Patents

Literature

536results about How to "Excellent magnetic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

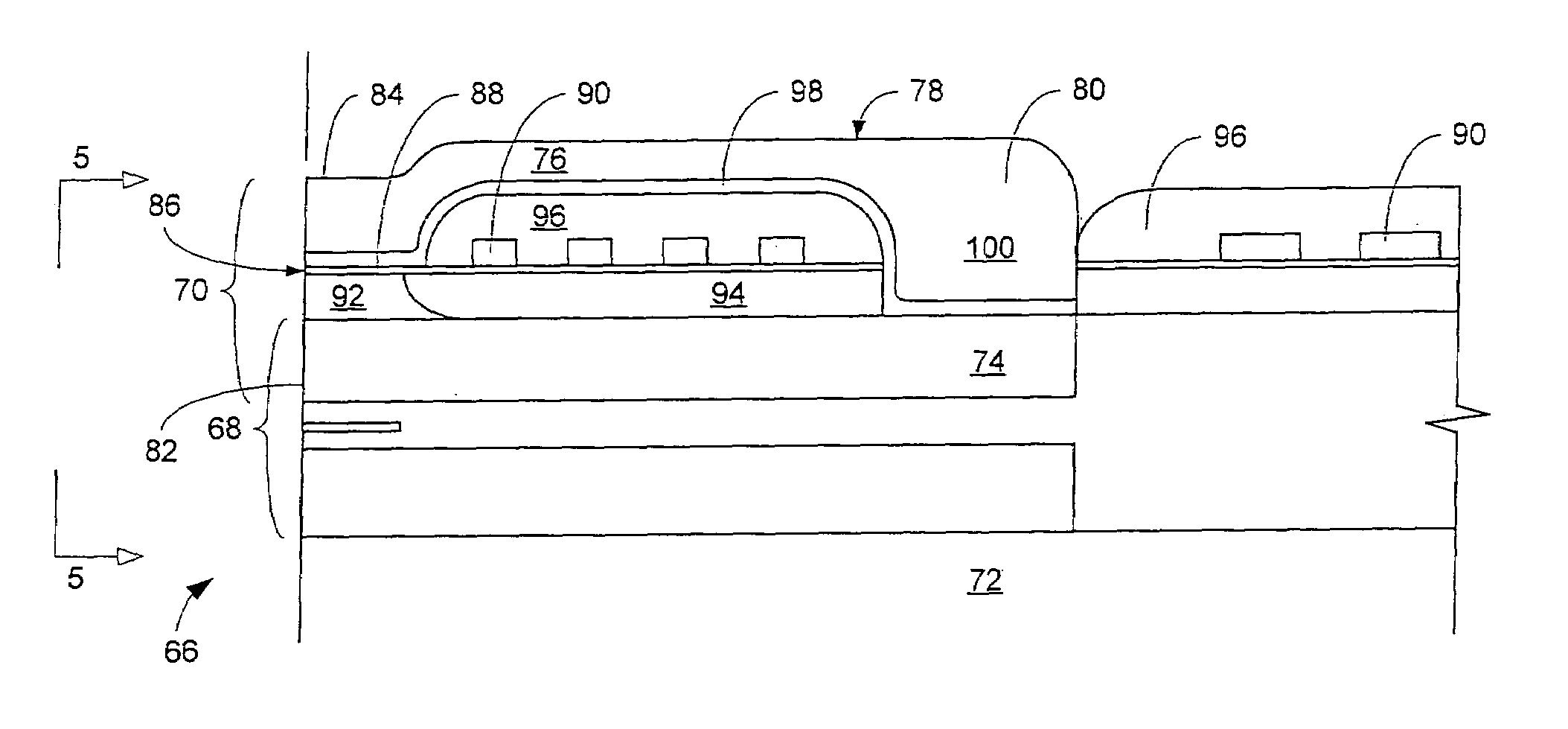

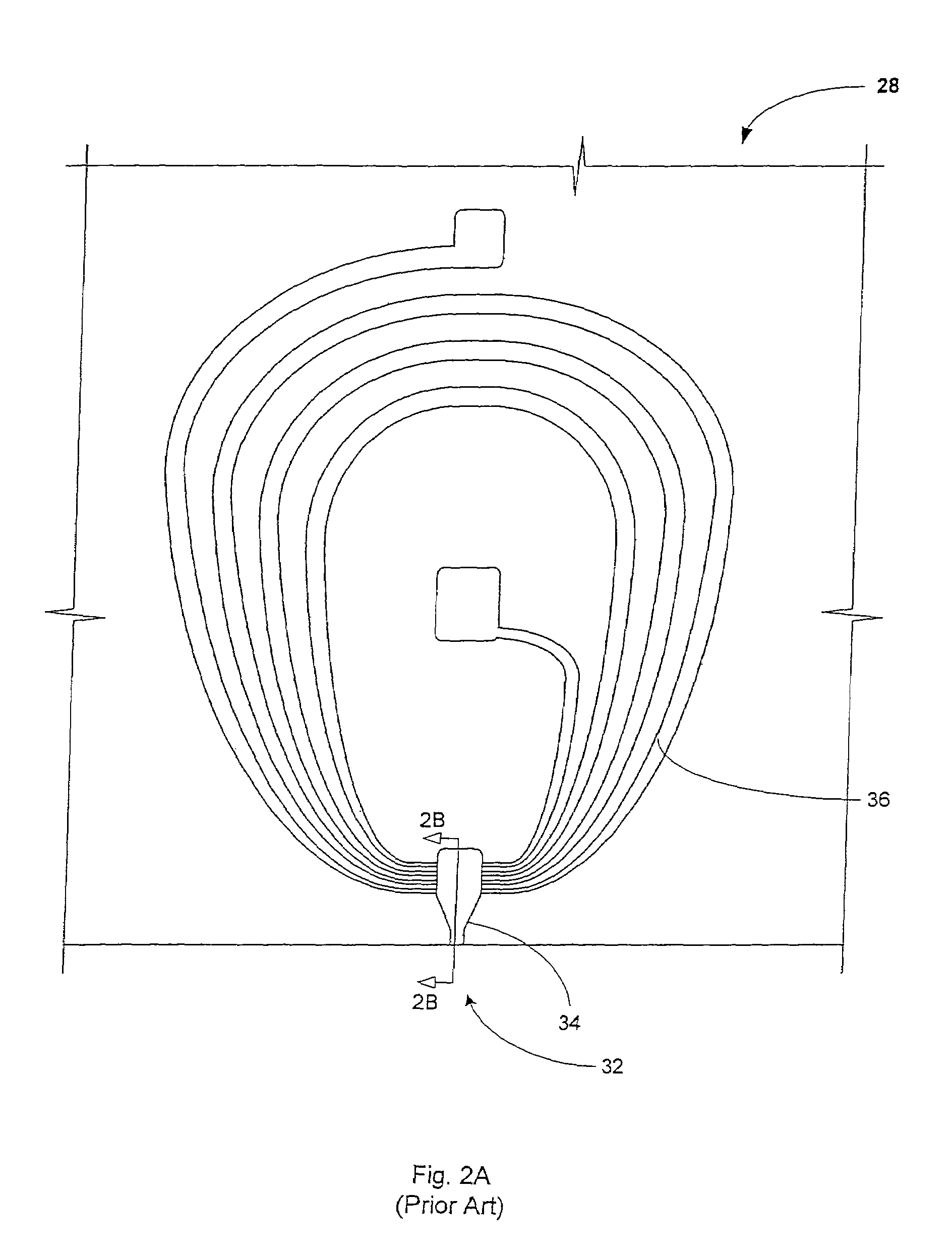

Method for making high speed, high areal density inductive write structure

InactiveUS7007372B1Excellent magnetic propertiesIncrease coverageDecorative surface effectsVacuum evaporation coatingMagnetic mediaMagnetic poles

An inductive write element is disclosed for use in a magnetic data recording system. The write element provides increased data rate and data density capabilities through improved magnetic flux flow through the element. The write element includes a magnetic yoke constructed of first and second magnetic poles. The first pole includes a pedestal constructed of a high magnetic moment (high Bsat) material, which is preferably FeRhN nanocrystalline films with lamination layers of CoZrCr. The second pole includes a thin inner layer of high Bsat material (also preferably FeRhN nanocrystalline films with lamination layers of CoZrCr), the remainder being constructed of a magnetic material capable of being electroplated, such as a Ni—Fe alloy. An electrically conductive coil passes through the yoke between the first and second poles to induce a magnetic flux in the yoke when an electrical current is caused to flow through the coil. Magnetic flux in the yoke produces a fringing field at a write gap whereby a signal can be imparted onto a magnetic medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

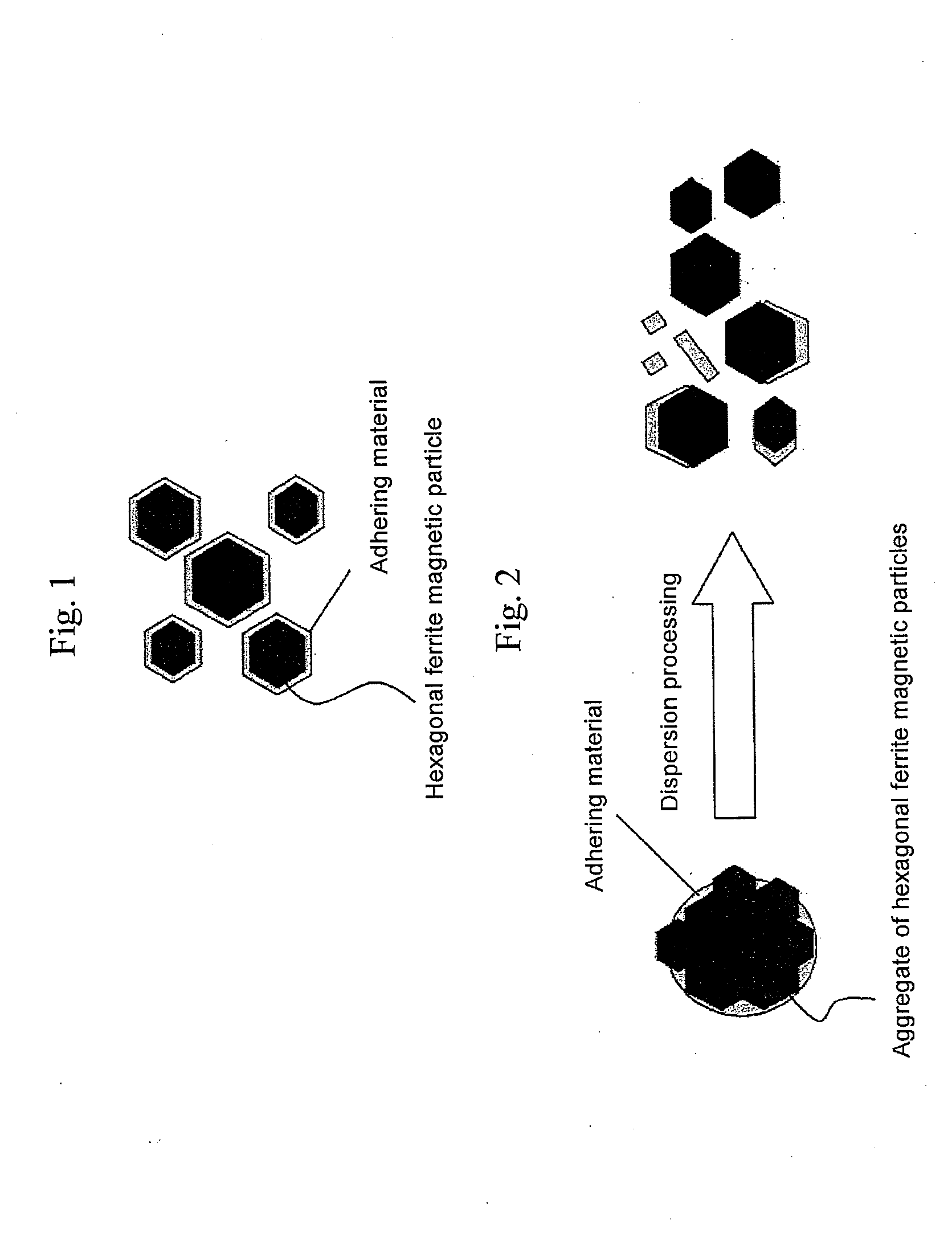

Hexagonal ferrite magnetic particle and method of manufacturing the same, and magnetic recording medium

ActiveUS20110244272A1Improve coercive forceReduce particlesMaterial nanotechnologyMagnetic materials for record carriersHeat treatedMaterials science

An aspect of the present invention relates to a method of manufacturing a hexagonal ferrite magnetic particle comprising melting an Al-containing starting material mixture to prepare a melt and quenching the melt to obtain an amorphous material; subjecting the amorphous material to heat treatment to cause a hexagonal ferrite magnetic particle to precipitate in a product obtained by the heat treatment; collecting a hexagonal ferrite magnetic particle by subjecting the product to treatment with an acid and washing, wherein the hexagonal ferrite magnetic particle collected has a particle size ranging from 15 to 30 nm, comprises 0.6 to 8.0 weight percent of Al, based on Al2O3 conversion, relative to a total weight of the particle, and Al adheres to a surface of the hexagonal ferrite magnetic particle.

Owner:FUJIFILM CORP

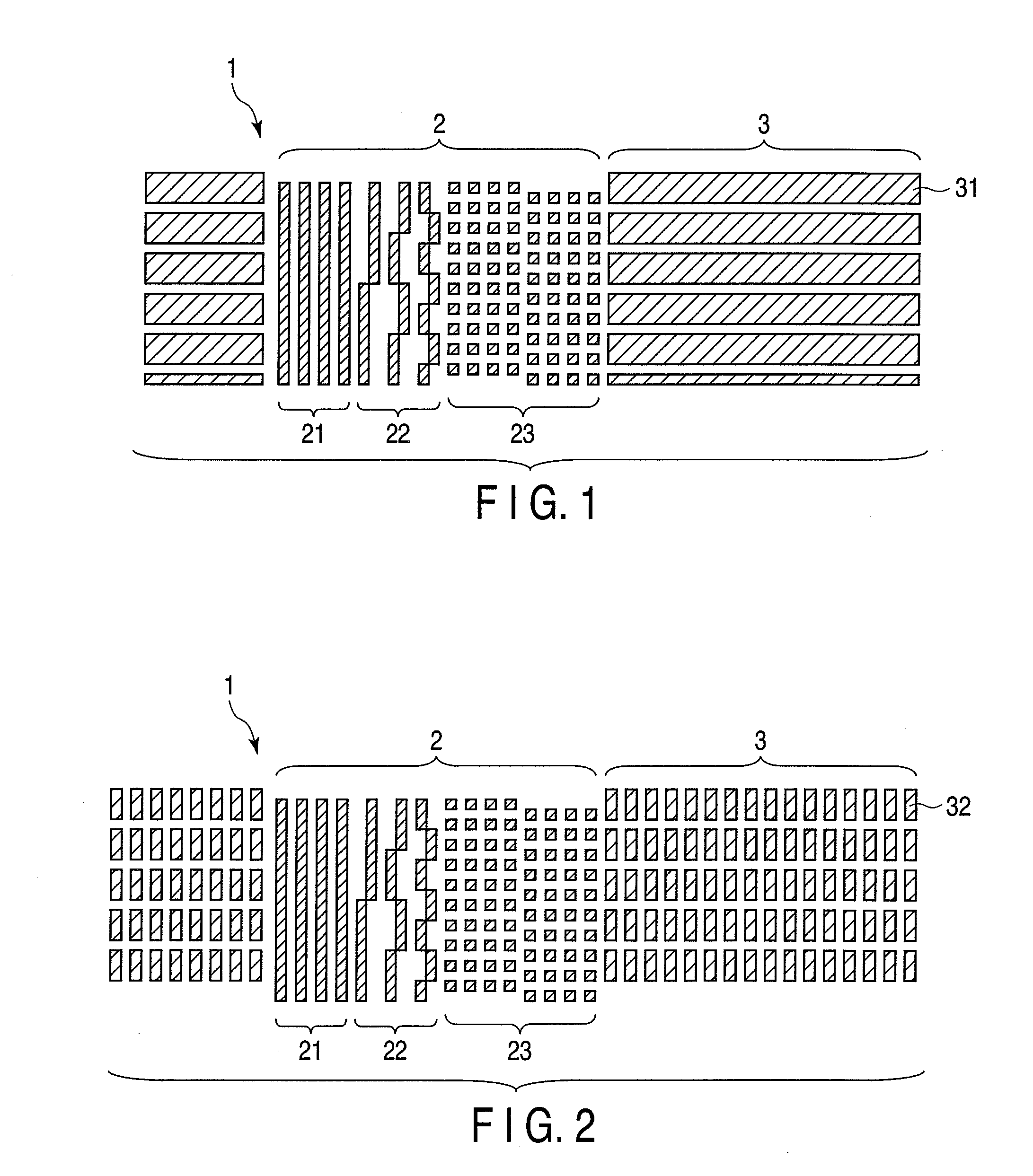

Method of manufacturing magnetic recording medium

InactiveUS20100000966A1Excellent magnetic propertiesLow positioning accuracy requirementsDecorative surface effectsConductive/insulating/magnetic material on magnetic film applicationEngineeringRecording layer

According to one embodiment, a method of manufacturing a magnetic recording medium includes depositing a magnetic recording layer on a substrate, forming masks on areas corresponding to recording regions of the magnetic recording layer, partially etching the magnetic recording layer in areas not covered with the masks with an etching gas to form protrusions and recesses on the magnetic recording layer, modifying the magnetic recording layer remaining in the recesses with Ne gas to form non-recording regions, and forming a protecting film on an entire surface.

