Patents

Literature

651results about How to "Not easy to mildew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

Method for manufacturing bamboo macrofiber composite material

InactiveCN101642923AImprove permeabilityMovement does not affectReed/straw treatmentFlat articlesAdhesiveVolumetric Mass Density

The invention relates to a method for manufacturing a bamboo macrofiber composite material. Bunchy bamboo fibers of which the green and yellow are removed are taken as raw materials and dipped with awater soluble phenol formaldehyde adhesive, and the production steps comprise material preparation (comprising the preparation of bamboo macrofiber reinforcement and a water soluble phenol formaldehyde resin matrix), adhesive dipping, extraction, warm-pressing, curing and post curing. The method has the advantages that: (1) the method has reasonable process, strong production continuity, high efficiency, low energy consumption, and no environmental pollution; (2) the manufactured bamboo macrofiber composite material has no mold and no crack, and has the density between 0.9 and 1.3g / cm<3>, thehardness between 60 and 150MPa, the static bending strength between 140 and 160MPa, the water-absorbing expansion rate between 0.3 and 2 percent, the surface wear resistance between 0.04 and 0.09g / 100r, and the formaldehyde emission between 0.1 and 0.4mg / L; and (3) the invention provides a more positive production technique for reasonably utilizing the bamboo resources, so that the reconstituted bamboo timber application prospect is better.

