Patents

Literature

94results about How to "Increase oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

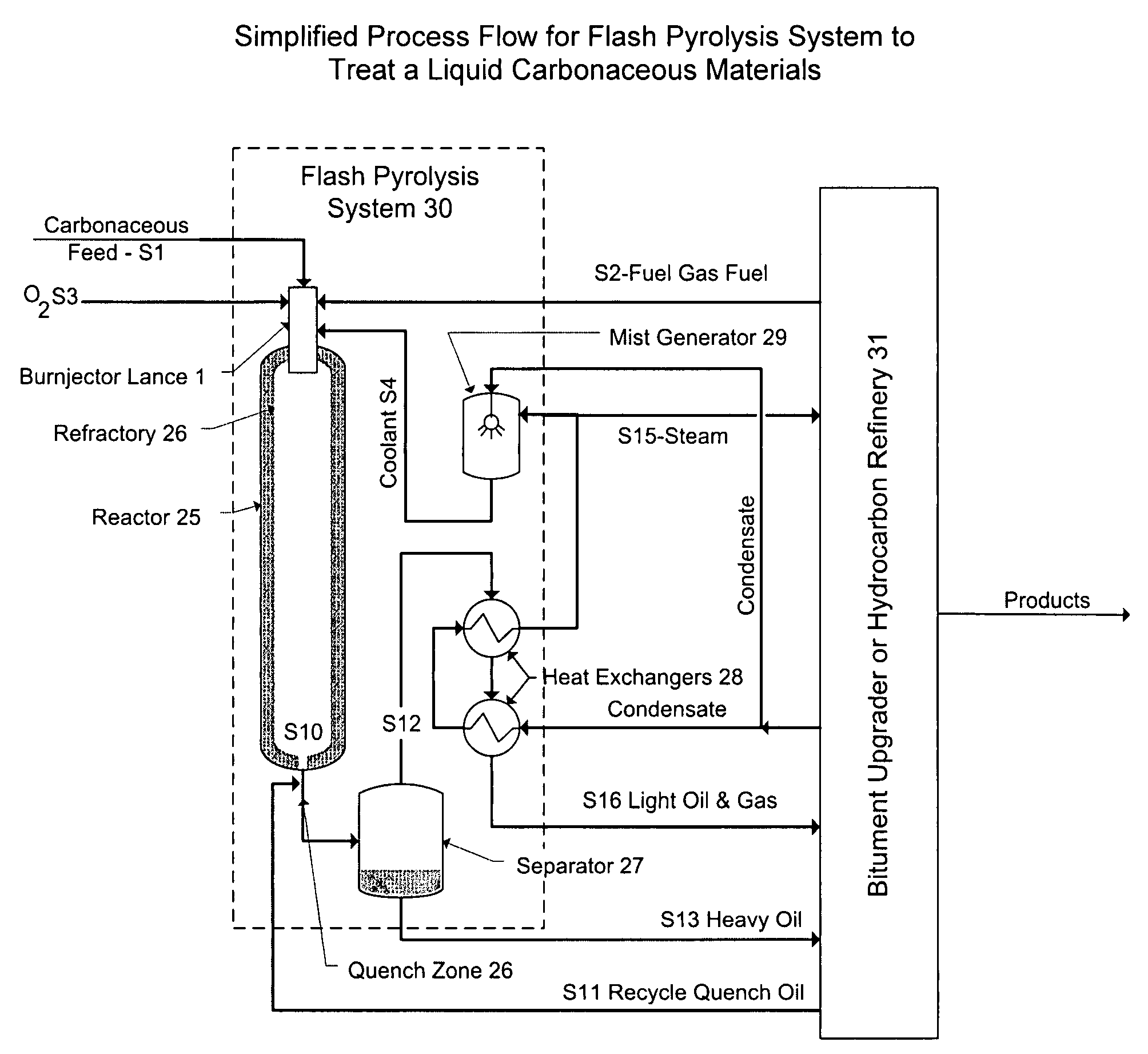

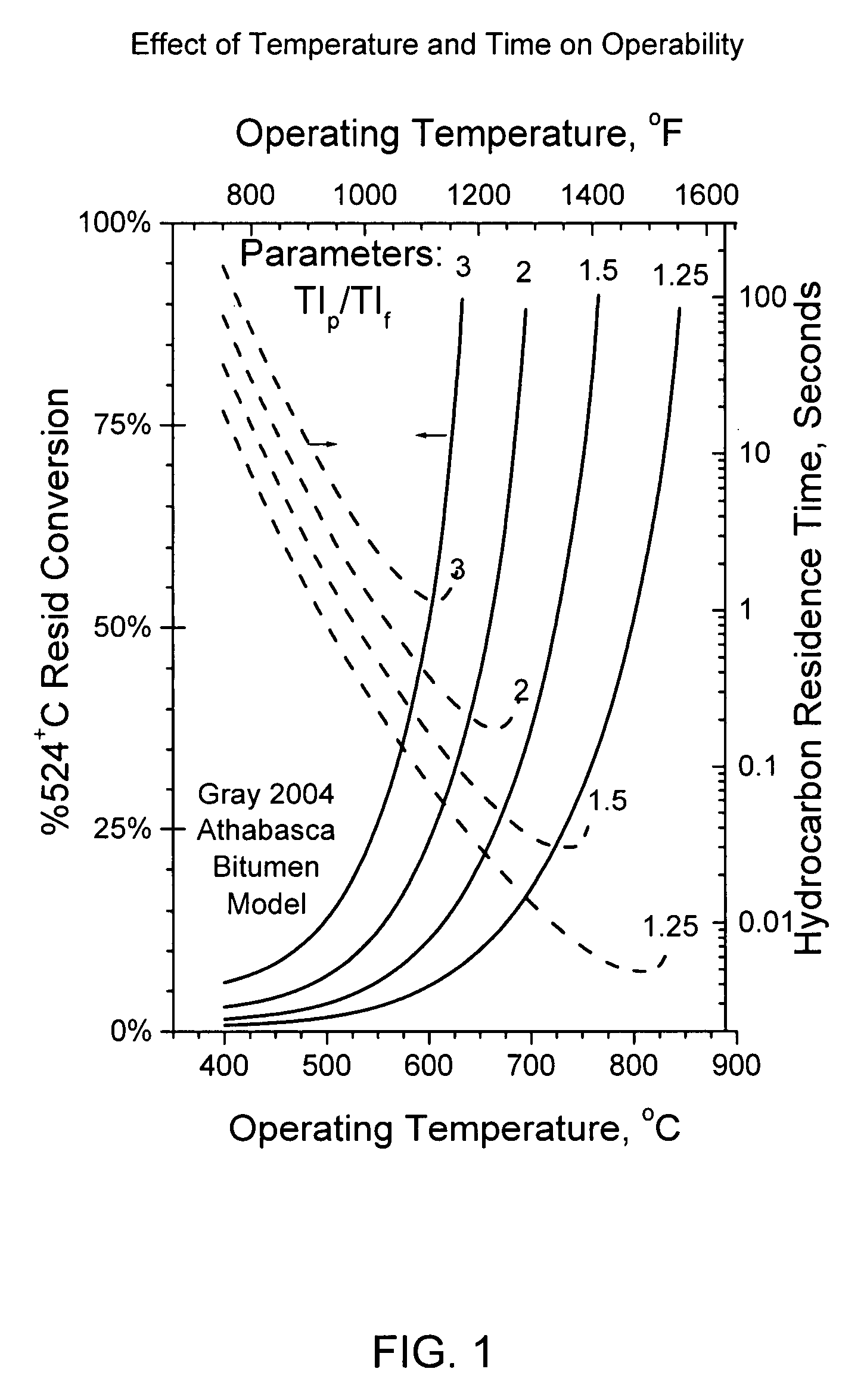

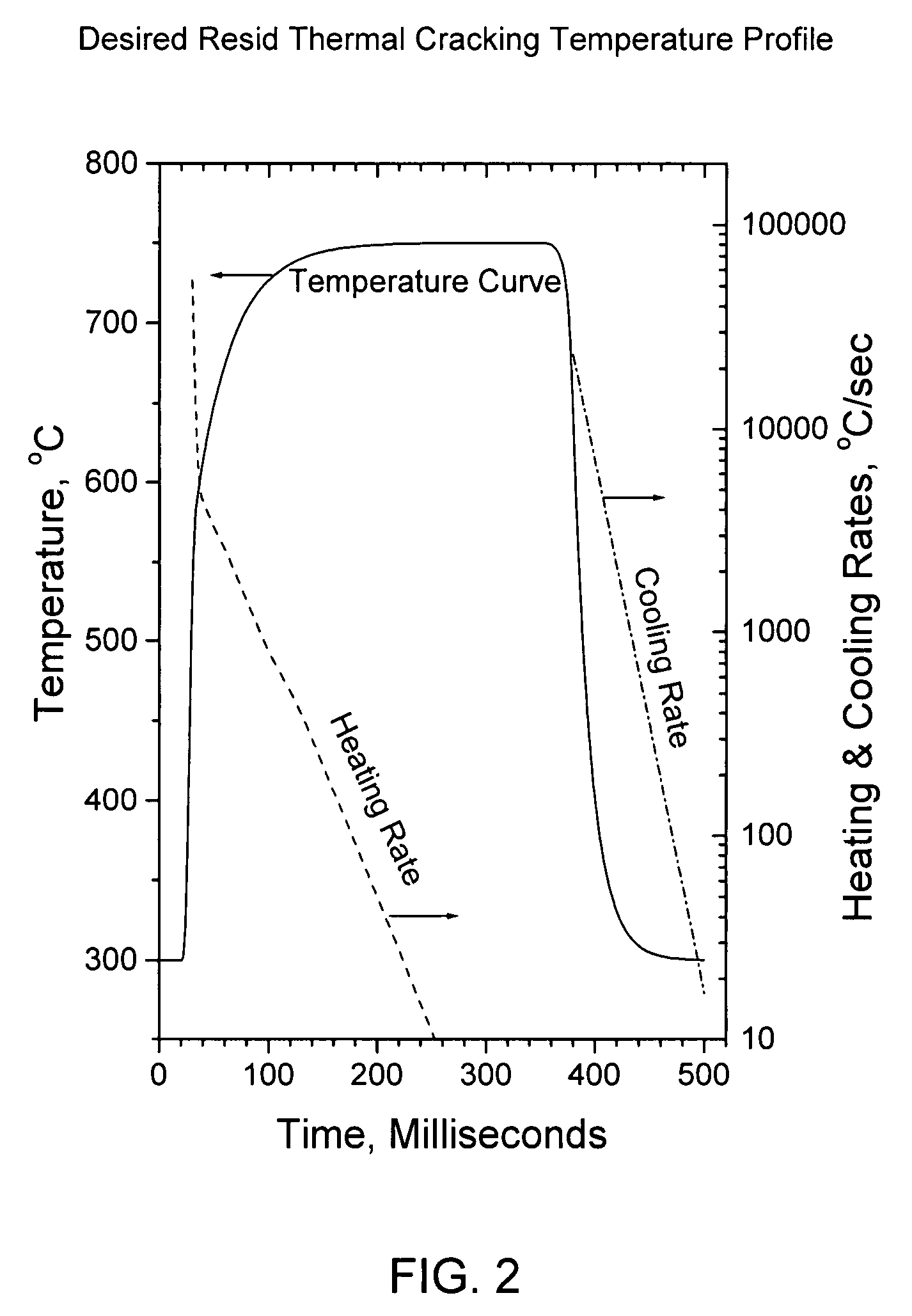

Flash pyrolosis method for carbonaceous materials

InactiveUS20070272538A1Efficient transferFast heatingThermal non-catalytic crackingDirect heating destructive distillationSufficient timeBoiling point

Methods are disclosed for pyrolizing carbonaceous materials to carbonaceous materials having lower boiling points by heating the carbonaceous material to a desired reaction temperature and holding the carbonaceous material in contact with the heat for a sufficient time to achieve the desired reaction to a lower boiling point carbonaceous materials, then rapidly cooling the desired reaction products. The heating source is a jet which will provide hot and high velocity gas streams to the carbonaceous material to be heated.