Owner:KK TOSHIBA

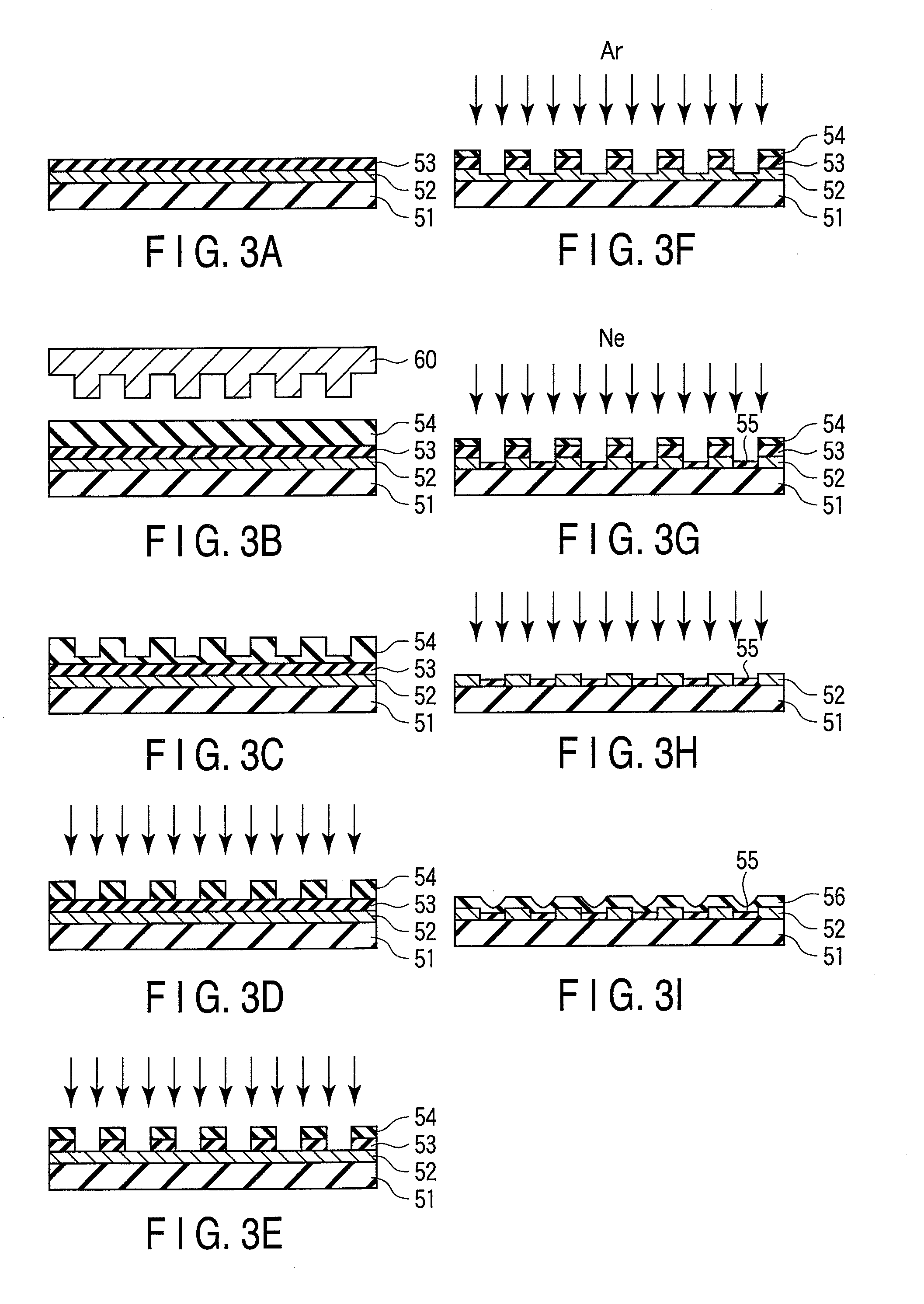

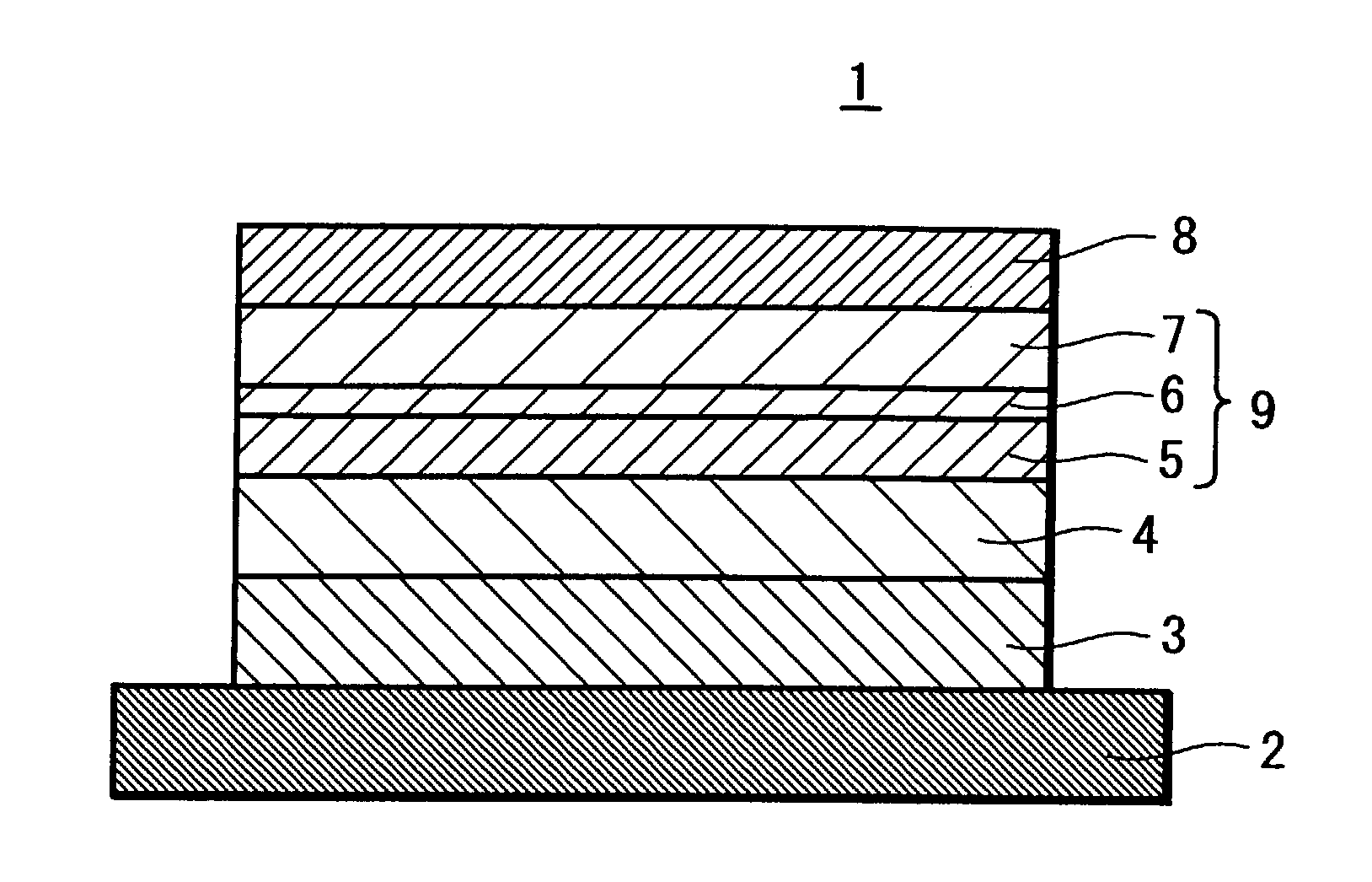

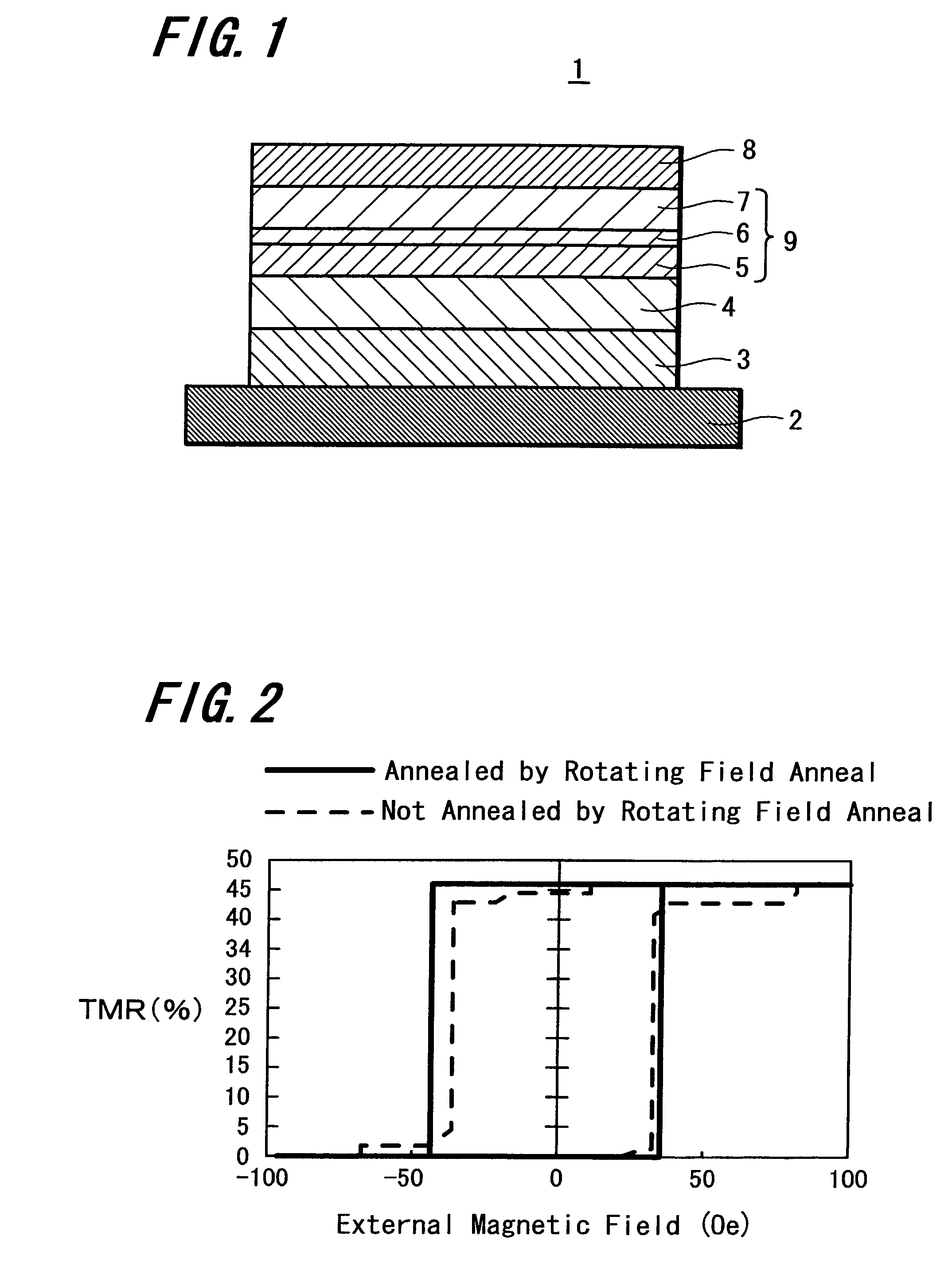

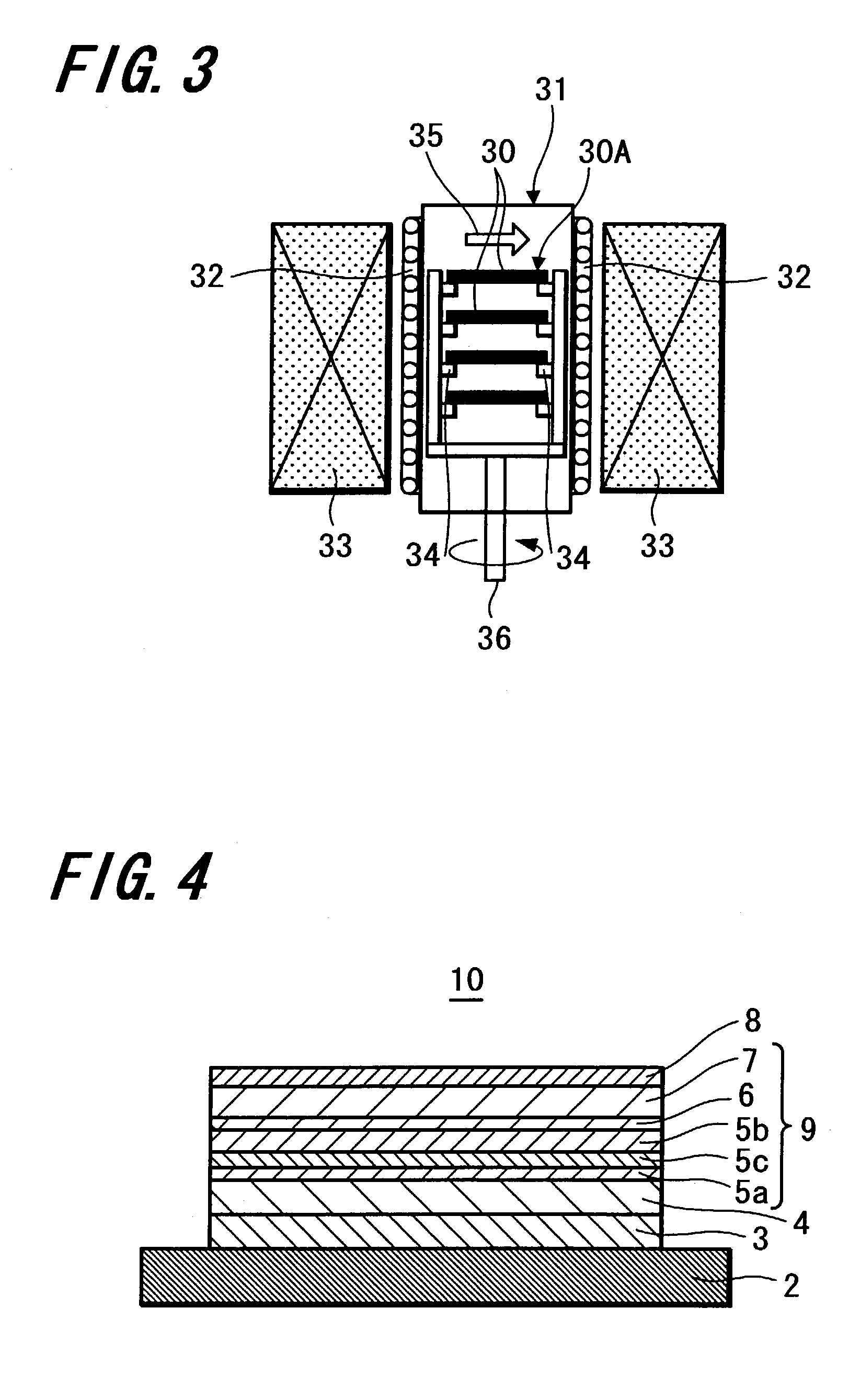

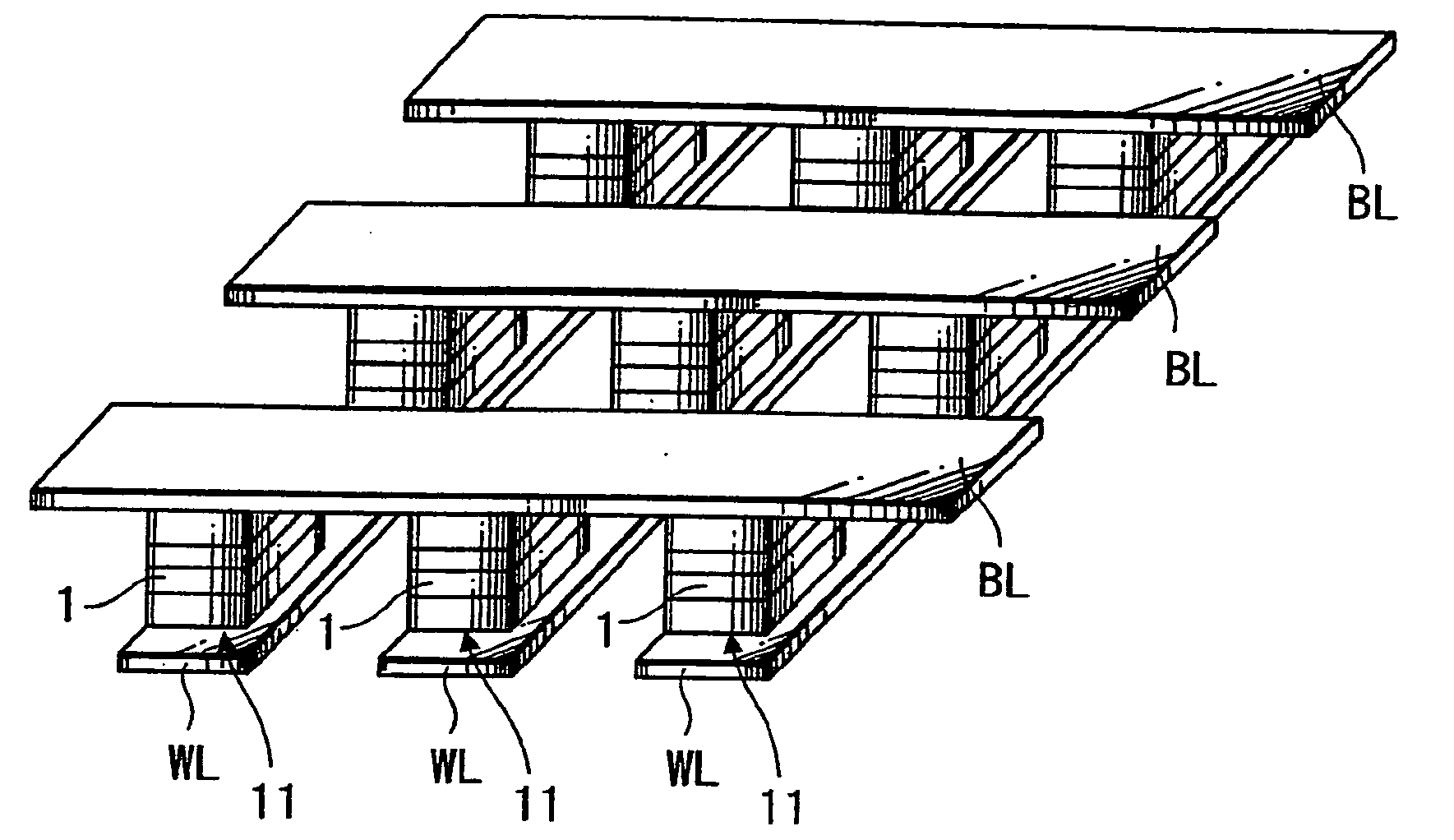

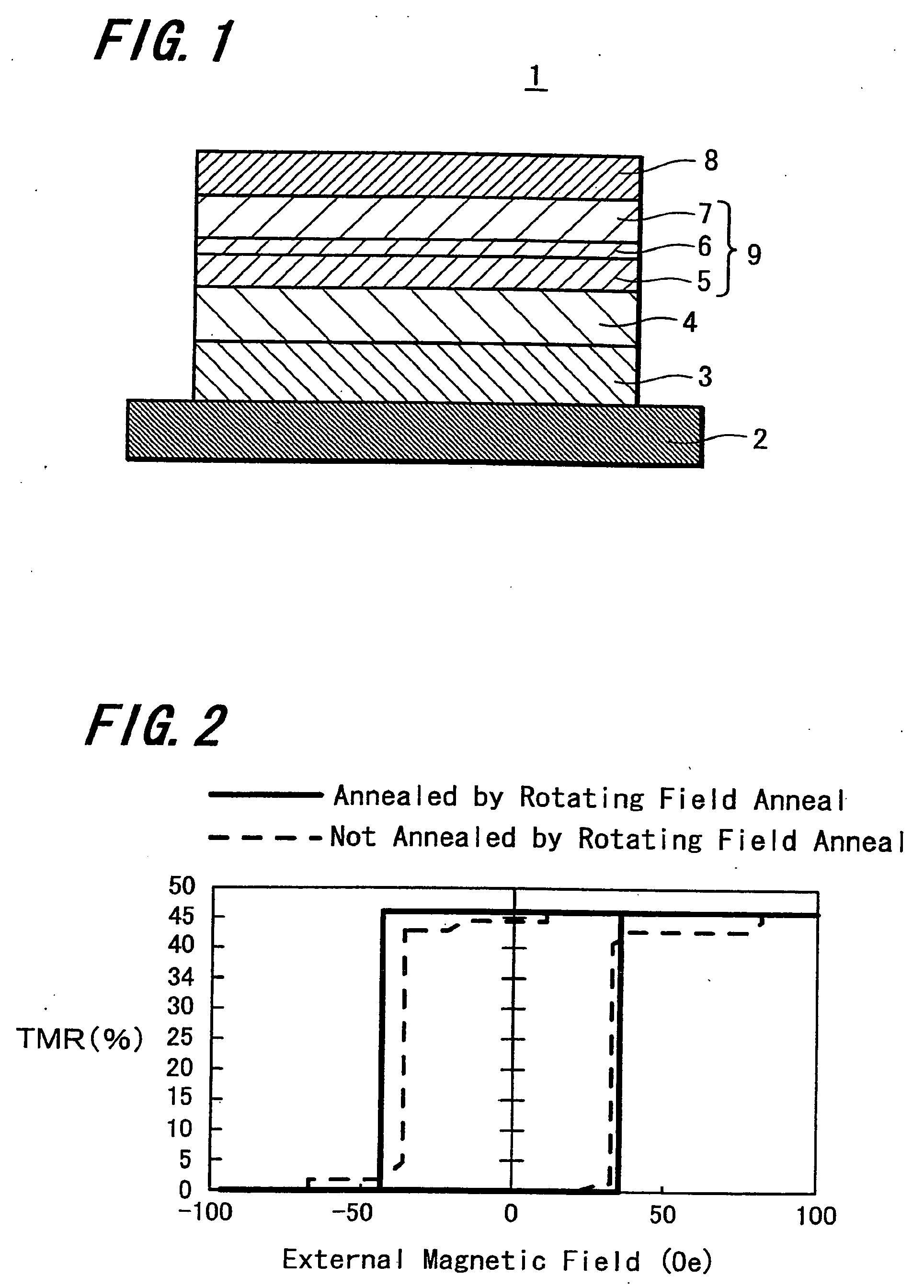

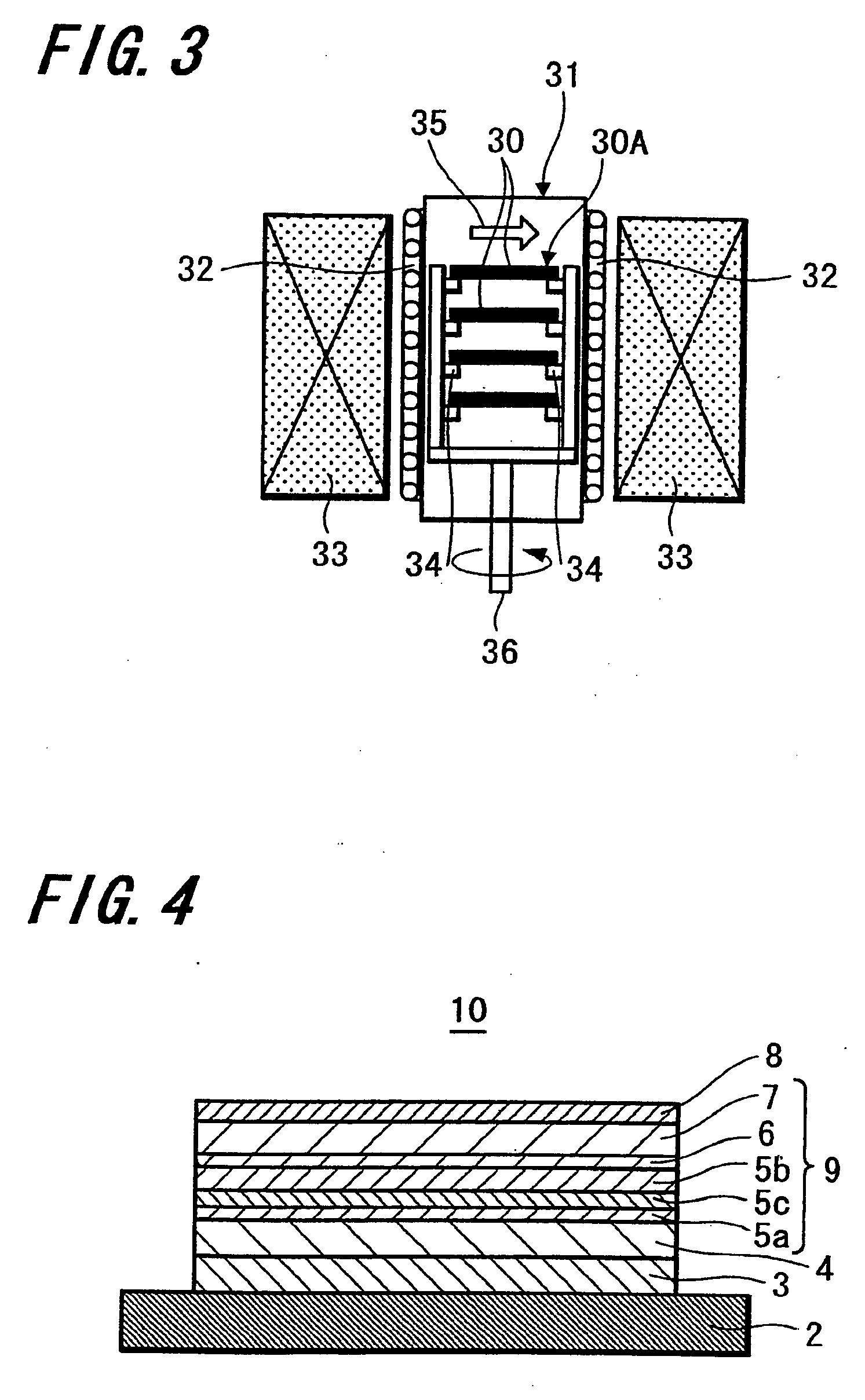

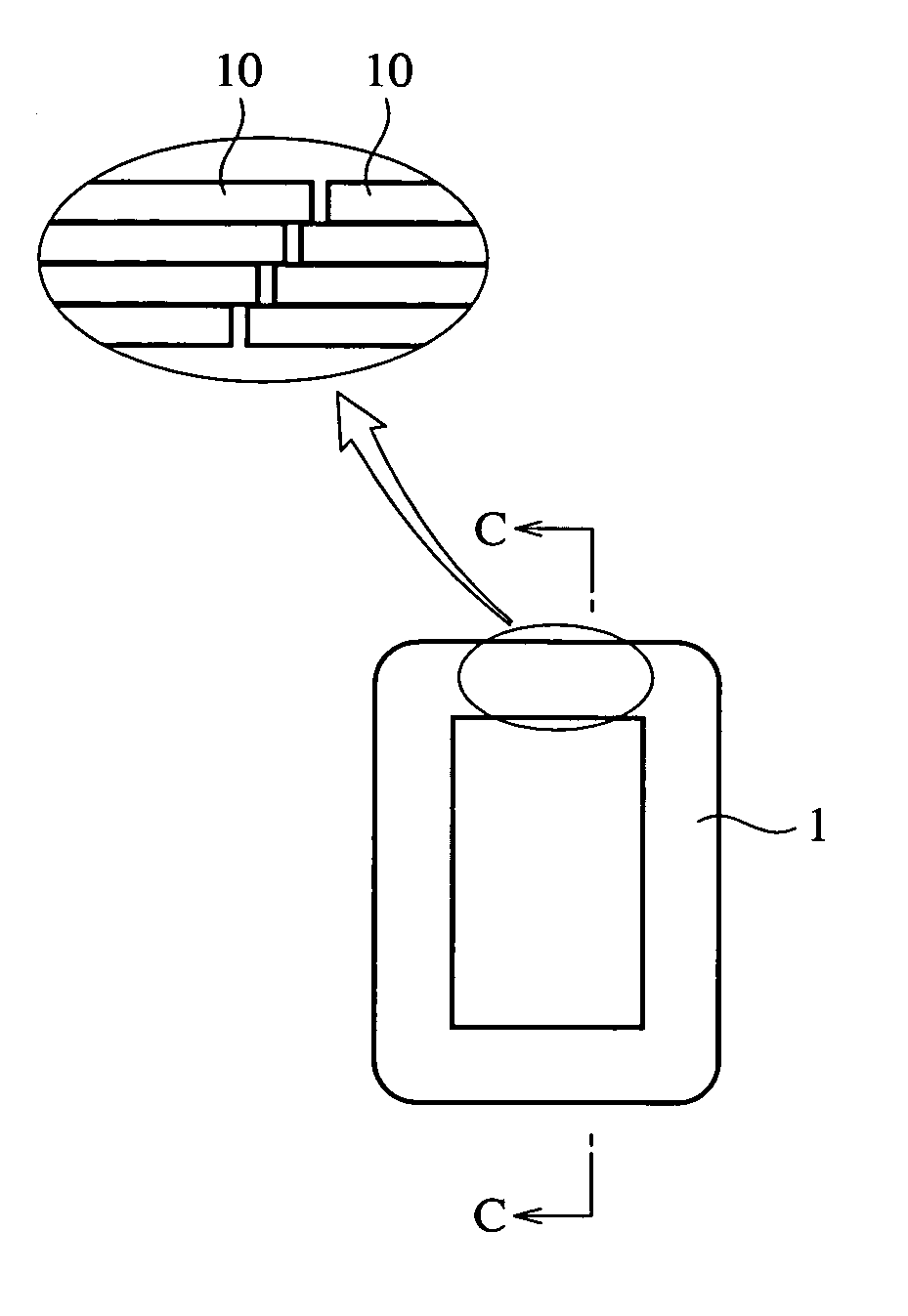

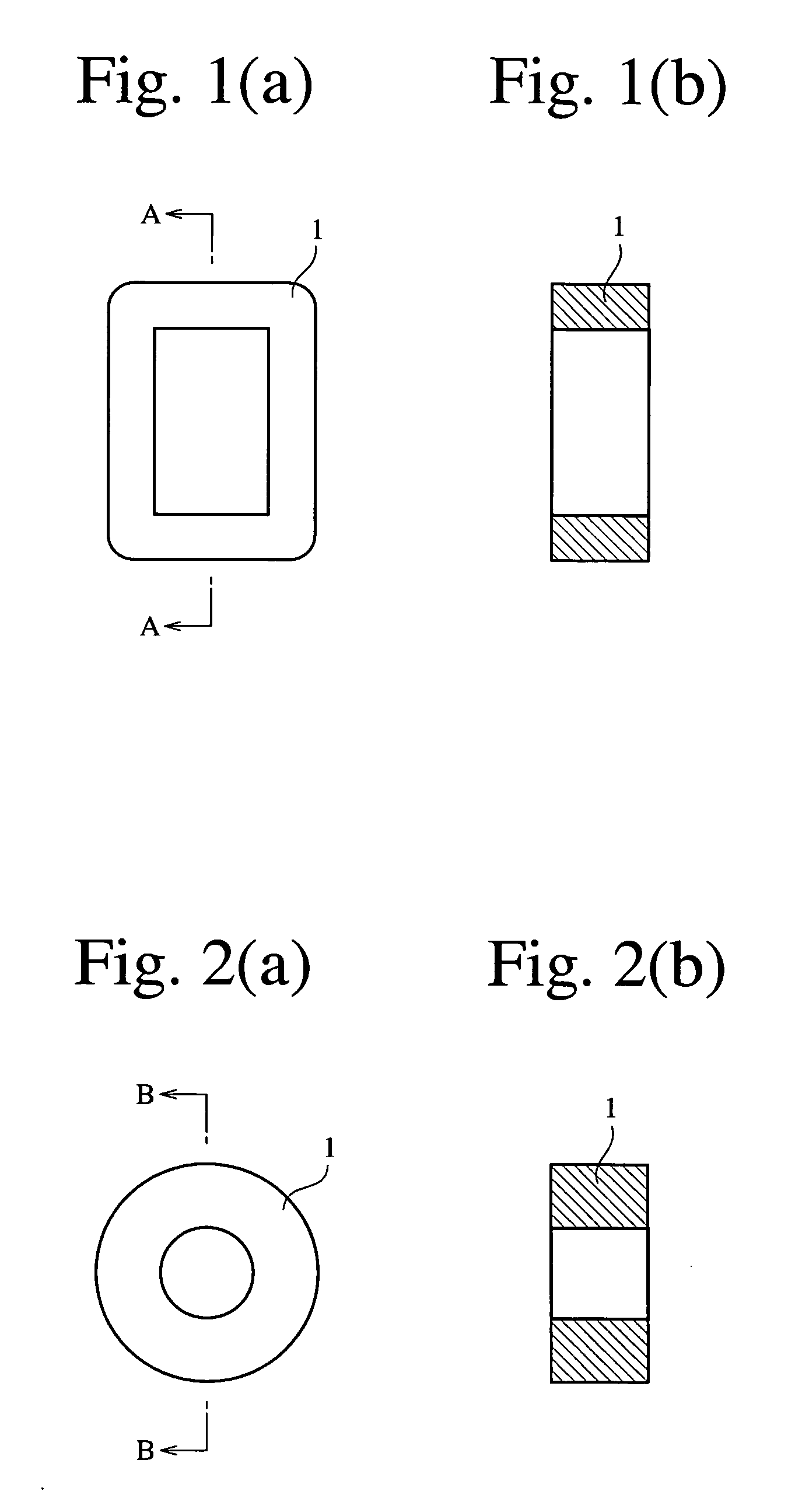

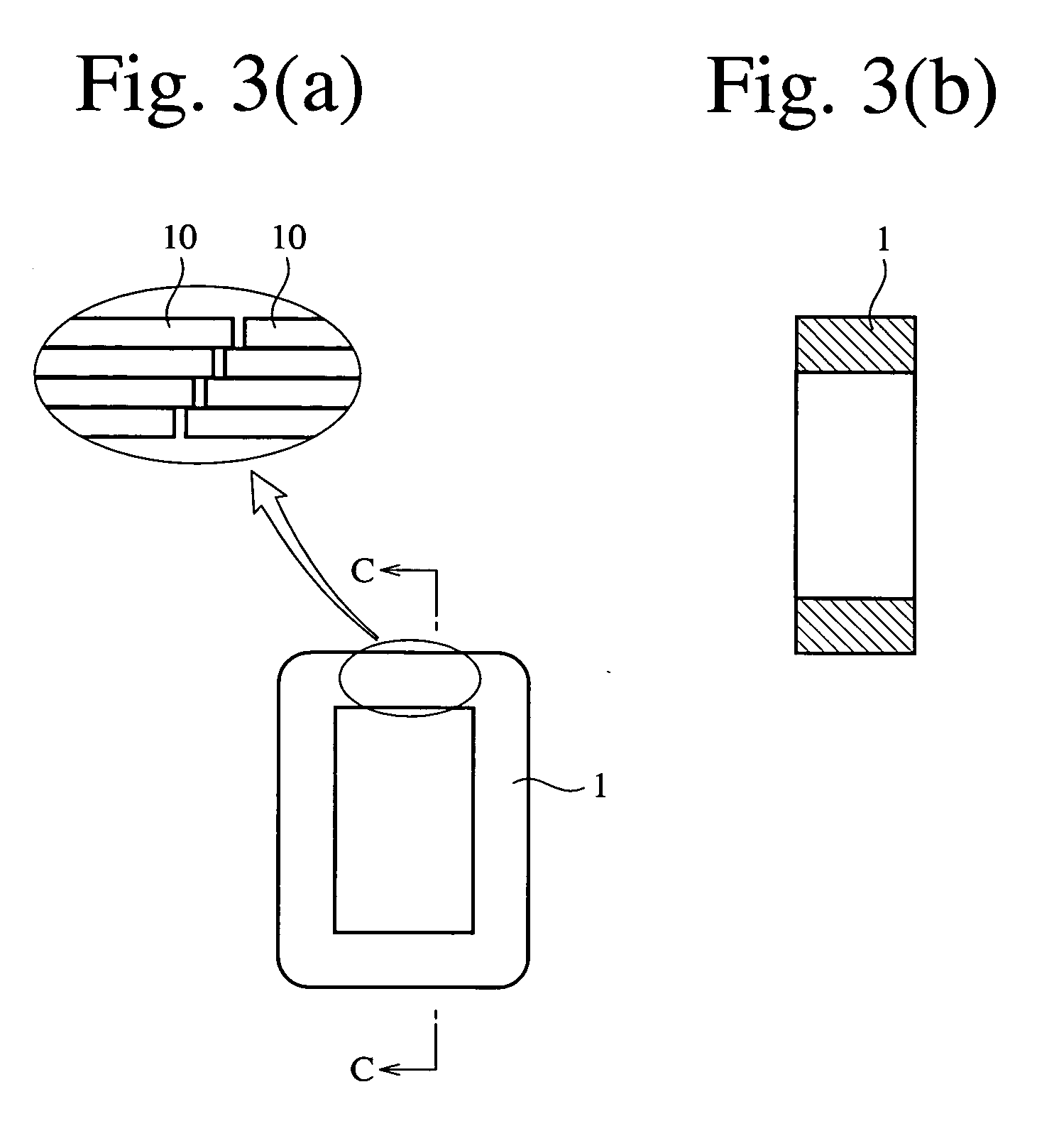

Magnetoresistive effect element, magnetic memory device and manufacturing method of magnetoresistive effect element and magnetic memory device

ActiveUS7026671B2Improve rectangle propertyImprove coercive forceNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

A magnetoresistive effect element (1) has an arrangement in which a pair of ferromagnetic material layers (magnetization fixed layer (5) and magnetization free layer (7)) is opposed to each other through an intermediate layer (6) to obtain a magnetoresistive change by causing a current to flow in the direction perpendicular to the layer surface and in which the ferromagnetic material layers are annealed by anneal including rotating field anneal and the following static field anneal. A magnetic memory device comprises this magnetoresistive effect element (1) and bit lines and word lines sandwiching the magnetoresistive effect element (1) in the thickness direction. When the magnetoresistive effect element (1) and the magnetic memory device are manufactured, the ferromagnetic material layers (5, 7) are annealed by rotating field anneal and the following static field anneal. There are provided the magnetoresistive effect element that can obtain excellent magnetic characteristics by controlling magnetic anisotropies of the ferromagnetic material layers, the magnetic memory device including this magnetoresistive effect element and which may have excellent write characteristics, and methods for manufacturing these magnetoresistive effect element and magnetic memory device.

Owner:DEXERIALS CORP

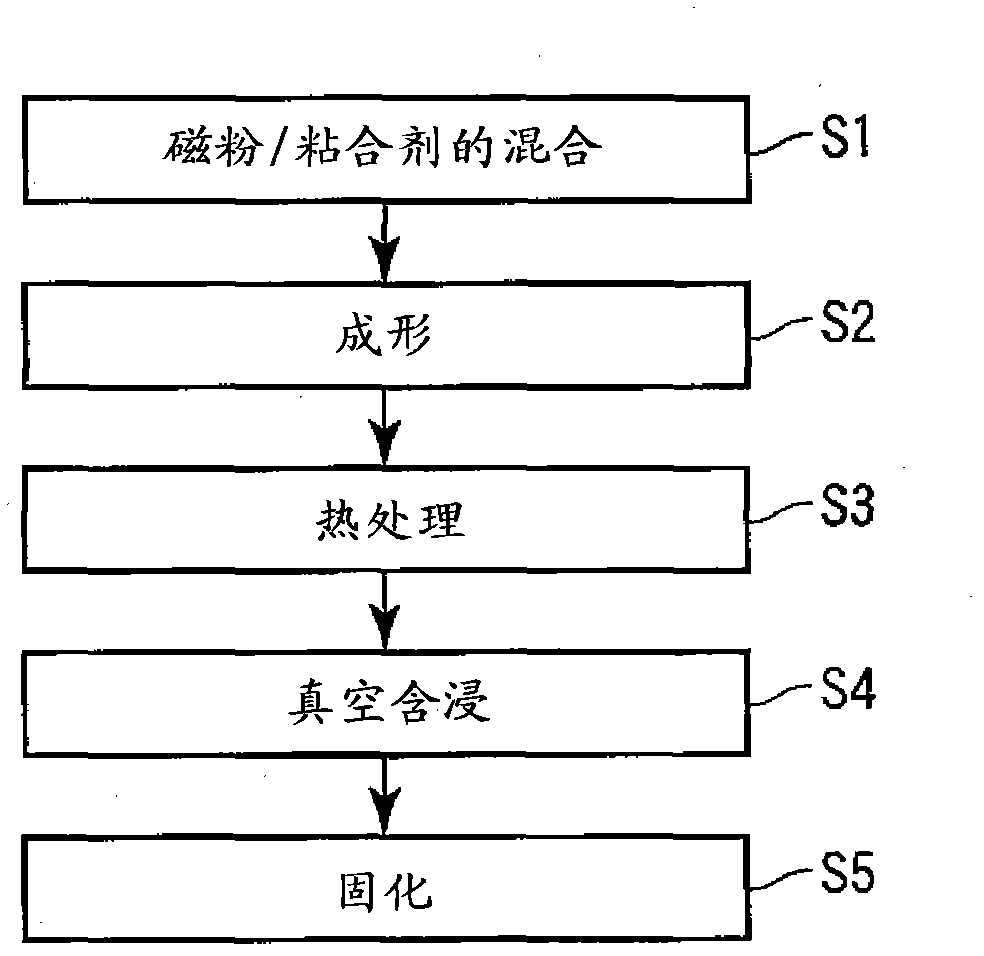

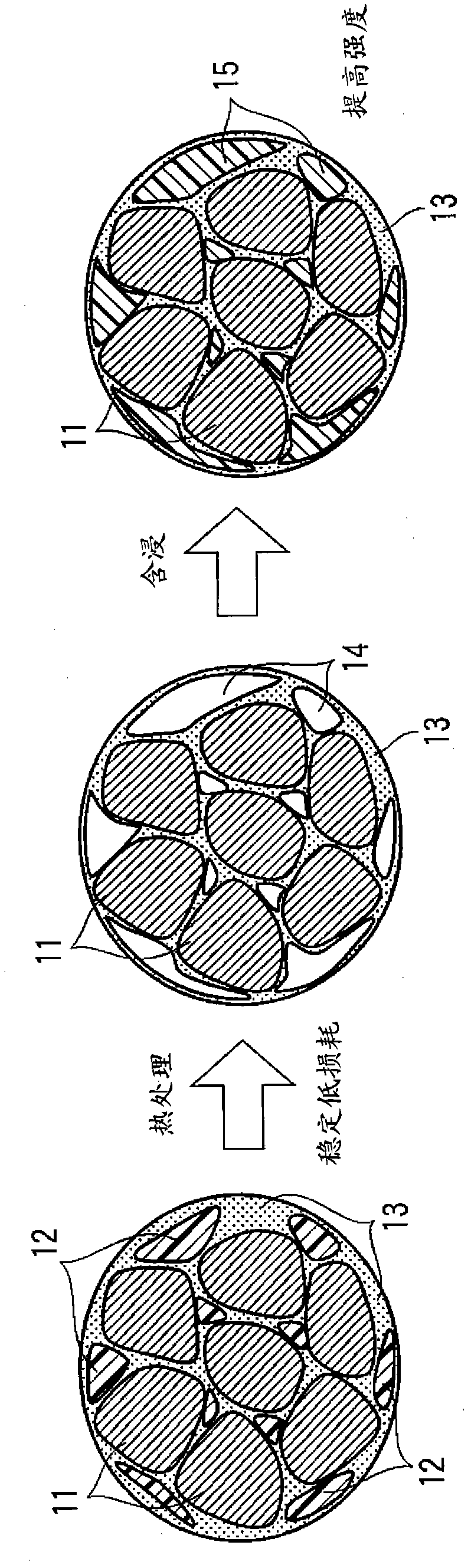

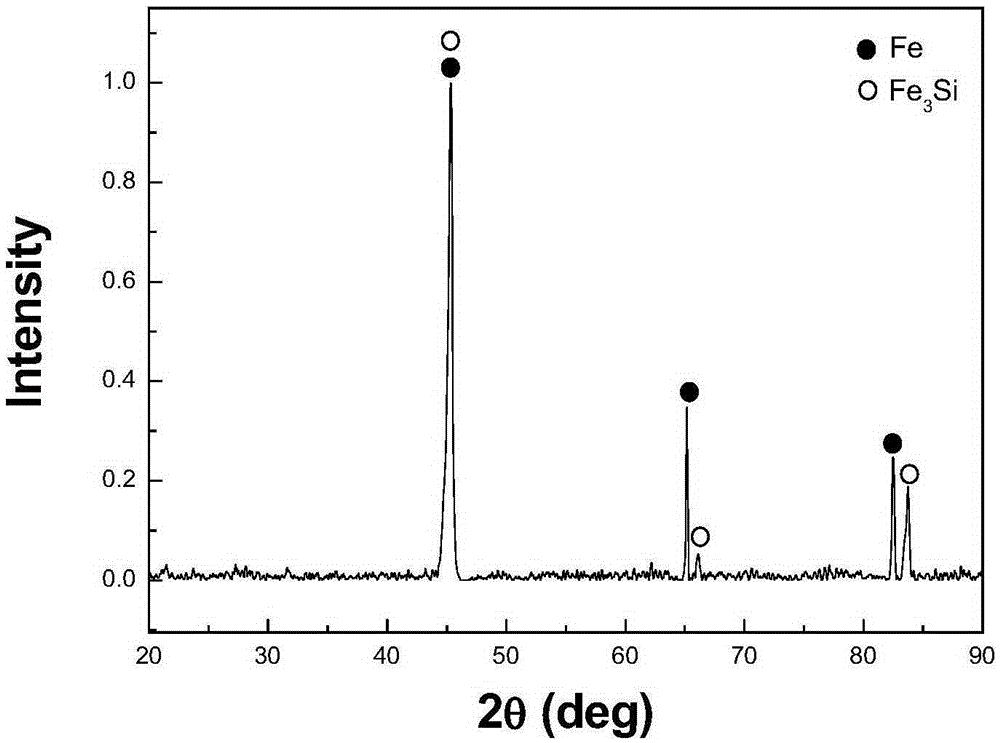

Composite magnetic material and method of manufacturing the same

InactiveCN102007549AExcellent magnetic propertiesEnsuring practical strengthTransportation and packagingMetal-working apparatusManufacturing cost reductionMetal particle

Provided is a composite magnetic material which provides superior magnetic properties such as magnetic permeability and core loss, and practical strength, and a manufacturing method for a composite magnetic material which improves the moldability of the dust core and lowers manufacturing costs. A composite magnetic material for an inductor which combines soft magnetic metal particles with a non-magnetic material and a manufacturing method thereof, wherein a first binder composed of a non-magnetic material is mixed at a specific ratio in soft magnetic metal particles; the mixture is molded into the desired shape; the molded body is heat treated under specified conditions; and a second binder composed of one or two or more materials selected from the group composed of silicone resin, organic resin, and water glass is impregnated under the specified conditions into the molded body after the heat treatment.