Owner:仇峰 +1

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

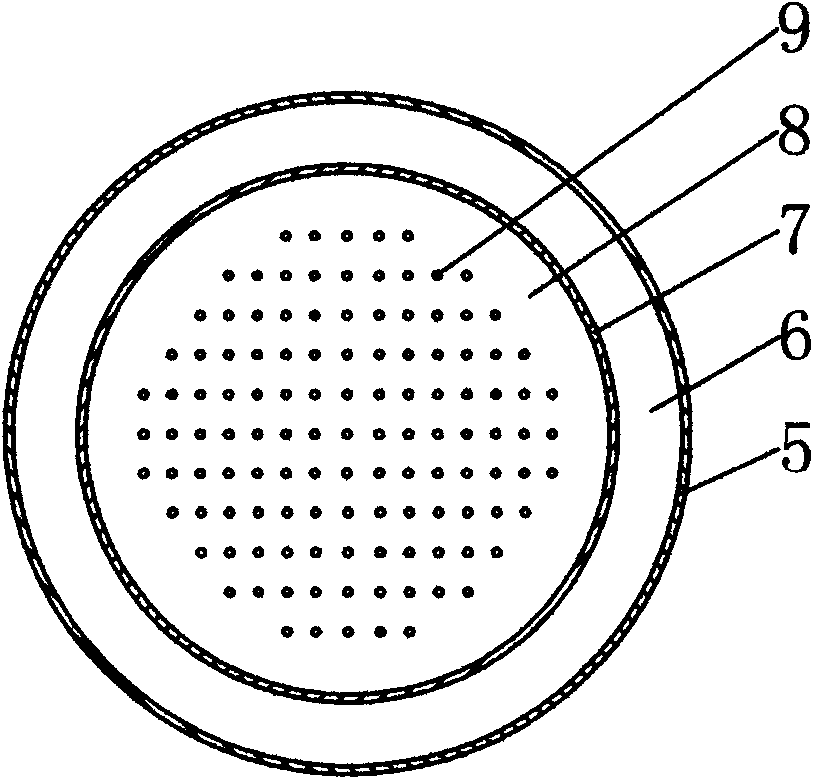

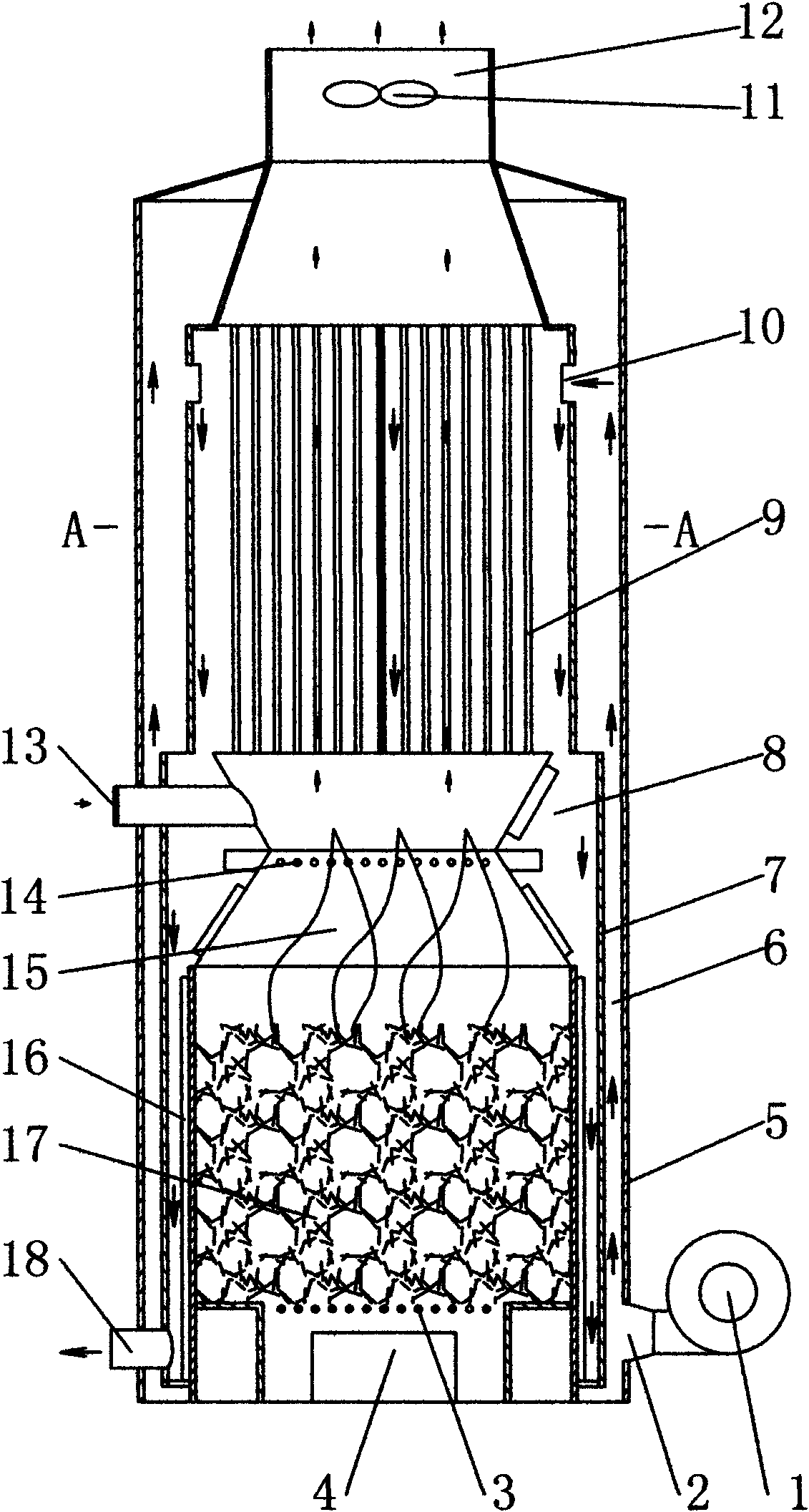

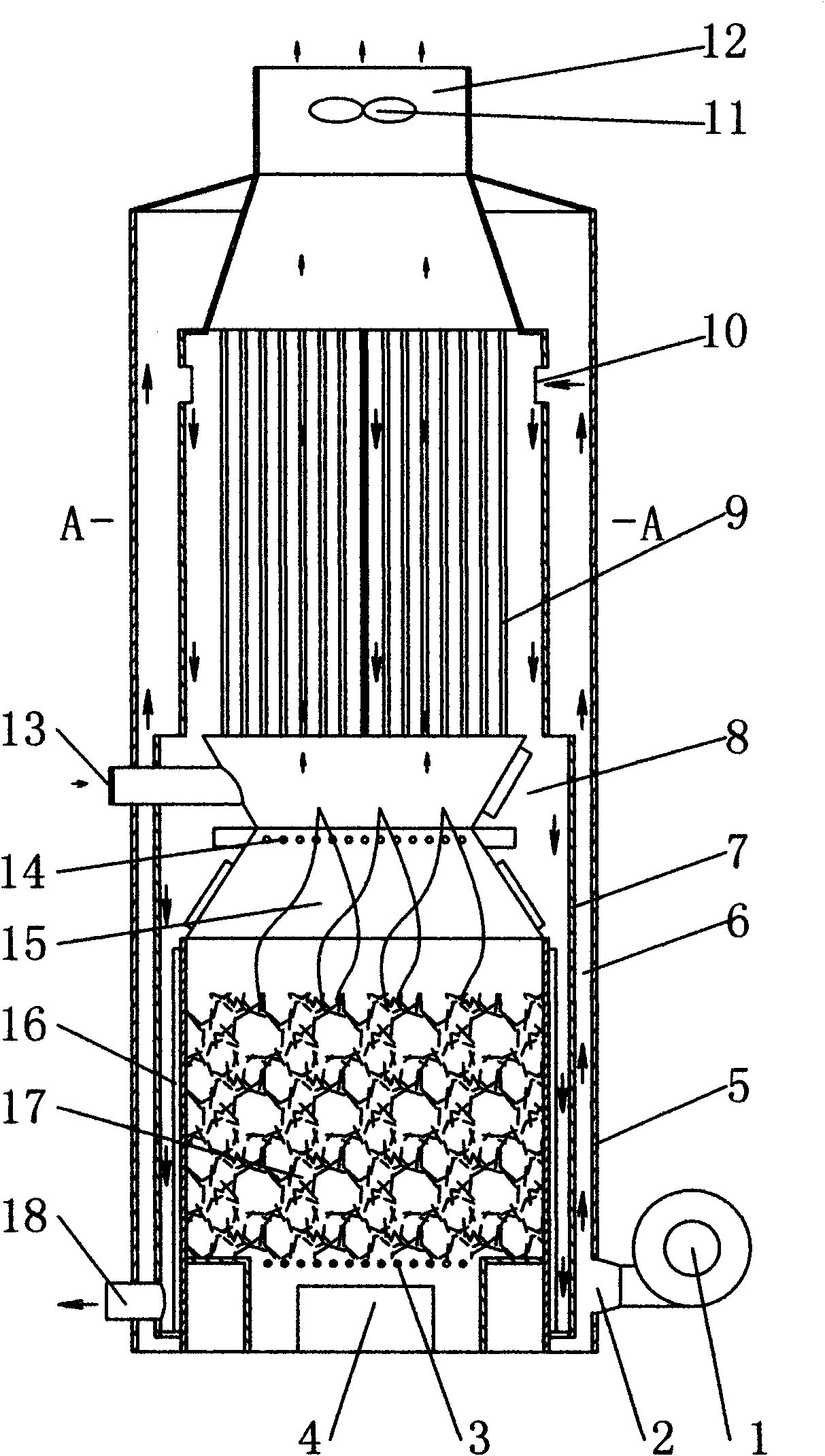

Hot-blast stove of biomass energy source

The invention discloses a hot-blast stove of a biomass energy source, comprising a flame bridge, a stove door, a shell, a smoke outlet, a feeding door, a burning bin and a fuel bin. The hot-blast stove of the biomass energy source is characterized in the shell is internally provided with a liner; the liner is internally provided with the flame bridge, the fuel bin, the burning bin, a heat transfer device and the smoke outlet from bottom to top; the lower part of the shell is provided with a cold air inlet; the outlet of a blower is connected with a cold air inlet; the inner wall of the shell and the outer wall of the liner form a cold air cavity; the inner wall of the liner and the outer walls of the heat transfer device, the burning bin and the fuel bin form a hot air cavity; an air inlet of the liner is arranged on the wall of the upper part of the liner, and a hot air outlet is arranged on the wall of the lower part of the liner; and the burning bin is provided with a feeding port, and the feeding door is arranged at the feeding port. The hot-blast stove has the advantages of scientific, reasonable, smart and flexible structure, convenient moving and higher heat utilization rate; the hot-blast stove is particularly suitable for roasting foxtail millet, maize and wheat in village by using the high-temperature hot air, has no mildewing and is economic and environment-friendly, thereby having promotional value.

Owner:SICHUAN HUINONG MACHINERY

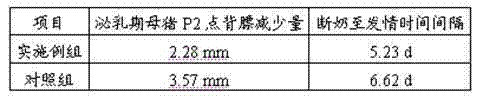

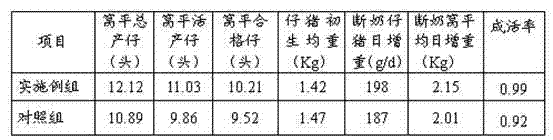

Lactation compound feed for sows and preparation method thereof

ActiveCN102763784AMeeting nutritional needsImprove immunityFood processingAnimal feeding stuffPhytaseAntioxidant

The invention discloses lactation compound feed for sows and a preparation method thereof. The lactation compound feed for sows is made from wheat, corn in northeast China, 46% soybean meal, soybean hull, calcium hydrophosphate, rice bran oil, liquid phytase, liquid compound enzyme, limestone flour, salt, 65% lysine, threonine, 60% choline chloride, antioxidant, plasma protein, potassium chloride, magnesium sulfate, vitamin prefix, and trace mineral premix. The preparation method include: weighing all materials by percent weight, and adding the materials into a crusher for crushing under the crushed size of 25-40 mesh; and adding the crushed materials into a pelletizer to make pellets at 85 DEG C with gelatinization degree reaching more than 90%. The lactation compound feed for sows has the advantages that the lactation compound feed for sows meets requirements of nursing sows for nutrition and is high in palatability, immunity, milk yield and milk quality are increased for the sows, and productivity of piglets is further improved.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Soaking finishing agent of rattan and corn straw as raw materials for weaving crafts and use method thereof

The invention discloses a soaking finishing agent of rattan and corn straw as raw materials for weaving crafts. The soaking finishing agent is prepared from the following raw materials in percentage by weight: 10-20 parts of kuh-seng, 10-15 parts of frutus cnidii, 10-15 parts of stemona root, 10-15 parts of betelnut, 1-2 parts of entomomycete pesticide, 20-30 parts of lime and 20-30 parts of tea.When the soaking finishing agent is in use, the raw materials are mixed and dissolved in water according to a certain proportion, and weaving materials are soaked in a soaking solution for a certain of time, taken out and dried or aired. The soaking finishing agent provided by the invention is non-toxic, harmless and environment-friendly, and the products woven with straw or rattan soaked by the soaking finishing agent provided by the invention can not be mildewed and damaged by worms for dozens of years and keep vivid color and luster.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Method for producing mulberry stamen tea

InactiveCN1647674AIncrease productionQuality improvementPre-extraction tea treatmentTea substituesBudBlood sugar

The present invention discloses the preparation process of mulberry stamen tea. The mulberry stamen tea is prepared with tender bud as the waste from mulberry garden management as main material and through deactivating enzyme, kneading, drying and other steps, and the drying step may be completed in different temperatures so as to form different types of mulberry stamen tea. The mulberry stamen tea is dark green, scented, sweet, mellow and nutritious, and has the health effects of diuresis, lowering blood pressure, reducing blood sugar, etc.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

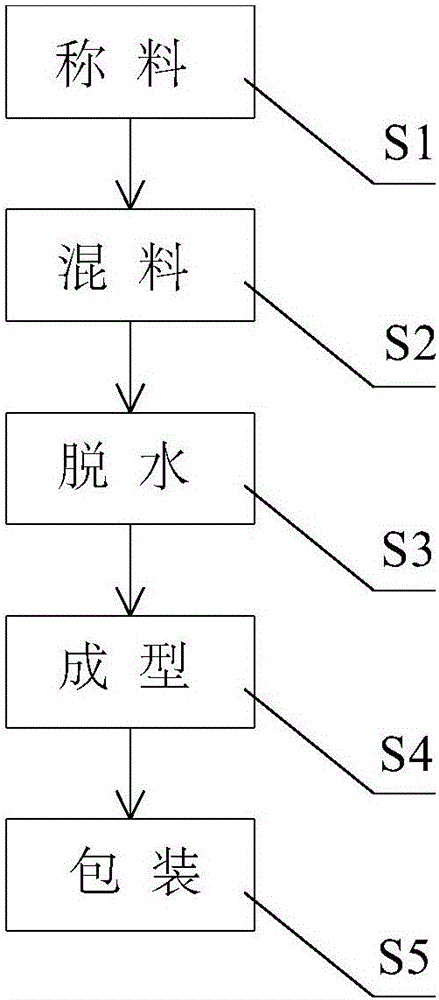

Fruit and vegetable cleaning powder and preparation method thereof

ActiveCN102296007ANot easy to mildewImprove decontamination abilitySurface-active non-soap compounds and soap mixture detergentsFlavorAntibiosis

The invention discloses a fruit and vegetable cleaning powder and its preparation method, the cleaning powder comprises the following raw materials by weight ratio: 60-90% of tea seed cake, 2-10% of Chinese honey locust, 5-30% of surfactant, 2-10% of synergist and 0-10% of plant flavor. The preparation method of fruit and vegetable cleaning powder comprises the following steps: crushing the dried product of the above raw materials into 80 meshes and mixing according to the above ratio. The invention has the advantages that: 1) the product is nontoxic. The formula components uses natural products, the surface of the fruit and vegetable has a few residue which is no harm to human body, to the contrary, due to the pharmacological activity of the antibiosis and antioxidation, taking with a proper amount is beneficial to human body. 2) the decontamination capability is strong. The tea seed cake is rich with tea saponin, the tea saponin has abundant foam and strong decontamination capability, wherein the pesticide clearance to the fruit and vegetable can reach to 86%. 3) the cleaning powder is easy to store with long shelf-life. The tea saponin has bactericidal and fungicidal effect and can not mildew in a solid state.

Owner:赣州哈克生物科技有限公司

Stachyose probiotics solid beverage

ActiveCN103653170AAntagonisticHigh purityFood ingredient functionsFood preparationBiotechnologyNutrition

The invention relates to a stachyose probiotics solid beverage which changes nutritional properties of food and comprises the following components by weight percent: 5-20 percent of stachyose, 2-10 percent of bifidobacterium powder, 2-10 percent of lactobacillus acidophilus powder, 3-8 percent of whey protein powder, 5-15 percent of milk powder, 10-40 percent of grain puffing powder, 5-15 percent of steviol glycoside, 5-15 percent of maltodextrin, 5-15 percent of citric acid and 0.5-2 percent of edible essence, wherein the sum of weight percentage of all the components is 100%. The stachyose probiotics solid beverage adopts natural raw materials, is scientific in formulation, nutritionally balanced, unique in flavor, and sweet and sour, and palatable in taste, not only is beneficial to intestinal health, but also has the health functions of improving immunity of the organisms, delaying senescence, inhibiting tumor and regulating blood lipids, and is convenient to carry and brew.

