Patents

Literature

44results about How to "Improve thermal properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

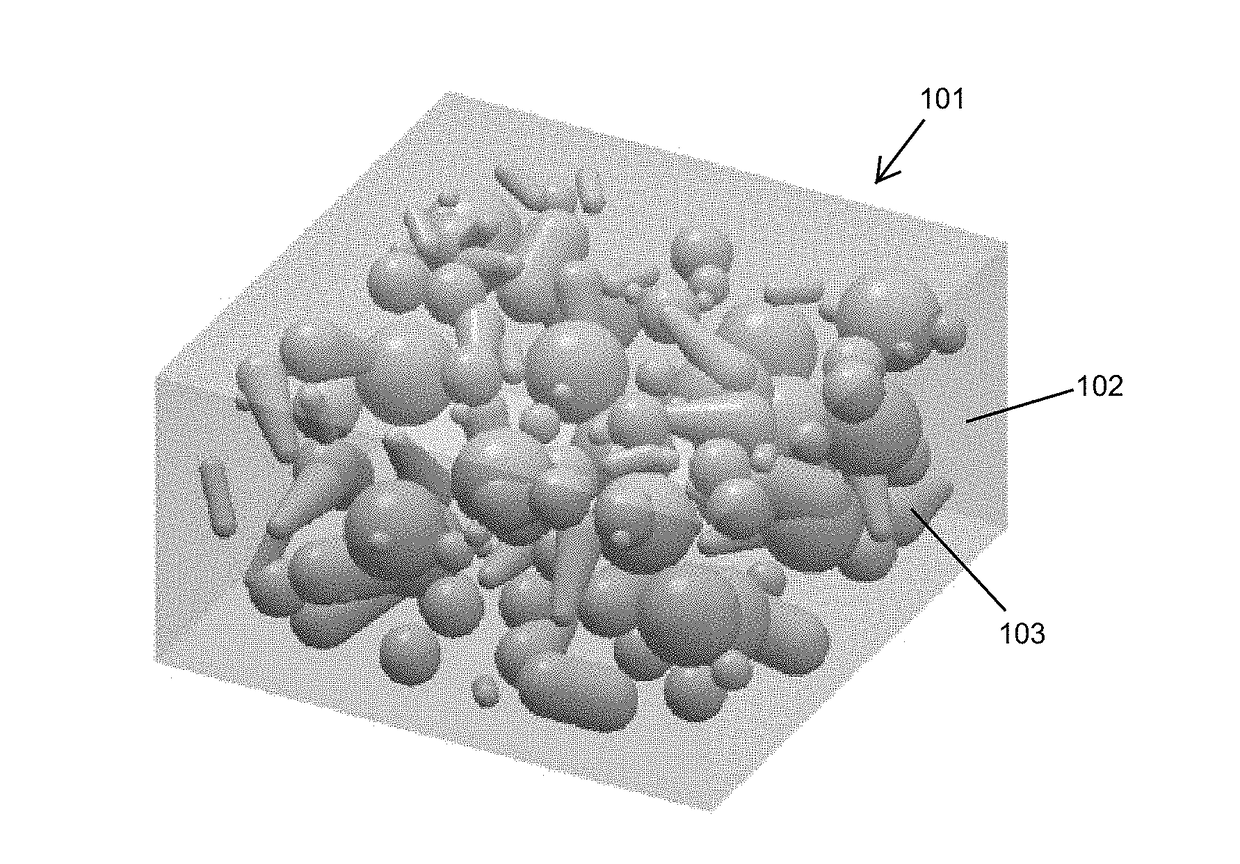

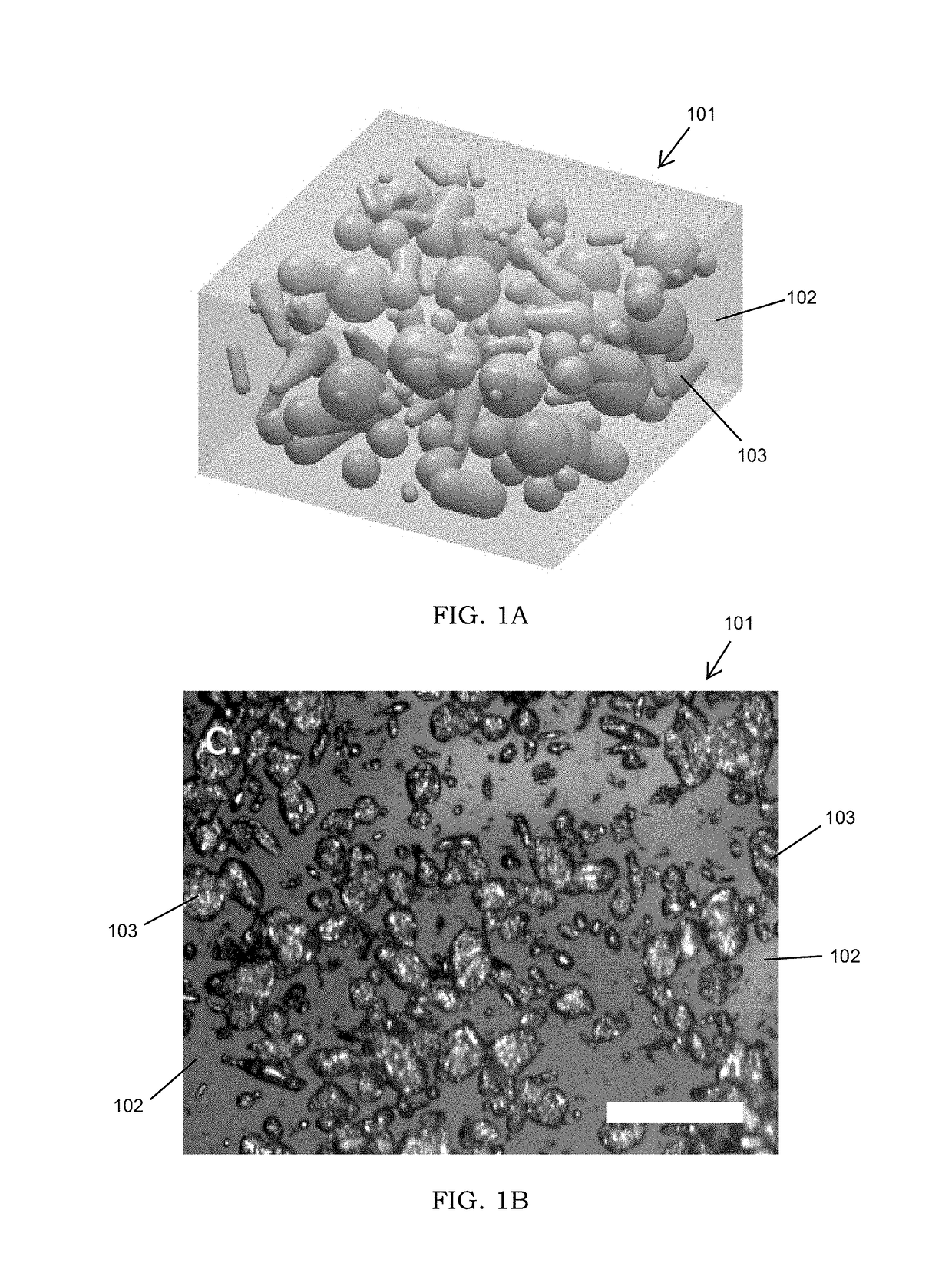

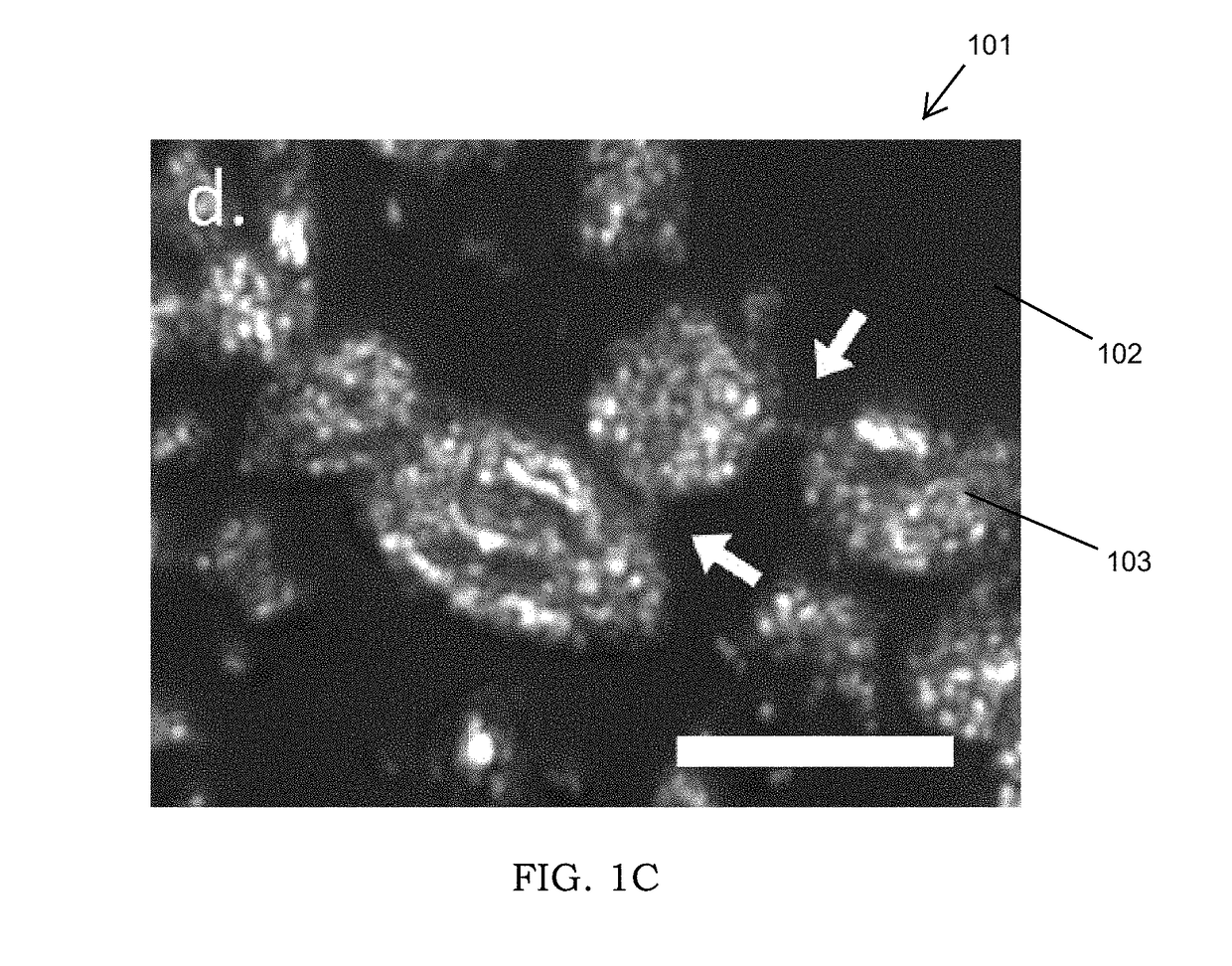

Polymer Composite with Liquid Phase Metal Inclusions

ActiveUS20170218167A1Improve electricityImprove thermal propertiesCircuit bendability/stretchabilityPrinted circuit aspectsElastomerLiquid state

Disclosed herein is a composite comprising an elastomer with an embedded network of liquid metal inclusions. The composite retains similar flexibility to that of an elastomer but exhibits electrical and thermal properties that differ from the properties of a homogeneous elastomer. The composite has applications for wearable devices and other soft matter electronics, among others.

Owner:CARNEGIE MELLON UNIV

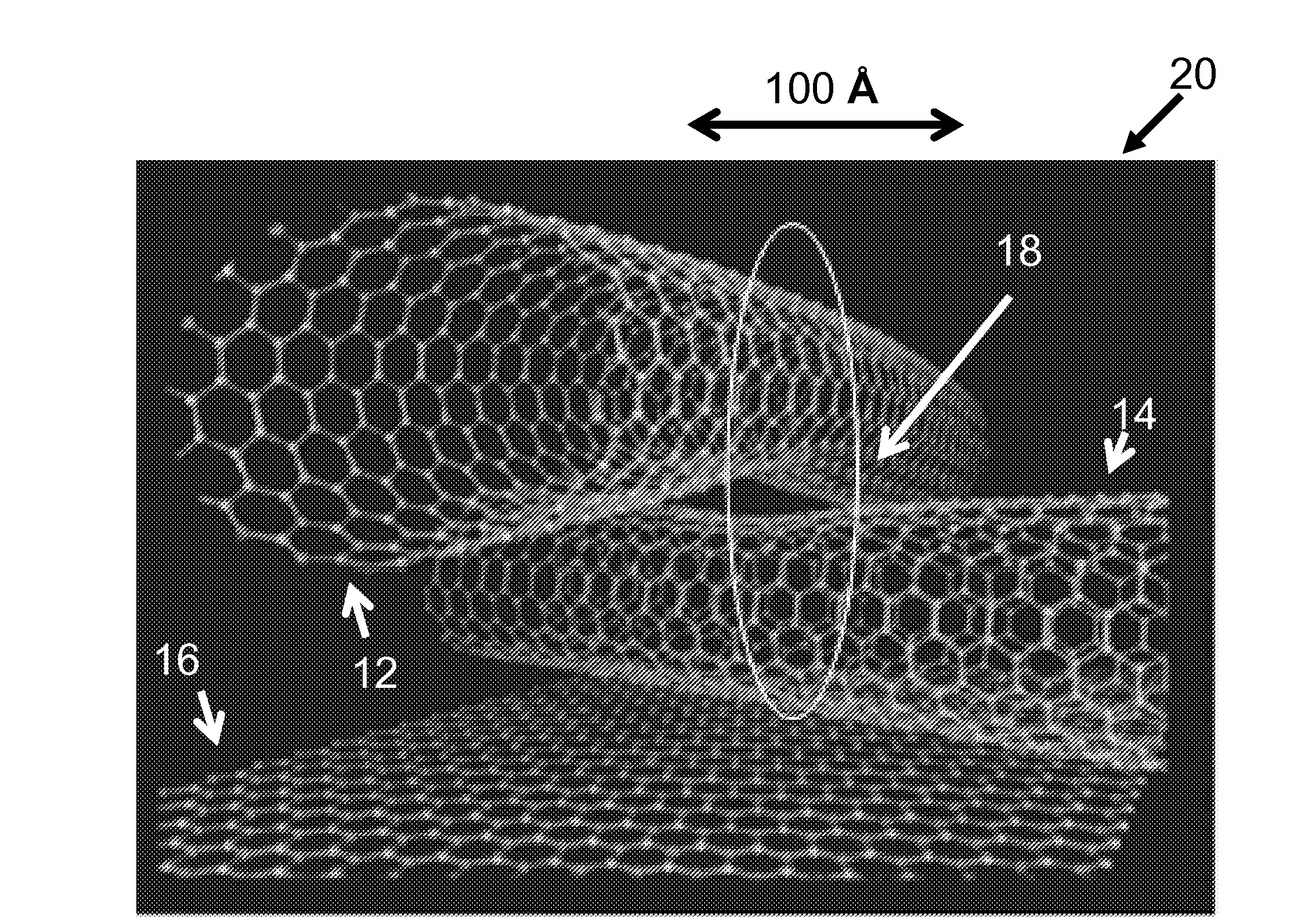

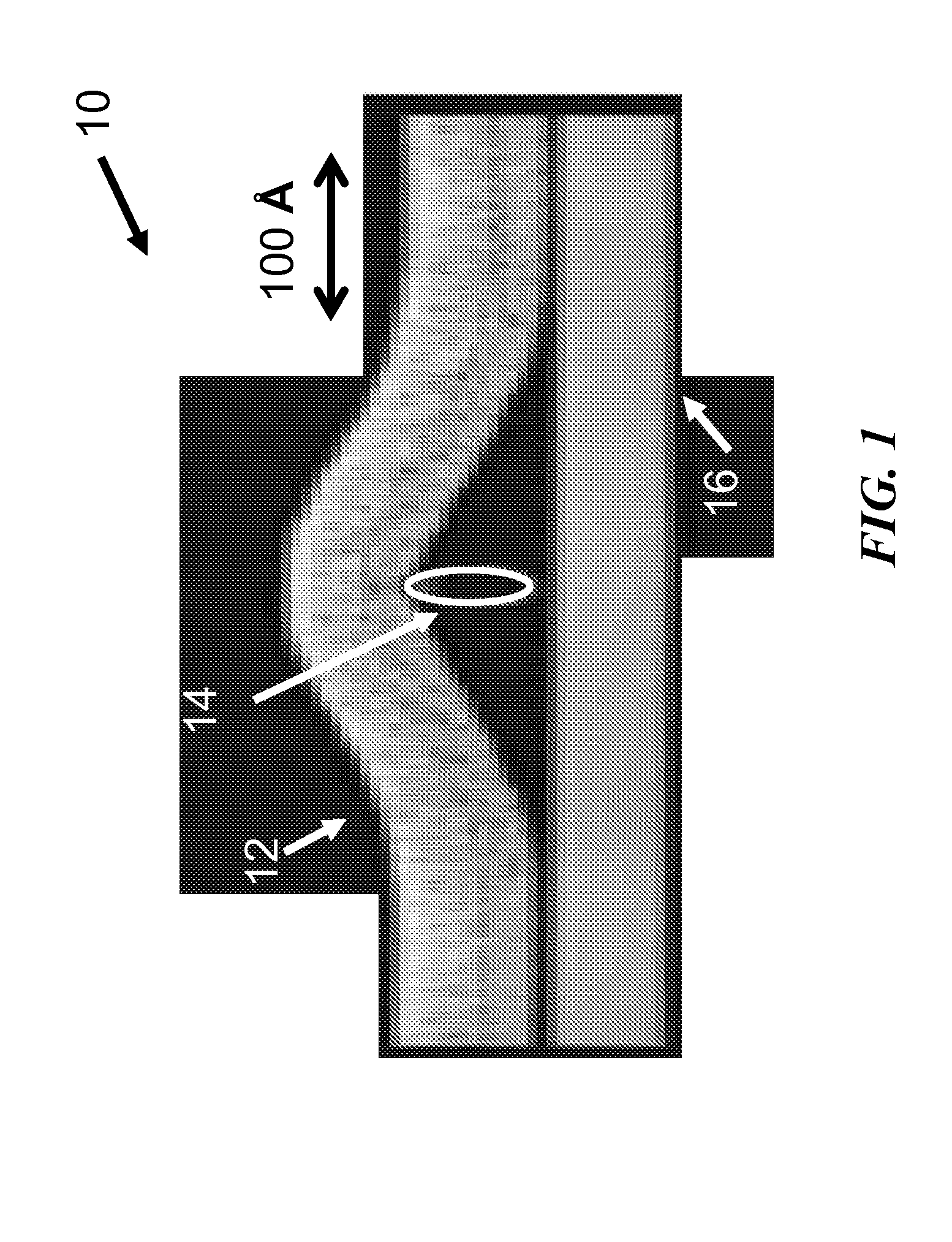

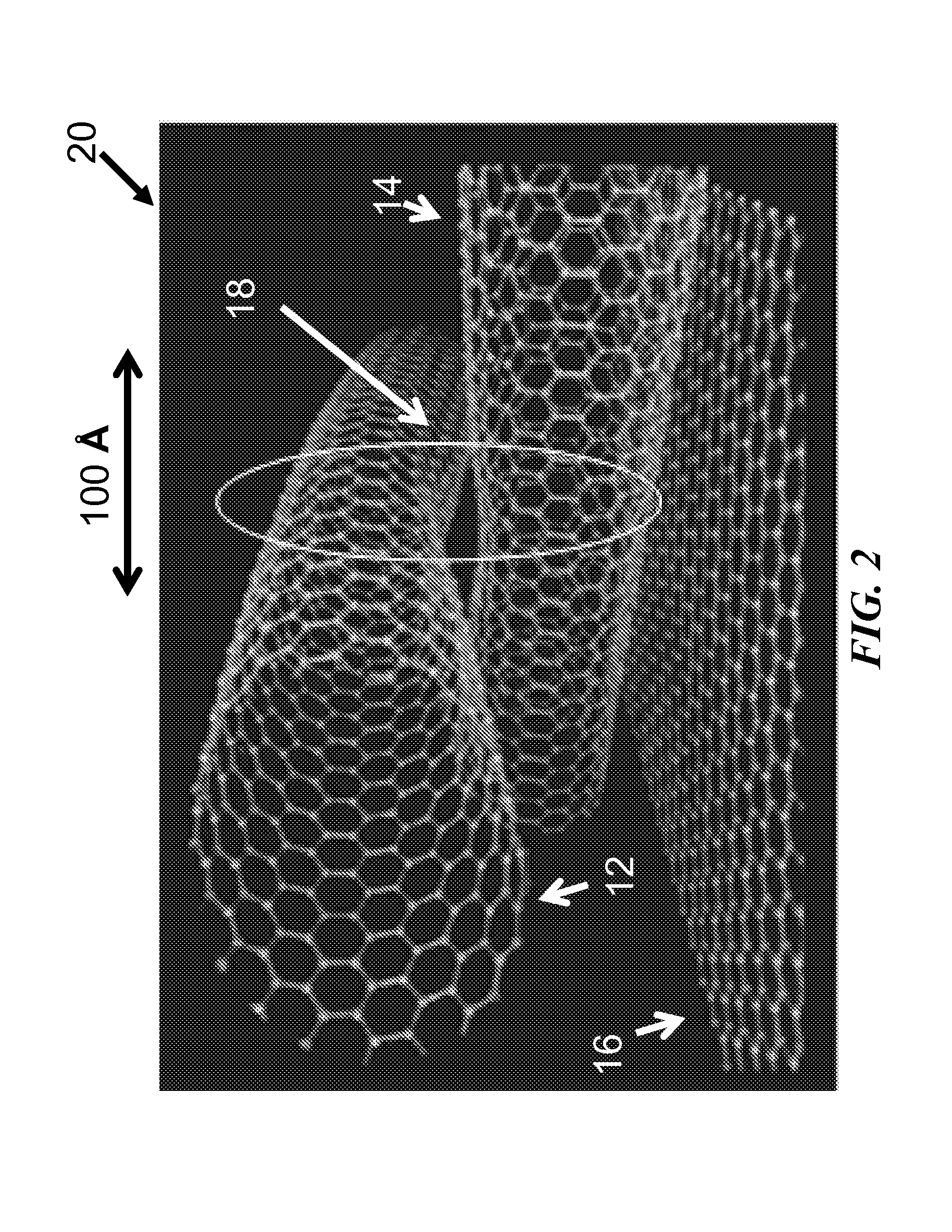

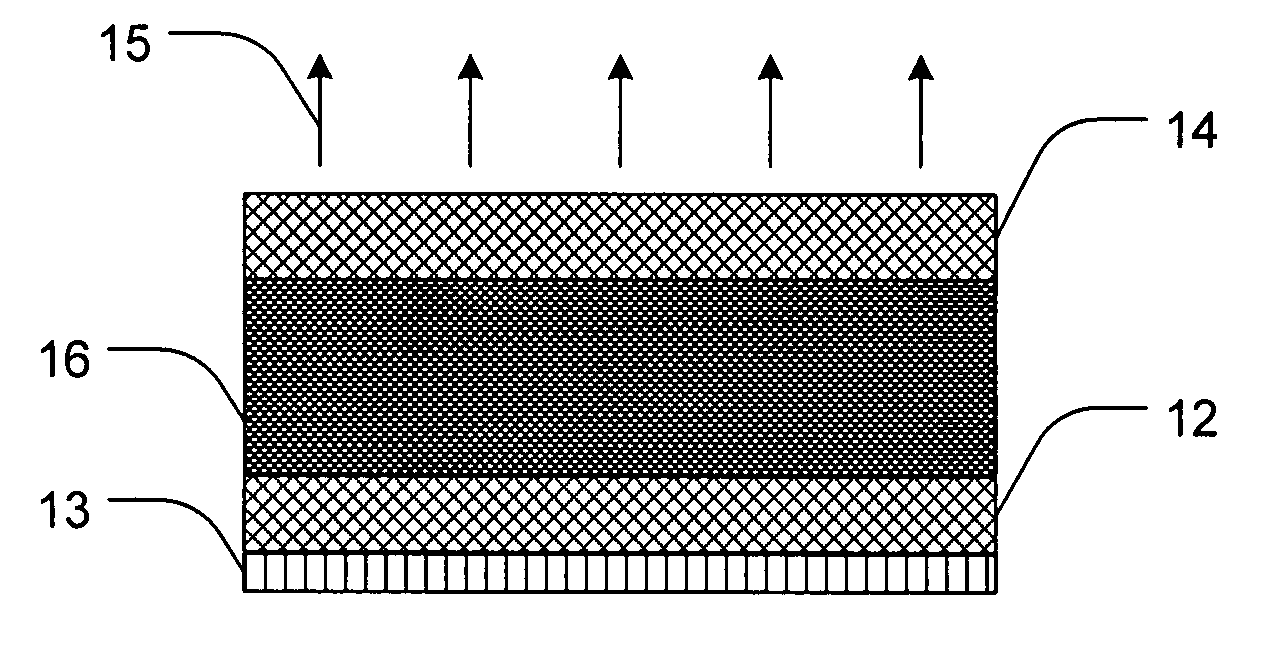

Method and system for improving conductivity of nanotube nets and related materials

InactiveUS20090320911A1Improve conductivitySpeed transmissionMaterial nanotechnologyCarbon compoundsCharge carrierElectric conductance

A method and system for improving the electrical conductivity of the nodes of a nanotube net and related materials. A method for adding material to the nodes of a nanotube net that provides more pathways and connections to guarantee good electrical conductance between one electrode and another and speeds the transmission of charge carriers by providing alternative pathways. These improvements may include an enhanced overall thermal conductivity of the CNT net and enhanced mechanical performance of the CNT net. The present disclosure improves, either independently or jointly, electrical, thermal, or mechanical properties of CNT nets. Further, optical transmission does not worsen significantly.

