Coated metal powder, powder magnetic core and method for producing same

A manufacturing method and technology of metal powder, which are applied in the field of coated metal powder, powder magnetic core and their manufacturing, can solve the problems of inability to obtain functional effects, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

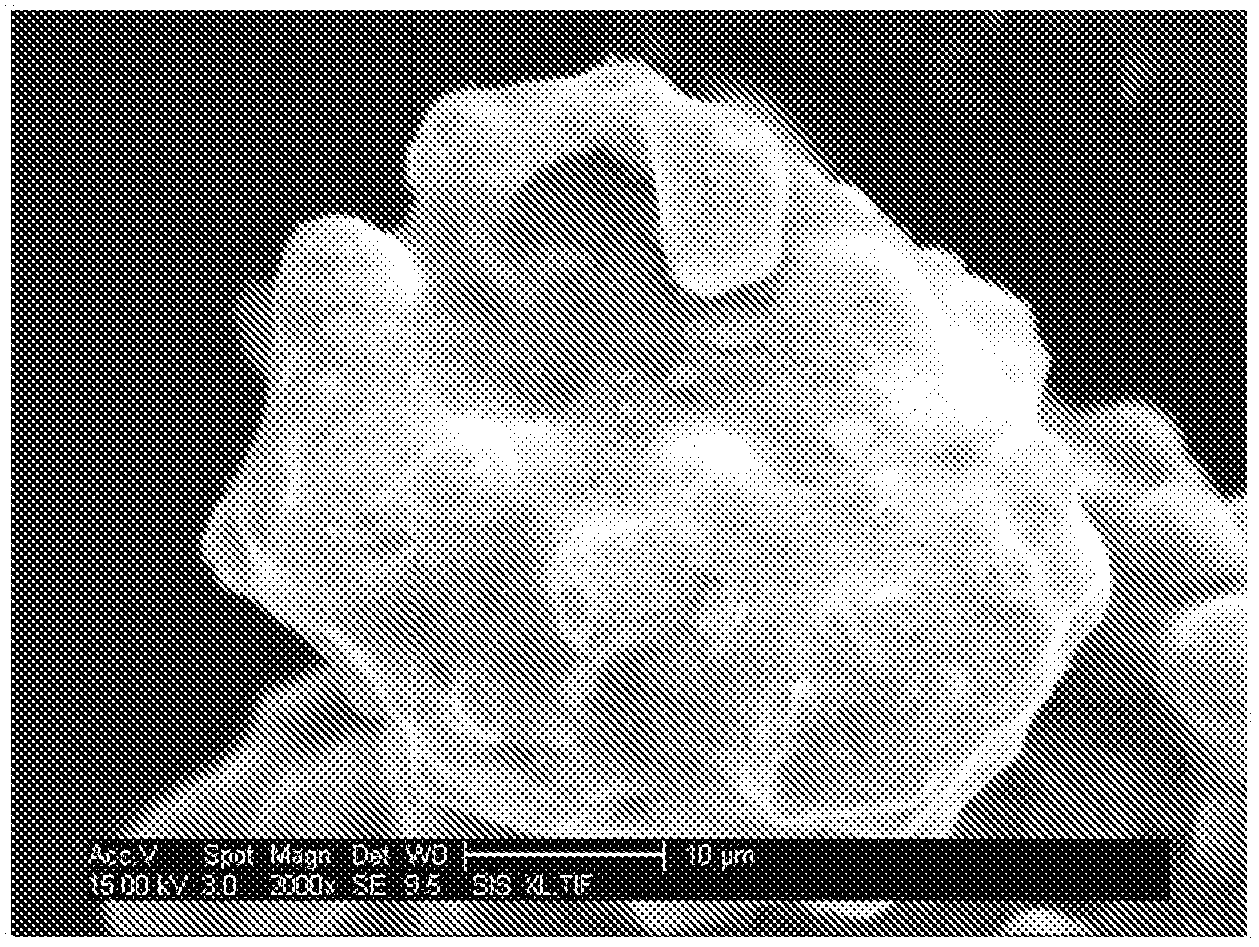

[0125] Put 30g of pure iron powder (water atomized powder, KIP-304AS manufactured by Kawasaki Iron and Steel Co., Ltd.) into a 50ml cylindrical container made of polypropylene, and add 3.4ml (0.358M) of calcium nitrate aqueous solution and 10ml of pure water to it. , 0.5ml 25% ammonia water, 3.4ml (0.215M) ammonium dihydrogen phosphate aqueous solution. Cap immediately after addition and stir with a mixing rotor set at 40 rpm. After 2 hours, the container was opened, and 2.0 g of ultra-high-purity colloidal silica (manufactured by Fuso Chemical Industry Co., Ltd. "Quartron PL-1", particle size 40 nm, SiO 2 Concentration is 12 mass %), cover again, and stir for 1.0 hour with the mixing rotor whose rotation number is set to 40 rpm.