Owner:WEIHAI BAIHE BIOTECH

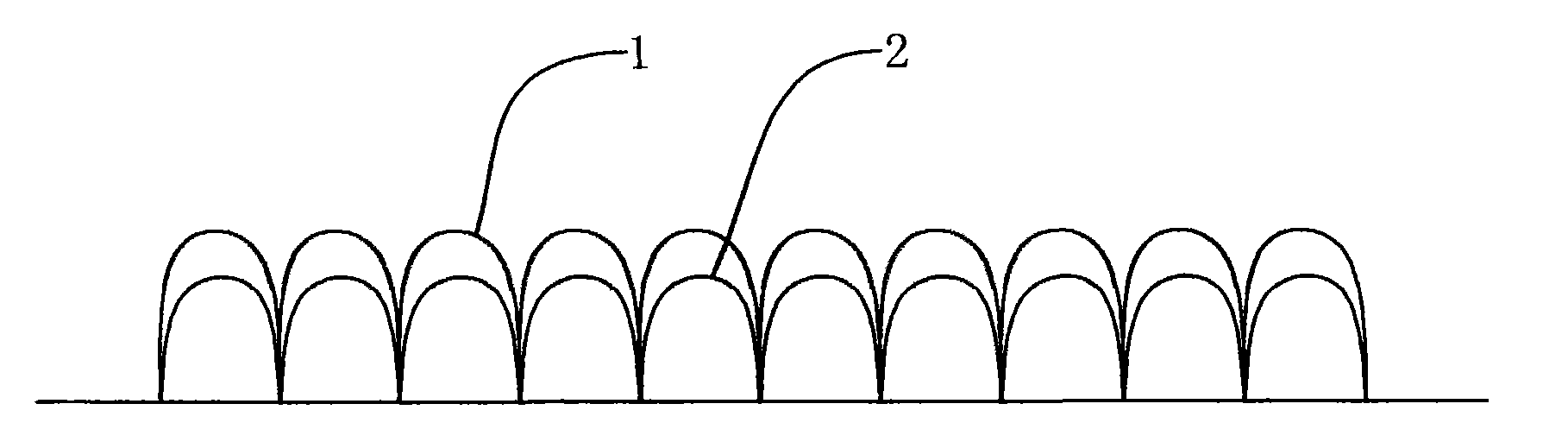

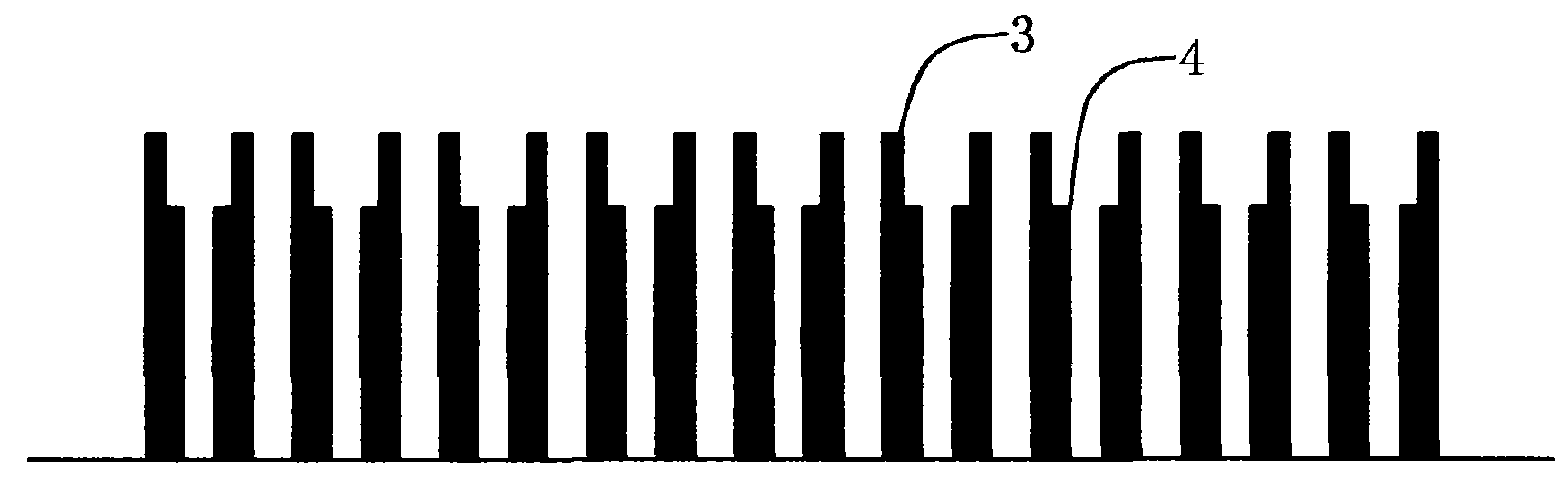

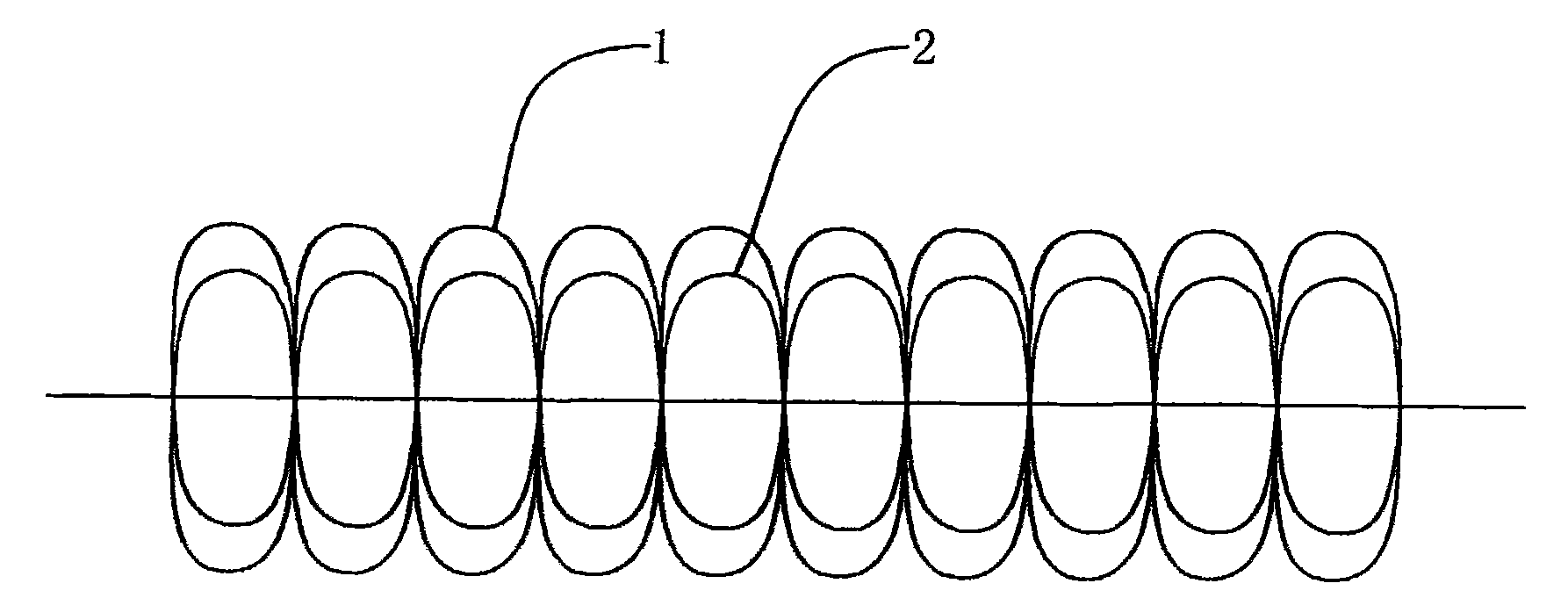

Novel pile loop fabric and method for producing same

ActiveCN102071517AGood comfortGood moisture absorption and air permeabilityWeft knittingWarp knittingNatural fiberMoisture

The invention discloses a method for producing a pile loop fabric. The fabric is a single-sided or double-sided pile loop fabric. Pile loops comprise outer pile loops and inner pile loops; and the pile loop fabric is a novel piled loop fabric which is produced by using natural fibers and ultrathin fibers as piled loop raw materials and chemical fiber filaments or natural fibers as base structure raw material, and by warping, greige cloth weaving, greige cloth post treatment. By combining the respective characteristics and functional advantages of the natural fibers and the ultrathin fibers, the piled loop fabric meets the requirements of people for high comfort degree, high moisture absorbability and high breathability of natural fiber products and enjoys great advantages over pure natural piled loop (velvet) fabrics in terms of bulkiness, softness, water absorbability, convenience for moisturizing, quickness for dying, durability, mildew proof performance and other performance.

