Patents

Literature

186results about How to "Avoid internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micromachined thermopile infrared detector

ActiveCN101575083AReduce stressNo high temperature annealing requiredTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileReflective layer

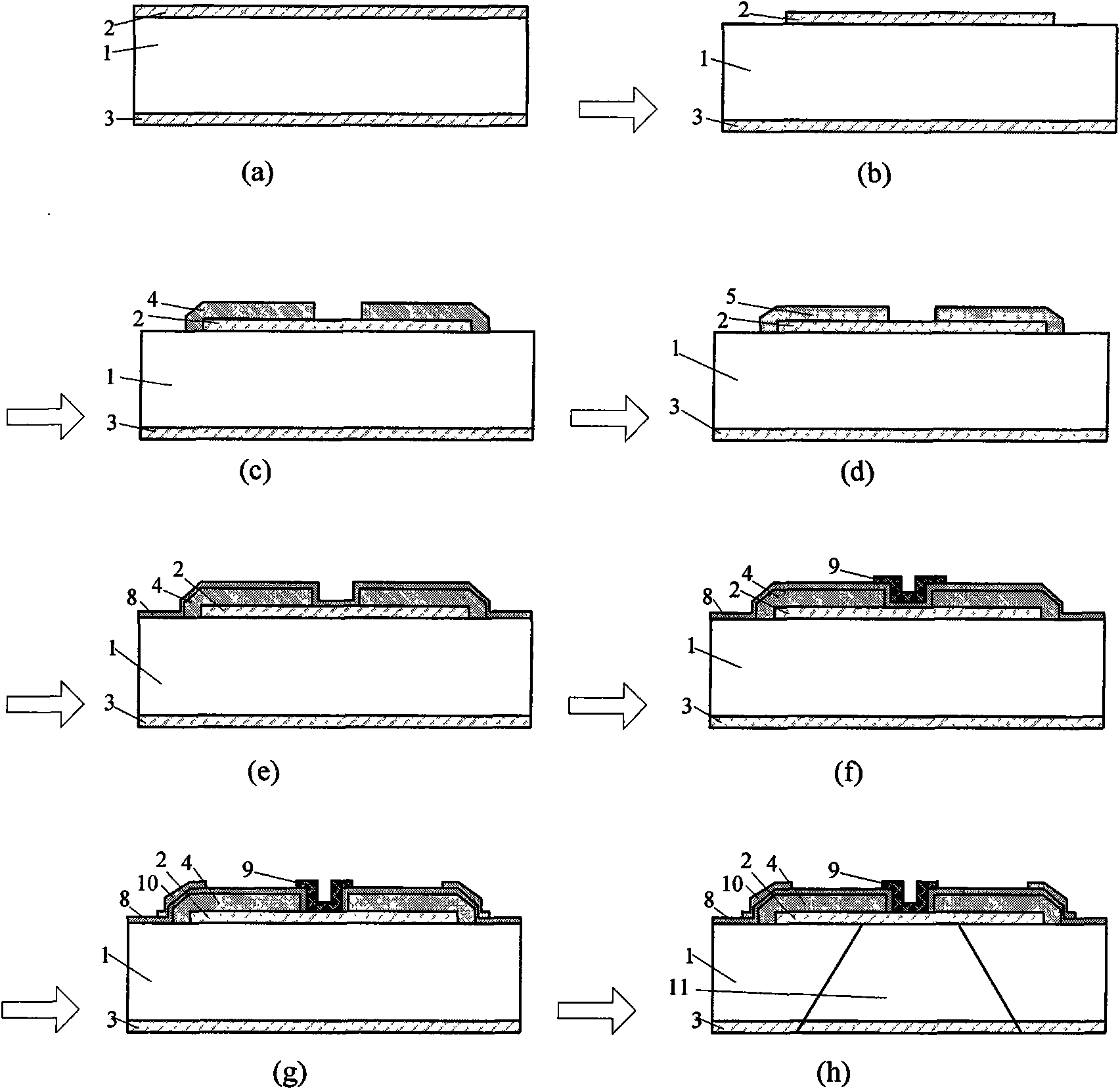

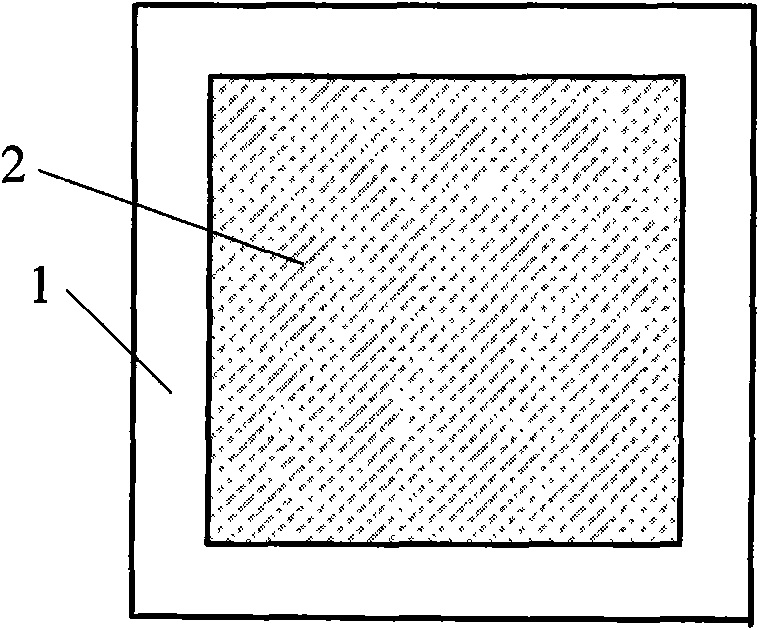

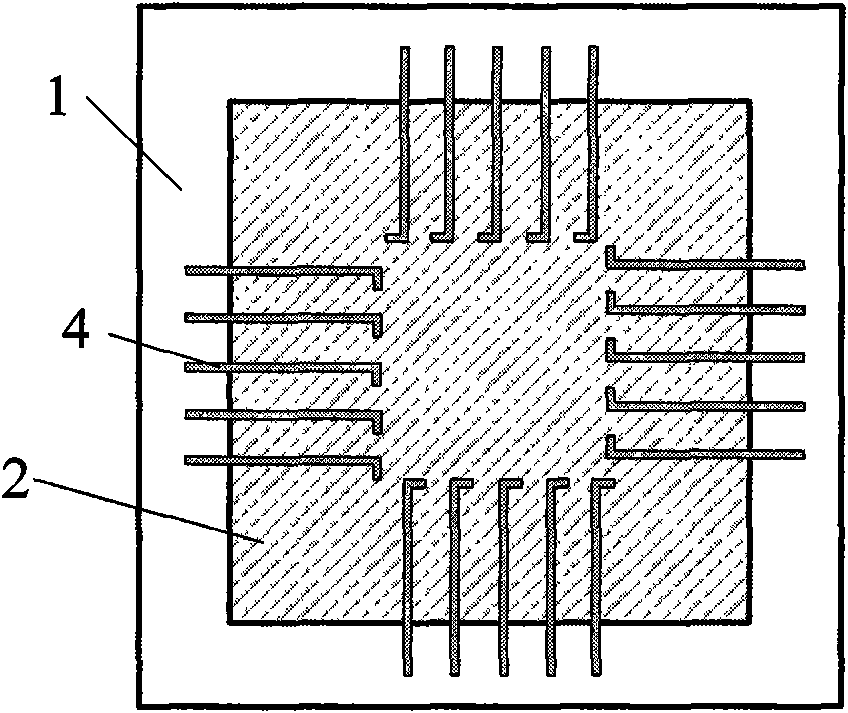

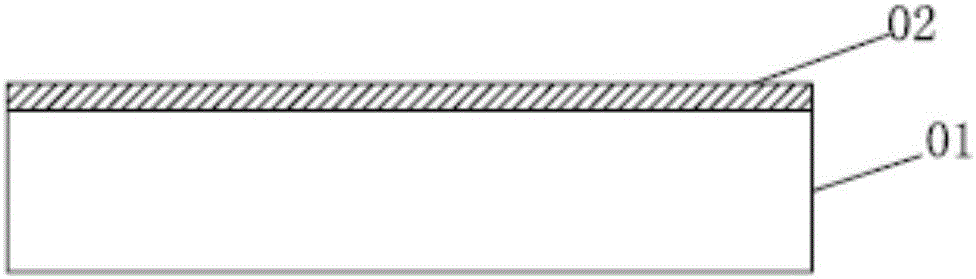

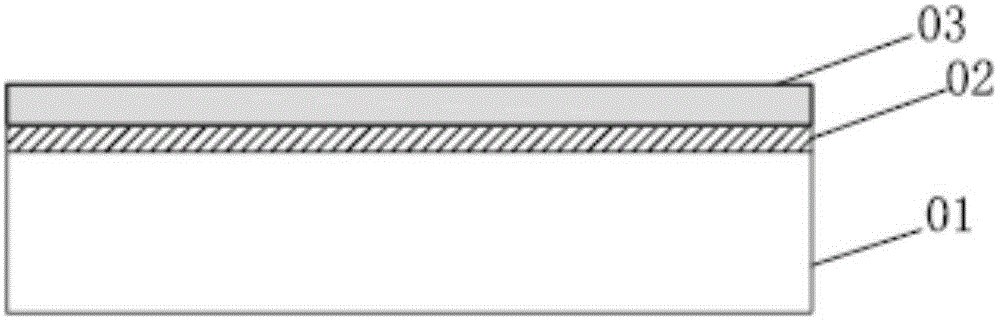

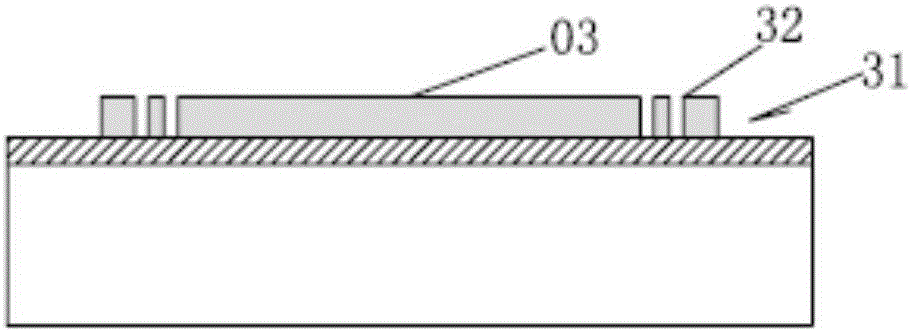

The invention relates to the field of an infrared detector, in particular to a micromachined thermopile infrared detector. The manufacturing technique is simplified and the performance and finished product rate are improved. The manufacture of the micromachined thermopile infrared detector comprises the following steps of: (1) depositing silicon nitride film on the both sides of a silicon substrate by an LPCVD method; (2) etching to remove peripheral silicon nitride film on the frontal side of the silicon substrate by lithography; (3) manufacturing a plurality of Poly-Si strips both ends of which are respectively arranged on the silicon nitride film and the silicon substrate by LPCVD method and photolithographic process; (4) manufacturing a plurality of aluminum strips which form a thermocouple with the plurality of Poly-Si strips by sputtering and photolithographic processes; (5) depositing the silicon nitride film on the frontal side of the silicon substrate by PECVD method; (6) manufacturing an infrared absorption layer (a carbonized photoresist layer) covering the hot junction area of the thermopile with photolithographic process; (7) manufacturing a metal reflective layer (a metal layer) covering the cold junction area of the thermopile with lift-off process; and (8) eroding the back side of the silicon substrate to form a square frustum pyramid shaped groove. The micromachined thermopile infrared detector has reasonable structure design, simple manufacturing process, high detector performance, high finished product rate, good development prospect and is easy to realize.

Owner:ZHONGBEI UNIV

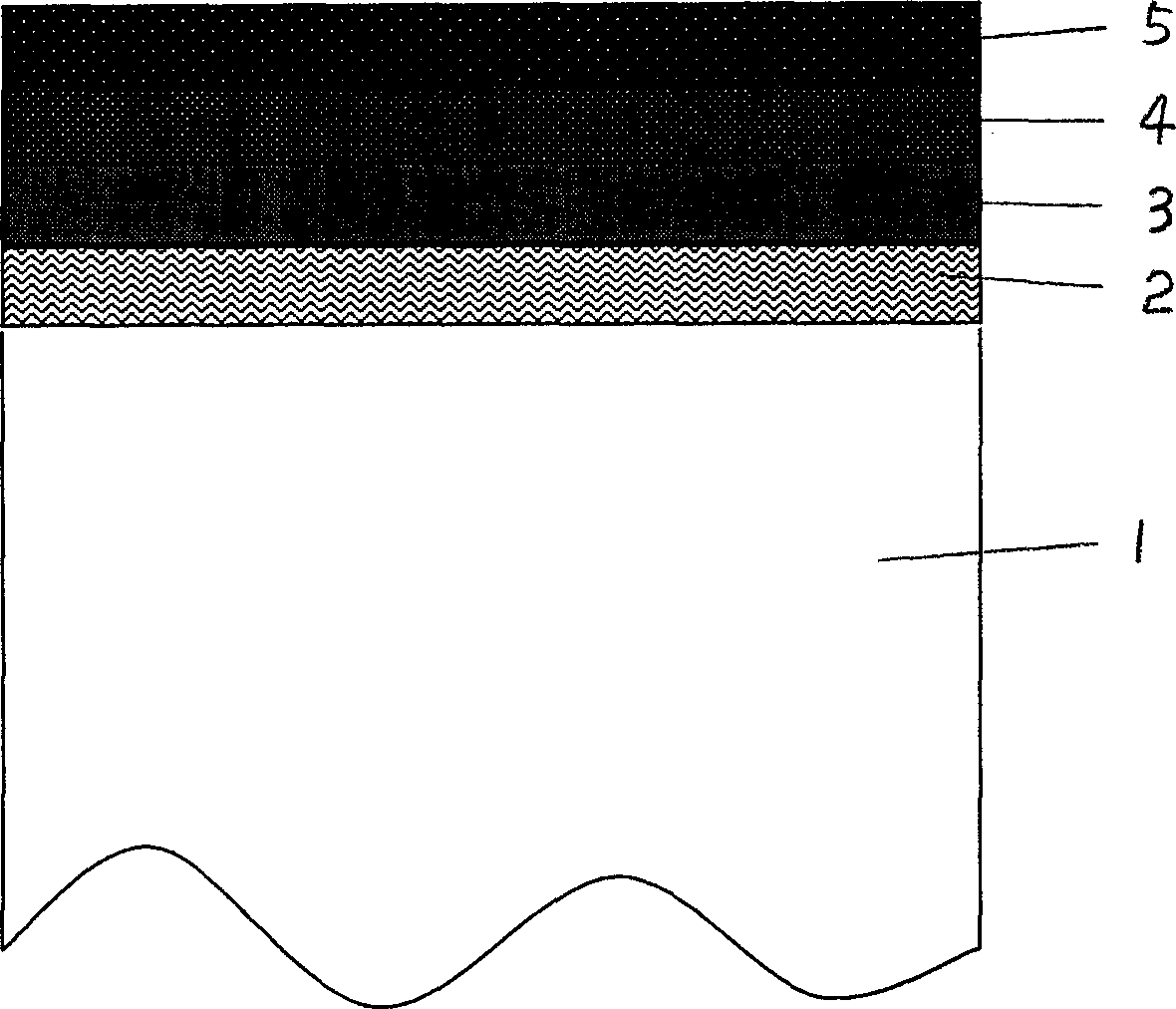

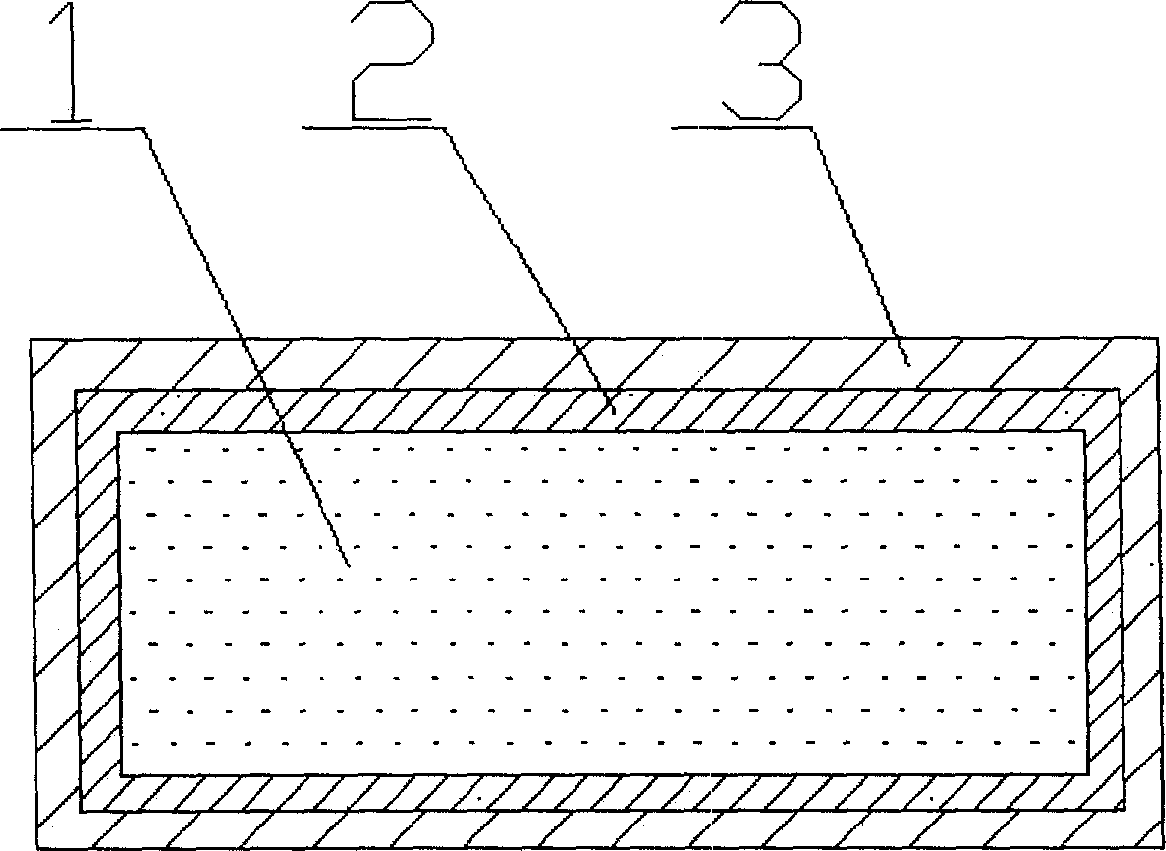

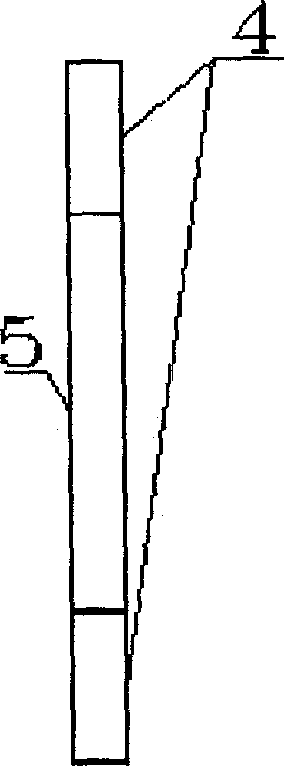

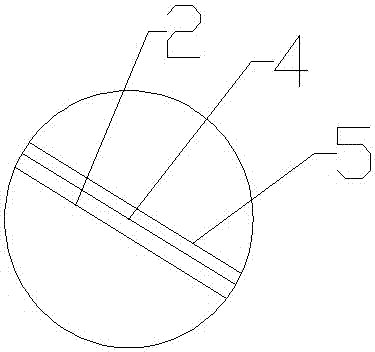

Bending-resistant multi-mode fiber

ActiveCN101840023AImprove mechanical propertiesFree from mechanical damageGlass optical fibreOptical fibre with multilayer core/claddingFiberRefractive index

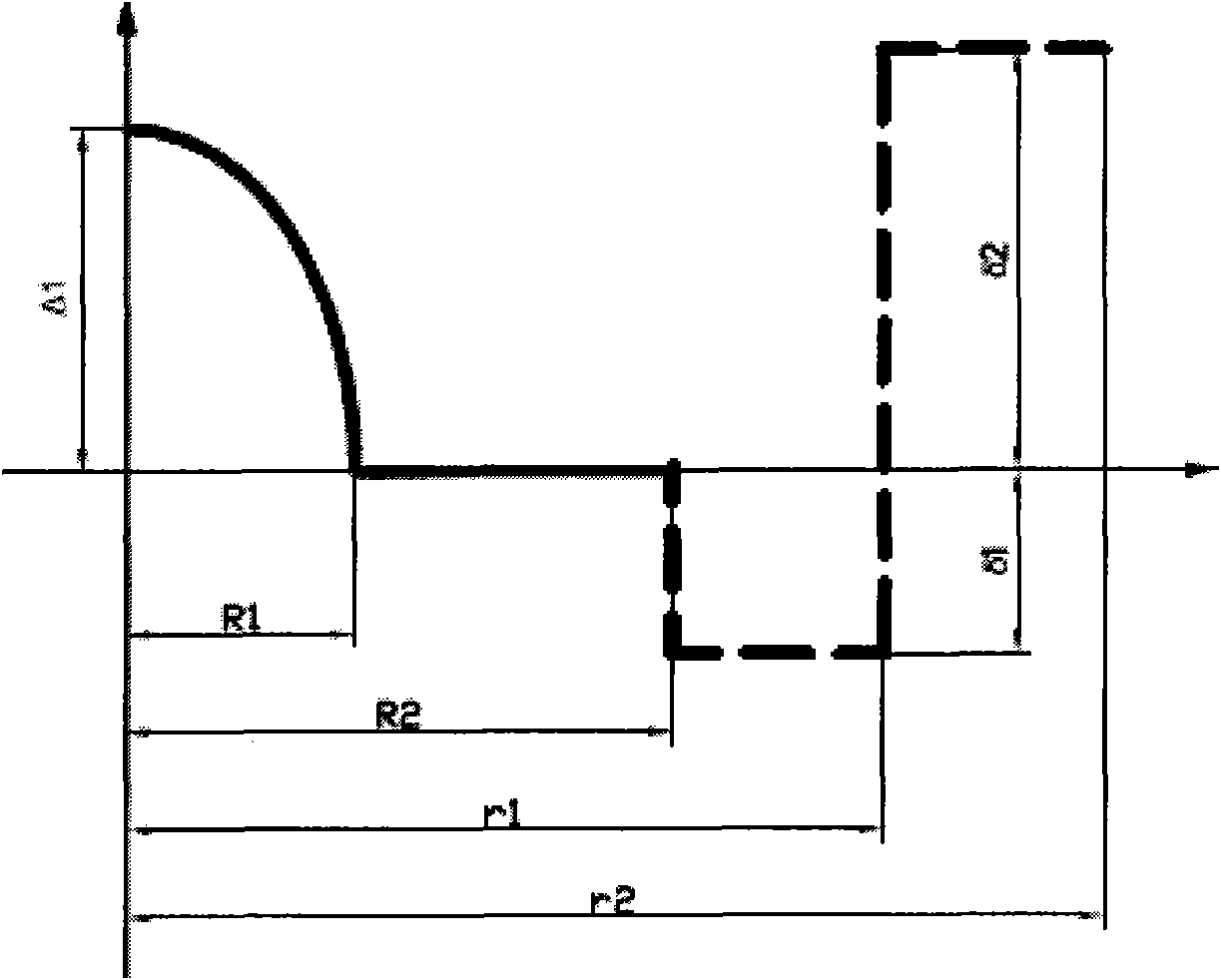

The invention relates to a bending-resistant multi-mode fiber used in an access network or a miniature optical device. The bending-resistant multi-mode fiber comprises an optical fiber and a coating coated on the outer surface of the optical fiber, wherein the fiber consists of a quartz glass core layer which has a section structure with a parabolic shape or step-type refraction index and a quartz glass cladding which surrounds the core layer. The optical fiber is characterized in that: the core layer has a diameter of between 20 and 200 mu m and consists of a germanium-and-fluorine-doped quartz glass material; and double solidified polymer coatings are coated out of the cladding, wherein an inner coating coated on the outer surface of the cladding is a low-refraction index flexible polymer coating while an outer coating is a high-Young's modulus polymer coating. Because of the design of the low-refraction index inner coating, an internal stress of the optical fiber is avoided, the mechanical performance of the optical fiber is greatly improved, and the use performance and the service life of the optical fiber working in a small-radius bending state are ensured. The bending-resistant multi-mode fiber has high bending-resistant performance; and at a wavelength of 850 nm, the additional attenuation of the bending caused by winding 1 circle with a bending radius of 10 mm is less than or equal to 0.15 dB. The bending-resistant multi-mode fiber has the characteristic of simple, convenient and effective manufacturing method, and is suitable for large-scale production.

