Patents

Literature

36results about How to "High-speed durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistant steel cords and pneumatic tires reinforced with same

InactiveUS6102095ALowering of resistance to corrosion fatigueHigh tensile strengthPneumatic tyre reinforcementsYarnSurface layerMetallurgy

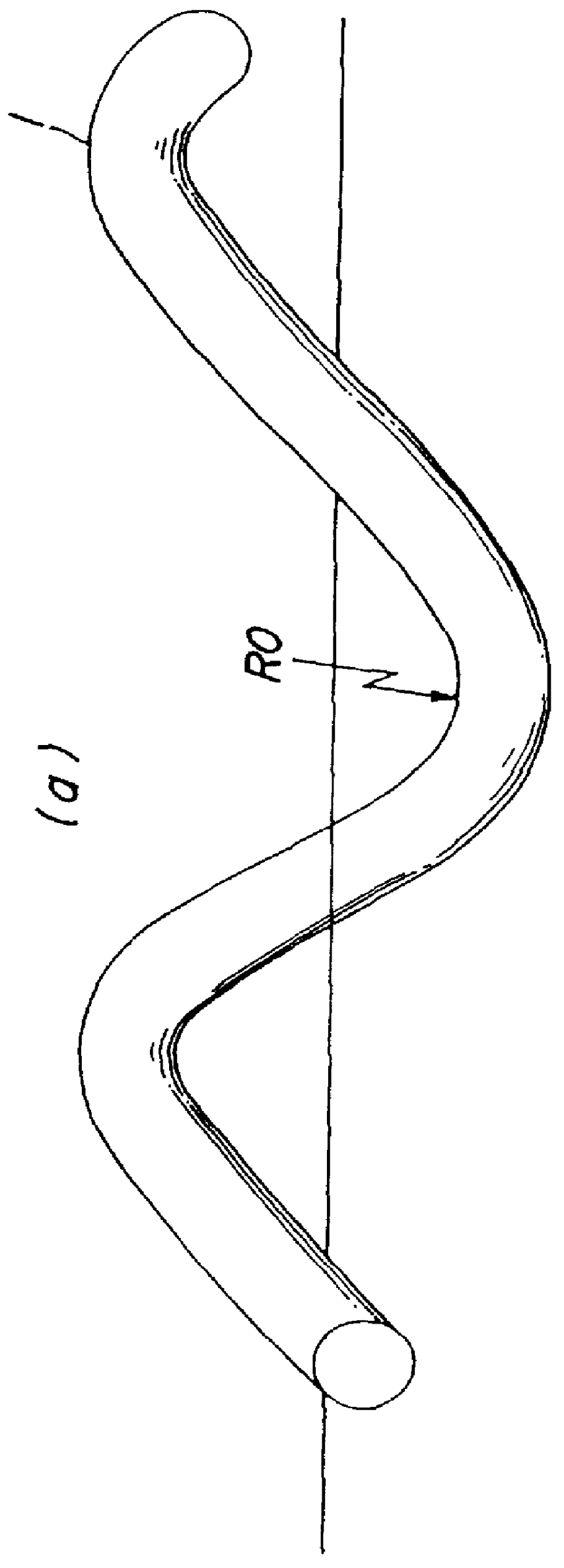

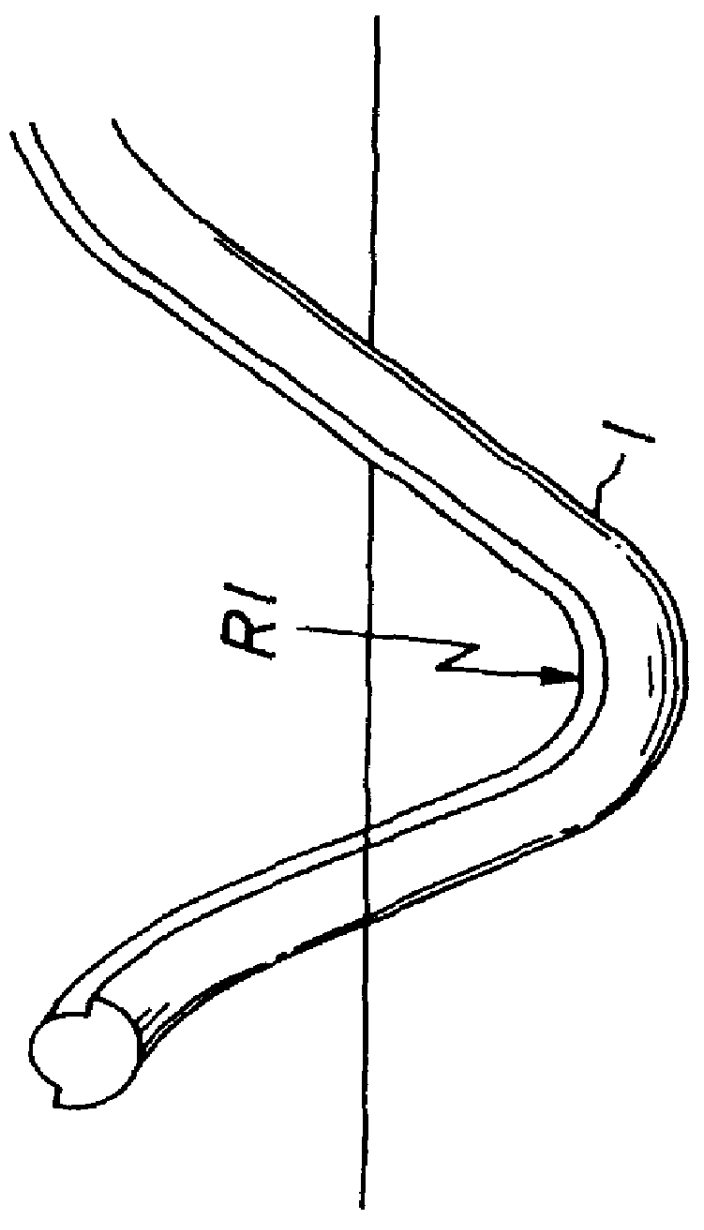

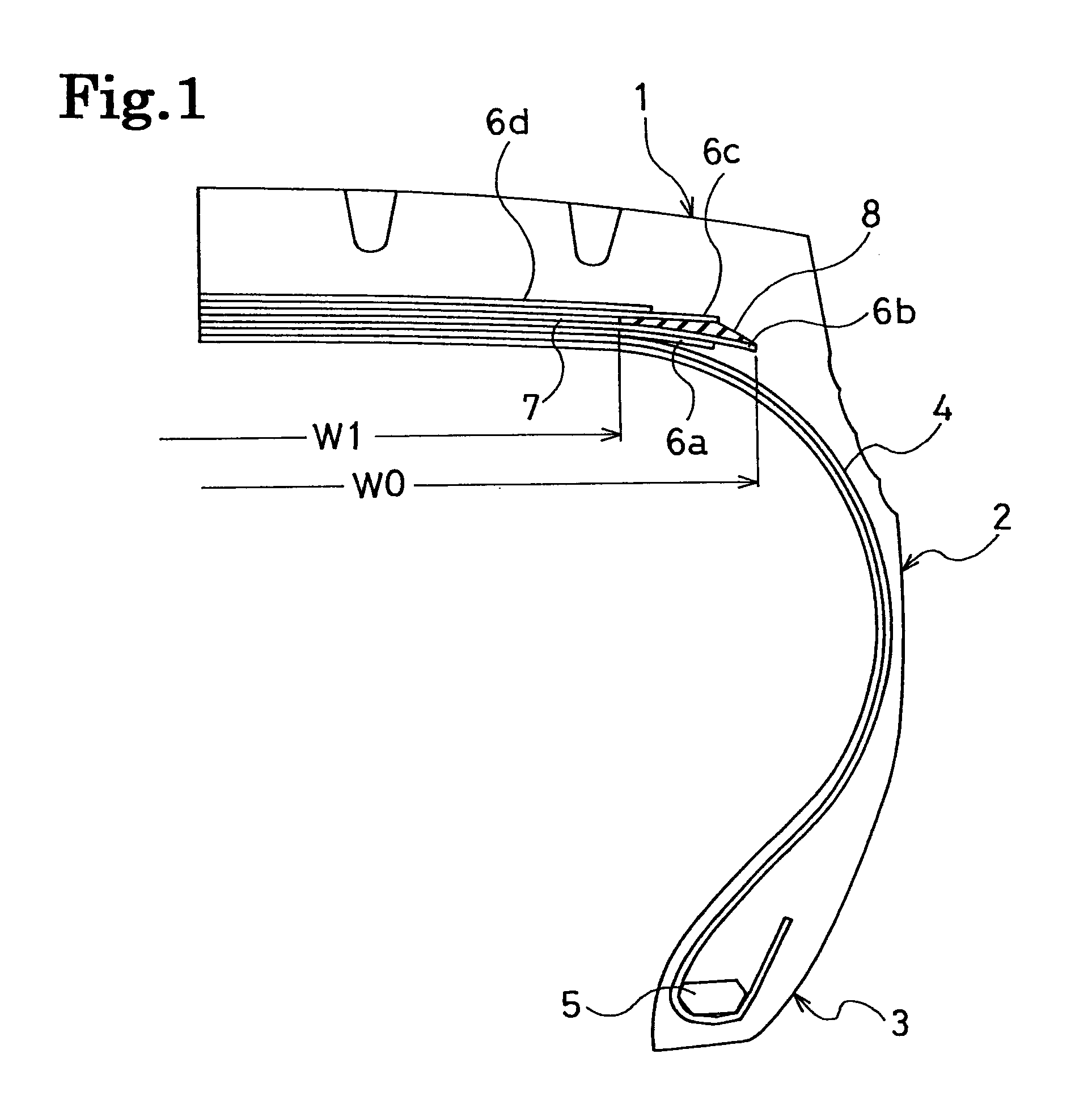

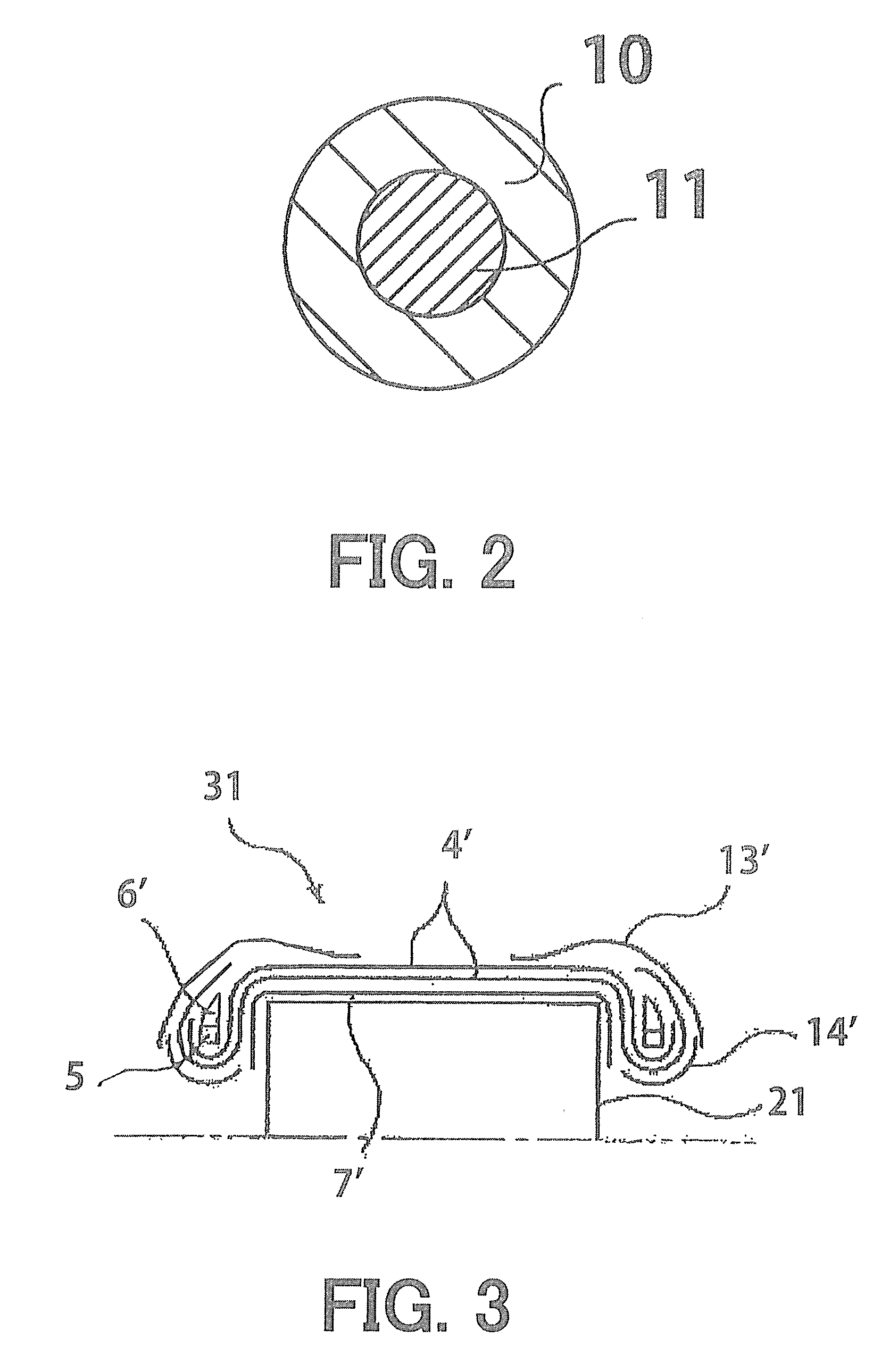

PCT No. PCT / JP97 / 01338 Sec. 371 Date Nov. 24, 1997 Sec. 102(e) Date Nov. 24, 1997 PCT Filed Apr. 18, 1997 PCT Pub. No. WO97 / 39176 PCT Pub. Date Oct. 23, 1997A corrosion resistant steel cord for reinforcing rubber articles, particularly a belt and / or carcass of a pneumatic tire, has a residual compressive stress inside the twisting helix of each steel filament such that a ratio R1 / R0 is less than one, where R0 is the radius of curvature of a helix in each helically formed steel filament obtained by untwisting of the cord and R1 is the radius of curvature of the helix after removal of a surface layer from the inside of the helix in the steel filament. The steel filaments have a tensile strength of 4,000-4,800 N / mm2. The cord does not have a wrapping wire around its outer peripheral surface and has either a single twisted construction obtained by twisting 3 to 6 steel filaments in an open structure having a space between adjacent filaments or a two-layer twisted construction obtained by surrounding a core of n=1-4 steel filaments with a sheath of n+(2-6) steel filaments in a rubber penetration structure having a space between adjacent filaments of the sheath or a three-layer twisted construction obtained by surrounding a core of a single steel filament with a first sheath of m=3-6 steel filaments and a second sheath of m+(2-6) steel filaments in a rubber penetration structure having a space between adjacent filaments of each sheath.

Owner:BRIDGESTONE CORP +1

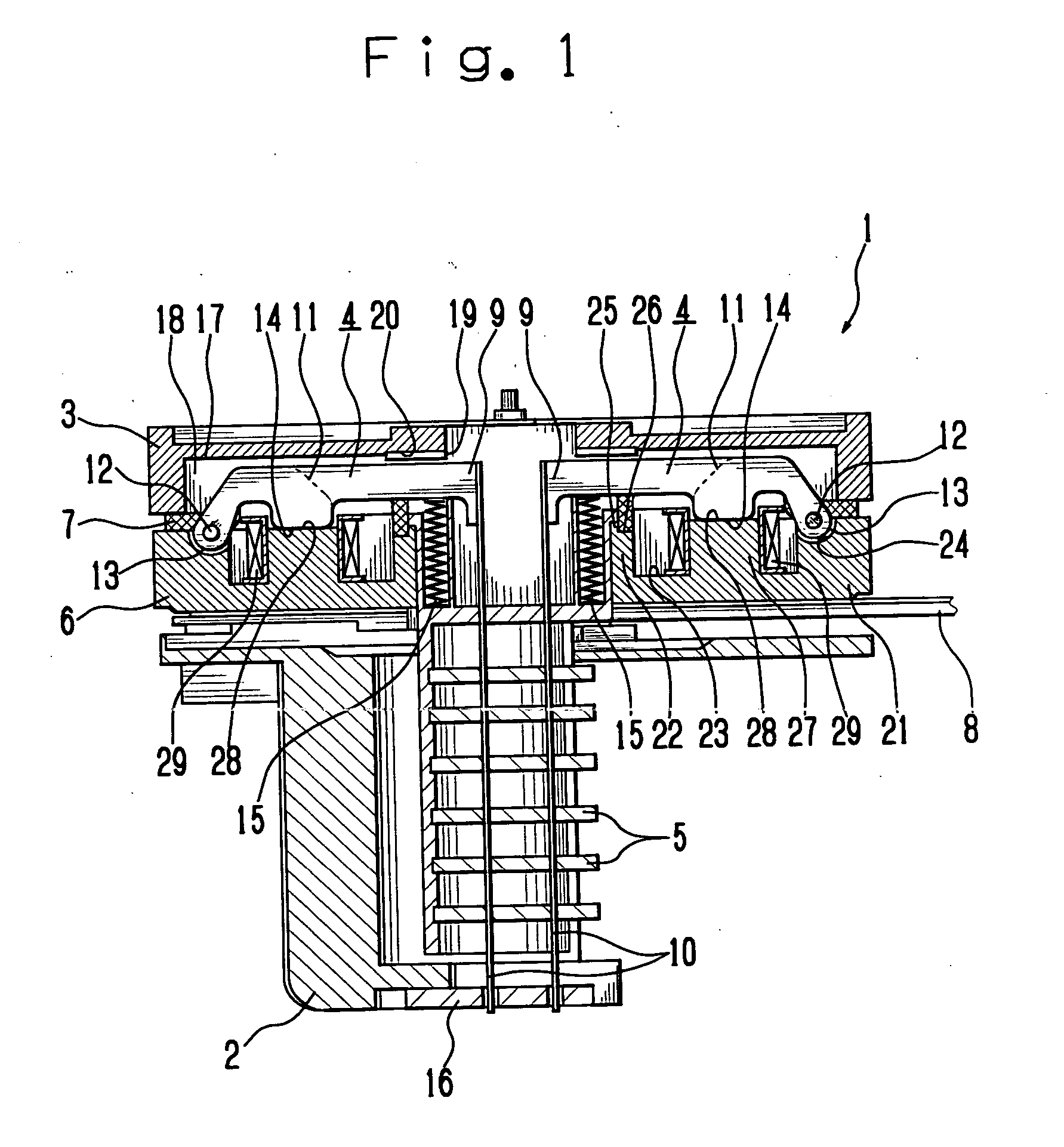

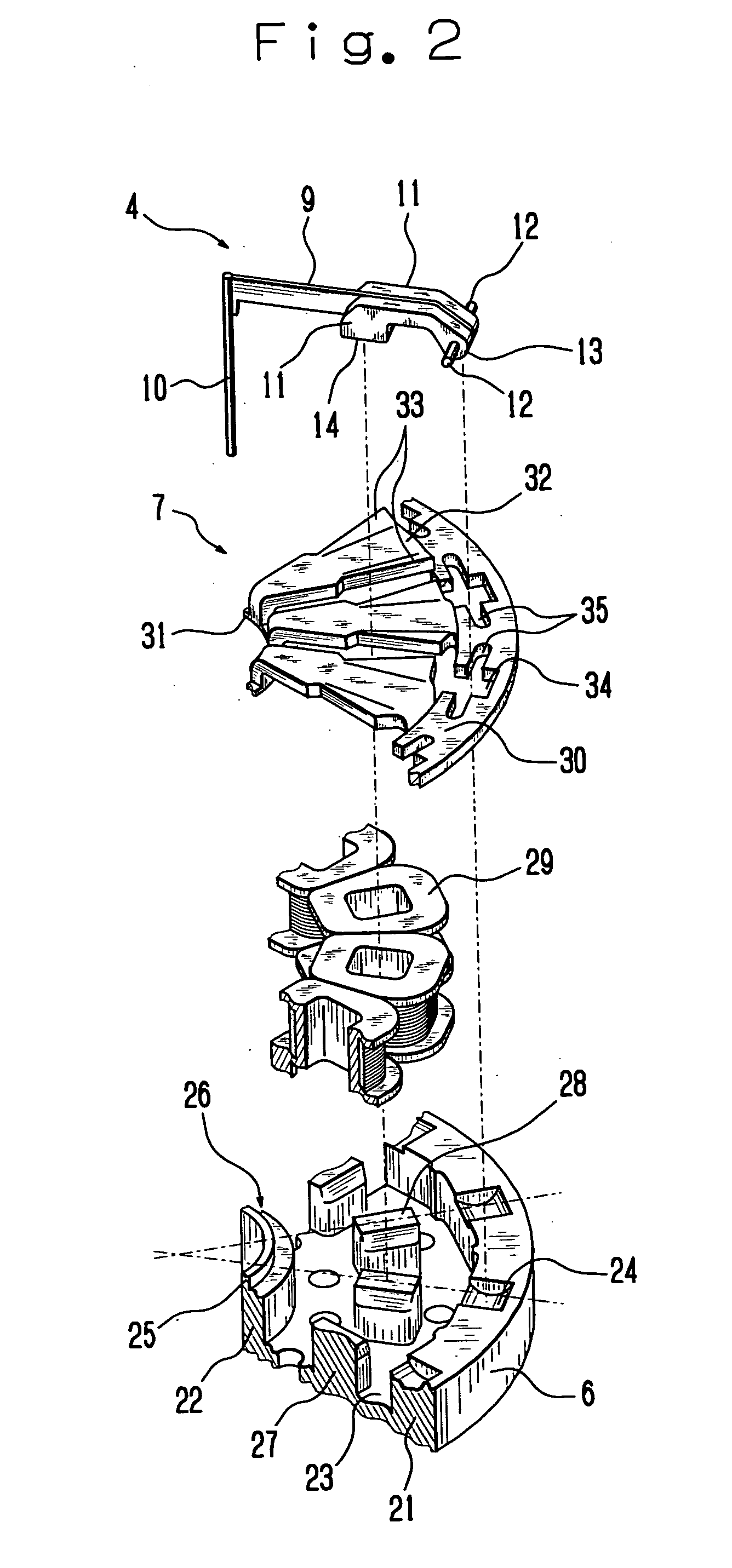

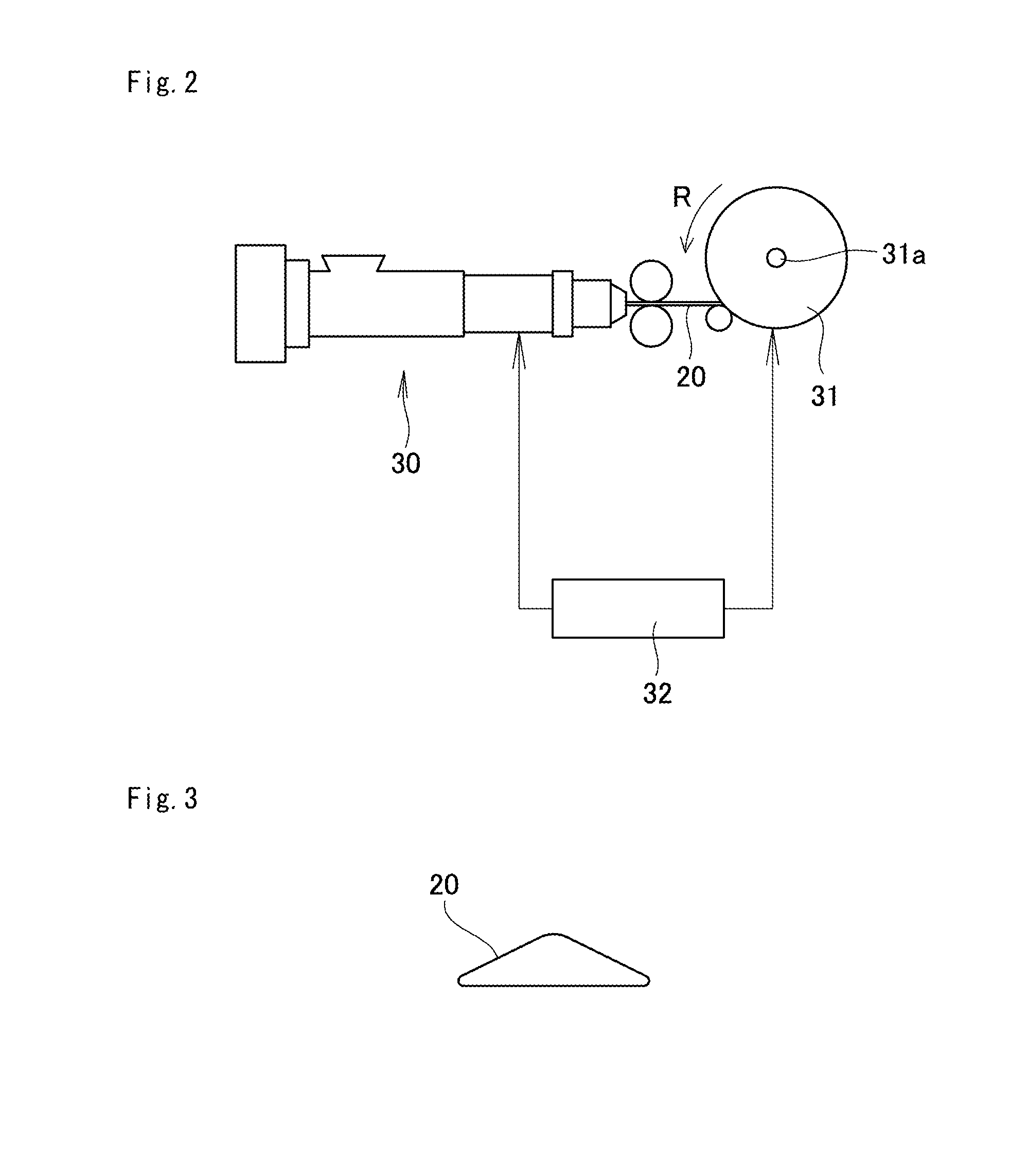

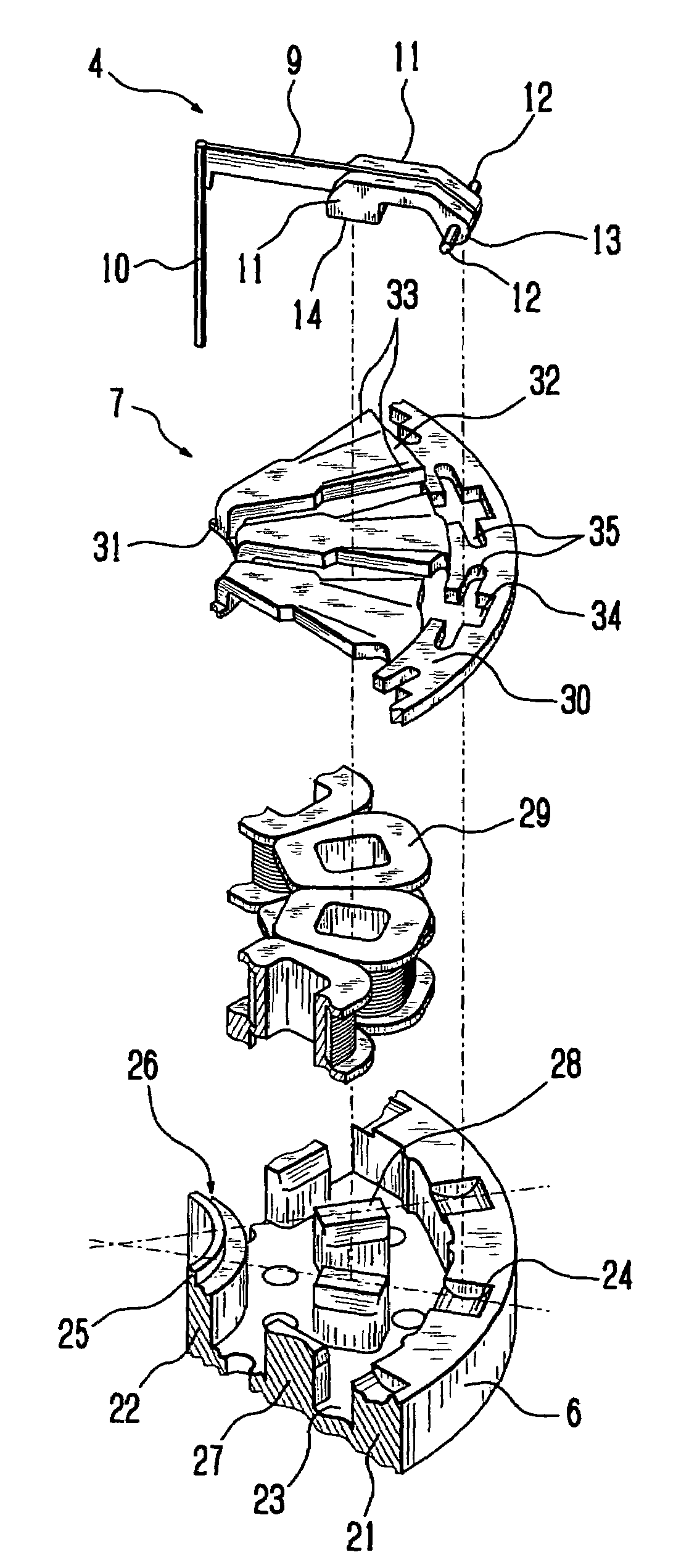

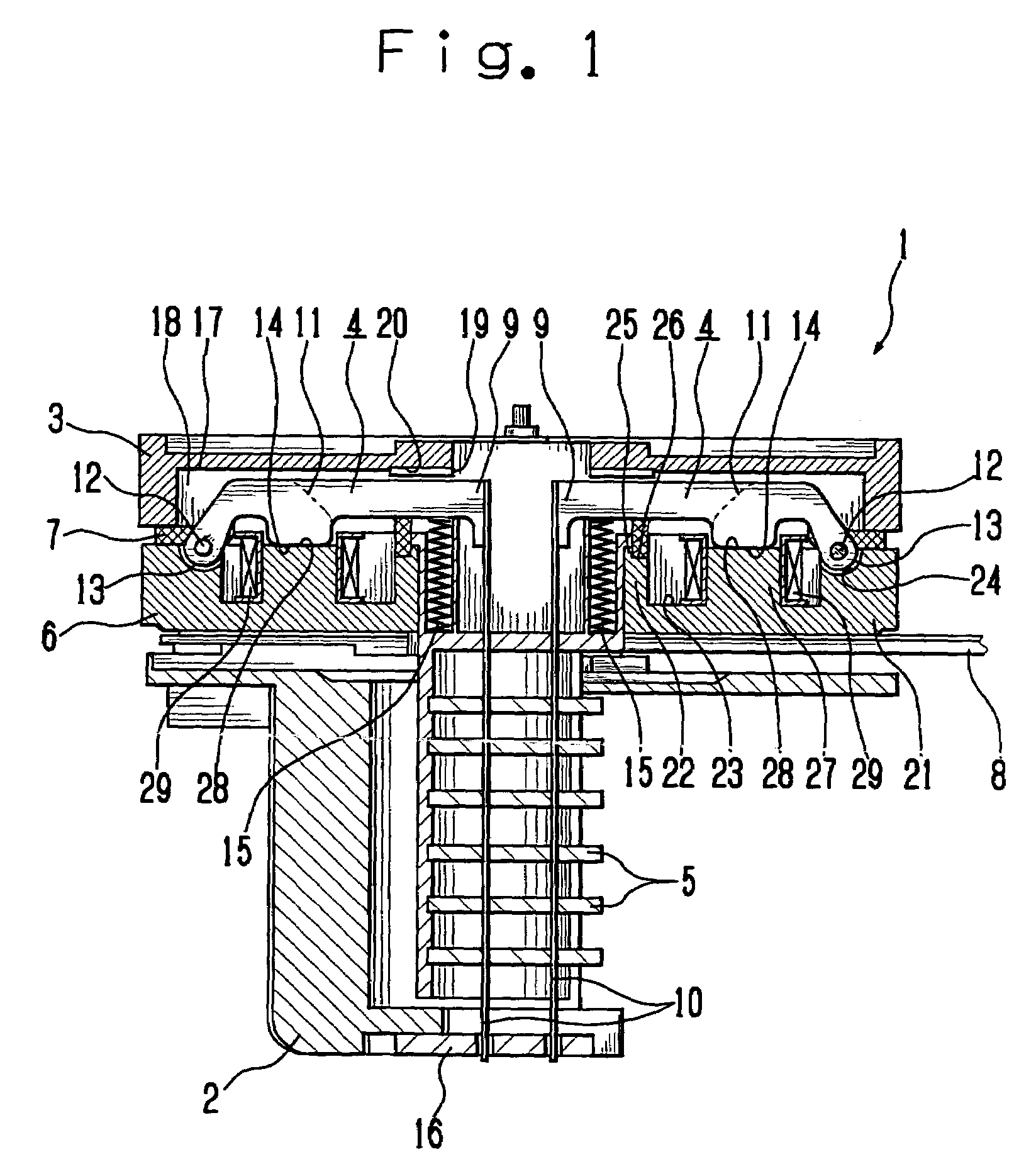

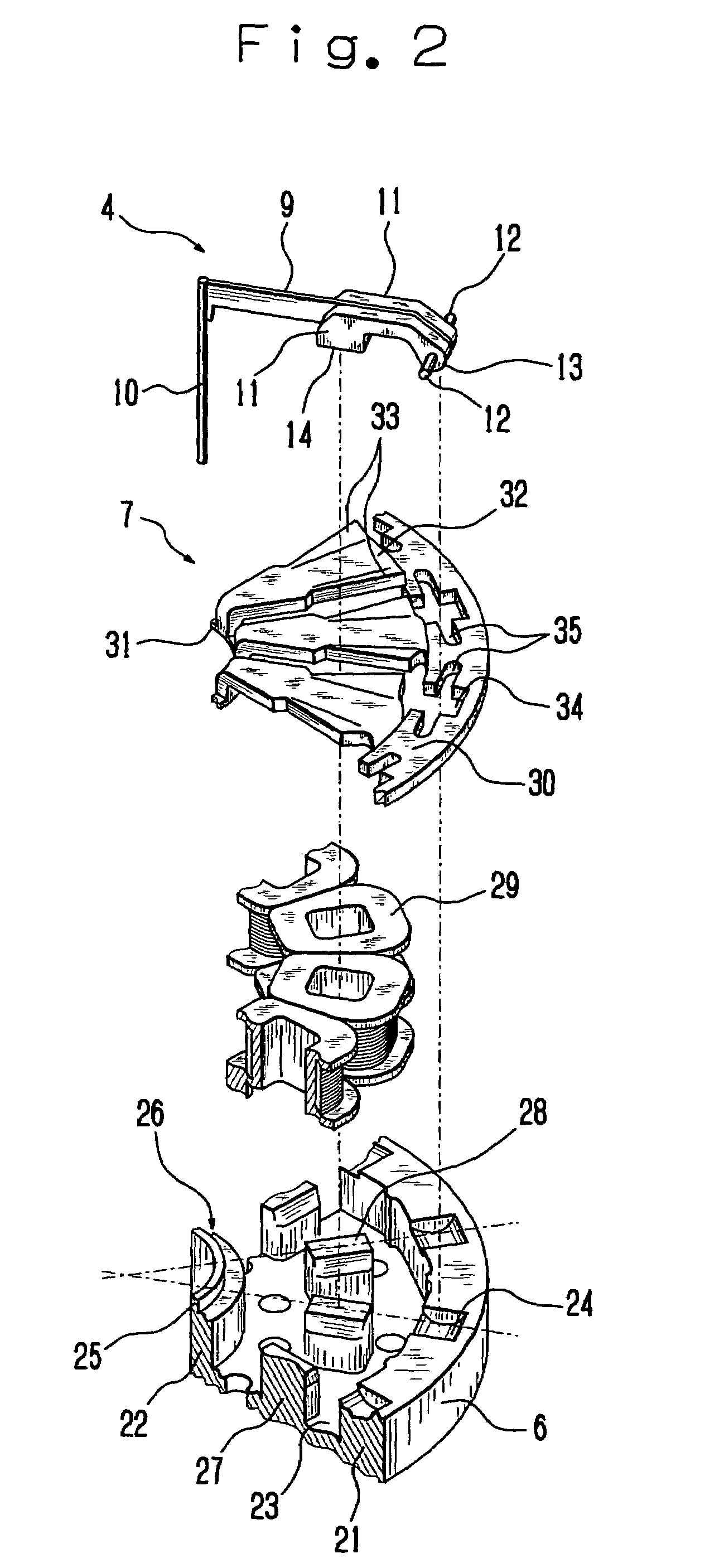

Armature, wire dot printer head and wire dot printer

InactiveUS20050201800A1Armature durabilityHigh-speed durabilityFranking apparatusPrintingEngineeringMagnetic characteristic

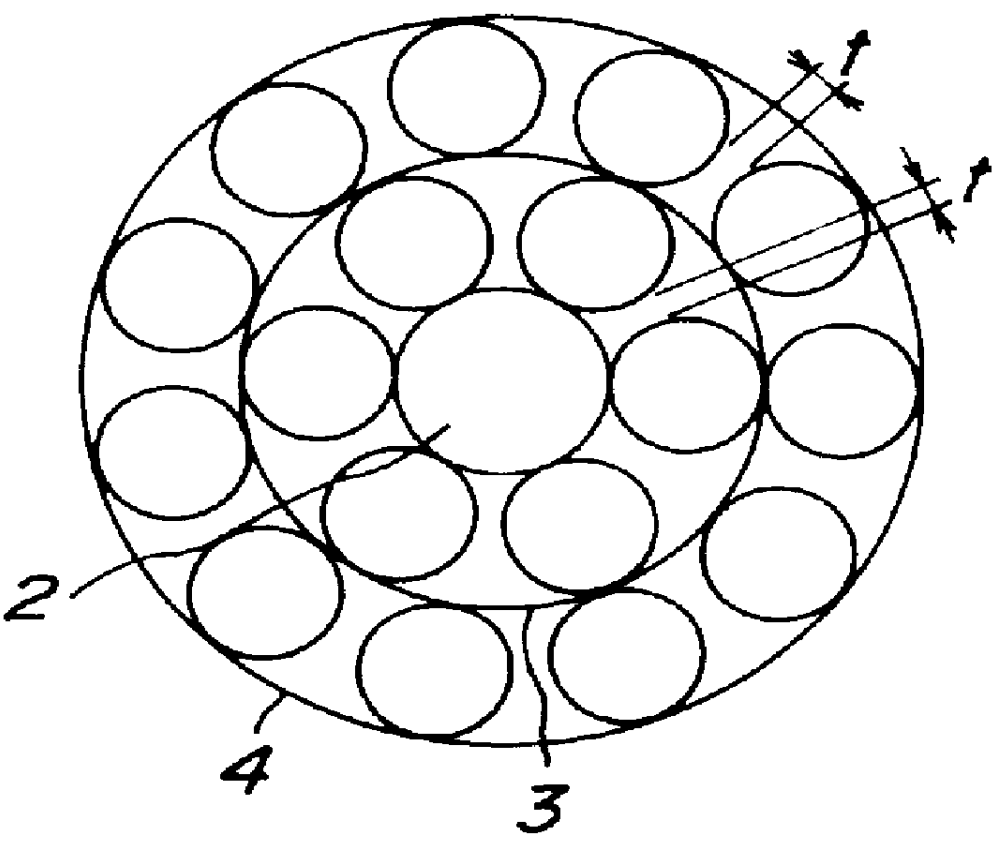

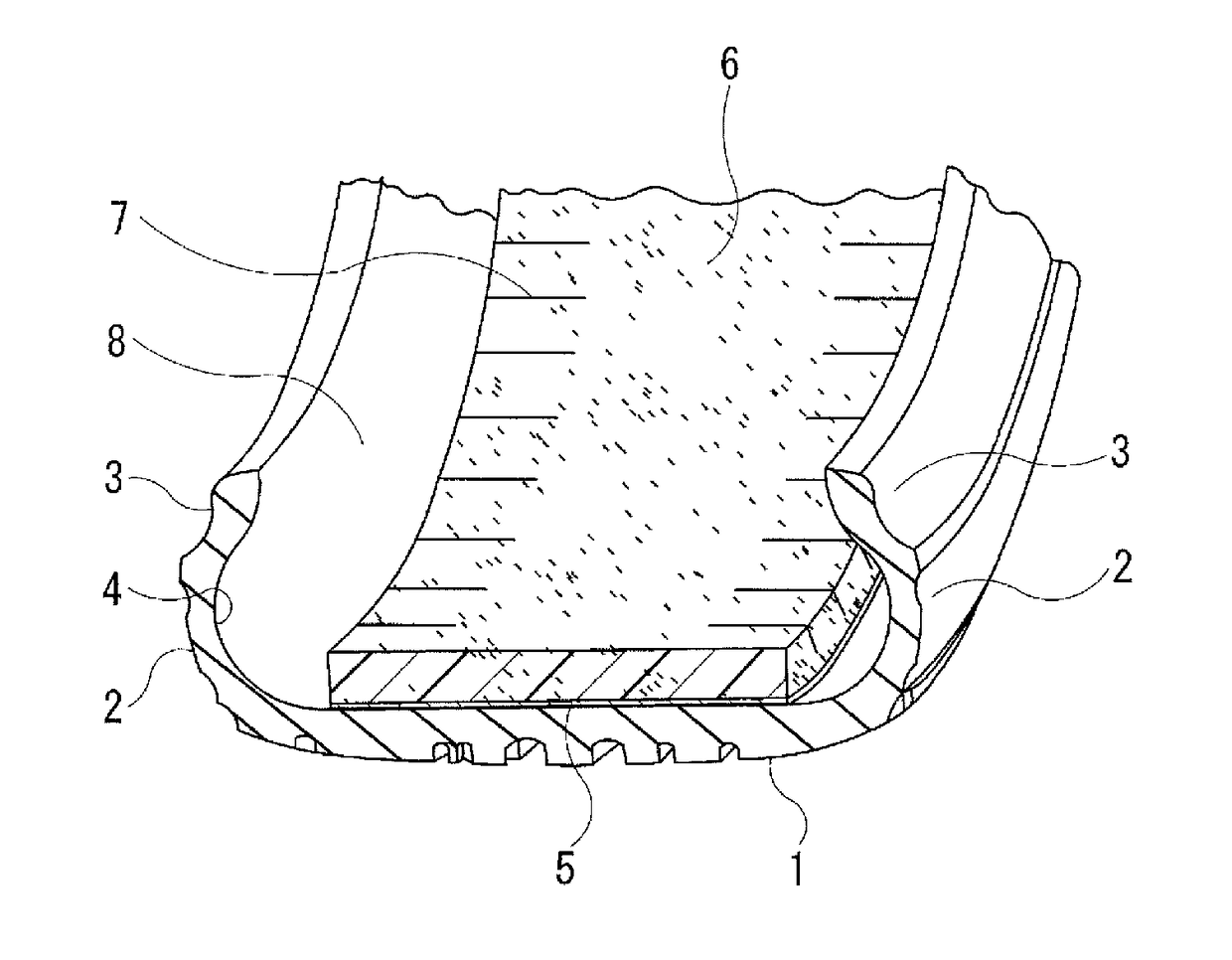

In order to obtain joining force endurable for high-speed printing and realize an enhancement in magnetic characteristic, a plate-like arm for supporting a printing wire is laminated with a magnetic circuit forming member that is composed by laminating plural plates for forming a magnetic circuit, wherein a weld zone is formed on the laminated surface of the arm and plates with laser beam irradiation for fixing the arm and the magnetic circuit forming member with the weld zone.