Owner:段宏伟

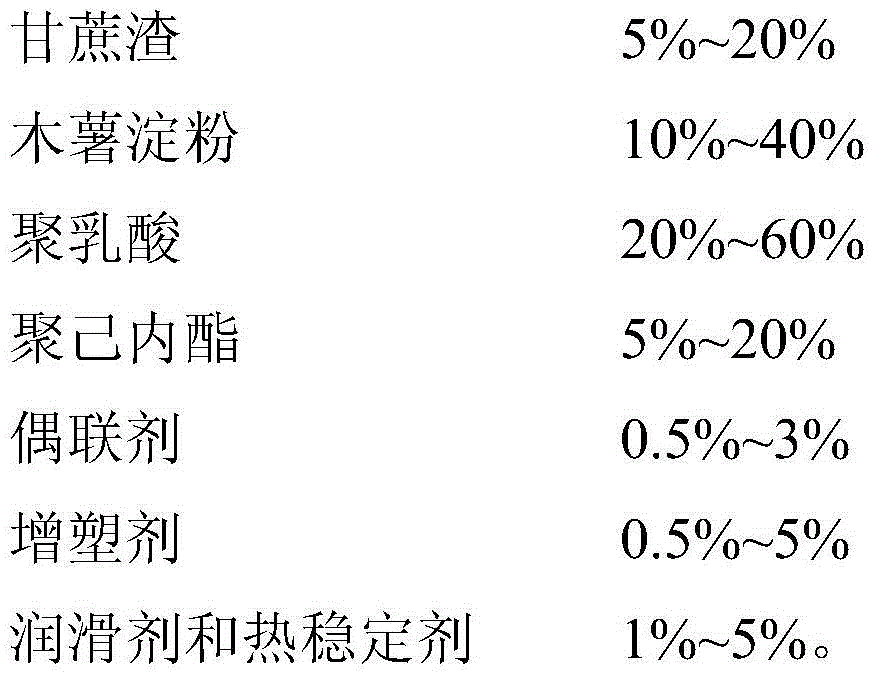

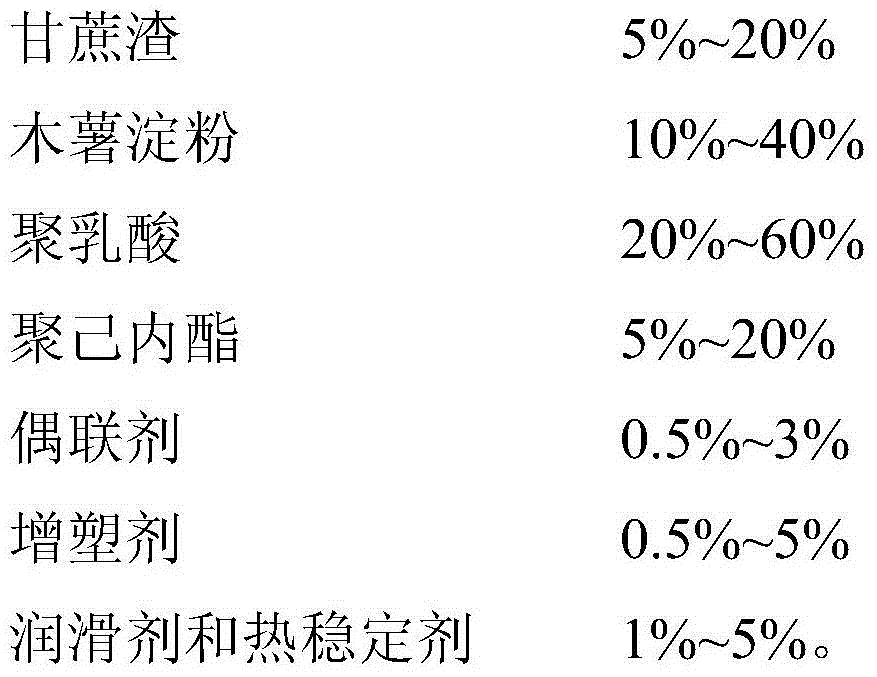

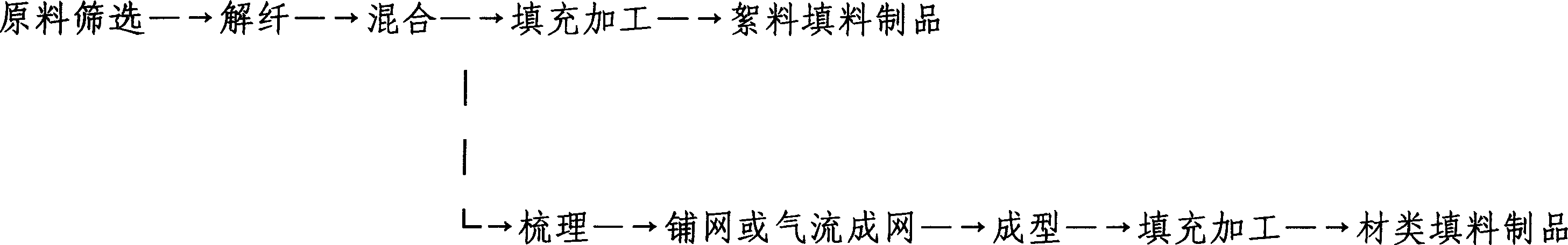

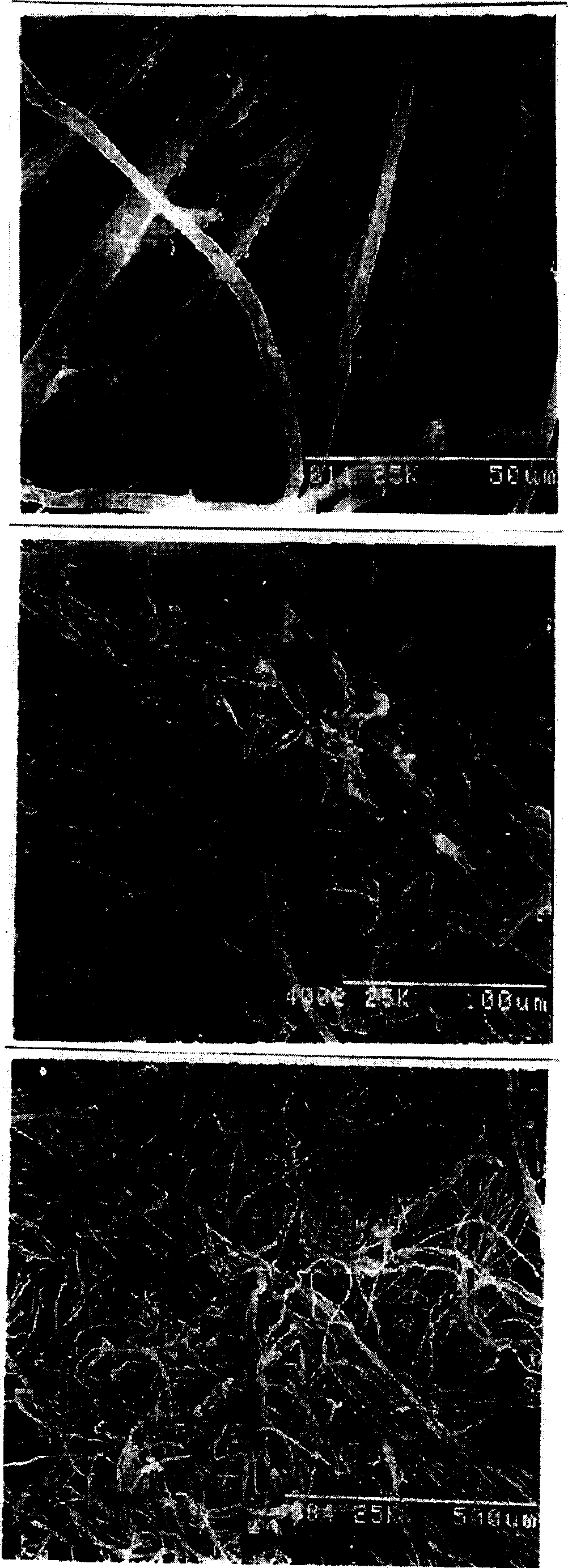

Bagasse/cassava starch polylactic acid biodegradable material, and preparation method and application thereof

The invention belongs to the technical field of biodegradable materials, and discloses a bagasse / cassava starch polylactic acid biodegradable material and a preparation method thereof. The bagasse / cassava starch polylactic acid biodegradable material comprises the following components in percentage by mass: 5-20% of bagasse, 10-40% of cassava starch, 20-60% of polylactic acid, 5-20% of polycaprolactone, 0.5-3% of coupling agent, 0.5-5% of plasticizer, and 1-5% of lubricant and heat stabilizer. The preparation method comprises the following steps: uniformly mixing the components, adding into a double screw extruder, and carrying out extrusion granulation at the extrusion temperature of 80-140 DEG C at the screw speed of 40-100 r / min to obtain the bagasse / cassava starch polylactic acid biodegradable material. The material has favorable biodegradability and mechanical properties, and can be used for preparing daily plastic products.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

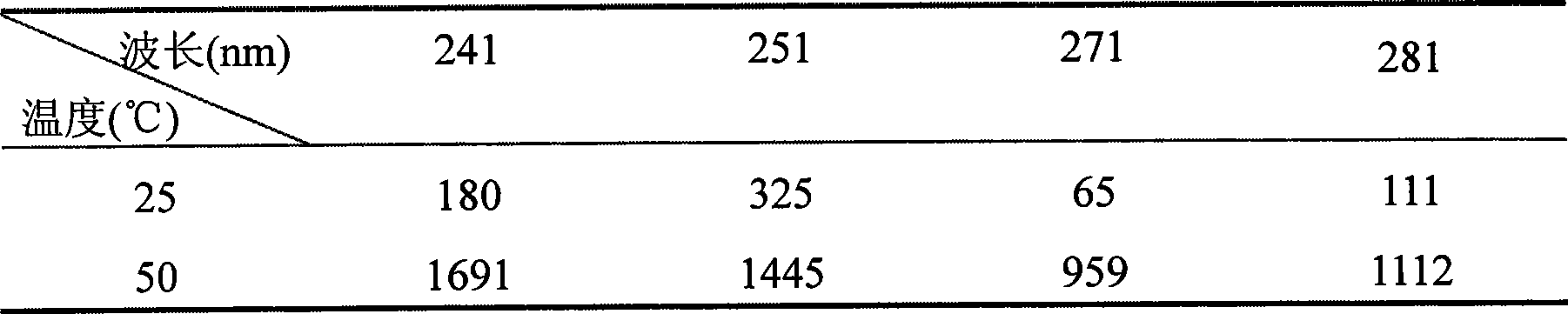

Method for removing nitrites in cubilose

The invention relates to a method for removing nitrites in cubilose, belonging to the technical field of standard-exceeding components in food. The nitrites in the cubilose are removed by combining an ultrasonic technology and an ozone technology, therefore, the content of the nitrites in the cubilose is reduced to be below 30mg / kg, and the cup type and the color of the cubilose can be kept unchangeable. The method comprises the following steps: putting the cubilose in water for ultrasonic treatment for 10-30min with ultrasonic power of 50-2500W and ultrasonic frequency of 20-50 kHz; washing with water for three times, placing into an ozone generator for ozone treatment for 6-120 min by using the water as a medium; and naturally drying. The invention can keep the cup type and the color of the cubilose unchangeable; no chemicals are added, the product after the ozone is oxidized is water without harmful substances so that the cubilose and the environment can not be polluted; the method is an environmental-friendly treatment technology; the ozone has the sterilizing function, and the treated cubilose is not easy to mould; and the invention has simple process, little equipment input and cost saving, and is suitable for the industrialized treatment.

Owner:厦门市燕之屋丝浓食品有限公司

Method for manufacturing silk quilt

InactiveCN101744484AQuality improvementImprove performanceUpholstery manufactureHand sewingHuman bodyBiomedical engineering

The invention relates to a method for manufacturing a silk quilt, which comprises the following process steps: purchasing raw materials and manufacturing silk floss; sewing a silk floss sleeve; and manufacturing the silk quilt. The silk quilt manufactured by the method is natural and environmental-friendly, and has reliable quality, stable performance and durability; the inner floss is not rolled, exposed or shrunk; and the silk quilt also has the effects of preventing insects, moulds and dusts and resisting static. The silk quilt has the characteristics of fine, smooth, fluffy and soft feelings, coolness in summer and warmness in winter, and affinity with skin, capacity of nourishing cells, promoting the blood circulation, improving the sleeping state, being beneficial to a human body after long-time use, and a best healthcare product in the modern house.