Owner:EVERPRO TECH COMPANY

Method for preparing multi-arc ion plating aluminium titanium chrome silicon yttrium nitride multi-component ultra-hard reaction film

InactiveCN101230448AQuality improvementGuaranteed repeatabilityVacuum evaporation coatingSputtering coatingAlloyTitanium

The invention relates to a method of preparing a multi-component super-hard reaction film for a multiple-arc ion-plated nitride of titanium, aluminum, chrome, silicon and yttrium. The method includes the following steps in sequence: the confirmation of the deposition technique and the design of the components of the target material (1); the preparation of a alloy target (2); the selection and pre-processing of a workpiece sample (3); the confirmation of the quantity of the electric arc source (4); the confirmation of the deposition technique (5); the acquirement of a transition layer (6); the processing of vacuum heating (7) and the rotation of the workpiece sample. The method confirms the variation range of the components of the Ti, Al, Cr, Si, Y elements in the complex Ti-Al-Cr-Si-Y alloy target and causes the super-hard reaction film of the (TiAlCrSiY)N to have the advantages of strong adhesive power (larger than or equal to 180 N) and high hardness (larger than or equal to HV3200).

Owner:SHENYANG UNIV

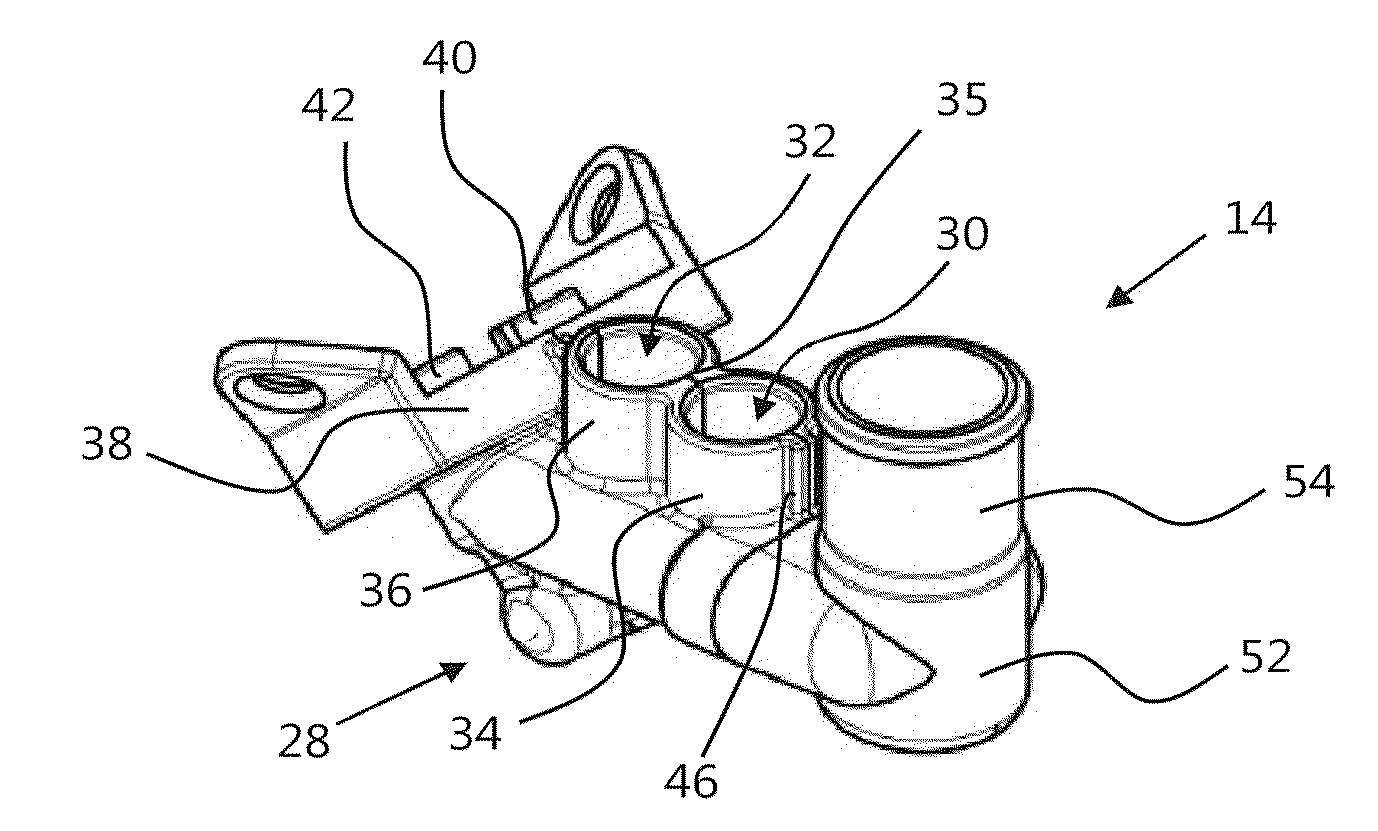

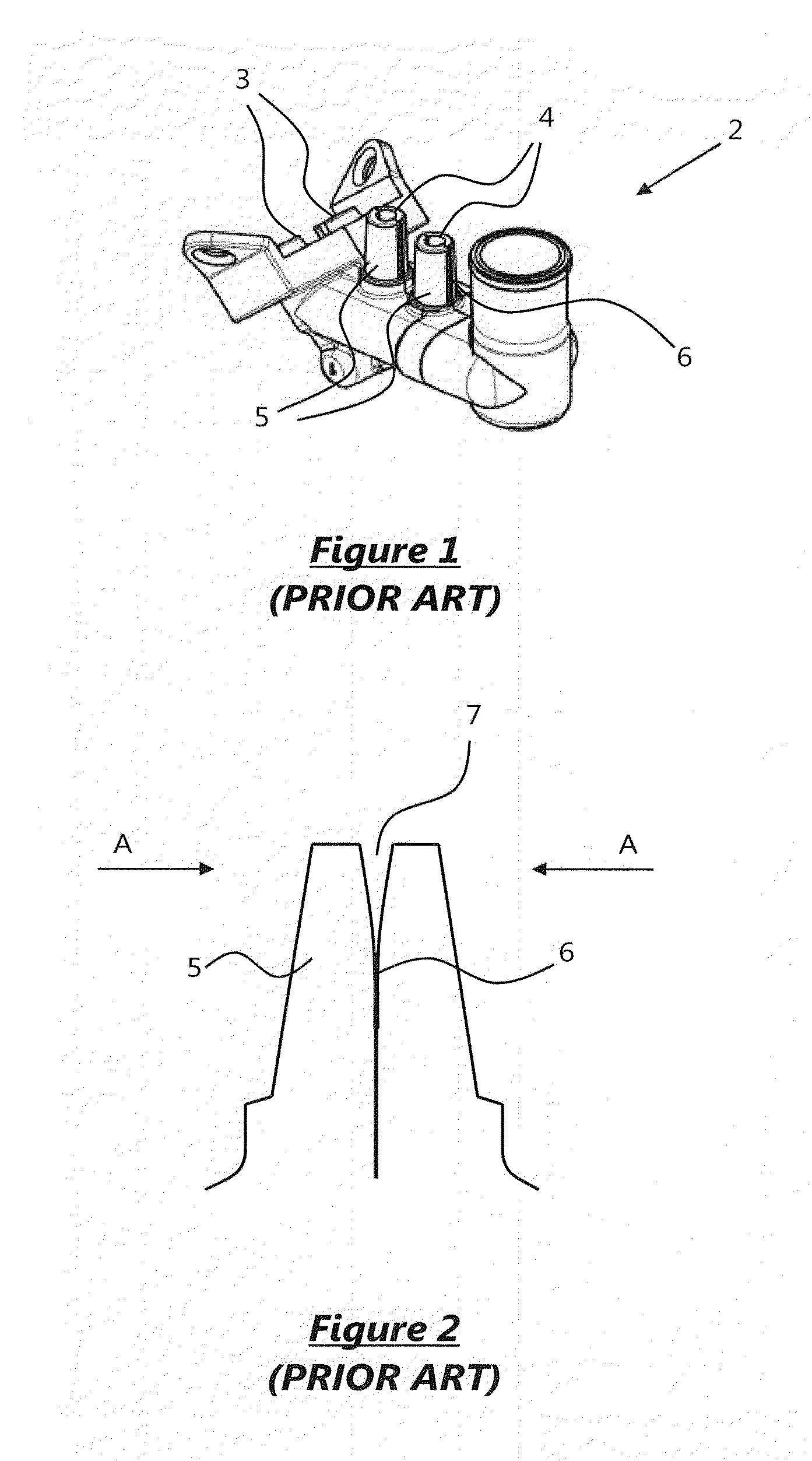

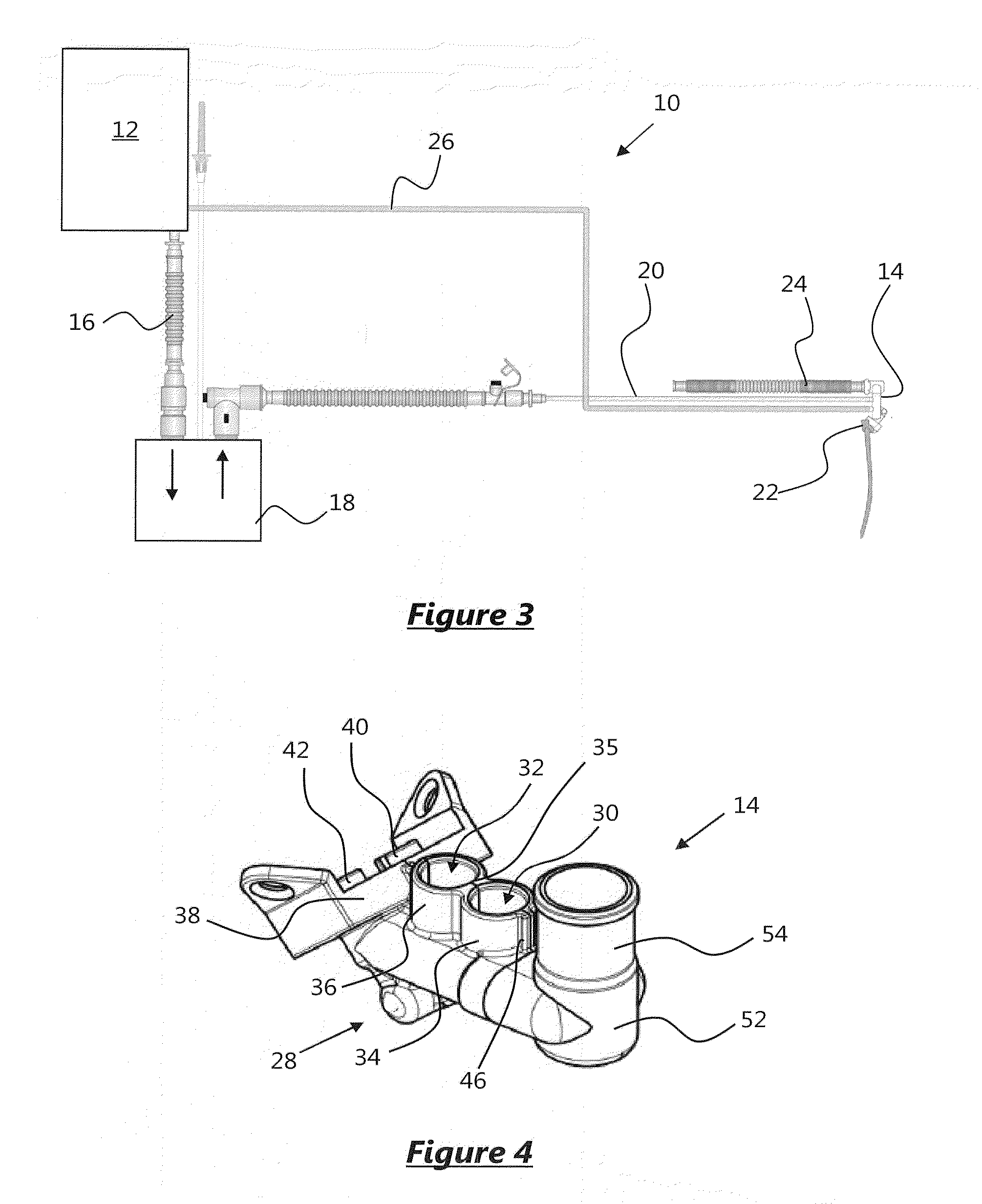

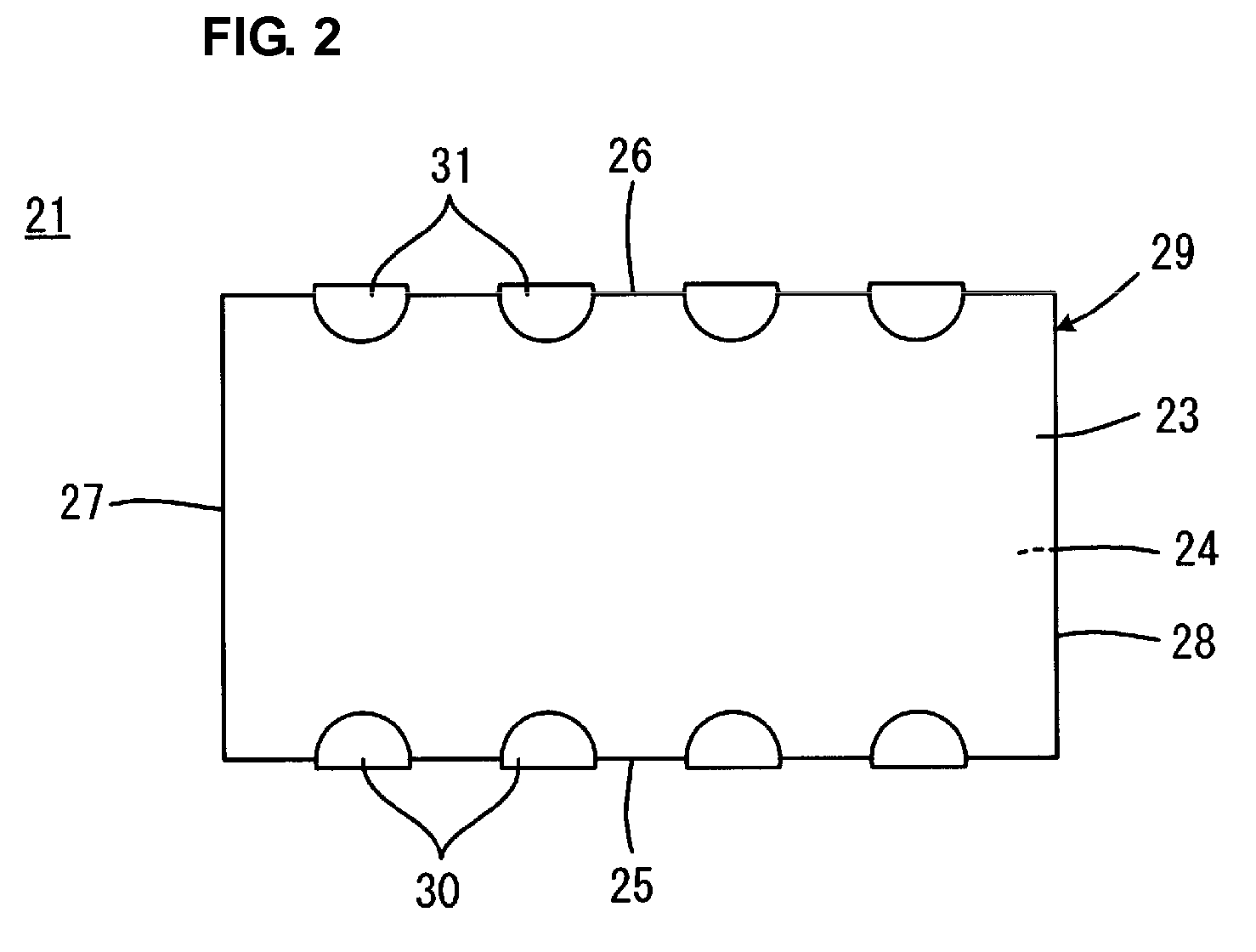

Respiratory system connector

InactiveUS20120227736A1Improve structural rigidityAvoid internal stressRespiratory masksRespiratory apparatusCatheterEngineering

The invention concerns a respiratory ventilation connector for connection in the flow path between a patient interface and one or more fluid conduits in a respiratory ventilation system. The connector has first and second opposing body portions joined together so as to define a connector body having a first port, a second port and an internal passageway for fluid communication between said first and second ports. Each body portion has respective first and second spigot portions arranged in use to form an upstanding circumferential spigot formation about the first port. The spigot formation has an internal diameter which is greater than the diameter of the port so as to allow reception of a tubular fluid conduit within the spigot for communication with the first port in use.

Owner:INTERSURGICAL AG

Protective coating and its preparing method

InactiveCN1858295AImprove antioxidant capacityReduce stressVacuum evaporation coatingSputtering coatingAlloyTin

The protective coating is made with TiAl alloy and pure Ti target material, and is one gradient TiAlN / TiN coating comprising TiN alloy layer deposited directly onto the substrate, and the successively deposited TiAl10N layer, TiAl20N layer and TiAl30N layer. The preparation process of the protective coating includes the first preparation of TiN alloy layer on the substrate, and the subsequent deposition of the TiAl10N layer, the TiAl20N layer and the TiAl30N layer. By means of proper target material components and reasonable technological parameters, the coating has less pinhole, pores and mutual diffusion of elements in different layers.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

