Patents

Literature

2070results about How to "Reduce rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

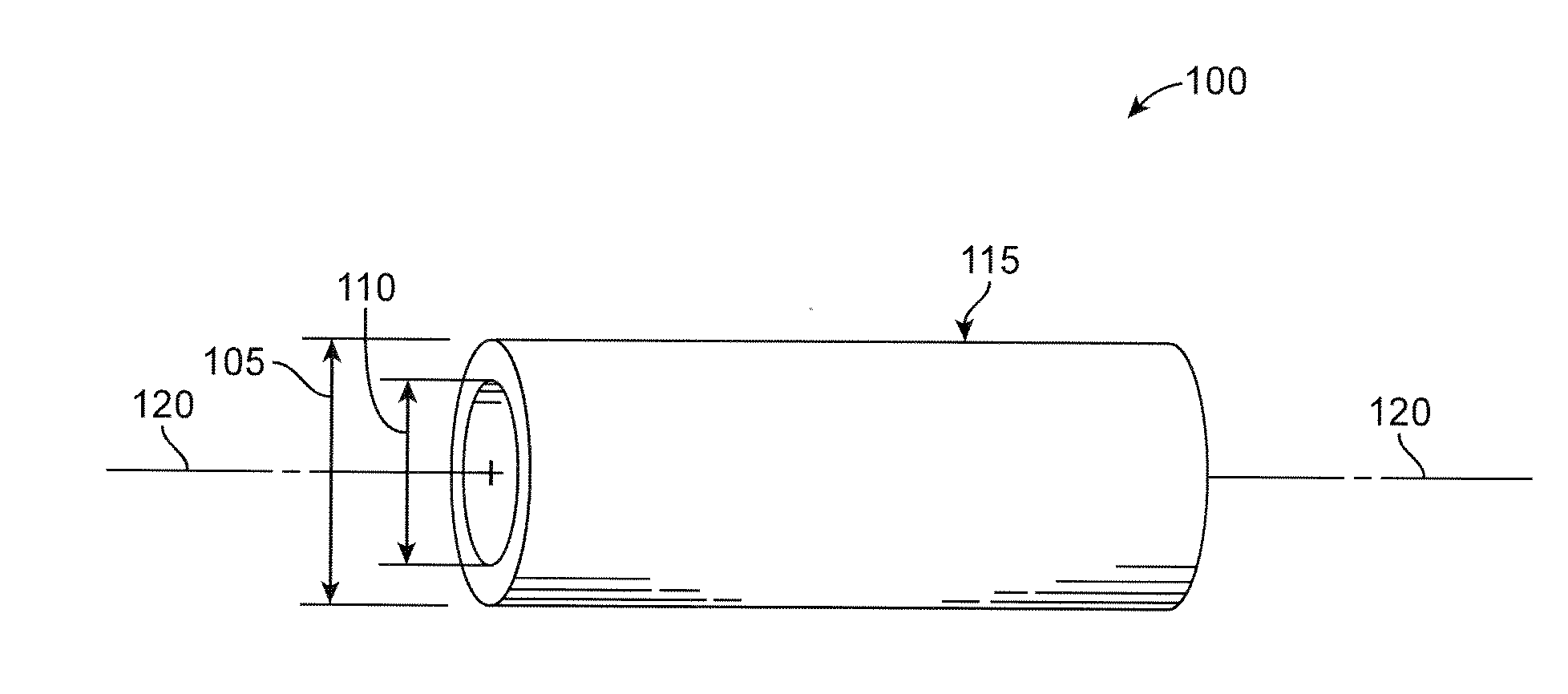

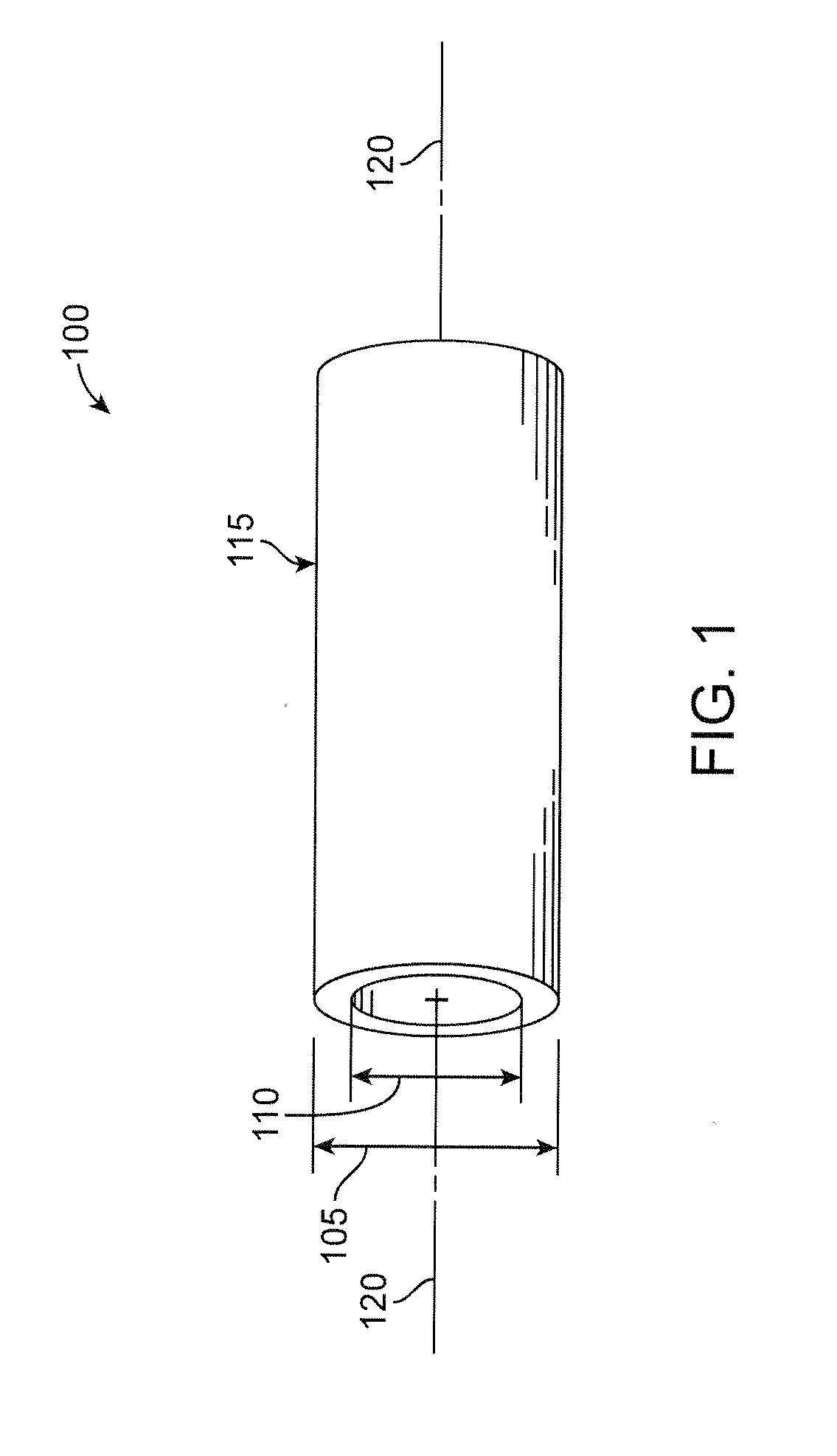

Crush Recoverable Polymer Scaffolds Having a Low Crossing Profile

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold, after being deployed by the balloon, provides a crush recovery of about 90% after the diameter of the scaffold has been pinched or crushed by 50%. The scaffold also has a reduced crimped profile and a modification of the scaffold's ring structure at the crowns that contributes to the reduced crimped profile.

Owner:ABBOTT CARDIOVASCULAR

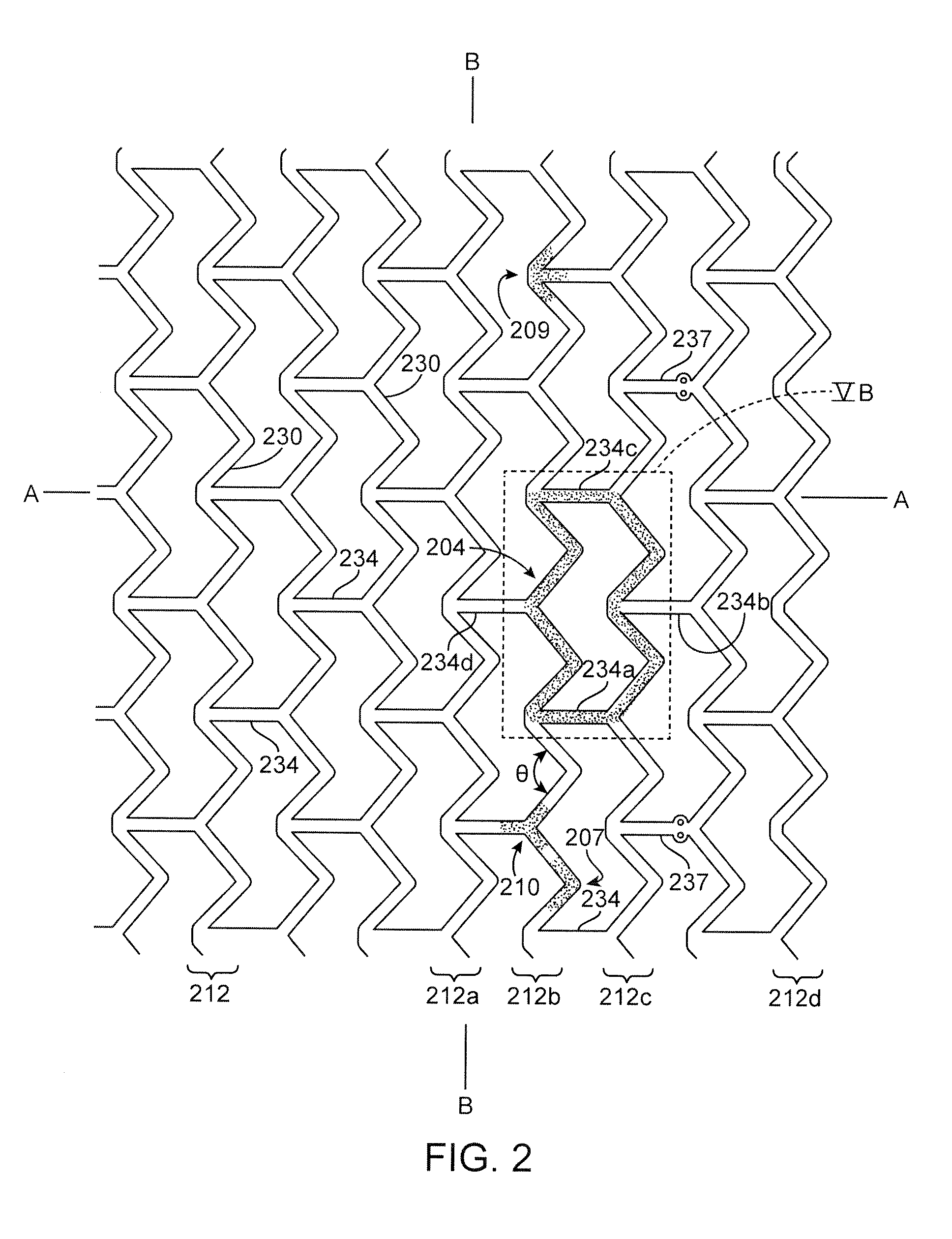

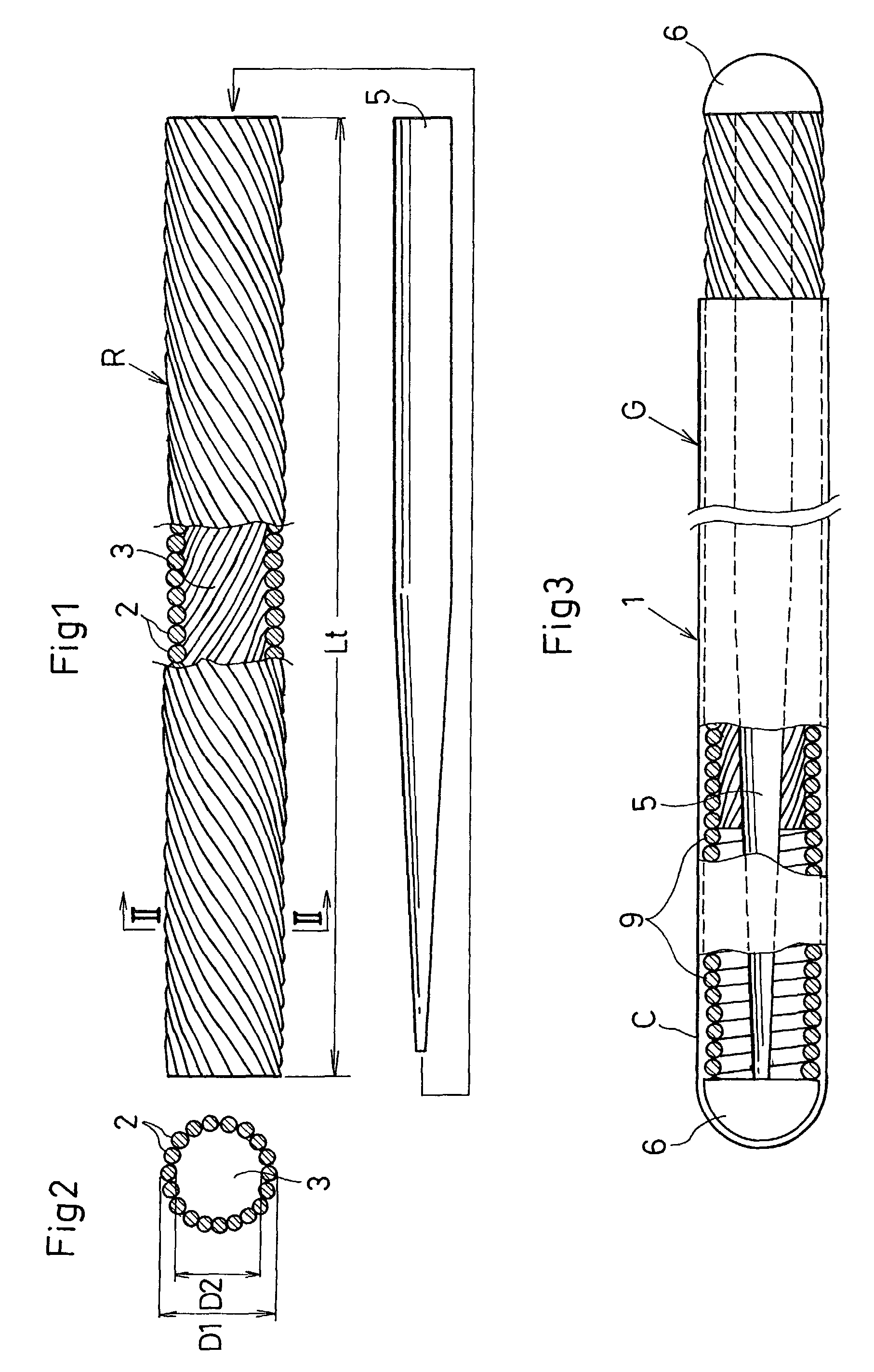

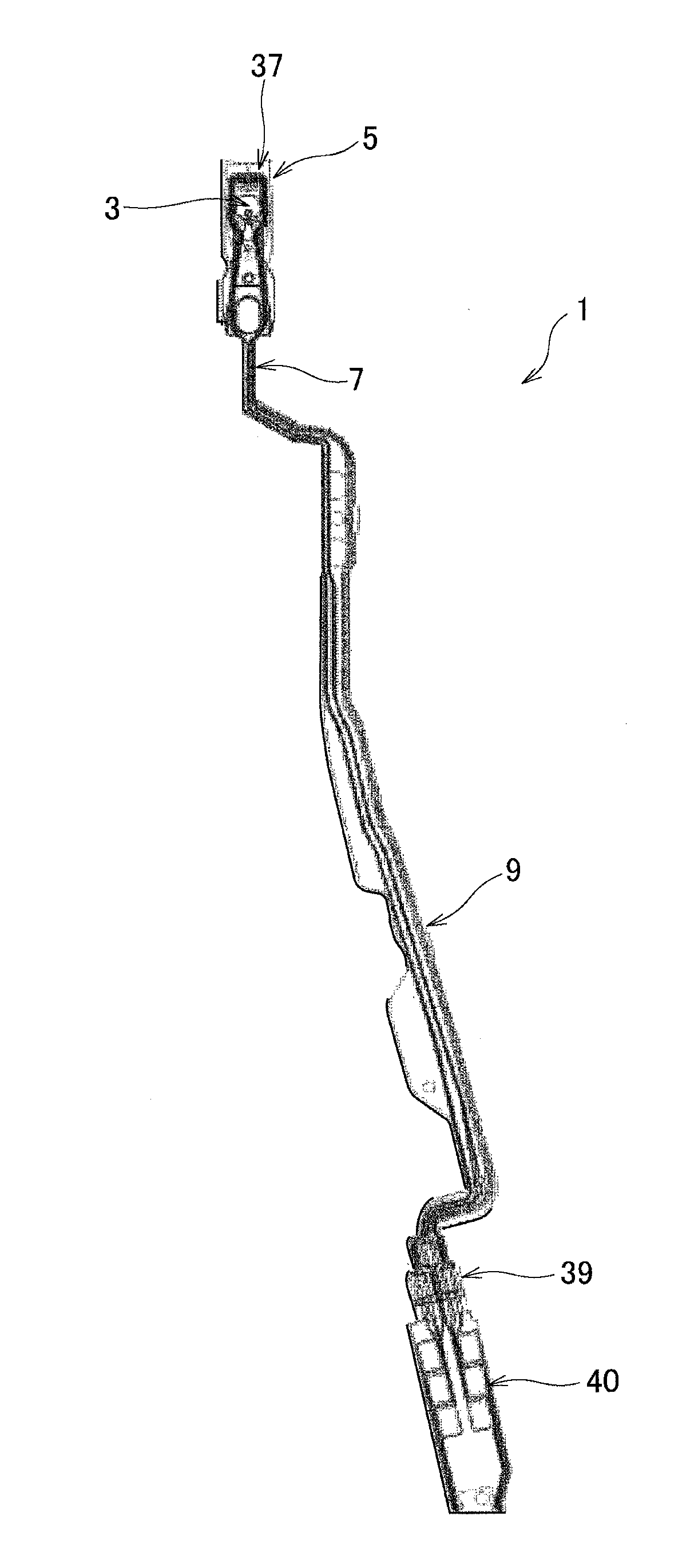

Wire-stranded hollow coil body, a medical equipment made therefrom and a method of making the same

InactiveUS7117703B2Improve rendering capabilitiesImprove straightnessStentsGuide wiresEngineeringMedical device

A wire-stranded hollow coil body (1) has a multitude of coil line elements (2) stranded along a predetermined circular line to form a flexible wire tube having a central axial hollow portion (3), the flexible wire tube is stranded under a strand-turn resistant load and heat treated to remove a residual stress upon formation so as to provide a high rotation-following capability and a high straightness. Further, a method provides a way to strand the coil line elements (2) under a strand-turn resistant load while heat treating the coil line elements (2).