Owner:TOSHIBA TEC KK

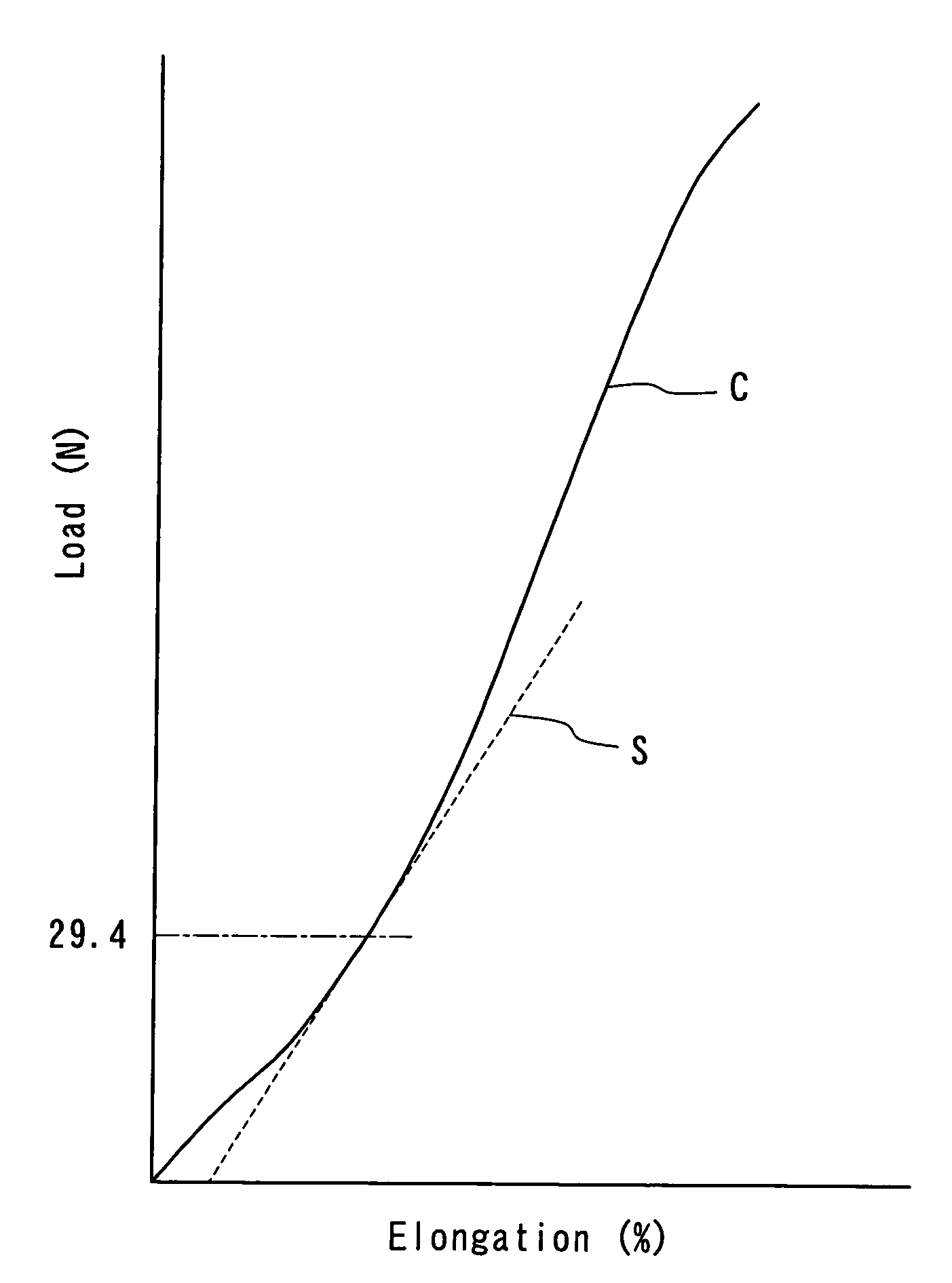

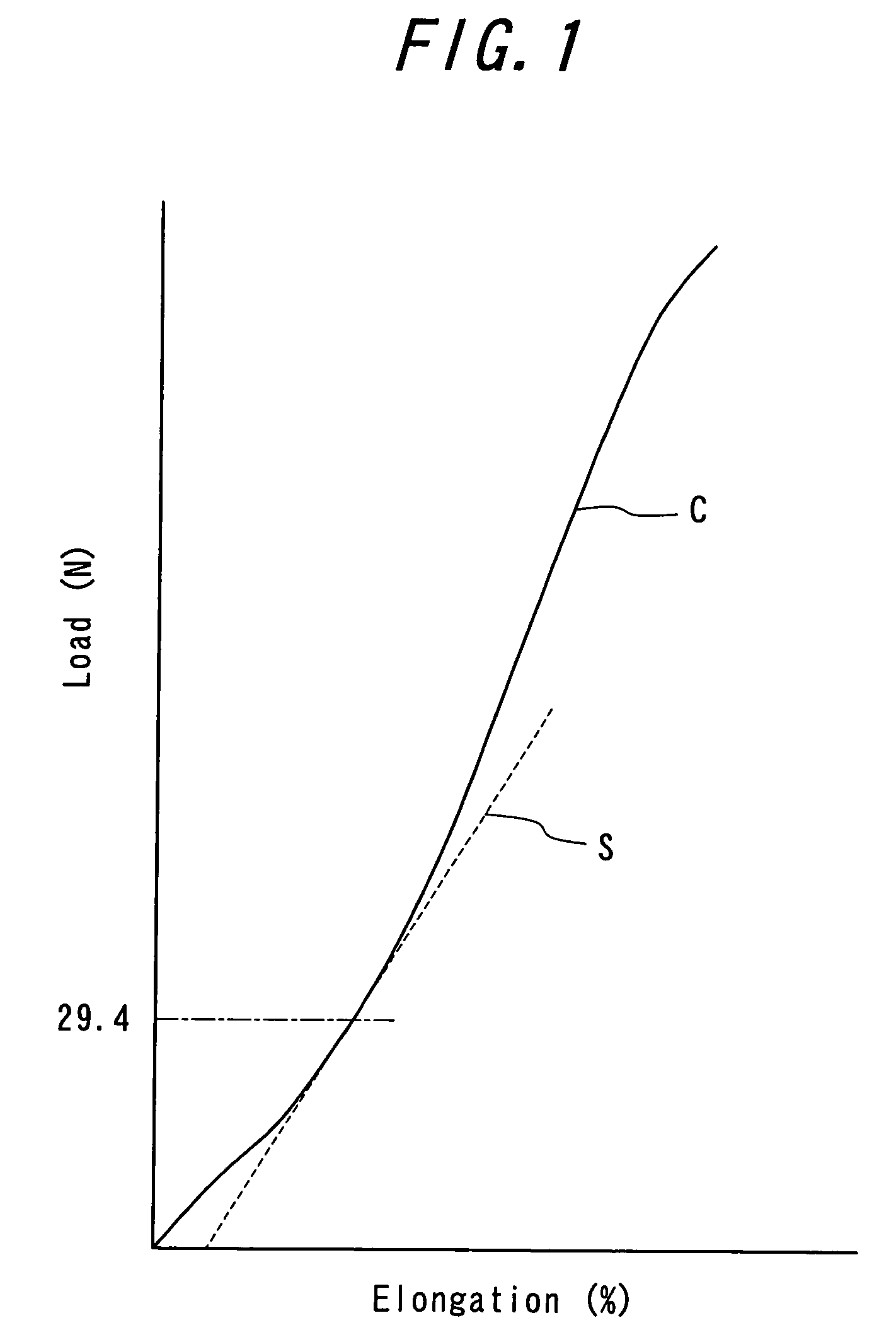

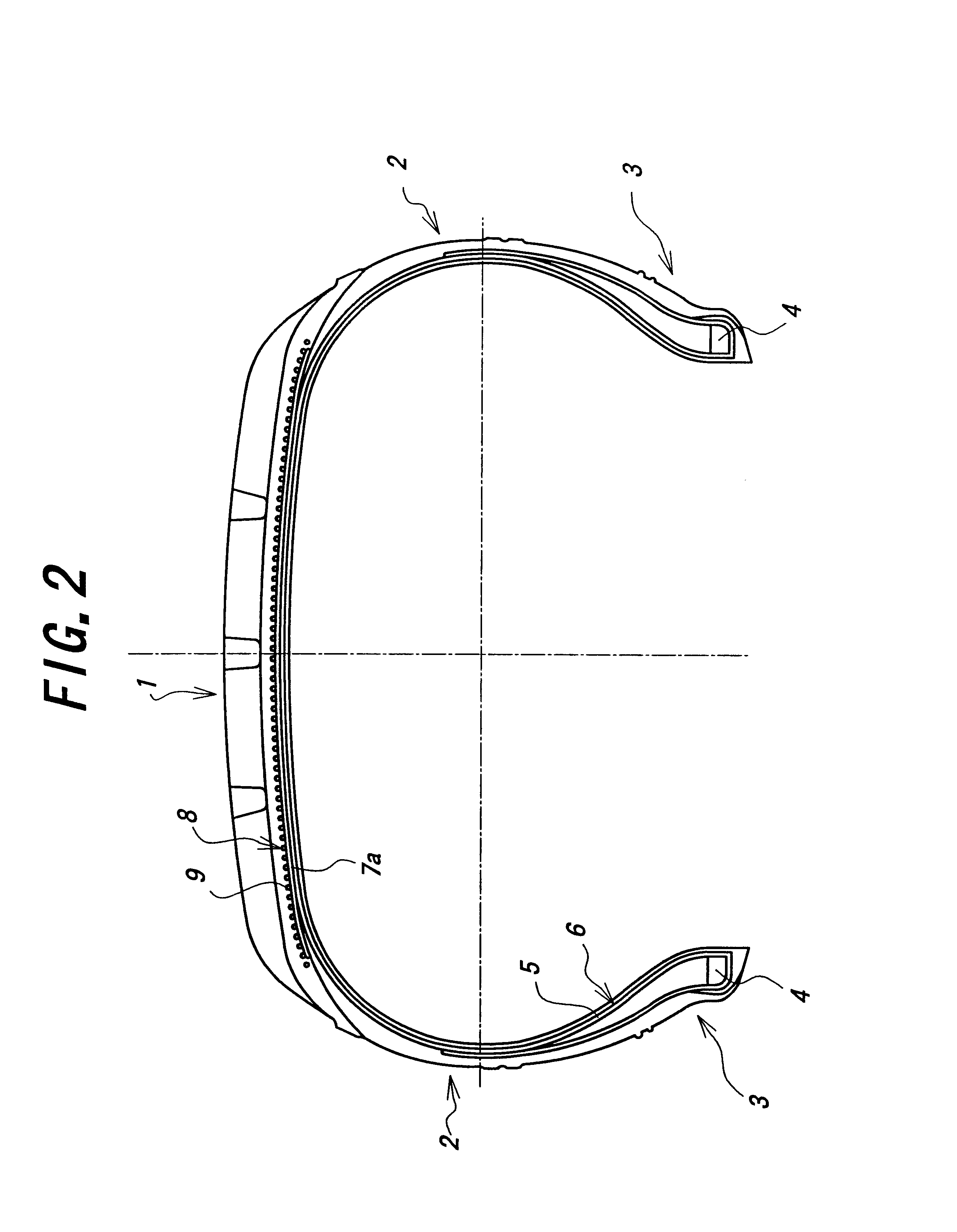

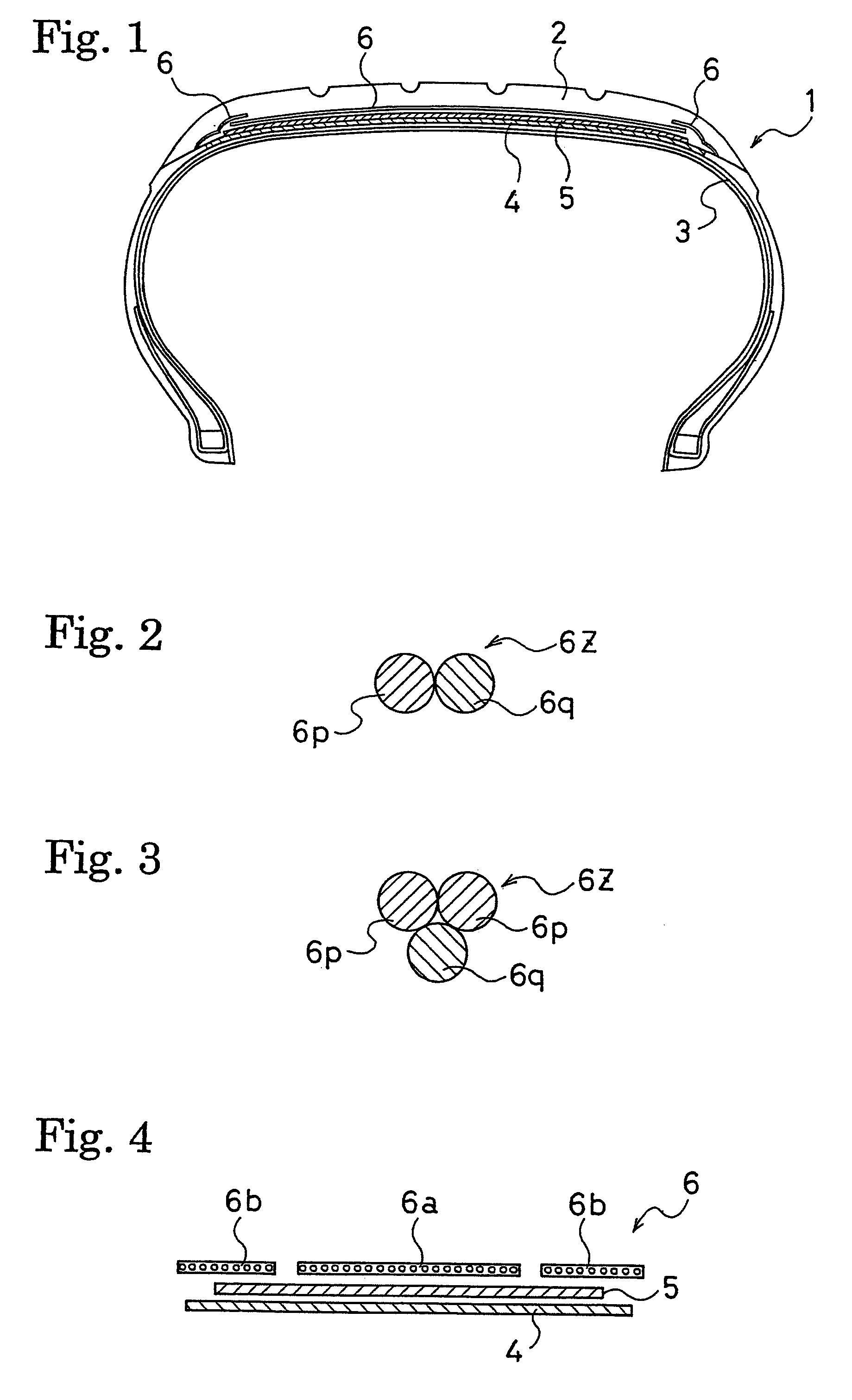

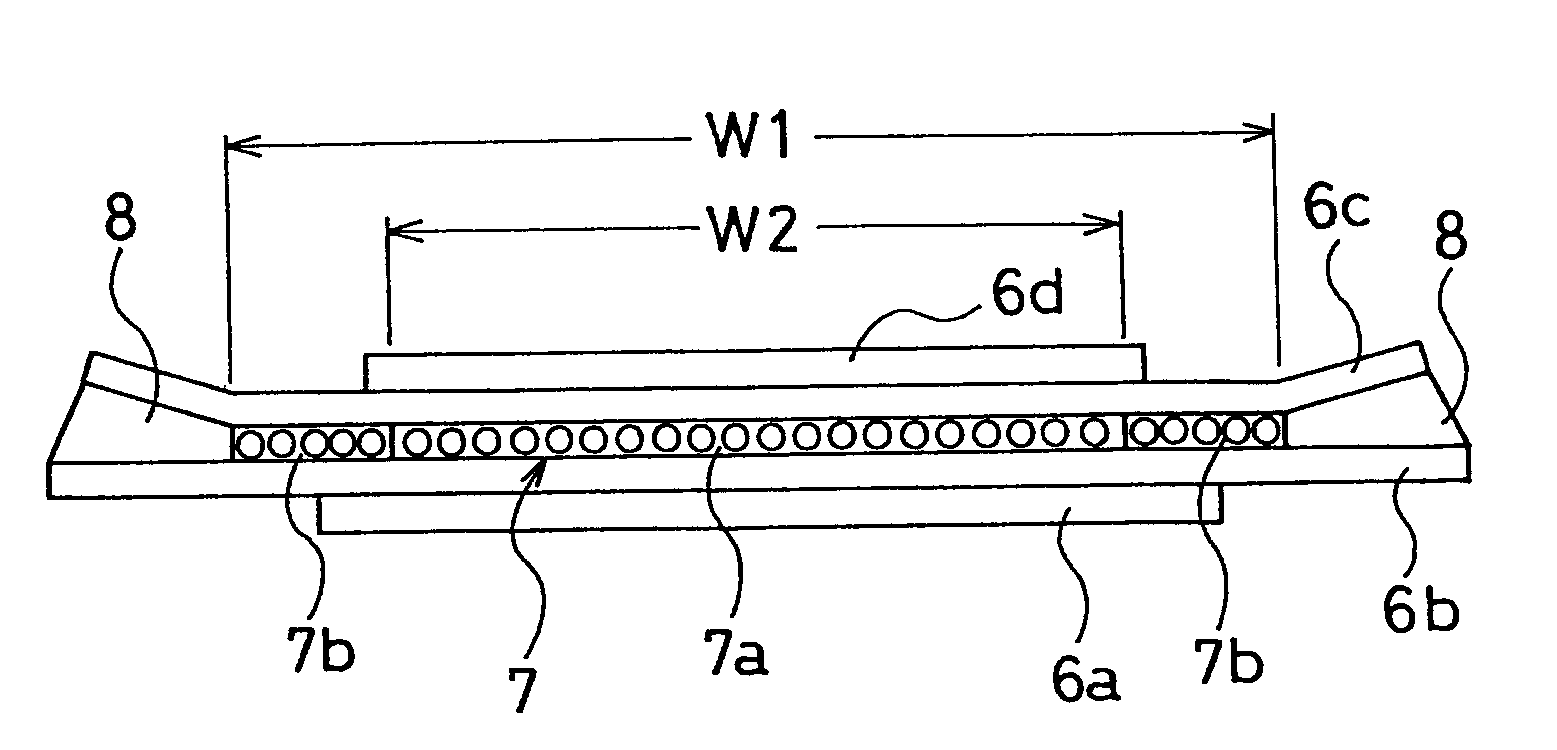

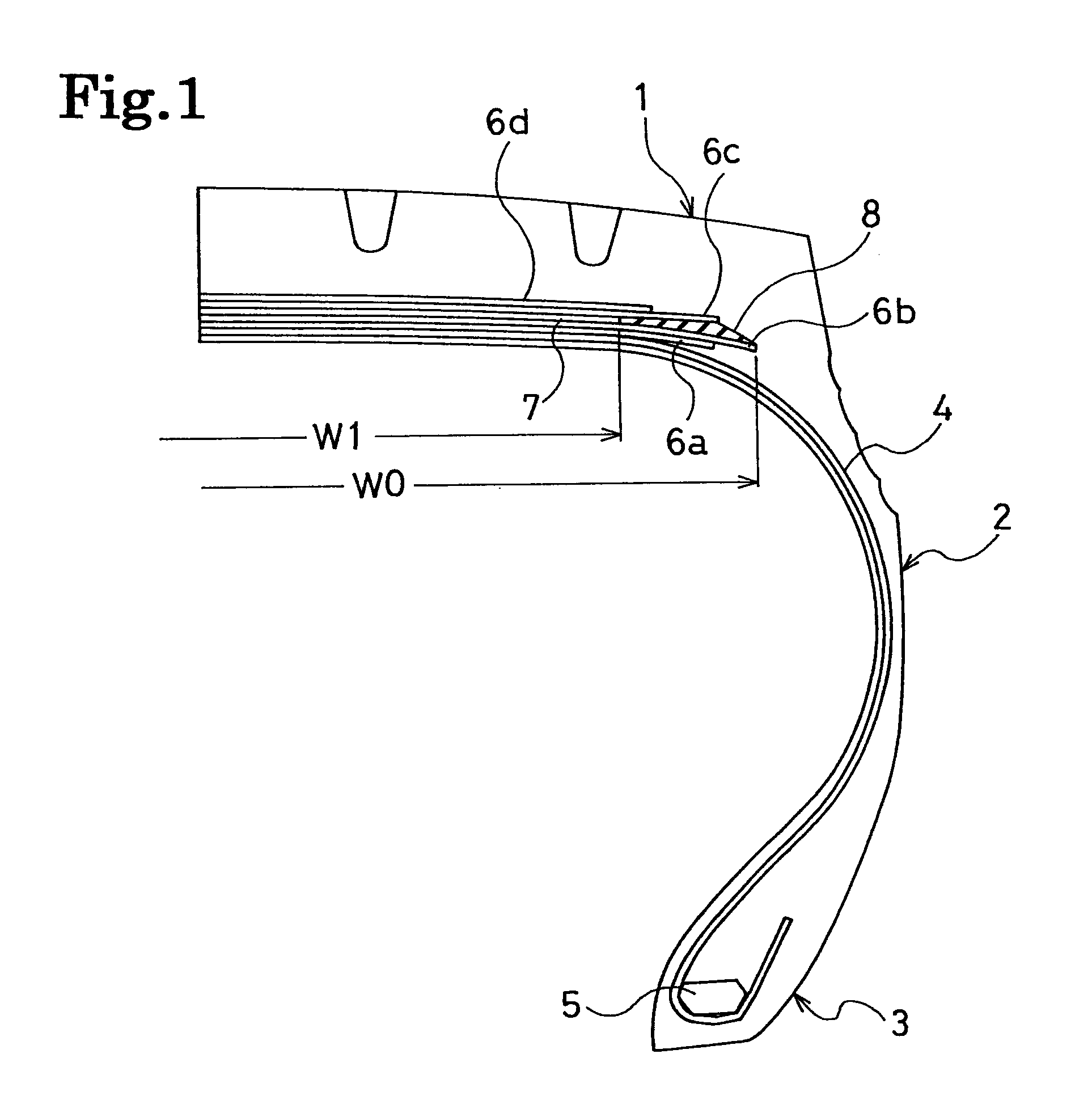

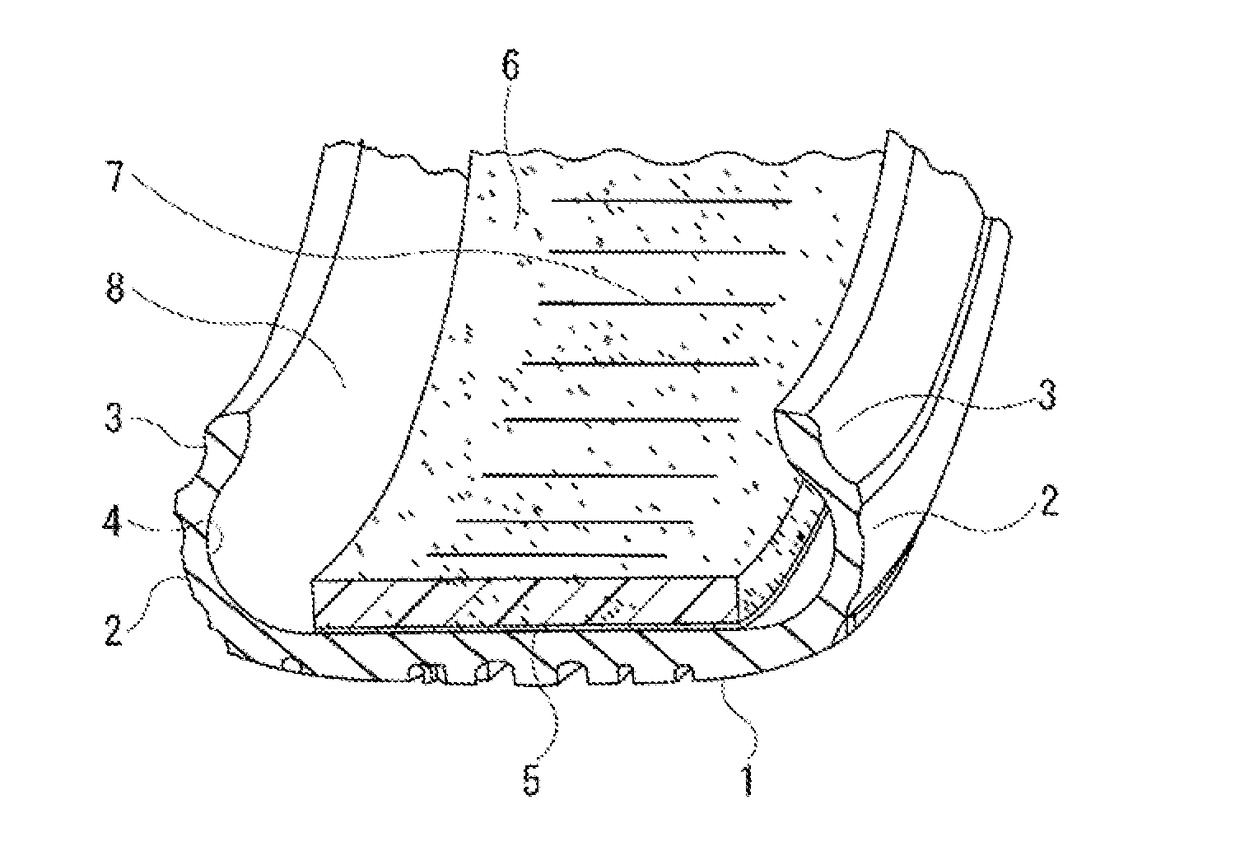

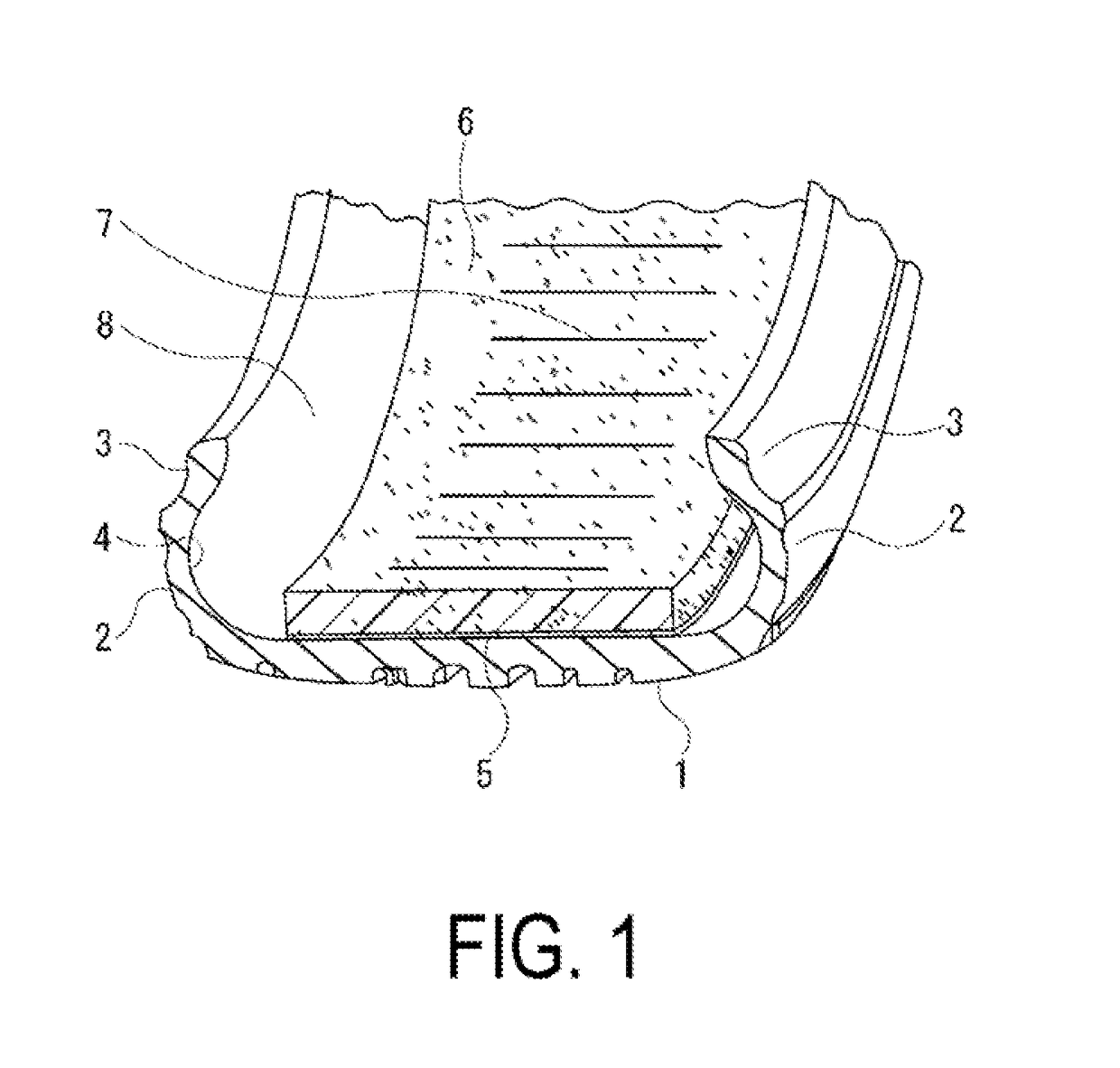

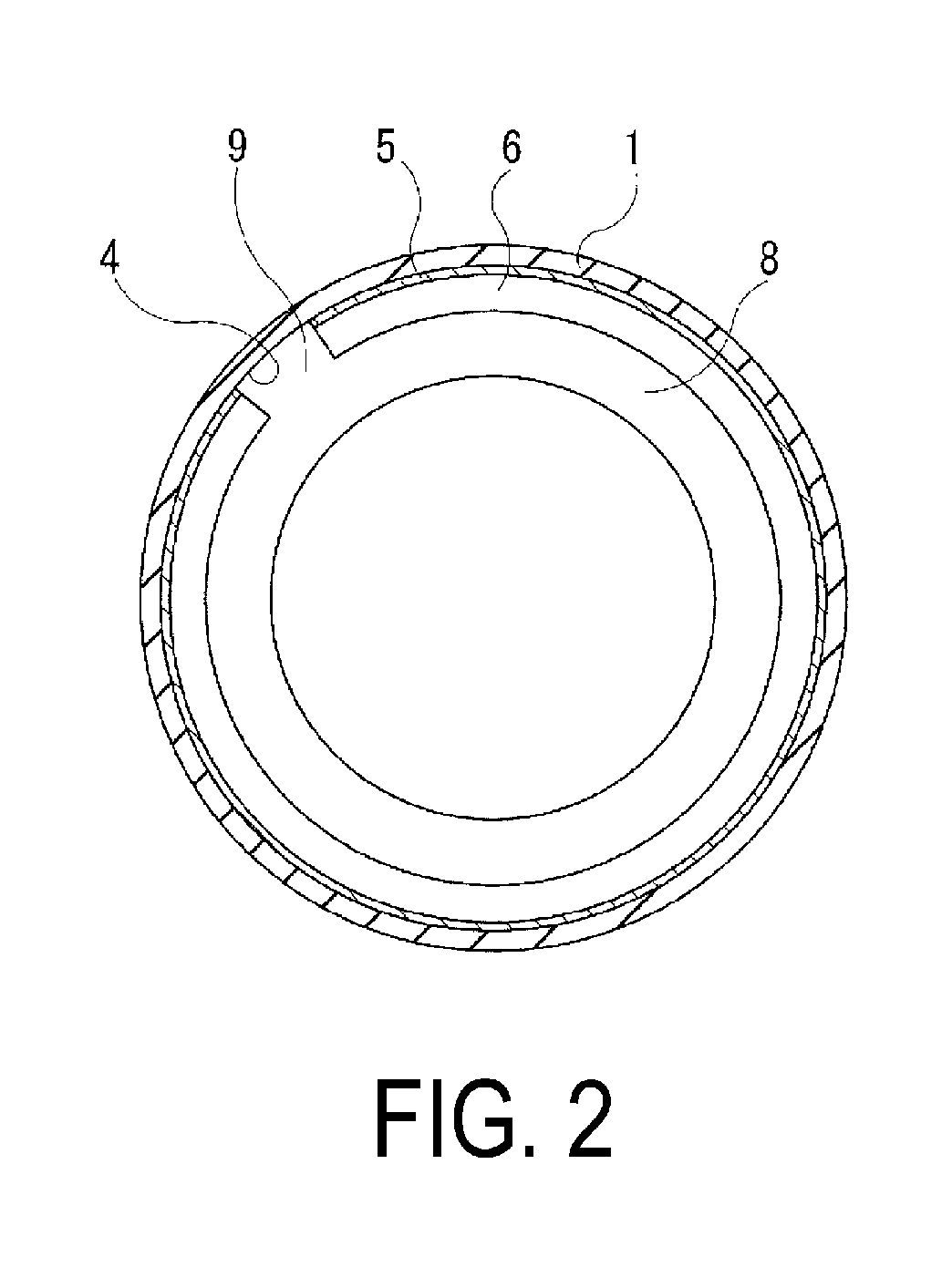

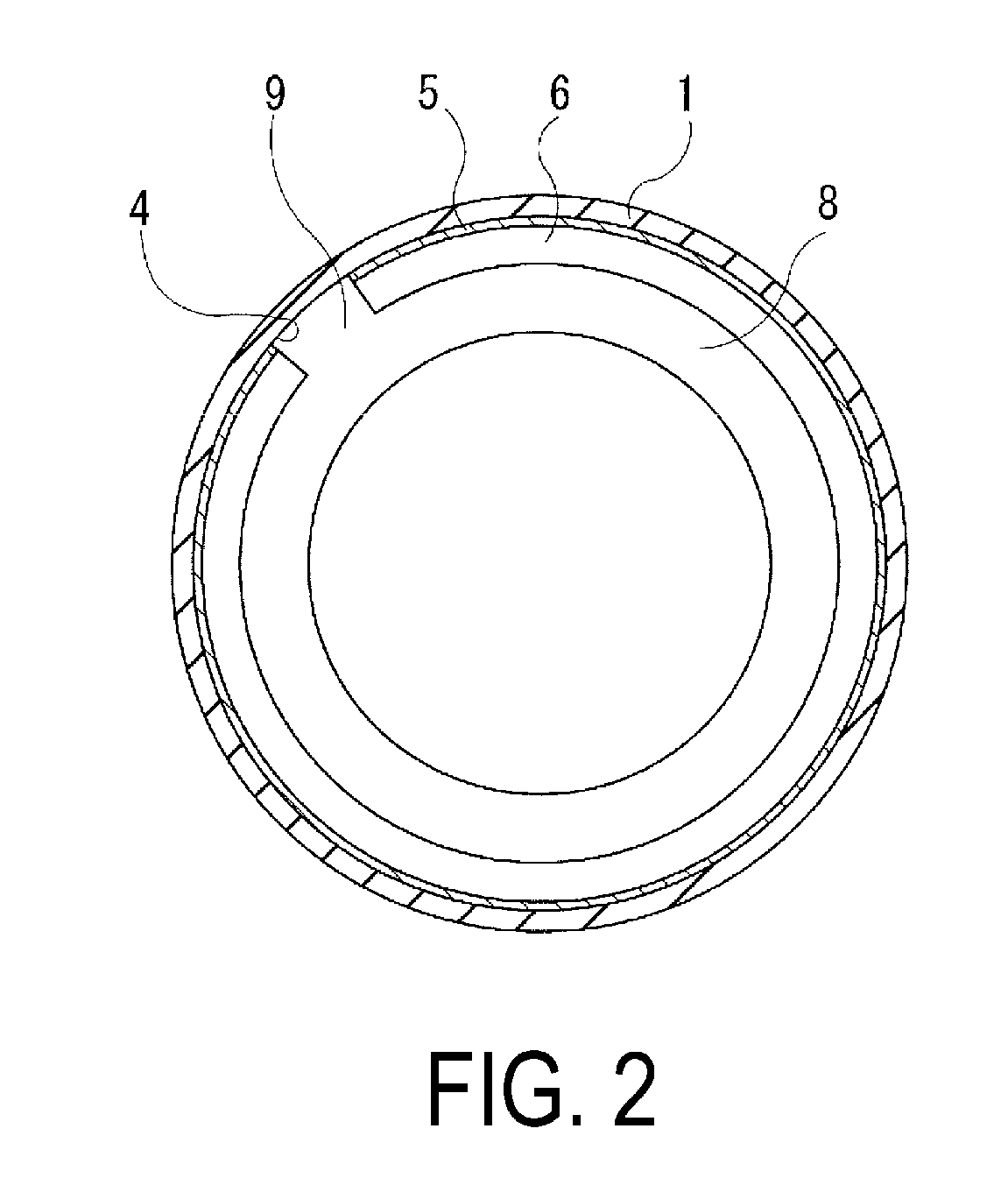