Owner:TOHO ZINC

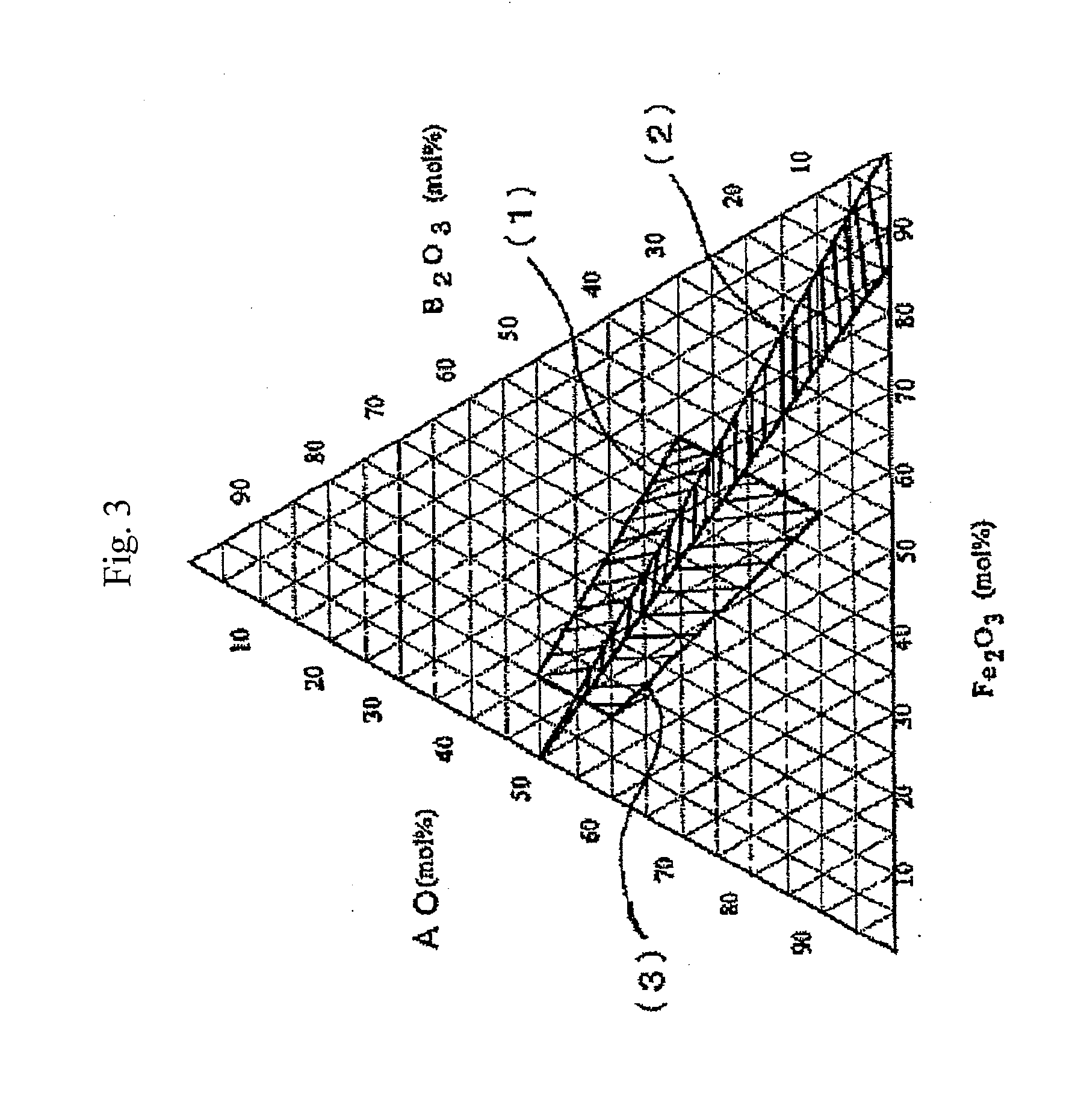

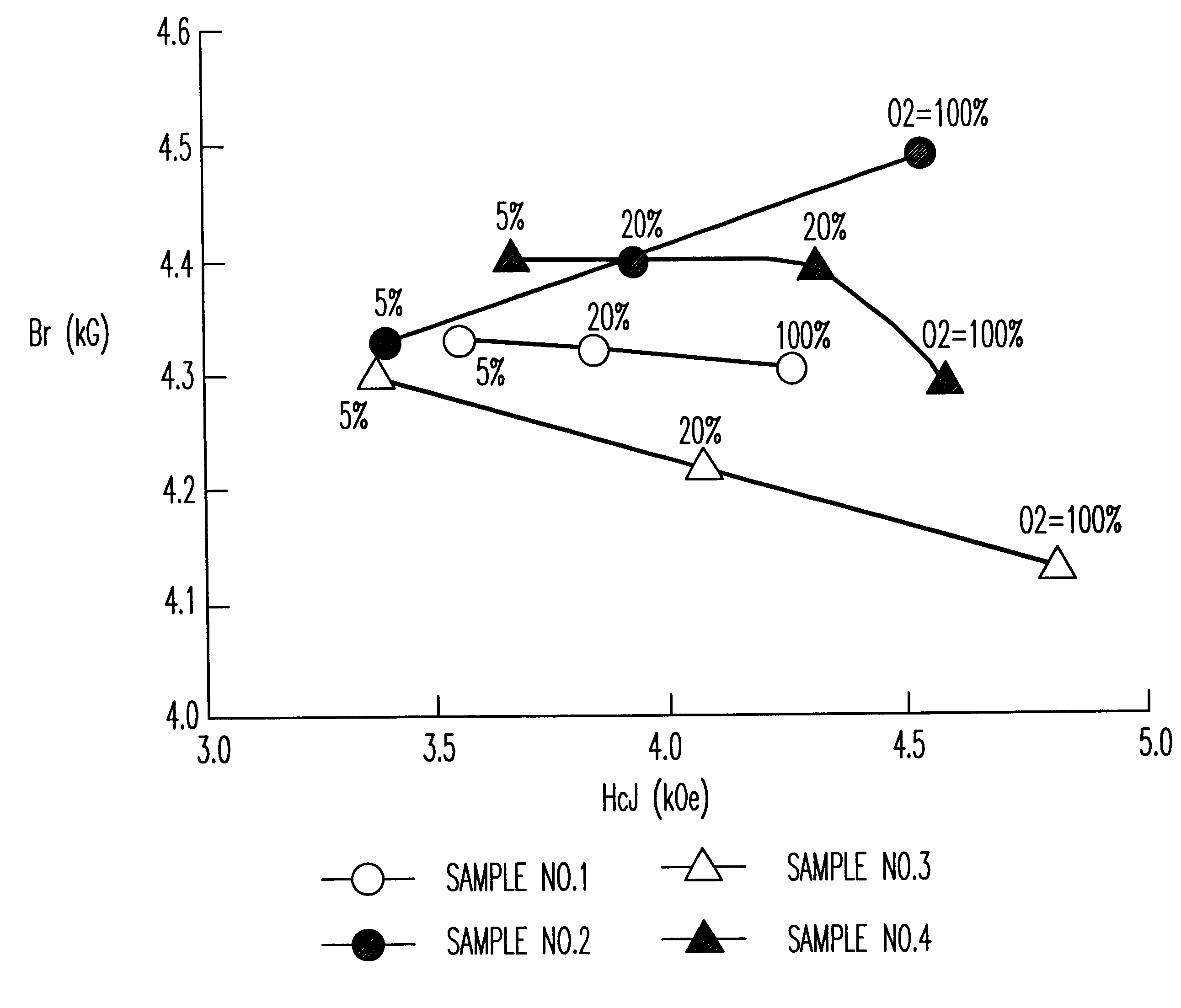

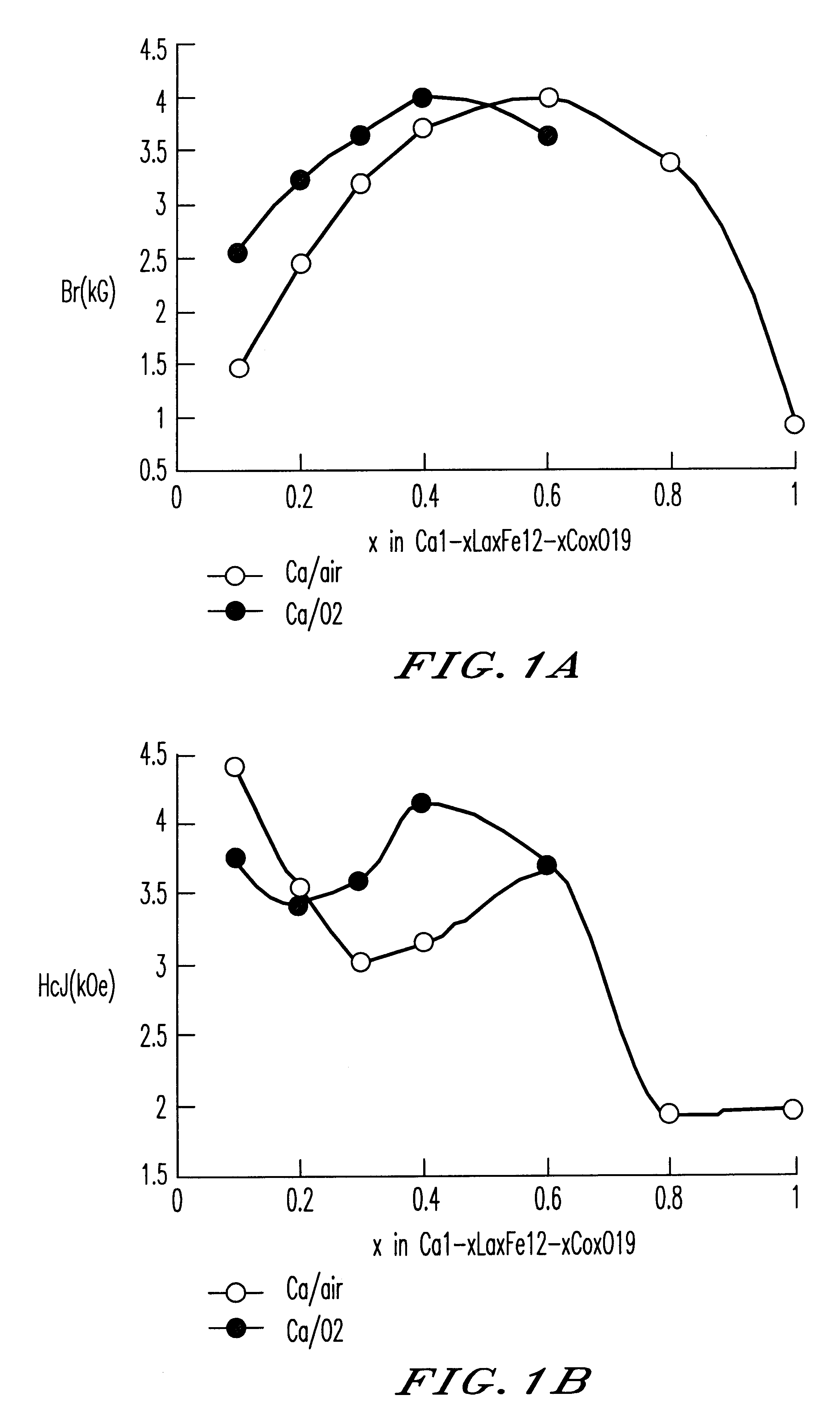

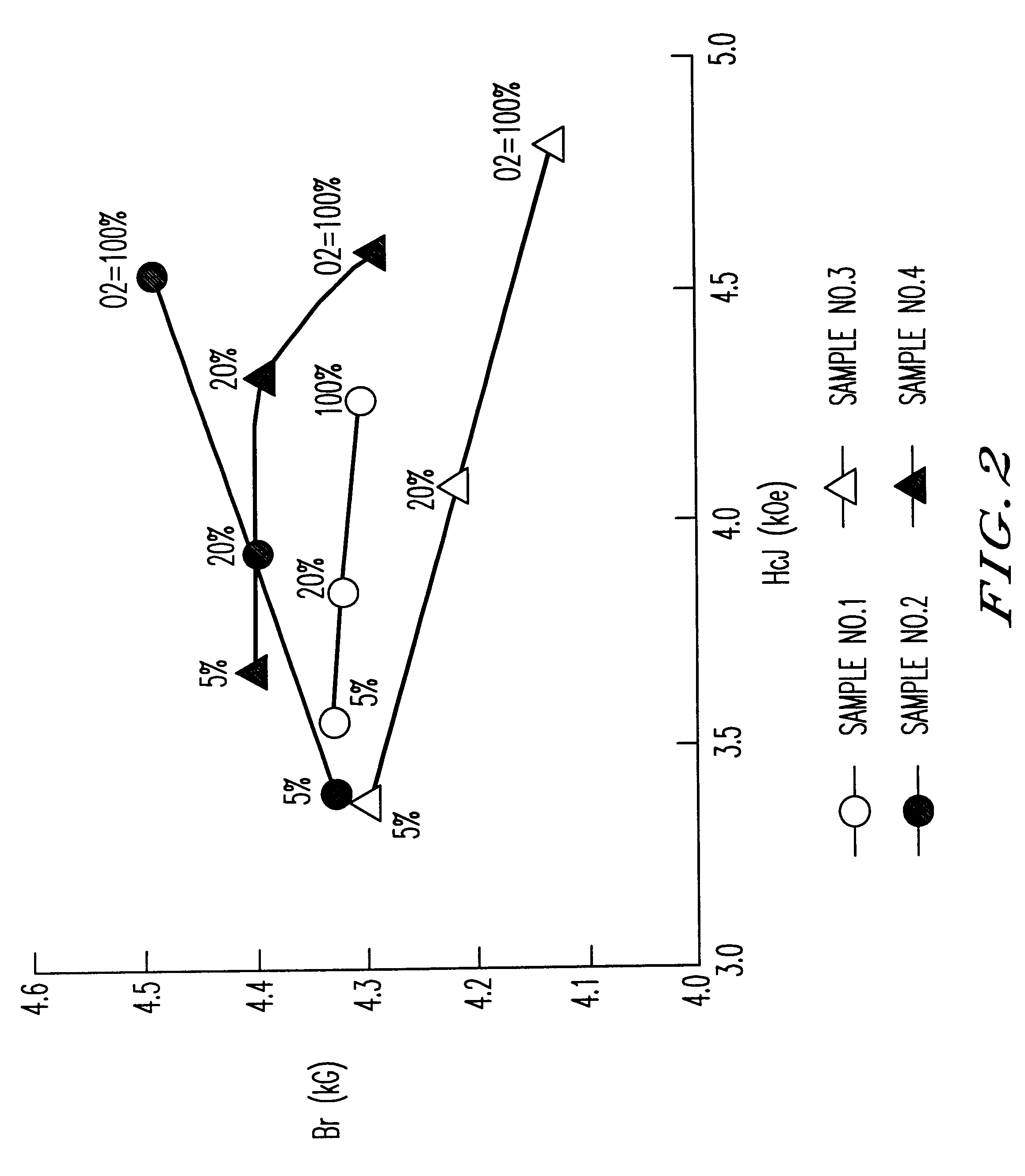

Oxide magnetic material, ferrite particles, bonded magnet, sintered magnet, process for producing the same, and magnetic recording medium

InactiveUS6402980B1Excellent magnetic propertiesIncrease valueMagnetic materials for record carriersInorganic material magnetismRare-earth elementSintered magnets

The present invention provides an oxide magnetic material, which includes a primary phase of a hexagonal ferrite containing metallic elements Ca, R, Fe and M, where M represents at least one element selected from the group including Co, Ni and Zn, and R represents at least one element selected from the group including Bi and rare earth elements including Y, with La being essentially included in R; wherein the proportions of the metallic elements Ca, R, Fe and M with respect to the total amount of the metallic elements are from 1 to 13 atomic % for Ca, from 0.05 to 10 atomic % for R, from 80 to 95 atomic % for Fe, and from 1 to 7 atomic % for M. The present invention also provides ferrite particles, a bonded magnet, a sintered magnet, a process for producing them, and a magnetic recording medium, which contain the oxide magnetic material.

Owner:TDK CORPARATION

Core-shell type magnetic particle and high-frequency magnetic material

ActiveUS20080220231A1Excellent magnetic propertiesSatisfactory characteristicShielding materialsNanomagnetismComposite oxideMagnetic powder

A core-shell type magnetic particle comprises magnetic metal particle and an oxide coating layer formed on the surface of the magnetic metal particle. The magnetic metal particle contains a magnetic metal containing at least one selected from the group consisting of Fe, Co and Ni, a nonmagnetic metal and at least one element selected from carbon and nitrogen. The oxide coating layer is constituted of an oxide or a composite oxide containing the nonmagnetic metal which is one of the constituents of the magnetic metal particle.

Owner:KK TOSHIBA

Magnetoresistive effect element, magentic memory device and manufacturing method of magnetoresistive effect element and magnetic memory device

InactiveUS20060187703A1Excellent magnetic propertiesExcellent write characteristicNanostructure applicationNanomagnetismBit lineMagnetic anisotropy

A magnetoresistive effect element (1) has an arrangement in which a pair of ferromagnetic material layers (magnetization fixed layer (5) and magnetization free layer (7)) is opposed to each other through an intermediate layer (6) to obtain a magnetoresistive change by causing a current to flow in the direction perpendicular to the layer surface and in which the ferromagnetic material layers are annealed by anneal including rotating field anneal and the following static field anneal. A magnetic memory device comprises this magnetoresistive effect element (1) and bit lines and word lines sandwiching the magnetoresistive effect element (1) in the thickness direction. When the magnetoresistive effect element (1) and the magnetic memory device are manufactured, the ferromagnetic material layers (5, 7) are annealed by rotating field anneal and the following static field anneal. There are provided the magnetoresistive effect element that can obtain excellent magnetic characteristics by controlling magnetic anisotropies of the ferromagnetic material layers, the magnetic memory device including this magnetoresistive effect element and which may have excellent write characteristics, and methods for manufacturing these magnetoresistive effect element and magnetic memory device.

Owner:SONY CORP

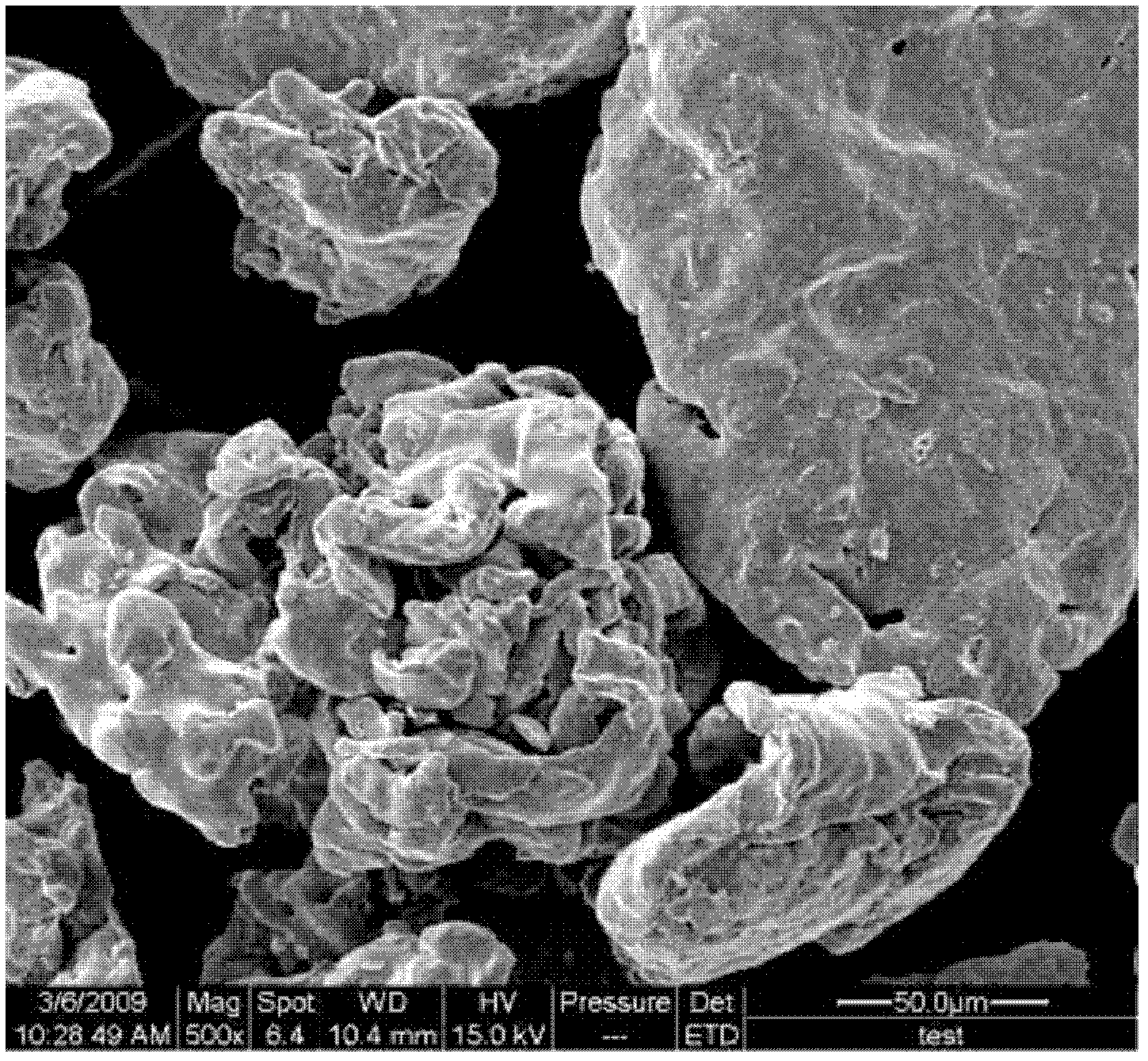

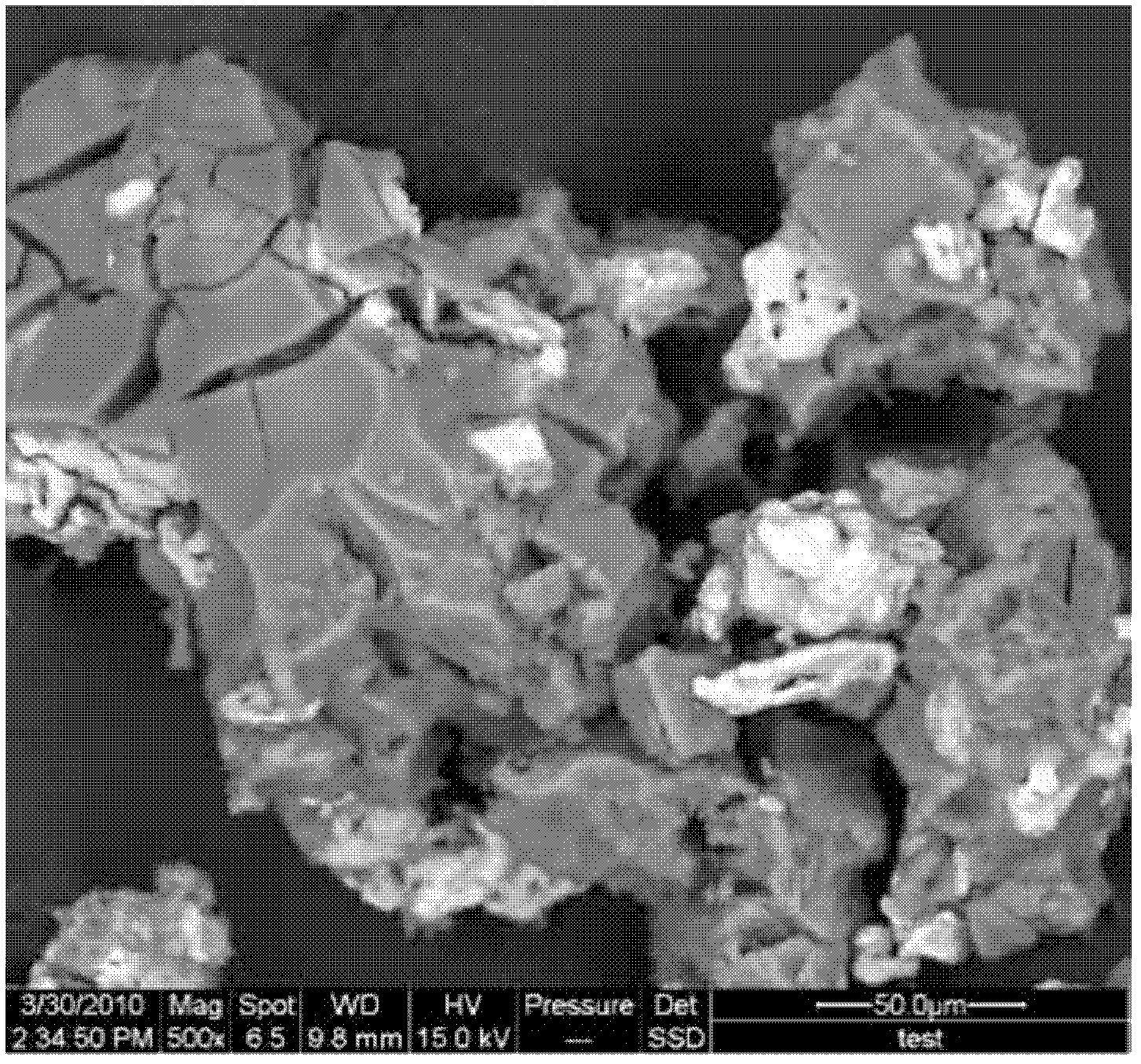

Iron nitride powder, method of manufacturing the same, and magnetic recording medium

InactiveUS20090087688A1Excellent magnetic propertiesSuited to high-density recordingPretreated surfacesRecord information storageMischmetalIron nitride

An aspect of the present invention relates to an iron nitride powder. The iron nitride powder is comprised chiefly of Fe16N2 and comprises, on at least a portion of the powder surface, a coating layer comprising at least one element selected from the group consisting of rare earth metal elements, aluminum, and silicon, and cobalt-containing ferrite having a composition denoted by (CoxFe1−x)Fe2O4, wherein 0<x≦1. The present invention further relates to a method of manufacturing iron nitride powders and a magnetic recording medium comprising the iron nitride powder.

Owner:FUJIFILM CORP

Nonoriented electromagnetic steel sheet

InactiveUS20040149355A1Reduce regionHigh magnetic flux densityInorganic material magnetismFurnace typesSheet steelElectrical steel

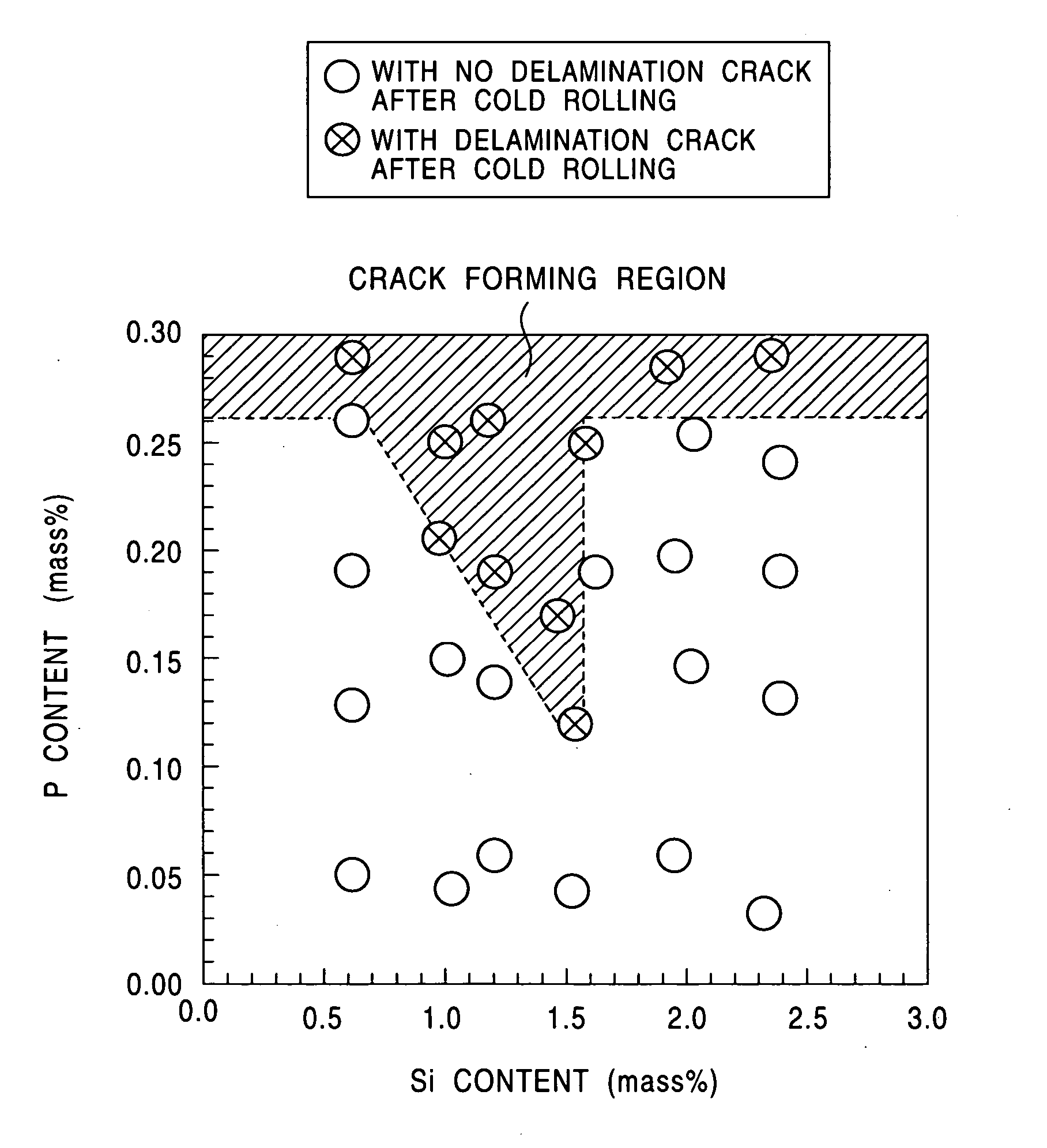

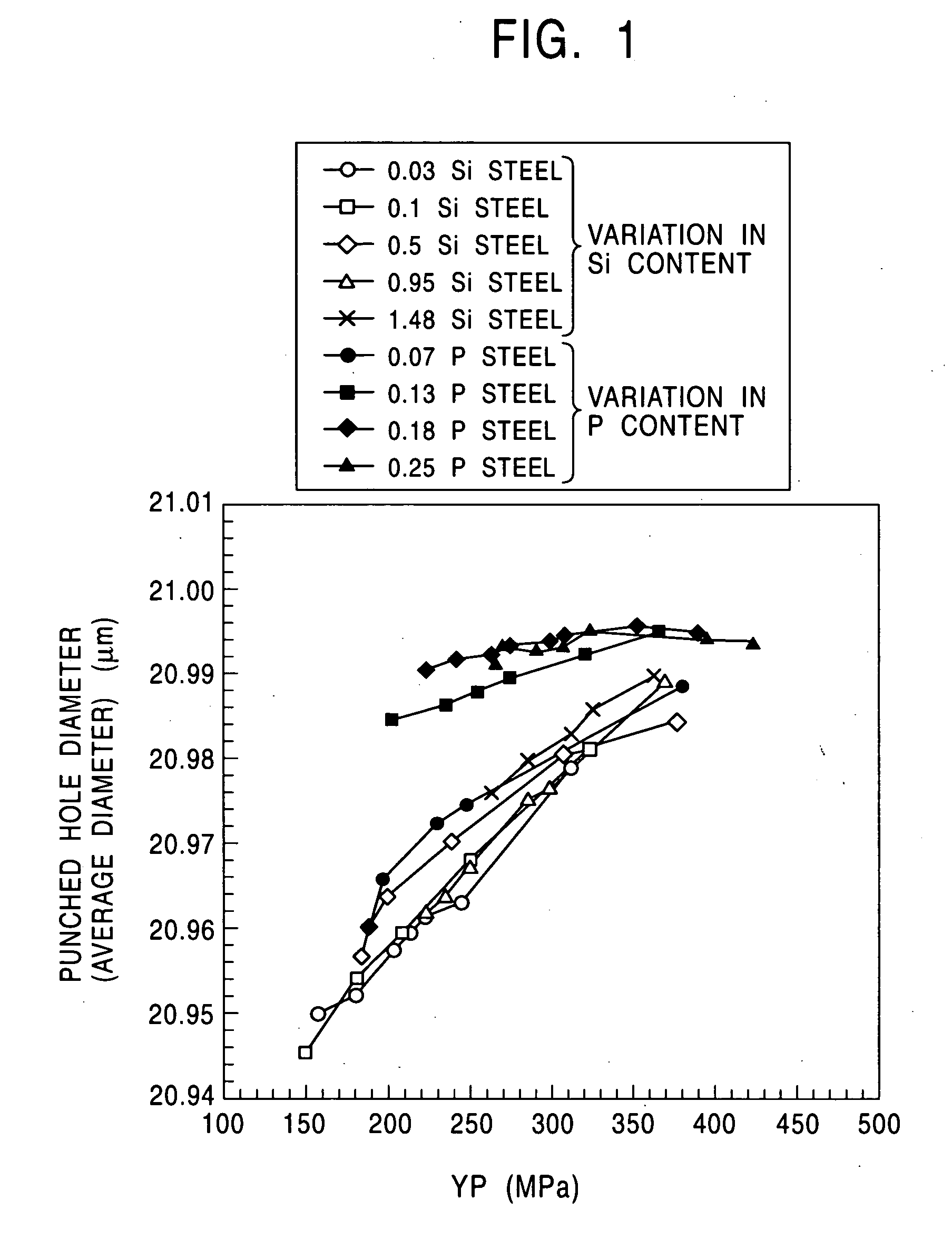

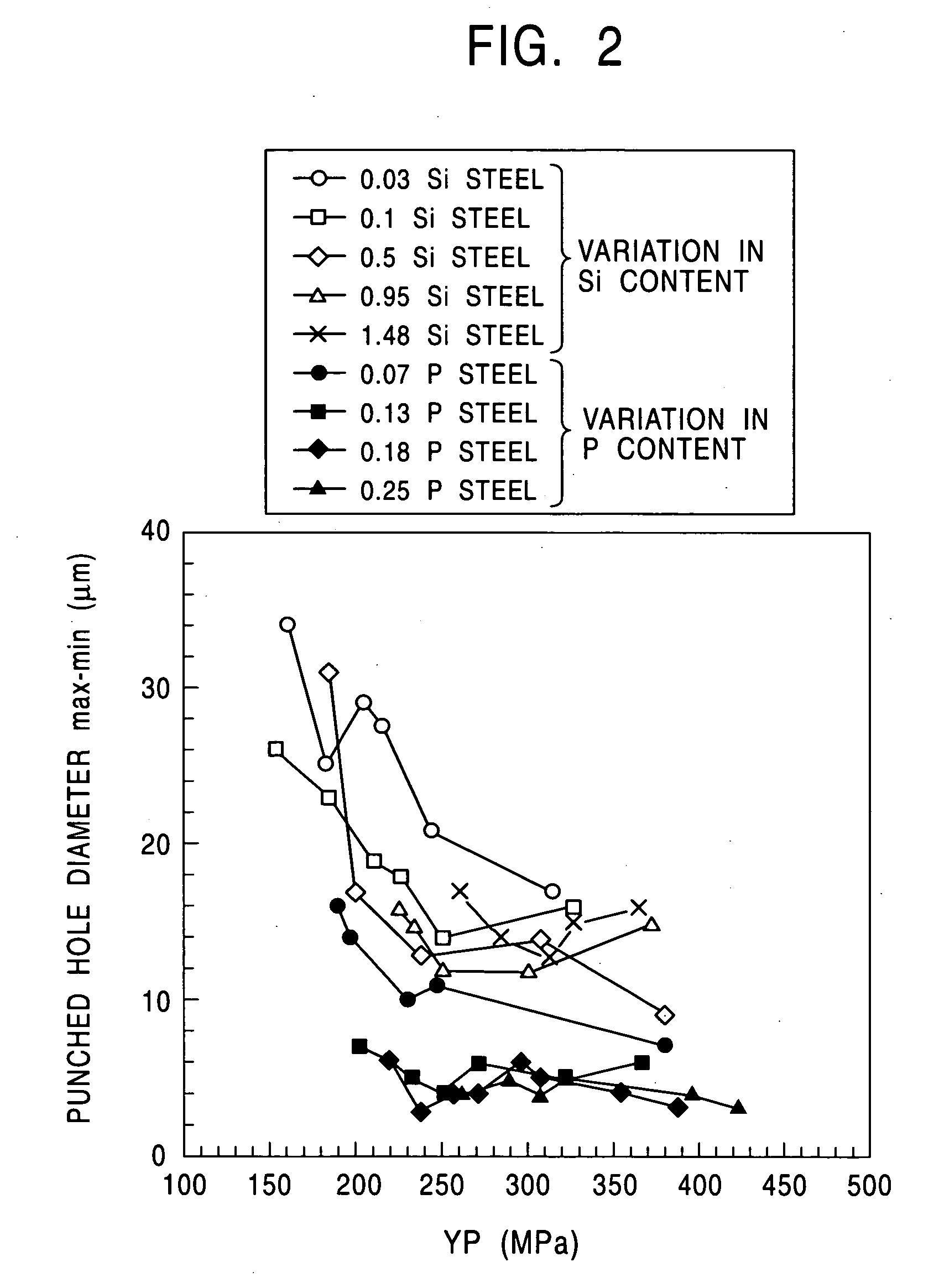

The present invention provides a non-oriented electrical steel sheet containing: 0-0.010% of C; at least one of Si and Al in a total amount of 0.03% to 0.5%, or more than 0.5% to 2.5%; 0.5% or less of Mn; 0.10% or more to 0.26% or less of P; 0.015% or less of S; and 0.010% or less of N, on a mass percentage basis, wherein the non-oriented electrical steel sheet has excellent dimensional accuracy during a punching step. When the Si content is low, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and low core loss. When the Si content is medium or high, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and high strength.

