Accurate control system and method for synchronous jack-up main jacks for aircraft

A technology of synchronous jacking and precise control, applied in the sequence/logic controller program control, electrical program control, lifting device and other directions, can solve the problems that the function can not meet the actual needs, the tolerance is poor, the synchronization accuracy is poor, etc. Achieve the effect of shortening maintenance preparation time, high fault tolerance and reliability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

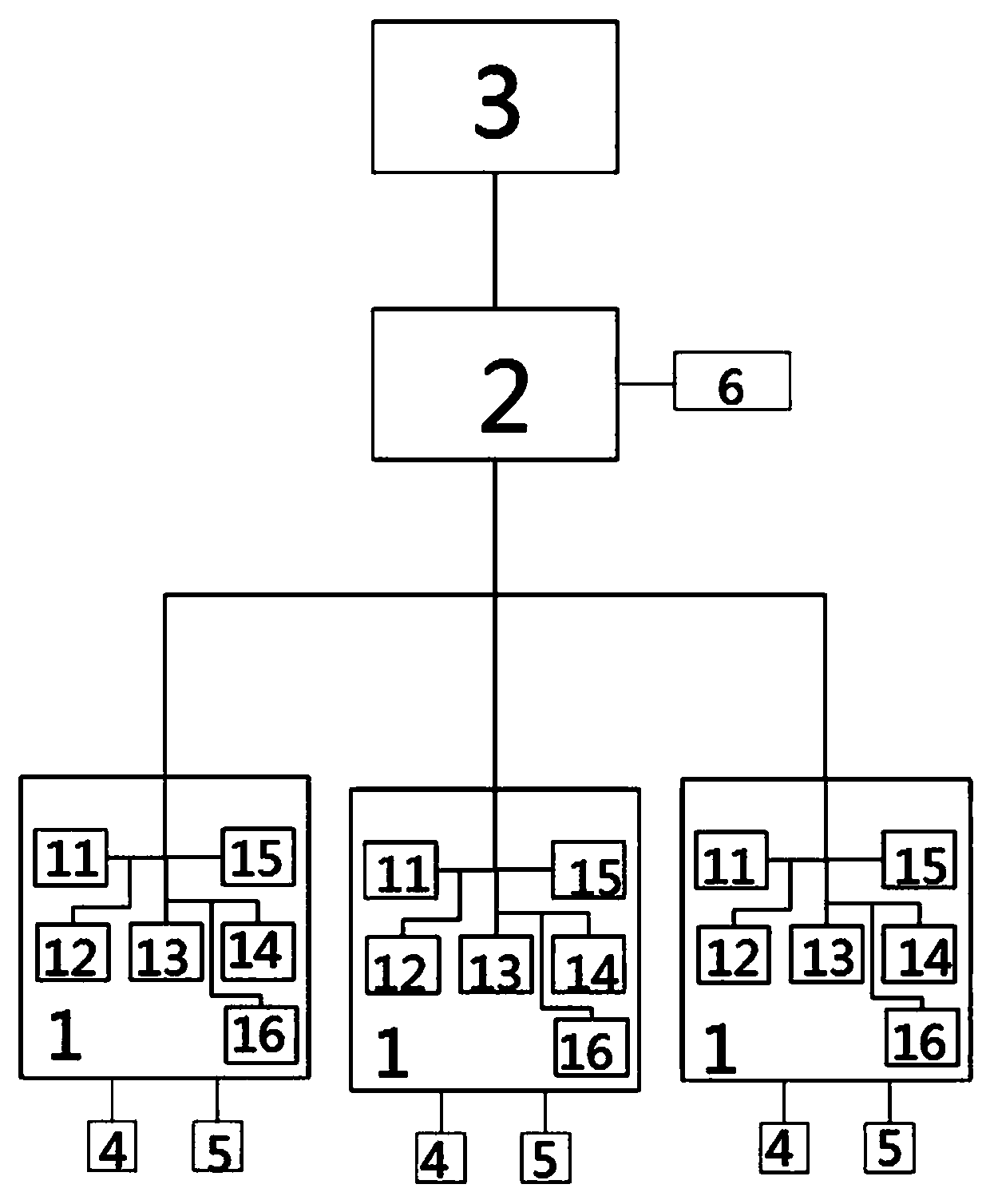

[0051] Such as figure 1 As shown, in this embodiment, a pressure sensor 4 is also provided on the actuator, and the pressure sensor 4 is electrically connected to the PLC controller 2; and the pipeline connecting the servo motor and the actuator of the main jack 1 is also provided There is a temperature sensor 5 which is electrically connected to the PLC controller 2.