Owner:RUOFF RODNEY

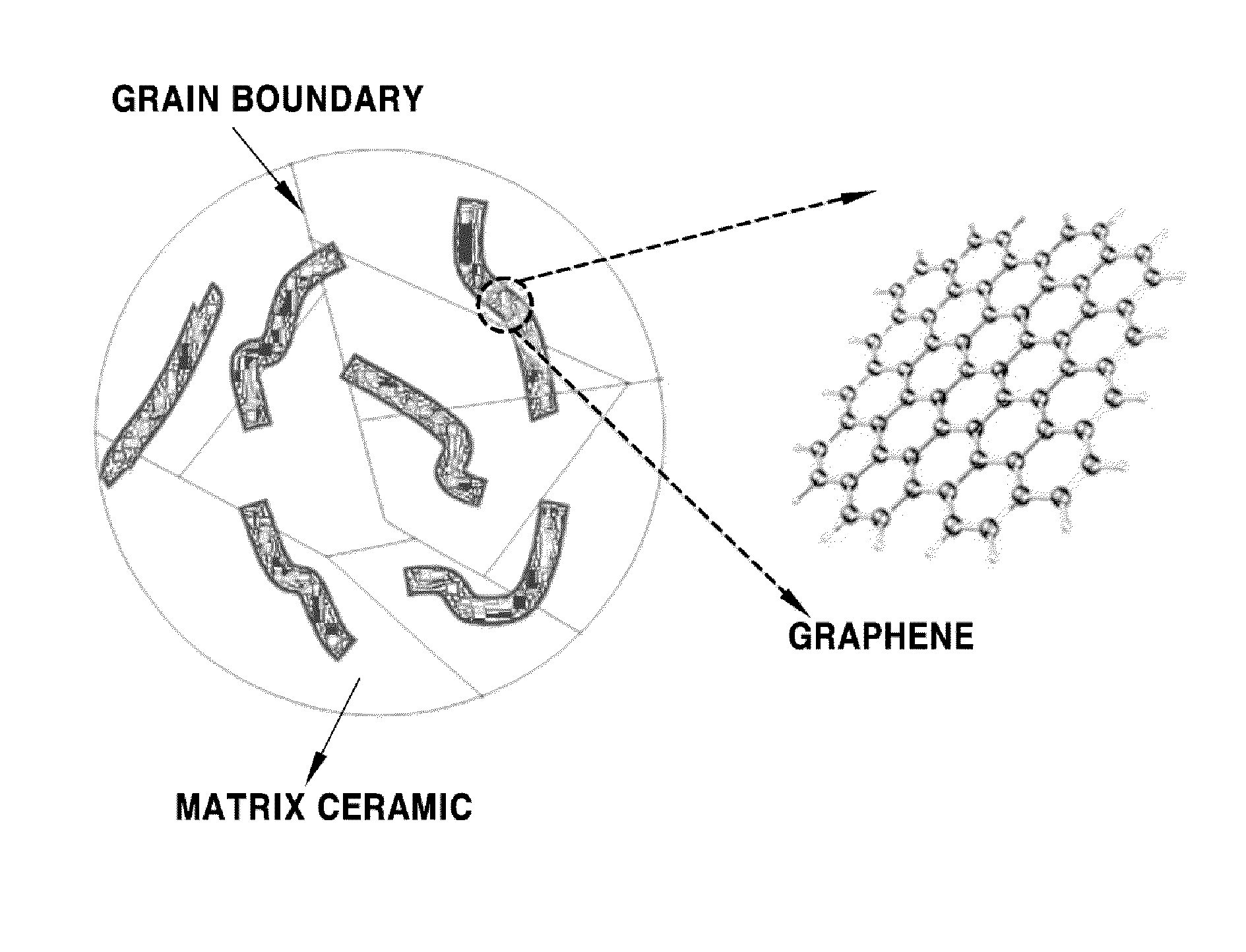

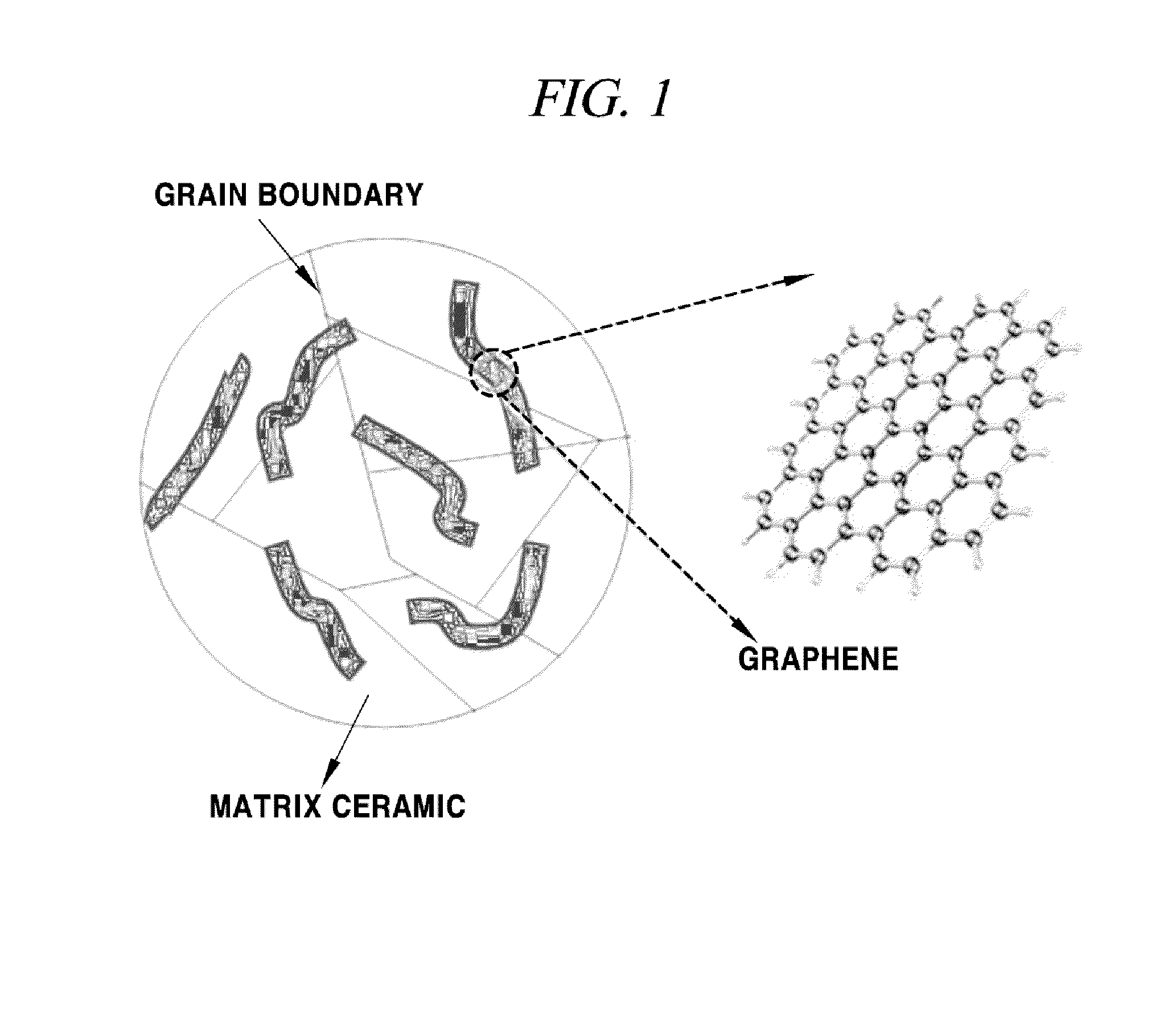

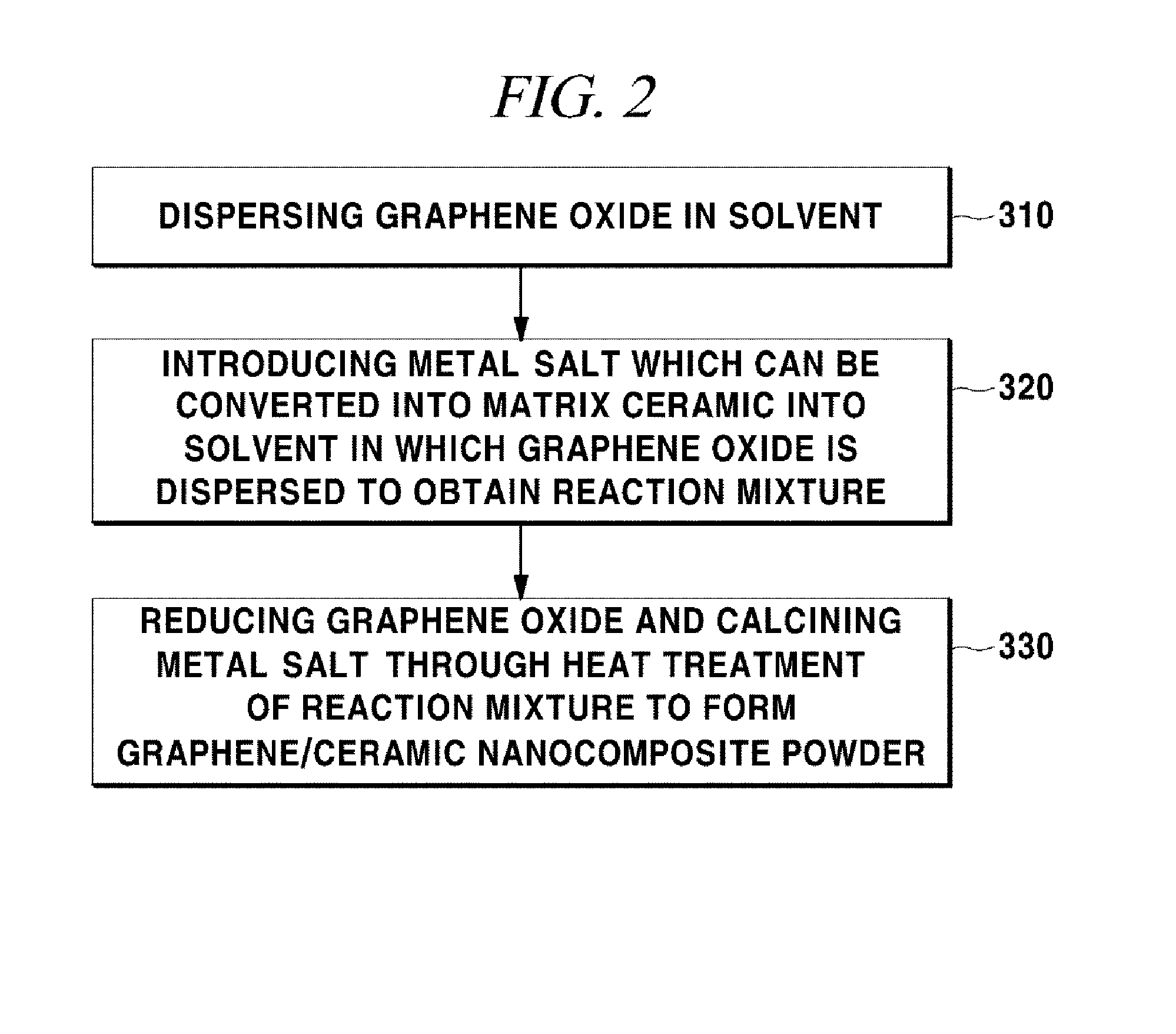

Graphene/ceramic nanocomposite powder and a production method therefor

InactiveUS20140197353A1Improve mechanical propertiesImprove electricitySpecific nanostructure formationGrapheneGrapheneCeramic

The embodiments described herein pertain generally to graphene / ceramic nanocomposite powder including a matrix ceramic; and graphene dispersed in the matrix ceramic and a preparation method thereof, and a graphene / ceramic nanocomposite material including the graphene / ceramic nanocomposite powder and a preparation method thereof.

Owner:KOREA ADVANCED INST OF SCI & TECH

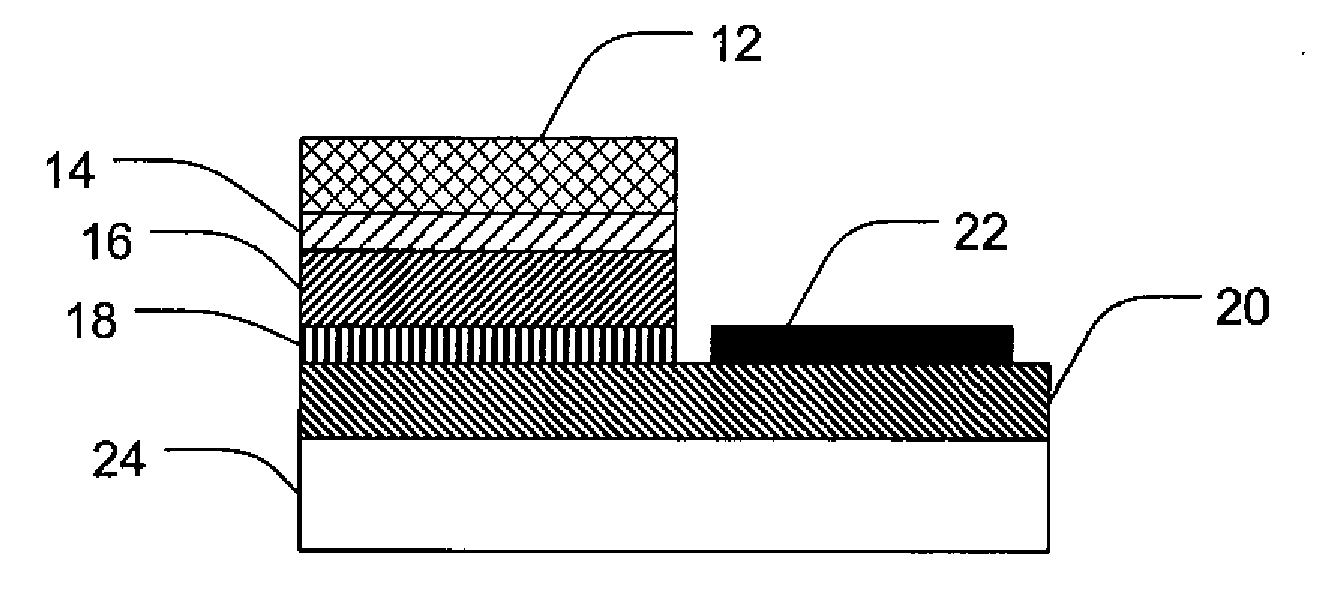

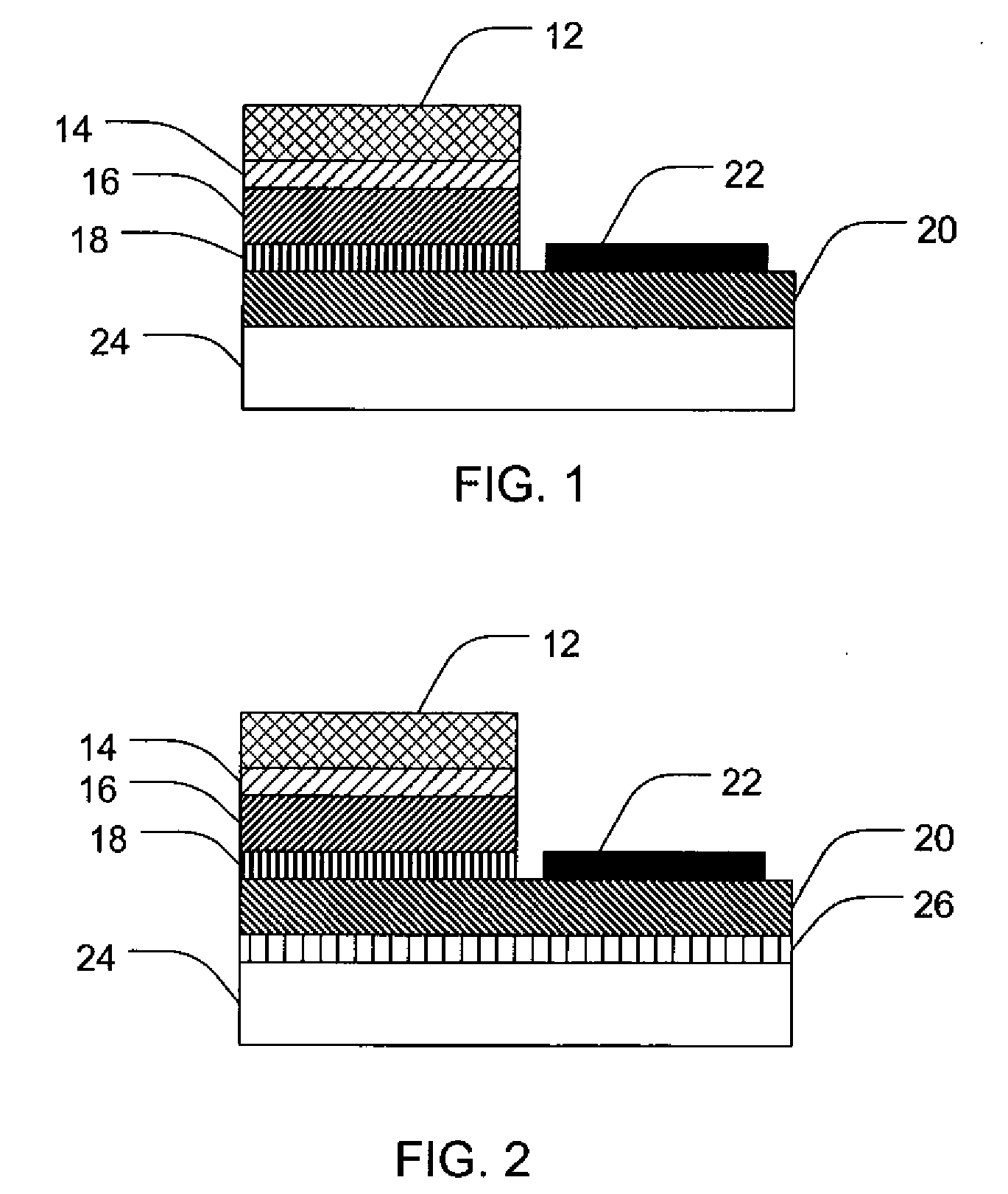

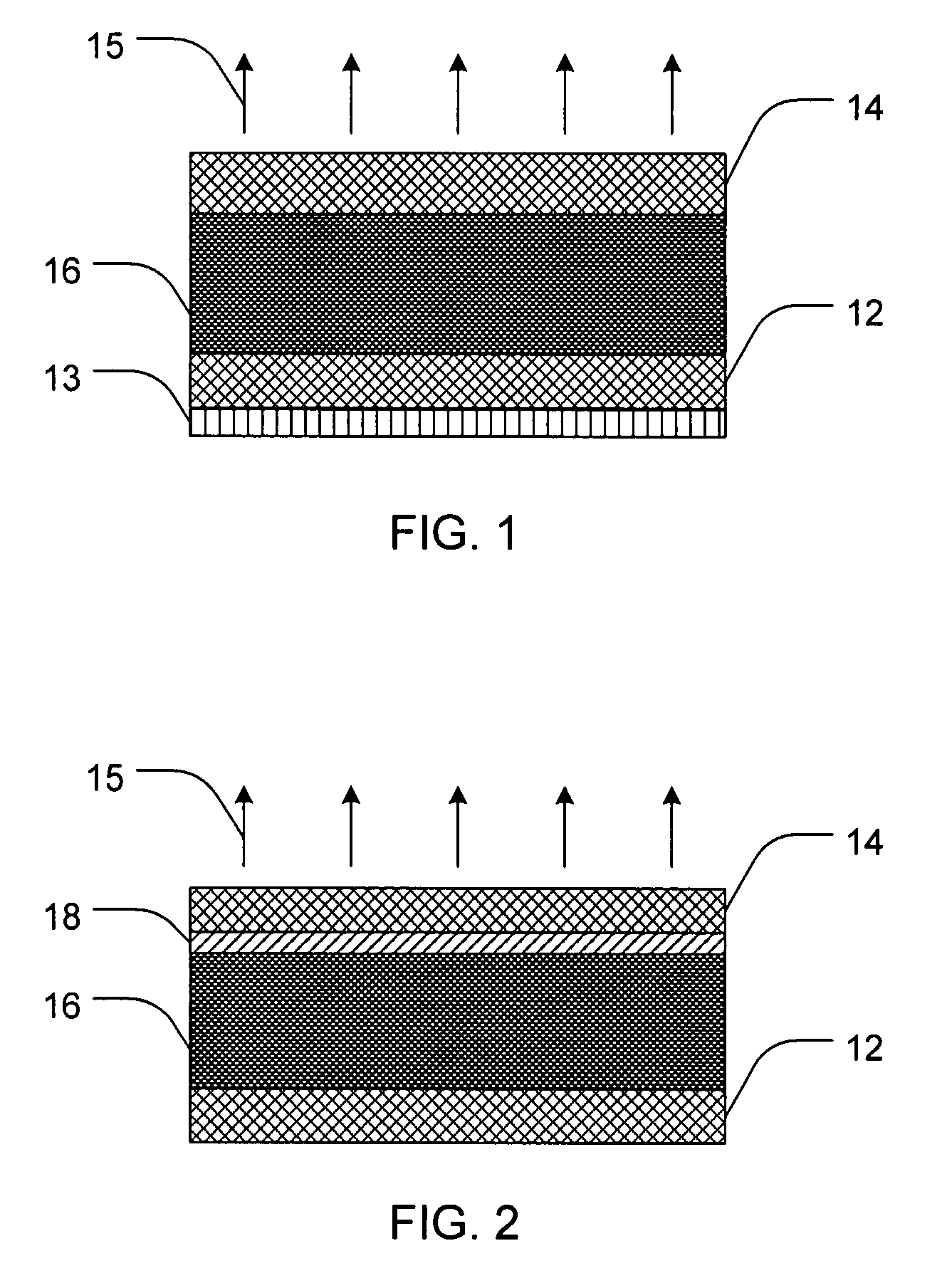

Doped Diamond LED Devices and Associated Methods

ActiveUS20090001383A1Improve thermal propertiesImprove methodSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor packageSingle crystal

LED devices and methods for making such devices are provided. One such method may include forming epitaxially a substantially single crystal SiC layer on a substantially single crystal Si wafer, forming epitaxially a substantially single crystal diamond layer on the SiC layer, doping the diamond layer to form a conductive diamond layer, removing the Si wafer to expose the SiC layer opposite to the conductive diamond layer, forming epitaxially a plurality of semiconductor layers on the SiC layer such that at least one of the semiconductive layers contacts the SiC layer, and coupling an n-type electrode to at least one of the semiconductor layers such that the plurality of semiconductor layers is functionally located between the conductive diamond layer and the n-type electrode.