Owner:ASAHI INTECC CO LTD

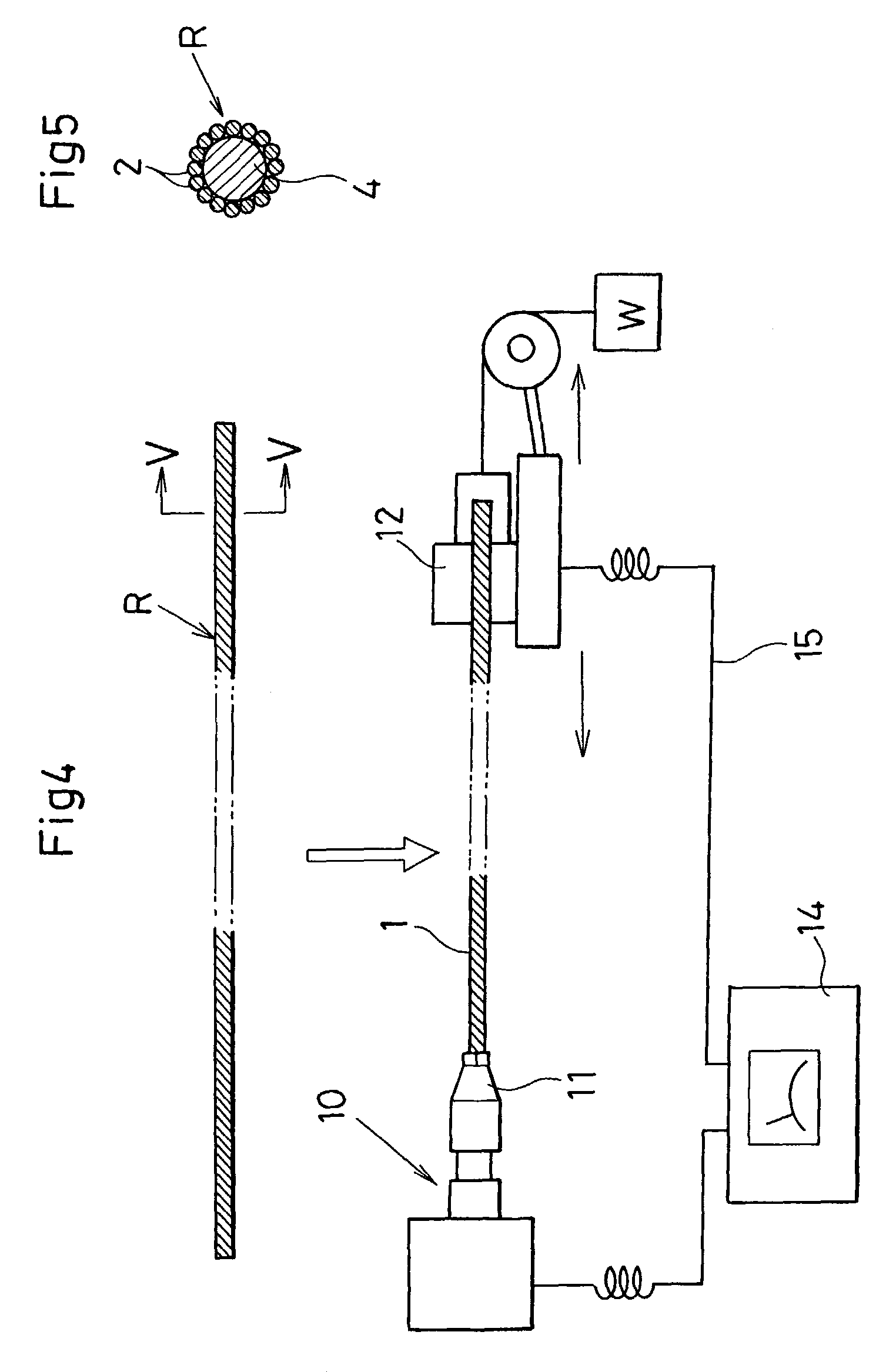

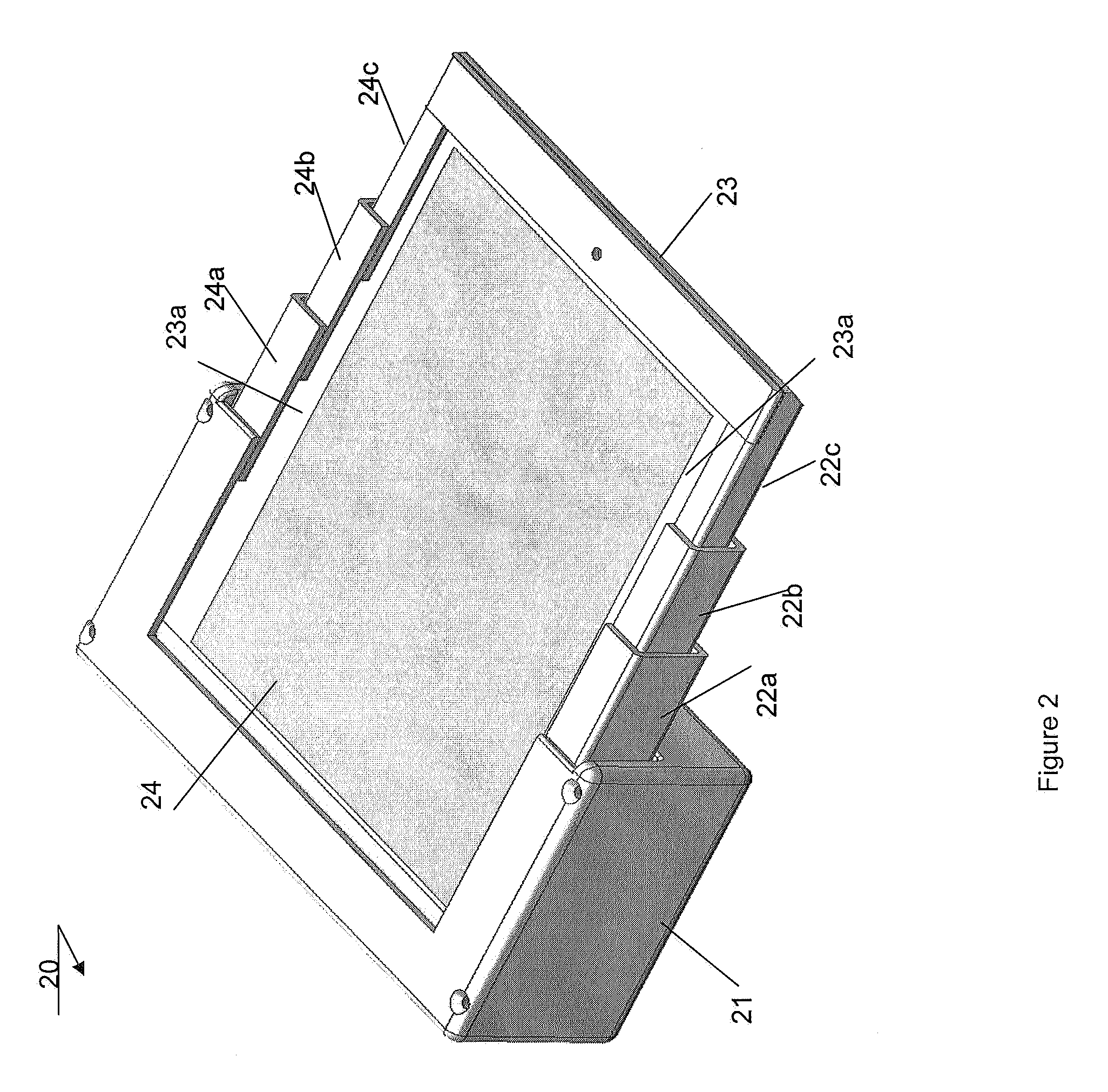

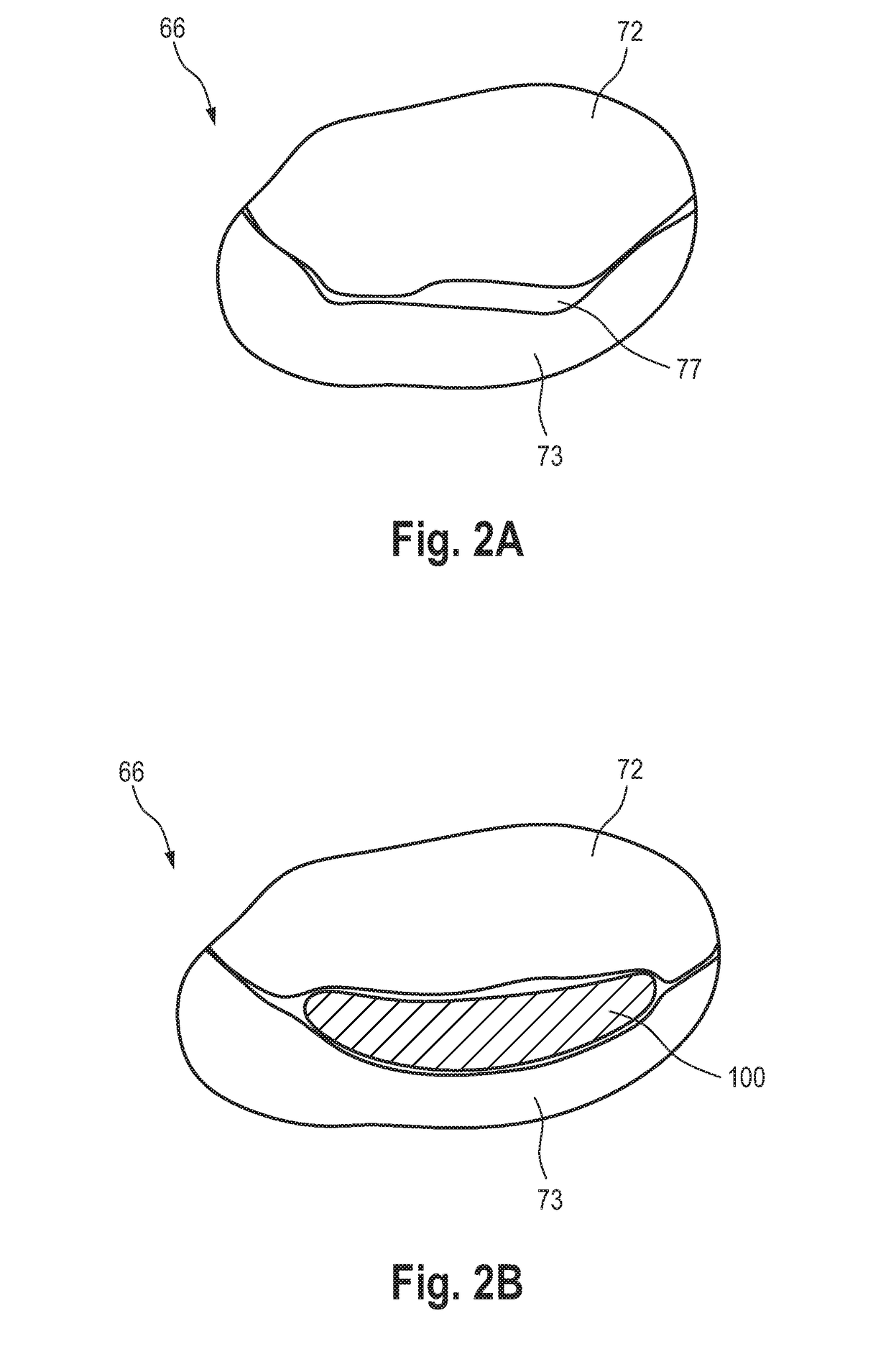

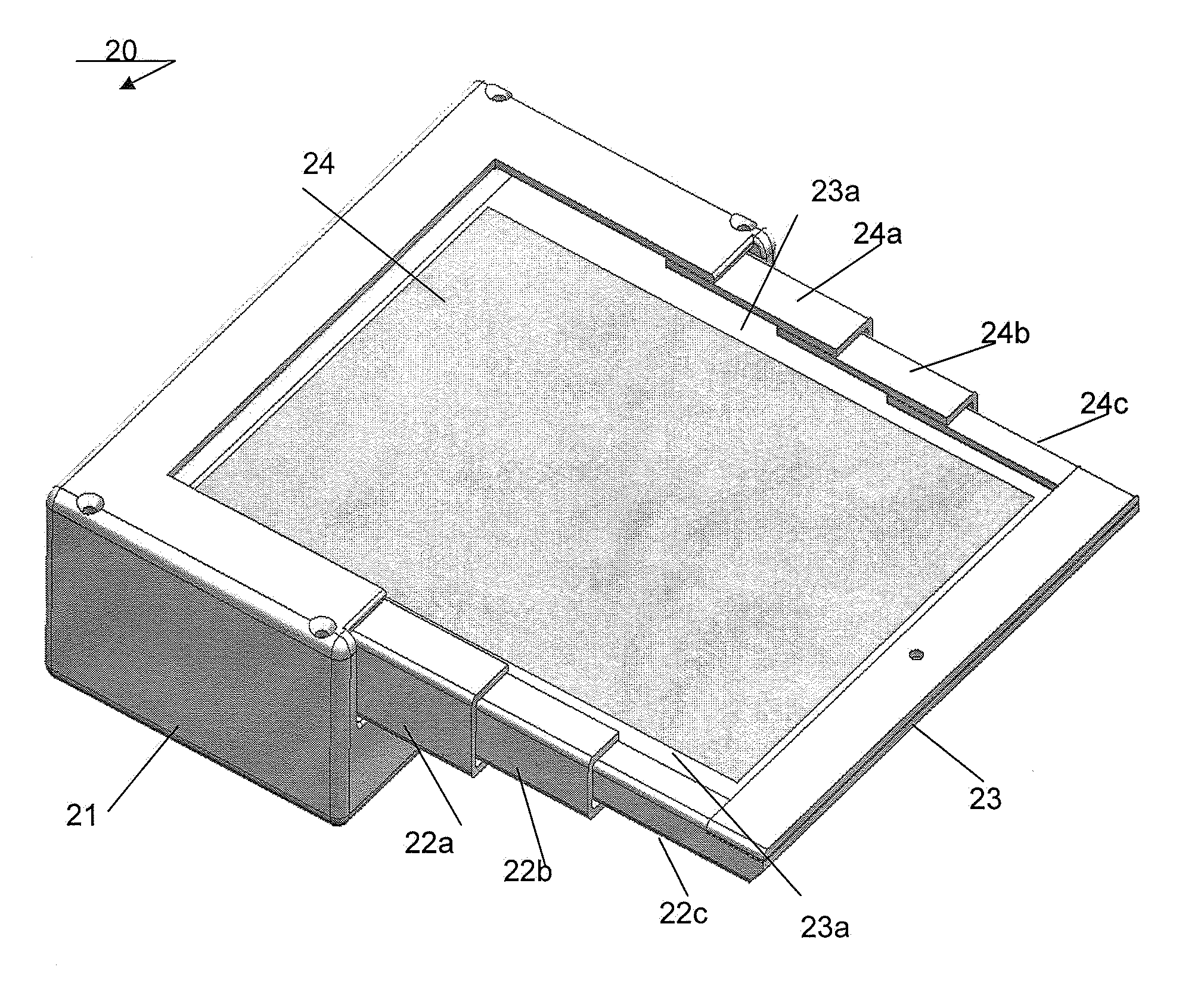

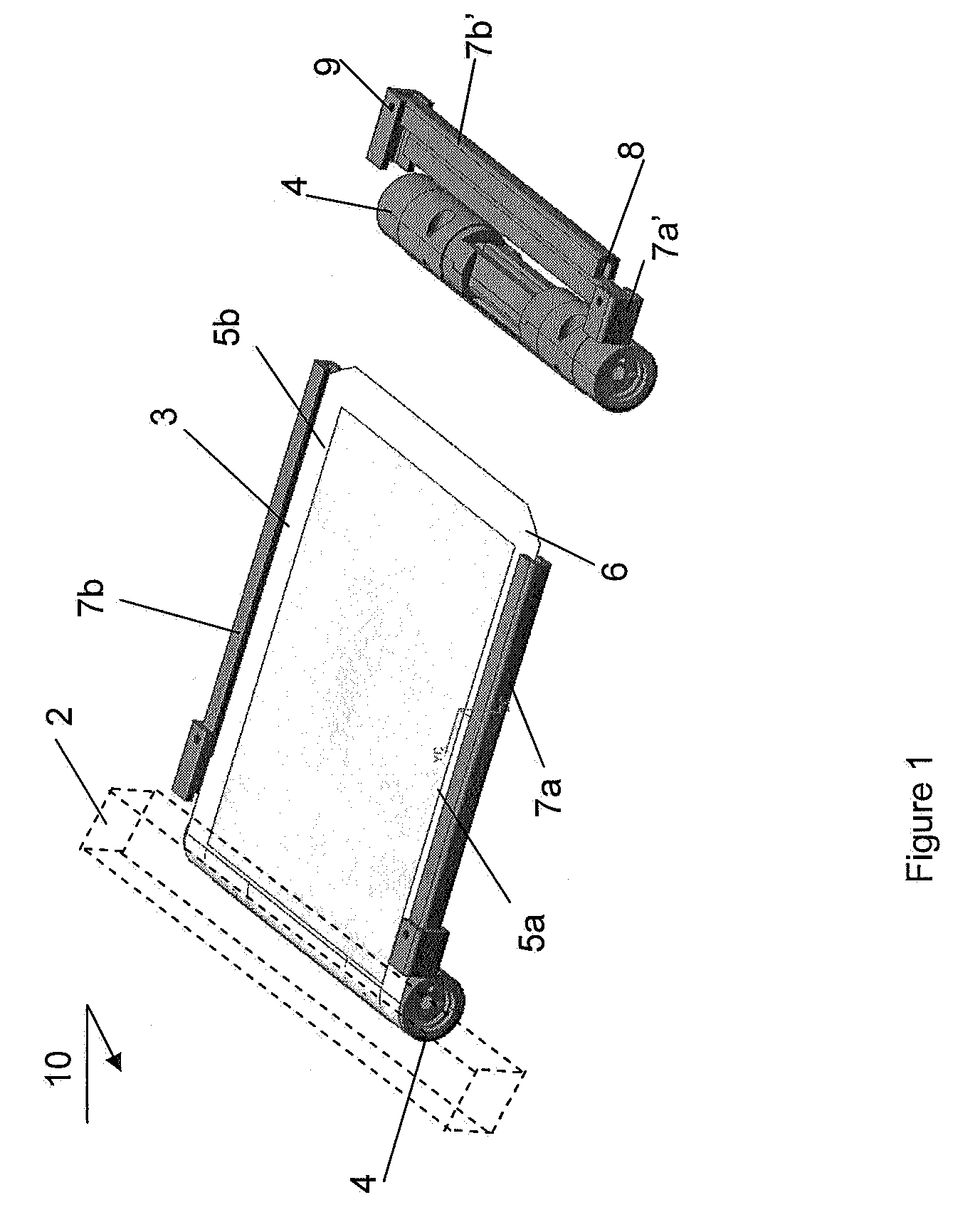

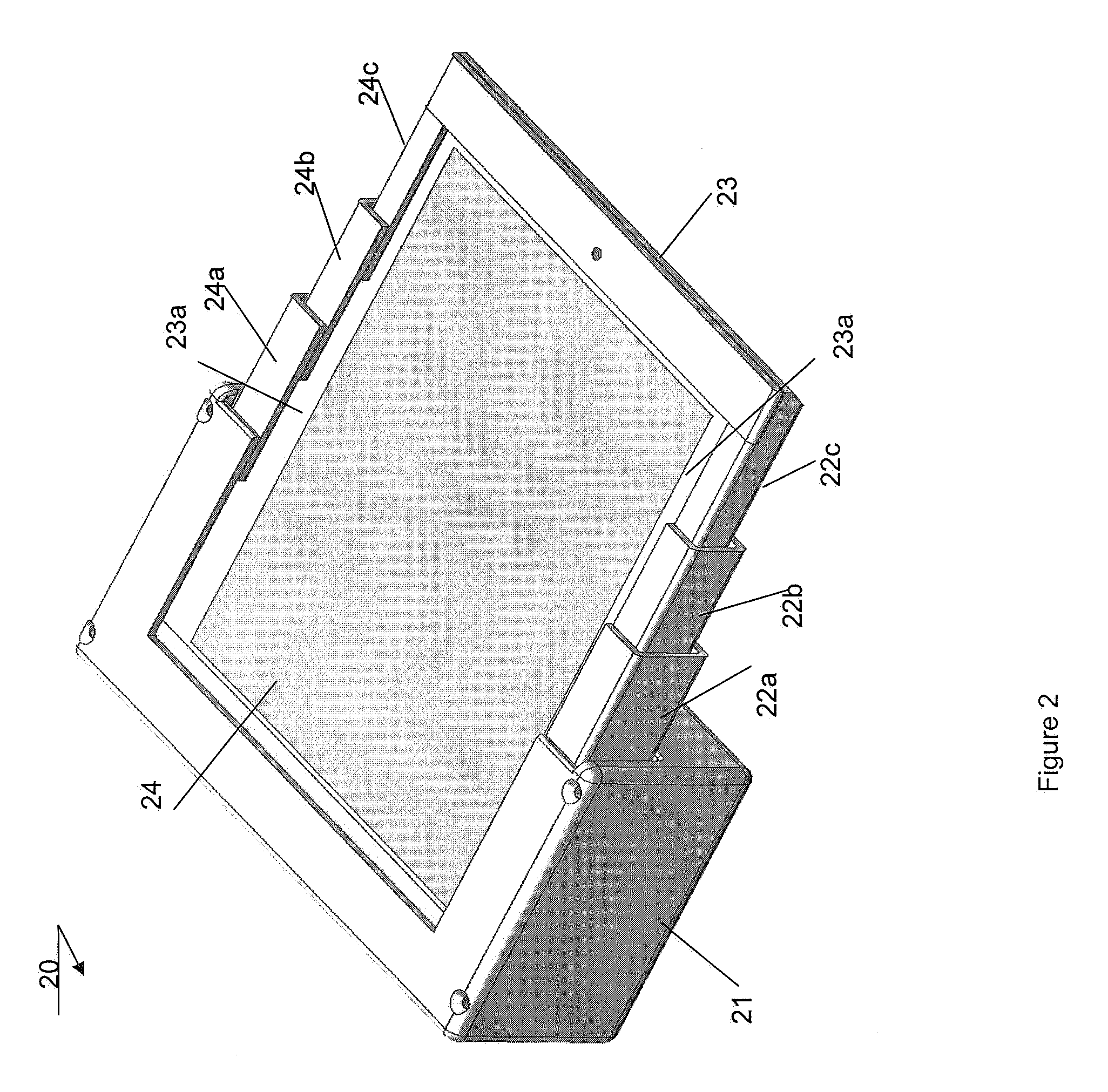

Electronic device comprising a flexible display with edge protectors

ActiveUS8493726B2Quality improvementRigidity is not compromisedDigital data processing detailsSubstation equipmentDisplay deviceEngineering

The invention relates to an electronic device 60 comprising a flexible display arranged to be alternated between a collapsed state and an extended state, said flexible display comprising edge portions, the flexible display being further provided with an edge protector cooperating with the edge portions, wherein the edge protector is conceived to be alternated between a collapsed state and an extended state. In the electronic device 60a the flexible display 65 is conceived to be wound about a roller 61. The edge protector comprises rigid segments 63a, 63b, 63c, 62a, 62b, 62c, 62c interconnected by suitable means 64a, 64b, 64c. Wiring, pins, bars may be used for interconnecting means 64a, 64b, 64c. In the embodiment 60a an extended position of the edge protector is shown. In the embodiment 60b a collapsed state of the edge protector is shown comprising aggregations of segments 62′, 62″. The bars 64a, 64b, 64c partly protect the back surface of the display. The invention further relates to the electronic device comprising a flexible display wherein the flexible display is provided with an edge protector attached at least partially to the edge portions of the flexible display.

