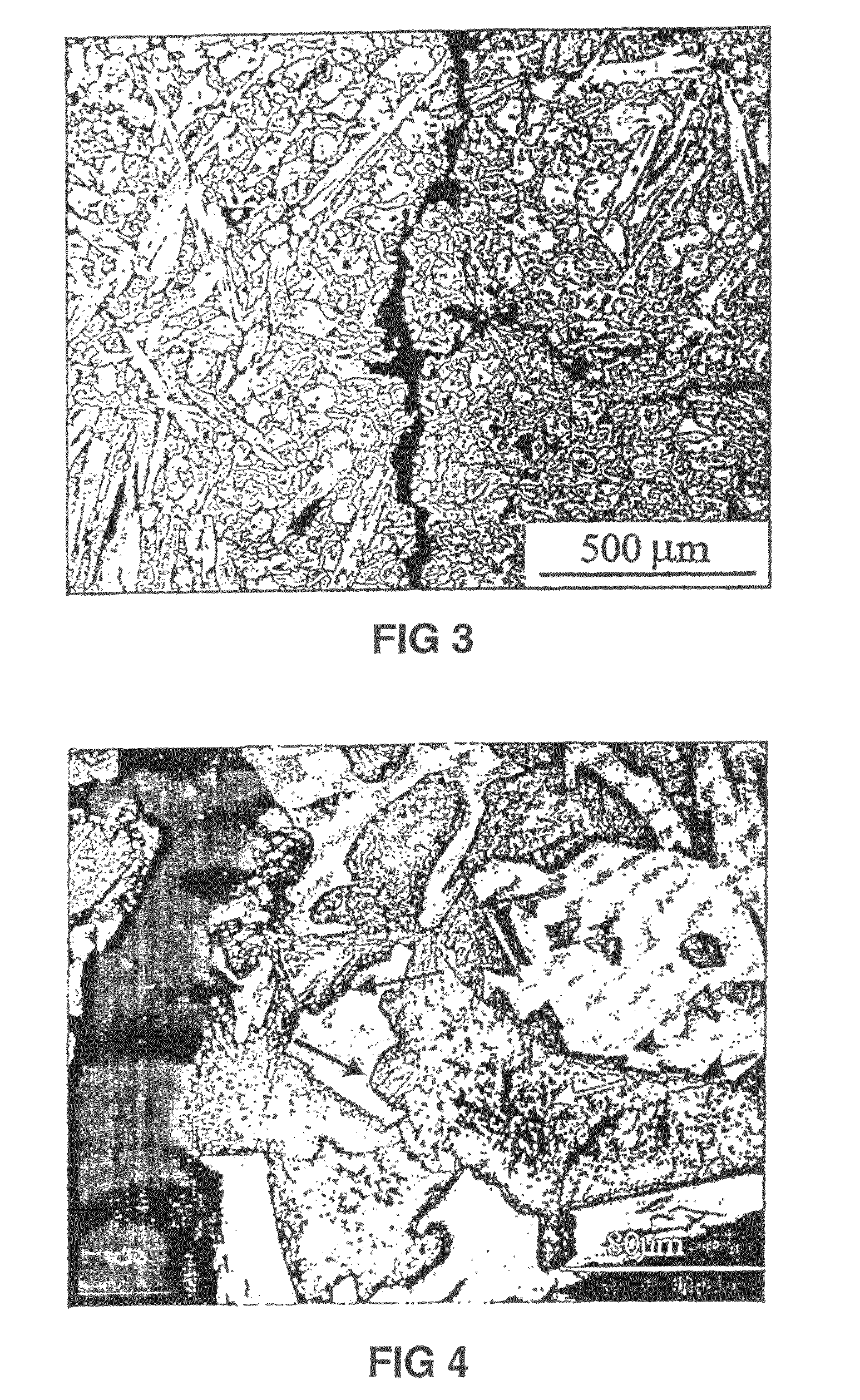

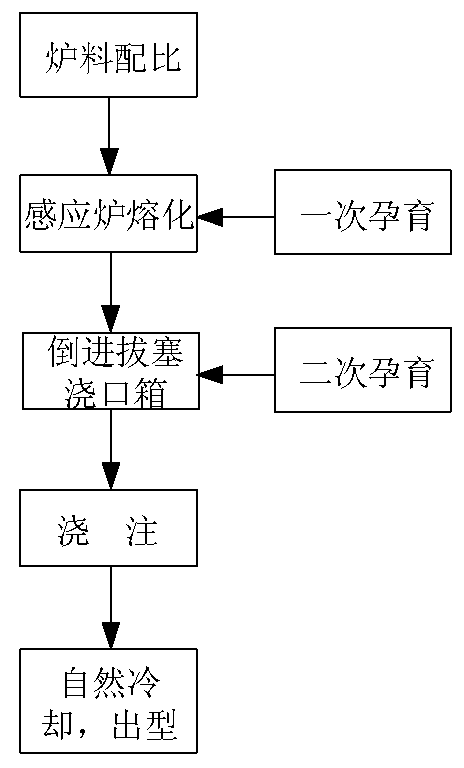

Wear resistant alloy and method of producing thereof

ActiveUS8187529B2Reduced risk of crackingImprove the level ofCooking-vessel materialsAngiosperms/flowering plantsWear resistantCrack free

Owner:GLOBAL TOUGH ALLOYS

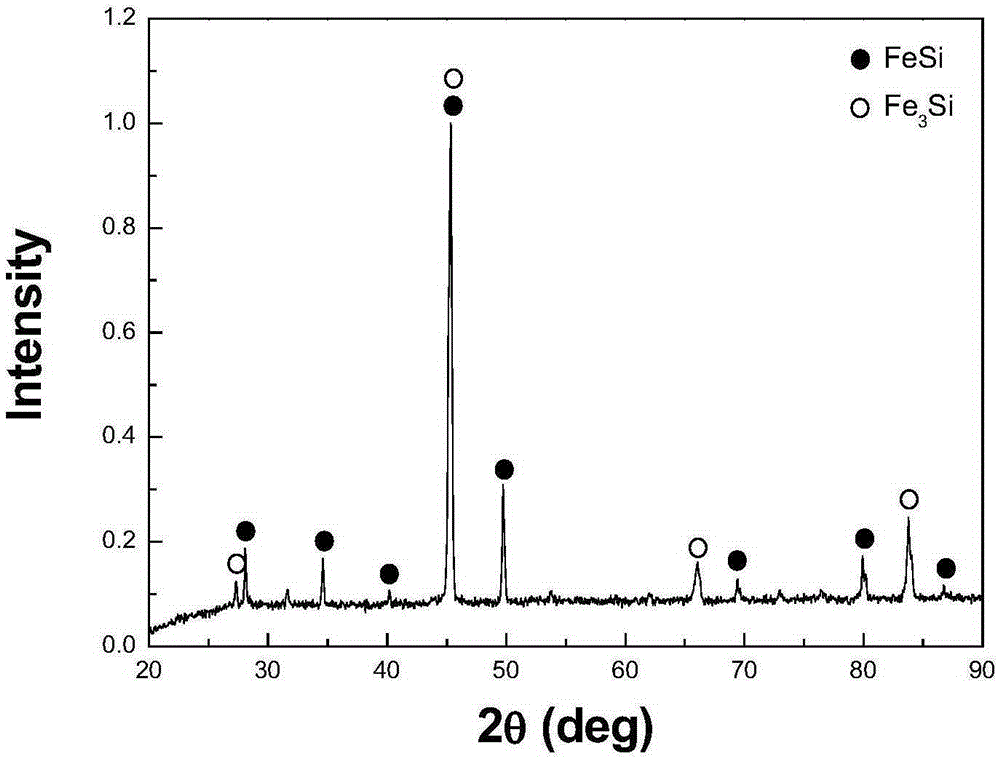

Preparation method of high silicon orientation silicon steel thin plate

InactiveCN100999822AHigh purityThickness is easy to controlLayered productsVacuum evaporation coatingFerrosiliconSpinel

The preparation process of high silicon orientation low carbon silicon steel sheet includes the technological steps of: sputtering target material onto two sides of low carbon silicon steel base material with silicon content lower than 3.0 wt % to form deposited layers of ferrosilicon film or multilayer Fe-Si film under vacuum or protecting atmosphere in a sputtering room; introducing N2 and / or O2 to the sputtering room to deposit Ti, Cr, Al or MgO target on the outer surface to form AlN, TiN, MgO or Cr-containing spinel type oxide coating; high energy particle implantation or diffusing annealing, rolling and final re-crystallization annealing treatment. The present invention has short preparation period, and the prepared high silicon orientation low carbon silicon steel sheet has very low surface C, P and O contents and deposited layer with crystal grains in regular size and orientation.