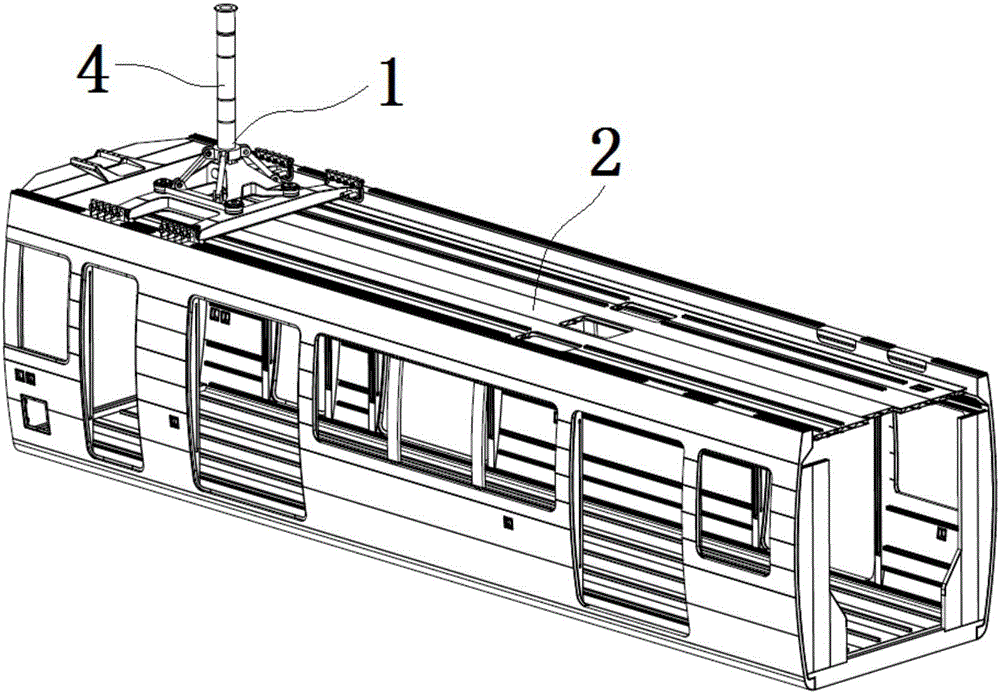

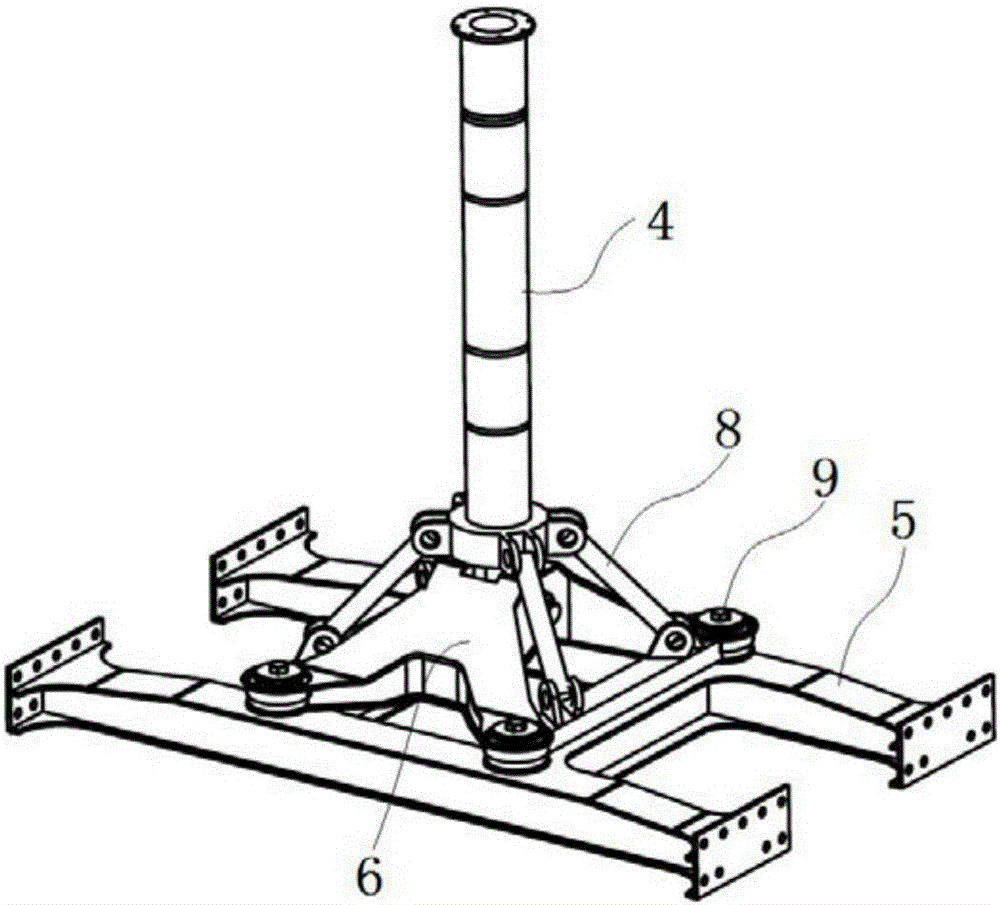

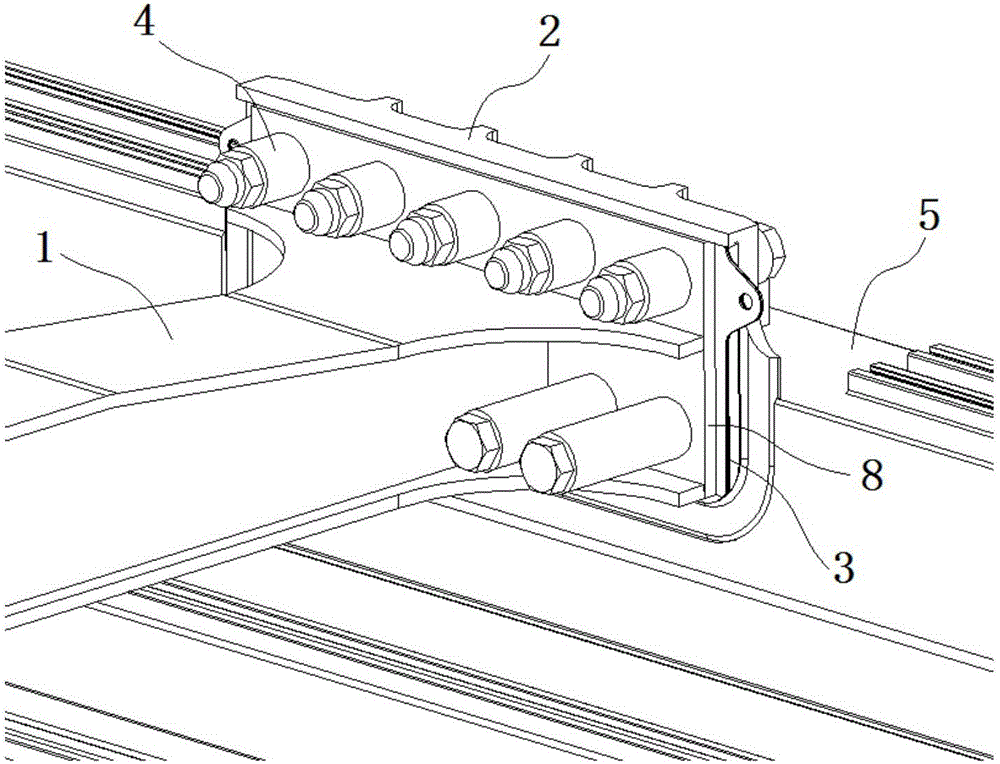

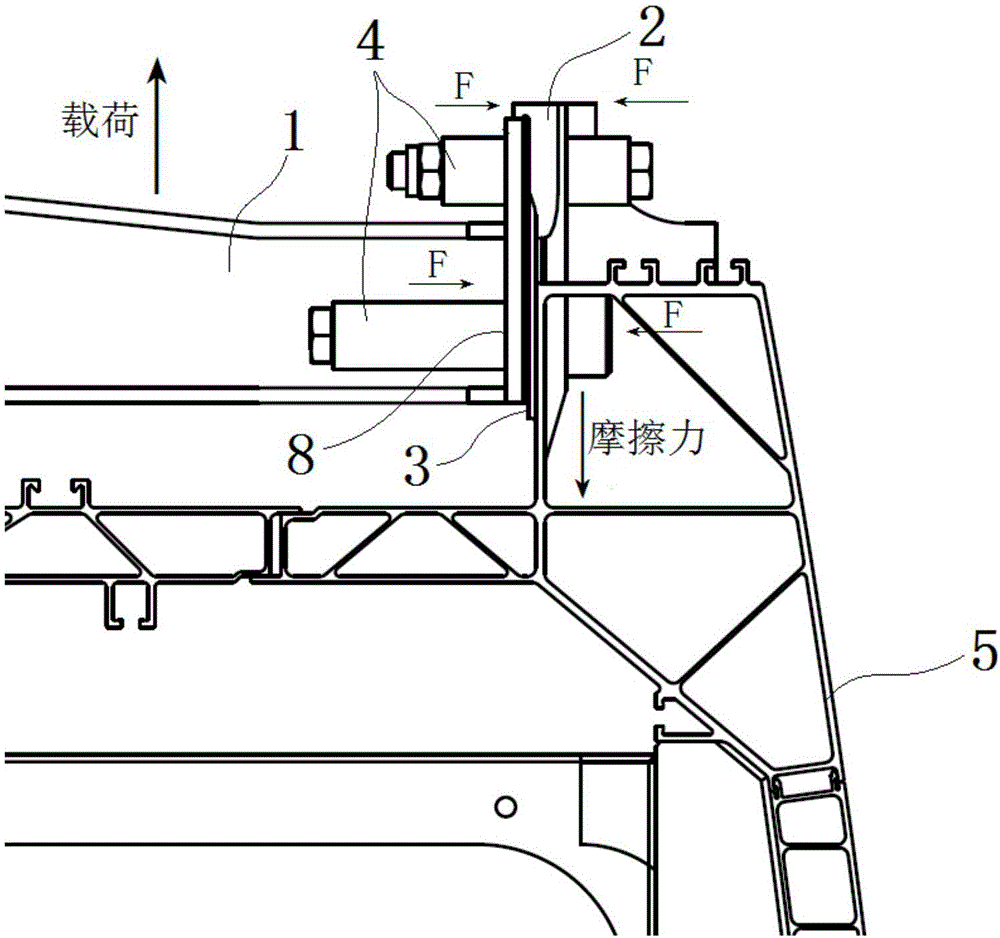

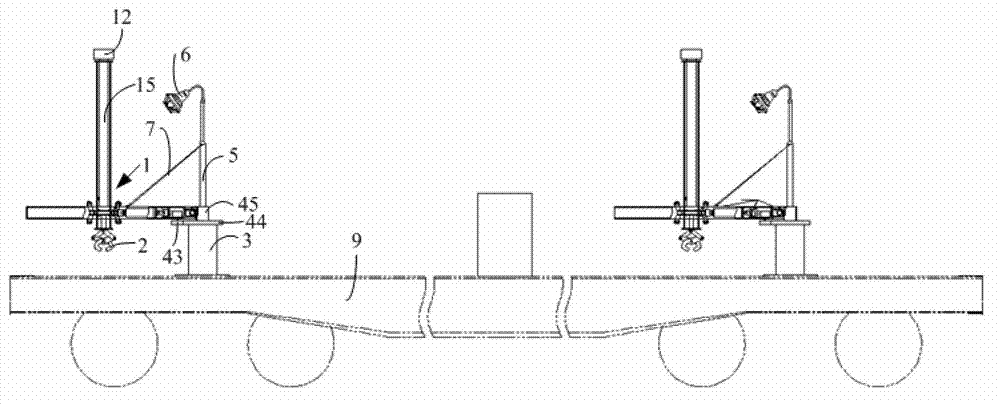

Parking connecting structure of suspension type monorail vehicle and suspension type monorail vehicle

ActiveCN106364512ASolve the problem of degrees of freedomFreedom releaseMonorailsBogiesBogieVertical load

The invention discloses a parking connecting structure of a suspension type monorail vehicle and the suspension type monorail vehicle. The parking connecting structure of the suspension type monorail vehicle comprises a connecting rod, a connecting seat and a connecting beam, wherein the connecting rod is used for transmitting vertical loads, longitudinal traction brake force and transverse swinging force between a suspension type vehicle body and a traveling component, the upper end of the connecting rod is used for being fixedly connected with the traveling component, the lower end of the connecting rod is hinged to the connecting seat, and the connecting seat is fixedly connected with the connecting beam. The parking connecting structure of the suspension type monorail vehicle realizes non-rigid connection between the suspension type monorail vehicle body and a bogie, and internal stress caused by movement of the suspension type monorail vehicle body is solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

High-tenacity oxidation-resistant anti-friction coating on substrate surface and preparation method thereof

ActiveCN102021513AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingDiamond-like carbonLow speed

The invention discloses a high-tenacity oxidation-resistant anti-friction coating on a substrate surface and a preparation method thereof. The coating is characterized in that nano-crystalline AlCrCN particles of a face-centered cubic structure are embedded into grids of diamond-like carbon with nano-thickness to form the composite coating, wherein the diameter of each nano-crystalline AlCrCN particle is 5-50 nanometers, the thickness of each grid of the diamond-like carbon is 1-5 nanometers, and the molar ratio of Al atoms to Cr atoms is greater than 1. The coating has higher oxidation resistance, also combines higher tenacity of ceramic composite materials and excellent friction performance of diamond-like carbon, can reduce the adhesion between abrasive dust and a substrate, is suitable for surfaces of cutters, molds and other substrates, and is especially suitable for low-speed processing of titanium-nickel alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

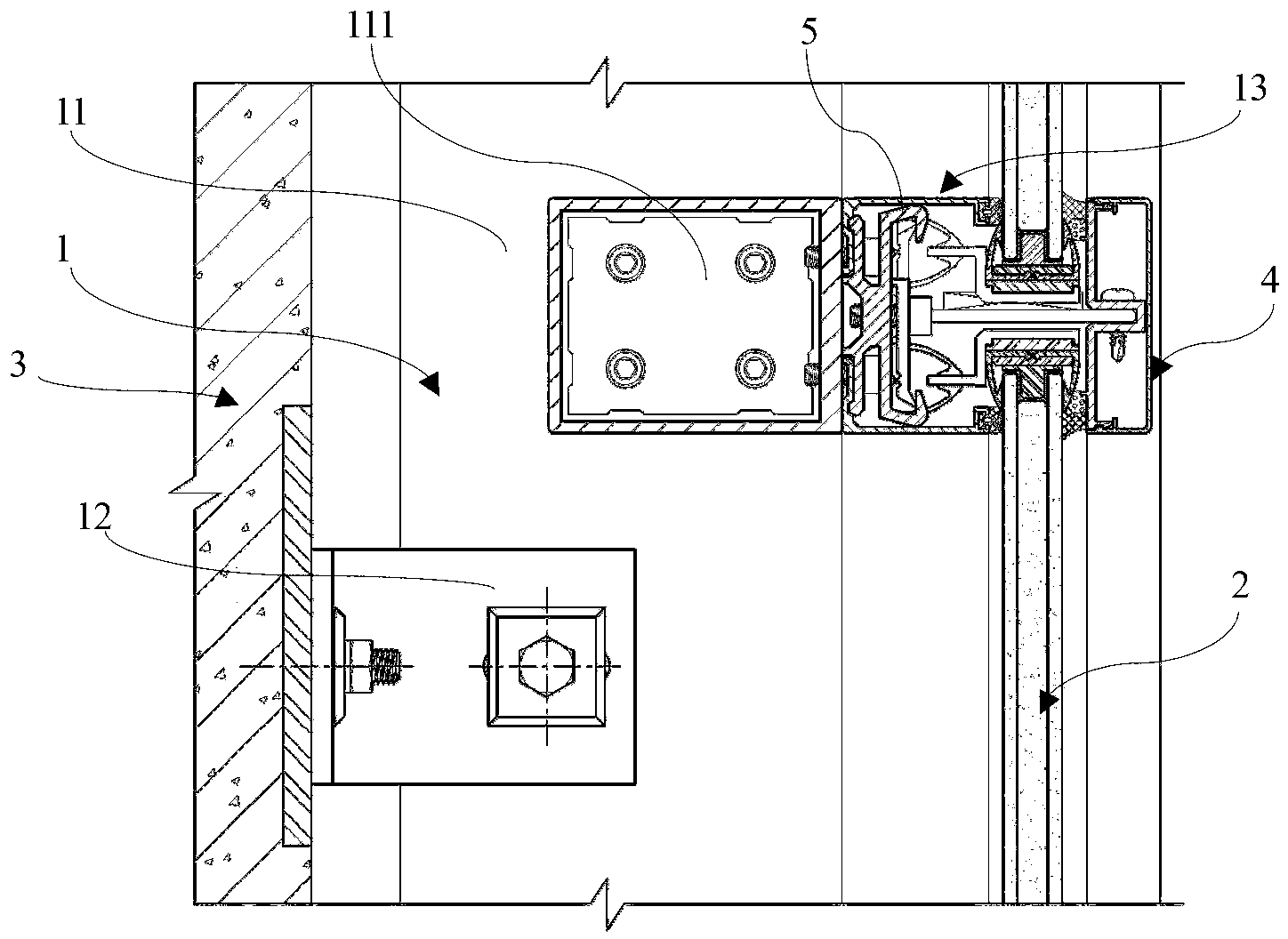

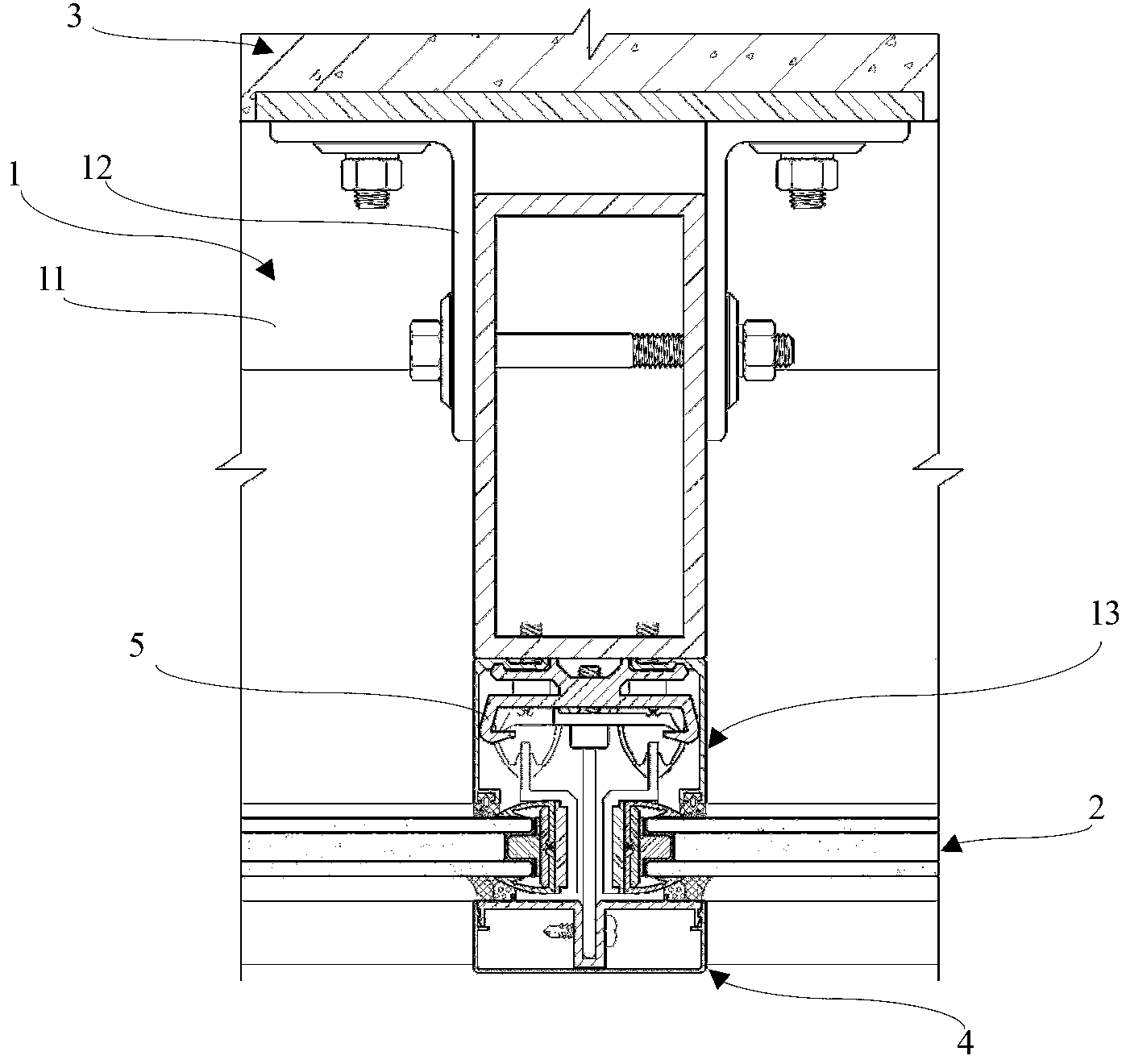

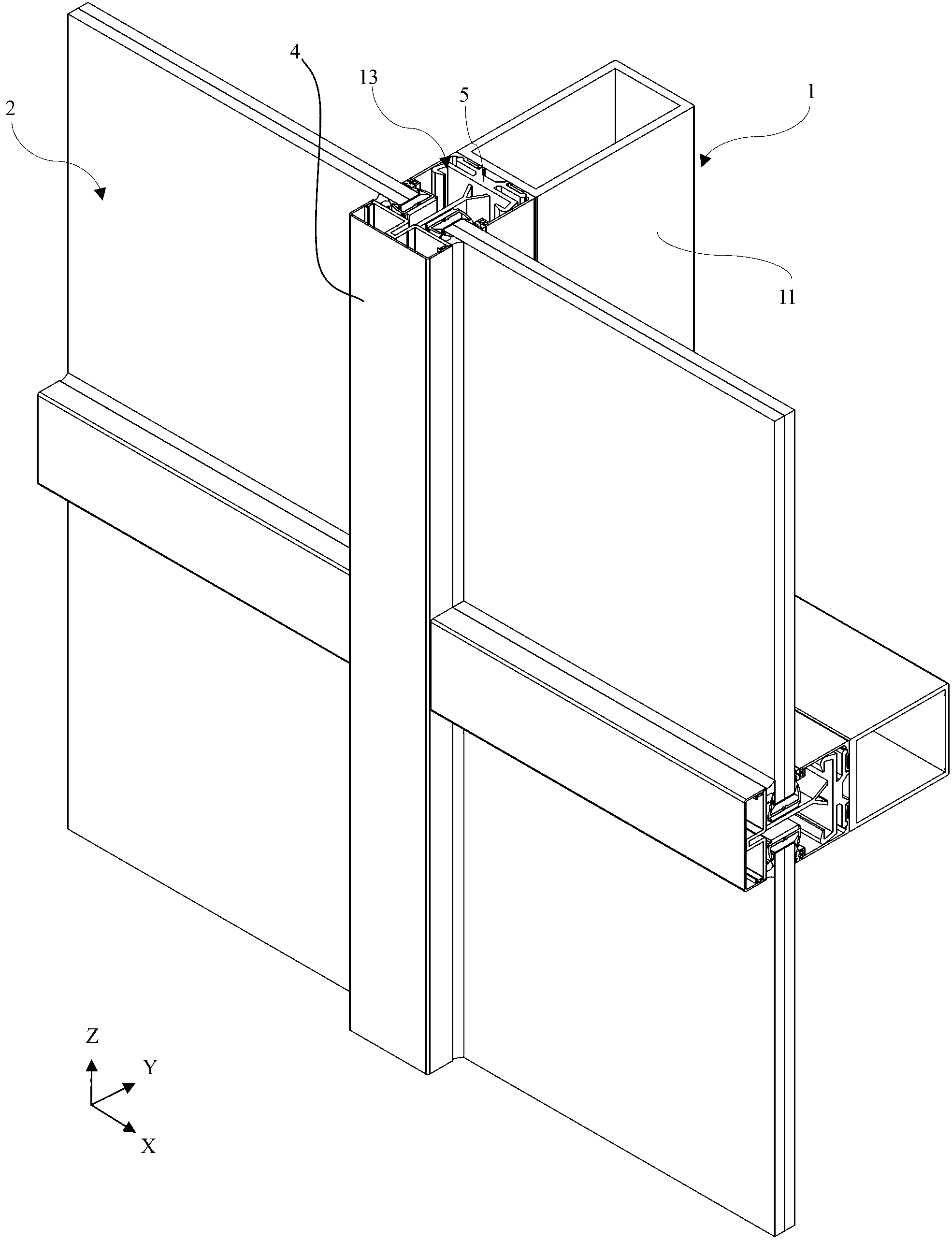

Mounting structure of anti-explosion glass curtain wall and curtain wall glass mounting method

ActiveCN103290960AReduce technical difficultyReduce operation links and contentWallsWar-like protectionPrestressed structureUltimate tensile strength

The invention discloses a mounting structure of an anti-explosion glass curtain wall. The mounting structure comprises a building body, curtain wall glass mounted on the building body and a mounting base plate, a decorating frame is covered on the outer wall surface of the curtain wall glass, the curtain wall glass is adjusted to a preset position via the mounting base plate and then fastened, the position of the curtain wall glass is not changed during fastening, and the decorating frame is fixed on the mounting base plate via a mounting piece. The curtain wall glass with edges covered by a prestressed structure is firmly fastened via a stand column and crossbeam frame, and in case of glass crushing or deformation caused by impact, and the glass cannot be integrally separated from the stand column and crossbeam frame, so that anti-explosion and separation functions are effectively realized, and indoor persons are protected to the greatest extend; since profile steel serving as the stand column and crossbeam frame is adopted to replace an existing aluminum profile frame, strength and rigidity of a whole curtain wall bearing system are greatly enhanced, and the anti-explosion glass curtain wall structure is stronger in capability for bearing impact loads from explosion and the like and good in safety performance.