Owner:SAMSUNG ELECTRONICS CO LTD

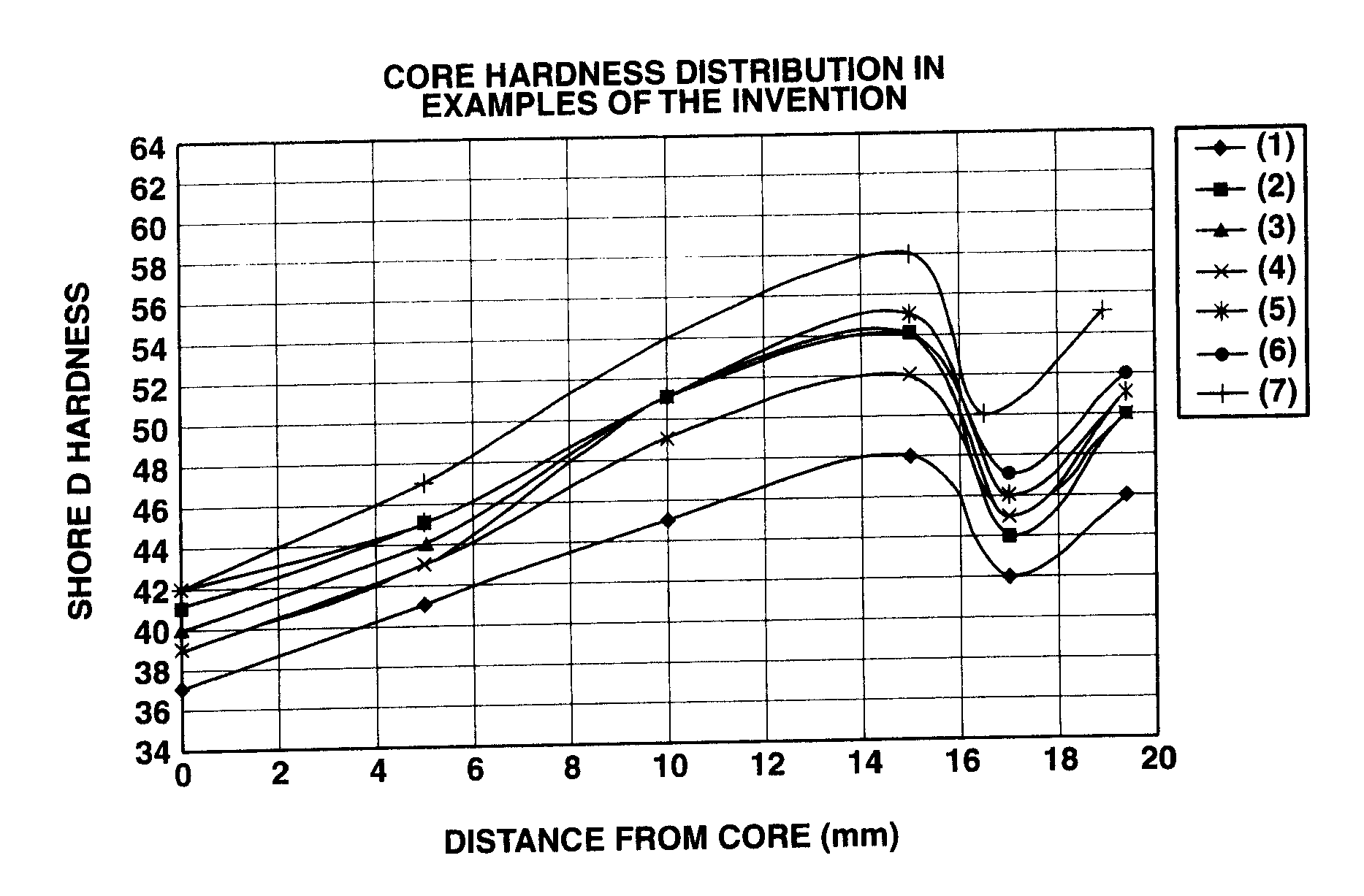

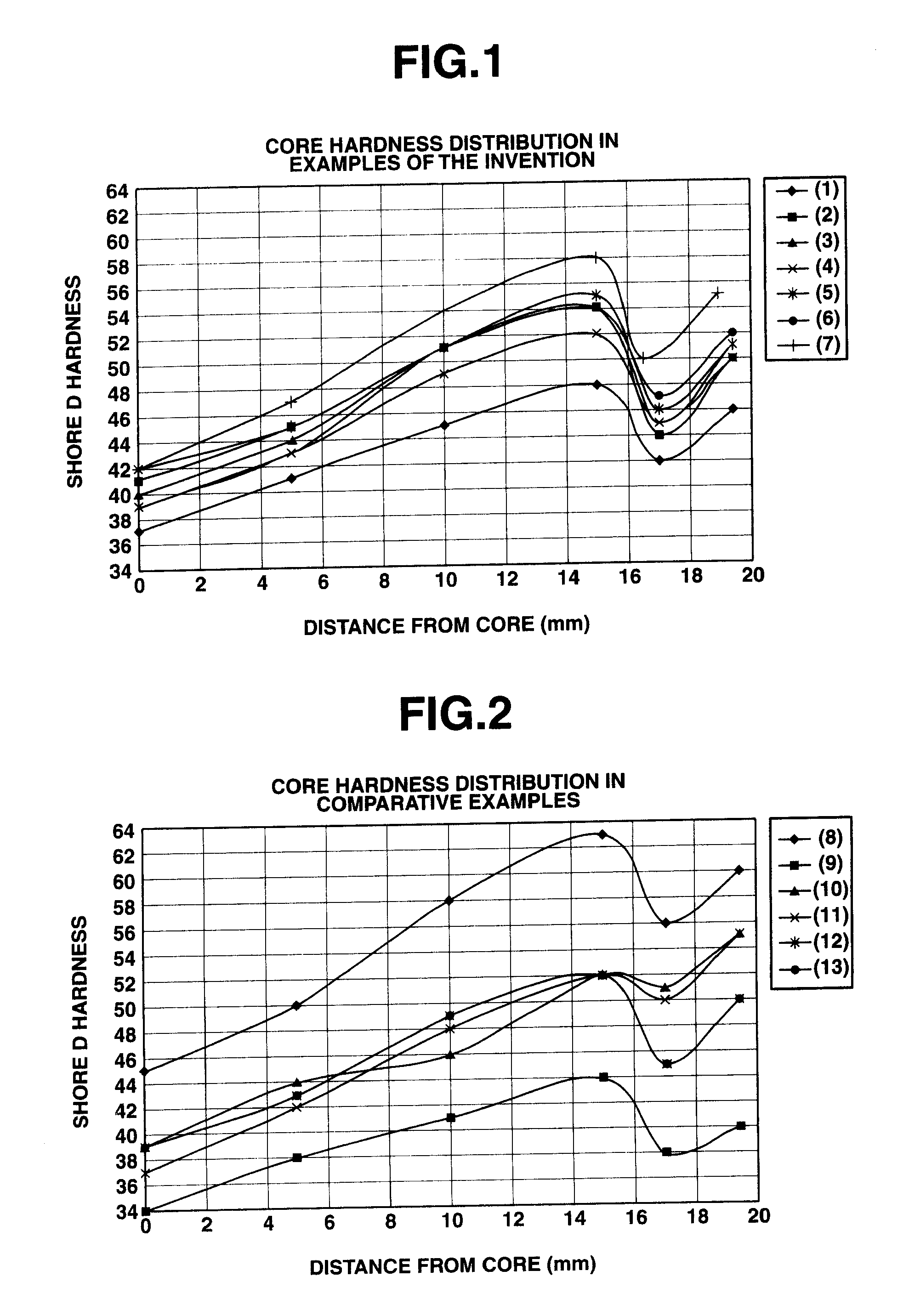

Solid golf ball

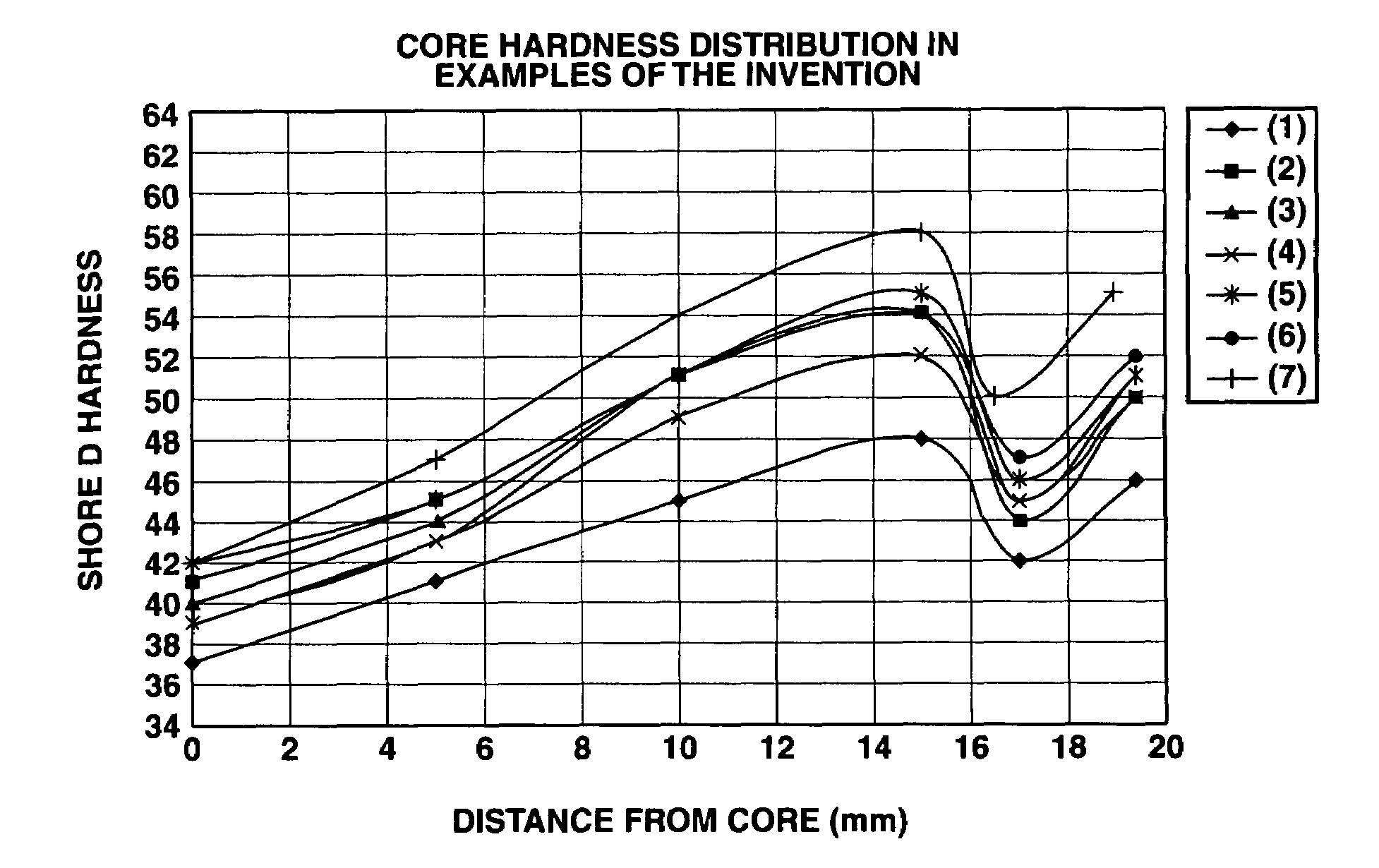

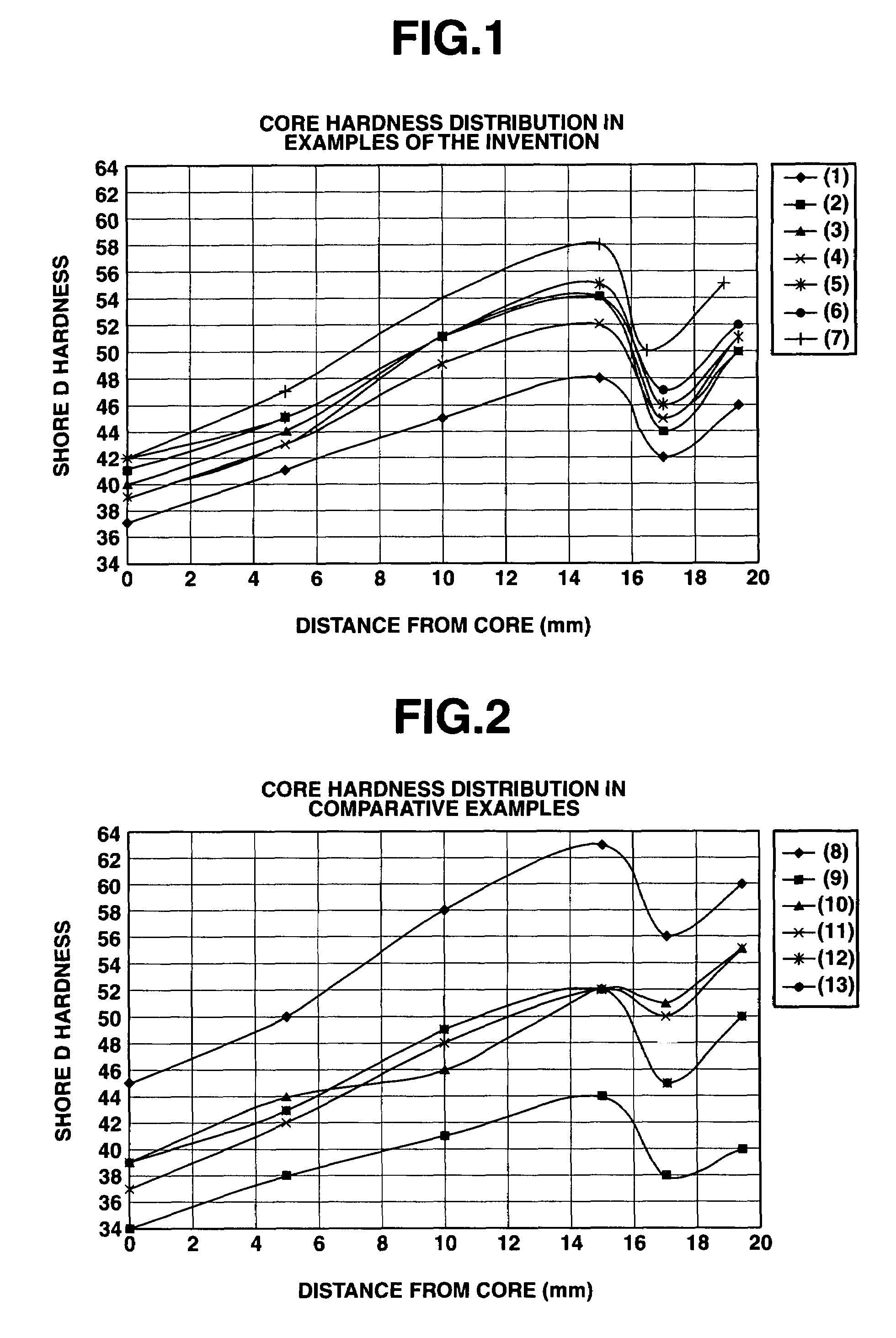

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

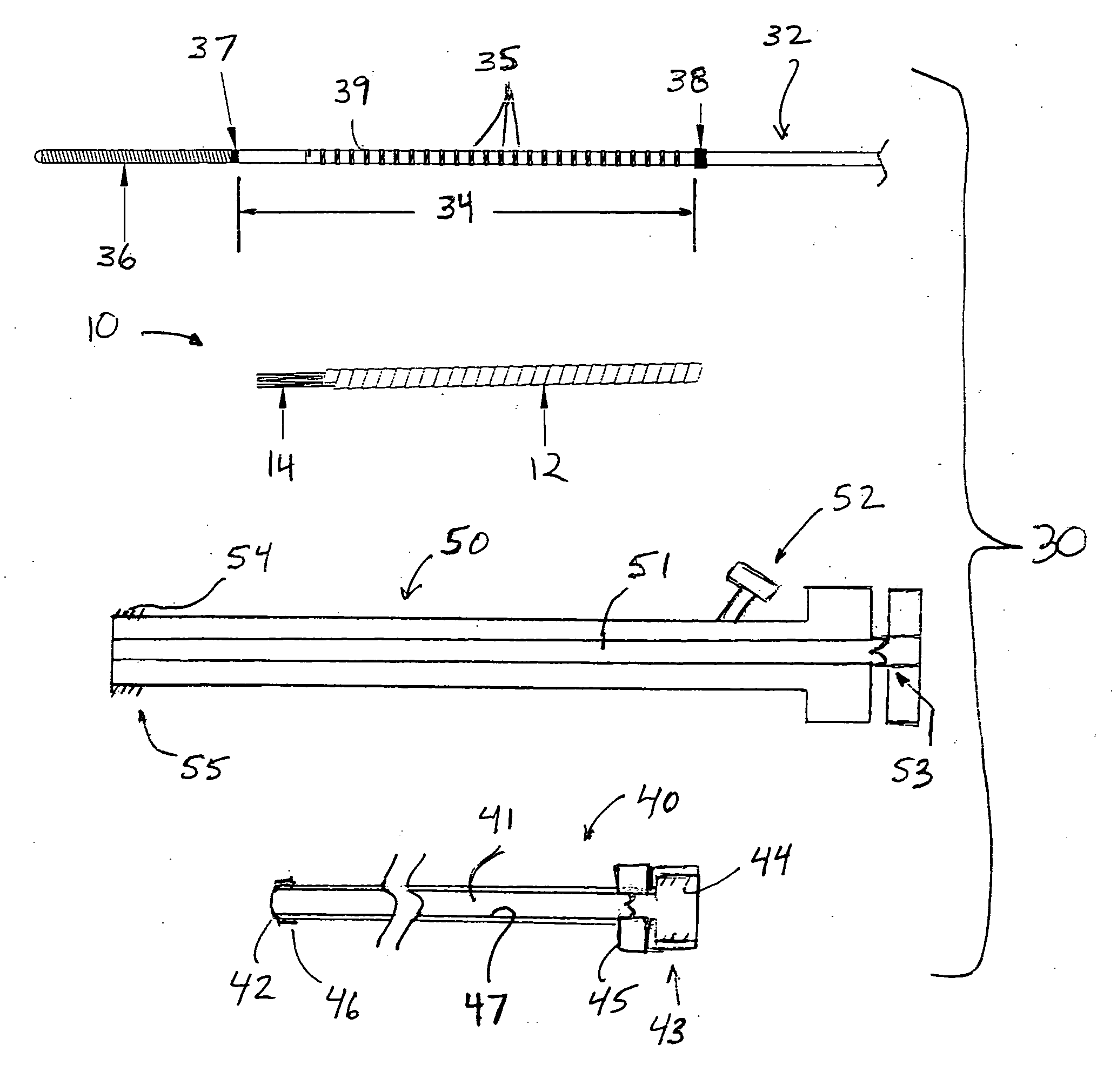

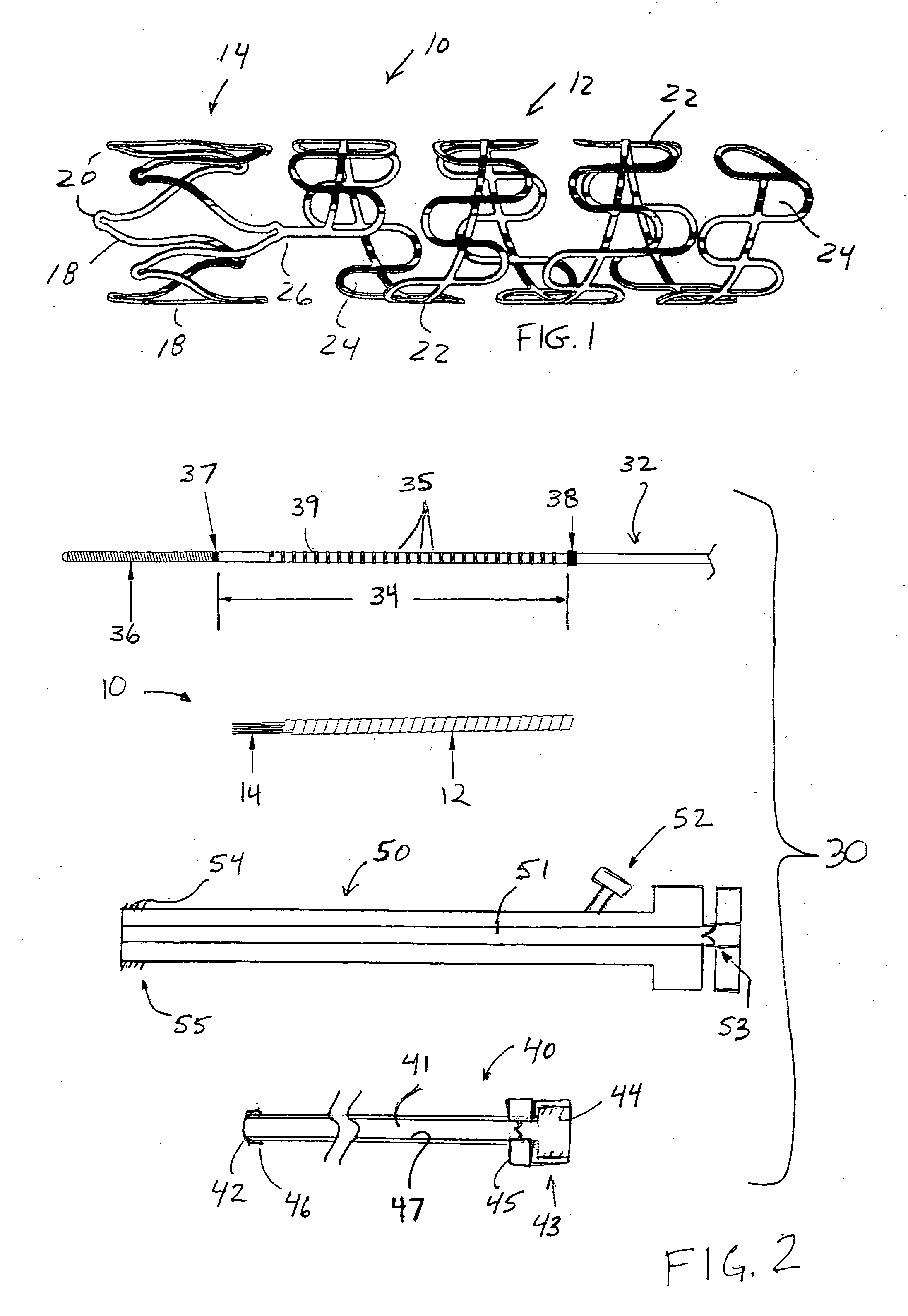

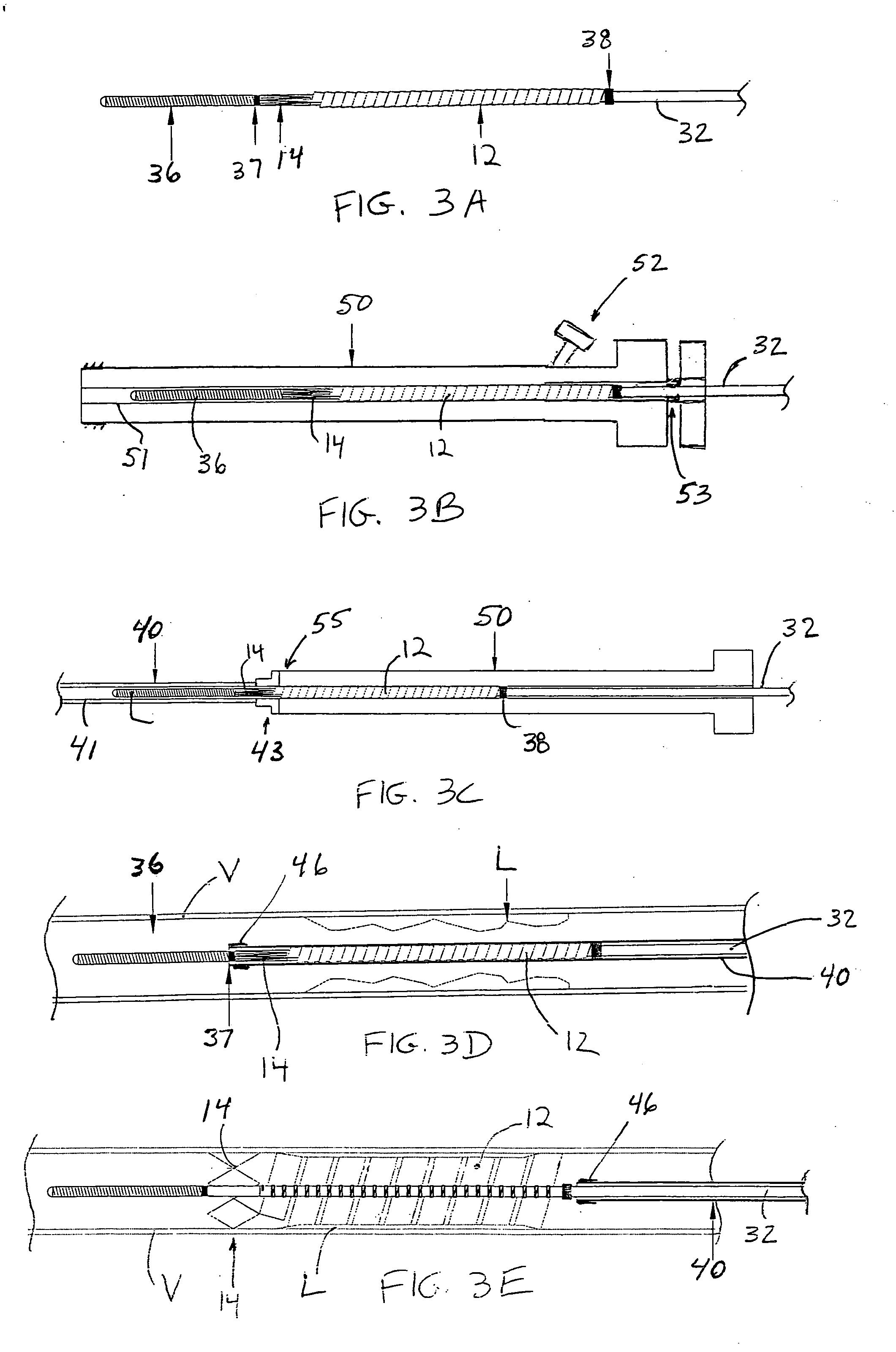

Delivery system for vascular prostheses and methods of use

InactiveUS20050246008A1Low profileSmall diameterStentsBlood vesselsVascular prosthesisBiomedical engineering

The present invention is directed to a delivery system for delivering a vascular prosthesis within a vessel, the vascular prosthesis having a contracted delivery configuration and a deployed configuration. The delivery system comprises a loader tube having a lumen preloaded with a delivery wire carrying a vascular prosthesis in the contracted delivery configuration. A separately inserted sheath includes a lumen configured to accept the vascular prosthesis, while retaining it in the contracted delivery configuration. The delivery wire is used to translate the vascular prosthesis to a distal end of the sheath for deployment in a vessel.

Owner:NOVOSTENT CORP

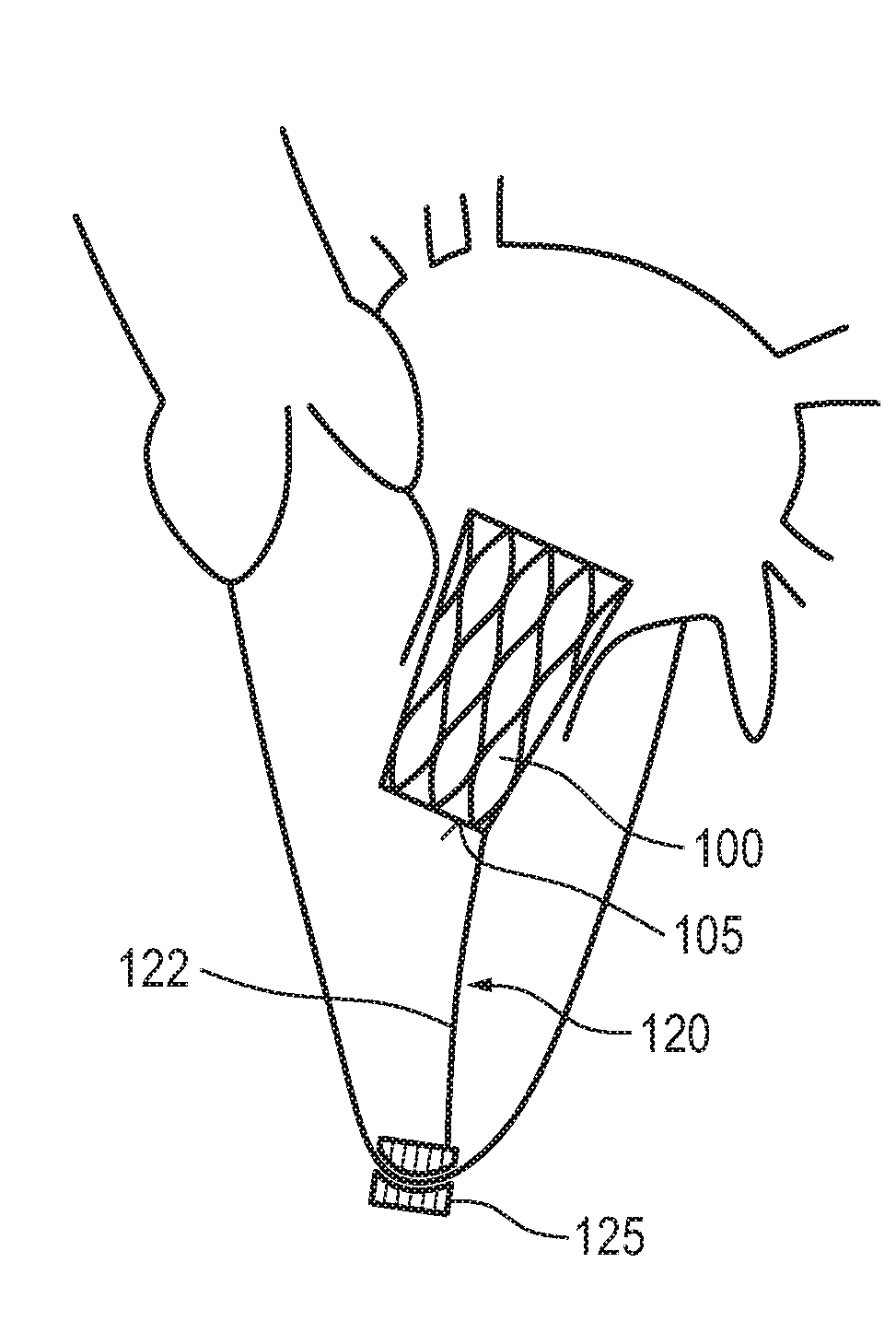

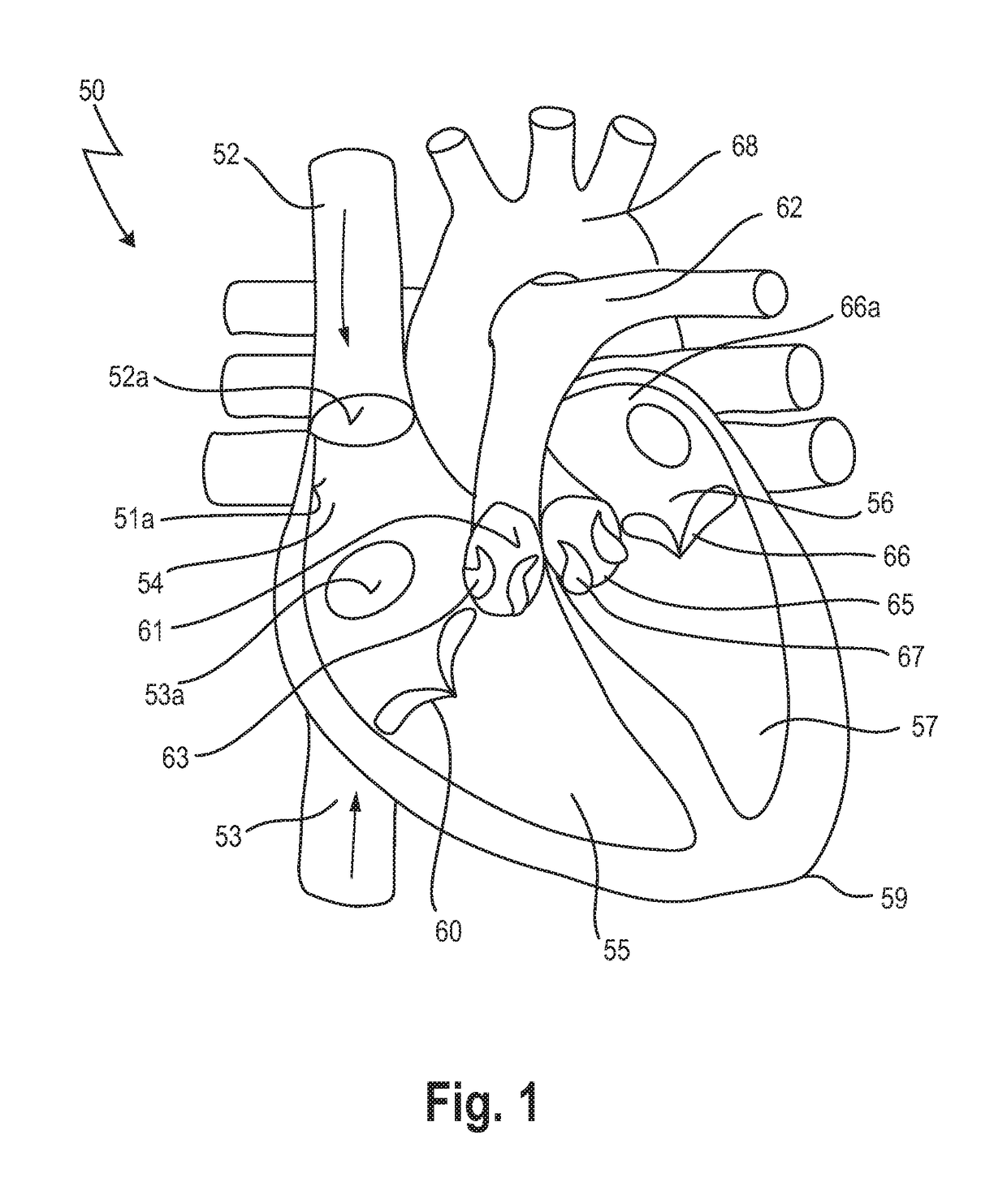

Prosthetic mitral valve coaptation enhancement device

ActiveUS20170172737A1Mitral regurgitation can be reduced and evenMinimizes gradientAnnuloplasty ringsSystoleMitral valve flow

The present invention relates to a prosthetic mitral valve device for implanting at the native mitral valve region of a heart. The prosthetic mitral valve coaptation enhancement device comprises a main body consisting of a stentframe and a valve element attached thereto, wherein the main body has a sealing section and a valve-bearing section, the valve-bearing section; the shape of the sealing section of the main body, in the compressed state, has a form that is adapted to the coaptation zone of the native mitral valve during systole, and the sealing section of the main body, the radial rigidity of the stentframe is lower than the radial rigidity of the valve-bearing section; the prosthetic mitral valve coaptation enhancement device further comprises at least one anchoring element, which anchoring element is coupled to the main body and is capable to anchor the main body within the native mitral valve region of a heart.