Owner:隋日宽

Collagen fiber stuffing product and processing method thereof

ActiveCN1730376AHigh heat retention rateHigh static stabilityMonocomponent protein artificial filamentUpholstery fillingTextile fiberEngineering

The invention provides a collagen fiber stuffing product which comprises 50%-100% collagen fiber in the stuffing and its Process for preparing. The said stuffing is oakum stuffing mixed collagen fiber deliberating from animal hide with at least another textile fiber; or materials stuffing arise from teasing, bedding web and modeling. The stuffing product in the invention is provided with advantages of well puffy, well rebound, well warming, flameproof and sound absorbing which the current stuffing can not get because it uses collagen fiber as main stuffing. The stuffing produced in the process provided in the invention has no peculiar smell, without putrefaction, without mouldy, and can be used in practice. The product is low cost and settles the problem of leftover bits and pieces of industrial material, so it is environment friendly.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Antiseptic fixing liquid composition for cadaver sample and preparation method thereof

InactiveCN101473812ANatural colorTissue flexibilityDead animal preservationChemistryLiquid composition

The invention discloses an antiseptic stationary liquid composition for corpse specimen, mainly comprising a metal complexing agent, a protein corsslinking agent, an osmoregulation agent and a food-grade antiseptic / mildew inhibitor and water; the metal complexing agent is ethylenediamine tetracetic acid disodium salt or ethylene glycol diethyl ether ethylenediamine tetracetic acid, the protein corsslinking agent is glyoxal, malonaldehyde, succinaldehyde or glutaraldehyde, the osmoregulation agent is a mixture, according to any proportion, of more than two substances selected from potassium nitrate, sodium nitrate, potassium chloride and sodium chloride, the food-grade antiseptic / mildew inhibitor is sodium dehydroacetate, sodium diacetate or potassium sorbate. The inventive composition is dedicated to antisepsis and fixing perfusion for animal or human corpses and has the advantages of strong antiseptic performance, good fixing performance and excellent safety without formaldehyde and toxicity. The invention also provides a method for preparing the antiseptic stationary liquid composition for corpse specimen.

Owner:WENZHOU MEDICAL UNIV

Corrugated board adhesive glue and preparation method therefor

InactiveCN103421446AReduce forceLow gelatinization temperatureNon-macromolecular adhesive additivesStarch adhesivesPolyvinyl alcoholAdhesive glue

The invention provides a corrugated board adhesive glue. The adhesive glue comprises the following raw materials, by weight, 400-600 parts of water, 80-120 parts of corn starch, 4-6 parts of polyvinyl alcohol, 0.8-1.2 parts of sodium borate and 8-12 parts of sodium hydroxide solution. The adhesive glue is advantaged by simple process, simple operation, low-cost raw materials, low-temperature technology requirement and firm adhesion.

Owner:天津市大港巨龙造纸厂

Method for preparing knitting technology paper with Salix integra bark as raw material

ActiveCN106192543AImprove toughnessHigh tensile strengthSpecial paperWater-repelling agents additionFiberWeather resistance

The invention discloses a method for preparing knitting technology paper with Salix integra bark as the raw material. The method includes the steps of raw material preparation, raw material treatment, raw stock preparation, mixed pulp preparation and papermaking. Compared with the prior art, the method has the advantages that Salix integra bark decoction is used for repulping fibers in Salix integra bark and Salix integra bark leaf stems, and the tensile strength can be improved; waxy corn pulp can permeate into fiber pores in the treatment process to be combined with the fibers, and the tenacity of the fibers can be improved; urea resin and other raw materials are used in synergism, and the waterproofness of the product can be improved; the raw material utilization rate is high in the product preparing process, and the obtained product has high strength and tenacity, easy to knit, stable in structure, high in weather resistance and not prone to mildew.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Novel interlayer fine dried noodles and processing method thereof

InactiveCN105380103AHas a clear fragranceNot stickyFood coatingFood ingredient as mouthfeel improving agentOff-flavourInsect pest

The invention discloses novel interlayer fine dried noodles, comprising upper flour slices and lower flour slices, as well as sweet potato or solanum tuberdsm flour slices pressed between the upper flour slices and the lower flour slices. The cooked interlayer sweet potato fine dried noodles are slightly white in surface color and internal red and external white in section, have unique fresh scent of the sweet potato, and are not pasty, not thick in soup, not sticky in taste, not gritty, are soft and tasty and refreshing, a cooking noodle break ratio is smaller than or equal to 5%, the irregularity is smaller than or equal to 15%, wherein, the natural noodle break ratio is smaller than or equal to 8%, physicochemical indexes of the fine dried noodles have a water content being smaller than or equal to 13.5%, acidity being smaller than or equal to 4.0, and a bending noodle break ratio being smaller than or equal to 15%; hygienic indexes achieve no impurity, no mildewing, no extraneous odor, no insect attack and no pollution, and raw materials and auxiliaries accord with national standards.

Owner:李少卫

High-temperature quick-drying processing method of honeysuckle tea

InactiveCN101971904AShorten the timeReduce processing costsTea substituesChlorogenic acidFree cooling

In order to improve the quality of honeysuckle tea, avoid the loss of effective component chlorogenic acids and prolong the storage time of honeysuckle tea, the invention provides a high-temperature quick-drying processing method of honeysuckle tea. The invention has the technical scheme that the high-temperature quick-drying processing method of honeysuckle tea comprises the following concrete steps: (1) taking honeysuckle buds as raw materials, spreading and airing the honeysuckle buds in a room for 3-4h after picking, and carrying out water-removing treatment in a water-removing pot, wherein the temperature is set as 160-250 DEG C, and the rotary water-removing time is 1-2min; (2) after the honeysuckle buds after water-removing treatment are taken out of the pot, naturally cooling the honeysuckle buds to the normal temperature; (3) drying: putting the honeysuckle buds into a drying box for drying, wherein the temperature is controlled at 80-120 DEG C, and the time is 8-12min; (4) after the dried honeysuckle buds are taken out of the drying box, naturally cooling the honeysuckle buds to the normal temperature to obtain the honeysuckle tea; and (5) carrying out vacuum packaging.

Owner:郧县智源生态农业科技开发有限公司

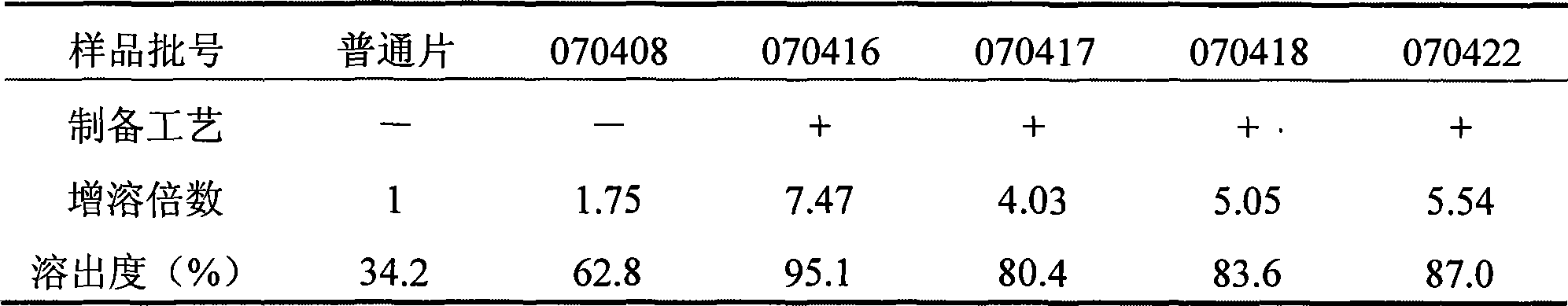

Pine pollen and cyclodextrin composition, method for preparing same, use of same in preparation of health-care products for resisting fatigue and improving immunity of organisms

InactiveCN101518552AHigh activitySolve the problem of easy oxidation and deterioration of nutrientsAntinoxious agentsPharmaceutical non-active ingredientsMass ratioAdditive ingredient

The invention disclose a pine pollen and cyclodextrin composition, a method for preparing the same and application of the same in the preparation of health-care products for resisting fatigue and improving immunity of organisms. The composition consists of extract of wall-broken pine pollen and cyclodextrin, and is characterized in that the mass ratio of the pine pollen or the extract of the pine pollen to the cyclodextrin is 1:0.6-5. The preparation method comprises the following steps of: adding pure water and the cyclodextrin into to the wall-broken pine pollen or the extract of the wall-broken pine pollen in an amount which are two times of that of the wall-broken pine pollen or the extract of the wall-broken pine pollen; uniformly stirring the mixture and grinding the mixture for 0.5 to 3 hours; drying the ground mixture under reduced pressure at a temperature below 50 DEG C; and crushing the mixture and passing the crushed mixture through a sieve to obtain the pine pollen and cyclodextrin composition. The application of the pine pollen and cyclodextrin composition in the preparation of the health-care products for resisting the fatigue and improving the immunity of the organisms has the advantages that: the composition is strong in stability; the preparations have good performance; the stability of active ingredients is obviously improved compared with the wall-broken pine pollen on the market; the products are long in storage time and convenient in transport; and the active ingredients of pine pollen can be absorbed by human bodies.

Owner:NANJING NORMAL UNIVERSITY +1

Method for producing bamboo board

InactiveCN1970259AUniform densityHigh static bending strengthFlat articlesDomestic articlesFiberBleach

It relates to bamboo plate production method. 1) it processes bamboo fiber to thread bamboo sheet, 2) bleach, carbonize and dry after modifying property, 3) soaking the said bamboo sheet in glue agent, dry to the water content 10-12%, taking the bamboo plate of the corresponding weight based on 1.1-1.3g / cm3 intensity to fill into the mold, 5) sending the bamboo sheet to heat compressor with compression force 6-10 MPa for 30-60 minutes, setting the compression temperature 100+-5DEG C for melamine resin adhesive, or 135+-5DEG C for phenol aldehyde resin adhesive, and 6)process the compressed plate. The made bamboo plate is even in intensity, high in static curve strength and hardness, anti wearing and good in stability.

