Fe-based amorphous alloy ribbon and magnetic core formed thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

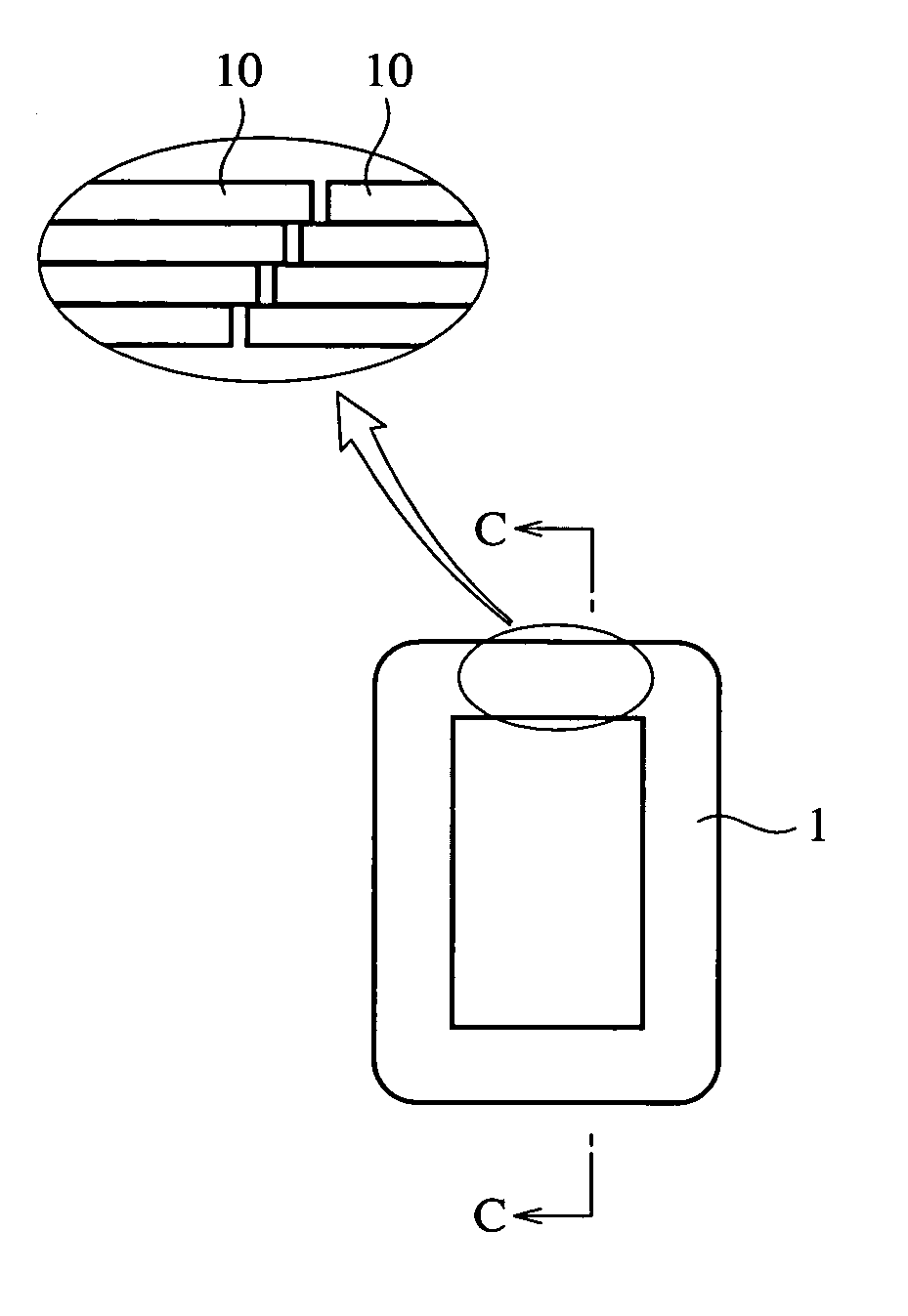

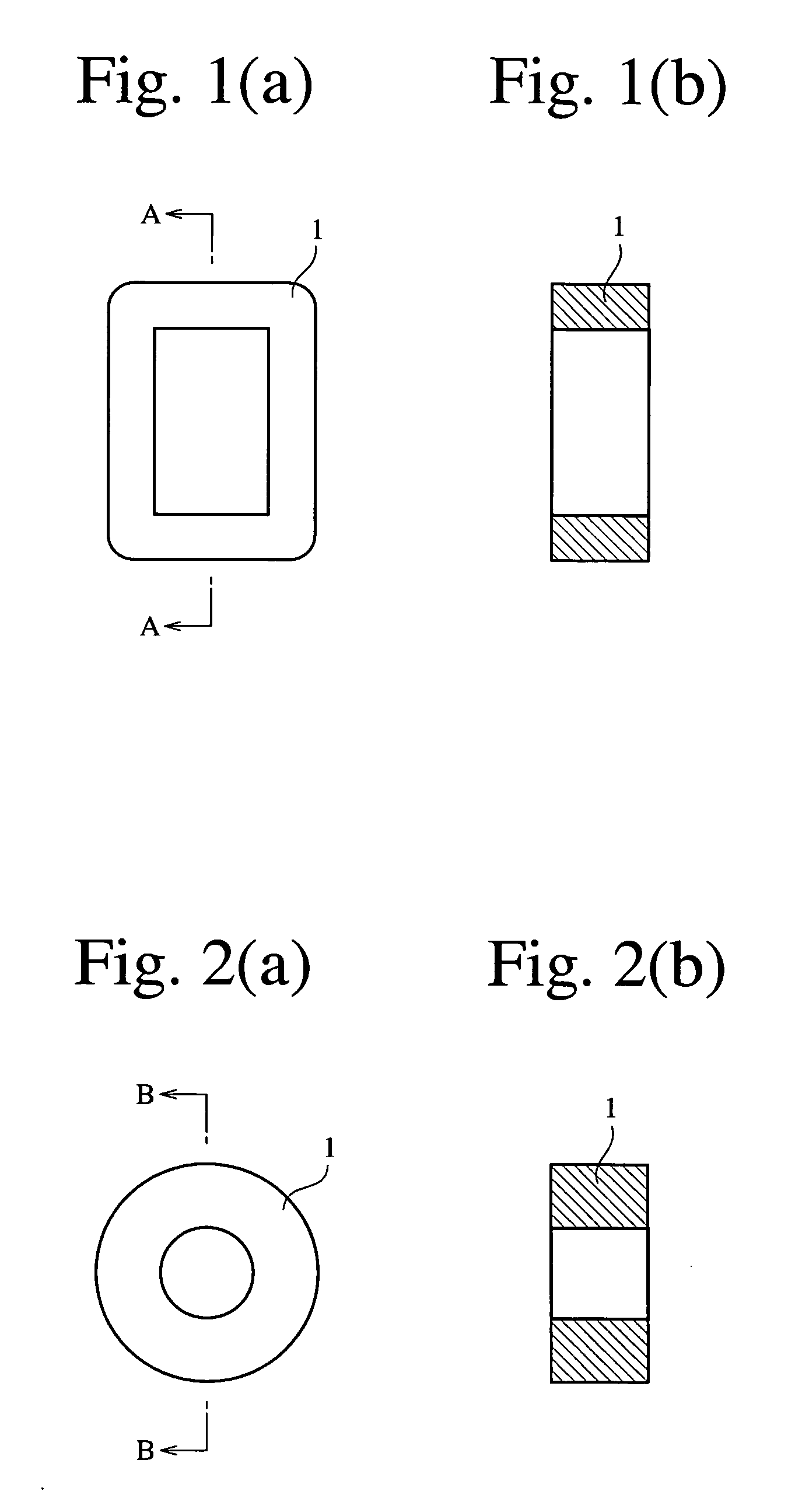

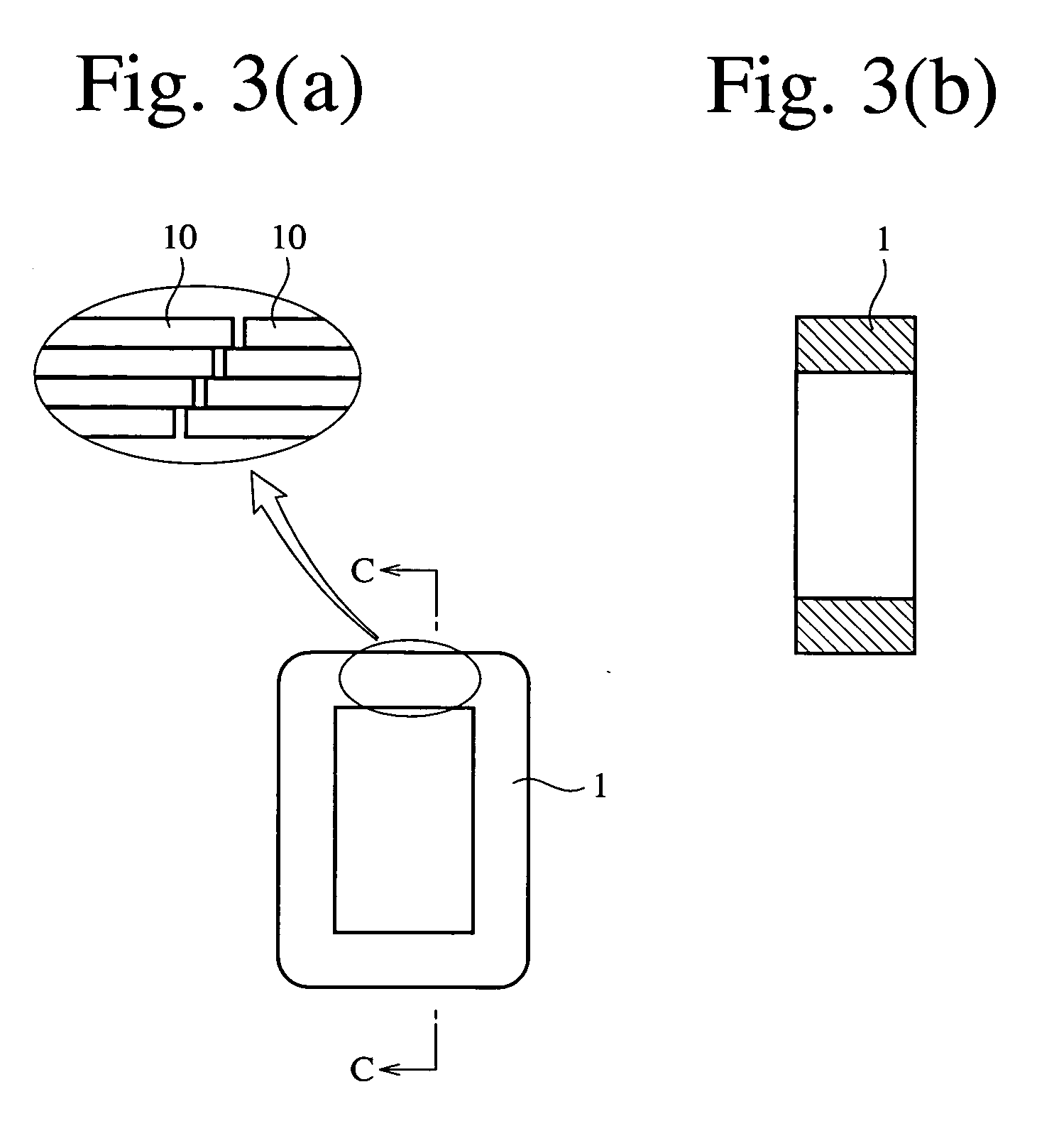

[0036] Alloy melts having compositions represented by FeaSibBcMx (a+b+c+x=100) as shown in Table 1 were rapidly quenched by a single roll method to produce amorphous alloy ribbons of 5 mm in width and 25 μm in thickness.

[0037] Each Fe-based amorphous alloy ribbon was wound to form a toroidal magnetic core of 19 mm in outer diameter and 15 mm in inner diameter, which was heat-treated in an Ar gas atmosphere. During the heat treatment, a magnetic field of 1 kA / m was applied in a direction aligned with the magnetic path of the core, and the temperature was elevated to an optimum heat-treating temperature between 320° C. and 370° C., at which the highest saturation magnetic flux density and other soft magnetic properties were obtained, over 2 hours, kept at each heat-treating temperature for 1 hour, and then cooled to 200° C. over 1 hour. The heat-treated ribbons were mostly amorphous. The resultant toroidal magnetic cores were measured with respect to a saturation magnetic flux densit...