[0052] The control terminal 3 may be a touch screen, a handheld controller, a notebook computer, a PC, etc.

[0053] An alarm 6 is also provided on the control terminal 3, and the alarm 6 is electrically connected to the PLC controller 2.

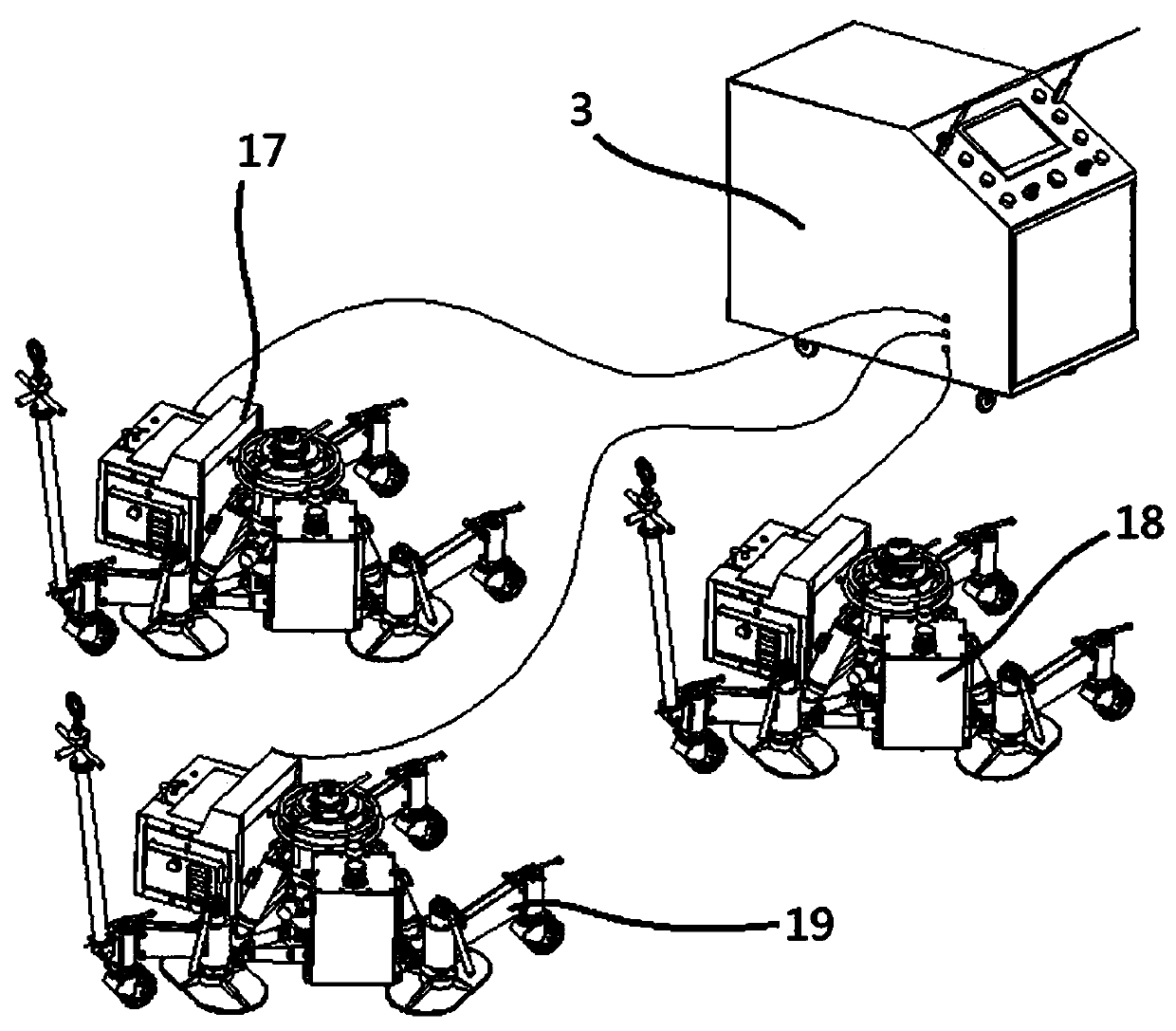

[0054] The system of the present invention includes three main jacks 1: a first front main jack 17, a second front main jack 18, and a rear main jack 19.