Owner:MEDIRA AG

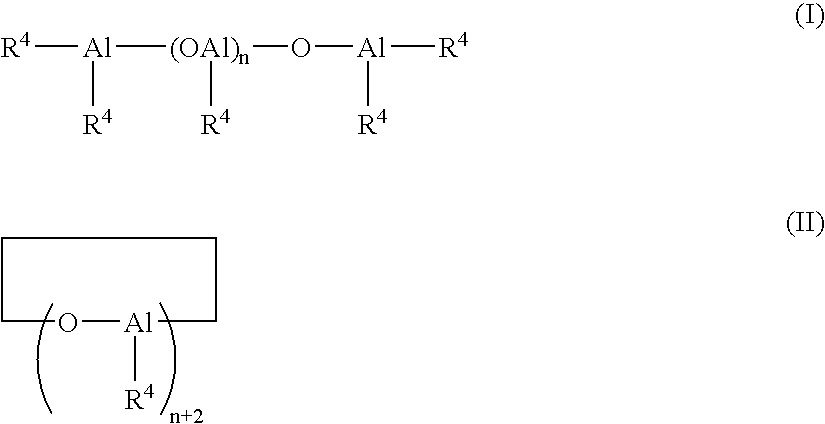

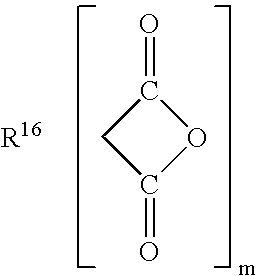

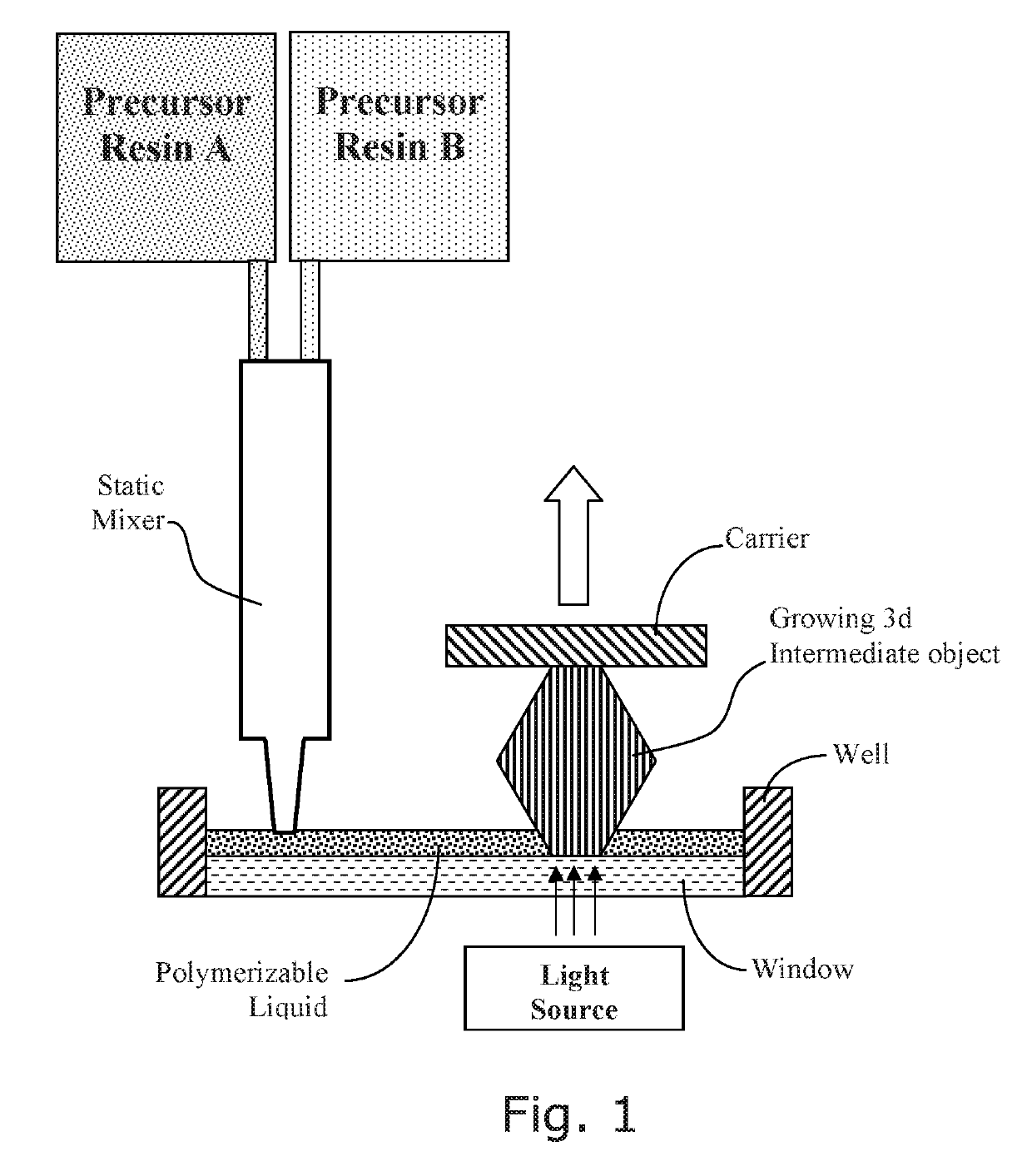

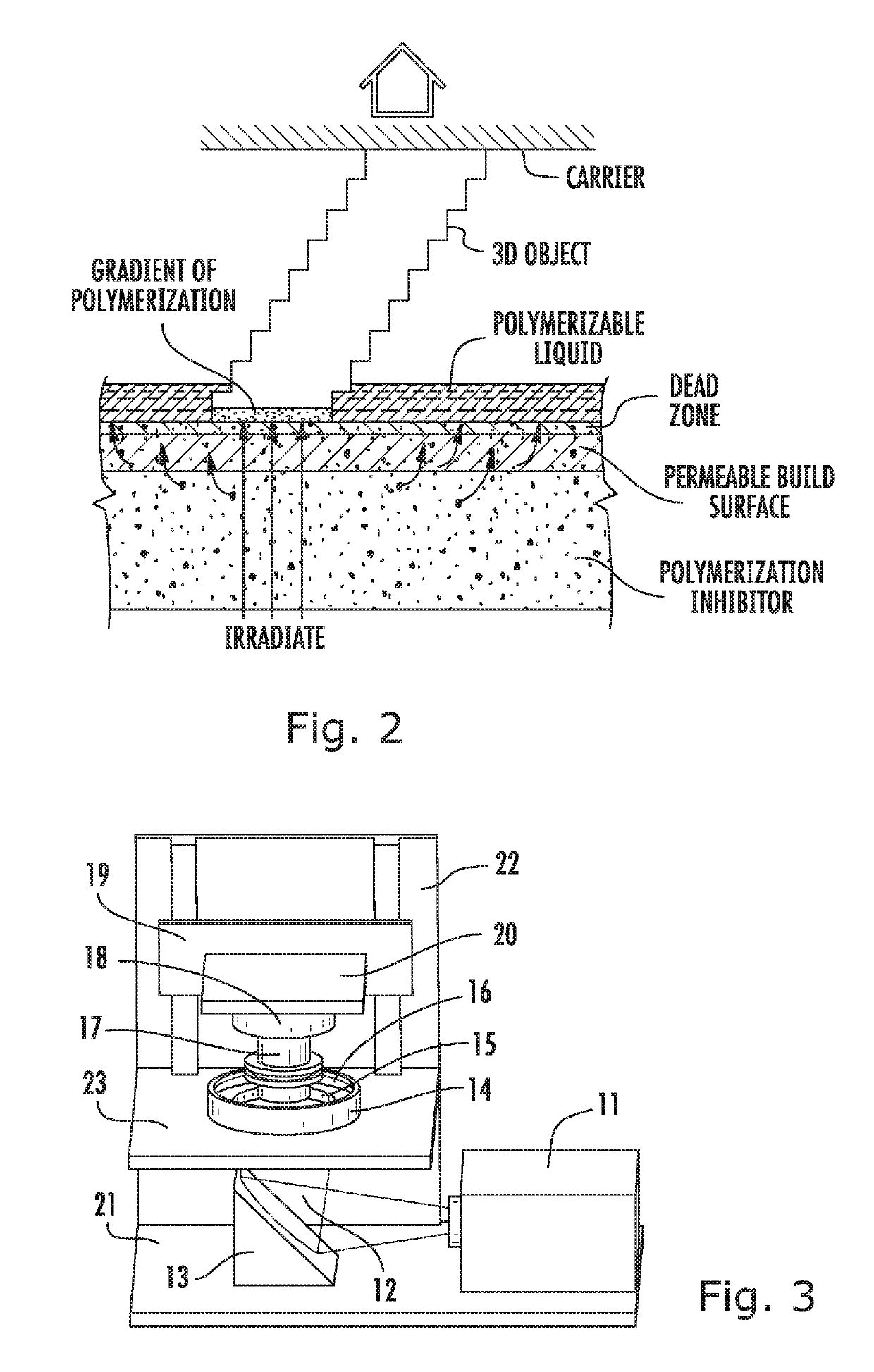

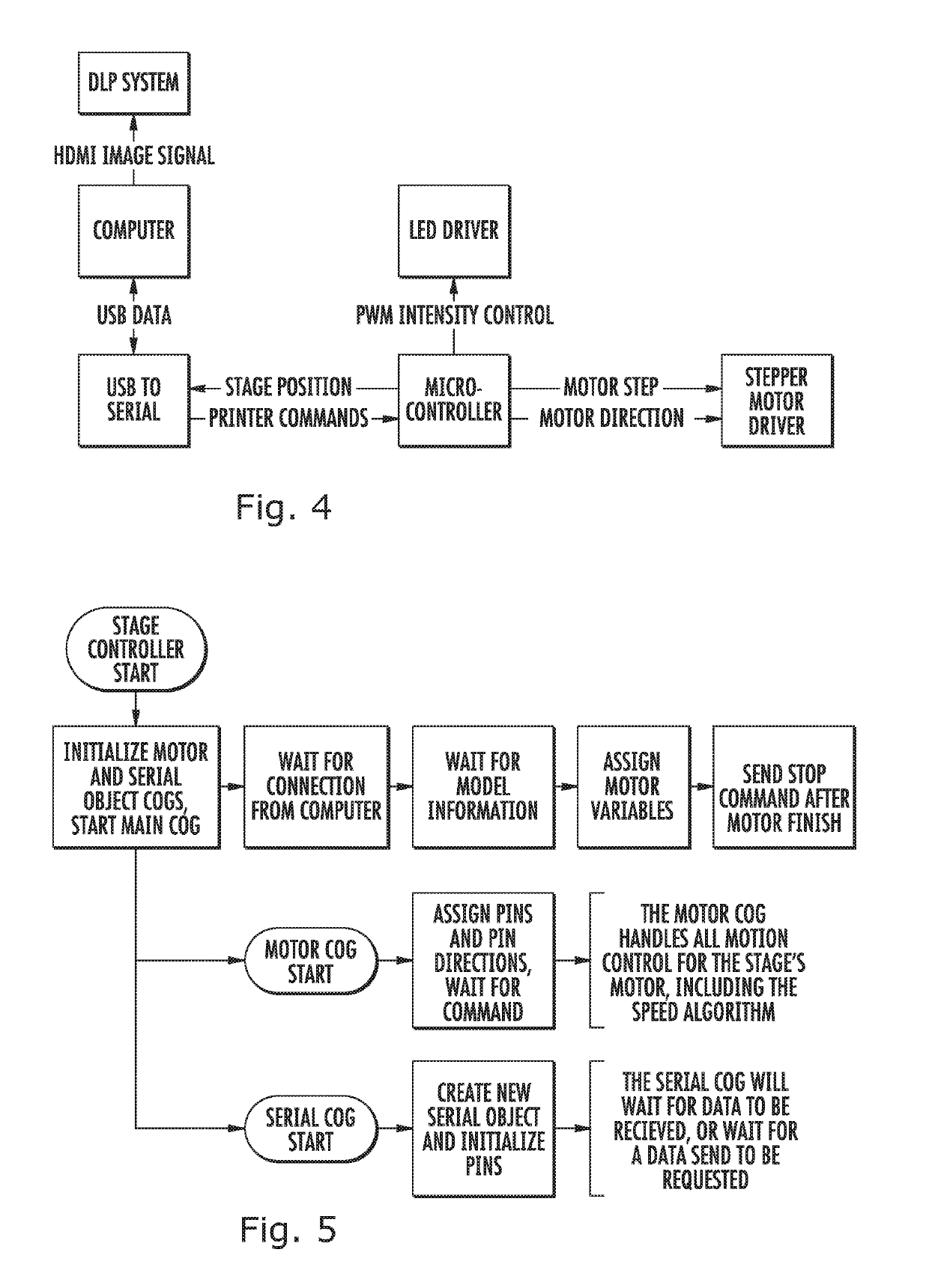

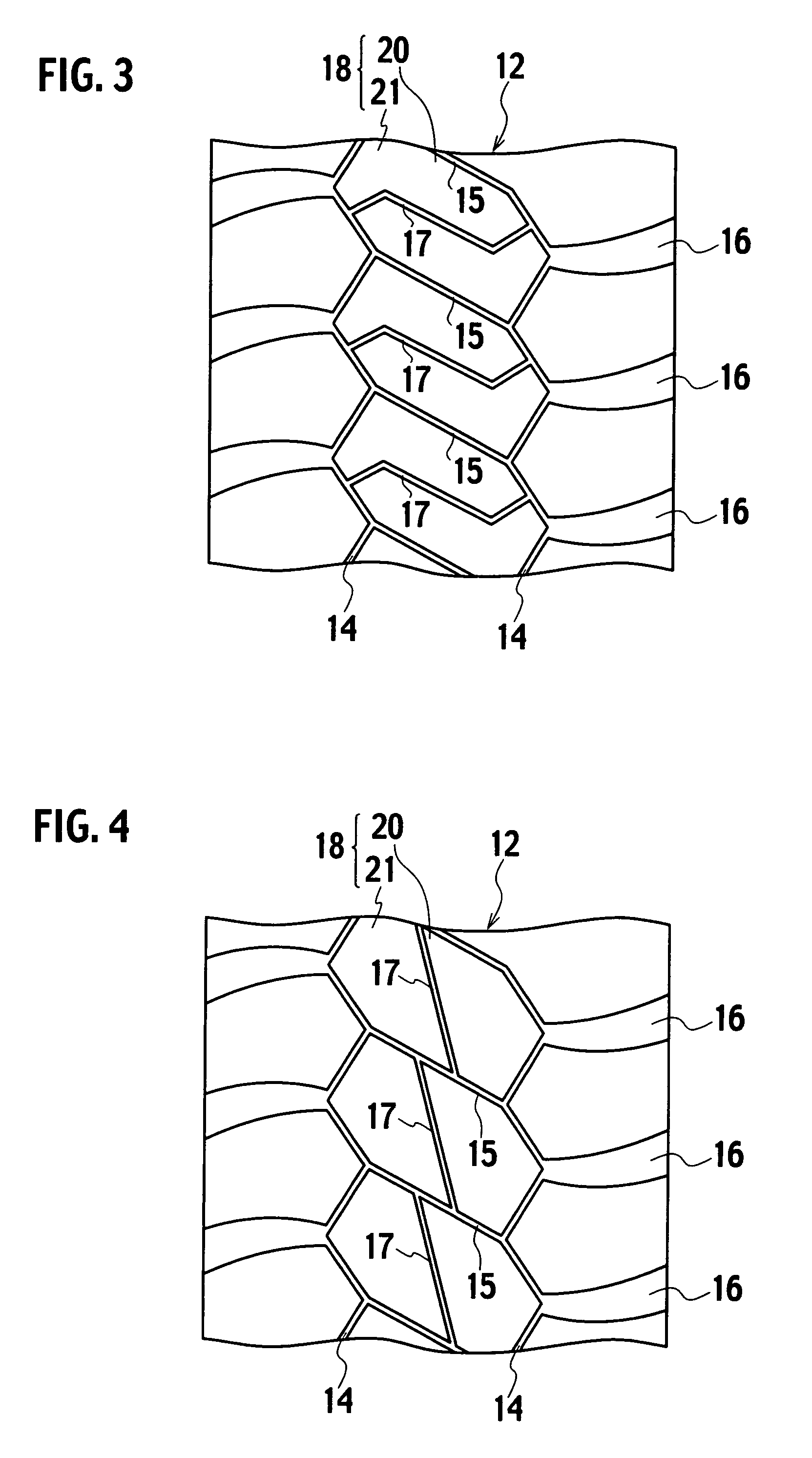

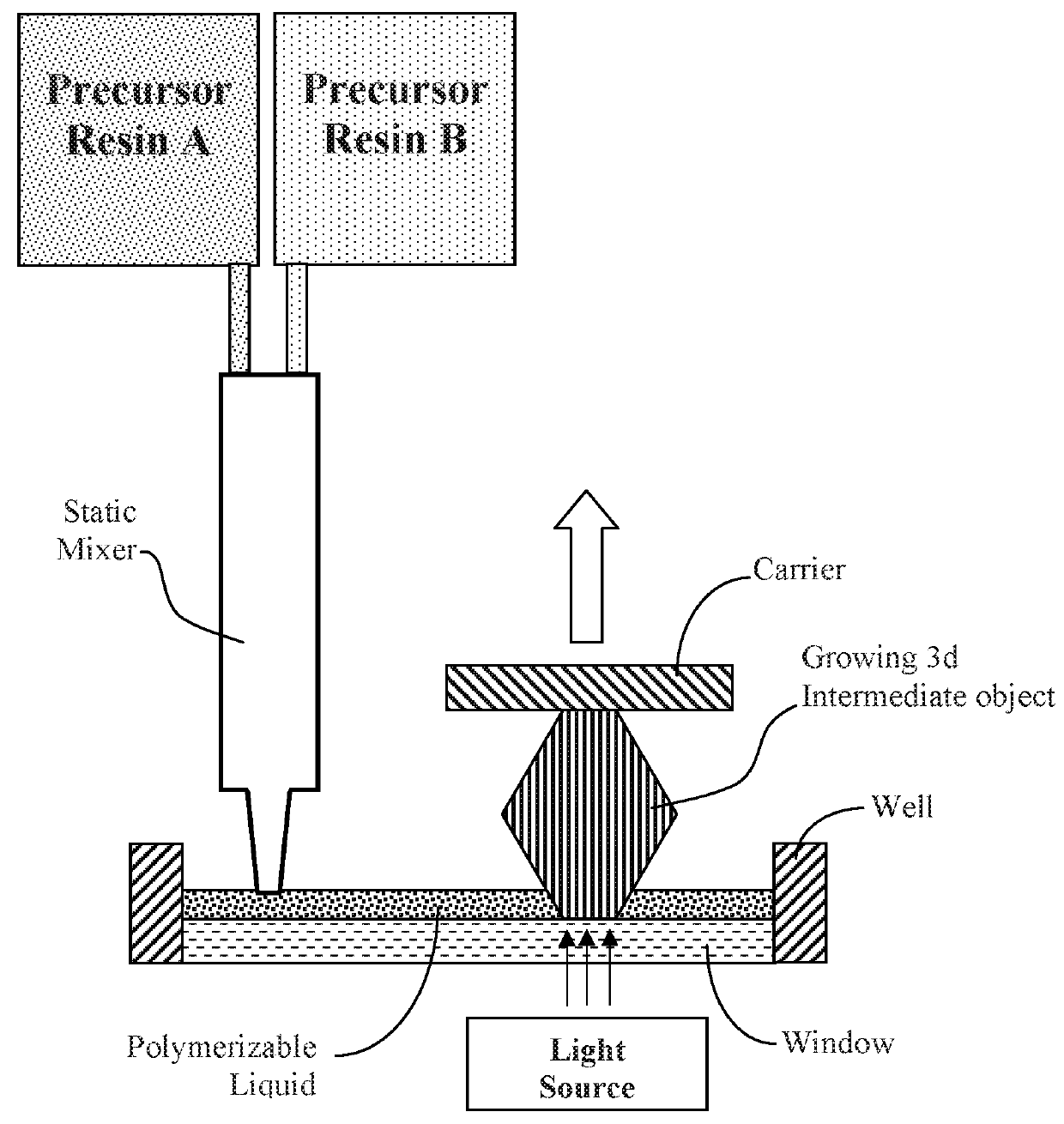

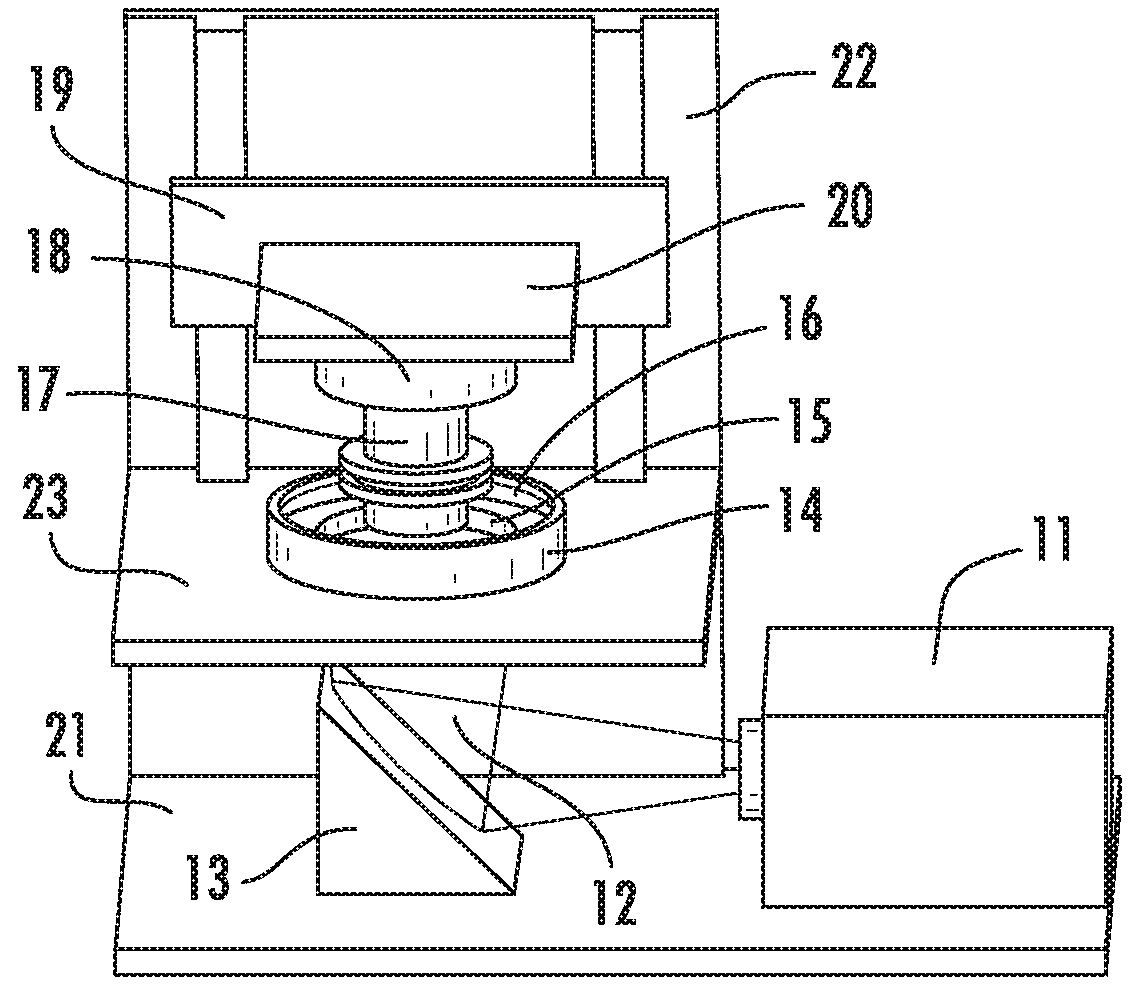

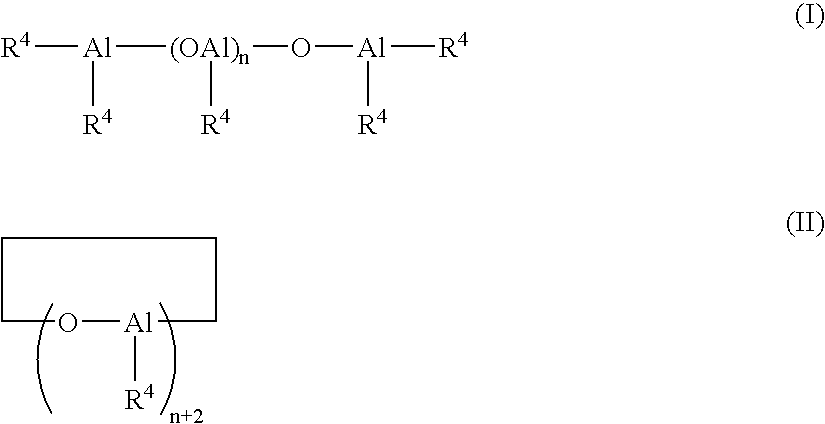

Dual precursor resin systems for additive manufacturing with dual cure resins

ActiveUS10350823B2Enhance or speed the refilling of the build regionIncreased formationAdditive manufacturing apparatusSolesDual curePolymer science

A method of forming a dual cure three-dimensional object by additive manufacturing may be carried out by mixing a first precursor liquid and a second precursor liquid to produce a polymerizable liquid comprising a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component (e.g., a second reactive component) that is different from the first component (e.g., that does not contain a cationic photoinitiator, or is further solidified by a different physical mechanism, or further reacted, polymerized or chain extended by a different chemical reaction). In the foregoing: (i′) at least one reactant of the second solidifiable component is contained in the first precursor liquid, and (ii′) at least one reactant or catalyst of the second solidifiable component is contained in the second precursor liquid. Once mixed, the three-dimensional object may be formed from the resin by a dual cure additive manufacturing process.

Owner:CARBON INC

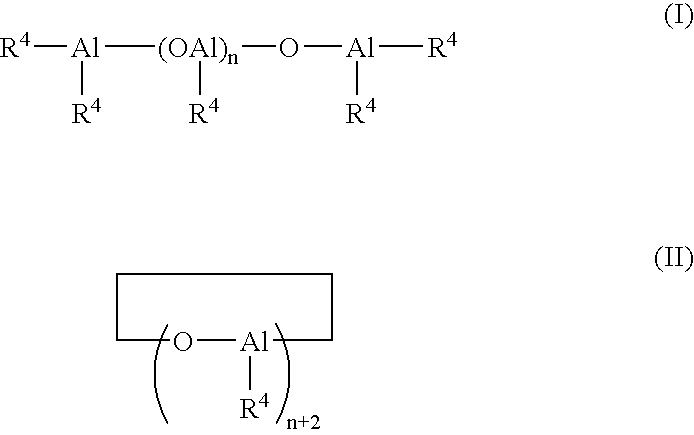

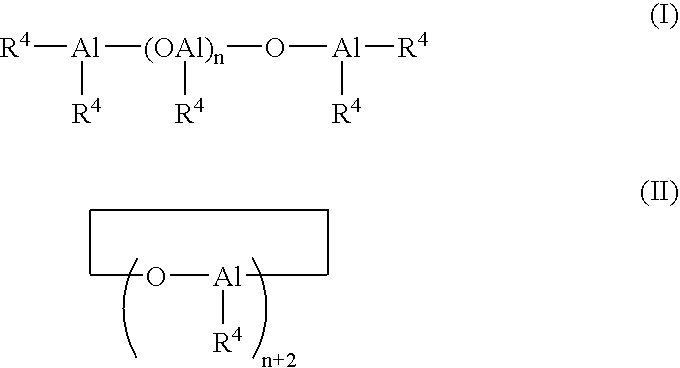

Solid golf ball

InactiveUS7344455B1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Glass-ceramic composition for recording disk substrate

InactiveUS6593257B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicOxide

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 15 wt % of ZrO2, wherein a value of ZrO2 / P2O5 is within a range from 1.1 to 8.5, expressed in terms of weight percent on the oxide basis.

Owner:HOYA CORP

Electronic device comprising a flexible display with edge protectors

ActiveUS20100246113A1Improve qualityQuality improvementDigital data processing detailsSubstation equipmentEngineeringDisplay device

The invention relates to an electronic device 60 comprising a flexible display arranged to be alternated between a collapsed state and an extended state, said flexible display comprising edge portions, the flexible display being further provided with an edge protector cooperating with the edge portions, wherein the edge protector is conceived to be alternated between a collapsed state and an extended state. In the electronic device 60a the flexible display 65 is conceived to be wound about a roller 61. The edge protector comprises rigid segments 63a, 63b, 63c, 62a, 62b, 62c, 62c interconnected by suitable means 64a, 64b, 64c. Wiring, pins, bars may be used for interconnecting means 64a, 64b, 64c. In the embodiment 60a an extended position of the edge protector is shown. In the embodiment 60b a collapsed state of the edge protector is shown comprising aggregations of segments 62′, 62″. The bars 64a, 64b, 64c partly protect the back surface of the display. The invention further relates to the electronic device comprising a flexible display wherein the flexible display is provided with an edge protector attached at least partially to the edge portions of the flexible display.

Owner:SAMSUNG ELECTRONICS CO LTD

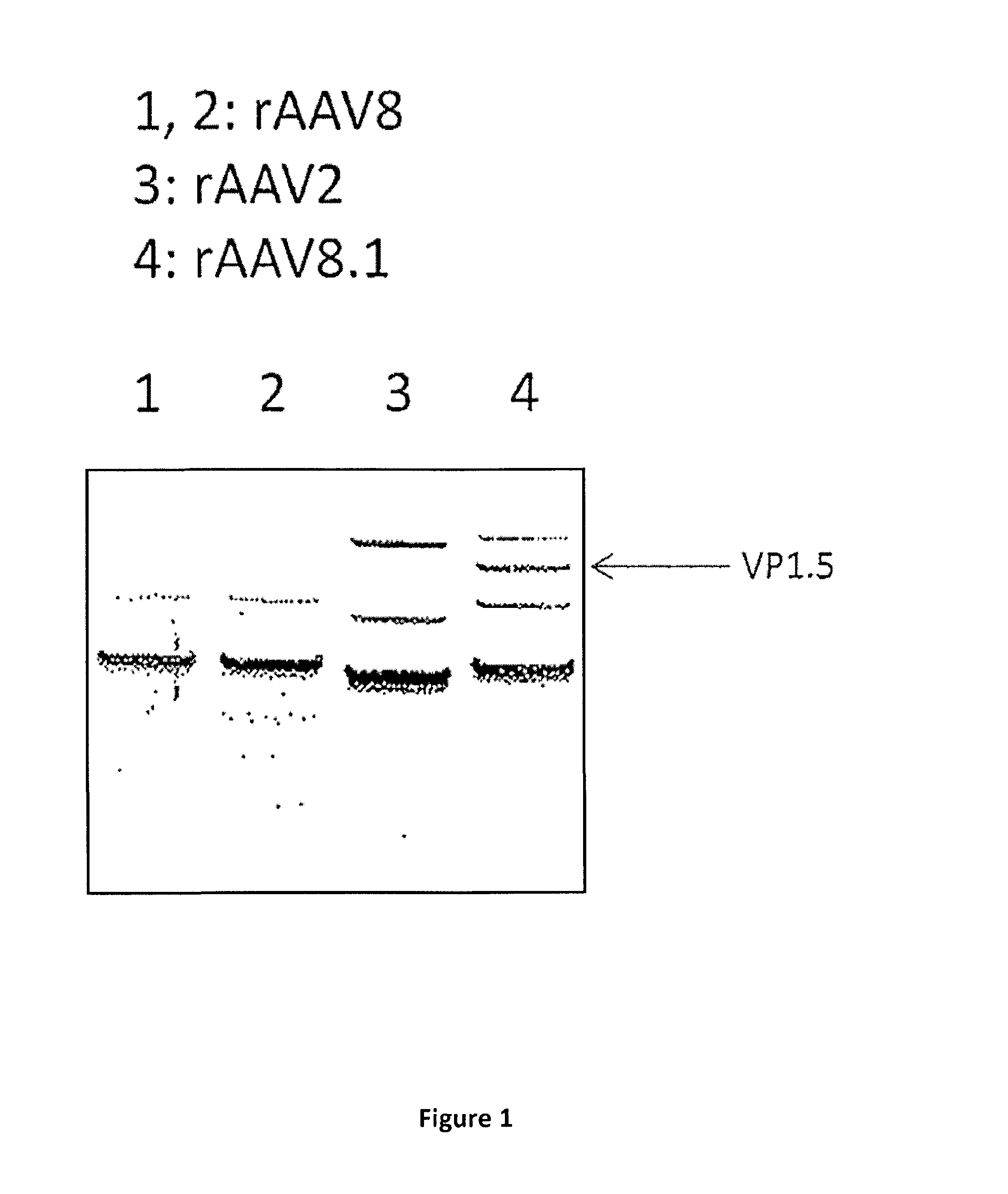

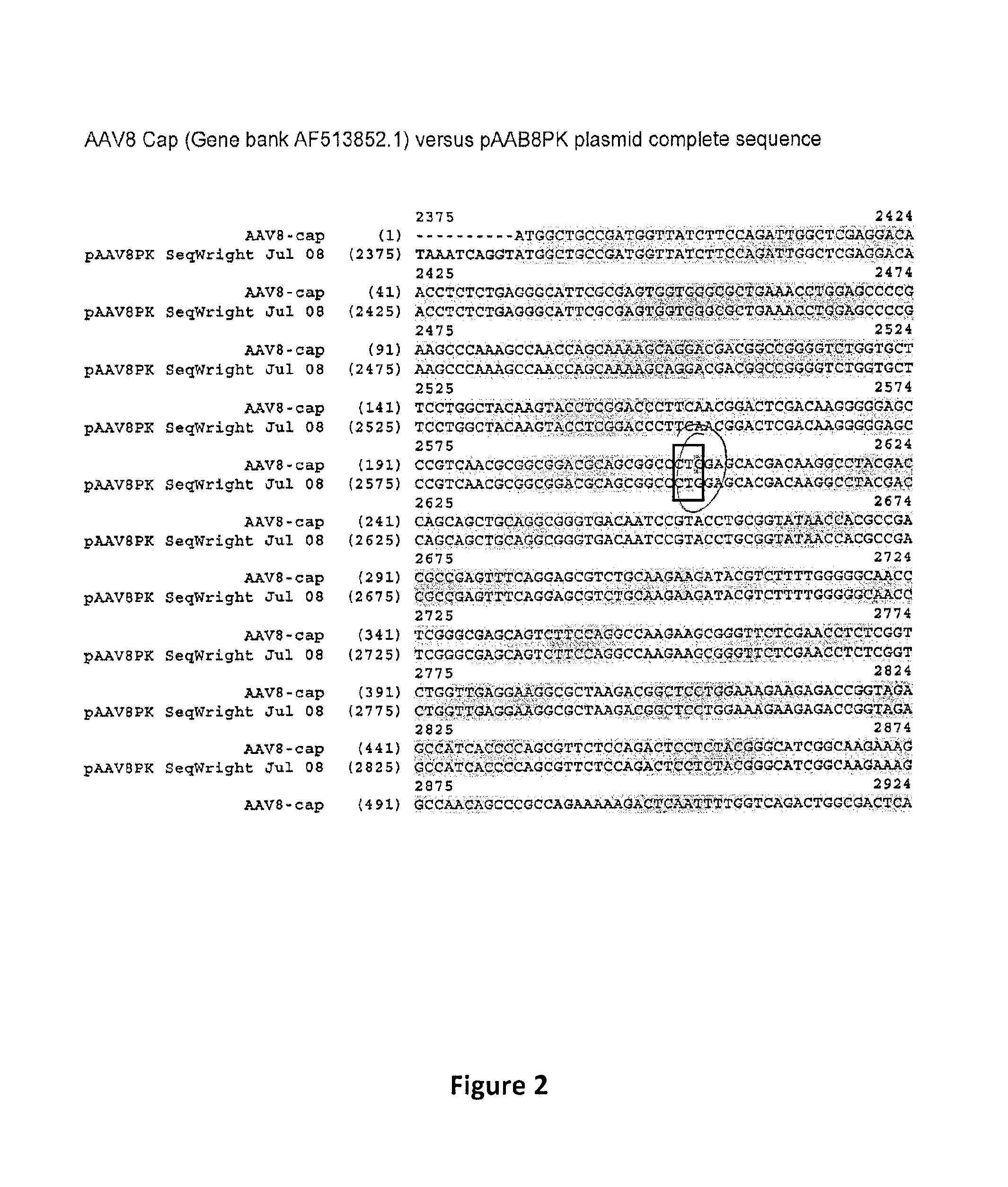

AAV8 Vector with Enhanced Functional Activity and Methods of Use Thereof

ActiveUS20140037585A1Reduced integrityReduce rigidityBiocidePeptide/protein ingredientsFunctional activityGene