Owner:BOC GRP INC

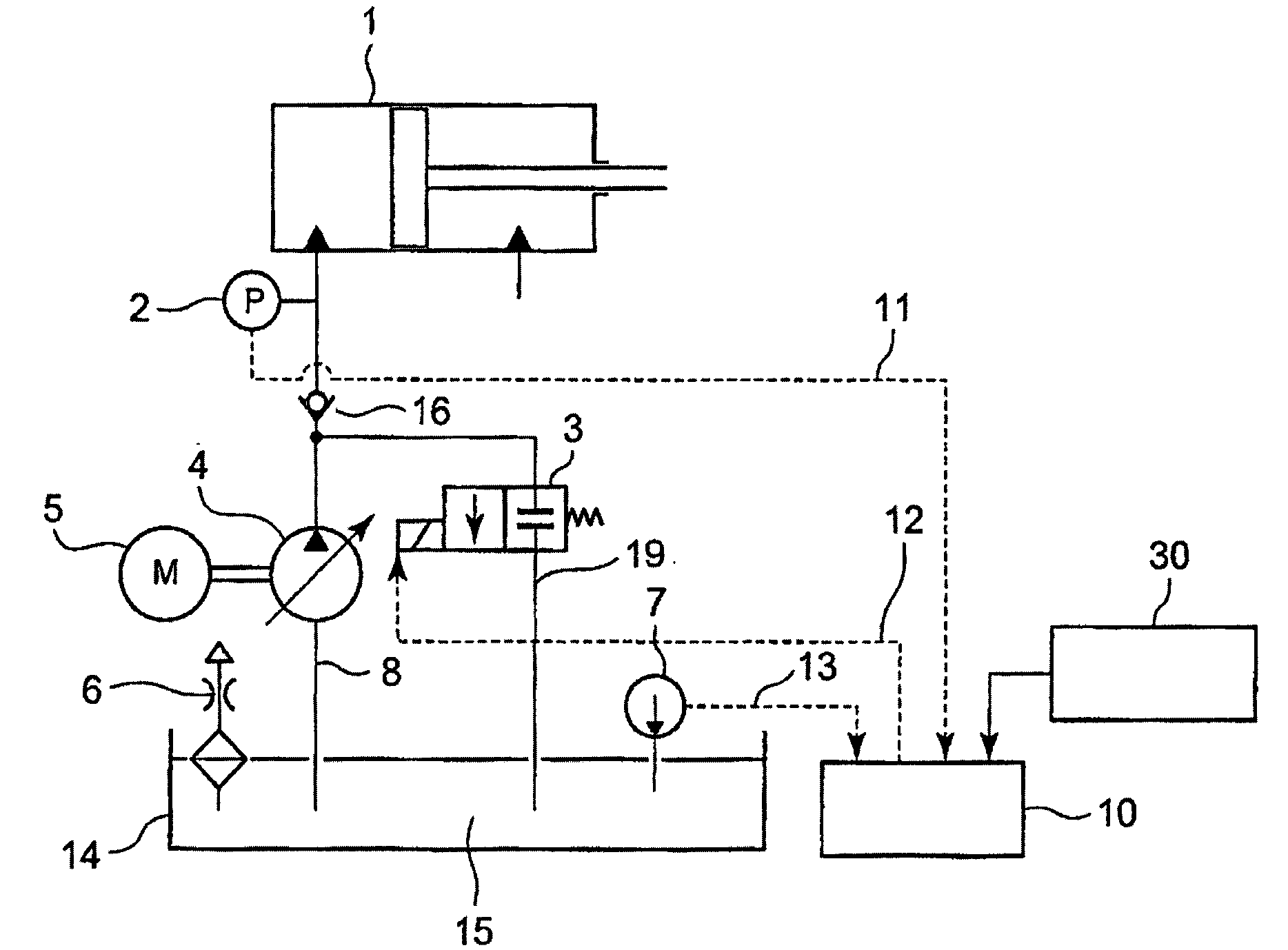

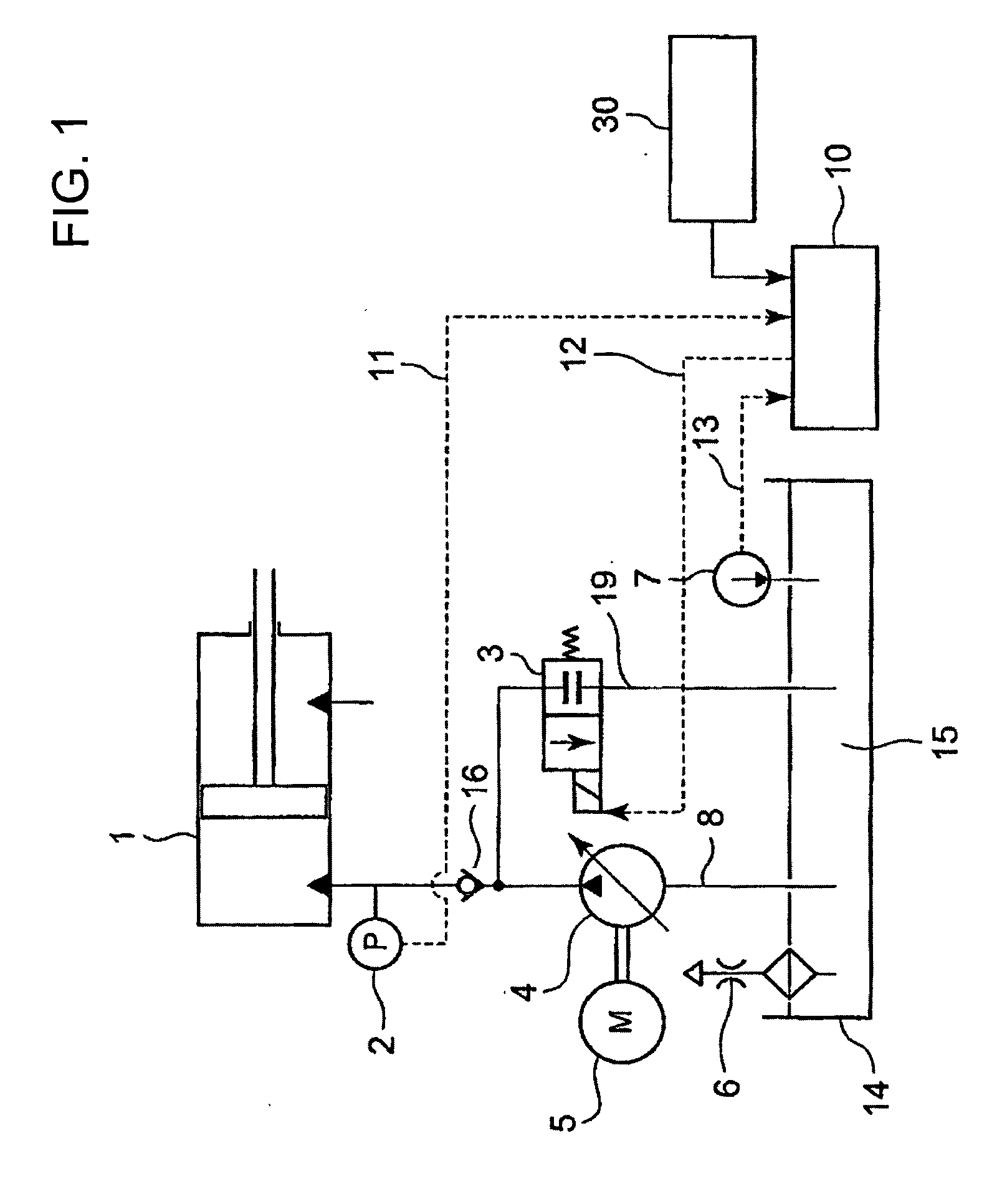

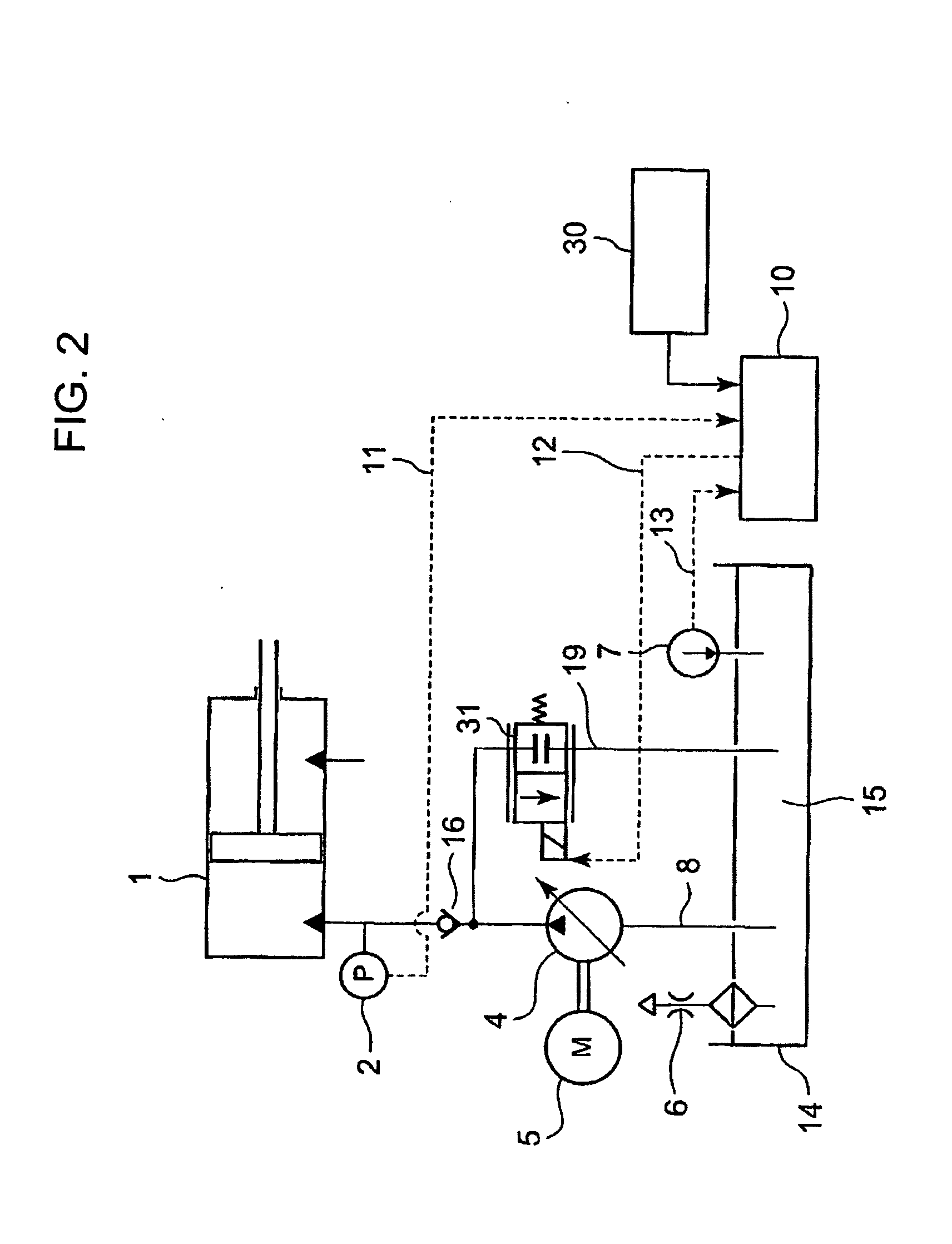

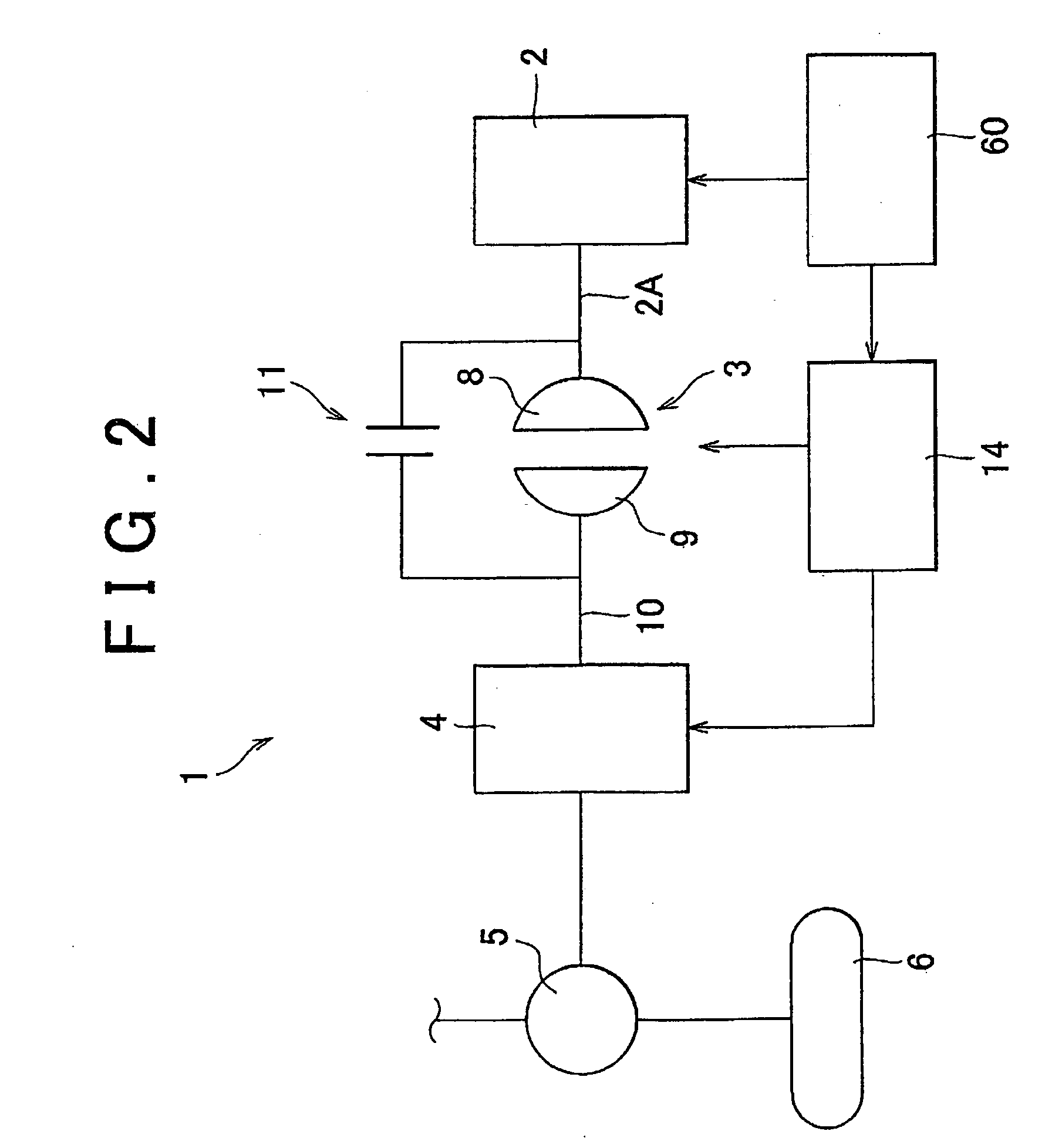

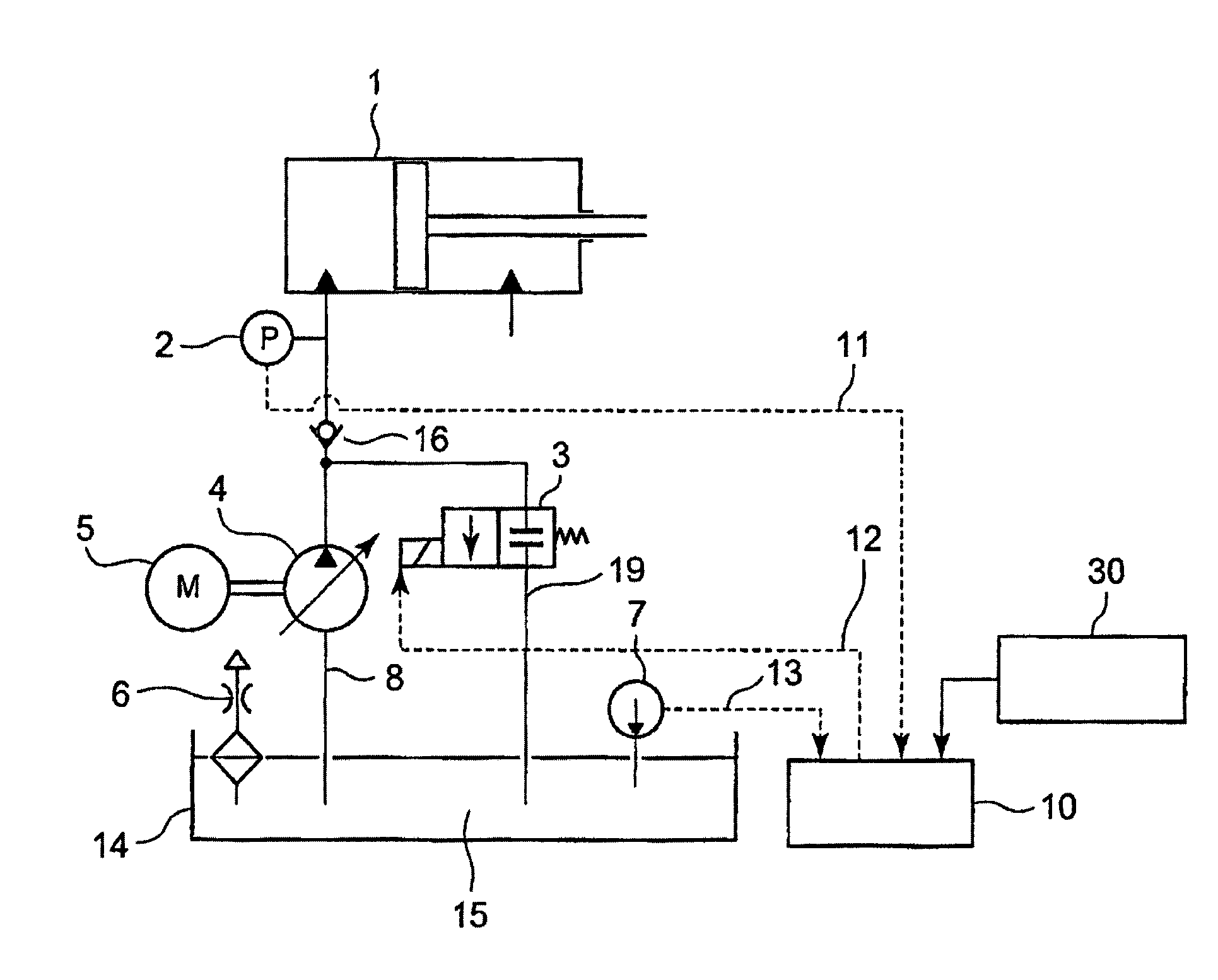

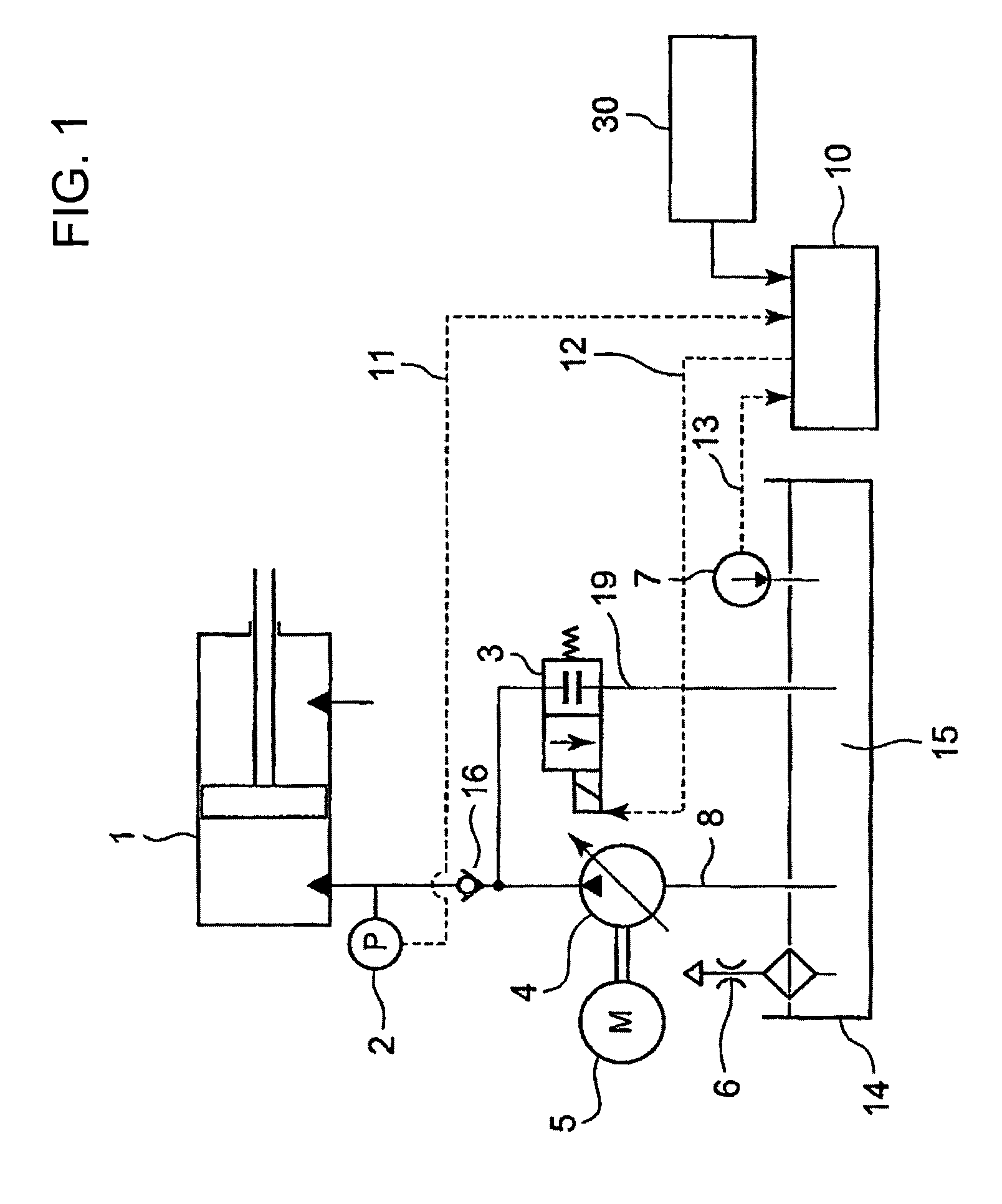

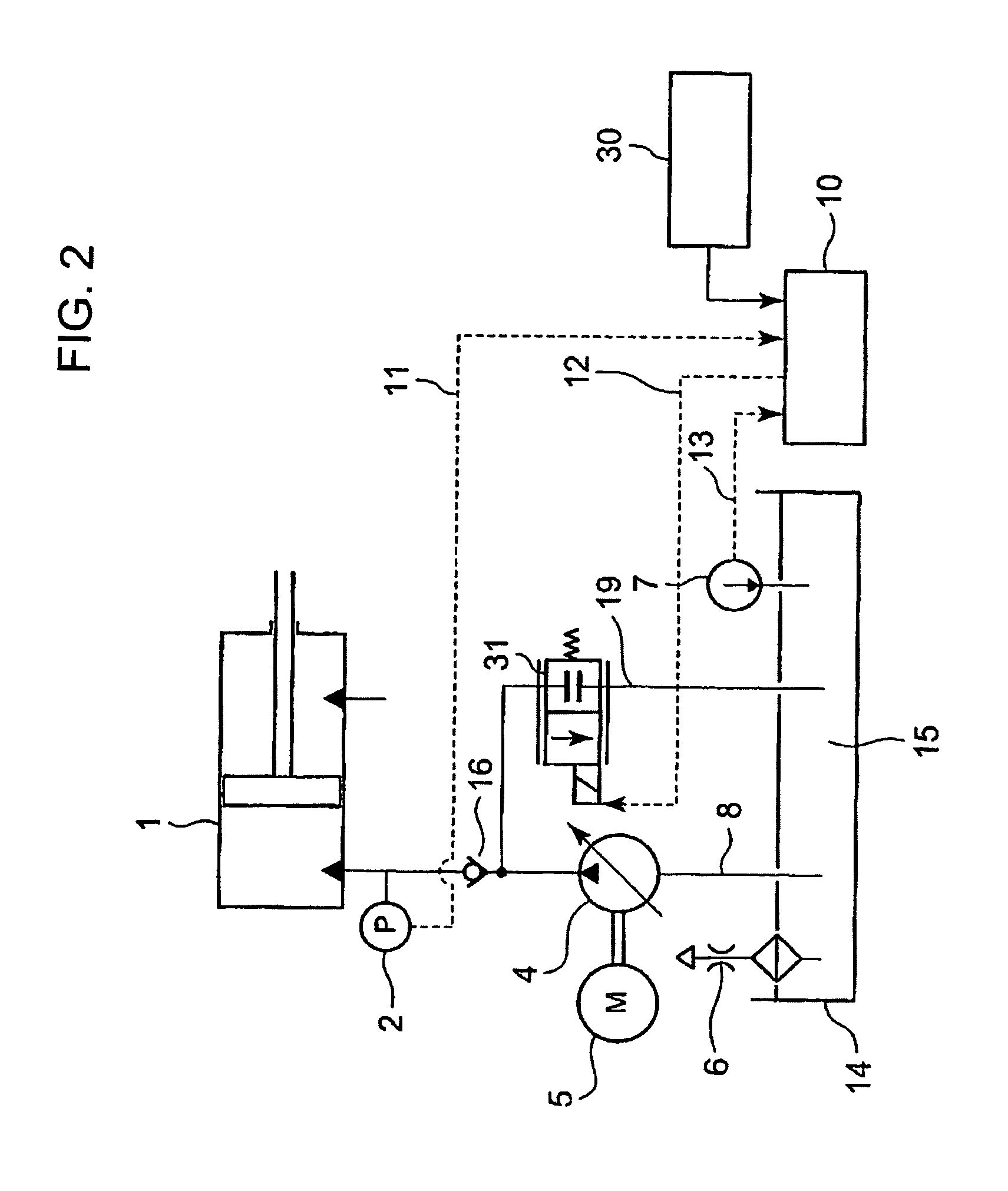

Hydraulic system and wind turbine generator provided therewith

ActiveUS20100104439A1Improve cold start performanceStartabilityPropellersWind motor controlFuel tankHydraulic pump

There is provided a hydraulic pump startup control device in a hydraulic system, which avoids an overloaded state at startup to enable low-temperature, fast startup and maintaining of the temperature with low-cost means in order to improve low-temperature startability. A bypass path 19 is placed in parallel with a hydraulic main line from a hydraulic tank, and the downstream of the bypass path is made merged with the hydraulic main line. A bypass valve 3 that opens or closes the bypass path is provided in the bypass path, and a pressure sensor is provided in the inlet of a hydraulic unit in the hydraulic main line. Further, a control device 10 to which a pressure detection value in the hydraulic main line is input from the pressure sensor to open the bypass valve based on the pressure detection value upon startup of the hydraulic unit. The control device repeats on-off control to circulate oil in the bypass path while keeping the pump discharge pressure and the flow rate to open the bypass path at startup so that the actuation power of the hydraulic unit will become the maximum in order to rise the hydraulic temperature of the hydraulic main line.

