Anisotropically bonded magnet and fabricating method, magnetic path thereof

A bonded magnet, anisotropic technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of decreased mechanical strength, unmaintainable shape, decreased magnetic properties, etc., to improve mechanical strength and protection. Magnetic properties, effect of improving lubricity

Inactive Publication Date: 2010-08-25

SEIKO INSTR INC

View PDF9 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for example, if the amount of magnetic powder is increased in order to improve magnetic properties, there is a problem that the amount of thermosetting resin (binder) binding the magnetic powder will decrease, and the mechanical strength will decrease.

However, the agglomeration, segregation, separation and cross-linking of micropowder are relatively severe. Even if the orientation magnetic field becomes stronger, it is difficult to move the micropowder to the desired direction and position, and the degree of orientation has always been low.

That is, since the degree of orientation is always low even if the density is increased, the magnetic properties are not ideal

In addition, due to the agglomeration, segregation, separation and cross-linking of the micropowder, the magnetic powder is unevenly filled in the forming metal mold. Decreased performance and corrosion resistance

According to this, there is a problem that the magnetic properties will further decrease, and the mechanical strength, heat resistance, and corrosion resistance will decrease due to the density (inhomogeneity) of the filling.

Due to the formation of the cavities (voids) 107, there is a problem that the magnetic powder is densified, the magnetic properties are degraded, and the mechanical strength of the anisotropic bonded magnet is degraded.

There is also a problem that the shape of the compressed powder body cannot be maintained even when it is taken out from the forming metal mold.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