Owner:SUNG CHIEN MIN

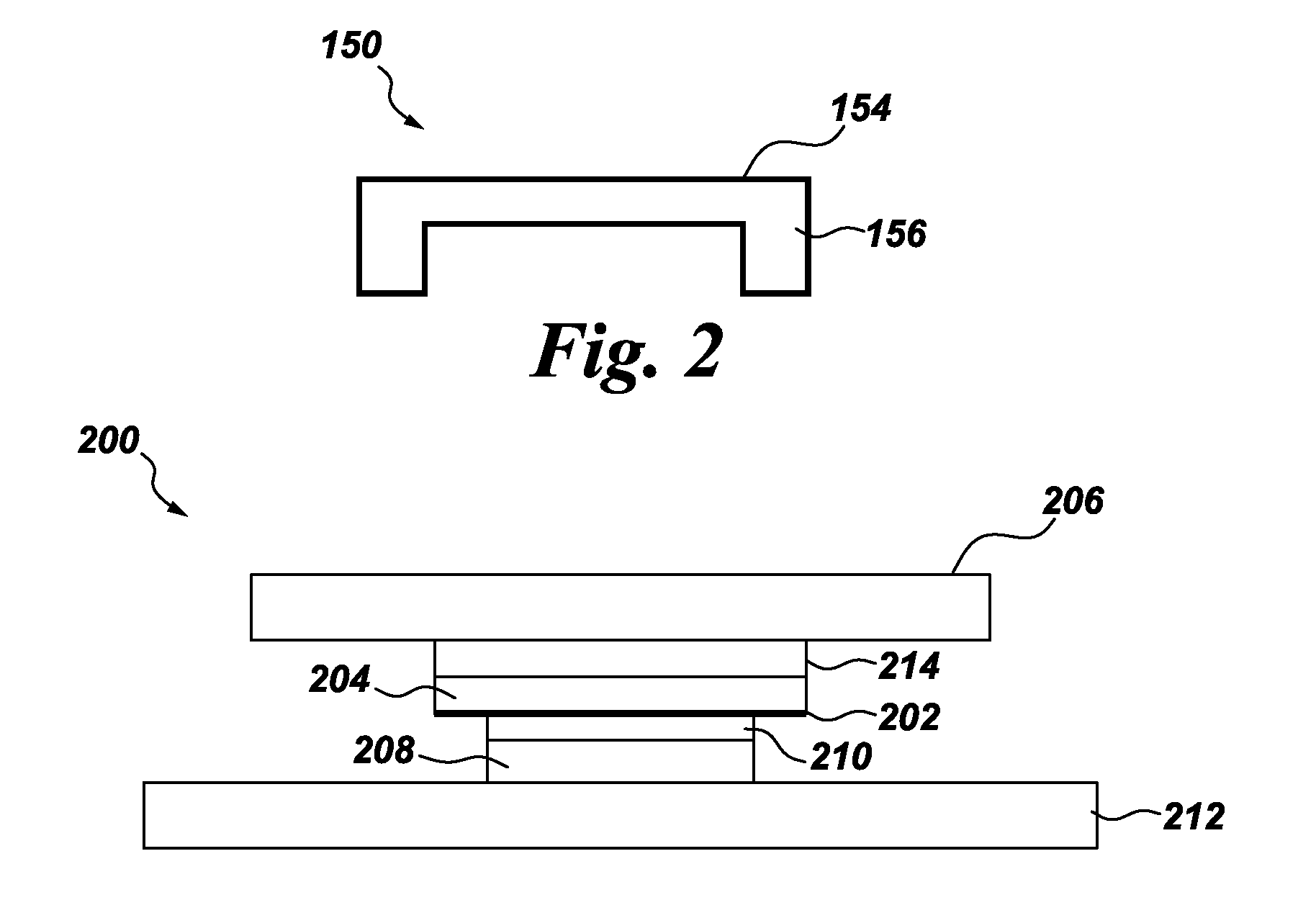

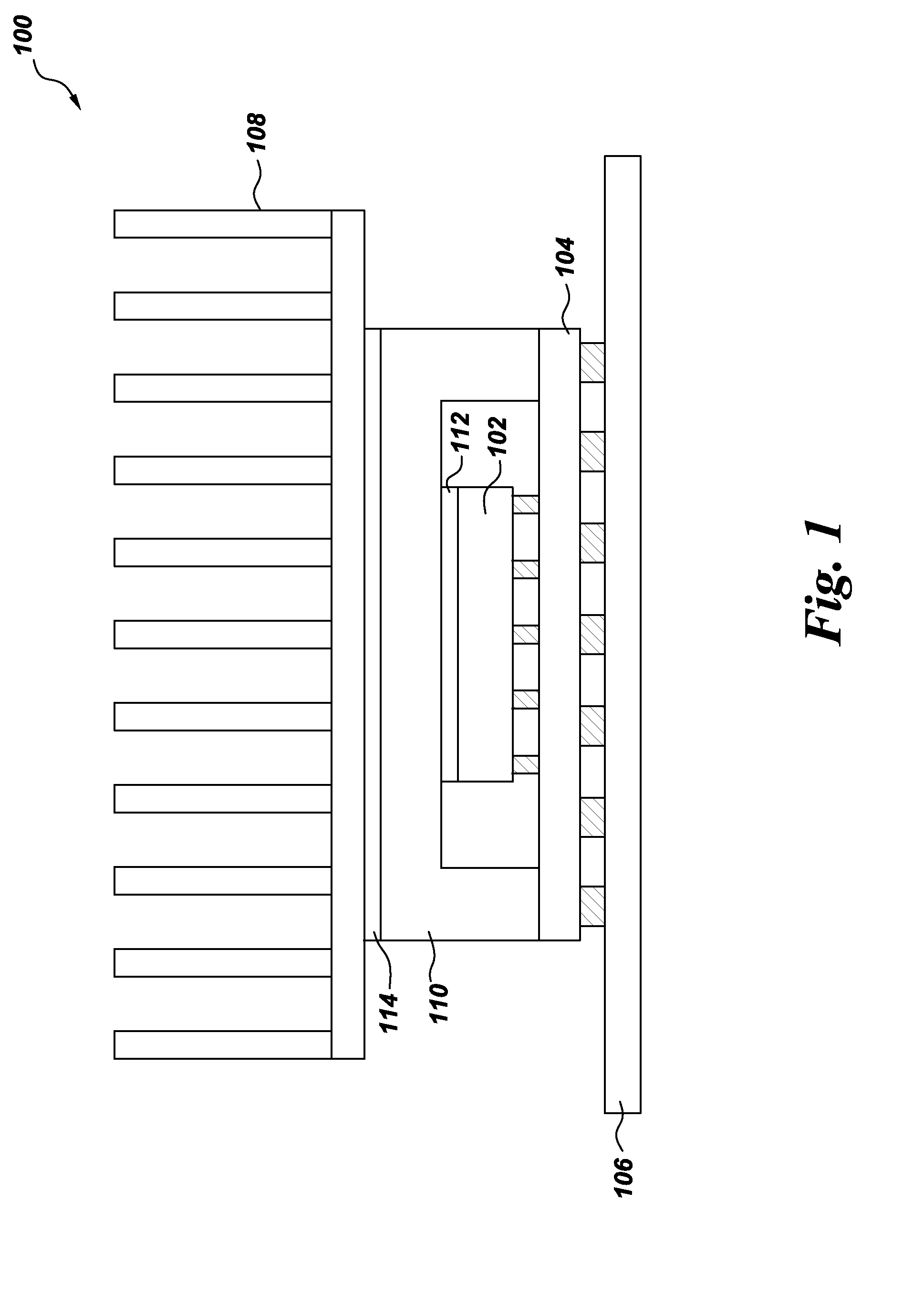

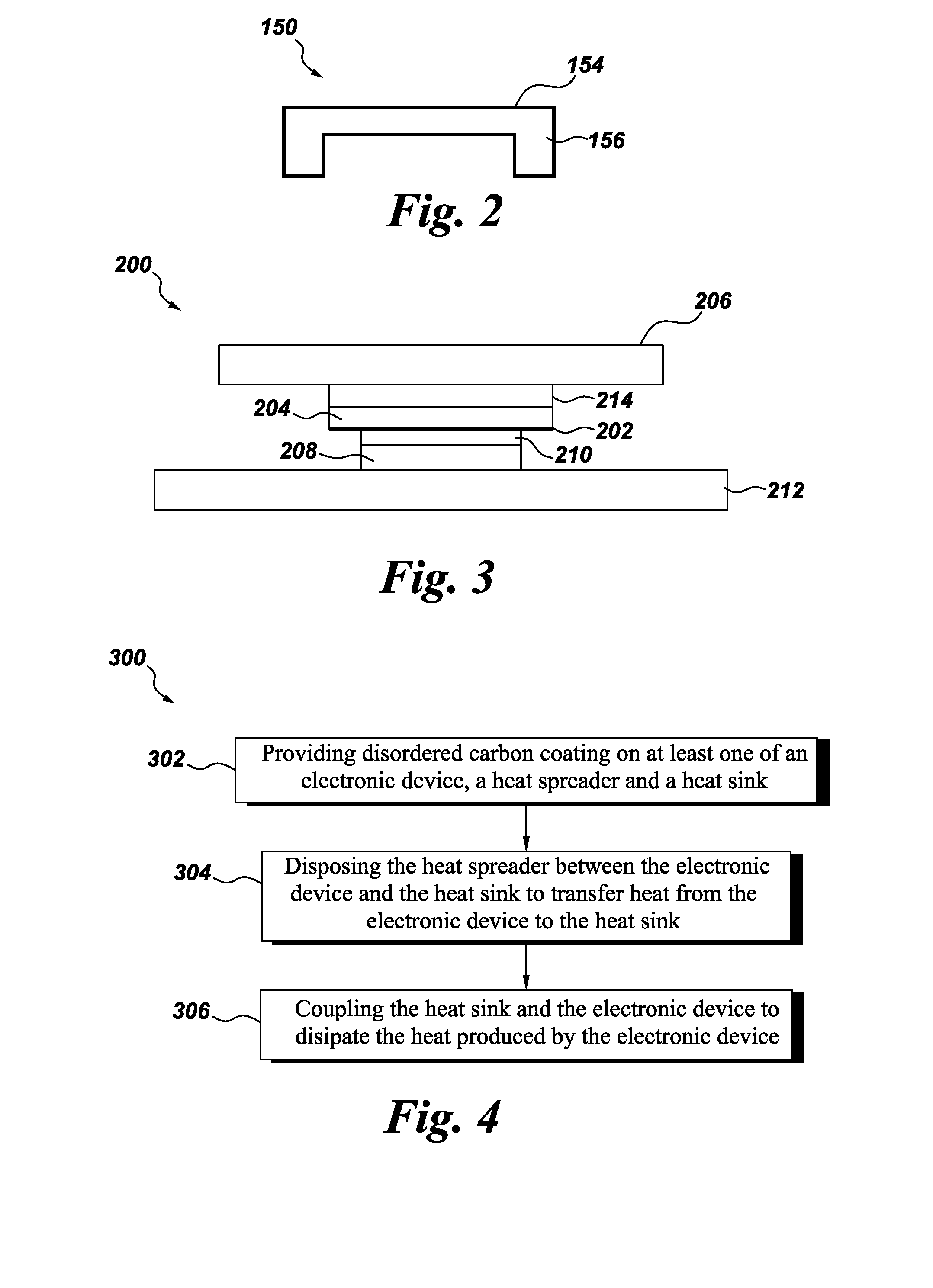

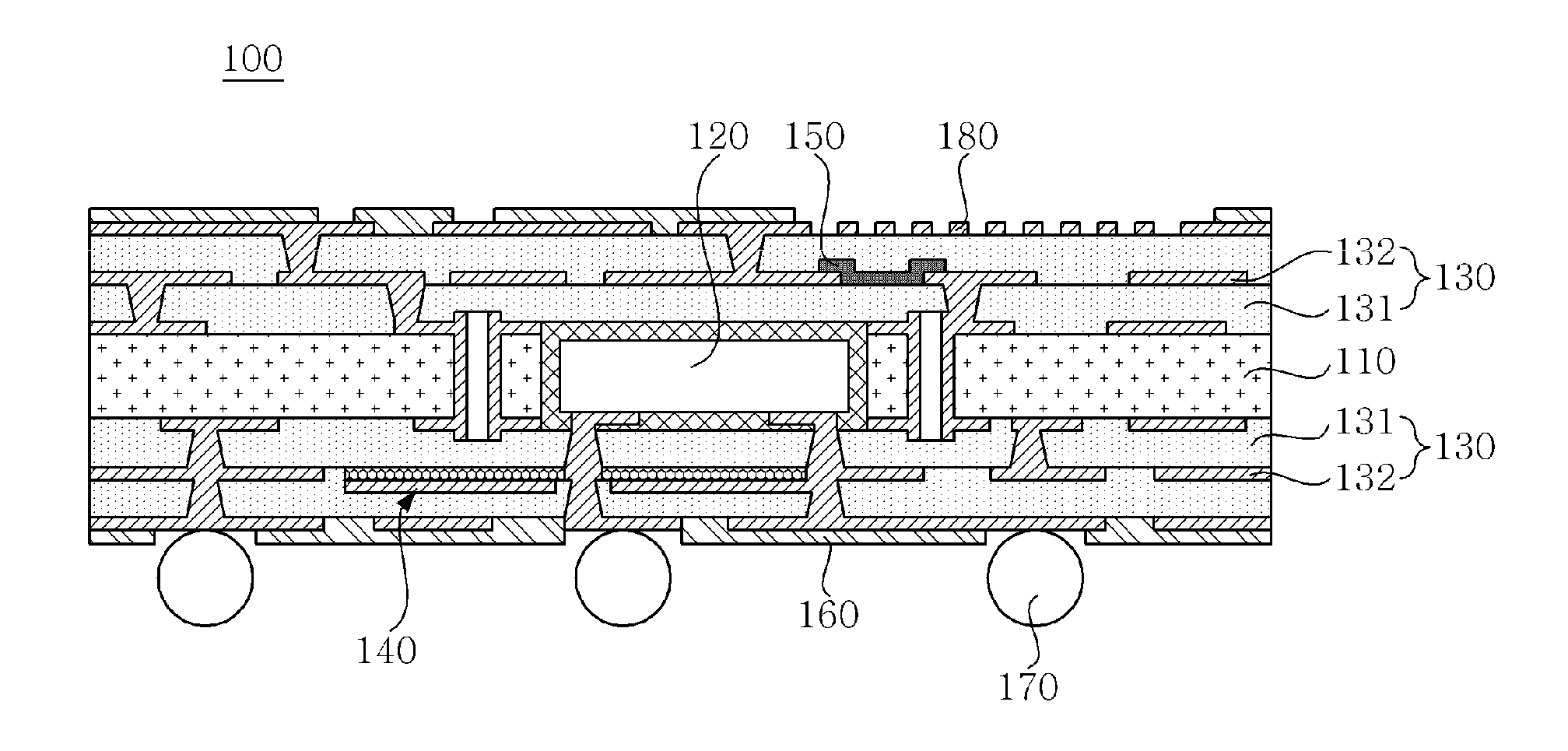

Electronic device assembly

InactiveUS20160021788A1Excellent dielectric propertiesImprove thermal propertiesSemiconductor/solid-state device detailsSolid-state devicesCarbon coatingEngineering

An electronic device assembly includes a heat sink coupled to an electronic device to dissipate the heat produced by the electronic device. A heat spreader is coupled between the electronic device and the heat sink to transfer heat from the electronic device to the heat sink. Furthermore, at least one of the electronic device, the heat spreader, and the heat sink is disposed with a disordered carbon coating.

Owner:GENERAL ELECTRIC CO

Purification method for quartz sand

InactiveCN106082238AReduce devitrificationImprove thermal propertiesSilicaPurification methodsQuenching

The invention discloses a purification method for quartz sand. The purification method comprises the following steps: crushing raw quartz ore, adding water, carrying out blending, then adding a grinding aid and successively carrying out ball milling, magnetic separation and drying so as to obtain a material A; subjecting the material A to heating, heat preservation, chlorination water and quenching and then carrying out filtering and drying so as to obtain a material B; and adding the material B into a mixed acid solution, carrying out ultrasonic treatment at 35 to 65 DEG C for 3 to 8 h and then successively carrying out filtering, washing until a pH value is 7, and drying so as to obtain purified quartz sand. The purification method for quartz sand is simple in steps, and the obtained quartz sand is high in purity and good in stability and can be applied to a plurality of fields.

Owner:安徽晶晶石英科技有限公司

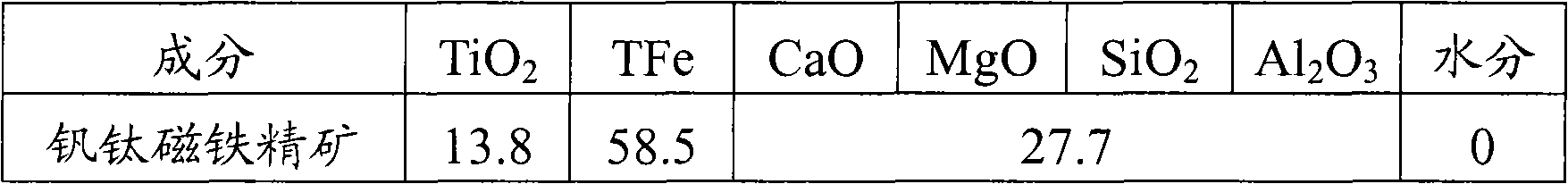

Coke for furnace protection and production method thereof

InactiveCN101787294ALow costReduce manufacturing costCoke ovensBlast furnace detailsFixed carbonBlast furnace

The invention provides a coke for furnace protection and a production method thereof. The coke for furnace protection comprises the following components in percentage by weight: 79-90% of fixed carbon, 9-18.5% of ash content, 0.55-1.5% of volatile and 0.45-1.0% of S, wherein the ash content comprises the following components in percentage by weight: 0.82-9.12% of TiO2 and 0.075-0.214% of V2O5. The coke of the invention has the characteristic of improving coke hot performance (namely the cold-to-hot reactivity of the coke (CRI)), has low production cost and can ensure long-term stable operation of a blast furnace while performing the action of protecting the furnace.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

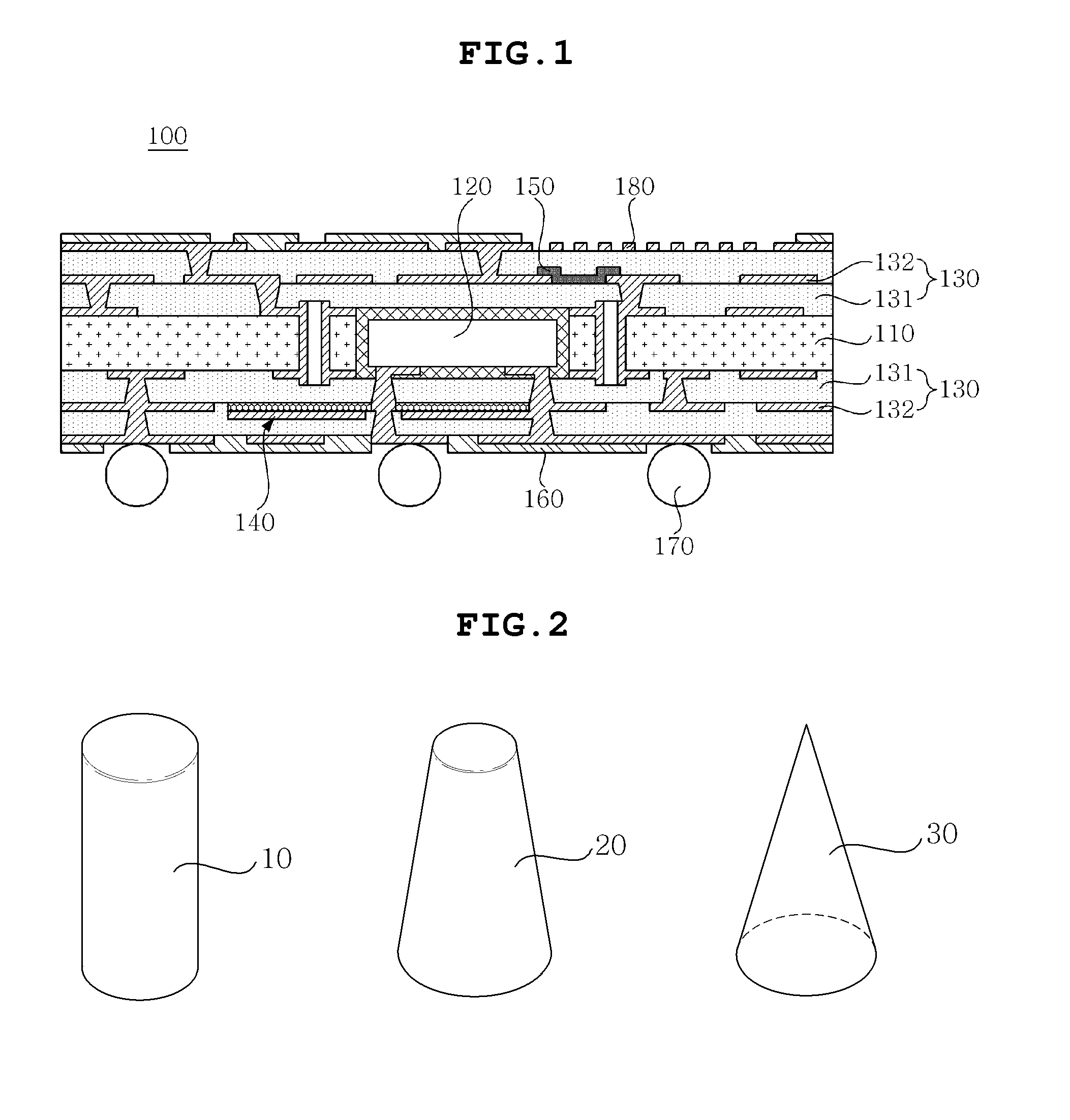

Resin composition with good workability, insulating film, and prepreg

InactiveUS20140187679A1Improve mechanical propertiesImprove thermal propertiesPrinted circuit aspectsPrinted circuit manufactureEpoxyPrinted circuit board

This invention relates to a resin composition with good workability, including a liquid crystal oligomer, an epoxy resin, or a resin mixture thereof, and an inorganic filler having a nanocone shape, and to an insulating film for a printed circuit board, and a prepreg, which are manufactured using the resin composition.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

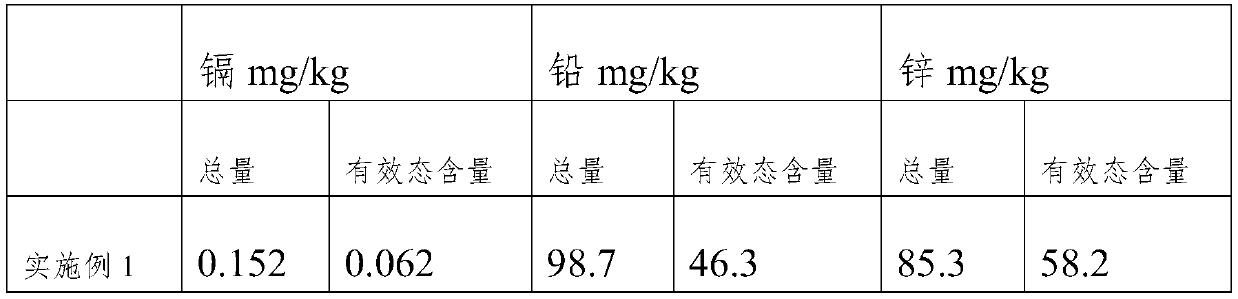

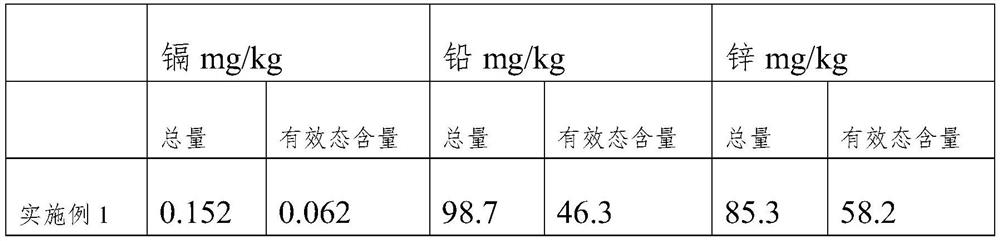

Method for remediation of lead-cadmium polluted soil

ActiveCN110586642AReduce heavy metal contentPrevention and treatment of heavy metalsContaminated soil reclamationHeavy metalsEnvironmental geology

The invention belongs to the technical field of soil remediation, and particularly relates to a method for remediation of lead-cadmium polluted soil. A combined remediation method of adsorption solidification and microbial remediation is adopted to remediate lead-cadmium polluted soil. The method particularly comprises the following steps: spreading an adsorbent and a passivator into the soil before crop seeds are sown, spraying water at the same time, then carrying out deep tillage by 5-8 cm, and standing the soil for 10-15 days; and spreading a compound bacterial preparation into the soil, carrying out shallow tillage by 3-5cm, then spraying a film forming solution into the soil, and standing the soil for 10-15 days. Through adoption of the combined remediation method of adsorption solidification and microbial remediation, heavy metals are firstly adsorbed and solidified under action of the adsorbent and the passivator, and then the adsorbed and solidified heavy metals are digested and converted by microorganisms, so that the content of the heavy metals in the soil is reduced, and the heavy metals are prevented from being dissolved again.

Owner:铜仁市万山区植保植检站

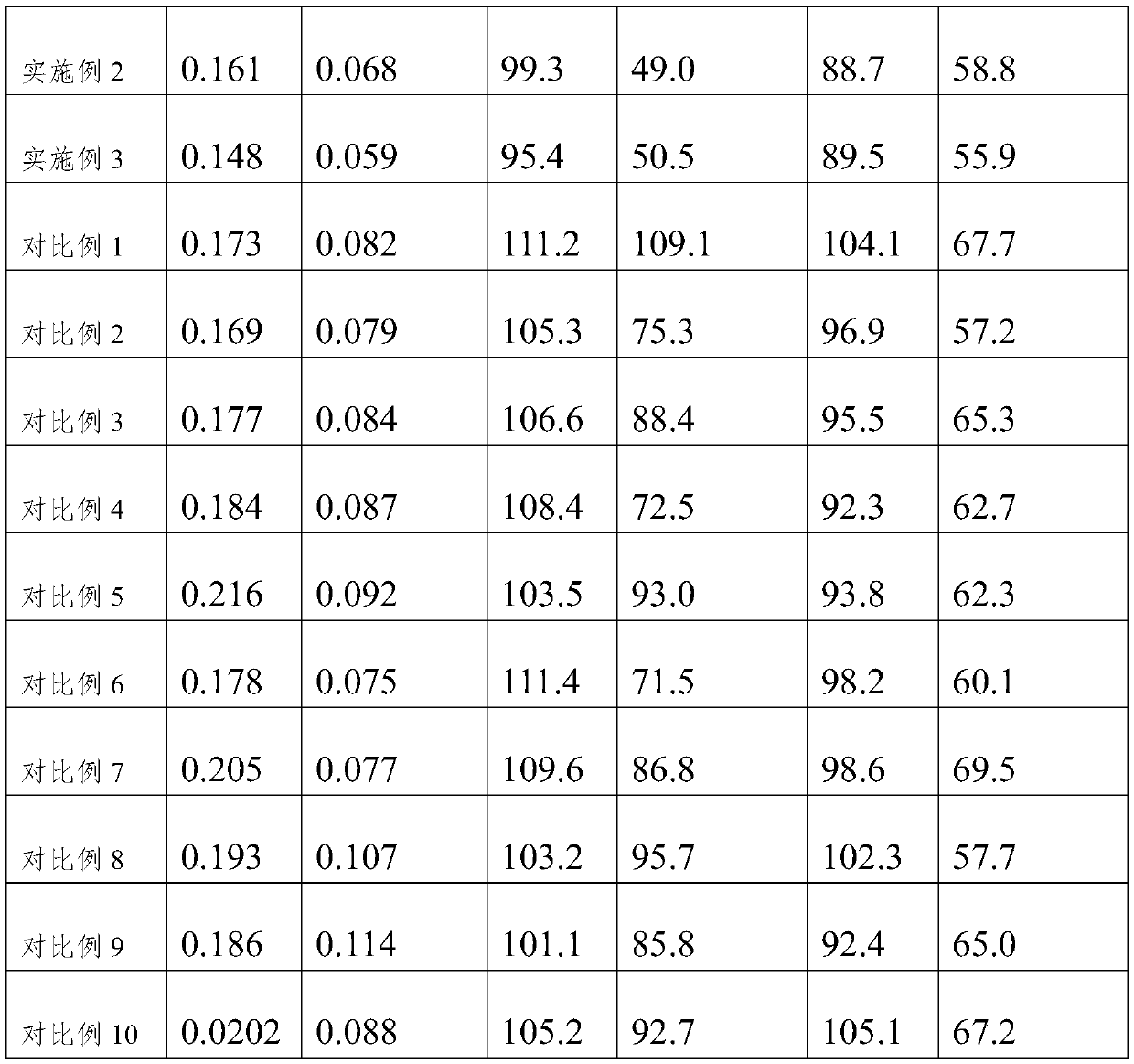

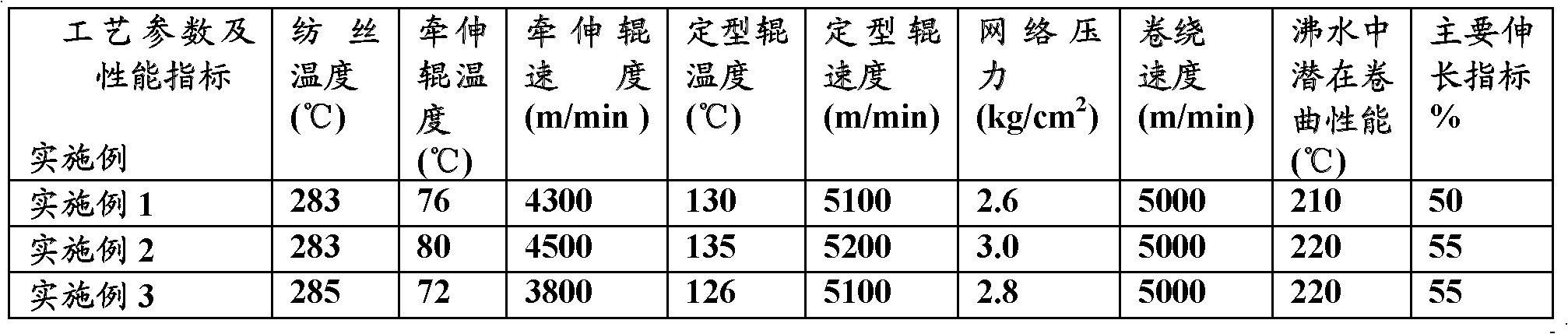

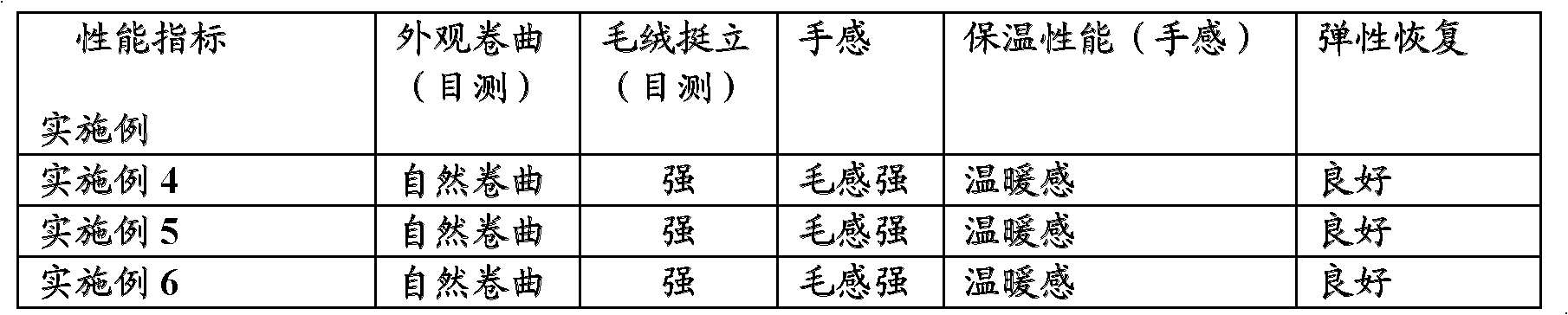

Method for preparing fibers with performance of sheep wool and imitated wool fabric

ActiveCN102425015AImprove moisture absorption performanceImprove thermal propertiesWeft knittingHollow filament manufactureWater solubleDyeing

The invention relates to a method for preparing fibers with performance of sheep wool and an imitated wool fabric. The method for preparing the fibers comprises the following steps that: (1) full dull polyethylene terephthalate (PET) slices with TIO2 content of between 2.8 and 3.6 weight percent and intrinsic viscosity of between 0.662 and 0.668 are used as a first raw material; (2) water-solublePET slices are used as a second raw material, and the consumption of the water-soluble PET slices is 2 to 3 percent of the total weight of the fibers; (3) the master batch of a far infrared material is used as a third raw material, and the consumption of the master batch is 1.5 to 4 percent of the total weight of the fibers; (4) nano calcium titanate master batch is used as a fourth raw material,and the consumption of the master batch is 0.5 to 0.8 percent of the total weight of the fibers; and (5) the four raw materials are mixed uniformly in a mixing device and spun through a medium hole plate to form the fibers, and the fibers are prepared into the imitated wool fabric by warp knitting, weft knitting, alkali treatment, dyeing, finishing, sizing and drying. The function of the imitatedwool fabric is 80 to 82 percent similar to that of a wool fabric. Moreover, the method is simple and low in cost.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Manufacturing process of high thermal-preservation, moisture absorption and sweat-releasing acrylic fibers and application thereof

The invention discloses a manufacturing process of high thermal-preservation, moisture absorption and sweat-releasing acrylic fibers. The process comprises following steps: (1) material selection; (2) cotton carding operation; (3) drawing operation; (4) roving operation; (5) spinning operation; (6) spooling operation. The invention further discloses a fabric manufacturing process utilizing fibers obtained by the above process as warp yarns. The process comprises following steps: (1) material selection: selecting 60% of cotton in 1.3D*33mm and 40% of lenzing viscose in 1.2 D*38 mm to be blended as weft yarns; (2) warping operation; (3) sizing operation; (4) denting operation; (5) weaving operation; (6) performing pre-treatment after manufacture; (7) printing. The manufacturing process of high thermal-preservation, moisture absorption and sweat-releasing acrylic fibers has following beneficial effects: acrylic fibers manufactured feel soft, has good spreadability, high water-carrying performance and soft lustre, are fluffy, dry and comfortable, breathable and comfortable to wear and easy to dye and resemble wool; and anti-solarization, weatherability and mildew-resistant and mothproof performance of ordinary acrylic fibers are obtained.