Owner:THE CHILDRENS HOSPITAL OF PHILADELPHIA

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

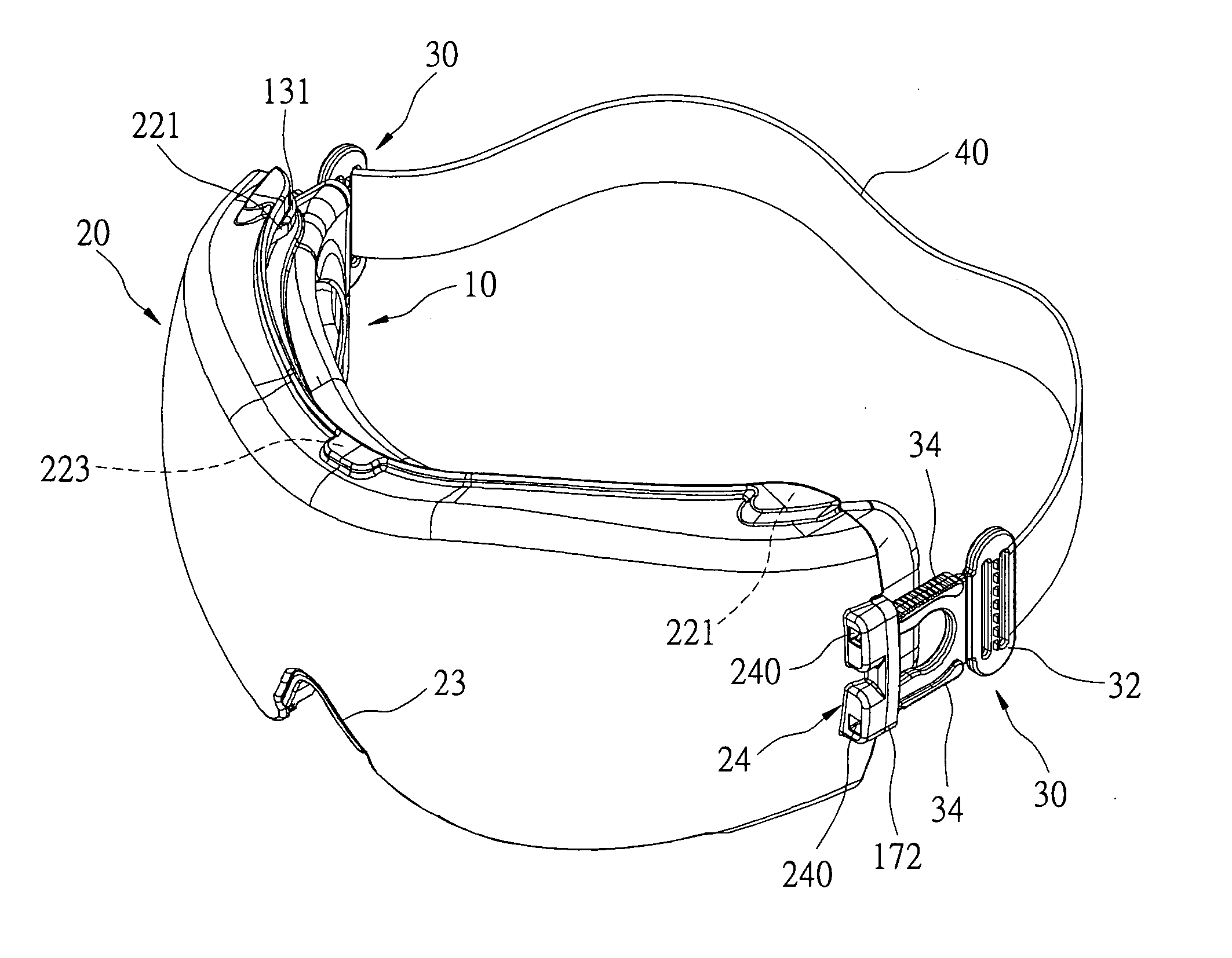

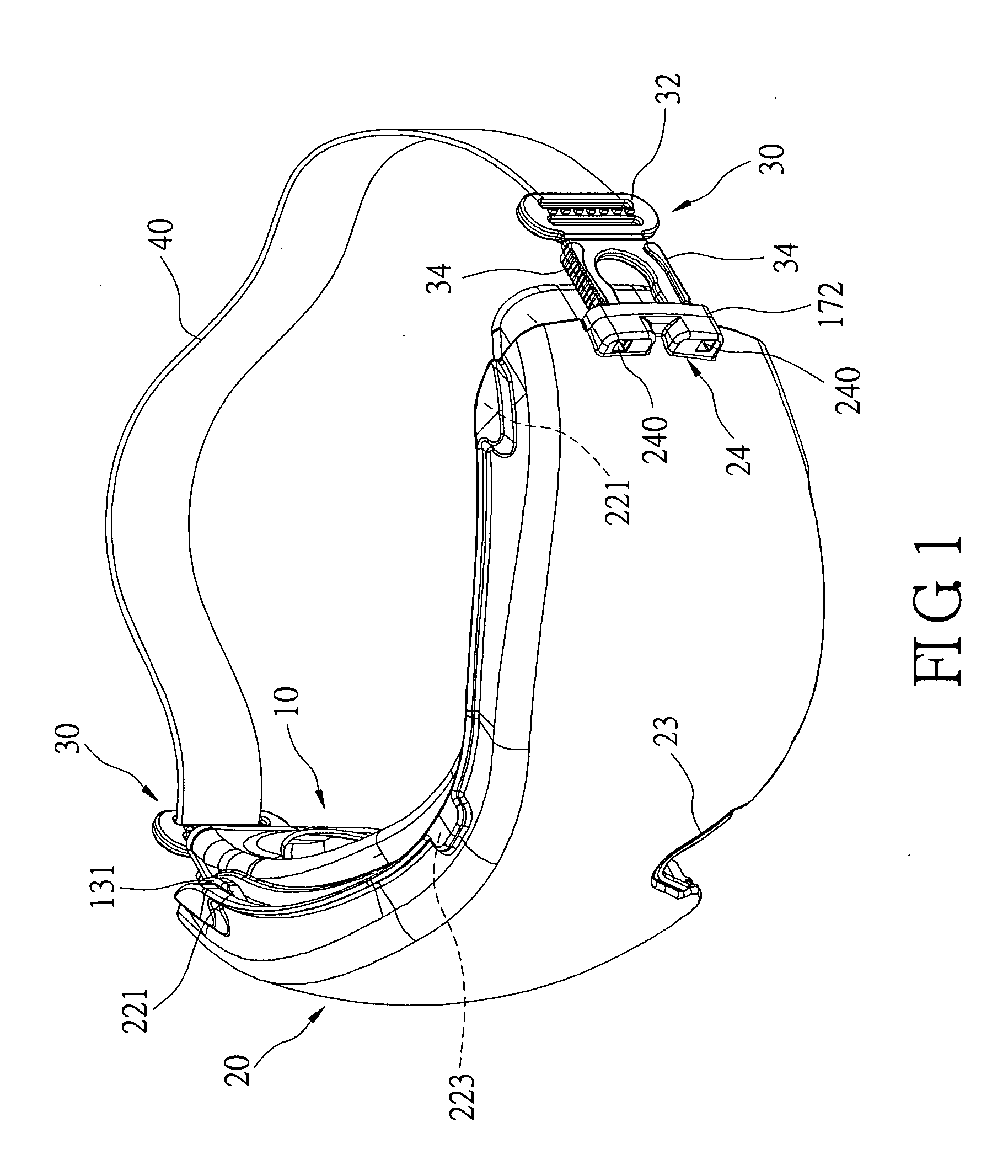

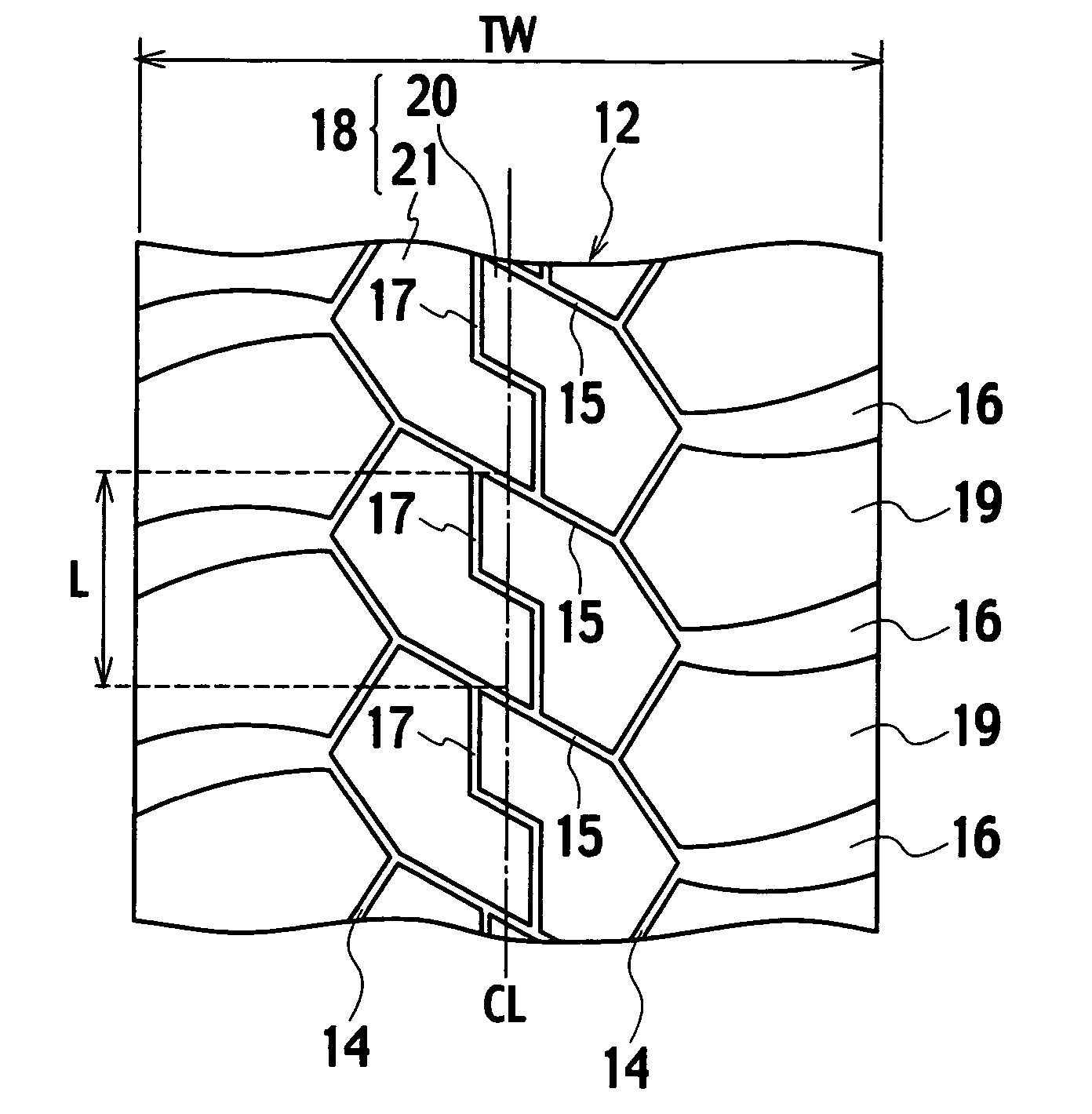

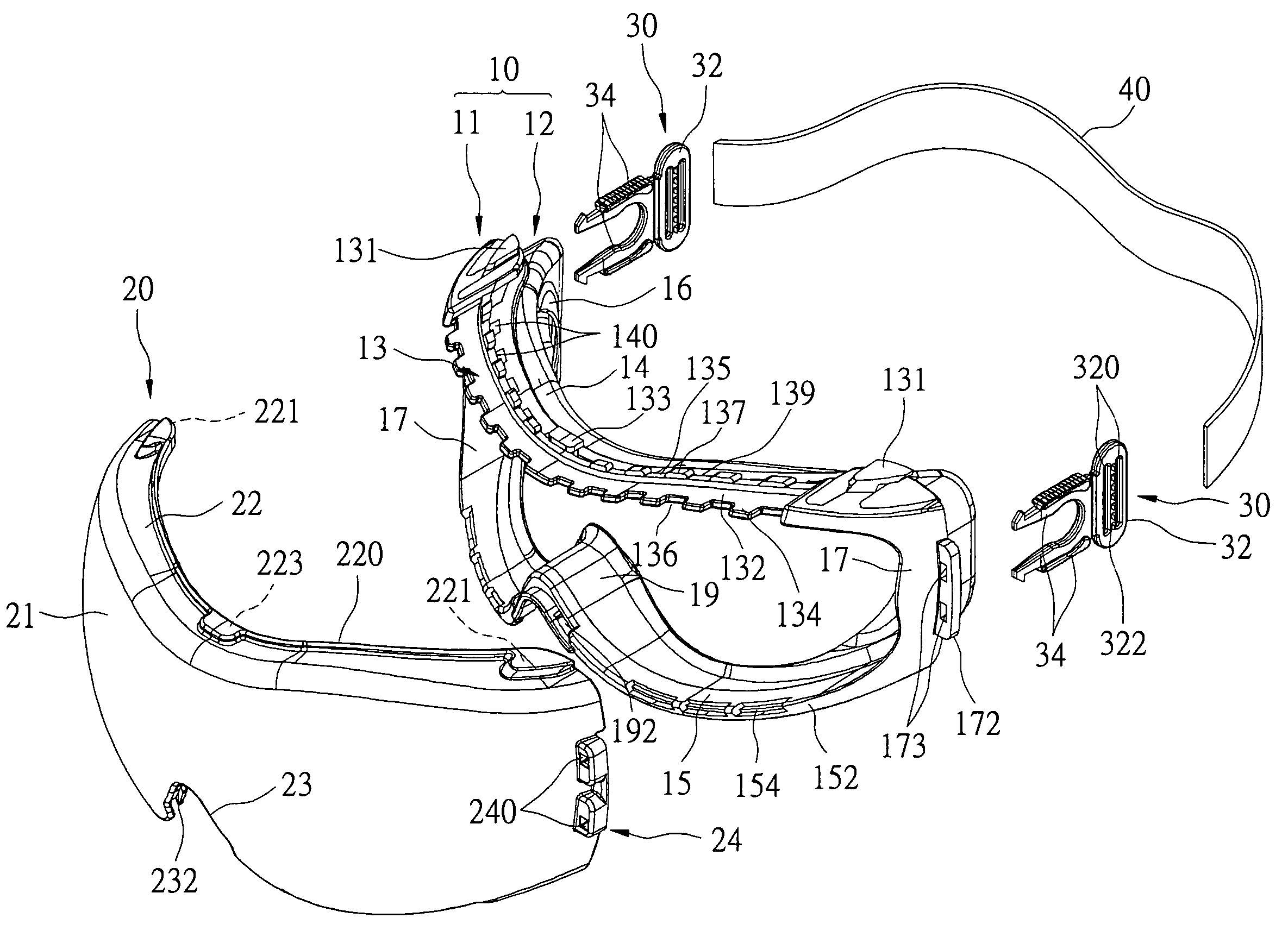

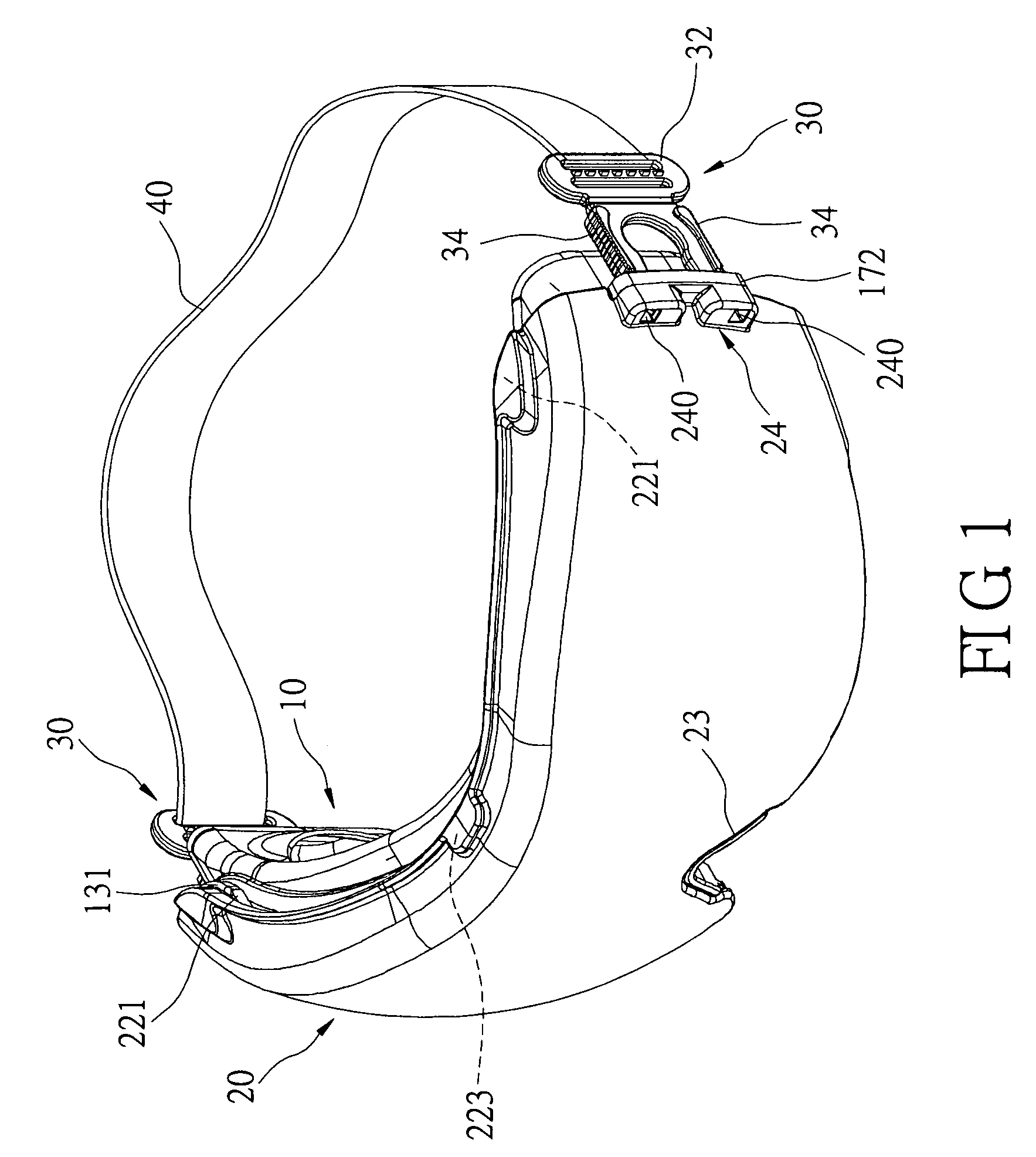

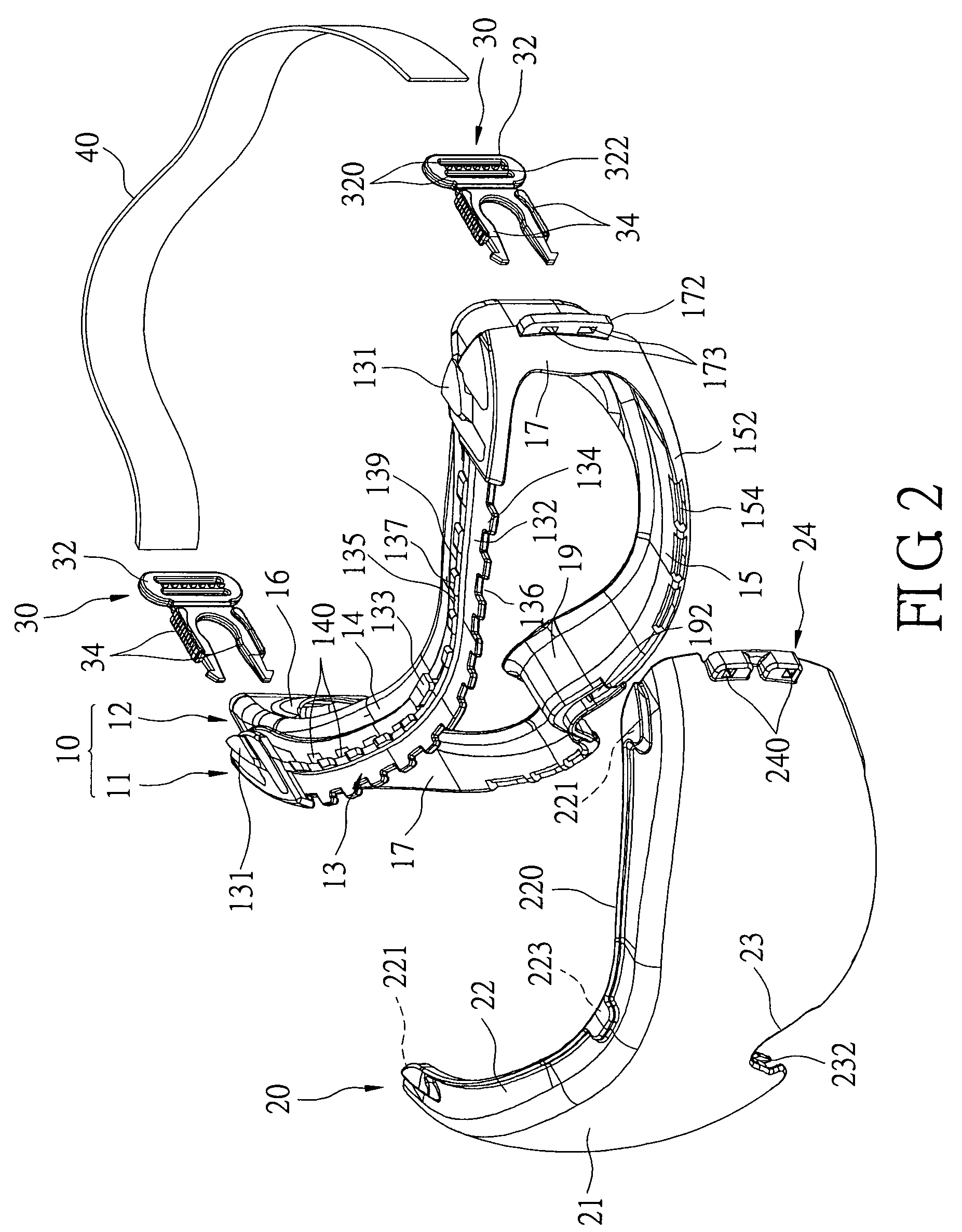

Goggles structure

Owner:JIURU

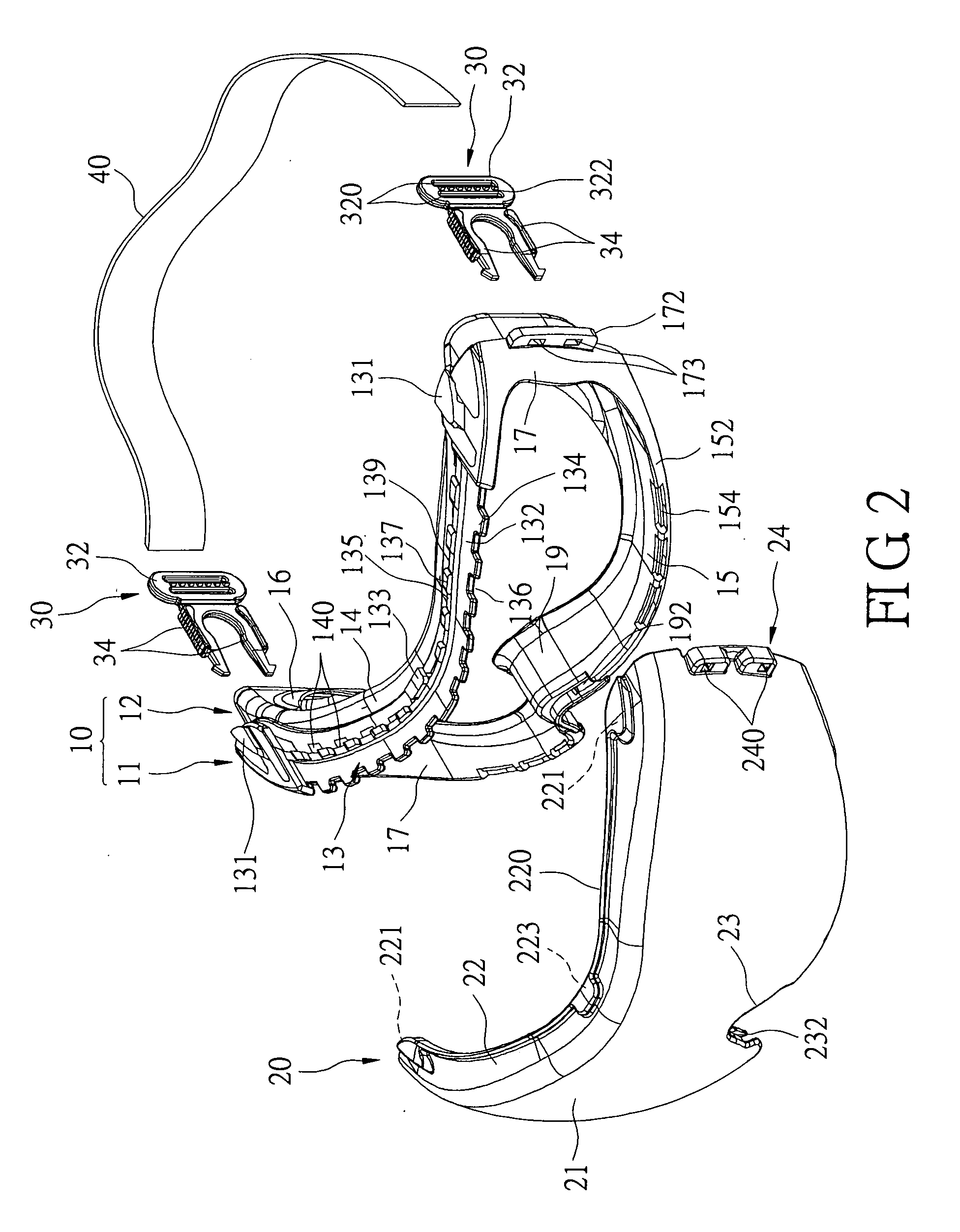

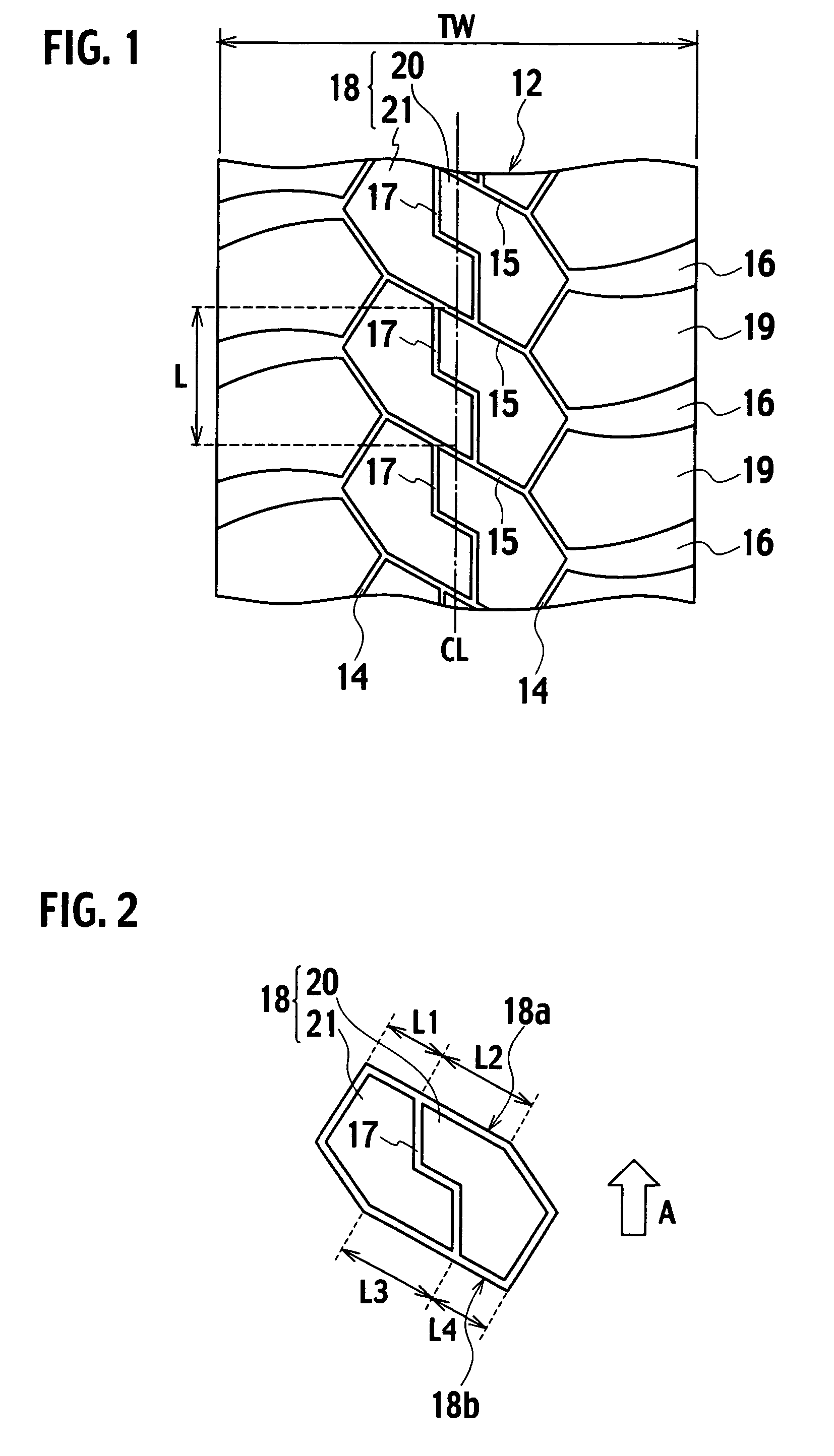

Pneumatic Tire

InactiveUS20070199633A1Reduce rigidityImprove cooling effectHeavy duty tyresTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire includes a column of center blocks (18) partitioned, on a tread center region, by circumferential thin grooves (14) formed along a tire circumferential direction and crosswise thin grooves (15) formed along a tire width direction, and columns of shoulder blocks (19) partitioned by the circumferential thin grooves (14) and main rag grooves (16) on shoulder portions. Each of the center blocks (18) includes one or more sub-thin grooves (17); each of which has a length of 100 to 180% of a circumferential length of the center block (18)

Owner:BRIDGESTONE CORP

Dual precursor resin systems for additive manufacturing with dual cure resins

ActiveUS20180264719A1Enhance or speed the refilling of the build regionIncreased formationAdditive manufacturing apparatusSolesDual curePolymer science

A method of forming a dual cure three-dimensional object by additive manufacturing may be carried out by mixing a first precursor liquid and a second precursor liquid to produce a polymerizable liquid comprising a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component (e.g., a second reactive component) that is different from the first component (e.g., that does not contain a cationic photoinitiator, or is further solidified by a different physical mechanism, or further reacted, polymerized or chain extended by a different chemical reaction). In the foregoing: (i′) at least one reactant of the second solidifiable component is contained in the first precursor liquid, and (ii′) at least one reactant or catalyst of the second solidifiable component is contained in the second precursor liquid. Once mixed, the three-dimensional object may be formed from the resin by a dual cure additive manufacturing process.

Owner:CARBON INC

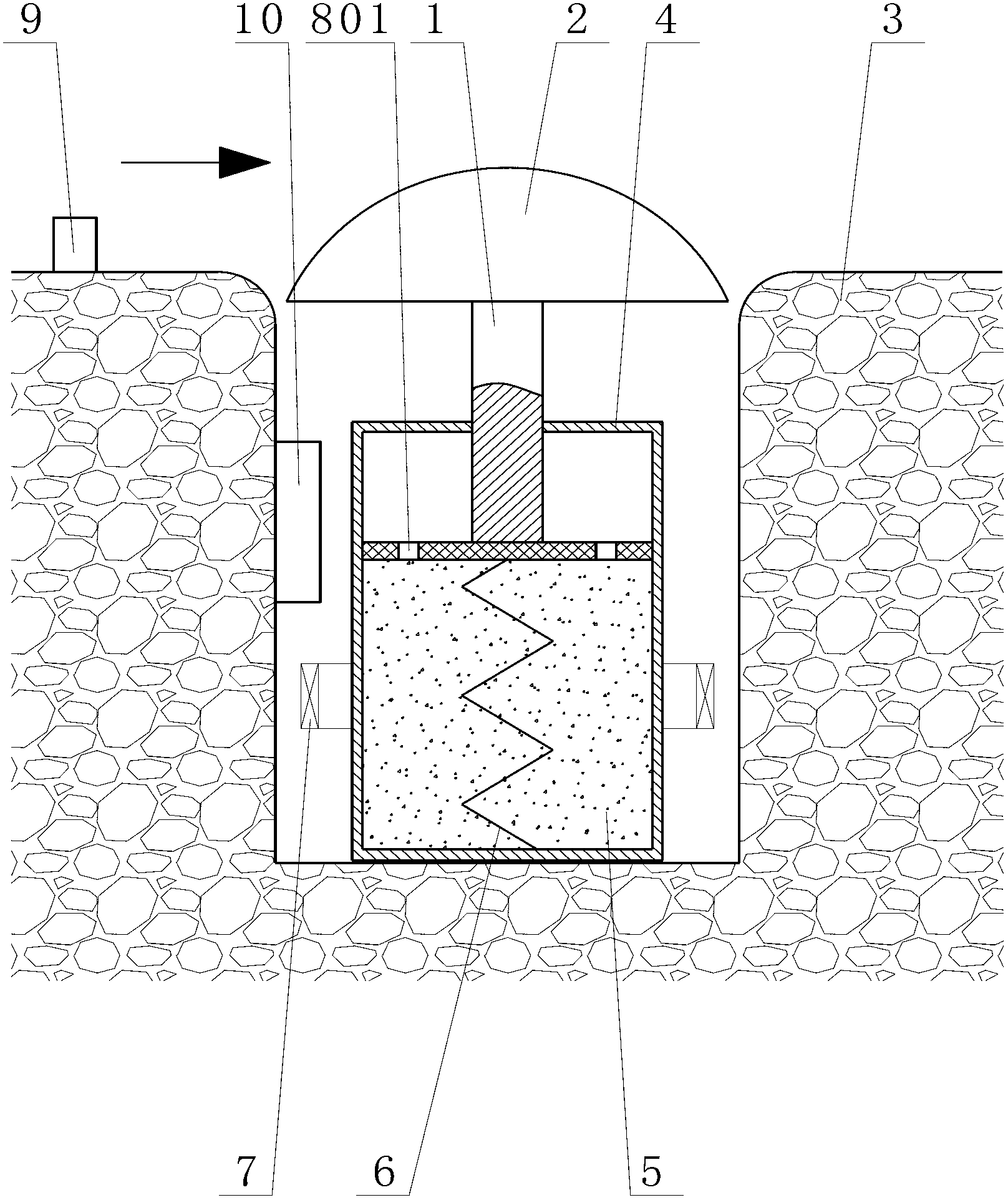

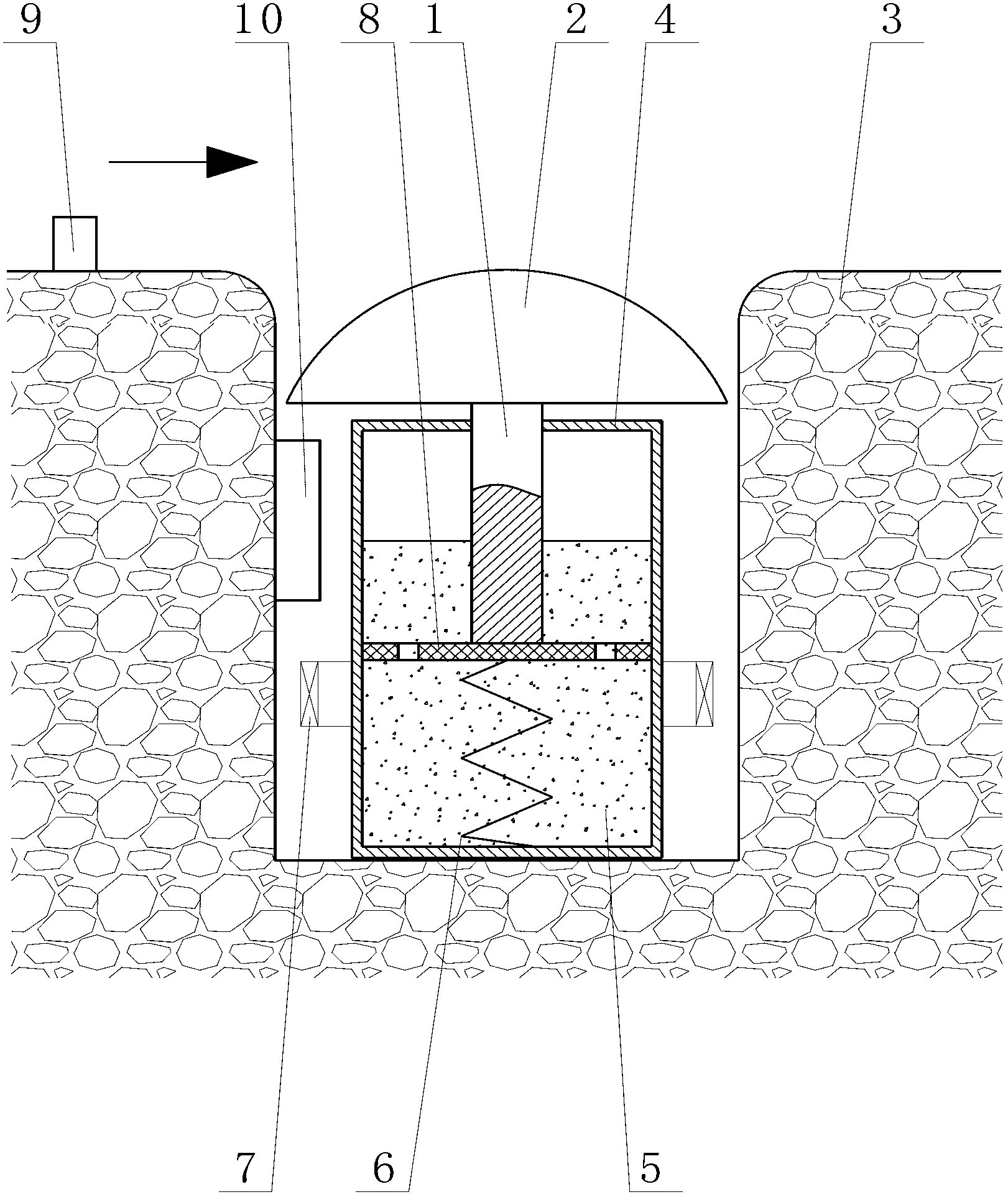

Magnetorheological fluid speed bump

InactiveCN103061287AGood liquidityGuaranteed smoothnessTraffic signalsRoad signsSpeed bumpPiston cylinder

Disclosed is a magnetorheological fluid speed bump. At least one rectangular channel is arranged in a direction perpendicular to the lane length direction on the entry side of a lane speed zone. A piston cylinder is disposed in each channel; a piston in the piston cylinder is provided with through holes; a spring is elastically compressed between the bottom wall of a cylinder block and the piston; the cylinder block is full of magnetorheological fluid below the piston; a solenoid coil is disposed around the magnetorheological fluid in a cavity of the channel; a piston rod at the top of the piston upwardly penetrates through the top of the cylinder block of the piston cylinder, and a speed bump is fixed at the top of the penetrating end; the speed bump covers an opening of the channel; the speed bump can horizontally move up and down in the channel. A speedometer is installed on the lane on the entry side of the speed bump and is in signal connection with an electric control unit. The rigidity of the speed bump is flexibly variable, rigid contact and stress between the speed bump and vehicles can be reduced within an allowable speed range, the vehicles and the speed bump are protected effectively, driving comfort is improved, and the speed of the vehicle exceeding the allowable speed range can be limited effectively.

