Method for preparing large-size sintered samarium cobalt permanent magnet

A permanent magnet and large-size technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve problems such as connection process and strength limitations, low pass rate, degumming, etc., to achieve no abnormal appearance of the magnet, excellent magnetic properties, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0049] The preparation method of samarium-cobalt alloy ingot: by weight, 25.5 parts of Sm, 52 parts of Co, 12.5 parts of Fe, 7 parts of Cu and 3 parts of Zr are placed in a vacuum intermediate frequency induction furnace, and the vacuum is evacuated to a vacuum degree of 0.08Pa. Then fill the furnace with argon until the pressure in the furnace is -0.05MPa, melt at 1500°C for 15 minutes, then heat-preserve and refine at 1440°C for 5 minutes, and finally pour it into a cooling mold for rapid cooling and casting.

Embodiment 1

[0051] (1) The samarium-cobalt alloy ingot obtained in Reference Example 1 is roughly crushed into coarse particles with an average particle size of 300 μm by a jaw crusher and a secondary crusher, and pulverized by a jet mill into jet mill magnetic powder with an average particle size of 3.8 μm. Add 120# aviation gasoline equivalent to 3% of its mass in the magnetic powder, and mix with a double-cone mixer for 1 hour to obtain magnetic powder;

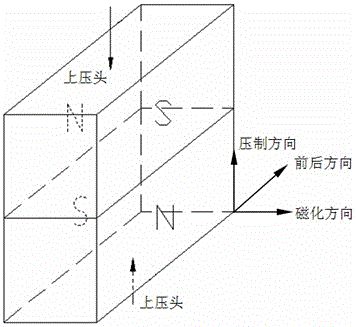

[0052] (2) Two parts of 1530g of the magnetic powder mixed in step (1) are respectively placed in a magnetic field of 1.6T and a pressure of 4MPa, orientated and press-molded into a size specification of 110 (front-back direction)×65 (pressing direction)× 58 (Magnetization direction) mm, density 3.69g / cm 3 The shrinkage rate of a single green body in the pressing direction is designed to be 1.313, that is, 65 (dimensions in the pressing direction of the green body) × 2 / 99 (dimensions in the direction of blank pressing) = 1.313, and th...

Embodiment 2

[0057] (1) Same as step (1) of Example 1;

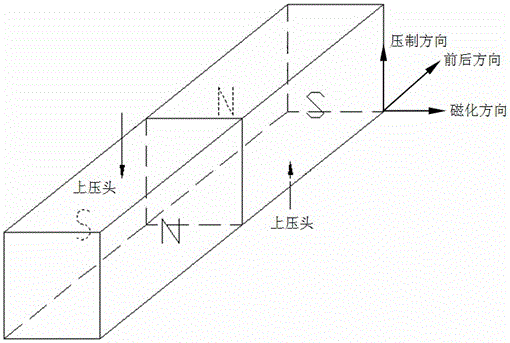

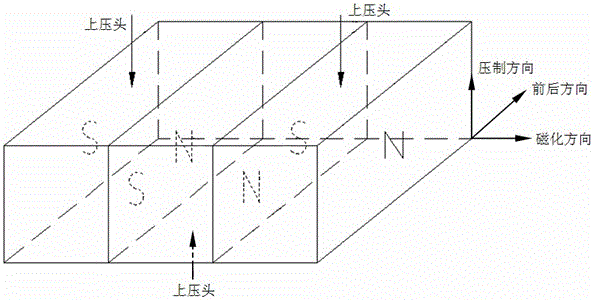

[0058] (2) Two parts of 1640g of the magnetic powder mixed in step (1) are placed in a magnetic field of 2.0T, respectively, under a pressure of 6MPa, and oriented and pressed into a size specification of 115 (front and rear direction) × 66 (pressing direction) × 60 (Magnetization direction) mm, density 3.60g / cm 3 The shrinkage rate of a single green body in the pressing direction is designed to be 1.320, that is, 66 (dimensions in the pressing direction of the green body) / 50 (dimensions in the direction of blank pressing) = 1.320, the shrinkage rate in the front and rear directions is 1.349, and the shrinkage rate in the direction of magnetization The corresponding value is 1.282, and two identical green bodies are obtained;

[0059] (3) Arrange the two green bodies obtained in step (2) along the front and back directions, and arrange the magnetization direction between the two green bodies crosswise, and arrange the upper indenter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com