Owner:SHANGHAI SHUIXING HOME TEXTILE

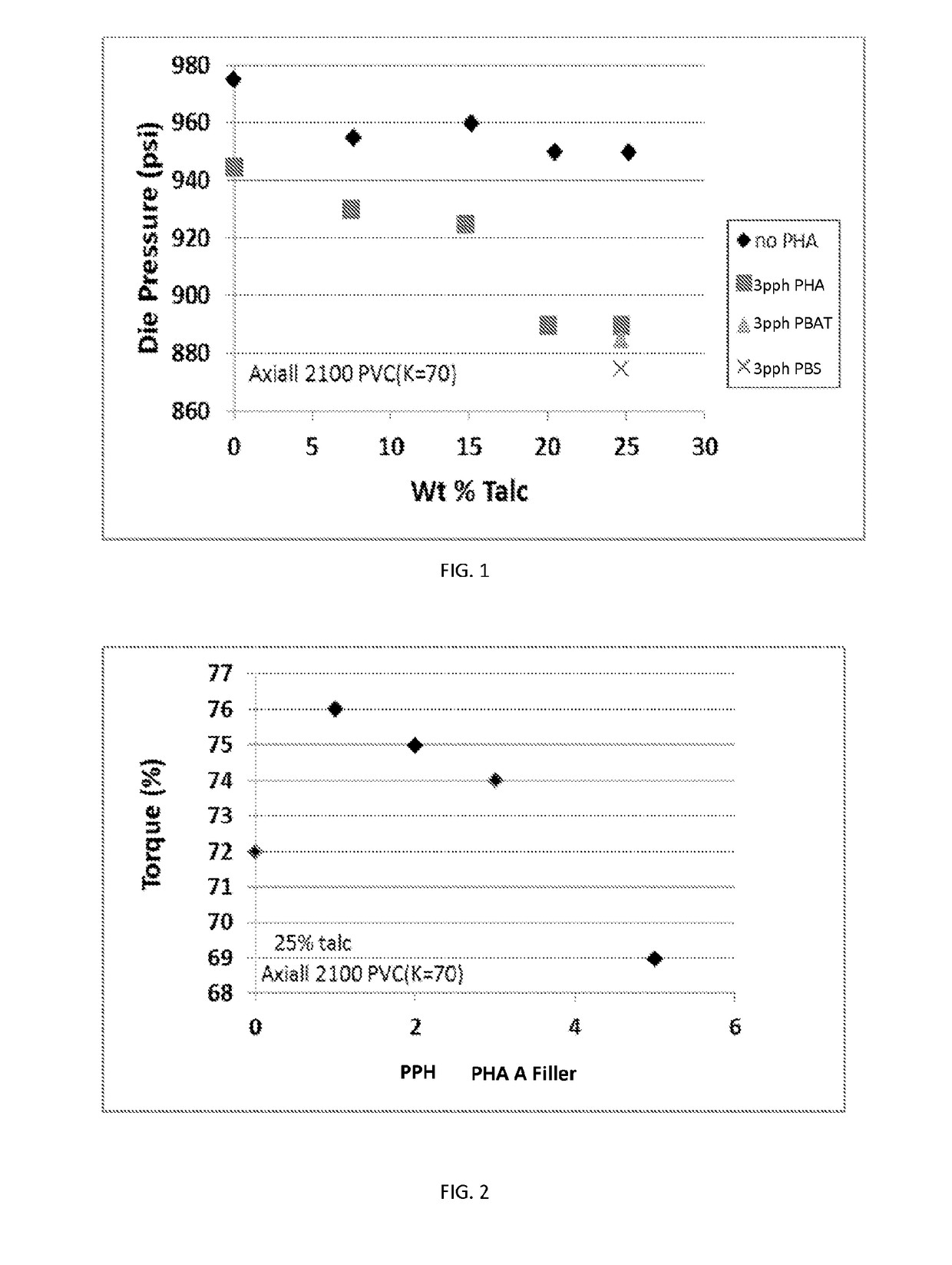

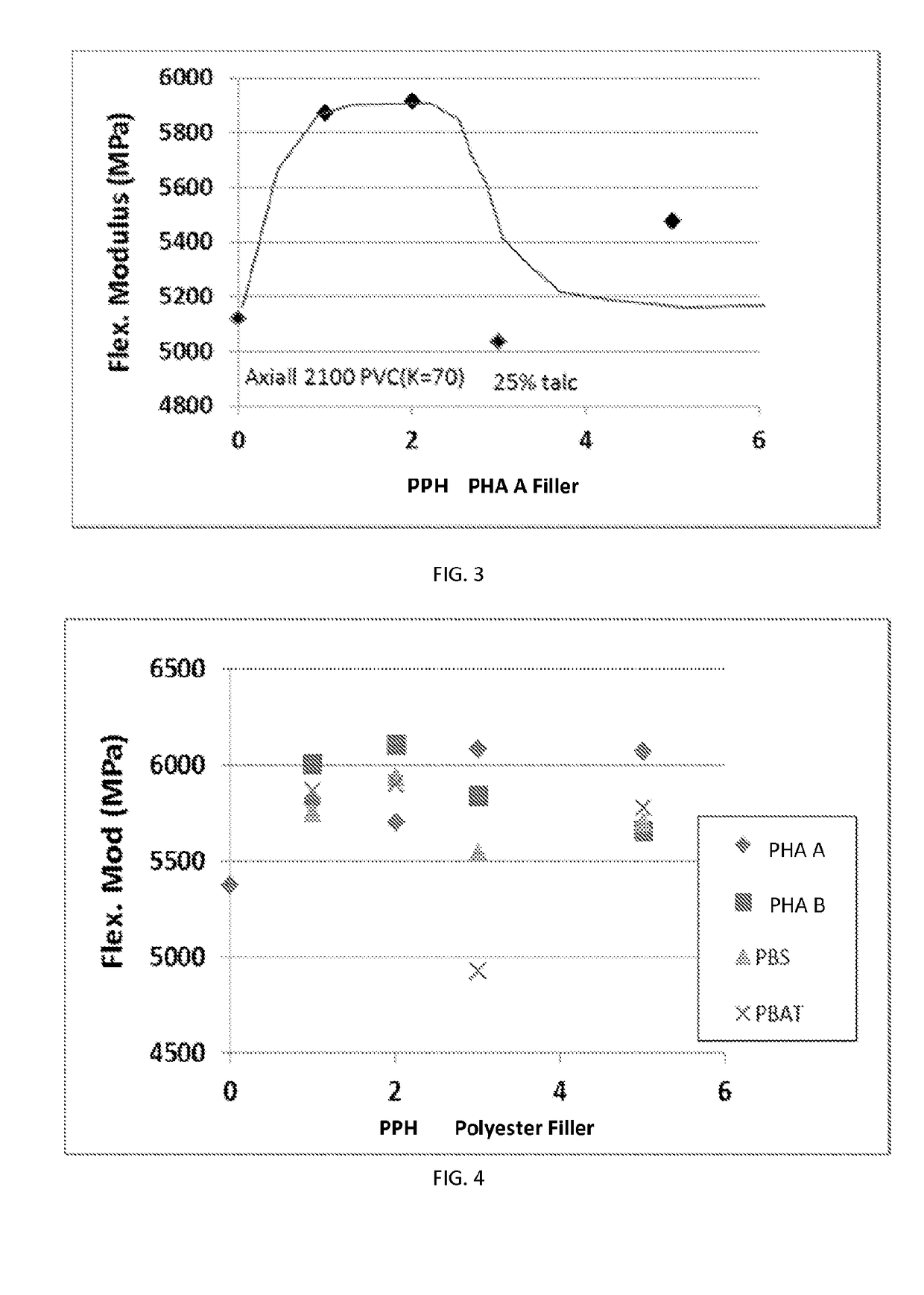

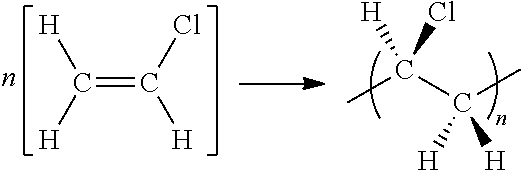

Highly filled polymer systems

Polymer systems comprising poly(vinyl chloride), a non-petroleum based filler, and a polyester additive, wherein the polymer system is highly filled, and articles made therefrom, are described. The high loading of filler (e.g., talc, calcium carbonate or a combination thereof) is achieved by incorporation of polyester additives such as polyhydroxyalkanoates. High filler loading without significant reduction of relevant material properties can be associated with cost savings and environmental benefits.

Owner:CJ CHEILJEDANG CORP

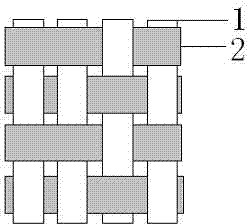

Novel warm-keeping fabric

The invention discloses a knitting product, namely novel warm-keeping fabric. The novel warm-keeping fabric comprises warps and wefts, and the warps and the wefts are mutually interlaced in a manner of two yarns on the top and one yarn on the bottom, wherein a polyester fiber is adopted as the warps, a novel blended fiber is adopted as the wefts, and the novel blended fiber comprises a mohair fiber, a rabbit hair fiber and a kapok fiber. The novel warm-keeping fabric disclosed by the invention has excellent warm keeping property and also has the characteristics of softness, comfort, moisture absorption, ventilation, no mould, static resistance and the like.

Owner:CHANGSHU FUJIALI WEAVING

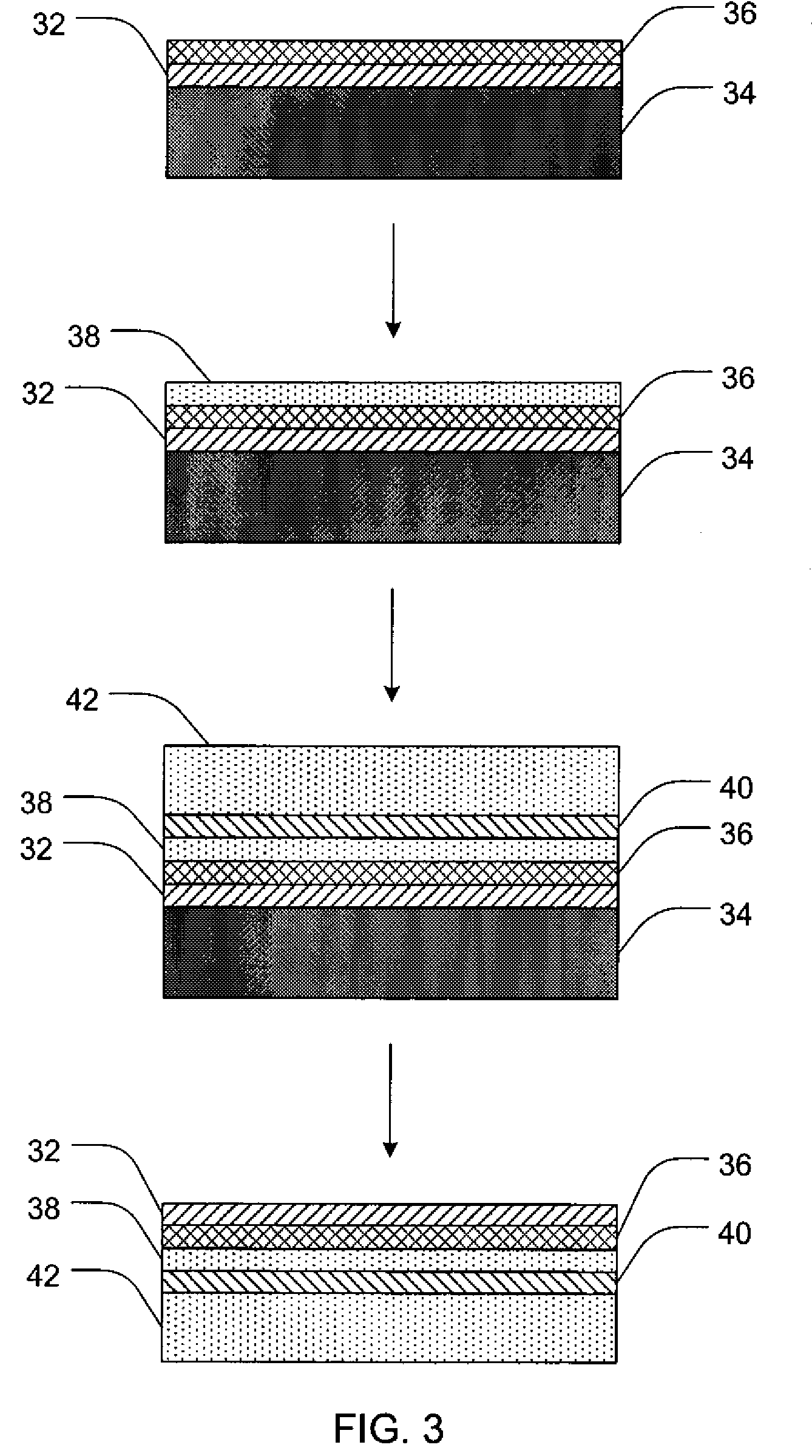

Diamond semiconductor devices and associated methods

ActiveUS20110068350A1Improve thermal propertiesImprove methodSemiconductor/solid-state device manufacturingSemiconductor devicesCrystal structureSemiconductor

Semiconductor devices and methods for making such devices are provided. One such method may include forming a transparent diamond layer having a SiC layer coupled thereto, where the SiC layer has a crystal structure that is substantially epitaxially matched to the transparent diamond layer, forming epitaxially a plurality of semiconductor layers on the SiC layer, and coupling a diamond substrate to at least one of the plurality of semiconductor layers such that the diamond support is oriented parallel to the transparent diamond layer. In one aspect such a method may further include electrically coupling at least one of a p-type electrode or an n-type electrode to at least one of the plurality of semiconductor layers.

Owner:SUNG CHIEN MIN

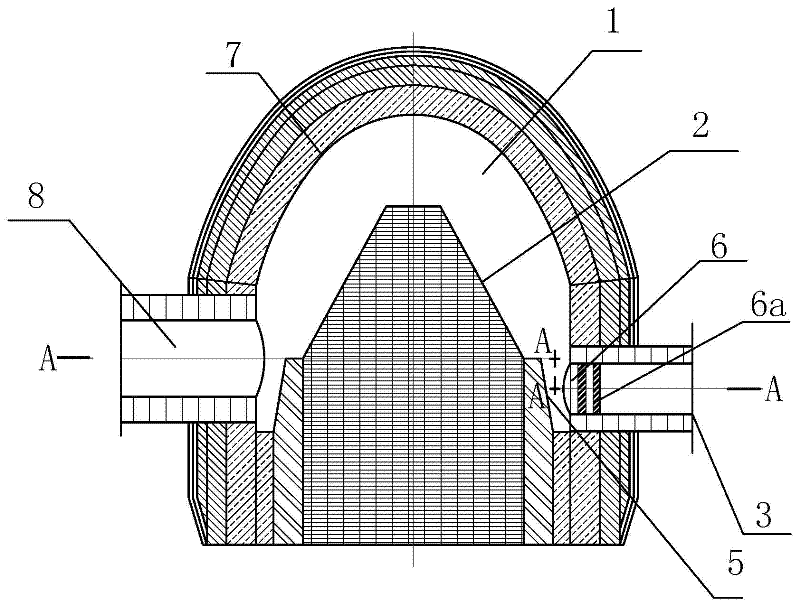

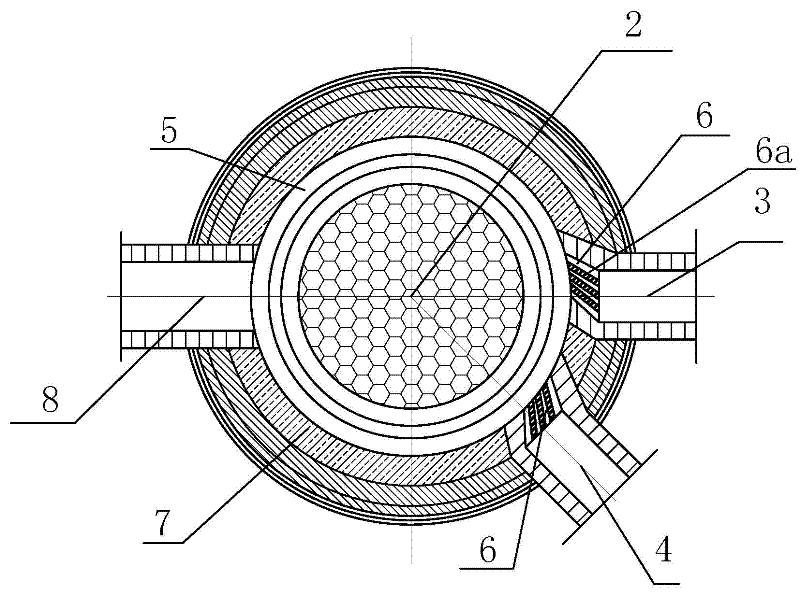

Burner with quick swirl mixing device for burning in porous cone

InactiveCN102410535ASave burning spaceSimple structureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention relates to a burner with quick swirl mixing device for burning in porous cone, which can effectively solve the problems that most of furnace burning devices are complex and need large burning space, the gas is not mixed uniformly, the burning is incomplete, the environment is polluted and energy is wasted; the swirl and reflux burning chamber is an annular space between the bell-shaped wall and the round porous heat storage cone; the side of the bell-shaped wall is provided with a gas and air inlet tube; the gas and air inlet tube is connected with the swirl and reflux burning chamber by an air inlet nozzle; a flow guild baffle is disposed in the air inlet nozzle, the opening is faced to the airflow mixing annular channel, so as to solve the problems that the burning of the low-heat value gas is not stable, the burning intensity is small and the burning temperature is low; the invention can not only realize quick airflow mixing, high temperature pre-heating in the porous cone and high-intensity burning under the condition of simple structure, but also the invention plays a vital role in simplifying the whole structure of industrial furnace and improving the thermal performance.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