Owner:SHANGHAI UNIV OF ENG SCI

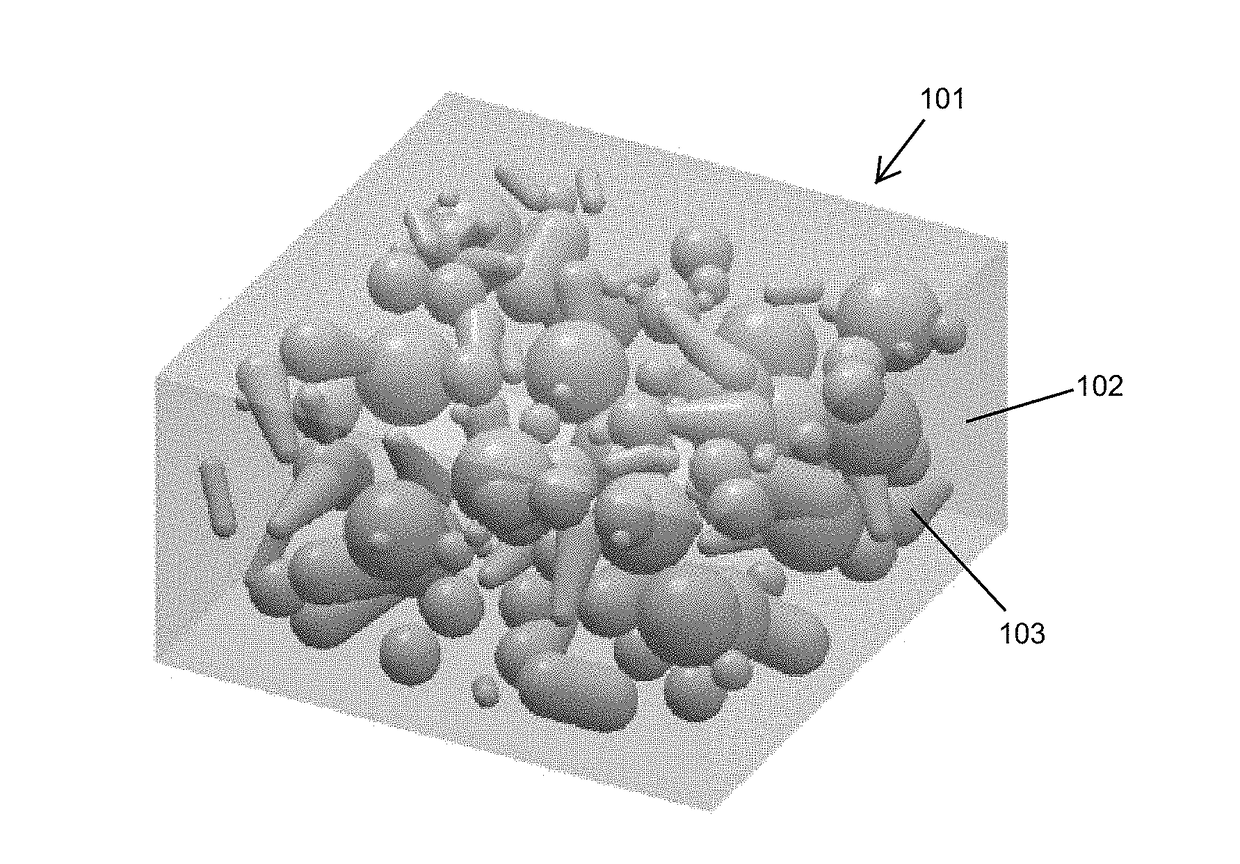

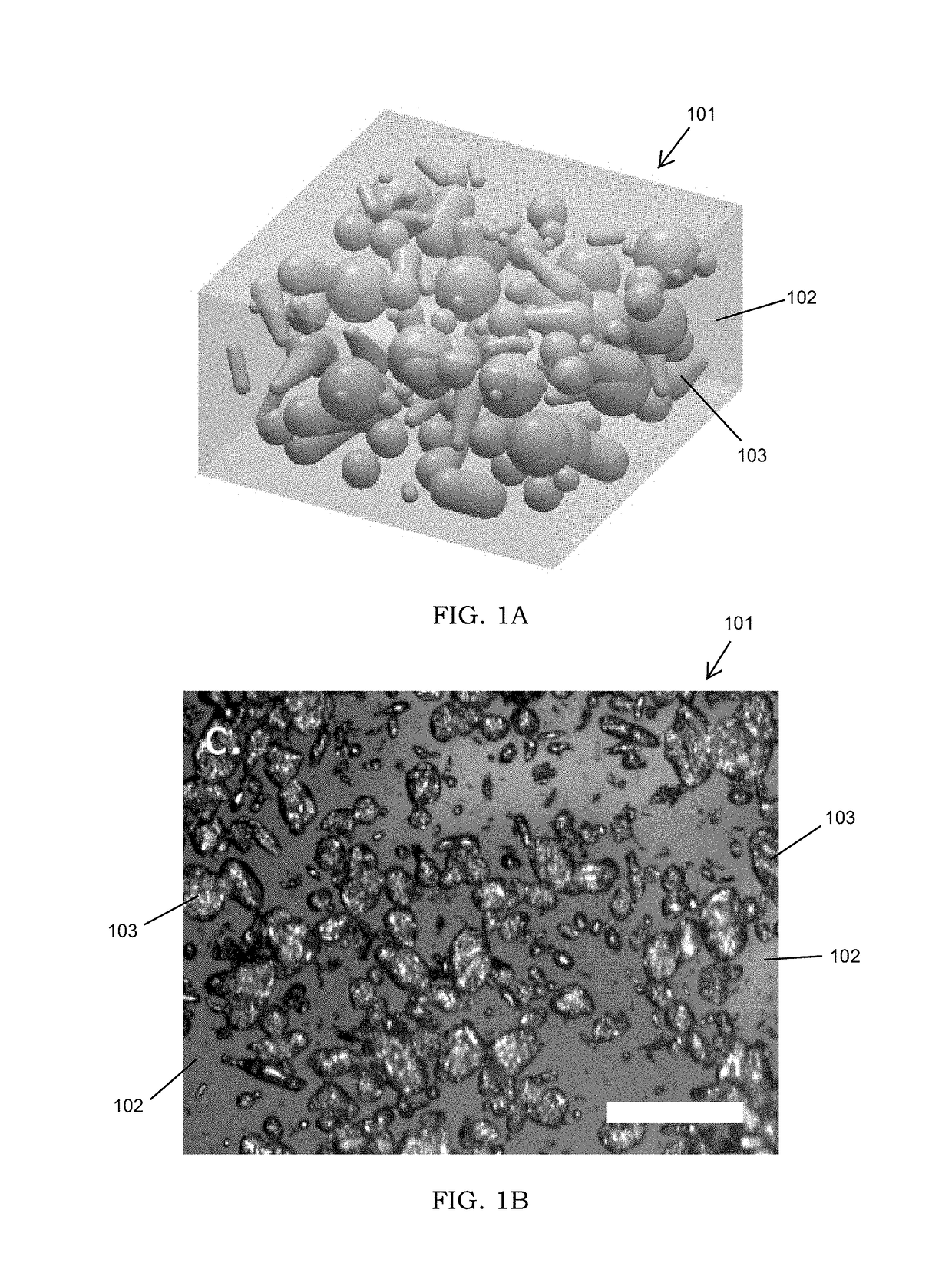

Polymer Composite with Liquid Phase Metal Inclusions

ActiveUS20170218167A1Improve electricityImprove thermal propertiesCircuit bendability/stretchabilityPrinted circuit aspectsElastomerLiquid state

Disclosed herein is a composite comprising an elastomer with an embedded network of liquid metal inclusions. The composite retains similar flexibility to that of an elastomer but exhibits electrical and thermal properties that differ from the properties of a homogeneous elastomer. The composite has applications for wearable devices and other soft matter electronics, among others.

Owner:CARNEGIE MELLON UNIV

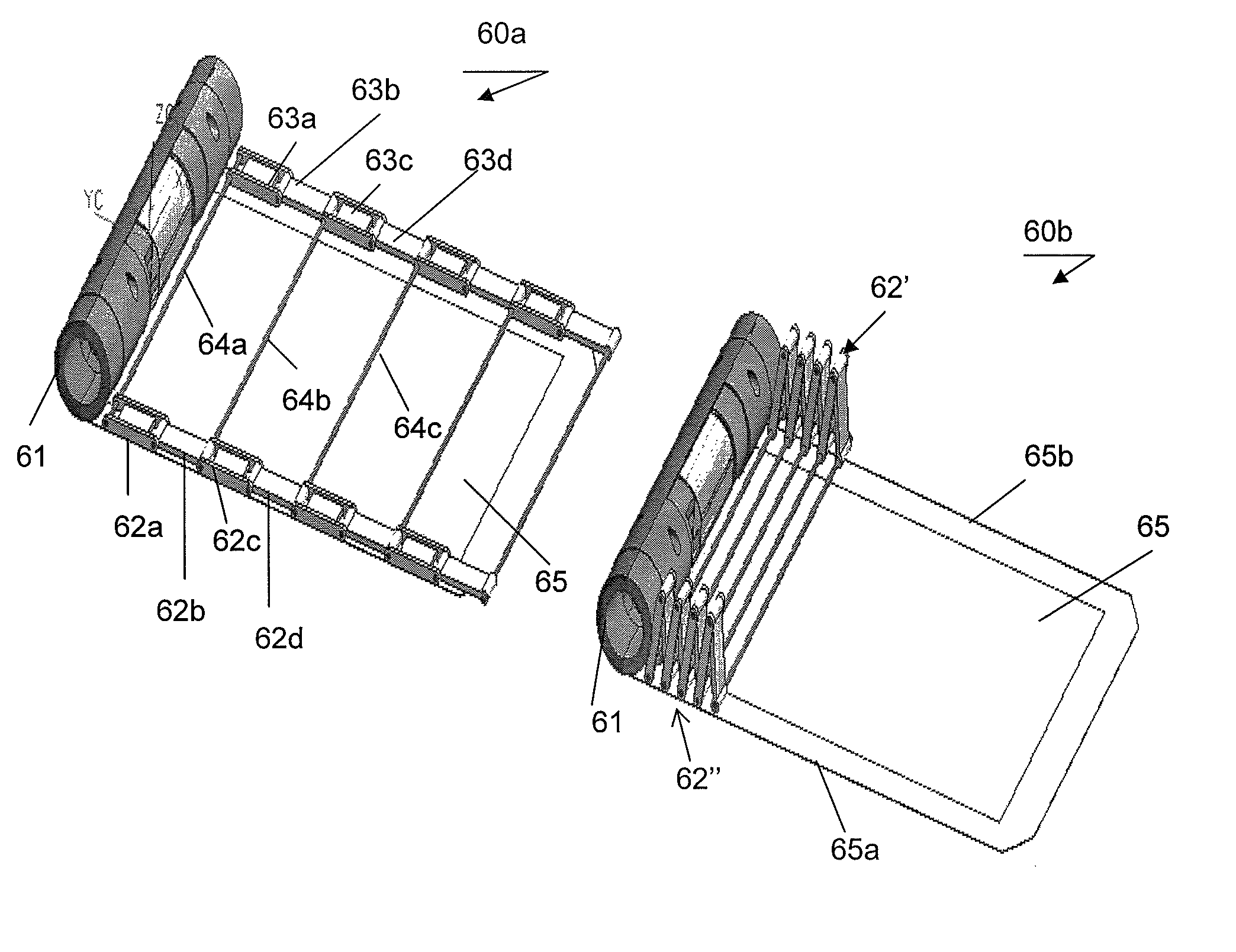

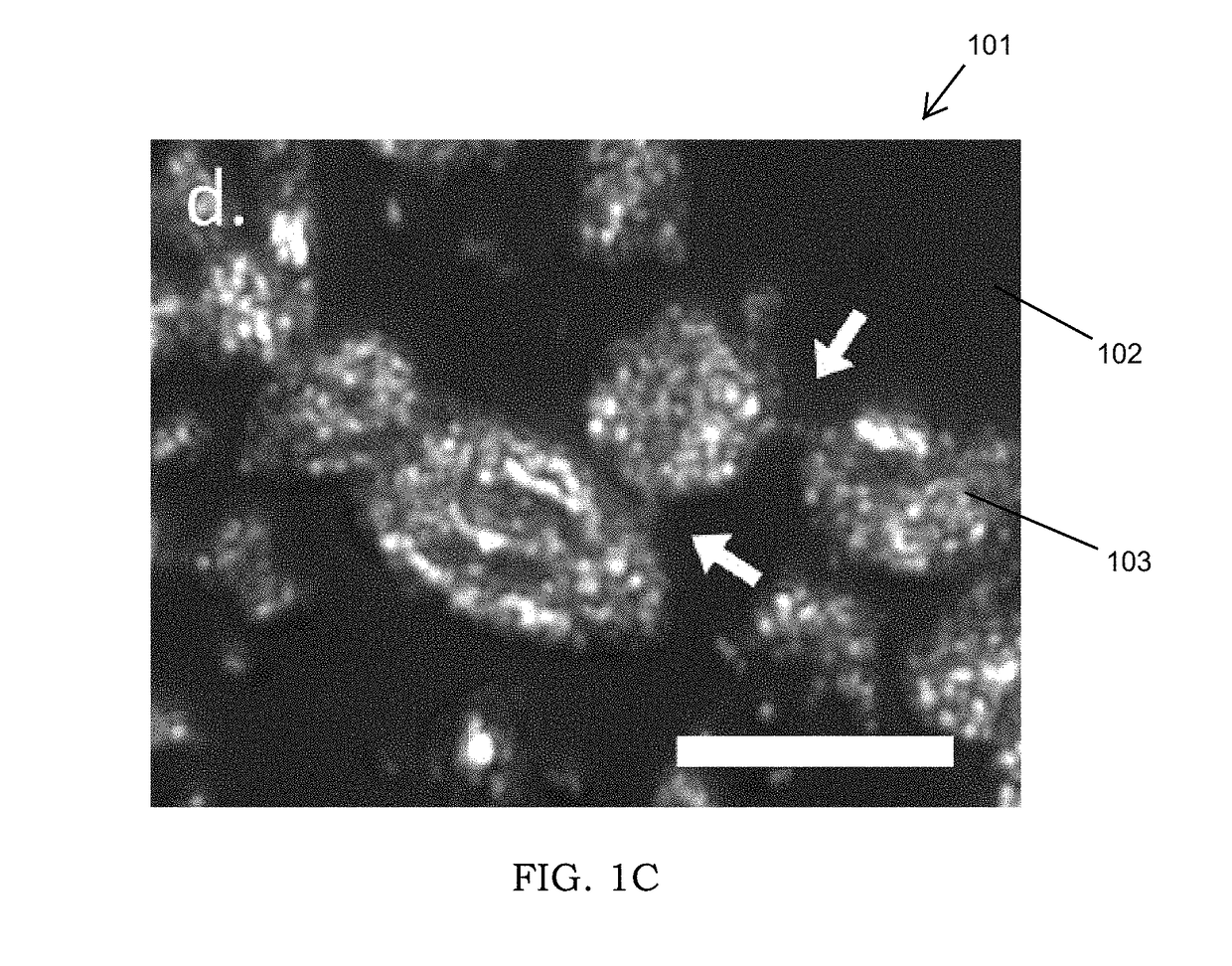

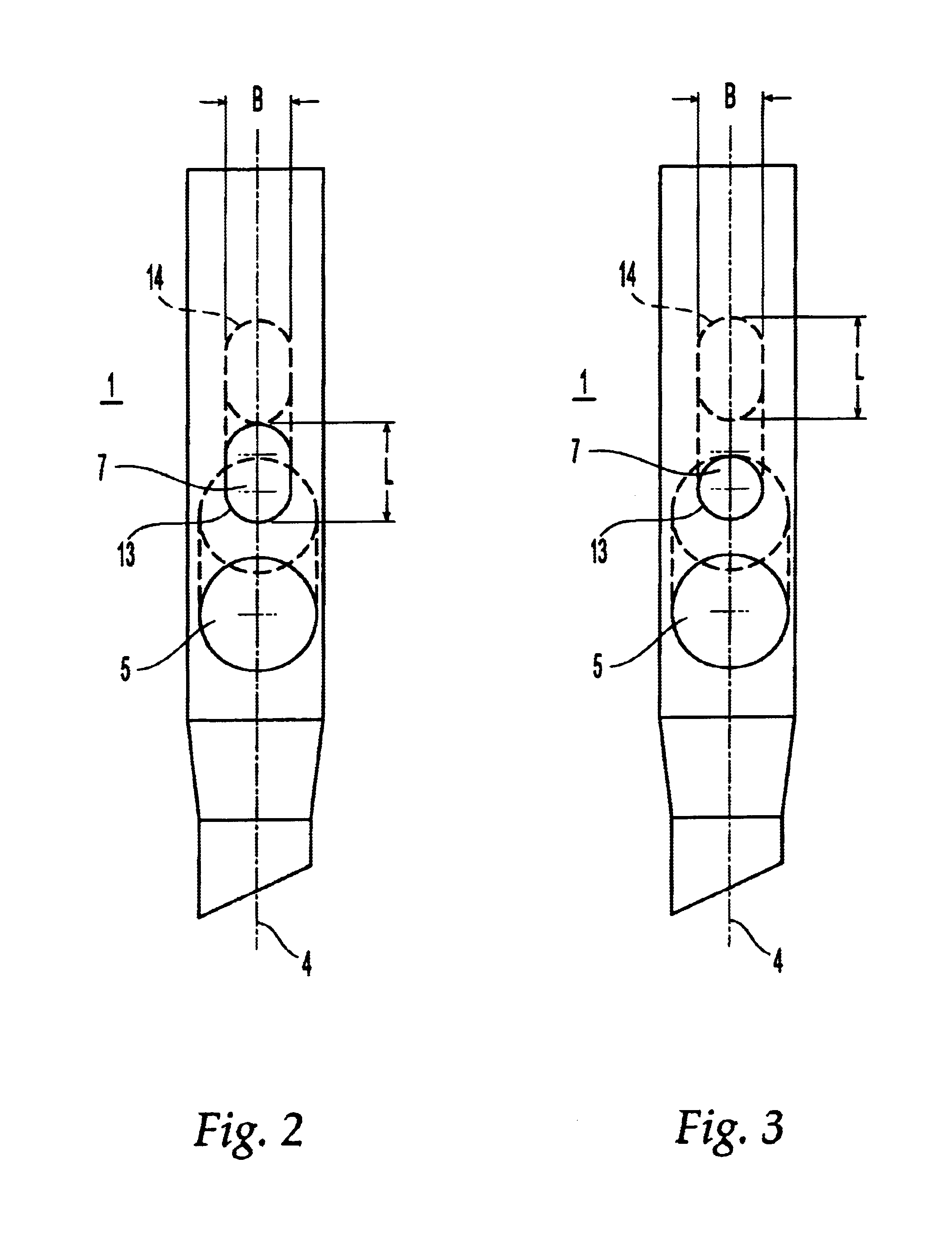

Intramedullary nail

InactiveUS6855146B2Eliminates angular rigidityPrevent rotationInternal osteosythesisJoint implantsRight femoral headIntramedullary rod

The invention relates to an intramedullary nail used for treating fractures of the femur. It comprises a distal end, which is appointed for insertion into the marrow cavity channel, a proximal end, and a longitudinal axis. A first bore is located adjacent the proximal end and extends through the proximal end and transversely intersects the longitudinal axis, and serves to accommodate a femoral head screw. The center axis of the first bore forms an angle with the longitudinal axis that ranges from 110° to 150°. A second bore is located between the first bore and the proximal end and extends through the proximal end and transversely intersects the longitudinal axis, and serves to accommodate a hip pin. The second bore is at least partially shaped as an oblong hole or slot with a width B and a length L>B, and the length L of the oblong hole extends in the direction of the longitudinal axis.

Owner:SYNTHES USA

Solid golf ball

InactiveUS20080194358A1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Walking control apparatus of robot and method of controlling the same

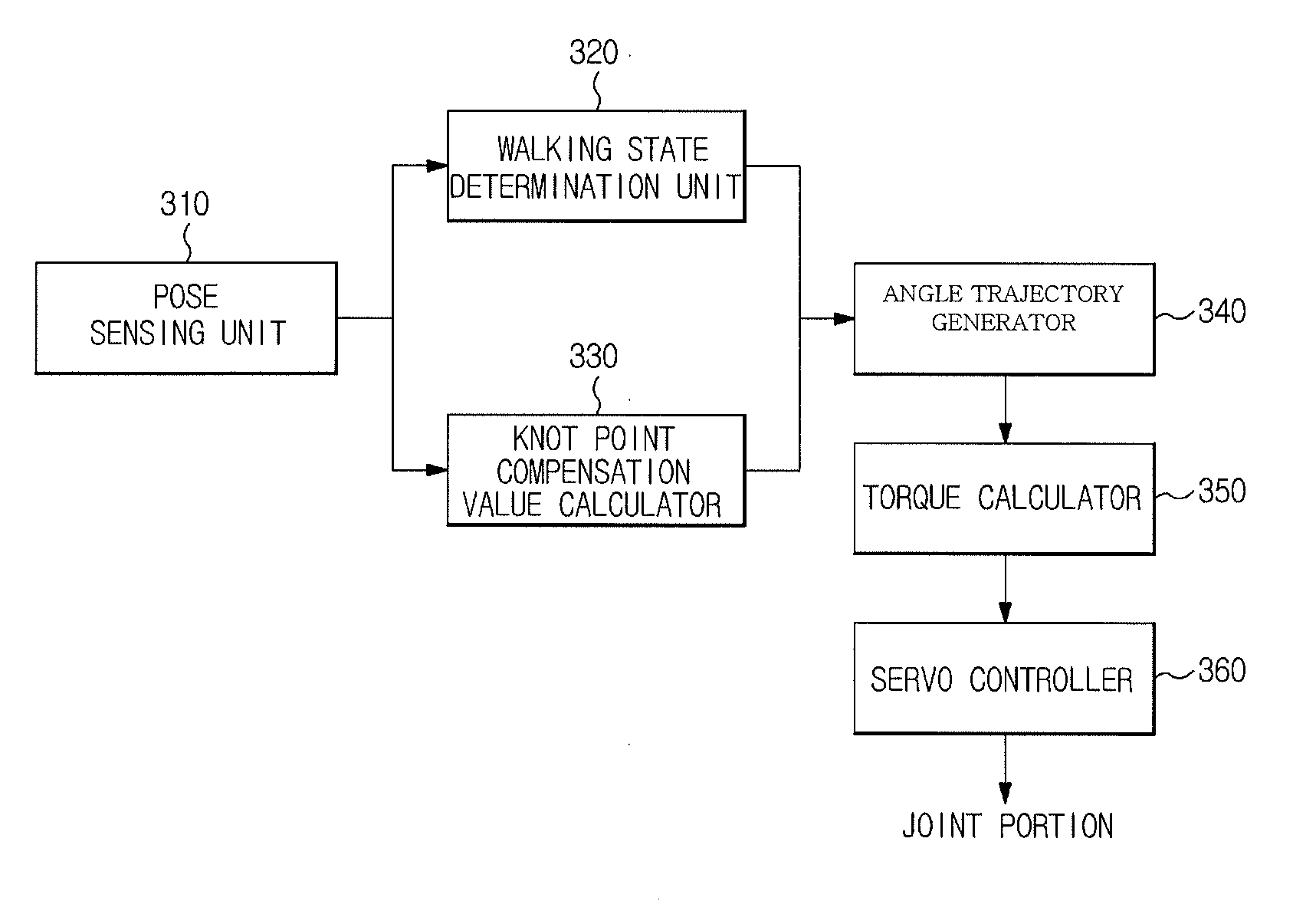

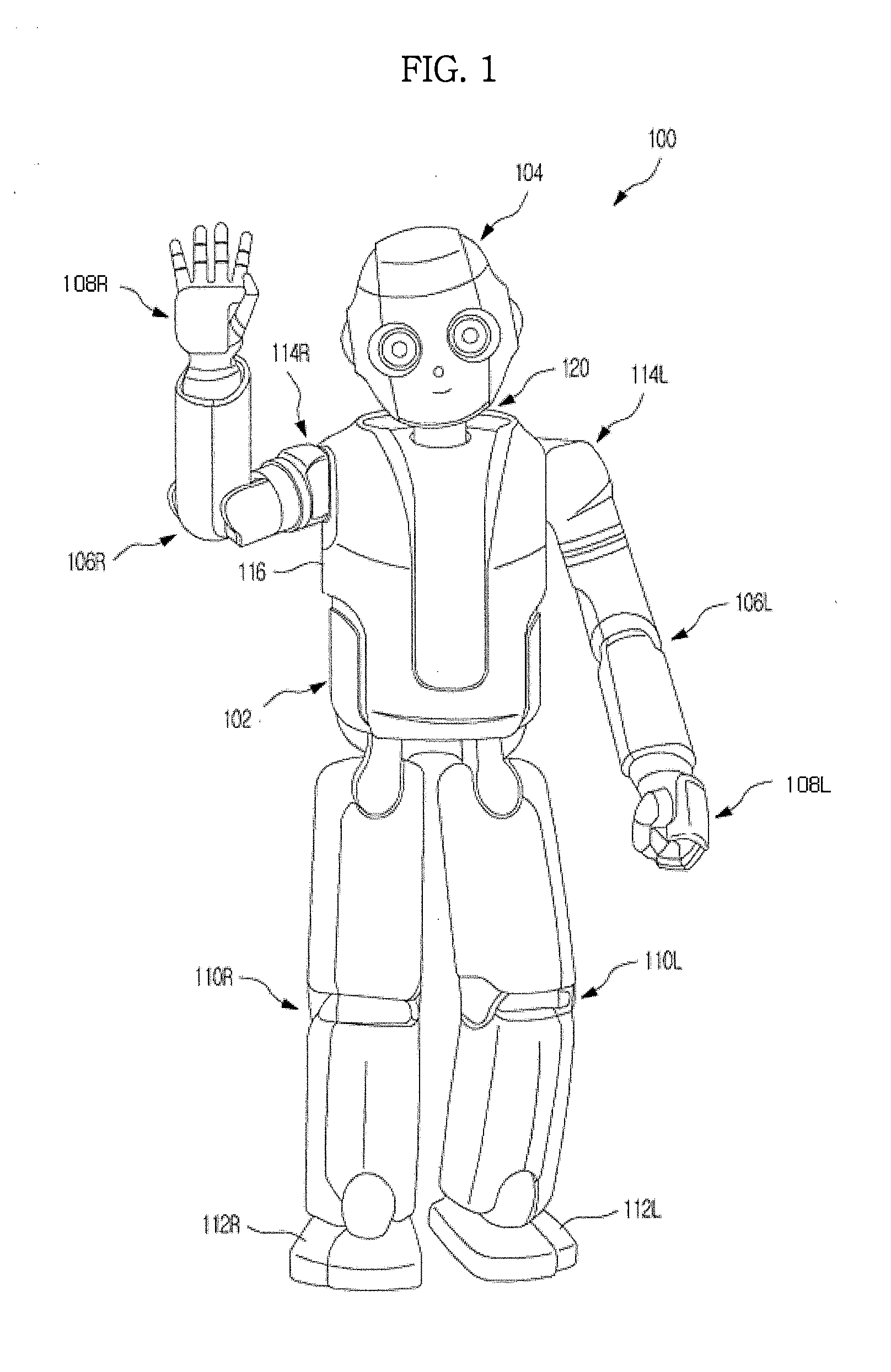

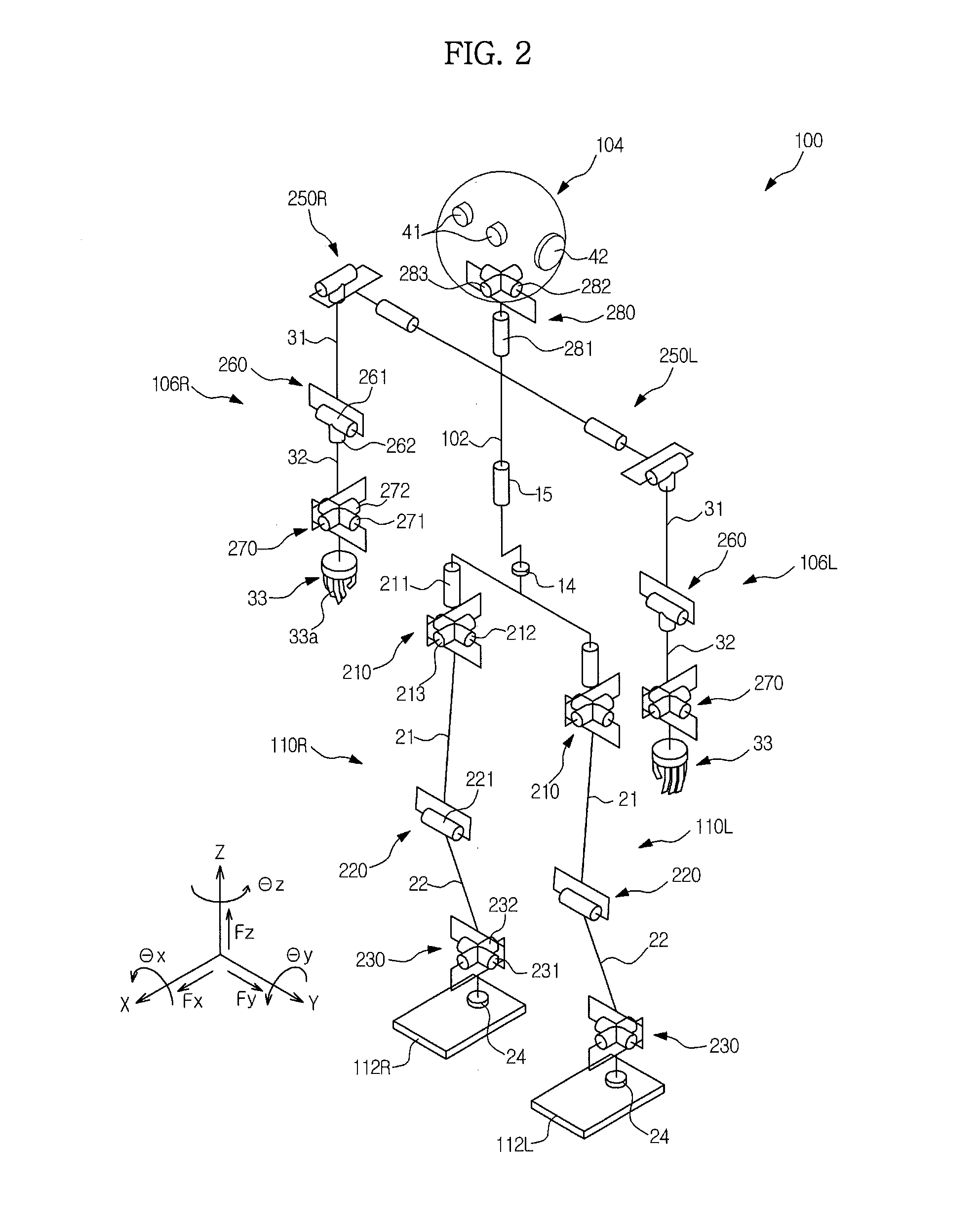

ActiveUS20110178637A1Maintain balanceWalking smoothlyProgramme-controlled manipulatorComputer controlControl theoryIntermediate point

A walking control apparatus of a robot includes a joint portion provided in each of a plurality of legs of the robot, a pose sensing unit to sense the pose of the robot, a walking state determination unit to determine a walking state from the pose of the robot, a knot point compensation value calculator to determine a Center Of Mass (COM) of the robot from the pose of the robot and to calculate a knot point compensation value, a desired angle trajectory generator to generate a reference knot point of the joint portion corresponding to the walking state, to compensate for the reference knot point using the knot point compensation value so as to generate a desired knot point, and to generate a desired angle trajectory of the joint portion using the desired knot point. The knot point which is the angle command of the joint portion of each of the legs to perform the next step is compensated for based on the COM, and the compensated desired knot point is smoothly connected using the spline curve such that the robot walks similar to a human. In addition, in order to maintain balance while walking, the angle of the joint portion of the intermediate point of the current step is fed back and the knot point of the next step is predicted and adjusted, such that the robot stably and smoothly walks.