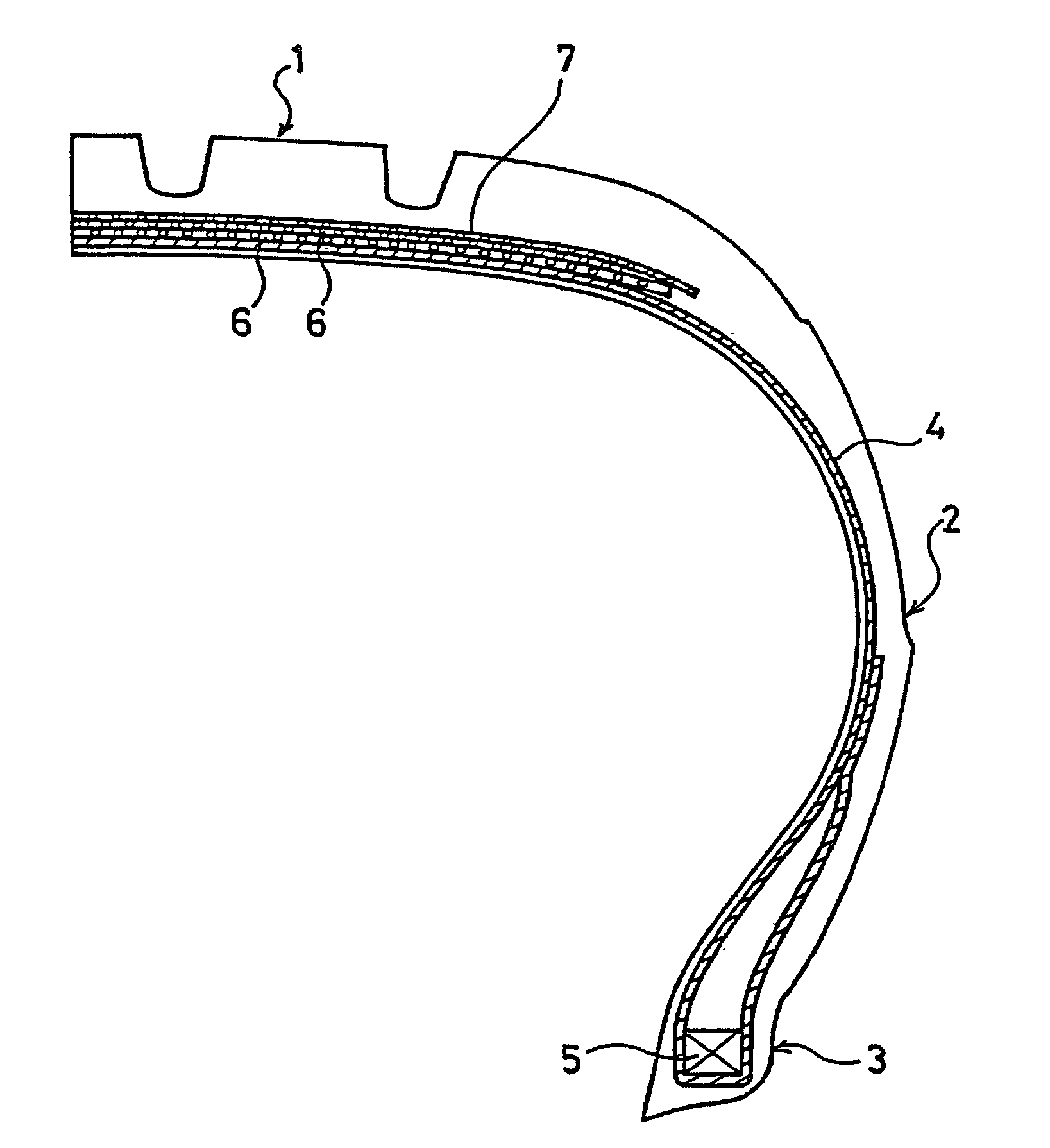

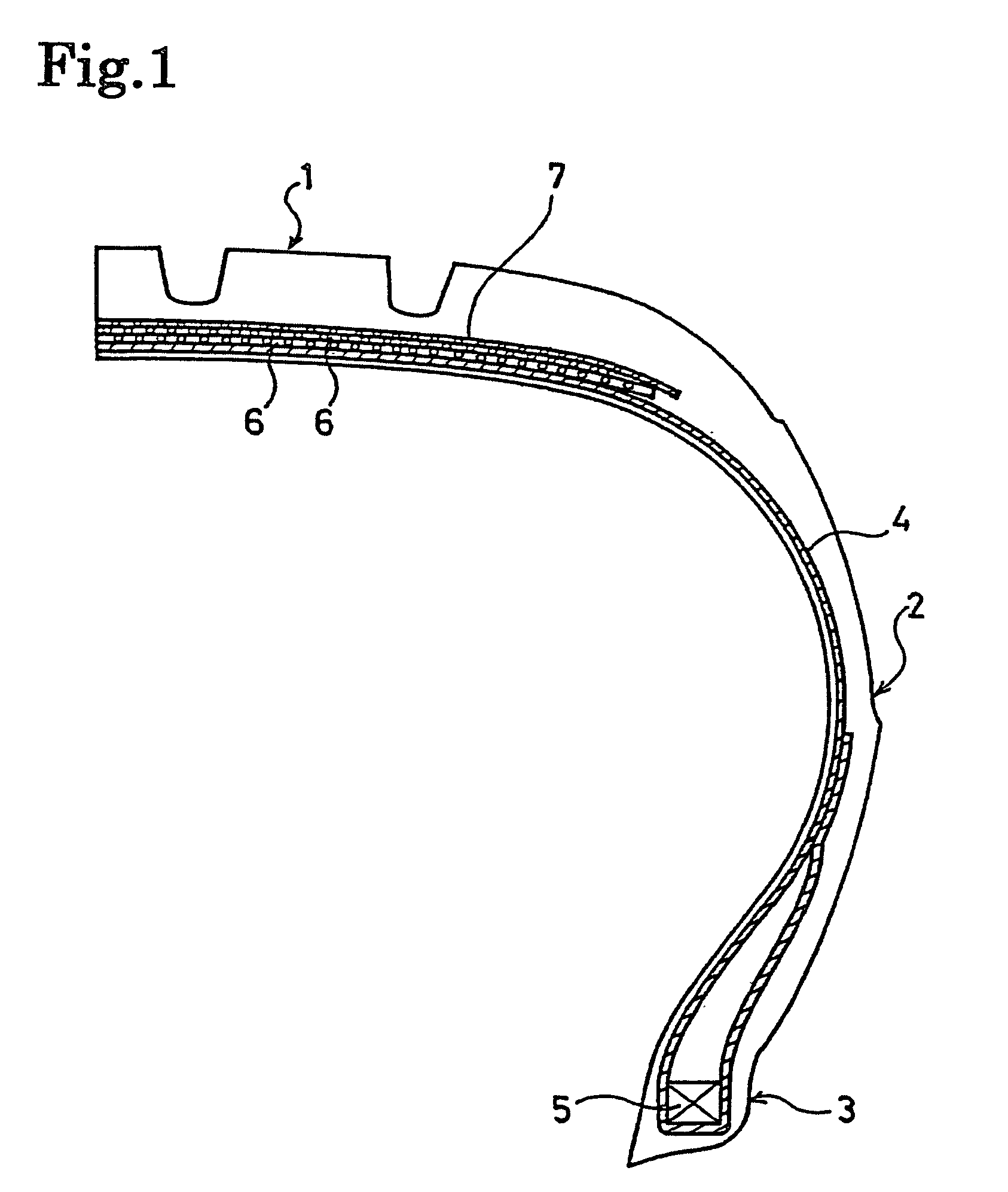

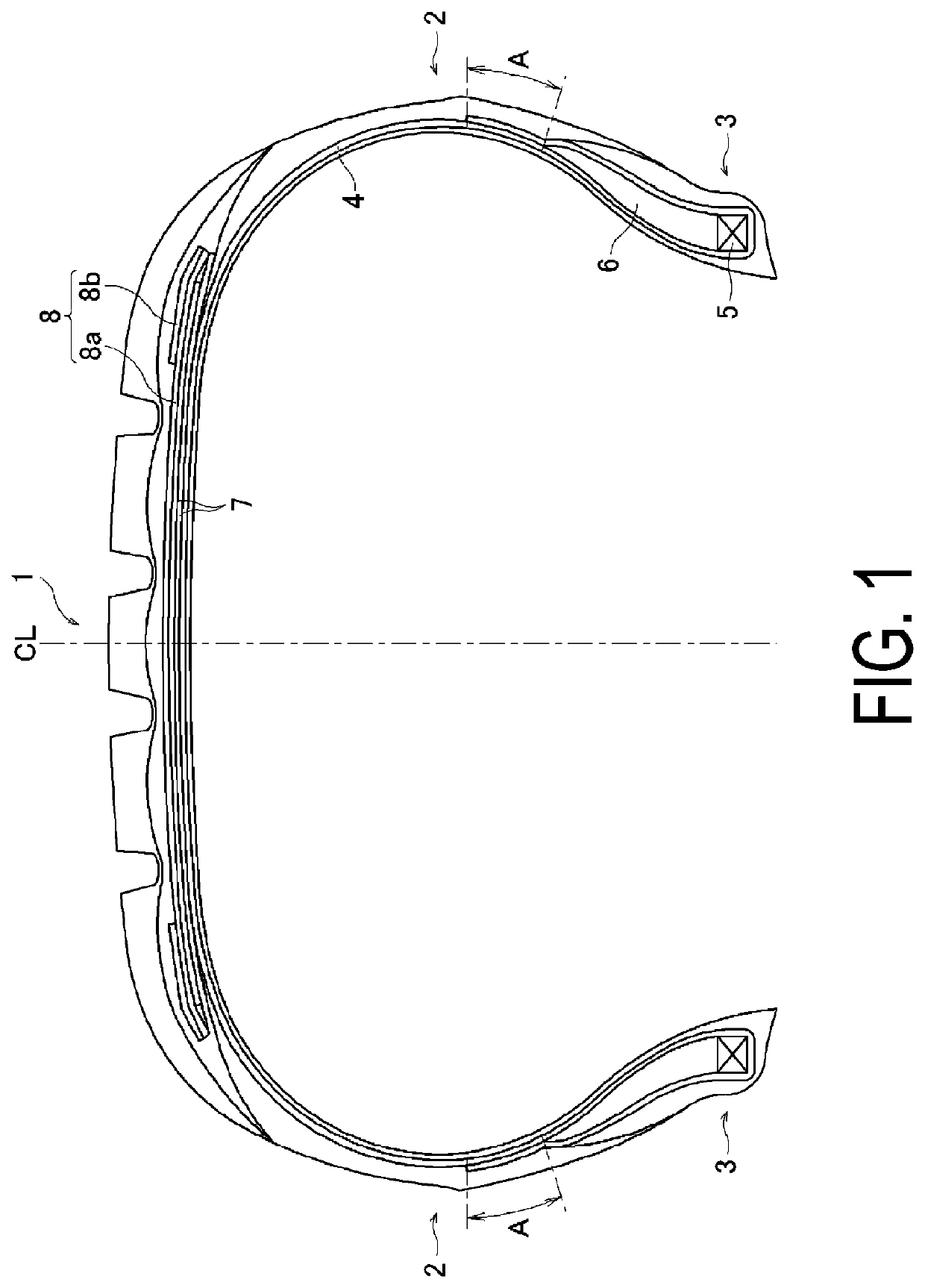

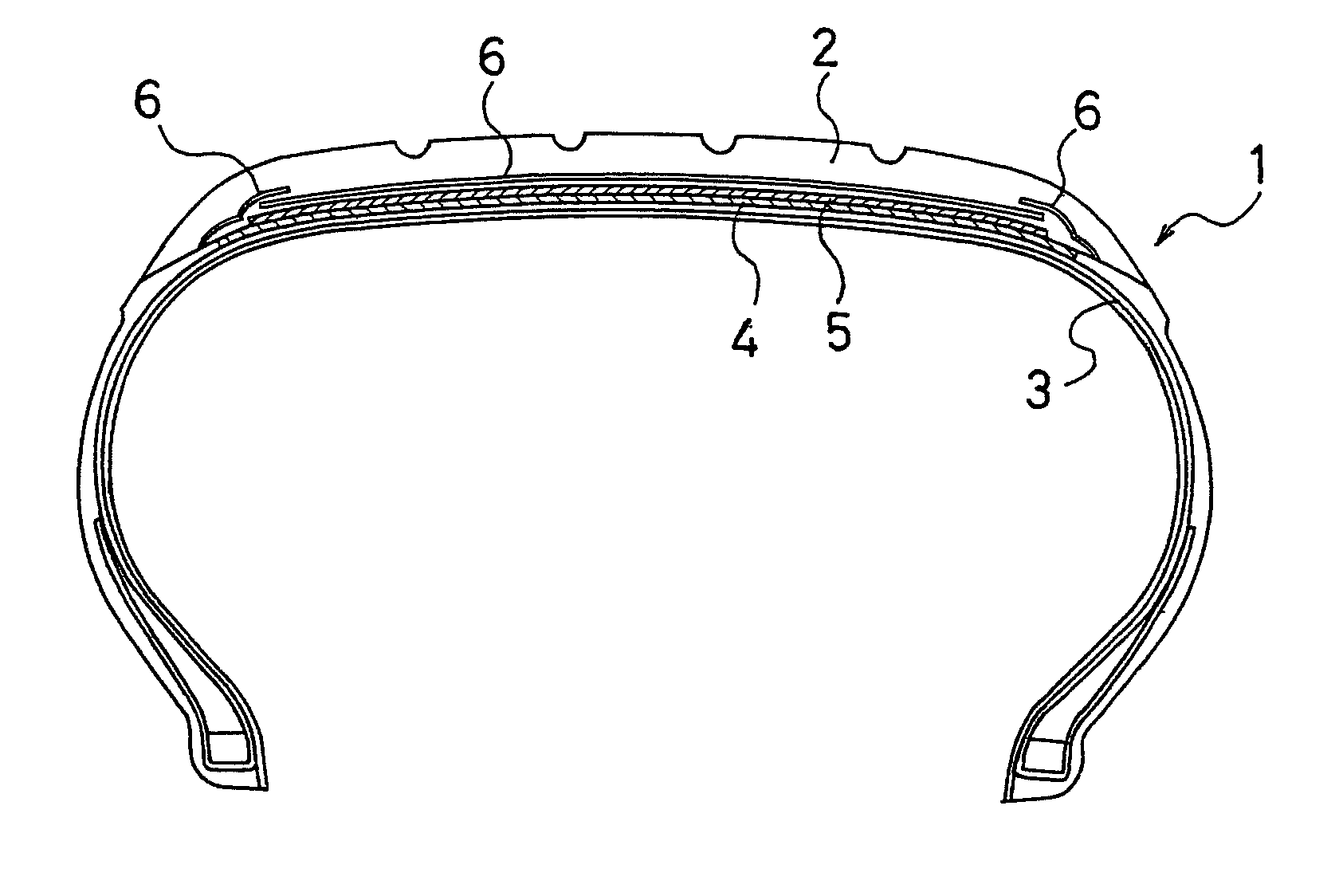

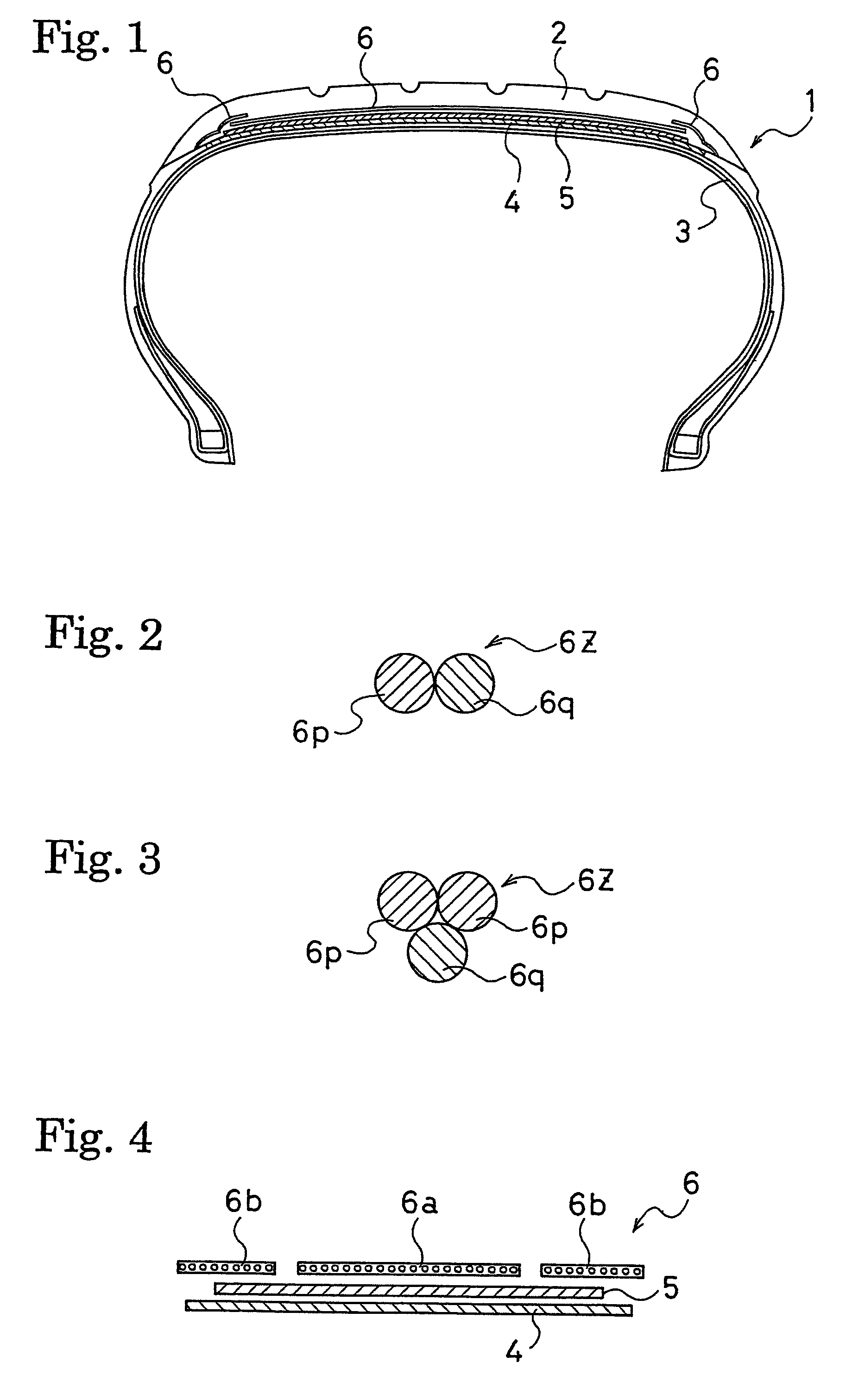

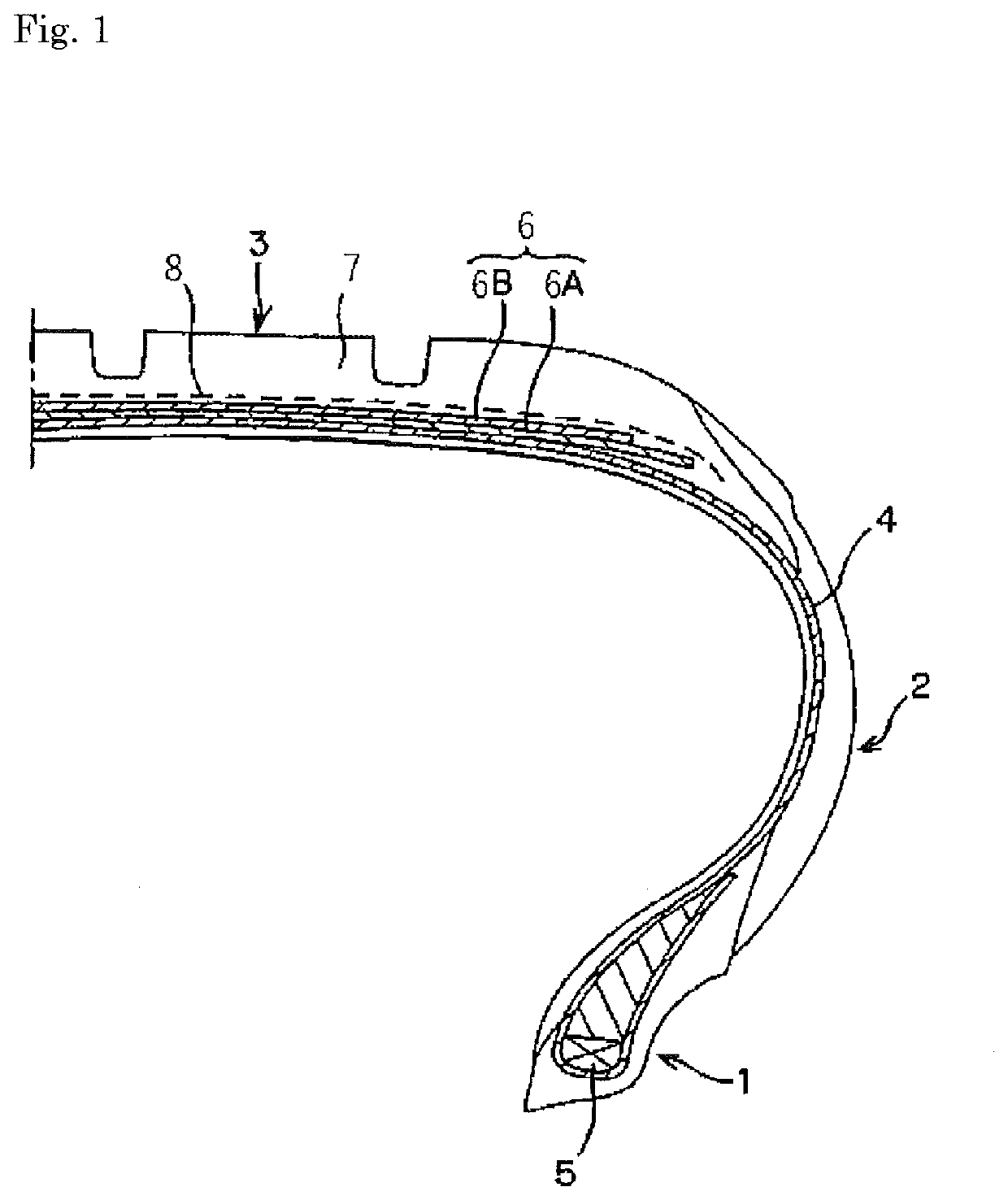

Pneumatic radial tire with polyethylene terephthalate cord belt reinforcing layer

ActiveUS7584774B2AdhesivenessInferior durabilityNon-macromolecular adhesive additivesFibre typesPolyethylene terephthalateEngineering