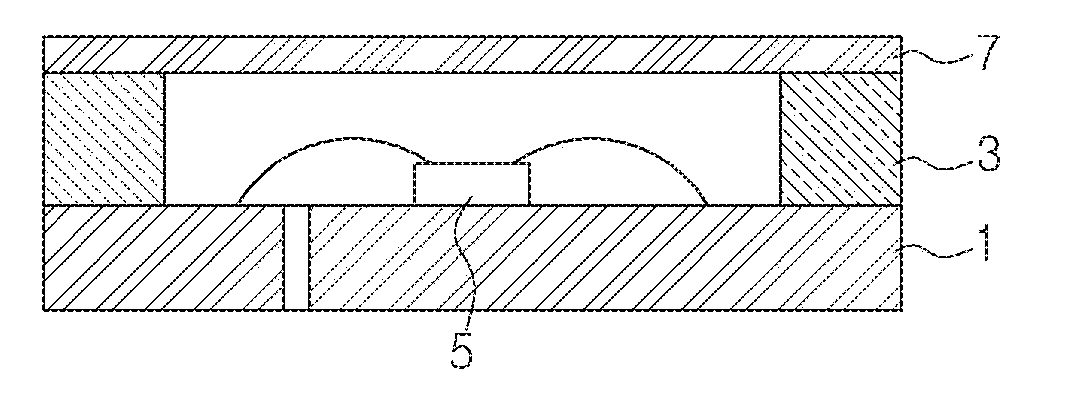

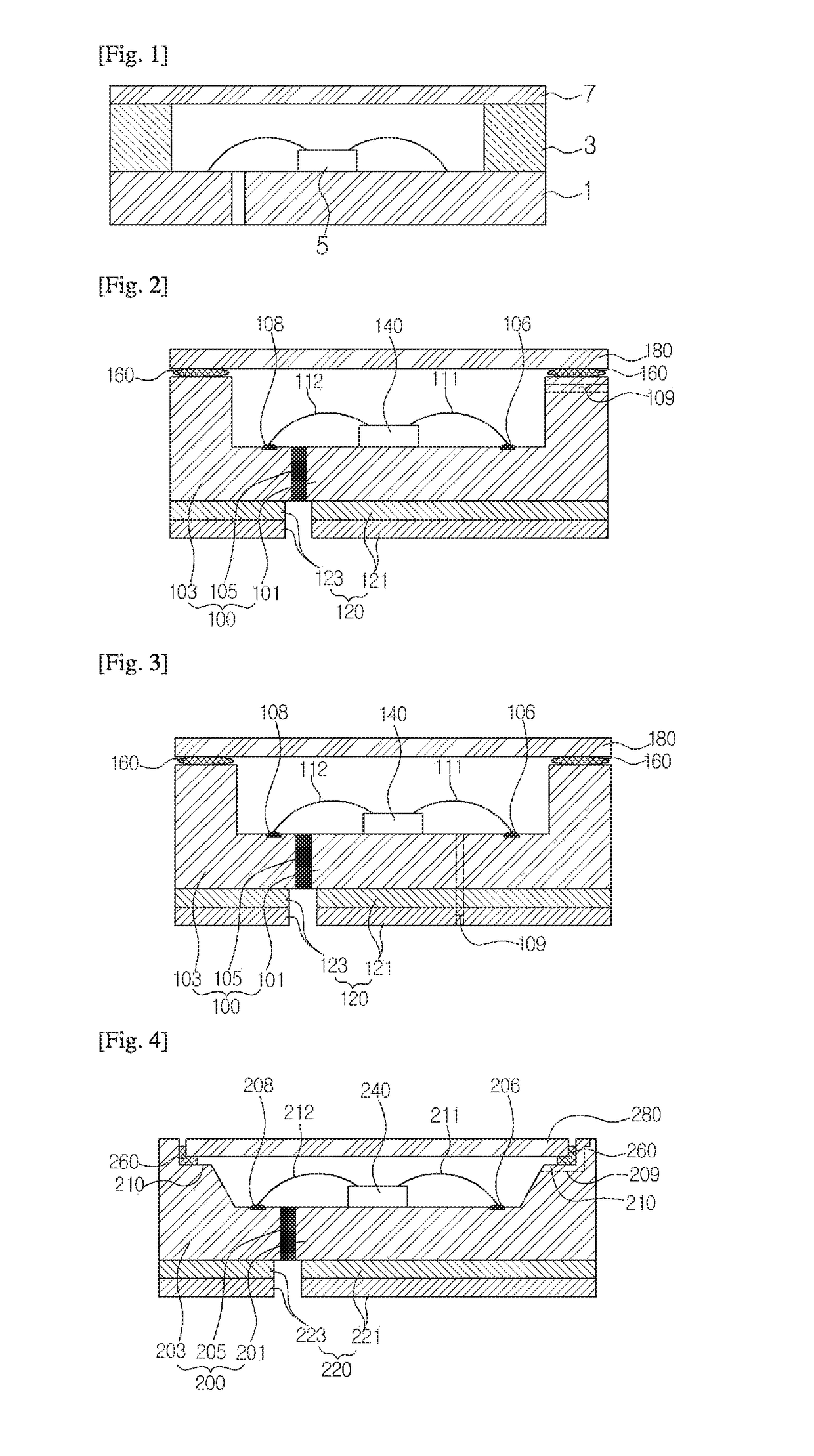

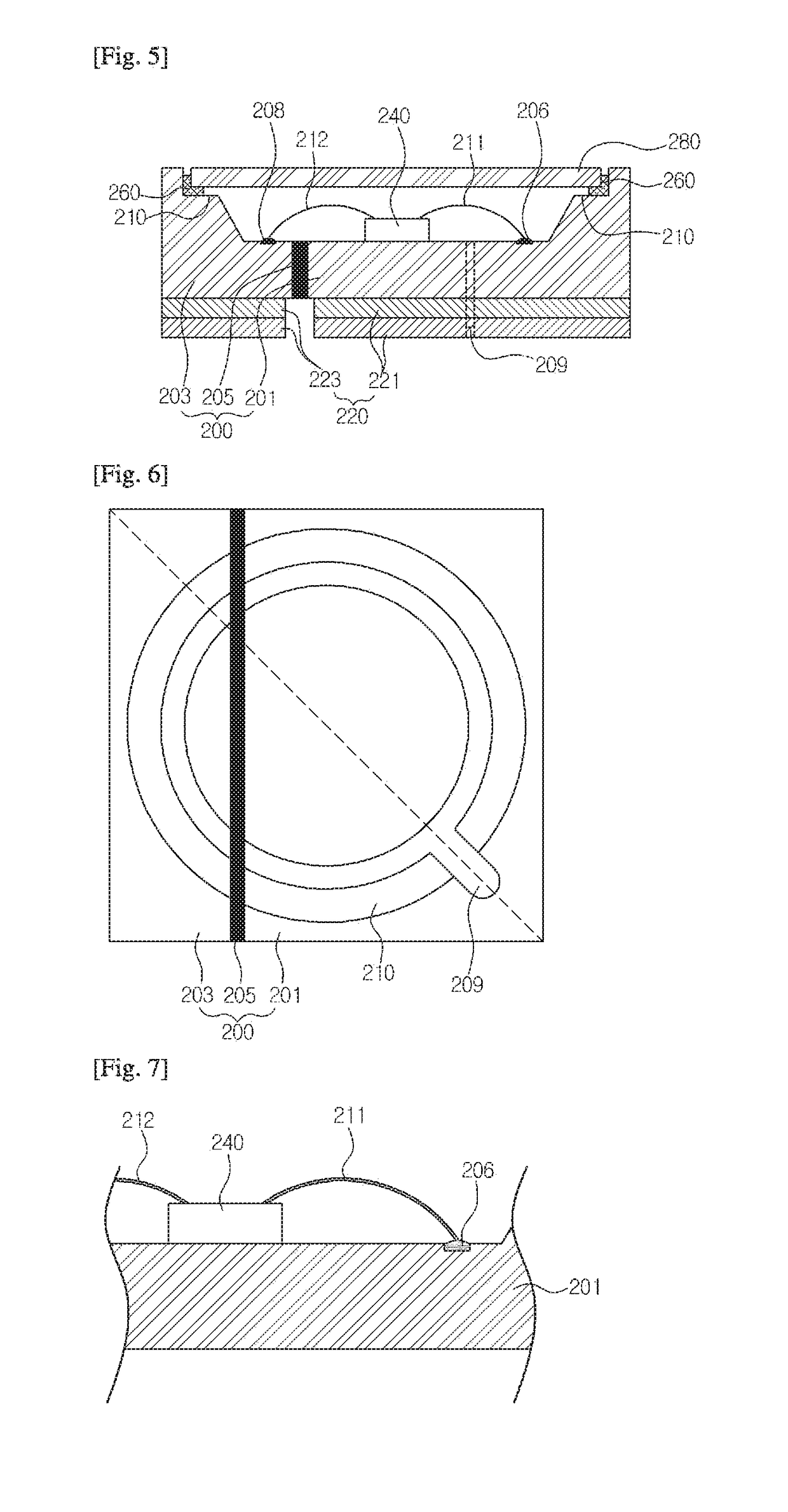

Light-emitting device and method of manufacturing the same

ActiveUS20170338382A1Improve thermal propertiesImproved property electrical connection propertySolid-state devicesSemiconductor devicesEngineeringLight emitting device

A light-emitting diode package includes a frame portion with a chip-mounting region defined in an upper portion thereof, and first and second frames spaced apart from each other. A light-emitting diode is mounted on at least a portion of the chip-mounting region with a bonding layer interposed therebetween. The frame portion includes a depressed portion formed on an upper surface thereof, and the depressed portion includes the chip-mounting region defined on a bottom thereof. The depressed portion also includes a step portion disposed at an outer upper end thereof.

Owner:SEOUL VIOSYS CO LTD

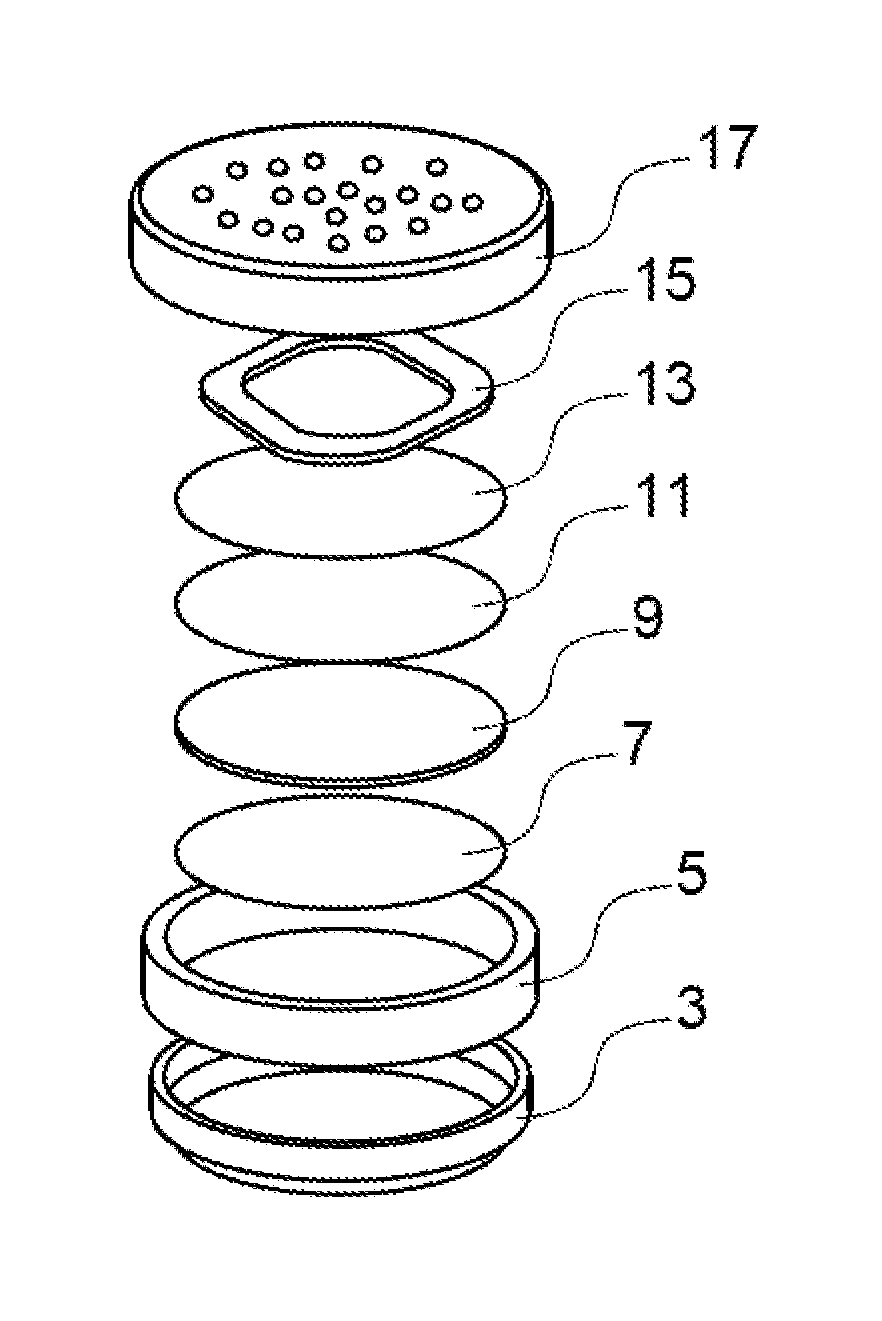

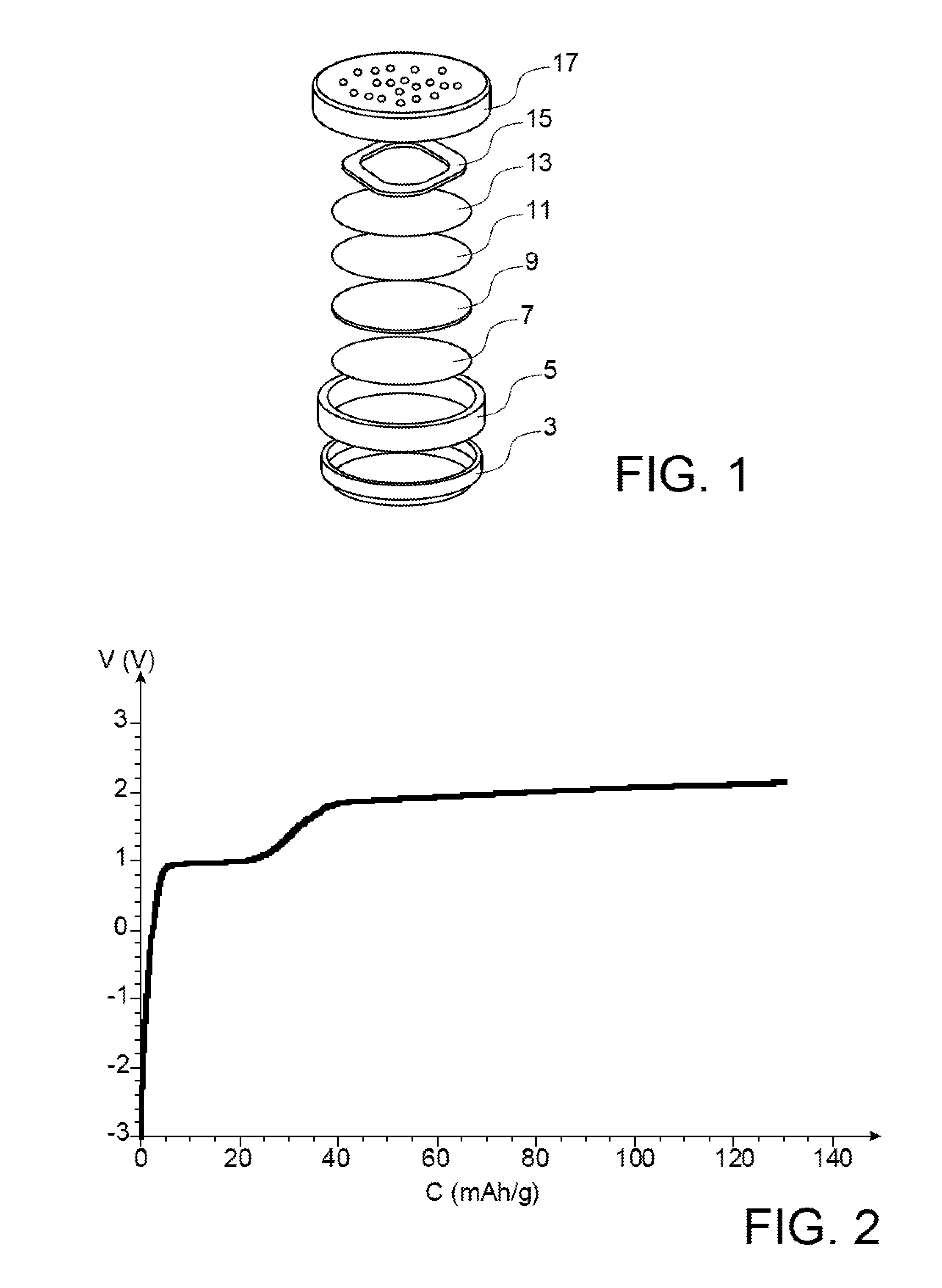

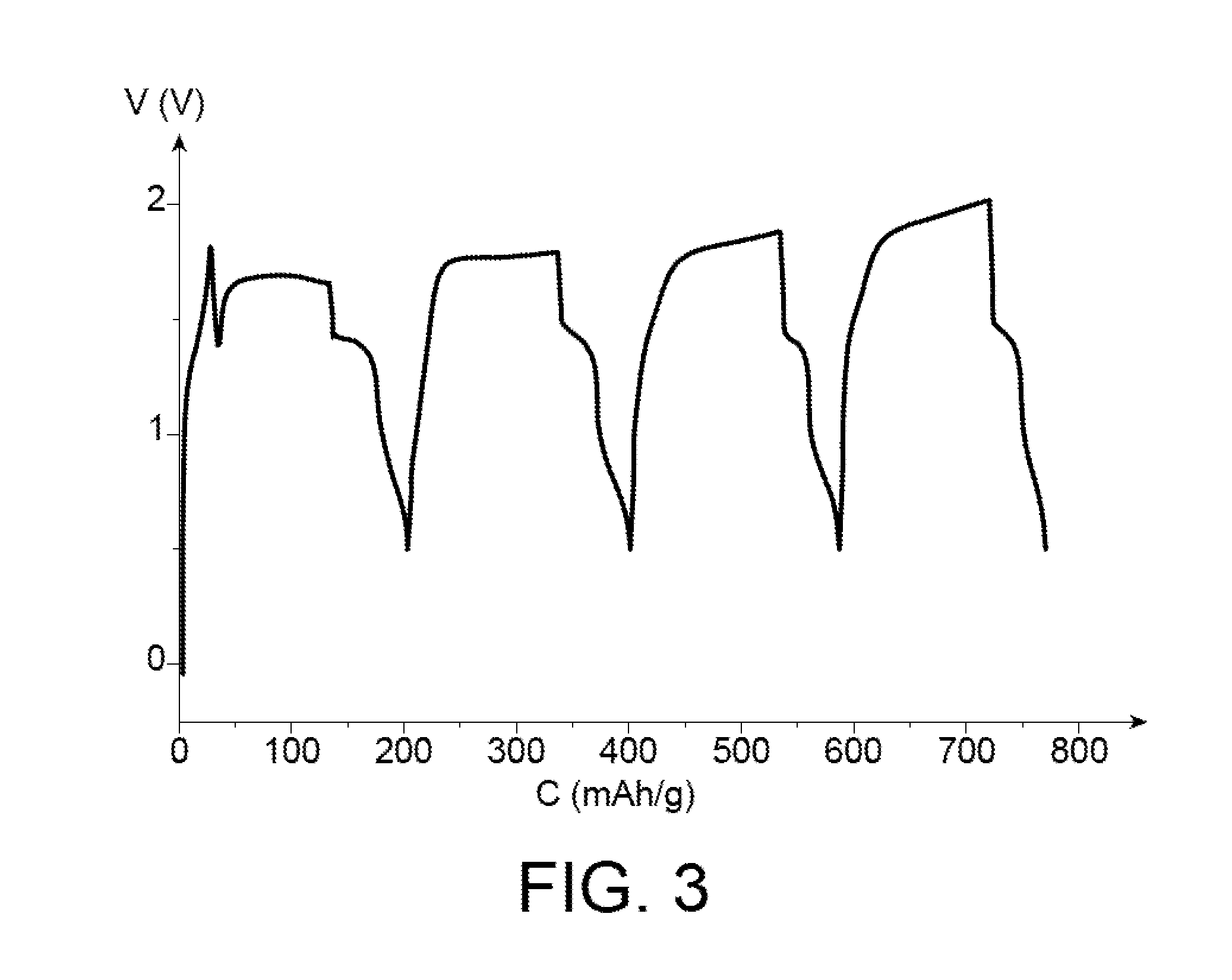

Lithium electrochemical storage battery of the lithium/air type

InactiveUS20150125762A1High mechanical strengthLarge Young modulusFuel and primary cellsFuel and secondary cellsLithiumPotential difference

A lithium-air storage battery having at least one electrochemical cell witha negative electrode, which is an air electrode;a positive electrode, which comprises a material for insertion of lithium; andan organic electrolyte conducting lithium ions, positioned between the negative electrode and positive electrode, the electrolyte not degrading, when it is subject to a voltage ranging from 3V to 5.5V expressed relatively to the Li+ / Li pair and the storage battery having a potential difference between the electrochemical potential of the positive electrode and the electrochemical potential of the negative electrode greater than 4.5V expressed relatively to the Li+ / Li pair.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

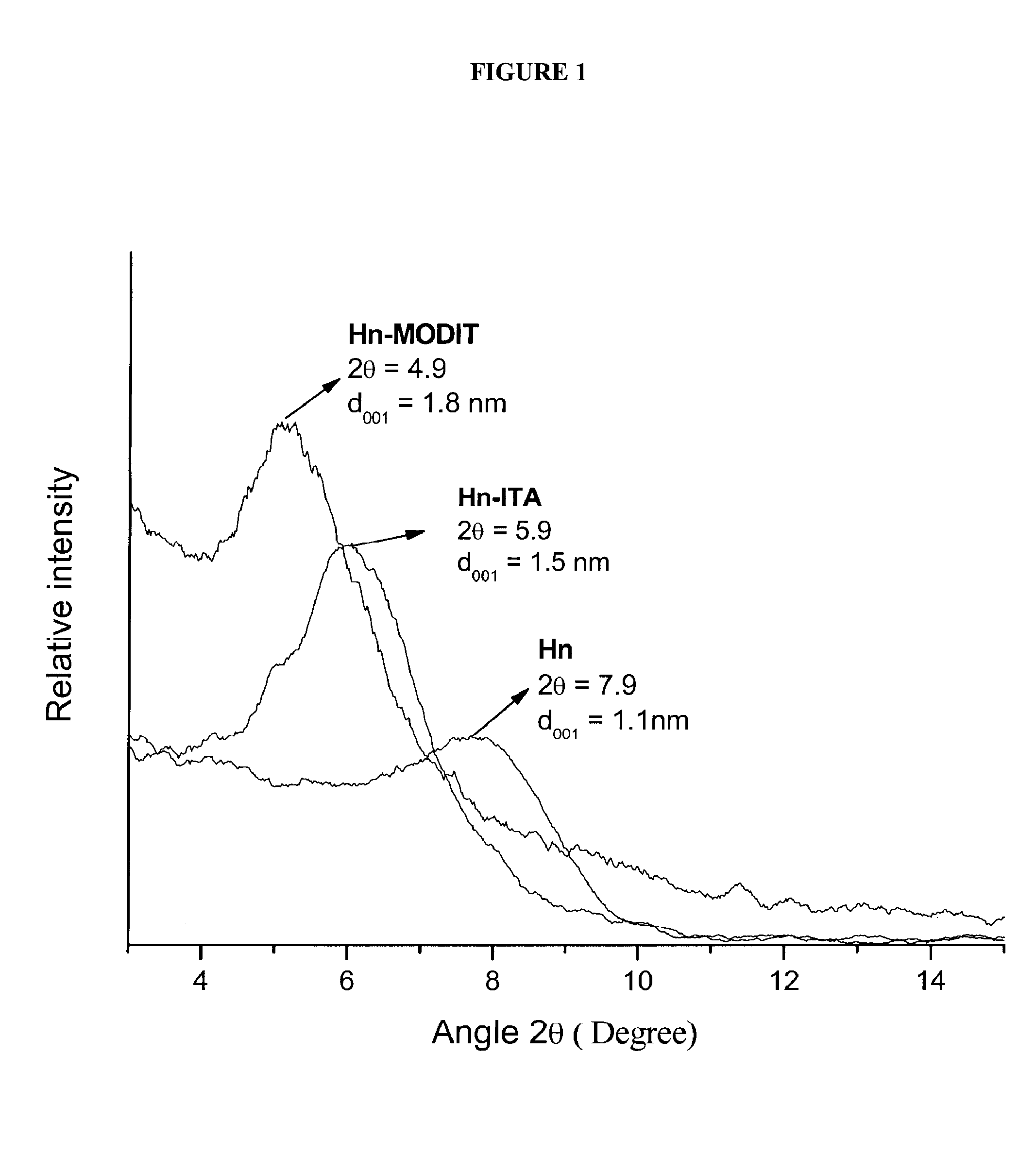

Hybrid clays for obtaining nanocomposites and a preparation process therefore

InactiveUS20090209687A1Easy to disperseImprove mechanical propertiesSilicon organic compoundsPigmenting treatmentPolyolefinItaconic acid

Hybrid clays for obtaining nanocomposites useful in the automotive, aviation, construction and packaging industry, among others. The hybrid clay comprises clays intercalated with the itaconic acid (ITA) monomer or its derivative monooctadecyl itaconate (MODIT), and a process for the preparation of these hybrid clays and the process to obtain polyolefin / clay nanocomposites.

Owner:UNIVERSITY OF CHILE

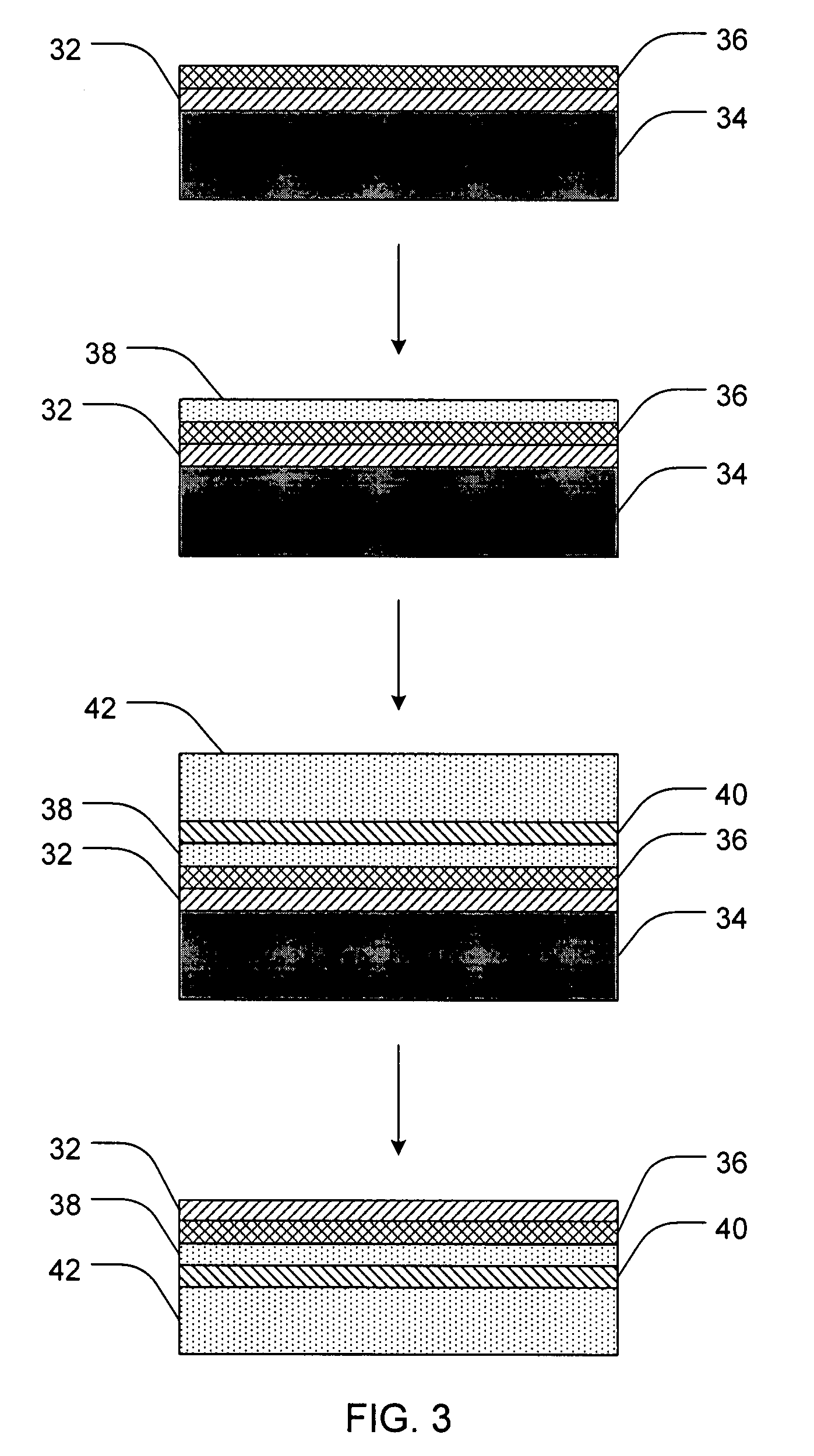

Method for preparation of diffusion sheet

ActiveUS20080299304A1Improve mechanical propertiesExcellent optical propertiesCoatingsSpecial surfacesMaterials scienceCoating

A low cost and simple method for preparation of diffusion sheets is disclosed. The diffusion sheet is made from low-cost inorganic nano-scale material by an energy-saving wet coating process. Moreover, the diffusion sheet manufactured by the present invention also has feature of abrasion and scratch resistance due to use of curable acrylic binder.