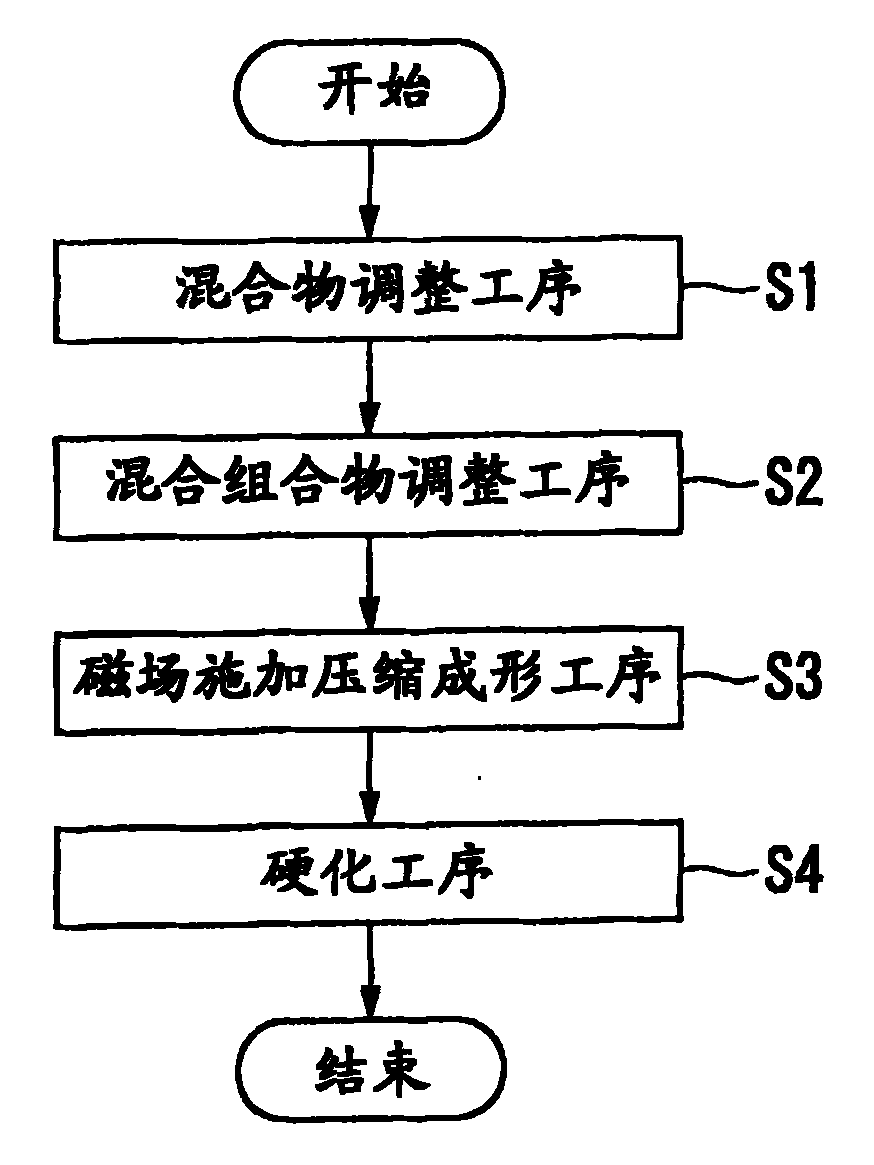

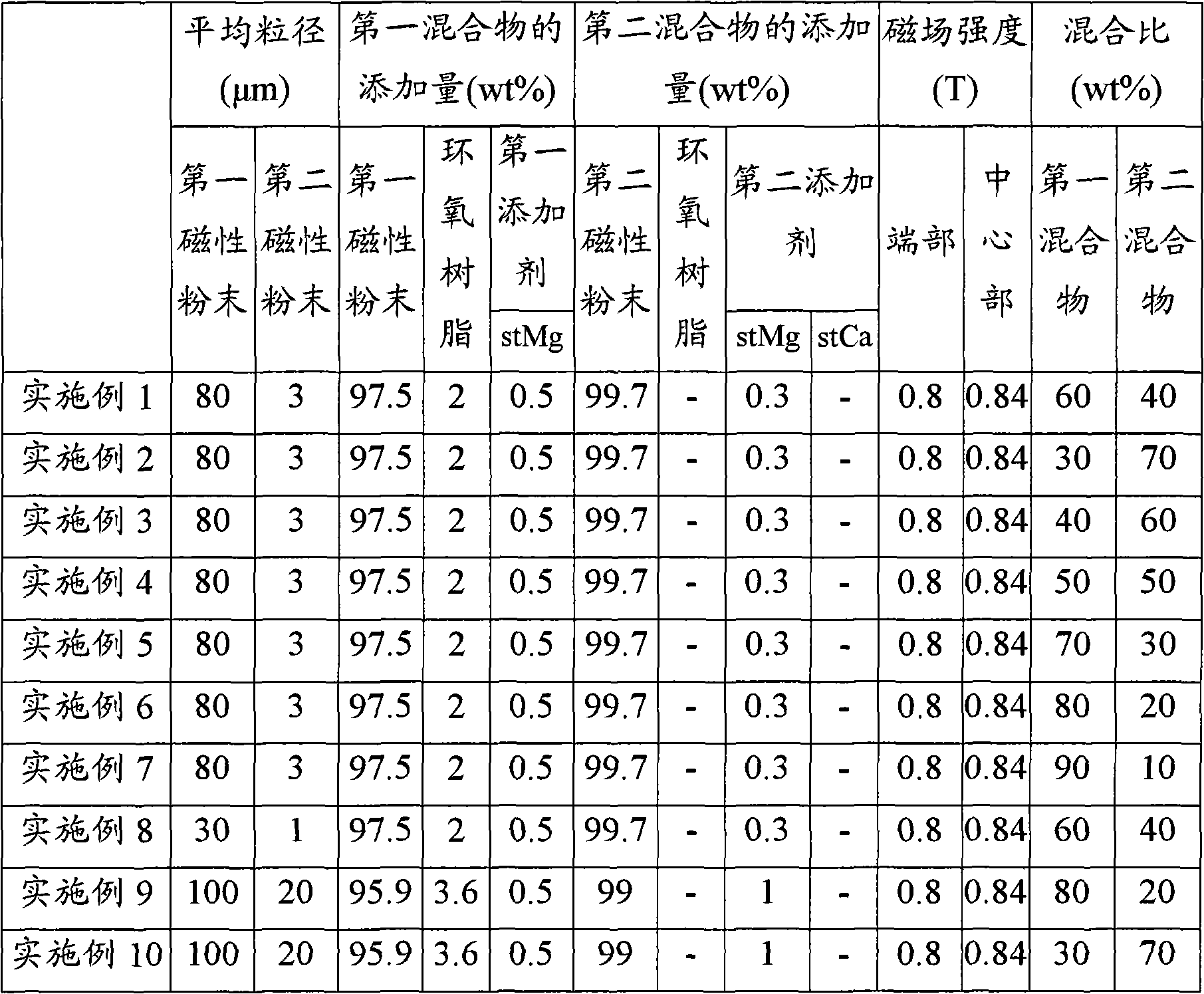

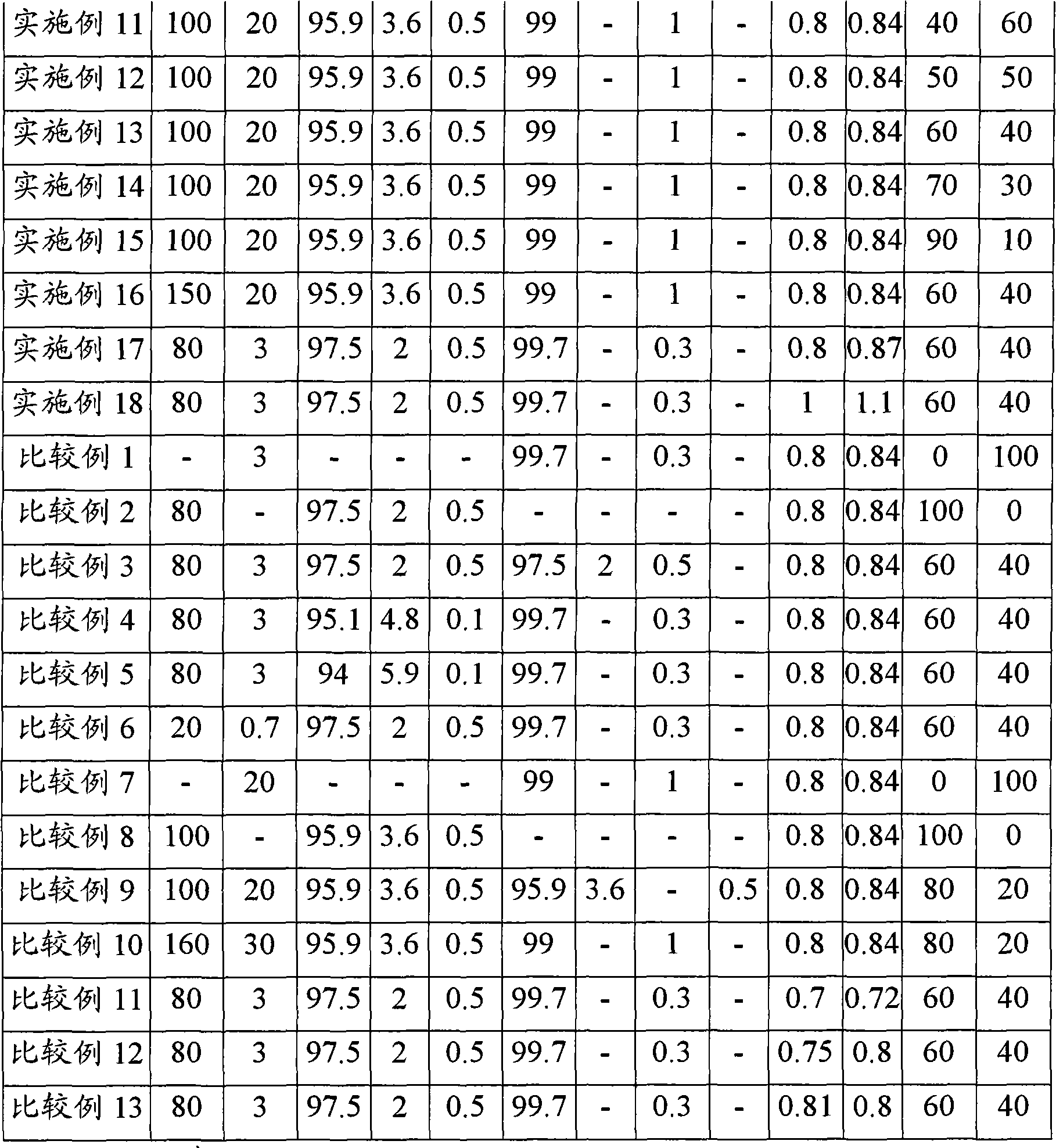

This invention relates to a fabricating method for anisotropically bonded magnet including: step S1 for adjusting the first mixture and the second mixture, where: the first mixture comprises the first magnetic powder, of which the grain size is in the range of 20-150mum, thermosetting resin of 2.0 wt%being added into the anisotropically bonded magnet, the first additive; the second mixture comprises the second magnetic powder, of which the grain size is in the range of 1-20mum, the second additive; step S2 for adjusting the first mixture and the second mixture; step S3 for making the magnetic intensity of the end part of the shaping metal die be under the 0.8T, the magnetic intensity of the central part of the shaping metal die is 5% higher than that of the said end part of the shaping metal die after said mixed compounds being filled into the metal die; step S4 for heating said mixed compounds at the atmosphere of inert gases or nitrogen gases so as to harden compounds.

Description

technical field The invention relates to a manufacturing method of an anisotropic bonded magnet, a magnetic circuit and an anisotropic bonded magnet. Background technique Permanent magnets are divided into bonded magnets (Bonded magnets), sintered magnets, cast magnets and the like. A bonded magnet refers to a composite permanent magnet formed by solidifying magnet powder with a binder. Main components are magnet powder and binder, and lubricant etc. are added as needed. Compared with sintered magnets, bonded magnets have poorer magnetic properties than sintered magnets due to the inclusion of a binder, but compared with sintered magnets, they have higher dimensional accuracy, higher degree of shape freedom (can form complex shapes), better mechanical properties, and are easy to use. The advantage of using metal mold forming for mass production (lower defect rate). Bonded magnets are classified into metal-bonded bonded magnets, ceramic-bonded bonded magnets, resin-bonded...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01F41/02B22F3/00B22F3/16

Inventor 中村芳文

Owner SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com