Owner:JFE STEEL CORP

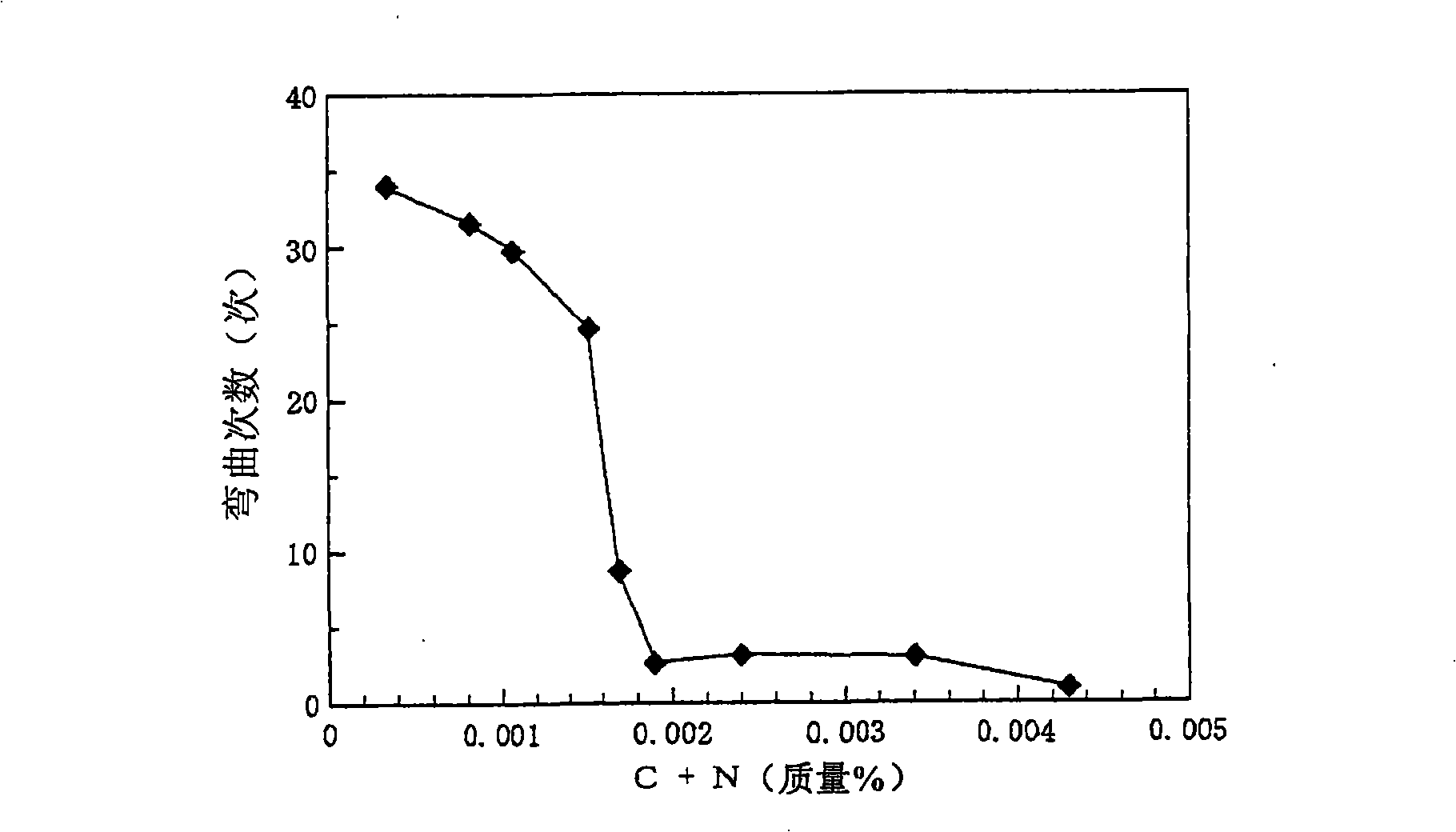

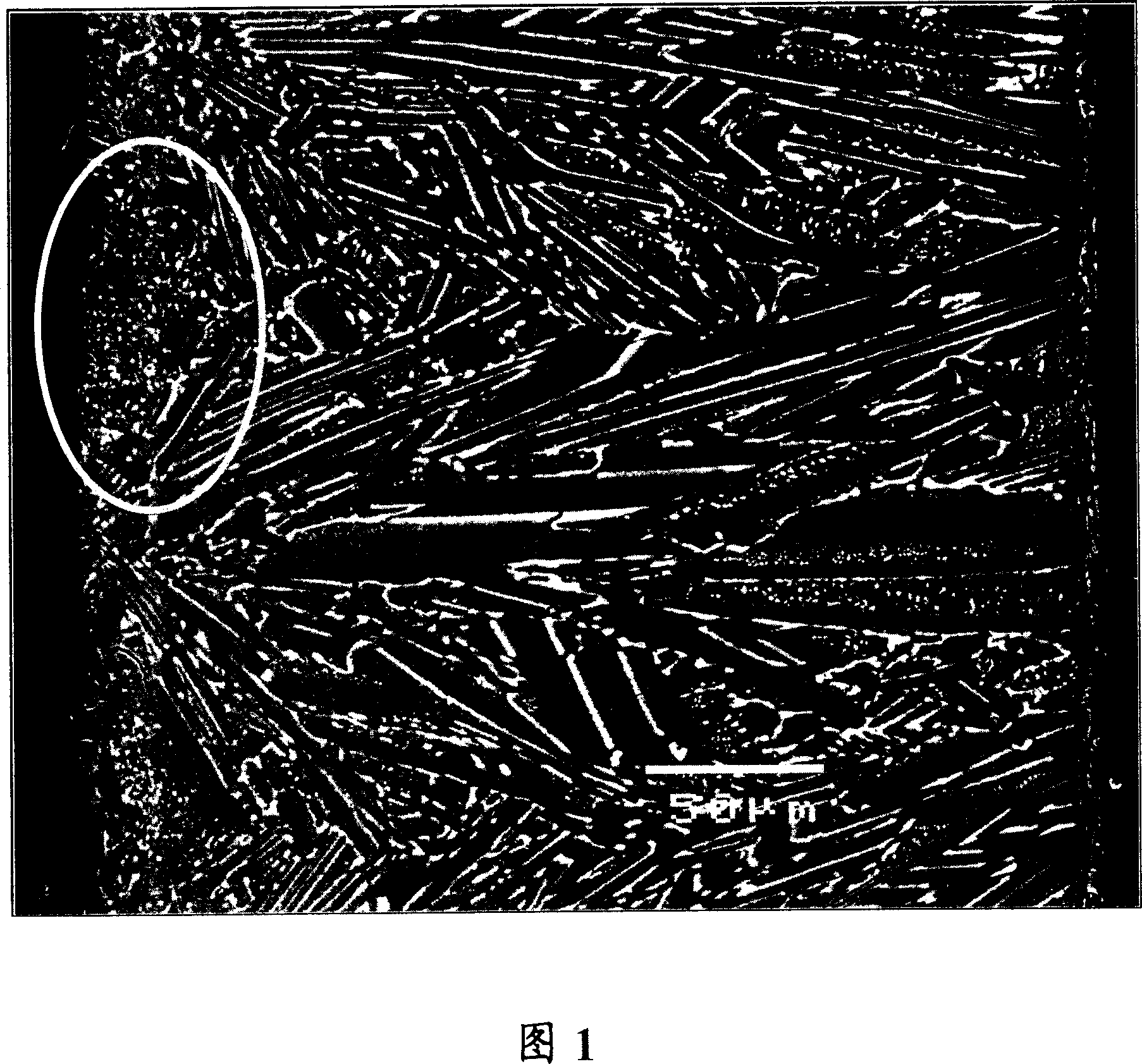

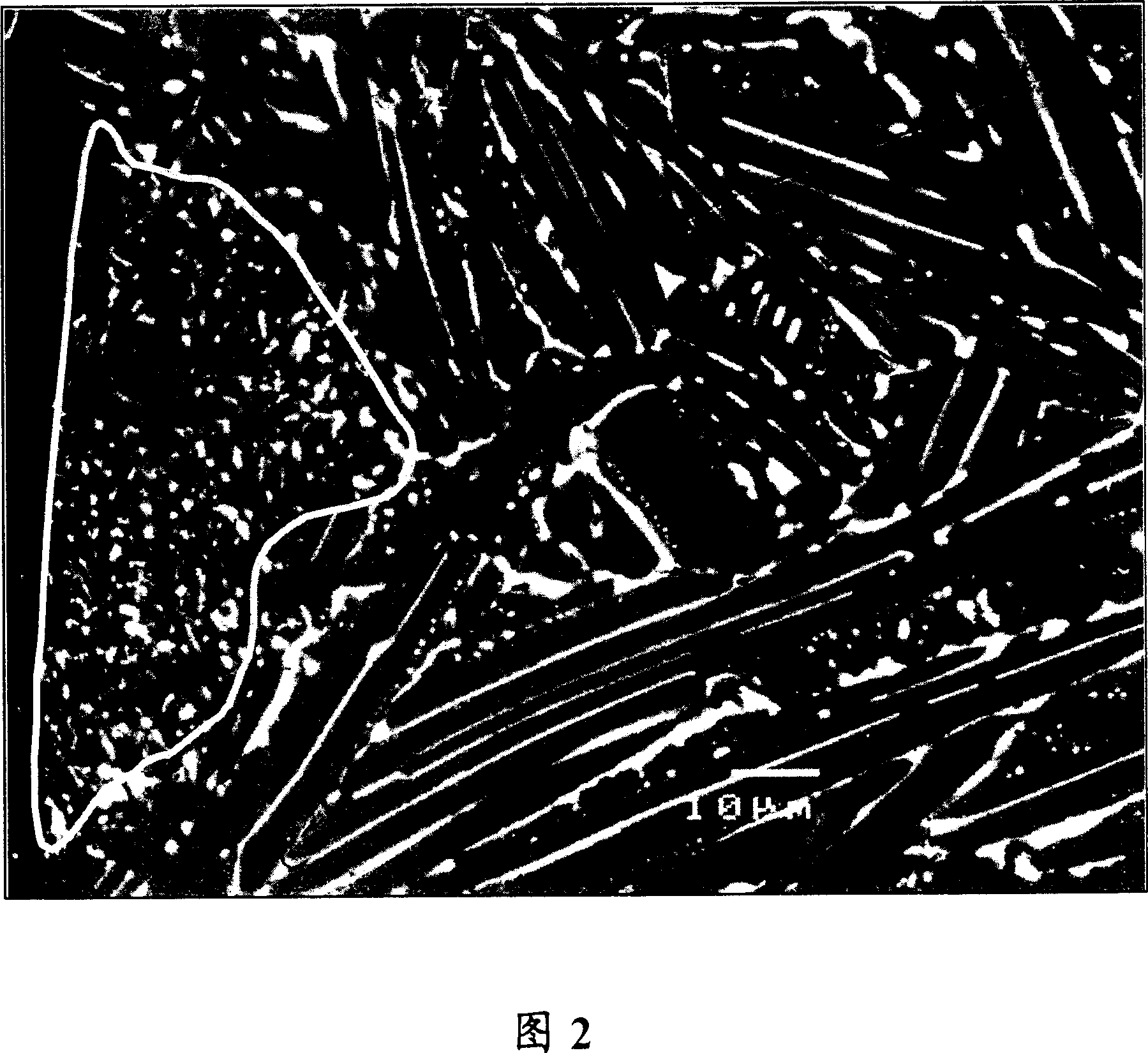

Soft magnetic thin strip, process for production of the same, magnetic parts, and amorphous thin strip

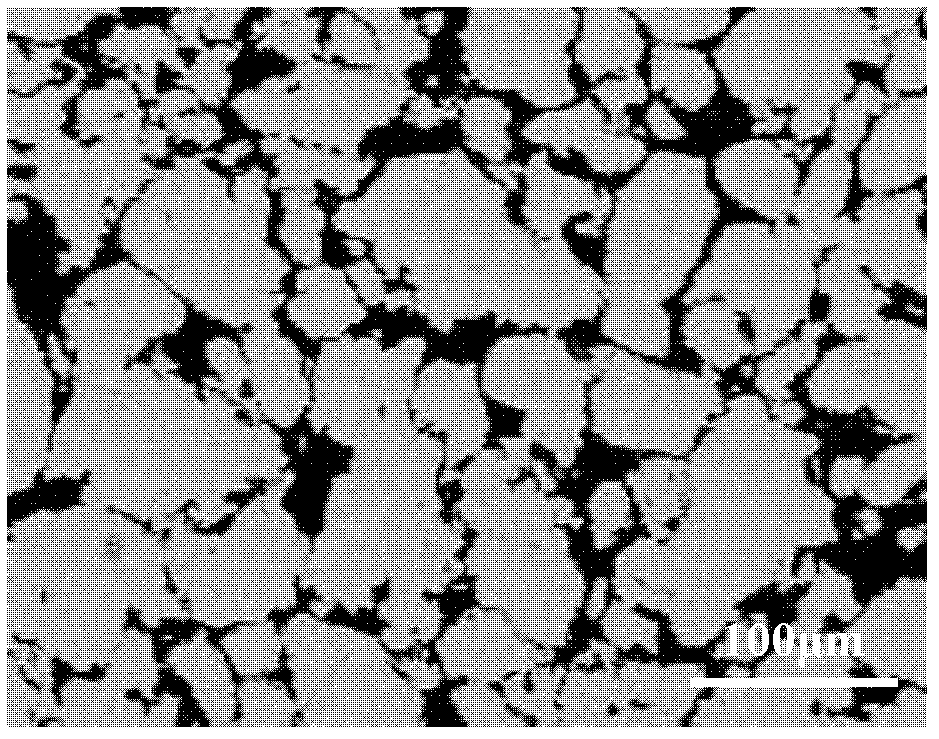

InactiveCN101663410AReduce lossHigh saturation flux densityInorganic material magnetismAmorphous phaseVolumetric Mass Density

The invention provides a soft magnetic thin strip which contains nanoscale fine grains and exhibits a high saturation magnetic flux density and excellent soft magnetic characteristics; a process for production of the same; magnetic parts; and an amorphous thin strip to be used in the production. In the invention, an amorphous thin strip is used, which is represented by the composition formula: Fe100-x-y-zAxMyXz-aPa (wherein A is at least one element selected from between Cu and Au; M is at least one element selected from among Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W and Mn; X is at least one elementselected from between B and Si; and x, y, z and a (in terms of atomic percentage) satisfy the relationships: 0.5<=x<=1.5, 0<=y<=2.5, 10<=z<=23, and 0.35<=a<=10 respectively) and permits 180 DEG bending. The amorphous thin strip can give through heat treatment a soft magnetic thin strip having a structure wherein grains of body-centered cubic structure having an average grain size of 60nm or beloware distributed in an amorphous phase with a grain volume fraction of 30% or above.

Owner:PROTERIAL LTD

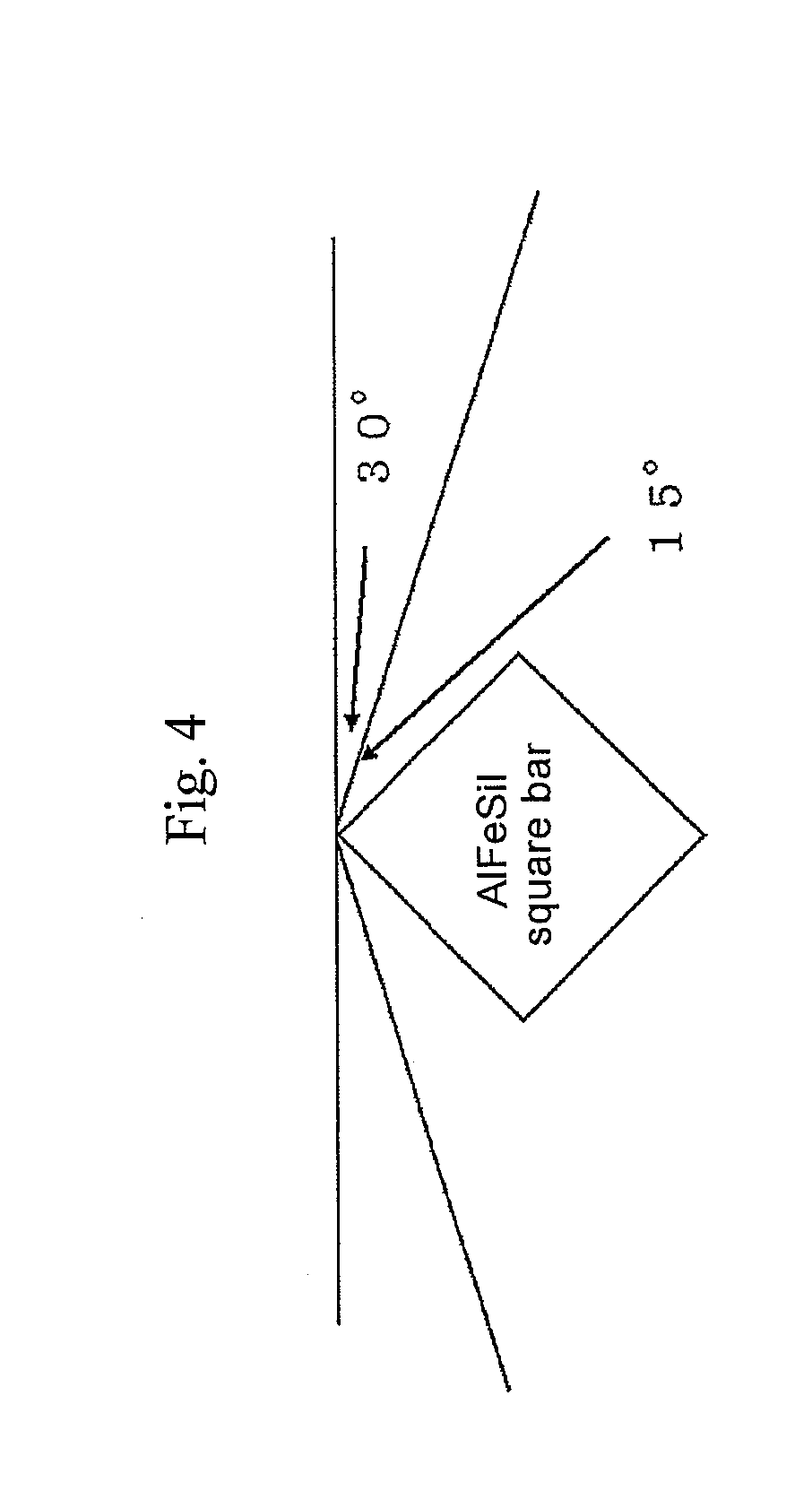

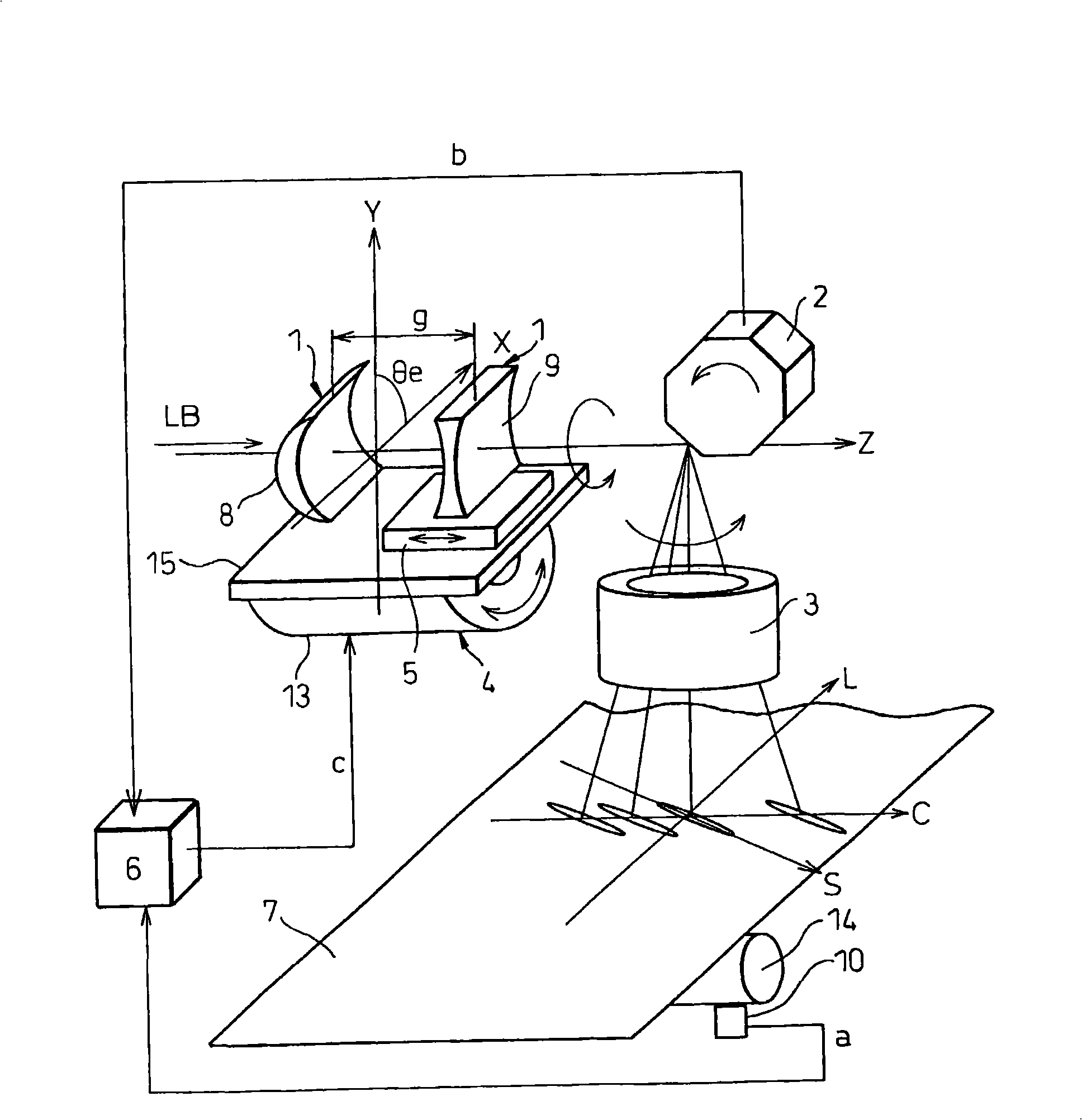

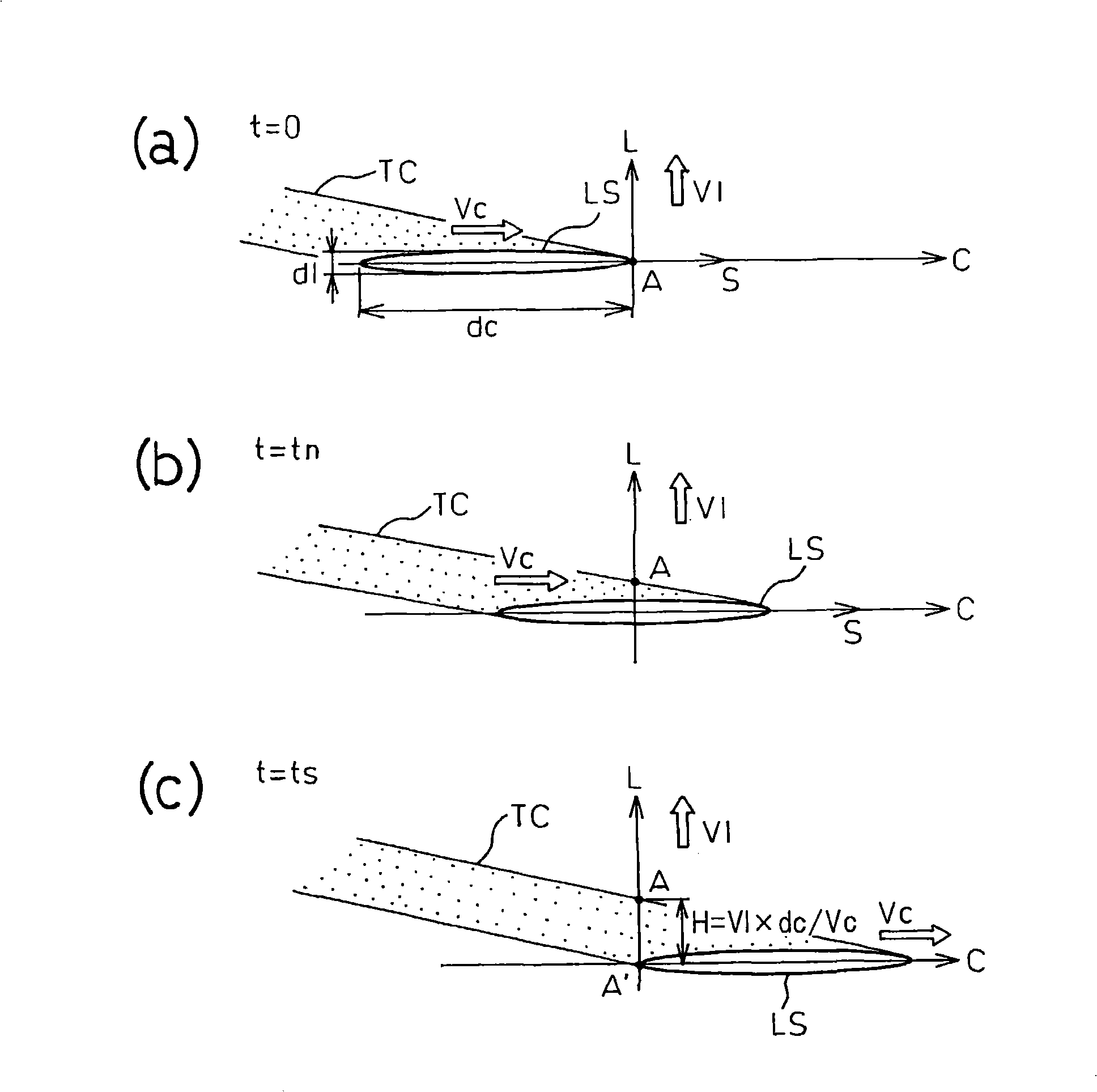

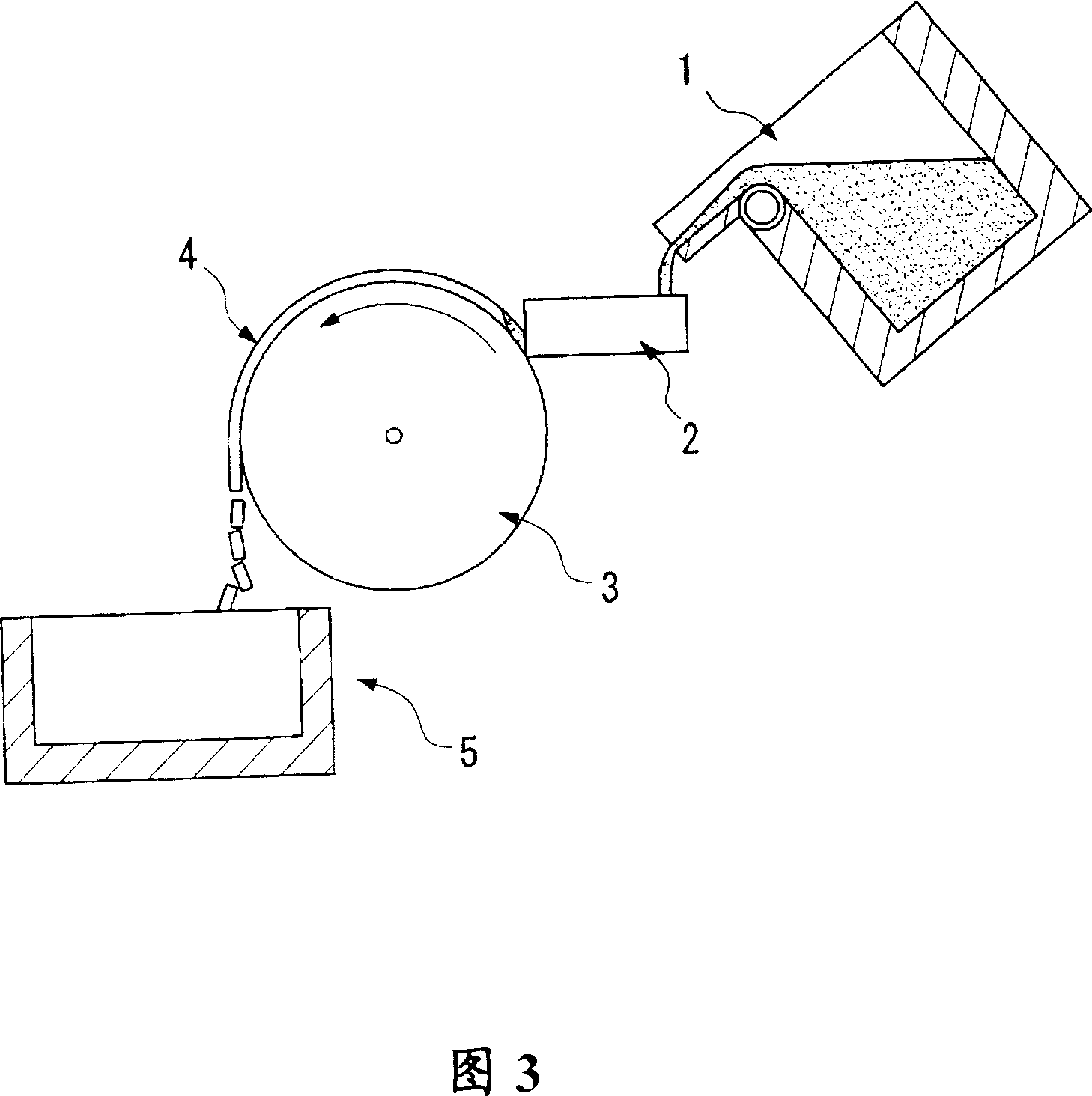

Production method and production system of directional electromagnetic steel plate having excellent magnetic characteristics

ActiveCN101297050AStable manufacturingExcellent magnetic propertiesInorganic material magnetismFurnace typesEllipseLong axis

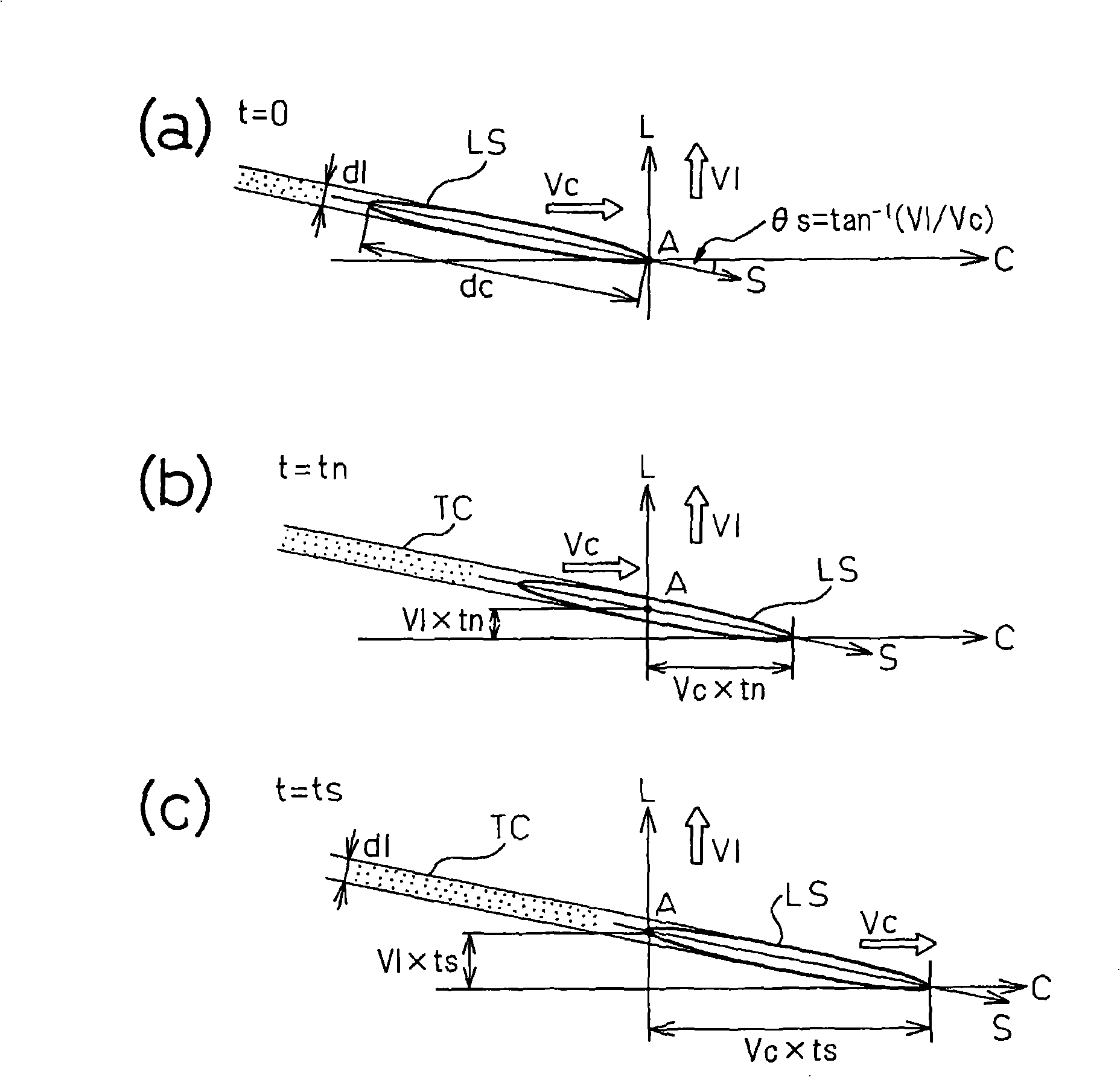

In a technology for improving iron loss of a directional electromagnetic steel plate moving in the rolling direction at a speed Vl by performing scanning irradiation with a laser beam of elliptical spot in the plate width direction at a speed Vc, the angle thetas between the scanning direction of the elliptical beam and the long axis of the ellipse is regulated based on an expression thetas=tan<-1>(Vl / Vc). The arrangement for regulating the thetas comprises an optical unit for laser irradiation where a cylindrical lens telescope, a scanning mirror, and an ftheta lens are arranged in this order, a device for altering the angle of the cylindrical lens telescope against the scanning direction of the scanning mirror, and a device for altering the distance between the lenses.