Owner:NAT CHUNG SHAN INST SCI & TECH

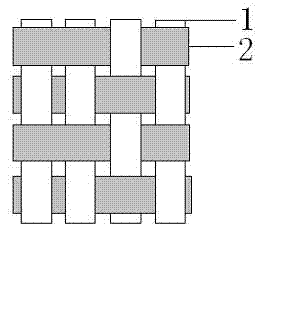

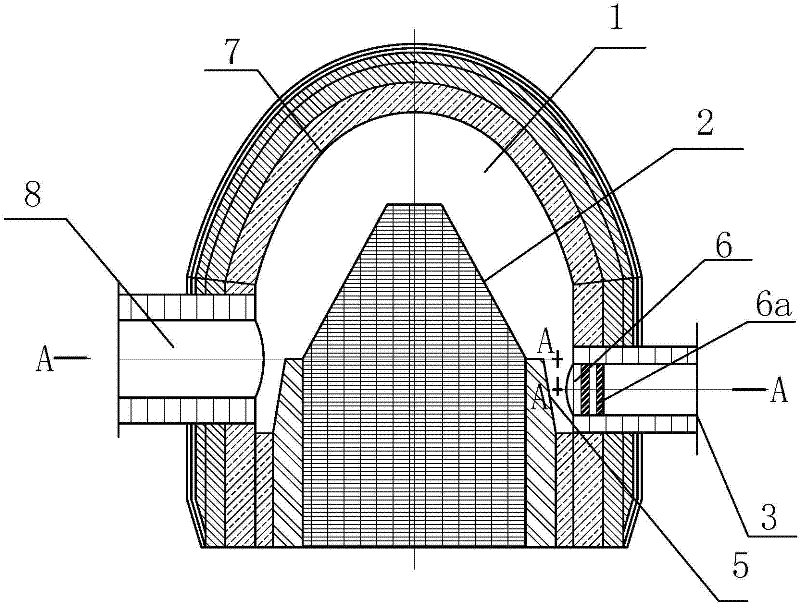

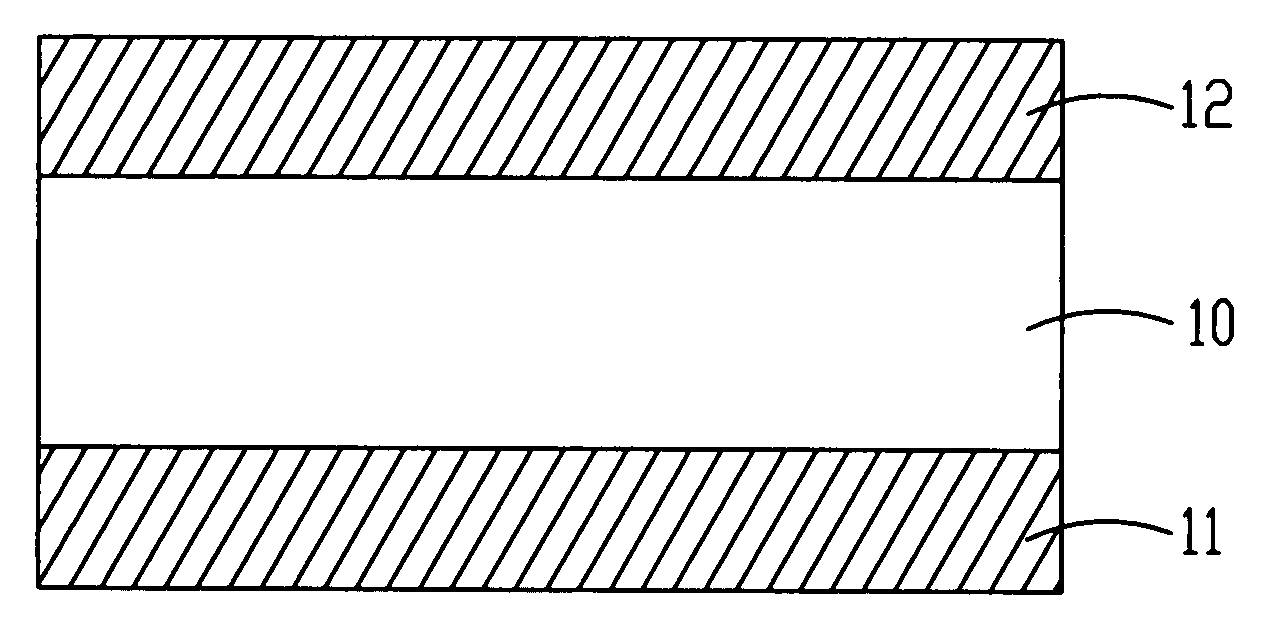

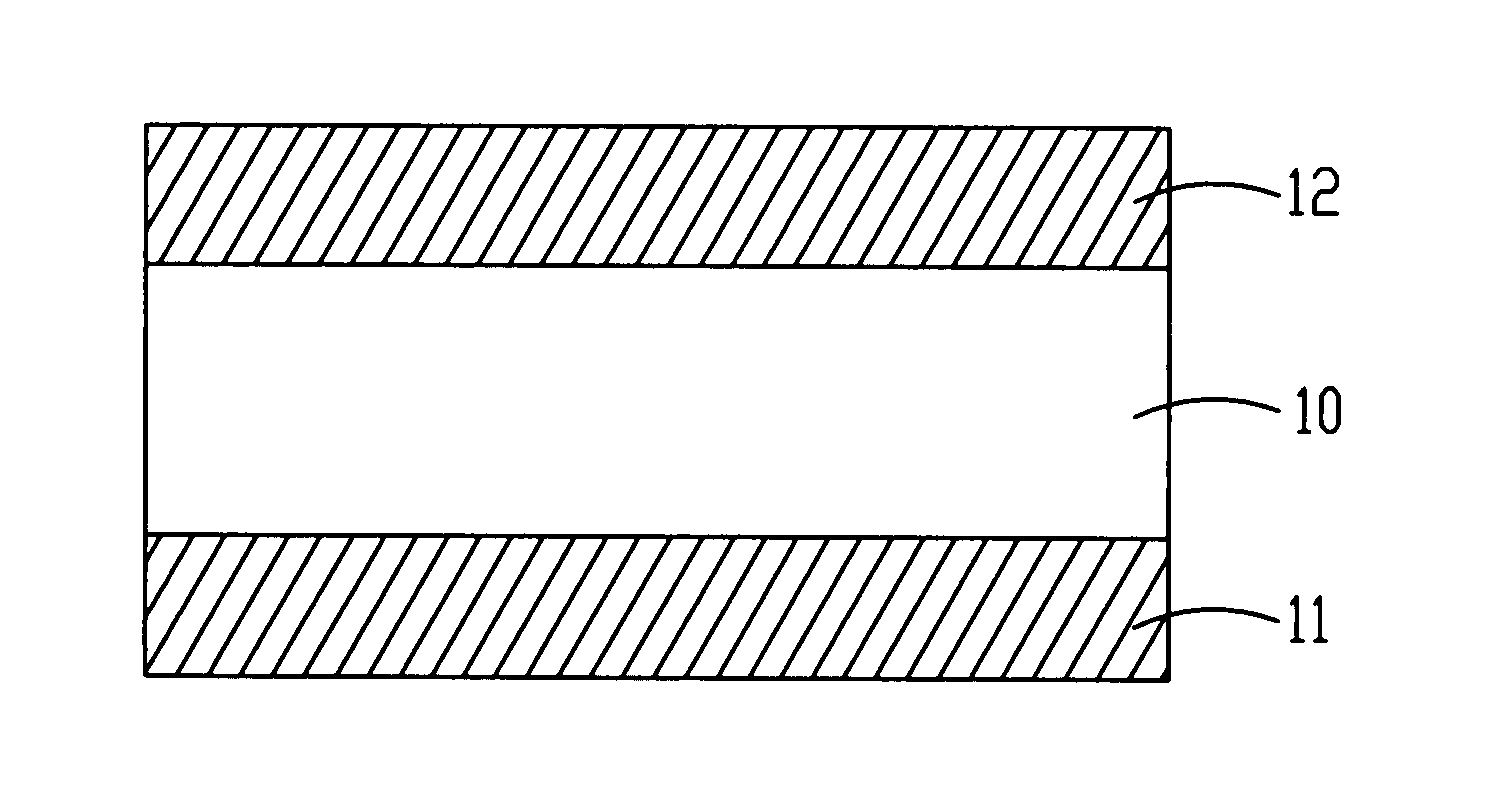

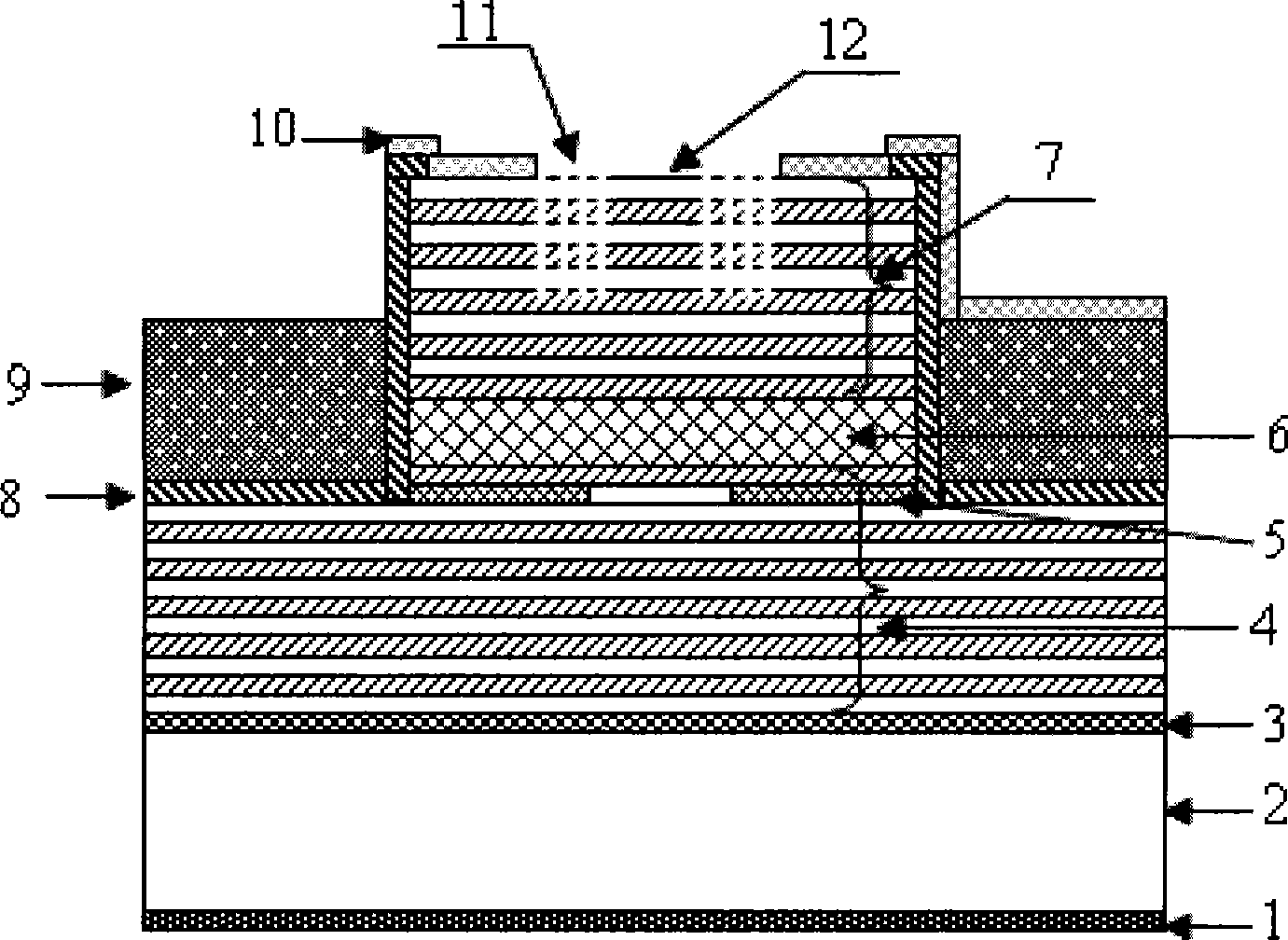

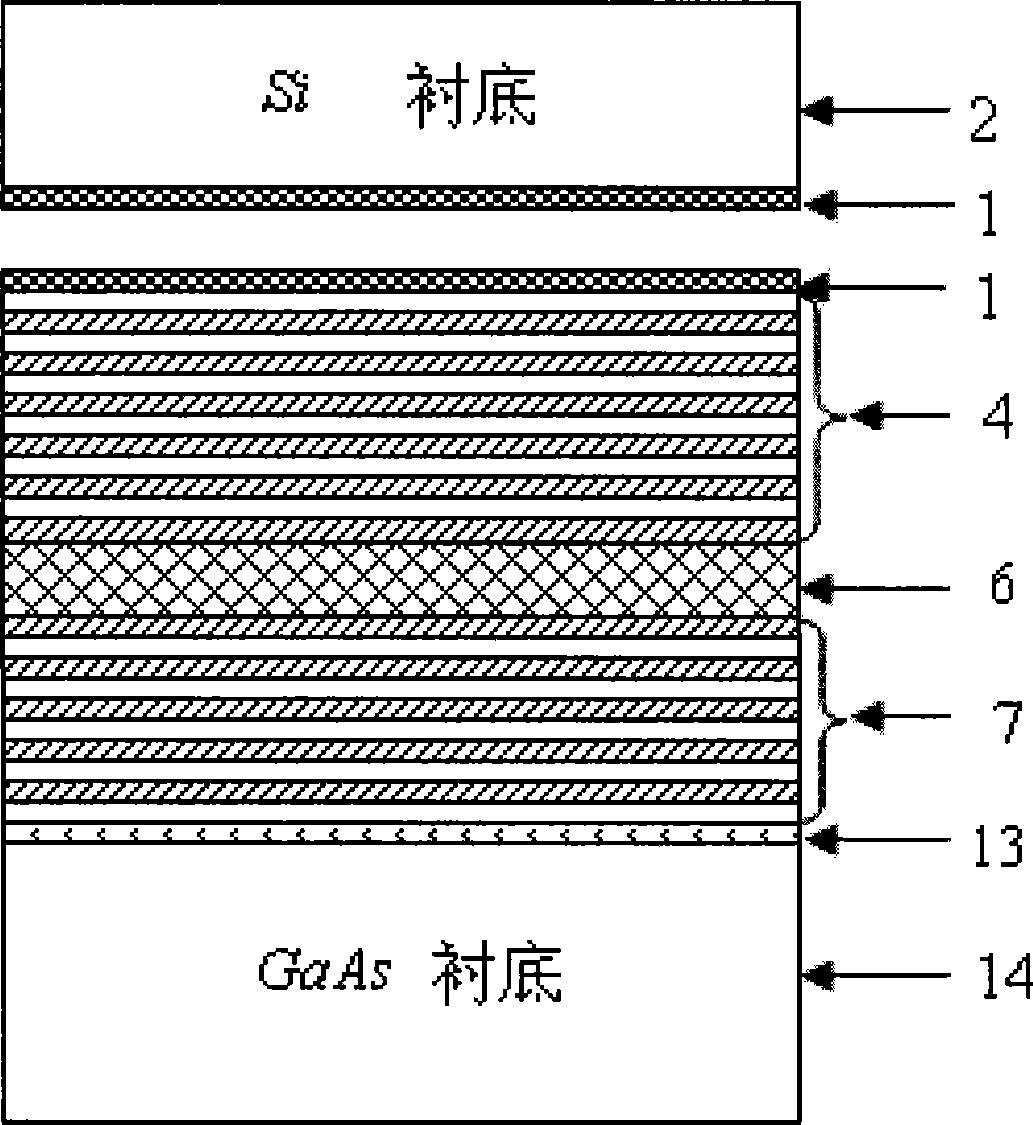

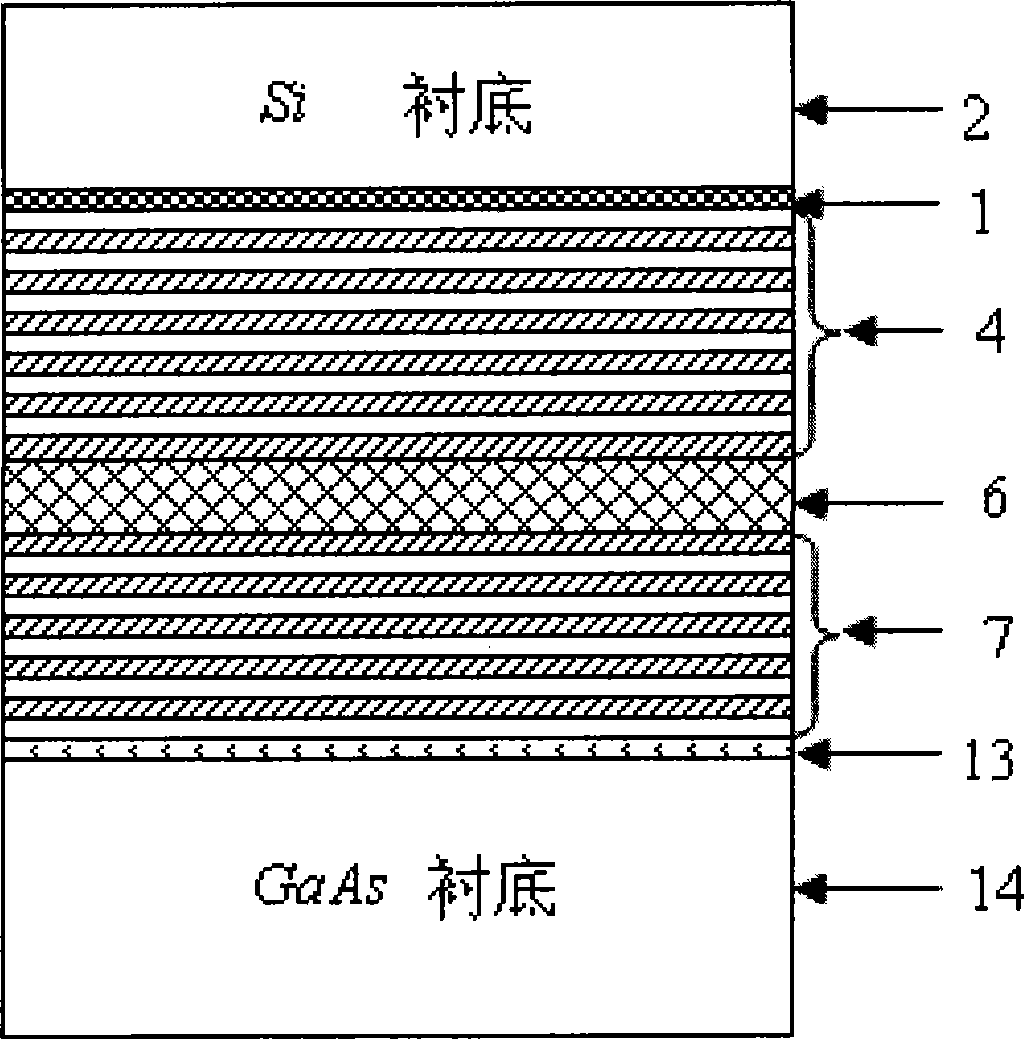

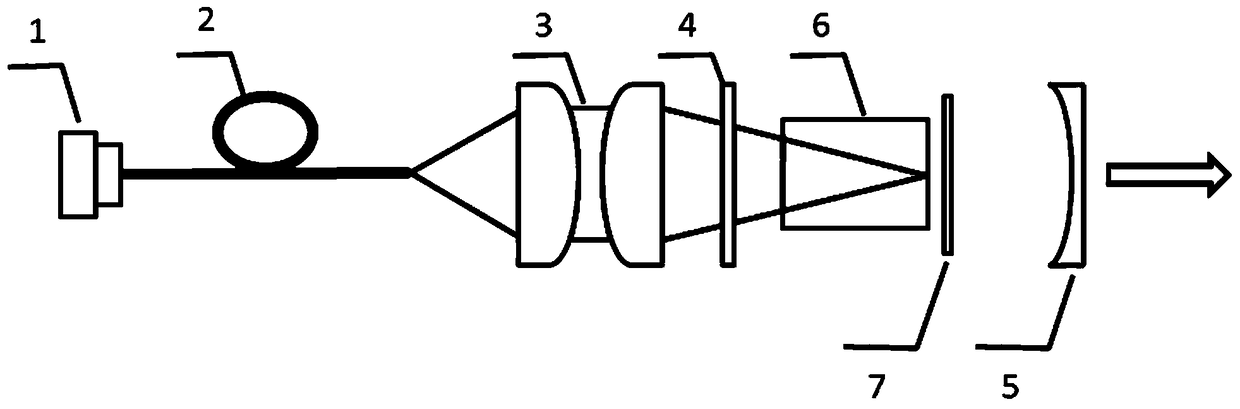

Single-mode high-power vertical cavity surface emitting laser and manufacturing method thereof

ActiveCN101667715BIncrease output powerImprove thermal propertiesLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserElectron

The invention relates to a single-mode high-power vertical cavity surface emitting laser (VCSEL), which belongs to the field of semiconductor photoelectronics. The laser is characterized by comprising a P-type electrode (1), a P-type Si substrate (2), a metal bonding layer (3), a P-type distributed Bragg reflector (DBR) (4), an oxide limiting layer (5), an active area (6), an N-type DBR (7), a SiO2 mask (8), polymide or benzocyclobutene (BCB) (9), an N electrode (10), a photonic crystal (11) and a light-exiting window (12). The introduction of the photonic crystal into the vertical cavity surface emitting laser with the structure can enlarge an oxidation aperture and improve the single-mode output power; and at the same time, the transfer of the conventional VCSEL epitaxial wafer to the Si substrate by adopting bonding technology and the adoption of a design of exiting light at the bottom are convenient for narrowing the distance between a VCSEL epitaxial wafer active area and the Si substrate, improving the thermal characteristics of devices and further improving the single-mode output power.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

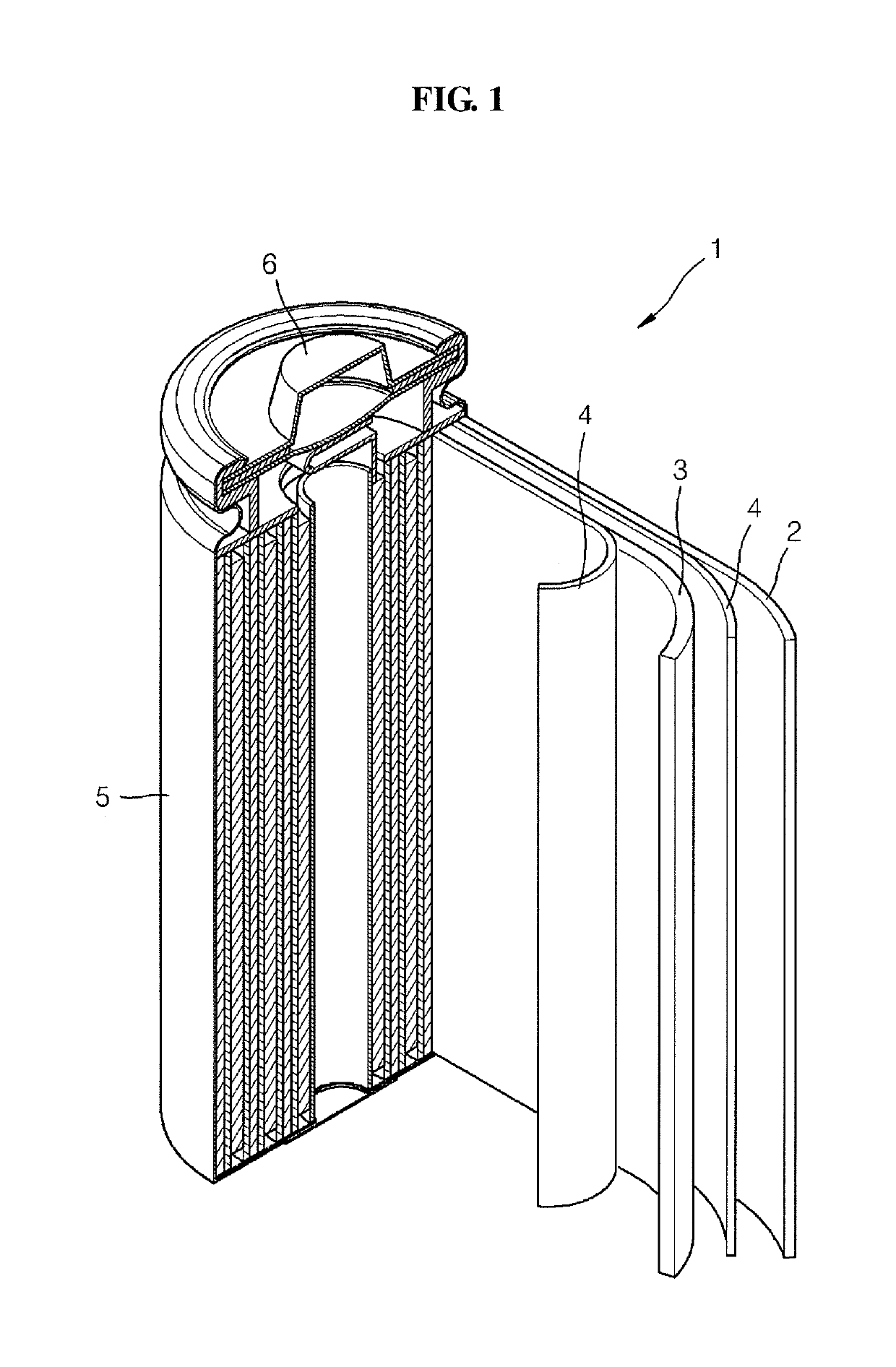

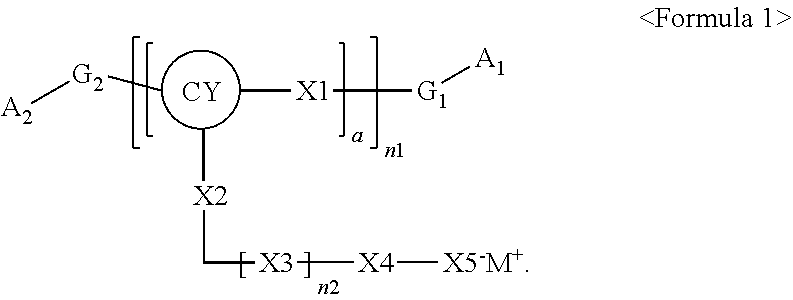

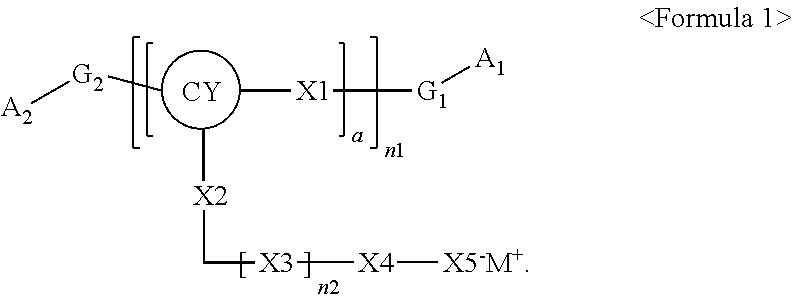

Polymer, electrolyte including the same, and lithium battery including the polymer

ActiveUS20190312305A1Improve ionic conductivityImprove mechanical propertiesFinal product manufactureCylindrical casing cells/batteryPolymer sciencePolymer

Provided are a polymer represented by Formula 1, an electrolyte including the same, and a lithium battery including the polymer.

Owner:SAMSUNG SDI CO LTD

Heat-sensitive gel preparation and preparing method thereof

InactiveCN100381159CImprove thermal propertiesGood stabilityDigestive systemPharmaceutical delivery mechanismTemperature sensingCamphor

The invention relates to temperature sensing gel preparation and its method of preparation. The preparation is made up of vegetable essential oil, boneol or mentha camphor alcohol solution, poloxamer 407 solution, and antiseptic. It is sensitive to temperature. It is flexible liquid at normal temperature. While near to 28-33 centigrade degree it forms gel. It can be used in human or animal cavity channel mucous membrane, such as oral cavity, nasal cavity, rectum, and vagina.

