Hot-blast stove of biomass energy source

A biomass energy, hot blast stove technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as being unsuitable for use in rural fields, complex structure, etc., and achieve high thermal utilization value and wide application range. , the effect of easy relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

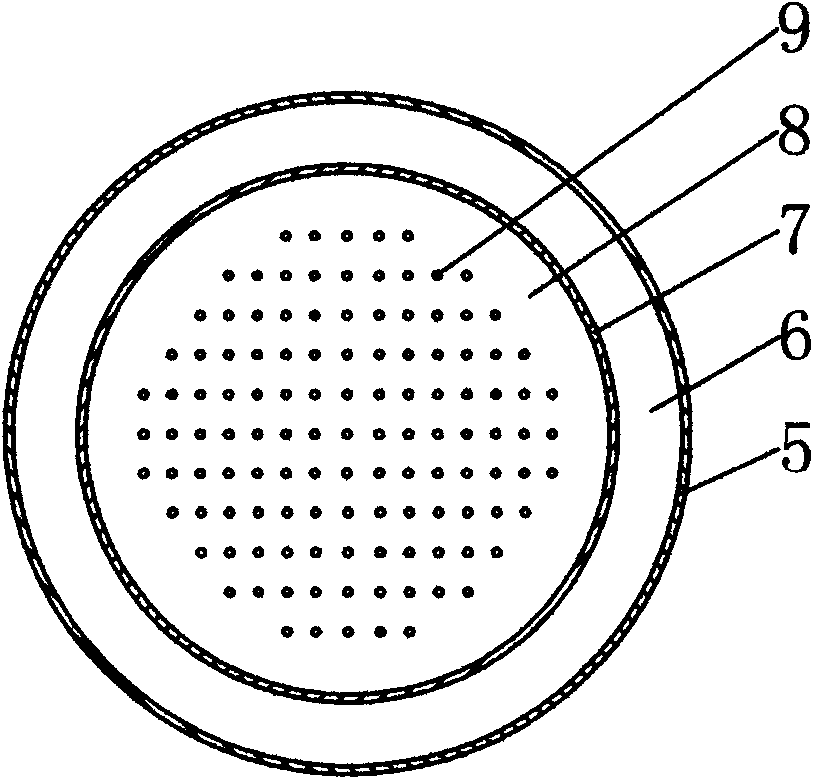

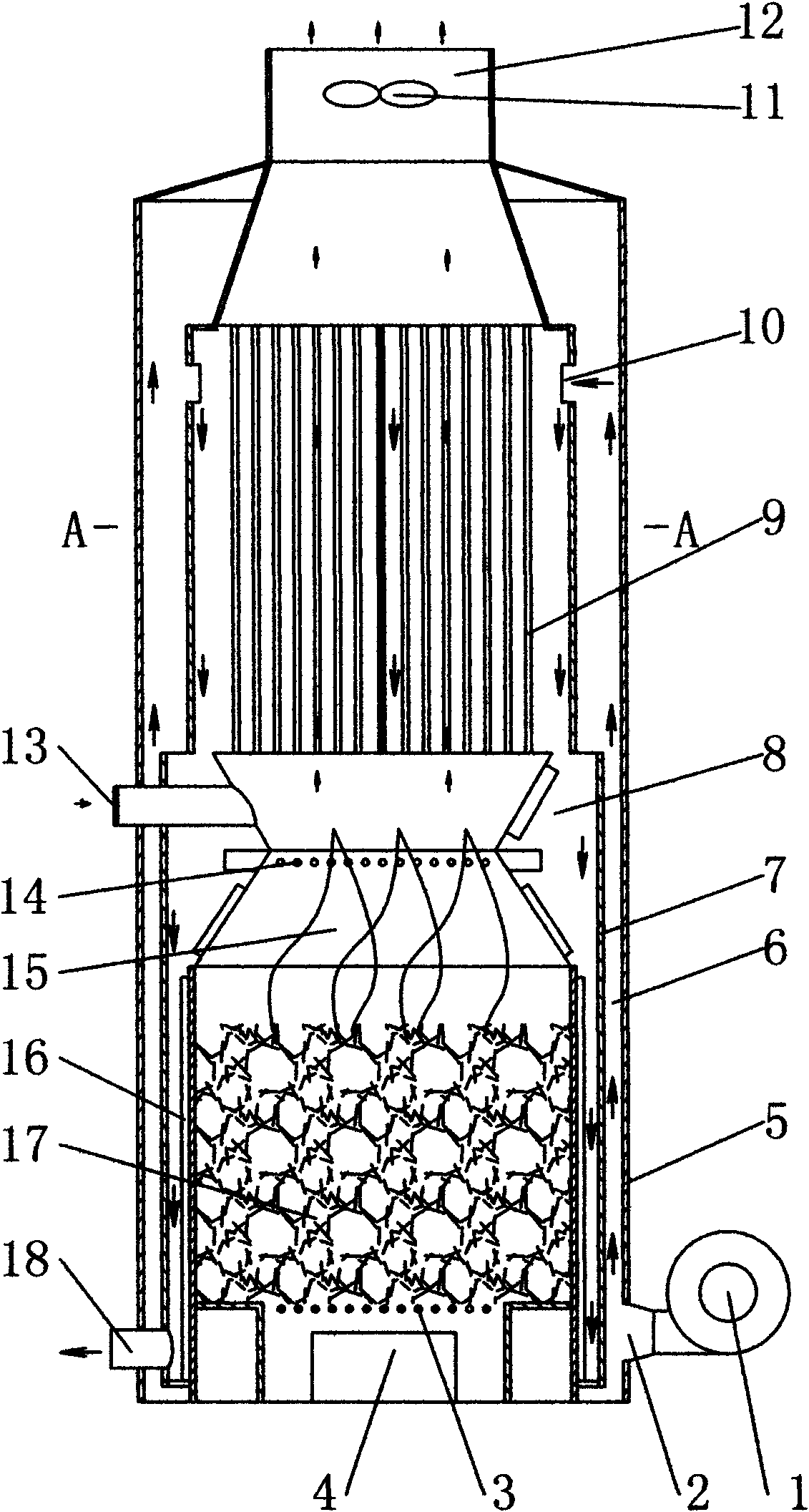

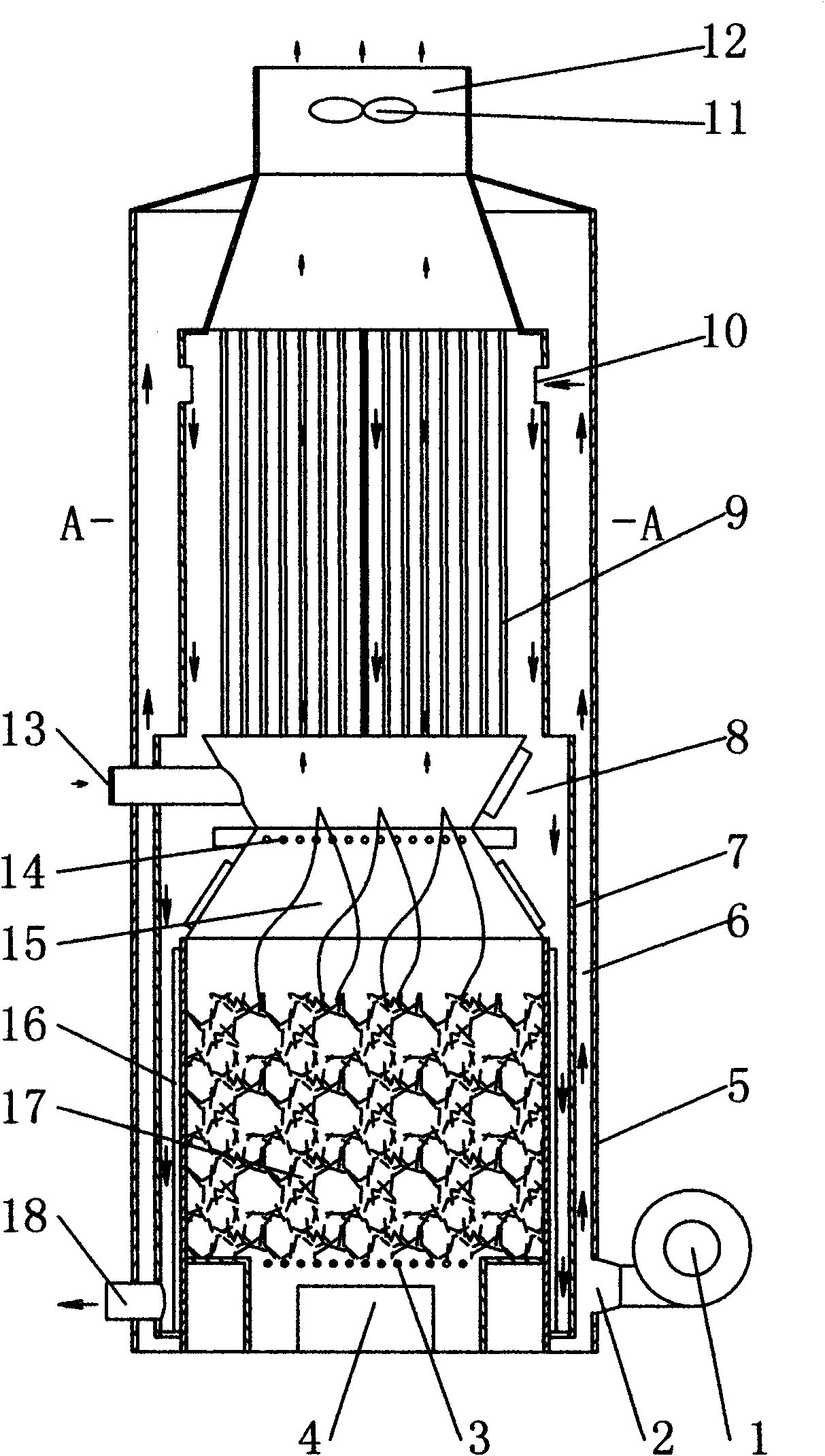

[0020] A biomass energy hot blast stove, comprising a furnace bridge 3, a furnace door 4, a casing 5, a smoke exhaust port 12, a feed door 13, a combustion bin 15, and a fuel bin 17; The inner tank 7 is provided with a furnace bridge 3, a fuel bin 17, a combustion bin 15, a heat conductor 9, and a smoke exhaust port 12 from bottom to top; a cold air inlet 2 is provided at the lower part of the shell 5, and the outlet of the blower 1 and the cold air inlet 2 connected; the inner wall of the shell 5 and the outer wall of the inner tank 7 form a cold air chamber 6; the inner wall of the inner tank 7 forms a hot air chamber 8 with the outer walls of the heat conductor 9, the combustion chamber 15, and the fuel bin 17; the upper wall of the inner tank 7 An inner container air inlet 10 is provided on the inner container 7, and a hot air outlet 18 is provided on the lower wall of the inner container 7; a feed port is provided at the combustion chamber 15, and a feed door 13 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com