Owner:DASSO INDASTRIAL GRUP KO LTD +1

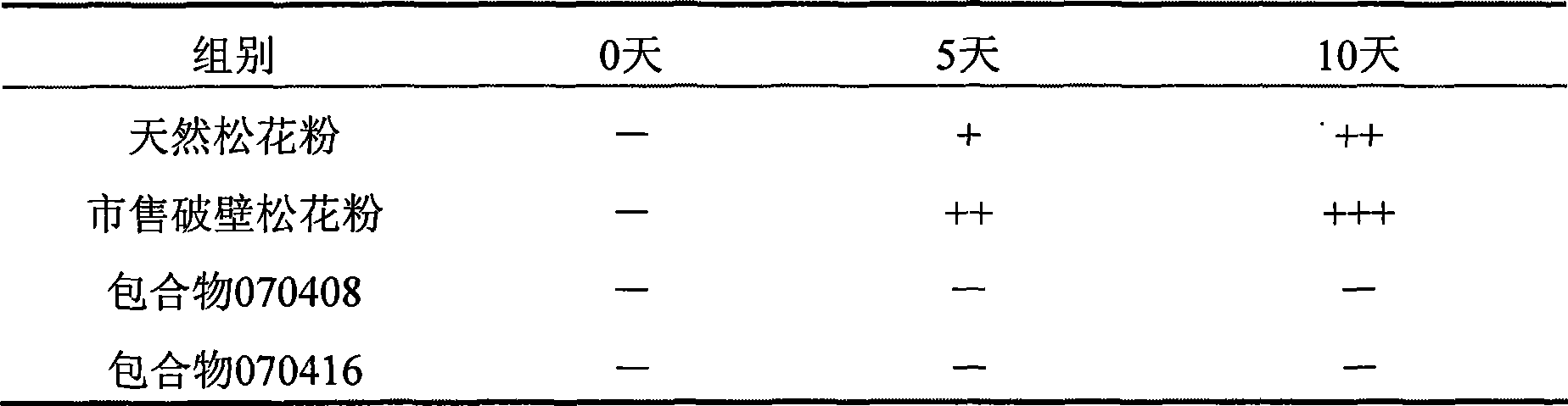

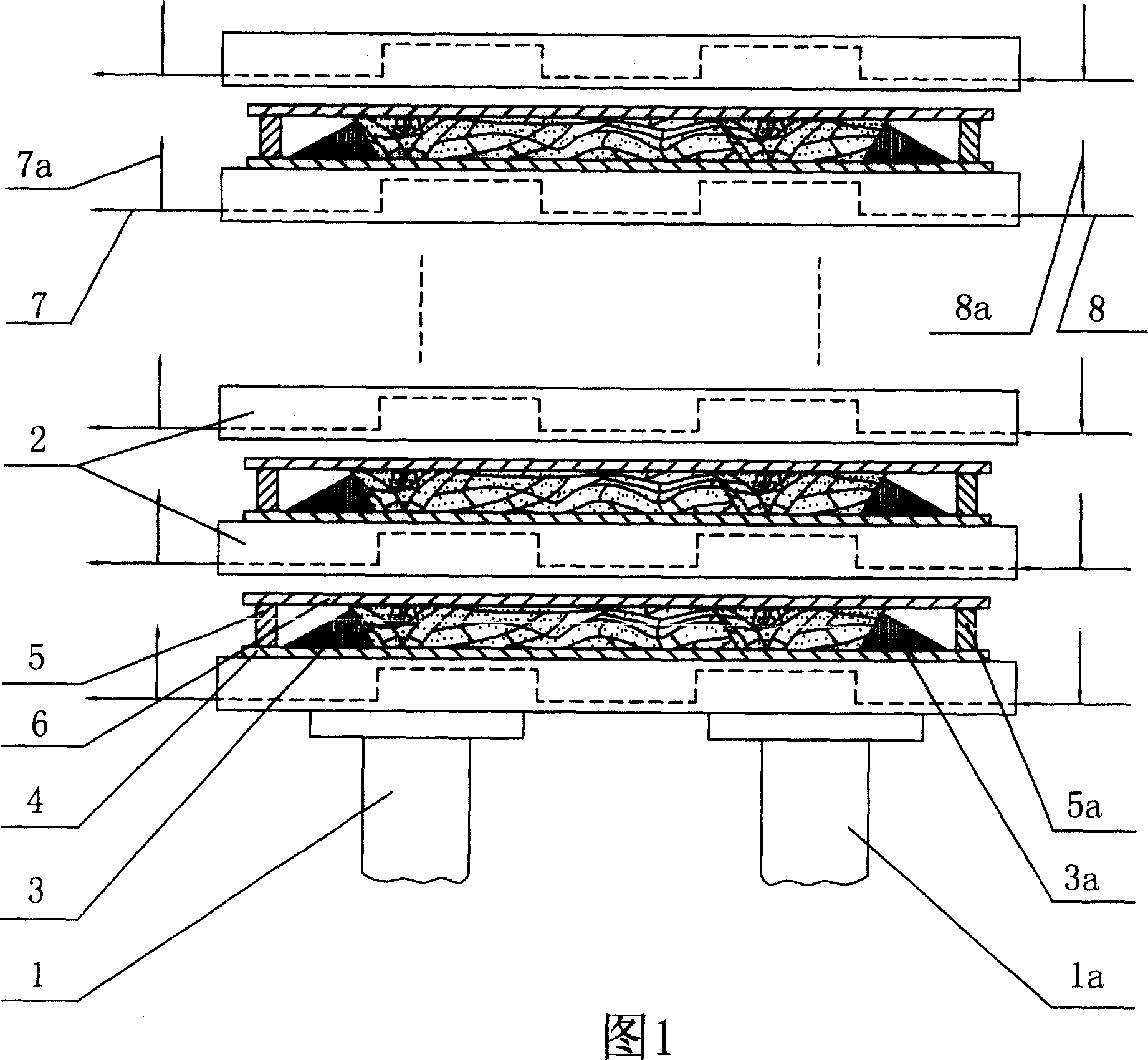

Glass fiber thin felt for plastic floor leather base material and preparation method thereof

The invention discloses a thin felt with glass fiber for the substrate of plastic floor ant the manufacturing method, comprising short-cut silk of glass fiber, dispersant, surfactant and organic binder. Said short-cut silk of glass fiber is middle-alkali or non-alkali, the diameter is 9-10 mum and the length is 6-12mm. Said dispersant is thickener belonging to cellulose acetate. Said surfactant is quaternary ammonium cationic surfactants. The organic binder is the mixture of polyethylene acetate emulsion thermosetting resin, KH560 coupling agent and water. Said thin felt with glass fiber is produced by wet technology, which comprises producing stock, preparing slurry, sizing forming, dipping and drying so on. The product is provided with high compactness, even thickness, widely applied temperature, and no-deformation under high temperature. The plastic floor surface with the felt as the substrate, is provided with flat and smooth, no shrinkage deformation, no-bending, no mildewing and stable dimension.

Owner:樊福定

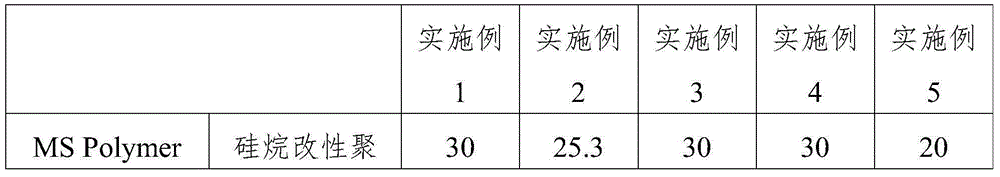

Mildew-proof silane-modified polyether sealant and preparation method therefor

InactiveCN105111992ASolve the problem of decreased elasticityIncrease elasticityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUltraviolet

The present invention discloses mildew-proof silane-modified polyether sealant. The sealant is prepared by mixing the following raw materials in proportion by weight: 20-30% of silane-modified polyether prepolymer, 20-30% of a plasticizer, 40-50% of reinforcing incremental powder, 3-5% of a brightener, 0.1-0.5% of a thixotropic agent, 0.1-0.3% of a mildew-proof agent, 0.1-0.3% of an ultraviolet absorbent, 0.1-0.3% of a light stabilizer, 0.5-1% of a dehydrating agent, 0.5-1% of a silane coupling agent and 0.1-0.3% of a catalyst. The mildew-proof silane-modified polyether sealant provided by the present invention adopts single-component sealed package, is cured after contacting moisture under the action of a catalyst and has wide adhesion to various materials. The sealant is simple in operation, environmentally friendly, cured quickly, mildew-proof in a moist environment and is an ideal adhesive sealing material in kitchen-bath and household aspects.

Owner:深圳市隆邦新材料科技有限公司

Rubber power for building

The invention relates to a rubber power for building. The rubber power comprises the following components according to the weight by parts: 20-30 parts of etherified starches, 25-35 parts of fiber, 30-40 parts of PVA, 45-70 parts of oxidized starch, 5-10 parts of plasticizer, 8-15 parts of tackifier, 0.5-2.5 parts of antiseptic, and 1-3 parts of water proofing agent. The rubber power for buildingis white and powered in appearance, is innoxious and tasteless, does not have hazardous substance, is convenient to transport, has the advantages of good quality, high viscocity, strong adhesive attraction, non-coming off power, no crack, washing resistance, high strength, fast solution, wide utilization area; and the preparation method is simple and has low cost.