Owner:WUHAN UNIV OF SCI & TECH

Geopolymer injecting paste material and preparing method and application thereof

ActiveCN105541140AHigh viscosityShorten the timeCement productionSoil preservationPolymer adhesiveGeopolymer

The invention discloses a geopolymer injecting paste material and a preparing method and application thereof. The geopolymer injecting paste material is prepared from the components in proportion: 50-80 parts of coal ash, 16-50 parts of zeolite powder, 4-10 parts of clay, 5-15 parts of alkali excitant, 0.5-2 parts of accelerator, 3-8 parts of water glass and a water cement ratio is 0.75-1.5; the method comprises: (1) dissolving the alkali excitant in water to prepare an alkali excitant solution; (2) uniformly mixing the coal ash and the zeolite powder with other components to obtain a mixture; (3) mixing the alkali excitant solution with the mixture, and stirring to obtain the target geopolymer injecting paste material. The geopolymer binding material taking the coal ash, zeolite powder and clay as raw materials has the characteristics similar to but superior to those of cement, and can serve as an excellent injecting paste material, and has excellent effects on road foundation strengthening and antiseepage in engineering.

Owner:SHANDONG UNIV

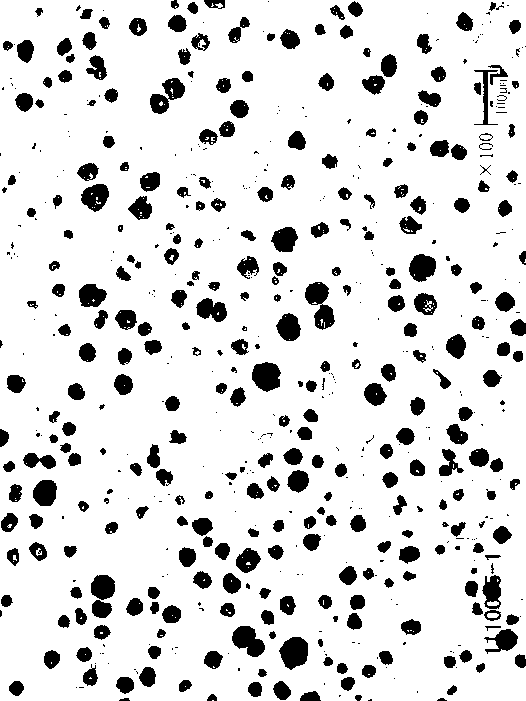

High-strength high-toughness low-temperature-resistant ferritic nodular cast iron

InactiveCN102703802AIncreased toughness-brittle transition temperatureReduce shockImpact toughnessDuctile iron

The invention discloses high-strength high-toughness low-temperature-resistant ferritic nodular cast iron. The high-strength high-toughness low-temperature-resistant ferritic nodular cast iron comprises the following components in percentage by weight: 3.62 to 3.80 percent of C, 1.90 to 2.35 percent of Si, less than 0.20 percent of Mn, 0.007 to 0.018 percent of RE, 0.043 to 0.060 percent of Mg, less than 0.035 percent of P, less than or equal to 0.020 percent of S, and the balance of iron and other impurity elements, wherein in the impurity elements, Mo is controlled to be less than 0.010 percent, and Ti is controlled to be less than 0.025 percent; and the ratio of the Si to the C is 0.50-0.63. Through a lot of test and research, the Si-C ratio is reasonably controlled, low-temperature nodular cast iron can obtain relatively high tensile strength and yield strength, and the low-temperature impact toughness of -40 DEG C can also be ensured; and the ideal low-temperature impact toughness is obtained while the function of a silicon reinforced metallic matrix is exerted, so that the performance requirements are met, and the cost is also greatly reduced.