Owner:珠海博曼建筑科技有限公司

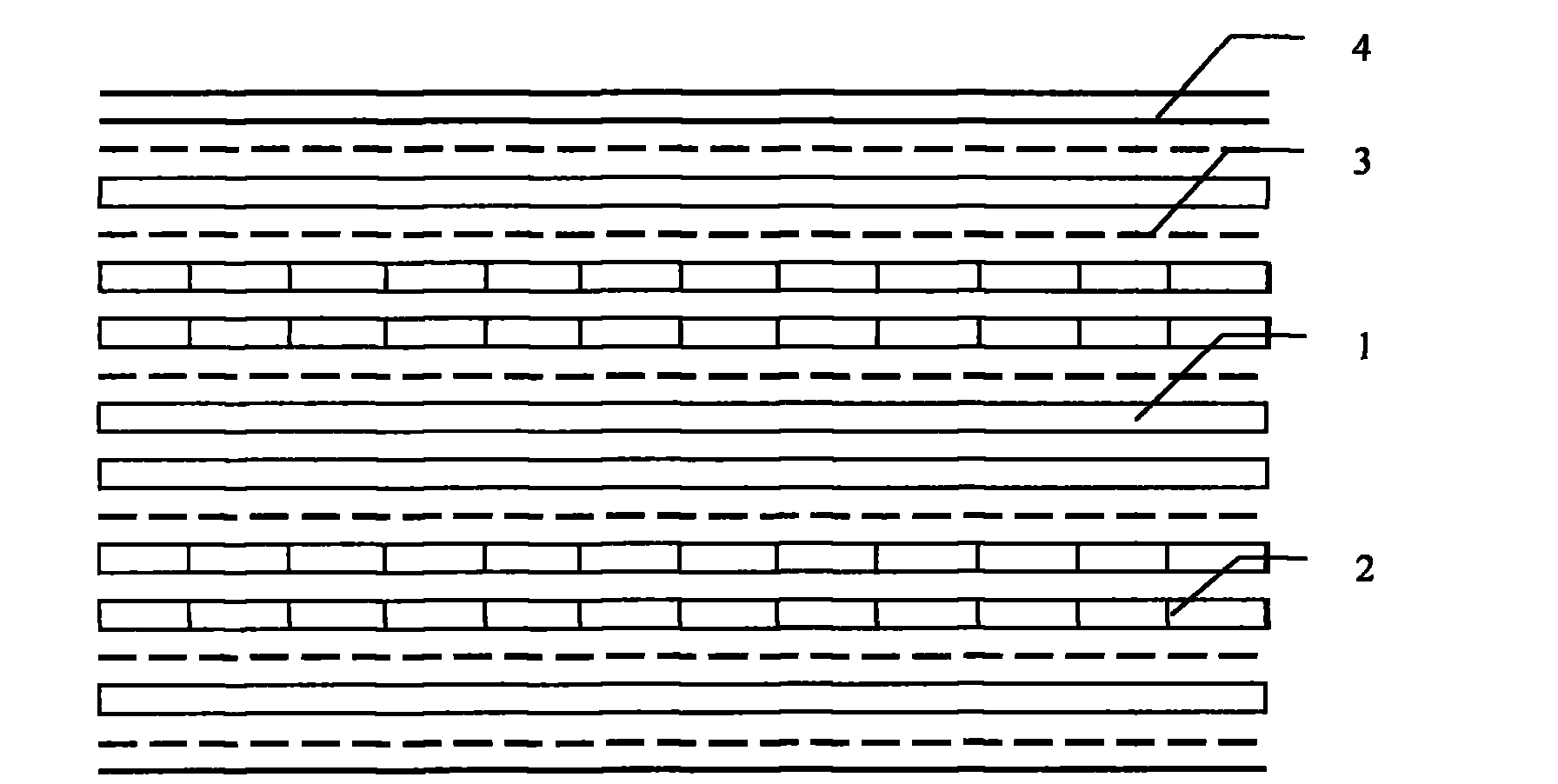

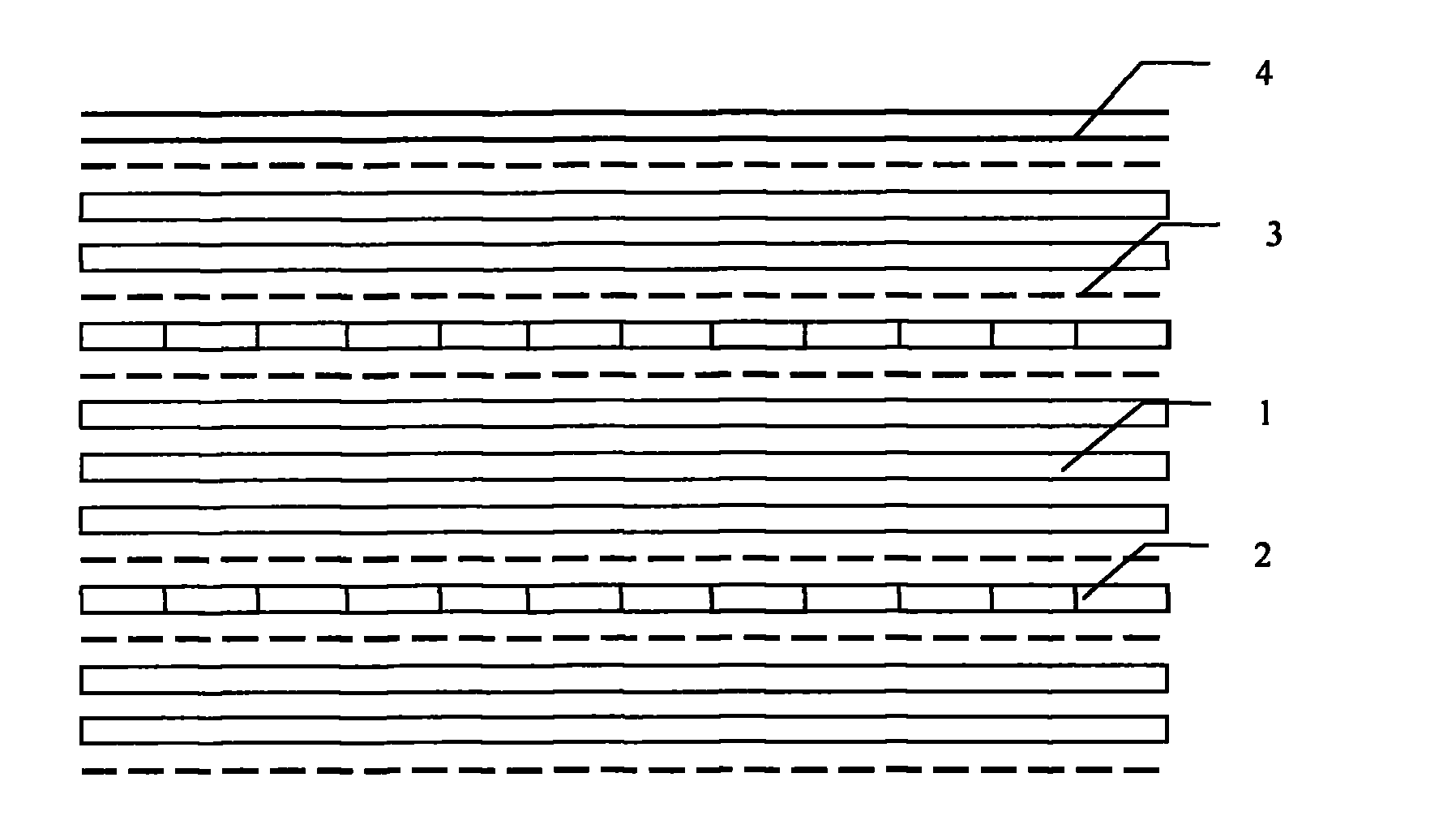

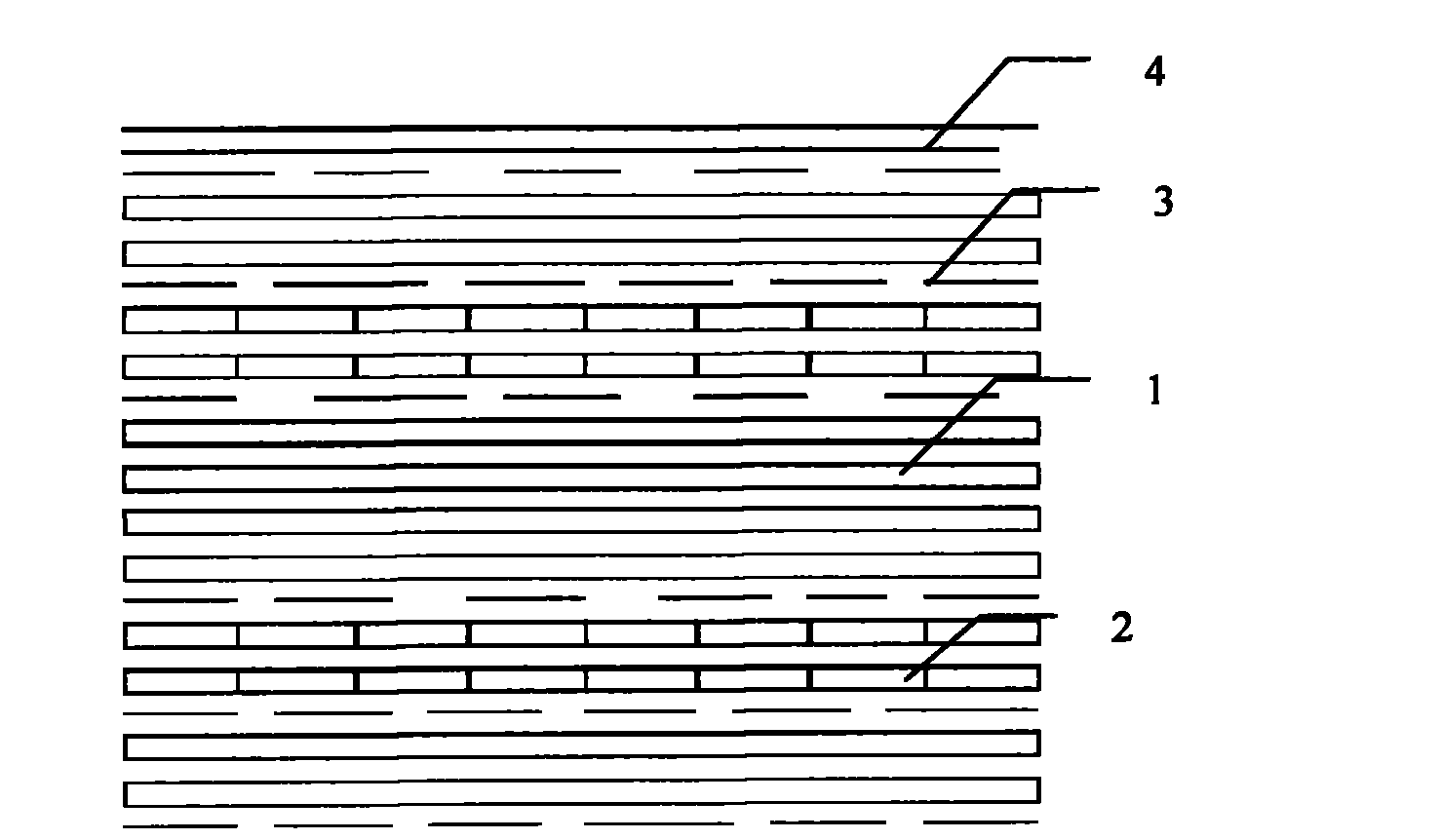

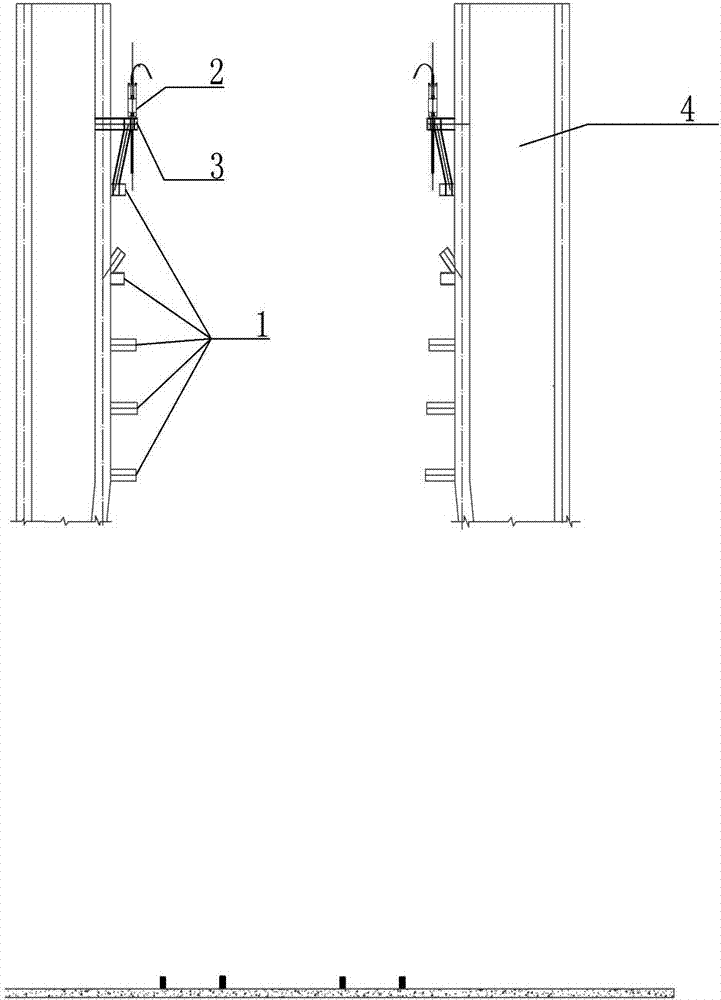

Bamboo composite plywood structure for bottom plate of container and production method thereof as well as product

InactiveCN102658569AQuality improvementIncrease profitWood veneer joiningWood layered productsEngineeringPhenol

The invention relates to a bamboo composite plywood structure for a bottom plate of a container and a production method thereof as well as a product. Bamboo chips are grinded and broomed to form bamboo beam single boards; and the bamboo beam single boards are mechanically weaved form bamboo beam single board curtains. The bamboo composite plywood structure consists of impregnated paper, the bamboo beam single board curtains and wooden single boards. A laminate is in a symmetrical structure; a veneer is double-layer impregnated paper; 4-10 layers of lengthways bamboo beam single board curtains, and 2-4 layers of transverse bamboo beam single board curtains are arranged; a layer of single wooden board is arranged between each lengthways bamboo beam single board curtain and each transverse bamboo beam single board curtain; the laminates are in tooth connection in a length direction when a long log is produced in the conditions, the conditions as follow: phenol glue with middle concentration and middle-low viscosity, and a cold-hot-cold technique are used; the pressure is 3.2-3.5 Mpa / cm<2>; and the hot pressing time is 1 min / mm when the temperature is 135-145 DEG C; the use ratio of a bamboo sheet material is more than 85%, and the used amount for labor is reduced by 40%; the internal stress problem of the bamboo material in a plywood is solved, and the problem that the gluing force is poor as the vertical and transverse bamboo beam single board curtains are directly glued is solved; and the quality is entirely improved, the volume-weight is entirely reduced, and the rigidity is improved.

Owner:福建省大田县华兴木业有限公司

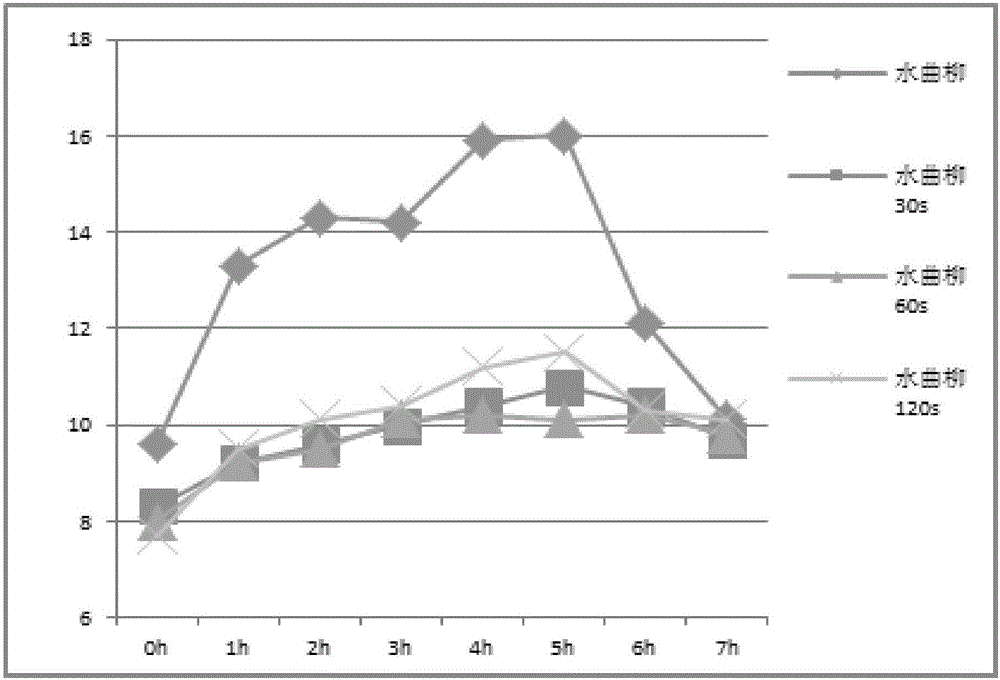

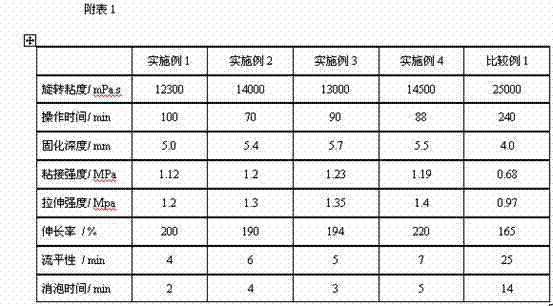

Preparation method of polyurethane elastomer

The invention provides a preparation method of a polyurethane elastomer, relating to polymers. The invention provides a preparation method of a polyurethane elastomer which has excellent impact resistance and machining characteristic and is especially suitable for preparing transparent polyurethane glasses frame products with high yields and low defects. The preparation method comprises the following steps: 1) preparing a prepolymer: mixing isocyanate with polyols to react to obtain the prepolymer; 2) preparing a curing agent: specifically, dehydrating the polyols, catalysts and anti-aging agents until the mass percent of the moisture is smaller than 0.05%, and adding chain extenders after reducing the temperature, thus obtaining the curing agent; and 3) mixing the prepolymer with the curing agent, then carrying out vacuum defoaming, injecting a reactive mixture after vacuum defoaming into a mold, then putting the mold in a microwave environment to be heated, and carrying out demolding, thus obtaining the polyurethane elastomer. The preparation method has the advantages of good processing properties, low material operating temperature, controllable operating time, high production efficiency and high yield.

Owner:XIAMEN MINGLAI TECH CO LTD

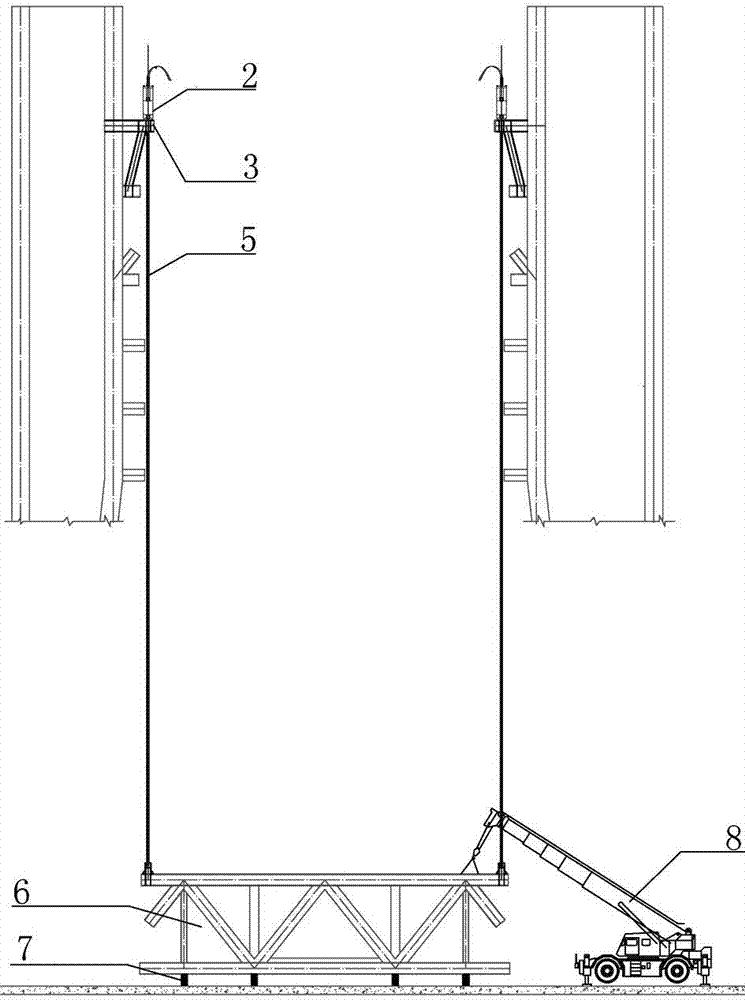

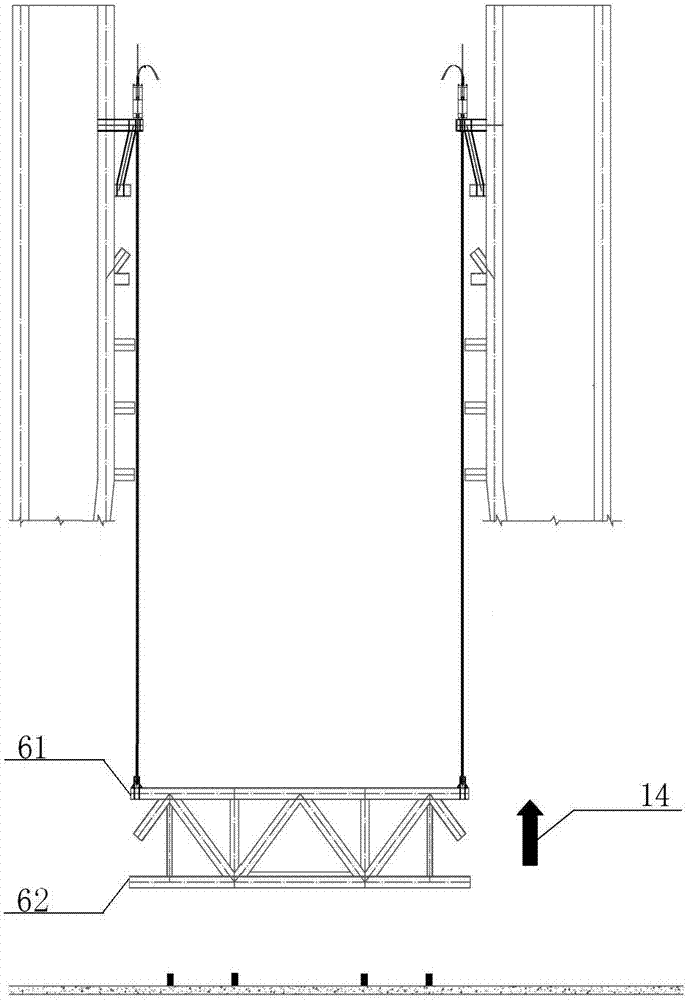

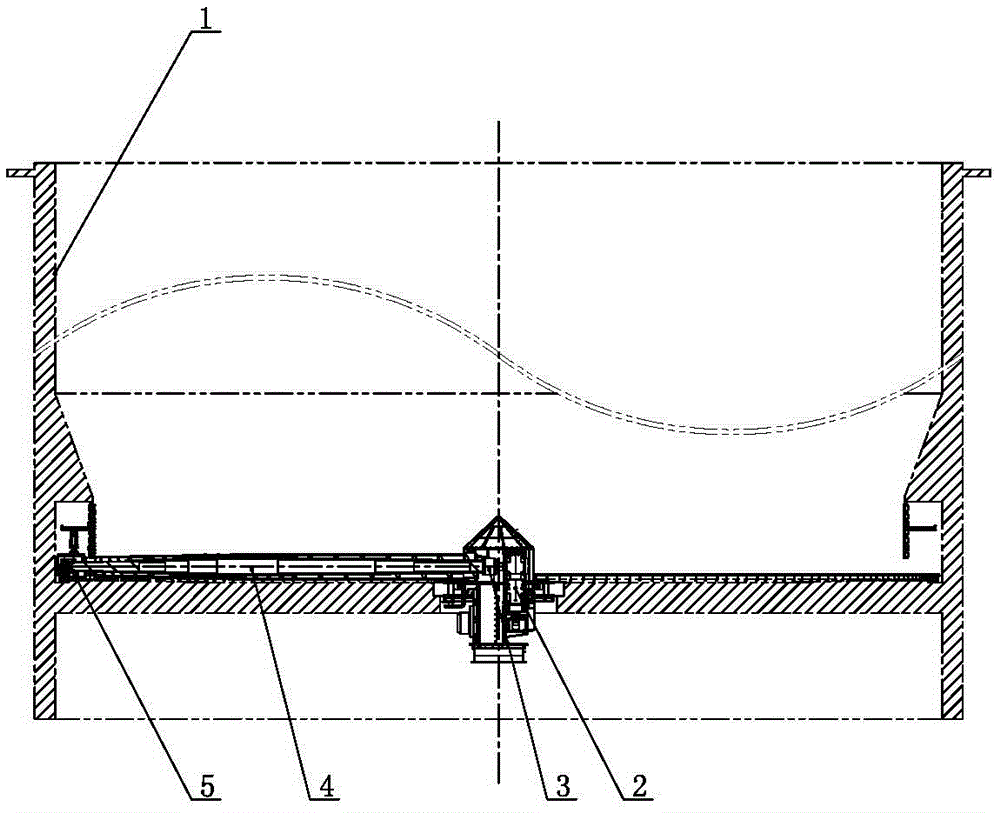

Construction method of suspended steel gallery

ActiveCN106930541AReduce workloadGuarantee the construction qualityBuilding material handlingBasementTime segment

The invention discloses a construction method of a suspended steel gallery. The suspended steel gallery is connected between main body structures; a preassembled bar is firstly arranged at designed elevation of the suspended steel gallery, a lifting platform is arranged, and meanwhile, a hydraulic lifter is arranged; an upper truss structure of the suspended steel gallery is spliced on the ground, the hydraulic lifter is debugged to lift in a segmented manner, wherein the lifting height of each time is the height of one layer of suspended structure; and the suspended steel gallery is lifted to the elevation for welding after assembly is completed. According to the method, one-time overall lifting method of the multi-layer suspended steel gallery is changed into a hydraulic multi-time segmented lifting method, so that large-range reinforcement of a basement roof is avoided, the construction period is shortened, the cost is reduced, the designed mechanical principle is matched and stress deformation and internal stress generation of a suspended structure are avoided. The appearance quality of the steel gallery and the quality of a welding line and a member meet the national current acceptance standard requirements; and the design idea is achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