Owner:SAMSUNG ELECTRONICS CO LTD

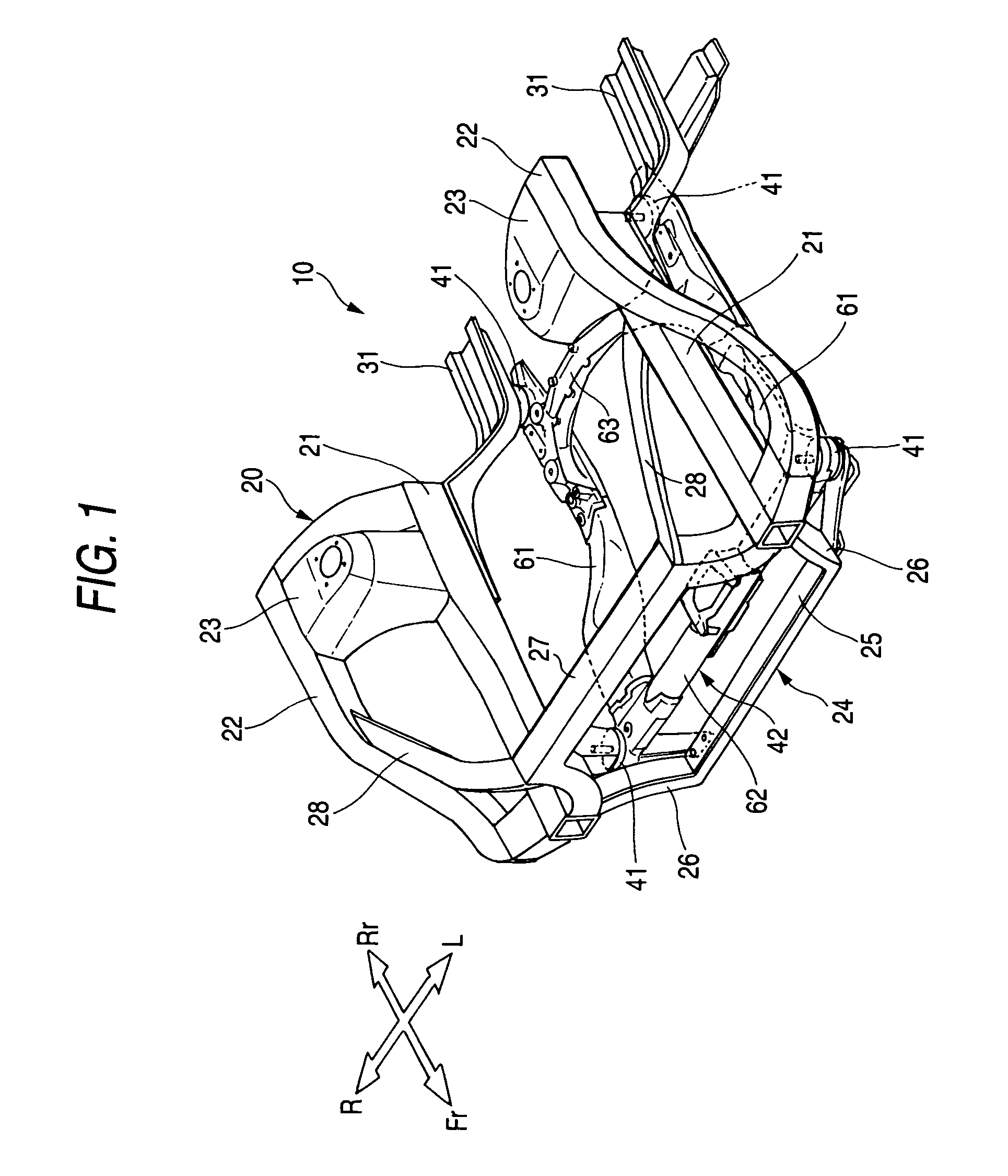

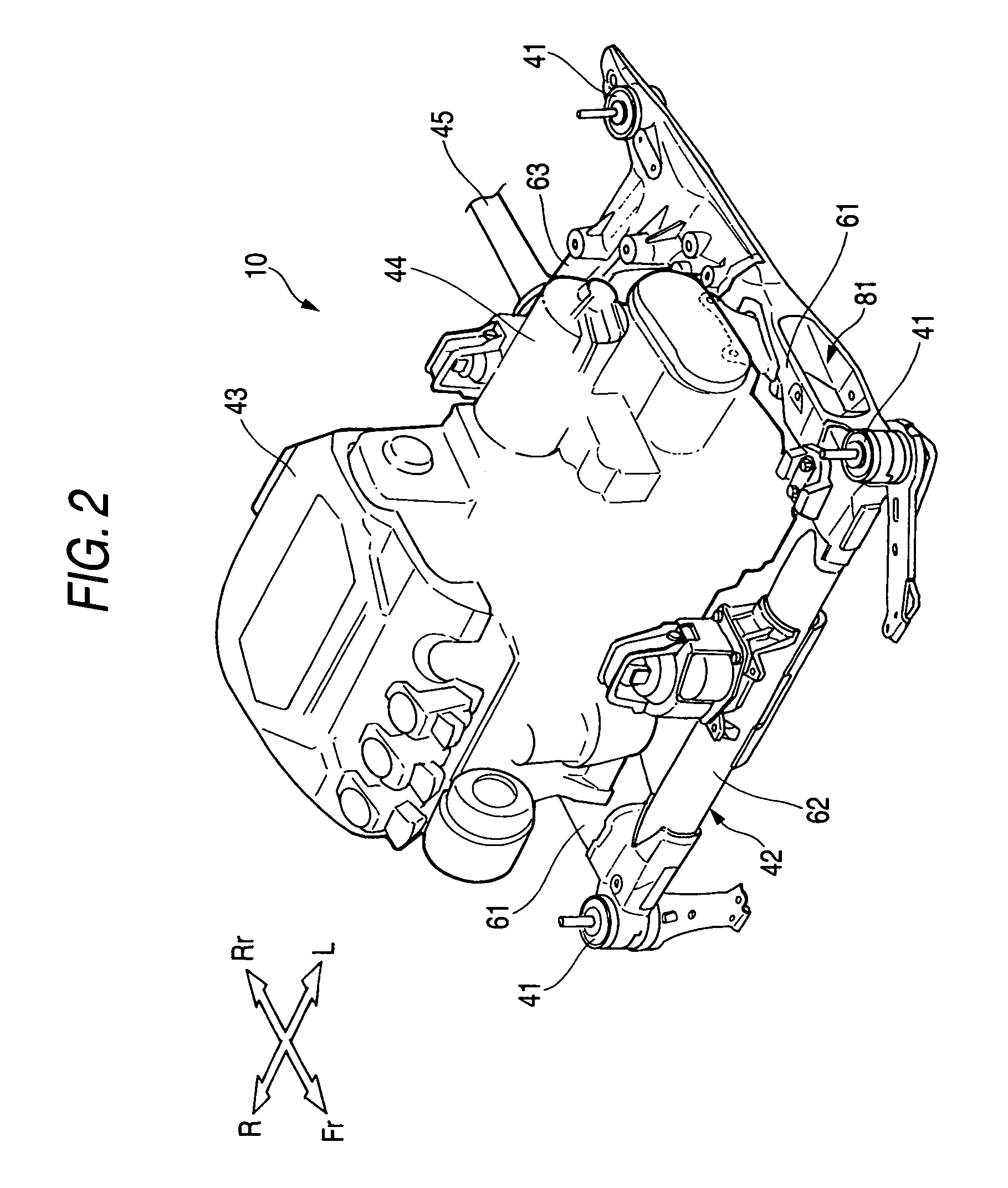

Body frame structure

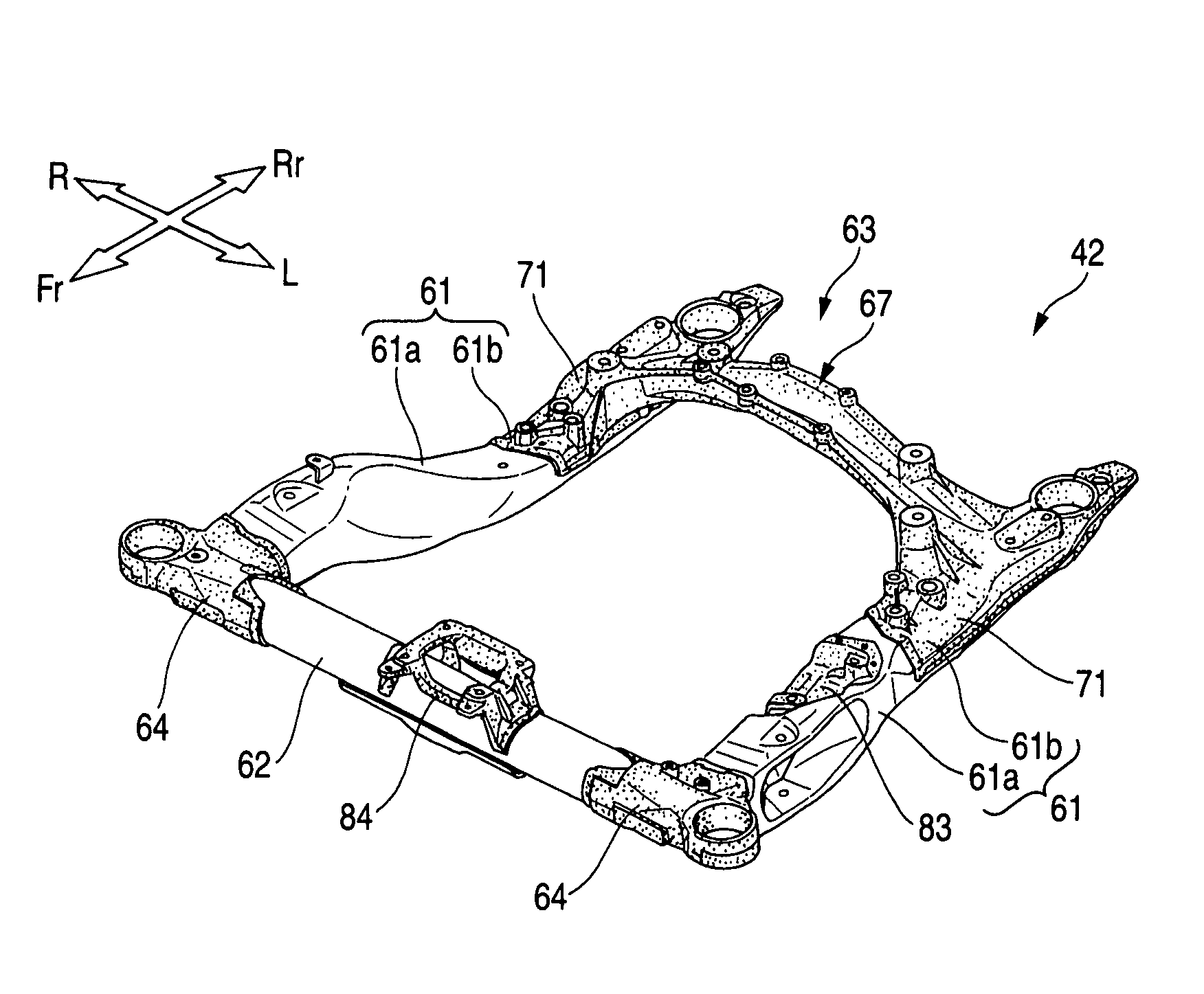

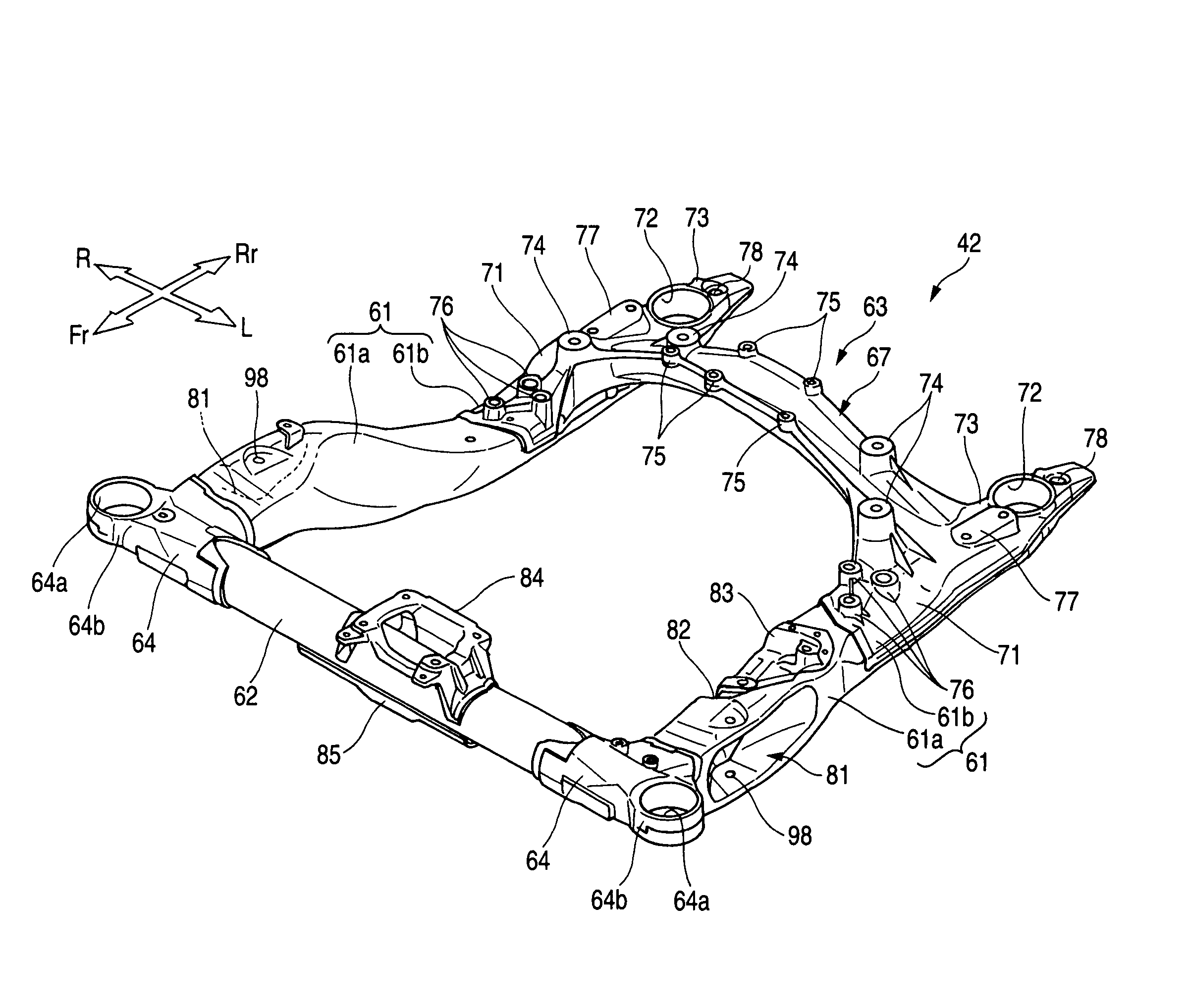

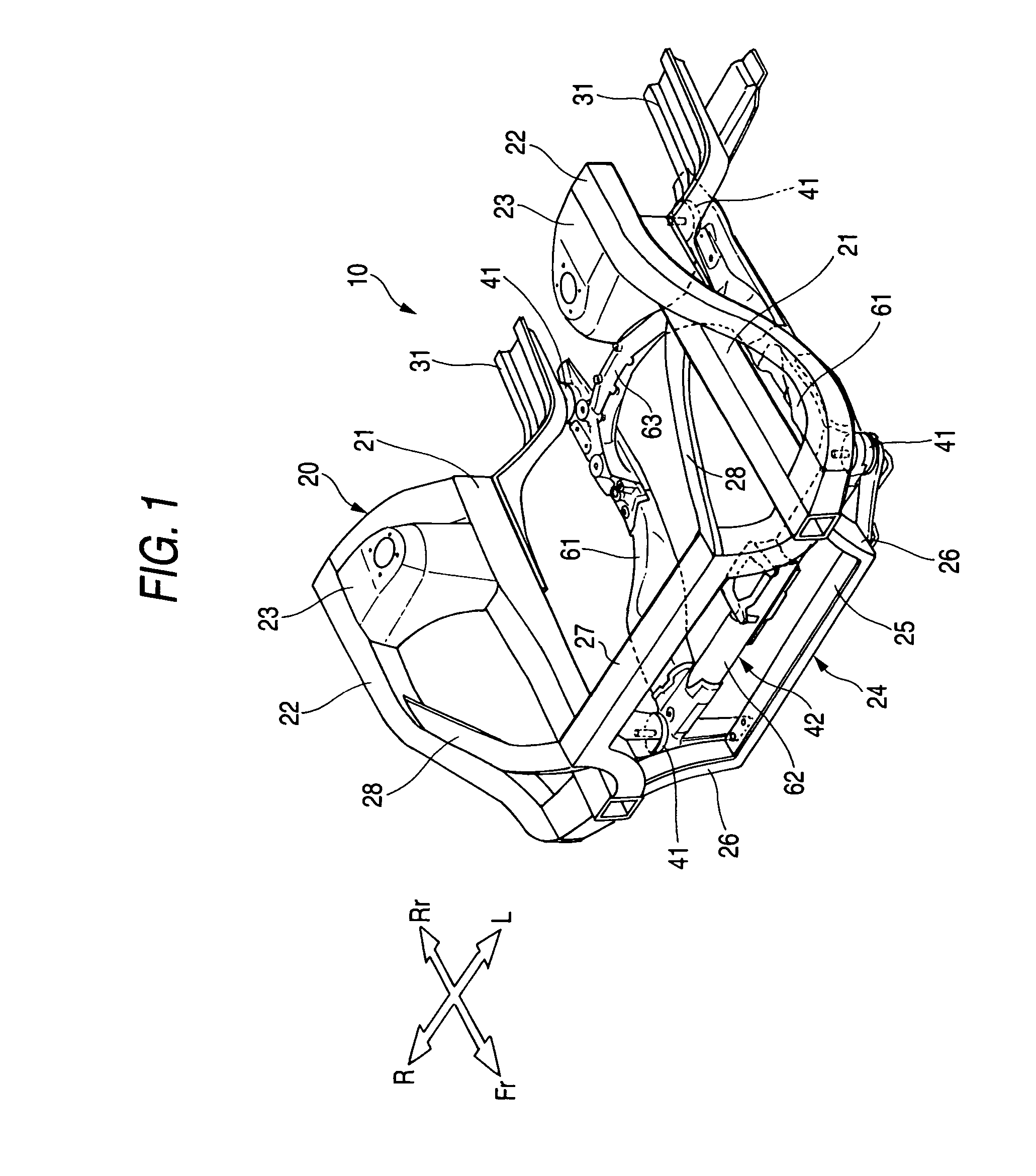

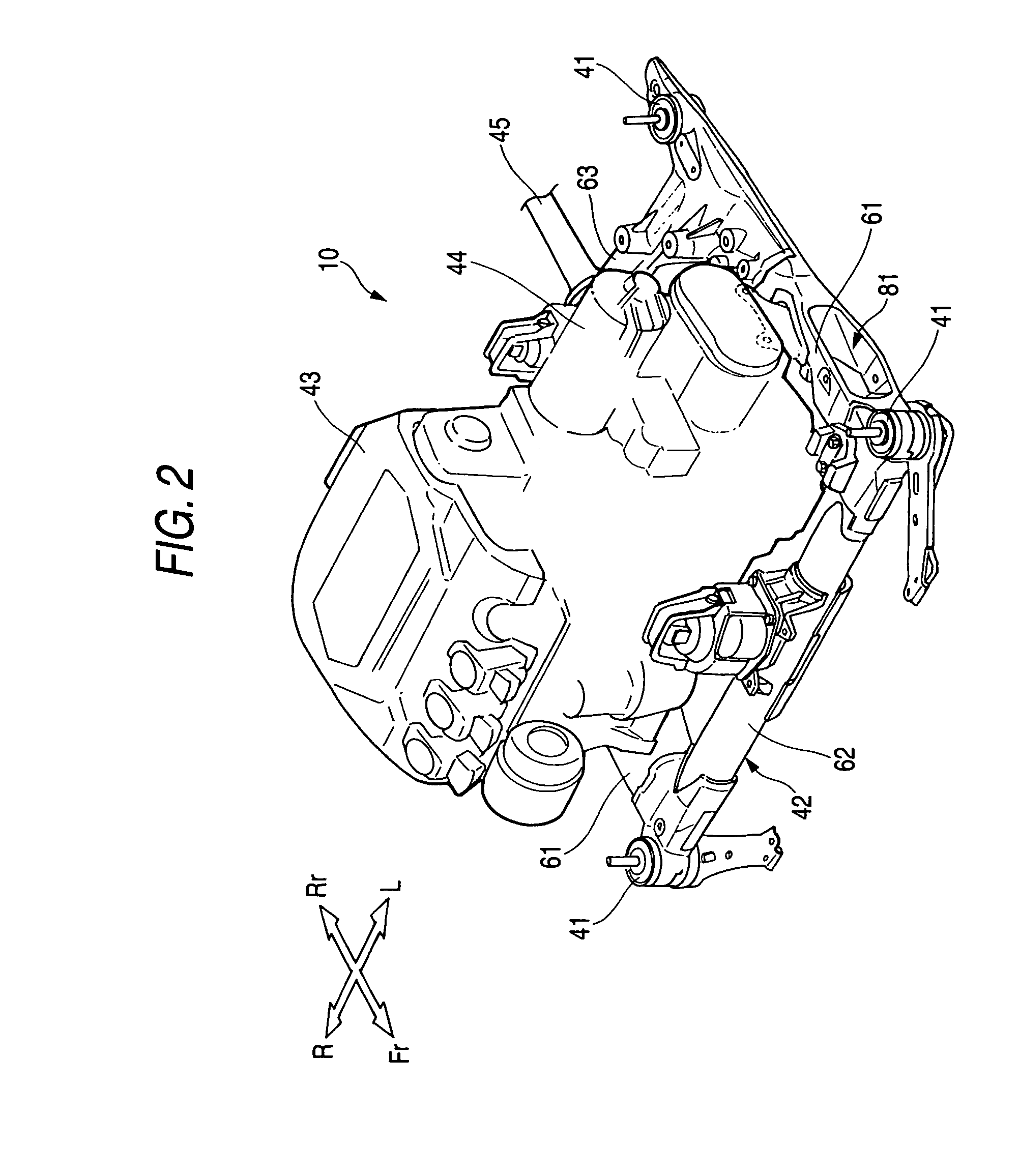

InactiveUS7520514B2Improve transmission performanceMaintain performanceUnderstructuresSuperstructure subunitsVehicle frameCamber angle

A front subframe 42 is formed of an aluminum alloy into a frame that is formed substantially into a shape of parallel crosses or into a rectangular shape and is made up of left and right front joint portions 64, 64 and left and right rear joint portions 71, 71 which are disposed at corners of the frame that is formed substantially into the shape of parallel crosses or the rectangular shape, and left and right longitudinal members 61, 61, and front and rear cross members 62, 67 which connect the joint portions 64, 64, 71, 71 together. The left and right front joint portions 64, 64 and the left and right rear joint portions 71, 71 are formed of an aluminum alloy die-cast product, whereas the left and right longitudinal members 61, 61 are formed of an aluminum alloy wrought product. In addition, connecting locations 76 . . . of a camber angle adjusting mechanism 157 are formed of an aluminum alloy die-cast product. Additionally, a rear cross member compound 63 is formed of an aluminum alloy die-cast product.

