Method for preparing high-silicon steel from low-silicon steel

A low-silicon steel and high-silicon steel technology, applied in the field of material preparation, can solve the problems of waiting, low price, low content, etc., and achieve the effect of suppressing eddy current loss and good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

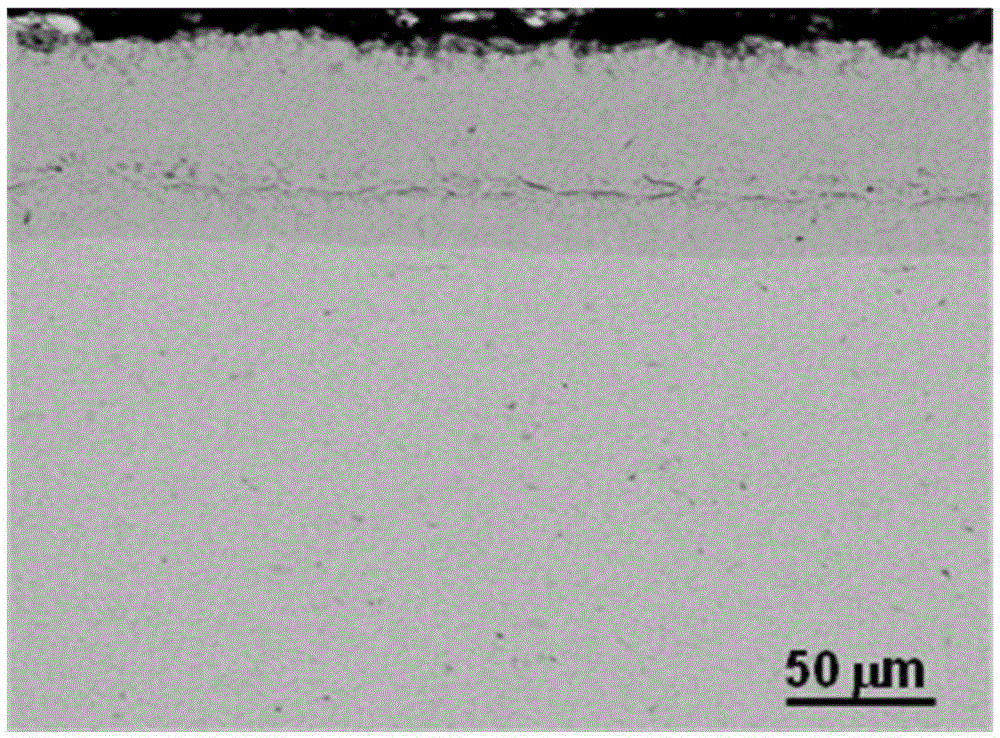

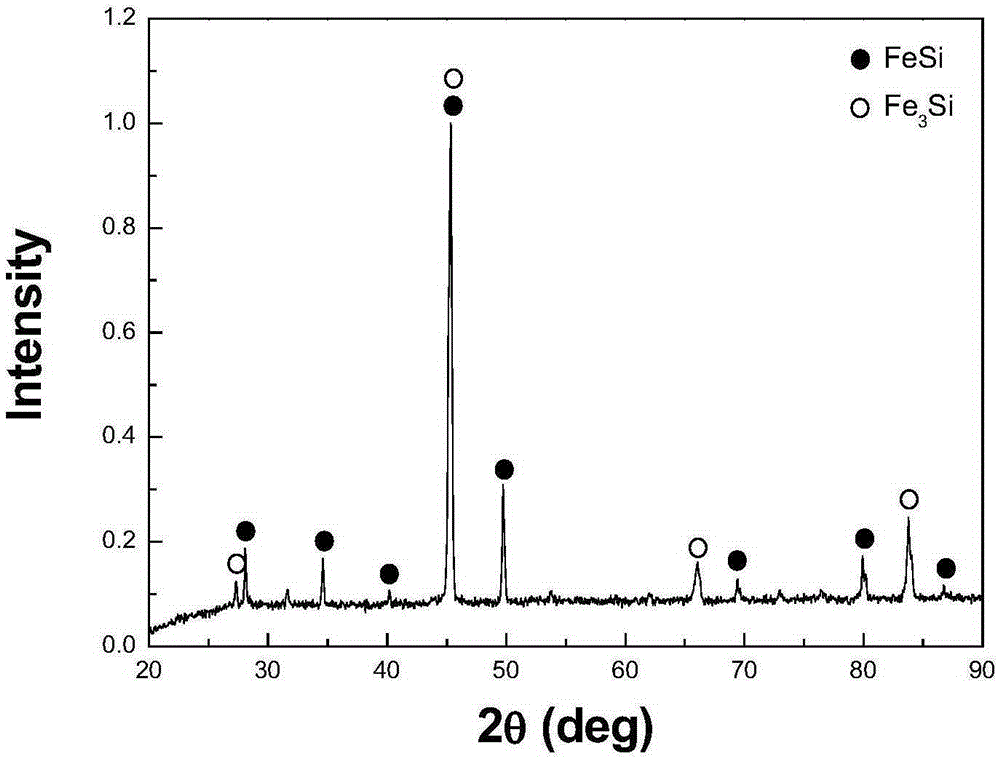

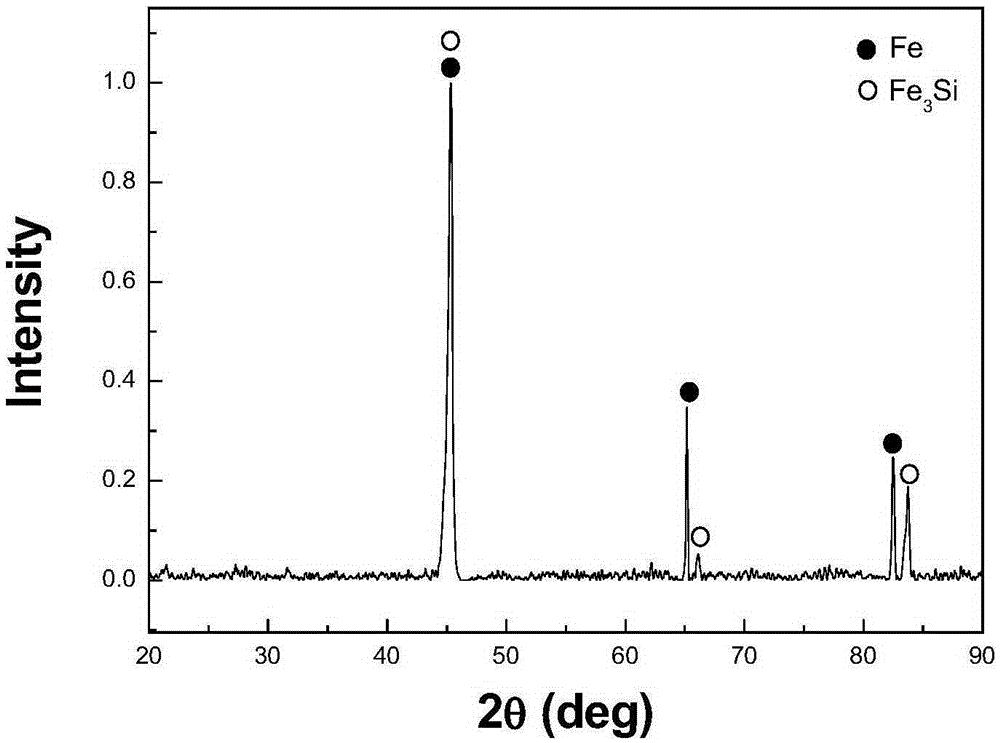

[0040] A 0.5wt% silicon steel hot-rolled sheet with a thickness of 2.2mm was used as a base material, and a conventional synchronous rolling mill was used for 3 passes of cold rolling with a reduction of 84% to obtain a thin sheet with a thickness of 0.35mm. Decontamination and rust removal by pickling. The siliconizing agent composed of silicon powder + 3.0wt% ammonium chloride is passed through argon gas at room temperature for 10 minutes, heated to 550° C., put into the thin plate, and kept for 30 minutes. Put the siliconizing agent composed of silicon powder + 0.5wt% ammonium chloride into the argon gas at room temperature for 10 minutes, heat it to 820°C, put it into the heat-preserved thin plate, carry out solid siliconizing for 25 minutes, and form on the surface of the thin plate A dense siliconized layer with a thickness of about 65 μm ( figure 1 ), its phase is Fe 3 Si+FeSi( figure 2). The thin plate is rolled at 400°C with a reduction of about 2%; according to ...

Embodiment 2

[0042] Using a 0.5wt% silicon steel hot-rolled sheet with a thickness of 2.2mm as the base material, a conventional synchronous rolling mill is used for 4 passes of cold rolling with a reduction of 95% to obtain a thin sheet with a thickness of 0.10mm. Decontamination and rust removal