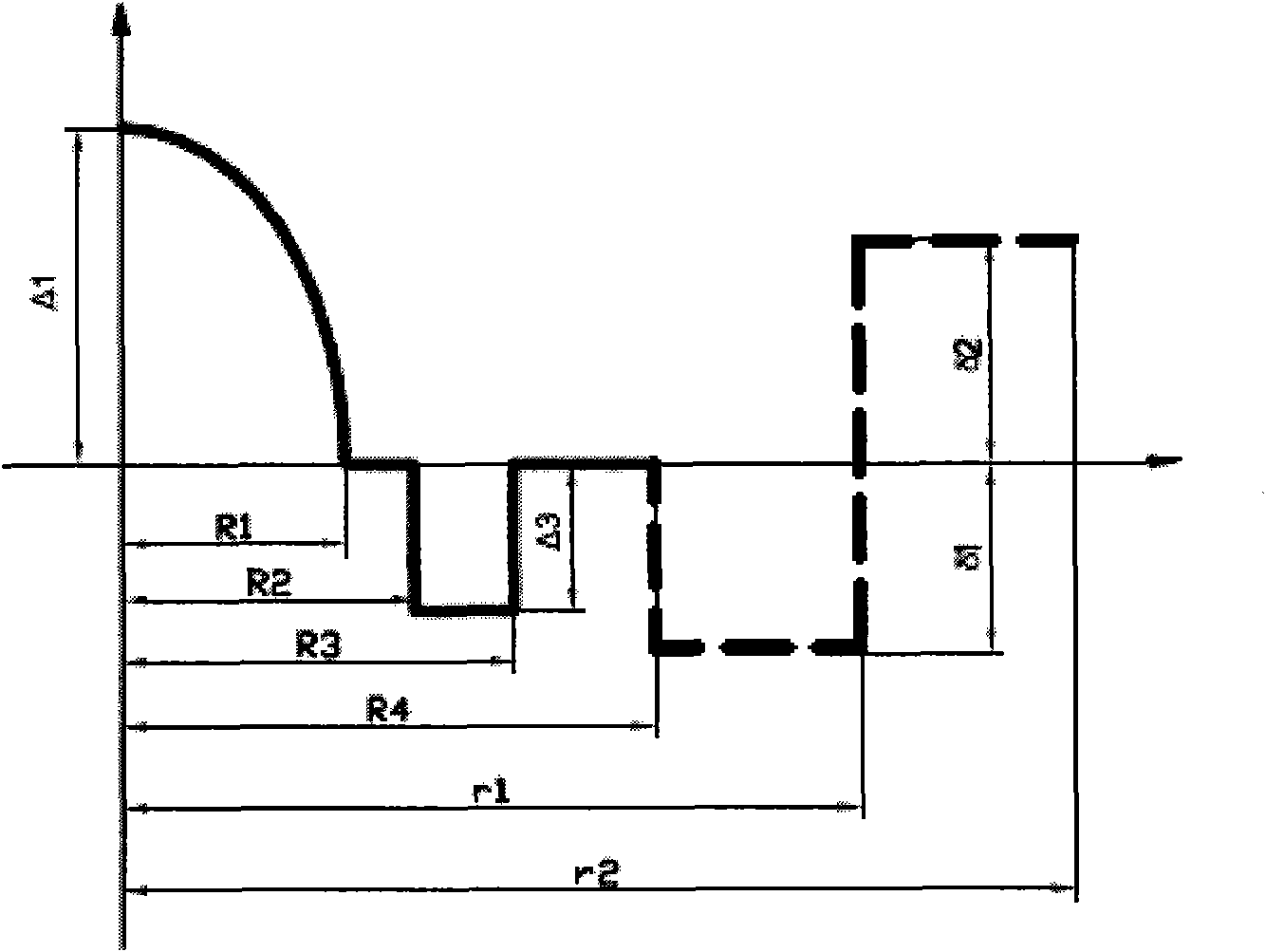

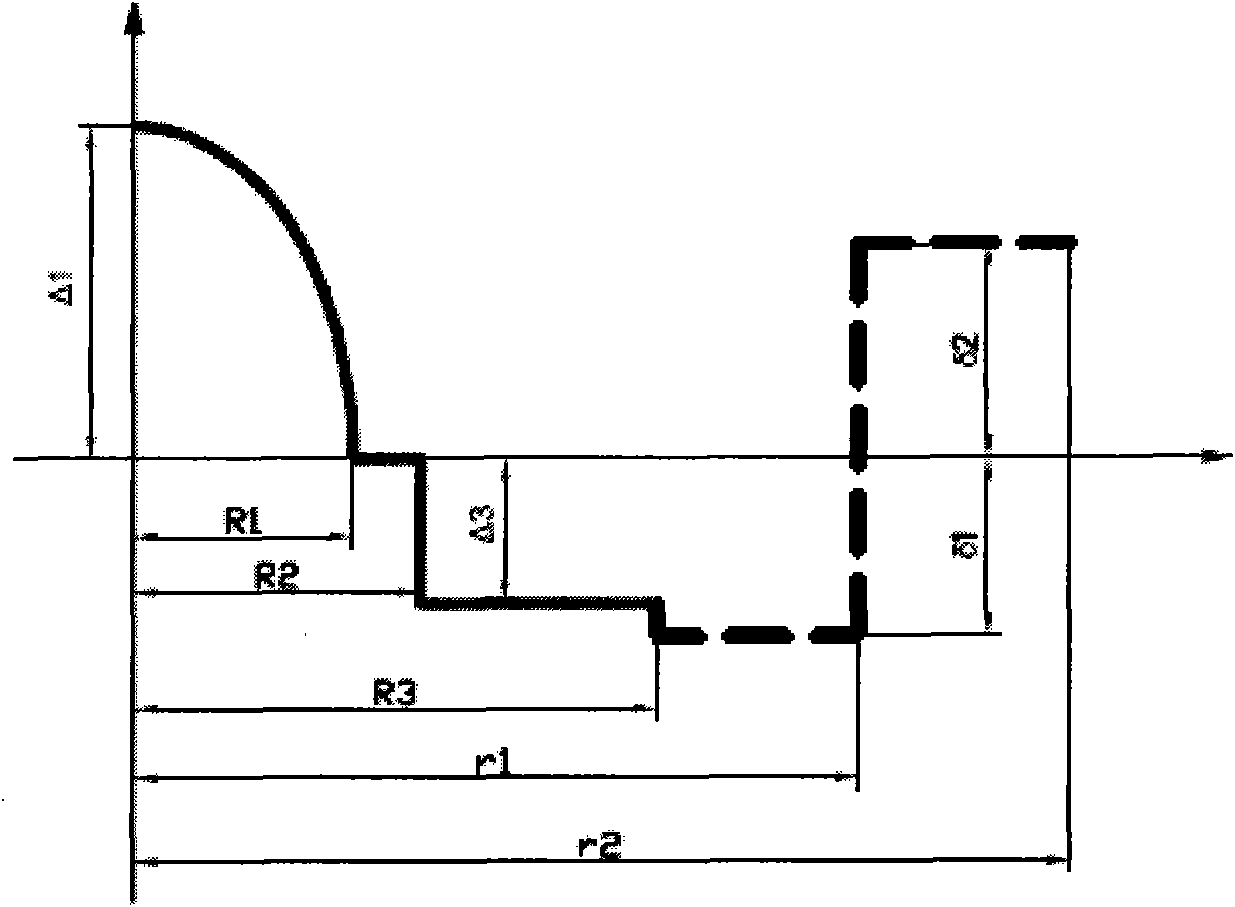

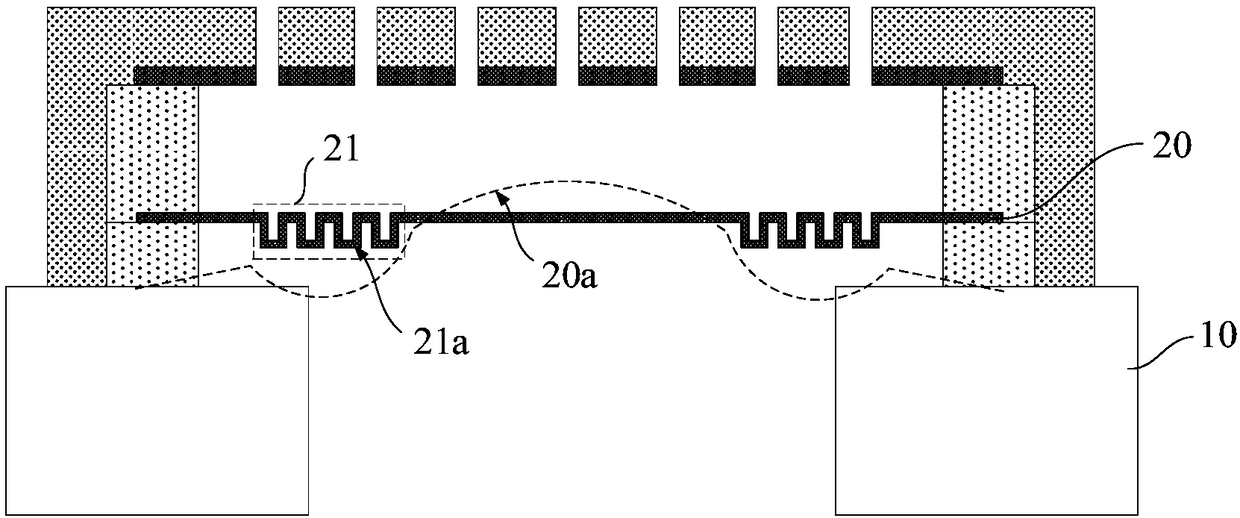

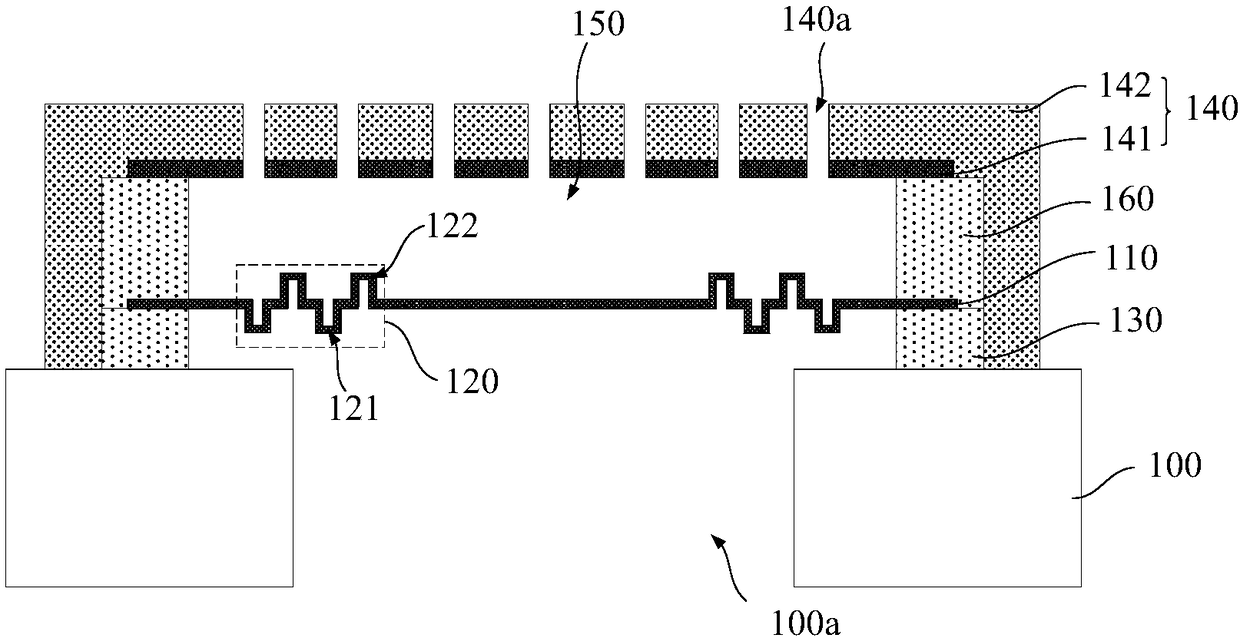

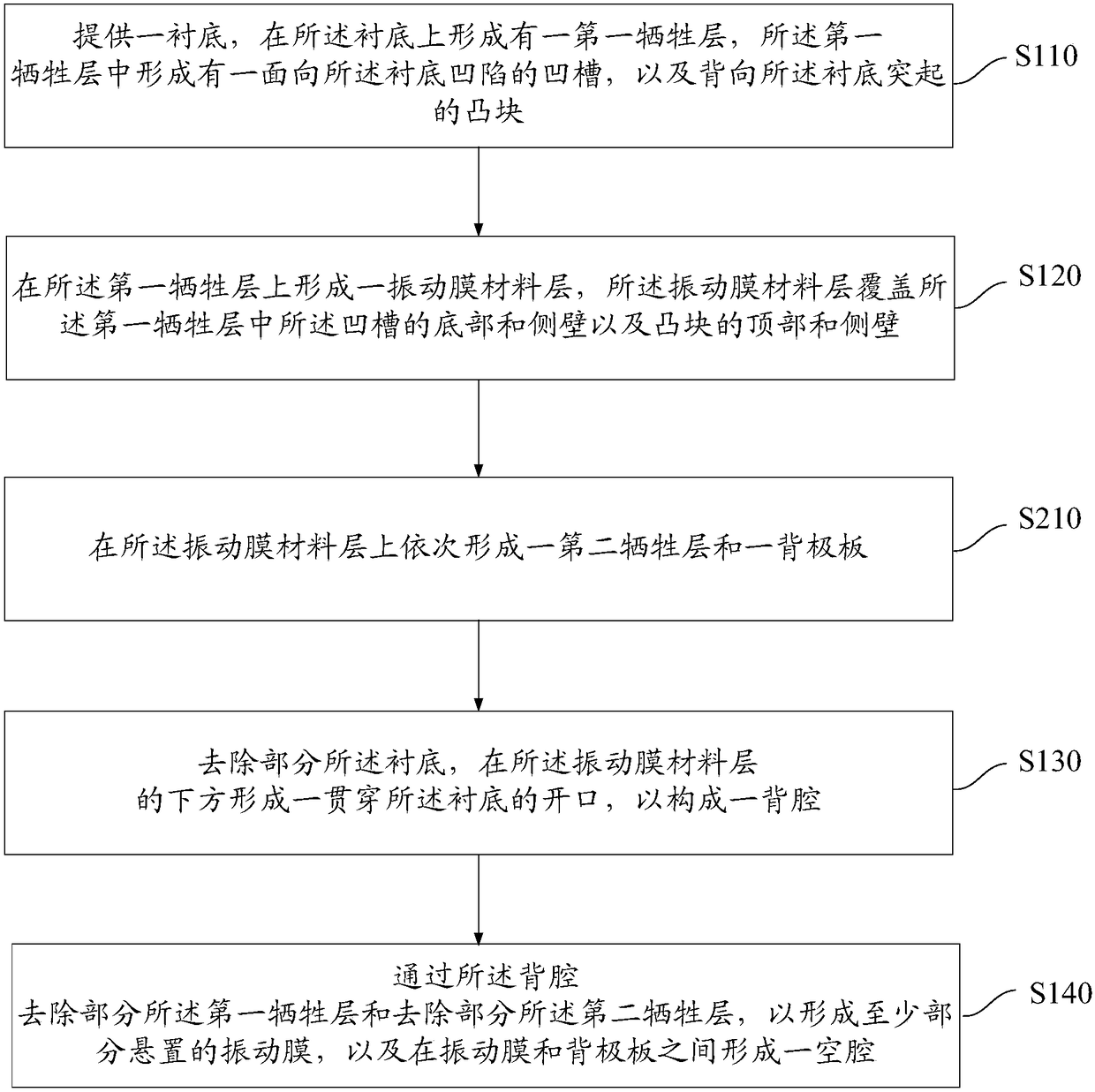

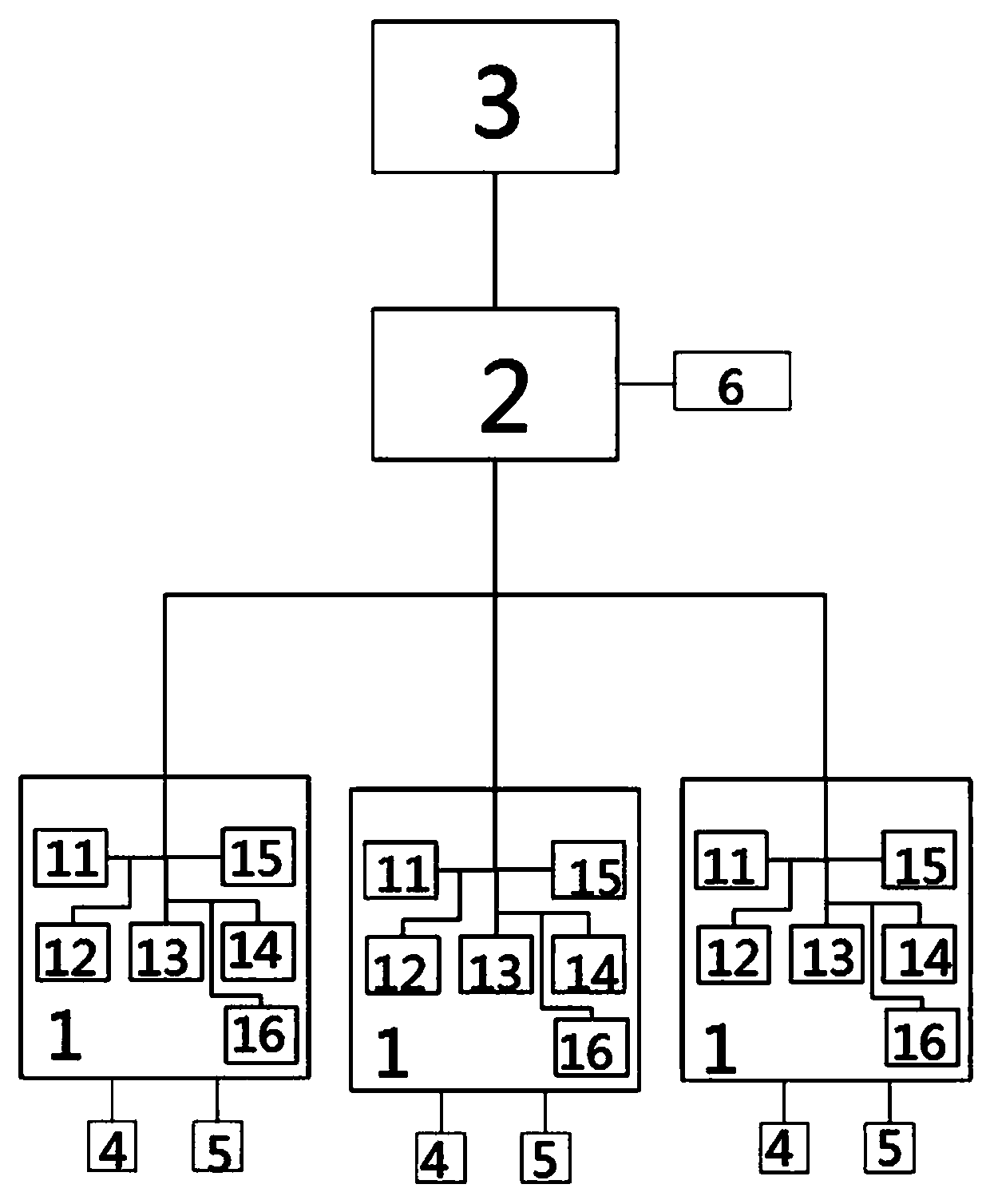

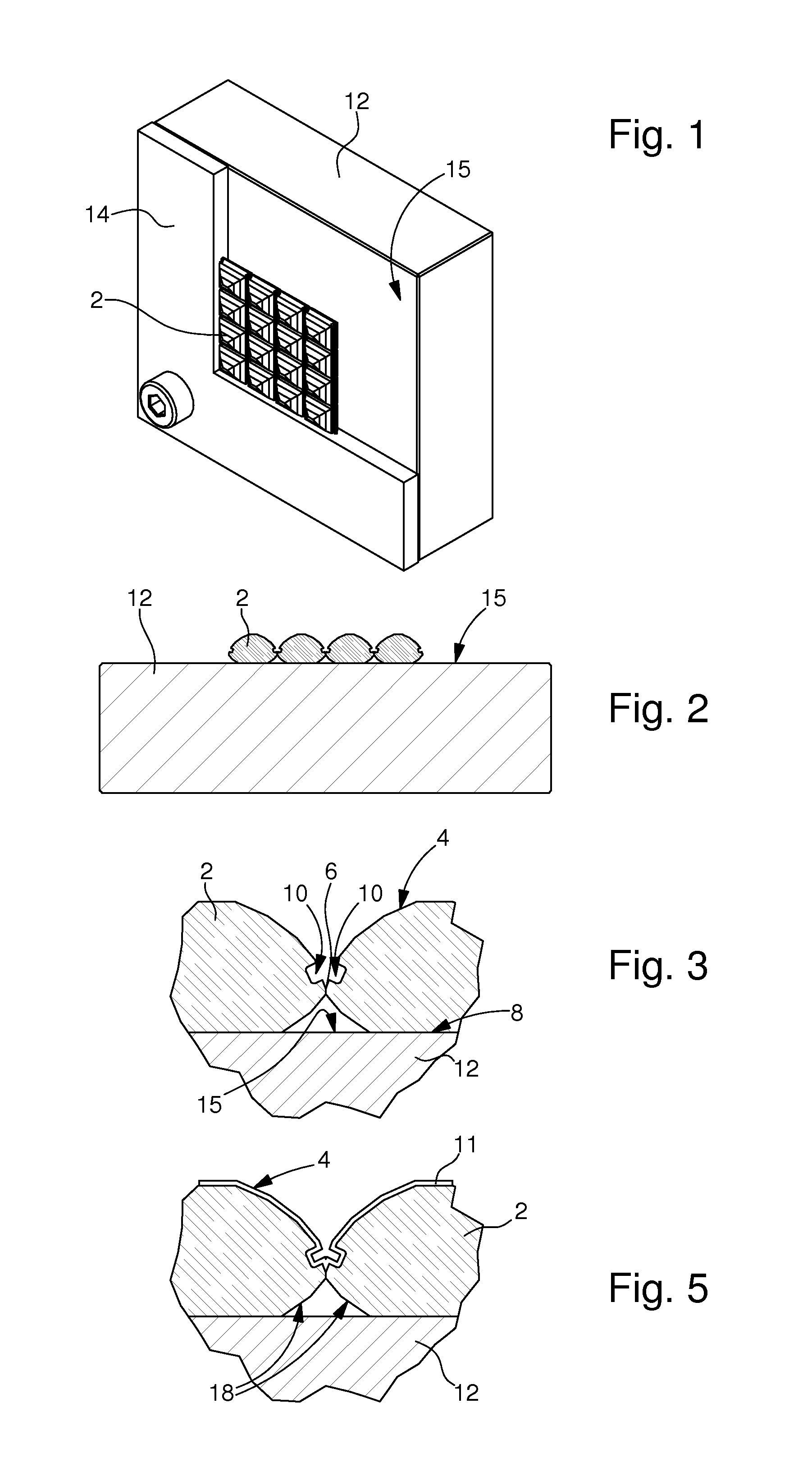

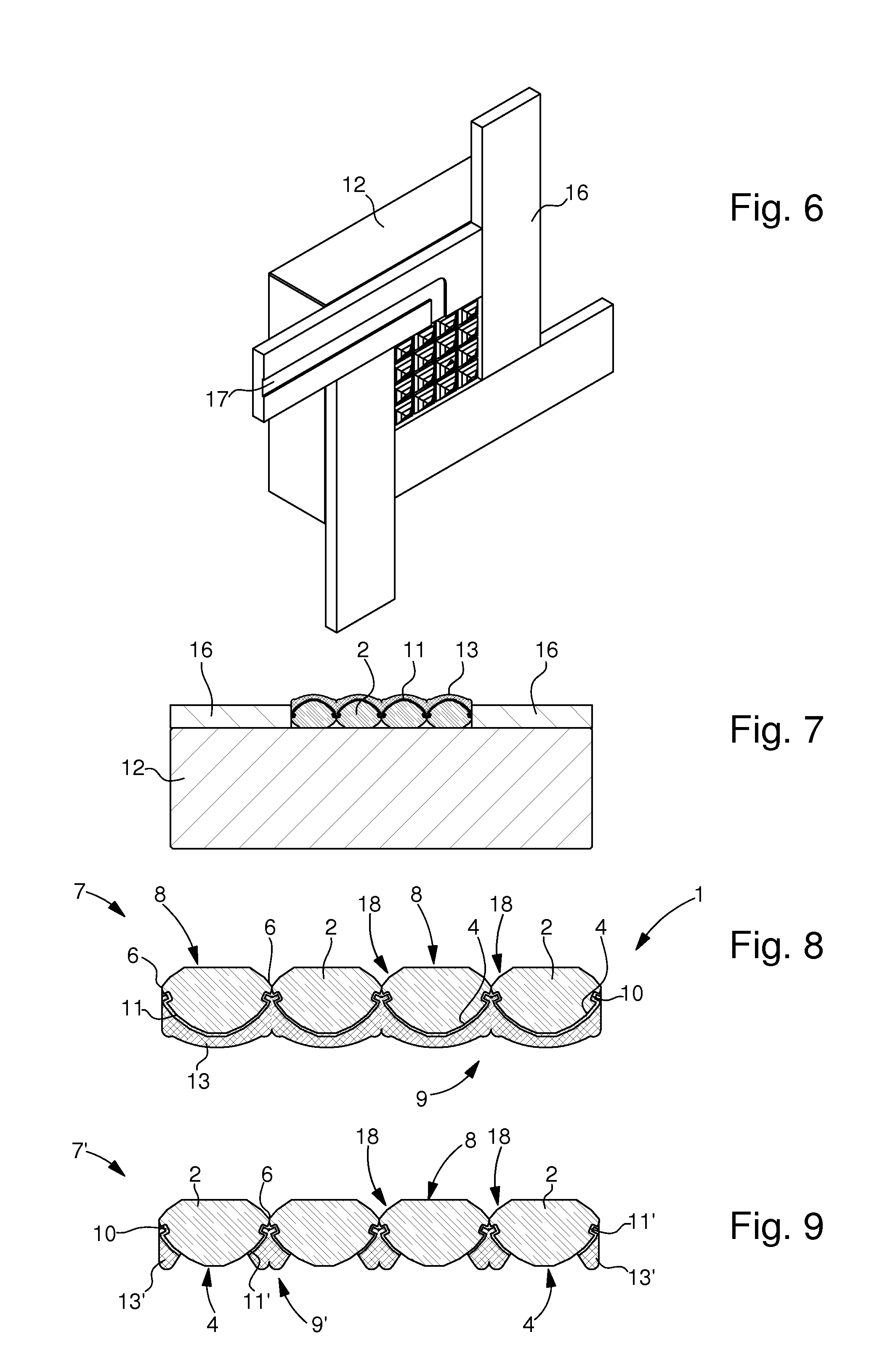

MEMS device and forming method thereof

InactiveCN108996466AIncreased reproducibility sensitivityHigh mechanical strengthTelevision system detailsImpedence networksVibrating membraneInternal stress

The invention provides an MEMS device and a forming method thereof. The device includes a vibrating membrane forming on a substrate. The vibrating membrane includes a first protrusion and a second protrusion that protrude in opposite directions. The first protrusion protrudes toward the substrate. Among a plurality of protrusions, the protrusions respectively extend in two different directions, thereby avoiding occurrence of internal stress in a corresponding direction due to the corrugation. Therefore, the internal stress in the vibrating membrane can be effectively released when the vibrating membrane is formed, and additional generation of the internal stress can be prevented, so that the formed deformation amount of the vibrating membrane is improved, and the sensitivity of the MEMS device is improved.