Owner:MITSUBISHI HEAVY IND LTD

Hydraulic control apparatus

ActiveUS20110046861A1Improve responsivenessIncrease oil temperatureDigital data processing detailsFluid actuated clutchesExecution controlBiological activation

A switching apparatus is provided in a hydraulic control apparatus having a fluid transmission apparatus; a lockup clutch; a switching valve that controls engagement of the lockup clutch; and a control oil pressure generation apparatus that pressurizes oil and outputs a control oil pressure to control activation of the switching valve. The switching apparatus executes a control to warm the oil input into the control oil pressure generation apparatus if the temperature of the oil is below a predetermined temperature and prohibits execution of the control to warm the oil input into the control oil pressure generation apparatus if the temperature of the oil equals or exceeds the predetermined temperature.

Owner:TOYOTA JIDOSHA KK

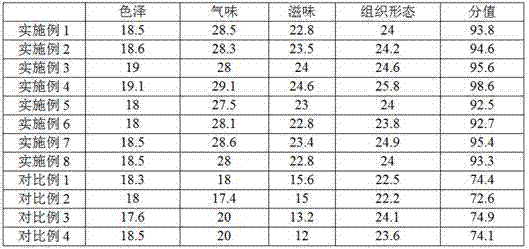

Spicy non-slag hotpot oil with sauce aroma and preparation method thereof

ActiveCN107006828AReduce aroma lossReduce odorLipidic food ingredientsNatural extract food ingredientsAllium fistulosumSOYBEAN SEED OIL

The invention discloses spicy non-slag hotpot oil with sauce aroma and a preparation method thereof and belongs to the field of hotpot condiments. The spicy non-slag hotpot oil with the sauce aroma comprises the following raw materials: soybean oil, palm oil, beef tallow, rapeseed oil, allium fistulosum, ginger, onion, sheep's-parsley, garlic, rock candy, fennel, cinnamon, anise, cumin, clove, black pepper, radix angelicae, Chinese prickly ash, pickled ginger, two-briers pepper, a new generation of pepper, Indian pepper, a broad-bean sauce, fermented soybeans, nutmeg, neolitsea ellipsoides allen, amomum tsao-ko, salt, white granulated sugar, aginomoto, a chicken essence, concentrated pork bone soup and Chinese white spirit. The prepared hotpot oil has a thick fragrance and a sauce aroma, and is spicy, and soft and mellow in taste.

Owner:郑州雪麦龙食品香料有限公司

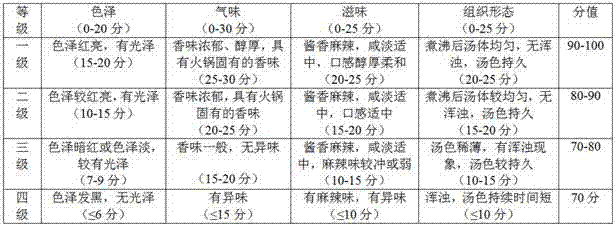

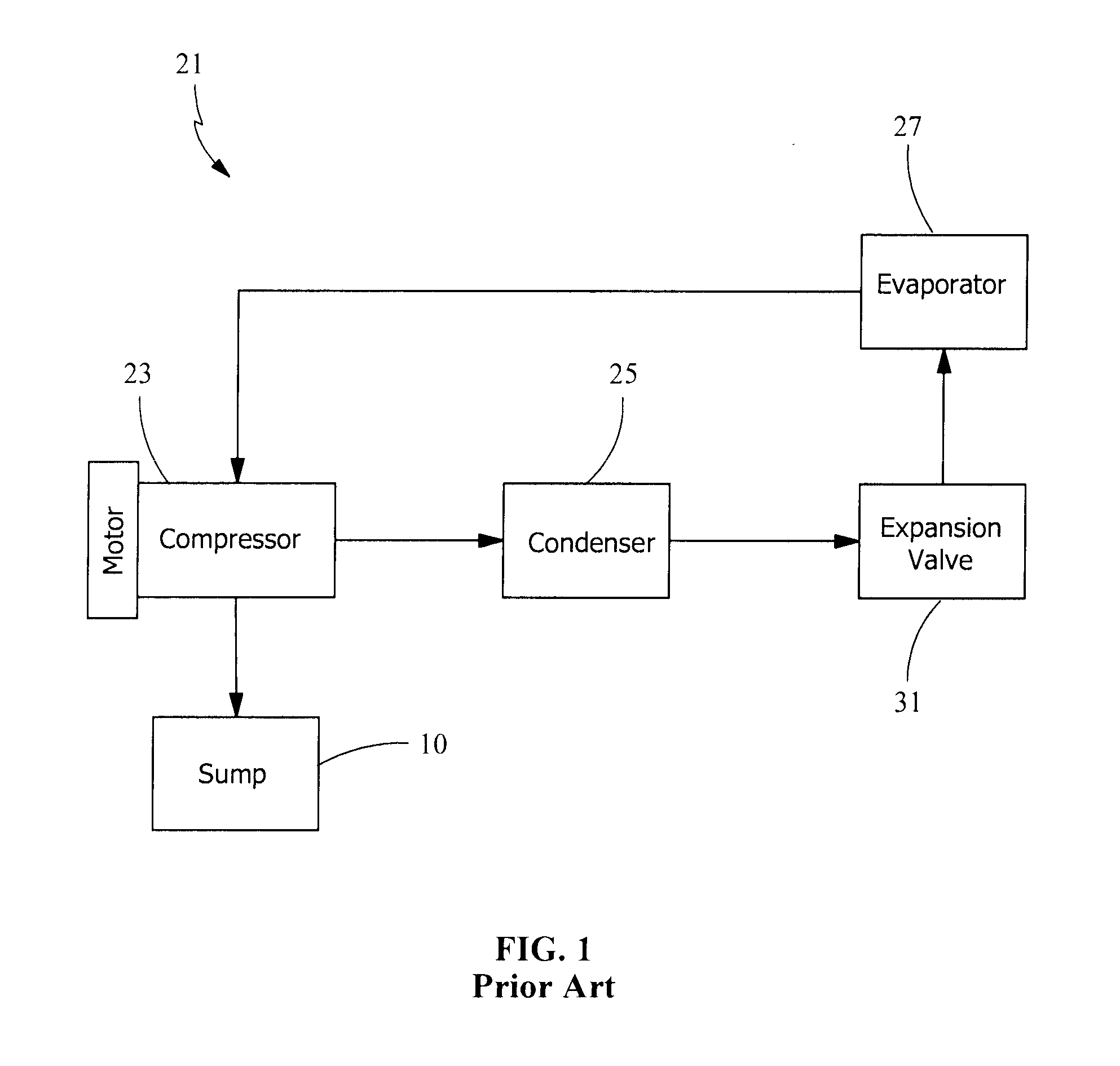

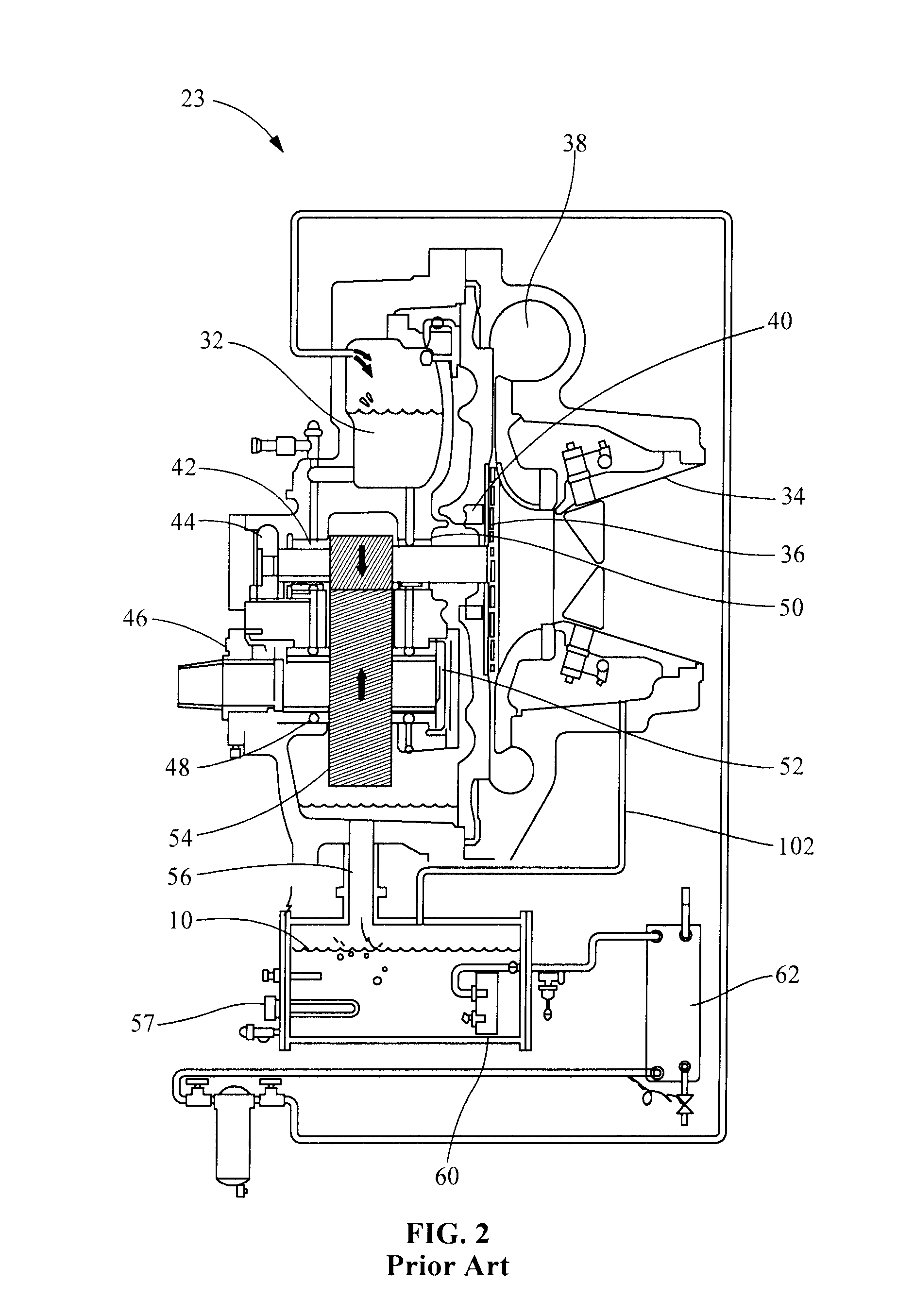

Lubrication and cooling system

ActiveUS20160003510A1Reduce pressureSolve absorptionCompressorPump componentsLubricationAutomotive engineering

A system for reducing the refrigerant pressure in an oil sump (10) or in a cavity (352) of a housing. The invention is particularly useful for reducing pressure in a compressor (23) for heat pump applications that has been validated for water chiller operations or in turbine and generator systems in ORC systems generating electricity using refrigerant, the ORC systems essentially being a heat pump application operating in reverse. An auxiliary compressor (509), an auxiliary condenser (709) or an ejector pump (609) may be used to reduce pressure in the oil sump (10), to separate refrigerant from oil. The auxiliary compressor (509), the auxiliary condenser (709) or the ejector pump (609) may also be used to reduce the pressure of refrigerant in the housing of a compressor in heat pump applications at temperatures and pressures at which the compressor was validated for water chiller applications and of the turbine and generator in ORC applications.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