[0126] The stirred iron powder dispersion was suction-filtered using No. 5C filter paper for quantitative analysis, and the filtrate was washed with acetone. The obtained iron powder was dried in a vacuum dryer to obtain a silicon dioxide / hydroxya...

Embodiment 2)

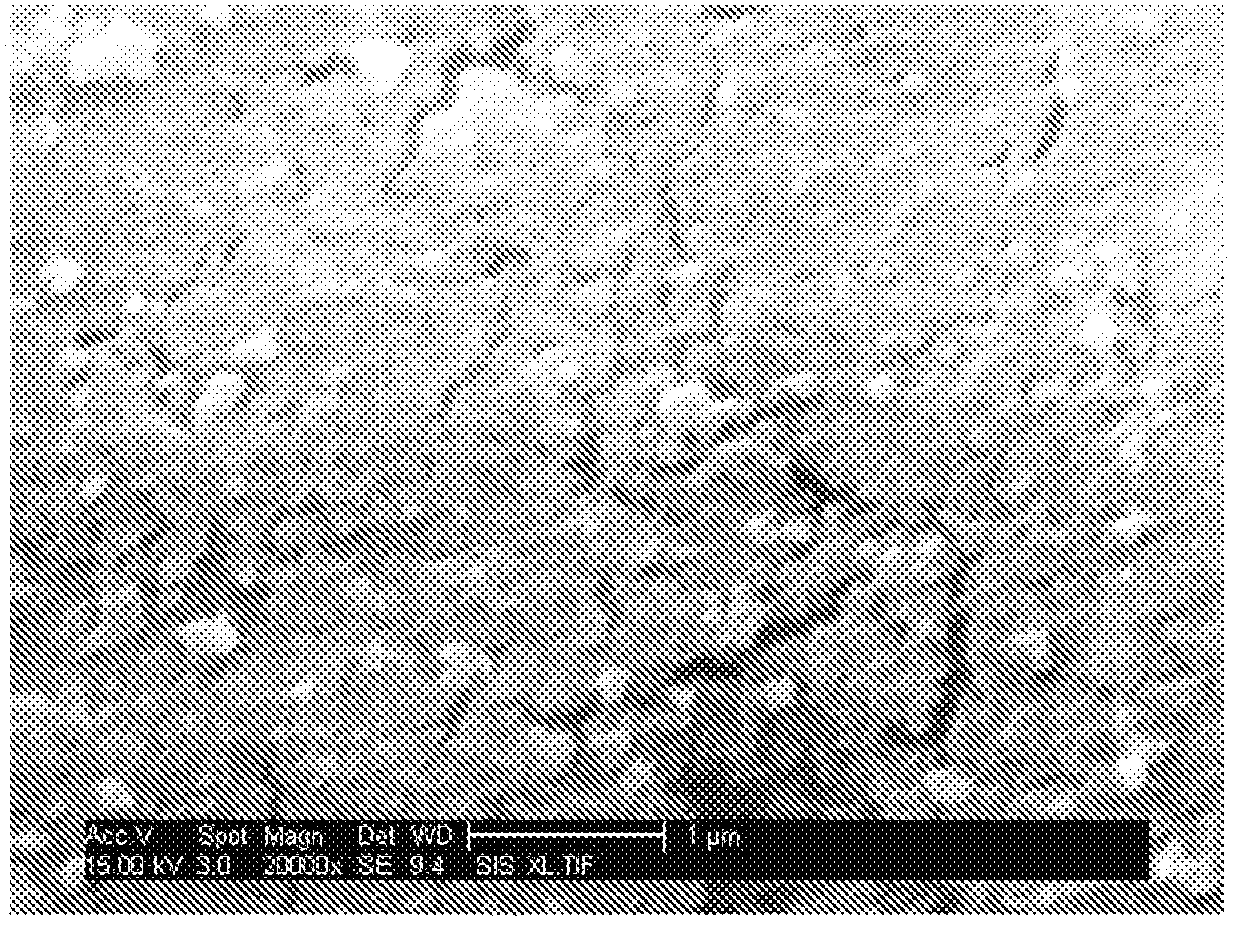

[0156] Put 30g of pure iron powder into a 50ml cylindrical container made of polypropylene, and add 3.4ml (0.358M) calcium nitrate aqueous solution, 10ml pure water, 0.5ml 25% ammonia water, 3.4ml (0.215M) diphosphate Aqueous solution of ammonium hydrogen. Cap immediately after addition and stir with a mixing rotor set at 40 rpm. After 2 hours, the container was opened, and 1.0 g of ultra-high-purity colloidal silica (manufactured by Fuso Chemical Industry Co., Ltd. "Quartron PL-7", particle size 120 nm, SiO 2 Concentration is 23% by mass), covered again, and stirred for 1.0 hour with a mixing rotor whose rotation number was set at 40 rpm.

