Preparation method of metal organic framework/nanofiber with bead-like structure

A metal-organic framework and nanofiber technology, which is applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problem of not controlling the crystal structure and morphology well, maintaining the polyhedral structure of MOF derivatives, and reducing the utilization rate of metal salts and other problems, to achieve the effect of solving difficult integrated utilization, improving physical and chemical properties, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a metal organic framework / nanofiber with a beaded structure.

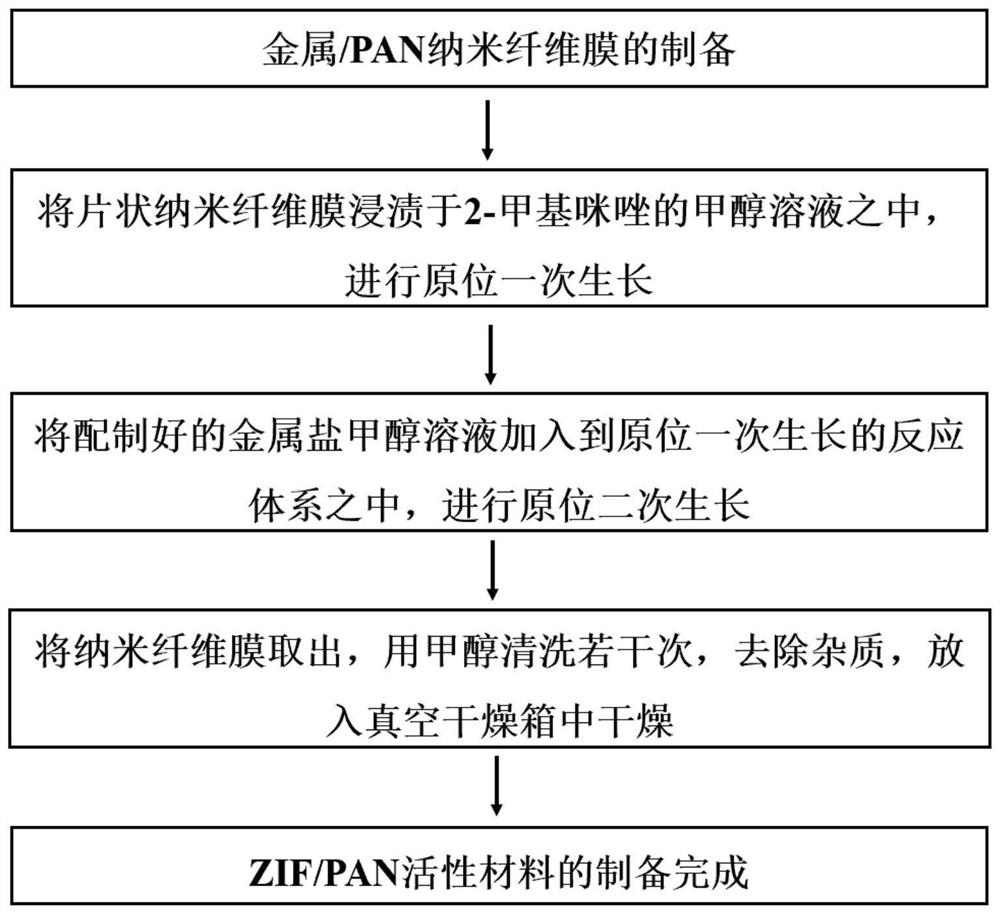

[0025] Such as figure 1 As shown, the method includes the following steps:

[0026] (1) Preparation of metal / PAN spinning solution: first, add DMF organic solvent in a glass bottle, under the condition of uniform stirring, add metal salt to the solvent, after the metal salt is dissolved, slowly add PAN, at a speed of 200 Stir evenly in a magnetic stirrer at ~1000rpm for 8~24h to obtain metal / PAN spinning solution;

[0027] (2) Synthesis of metal / PAN nanofibers by electrospinning technology: transfer the metal / PAN spinning solution obtained in step (1) to the syringe, adjust the advancing speed, receiving distance and electrospinning voltage, and perform double-needle spinning, The metal / PAN nanofiber membrane is obtained by electrospinning technology, and the obtained nanofiber membrane is dried in a vacuum oven at 50-100°C for 12-24 hours;

[0028] (3) Obtain...

Embodiment 1

[0032] A ZIF / PAN nanofiber electrode material with beaded structure based on candied haws and a preparation method thereof, comprising the following steps:

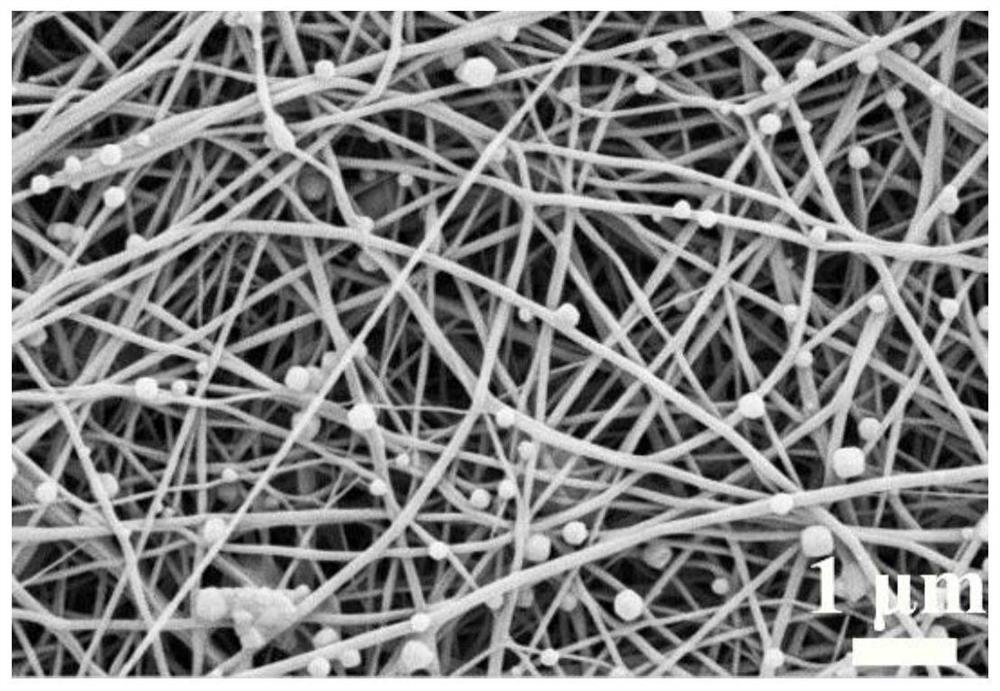

[0033] ZIF-67 / PAN nanofiber composites with "dotted" distribution were prepared by one-time growth of in-situ metal salts:

[0034] (1) Preparation of Co 2+ / PAN / spinning solution: 0.5g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 0.9g PAN were dissolved in 10mL DMF, stirred evenly at room temperature for 12h to obtain Co 2+ / PAN spinning solution;

[0035] (2) Preparation of Co 2+ / PAN / nanofiber composite film: the resulting Co 2+ The / PAN spinning solution was transferred to two 5mL syringes for double-needle spinning, the advancing speed was 0.08mm / min, the receiving distance was 15cm, and the voltage was 17kV. The obtained nanofibers were dried in a vacuum oven at 80 °C for 12 h to obtain Co 2+ / PAN / nanofiber membrane;

[0036] (3) Preparation of a methanol solution of 2-methylimidazole: add 6.6 g of 2-methylimid...

Embodiment 2

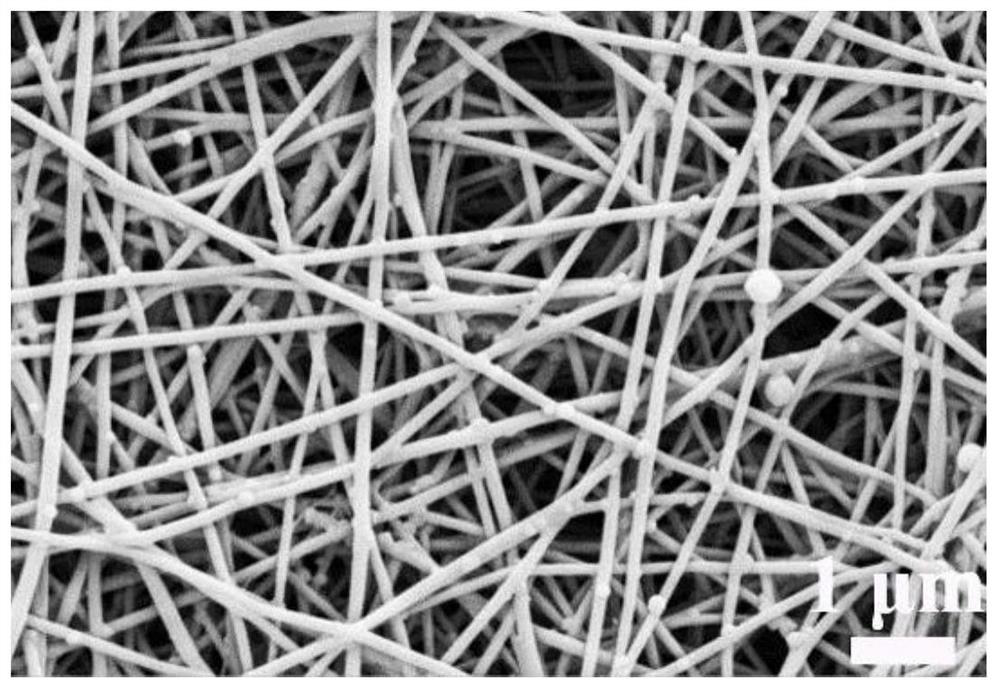

[0039] A grape-type beaded structure ZIF / PAN nanofiber material and a preparation method thereof, comprising steps as follows:

[0040] The ZIF-67-ZIF-8 bimetallic ZIF material with "dotted" distribution was prepared by in situ mixed metal salt growth method:

[0041] (1) Preparation of Co 2+ -Zn 2+ / PAN spinning solution: 0.25g Co(NO 3 ) 2 ·6H 2 O, 0.25g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.9g PAN were dissolved in 10mL DMF, stirred evenly at room temperature for 12h to obtain Co 2+ -Zn 2+ / PAN spinning solution;

[0042] (2) Preparation of Co 2+ -Zn 2+ / PAN nanofiber composite film: the resulting Co 2+ -Zn 2+ The / PAN spinning solution was transferred to two 5mL syringes for double-needle spinning, the advancing speed was 0.08mm / min, the receiving distance was 15cm, and the voltage was 17kV. The obtained nanofibers were dried in a vacuum oven at 80 °C for 12 h to obtain Co 2+ -Zn 2+ / PAN nanofiber membrane;

[0043] (3) Preparation of a methanol solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com