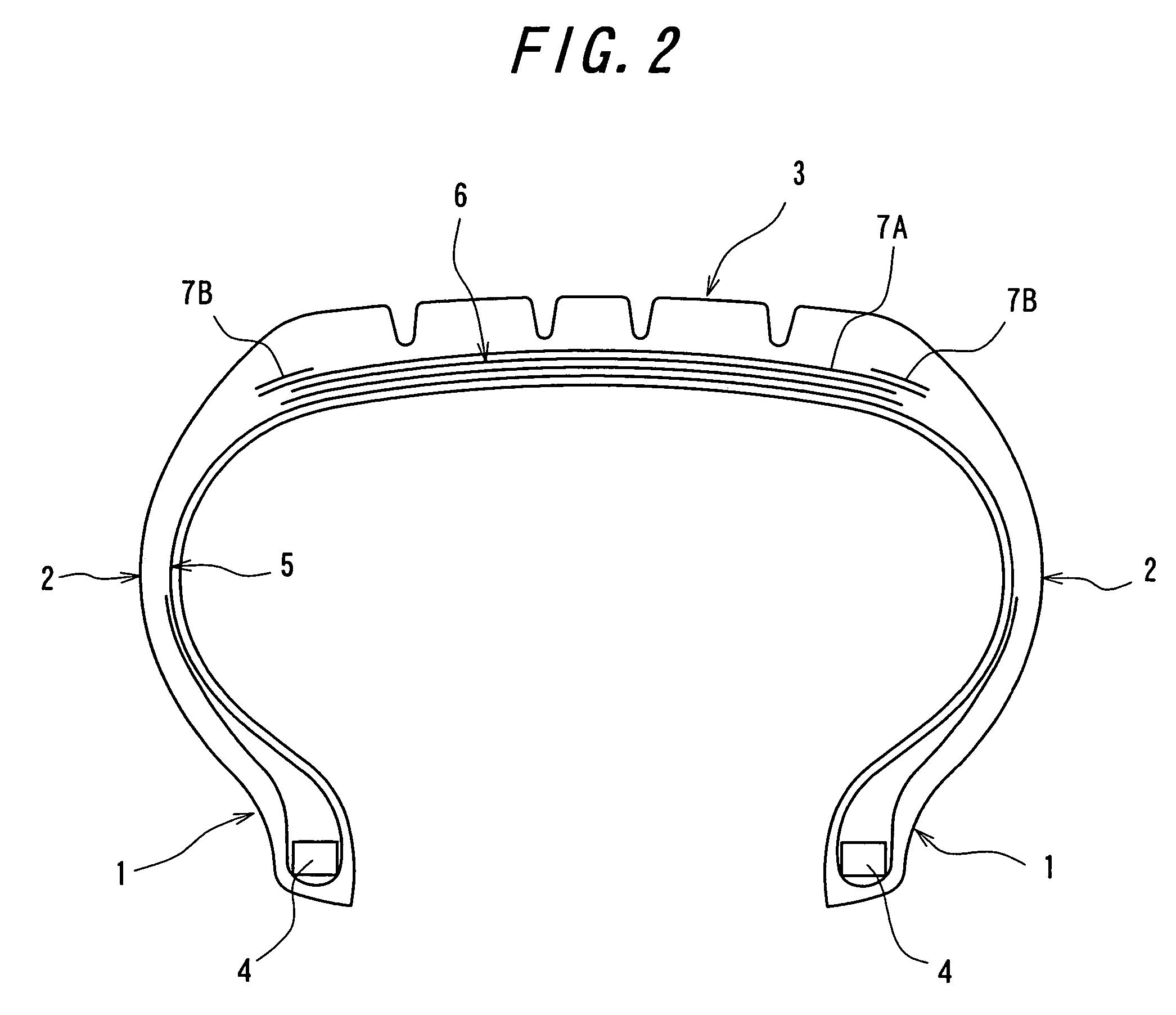

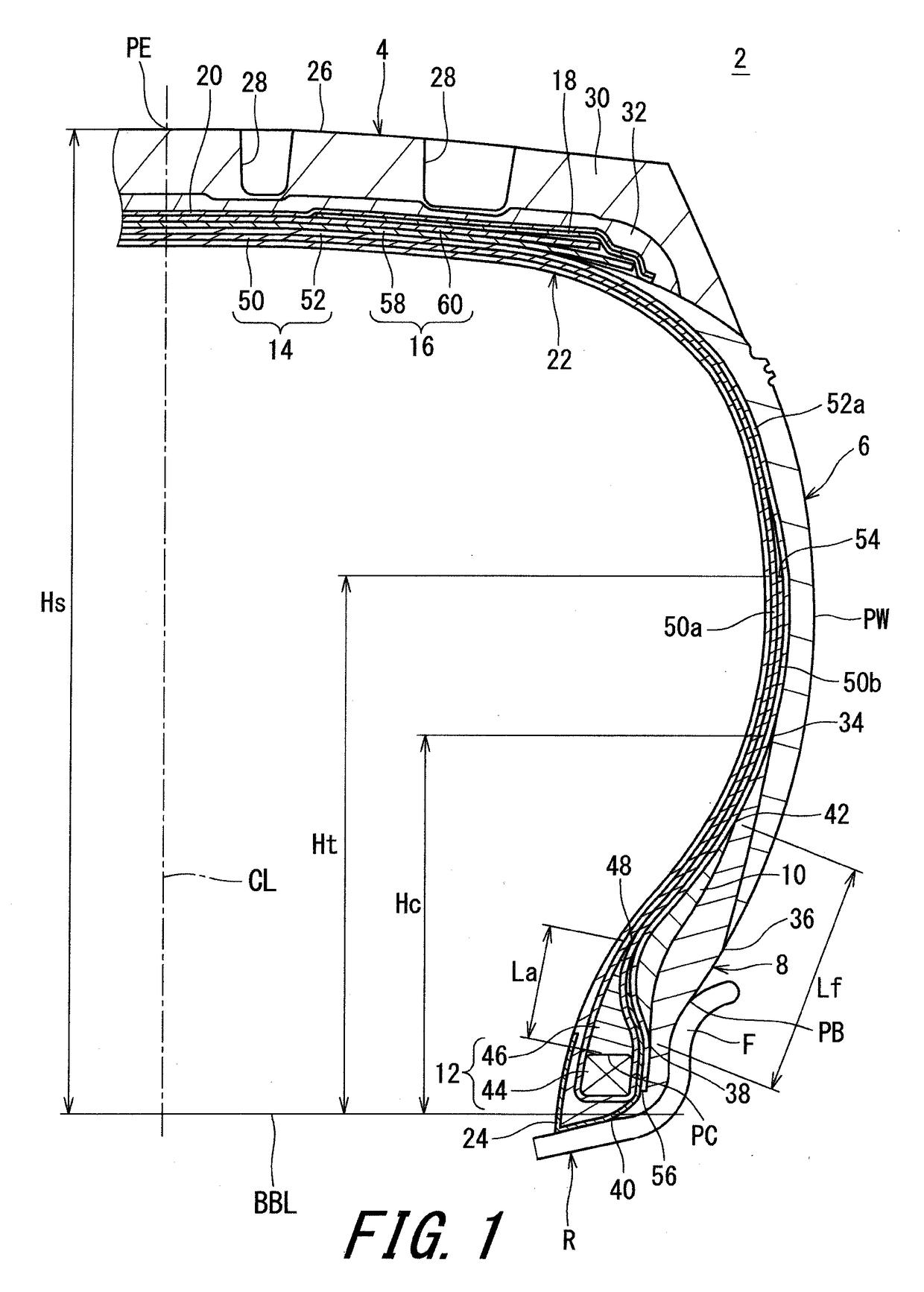

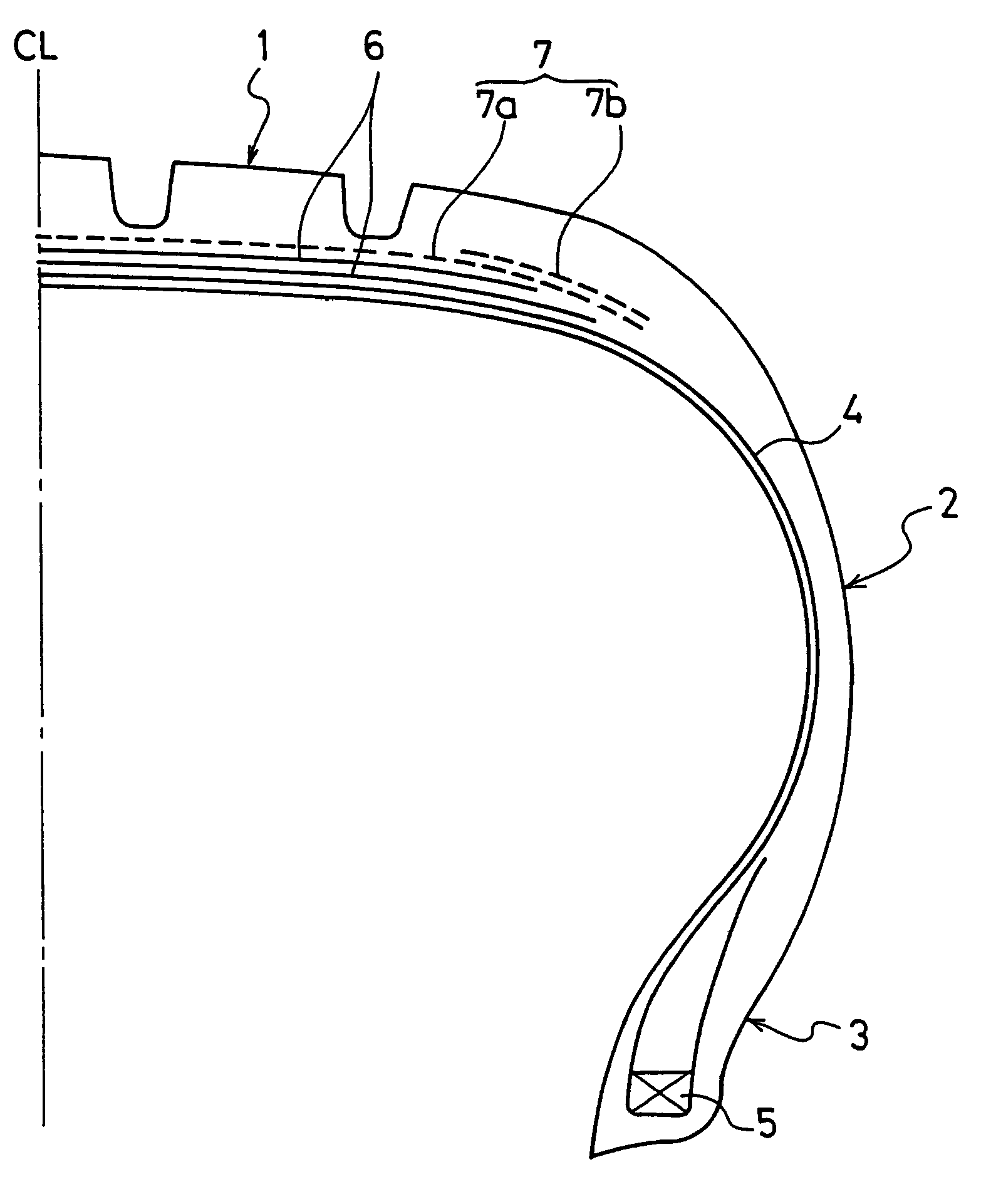

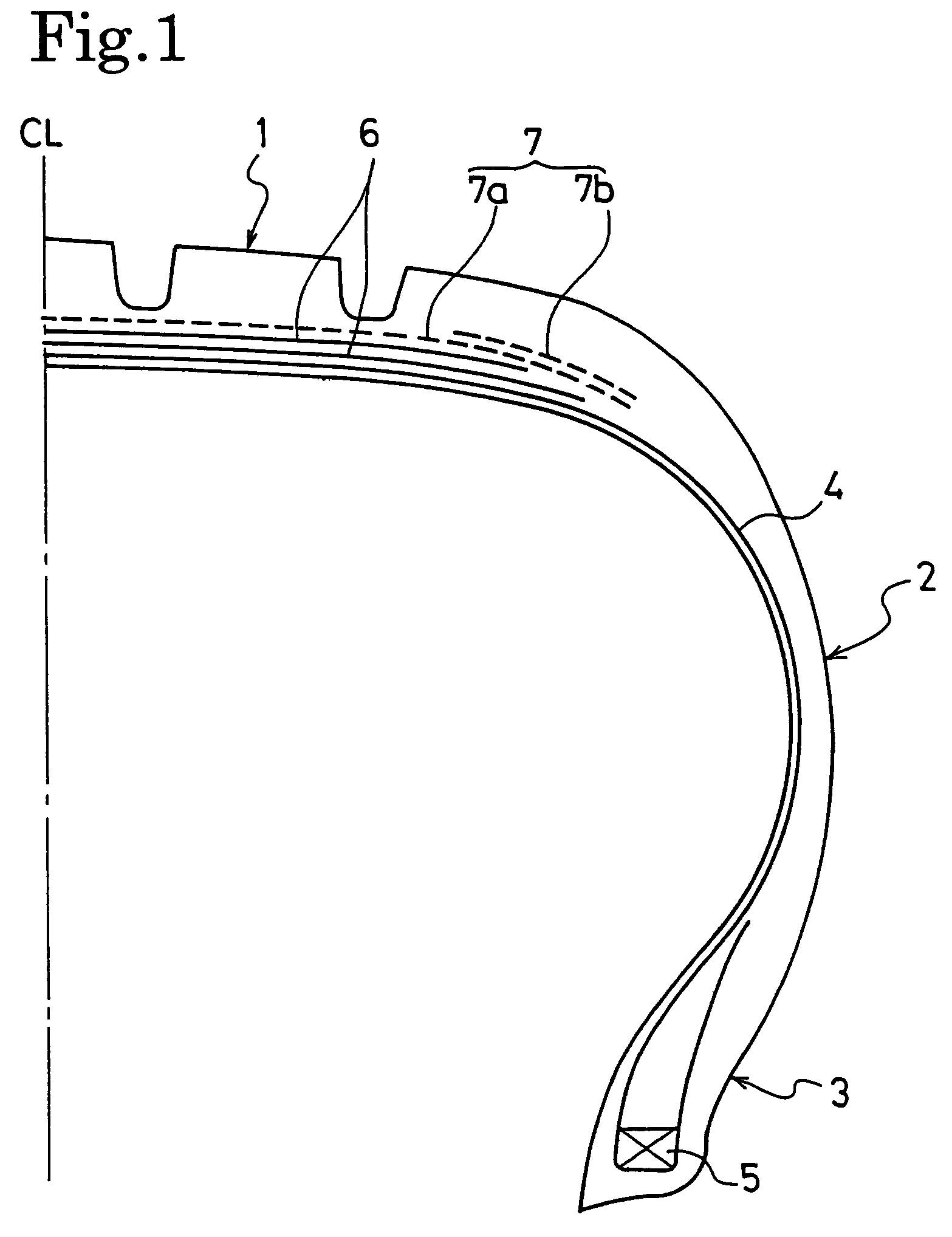

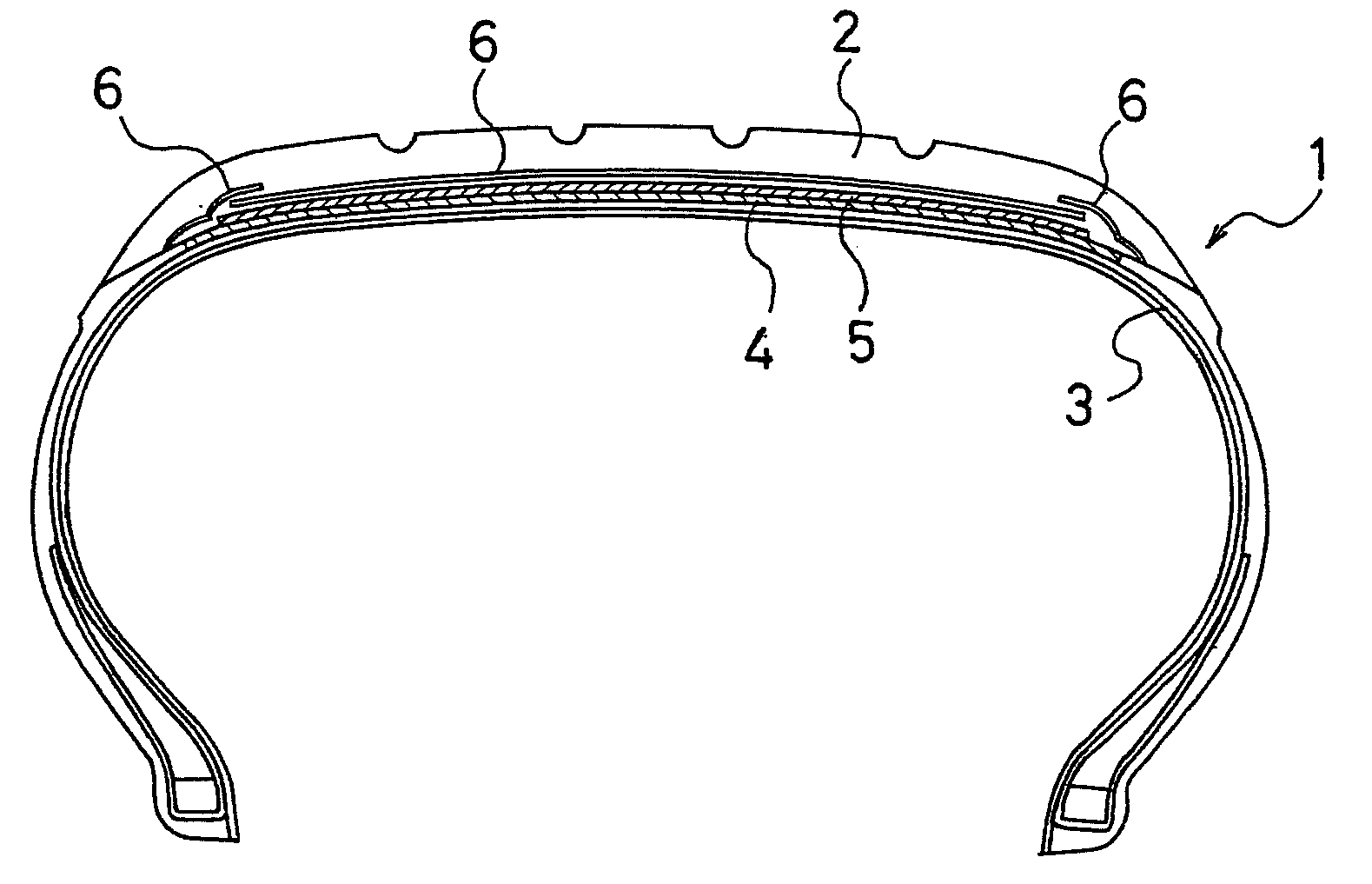

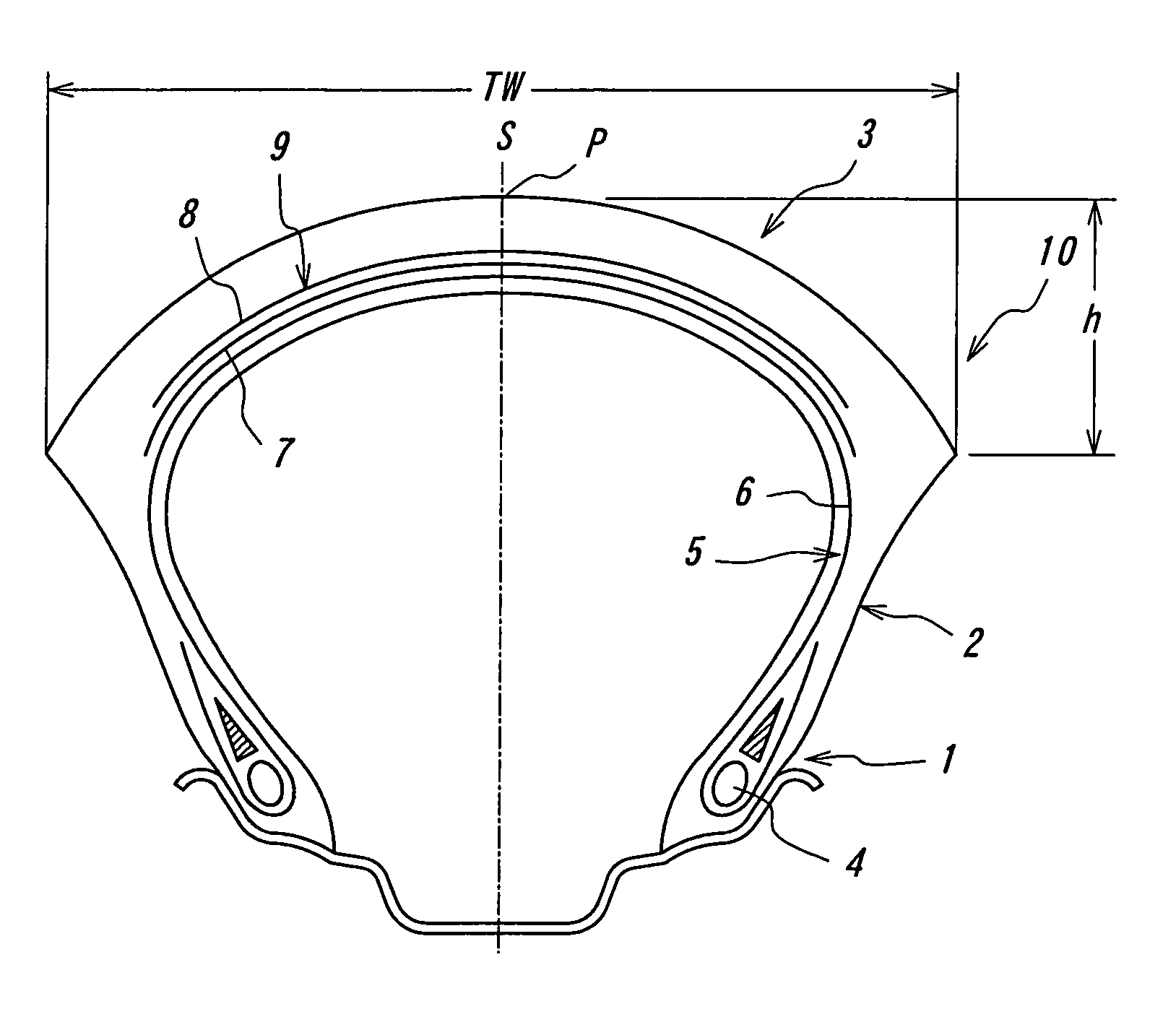

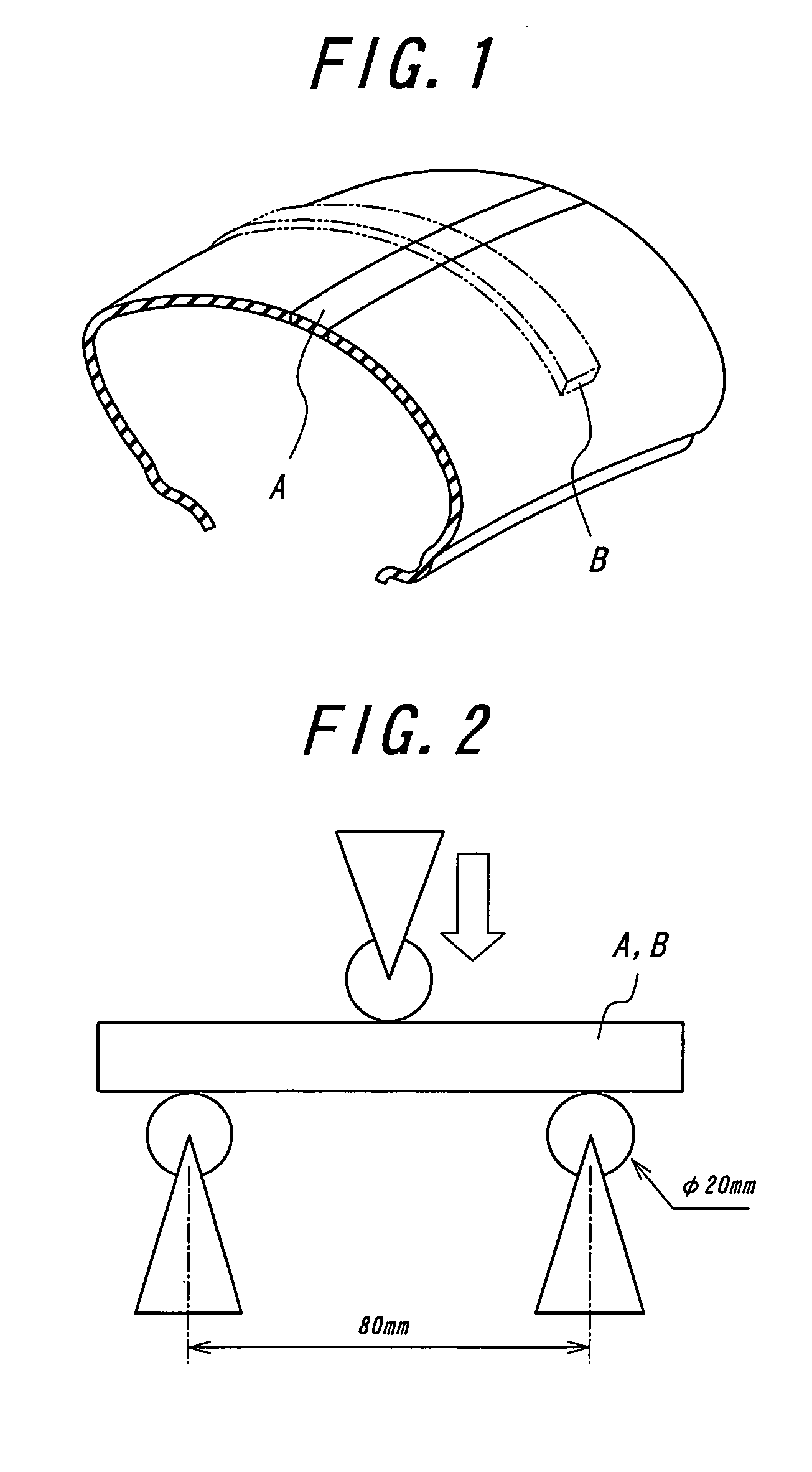

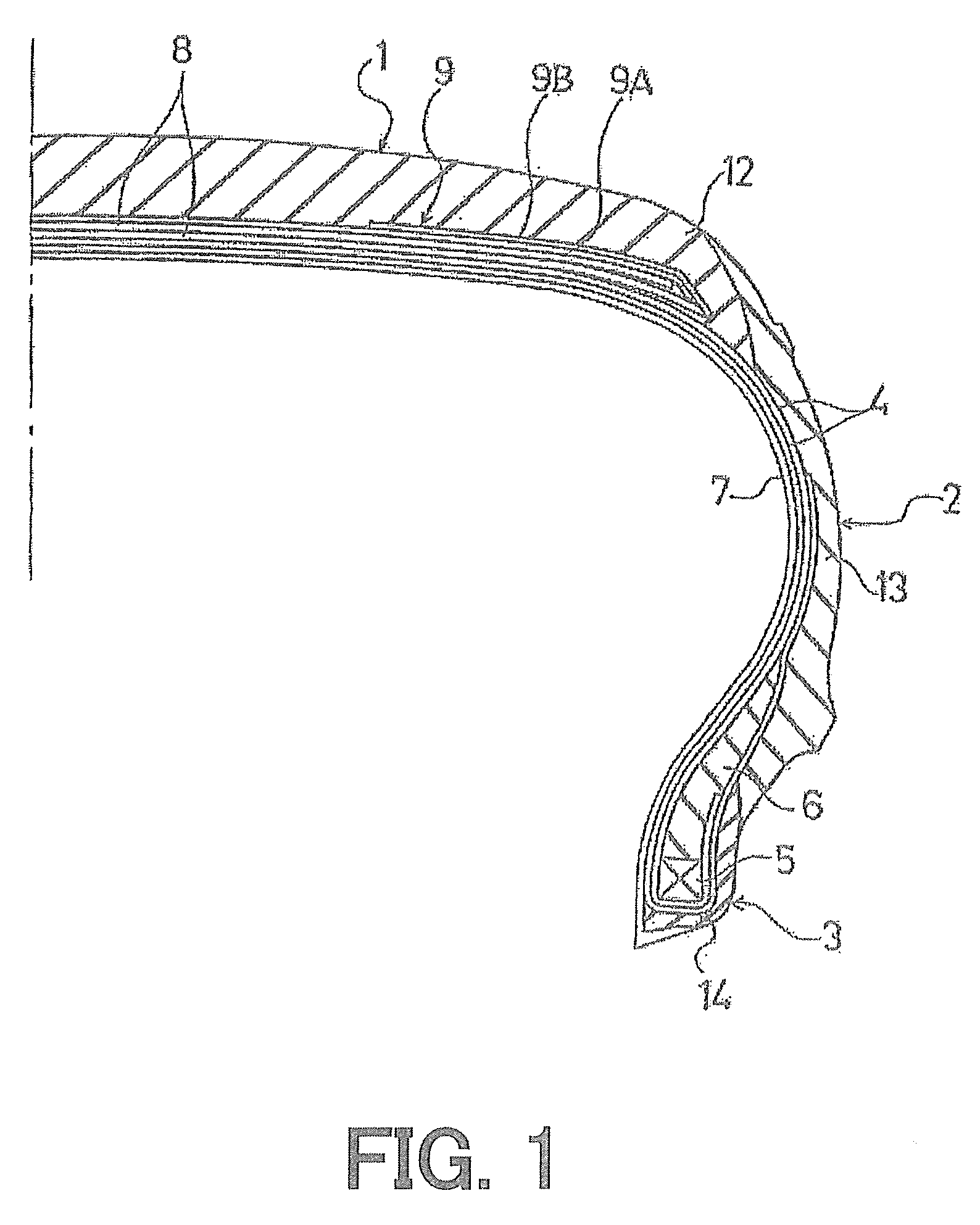

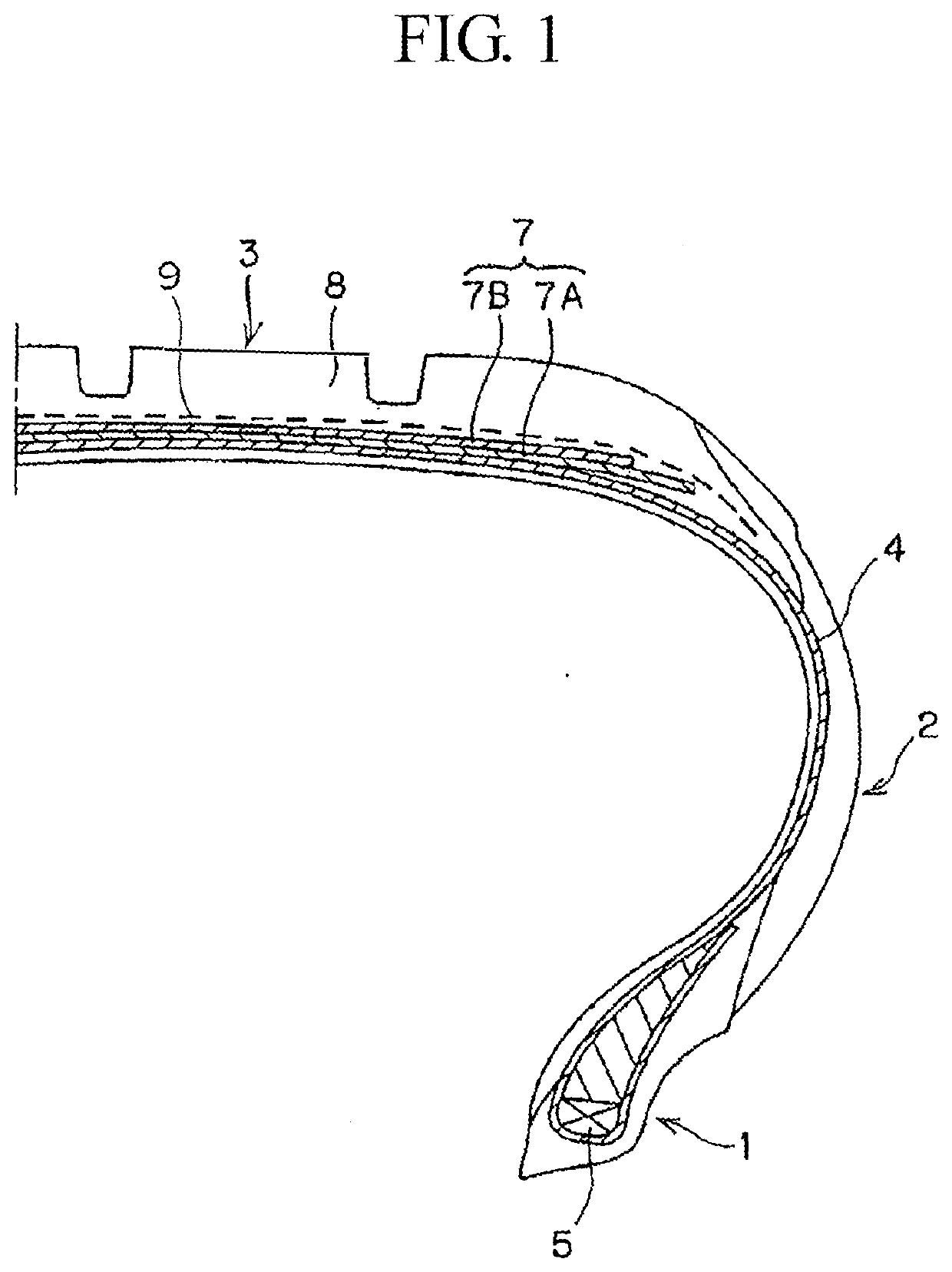

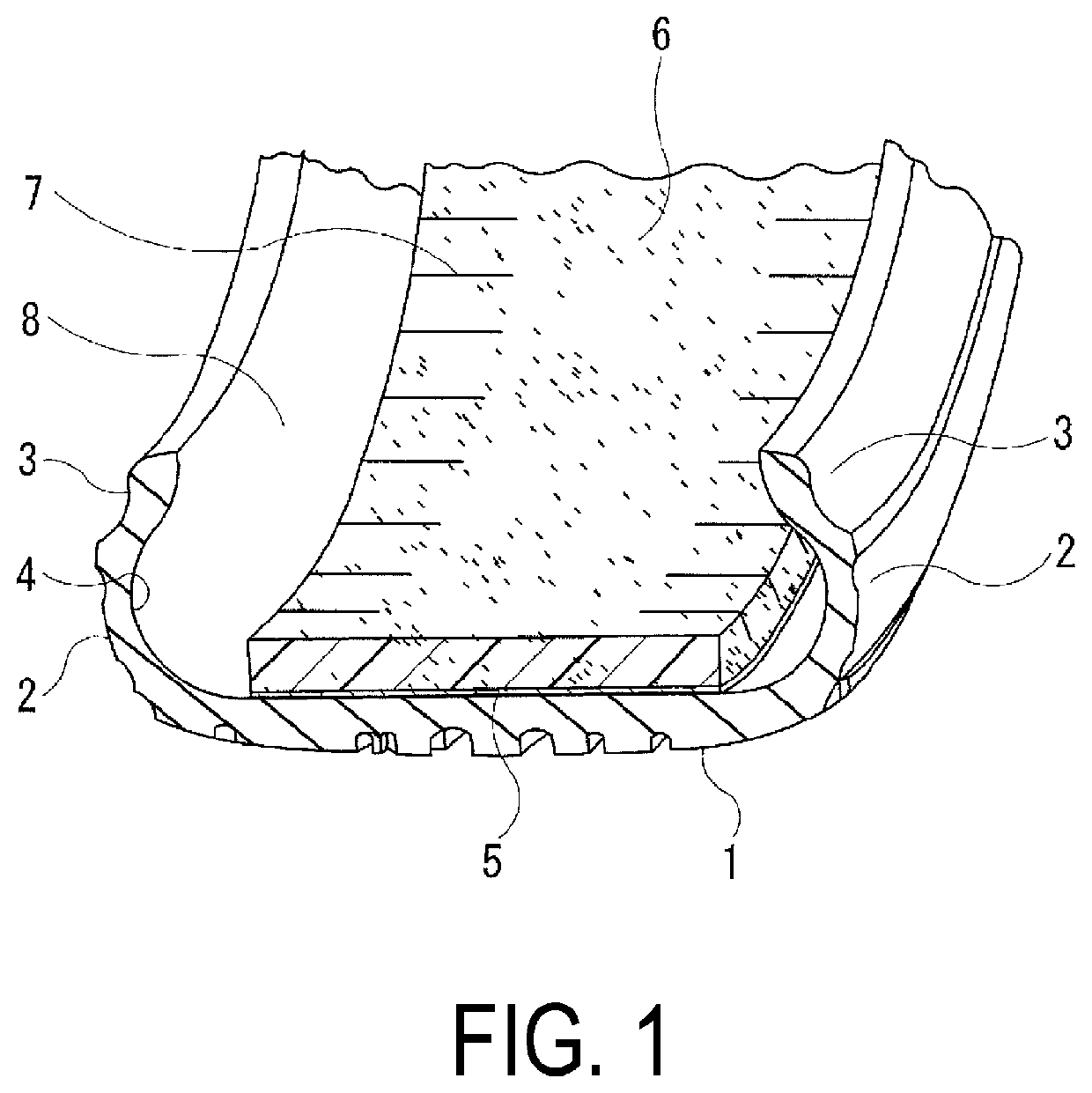

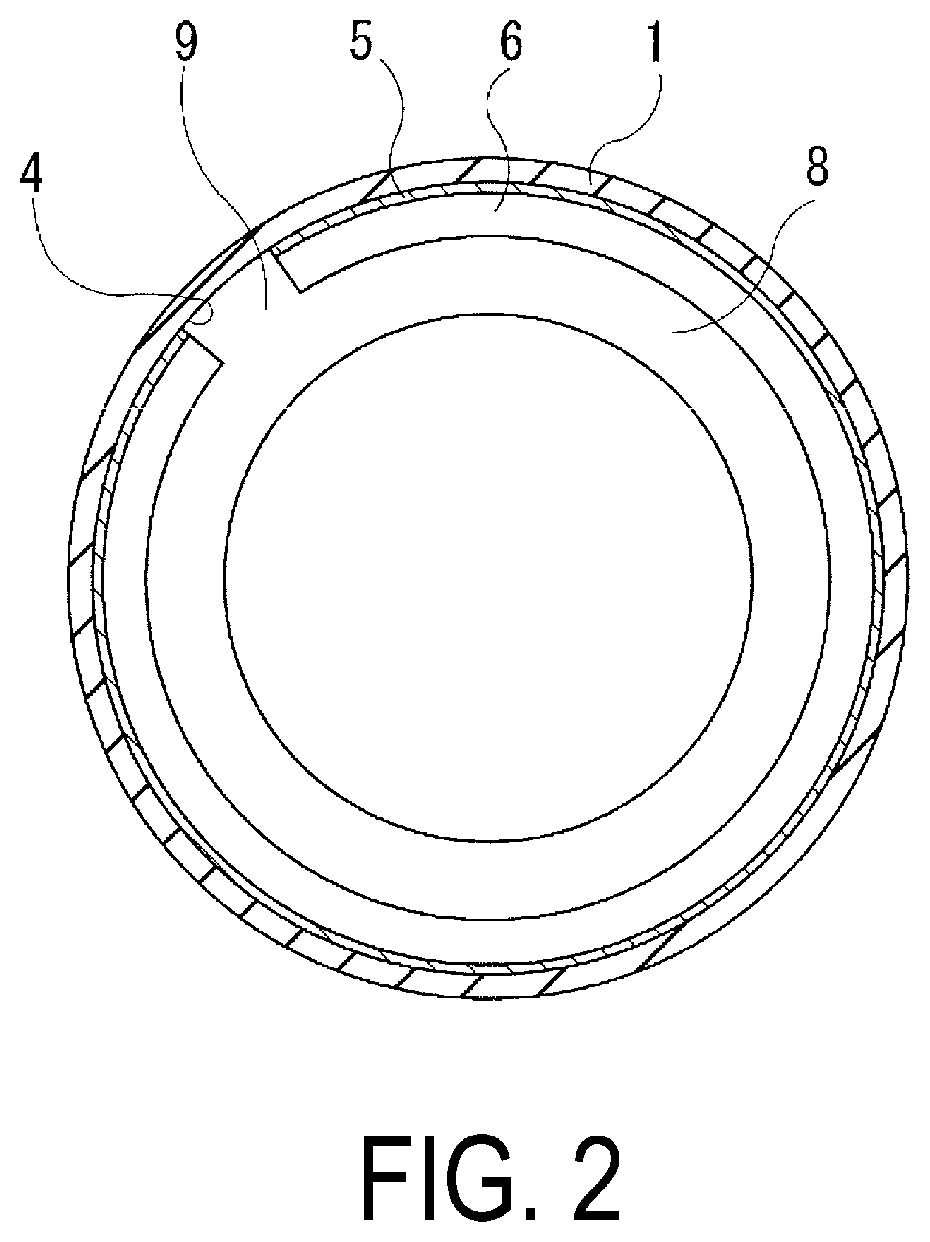

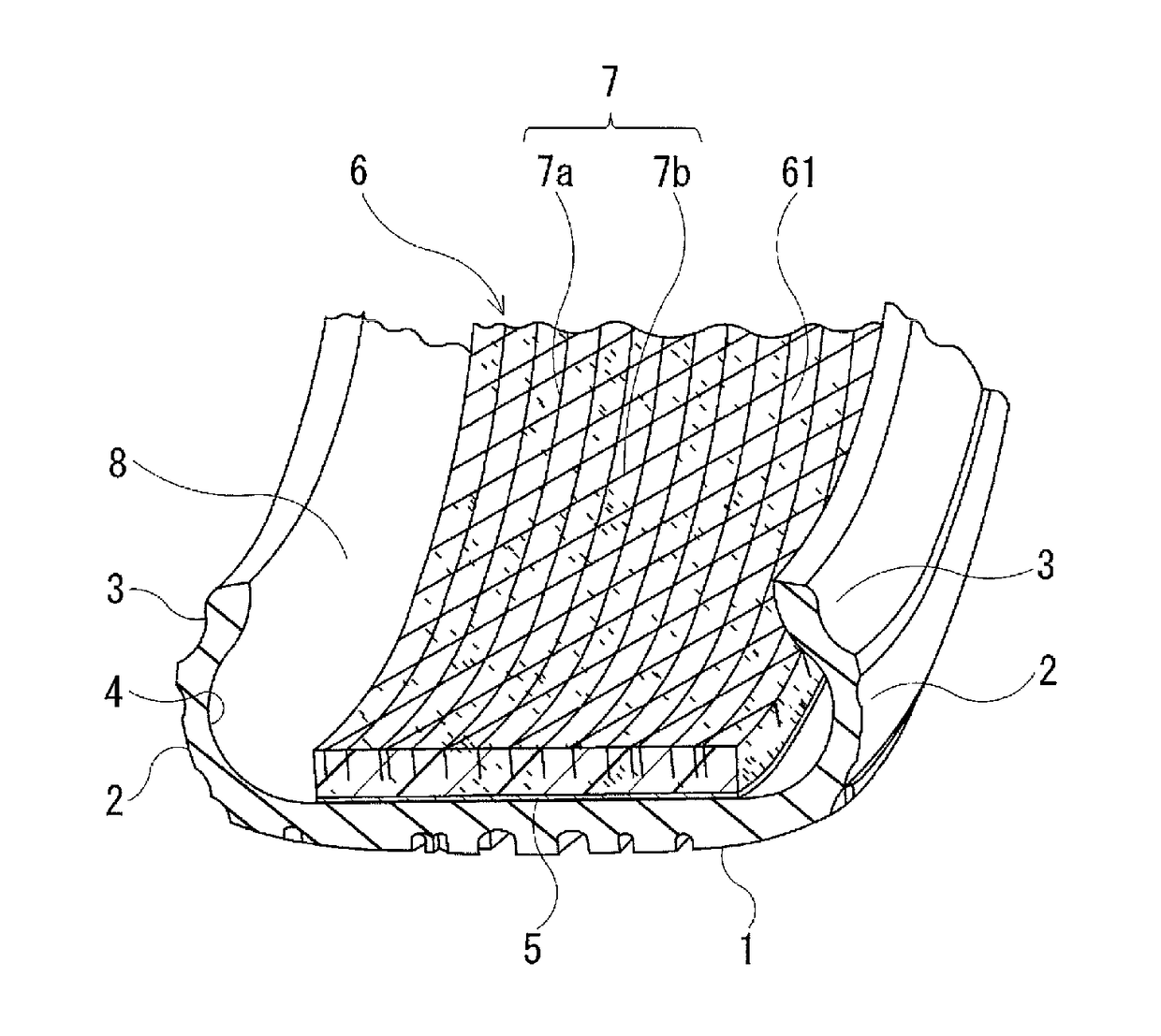

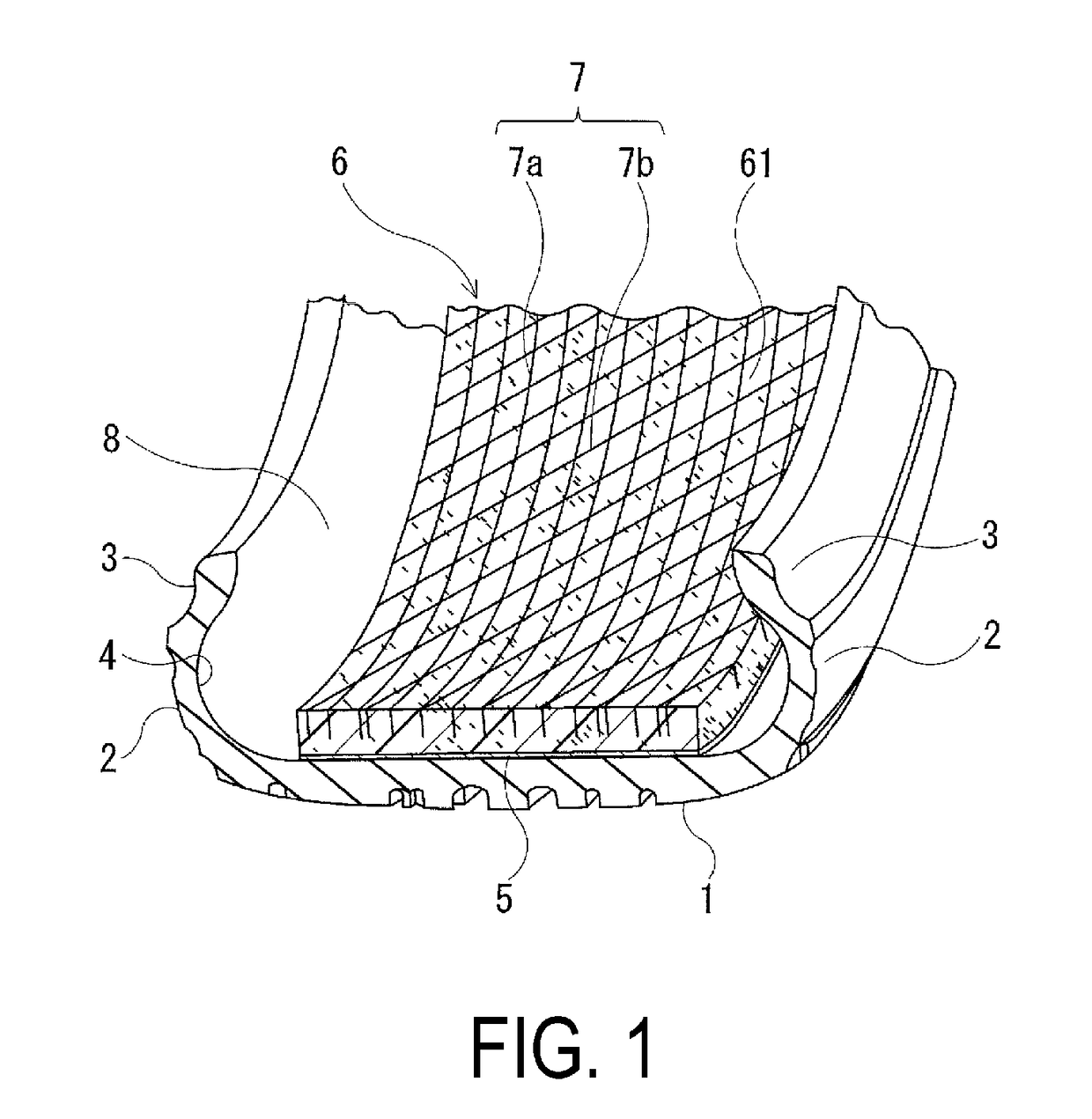

This invention relates to a pneumatic radial tire having low road noise and flat spot and a high high-speed durability, and more particularly to a pneumatic radial tire comprising a radial carcass (5), a belt (6) disposed outside a crown portion of the carcass in a radial direction and comprised of at least two belt layers, and a belt reinforcing layer (7A, 7B) disposed outside the belt in the radial direction, characterized in that the belt reinforcing layer 7A, 7B is formed by continuously and spirally winding a polyethylene terephthalate cord(s) in a circumferential direction of the tire, and this cord has an elastic modulus of not less than 2.5 mN / dtex·% under a load of 29.4 N measured at 160° C.