[0157] The stirred iron powder dispersion was suction-filtered using No. 5C filter paper for quantitative analysis, and the filtrate was washed with acetone. The resulting iron powder was dried in a vacuum desiccator to obtain SiO 2 / HAP coated iron powder.

[0158] Next, 30g of the above SiO 2 / HAP-coated iron powder was placed in a...

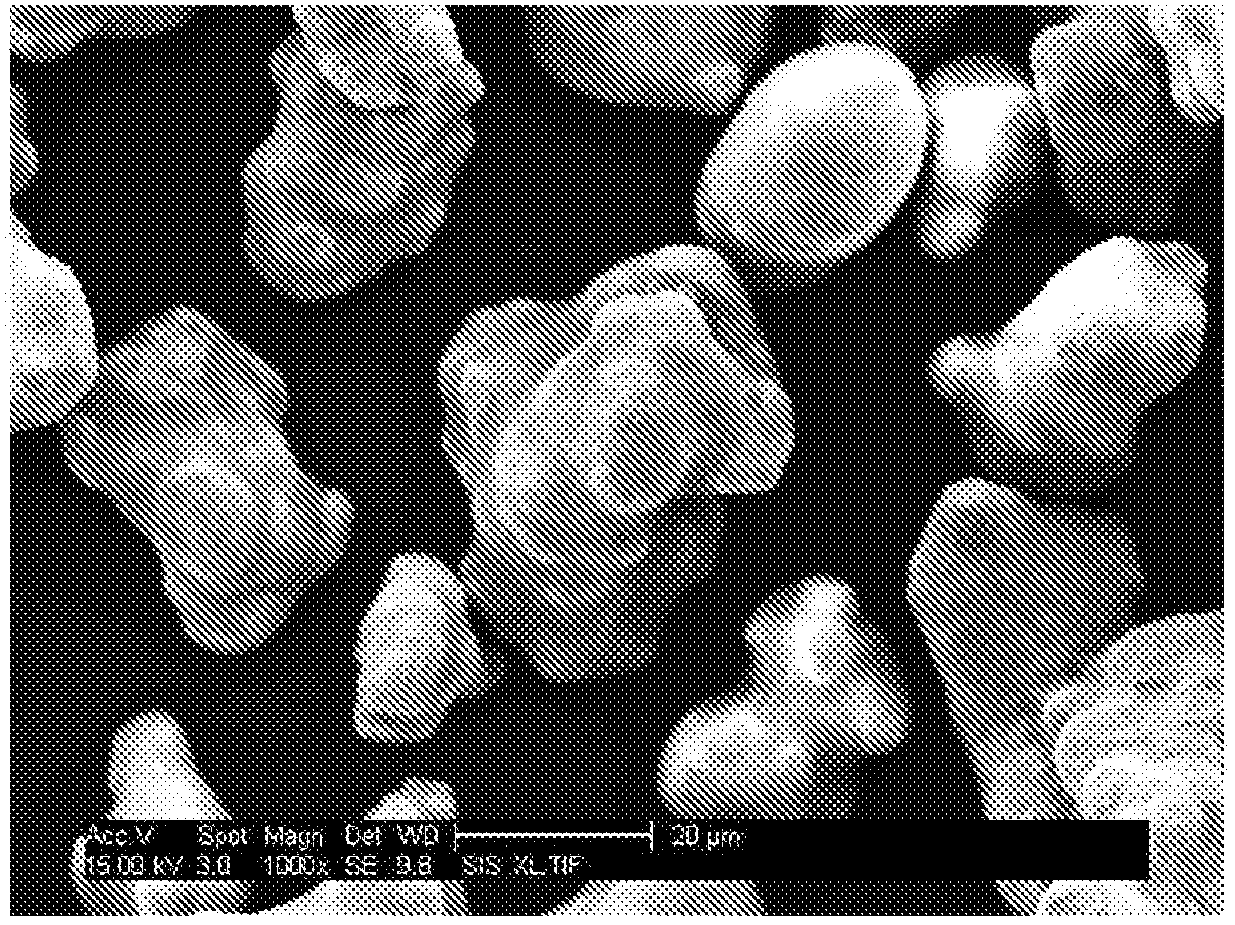

Embodiment 3)

[0165] In Example 2, the SiO 2 Change to alumina (Al 2 o 3 , manufactured by Nissan Chemical Industry Co., Ltd., alumina sol 100, Al 2 o 3 concentration is 10% by mass). The input amount of each material to the iron powder and the coating method are all the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com