Composite magnetic material and method of manufacturing the same

A technology of composite magnetic materials and non-magnetic materials, applied in the field of inductors, can solve the problems of poor formability, difficult to increase the forming speed, damage of molds and punches, etc., to improve product characteristics, improve magnetic characteristics, and ensure the effect of practical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] (Preparation of inductors)

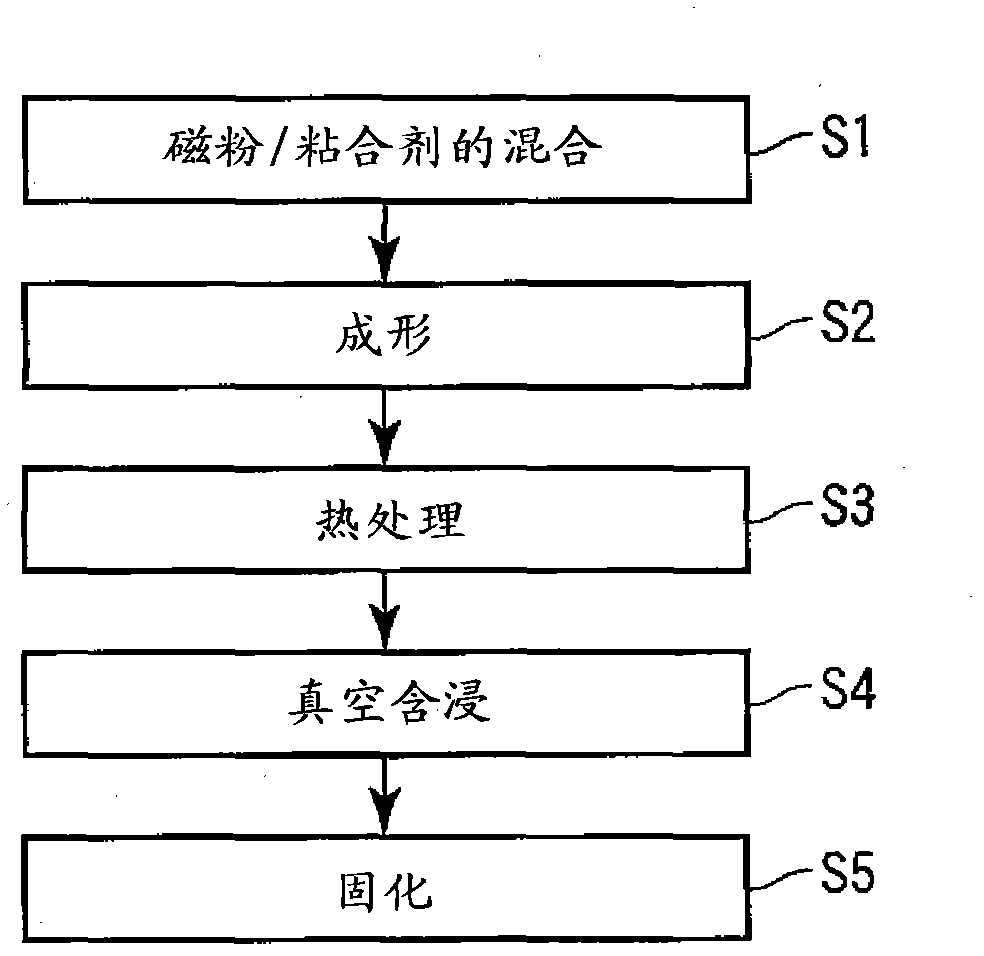

[0086] Below, refer to Figure 3A ~ Figure 6C , the case of manufacturing various inductors (coils) will be described.

[0087] exist Figure 3A , Figure 3B , Figure 4A and Figure 4B In the figure, respectively, the inductors 1A and 1B in which the second binder is impregnated into a composite magnetic material (powder iron core) molded body 2 formed into a ring shape and subjected to heat treatment, and a wire-wound conductor 3 is wound . Such as Figure 3A and Figure 3B The inductor shown is a type in which both ends of a wound conductor 3 are used as lead terminals 3a, protruding toward the side surface of a ring-shaped molded body 2, and the side surface of the molded body 2 is mounted on a printed circuit board. The longitudinal coil (inductor). Figure 4A and Figure 4B The inductor shown is a type in which both ends of a wound conductor 3 are used as lead terminals 3b, protruding toward the side of an annular molded body...

Embodiment

[0092] Hereinafter, various embodiments and examples of the present invention will be described with reference to specific examples.