Owner:江阴市北国新型建筑材料厂

Technology for producing silage by utilizing smilax riparia and wheat straws

ActiveCN103518957AMaintain nutritional valueImprove palatabilityFood processingAnimal feeding stuffBiotechnologyNutritive values

The invention relates to a technology for producing silage by utilizing smilax riparia and wheat straws. The technology comprises the following steps: (1) separately pretreating smilax riparia and wheat straws to obtain pretreated smilax riparia and pretreated wheat straws; (2) evenly mixing the pretreated smilax riparia and pretreated wheat straws in proportion to obtain a mixed raw material A; (3) respectively adding maize flour and white sugar into the mixed raw material A, and evenly mixing to obtain a mixed raw material B; (4) evenly spraying lactic acid bacteria mixture culture solution into the mixed raw material B, then mechanically grinding so that water in the mixed raw material B can be relatively evenly distributed, and finally filling in a closed container, compacting, sealing, and fermenting at room temperature for 60-90 days. The technology is simple and fast, low in raw material cost, the obtained product is good in palatability, green, juicy and rich in nutrition, and can maintain the nutrition values for a long time.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

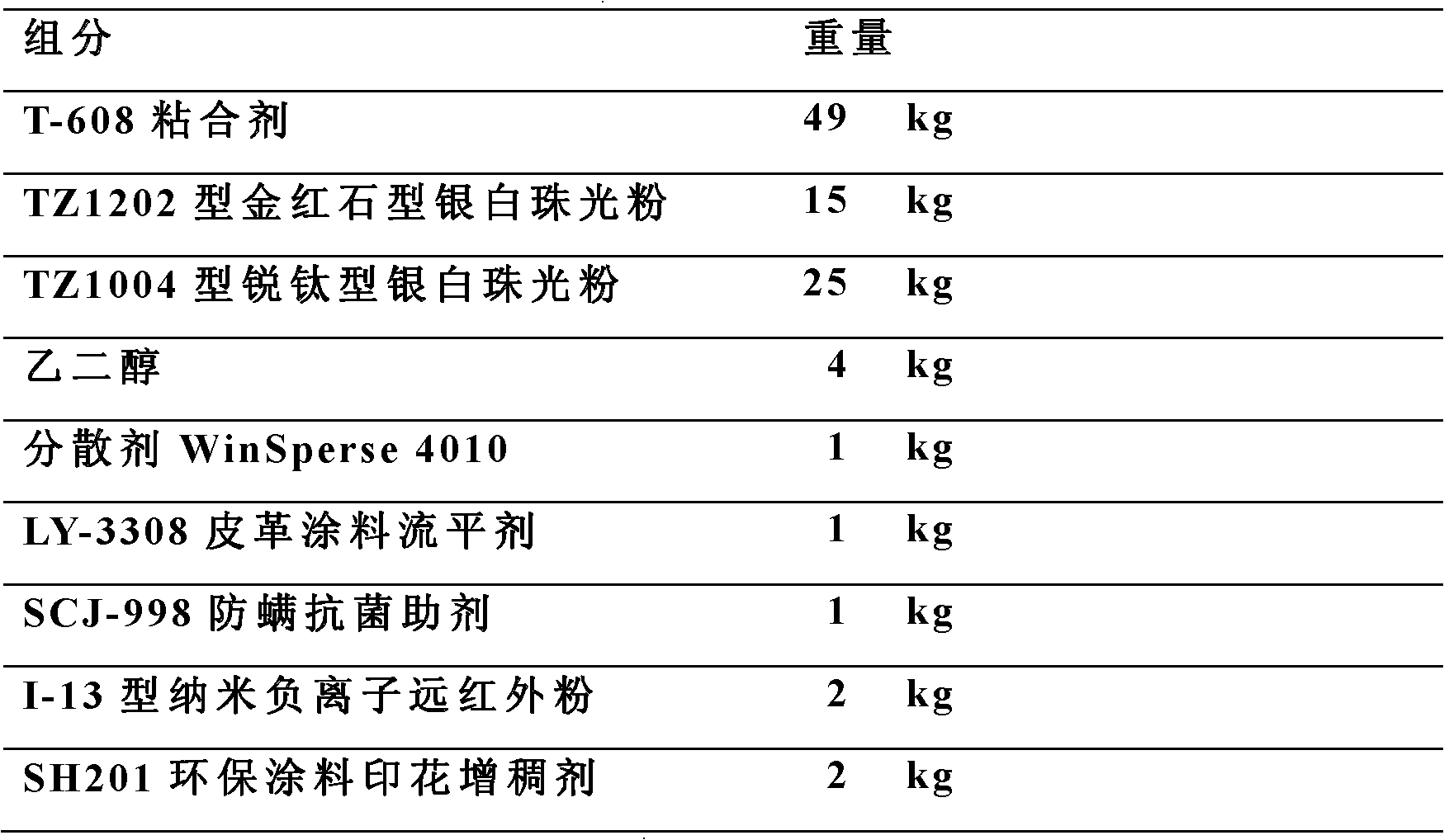

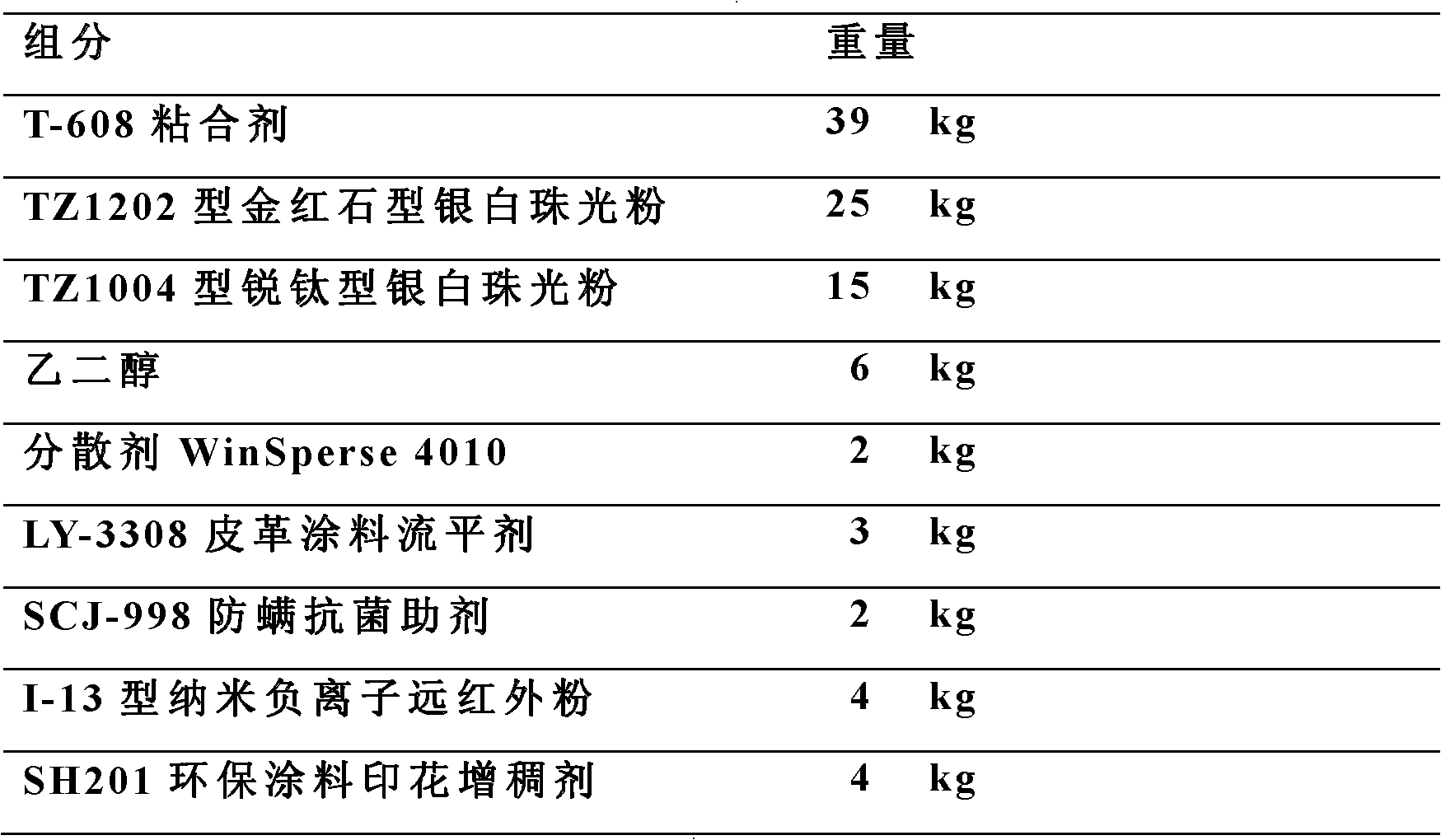

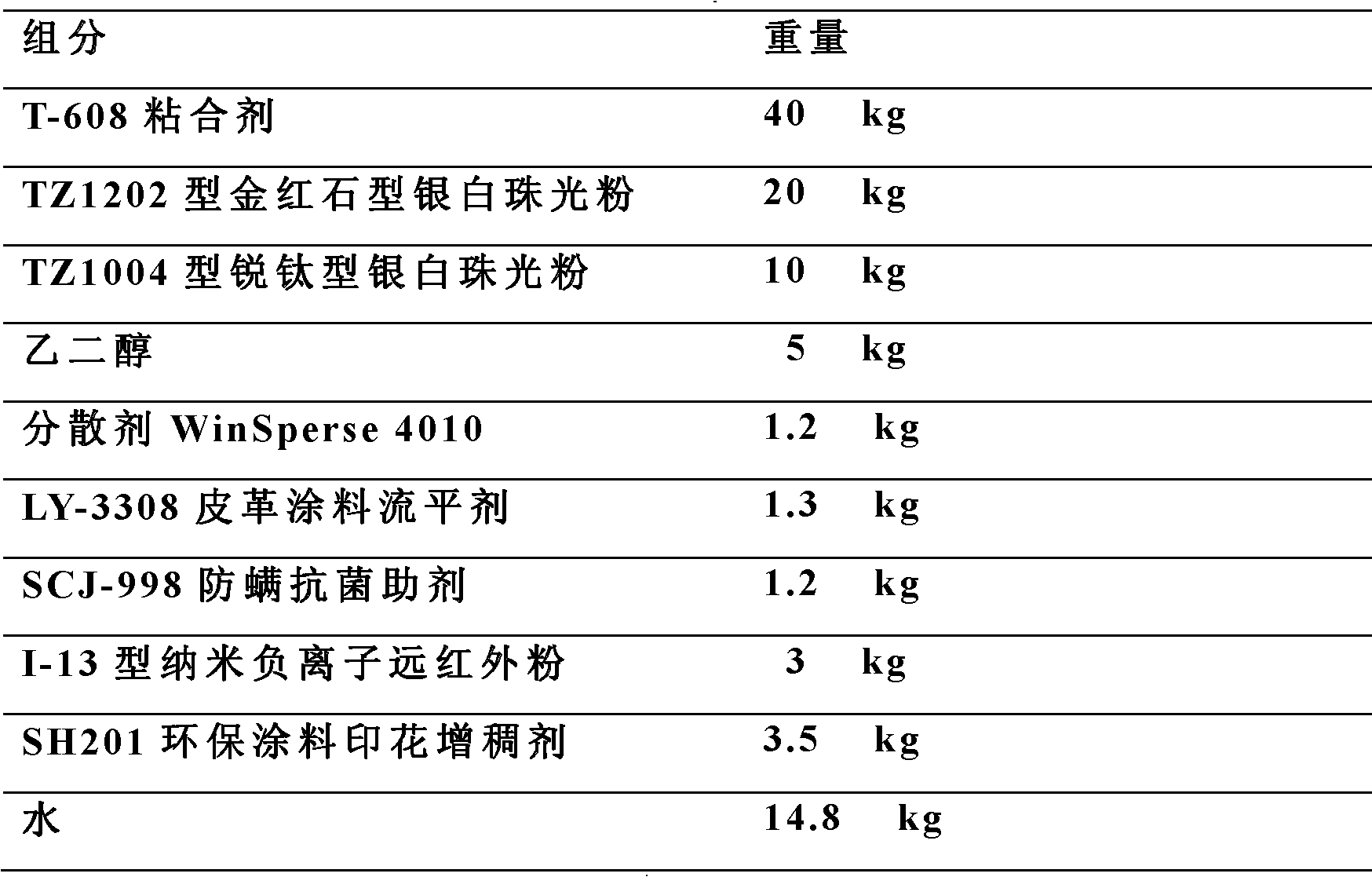

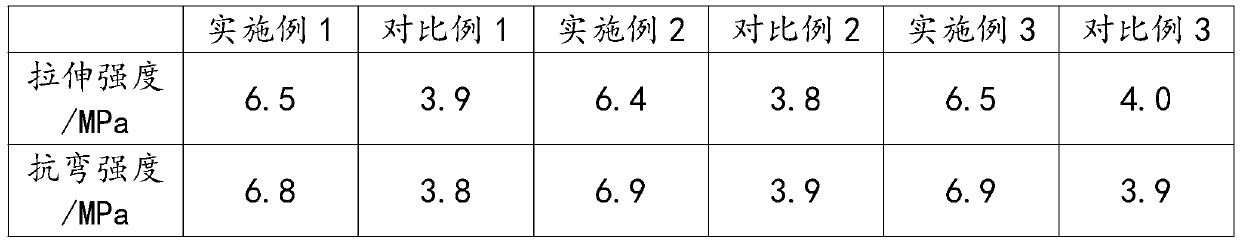

Environment-friendly textile printing pearlescent adhesive cement and preparation method and application thereof

InactiveCN102174747ARich graphic expression techniquesInhibition of proliferative abilityDyeing processAdhesive cementSpontaneous combustion

The invention discloses an environment-friendly textile printing pearlescent adhesive cement and a preparation method and application thereof. The adhesive cement comprises the following components in percentage by weight: 49 to 39 percent of environment-friendly ultra-soft adhesive, 15 to 25 percent of rutile silvery white pearlescent powder in the particle size range of between 5 and 25 microns, 15 to 25 percent of anatase silvery white pearlescent powder in the particle size range of between 10 and 60 microns, 4 to 6 percent of glycol, 1 to 2 percent of dispersing agent, 1 to 3 percent of leveling agent, 1 to 2 percent of mould-proof antibacterial auxiliary agent, 2 to 4 percent of nano negative ion far-infrared powder and 2 to 4 percent of thickening agent. The adhesive cement cannot block a screen during screen printing, has high weather resistance and has the obvious advantages of environment friendliness, no toxic hazard, high-temperature resistance, acid-base resistance, incapability of spontaneous combustion and combustion supporting, high oxidation resistance, high covering power and the like which are obviously distinguished from those of the common dye and pigment.

Owner:SUZHOU UNIV

Sugar-free cream egg roll and method for producing the same

InactiveCN101461398AEasy to eatExtended shelf lifeBakery productsFood preparationBiotechnologyGluten

The invention relates to a sugar-free butter roll, characterized by comprising the materials with the weight percent: egg 150-900 parts, sugar-free modifier 50-200 parts, low gluten powder 200-800 parts, baking powder 2-10 parts, milk sachet 2-10 parts, cake oil 10-100 parts, milk essence 2-10 parts, liquid edible oil 20-100 parts, butter 500-2000 parts. The inventive butter roll is fragrant and soft in mouth feel, particularly the sugar-free modifier is used as main materials, blood glucose value is not increased after being eaten, more suitable for the diabetics.