by pickling. The siliconizing agent composed of silicon powder + 1.0wt% ammonium chloride is passed through argon gas at room temperature for 10 minutes, heated to 500° C., put into the thin plate, and kept for 20 minutes. Put the siliconizing agent composed of silicon powder + 0.7wt% ammonium chloride into argon gas at room temperature for 10 minutes, heat it to 800°C, put it into the heat-preserved thin plate, and carry out solid siliconizing for 25 minutes, forming on the surface of the thin plate A dense siliconized layer with a thickness of about 20 μm, whose phase is Fe 3 Si+FeSi. The thin plate is rolled at 400°C with a reduction of about 2%; according to the volume percentage, under the...

Embodiment 3

[0044] A 1.0wt% silicon steel hot-rolled sheet with a thickness of 2.2mm was used as a base material, and a conventional synchronous rolling mill was used for 4 passes of cold rolling with a reduction of 86% to obtain a thin sheet with a thickness of 0.30mm. Decontamination and rust removal by pickling. The siliconizing agent composed of silicon powder + 2.0wt% ammonium chloride is passed through argon gas at room temperature for 10 minutes, heated to 550° C., put into the thin plate, and kept for 30 minutes. Put the siliconizing agent composed of silicon powder + 0.5wt% ammonium chloride into the argon gas at room temperature for 10 minutes, heat it to 820°C, put it into the heat-preserved thin plate, carry out solid siliconizing for 20 minutes, and form on the surface of the thin plate A dense siliconized layer with a thickness of about 56 μm, whose phase is Fe 3 Si+FeSi. The thin plate is rolled at 400°C with a reduction of about 2%; according to the volume percentage, un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com