Owner:NIPPON STEEL CORP

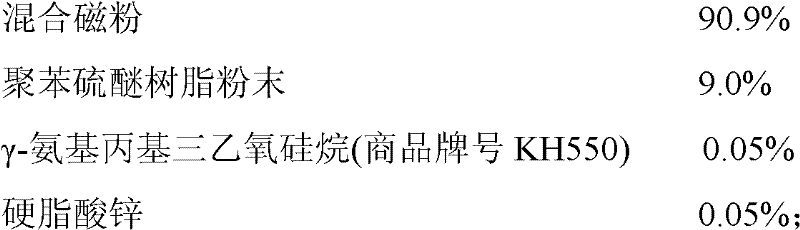

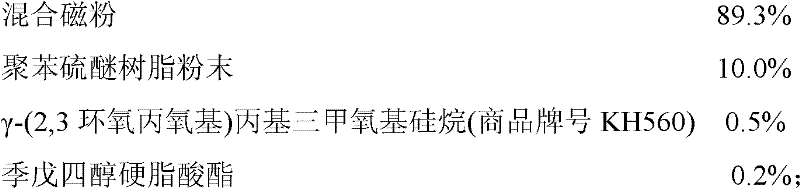

Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

ActiveCN102504534AExcellent overall performanceExcellent magnetic propertiesMagnetic powderNeodymium iron boron

An injection molding permanent magnet composite material containing polyphenylene sulfide includes the following components by mass: 78% to 91% of mixed magnetic powder, 8% to 21% of polyphenylene sulfide resin and 0.05% to 1% of coupling agents. The mixed magnetic powder includes the following components by mass: 50% to 96% of neodymium iron boron permanent magnetic powder, 1% to 49% of samariumiron nitrogen permanent magnetic powder and 1% to 45% of ferrite permanent magnetic powder. A preparation method of the injection molding permanent magnet composite material includes the following processing steps: (1) preparing multi-element composite magnetic powder, (2) mixing and pelleting and (3) injection molding.

Owner:SICHUAN UNIV

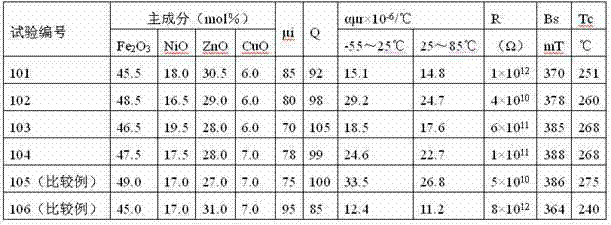

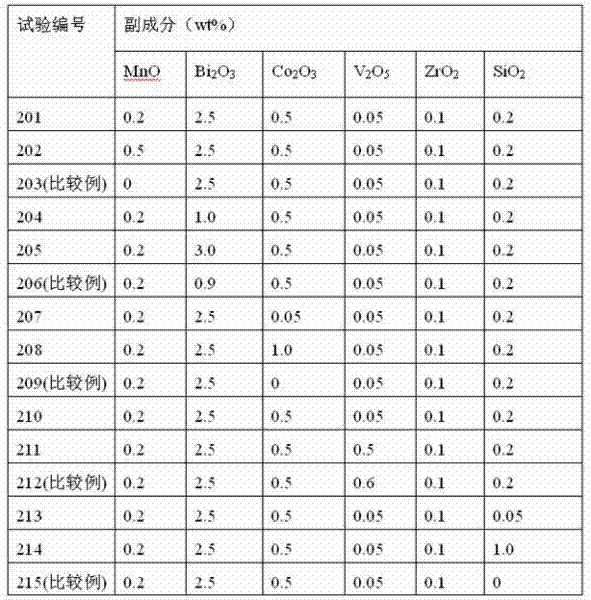

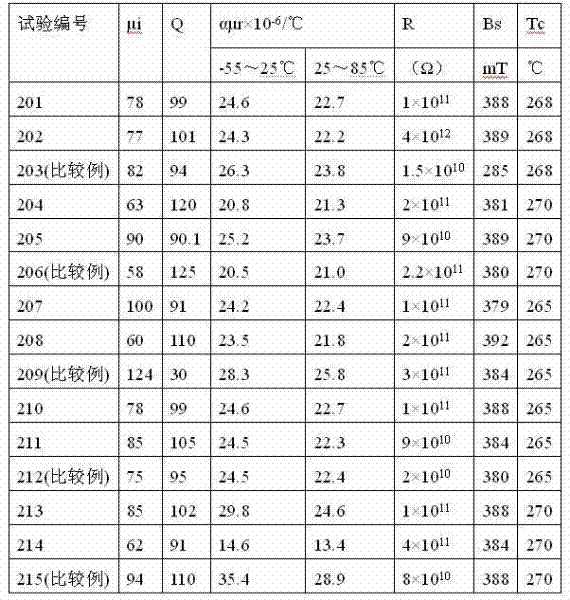

NiCuZn soft magnetic ferrite material used for low temperature co-sintering and preparation method thereof

The invention belongs to the field of soft magnetic ferrite materials, and in particular, relates to a NiCuZn soft magnetic ferrite material used for low temperature co-sintering. The material comprises major constituents and accessory constituents, wherein: the major constituents consist of ferric oxide, nickel oxide, zinc oxide and copper oxide, the molar percentage content of each major constituent being Fe2O3 45.5-48.5 mol%, NiO 16.5-19.5 mol%, ZnO 28.0-30.5 mol% and CuO 6.0-8.0 mol%; the accessory constituents comprise manganic oxide and bismuth oxide, compared with the gross weight of the major constituents, the weight percentage gross of the accessory constituents being 1.1-3.5 wt% calculated by taking MnO and Bi2O3 as standard. The invention also provides a preparation method for the ferrite material. When used for preparing MLCI devices under high frequency usage, the material of the invention has advantages in that: the material has a relatively low sintering temperature and metallic silver is not easy to diffuse during co-sintering; and the material ensures that the MLCI devices can obtain excellent magnetic properties and have a relatively good consistency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

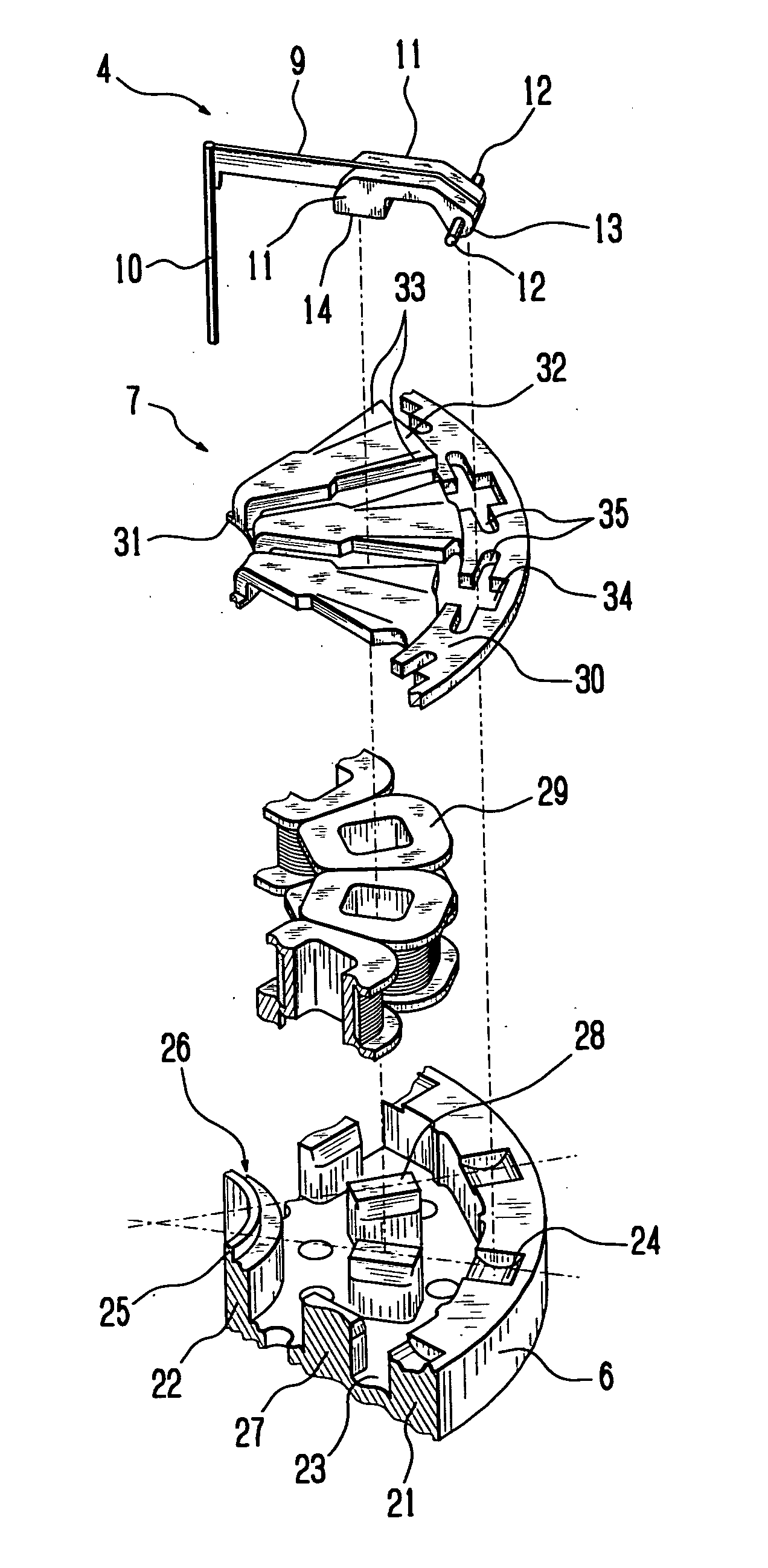

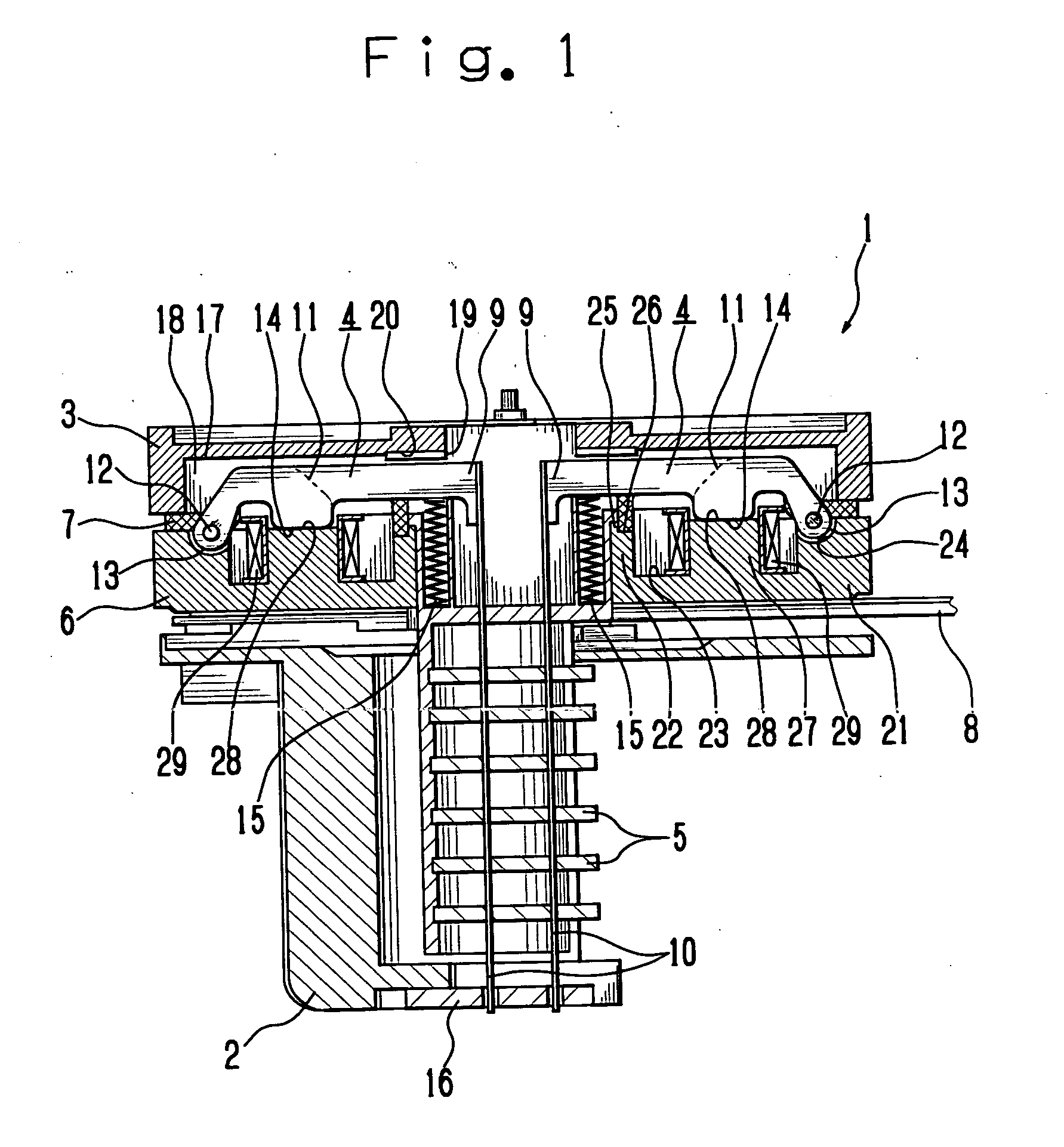

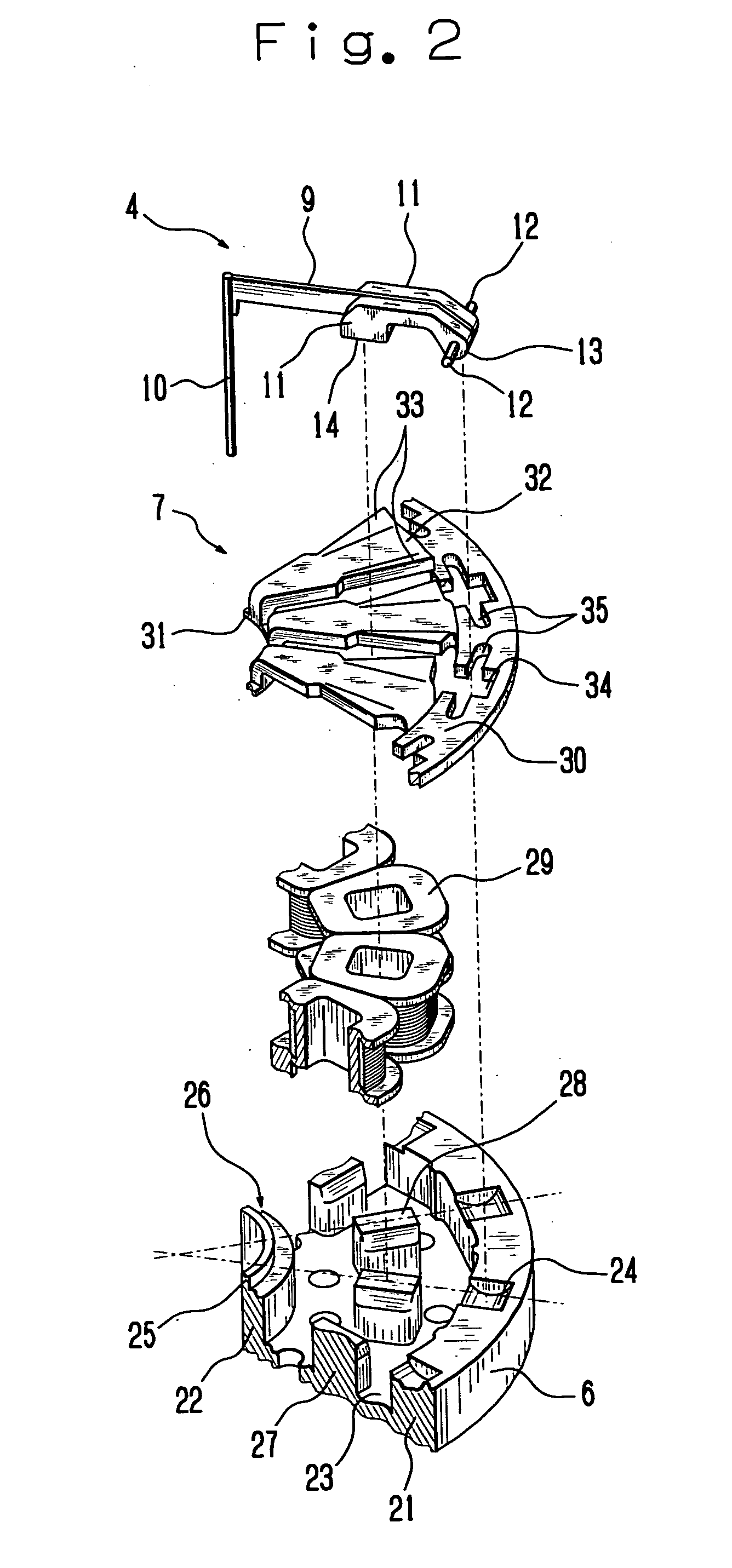

Armature, wire dot printer head and wire dot printer

InactiveUS20050201800A1Armature durabilityHigh-speed durabilityFranking apparatusPrintingEngineeringMagnetic characteristic

In order to obtain joining force endurable for high-speed printing and realize an enhancement in magnetic characteristic, a plate-like arm for supporting a printing wire is laminated with a magnetic circuit forming member that is composed by laminating plural plates for forming a magnetic circuit, wherein a weld zone is formed on the laminated surface of the arm and plates with laser beam irradiation for fixing the arm and the magnetic circuit forming member with the weld zone.

Owner:TOSHIBA TEC KK

Soft magnetic composite material of glass insulating layer and preparation method thereof

ActiveCN102360665AExcellent magnetic propertiesImprove mechanical propertiesInorganic material magnetismMagnetic powderHot pressing

A preparation method of a soft magnetic composite material containing a glass insulating layer, relates to a preparation method of a soft magnetic composite material. The soft magnetic composite material of the glass insulating layer and the preparation method thereof disclosed by the invention solve technical problems that high-temperature annealing cannot be performed on existing soft magnetic composite materials to remove residual stress generated in the preparation process and to further improve magnetic performance of the soft magnetic composite material and magnetic performance cannot be kept steady all the time when the material emits heat in an environment with a great temperature difference or in long-term use process. The soft magnetic composite material containing the glass insulating layer disclosed by the invention is formed by depositing amorphous substances on magnetic powder and then annealing after cold-pressing or hot-pressing. The soft magnetic composite material containing the glass insulating layer disclosed by the invention has an initial magnetic conductivity up to 200 or more, a maximum magnetic conductivity up to 900 or more, a saturated magnetization intensity up to 1.5 T, and a coercive force less than 250 A / m; and iron loss at 50 Hz and 1 T alternating current magnetic field can be less than 3 W / Kg.