Owner:SHANGHAI HUATUO MEDICAL SCI CO LTD

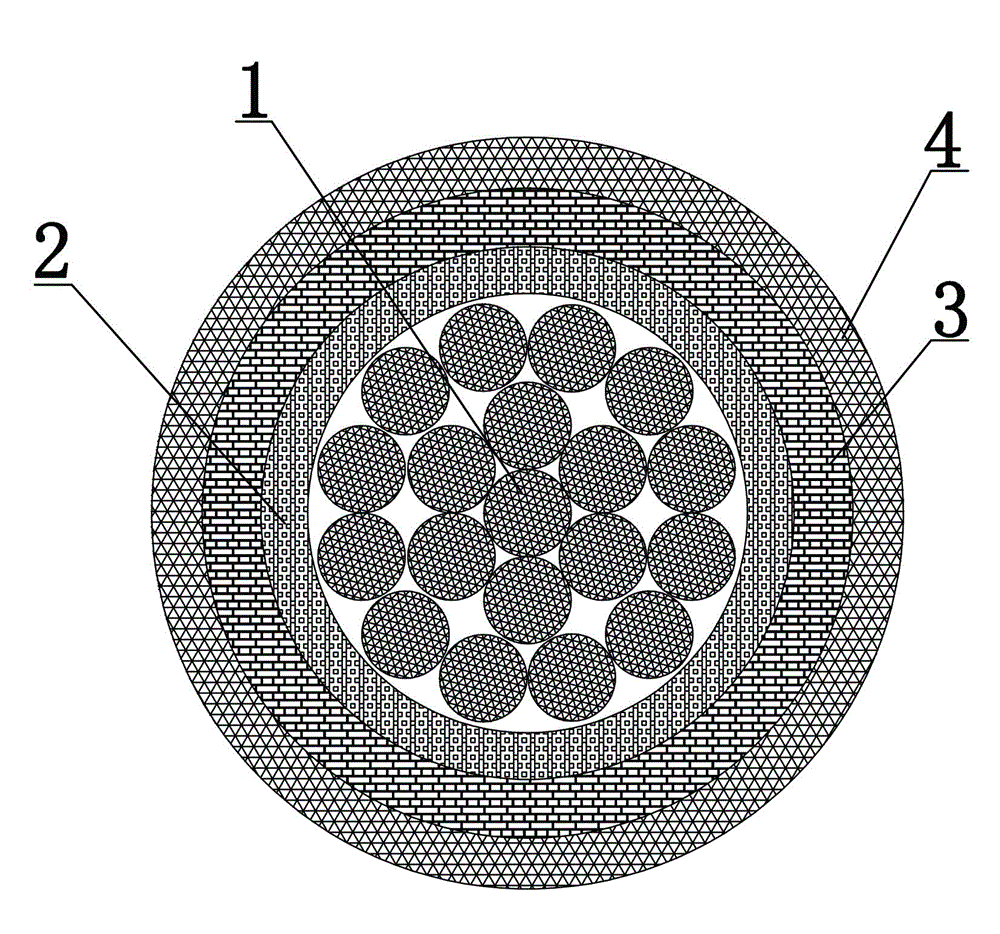

Low-smoke zero-halogen flame-retardant photovoltaic cable and manufacture method thereof

InactiveCN103337283AIncrease lossIncreased risk of short circuitInsulated cablesPower cablesInsulation layerUltraviolet

The invention provides a low-smoke zero-halogen flame-retardant photovoltaic cable which comprises a conductive wire core, insulating layers, an insulation layer, and a sheathing layer, wherein the conductive wire core is formed by twisting a plurality of tinned copper monofilaments; the insulating layers made of low-smoke zero-halogen flame-retardant glass fabric are wrapped on the conductive wire core in an overlapped manner; the insulation layer is extruded outside the insulating layers; the sheathing layer is extruded outside the insulation layer. The invention further provides a manufacture method of the low-smoke zero-halogen flame-retardant photovoltaic cable. The low-smoke zero-halogen flame-retardant photovoltaic cable and the manufacture method thereof have the advantages of scientific design, environmental protection, zero contamination, and wind, rain, ultraviolet and ozone corrosion resistance, and can bear temperature variation in a larger range.

Owner:HENAN KAIQI POWER IND

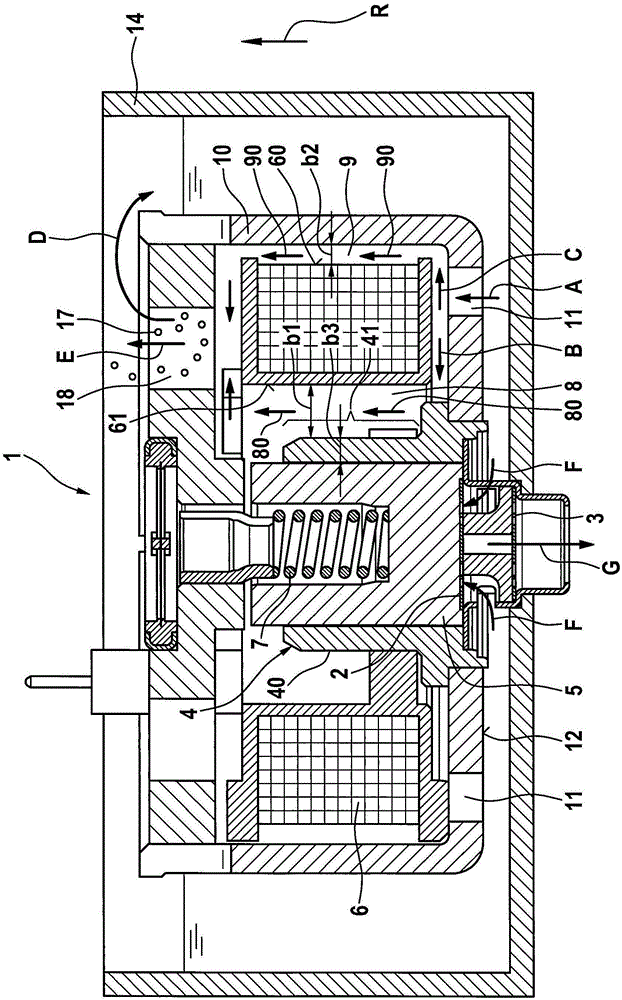

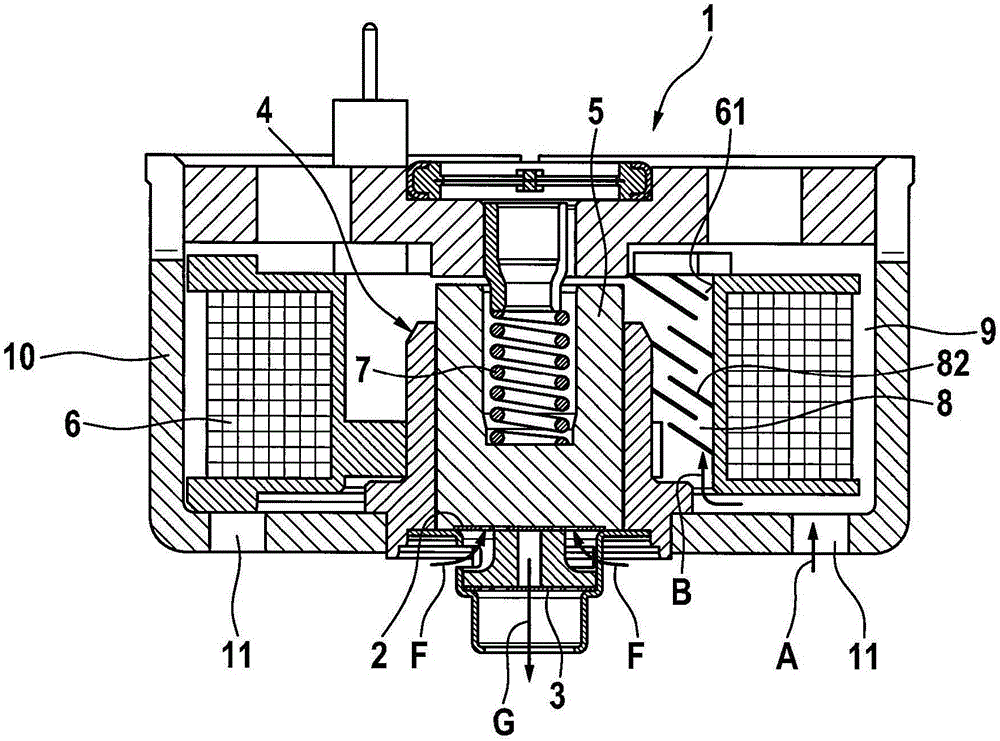

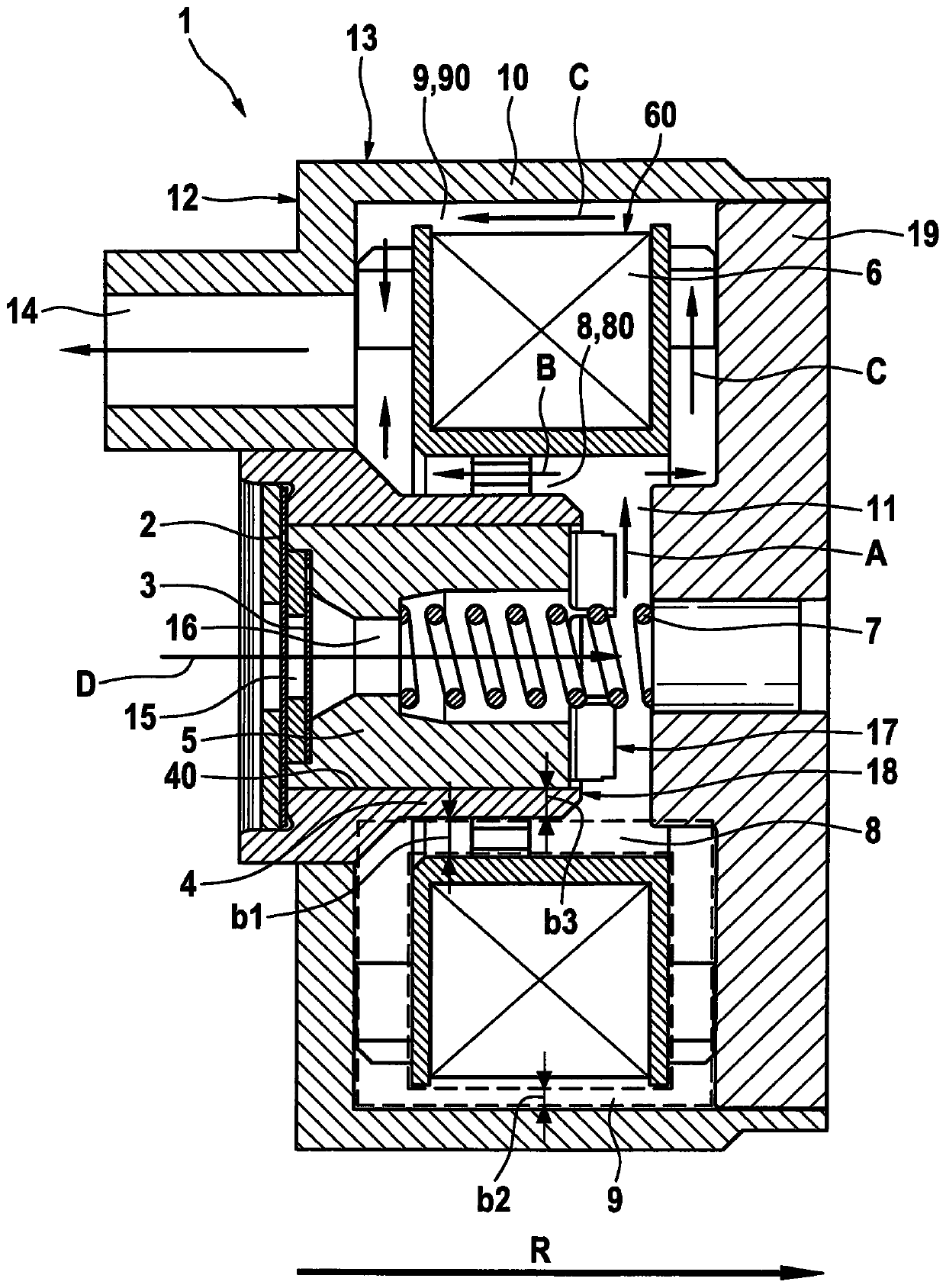

Fuel pump

InactiveCN106460742ACompact structureReduce heatInternal combustion piston enginesPositive displacement pump componentsInlet valveEngineering

The present invention relates to a fuel pump for conveying fuel, comprising an inlet valve (2), an output valve (3), a cylinder (4), a piston (5), said piston being arranged in the cylinder (4), a heat-generating actuator (6) for activating the piston (5), and a returning element (7) for returning the piston (5) into an initial position. According to the invention, the fuel pump (1) comprises a first gap (8) which is configured between the cylinder (4) and the heat-generating actuator (6), wherein a first fuel path (80) runs through the first gap (8). The invention further relates to a method for operating a fuel pump (1) according to the invention.

Owner:ROBERT BOSCH GMBH

Large rib and cotton slipper molding treatment process

InactiveCN111138866AGood antibacterial and deodorant effectNot easy to ageFootwearBiotechnologyDeodorant

The invention discloses a large rib and cotton slipper molding treatment process, and belongs to the technical field of cotton slippers, wherein the raw materials comprise: 40-60 parts of a goose downfiller, 4-6 parts of a deodorant, 1-2 parts of an antioxidant, 1-3 parts of a flame retardant, 6-12 parts of bamboo charcoal fiber, 5-10 parts of calcium carbonate, 3-5 parts of amomum kravanh, 4-8 parts of agastache rugosus, 10-20 parts of honeysuckle, 8-14 parts of liquorice, 2-6 parts of clove, 5-7 parts of toner and 3-5 parts of a cross-linking agent. The process comprises the following steps: a, feeding; b, stirring; c, injecting into a mold; d, air blowing; and e, detection. According to the invention, the cotton slippers prepared by the invention have good antibacterial and deodorant properties, are not easy to age and have a warm-keeping property; bamboo charcoal fibers can adsorb indoor peculiar smell and generate negative ions, and the negative ions can effectively purify air and remove harmful toxins generated by microorganisms; goose down as a main raw material can improve, the warmth retention property of the cotton slippers and the use comfort of people; and the manufacturing process is simple, and materials are easy to obtain.

Owner:SHANDONG TIANYI EQUIP TECH CO LTD

A method for repairing lead and cadmium polluted soil

ActiveCN110586642BReduce heavy metal contentAvoid remeltingBacteriaContaminated soil reclamationMicroorganismSoil science

The invention belongs to the technical field of soil remediation, and specifically relates to a method for remediating lead-cadmium-contaminated soil. Aiming at the combined remediation of lead-cadmium contaminated soil, a combined remediation method of adsorption solidification and microbial remediation is adopted, which specifically includes the following steps: Sprinkle the soil with adsorbent and passivation agent, spray water at the same time, then deep plow 5-8cm, and place it for 10-15 days; sprinkle the compound bacterial preparation into the soil, shallow plow 3-5cm, then spray the film-forming liquid on the soil, set aside 10‑15 days; adopt the combined repair method of adsorption solidification and microbial repair, firstly absorb and solidify heavy metals through the action of adsorbents and passivators, and then use microorganisms to digest and transform the adsorbed and solidified heavy metals, Then reduce the content of heavy metals in the soil and prevent heavy metals from redissolving.

Owner:铜仁市万山区植保植检站

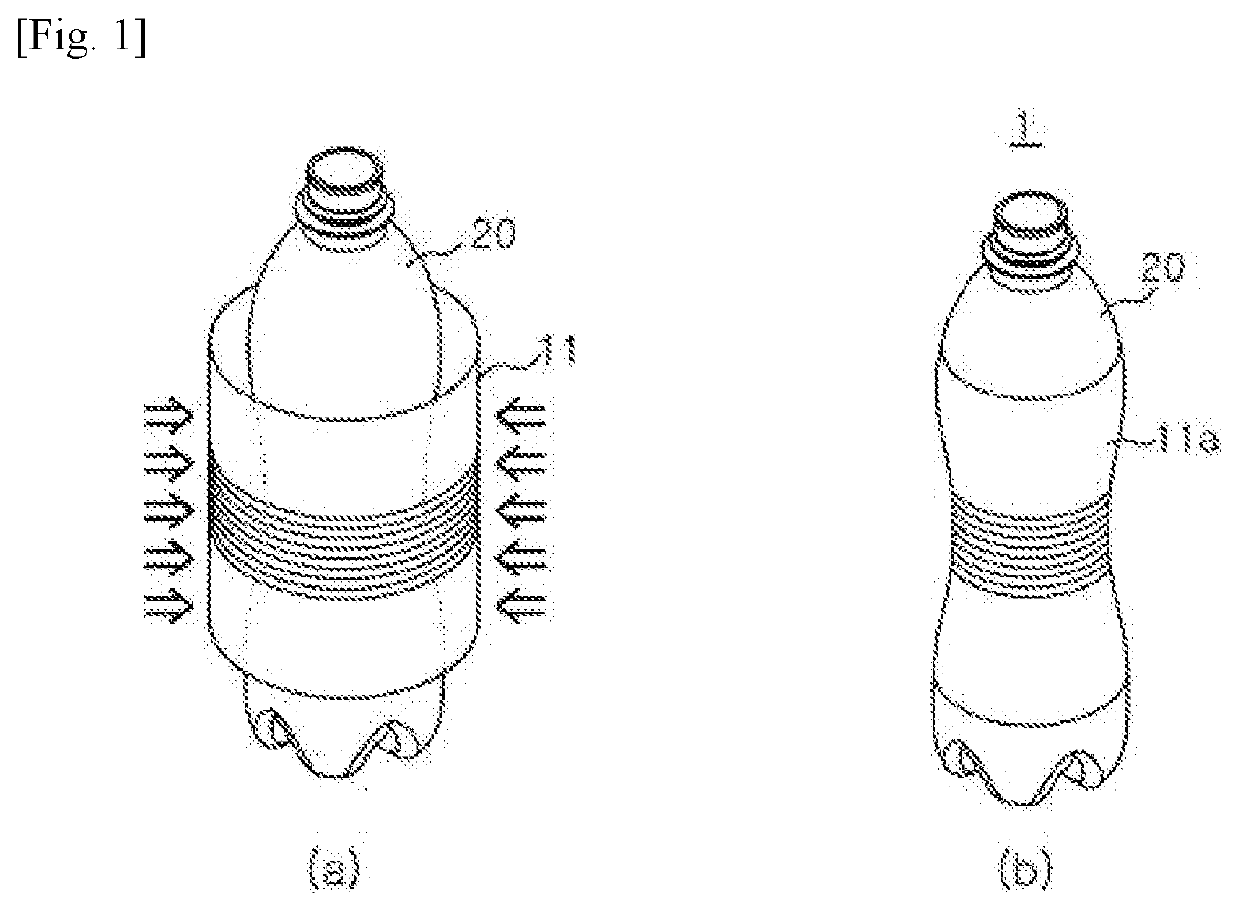

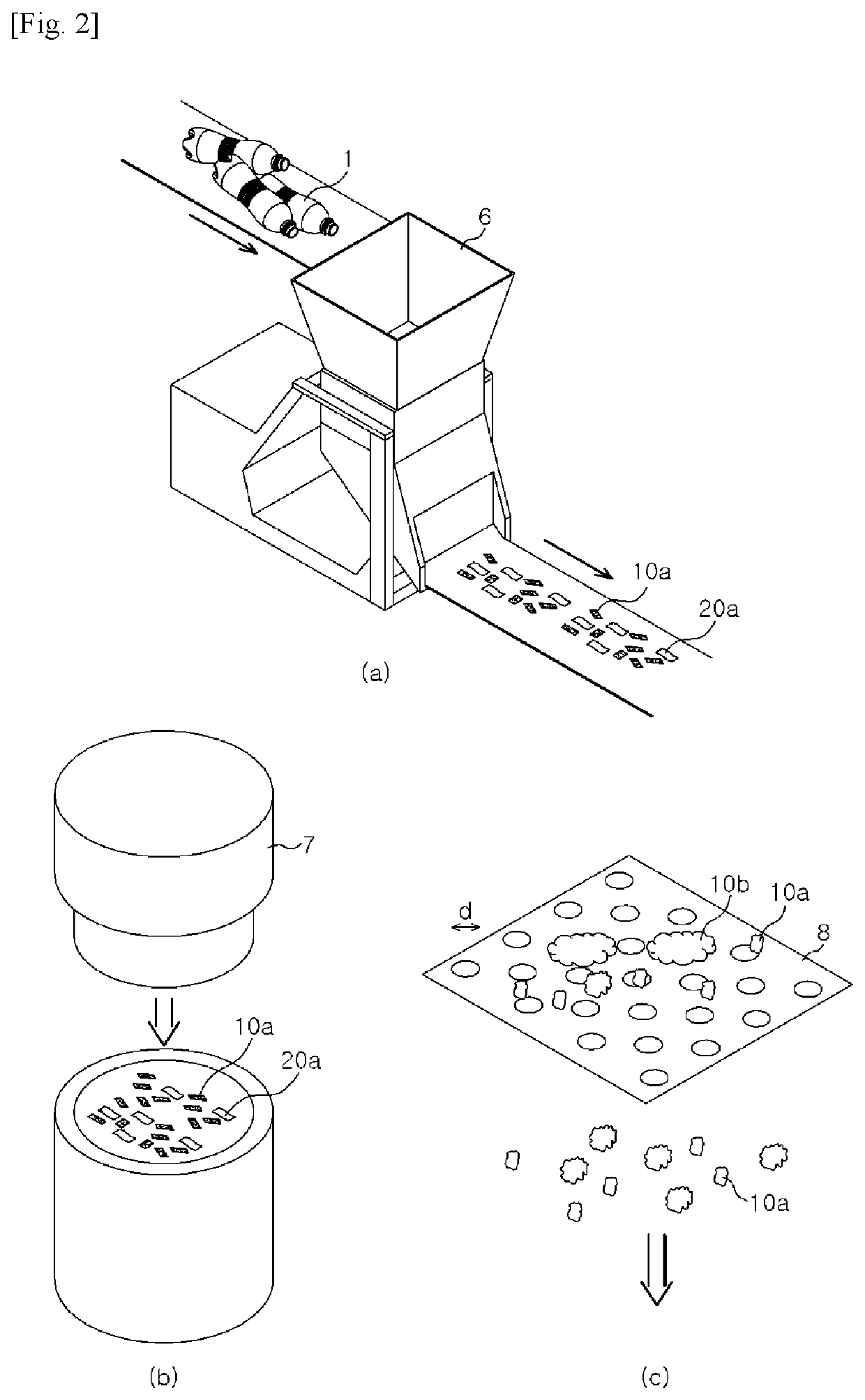

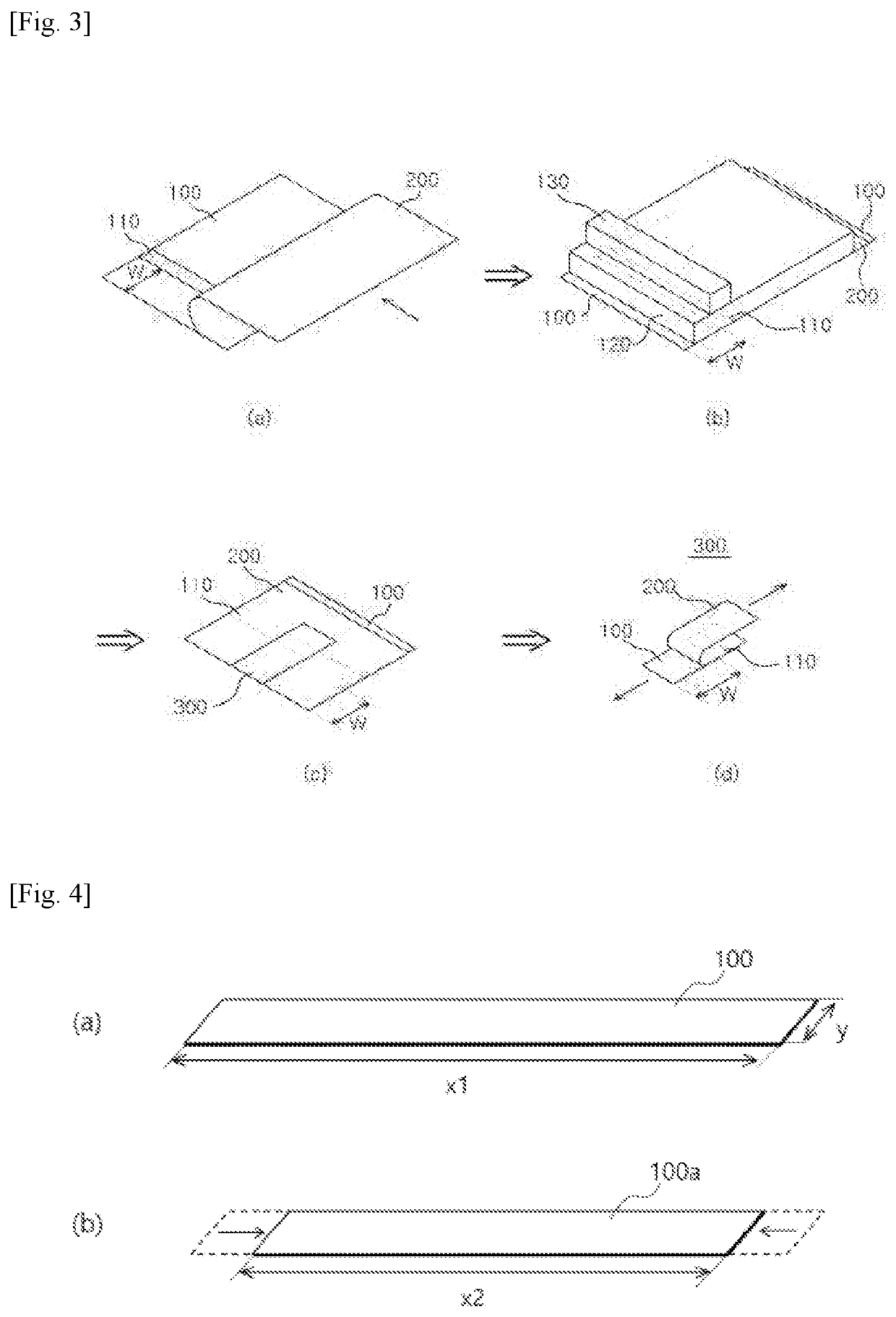

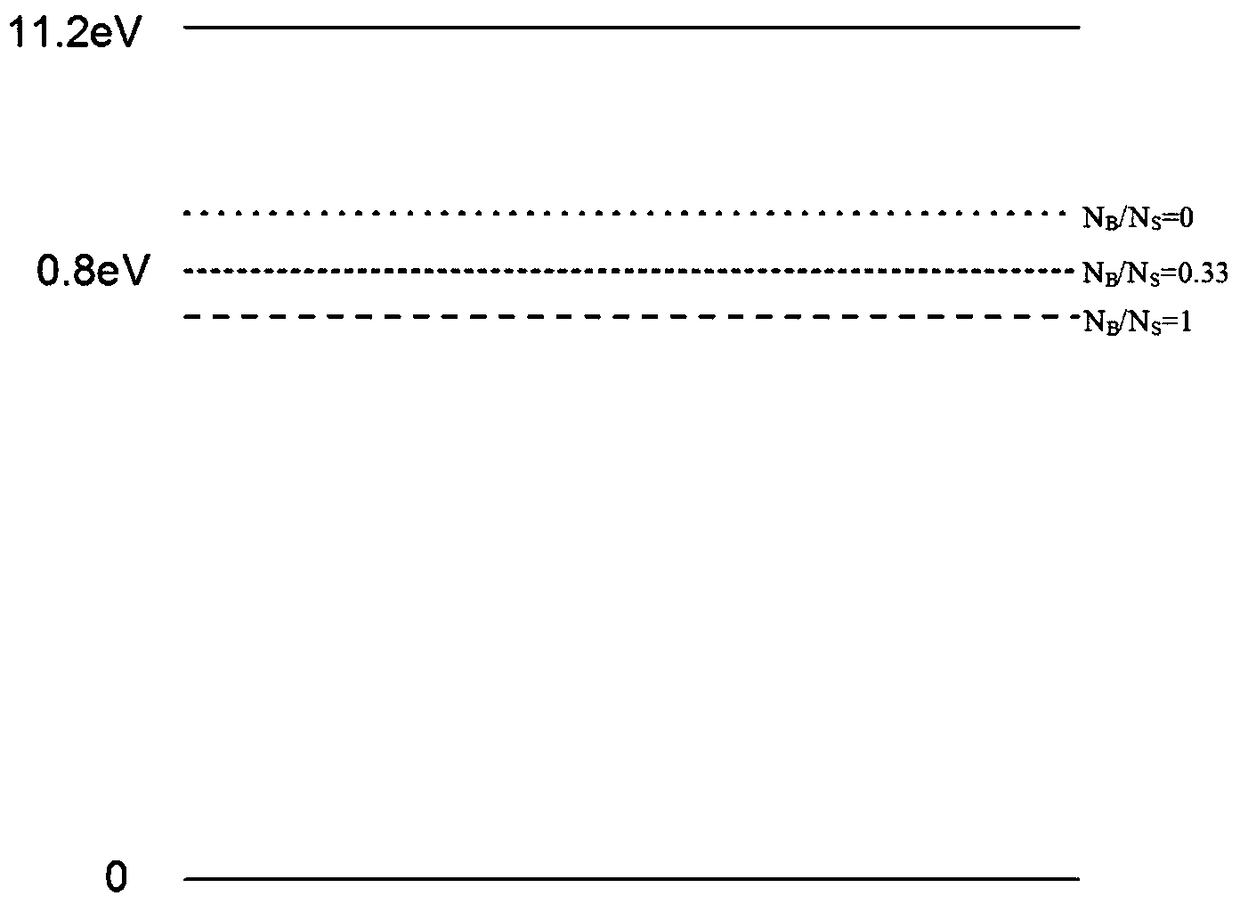

Polyester film, preparation method thereof and method for reproducing polyethyleneterephthalate container using same