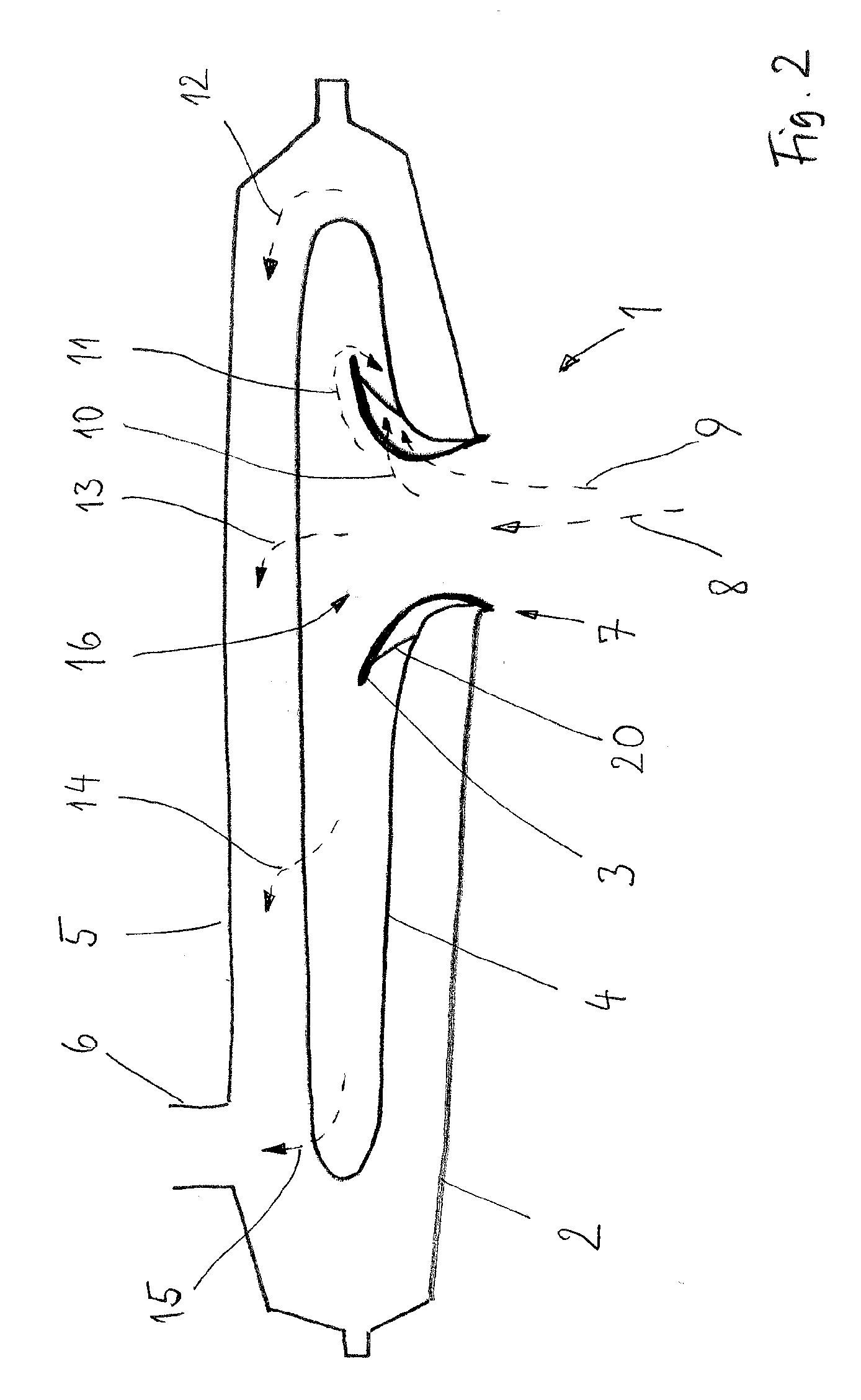

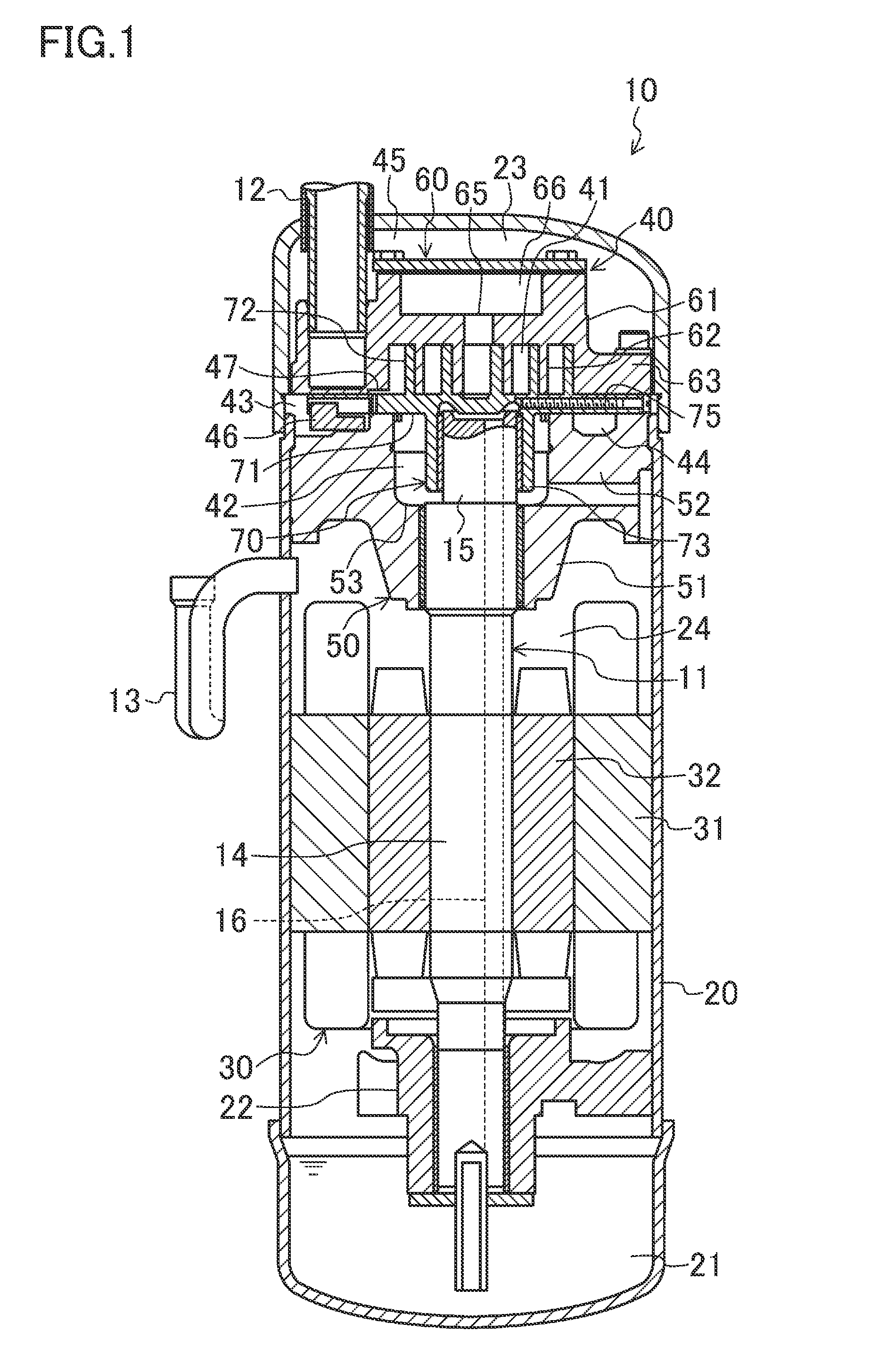

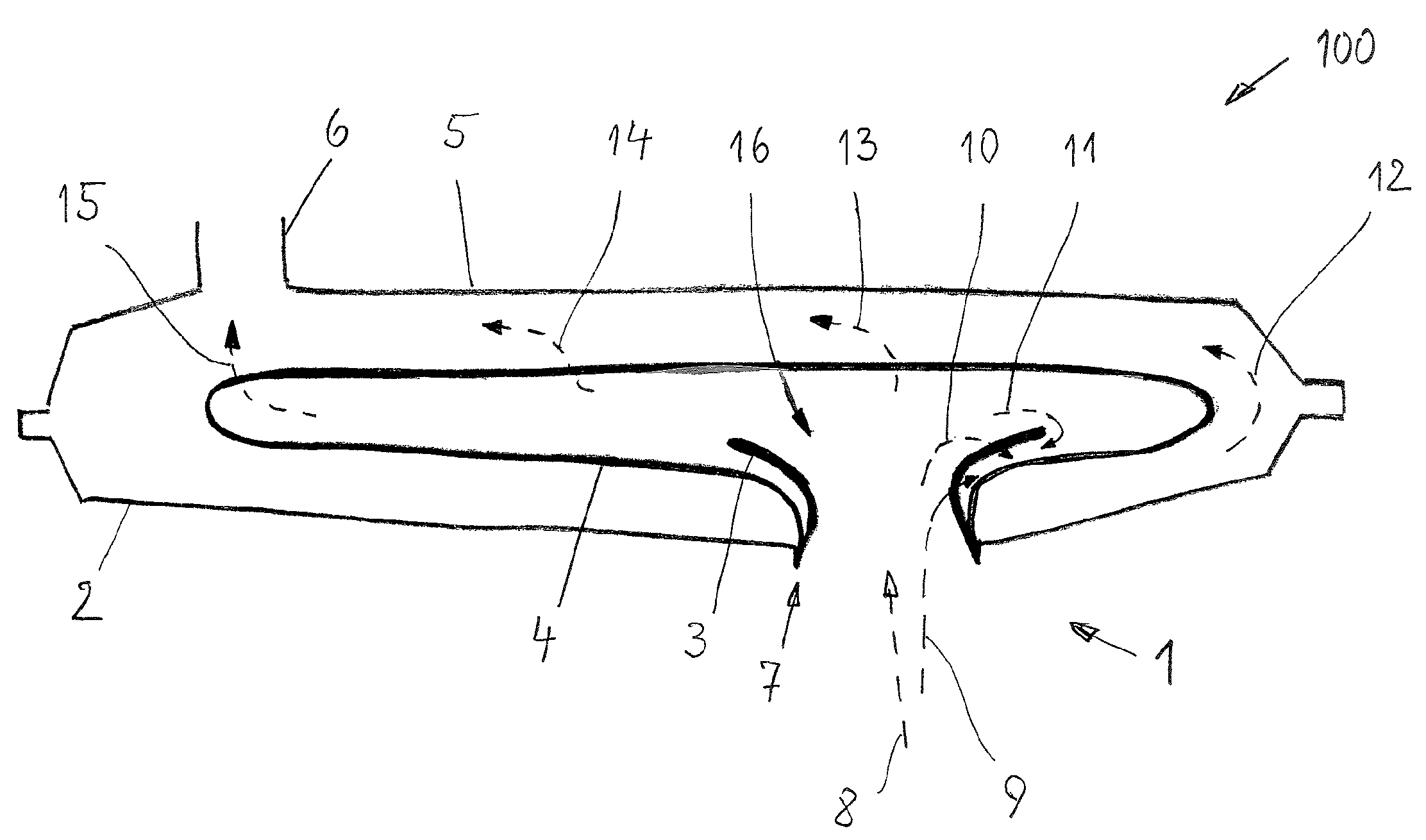

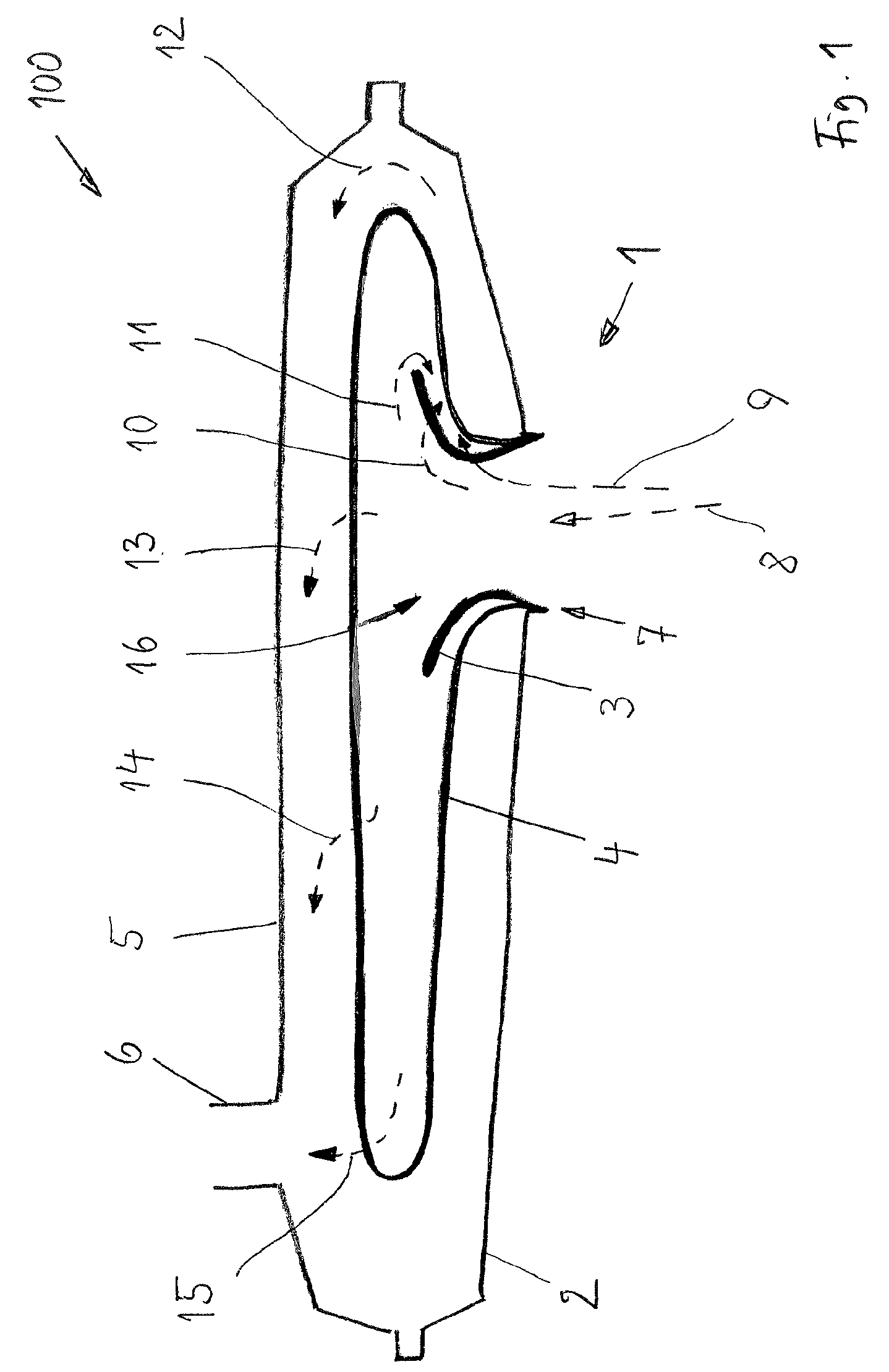

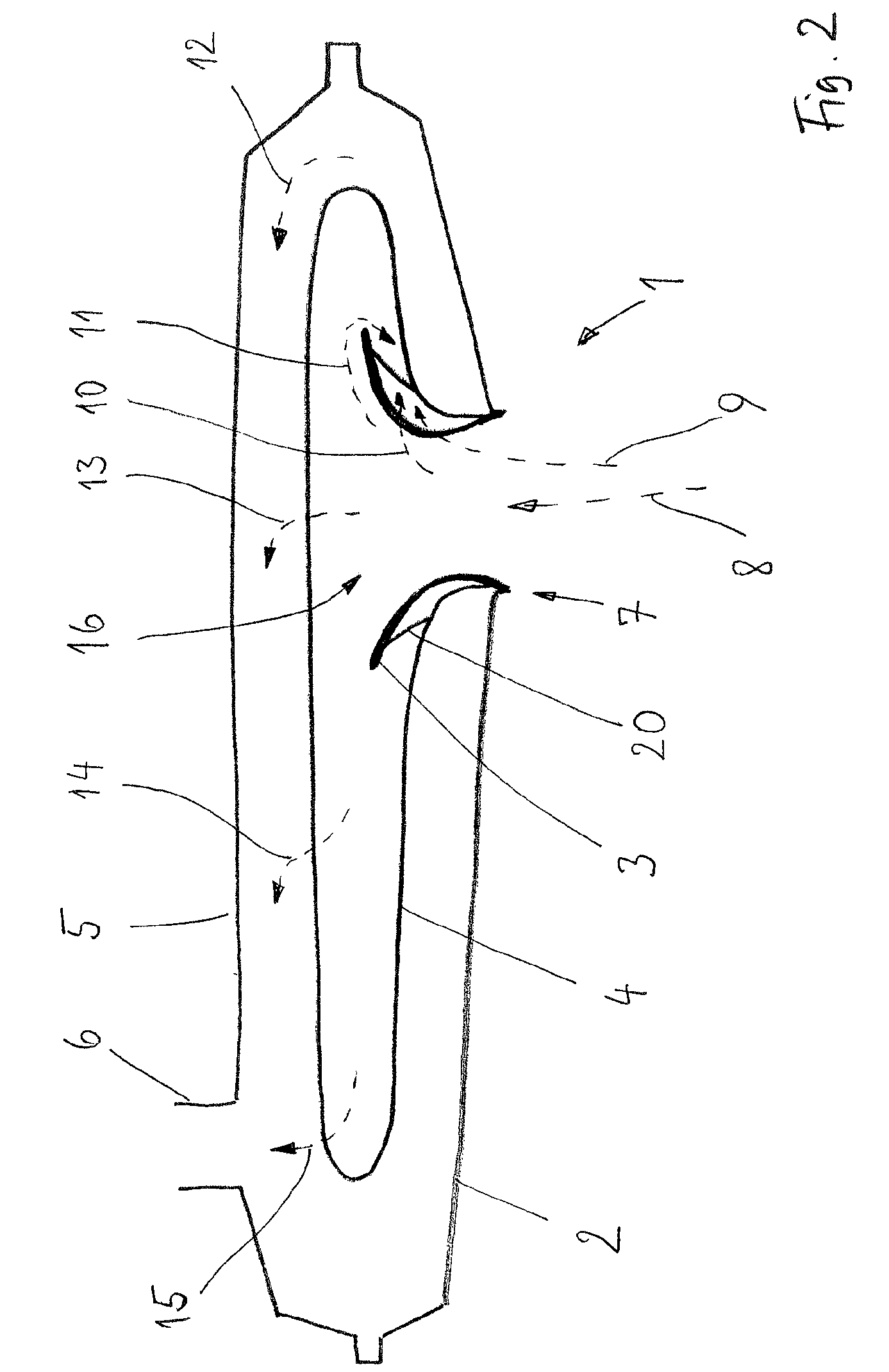

Oil filter device

ActiveUS20090230049A1Work lessImprove filtering effectMembrane filtersMachines/enginesFilter mediaOil filter

The present invention provides a suction oil filter device for an engine or a transmission that has an oil inlet and an oil outlet on the filter housing, a suction oil pump connectable to the oil outlet, using which a partial vacuum may be generated between oil inlet and oil outlet, a fine filter medium and an ultrafine filter medium, which are situated between the oil inlet and the oil outlet. The fine filter medium is attached to the oil inlet or to the oil outlet, and the ultrafine filter medium is situated before the fine filter medium in the flow direction and in a secondary flow area of the filter housing. A high filtration performance may thus be achieved at low production outlay.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

Underground ignition technology of combustion drive oil layer by injecting steam

ActiveCN101864938AAchieve high temperature and strong oxidation effectAchieve the purpose of ignitionFluid removalSteam pressureOil field

The invention relates to underground ignition technology of a combustion drive oil layer by injecting steam. Above 3000 meters oil layer, under a strong oxidation effect of the crude oil in the oil layer, the crude oil, namely carbohydrate, and the O2 at a high temperature generate CO2 plus H2O plus heat, thereby reaching the effect of displacement of reservoir oil. The injected steam is used for heating the oil layer so that the oil layer directly reaches the combustible temperature of oil with the help of the heat of the steam and air is directly injected, thus the high and strong oxidation effect that is combustion is generated. The carbon dioxide recombined with multiple drive oil layers is sent out. The thickness is less than 2 meters. A well section is arranged near the bottom of the oil layer. In addition the injection steam has the standard that a steam quantity is not less than 300cm<3>, the injection steam dryness is more than 5%, the injection steam temperature is more than 350 DEG C, and the injection steam pressure is between 2 and 20 MPa. The technology dispenses with physical simulation before ignition, manufactures the underground electric heater, shortens the ignition time and is high in success rate.

