Bamboo composite plywood structure for bottom plate of container and production method thereof as well as product

A container floor, bamboo and wood composite technology, applied in the direction of layered products, wood layered products, wood veneer joints, etc., can solve the problems of reduced labor, poor gluing force, etc. The effect of reducing bulk density and realizing industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

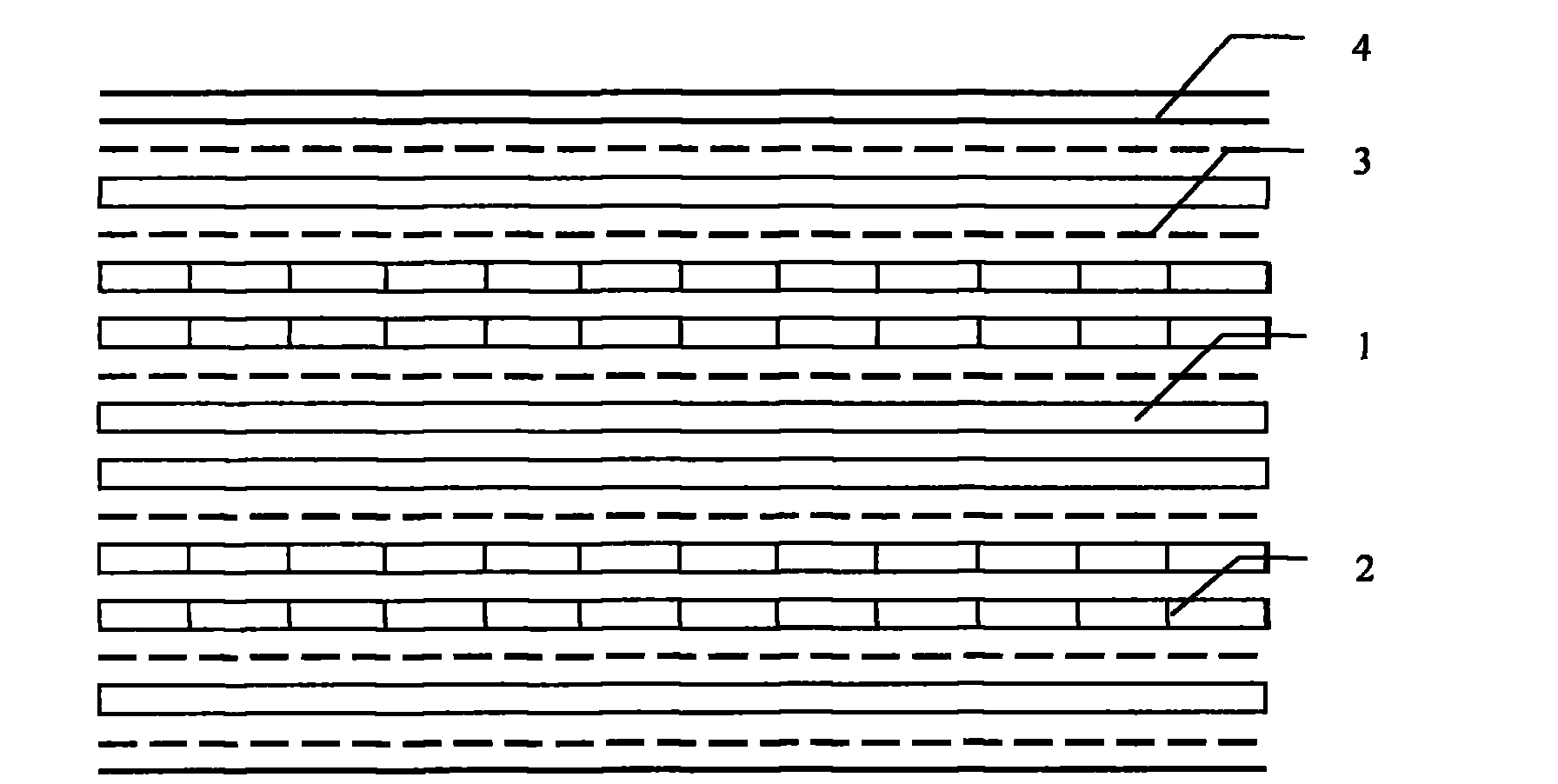

[0032] Use the upper platen with patterns, take 3 sheets of impregnated paper, 4 sheets of vertical bamboo bundle veneer curtains, 4 sheets of horizontal bamboo bundle veneer curtains, and 6 sheets of wood veneer, press as follows figure 1 The structure shown is assembled into blanks, and the finished product is formed by hot pressing, trimming the edges, fine sawing, tenoning, chamfering, and edge sealing.

[0033] The wood veneer used can be pine, eucalyptus, larch or other hard broad-leaved trees. The thickness of the wood veneer is 1.8mm, the error is ± 0.1mm, and the length and width allowable error + 10m; the veneer after gluing is required to be assembled as soon as possible Blanks, horizontal grains and horizontal grains are spliced with a width of 5-10mm.