Owner:上海宏钢电站设备铸锻有限公司

High-performance cold extrusion die steel and metallurgical manufacturing method thereof

ActiveCN101649419AReduced brittle tendencyImprove metallurgical qualitySteelmakingChemical composition

The invention provides high-performance cold extrusion die steel and metallurgical manufacturing method thereof. The high-performance cold extrusion die steel comprises the following chemical components in percentage by mass: 0.95 to 1.02 percent of C, 0.20 to 0.40 percent of Mn, 8.60 to 9.00 percent of Cr, 0.87 to 1.10 percent of Si, 1.80 to 2.00 percent of Mo, 0.40 to 0.60 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. According to the component proportion, the toughness performance of the high-performance cold extrusion die steel can be greatly improved. The metallurgical manufacturing method comprises theprocesses of electric furnace steel making, electroslag remelting and steel forging by a radial forging press. In the process of electroslag remelting, the voltage is between 57 and 59V, and the current is between11,000 and 12,000A; and in the process of steel forging by the radial forging press, steel ingots are heated to between 1,150 DEG C and 1,170 DEG C, and the temperature keeps for 2 to 4hours. The method is simple and convenient, and can remarkably improve the performance index of the steel.

Owner:宝武特种冶金有限公司

Oligosaccharide/silicon-containing block copolymers for lithography applications

InactiveUS20130022785A1Improve etch selectivitySmall structureMaterial nanotechnologySugar derivativesChemistryAzide

The present invention discloses diblock copolymer systems that self-assemble to produce very small structures. These co-polymers consist of one block that contains silicon and another block comprised of an oligosaccharide that are coupled by azide-alkyne cycloaddition.

Owner:CERMAV CNRS +1

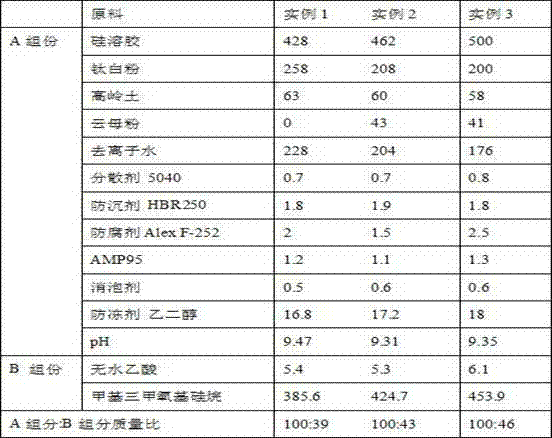

A two-component water-based inorganic non-intumescent fireproof coating and its preparation method

InactiveCN102268221AImprove film formationHigh temperature resistantFireproof paintsAcetic acidMeth-

The invention discloses a two-component water-based inorganic non-intumescent fireproof coating and a preparation method thereof, which is composed of two components A and B. The A component is composed of the following raw materials in mass percentage: 42-50% of silica sol, 29-33% of pigment and filler, 18-23% of deionized water, 0.07-0.08% of dispersant, 0.18-0.20% of anti-settling agent, Preservative 0.1-0.3%, AMP950.1-0.15%, defoamer 0.05-0.07%, antifreeze 1.6-1.8%; the mass percentage of the B component is composed of: anhydrous acetic acid 1.2-1.8%, methyl trimethyl Oxysilane 98.2-98.8%. When using, stir and mix components A and B according to a certain ratio, then mature, and then air spray on acid-resistant substrates such as aluminum alloys and stainless steels that have been sandblasted. The coating of the invention has the advantages of environmental protection, high temperature resistance, noncombustibility in case of fire, no expansion, no smoke emission, acid and alkali resistance, long shelf life at normal temperature, and curing at normal temperature.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for preparing optical fiber preform rod

InactiveCN102320732AHigh silicon contentEasy to purifyGlass deposition burnersGlass fibre productsSilanesUltimate tensile strength

The invention relates to a method for preparing optical fiber preform rod, which comprises the following steps: directly coating a uniform quartz loose body on an external surface of a core rod by using silane or siloxane as a raw material through an external vapor deposition method so as to form a loose-body preform rod, slowing heating the loose-body preform rod at a high temperature for dehydration, and sintering the loose-body preform rod to obtain a transparent optical fiber preform rod. The invention adopts clean silane or siloxane as a raw material for forming the quartz coating, does not generate a lot of harmful hydrogen chloride, overcomes the disadvantage that chlorine-containing raw material introduces single bonds which can block atomic bonds into the coating, increases the purity and strength of the preform rod material, and improves the mechanical strength of optical fibers.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Production method of austenitic stainless steel