Owner:中嵘能源科技集团有限公司

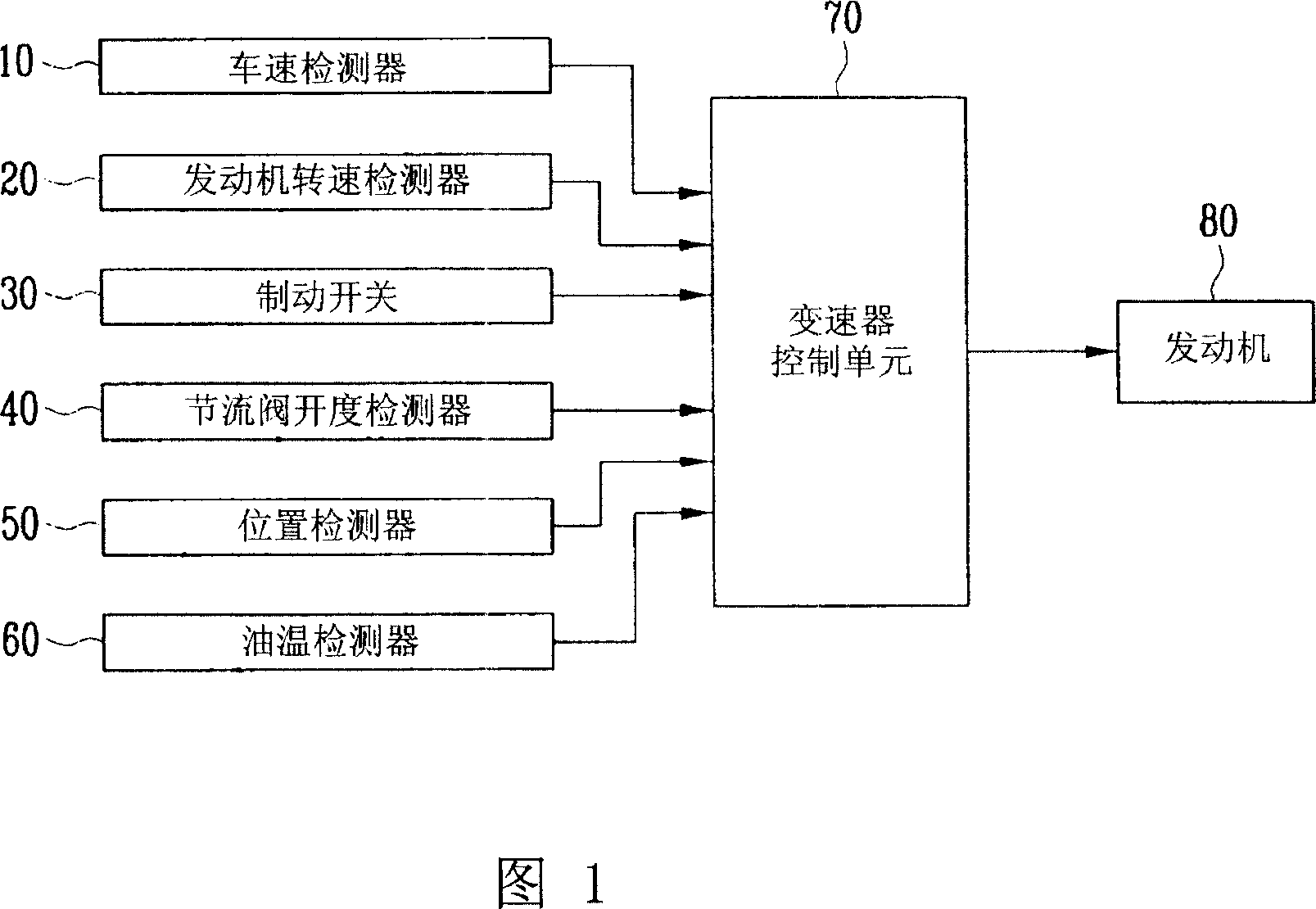

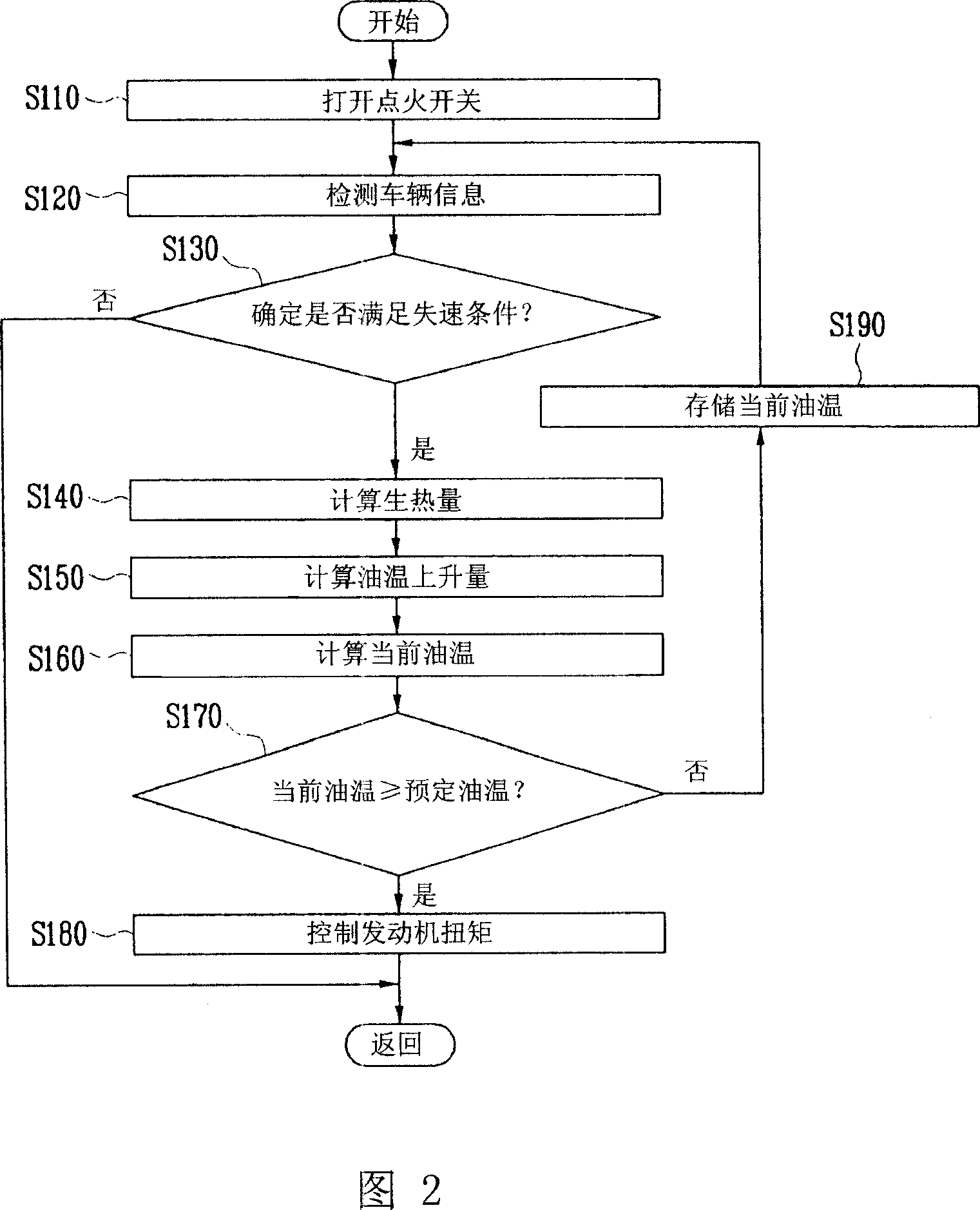

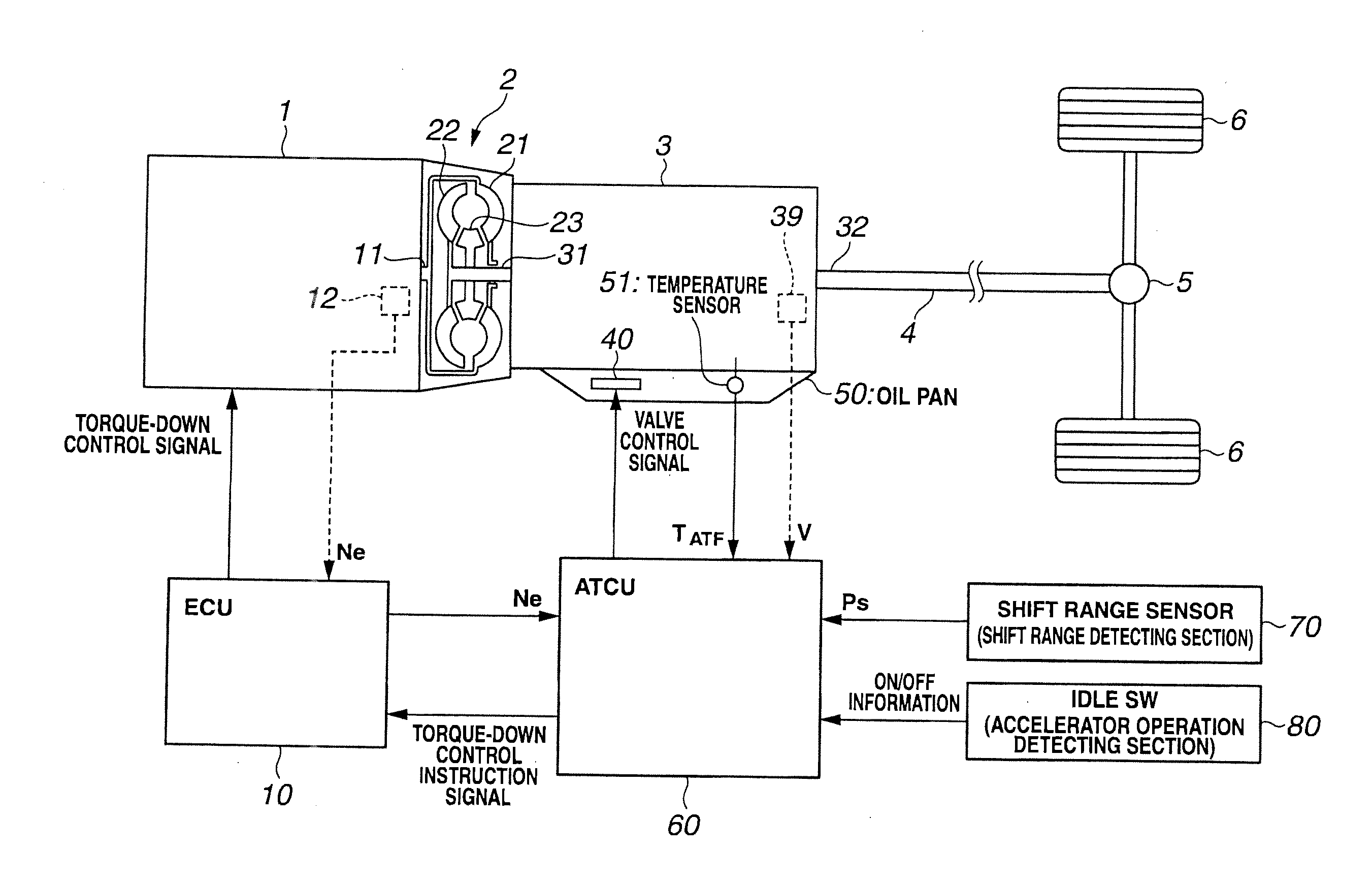

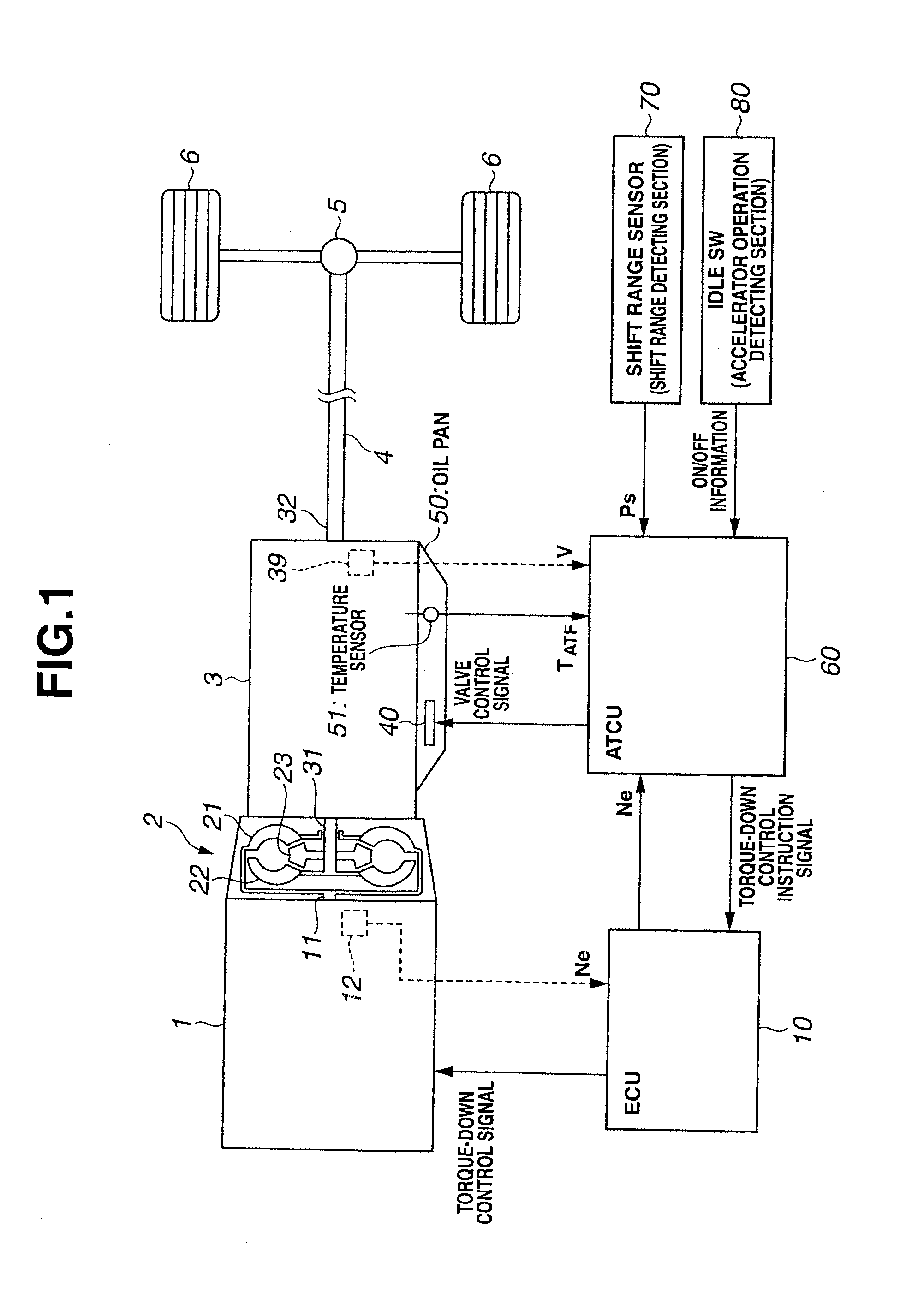

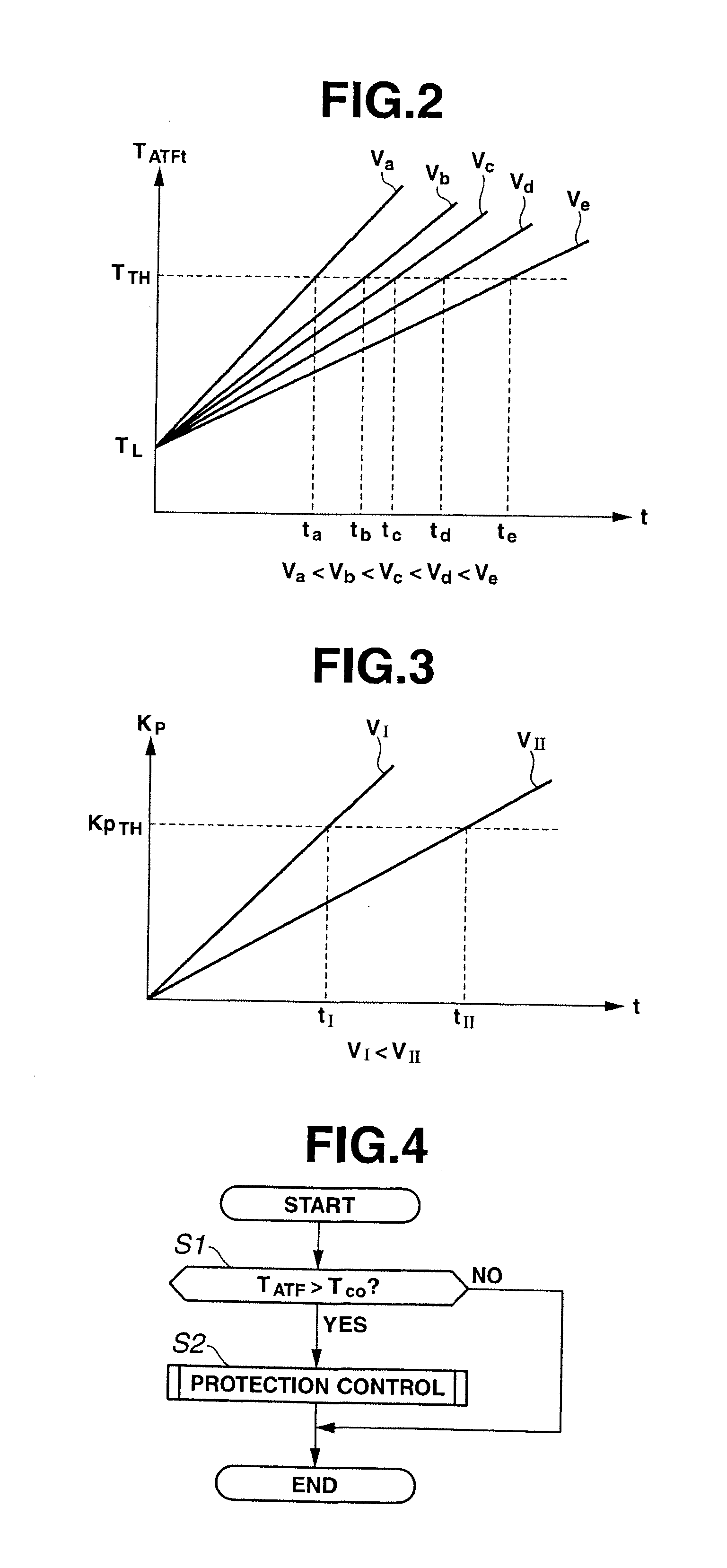

Method for controlling engine torque of automatic transmission for vehicles and system thereof

InactiveCN101118013AIncrease oil temperatureElectrical controlGearing controlAutomatic transmissionControl theory

A method and system of controlling an engine torque of an automatic transmission calculate a current oil temperature in a torque converter and restrict an engine torque based on the calculated current oil temperature if the torque converter is determined to be in a stall state. The method may include detecting vehicle information; determining whether a stall condition is satisfied; calculating, if the stall condition is satisfied, a current oil temperature in a torque converter; comparing the current oil temperature to a predetermined temperature; and controlling the engine torque when the current oil temperature is higher than or equal to the predetermined temperature.