Owner:SEMICON MFG INT TIANJIN +1

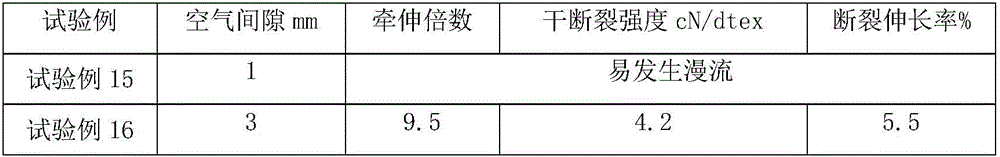

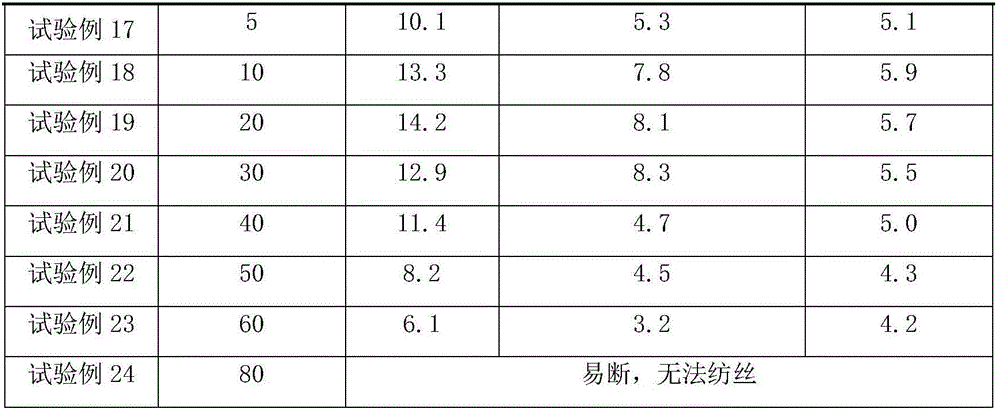

Method for preparing cellulose fibers by dry-wet spinning

ActiveCN106048741AImprove solubilityReduce processing timeArtificial filaments from cellulose solutionsFilament manufacturePolymer sciencePhosphoric acid

The invention discloses a method for preparing cellulose fibers by dry-wet spinning. The method comprises the following steps: dissolving cellulose fibers in phosphoric acid / polyphosphoric acid compound solution and preparing the original liquid glue in the liquid crystal state by using a double-screw extruder; preheating the original liquid glue and then feeding to a metering pump; adjusting glue feeding quantity; spraying out the original liquid glue through a spinneret plate; allowing the original liquid glue to be subjected to air bath, first coagulating bath and second coagulating bath successively, wherein the air gap is 3-50mm and a solution comprising three components is used in each of the first coagulating bath and the second coagulating bath; carrying out water washing, neutralization, hot water washing, oil applying, drying, winding and the like to prepare the finished fire. The method is characterized in that filament spinning and forming time is short; filaments are formed quite uniformed; production efficiency is high, the fiber index is excellent and the like; no by-product is generated; the environment is less polluted; and cost is low.

Owner:吉林国兴复合材料有限公司

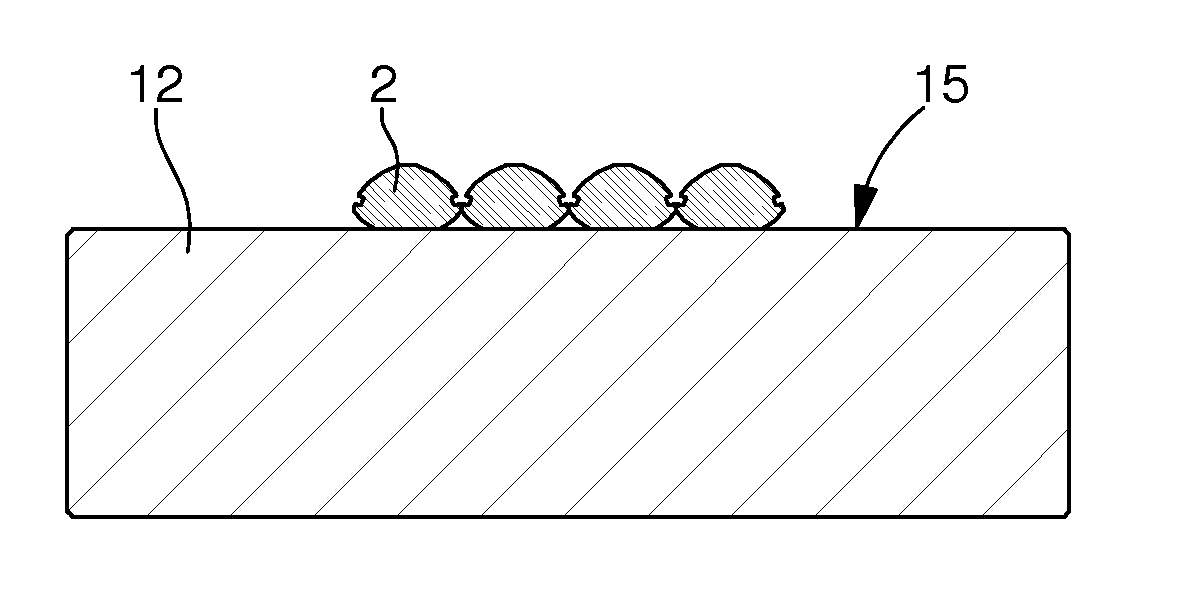

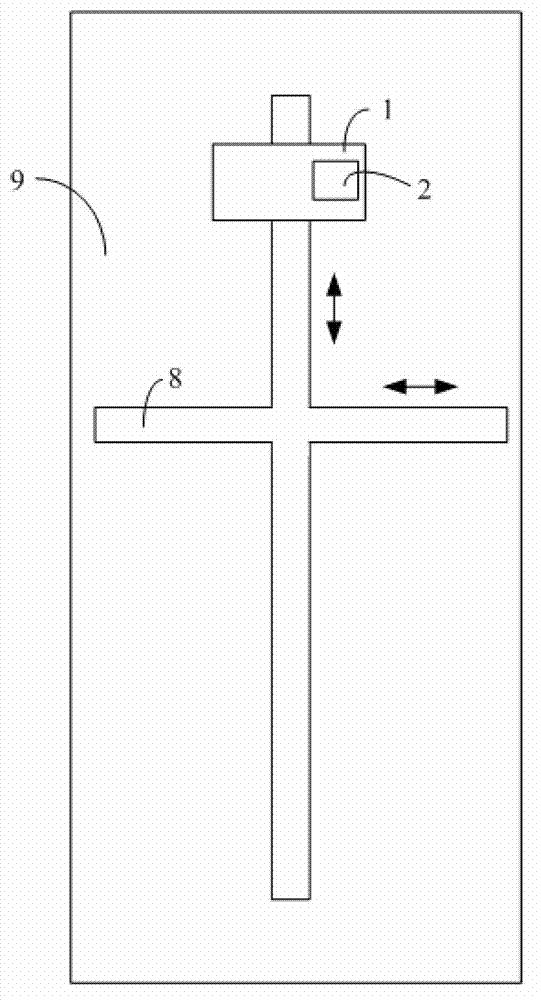

Micro silicon microphone and manufacturing method thereof

InactiveCN106412782AAvoid internal stressSuppress irregular stressMicrophonesLoudspeakersVibrating membraneManufacturing technology

The invention discloses a micro silicon microphone and a manufacturing method thereof. And the microphone and the method are used for solving a technical problem that a micro silicon microphone stress influences sensitivity and a manufacturing technology. The micro silicon microphone comprises a vibrating membrane layer. The vibrating membrane layer comprises a vibration beam and a vibration membrane. The vibration beam is uniformly arranged around an edge of the vibration membrane. One end of the vibration beam is fixed to the edge of the vibration membrane and the other end of the vibration beam is fixed to a support structure.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

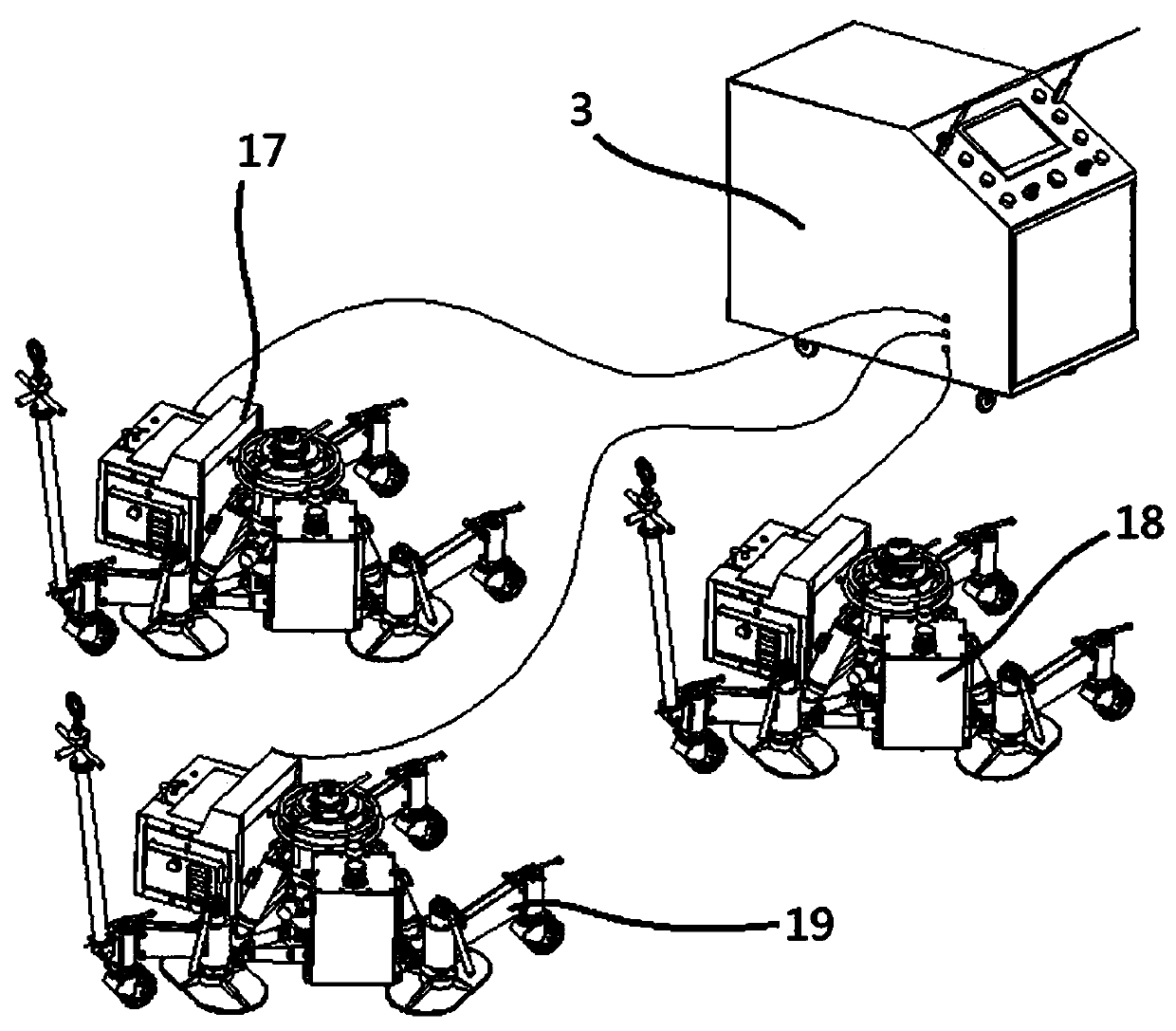

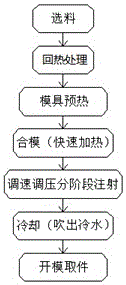

Accurate control system and method for synchronous jack-up main jacks for aircraft

PendingCN108681306AReduce labor intensityShorten maintenance preparation timeLifting devicesProgramme control in sequence/logic controllersElectricityElectric machine

The invention discloses an accurate control system and method for synchronous jack-up main jacks for an aircraft. The control system comprises at least three main jacks and further comprises a PLC controller electrically connected with each main jack, and a control end electrically connected with the PLC controller, wherein each main jack is equipped with a servo driver, the servo drivers are electrically connected with servo motors of the main jacks, a pipeline on which the servo motors are communicated with main jack acting cylinders is further provided with a proportion valve and an electromagnetic valve, pull wire sensors are further connected between supporting heads of the main jack acting cylinders and the main jack acting cylinders, and the servo drivers, the proportion valve, theelectromagnetic valve and the pull wire sensors are electrically connected with the PLC controller. The accurate control system is advantaged in that an automatic full-machine synchronous jack-up modeis employed, labor intensity of the aircraft staff is greatly reduced, the preparation time for military aircraft maintenance is shortened, and economic benefits of civil aircrafts are improved.

Owner:西安飞豹科技有限公司

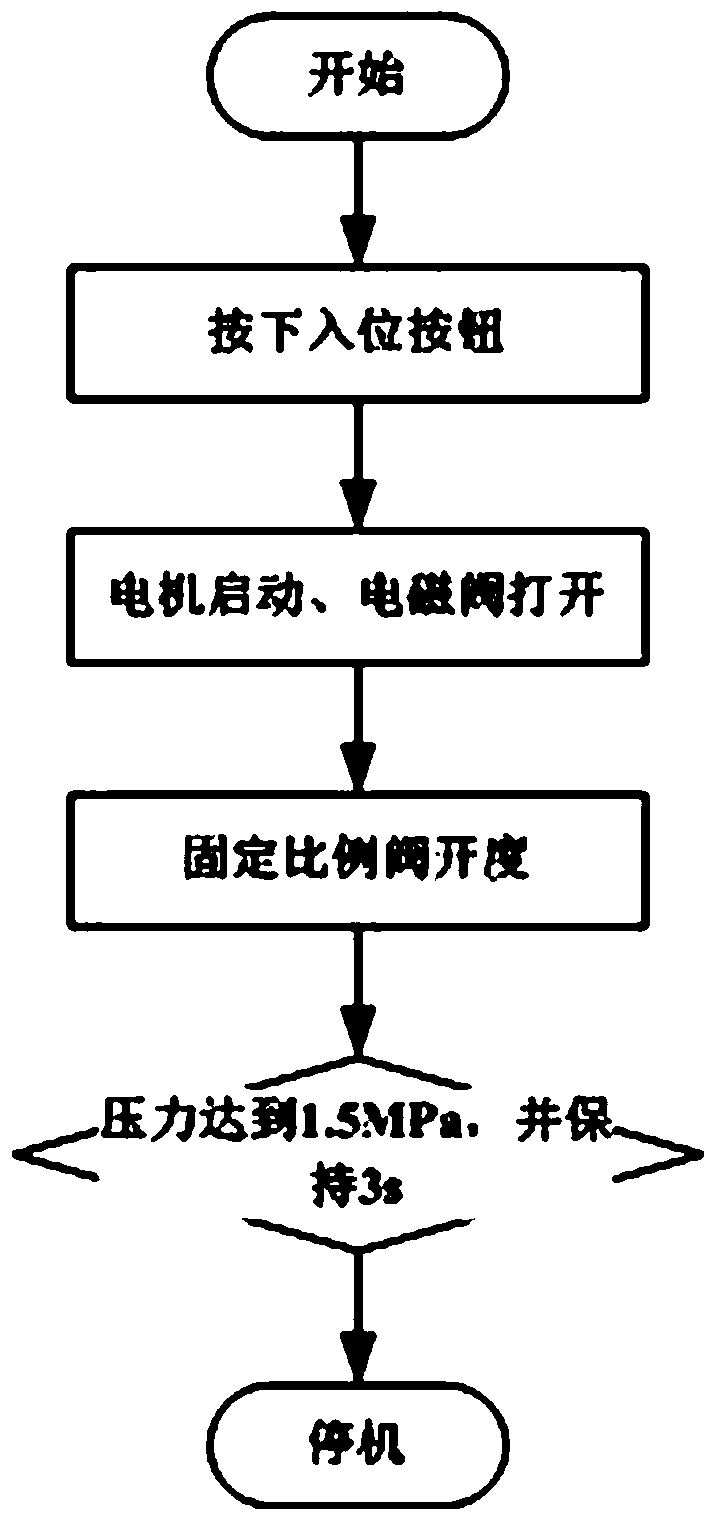

Steam type high fineness and no-weldlines injection moulding process for complex precise plastic product

The invention discloses a steam type high fineness and no-weldlines injection moulding process for a complex precise plastic product. The process comprises the following steps: (1) material selection; (2) backheating treatment; (4) mold preheating; (5) die assembly and quick heating; (6) speed-regulating and pressure-regulating injection in stages; (7) quick cooling; and (8) mold opening to take piece. According to the process disclosed by the invention, corresponding backheating treatment is performed on a material body, so that the internal stress problem of the material body is solved; then, an injection mold is of a design of a hot runner and a cold runner multipoint feeding subsurface gate, and meanwhile, the travel times of the corresponding hot runner and cold runner are added for a key portion of a product, so that the problems that a plastic melt is slow to flow at a far end to generate sink marks and the internal stress exists and the like are solved, and therefore, the appearance quality and the forming percent of pass of the product are extremely improved, the process cost and the like are reduced, and the actual using demand is met.

Owner:滁州市天悦塑胶制品有限公司

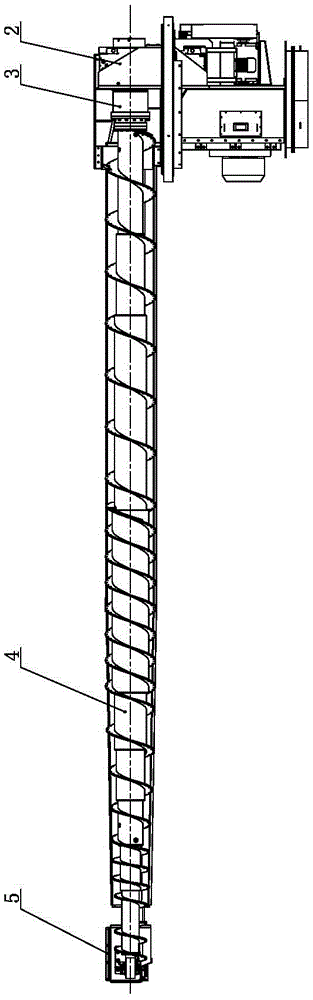

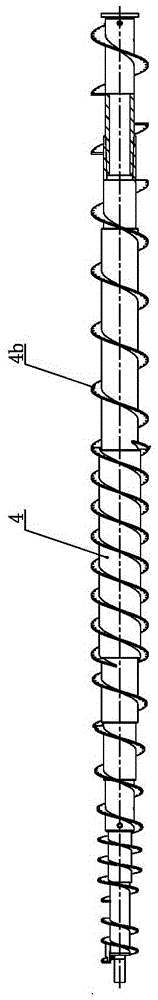

Bin discharge mechanism of circular bin

ActiveCN105645127AImprove the lubrication effectFlexible and adjustablePackagingLoading/unloadingFailure rateBall bearing

The invention relates to a bin discharge mechanism of a circular bin. The bin discharge mechanism comprises a main speed reducer, a coupling, a discharge auger and a tail mechanism; the main speed reducer is positioned in center of the bin; an output shaft of the main speed reducer is connected with an auger shaft of the discharge auger through the coupling; an outer end of the auger shaft is connected with the tail mechanism; the part, beside two ends, of the auger shaft is formed by embedding and welding multiple hollow long shafts in sequence; the number of embedded layers near the middle part of the auger shaft is bigger; spiral blades are axially wound at the outer periphery of the auger shaft, and are uniform in pitches on each section of step shaft; and the volumes in the pitches of the spiral blades are gradually increased from tail ends to center ends. Blades for shearing materials are respectively mounted on the outer edges of all the spiral blades. The output shaft of the main speed reducer is supported on wall boards on two sides of the main speed reducer through double rows of radial spherical roller bearings; and a two-way thrust ball bearing is mounted at one end, far from the discharge auger, of the output shaft of the main speed reducer. The bin discharge mechanism can bear higher radial force and two-way axial force, and is low in failure rate.

Owner:MYANDE GRP CO LTD

Wood modifying reinforcer

ActiveCN105690521AImprove permeabilityStable moisture contentWood treatment detailsWood impregnation detailsDiluentTannic acid

The invention provides a wood modifying reinforcer. The wood modifying reinforcer comprises a component A, a component B and a component C, wherein the component A comprises 60-90 parts by weight of modified polyurethane resin, 0.6-1.0 part by weight of a defoaming agent, 0-1 part by weight of a dispersing agent, 0.2-0.5 part by weight of a flatting agent, 0-1 part by weight of bentonite and 0-30 parts by weight of talcum powder; the component B is isocyanate polymer; and the component C is a diluent. The wood modifying reinforcer provided by the invention is extremely strong in permeability to a wood substrate, can obviously stabilize moisture content of wood, and can slow down changes of moisture content, so that inner stress generated by rapid changes of moisture content inside the wood is reduced, the wood cracking and bending problem is prevented, and the effect of sealing tannic acid further can be remarkably achieved; and the treated wood is almost free of resin residues on surface, and is free of an obvious reinforcing phenomenon, so that convenience is provided for a follow-up processing process.