example 2

[0043] 20 Samples 2-1 to 2-11 and 2-12 to 2-16 of various compositions were produced and heat-treated in the same manner as in Example 1. The core loss increase ratio Wr of each resultant Fe-based amorphous alloy ribbon is shown in Table 2 together with a composition, a heat treatment temperature, a saturation magnetic flux density Bs, a stress relaxation rate Rs, an average surface roughness Ra, and a space factor. The saturation magnetic flux density Bs and the stress relaxation rate Rs were measured in the same manner as in Example 1.

[0044] The core loss increase ratio Wr is a parameter expressing an increase ratio of the core loss when the operating magnetic flux density increases from 1.3 T to 1.4 T, which is represented by the following equation:

Wr=(W14 / 50−W13 / 50) / W13 / 50×100 [%] (2),

wherein W13 / 50 represents a core loss at a magnetic flux density of 1.3 T and a frequency of 50 Hz, and W14 / 50 represents a core loss at a magnetic flux density of 1.4 T and a frequency of 50 ...

example 3

[0049] Alloy melts having compositions represented by FeaSibBcCdMx (a+b+c+d+x=100) as shown in Table 3 were rapidly quenched by a single roll method, to form Fe-based amorphous alloy ribbons of 5 mm in width and 25 μm in thickness. Each of the resultant Fe-based amorphous alloy ribbons was wound to form a toroidal magnetic core of 19 mm in outer diameter and 15 mm in inner diameter, and heat-treated in the same manner as in Example 1. The heat-treated alloys were mostly amorphous.

[0050] Each Sample was measured in the same manner as in Example 1 with respect to a saturation magnetic flux density Bs, a magnetic flux density B80 in a magnetic field of 80 A / m, a core loss W13 / 50 at a magnetic flux density of 1.3 T and a frequency of 50 Hz, a core loss W14 / 50 at a magnetic flux density of 1.4 T and a frequency of 50 Hz, and a stress relaxation rate Rs. The results are shown in Table 3.

TABLE 3Sam-pleBsB80W13 / 50W14 / 50RsNo.Composition[T][T][W / kg][W / kg][%]3-1Fe82Si2B13.95C2Cr0.051.641.61...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com