Owner:BRIDGESTONE CORP

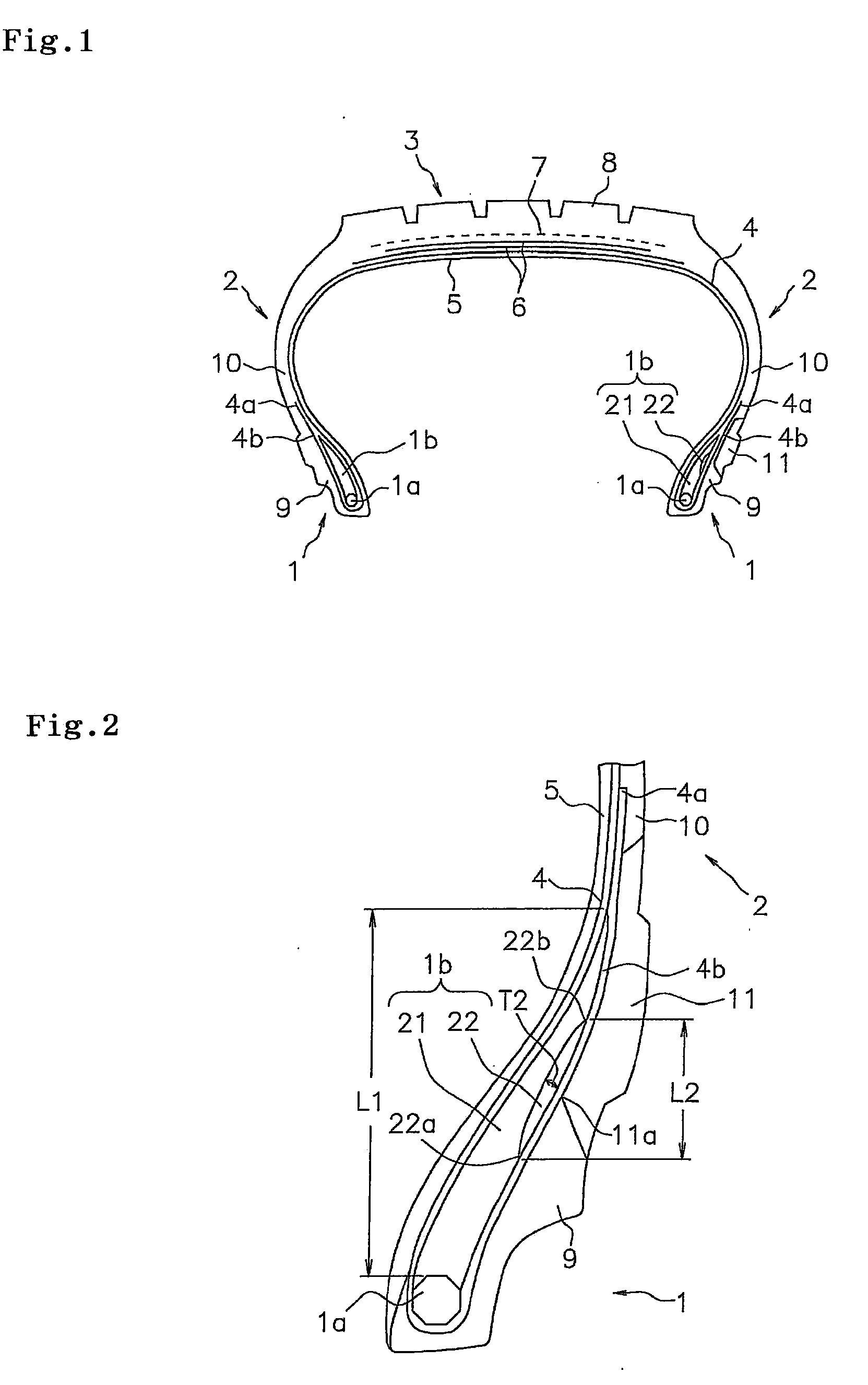

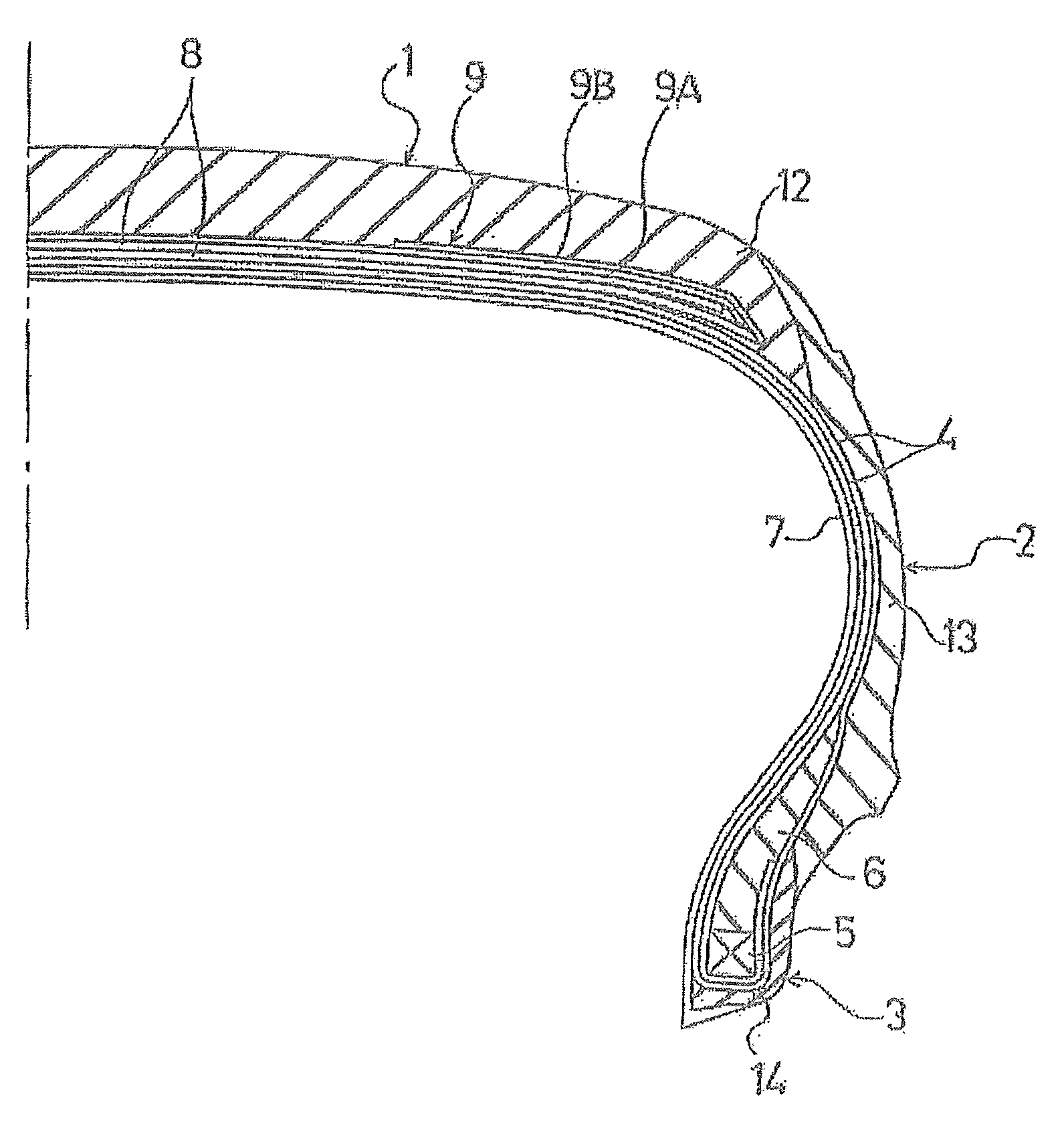

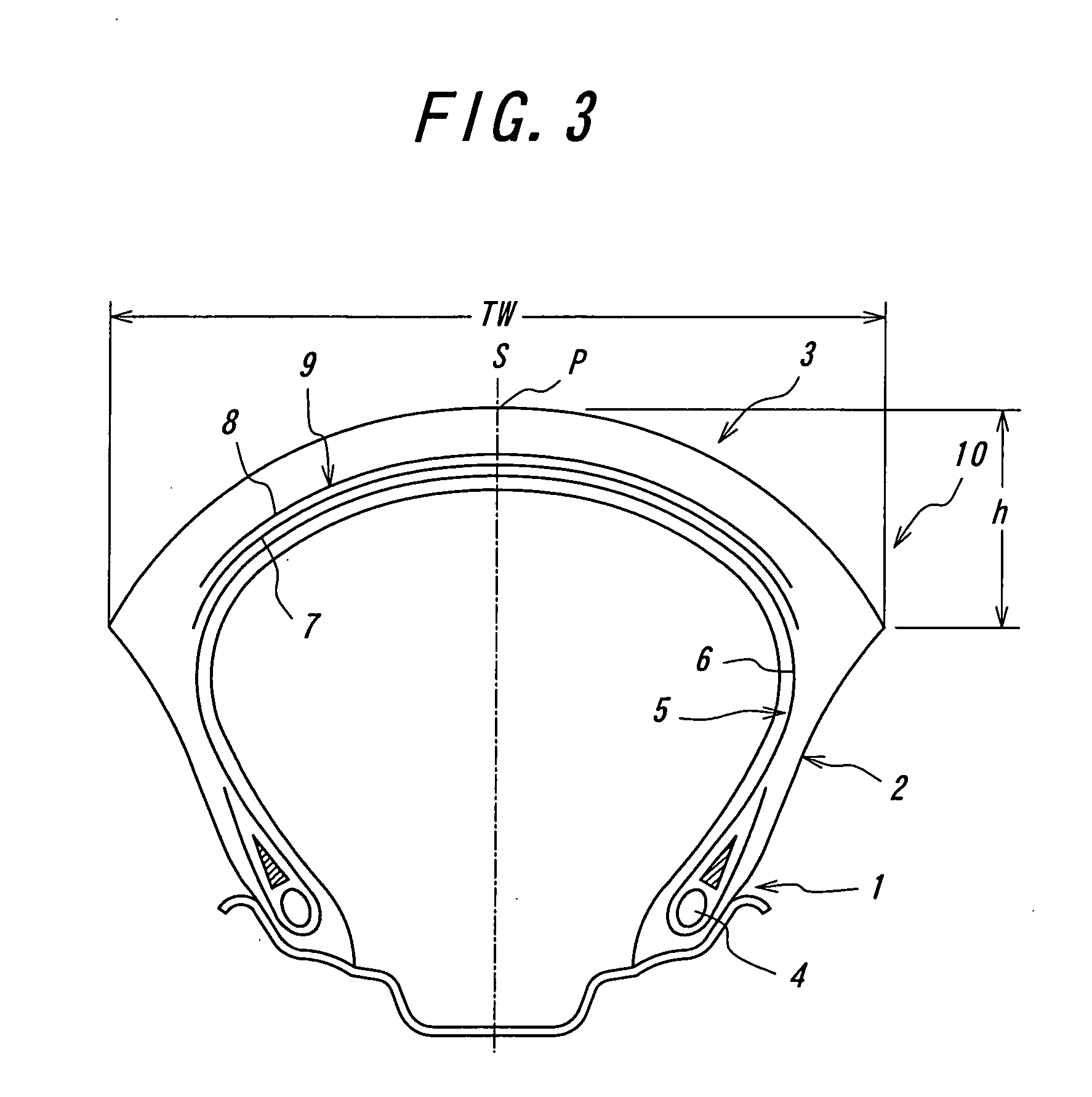

Pneumatic tire

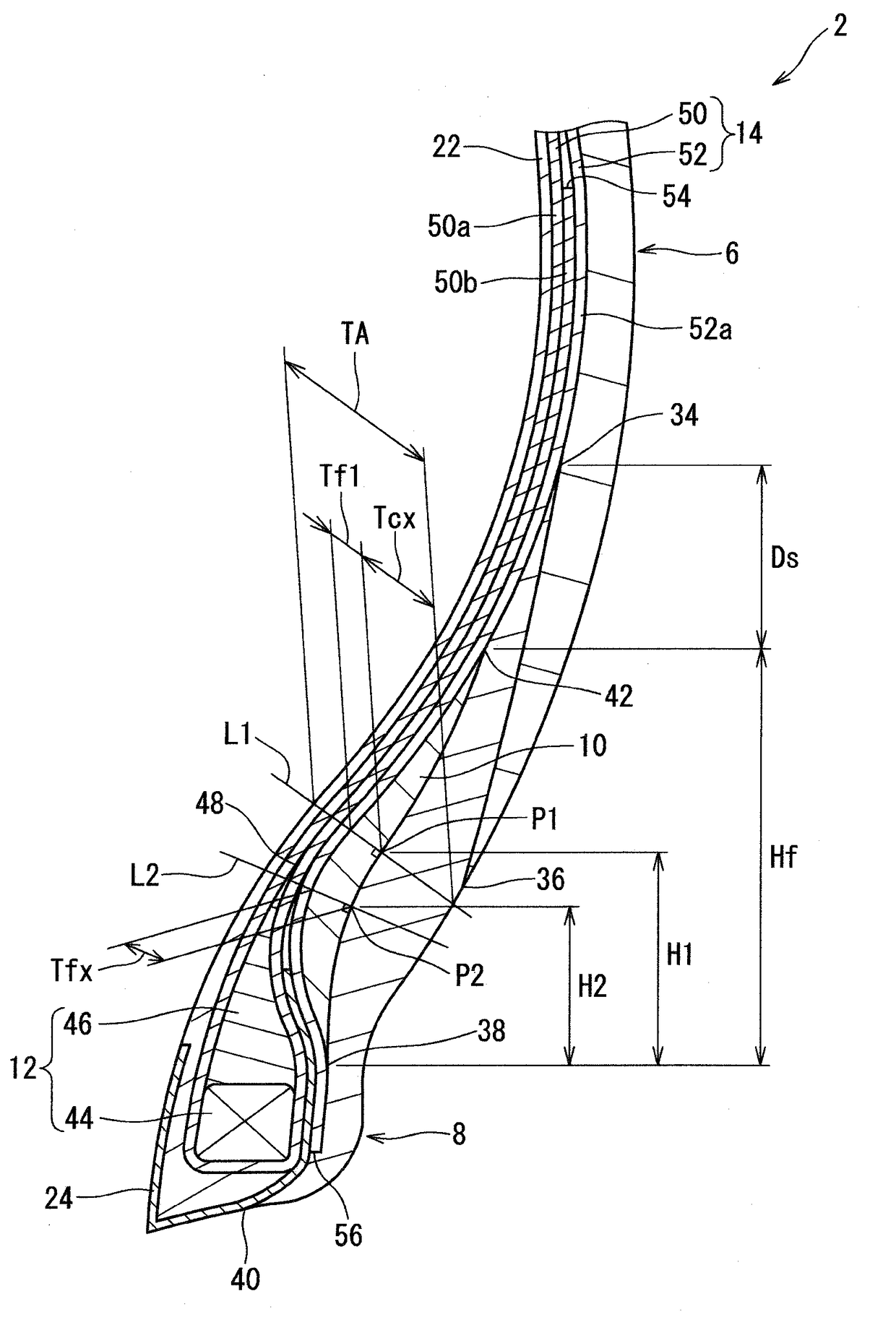

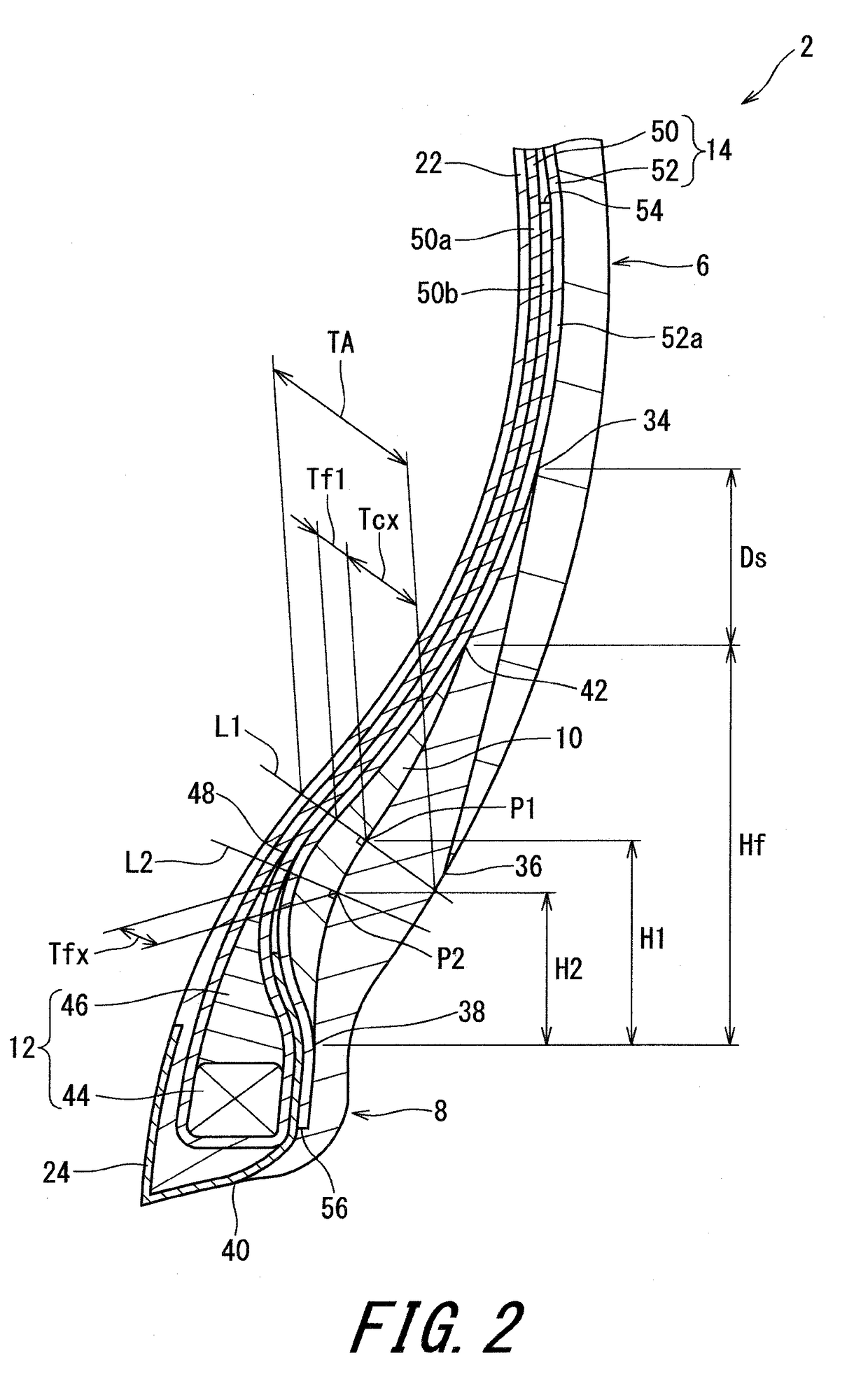

ActiveUS20170274710A1Less bendingConcentration of strain is preventedTyresPneumatic tyre reinforcementsEngineeringElastic modulus

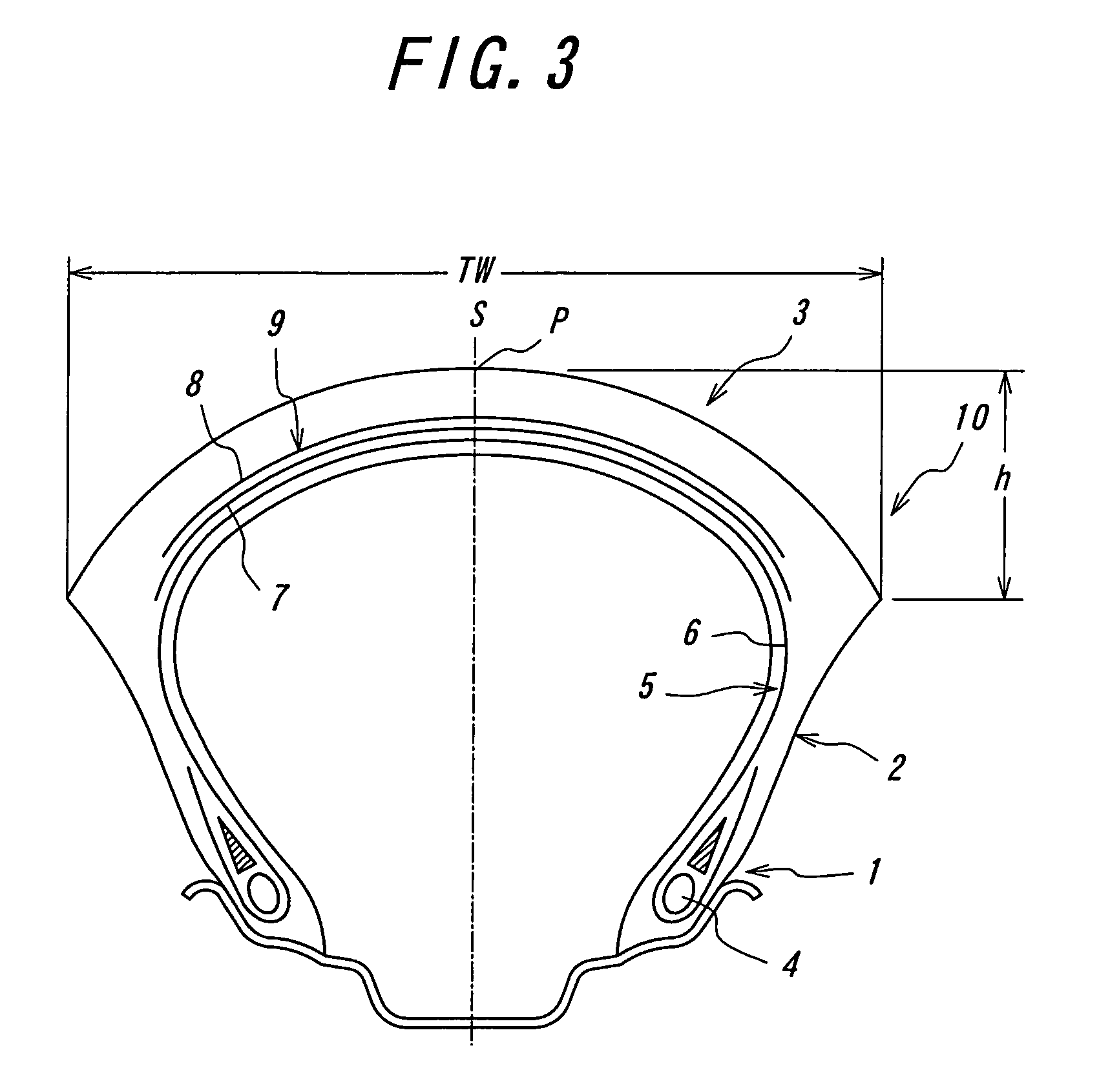

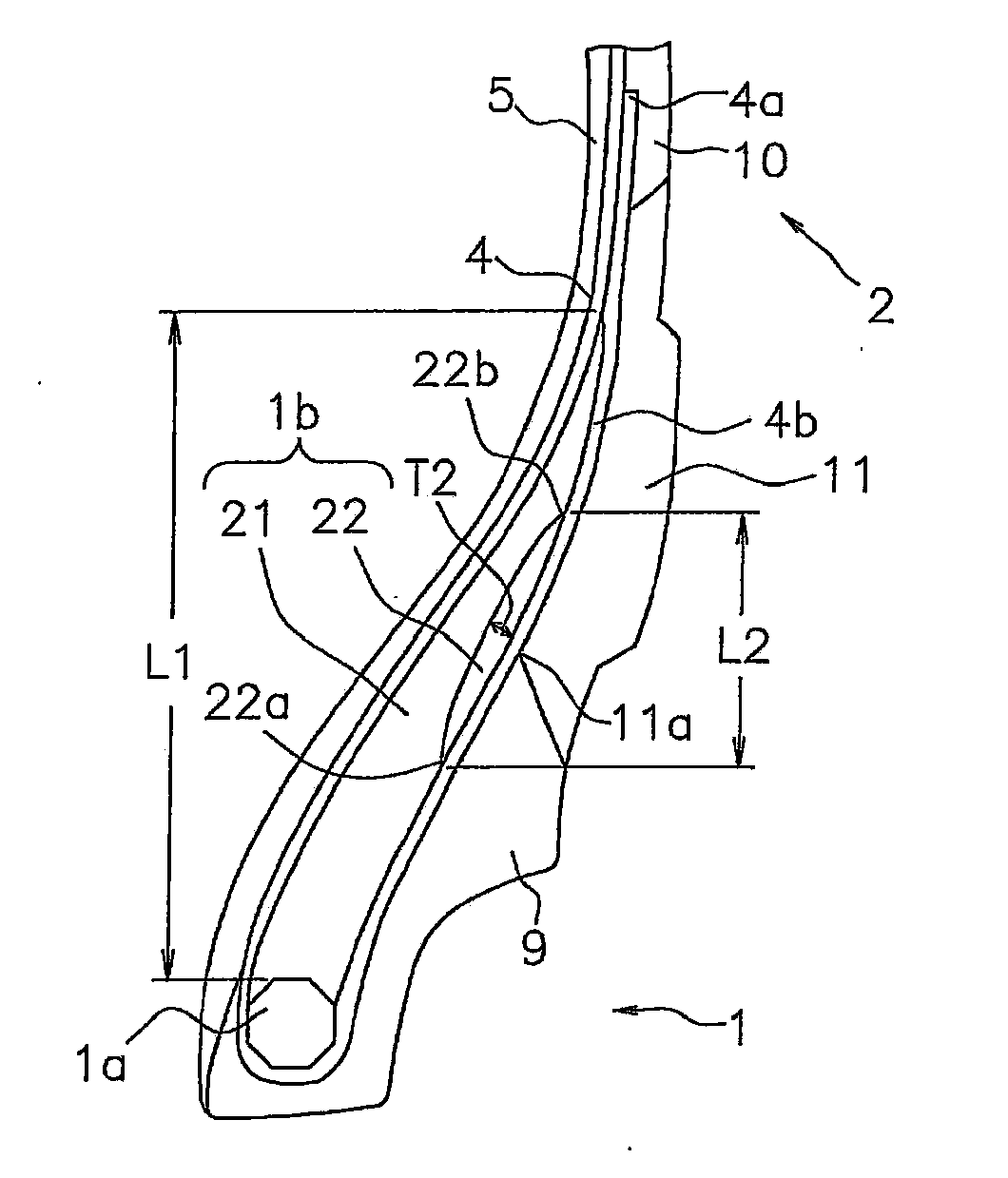

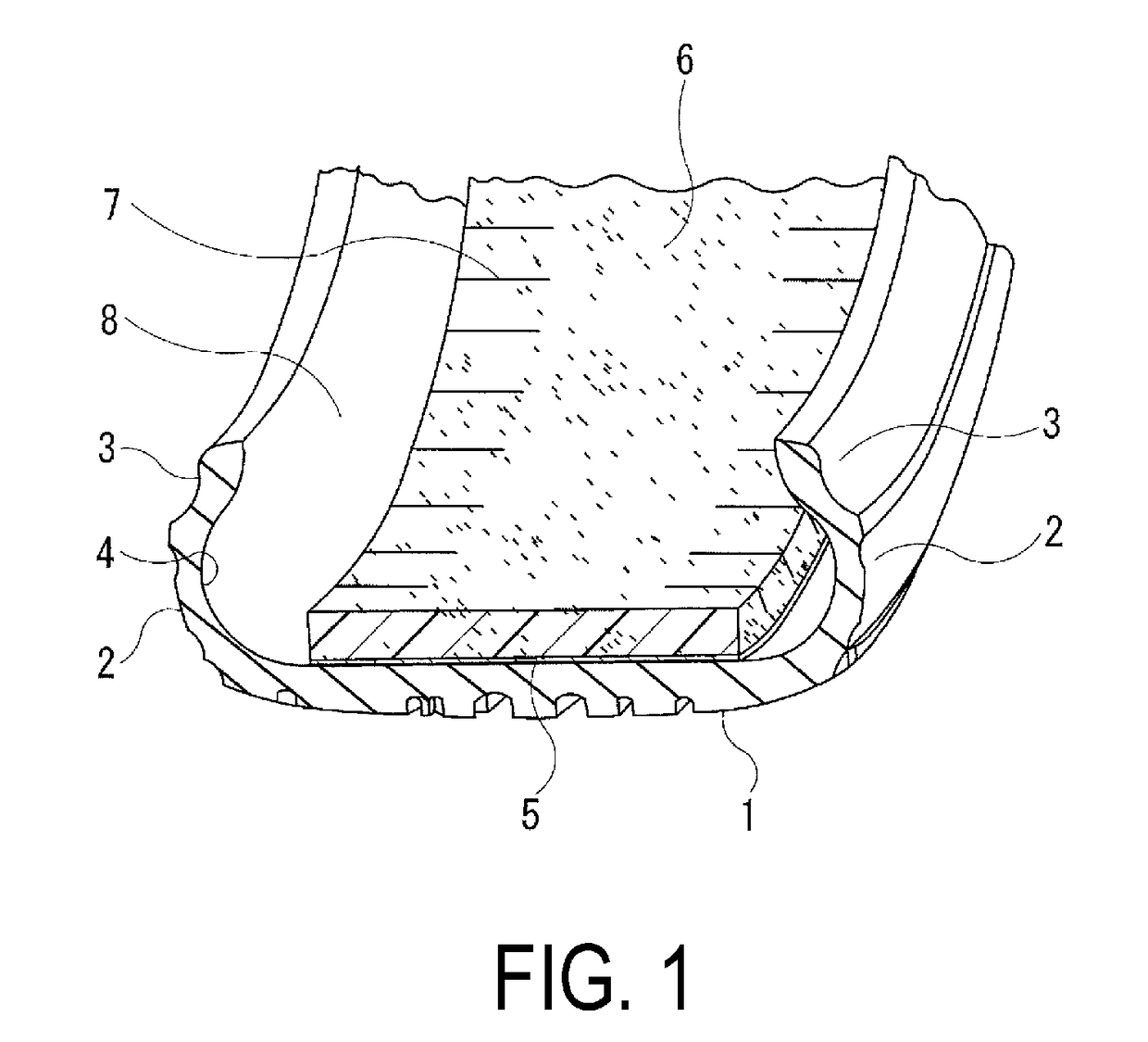

In the tire 2, fillers 10 are layered over clinches 8 in portions outward of a carcass 14 in the axial direction. A carcass ply 50 is turned up around cores 44. Turned-up portions 50a are disposed between the fillers 10 and apexes 46. Each clinch 8 has a maximum thickness Tcx that is measured along a line normal to an inner surface, in the axial direction, of the clinch 8. A ratio of a thickness Tf1 of the filler 10 to a sum of the thickness Tf1 and the thickness Tcx is greater than or equal to 0.1 and not greater than 0.6. A percentage of a complex elastic modulus E*f of the filler 10 relative to a complex elastic modulus E*a of the apex 46 is greater than or equal to 70% and not greater than 125%.

Owner:SUMITOMO RUBBER IND LTD

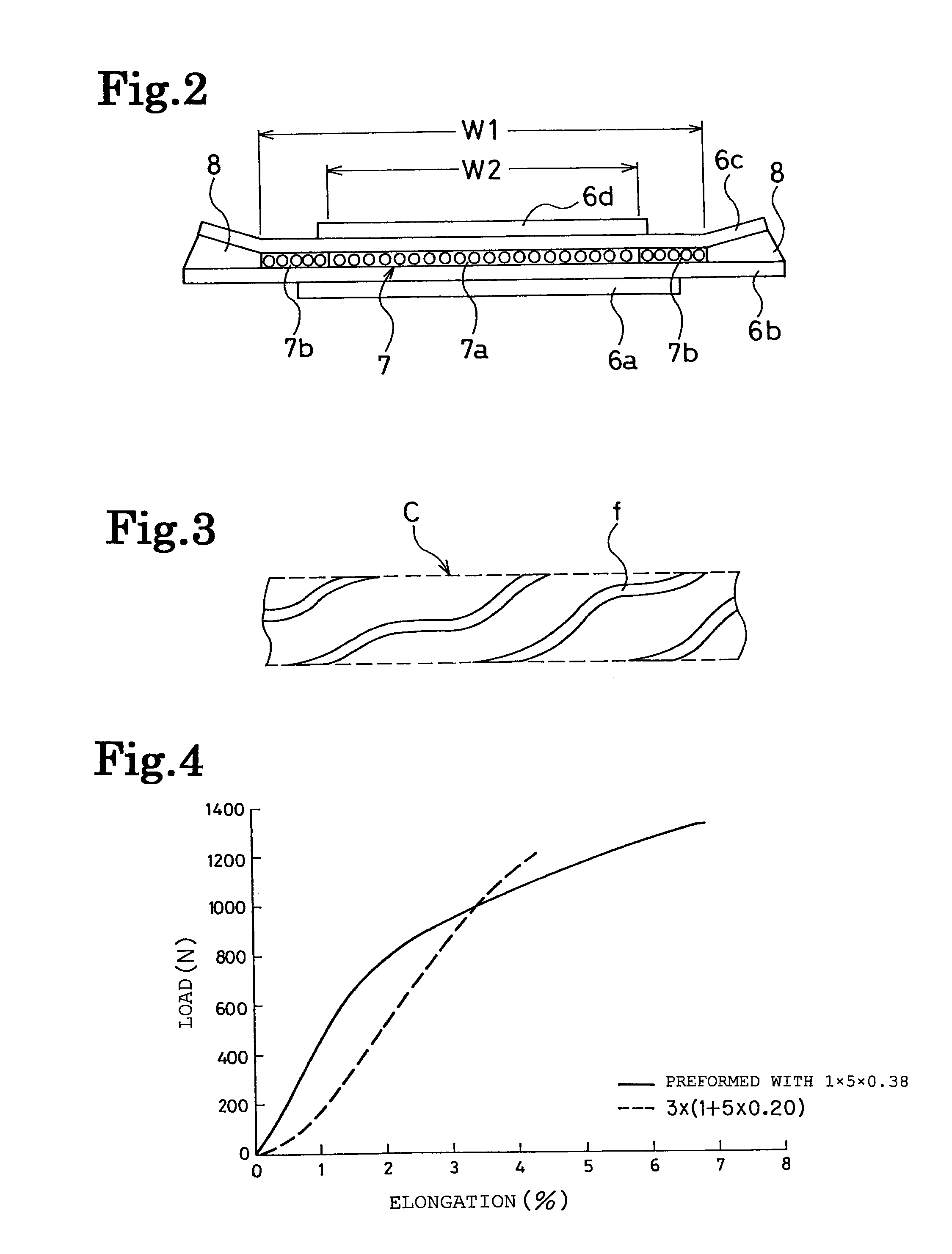

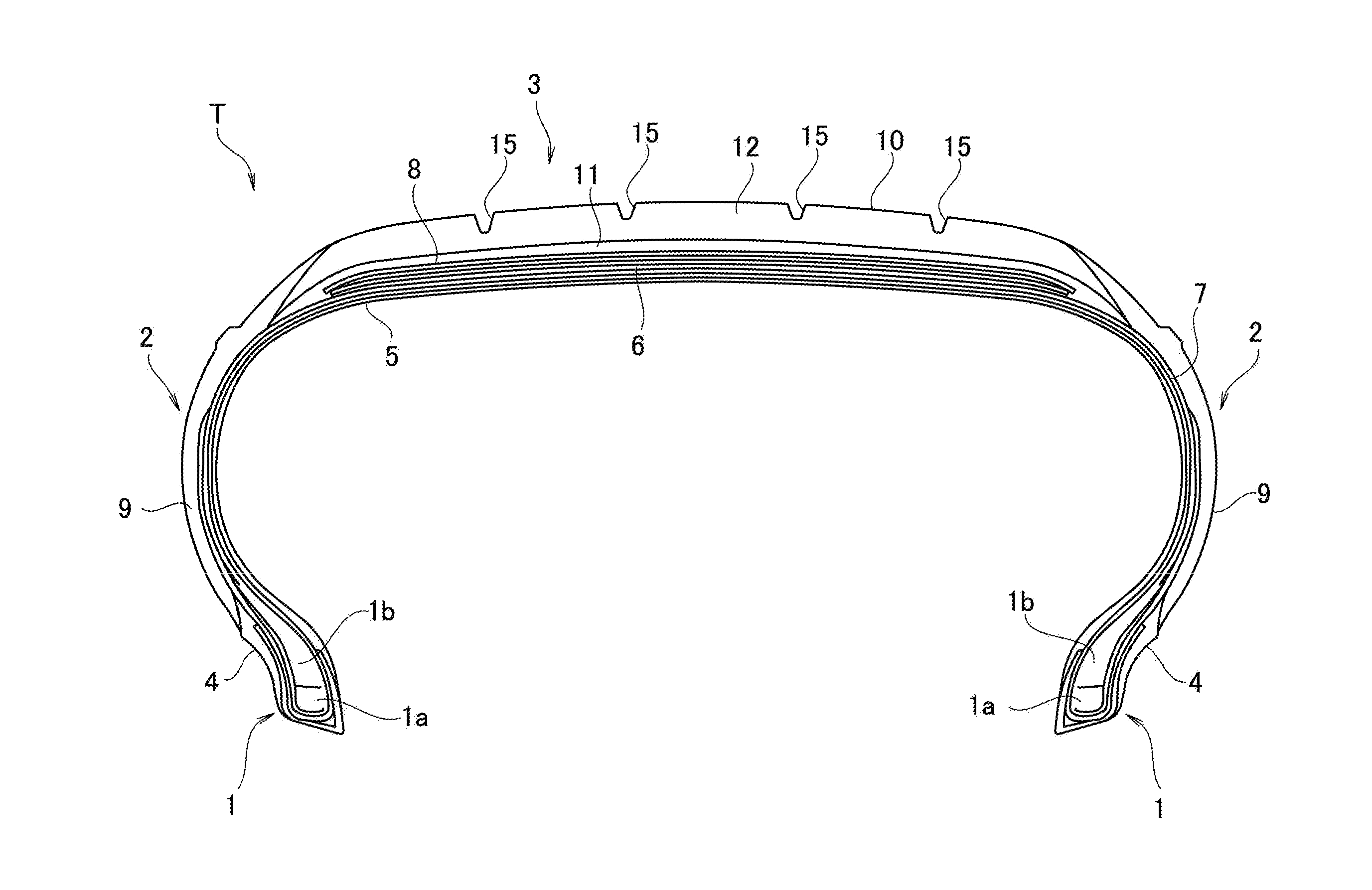

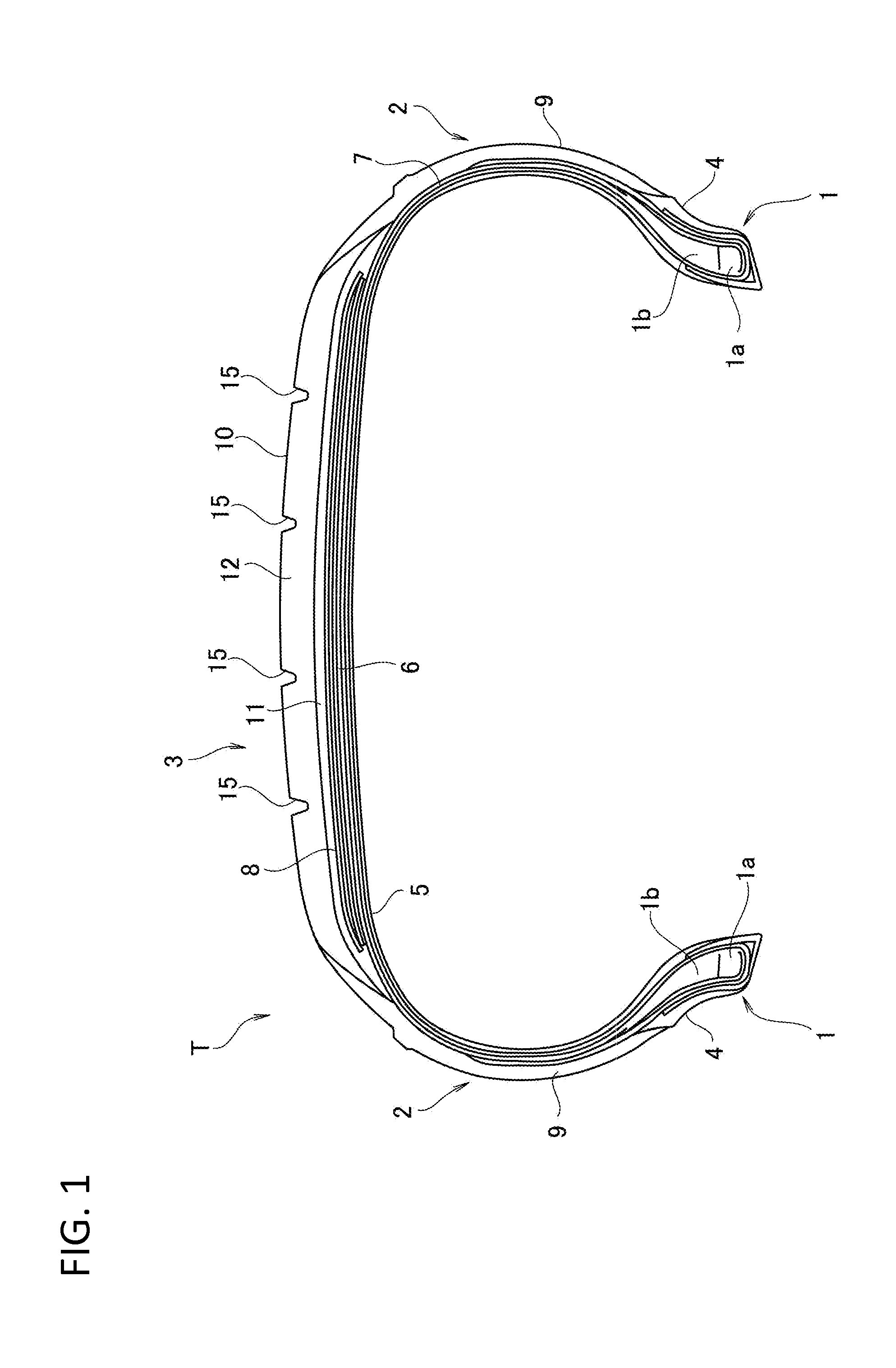

Pneumatic radial tire

ActiveUS8225835B2Suppress fatigueHigh-speed durabilityHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

