Bagasse/cassava starch polylactic acid biodegradable material, and preparation method and application thereof

A biodegradable material and tapioca starch technology are applied in the field of sugarcane bagasse tapioca starch polylactic acid biodegradation materials and their preparation, which can solve the problems of low comprehensive utilization rate, low added value, environmental pollution, waste of resources, etc., and solve the problem of raw material supply, The effect of reducing production costs and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

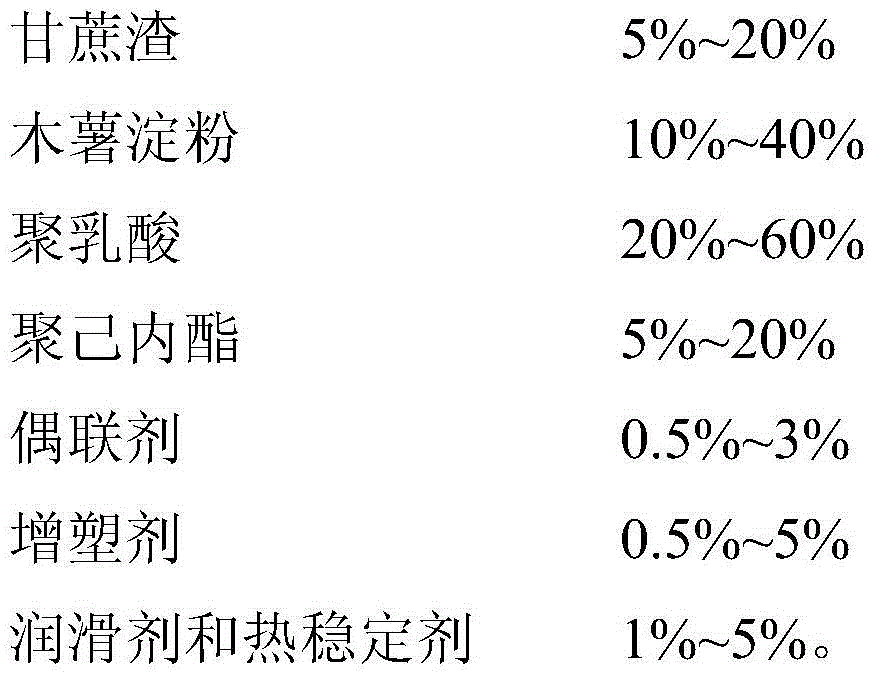

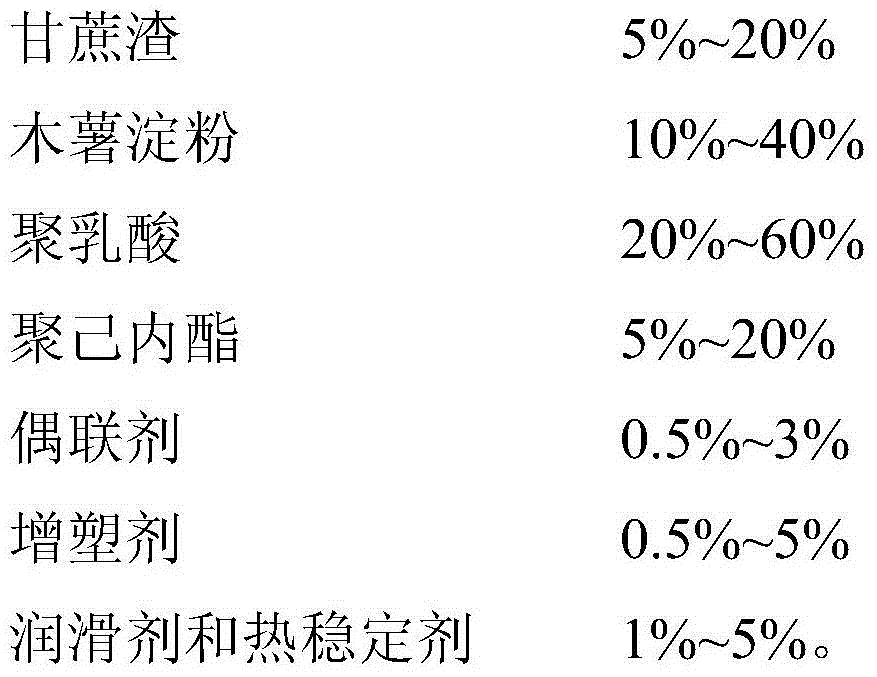

Method used

Image

Examples

Embodiment 1

[0024] The bagasse shipped from the sugar factory is firstly depulped twice through a pitting machine with a sieve hole of 7-8mm so that the pith content of the bagasse is less than 5%, and then the bagasse after depulping by the pitting machine is removed Wet storage, after wet storage, the bagasse after wet storage will go through a wet depitting process to make the bagasse content of pith less than 1%, and finally dry and crush to a particle size of 80 mesh to obtain pretreated bagasse ;

[0025] The tapioca starch was dried for 24 hours at 60° C. of an oven, and the dried tapioca starch was added with 1% citric acid, 2% glycerol and 2% acetamide and mixed to obtain a mixed material, citric acid, glycerol and ethyl The purity specification of the amide is chemically pure, and the mixed material is added to a twin-screw extruder at an extrusion temperature of 100°C and a screw speed of 60r / min for extrusion modification to obtain pre-modified tapioca starch;

[0026] The ma...

Embodiment 2

[0030] The bagasse shipped from the sugar factory is firstly depulped twice through a pitting machine with a sieve hole of 7-8mm so that the pith content of the bagasse is less than 5%, and then the bagasse after depulping by the pitting machine is removed Wet storage, after wet storage, the bagasse after wet storage will go through a wet depitting process to make the bagasse content of pith less than 1%, and finally dry and crush to a particle size of 100 mesh to obtain pretreated bagasse ;

[0031] Tapioca starch was dried 18 hours at 80 DEG C of oven, in the tapioca starch after drying, add the citric acid of tapioca starch weight 1.5%, the glycerin of 2.5% and the acetamide of 3% mix to obtain mixed material, citric acid, glycerol and ethyl The purity specification of the amide is chemically pure, and the mixed material is added to a twin-screw extruder at an extrusion temperature of 120°C and a screw speed of 80r / min for extrusion modification to obtain pre-modified tapio...

Embodiment 3

[0036] The bagasse transported from the sugar factory is firstly depulped twice through a pitting machine with a sieve hole of 7-8mm so that the pith content of the bagasse is less than 5%, and then the bagasse after depulping by the pitting machine is removed Wet storage, after wet storage, the bagasse after wet storage will go through a wet depitting process to make the bagasse content less than 1%, and finally dry and crush to a particle size of 150 mesh to obtain pretreated bagasse ;

[0037]The tapioca starch was dried for 12 hours at 80° C. of an oven, and the dried tapioca starch was added with 1% citric acid, 3% glycerol and 3% acetamide and mixed uniformly to obtain a mixed material, citric acid, glycerol and ethyl The purity specification of the amide is chemically pure, and the mixed material is added to a twin-screw extruder at an extrusion temperature of 110°C and a screw speed of 70r / min for extrusion modification to obtain pre-modified tapioca starch;

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com