Owner:HARBIN INST OF TECH

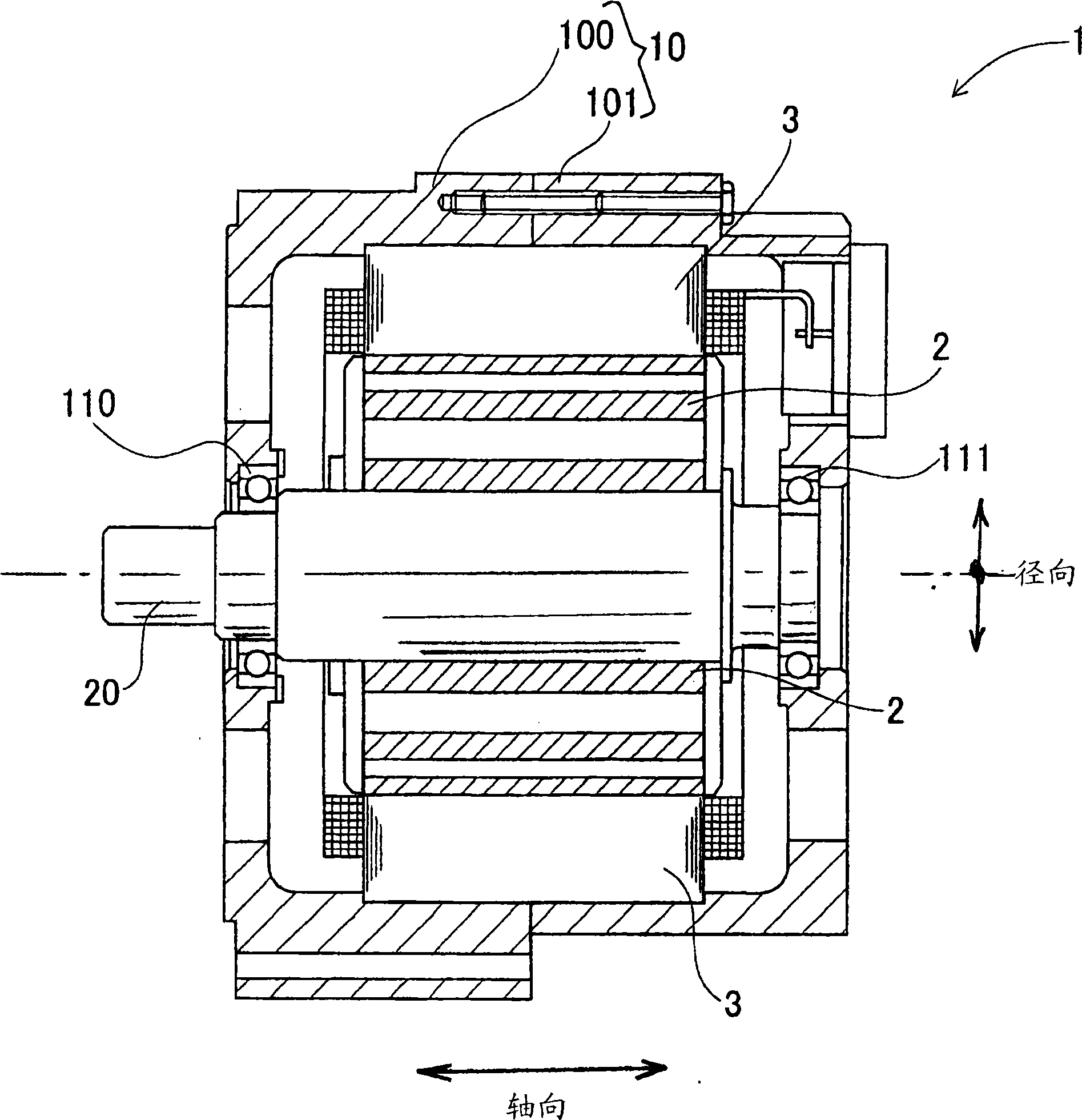

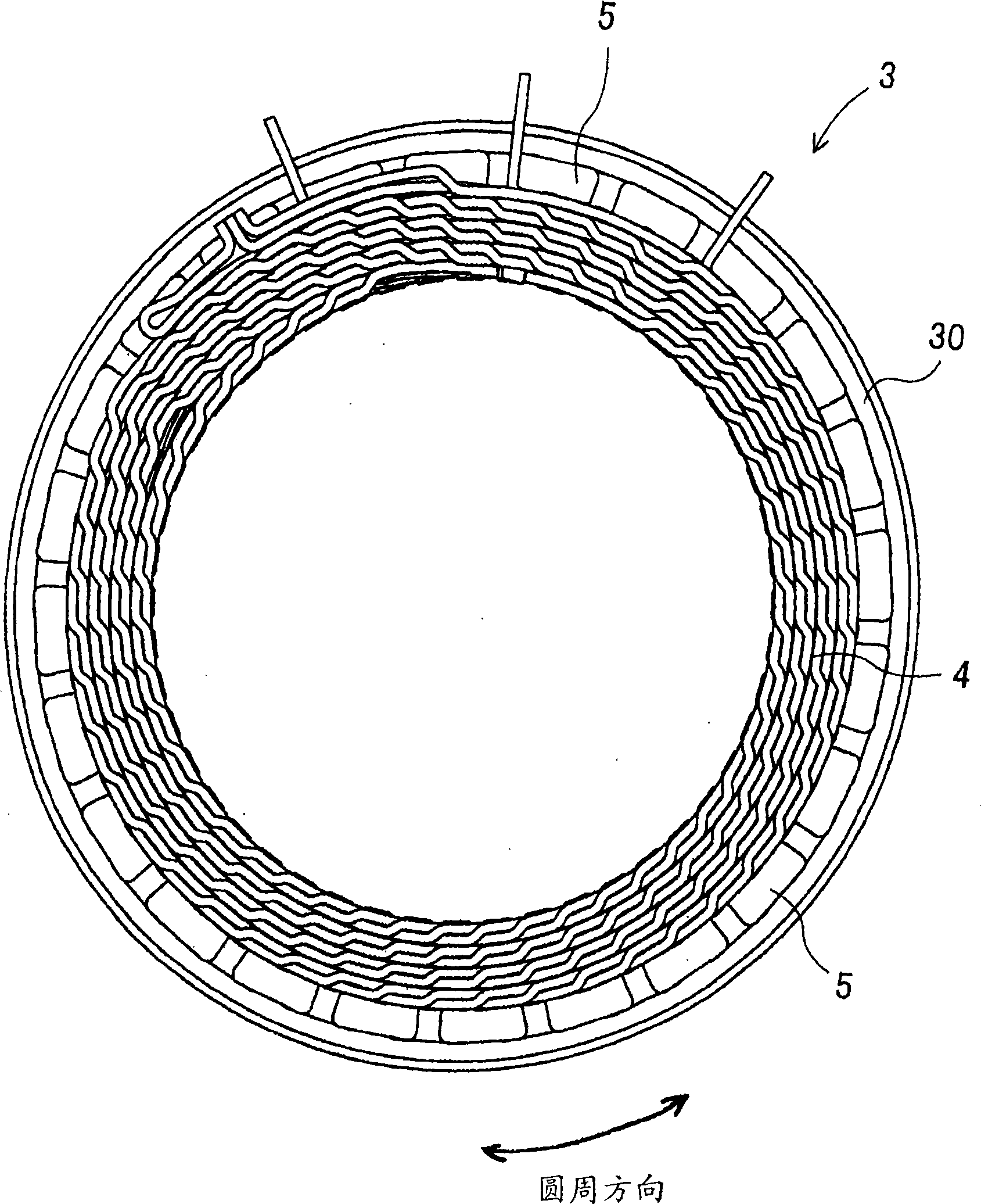

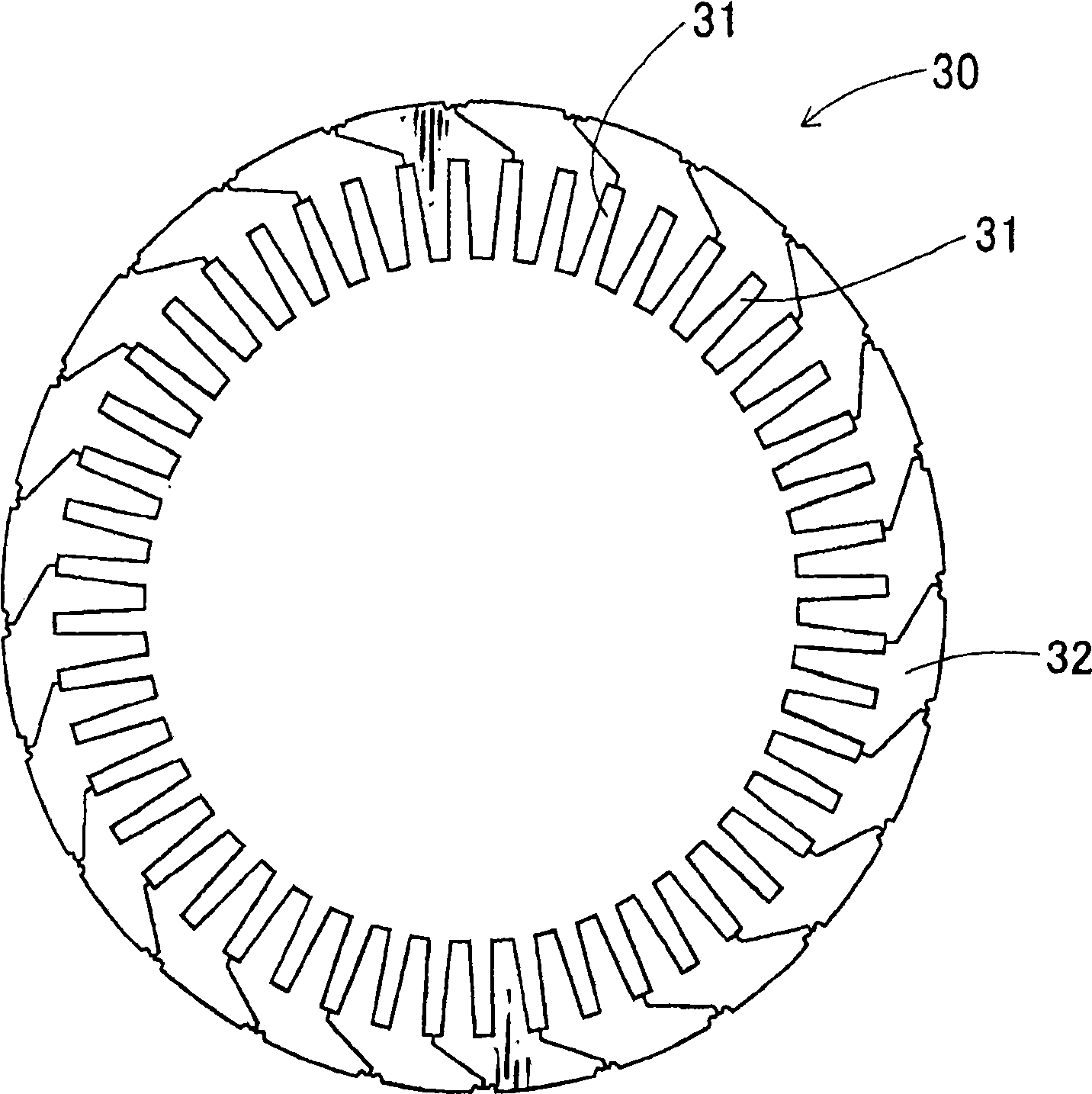

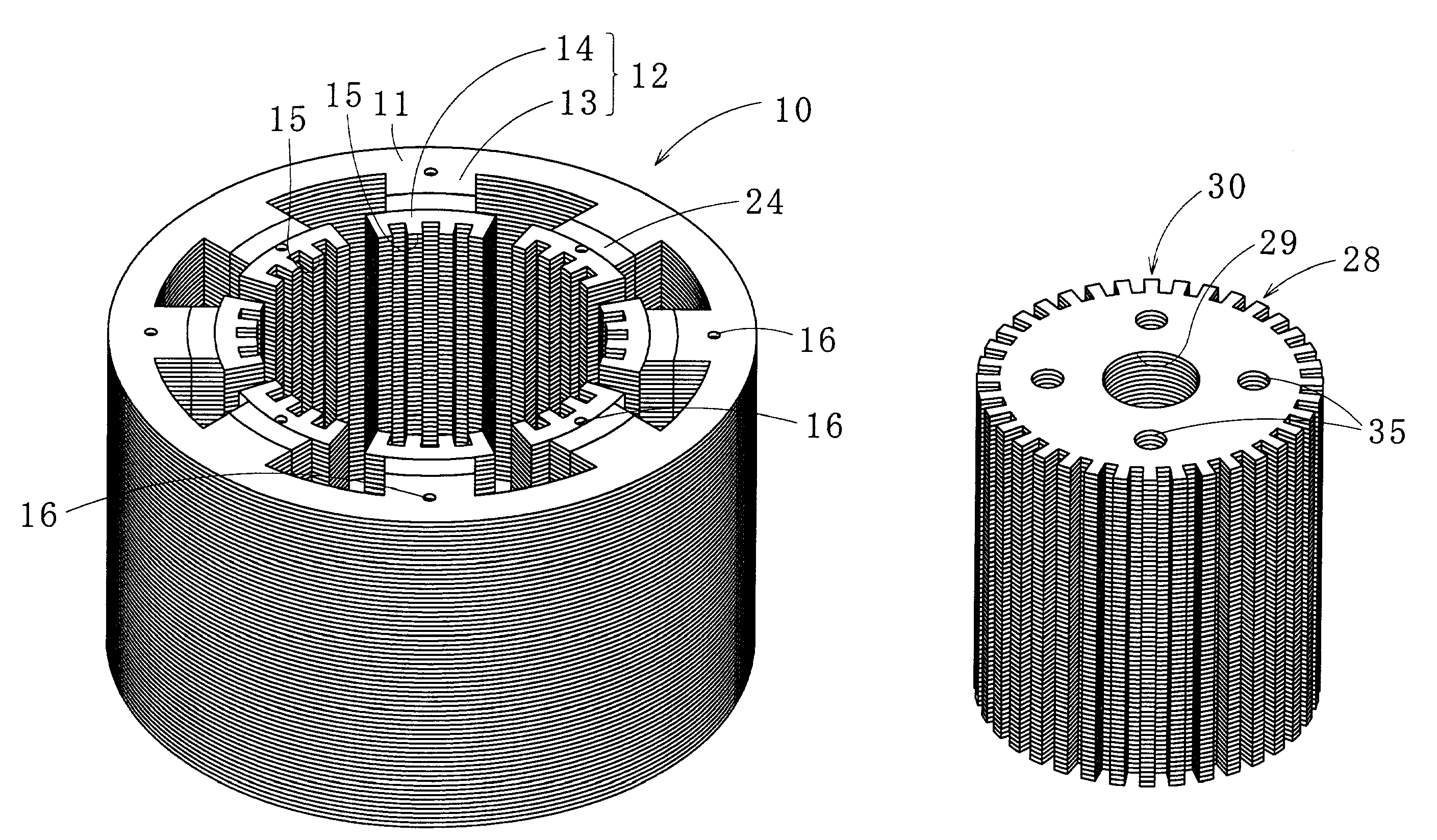

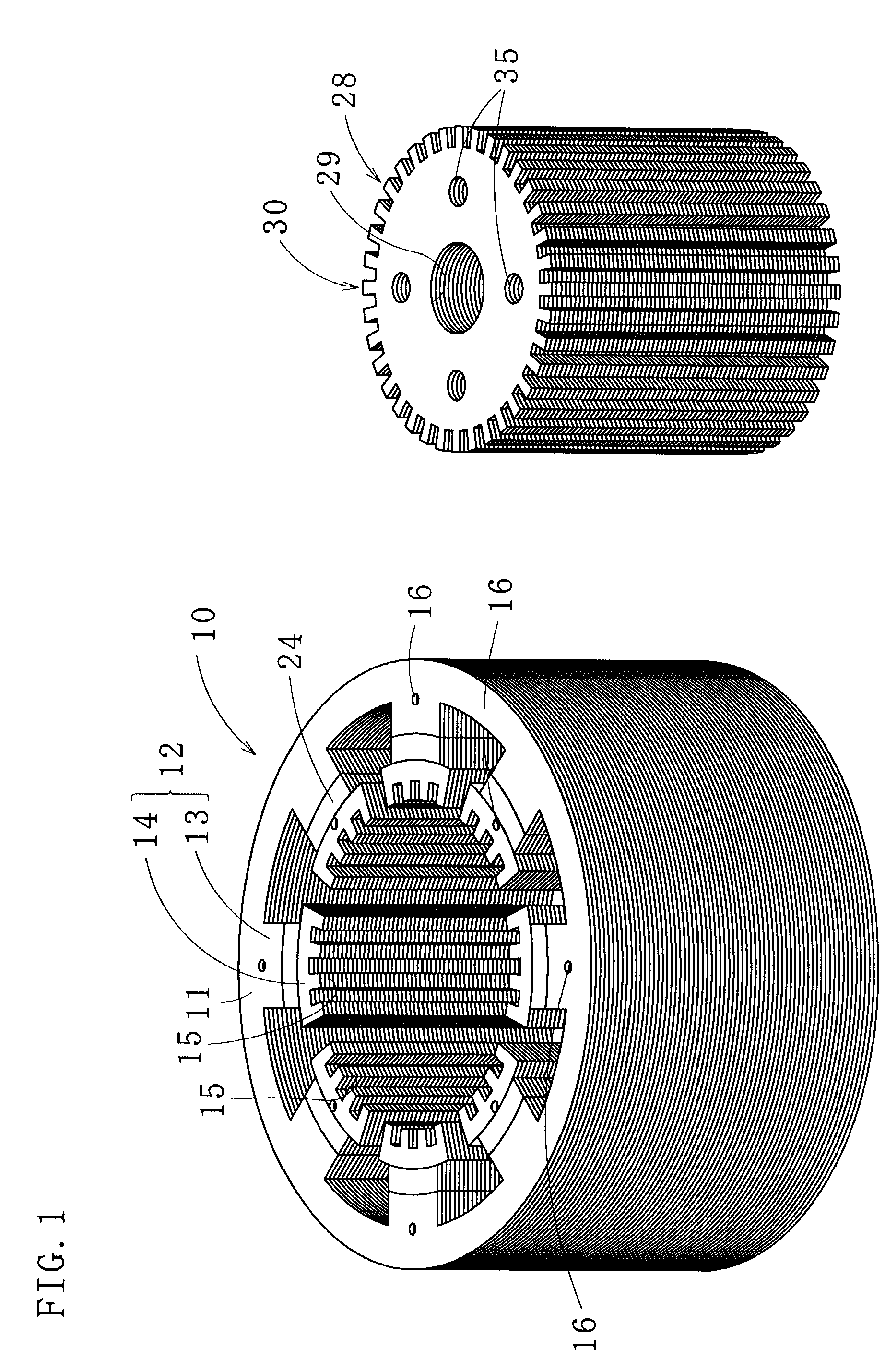

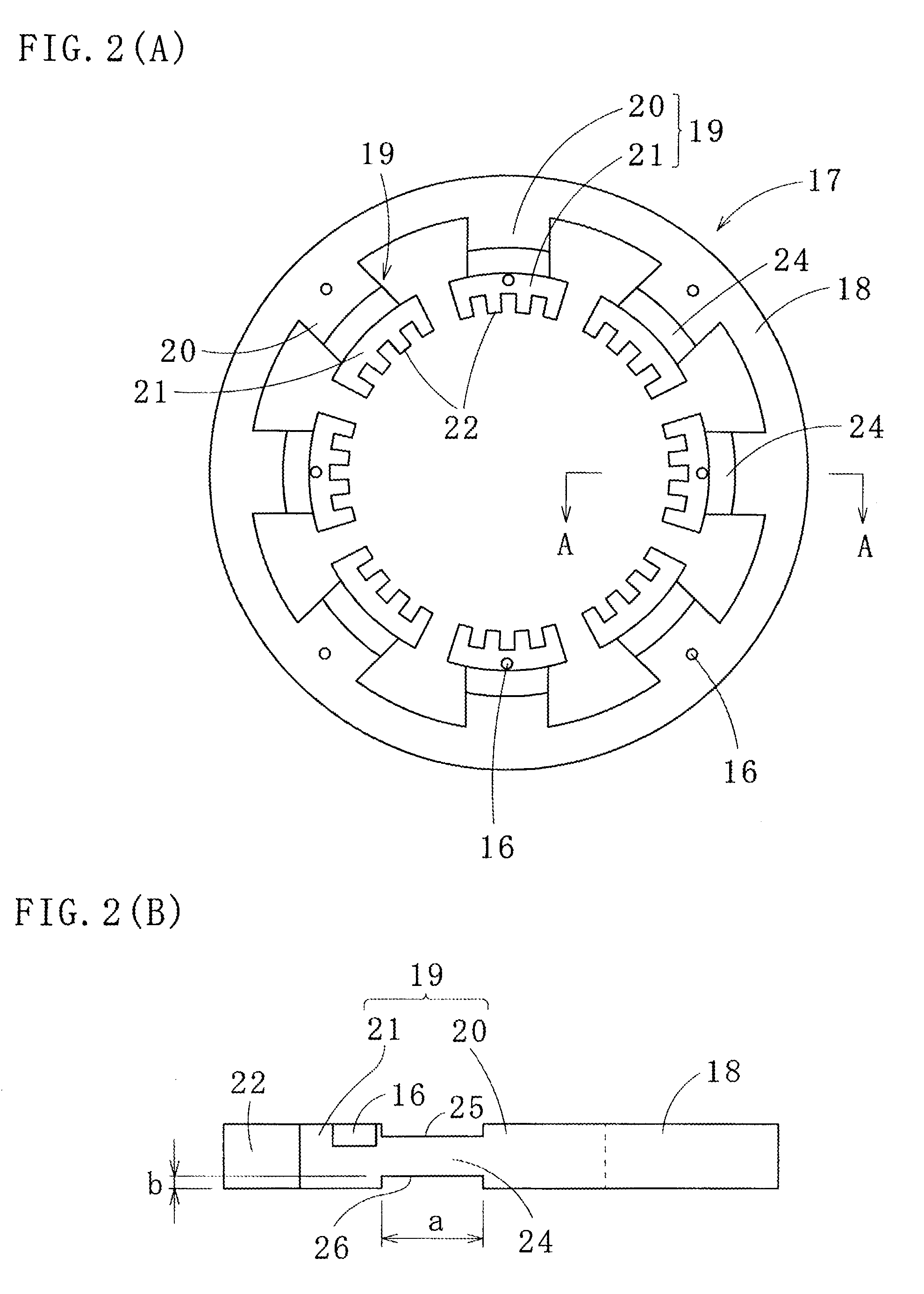

Stator for rotary electric machine, and rotary electric machine using the stator

ActiveCN101478184AReduce performanceAvoid interferenceMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineConductor Coil

Owner:DENSO CORP

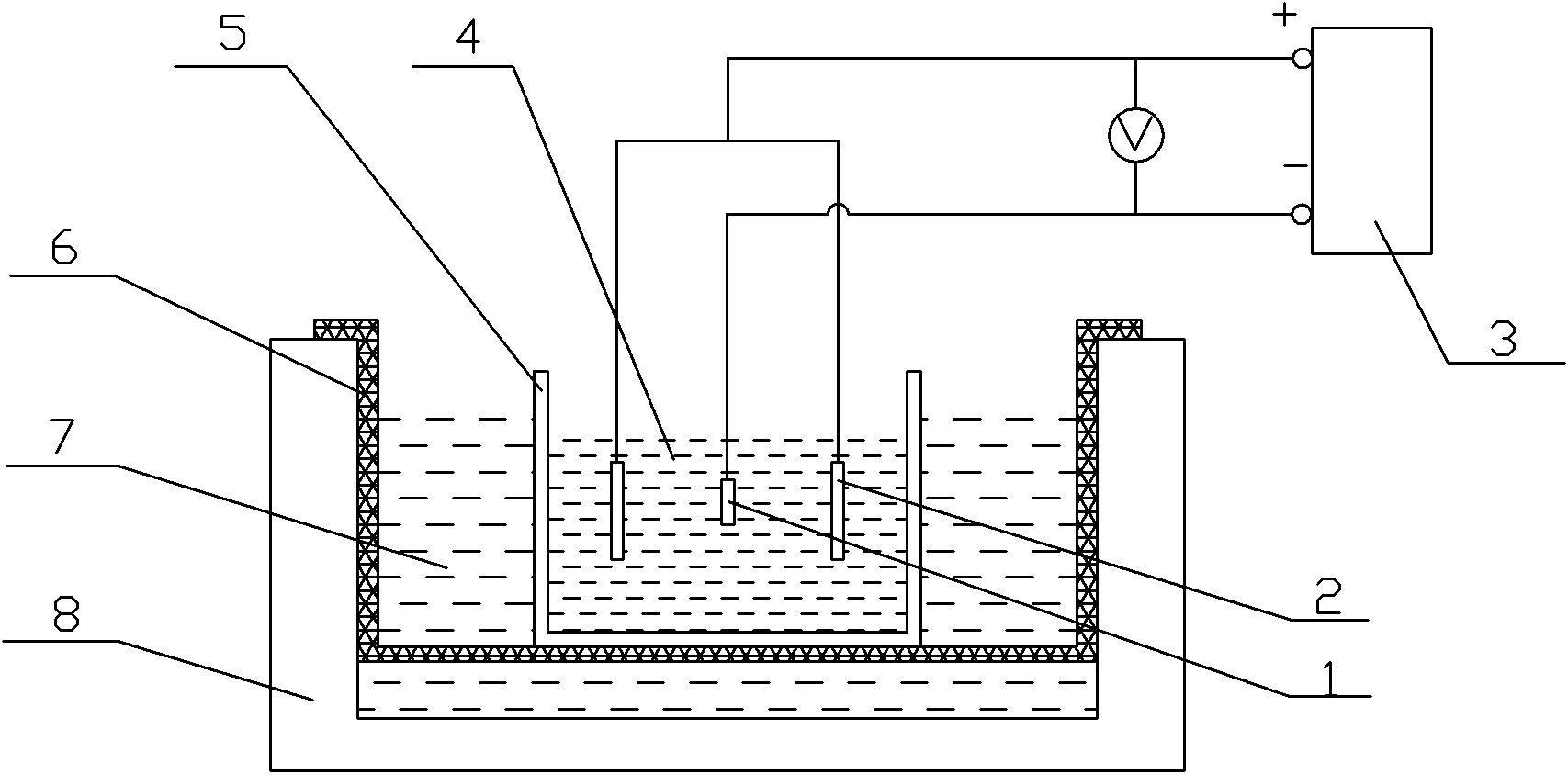

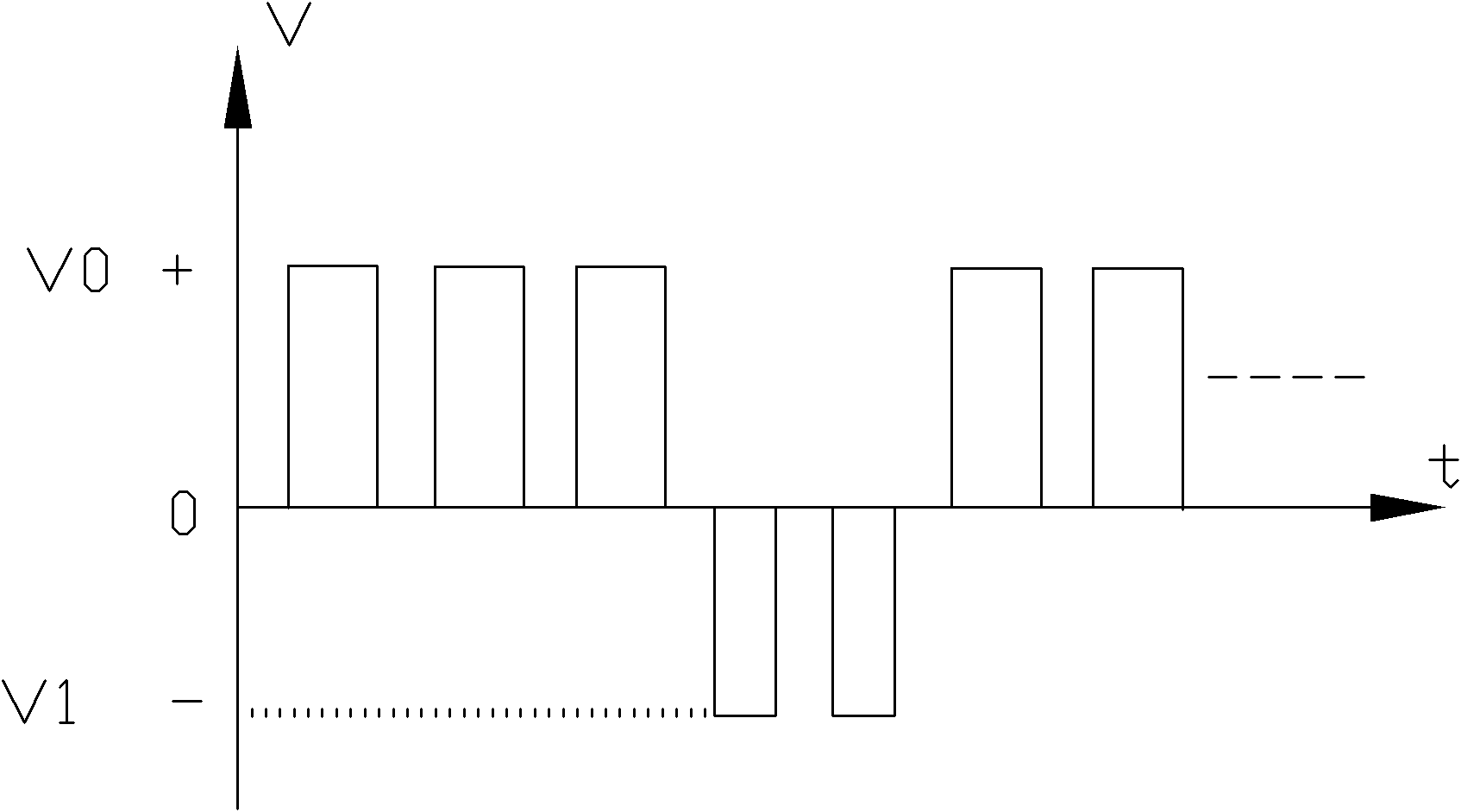

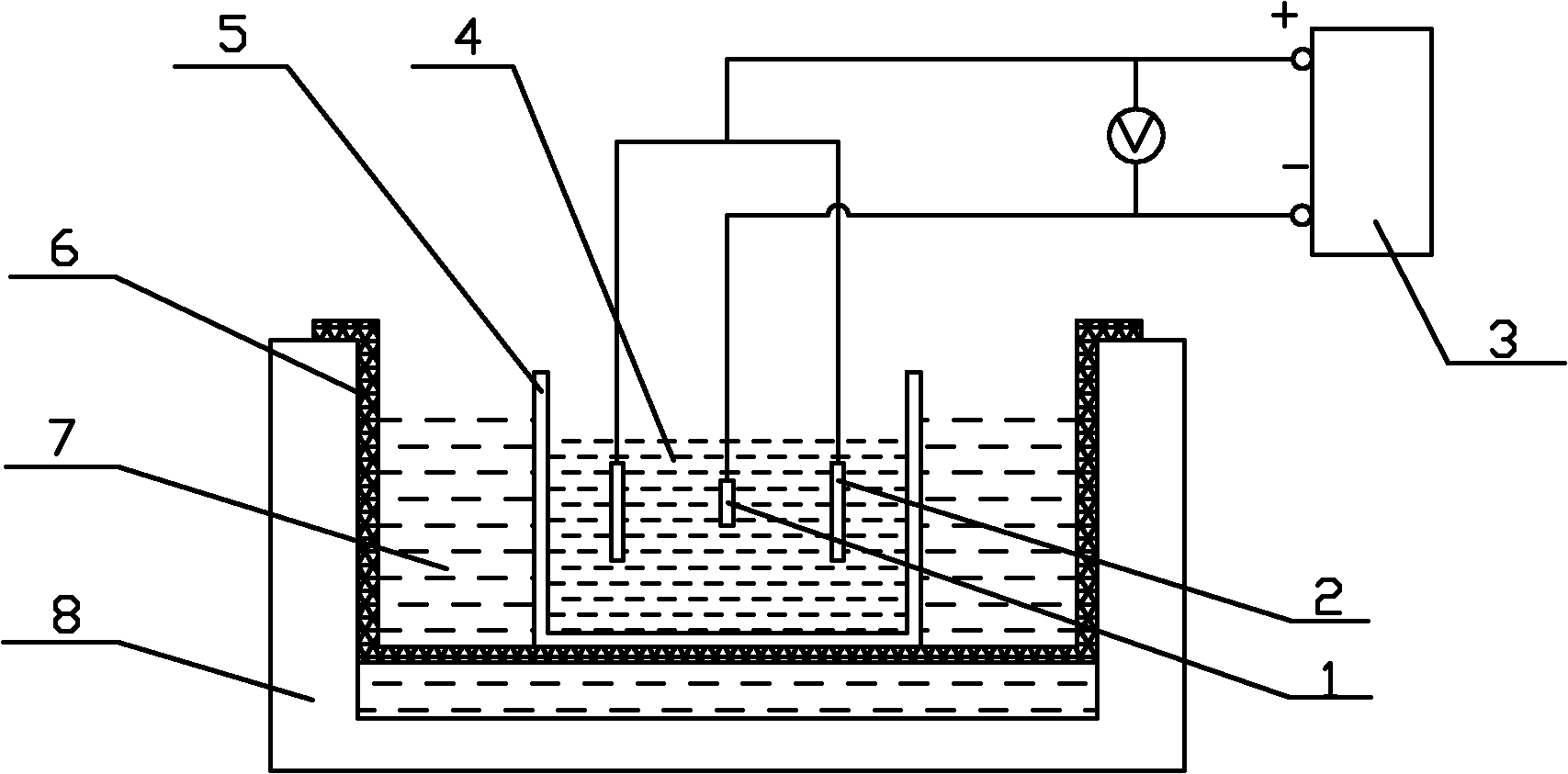

Method for preparing ferromagnetic nano composite material with pulse-ultrasound electrodeposition

InactiveCN102002748AGood mechanical propertiesExcellent magnetic propertiesElectrolytic coatingsPulsed UltrasoundElectric field

The invention relates to a method for preparing a composite material, which comprises the following steps of: putting a basal body subjected to pretreatment into a conventional electroplating bath, and applying an electric field and an ultrasonic field on the plating bath with an ultrasonic generator and a pulsing power source. The process of pulse-ultrasound electrodeposition generally comprises the following steps of: 1, elecroplating pretreatment comprising pretreatment of the basal body and preparation of electroplate liquid; 2, electrodeposition process: putting the basal body which is pretreated in the step one into the prepared electroplate liquid for electrodeposition; and3, post treatment of plating parts, mainly comprising the working procedures of ultrasonic cleaning for the plating parts which are deposited in the step two and anhydrous alcohol cleaning. In the invention, in the electroplate liquid containing nickel and iron ions and insoluble nanoparticles, the nanoparticles are uniformly distributed in the liquid by using ultrasonic stirring, the nanoparticles and substrate metal ions are simultaneously deposited to obtain the ferromagnetic nano composite material composed of substrate metal nickel-iron and the nanoparticles under the condition that positive and negative pulse current or voltage are applied.

Owner:DALIAN UNIV

R-t-b sintered magnet

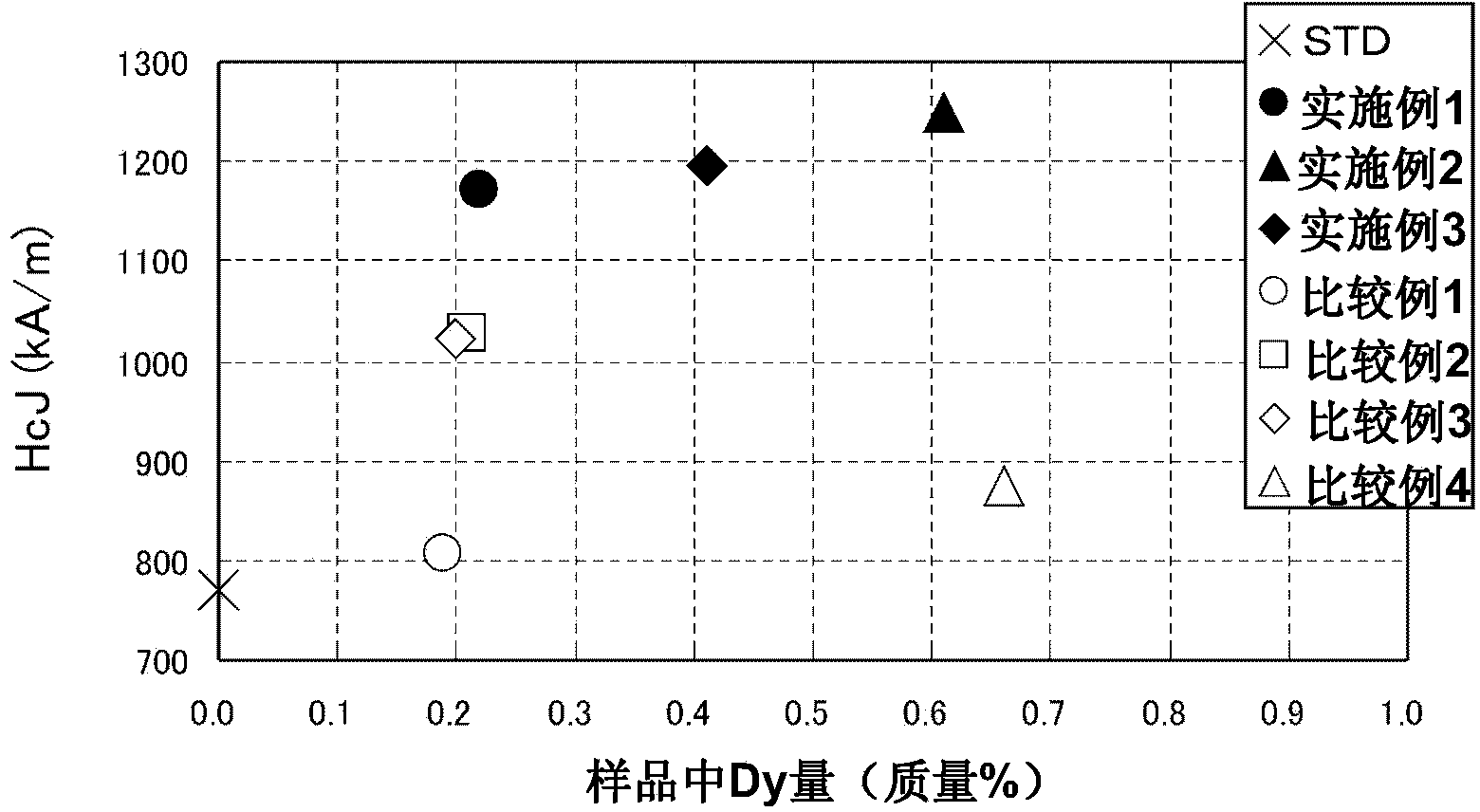

ActiveCN103890868AExcellent magnetic propertiesReduce usageInorganic material magnetismRare-earth elementSintered magnets

An R-T-B based sintered magnet maintains high magnetic properties and decreases usage of heavy rare earth elements. The magnet includes main phase grains and grain boundary phases, the main phase grain containing a core portion and a shell portion. X in the main phase LR(2-x)HRxT14B of the core portion ranges from 0.00 to 0.07; x in the main phase LR(2-x)HRxT14B of the shell portion ranges from 0.02 to 0.40; and the maximum thickness of the shell portion ranges from 7 nm to 100 nm. LR contains Nd and one or more light rare earth elements consisting of Y, La, Ce, Pr and Sm; HR contains Dy or / and Tb and one or more heavy rare earth elements consisting of Gd, Ho, Er, Tm, Yb and Lu; T contains Fe or / and Co and one or two kinds of Mn and Ni; and B represents boron partly replaced by C (carbon).

Owner:TDK CORPARATION

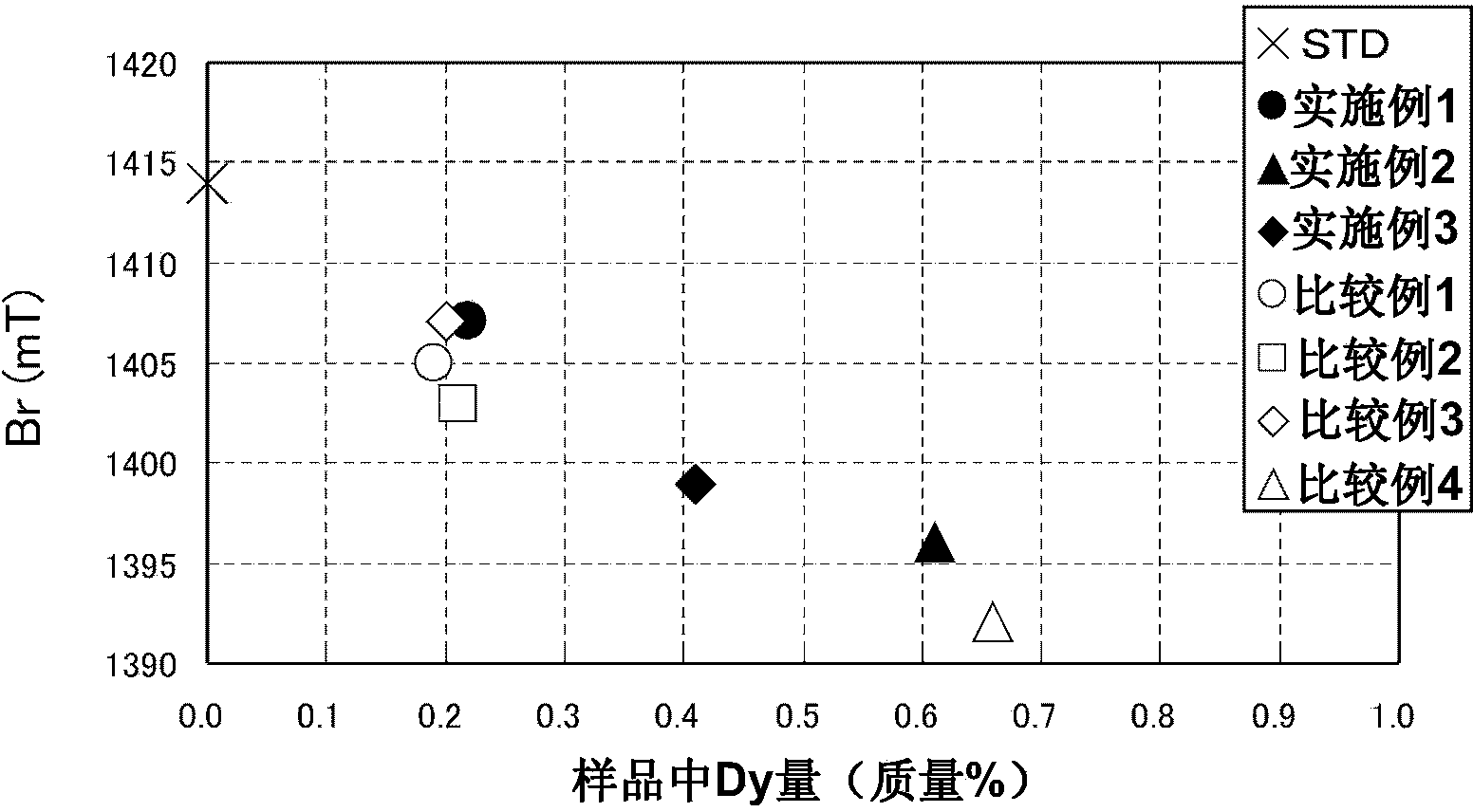

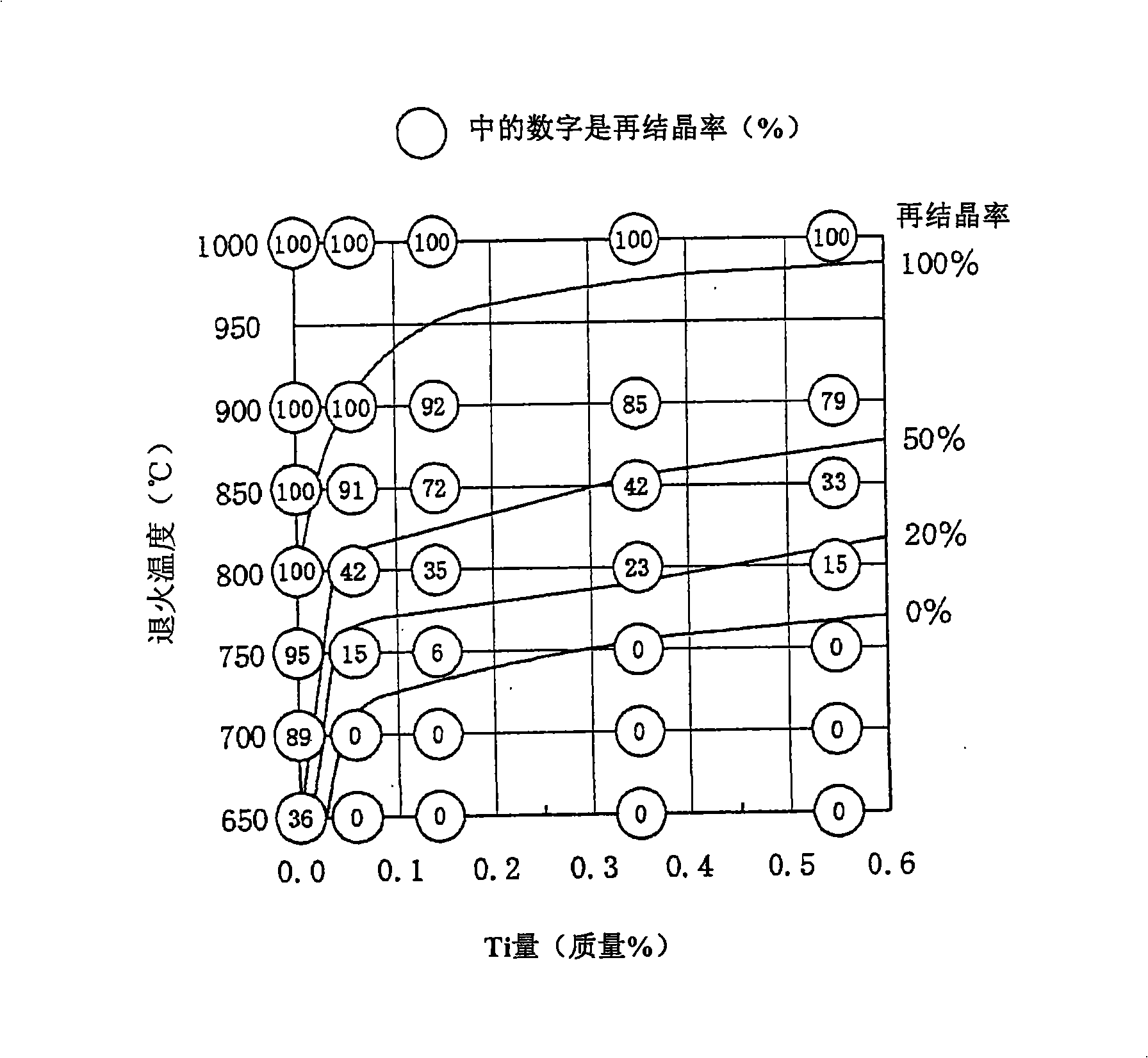

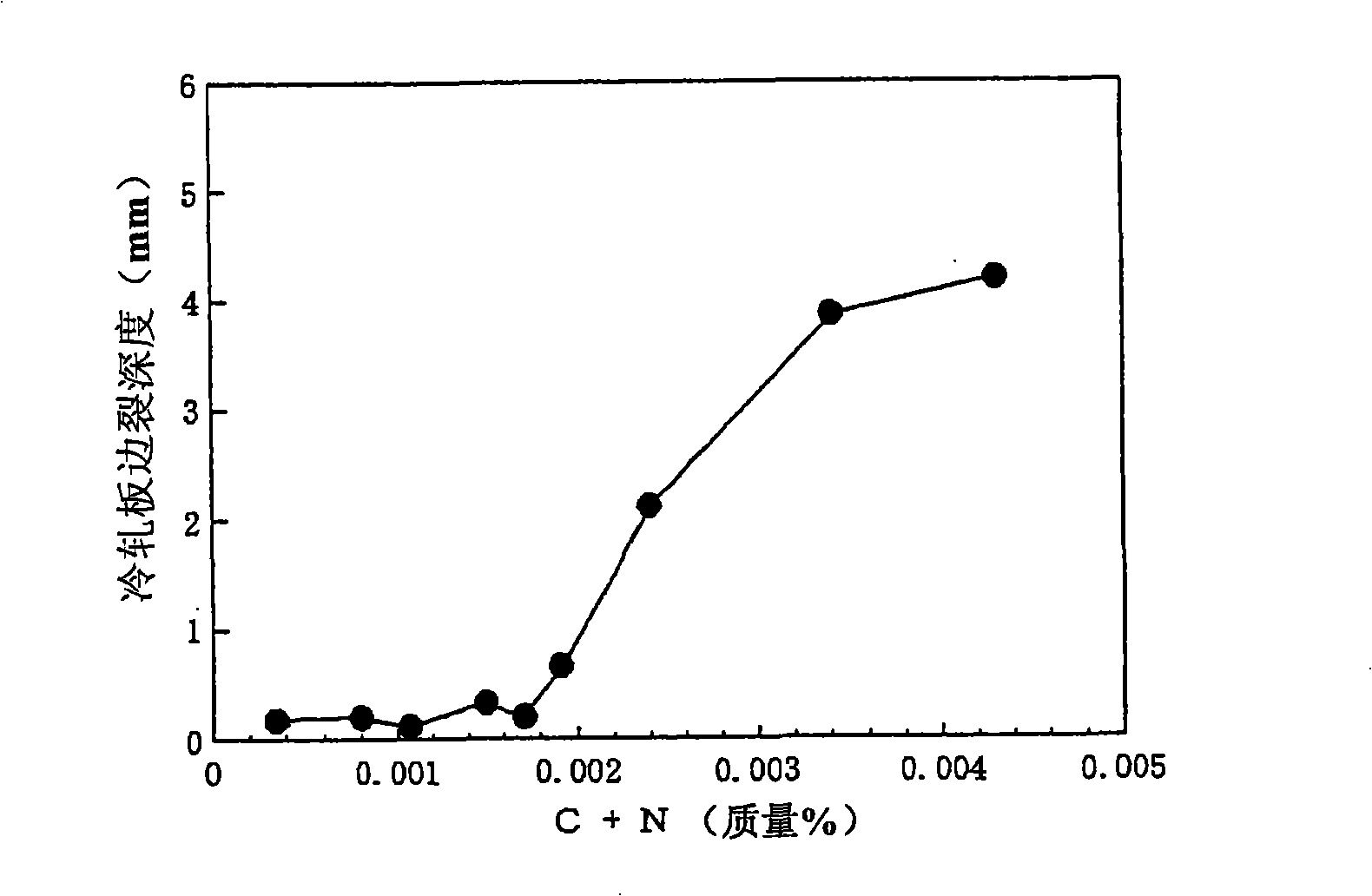

Highly strong, non-oriented electrical steel sheet and method for manufacture thereof

ActiveCN101310034AShape and magnetic properties of high-strength steel sheetsExcellent magnetic propertiesInorganic material magnetismMetal rolling arrangementsElectrical steelHigh intensity

Disclosed is a non-oriented electrical steel sheet having a high strength, excellent magnetic properties and excellent productivity. The steel sheet comprises 0.010% by mass or less of C and 0.010% by mass or less of N, provided that C + N = 0.010% by mass, and also comprises 1.5 to 5.0% by mass of Si and 0.8% by mass or less of Ti or a mixture of Ti and V, provided that (Ti + V) / (C + N) = 16. The steel sheet may also have a content of a non-recrystallized recovery structure of 50% or more.