ActiveUS20220235187A1Improve thermal propertiesImproved chemical characteristicPlastic recyclingDomestic articlesPolyesterPolymer science

The embodiments relate to a polyester film, to a process for preparing the same, and to a process for regenerating a polyethylene terephthalate (PET) container using the same. The polyester film has excellent seaming characteristics and recyclability by virtue of controlled crystallinity, whereby clumping rarely occurs even if it is thermally treated for a long period of time in the regeneration process.

Owner:SK MICROWORKS AMERICA INC +1

Silicon-based optical pulse modulation device and its application

The invention relates to a silicon-based optical pulse modulator device and application. The silicon-based optical pulse modulator is characterized in that monocrystalline silicone is processed into a silicon wafer, 32S or 32S and 11B together are injected into the silicon wafer by an ion injection method, the silicon wafer is subjected to twin polishing, and a high-penetration medium film of 1.3-1.6 micrometers is plated or not on the surface of the silicon wafer. The silicon-based optical pulse modulator device is used for a laser, pump light passes a laser gain medium and then passes a silicon-based optical pulse component, and a front endoscope in front of the laser gain medium and a rear endoscope behind the silicon-based optical pulse component constitute a resonance cavity. The silicon-based optical pulse modulator device is used for adjusting loss of laser of 1.3-1.6 micrometers. The silicon-based optical pulse modulator device is simple to manufacture and low in cost, miniaturization of products and industrialized production are facilitated.

Owner:济南晶众光电科技有限公司

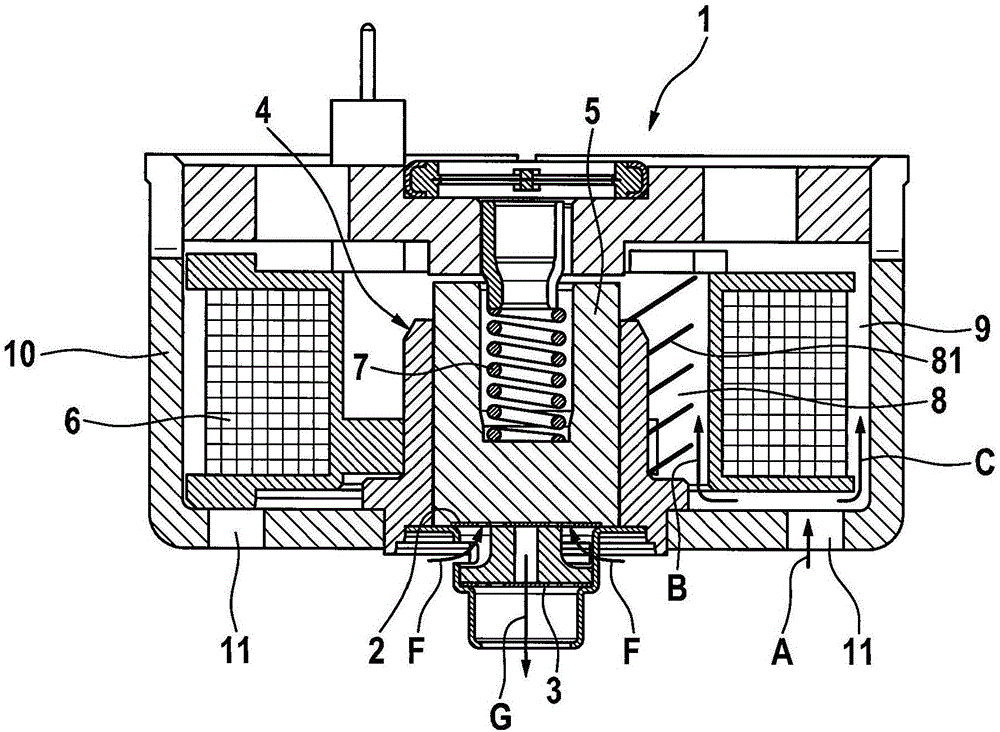

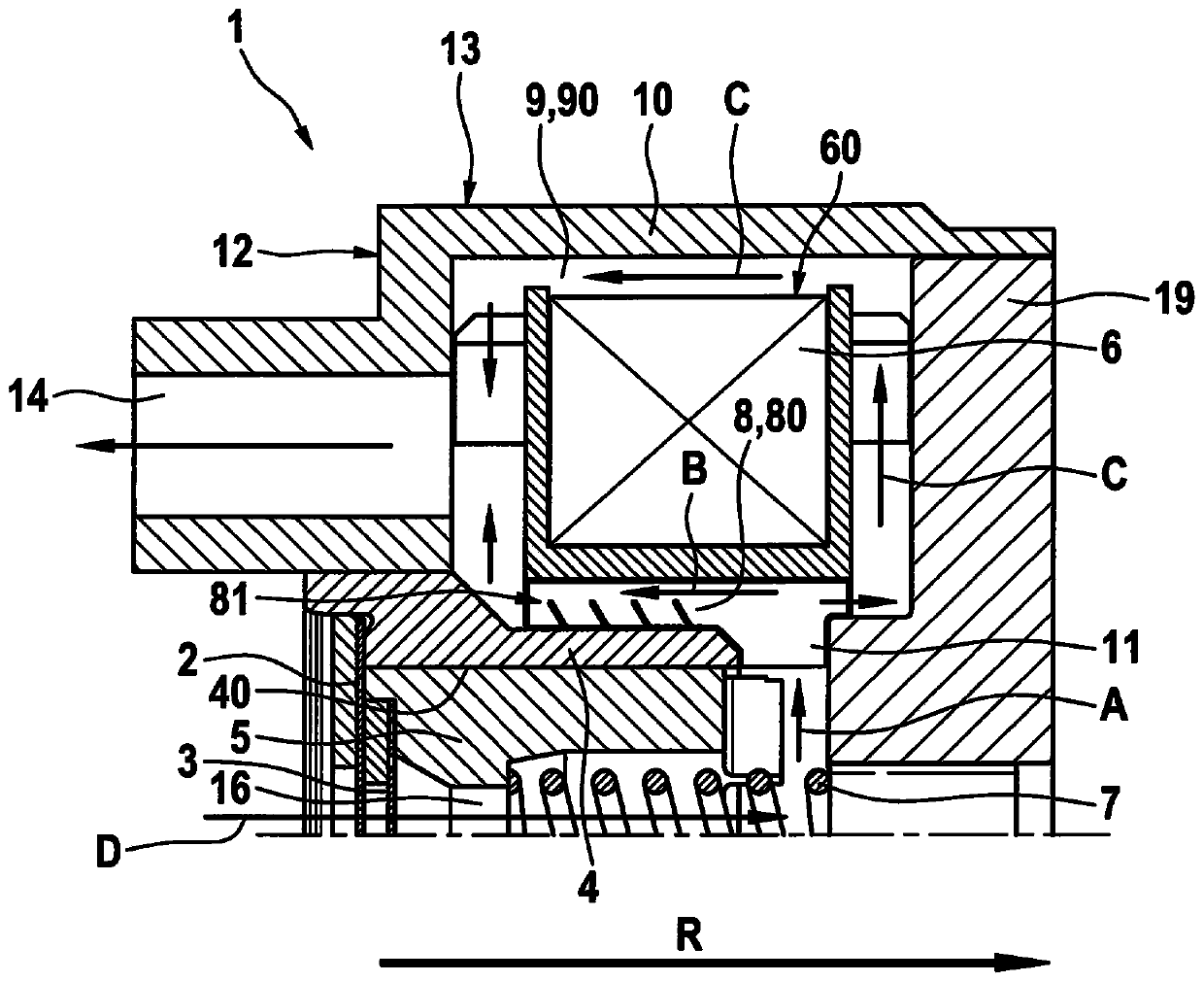

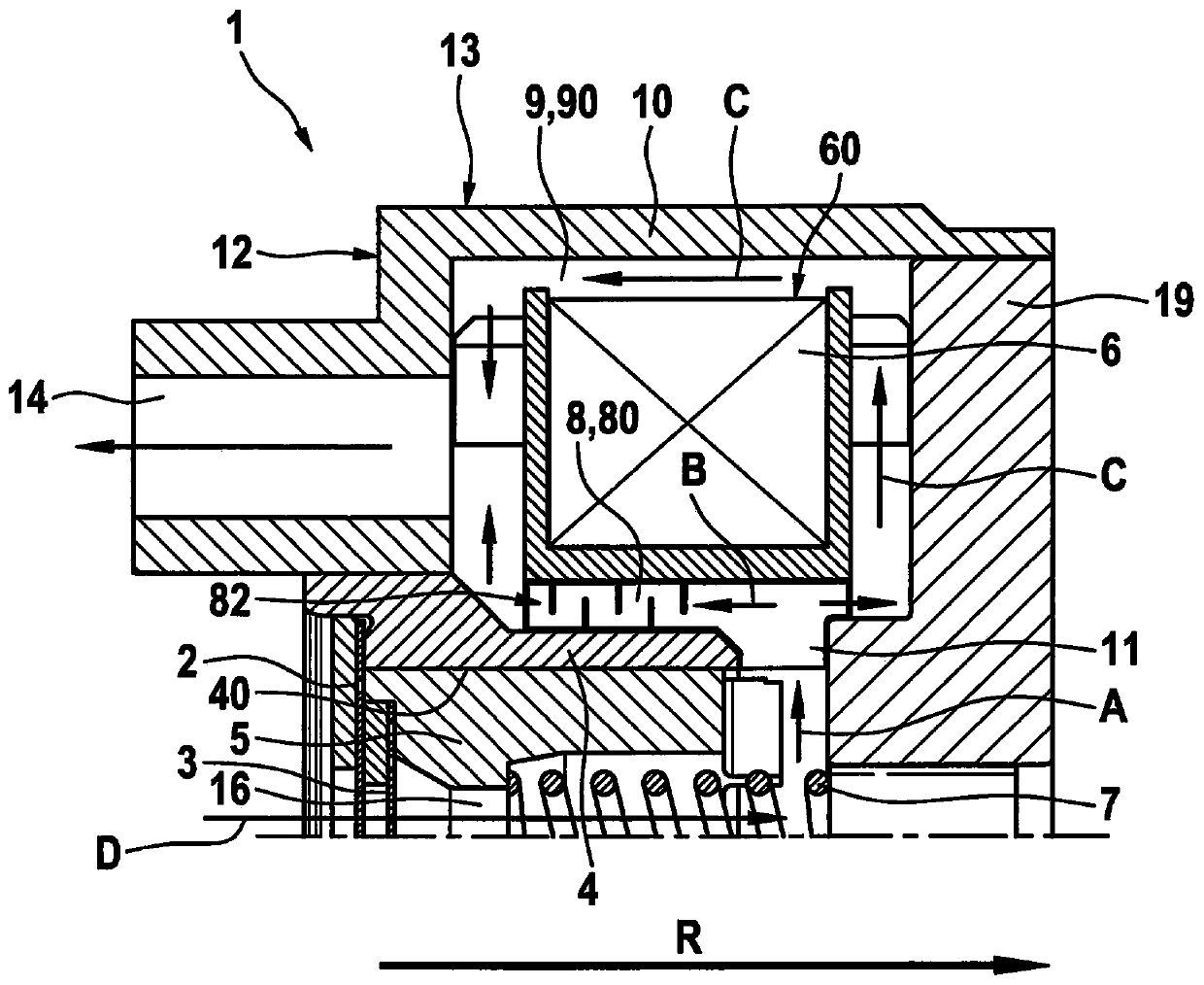

Fuel pump with outlet valve in piston and fuel path of flushing actuator

ActiveCN107035585BImprove featuresImprove efficiencyPositive displacement pump componentsLow pressure fuel injectionInlet valveActuator

The invention discloses a fuel pump having an outlet valve in the piston and a fuel path flowing around the actuator. The fuel pump for delivering fuel, comprises a casing (10), a cylinder (4), a piston (5) which is arranged in the cylinder (4), a heat-producing actuator (6) for actuating the piston (5), and a return element (7) for returning the piston (5) to a starting position, a first gap (8), which is formed at the heat-producing actuator (6), in particular between the cylinder (4) and the heat-producing actuator (6), wherein a first fuel path (80) passes through the first gap (8), an inlet valve (2), an outlet valve (3), wherein the outlet valve (3) is arranged in the piston (5) and the piston (5) has a passage (16), via which a fuel can flow from the outlet valve (3) in the direction of the first gap (8).

Owner:ROBERT BOSCH GMBH

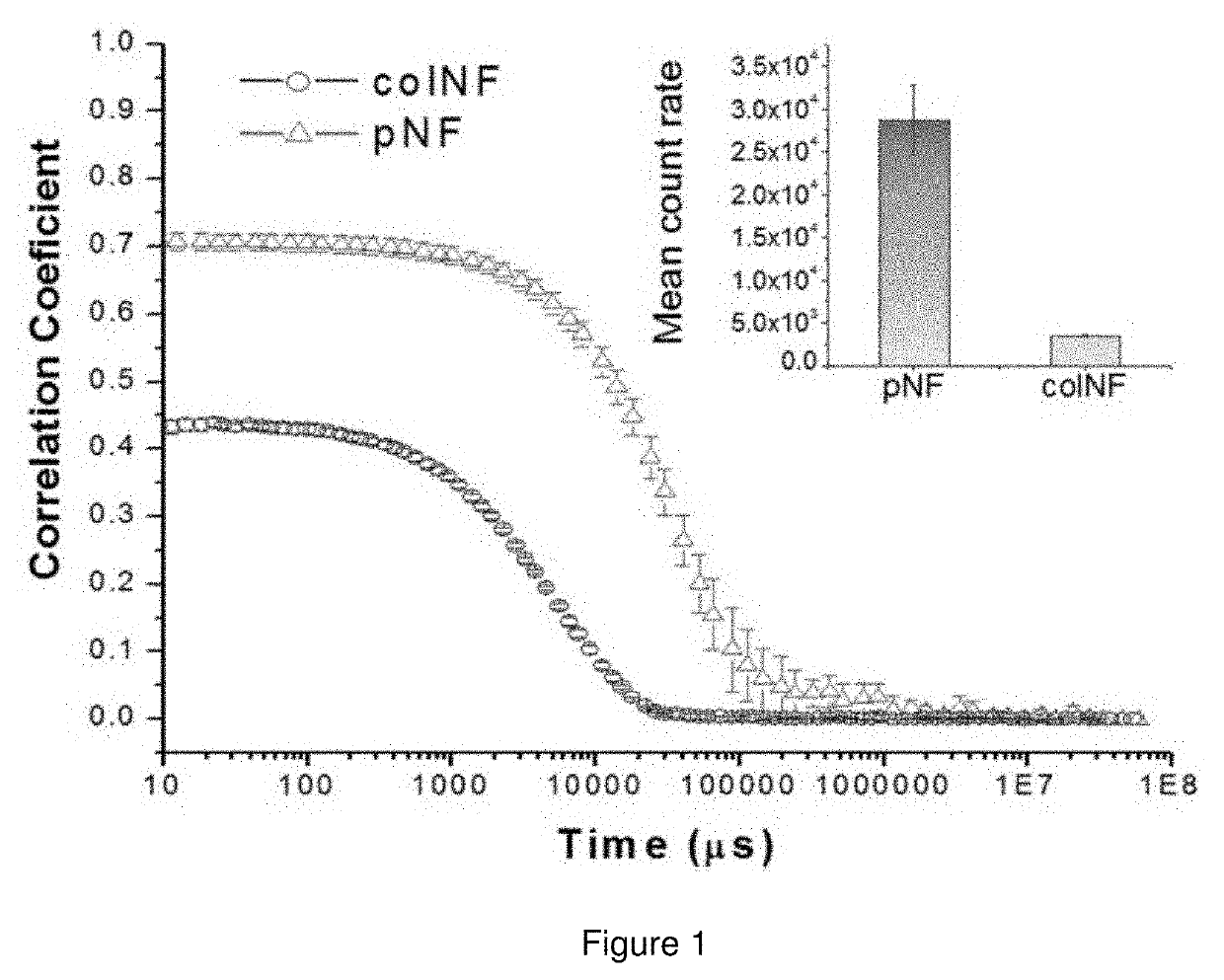

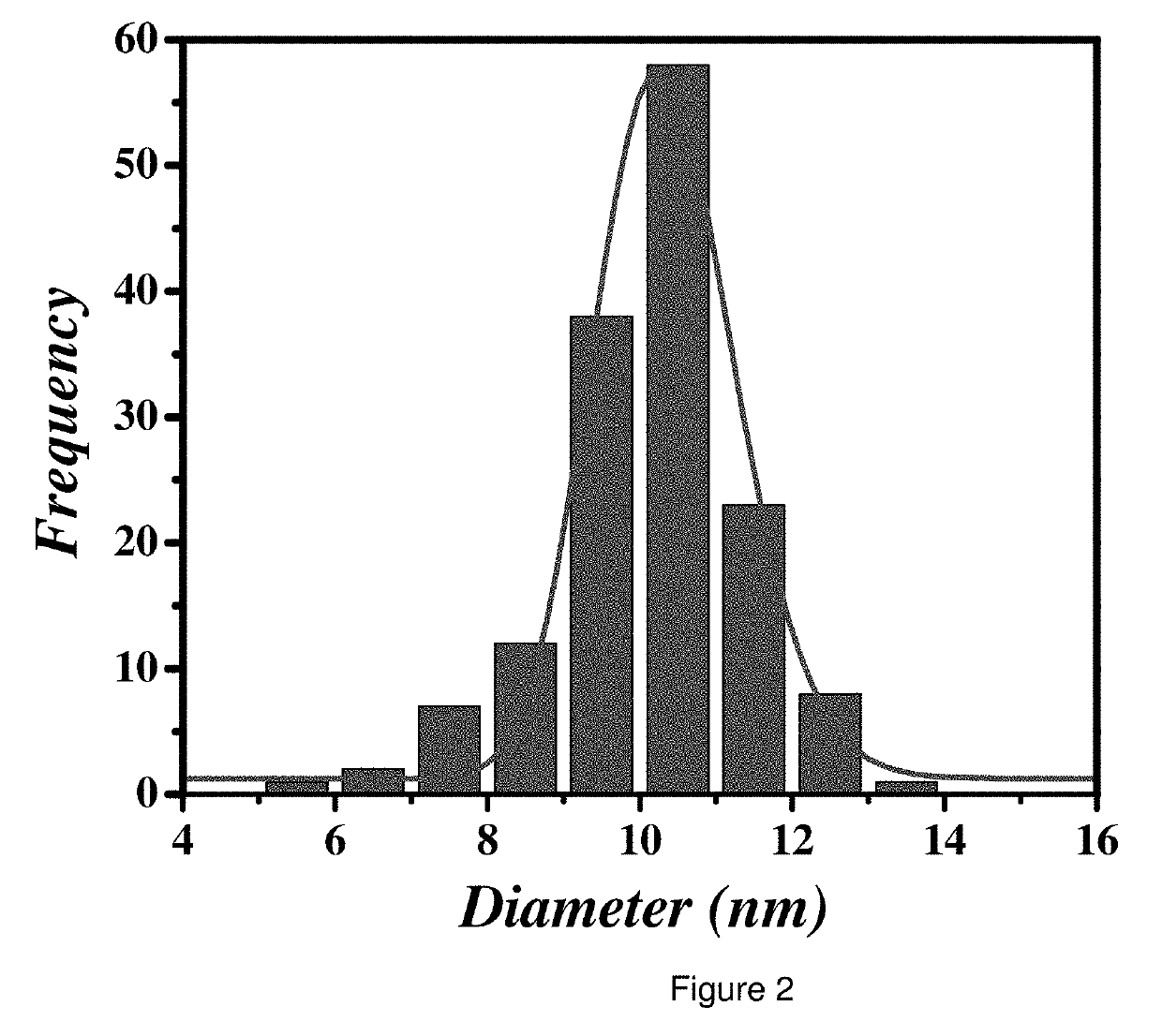

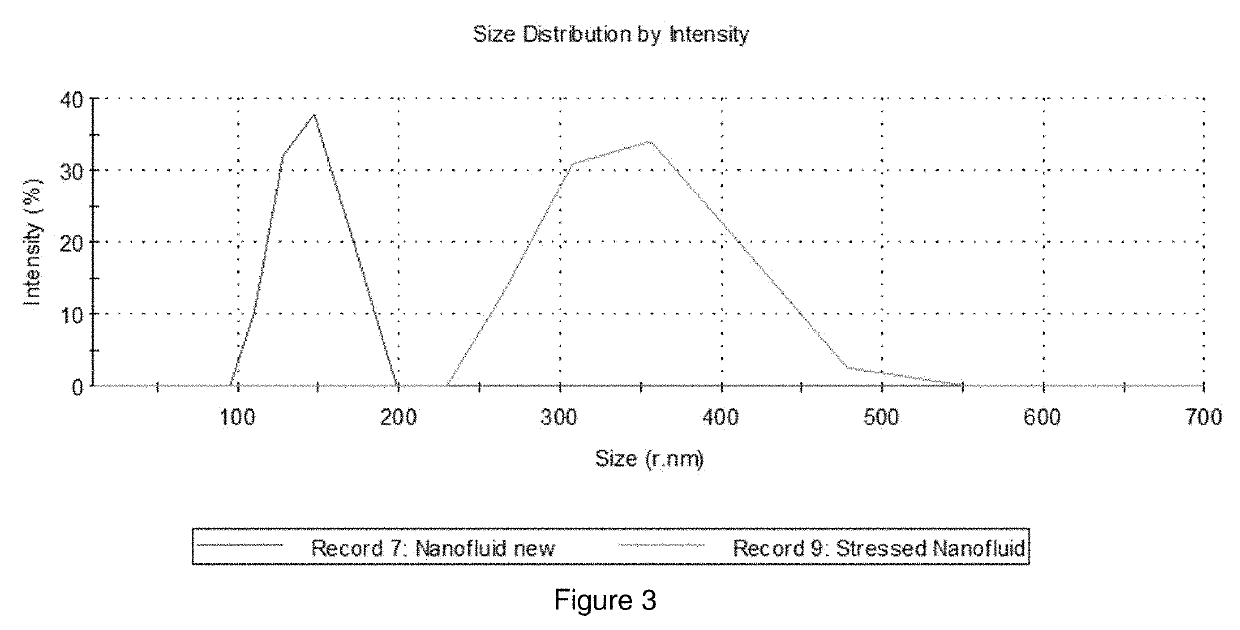

Method of making and synthesizing dielectric nanofluids

InactiveUS20190276673A1Good dielectricImprove thermal propertiesPigmenting treatmentTransformers/inductances coolingDielectricPolymer science

A method of making and synthesizing dielectric nanofluids with hybrid colloidal iron oxide nanoparticles coated with oleic acid and by usage of natural ester oil matrix instead of mineral oil. The final product of dielectric nanofluid has enhanced dielectric and thermal properties without agglomeration and precipitation of the nanoparticles. The final product is intended to be used as dielectric insulation and cooling media for high voltage equipment / applications and / or other applications.

Owner:UNIVERSTY OF PATRAS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com