Embodiment 2

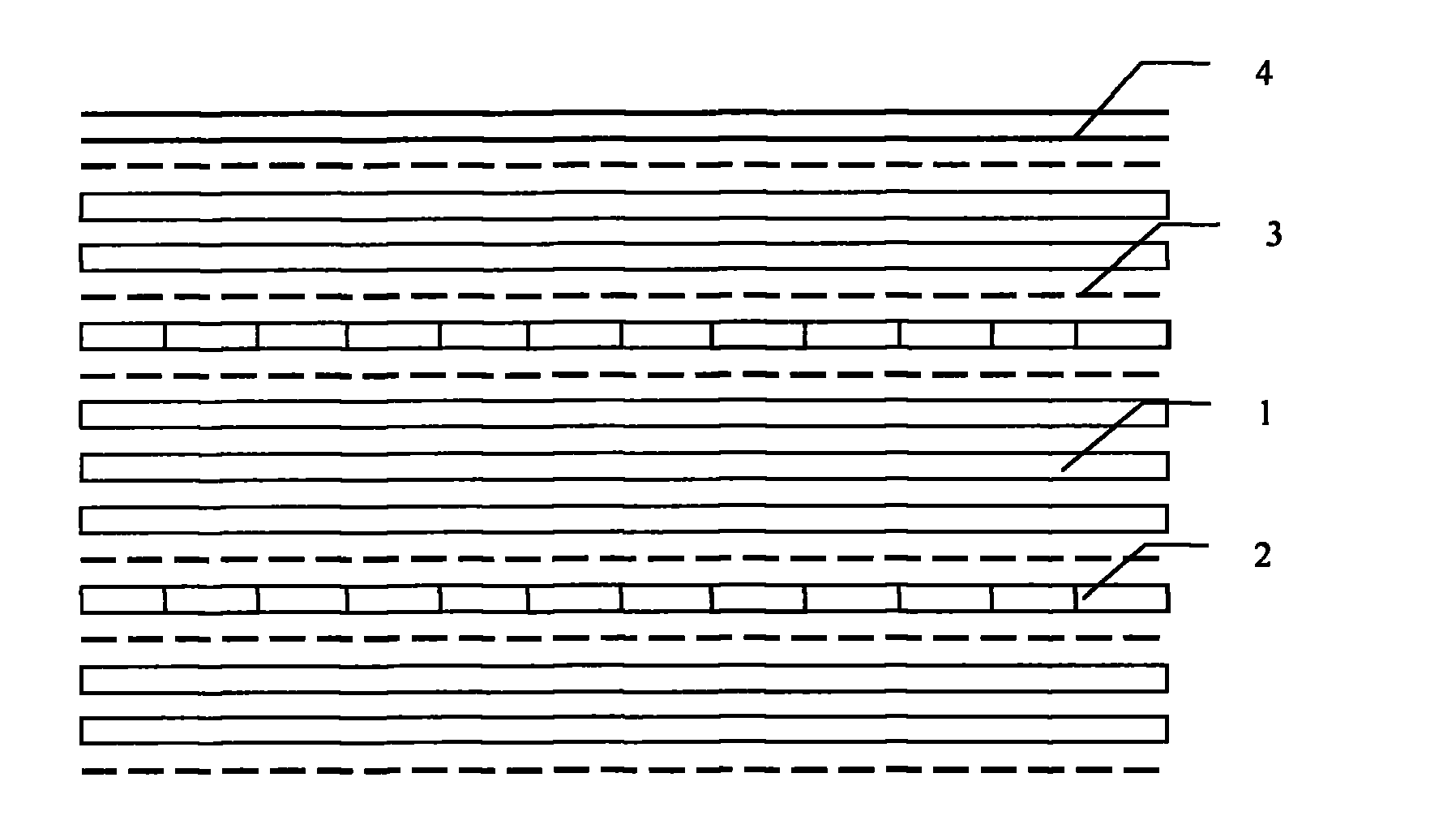

[0035] Use the upper platen with patterns, take 2 sheets of impregnated paper, 7 sheets of vertical bamboo bundle veneer curtains, 2 sheets of horizontal bamboo bundle veneer curtains, and 6 sheets of wood veneer, press as follows figure 2 The structure shown is assembled into blanks, and the finished product is formed by hot pressing, trimming the edges, fine sawing, tenoning, chamfering, and edge sealing.

[0036] The wood veneer used can be pine, eucalyptus, larch or other hard broad-leaved trees. The thickness of the wood veneer is 1.8mm, the error is ± 0.1mm, and the length and width allowable error + 10m; the veneer after gluing is required to be assembled as soon as possible Blanks, horizontal grains and horizontal grains are spliced with a width of 5-10mm.

Embodiment 3

[0038] Use the upper platen with patterns, take 2 sheets of impregnated paper, 8 sheets of vertical bamboo bundle veneer curtains, 4 sheets of horizontal bamboo bundle veneer curtains, and 6 sheets of wood veneer, press as follows figure 1 The structure shown is assembled into blanks, and the finished product is formed by hot pressing, trimming the edges, fine sawing, tenoning, chamfering, and edge sealing.

[0039] The wood veneer used can be pine, eucalyptus, larch or other hard broad-leaved trees. The thickness of the wood veneer is 1.8mm, the error is ± 0.1mm, and the length and width allowable error + 10m; the veneer after gluing is required to be assembled as soon as possible Blanks, horizontal grains and horizontal grains are spliced with a width of 5-10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com