Owner:SHENZHEN EGO NEW MATERIALS CO LTD

Single-component room temperature vulcanized silicon rubber for sticking insulator

InactiveCN102516923AHigh bonding strengthIncreased curing speed in deep layersNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a single-component room temperature vulcanized silicon rubber for sticking an insulator, which belongs to the technical field of an adhesive for sticking the insulator and mainly solves the problems of the existing adhesive of being poor in leveling property, low in adhesive strength and slow in curing. Components of the single-component room temperature vulcanized silicon rubber for sticking the insulator comprise 100 parts of monohydroxyl-terminated polydimethylsiloxane polymer, 10-15 parts of gas phase white carbon black, 18-25 parts of silicone oil plasticizer, 6-10 parts of cross-inking agent, 1.7-4 parts of coupling agent, 10-15 parts of mineral oil and 0.1-1 part of catalyst. The single-component room temperature vulcanized silicon rubber has good leveling property, is high in adhesive strength, fast in deep curing, convenient to construct and operate and widely applicable to sticking and assembling of the insulator.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

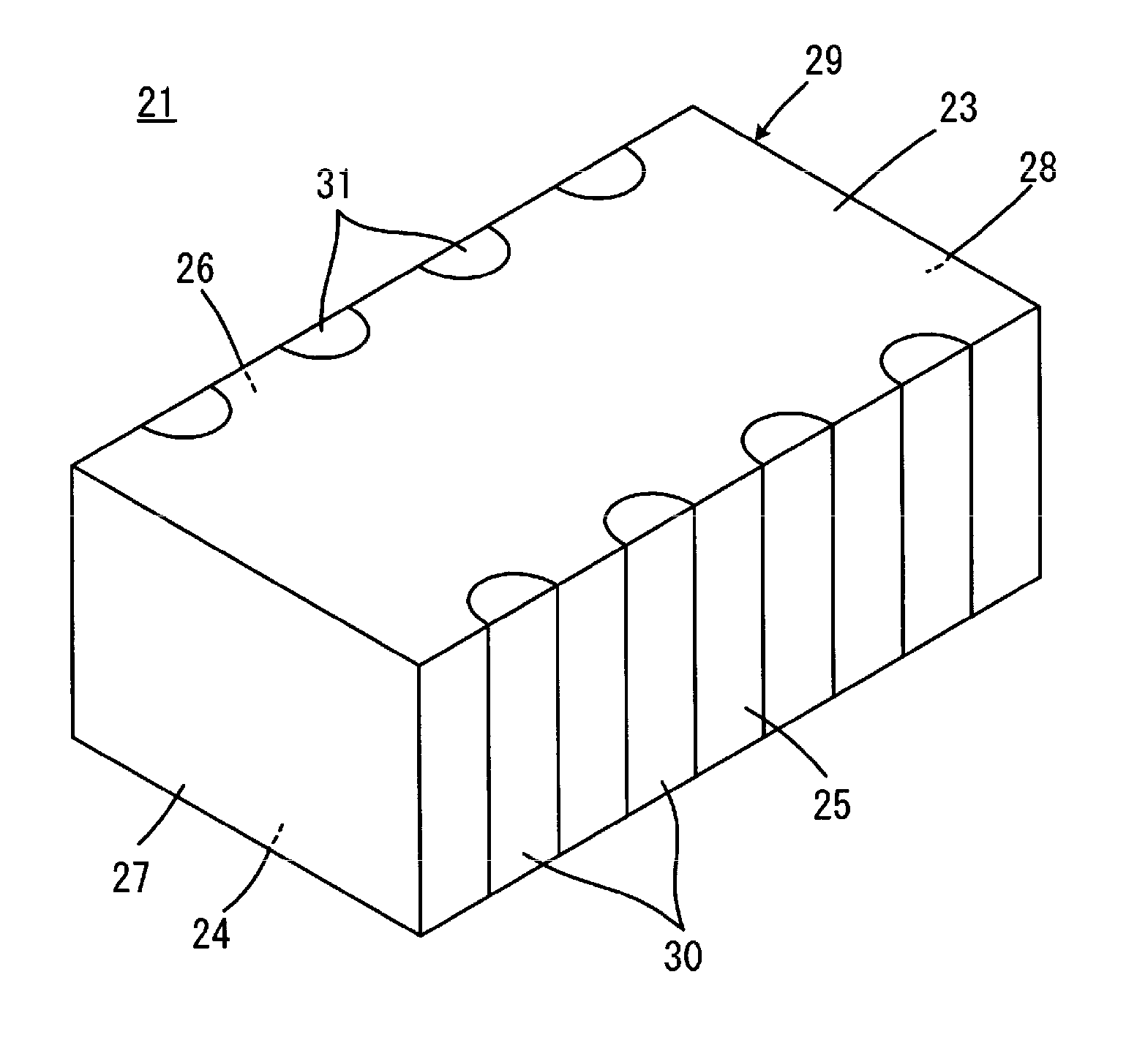

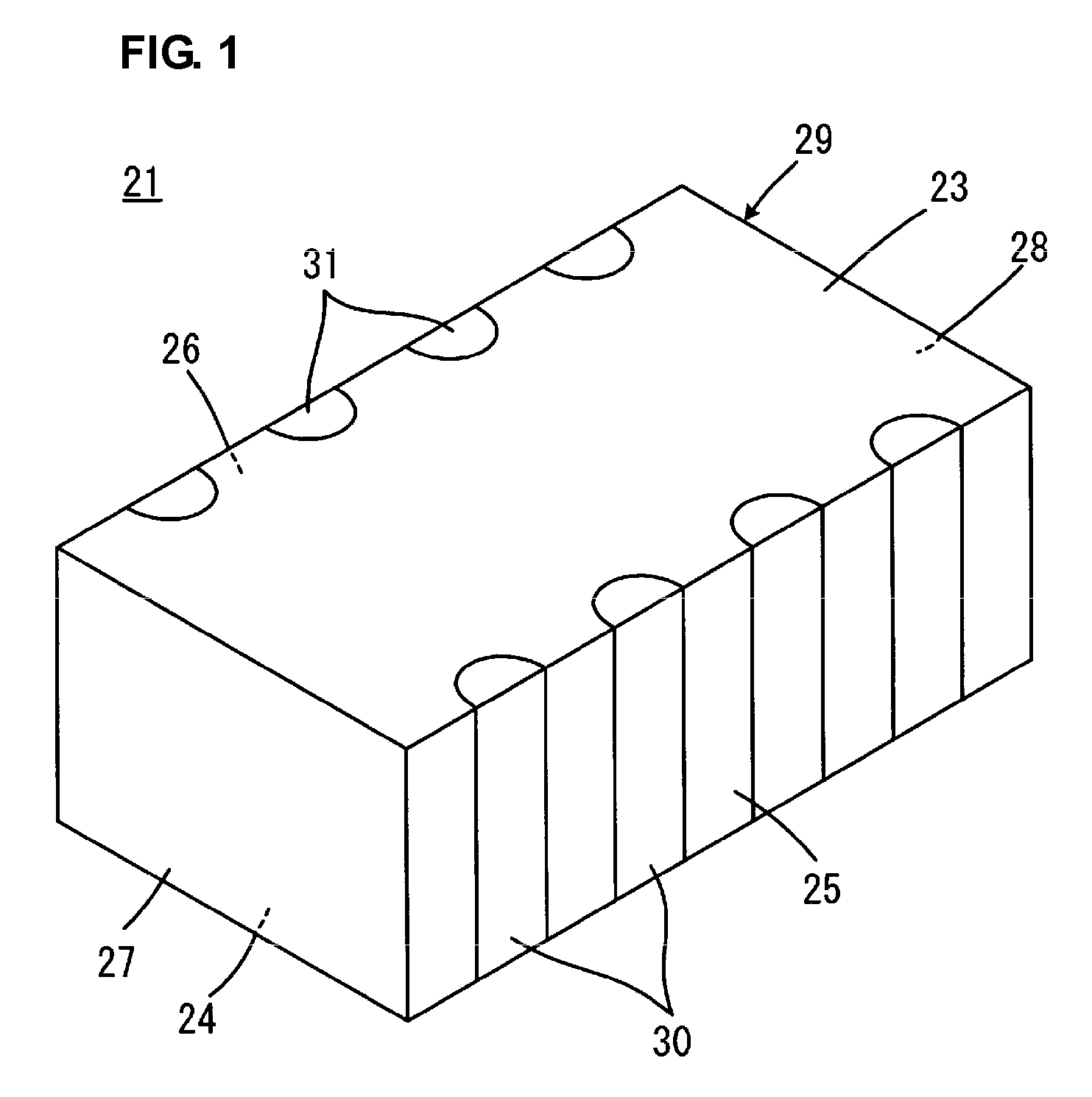

Monolithic ceramic electronic component

ActiveUS7567427B2Avoid internal stressImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricMetallurgyElectronic component

Owner:MURATA MFG CO LTD

Invisible set decorative part

ActiveUS20120225314A1High precisionHigh quality settingJewelleryThin material handlingMechanical engineeringIndustrial engineering

Owner:DRESS YOUR BODY SA

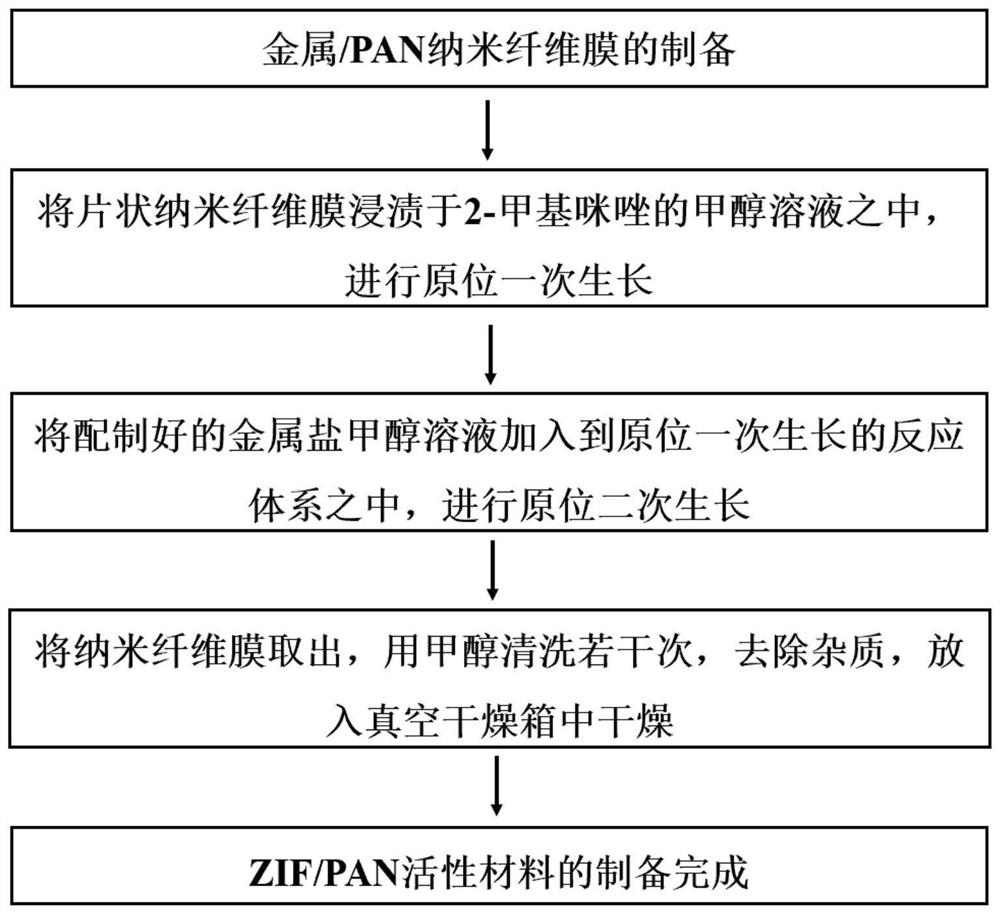

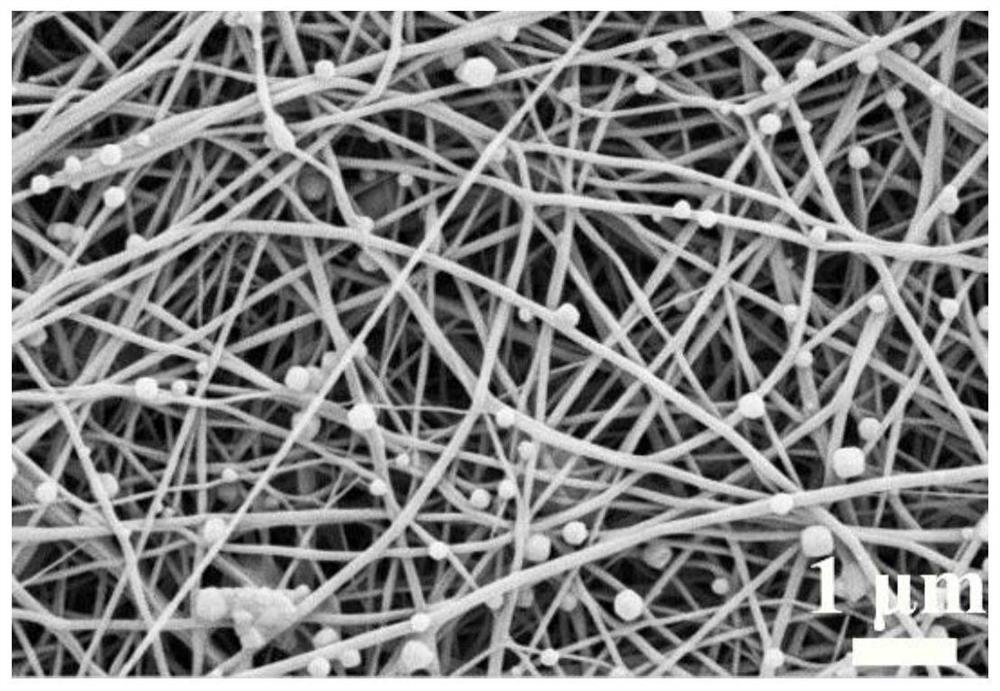

Preparation method of metal organic framework/nanofiber with bead-like structure

ActiveCN112981960AImprove utilization efficiencyHigh catalytic activityFibre typesMonocomponent synthetic polymer artificial filamentFiberMetal-organic framework

The invention provides a preparation method of a metal organic framework / nanofiber with a bead-like structure, and belongs to the technical field of nano material preparation. The method includes the following steps: firstly, bridging metal salt nodes on the surfaces of metal / PAN nanofibers with 2-methylimidazole in a solution for coordination, and generating ZIF particles distributed along the nanofibers in an in-situ one-time growth manner; and then adding a metal salt solution, wherein metal ions enriched on the surfaces of the fibers and the organic ligands are subjected to a strong cross-linking effect, and a ZIF / PAN nanofiber composite material with a layered heterostructure is obtained through in-situ secondary growth. The method can promote the uniform growth of ZIF particles along the orientation of the nanofibers, so that more crystal face positions are exposed, the crystal face utilization of the ZIF is maximized, the specific surface area and the activity are greatly improved, and the application field of the ZIF is expanded. The method is simple, the process is controllable, the problems of MOF particle aggregation, MOF derivative structure collapse and the like are greatly solved, the method can be applied to the field of fuel cell catalysis, and the catalytic activity and stability are improved.

Owner:UNIV OF SCI & TECH BEIJING

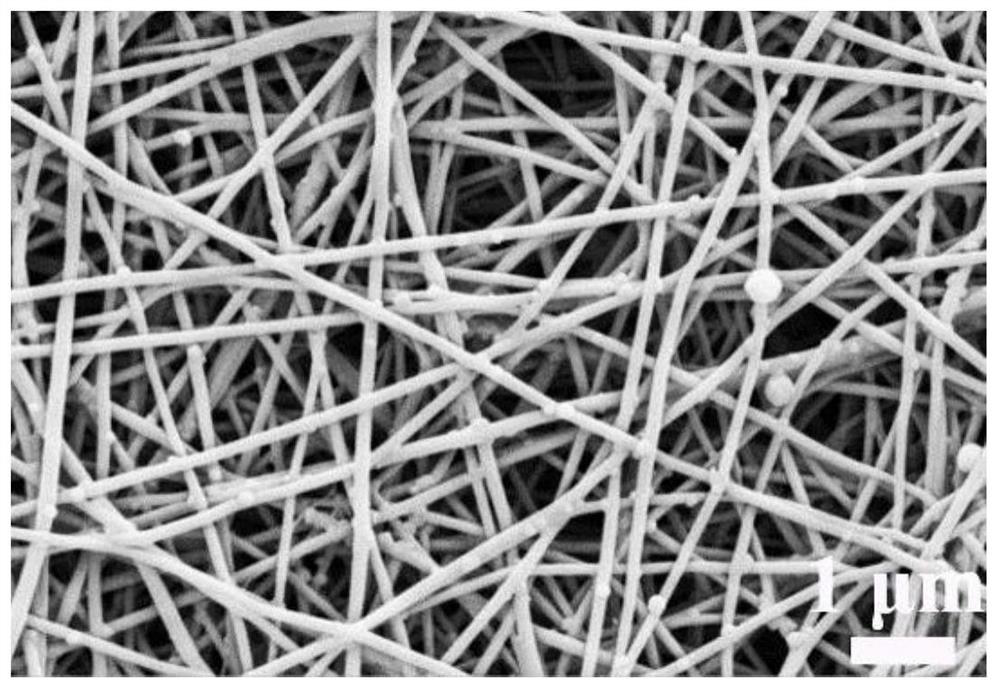

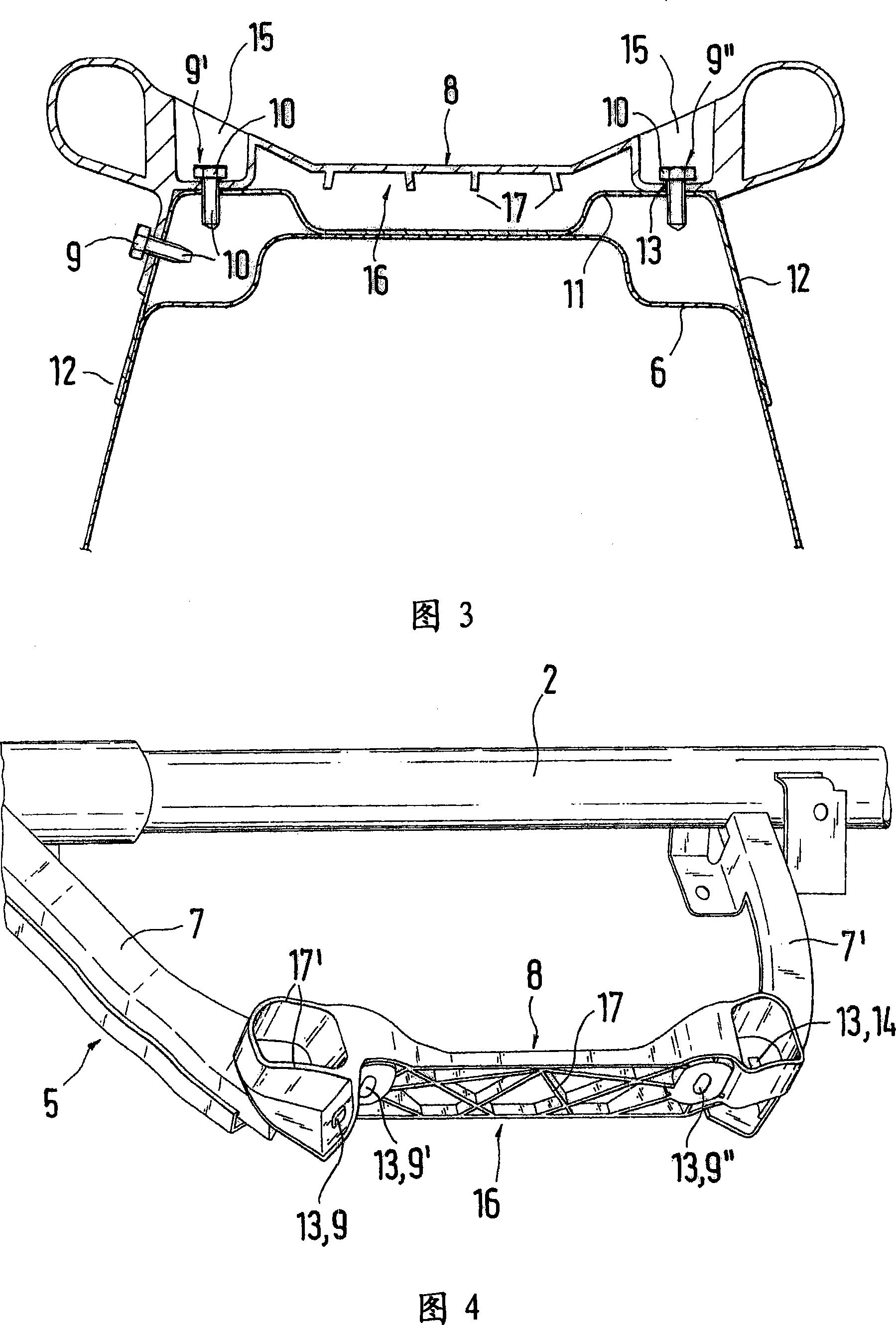

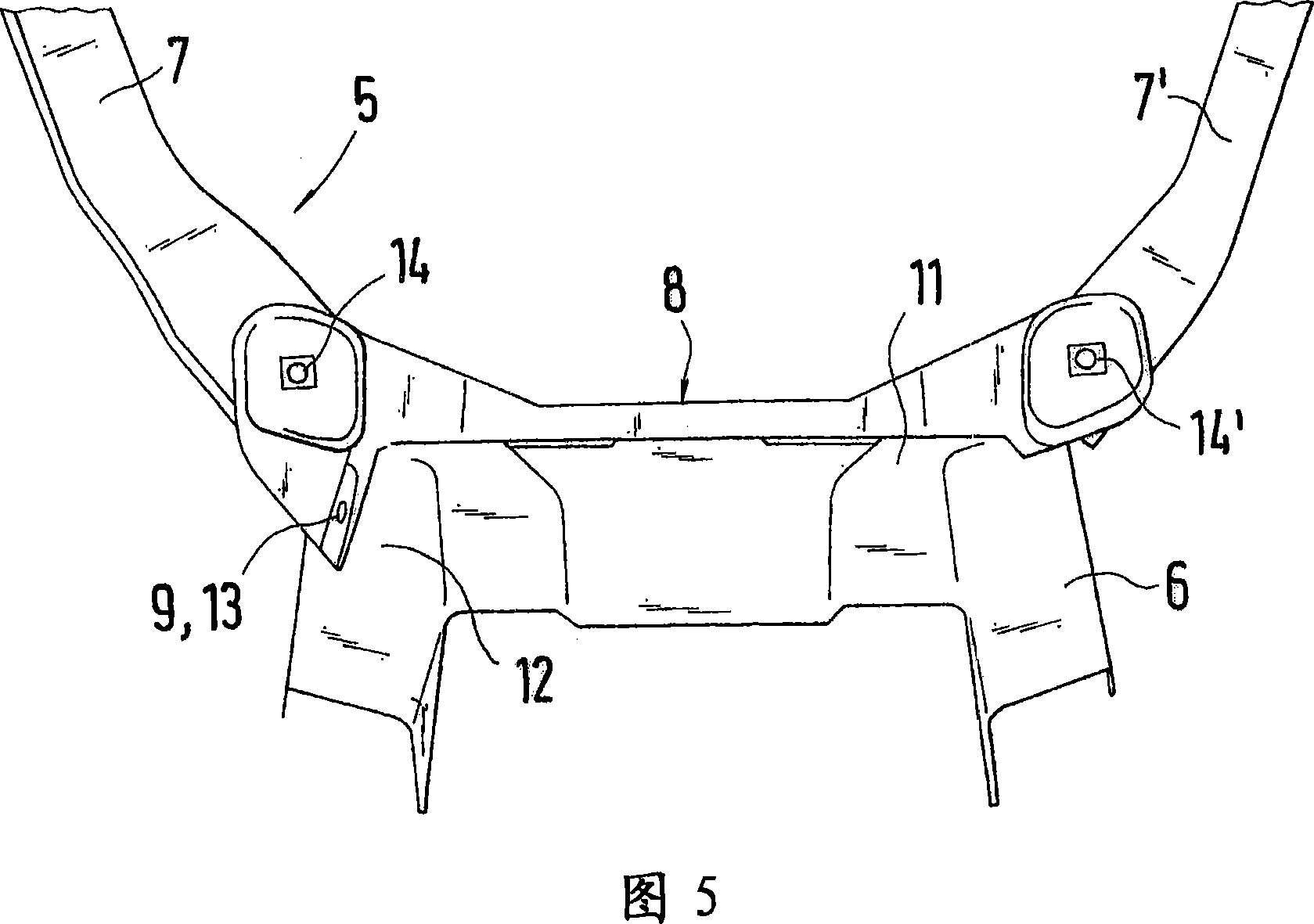

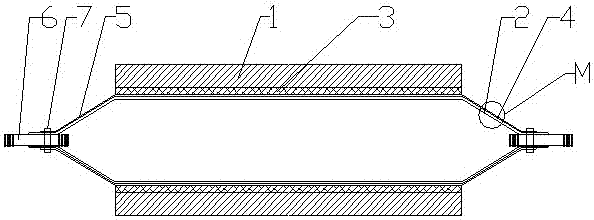

Cross member

InactiveCN101186220AEasy to assembleGood compensationSuperstructure subunitsEngineeringElectrical and Electronics engineering

The invention relates to a crossbeam (2) in an automobile, especially a crossbeam (2) of a driver's cab, the longitudinal end of the crossbeam (2) is connected with the A-pillar of the front vehicle structure (1) of the automobile, and the crossbeam (2) Supported at its center (4) on the longitudinal center tunnel (6) of the vehicle by means of a bracket (5), wherein the bracket (5) has two downward supports (7, 7') and a connecting beam (8), said connecting beam (8) connects the lower ends of said two supports (7, 7'), the invention proposes that said connecting beam (8) can be passed through at least one fixing device (9 ) is fixed on the longitudinal central channel (6), and the fixing device (9) enables the connecting beam (8) to be adjustable on the longitudinal central channel (6) of the vehicle. This enables a stress-free and simple assembly of the cross member (2).