Owner:天津金世制药有限公司

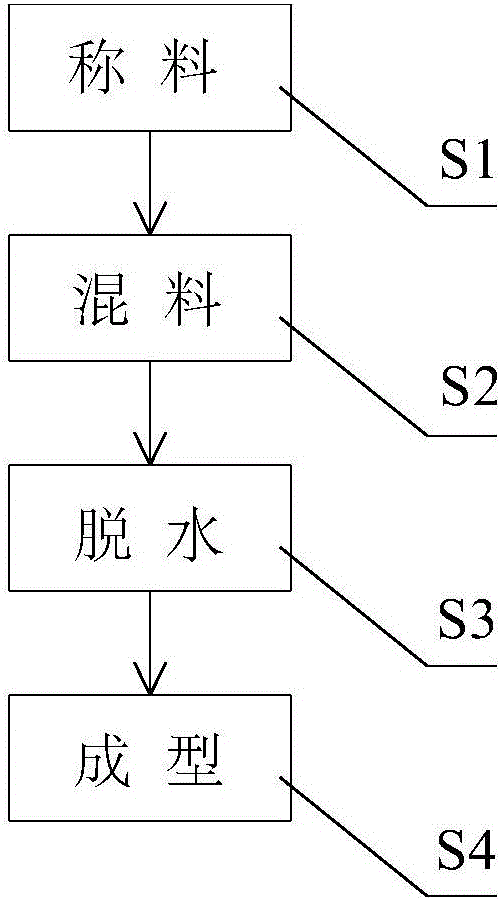

Method for preparing solid forming fuel with pig manure as raw material

ActiveCN103421573AAvoid crackingAvoid product qualityBiofuelsSolid fuelsDry weightResource utilization

The invention discloses a method for preparing solid forming fuel with pig manure as raw material. The method comprises the steps as follows: firstly, drying the pig manure to enable the moisture content of the pig manure to be reduced to 10%-25%, then crushing the pig manure and adding the additive capable of desulfuration, deodorization and mold prevention via 2%-5% dry basis quality of the pig manure so as to form the dried pig manure raw material; uniformly mixing and stirring 20%-100% of the dried pig manure raw material, 0%-80% of biomass and 0%-20% of coal by dry weight to obtain the raw material mixture, and then utilizing forming machine to perform hot-pressing formation, so as to obtain the solid forming fuel. The method has the characteristics of simplicity, convenience, feasibility, energy conservation and environmental protection, high treatment efficiency, low production cost, and high convenience for large-scale industrialized production, and the solid forming fuel has no odor, is not easy to mildew, is convenient in transportation and storage and high in combustion efficiency and has fewer secondary pollutant emissions. Therefore, harmless treatment and resource utilization of the pig manure are realized, and the problem about treatment and disposal of the excessive pig manure can be effectively solved.

Owner:HUNAN UNIV

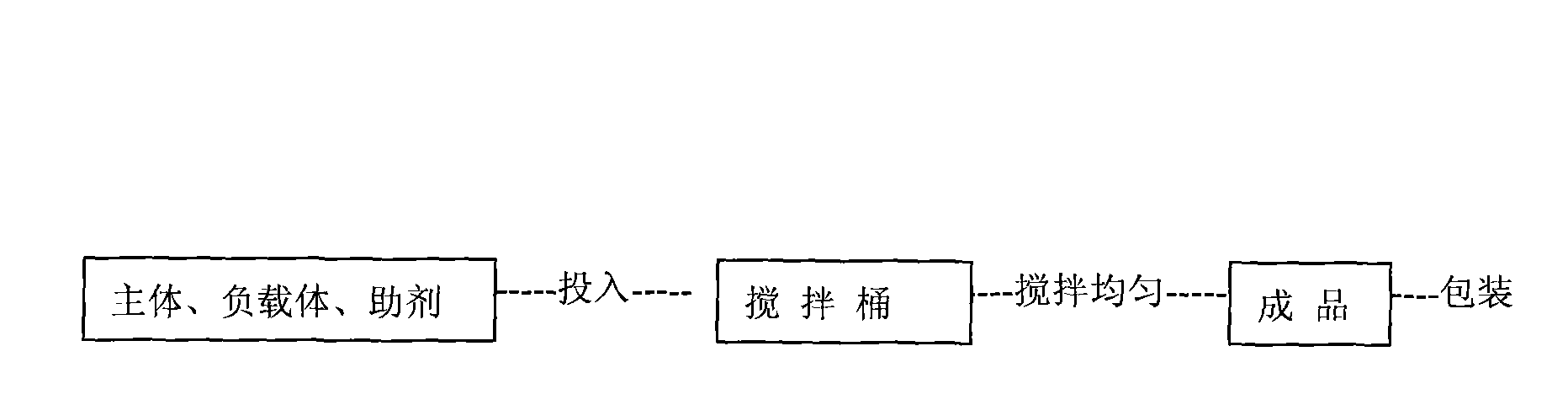

Environment-friendly bamboo fiber material and preparation method thereof

InactiveCN109705549AIncrease the effective contact areaEnhanced mechanical adhesionPlasticizerHot pressing

The invention discloses an environment-friendly bamboo fiber material which is prepared from the following raw materials in parts by weight: 30-40 parts of polylactic acid, 10-18 parts of poly (butylene succinate), 20-30 parts of modified bamboo fiber, 10-15 parts of a plasticizer and 2-3 parts of an antibacterial agent; the invention further discloses a preparation method of the environment-friendly bamboo fiber material, and the preparation method comprises: step 1, sealing and placing; step 2, mixing; step 3, after being cooled, crushing the mixture into particles through a strong crusher,and pouring the particles into a hot-pressing mold; and step 4, carrying out hot pressing. According to the invention, the polylactic acid and the poly (butylene succinate) are used as a matrix of materials, and are both biodegradable resin, and the mechanical property and the heat resistance of the composite material can be improved by enhancing effect of the modified bamboo fiber; meanwhile, dueto the addition of the plasticizer, the composite material not only has relatively high strength, and the elongation at break and the water resistance are good; due to the addition of the antibacterial agent, the composite material is not easy to mildew, and the service life of the composite material can be effectively prolonged.

Owner:金华市秸和环保技术咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com