Owner:HONDA MOTOR CO LTD

Goggles structure

Owner:JIURU

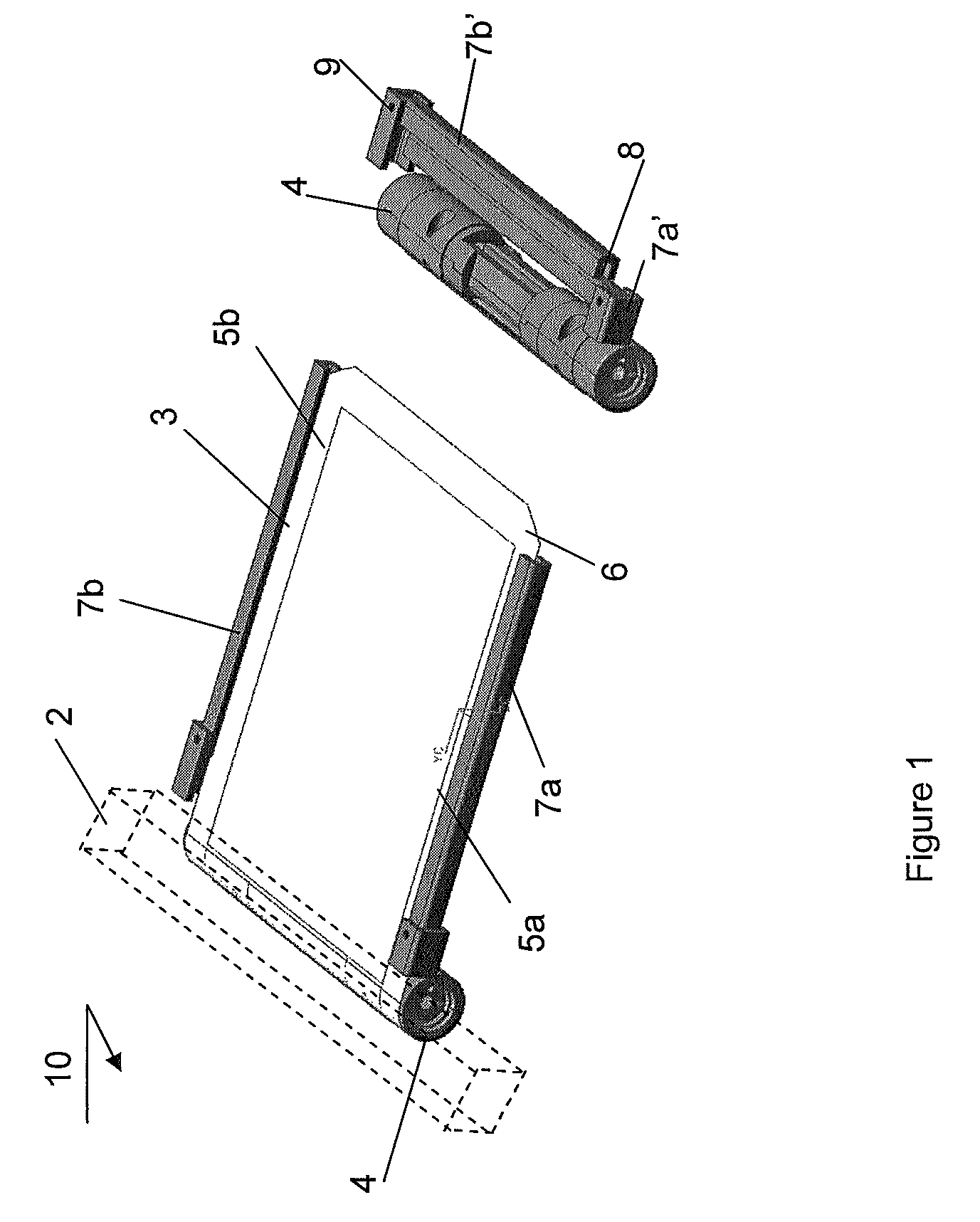

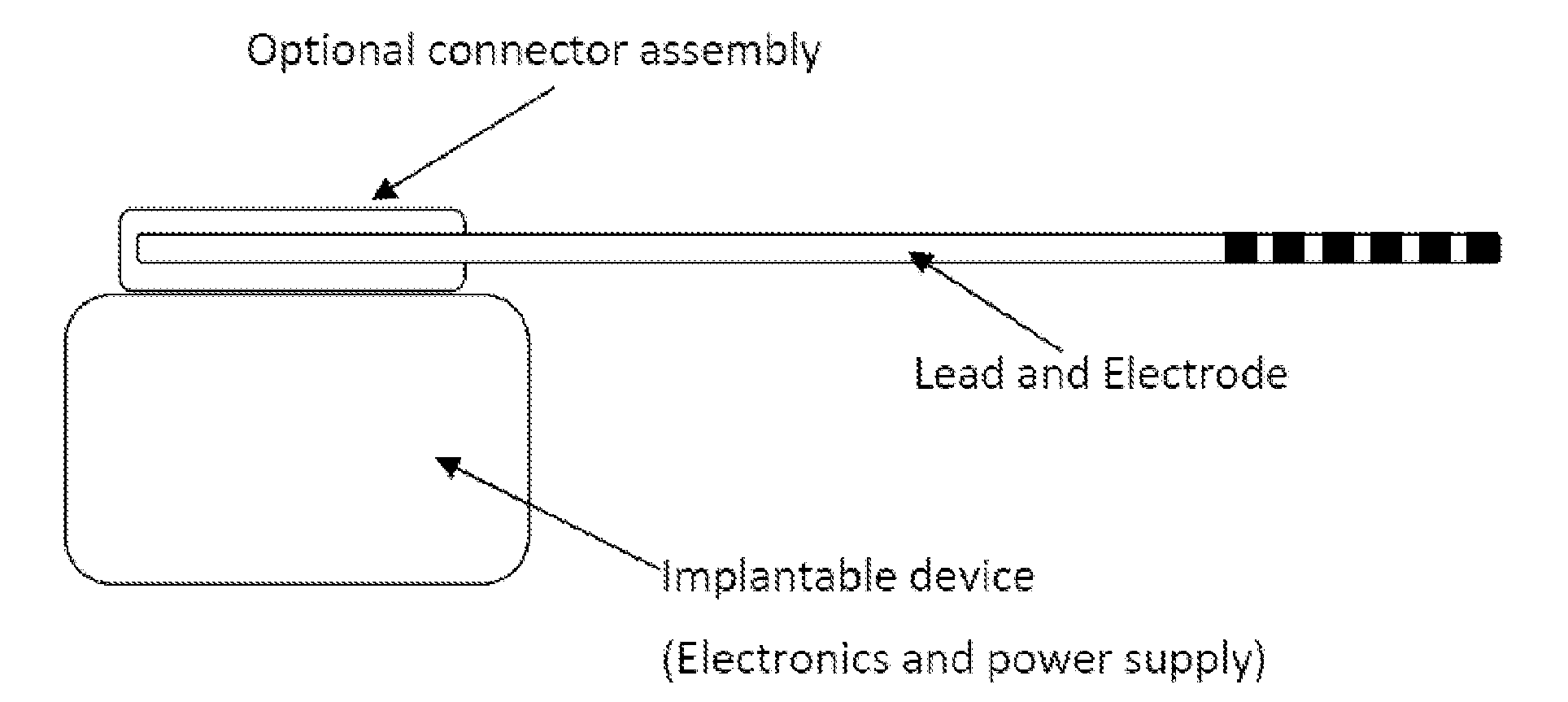

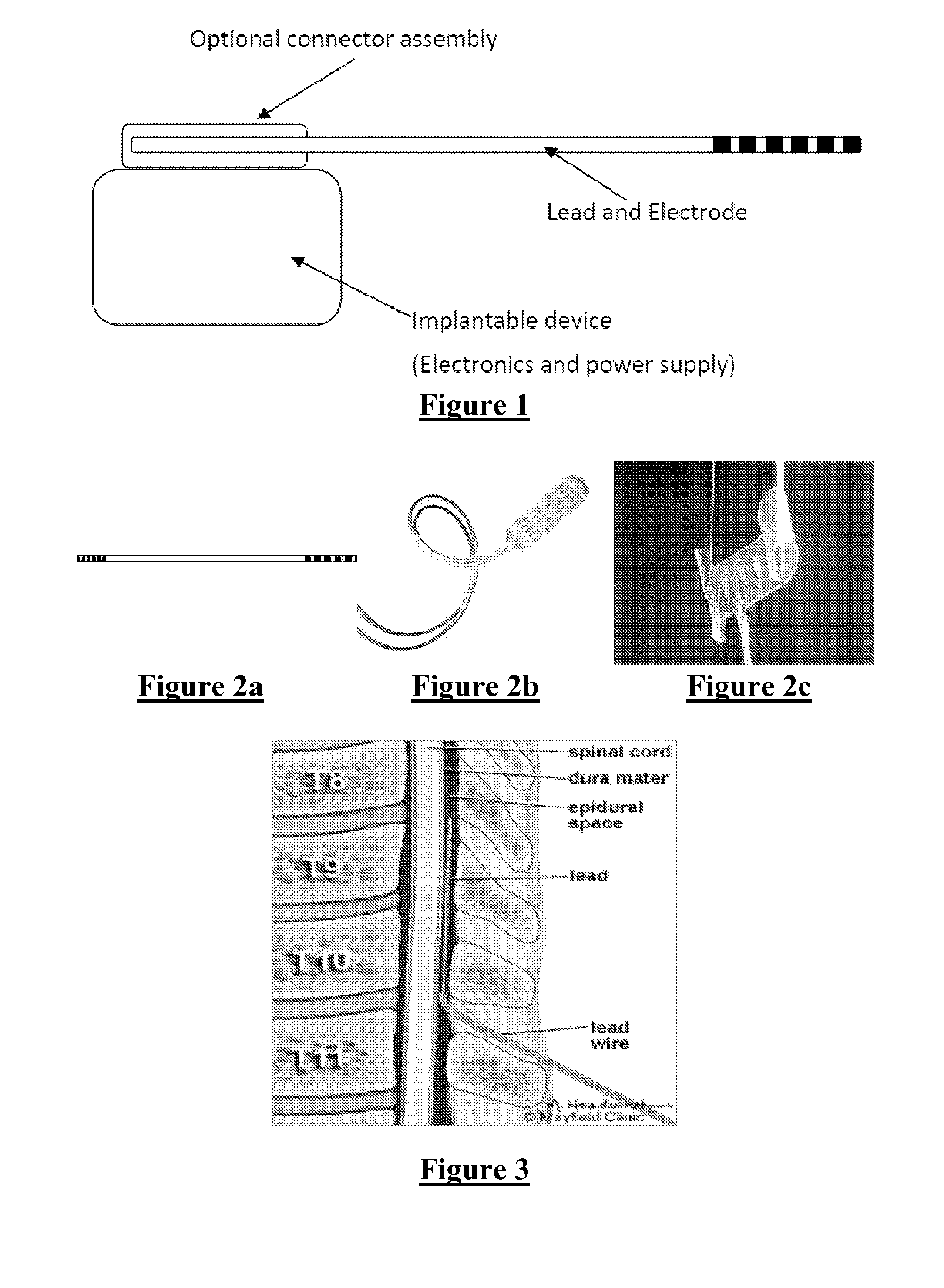

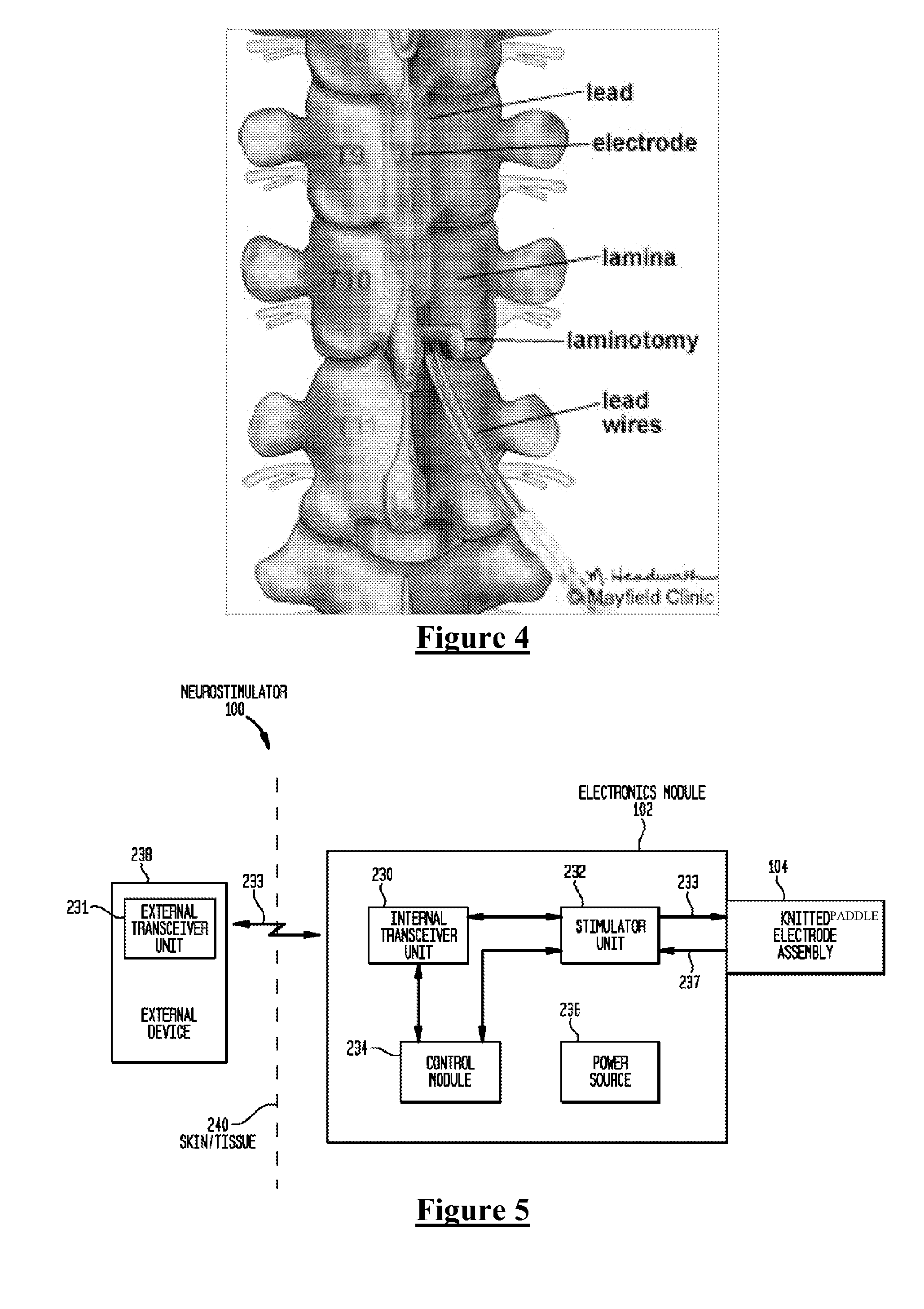

Electrode Assembly for an Active Implantable Medical Device

InactiveUS20140288577A1Reduce exerciseIncrease coverageSpinal electrodesContact member assembly/disassemblyCatheterMedical device

An electrode assembly for an active implantable medical device can be delivered by catheter but expands to become a paddle electrode once implanted. The electrode assembly comprises a support member carrying wires for electrically connecting a control unit to electrodes of the electrode assembly. At least one, and usually two resilient deformable paddle wings are mounted to the support member. The paddle wings can be furled close to the support member under a deformation force to permit implantation via an introducer. The paddle wings resiliently unfurl away from the support member upon release of the deformation force. The paddle wings bear rows and columns of electrodes, and the electrode assembly as a whole has sufficient longitudinal rigidity for implantation via an introducer.

Owner:SALUDA MEDICAL PTY LTD

Glass-ceramic composition for recording disk substrate

InactiveUS6514890B1Improve productivityRaise the ratioMagnetic materials for record carriersBase layers for recording layersGlass-ceramicMaterials science

A glass ceramics composition for recording disk substrate consists essentially, expressed in terms of weight percent on the oxide basis, of from 65 to 80 wt % of SiO2, from 3 to 15 wt % of Al2O3, from 3 to 15 wt % of Li2O, from 0.2 to 5 wt % of P2O5, and from 0.1 to 0.8 wt % of ZrO2.

Owner:HOYA CORP

Body frame structure

InactiveUS20070169982A1Improve transmission performanceMaintain performanceUnderstructuresSteering partsCamber angleDie casting

A front subframe 42 is formed of an aluminum alloy into a frame that is formed substantially into a shape of parallel crosses or into a rectangular shape and is made up of left and right front joint portions 64, 64 and left and right rear joint portions 71, 71 which are disposed at corners of the frame that is formed substantially into the shape of parallel crosses or the rectangular shape, and left and right longitudinal members 61, 61, and front and rear cross members 62, 67 which connect the joint portions 64, 64, 71, 71 together. The left and right front joint portions 64, 64 and the left and right rear joint portions 71, 71 are formed of an aluminum alloy die-cast product, whereas the left and right longitudinal members 61, 61 are formed of an aluminum alloy wrought product. In addition, connecting locations 76 . . . of a camber angle adjusting mechanism 157 are formed of an aluminum alloy die-cast product. Additionally, a rear cross member compound 63 is formed of an aluminum alloy die-cast product.

Owner:HONDA MOTOR CO LTD

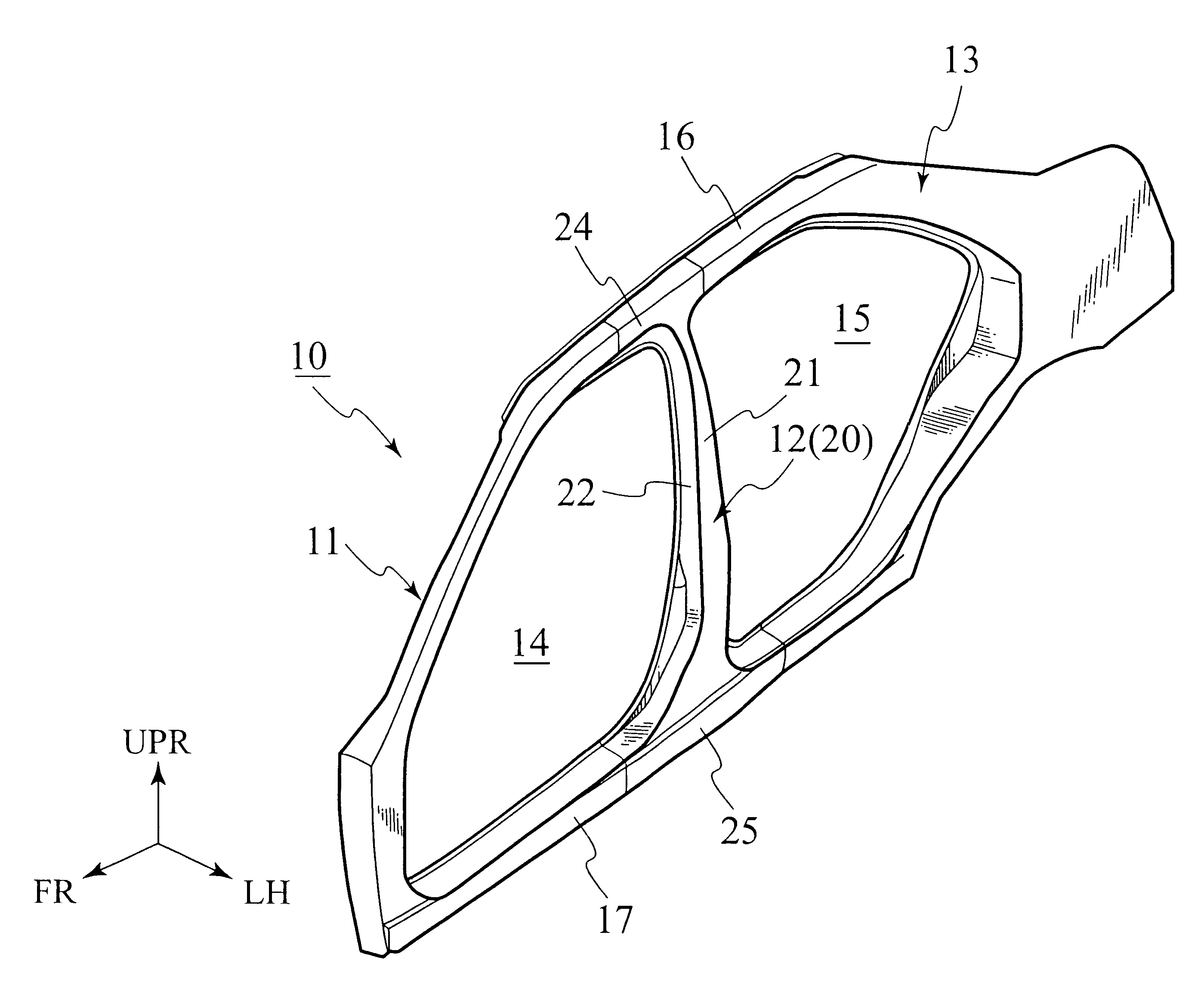

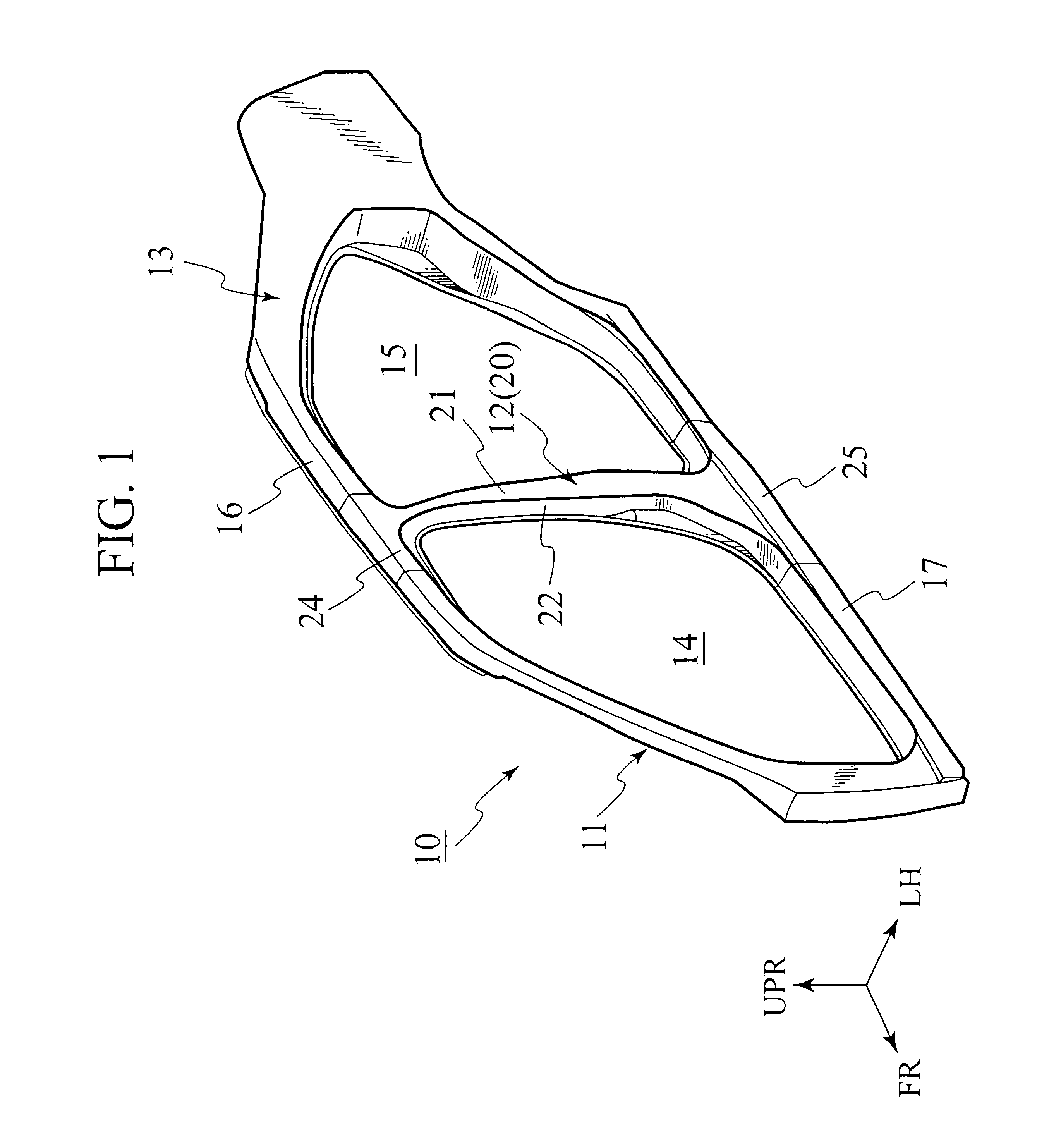

Pillar structure of a vehicle

InactiveUS6702368B1Control deformationIncrease a geometrical moment of inertiaVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD

Solid golf ball

InactiveUS7481722B2Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

Owner:BRIDGESTONE SPORTS

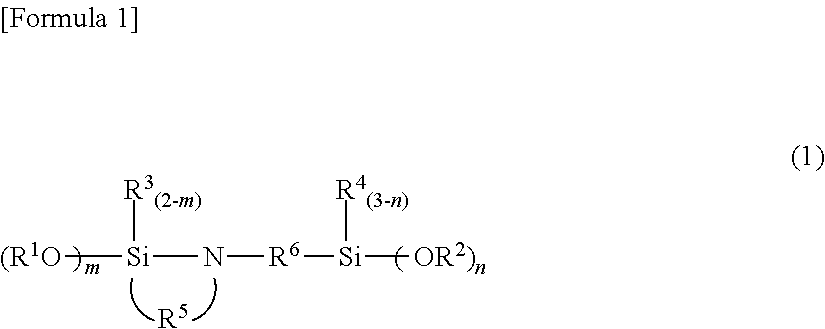

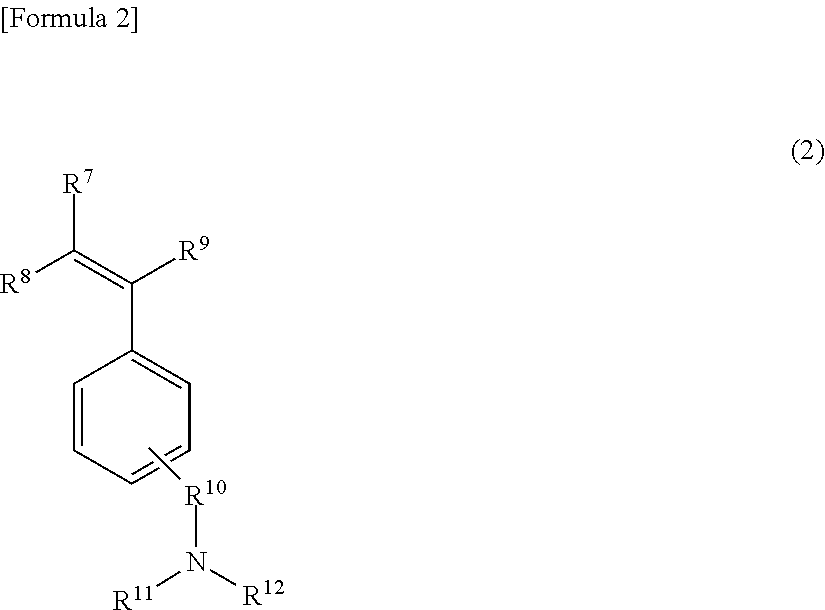

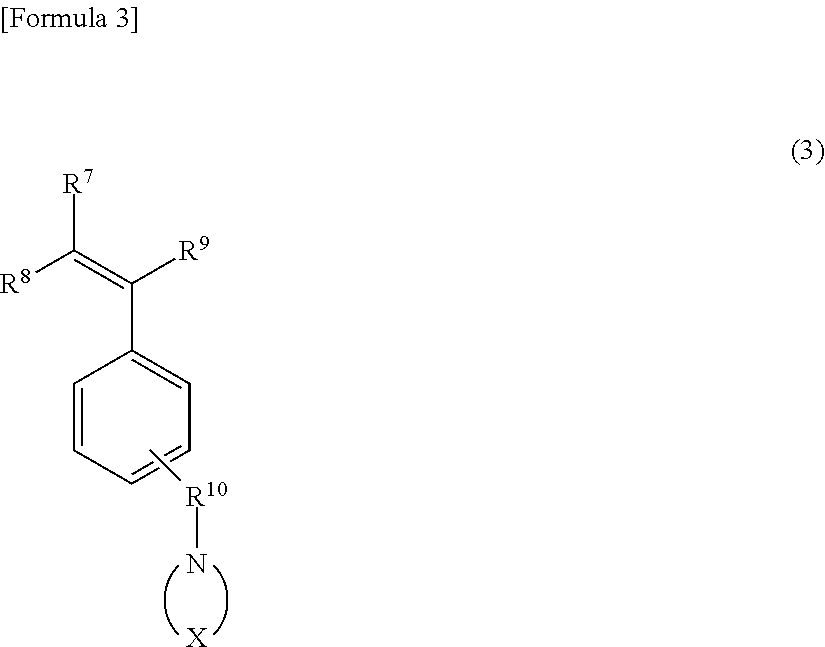

Method for Producing Modified Conjugated Diene Polymer, Modified Conjugated Diene Polymer, Modified Conjugated Diene Polymer Composition, Rubber Composition and Tire

ActiveUS20140371383A1Improve balanceLow hysteresis loss propertySpecial tyresAlkaline earth metalPolymer science

A method for producing a modified conjugated diene polymer comprising a polymerization step of obtaining a conjugated diene polymer containing a nitrogen atom in a polymer chain and an active end by copolymerizing a conjugated diene compound and a nitrogen atom-containing vinyl compound, or a conjugated diene compound, an aromatic vinyl compound and a nitrogen atom-containing vinyl compound by use of an alkali metal compound and / or an alkaline earth metal compound as a polymerization initiator, and a modification step of reacting a modifier.

Owner:ASAHI KASEI CHEM CORP

Polypropylene-based resin composition and injection molded article thereof

InactiveUS6011102AReduced impact strengthInferior appearanceFilm/foil adhesivesMixingPolymer scienceOctene

A polypropylene-based resin composition comprising: (1) 55 to 75% by weight of a polypropylene-based resin (A) selected from the following (i) and (ii); (i) a crystalline propylene-ethylene block copolymer composed of a propylene homopolymer portion as a first segment and a propylene-ethylene random copolymer as a second segment, and (ii) a mixture of the crystalline propylene-ethylene block copolymer (i) and a crystalline propylene homopolymer; (2) 10 to 15% by weight of an ethylene-octene copolymer rubber (B) having a melt flow rate (measured according to JIS-K-6758, 190 DEG C.) of 0.5 to 10 g / min., an octene content of 20 to 25% by weight and a density of 0.860 to 0.875; and (3) 15 to 30% by weight of talc (C) having an average particle diameter of not more than 3 mu m, the total amount of (A), (B) and (C) being 100% by weight, wherein said polypropylene-based resin composition satisfies the following expression:0.25< / =(A)' / [(A)'+(B')]< / =0.40in which (A)' represents an amount by weight of the second segment of the crystalline propylene-ethylene block copolymer (i) in the polypropylene-based resin composition and (B') represents an amount by weight of the ethylene-octene copolymer rubber (B) in the polypropylene-based resin composition, and further has a specific flexural modulus, Izod impact strength, elongation, melt flow rate and density.

Owner:TOYOTA JIDOSHA KK +1

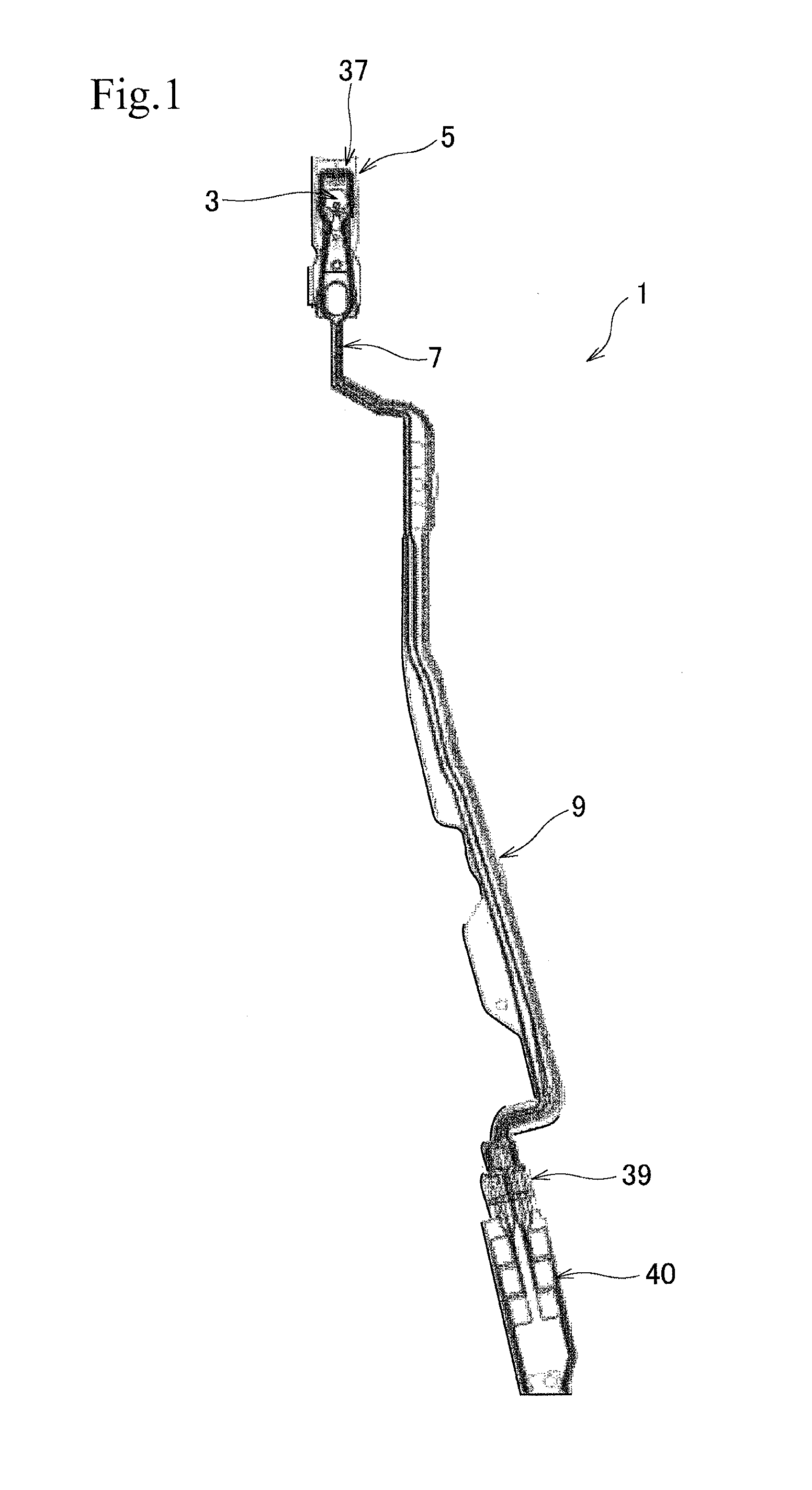

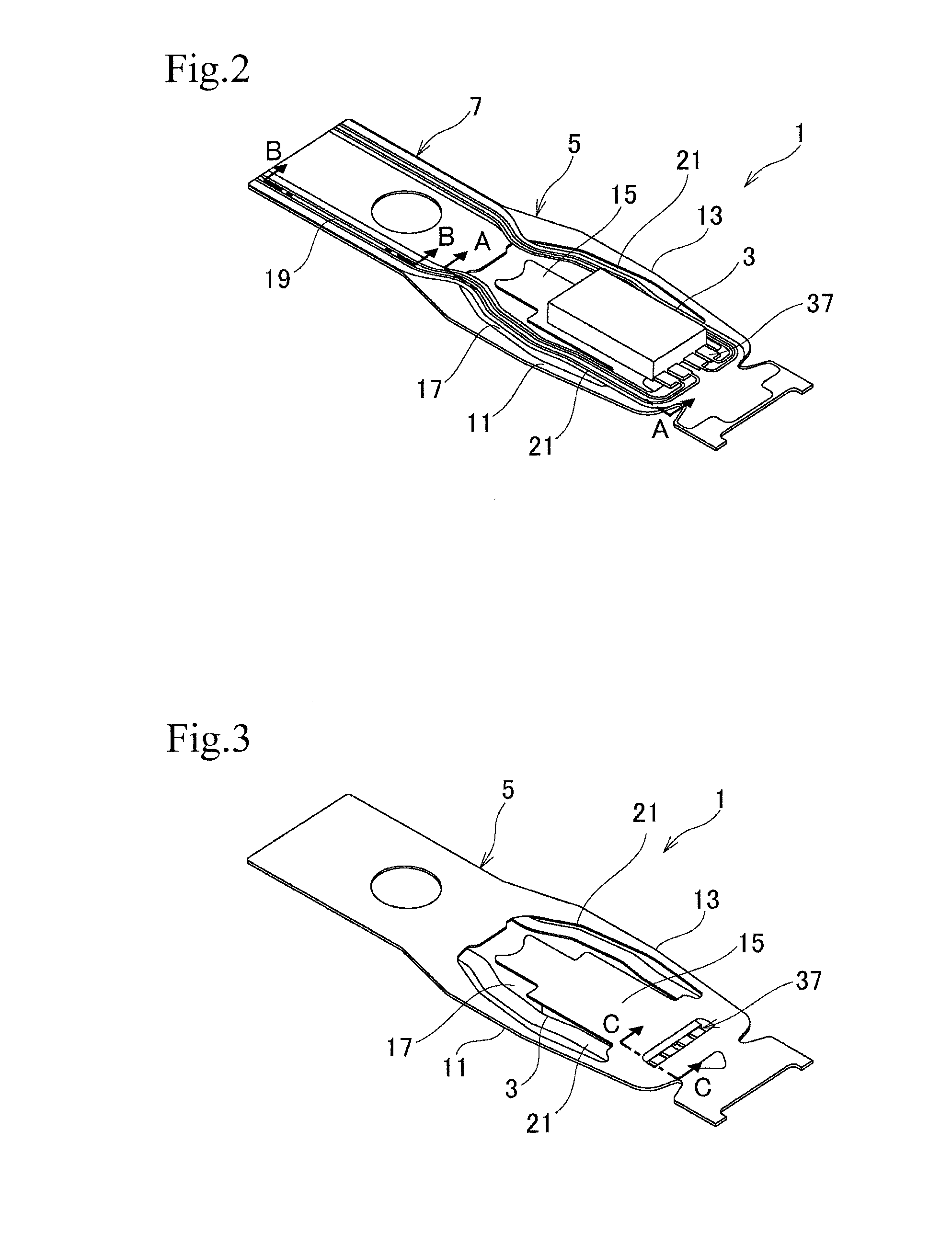

Flexure and method of forming part of flexure

ActiveUS20150241788A1Lower ratioReduce rigidity and rigidity contribution ratioElectrical connection between head and armPrinted circuit aspectsElectrical conductorStructural engineering

A flexure includes a metal substrate whose front end supports a slider and a wiring part having a base insulating layer and a conductor layer formed on the base insulating layer. The wiring part includes a normal wiring part that is on the metal substrate and an aerial wiring part that is on a space separated from the metal substrate. The base insulating layer of the aerial wiring part is formed to be thinner than that of the normal wiring part. This configuration reduces a rigidity contribution ratio of the wiring part.

Owner:NHK SPRING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com