Owner:DR ING H C F PORSCHE AG

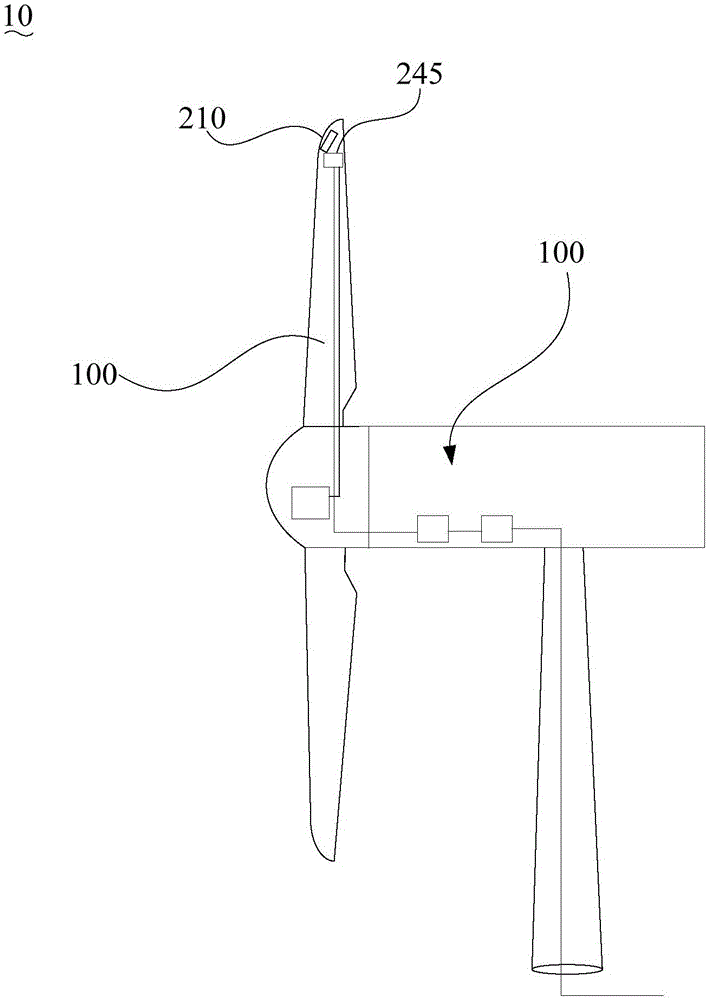

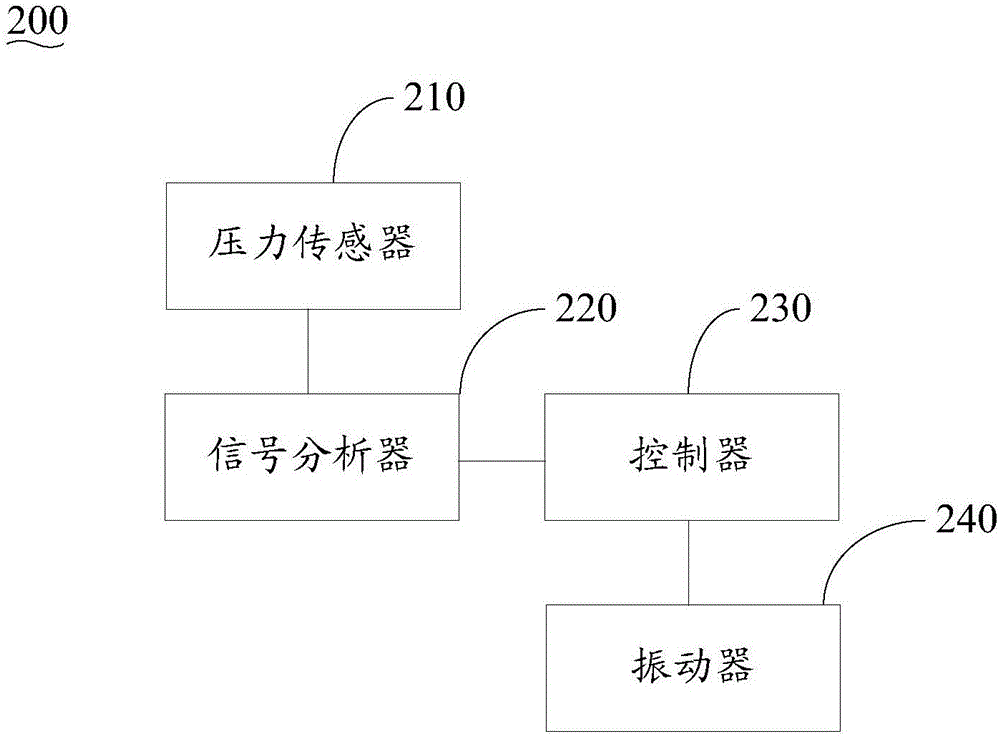

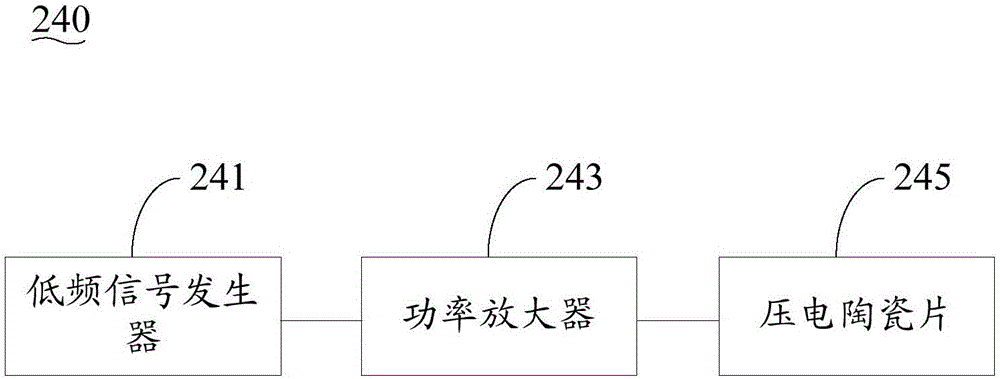

Offshore wind turbine as well as blade damage preventing device and method

ActiveCN106438194AAvoid gatheringAvoid icingActive/predictive/anticipative controlMachines/enginesSurface pressureTurbine

The invention relates to an offshore wind turbine as well as a blade damage preventing device and method. Surface pressure on blades can be sensed by pressure sensors. When the blades are hit by falling snow or raindrops, the surface pressure on the blades is increased until preset conditions are met, and thus a trigger signal is sent out. Further, a controller sends out a vibration signal, vibrators arranged in the blades produce vibration at the vibration frequency. The falling snow and the raindrops which hit the blades can be thrown off and can be prevented from being attached to surfaces of the blades through vibration and high-speed rotation of the blades. The falling snow and super-cooled water drops are major causes for icing of the surfaces of the blades. Besides, vibration produced by hitting of the raindrops can be offset by vibration of the blades, so that the internal stress is prevented from being accumulated in the blades. Thus, with the blade damage preventing device and method, icing and the internal stress can be effectively prevented.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Method for realizing co-curing of L-shaped reinforcing rib and C-shaped frame-structure composite part through high-strength soft tool

ActiveCN110370676AAvoid problems such as agingShorten the manufacturing cycleNon destructiveAviation

The invention provides a method for realizing co-curing of an L-shaped reinforcing rib and a C-shaped frame-structure composite part through a high-strength soft tool. The method has the beneficial technical effects that first, co-curing of the L-shaped reinforcing rib and the C-shaped frame-structure composite part is achieved through the cooperation of a soft mold and a metal forming tool, it isguaranteed that the key parameters, such as the profile tolerance, thickness and the L-shaped axis, of the part all meet the high civil aviation manufacturing standard, and the problem of aging caused by repeated curing of materials is solved; second, in the forming process, pressure is uniformly and accurately applied to all positions of the L-shaped vertical rib and a C-shaped frame, and the temperature rise rates of all the portions of the part are kept consistent, so that the problem that the thickness of an R-angle area of the part is out of tolerance is solved; and third, non-cured preforms of the L-shaped vertical rib and a C-shaped web are combined through the soft tool, so that internal stress caused by combination after curing of an assembly is avoided, and the problems of out-of-tolerance profiles and internal non-destructive defects caused by forced assembly in the prior art are solved.

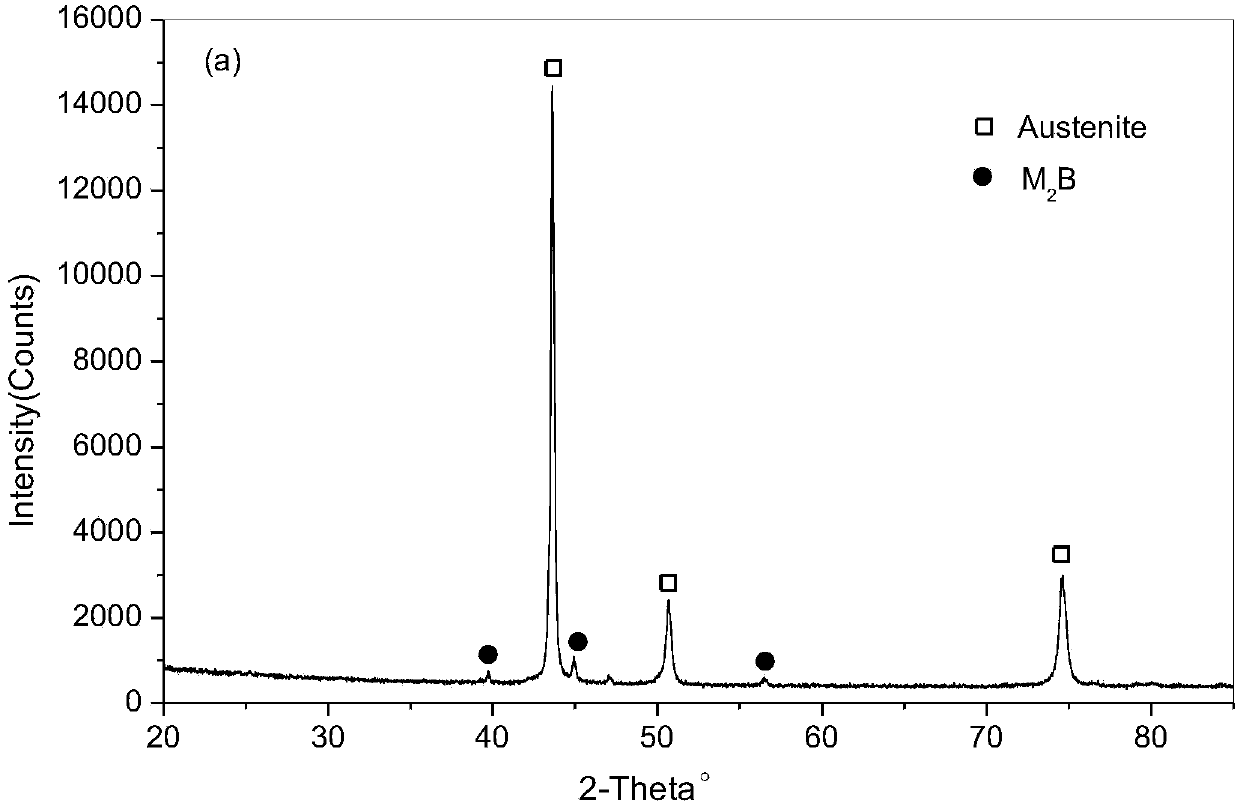

Copper alloy die-casting die steel and manufacturing method thereof

The invention relates to copper alloy die-casting die steel and a manufacturing method of the copper alloy die-casting die steel, and belongs to the technical field of steel and iron materials. The steel is hot work die steel with high-hardness high-heat-stability hard boride strengthening phases distributed on a single Austenite base body, the steel does not contain W, Mo, V, Co and other metal. Chemical compositions of the steel comprise, by weight, 0.3 percent to 0.6 percent of C, 0.1 percent to 1.2 percent of Si, 6.0 percent to 14.0 percent of Mn, 8.0 percent to 16.0 percent of Cr, 3.0 percent to 8.0 percent of Ni, 0.5 percent to 1.0 percent of Cu, 0.1 percent to 0.8 percent of B, P smaller than 0.015 percent, S smaller than 0.015 percent and the balance Fe. According to the method, raw materials are smelted, casting and ingoting are carried out under the argon atmosphere protection, and the copper alloy die-casting die steel is obtained after heat treatment and forging treatment. According to the high-temperature mechanical property of the copper alloy die-casting die steel, the 850 DEG C high-temperature tensile strength is 200 MPa to 310 MPa, the yield strength is 160 MPa to 200 MPa, the 850 DEG C high-temperature compressive strength is 270 MPa to 310 MPa, and the yield strength is 170 MPa to 210 MPa. Under the same test condition, the high-temperature tensile strength and the high-temperature compressive strength of the copper alloy die-casting die steel are obviously higher than those of H13 steel

Owner:TSINGHUA UNIV +1

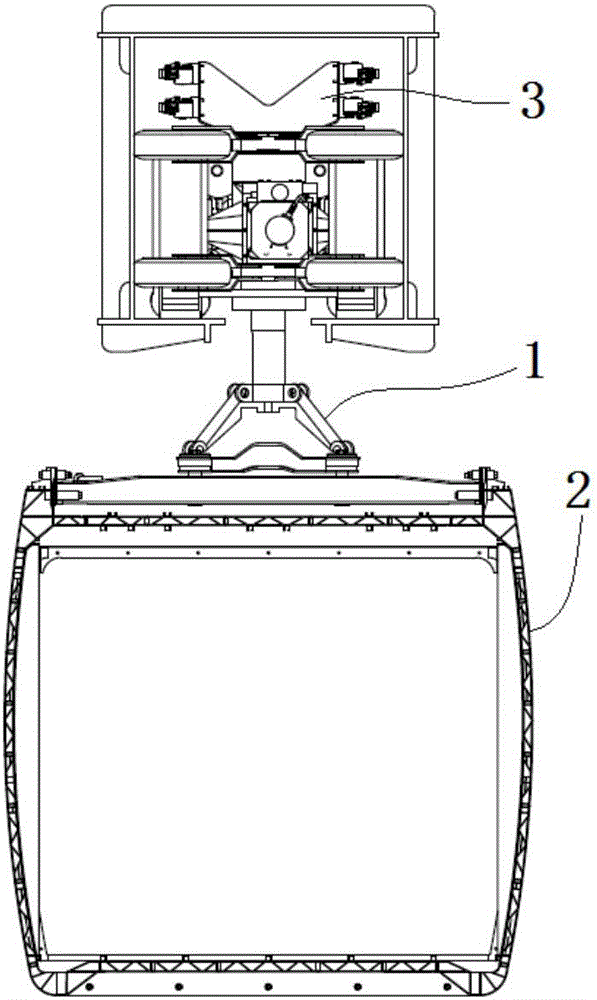

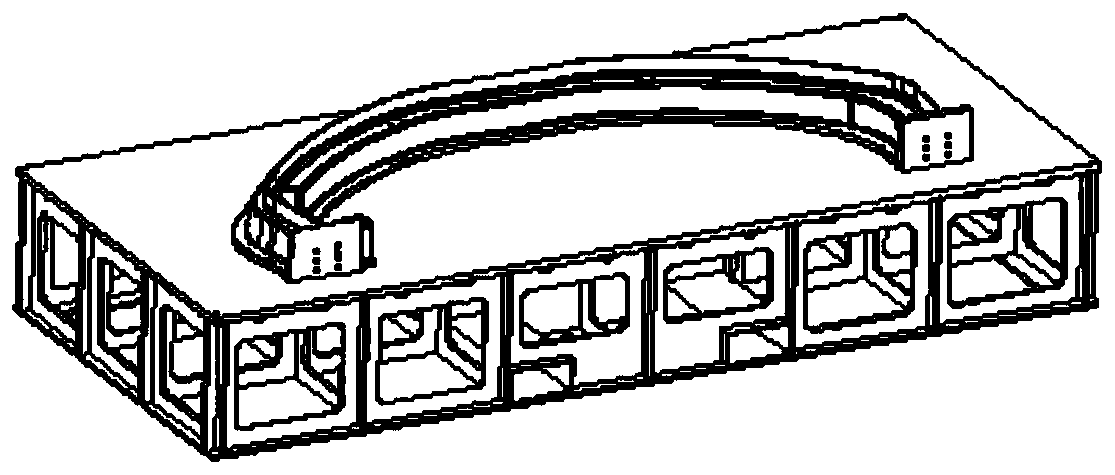

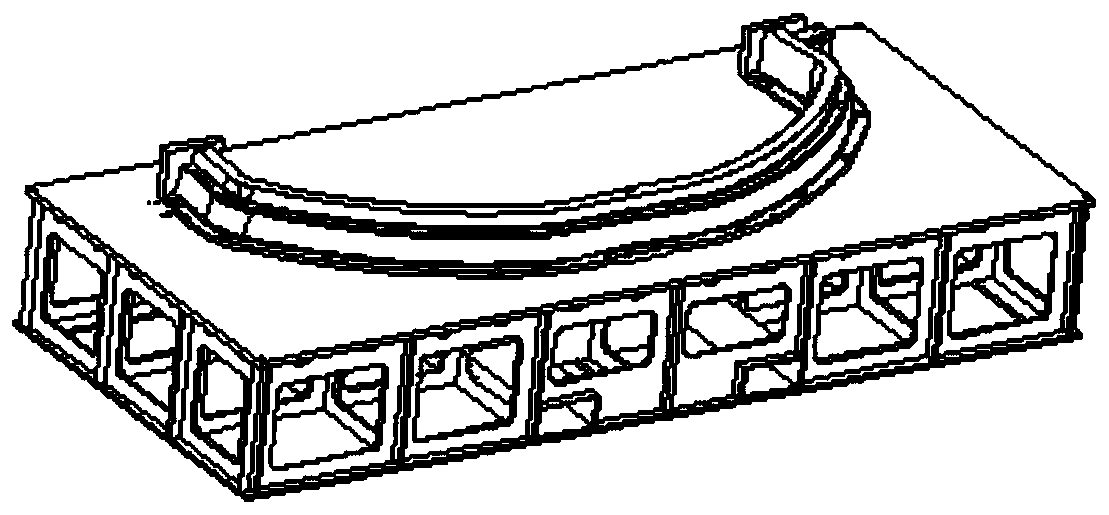

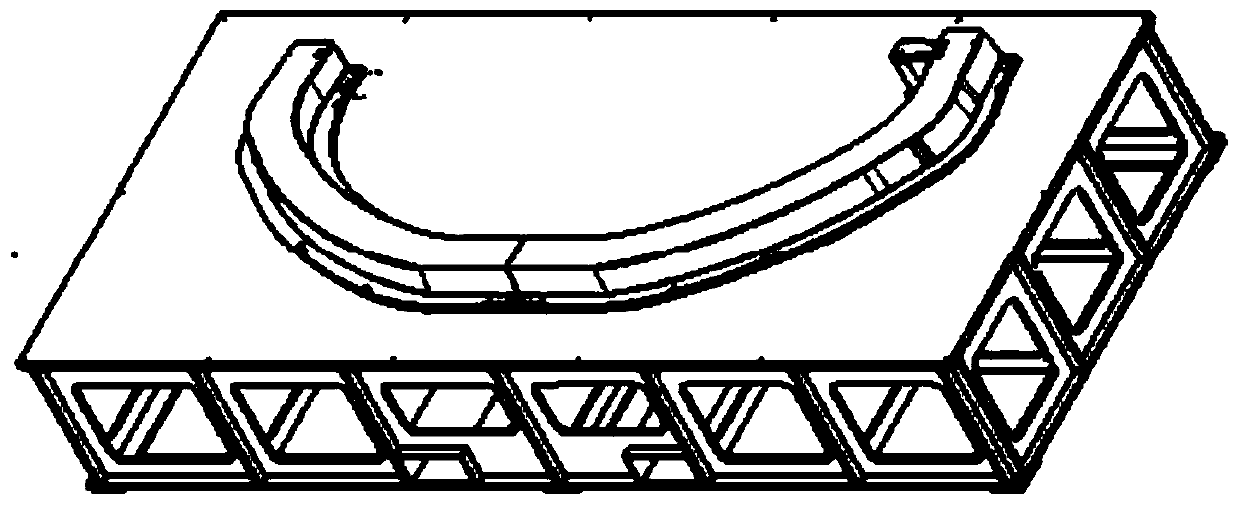

Suspension type monorail vehicle body and cross beam connection structure and suspension type monorail vehicle

ActiveCN106218648ASolve the problem of degrees of freedomFreedom releaseMonorailsRailway transportEngineeringMonorail

The invention discloses a suspension type monorail vehicle body and cross beam connection structure and a suspension type monorail vehicle. The suspension type monorail vehicle body and cross beam connection structure comprises connection plates fixed to the two ends of an edge beam of a top cover of a suspension type vehicle body, and a cross beam used for being fixedly connected with a traveling component. Barbs are arranged on the inner side faces of the tops of the connection plates. End plates are arranged at the two ends of the cross beam. The top of each end plate is located in the barb of the corresponding connection plate. Each end plate is fixedly connected with the corresponding connection plate. Preferably, the cross beam and the end plates are of an integrally formed structure. Through the arrangement of the barb structure, the cross beam is matched with the barbs of the connection plates, so that connection between the cross beam and the suspension type vehicle body is more reliable, and meanwhile the independence on the welding mode is avoided.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Composite high temperature electrical heating element and its making method

InactiveCN1838841AImprove bindingNot easy to peel offHeating element shapesHeating element materialsSolid reactionGraphite

The invention relates to a composite high-temperature electric heating element and relative producing method, which is formed by graphite, carbon silicon and molybdenum silicide. Wherein, the graphite is used as basis layer, which is coated with carbon silicon layer to be coated with molybdenum silicide layer. The invention uses the high-temperature solid reaction disperse method to composite three materials, to realize the continuous gradient change from inner to outer. The invention has lower cost, less high-temperature creep, high high-temperature strengthen, and the application for high-temperature oxide area.

Owner:GUIYANG AL-MG DESIGN & RES INST

Molding method of tubular composite material part

InactiveCN107020760AImprove working conditionsLow costDomestic articlesMaterials processingMechanical engineering

The invention relates to the field of machining and molding of materials, in particular to a molding method of a tubular composite material part. The method comprises the following steps: 1) mounting a special molding tool in a tubular rigid mould; 2) calculating the size of a core model; 3) sequentially wrapping a molding air bag, a nylon film and predregs on the core model; 4) removing the core model and putting into the tubular rigid mould; 5) placing fluid joints at the two ends of the air bag and tying the fluid joints by using high-temperature adhesive tapes; 6) introducing high-temperature gas or liquid into the air bag. According to the molding method of the tubular composite material part, internal stress caused by uneven heating of required products is avoided, the expansive and heavy rigid mould is abandoned, the labor conditions of workers are improved, the energy consumption is reduced to 90% or above, mould and energy source cost are saved, and the price competitive advantage of products is improved.

Owner:TAISHAN SPORTS IND GRP +1

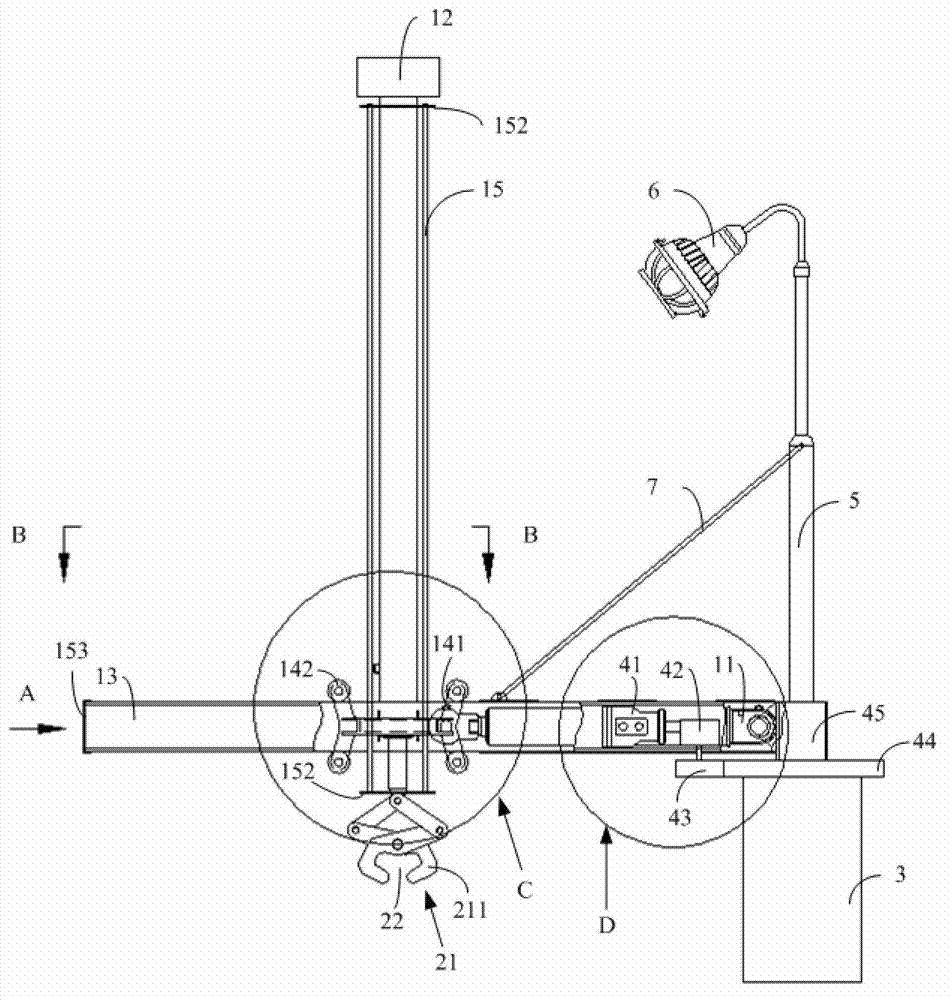

Lifting device and long steel rail transport vehicle set

InactiveCN102963378AAvoid internal stressPrecise hydraulic power controlRailway device loading/unloadingInternal stressAutomotive engineering

The invention provides a lifting device and a long steel rail transport vehicle set, wherein the lifting device comprises a hydraulic power component and a clamping component; the hydraulic power component is movably arranged on the long steel rail transport vehicle set and can move horizontally and vertically relative to the long steel rail transport vehicle set; the clamping component is connected with the hydraulic power component; the hydraulic power component drives the clamping component to move; and the clamping component is used for clamping steel rails. According to the lifting device, the hydraulic power component serves as a power source, the hydraulic power can be controlled precisely, the movement is sensitive, and a rigid acting force can be provided, so that internal stresses of the steel rails in a curve state are overcome in the handling process, the probability of shaking and straightening trends of the lifting device is low, and the safety in the operation process is improved.

Owner:CRRC SHENYANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com