Coke for furnace protection and production method thereof

A production method and coke technology, which are applied in the field of furnace protection coke with improved quality and the production field thereof, can solve the problems of unmentioned coke quality and high cost of technical solutions, and achieve the effects of simplified operation, low production cost and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

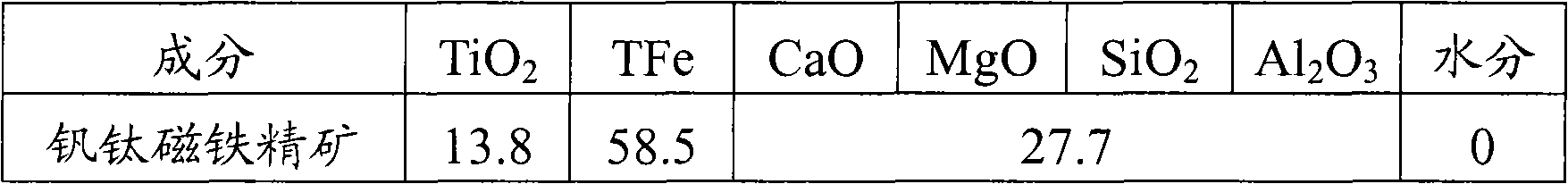

[0043] Take 400g of coal in the ratio shown in Table 1 and 2g of vanadium-titanium magnetite concentrate shown in Table 2, mix the two evenly, and then put them into a corundum crucible (Φ80mm×110mm), and then use a 3kg weight to put the The coal is compacted for 5 minutes, the counterweight is removed and sealed, put into a muffle furnace (400mm×150mm×200mm) for dry distillation, the heating rate is 3°C / min, the temperature is raised to 950°C, and the temperature is kept constant for 150min, and the coke is taken out and quenched with water to obtain coke 321.6 g, measured coke thermal reactivity (CRI) is 41.16%. The coke components include by weight percentage: 88.42% of fixed carbon, 10.14% of ash, 1.44% of volatile matter and 0.60% of S. Contains 0.82% TiO by weight in the ash 2 , 3.28% TFe, 0.075% V 2 o 5 .

[0044] Because the proportion of vanadium-titanium-magnetite concentrate is increased in the above-mentioned coke, the reactivity of the coke is improved by 0.09...

Embodiment 2

[0046] Take 400g of coal in the ratio shown in Table 1 and 8g of vanadium-titanium magnetite concentrate shown in Table 2, mix the two evenly, then put them into a corundum crucible (Φ80mm×110mm), and then use a 3kg weight to put the The coal is compacted for 5 minutes, the counterweight is removed and sealed, put into a muffle furnace (400mm×150mm×200mm) for dry distillation, the heating rate is 8°C / min, the temperature is raised to 1050°C, and the temperature is kept constant for 60 minutes. Take out and quench with water to obtain coke 326.4 g, measured coke thermal reactivity (CRI) is 40.35%. The coke components include by weight percentage: 85.76% of fixed carbon, 12.96% of ash, 1.28% of volatile matter and 0.52% of S. Contains 2.25% TiO by weight in the ash 2 , 8.56% TFe, 0.097% V 2 o 5 .

[0047] Because the proportion of vanadium-titanium-magnetite concentrate is increased in the above-mentioned coke, the reactivity of the coke is improved by 0.90 percentage points...

Embodiment 3

[0049] Take 400g of coal in the ratio shown in Table 1 and 9.5g of vanadium-titanium magnetite concentrate shown in Table 2, mix the two evenly, and then put them into a corundum crucible (Φ80mm×110mm), and then use a 3kg weight to put the The coal is compacted for 5 minutes, the counterweight is removed and sealed, put into a muffle furnace (400mm×150mm×200mm) for dry distillation, the heating rate is 10°C / min, the temperature is raised to 1000°C, and the temperature is kept for 150min, and the coke is taken out and quenched with water to obtain coke 348g, and the measured coke thermal reactivity is 40.67%. The components of coke are calculated by weight percentage: 85.17% of fixed carbon, 13.69% of ash, 1.14% of volatile matter and 0.56% of S. Contains 2.6% TiO by weight in the ash 2 , 10.62% TFe, 0.098% V 2 o 5 .

[0050] Due to the increase of the ratio of vanadium-titanium magnetite concentrate in the above-mentioned coke, the reactivity of the coke has been improved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com