Owner:HYUNDAI MOTOR CO LTD

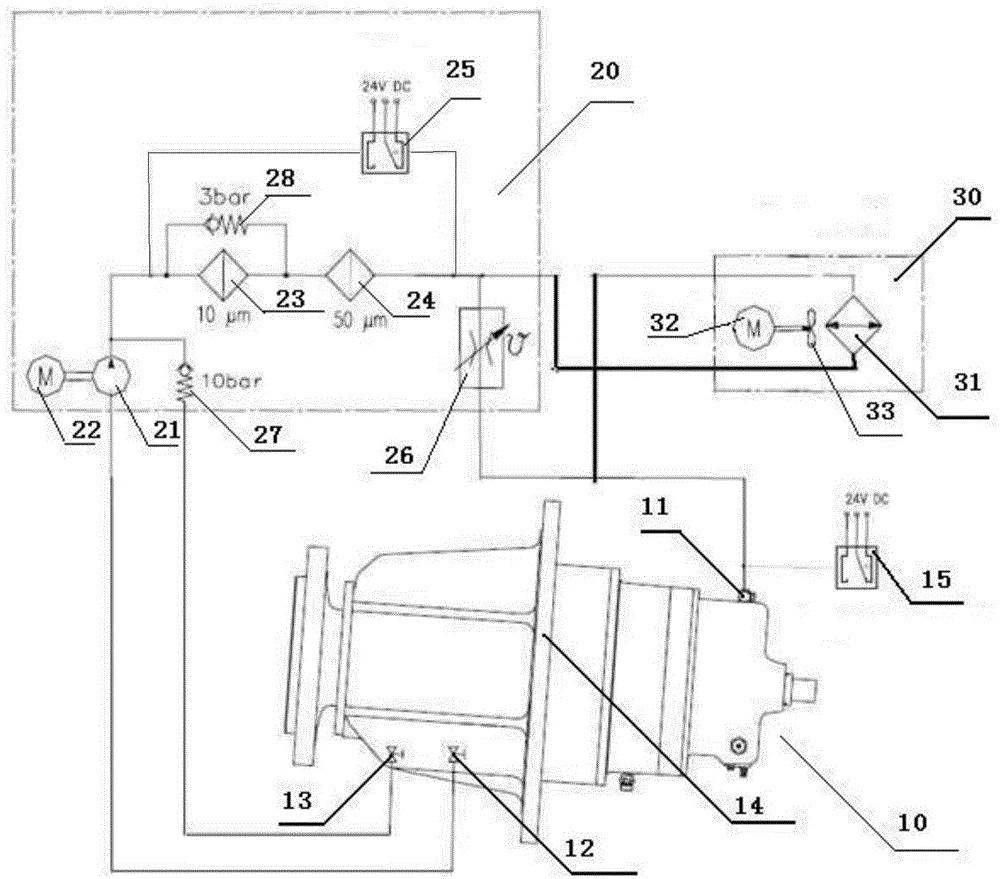

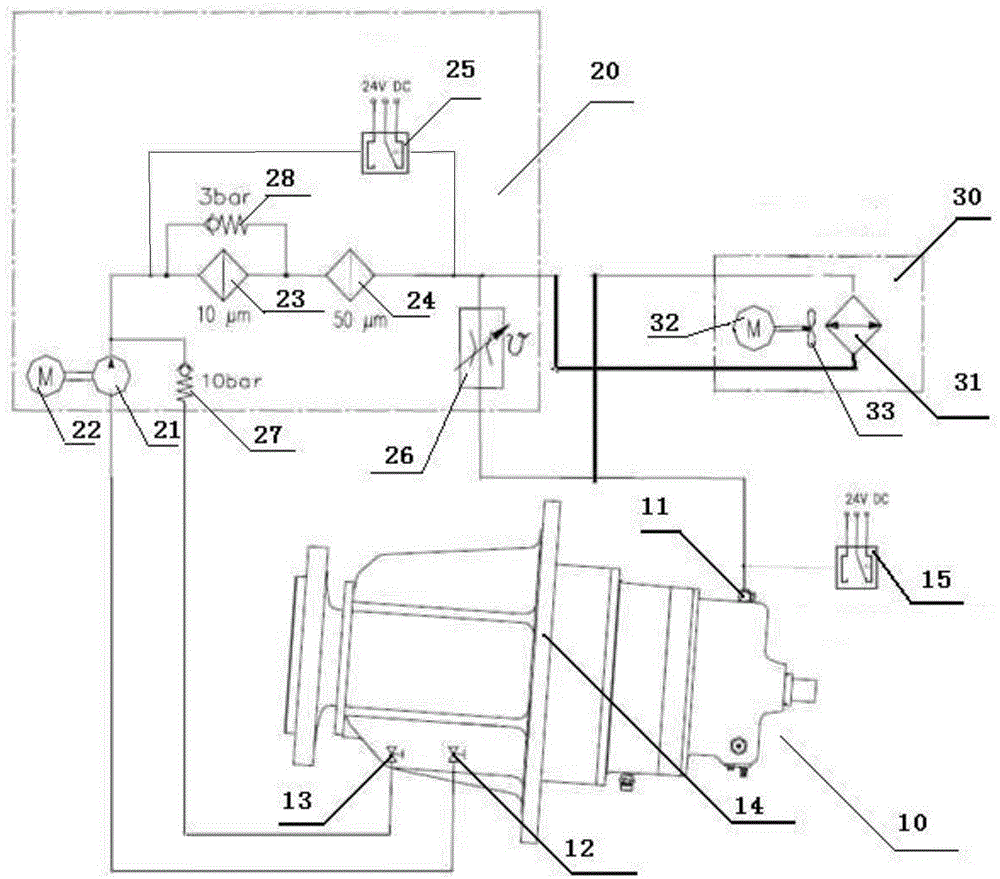

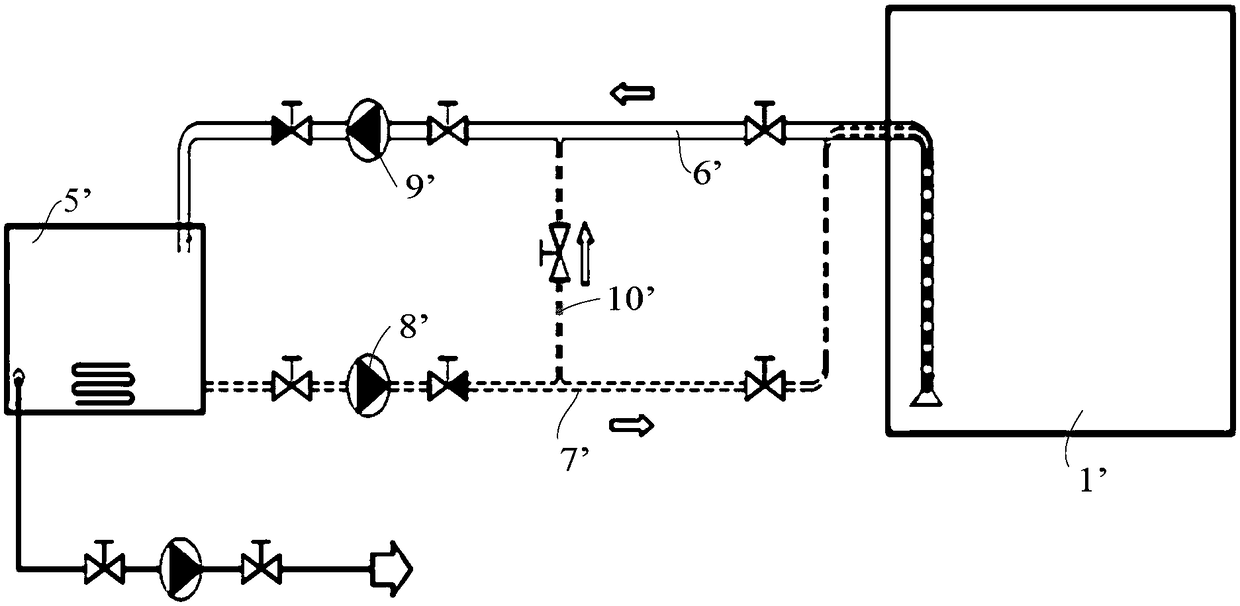

Cooling and dedusting method of gearbox lubricating and cooling system

ActiveCN104534072AEnergy savingSolve the insufficient utilization of cooling areaGear lubrication/coolingAutomatic controlChiller

A cooling and dedusting method of a gearbox lubricating and cooling system comprises the following steps that S1, the gearbox lubricating and cooling system is assembled; S2, the speed of an oil pump motor is regulated in the starting or running process; S3, dust and oil films bonded on a cooler and a cooler fan are removed. According to temperature information fed back by mounting in an oil tank of a gearbox, PID automatic control is carried out over the running frequency of the oil pump motor and a fan motor so that a frequency converter can control the running speed of the fan and the running torque of the oil pump motor. In the starting and running process of the oil pump motor, the oil pump motor is made to be started smoothly according to the temperature and viscosity condition of lubricating oil, and the aim of saving energy under the working condition of high temperature is achieved.

Owner:DALIAN SHINERGY SCI & TECH DEV

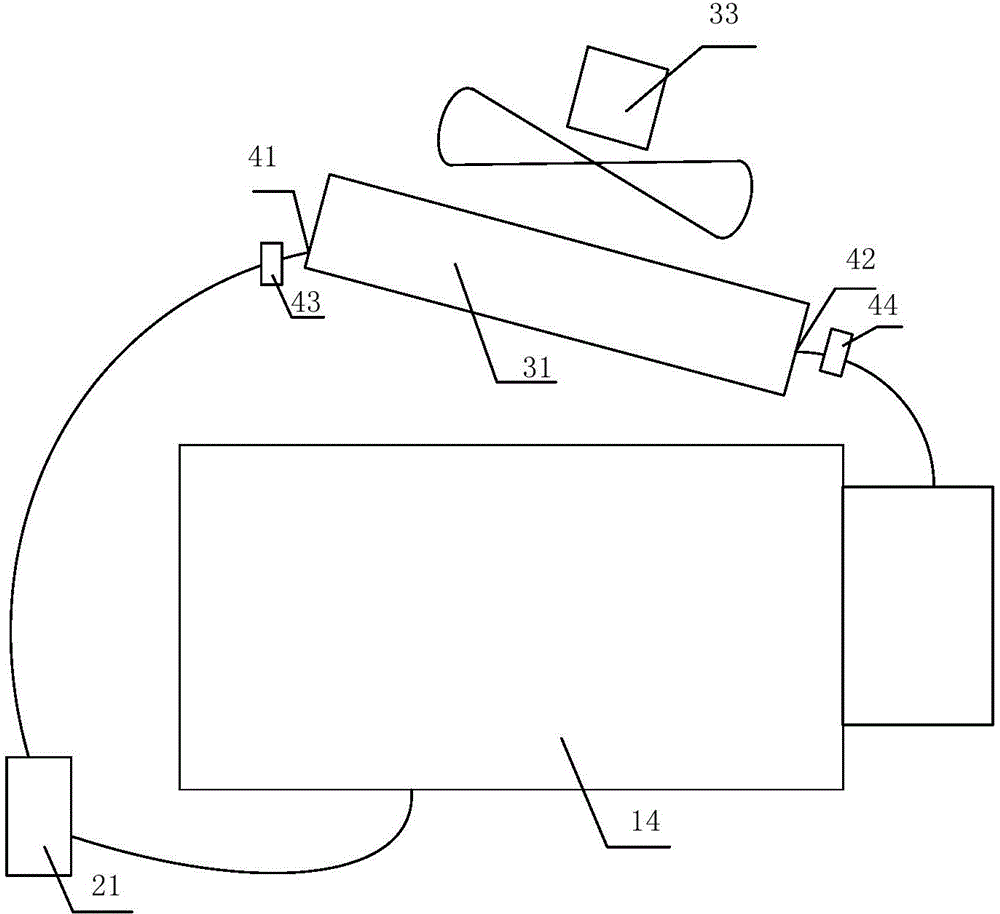

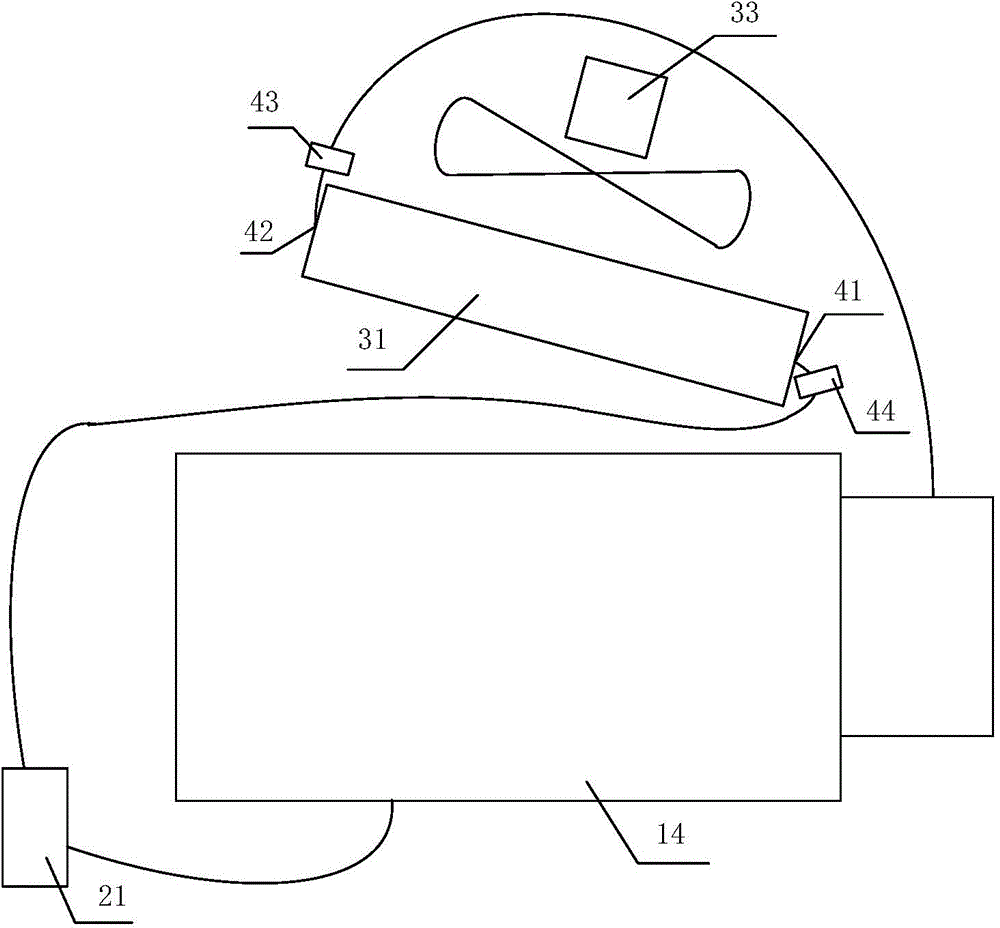

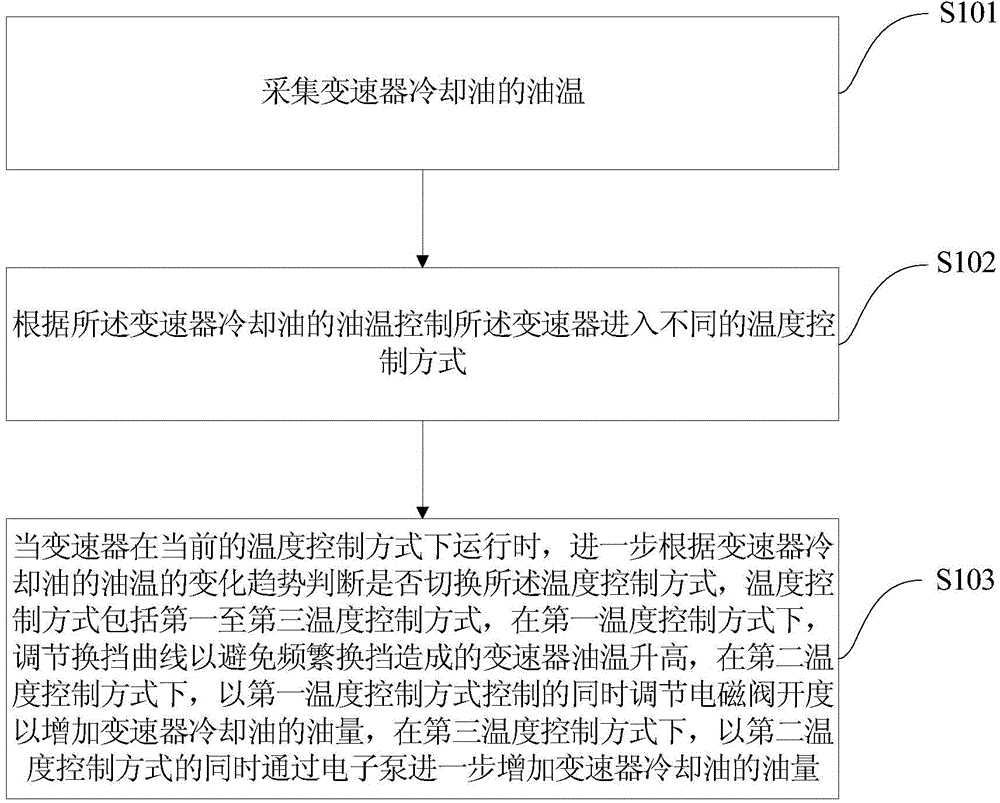

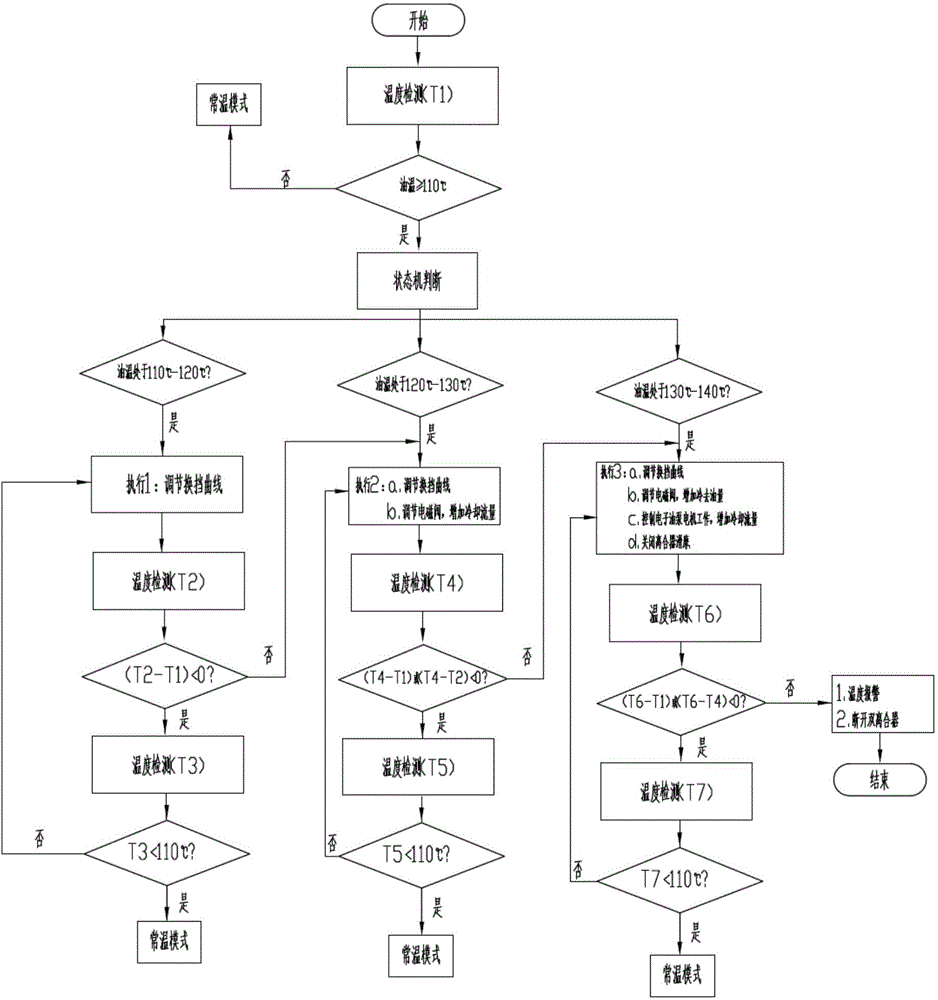

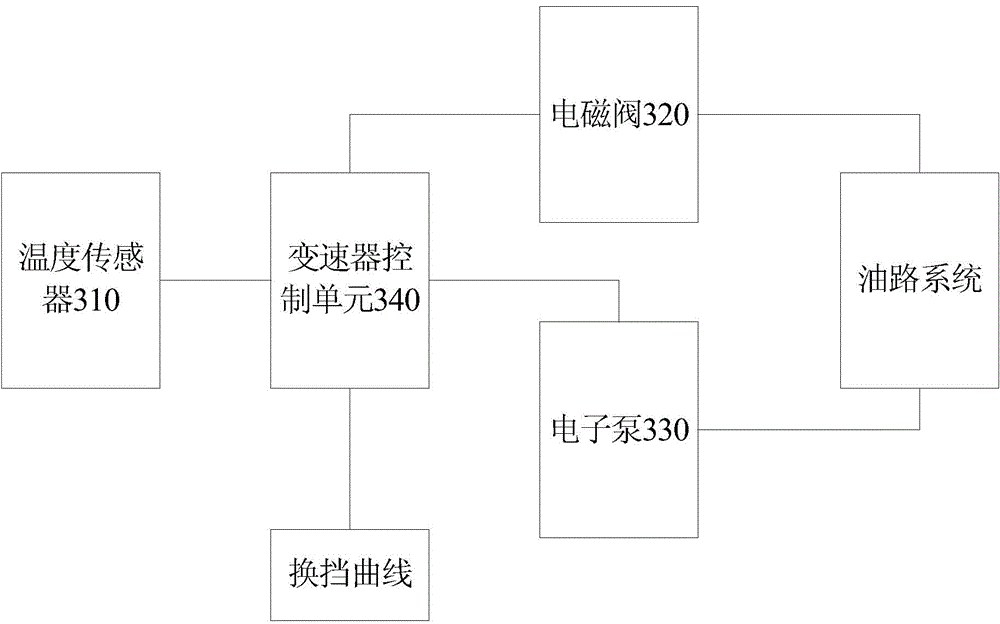

Oil temperature control method and system for speed changer

ActiveCN104315125AIncrease oil temperatureImprove operating conditionsGear lubrication/coolingTransmission elementsSolenoid valveControl manner