Owner:JFE STEEL CORP

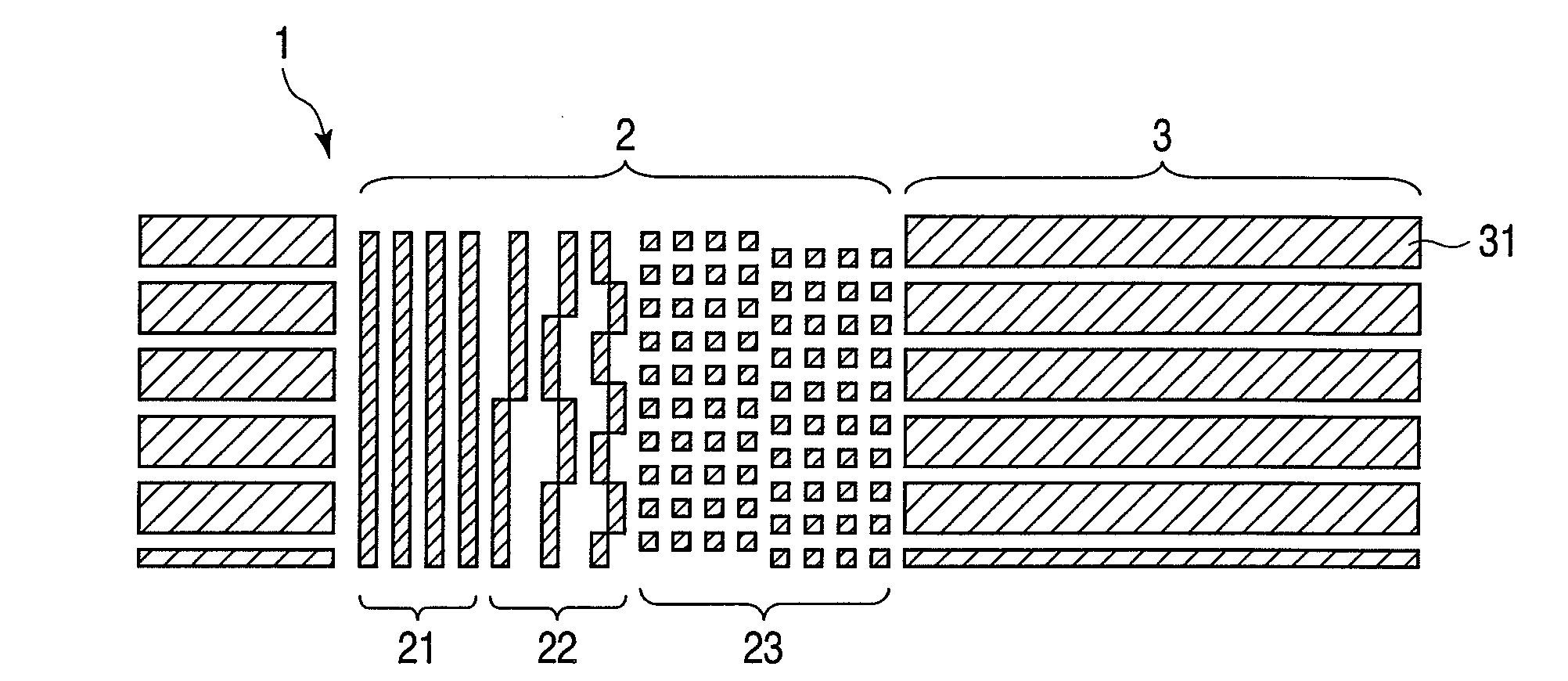

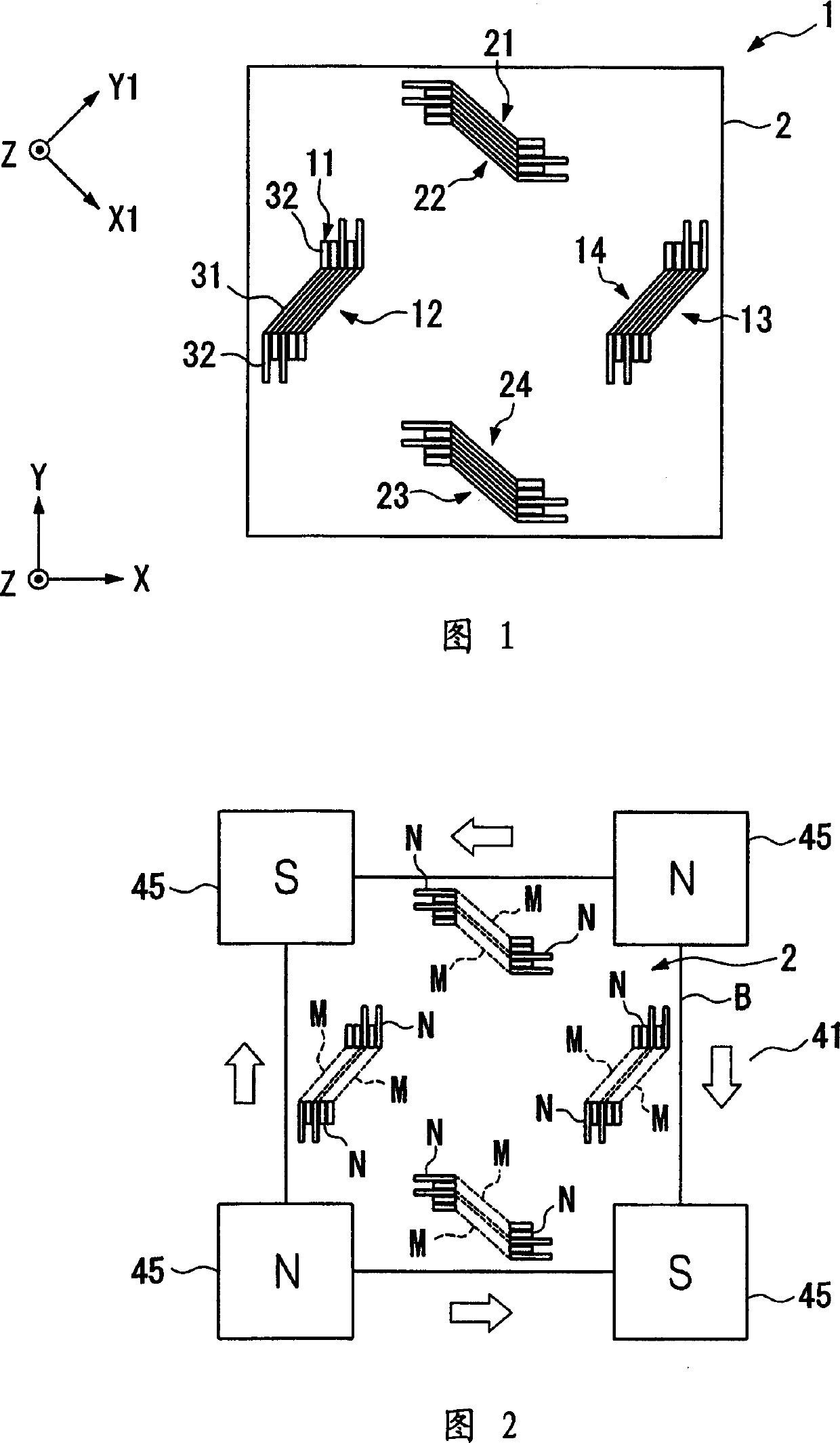

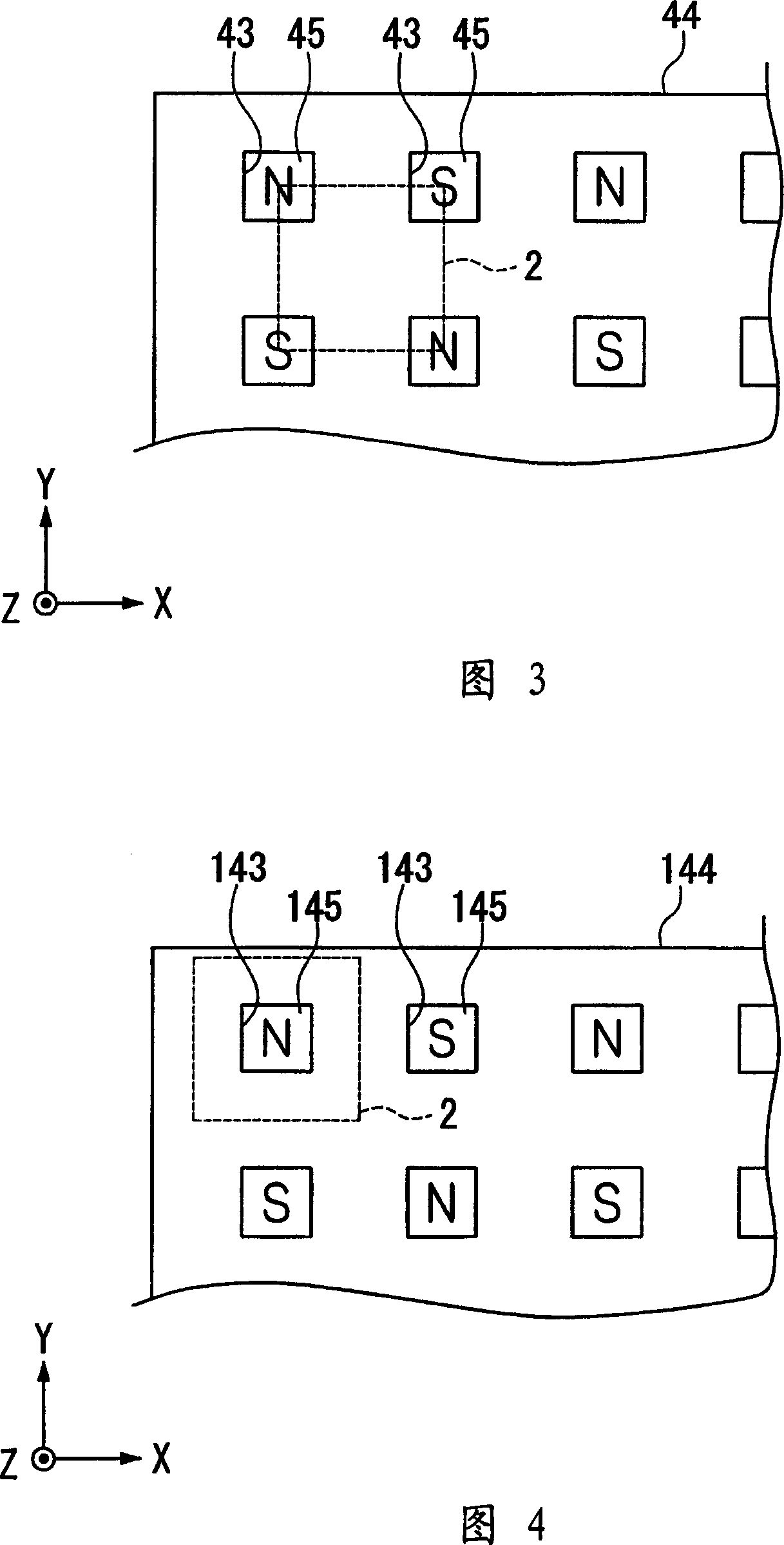

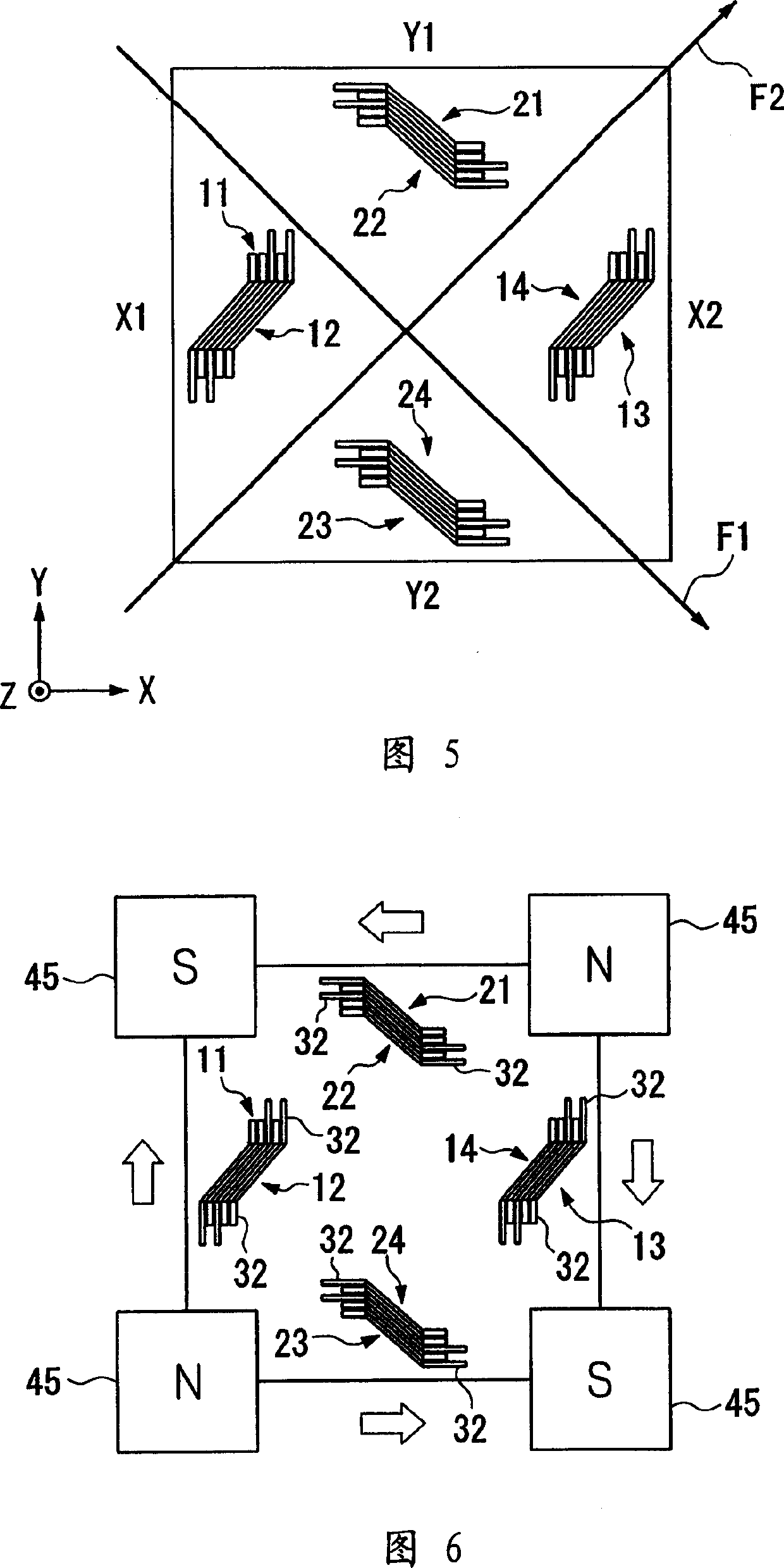

Magnetic inductor and its manufacturing method

InactiveCN1497749AExcellent magnetic propertiesMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentPhysicsInductor

A magnetic sensor comprises magnetoresistive elements (31) and permanent magnet films (32), which are combined together to form GMR elements (11-14, 21-24) formed on a quartz substrate (2) having a square shape, wherein the permanent magnet films are paired and connected to both ends of the magnetoresistive elements, so that an X-axis magnetic sensor and a Y-axis magnetic sensor are realized by adequately arranging the GMR elements relative to the four sides of the quartz substrate. Herein, the magnetization direction of the pinned layer (PD) of the magnetoresistive element forms a prescribed angle of 45 DEG relative to the longitudinal direction of the magnetoresistive element or relative to the magnetization direction of the permanent magnet film. Thus, it is possible to reliably suppress offset variations of bridge connections of the GMR elements even when an intense magnetic field is applied; and it is therefore possible to noticeably improve the resistant characteristics to an intense magnetic field.

Owner:YAMAHA CORP

Magnetic material and method for producing same

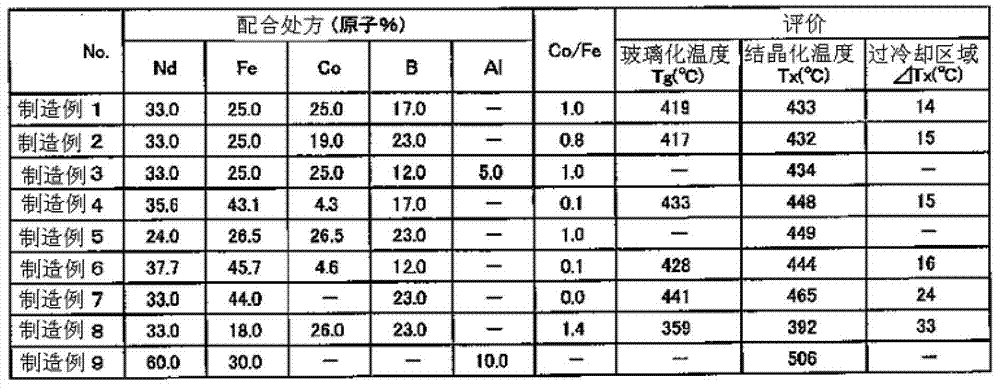

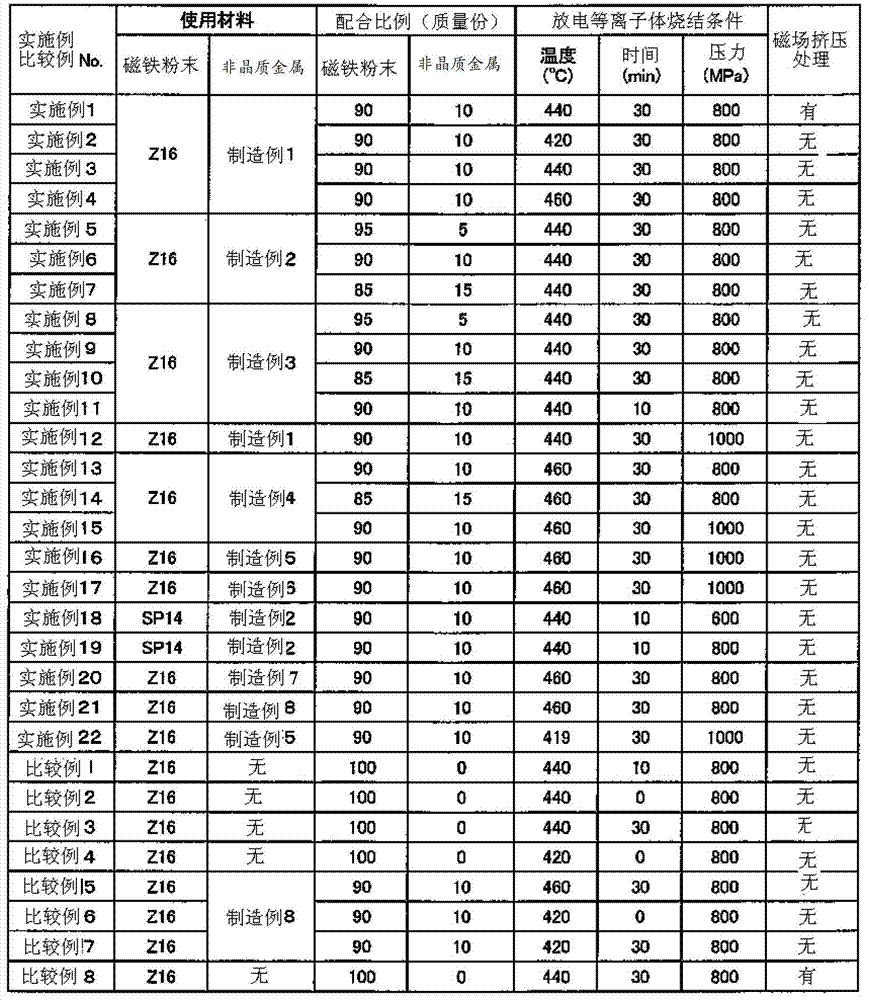

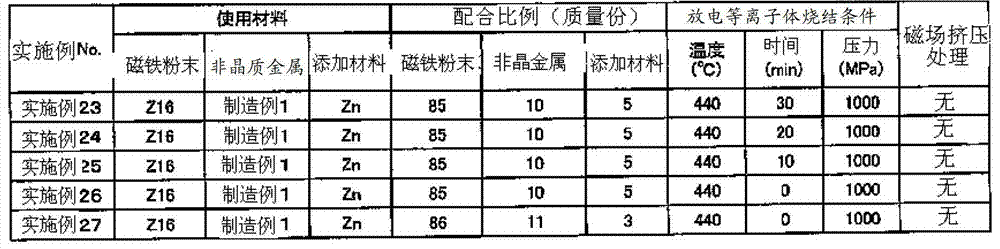

InactiveCN103081035AExcellent magnetic propertiesLower sintering temperatureInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementVitrification

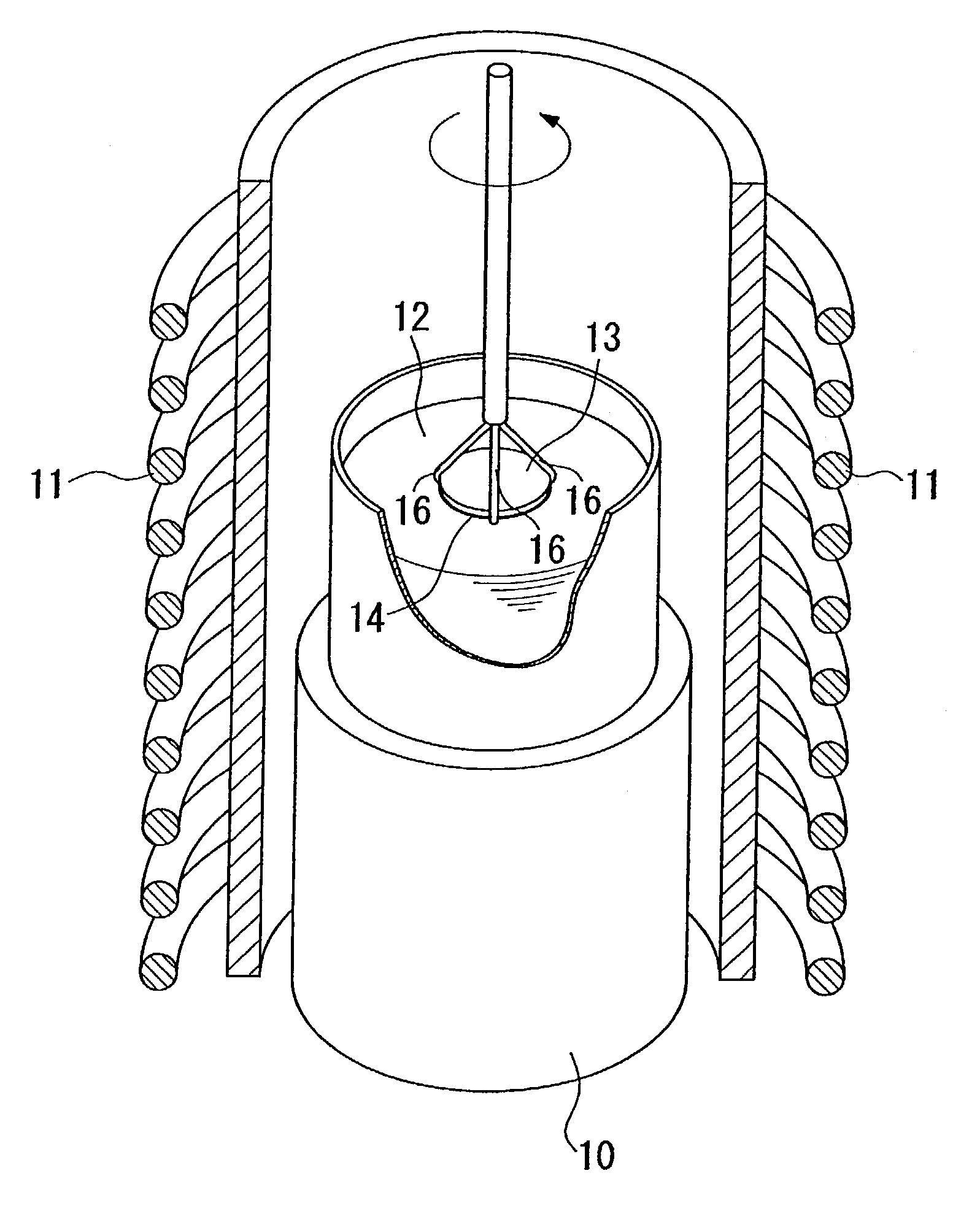

This method produces a magnetic material containing magnetic powder, a rare earth element, iron, and boron, forming a mixture with an amorphous metal in which the atomic proportion of the rare earth element is in a range of 22-44 atomic percent and the atomic proportion of the boron is in a range of 6-28 atomic percent and heating to a temperature of 30 DEG C lower than the crystallization temperature of the amorphous metal or higher, or, when the amorphous metal is a metallic glass, to the glass transition temperature thereof or higher.

Owner:DAIHATSU MOTOR CO LTD

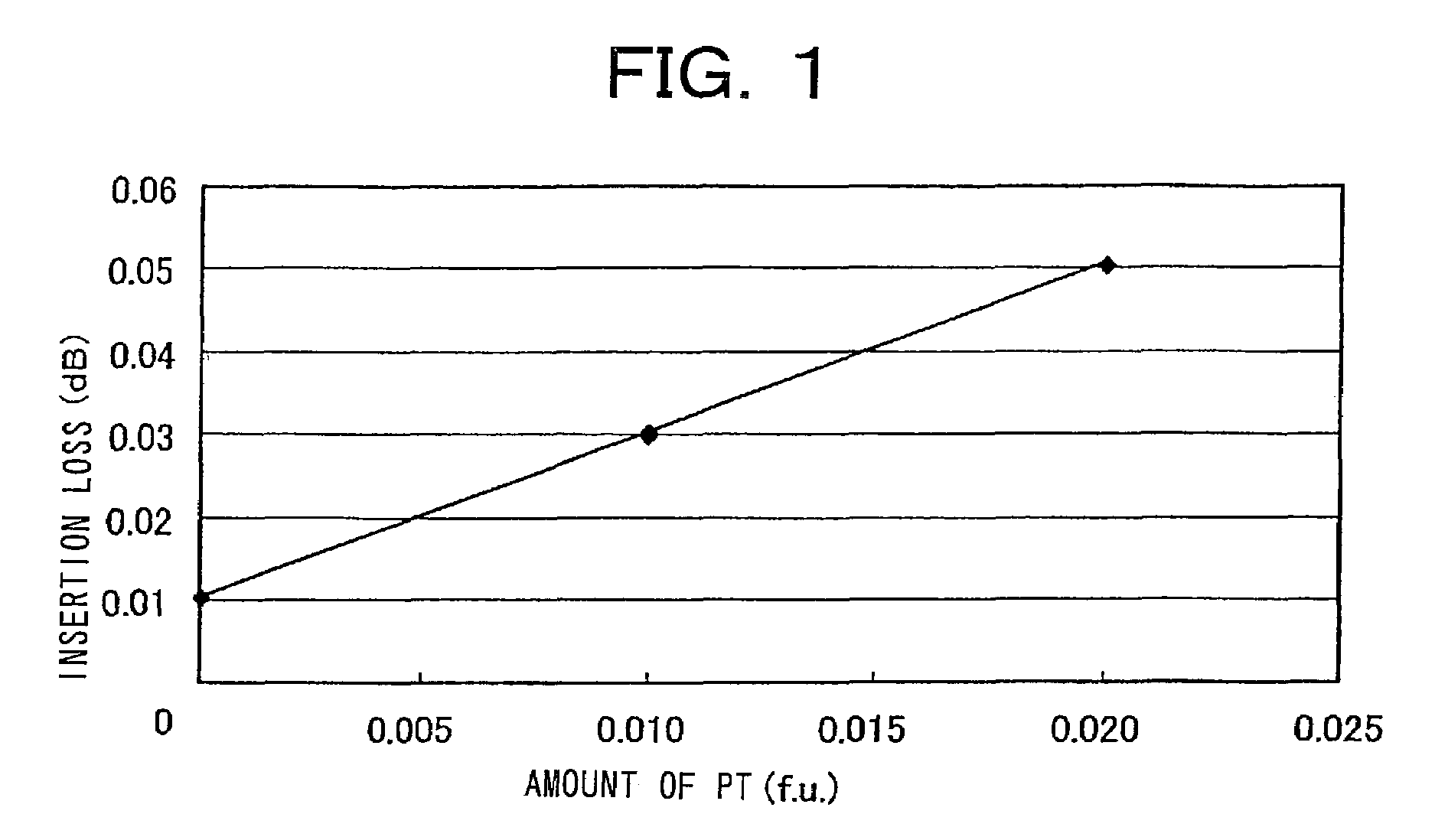

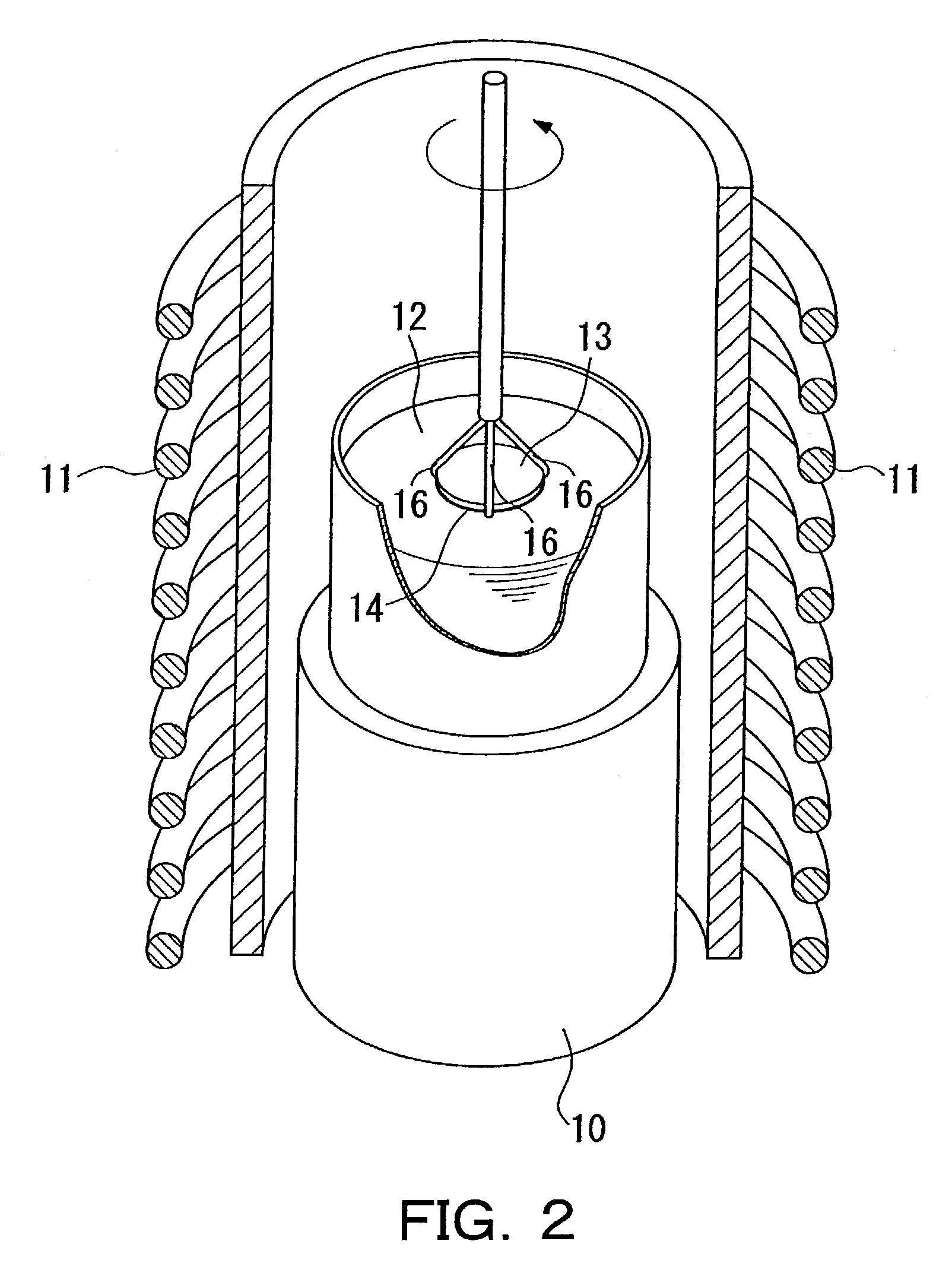

Magnetic garnet material, faraday rotator, optical device, bismuth-substituted rare earth-iron-garnet single-crystal film and method for producing the same and crucible for producing the same

ActiveUS7133189B2Excellent magnetic propertiesReduced insertion lossPolycrystalline material growthLiquid-phase epitaxial-layer growthCrucibleRare earth

Proposed is a technique of producing a magnetic garnet material of which the light absorption characteristics worsen little even though it is produced through LPE. The crucible for LPE is formed of a material containing Au. The amount of Au to be taken in single crystal formed in an Au crucible is smaller than that of Pt to be taken therein formed in a Pt crucible. As compared with Pt, the influence of Au on magnetic garnet film that increases the insertion loss in the film is small.