[0055] The system of this embodiment has the following functions:

[0056] (1) The alignment function of the ball socket on the supporting head of each main jack 1 and the quasi-aircraft ball head:

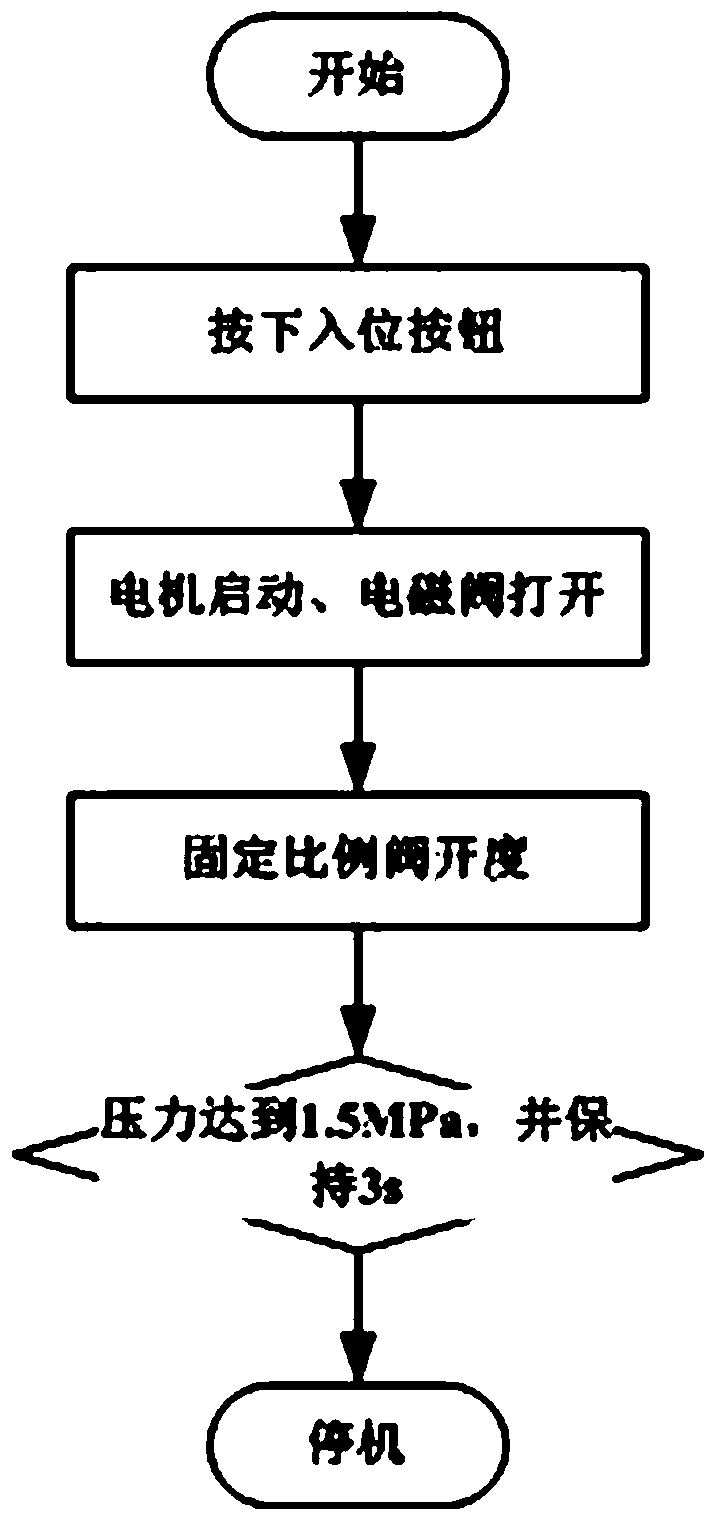

[0057] Such as image 3 As show...

Embodiment 2

[0069] Such as figure 1 As shown, as a preferred embodiment of the above embodiment, in this embodiment, a manual reversing valve 15 is also provided on the pipeline connecting the servo motor and the main jack 1 actuator cylinder, and the manual reversing valve 15 is connected to the PLC The controller 2 is electrically connected.

[0070] The control terminal 3 may be a touch screen, a handheld controller, a notebook computer, a PC, etc.

[0071] A speed regulating valve 16 is also provided on the pipeline connecting the servo motor and the actuator cylinder of the main jack 1, and the speed regulating valve 16 is electrically connected to the PLC controller 2

[0072] The system includes three main jacks 1: the first front main jack 17, the second front main jack 18, and the rear main jack 19.

[0073] A pressure sensor 4 is also provided on the actuator, which is electrically connected to the PLC controller 2, and a temperature sensor 5 is also provided on the pipeline connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com