The invention discloses an oil temperature control method and system for a speed changer. The method comprises the following steps: acquiring the oil temperature of speed changer cooling oil; controlling the speed changer to enter different temperature control modes according to the oil temperature of the speed changer cooling oil; when the speed changer runs in a current temperature control mode, judging whether the temperature control mode is switched or not according to the change trend of the oil temperature of the speed changer cooling oil, adjusting a gear shift curve to avoid the temperature rise of the speed changer cooling oil caused by frequent gear shift in the first temperature control mode, adjusting the opening of a solenoid valve to increase the oil amount of the speed changer cooling oil while controlling by the first temperature control mode in the second temperature control mode, and adjusting the oil pressure to further increase the oil temperature of the speed changer cooling oil while controlling by the second temperature control mode in the third temperature control mode. According to the oil temperature control method provided by the embodiment of the invention, the oil temperature of the speed changer cooling oil can be comprehensively and accurately controlled and the service life of the speed changer is effectively prolonged.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

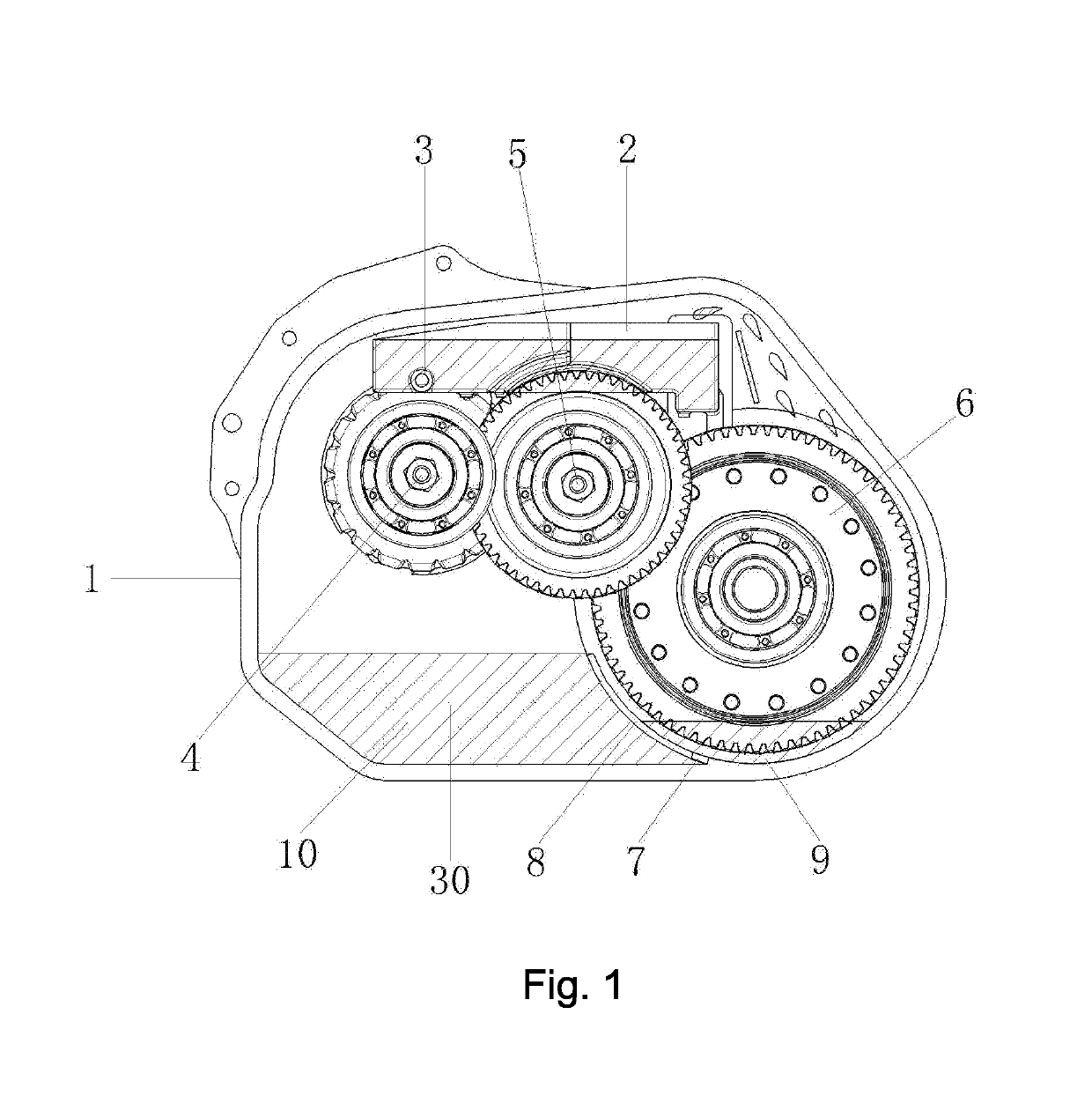

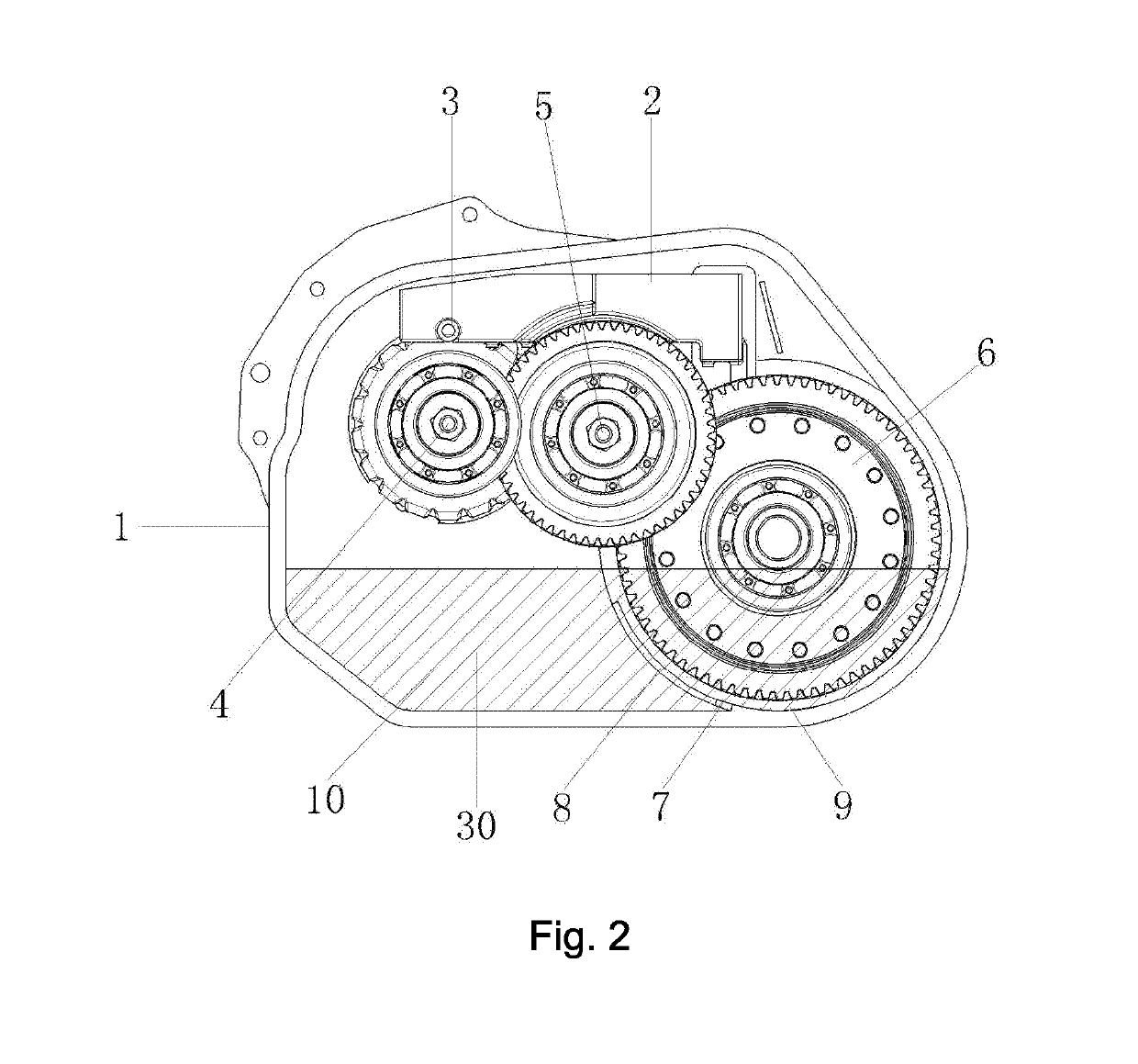

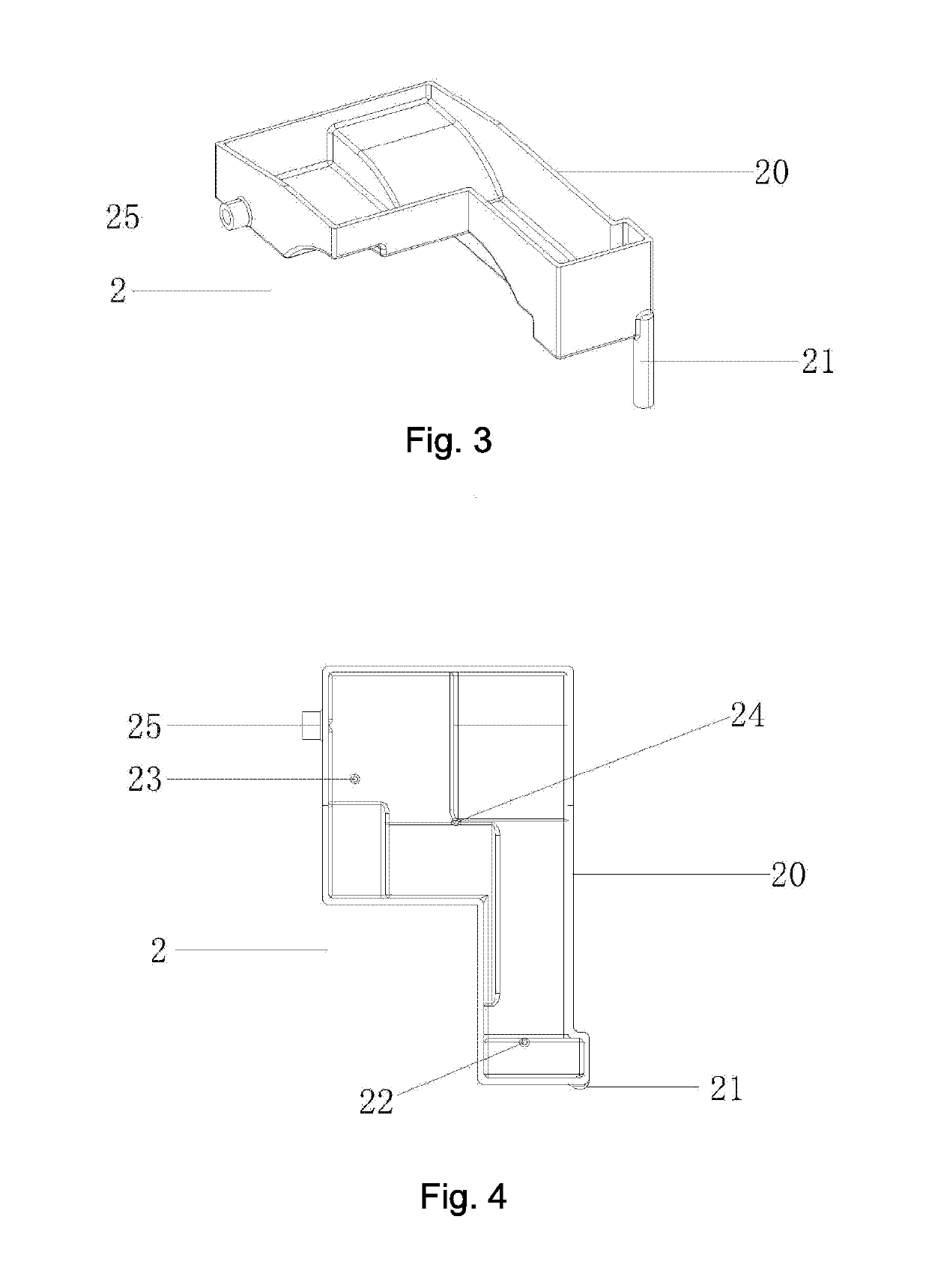

Pure electric vehicle transmission with novel lubrication structure

ActiveUS20190145509A1Good flexibilityAvoids unnecessary agitationGear lubrication/coolingTransmission elementsCouplingGear wheel

A pure electric vehicle transmission includes a transmission box, a top side of the transmission box is provided with a temporary oil storage case, a bottom side thereof is stored with lubricating oil, the temporary oil storage case is provided with a plurality of lubricating oil holes, a gear-connected transmission input shaft and an intermediate coupling are located at a lower side of the oil storage case and arranged above a lubricating oil surface, an intermediate coupling gear is connected with a differential gear, a lower side of the differential gear is immersed in the lubricating oil, the lubricating oil at the bottom side of the transmission box is splashed in the temporary oil storage case via the rotation of the differential gear, the lubricating oil lubricates various parts of the transmission through the lubricating oil holes, and then returns to the bottom side of the transmission box to form circulation.