Owner:TDK CORPARATION

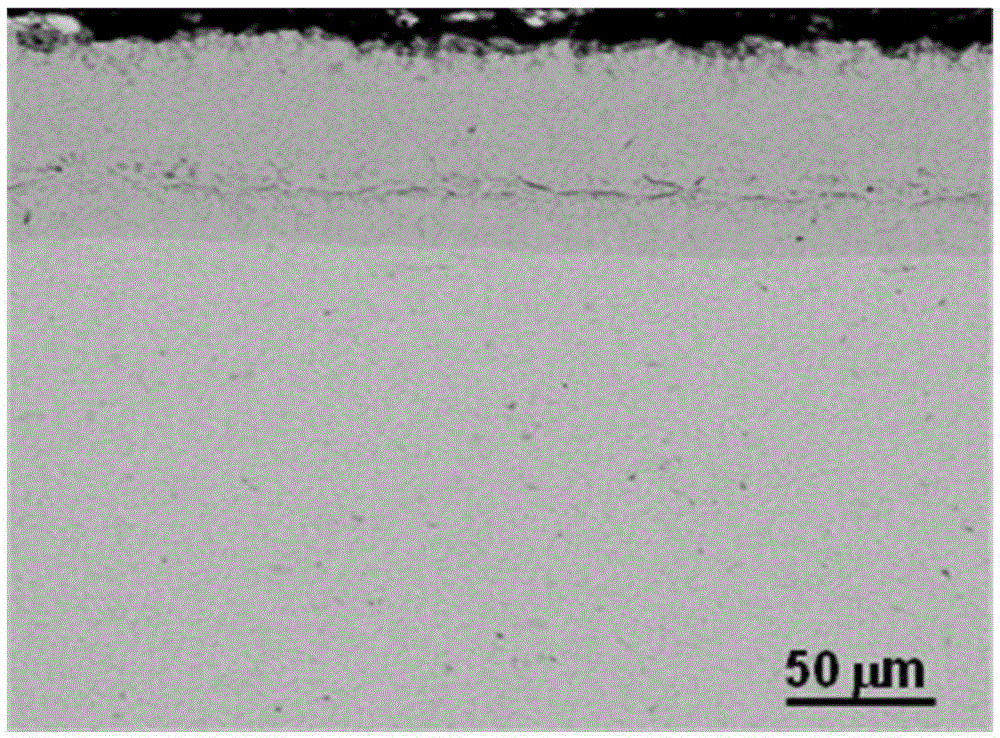

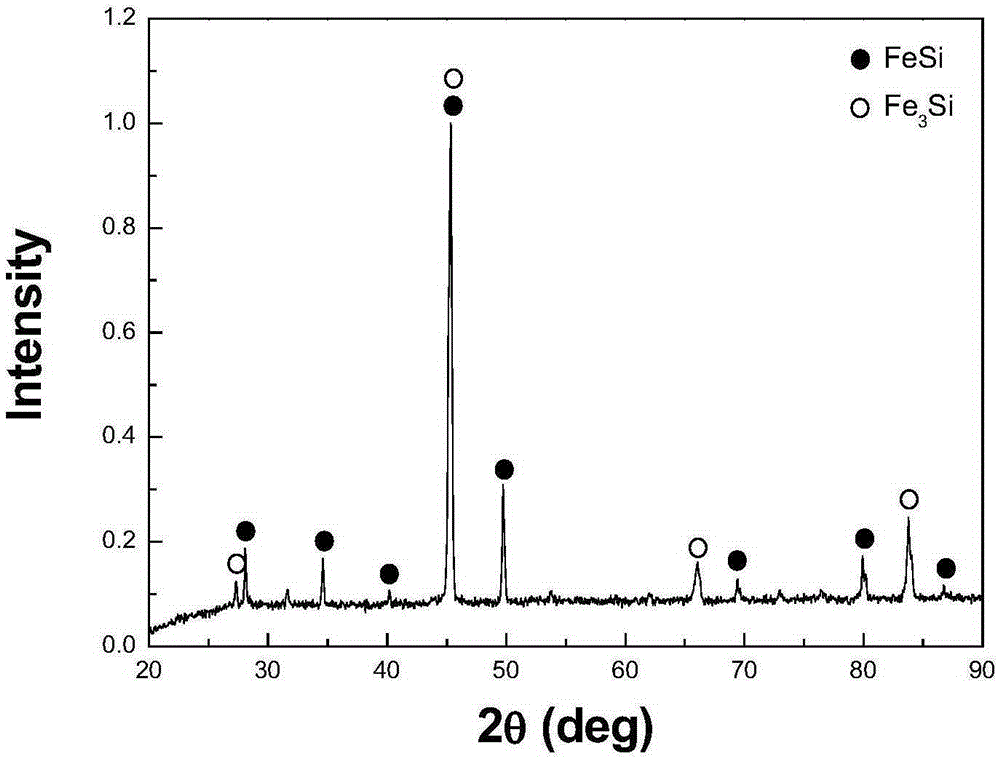

Method for preparing high-silicon steel from low-silicon steel

ActiveCN105296917AExcellent magnetic propertiesSuppression of eddy current lossSolid state diffusion coatingSuperimposed coating processIonCorrosion

The invention belongs to the field of material preparation, in particular to a method for preparing high-silicon steel from low-silicon steel. The method comprises the following steps: a, using a low-silicon steel hot-rolled plate with a smooth surface as a base material, and carrying out cold rolling so as to obtain a thin plate; b, carrying out acid pickling on the thin plate so as to remove oil stains and an oxide film on the surface; c, in a temperature range of 450-550DEG C, carrying out thermal insulation on the cold-rolled thin plate in a solid siliconizing agent for 20-30 minutes; d, in a temperature range of 750-820DEG C, carrying out solid siliconizing on the thermally insulated thin plate for 10-30 minutes in the solid siliconizing agent; e, rolling the thin plate at a temperature of 350-450DEG C; f, at a non-oxidization atmosphere, carrying out diffusion annealing on the siliconized thin plate at a temperature of 850-1100 DEG C for 30-480 minutes; and g, under nitrogen protection, rapidly cooling the thin plate subjected to diffusion annealing to a room temperature and coating a MgO coating. The method is characterized by low raw materials and simple processing and treating. The problems of steel band surface serious corrosion and Fe losses, caused by high Cl-ion concentration in the process of preparing the high-silicon steel by a vapor deposition process are solved.

Owner:NORTHEASTERN UNIV

Fe-based amorphous alloy ribbon and magnetic core formed thereby

InactiveUS20060000525A1Improve saturation magnetic flux densityStress be relaxMagnetic materialsCores/yokesMagnetic coreTransformer

A magnetic core provided with a shape for a transformer by a cut-lap or step-lap method, which is constituted by an Fe-based amorphous alloy ribbon having excellent magnetic characteristics, which is represented by the general formula: FeaSibBcMx or FeaSibBcCdMx wherein M is Cr and / or Ni, a is 78 to 86 atomic %, b is 0.001 to 5 atomic %, c is 7 to 20 atomic %, x is 0.01 to 5 atomic %, and d is 0.001 to 4 atomic %, (a+b+c+x) or (a+b+c+d+x) being 100.

Owner:HITACHI METALS LTD

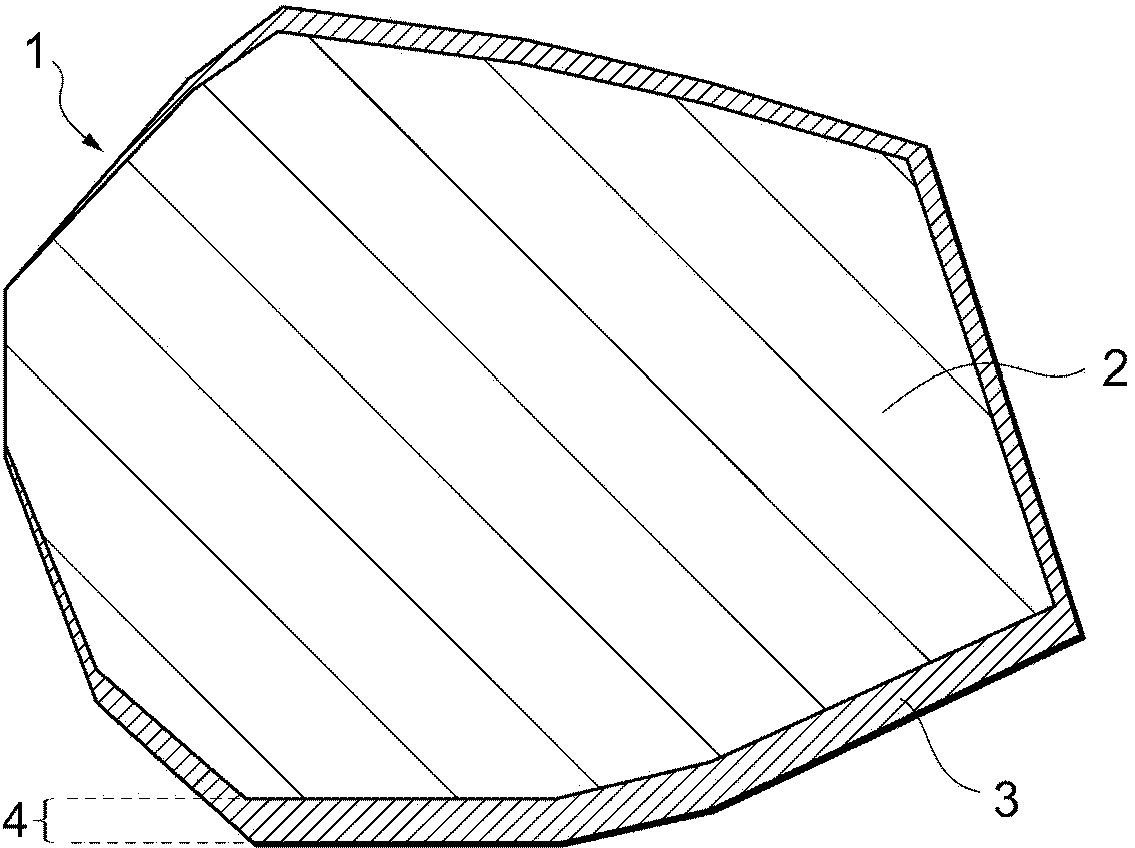

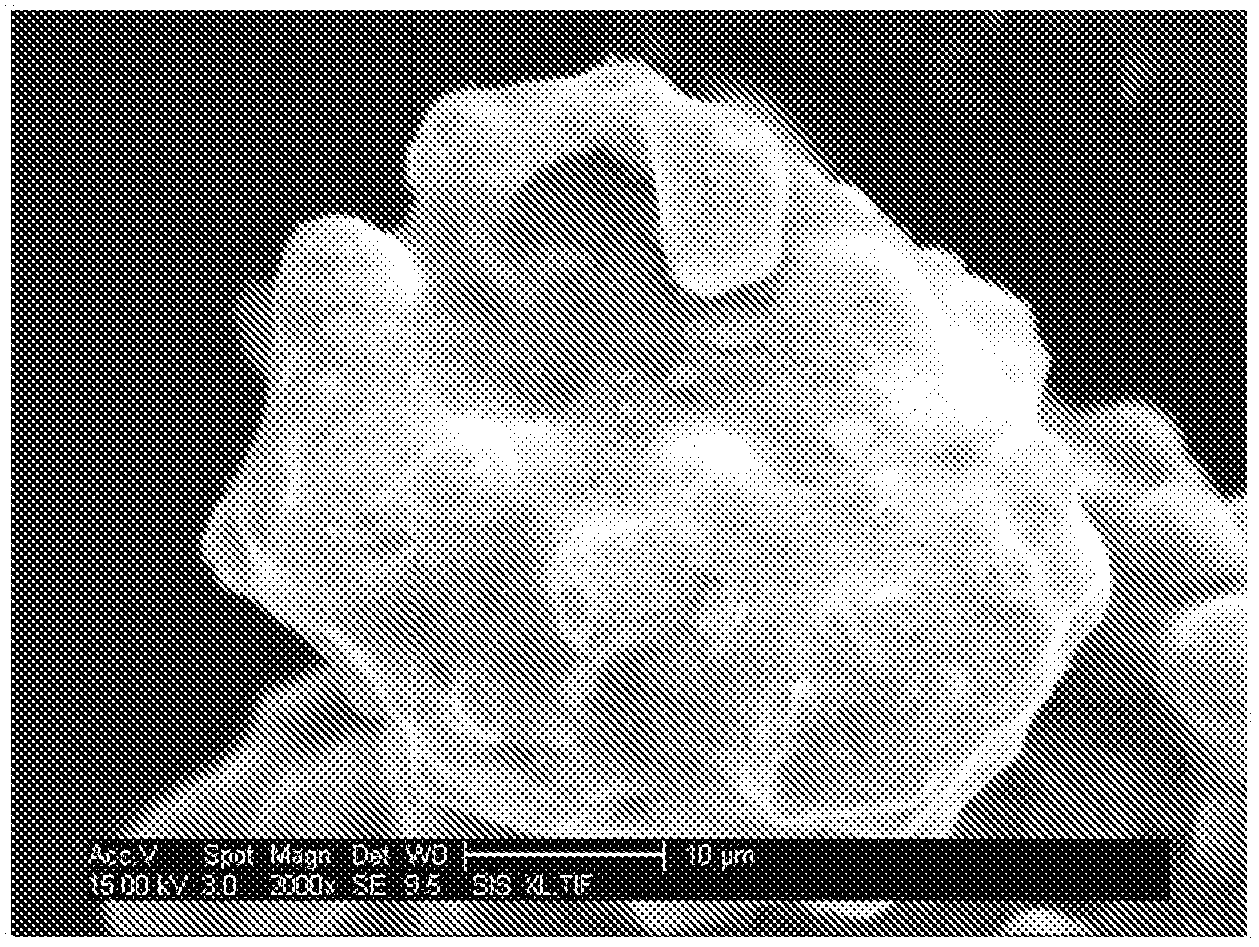

R-T-B type alloy, production method of r-t-b type alloy flake, permanent magnet, and fine powder for manufacturing the same

ActiveCN1958824AImprove coercive forceExcellent magnetic propertiesTransportation and packagingMetal-working apparatusRare-earth elementAlloy

The present invention provides an R-T-B type alloy as a raw material of a rare earth-based permanent magnet having excellent magnetic characteristics. The present invention provides an R-T-B type alloy (wherein R is at least one member selected from rare earth elements including Y, T is a transition metal essentially comprising Fe, and B is boron) which is a raw material for use in a rare earth-based permanent magnet, wherein the volume percentage of the region containing an R 2 T 17 phase having an average grain diameter of 3 m or less in the short axis direction is from 0.5 to 10%.

Owner:TDK CORPARATION

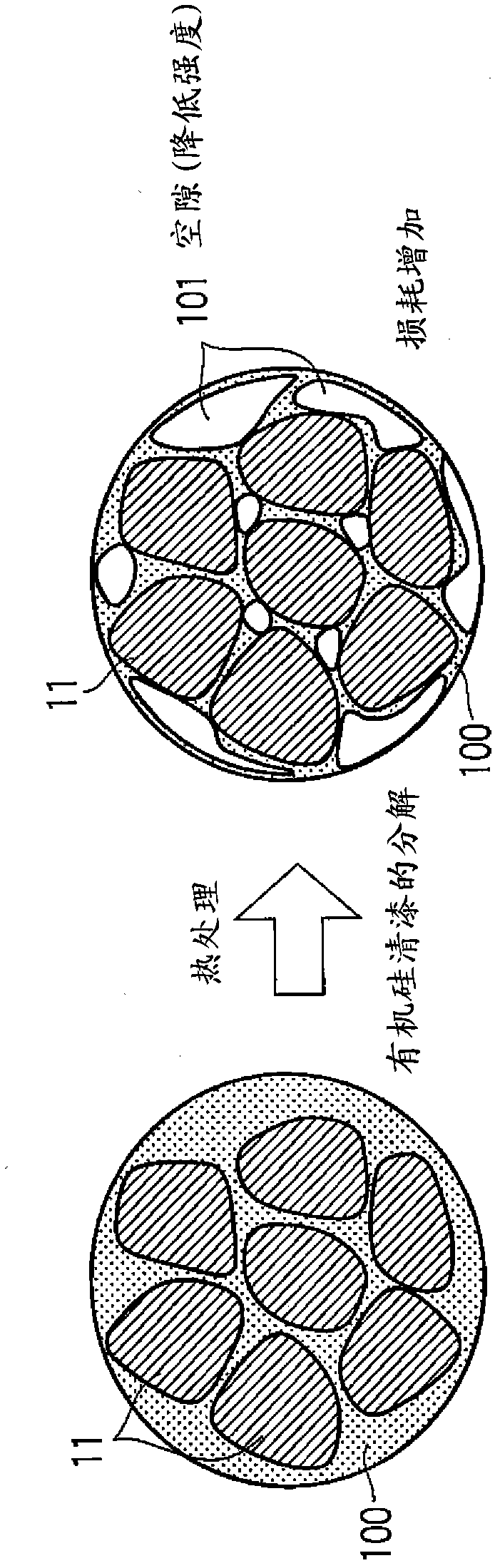

Coated metal powder, powder magnetic core and method for producing same

InactiveCN102917818AExcellent magnetic propertiesExcellent mechanical propertiesMetal-working apparatusInorganic material magnetismCalcium biphosphateMetal powder

A coated metal powder is a metal powder that contains iron as a main component, and an insulating layer that is formed on a surface of the metal powder and is formed from calcium phosphate and a metal oxide, in which an organosilicon compound is contained on a surface of the insulating layer or inside the insulating layer.

Owner:RESONAC CORPORATION +1

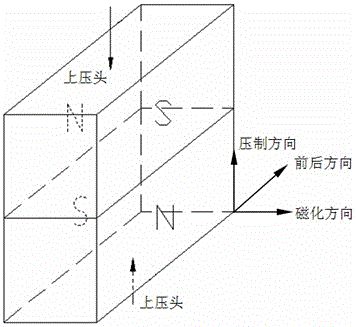

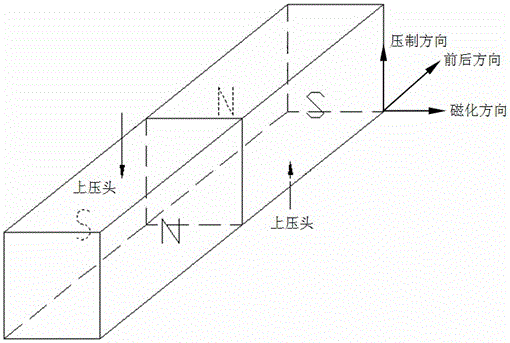

Method for preparing large-size sintered samarium cobalt permanent magnet

ActiveCN106782977AExcellent magnetic propertiesThe appearance of the magnet is normalInorganic material magnetismFatigue testingMagnetic powder

A method for preparing a large-size sintered samarium cobalt permanent magnet includes the following steps that firstly, a samarium cobalt alloy ingot is smashed, milled and mixed to obtain magnetic powder; secondly, oriented-pressing and forming are conducted in a magnetic field to obtain blanks; thirdly, two or more blanks are spliced together and tightly wrapped by fresh-keeping films, vacuum packaging is conducted, cold isostatic pressing is conducted, and a formed blank is obtained; fourthly, the formed blank is subjected to vacuum pre-sintering, inert gas is introduced for sintering, solid solution is conducted, air cooling is conducted to normal temperature, and a sintered blank is obtained; fifthly, the sintered blank is subjected to aging treatment, cooling and heat preservation are conducted, air cooling is conducted to normal temperature, and the large-size sintered samarium cobalt permanent magnet is obtained through machining. The ultra-large sintered samarium cobalt permanent magnet with the unilateral size larger than 130 mm can be prepared through the method, is good in magnetic property, and can reach the XGS30H trademark magnet standard, the product yield reaches 94% or above, the magnetic property is not changed after temperature-resistant and fatigue testing, and the appearance is normal. The process is simple, large-scale production can be achieved, and the cost is low.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

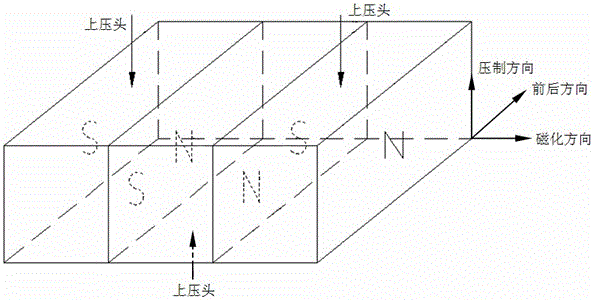

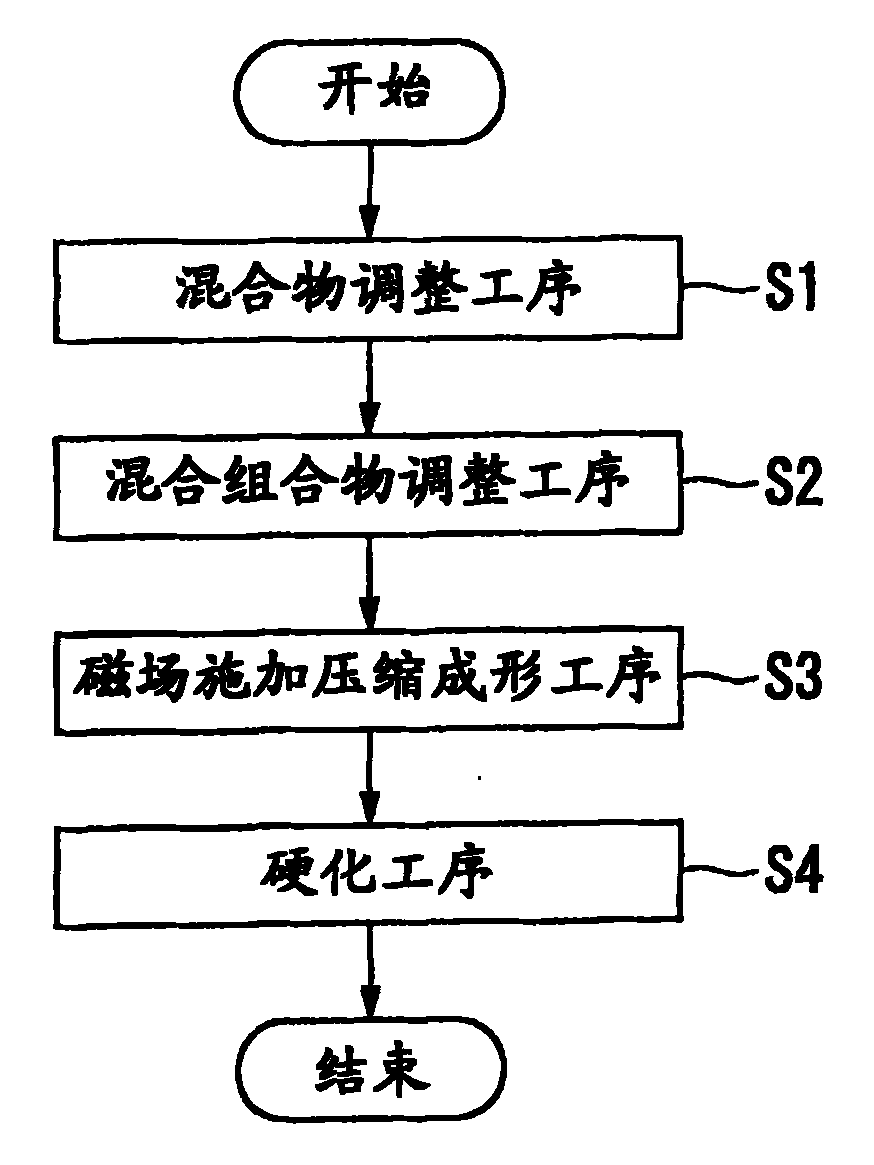

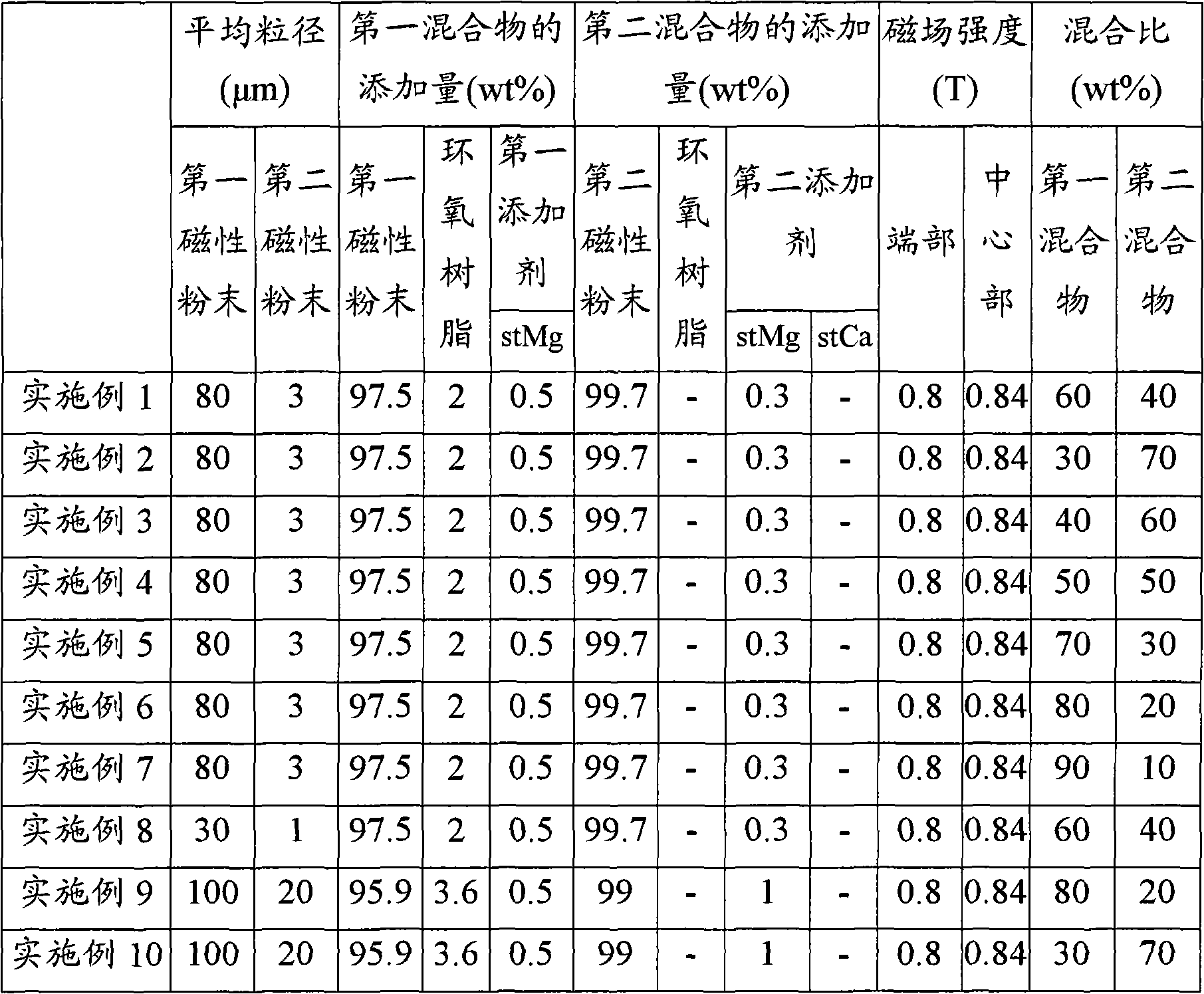

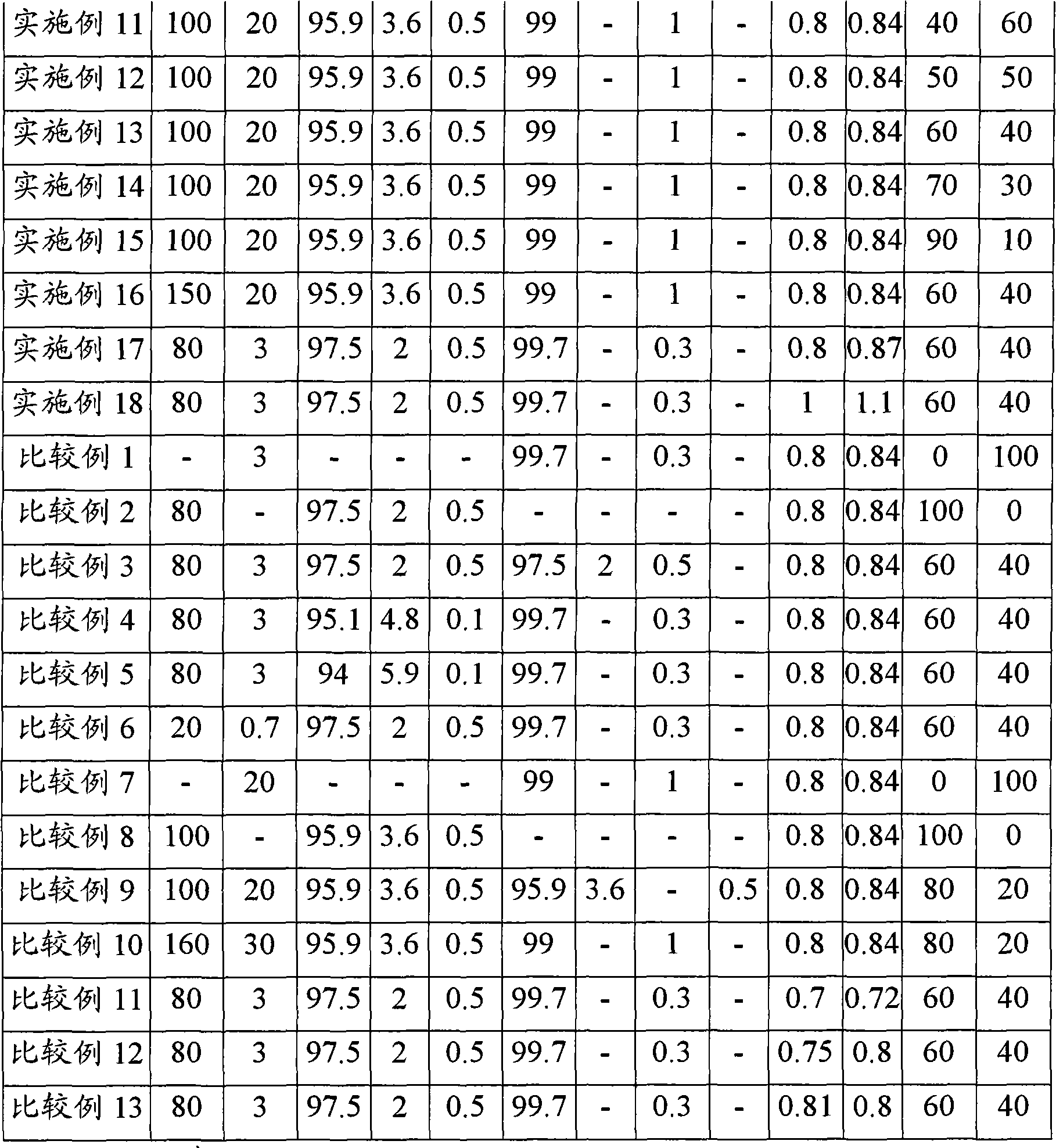

Anisotropically bonded magnet and fabricating method, magnetic path thereof

InactiveCN101814368AExcellent magnetic propertiesHigh mechanical strengthInductances/transformers/magnets manufactureMetallurgyNitrogen

This invention relates to a fabricating method for anisotropically bonded magnet including: step S1 for adjusting the first mixture and the second mixture, where: the first mixture comprises the first magnetic powder, of which the grain size is in the range of 20-150mum, thermosetting resin of 2.0 wt%being added into the anisotropically bonded magnet, the first additive; the second mixture comprises the second magnetic powder, of which the grain size is in the range of 1-20mum, the second additive; step S2 for adjusting the first mixture and the second mixture; step S3 for making the magnetic intensity of the end part of the shaping metal die be under the 0.8T, the magnetic intensity of the central part of the shaping metal die is 5% higher than that of the said end part of the shaping metal die after said mixed compounds being filled into the metal die; step S4 for heating said mixed compounds at the atmosphere of inert gases or nitrogen gases so as to harden compounds.

Owner:SEIKO INSTR INC

Stator core and method of manufacturing same

ActiveUS20120086302A1Avoid bendingIncreased interMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesEngineering

A stator core 10 and its manufacturing method, the stator core 10 including laminated stator core sheets 17, each of the stator core sheets 17 punched out from a magnetic metal sheet 32, a central portion of the magnetic metal sheet 32 previously punched out to form a rotor core sheet 36, the stator core 10 including a thin section 24 formed in a magnetic pole piece 19 of each of the stator core sheets 17, the thin section 24 formed by pressing both sides of the magnetic pole piece 19 in a thickness direction and radially-inwardly elongating the magnetic pole piece 19. The present invention prevents the magnetic pole piece 19 from being curved and improves interlocking accuracies and dimensional accuracies in blanking the rotor core sheet 36 and the start core sheet 17 from one magnetic metal sheet 32.

Owner:MITSUI HIGH TEC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com