InactiveCN101928804AHigh yieldAvoid the problem of high loss and low chromium yieldProcess efficiency improvementElectric furnaceNichromeSS - Stainless steel

The invention relates to a production method of austenitic stainless steel, which comprises the following steps of: a, mixing different low-grade nickel-chromium pig iron in an electric furnace, blowing, desiliconizing and decarbonizing to obtain a stainless steel mother liquor; preparing Cr to be about half of a finished product according to the content requirement of a stainless steel finished product, and properly preparing Ni in the stainless steel mother liquor in the electric furnace by using a grade high-carbon ferrochrome; b, adding the stainless steel mother liquor obtained in the step a to an AOD furnace, adding the high-carbon ferrochrome, laterally blasting air, oxidizing by using a gun and flowing out slag; c, adding metallurgical lime, high-carbon ferrochrome, ferronickel and waste steel to carry out primary decarbonization and secondary decarbonization, adjusting carbon content to the level required by the finished product; and e, finely adjusting components and adjusting temperature in an LF furnace to obtain the austenitic stainless steel. The invention has the advantages of low energy consumption, low cost and stable product quality.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

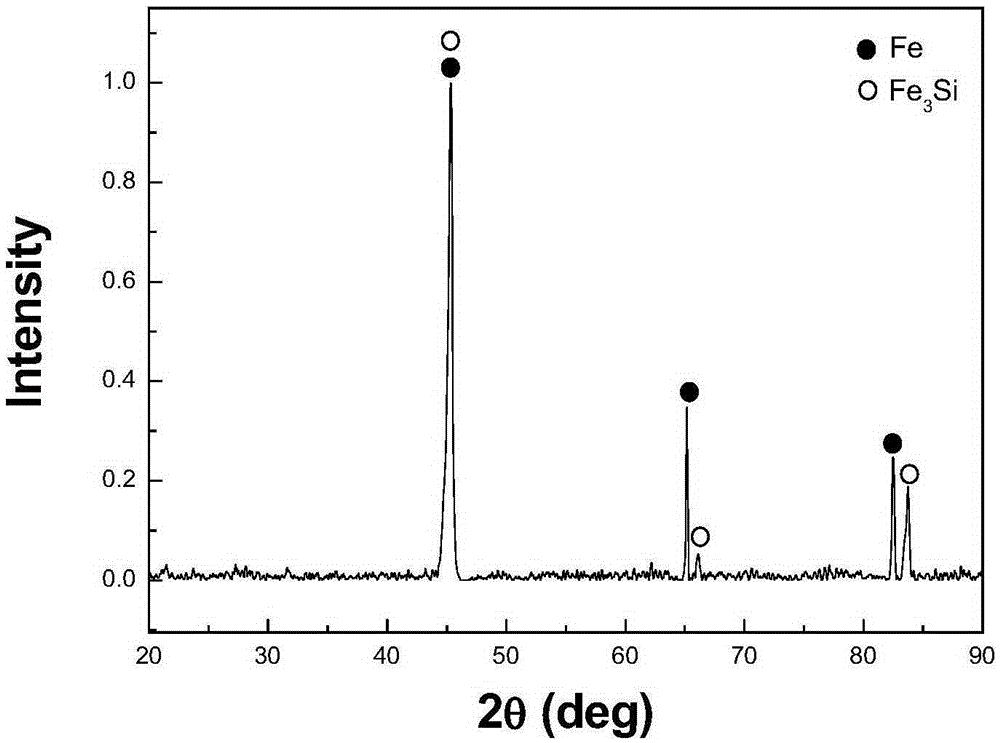

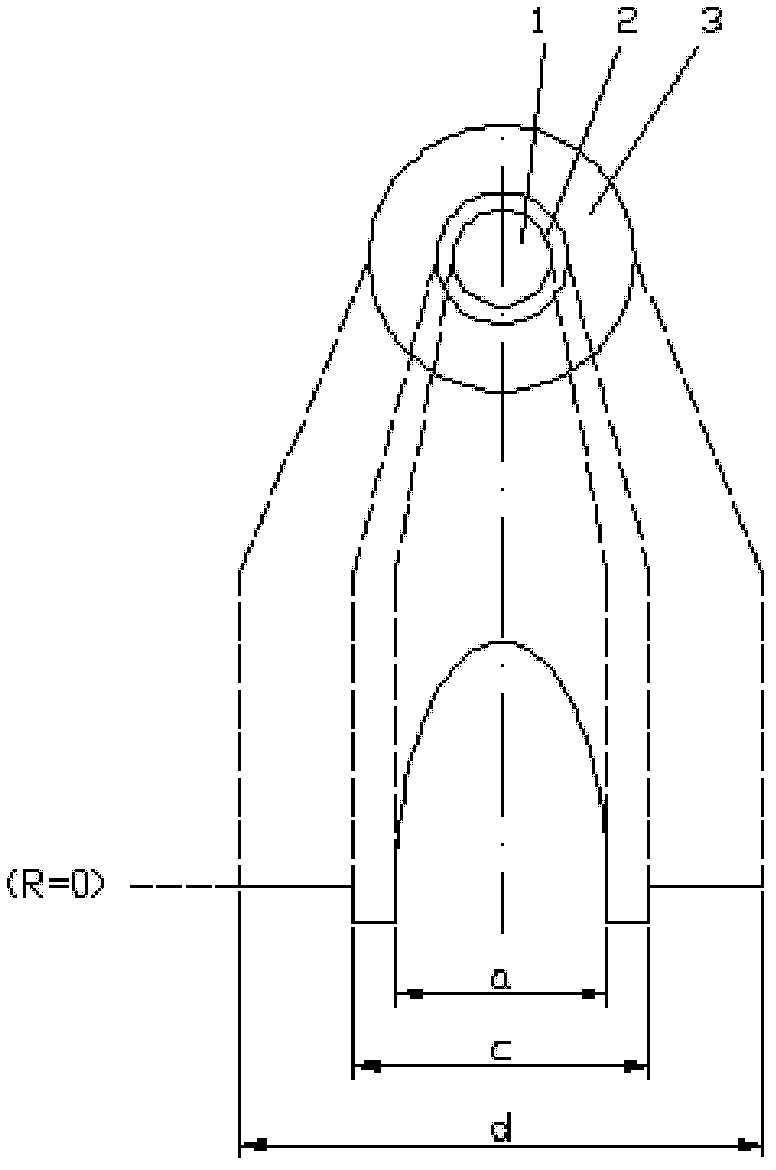

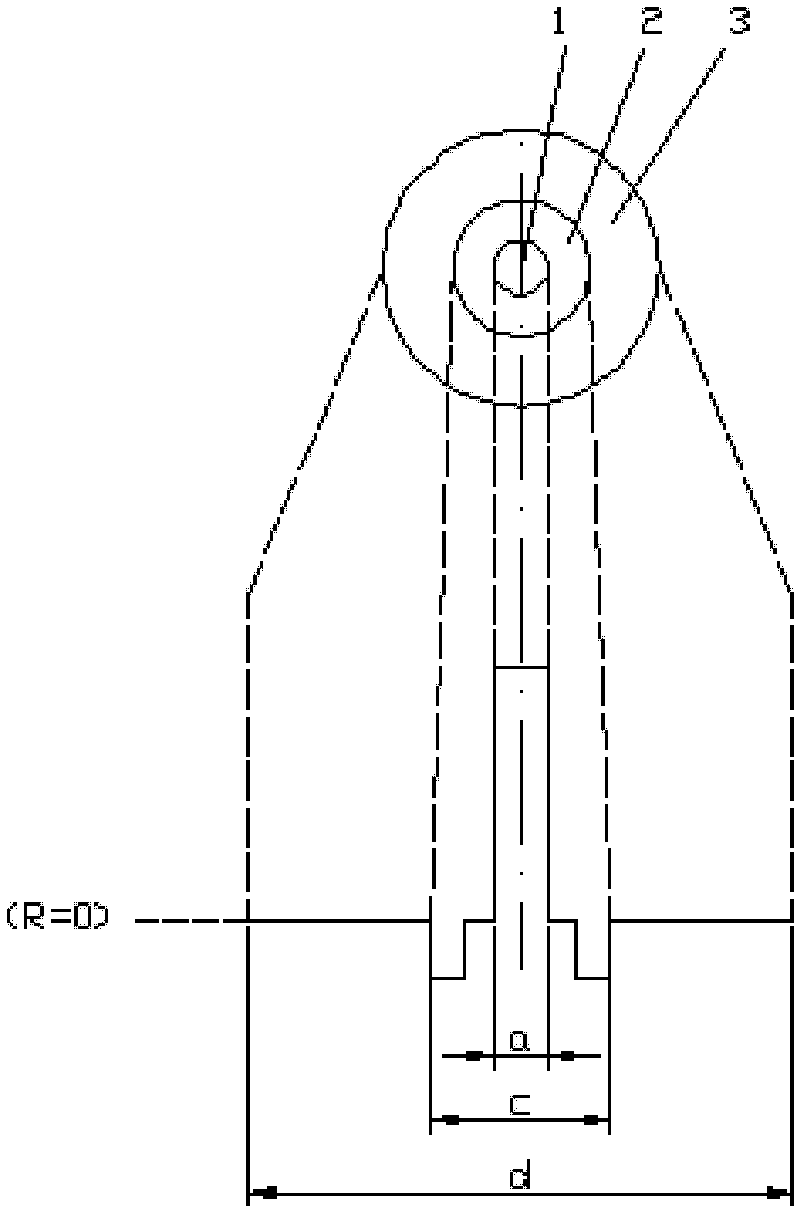

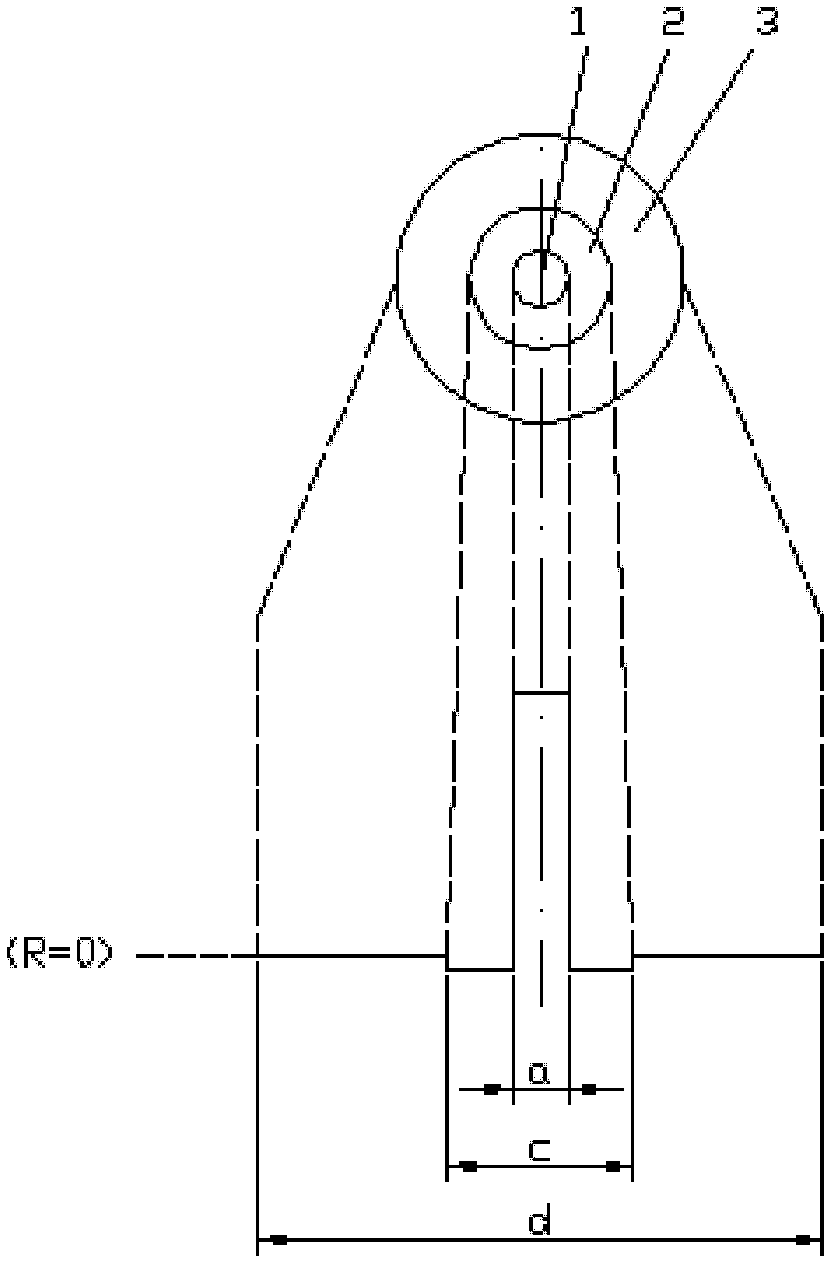

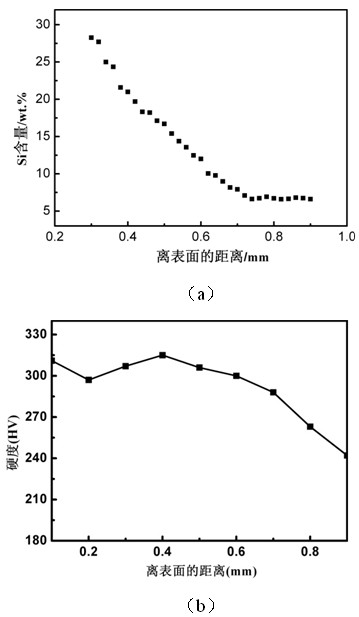

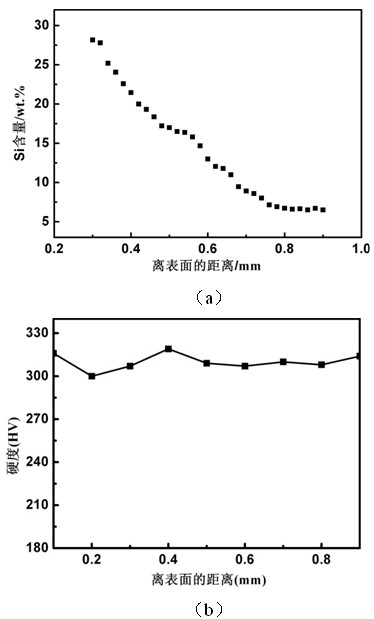

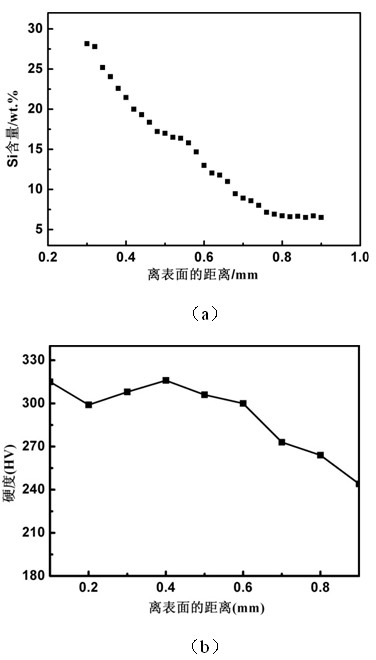