no. 1 Embodiment approach

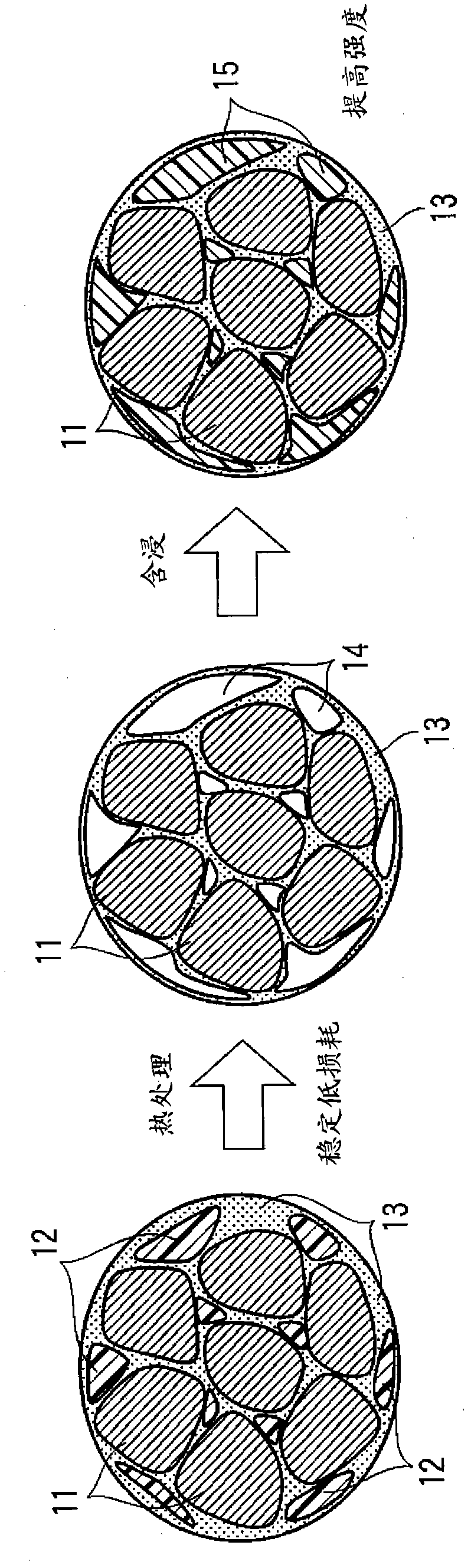

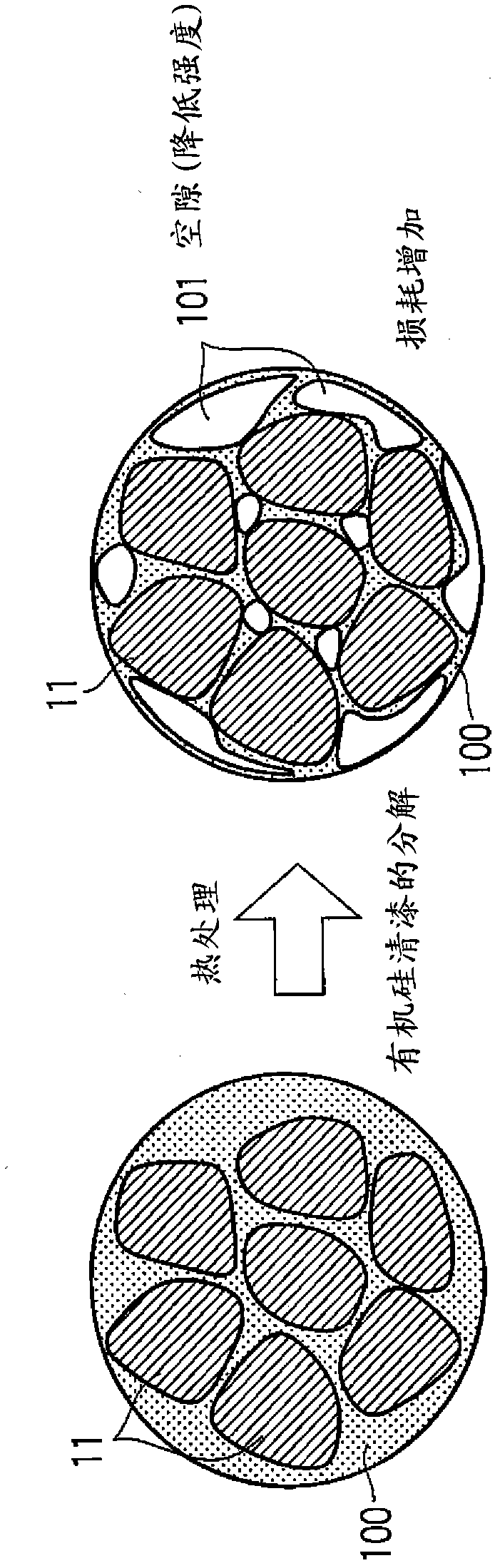

[0094] As the first embodiment of the present invention, an alloy whose main composition is Fe-9.6%Si-5.5%Al obtained by the vacuum dissolution method is produced, and the powder treatment process conditions are controlled and sieved by mechanical pulverization, and the sphericity is different. alloy powder. A first binder (forming aid) was added at a mass ratio of 0.04 to the alloy powder, wet-mixed with methyl ethyl ketone, and granulated while heating and drying to obtain a mixed powder. Furthermore, as the first binder, a ratio of silicone resin:organic resin=1:1 was blended.

[0095] Further add and mix zinc stearate with a mass ratio of 0.012 relative to the mixed powder, and use a mechanical forming machine to form a product shape with an outer diameter of 21 mm, an inner diameter of 12 mm, and a height of 7 mm under a pressure of about 1.5 GPa. Place the molded body in a nitrogen environment, heat-treat at 650°C for 1 hour, further vacuum impregnate the epoxy resin as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com