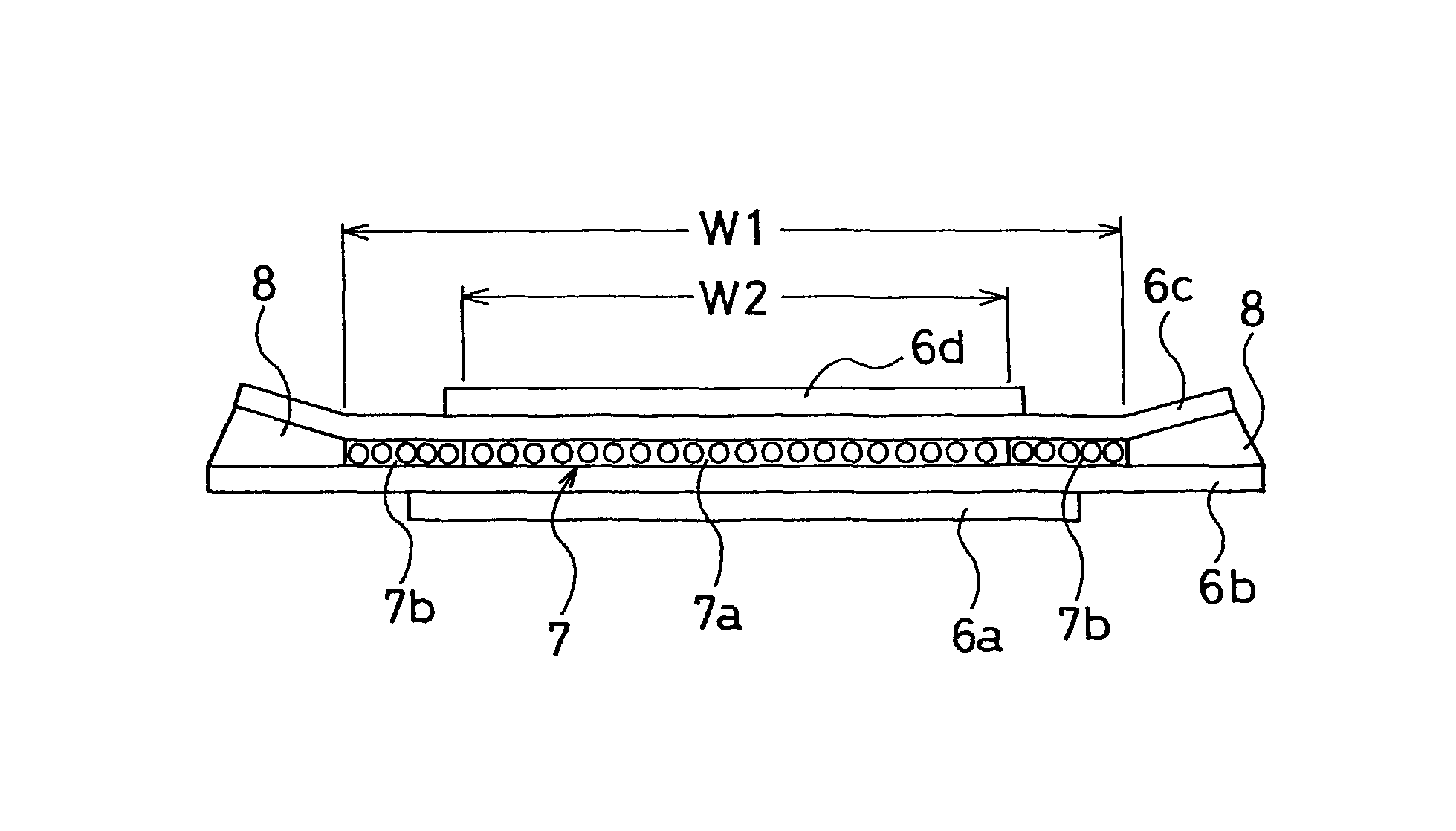

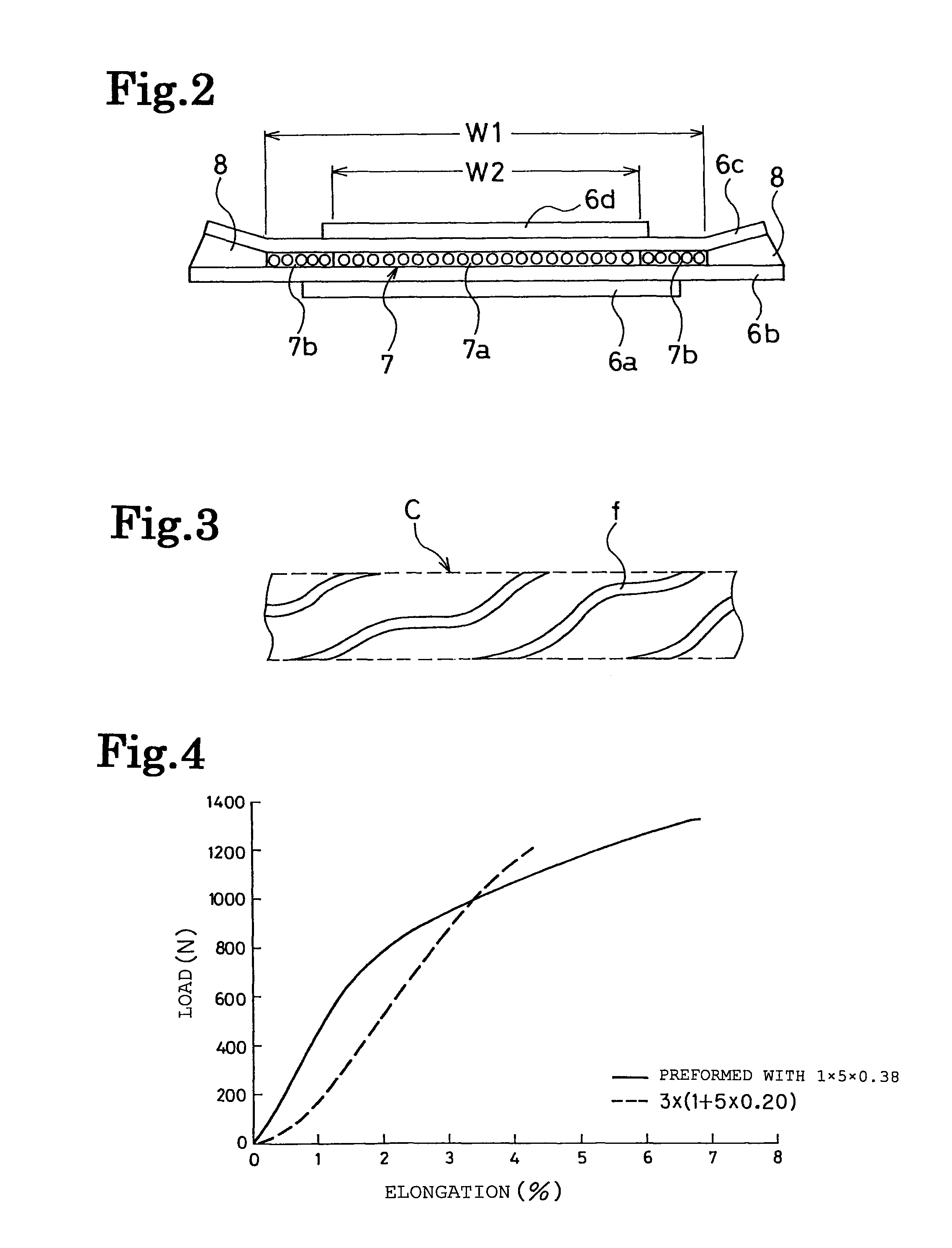

Provided is a pneumatic radial tire: that includes a circumferential-direction reinforcement layer having a width increased with fatigue break of the circumferential-direction reinforcement layer being suppressed at edge portions thereof; and that suppresses separation in each of cross belt layers at edge portions thereof. A pneumatic radial tire according to the present invention is a pneumatic tire including: at least two cross belt layers disposed on an outer circumferential side of a carcass layer in a tread portion; and at least one circumferential-direction reinforcement layer disposed between these cross belt layers, a width of the circumferential-direction reinforcement layer being smaller than that of each cross belt layer. The pneumatic radial tire is configured so that: the cross belt layers are separated away from each other at outer sides respectively of end positions, in a width direction, of the circumferential-direction reinforcement layer; the circumferential-direction reinforcement layer includes steel cords of two types which differ in elongation at break; and the steel cord having relatively small elongation at break is disposed in a center portion of the circumferential-direction reinforcement layer, whereas the steel cord having relatively large elongation at break is disposed in each of outer side portions of the circumferential-direction reinforcement layer.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

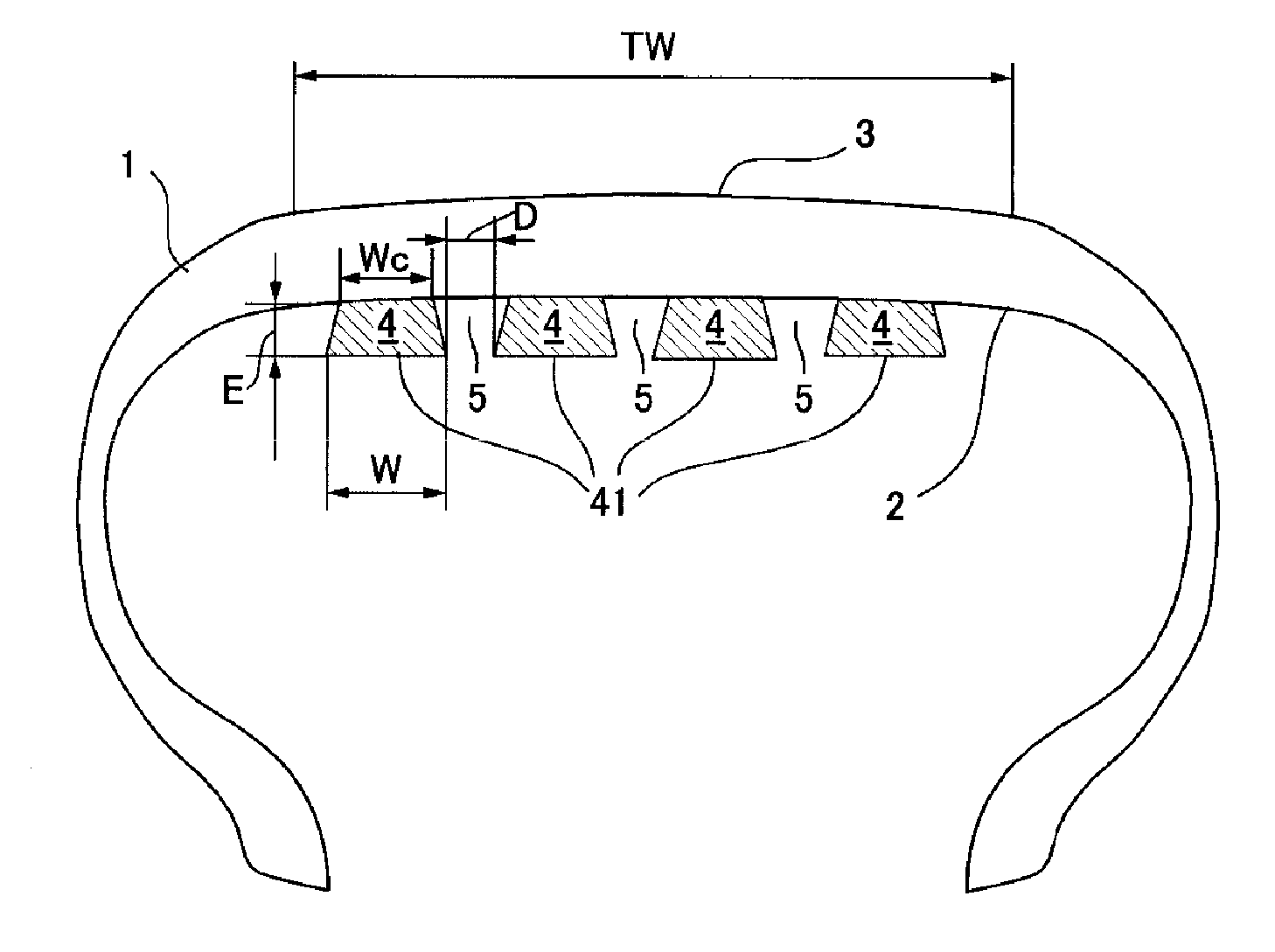

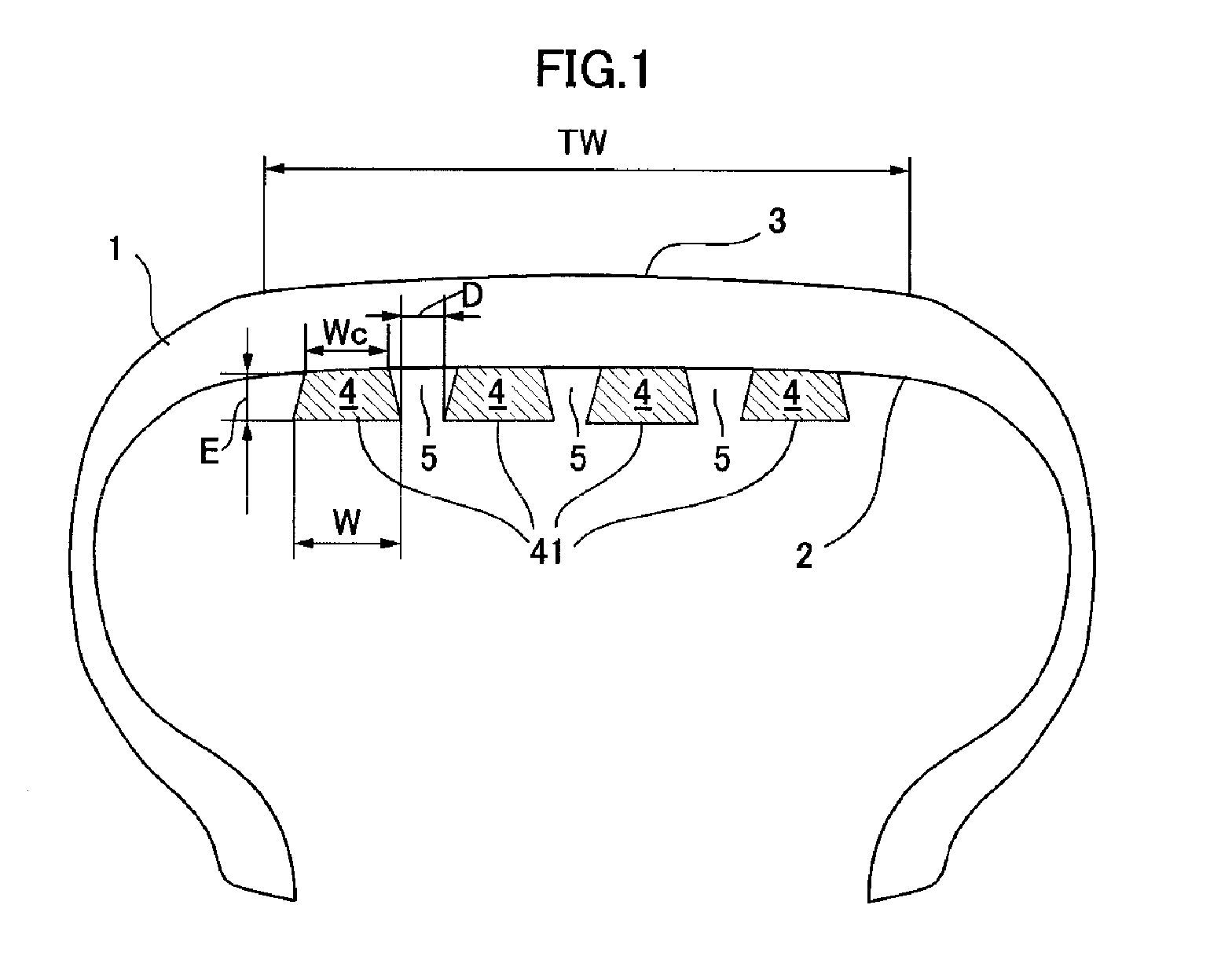

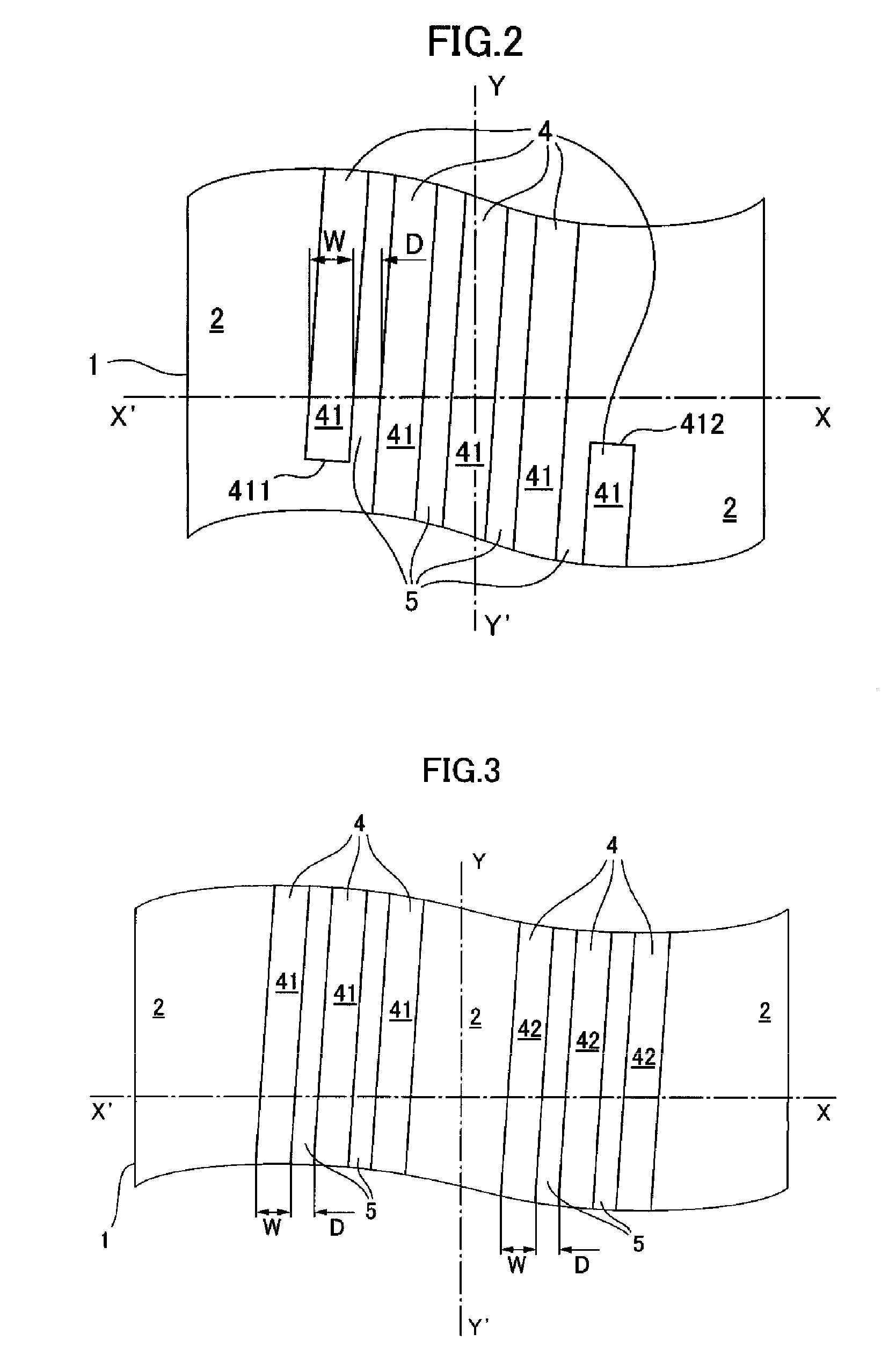

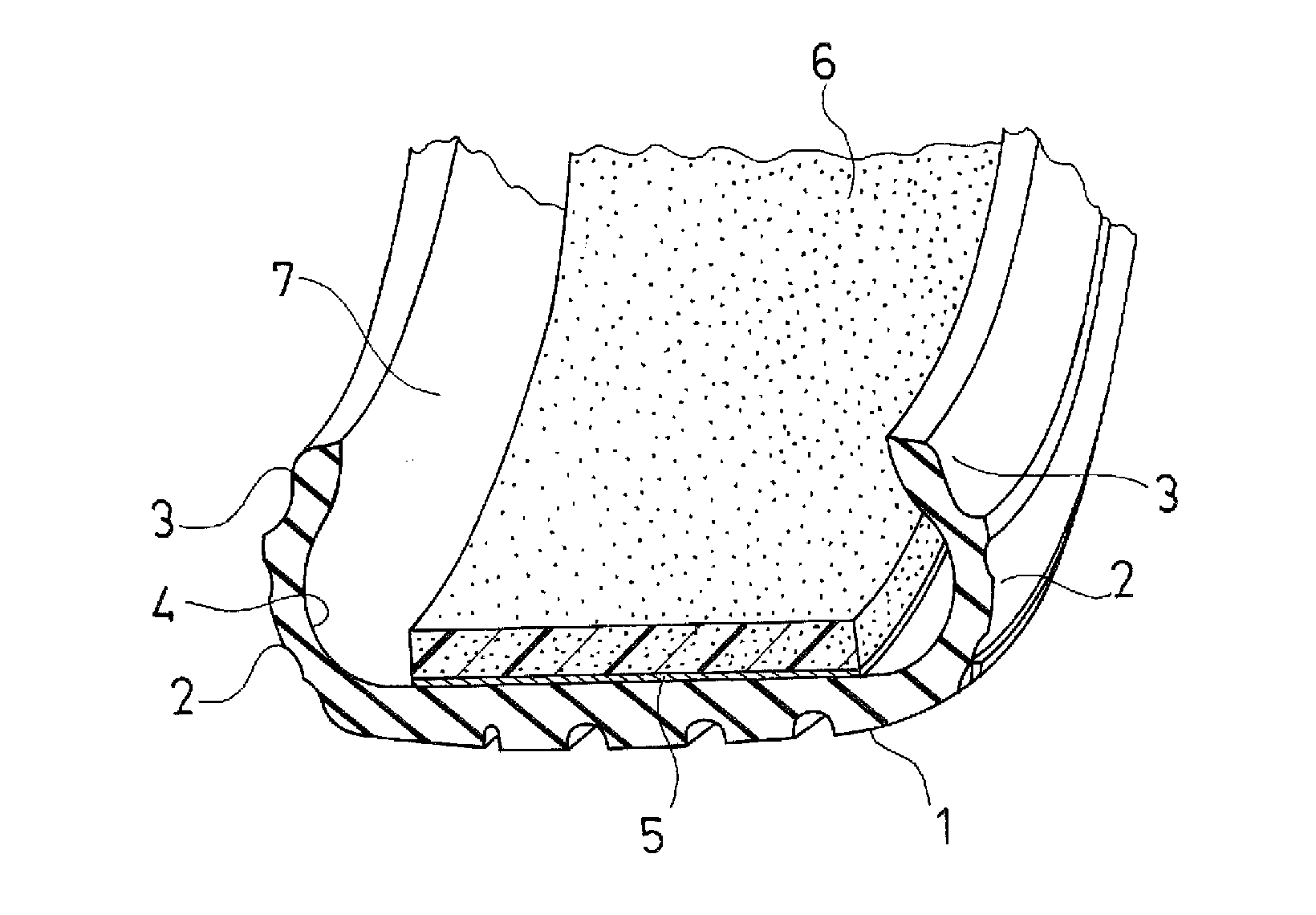

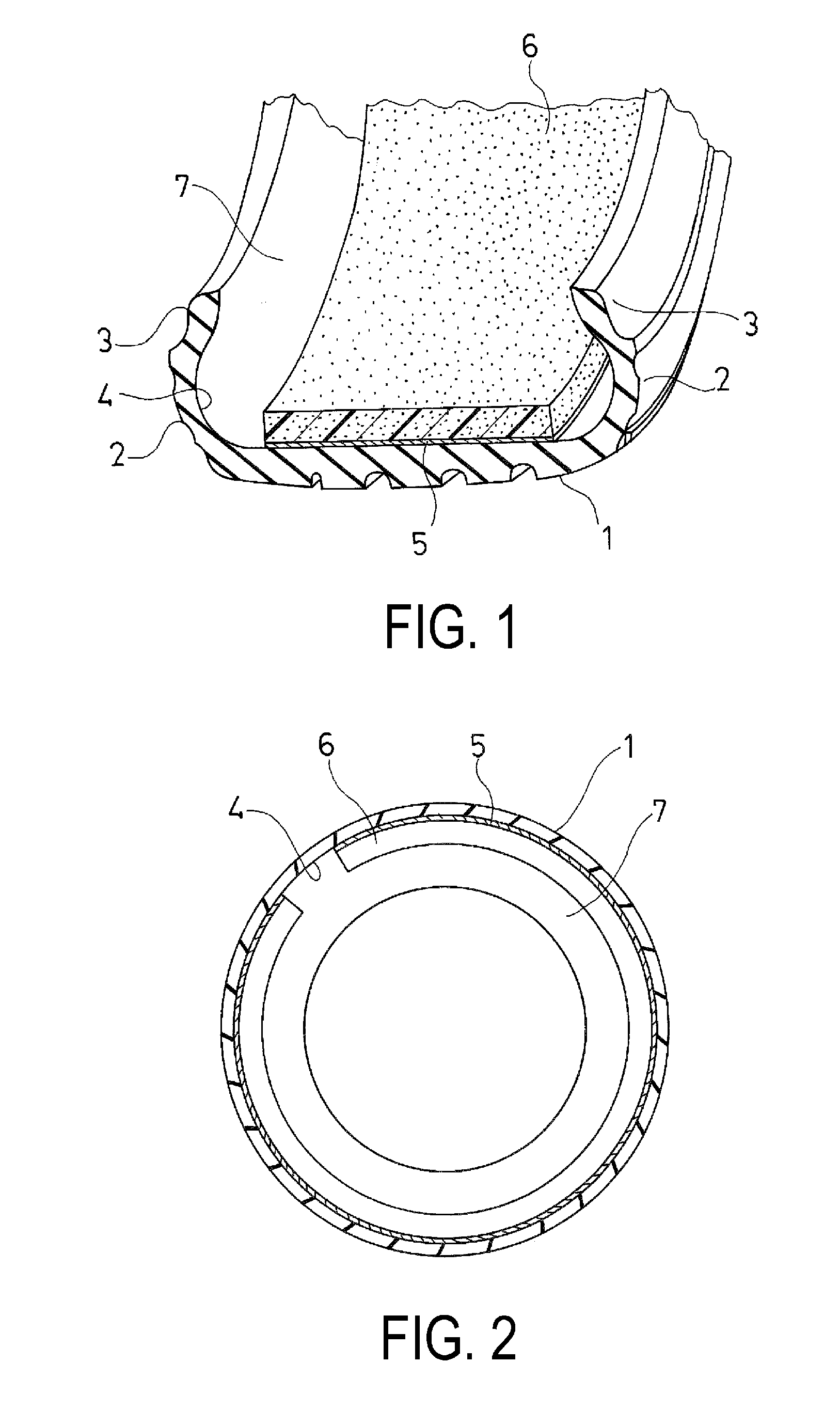

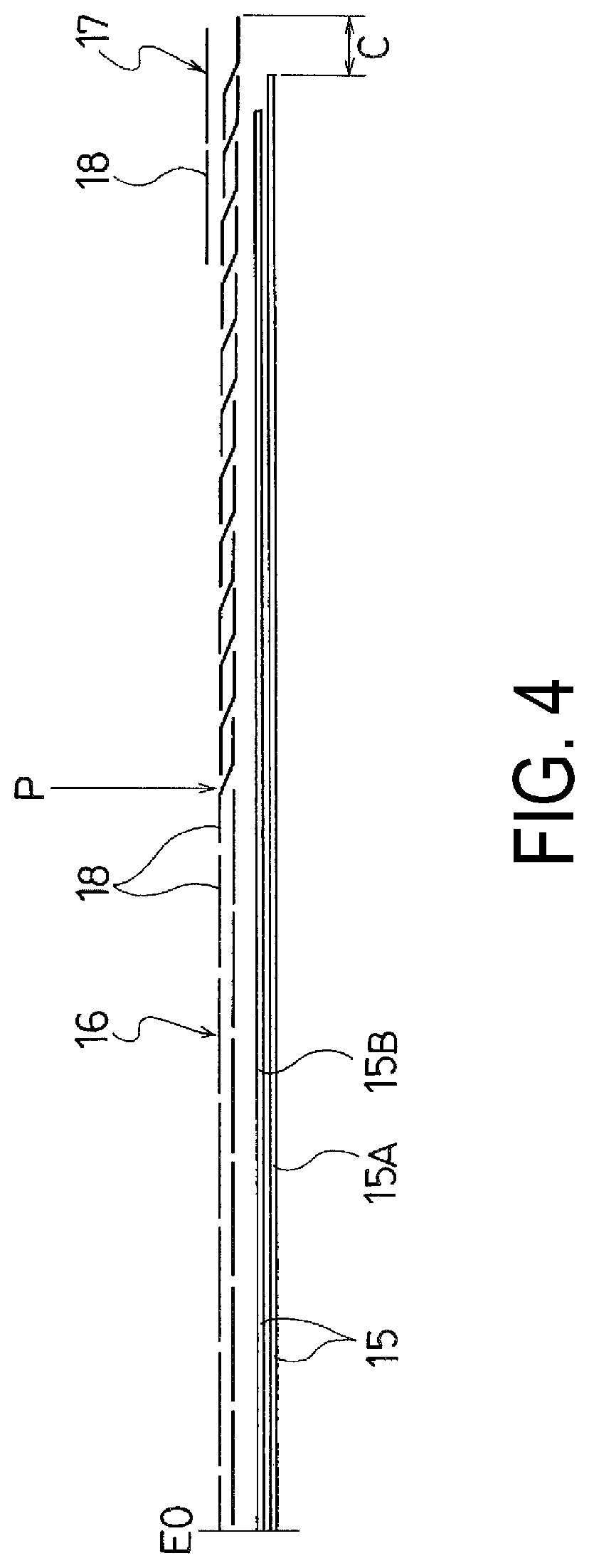

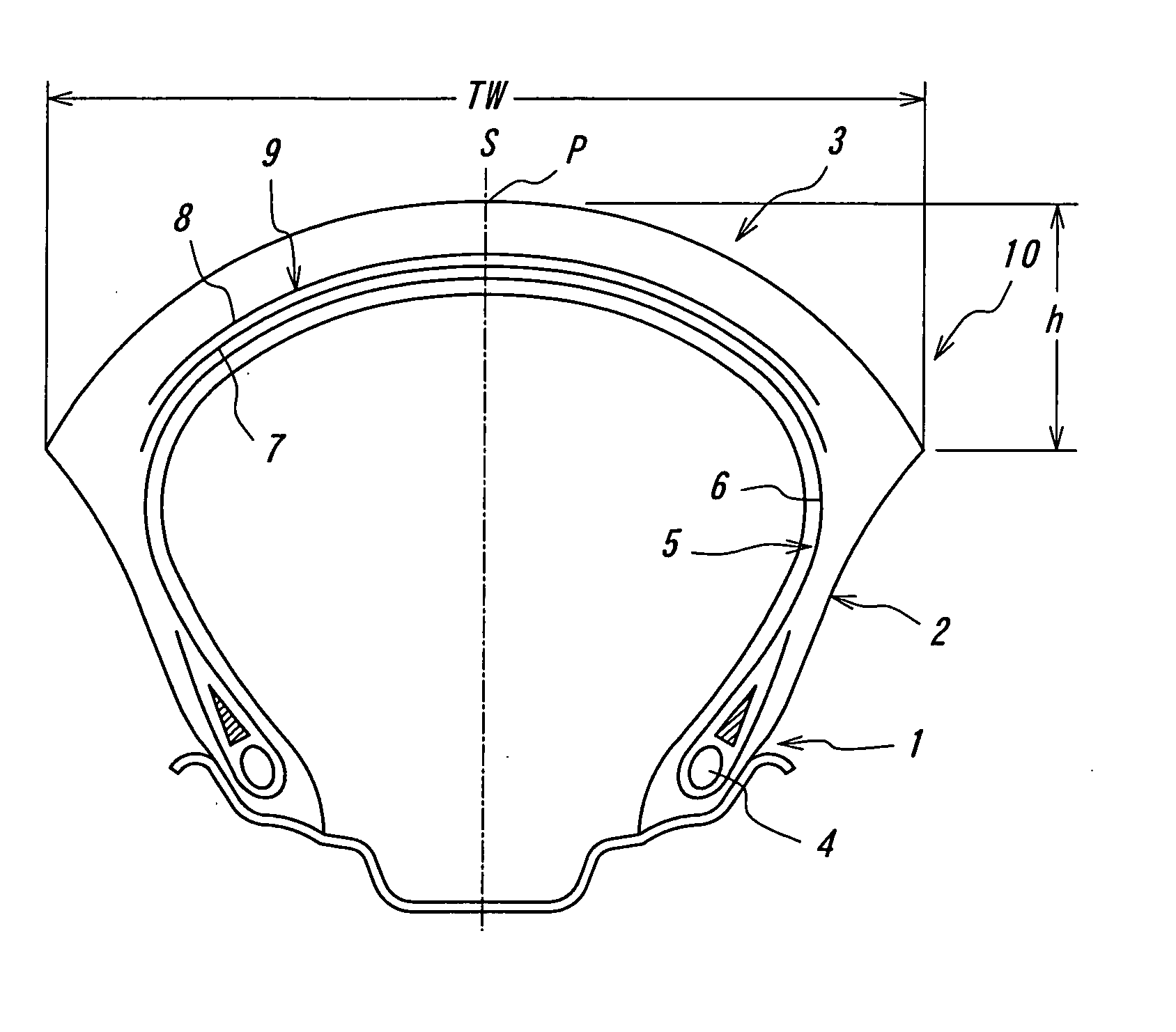

InactiveUS20140020806A1Reduce cavity resonanceHigh-speed durabilityTyresInflatable tyresGround contactGroove width

A pneumatic tire provided with a noise damper in the tire cavity, which can maintain high-speed durability and productivity while also reducing cavity resonance, comprising a tread having a width TW in contact with the ground during travel, in which a noise damper made of a sound-absorbing material is attached to the tire internal surface in order to reduce cavity resonance, wherein the noise damper is at least one continuous ribbon made of a sound-absorbing material and having a width W and a thickness E, which is fixed over an attachment width Wc to the tire internal surface over a range of at least 30% of the inside of the tread in the radial direction, the start end and terminal end which are the two ends of the continuous ribbon are disposed in such a way as to be offset from each other in the axial direction, and the continuous ribbon forms, together with the tire internal surface, a continuous groove having a groove width D which is at least equal to 10% of the width W of the continuous ribbon.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Pneumatic tire comprising carcass and belt of organic fiber cords with specified modulus of elasticity

InactiveUS6568445B1Reduce rigidityDegradation of steering stability and wear resistancePneumatic tyre reinforcementsWheelsFiberEngineering

A pneumatic tire comprises a carcass comprised of one or more carcass plies and a belt disposed on an outer periphery side of a crown portion of the carcass and comprised of one or more belt layers, wherein each of at least one carcass ply and at least one belt layer is constituted with organic fiber cords having a modulus of elasticity within a specified range.