Method for preparing high-silicon coating on aluminum alloy surface

InactiveCN102534467AHigh hardnessImprove wear resistanceSolid state diffusion coatingLaser assistedErbium lasers

The invention discloses a method for preparing a high-silicon coating on an aluminum alloy surface. The method comprises the steps that: firstly, the aluminum alloy surface is ground and polished and is soaked in NaOH solution with the mass percentage of 5 percent for blackening treatment, then, acetone and alcohol are used for cleaning and drying in the air, Si powder and light absorption paint capable of enhancing the CO2 laser absorption rate are uniformly stirred and are then uniformly coated on the surface of an aluminum alloy covered base body to be melted, and the preset coating thickness is within 3mm; under the argon gas atmosphere protection, and a 7kW transverse flow CO2 laser is used for carrying out laser enforcement on the preset layer; samples after laser enforcement treatment are placed in a vacuum condition to be heated to 450 DEG C to 550 DEG C, in addition, the heat insulation is carried out for 36 hours, and the high-silicon coatings are prepared. The method has the advantages that the goal of improving the silicon content of the aluminum alloy surface is realized, the laser-assisted siliconizing technology combining laser melting cladding and diffusion heating is adopted, the high-silicon aluminum alloy with high surface hardness and high internal roughness is prepared, and the high-silicon aluminum alloy has the characteristics that certain depth requirements are met, the hardness is high, the abrasion performance is good, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com