Owner:BRIDGESTONE CORP

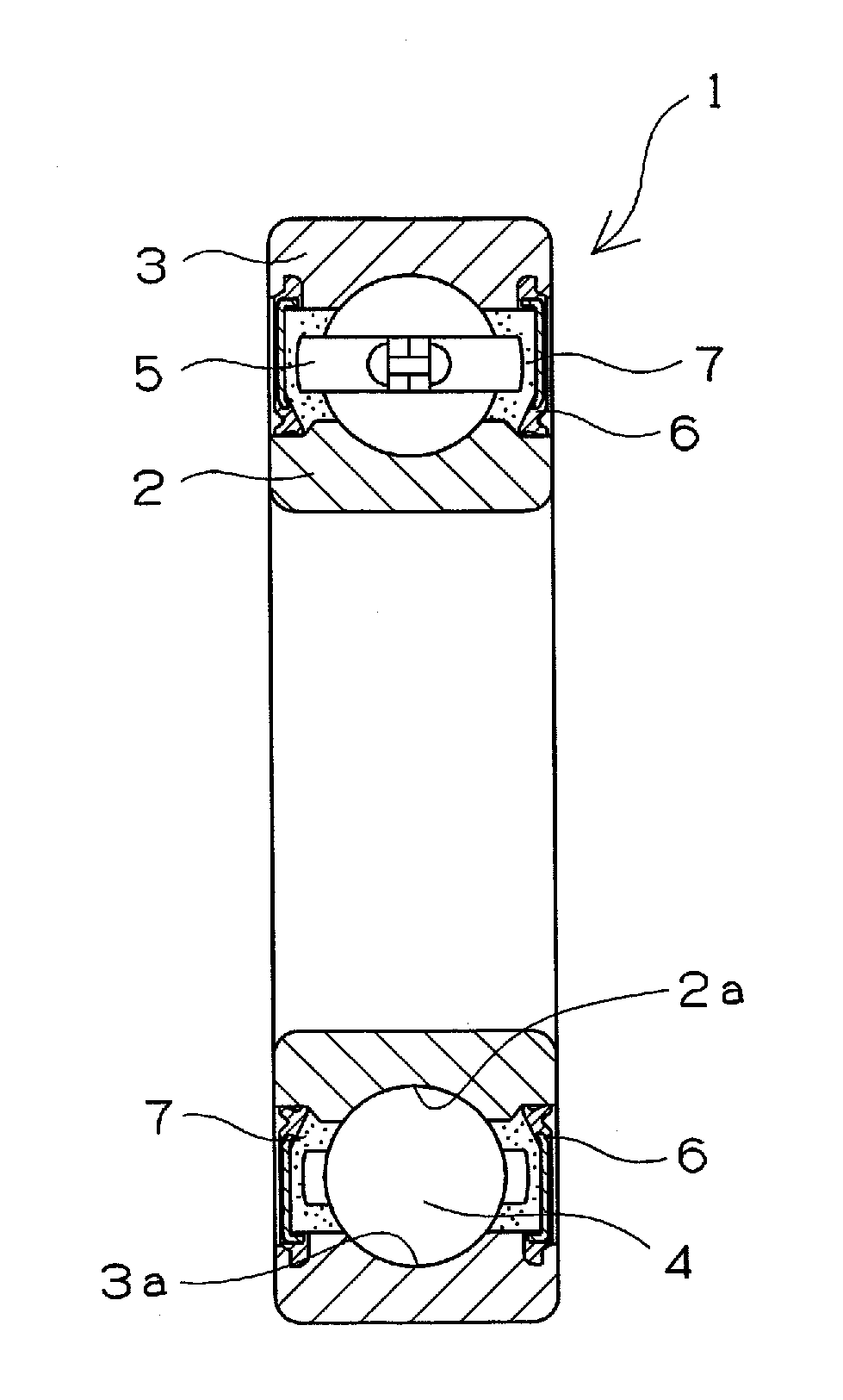

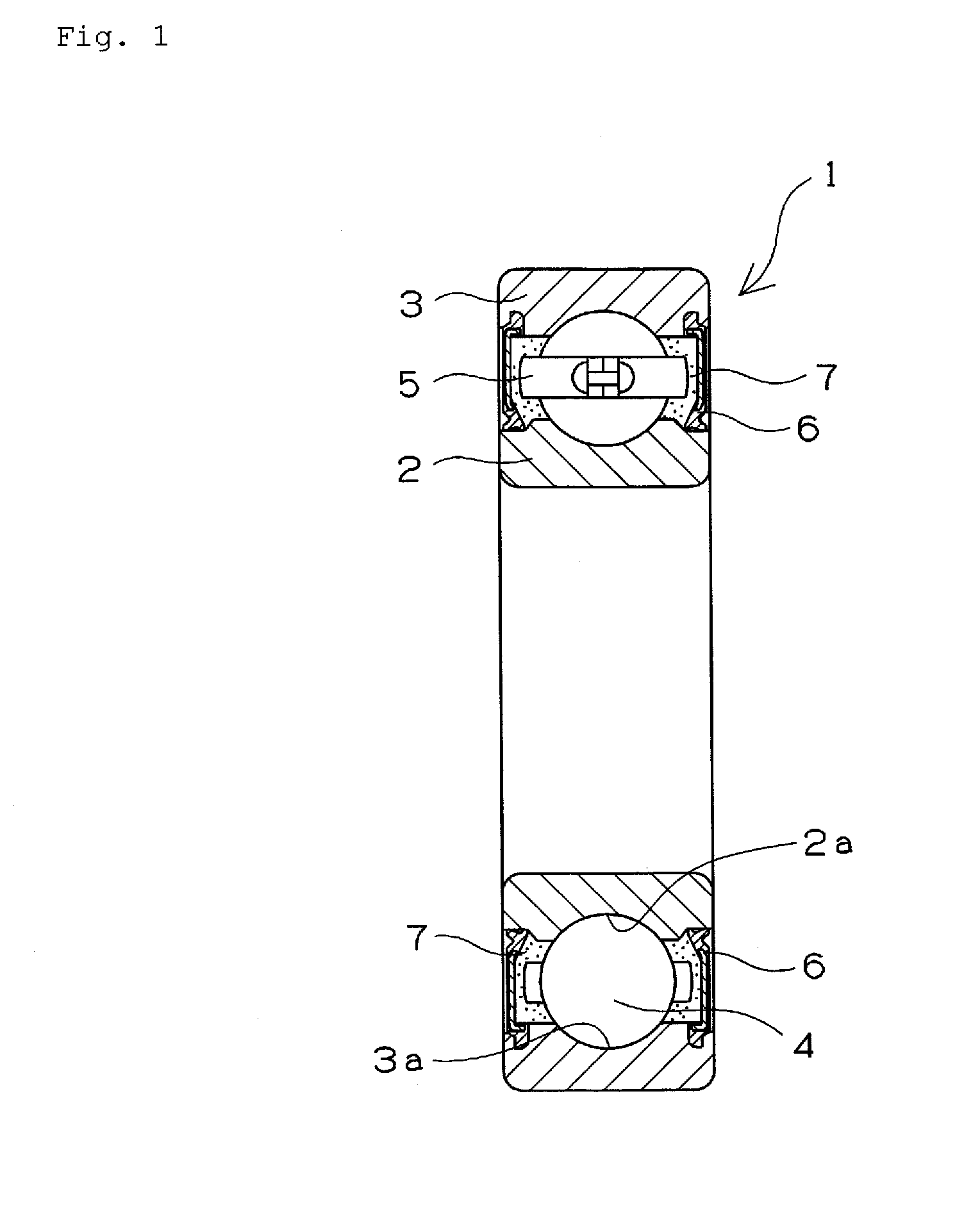

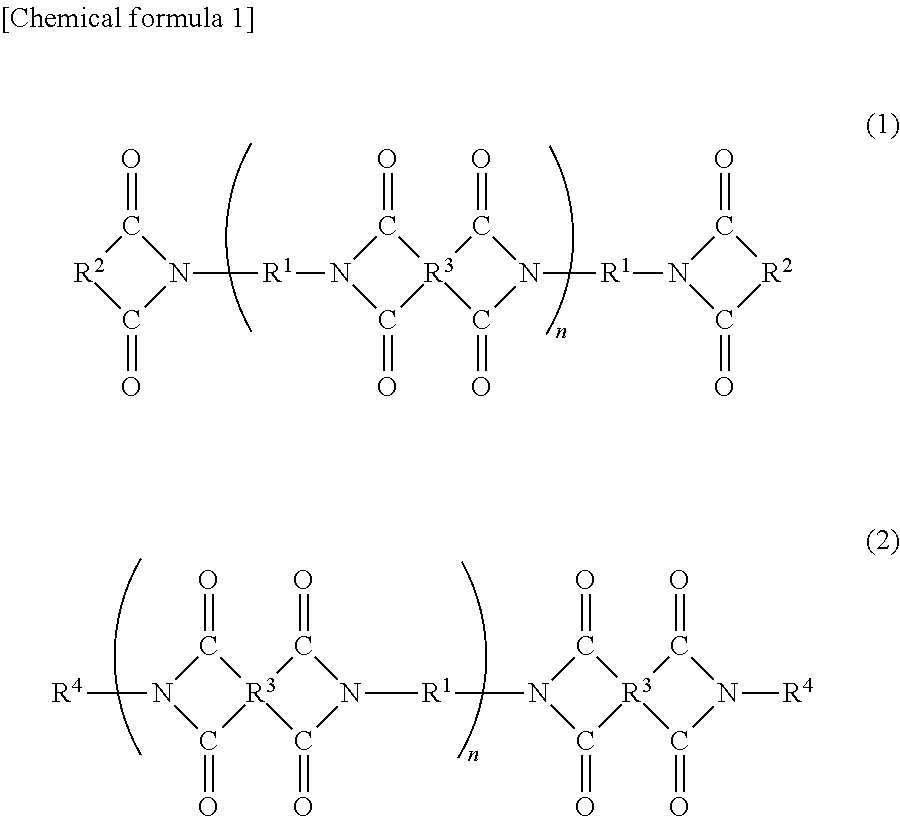

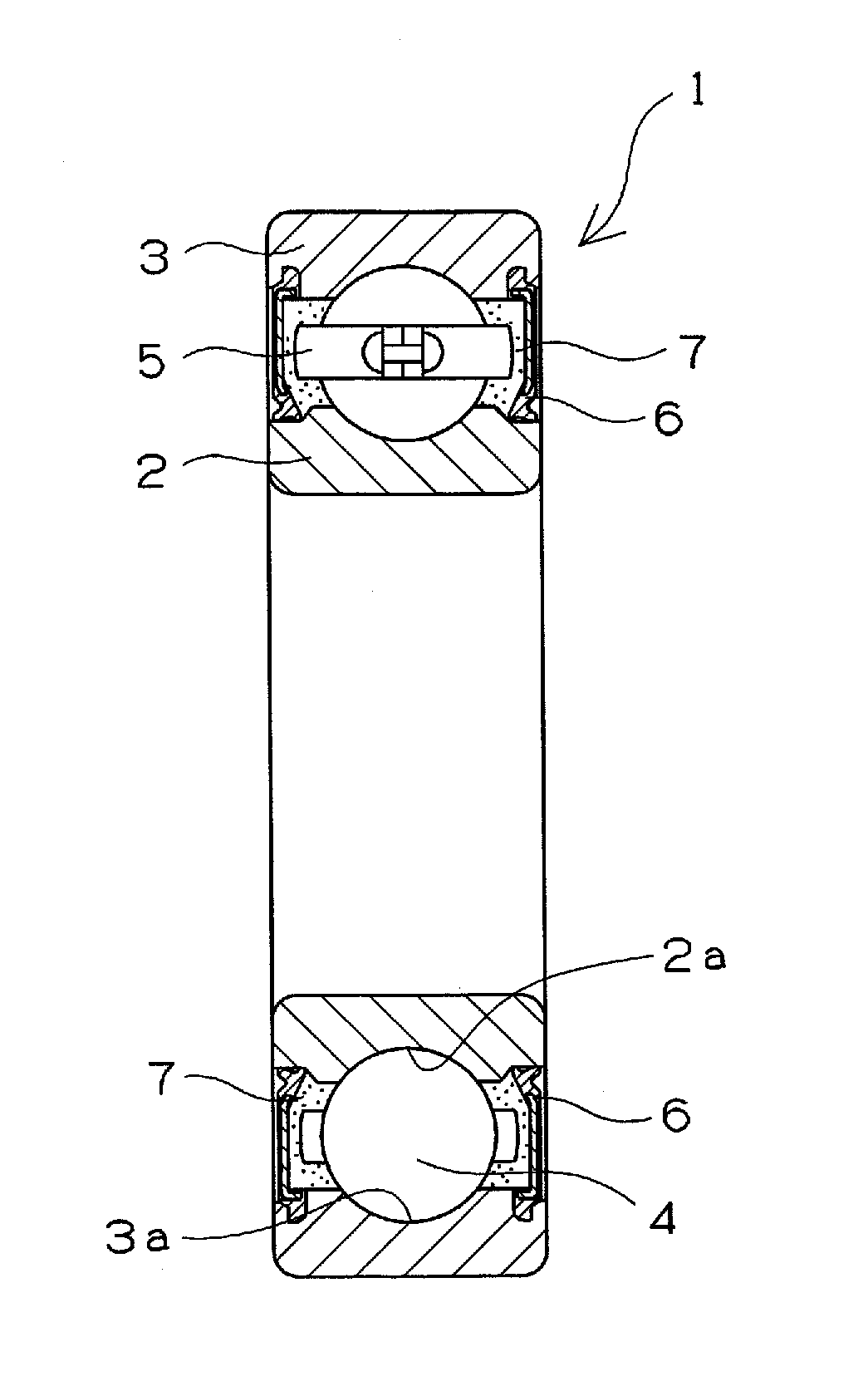

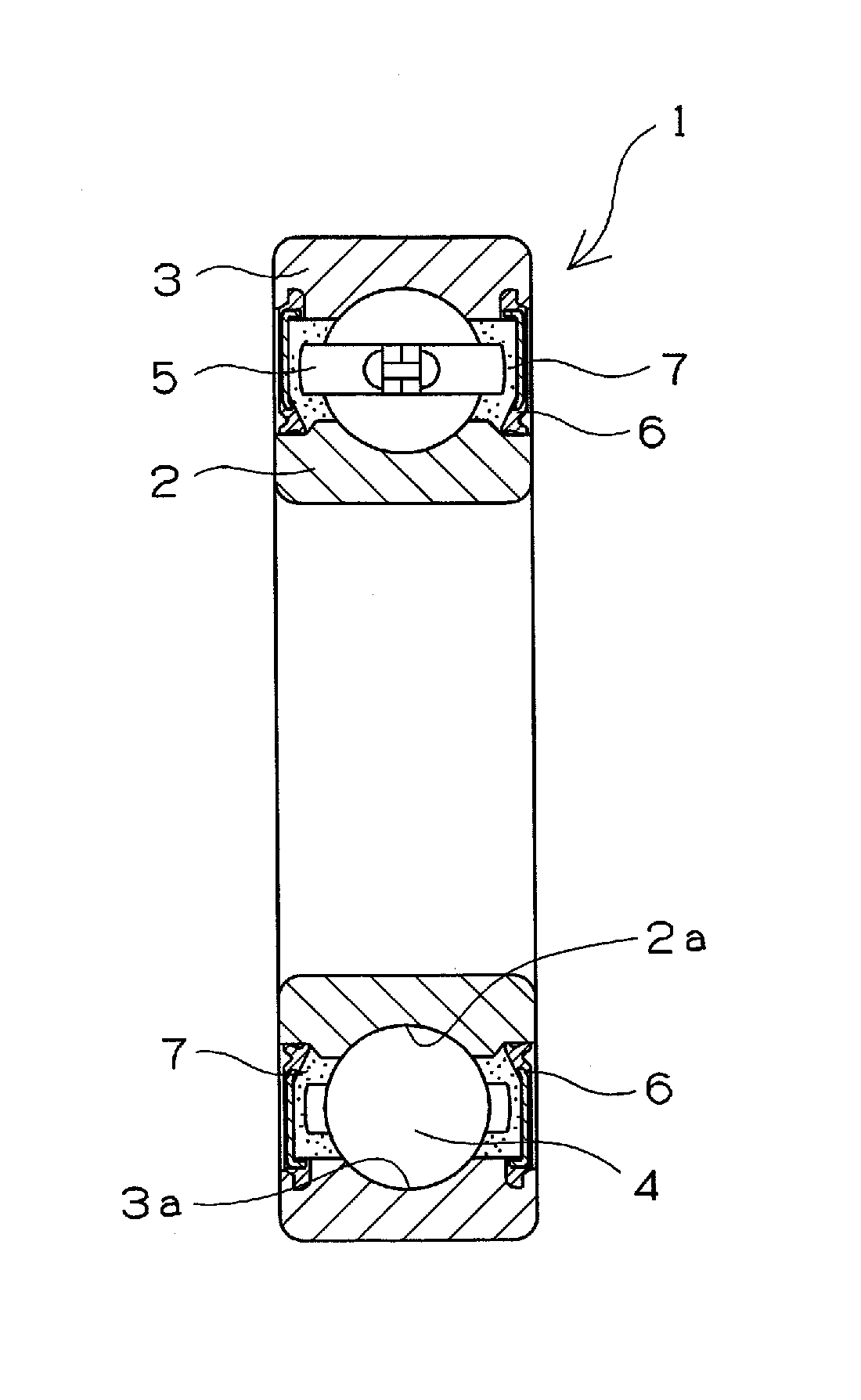

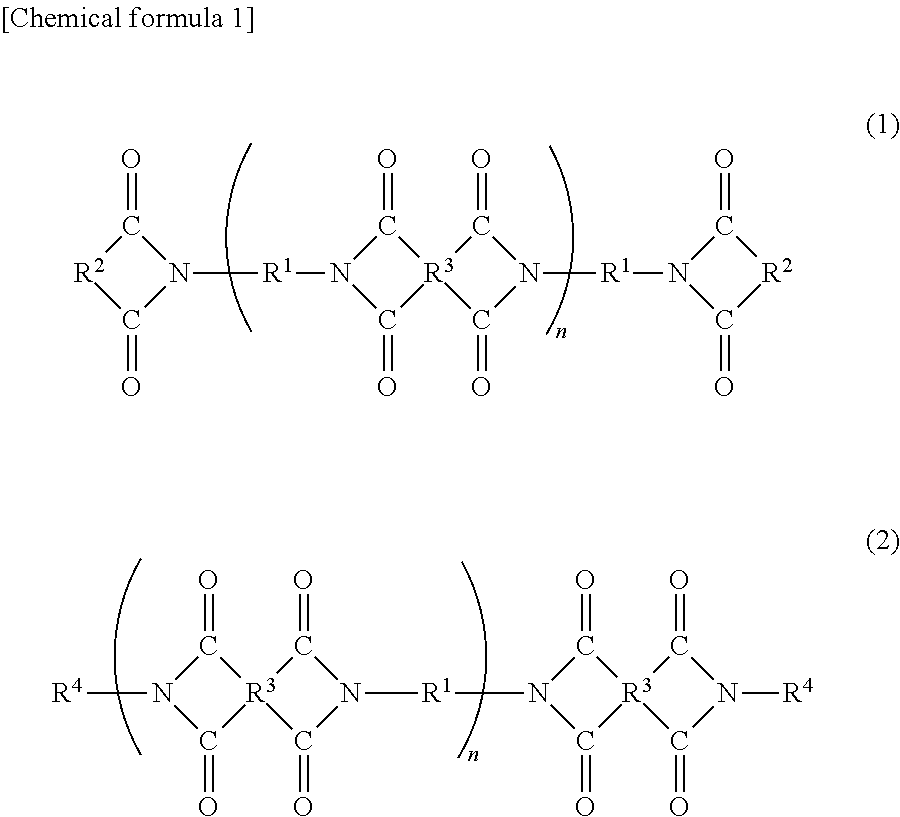

Thickener, grease, method for producing the same,and grease-packed bearing

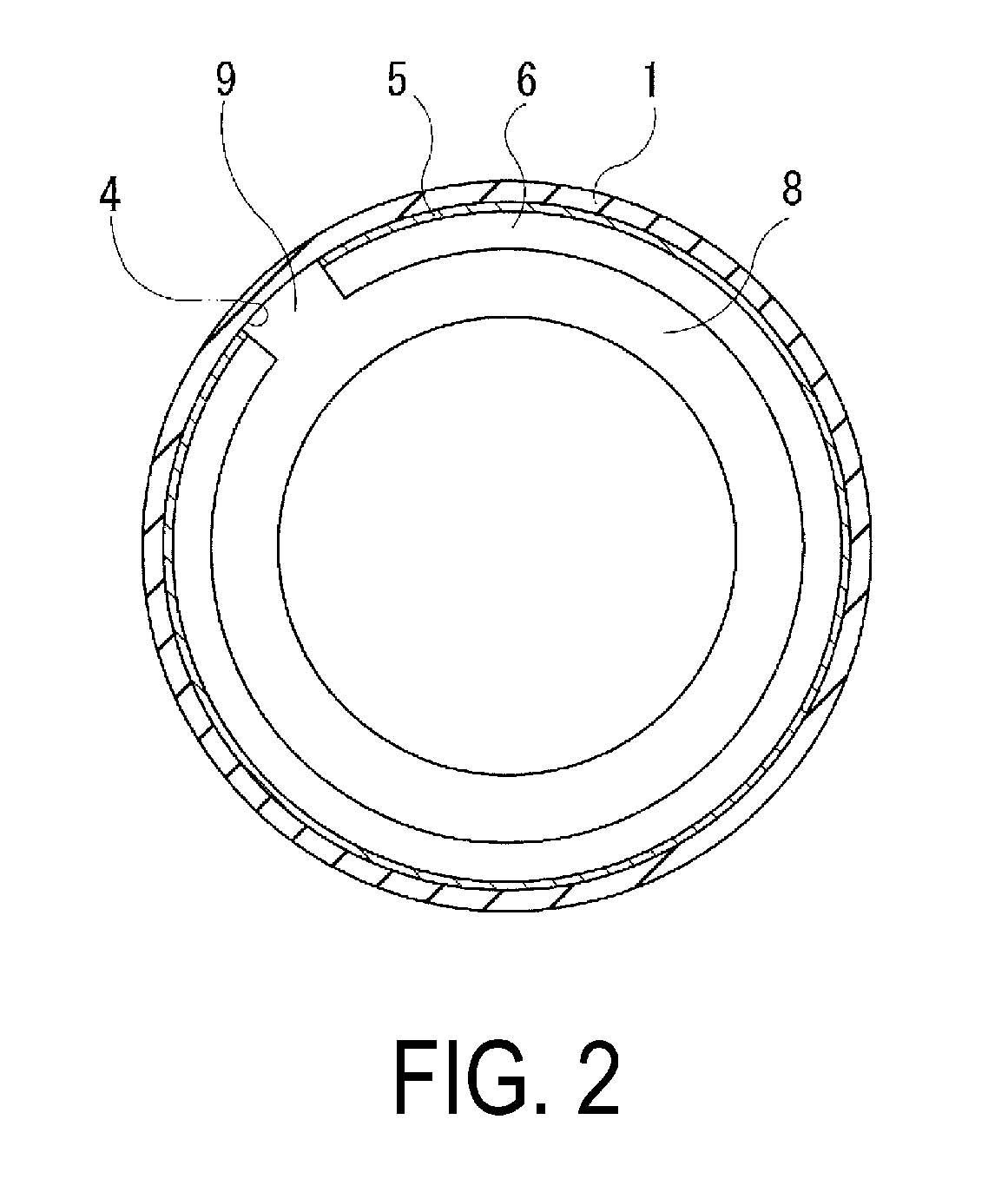

InactiveUS20120316091A1Improve high temperatureImprove high-speed durabilityOrganic chemistryBall bearingsImideHydrogen atom

The present invention provides a thickener which allows grease having an excellent durability in a high-temperature and high-speed condition to be produced, the grease containing the thickener, a method of producing the thickener and the grease, and a grease-packed bearing. A grease (7) to be packed in a bearing (1) is obtained by adding a thickener for a grease comprising a compound shown by a chemical formula (1) shown below or a compound shown by a chemical formula (2) shown below;In the chemical formula (1) or the chemical formula (2), R1 shows a diamine residue or a diisocyanate residue; R2 shows a residue of a dicarboxylic acid in which two adjacent carbon atoms form an imide ring or residues of derivative of the dicarboxylic acid; R3 shows a tetracarboxylic acid residue or residues of derivatives of the tetracarboxylic acid; R4 shows a hydrogen atom residue, a monoamine residue or a monoisocyanate residue; and n indicates integers of 0 through 5.

Owner:NTN CORP

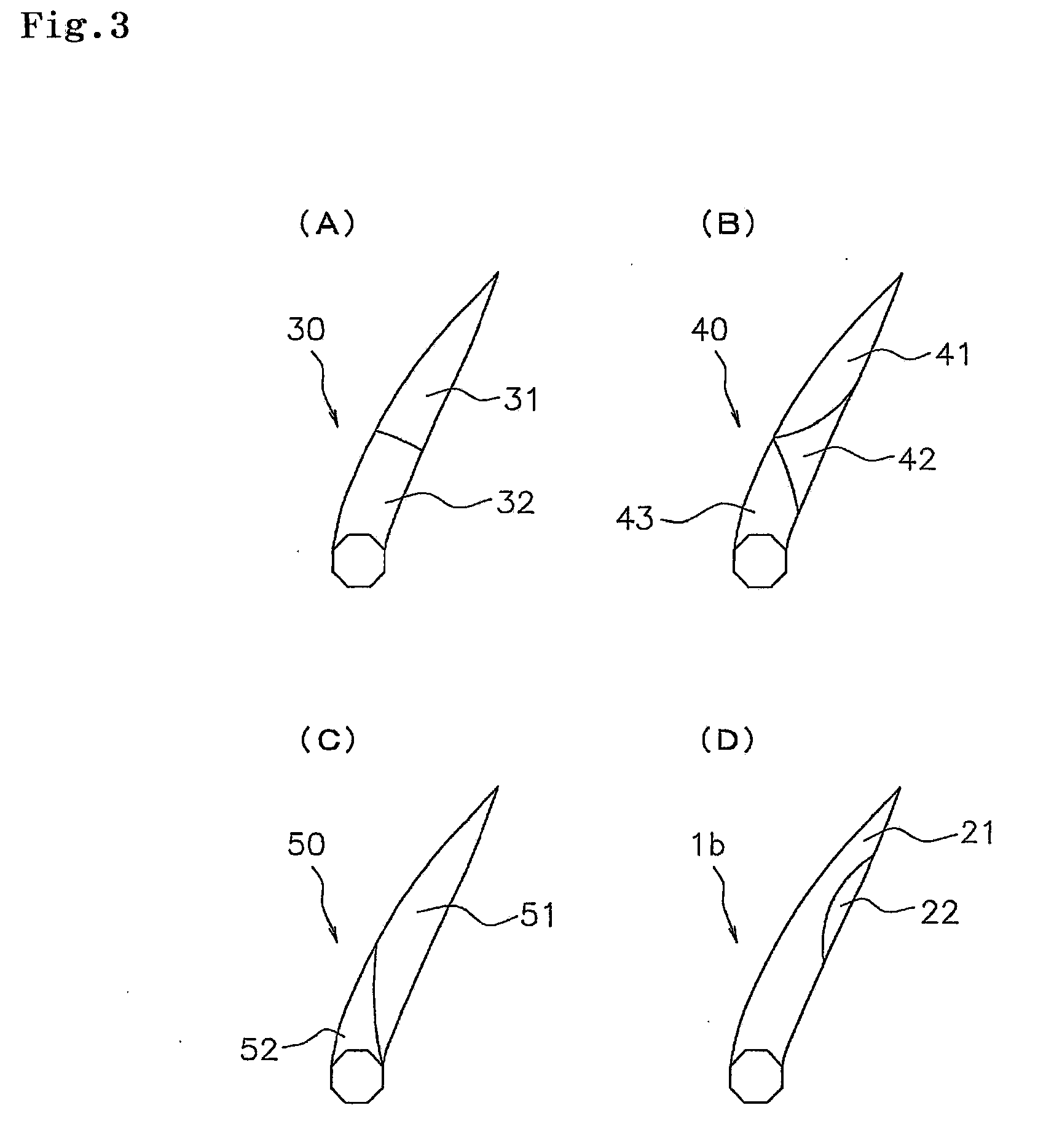

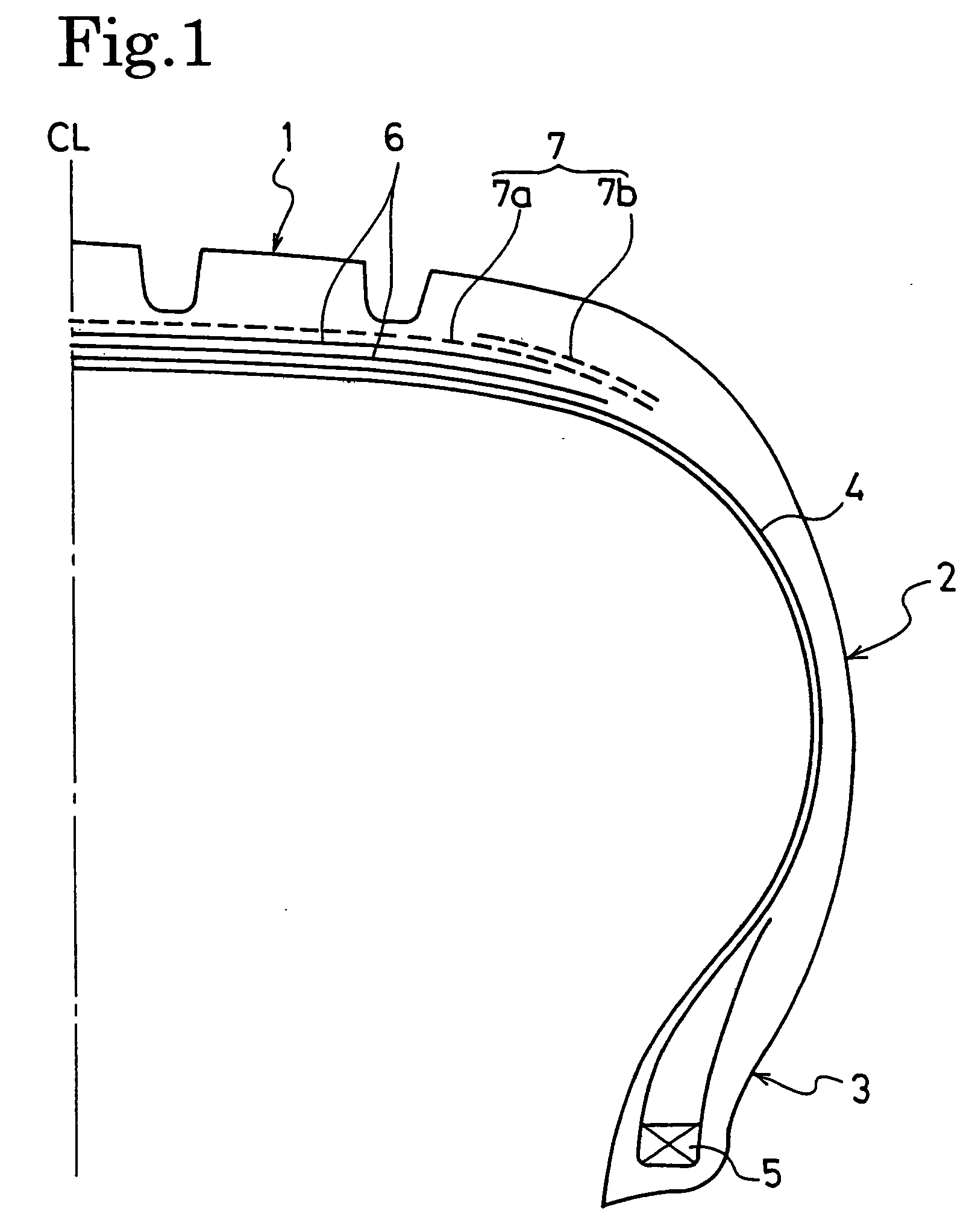

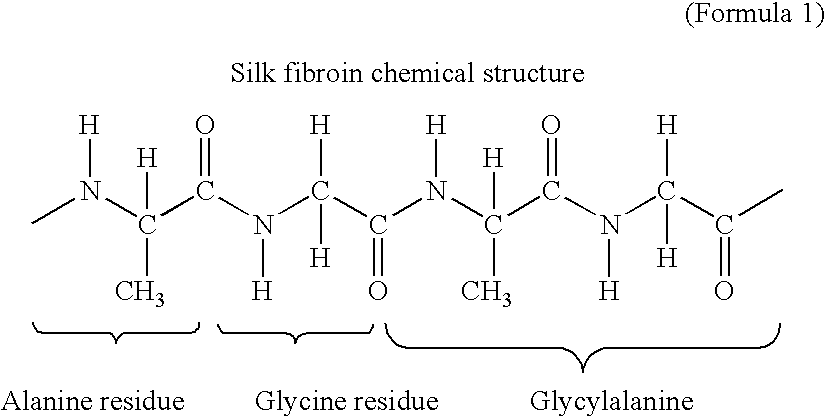

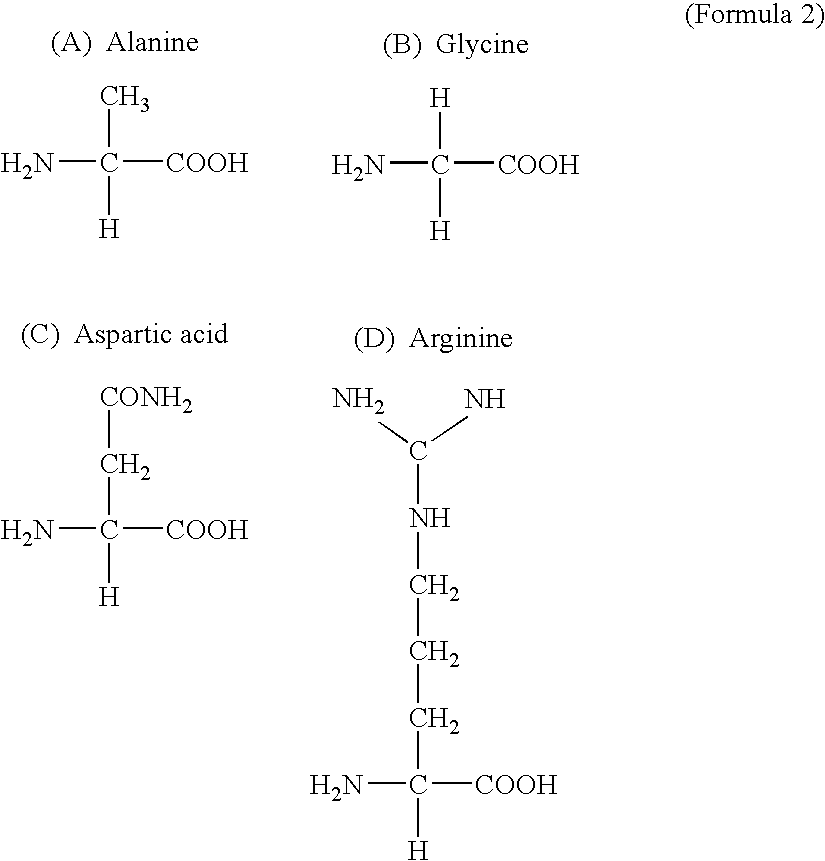

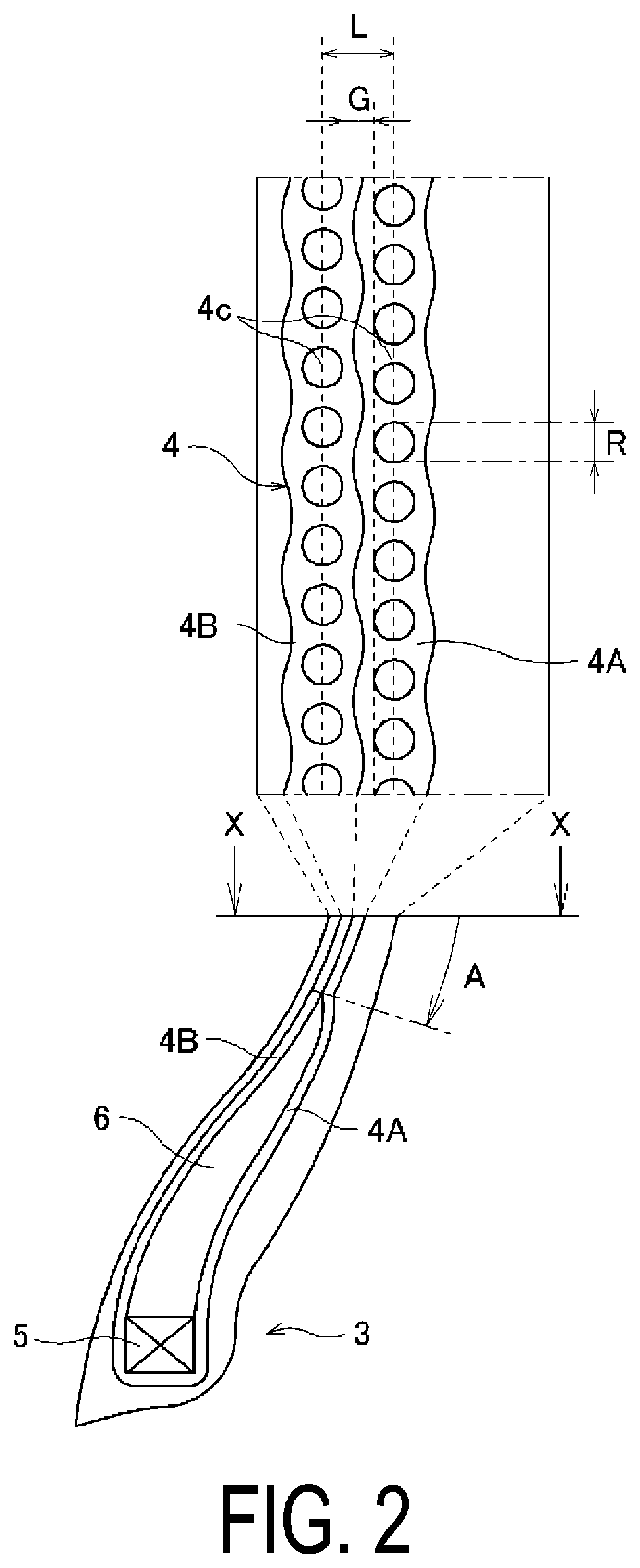

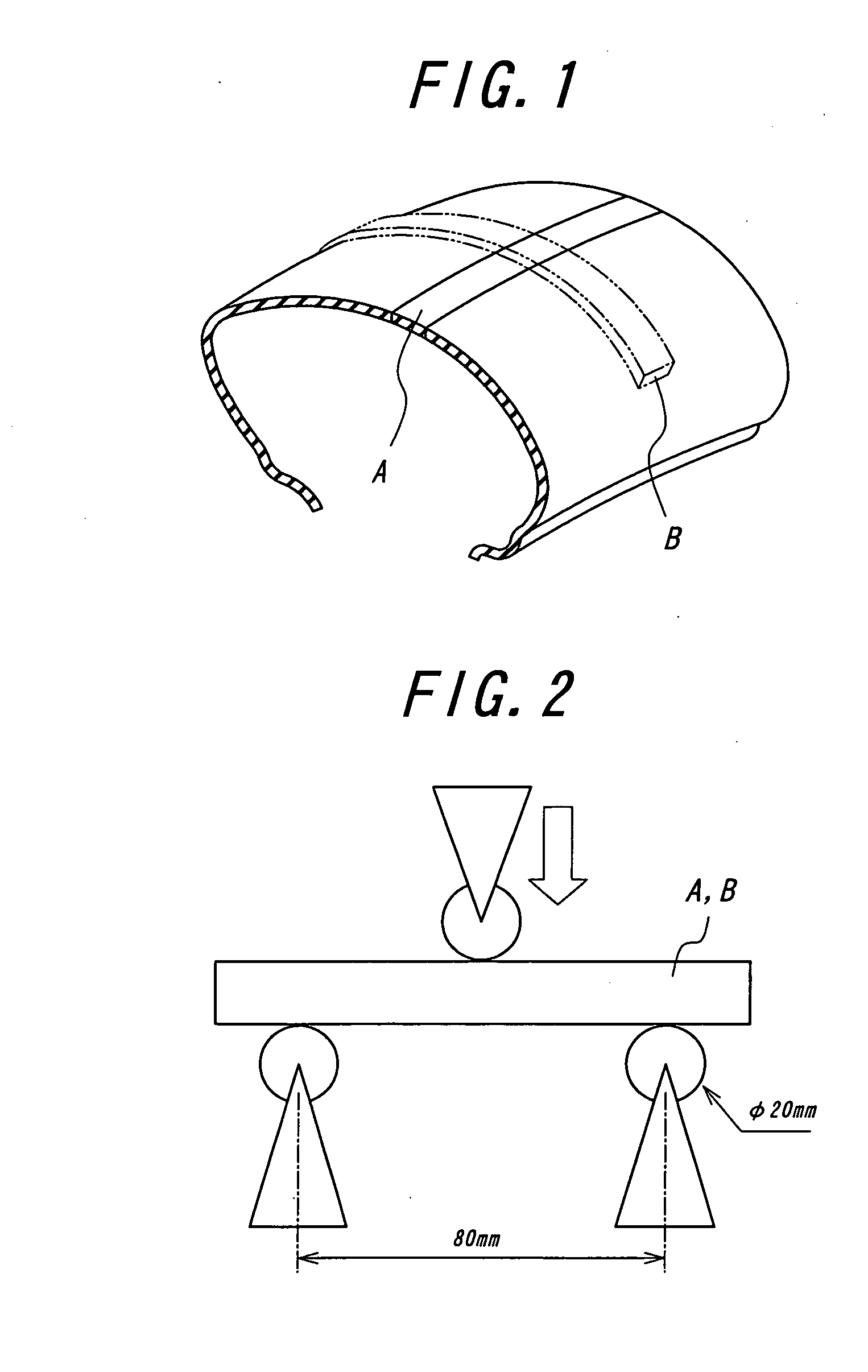

Rubber reinforcing fiber cord, method of manufacturing the same, and radial pneumatic tire for passenger car using the same

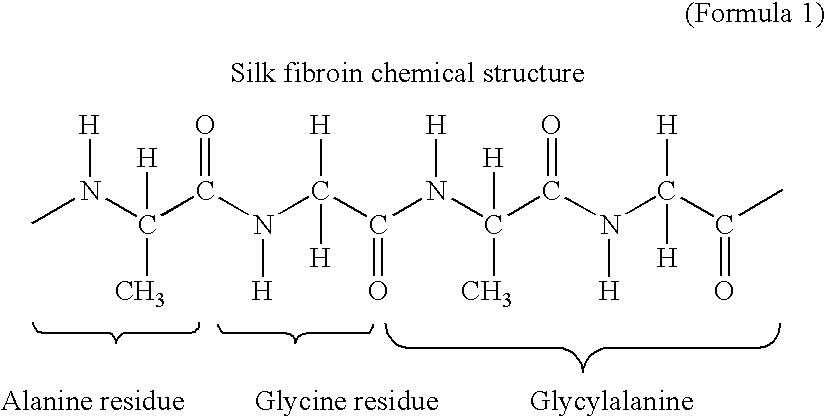

InactiveUS7163736B2High-speed durabilityHigh-speed effectPneumatic tyre reinforcementsCeramic layered productsEngineeringMoisture absorption

Disclosed is a rubber reinforcing fiber cord in which an eco-friendly silk material is made usable for applications in an automobile pneumatic tire and the like acted upon by large loads. The rubber reinforcing fiber cord of the present invention is characterized in that: a multi-filament twisted cord formed of silk fibroin fibers having a total fineness of 1500 to 9000 dtex is covered with an adhesive agent formed of resorcin, formalin and rubber latex in order that a dip pickup thereof on the cord can become 4.0 to 8.0% per unit weight of the fibers; and the cord has an initial tensile strength not less than 3.5 cN / dtex, a high-temperature strength retention rate not less than 80%, and a post-moisture-absorption strength retention rate not less than 85%. The cord is usable in a belt reinforcing later and / or a carcass layer of a radial pneumatic tire for a passenger car.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic radial tire

ActiveUS20090139625A1Improve flat spot resistanceHigh-speed durabilityPneumatic tyre reinforcementsWheelsElastic modulusYarn

Disclosed is a pneumatic radial tire having improved flat spot resistance without sacrificing its high-speed durability, when a belt auxiliary reinforcement layer thereof is constituted of a hybrid fiber cord including a general-purpose nylon as a low-elastic fiber yarn. In the pneumatic radial tire, the belt auxiliary reinforcement layer is formed by winding an organic fiber cord around the outer periphery of belt layers in the tire circumferential direction. The organic fiber cord constituting the belt auxiliary reinforcement layer is obtained by twisting a highly-elastic fiber yarn with an elastic modulus of 10000 MPa or more and a low-elastic fiber yarn made of nylon 46.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic radial tire

ActiveUS20100024944A1Suppress fatigue breakOptimal structureHeavy duty tyresHeavy duty vehicleEngineeringRadial tire

Provided is a pneumatic radial tire: that includes a circumferential-direction reinforcement layer having a width increased with fatigue break of the circumferential-direction reinforcement layer being suppressed at edge portions thereof; and that suppresses separation in each of cross belt layers at edge portions thereof. A pneumatic radial tire according to the present invention is a pneumatic tire including: at least two cross belt layers disposed on an outer circumferential side of a carcass layer in a tread portion; and at least one circumferential-direction reinforcement layer disposed between these cross belt layers, a width of the circumferential-direction reinforcement layer being smaller than that of each cross belt layer. The pneumatic radial tire is configured so that: the cross belt layers are separated away from each other at outer sides respectively of end positions, in a width direction, of the circumferential-direction reinforcement layer; the circumferential-direction reinforcement layer includes steel cords of two types which differ in elongation at break; and the steel cord having relatively small elongation at break is disposed in a center portion of the circumferential-direction reinforcement layer, whereas the steel cord having relatively large elongation at break is disposed in each of outer side portions of the circumferential-direction reinforcement layer.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic radial tire with specified tread portion bending rigidity ratio

InactiveUS7025101B2Weight increaseLowering straight-runningPneumatic tyre reinforcementsMotorcycle tyresIn planeCamber angle

There is provided a pneumatic radial tire for a motorcycle capable of developing an excellent steering stability in a high-speed cornering subjected to a large camber angle, and having an aspect ratio of 0.50–0.85, in which a tensile strength at break of a carcass ply cord is not less than 980 MPa, and an absolute value of a carcass total rigidity obtained by adding carcass rigidities of carcass plies is not less than 30000, and a tensile strength at break of a belt layer cord is not less than 2350 MPa, and an absolute value of a belt total rigidity obtained by adding belt rigidities of belt layers is not less than 170000, and a bending rigidity ratio as a ratio of out-of-plane bending rigidity to in-plane bending rigidity is within a range of 4.20–9.10.

Owner:BRIDGESTONE CORP

Pneumatic Tire

ActiveUS20100116401A1Avoid separationIncreased durabilitySpecial tyresInflatable tyresEngineeringMechanical engineering

A pneumatic tire has an annular bead core, a bead filler, a carcass ply rolled up in such a manner as to pinch the bead core and the bead filler, and a white rubber arranged in an outer side of the carcass ply of the side wall portion. The white rubber has an inner peripheral end positioned in an outer side of the bead filler. The bead filler has a main body rubber portion running into the bead core from a leading end, and a soft rubber portion constructing a part of an outer surface of the bead filler and positioned in an inner side of the inner peripheral end of the white rubber. The soft rubber portion is harder than the white rubber and softer than the main body rubber portion.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire and manufacturing method of the same

InactiveUS20130340904A1Improve molding efficiencyInhibition defectTyresInflatable tyresEngineeringTire rotation

A tread rubber of a pneumatic tire is formed by a ribbon rubber which is spirally wound around a tire rotating axis. The ribbon rubber is wound toward one side in a tire width direction from a start point which is positioned closer to a center side than tread ends in a tire meridian cross section, is next folded back to the other side in the tire width direction at the tread end on the one side, is wound toward the tread end on the other side beyond the start point, is next folded back to the one side in the tire width direction at the tread end on the other side, and is wound toward an end point. The ribbon rubber has the winding start end and the winding terminal end at tread end vicinity portions avoiding the tread ends and a tread center portion.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic Tire

ActiveUS20180319224A1Improve cooling effectRelieve pressureTyresInflatable tyresEngineeringMechanical engineering

A pneumatic tire includes: an annular-shaped tread portion extending in a tire circumferential direction; a pair of sidewall portions disposed on both sides of the tread portion; and a pair of bead portions disposed on an inner side in a tire radial direction of the sidewall portions; and a band-like sound absorbing member being adhered on an inner surface of the tread portion in the tire circumferential direction; wherein the band-like sound absorbing member has a plurality of cuts, and both terminals of the cuts terminate at an inner side of the band-like sound absorbing member.

Owner:THE YOKOHAMA RUBBER CO LTD

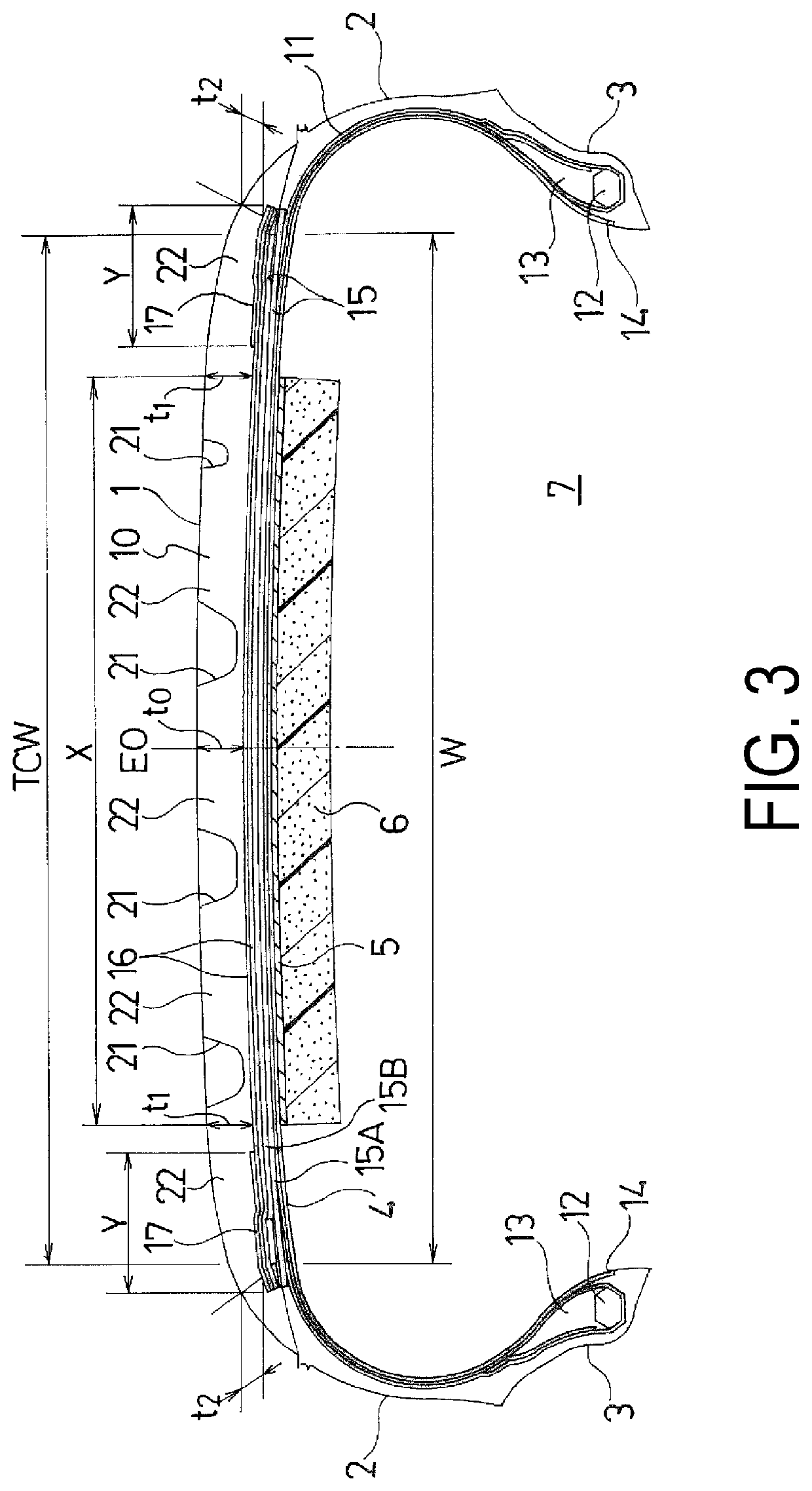

Pneumatic Tire

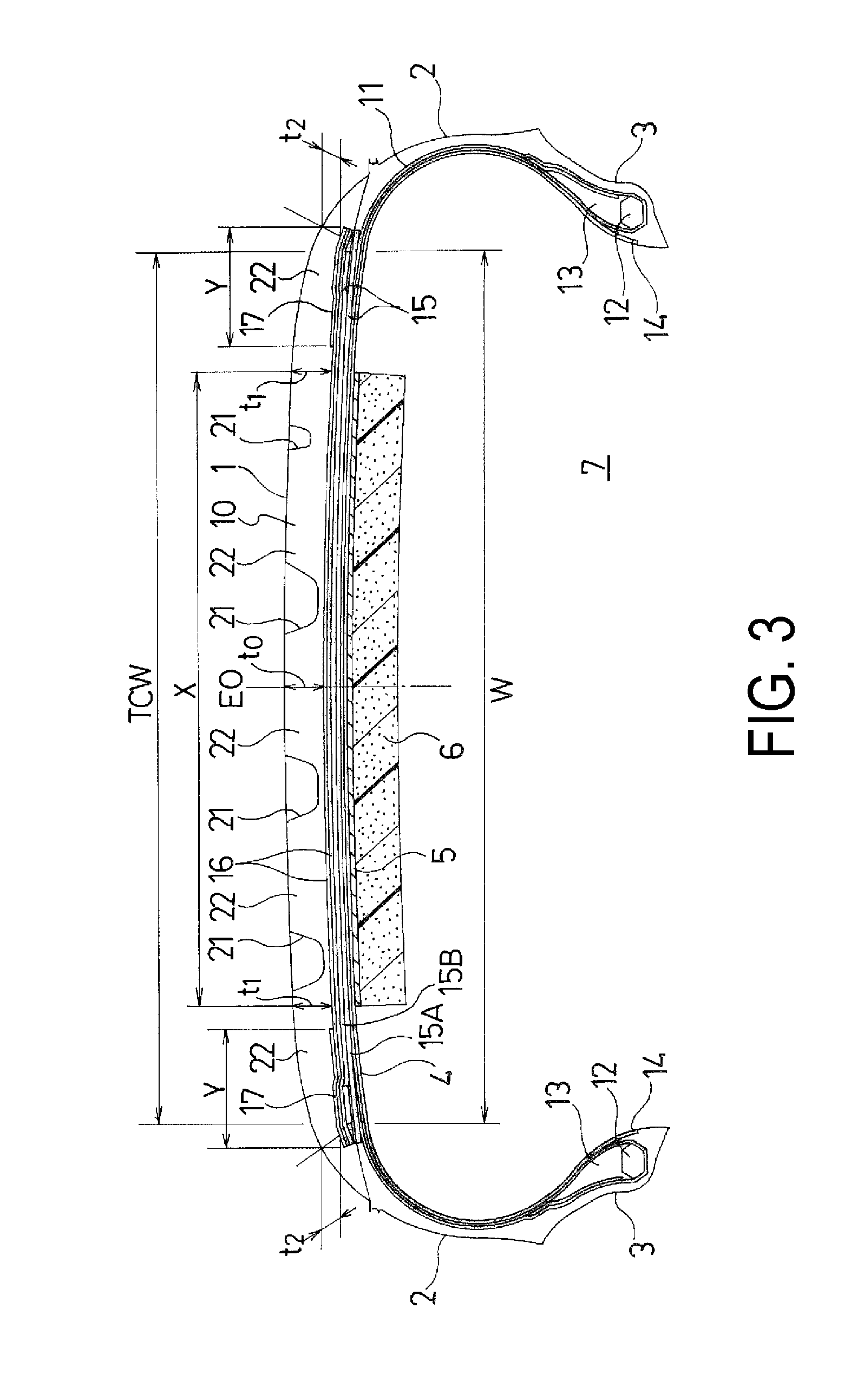

ActiveUS20170008353A1Easy to carryImprove the fixing strengthPneumatic tyre reinforcementsTyre tread bands/patternsEngineeringTread

The present technology provides a pneumatic tire having a strip-shaped sound-absorbing member bonded on the inner surface of the tire includes a plurality of belt layers, two or more belt cover layers, one or more belt edge cover layers, and a thread rubber layer. The thickness of the tread rubber layer is substantially uniform in the region X where the sound-absorbing member is located so that the difference between the thickness t1 at an end of the sound-absorbing member and the thickness t0 at the position of the tire equator is equal to or less than 0.5 mm. The thickness of the tread rubber layer is smaller in the region Y where the belt edge cover layer is located than in the region X so that the difference between the minimum value t2 of the thickness in the region Y and the thickness t0 ranges from 1.0 to 4.0 mm.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire for passenger car and method of manufacturing the same

InactiveUS20110290398A1High-speed durabilityHigh-speed performanceTyresPneumatic tyre reinforcementsEngineeringWire rope

A pneumatic tire for a passenger car includes a belt layer and a belt cover layer formed by winding a steel cord member in the tire circumference direction on the outer peripheral side of the belt layer. The steel cord member has a structure in which element wires made of steel and having a diameter smaller than 0.18 mm are twisted together to form each strand and the strands are twisted together in the same direction as the direction of twisting of the element wires. The twist pitch on each of the strands is smaller than the twist pitch on the steel cord member, the twist pitch on the strand is 1.0 mm to 2.1 mm, and the twist pitch on the steel cord member is 2.0 mm to 5.25 mm.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic Tire

ActiveUS20180312013A1Improve cooling effectImprove high-speed durabilityInflatable tyresMechanical engineeringTread

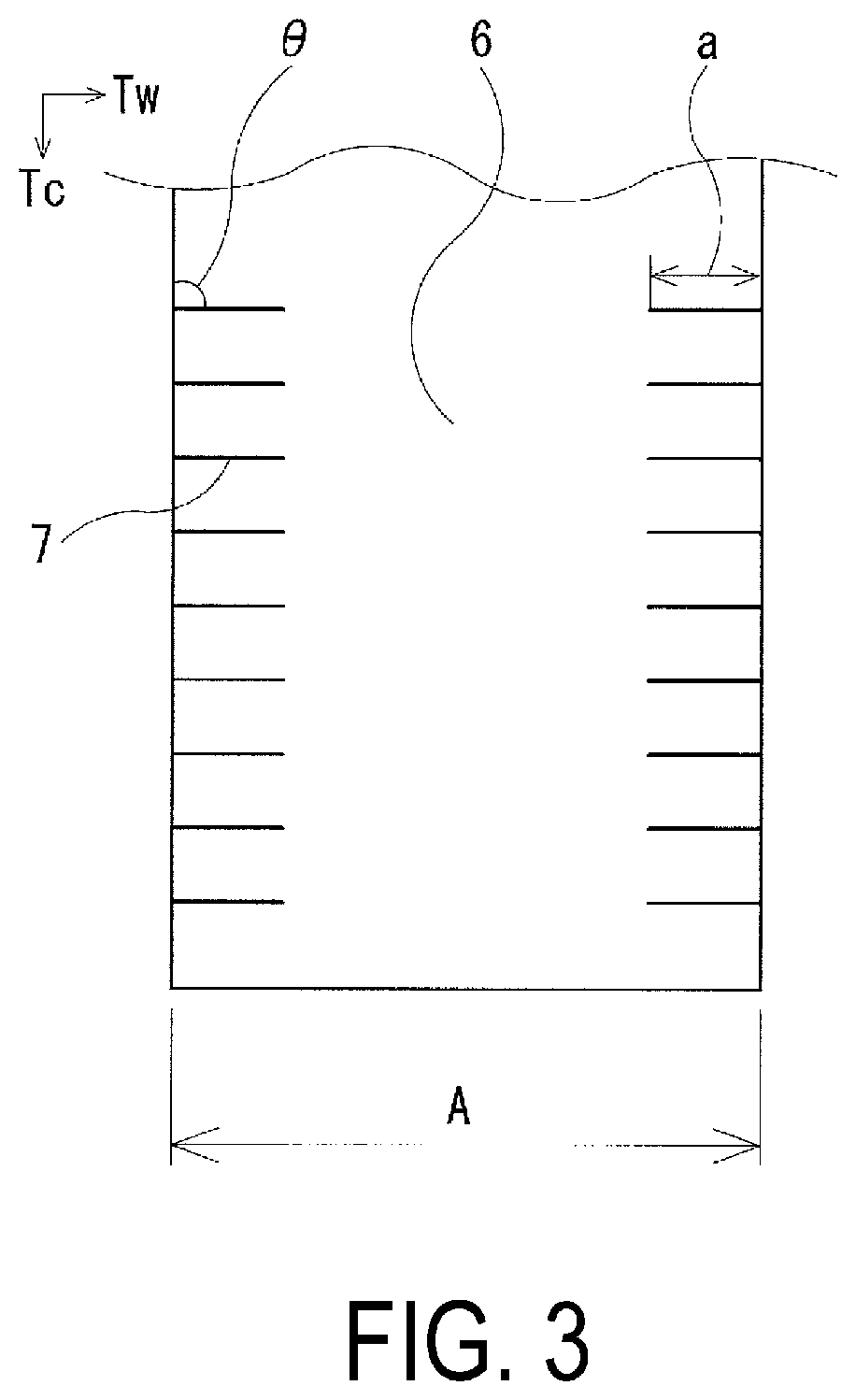

A pneumatic tire includes: an annular-shaped tread portion extending in a tire circumferential direction; a pair of sidewall portions disposed on both sides of the tread portion; and a pair of bead portions disposed on an inner side in a tire radial direction of the sidewall portions; wherein a band-like sound absorbing member is adhered on an inner surface of the tread portion in the tire circumferential direction; and a plurality of cuts with an angle θ with regard to the tire circumferential direction within a range of 40°≤θ≤90° are formed on both end portions in a lateral direction of the band-like sound absorbing member, and the cuts are connected only to one end portion in the lateral direction of the band-like sound absorbing member.

Owner:YOKOHAMA RUBBER CO LTD

Rubber reinforcing fiber cord, method of manufacturing the same, and radial pneumatic tire for passenger car using the same

InactiveUS20060188716A1High-speed durabilityHigh-speed effectPneumatic tyre reinforcementsCeramic layered productsMoisture absorptionUltimate tensile strength

Disclosed is a rubber reinforcing fiber cord in which an eco-friendly silk material is made usable for applications in an automobile pneumatic tire and the like acted upon by large loads. The rubber reinforcing fiber cord of the present invention is characterized in that: a multi-filament twisted cord formed of silk fibroin fibers having a total fineness of 1500 to 9000 dtex is covered with an adhesive agent formed of resorcin, formalin and rubber latex in order that a dip pickup thereof on the cord can become 4.0 to 8.0% per unit weight of the fibers; and the cord has an initial tensile strength not less than 3.5 cN / dtex, a high-temperature strength retention rate not less than 80%, and a post-moisture-absorption strength retention rate not less than 85%. The cord is usable in a belt reinforcing later and / or a carcass layer of a radial pneumatic tire for a passenger car.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20080295944A1Improve performanceDecrease in coefficientPneumatic tyre reinforcementsYarnFinenessEngineering

Provided is a pneumatic tire improved in a performance against the flat spot with a high-speed durability desirably maintained. The pneumatic tire of the present invention includes: a belt reinforcing layer which is disposed on an outer circumferential side of a belt layer buried in a tread portion, and which is composed of an organic fiber cord wound in a circumferential direction of the tire. At least 60% of the total count of the organic fiber cord composing the belt reinforcing layer is a polytetramethylene adipamide fiber cord. The creep set strain of the polytetramethylene adipamide fiber cord is 2.5% or less. The twist coefficient K of the polytetramethylene adipamide fiber cord satisfies a condition of 600≦K≦1700, and is represented by the following formula (1):K=T×√{square root over ( )}D (1)where T is the twist number (turn / 10 cm) of the cord, and D is the total fineness (dtex) of the cord.

Owner:YOKOHAMA RUBBER CO LTD

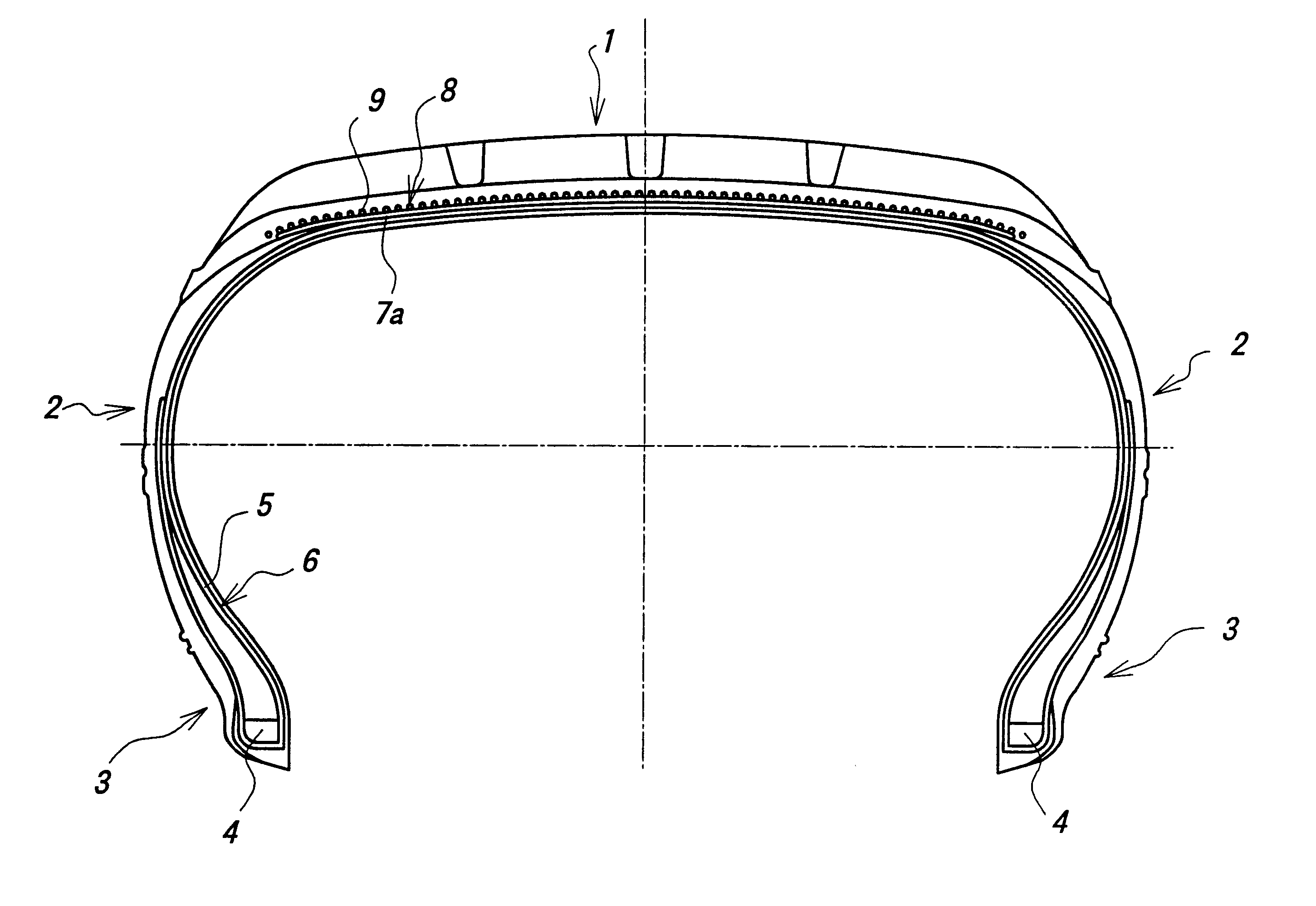

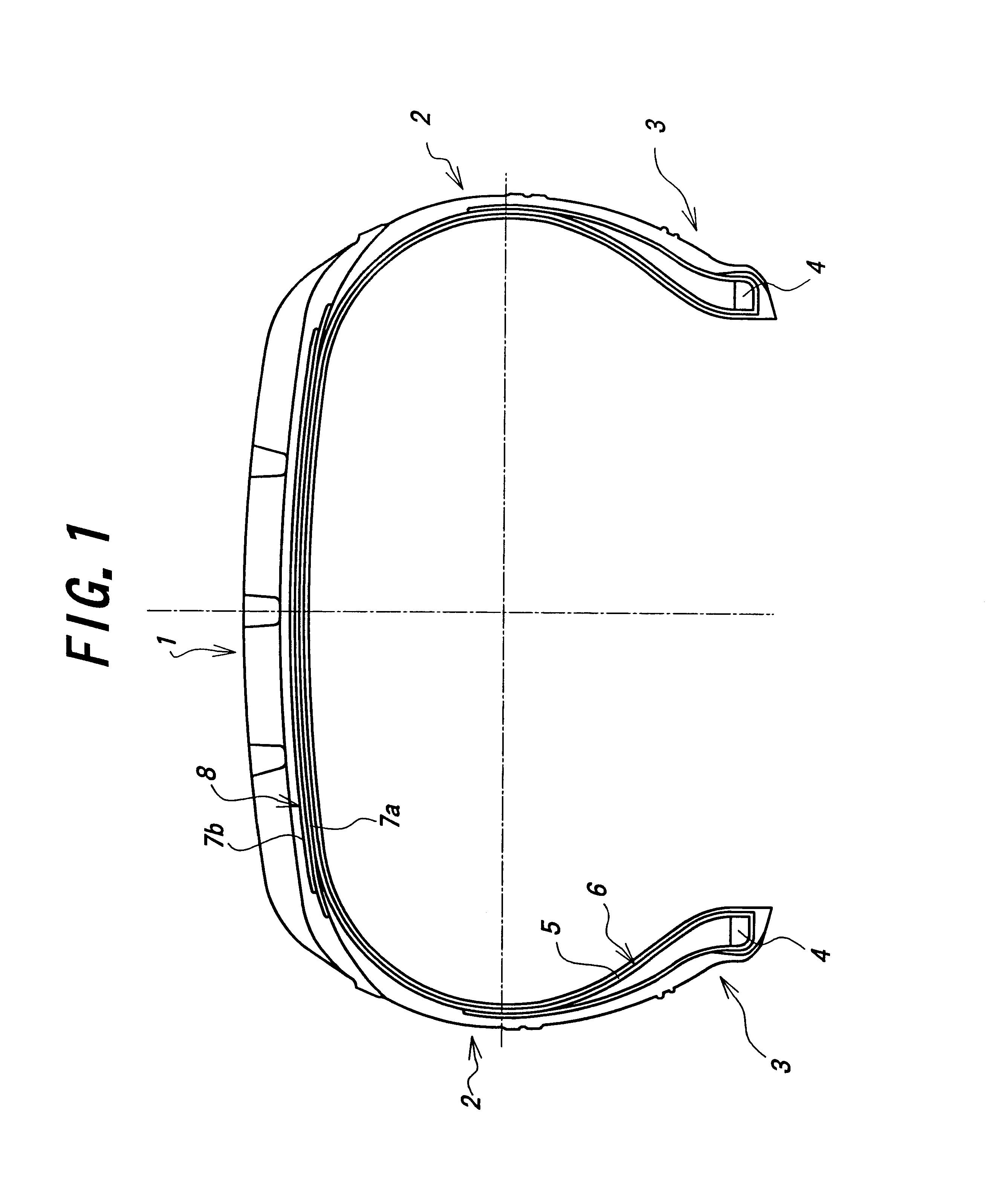

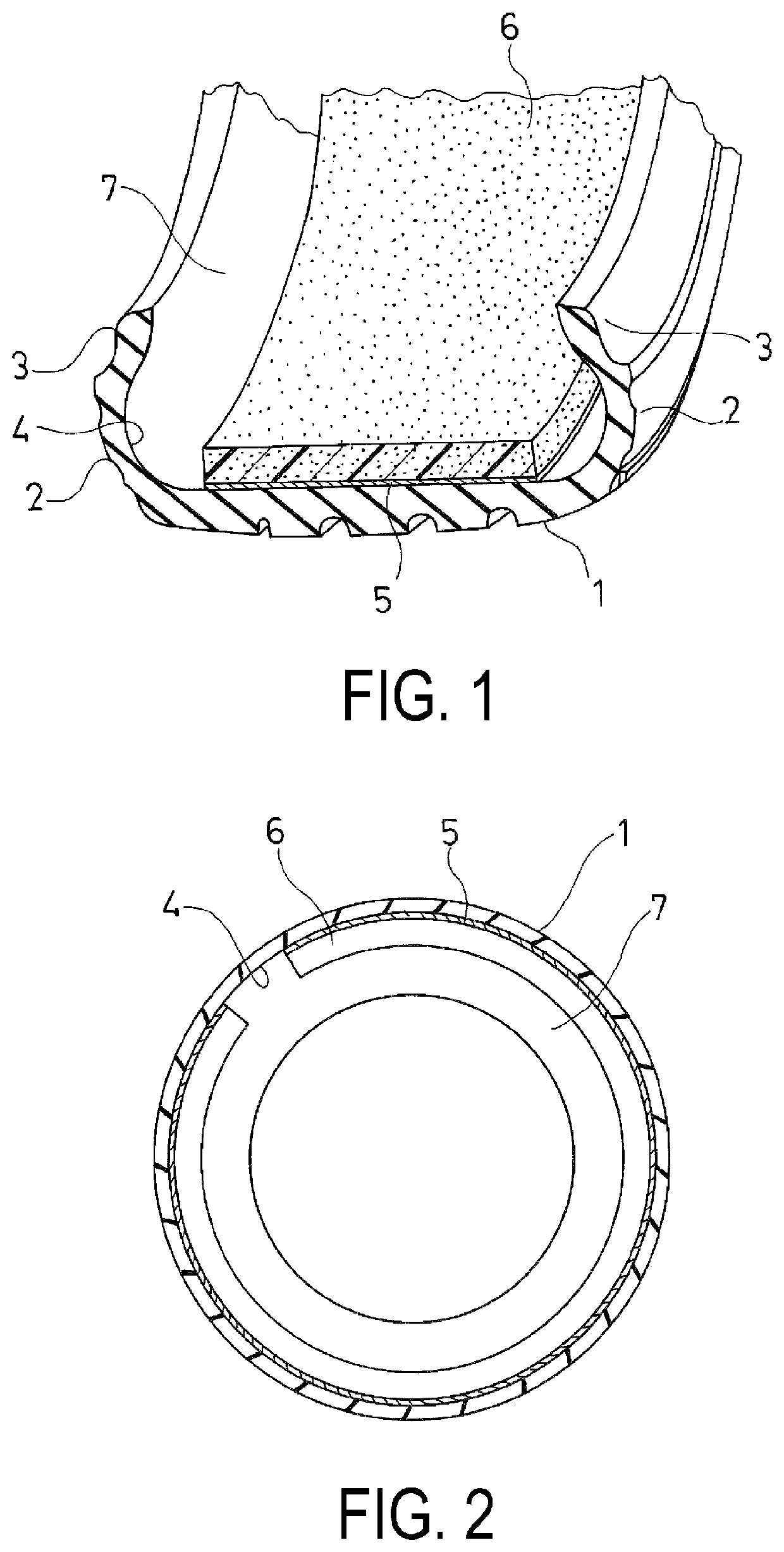

Pneumatic tire with specified tread rubber layer thickness and sound-absorbing member width

ActiveUS10723181B2Relieve pressureHigh-speed durabilityPneumatic tyre reinforcementsTyre tread bands/patternsEngineeringAcoustics

The present technology provides a pneumatic tire having a strip-shaped sound-absorbing member bonded on the inner surface of the tire includes a plurality of belt layers, two or more belt cover layers, one or more belt edge cover layers, and a thread rubber layer. The thickness of the tread rubber layer is substantially uniform in the region X where the sound-absorbing member is located so that the difference between the thickness t1 at an end of the sound-absorbing member and the thickness t0 at the position of the tire equator is equal to or less than 0.5 mm. The thickness of the tread rubber layer is smaller in the region Y where the belt edge cover layer is located than in the region X so that the difference between the minimum value t2 of the thickness in the region Y and the thickness t0 ranges from 1.0 to 4.0 mm.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

PendingUS20220041018A1Good physical propertiesHigh-speed durabilitySpecial tyresPneumatic tyre reinforcementsTire beadFiber

In a pneumatic tire, at least one carcass layer mounted between a pair of bead portions is formed from a carcass cord formed of an organic fiber cord having filament bundles of organic fibers intertwined together, a fineness based on corrected mass of the carcass cord is from 4000 dtex to 8000 dtex, an intermediate elongation of the carcass cord at a sidewall portion under 1.0 cN / dtex load is from 3.3% to 4.2%, and a ratio G / R of an interlayer rubber gauge G between a body portion and a folded back portion to a cord diameter R of the carcass cord, at a contact region where the body portion and the folded back portion are in contact in the carcass layer, is from 0.50 to 0.60.

Owner:YOKOHAMA RUBBER CO LTD

Thickener, grease, method for producing the same, and grease-packed bearing

InactiveUS9150809B2Improve high-temperature and high-speed durabilityHigh-speed durabilityOrganic chemistryBall bearingsOil and greaseImide

The present invention provides a thickener which allows grease having an excellent durability in a high-temperature and high-speed condition to be produced, the grease containing the thickener, a method of producing the thickener and the grease, and a grease-packed bearing. A grease (7) to be packed in a bearing (1) is obtained by adding a thickener for a grease comprising a compound shown by a chemical formula (1) shown below or a compound shown by a chemical formula (2) shown below;In the chemical formula (1) or the chemical formula (2), R1 shows a diamine residue or a diisocyanate residue; R2 shows a residue of a dicarboxylic acid in which two adjacent carbon atoms form an imide ring or residues of derivative of the dicarboxylic acid; R3 shows a tetracarboxylic acid residue or residues of derivatives of the tetracarboxylic acid; R4 shows a hydrogen atom residue, a monoamine residue or a monoisocyanate residue; and n indicates integers of 0 through 5.

Owner:NTN CORP

Pneumatic radial tire

ActiveUS8376009B2Improved flat spot resistanceImproving flat spot resistancePneumatic tyre reinforcementsWheelsYarnFiber

Disclosed is a pneumatic radial tire having improved flat spot resistance without sacrificing its high-speed durability, when a belt auxiliary reinforcement layer thereof is constituted of a hybrid fiber cord including a general-purpose nylon as a low-elastic fiber yarn. In the pneumatic radial tire, the belt auxiliary reinforcement layer is formed by winding an organic fiber cord around the outer periphery of belt layers in the tire circumferential direction. The organic fiber cord constituting the belt auxiliary reinforcement layer is obtained by twisting a highly-elastic fiber yarn with an elastic modulus of 10000 MPa or more and a low-elastic fiber yarn made of nylon 46.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20210370721A1High-speed durabilityImprove steering stabilityPneumatic tyre reinforcementsMechanical engineeringAutomotive engineering

In a pneumatic tire according to an embodiment, a belt layer is configured such that the angle of a belt cord relative to the tire circumferential direction is more than 30° and 40° or less. An organic fiber cord of a belt-reinforcing layer, which is placed on the radially outer side of the belt layer, is configured such that when the number of twists per 10 cm length is T (twists / 10 cm), the fineness is D (dtex), and the fiber density is ρ (g / cm3), the twist coefficient K defined as T×(D / ρ)1 / 2 is 900 to 2,600, and the product of the load at 5% elongation LASE 5% (N) of the organic fiber cord and the end count E (cords / 25 mm) of the organic fiber cord is 1,000 N or more.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

ActiveUS11331966B2Improve cooling effectImprove high-speed durabilityInflatable tyresTire beadEngineering

A pneumatic tire includes: an annular-shaped tread portion extending in a tire circumferential direction; a pair of sidewall portions disposed on both sides of the tread portion; and a pair of bead portions disposed on an inner side in a tire radial direction of the sidewall portions; wherein a band-like sound absorbing member is adhered on an inner surface of the tread portion in the tire circumferential direction; and a plurality of cuts with an angle θ with regard to the tire circumferential direction within a range of 40°≤θ≤90° are formed on both end portions in a lateral direction of the band-like sound absorbing member, and the cuts are connected only to one end portion in the lateral direction of the band-like sound absorbing member.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic radial tire for motorcycle

InactiveUS20050205188A1Lowering straight-running stabilityGood rigidity balancePneumatic tyre reinforcementsMotorcycle tyresIn planeCamber angle

There is provided a pneumatic radial tire for a motorcycle capable of developing an excellent steering stability in a high-speed cornering subjected to a large camber angle, and having an aspect ratio of 0.50-0.85, in which a tensile strength at break of a carcass ply cord is not less than 980 MPa, and an absolute value of a carcass total rigidity obtained by adding carcass rigidities of carcass plies is not less than 30000, and a tensile strength at break of a belt layer cord is not less than 2350 MPa, and an absolute value of a belt total rigidity obtained by adding belt rigidities of belt layers is not less than 170000, and an out-of-plane bending rigidity in widthwise direction of a tread portion is 0.40-0.70 kg / mm and an in-plane bending rigidity in peripheral direction thereof is 0.05-0.15 kg / mm and a bending rigidity ratio as a ratio of out-of-plane bending rigidity to in-plane bending rigidity is within a range of 4.20-9.10.

Owner:BRIDGESTONE CORP

Pneumatic tire

InactiveUS20200164687A1Reduce weightHigh speed durabilityPneumatic tyre reinforcementsPolyamide fibersManufacturing engineering

A pneumatic tire that can improve high speed durability while reducing a tire weight is provided. The pneumatic tire comprises a carcass, a belt layer comprising a cord inclined to a tire circumferential direction and arranged on the periphery of a crown of the carcass, and a belt reinforcing layer comprising an organic fiber cord arranged on the periphery of the belt layer along a tire circumferential direction. The organic fiber cord comprises an aromatic polyamide fiber having a fineness of 500 to 3,000 dtex, and has a single twist construction having a twist coefficient of 800 to 2,000.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic Tire

A pneumatic tire is provided, including: an annular-shaped tread portion extending in a tire circumferential direction; a pair of sidewall portions disposed on both sides of the tread portion; and a pair of bead portions disposed on an inner side in a tire radial direction of the sidewall portions; wherein a band-like sound absorbing member is adhered on an inner surface of the tread portion in the tire circumferential direction; and the band-like sound absorbing member has a plurality of cuts extending in two mutually intersecting directions, and of the cuts, a cut extending in one direction is a cut extending parallel with regard to a tire lateral direction or tire circumferential direction.

Owner:YOKOHAMA RUBBER CO LTD

Armature, wire dot printer head and wire dot printer

InactiveUS7331726B2High-speed durabilityExcellent magnetic propertiesTypewritersFranking apparatusMagnetic characteristicLaser beams

In order to obtain joining force endurable for high-speed printing and realize an enhancement in magnetic characteristic, a plate-like arm for supporting a printing wire is laminated with a magnetic circuit forming member that is composed by laminating plural plates for forming a magnetic circuit, wherein a weld zone is formed on the laminated surface of the arm and plates with laser beam irradiation for fixing the arm and the magnetic circuit forming member with the weld zone.

Owner:TOSHIBA TEC KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com