Owner:ZHEJIANG XIN PRECISION MACHINERY CO LTD

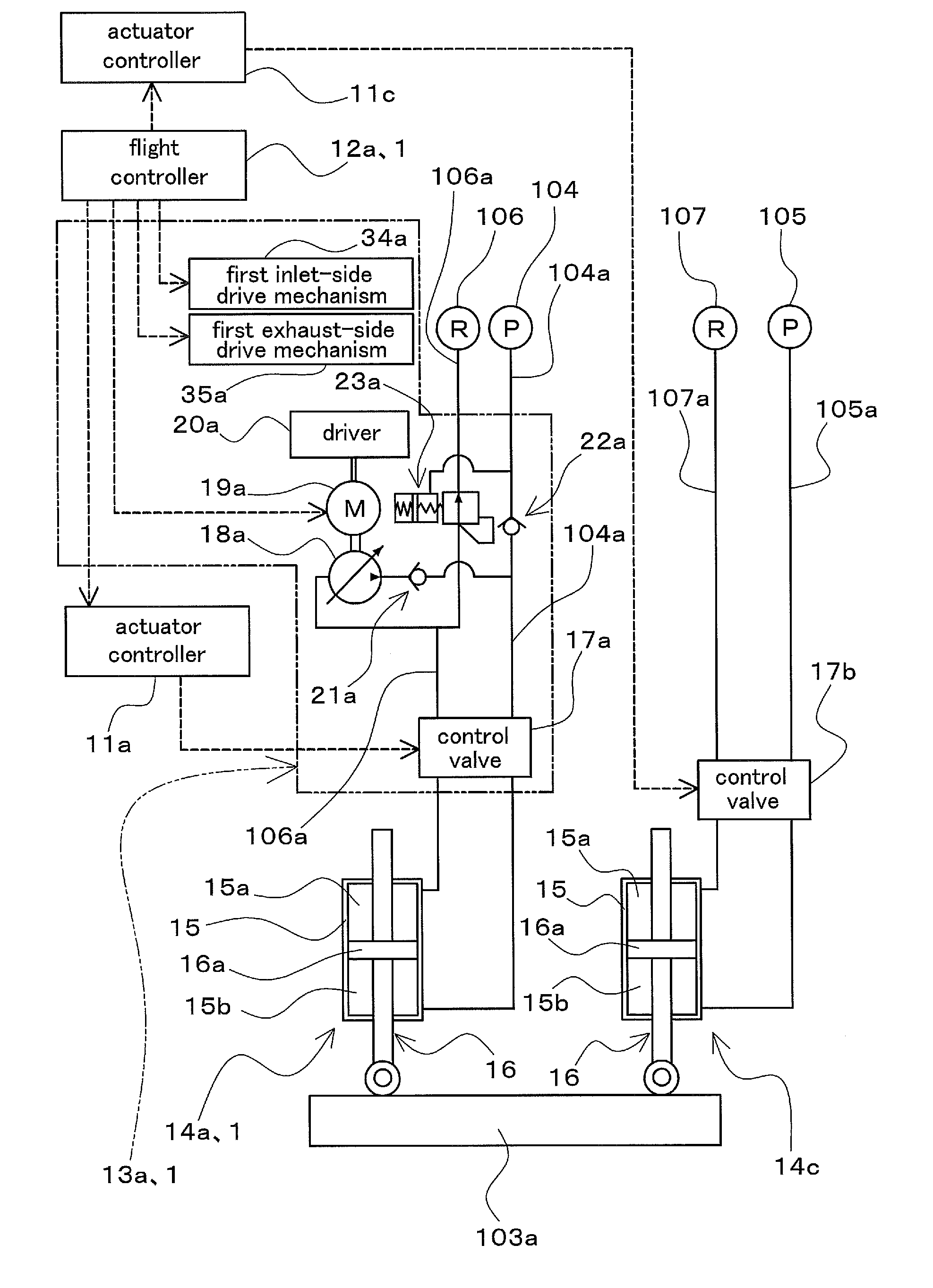

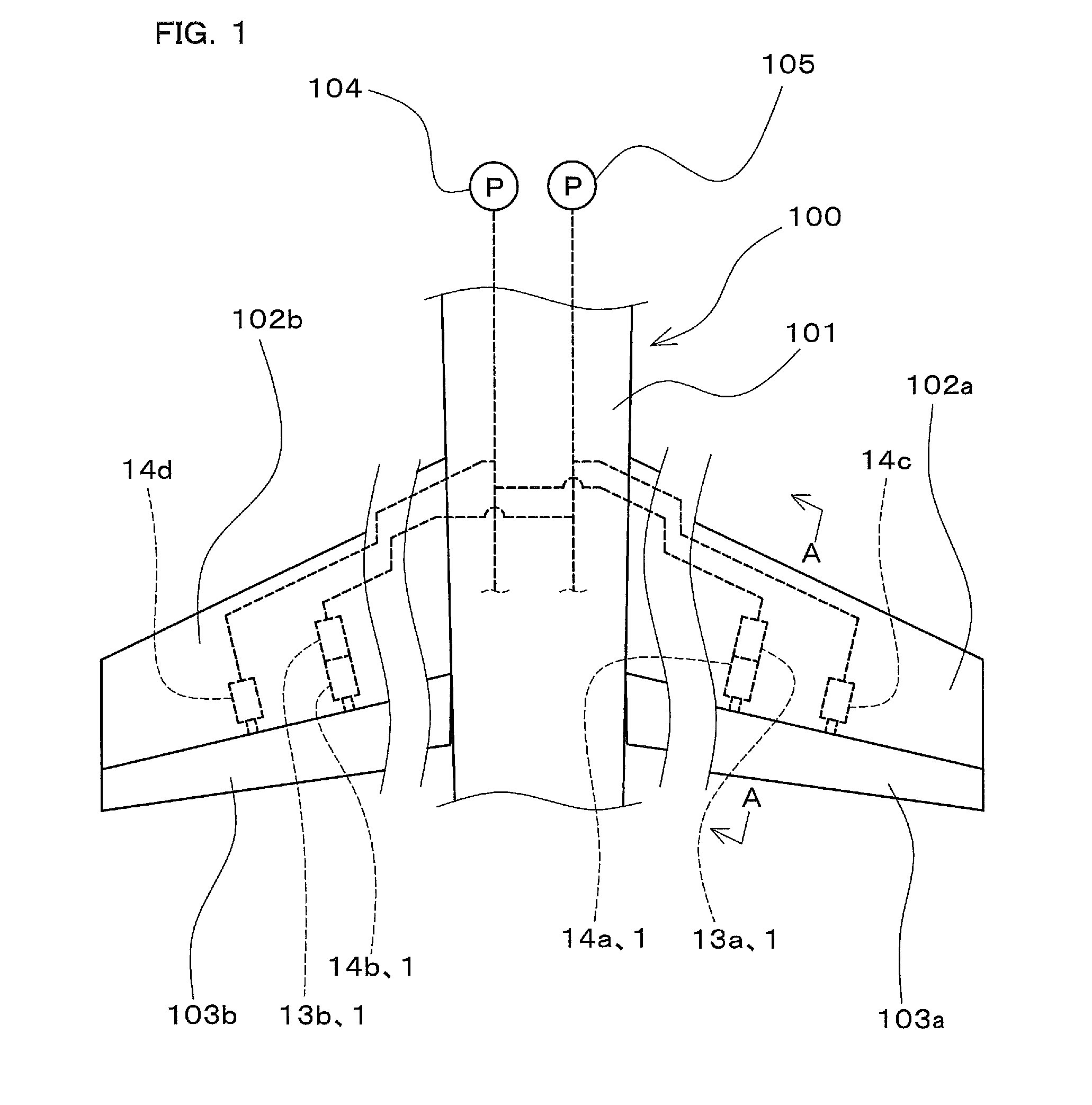

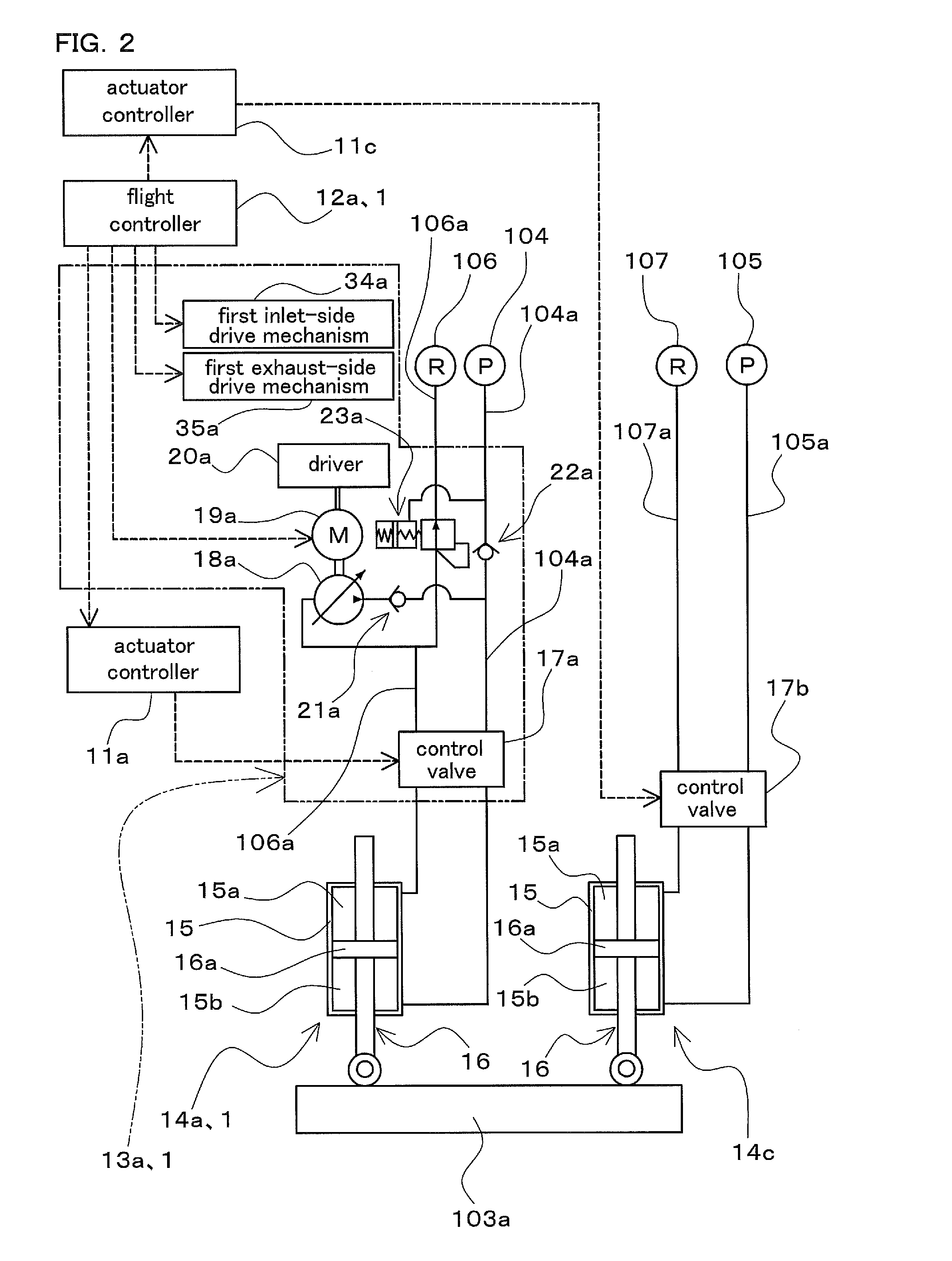

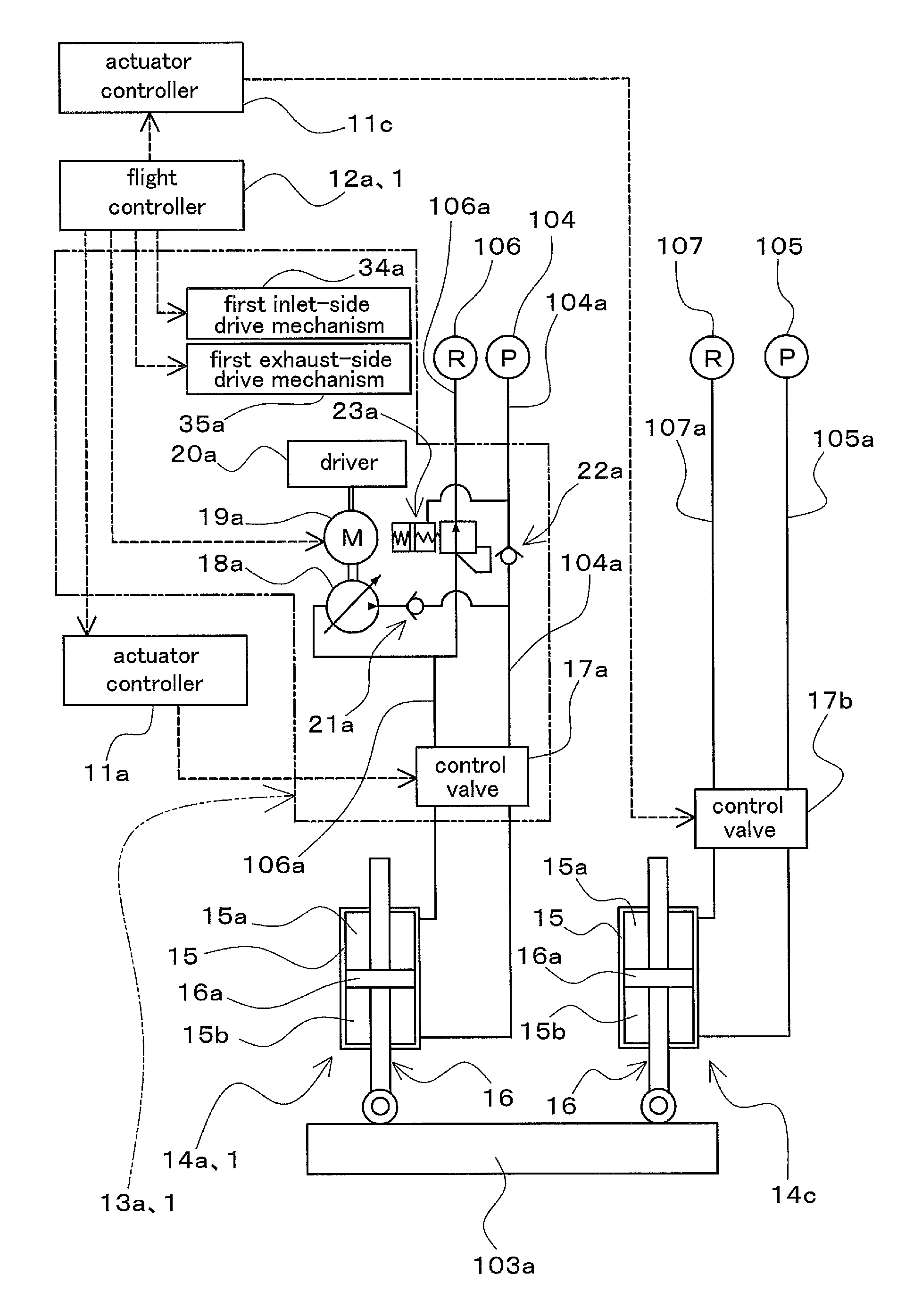

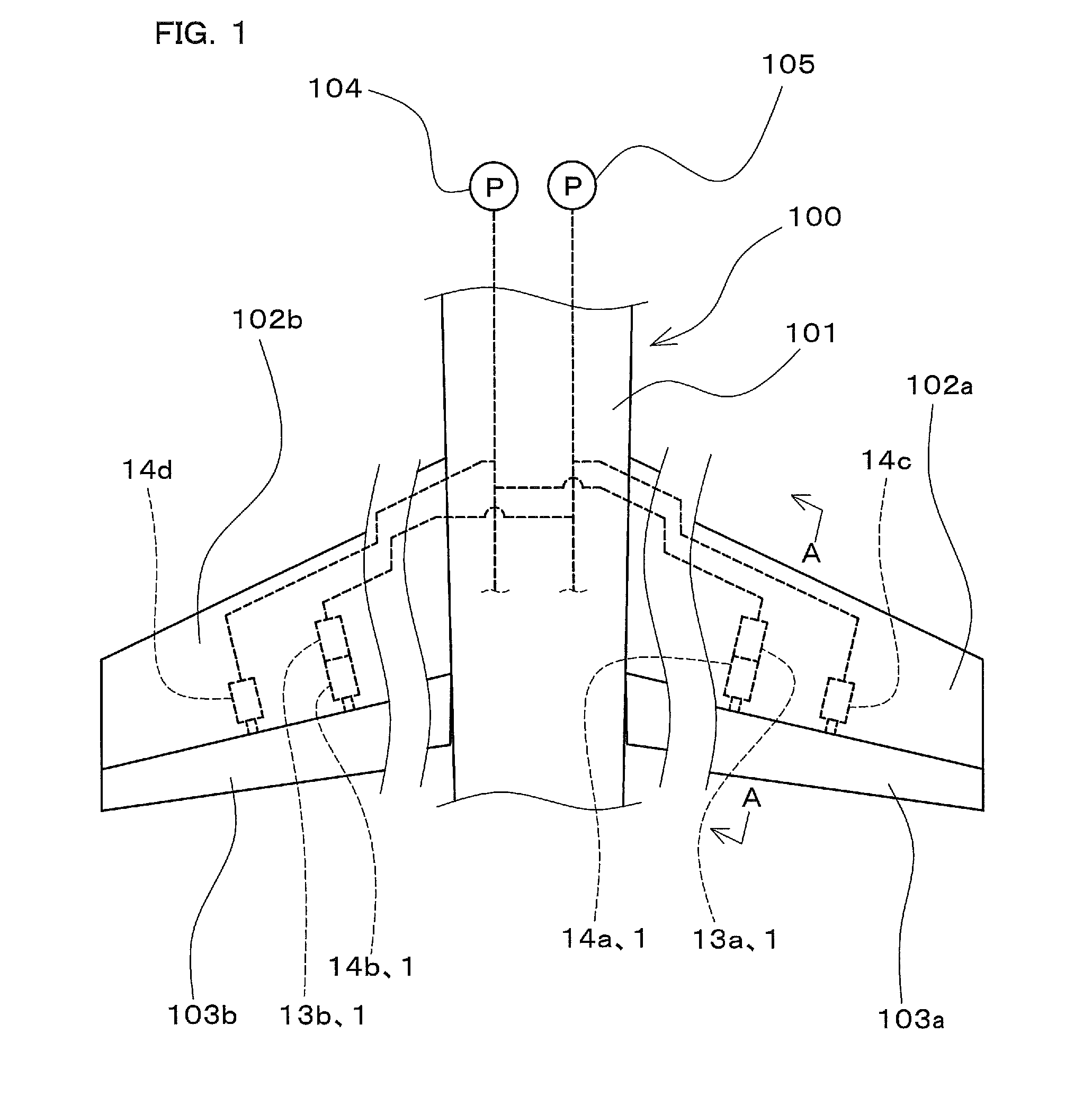

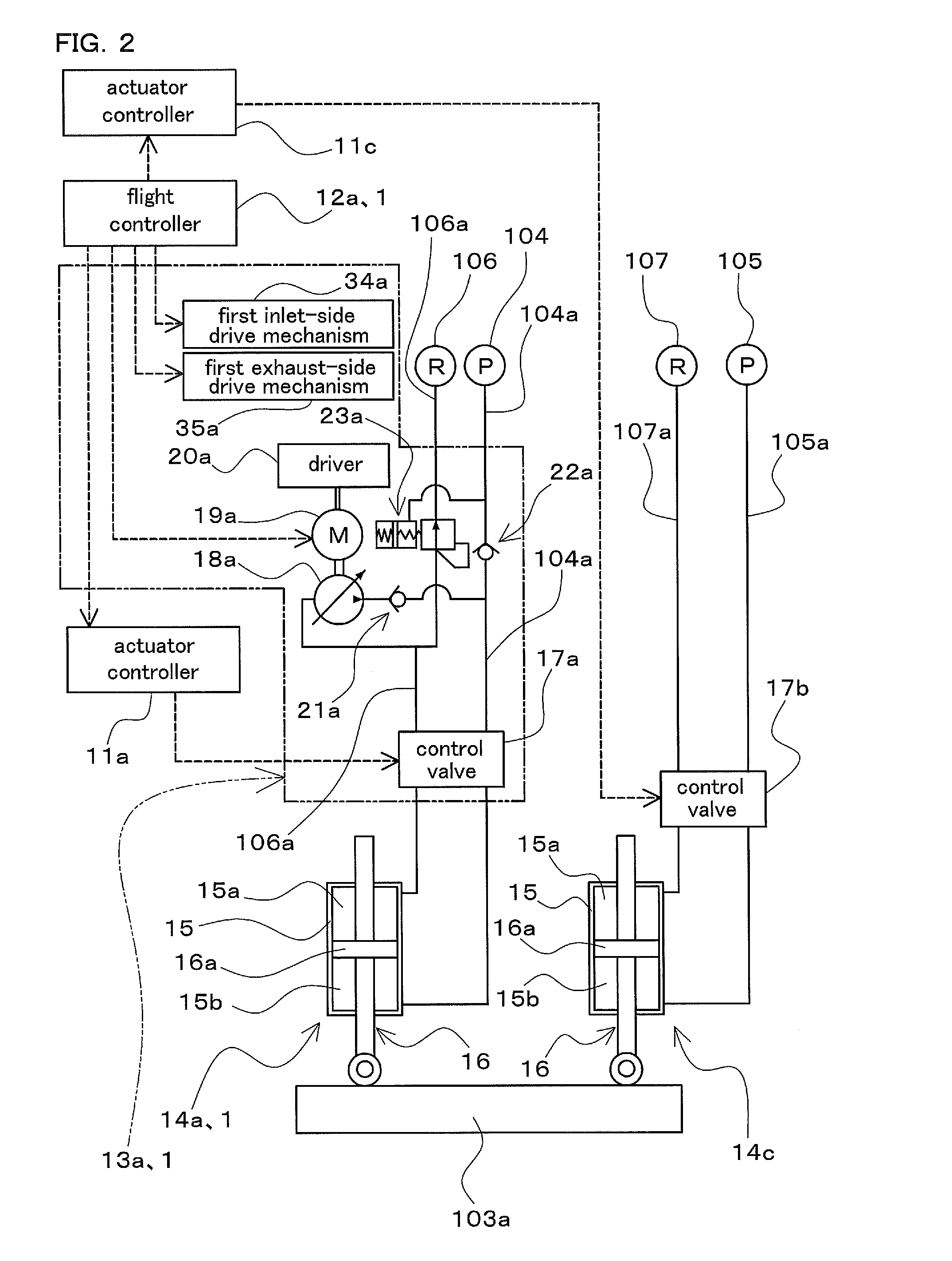

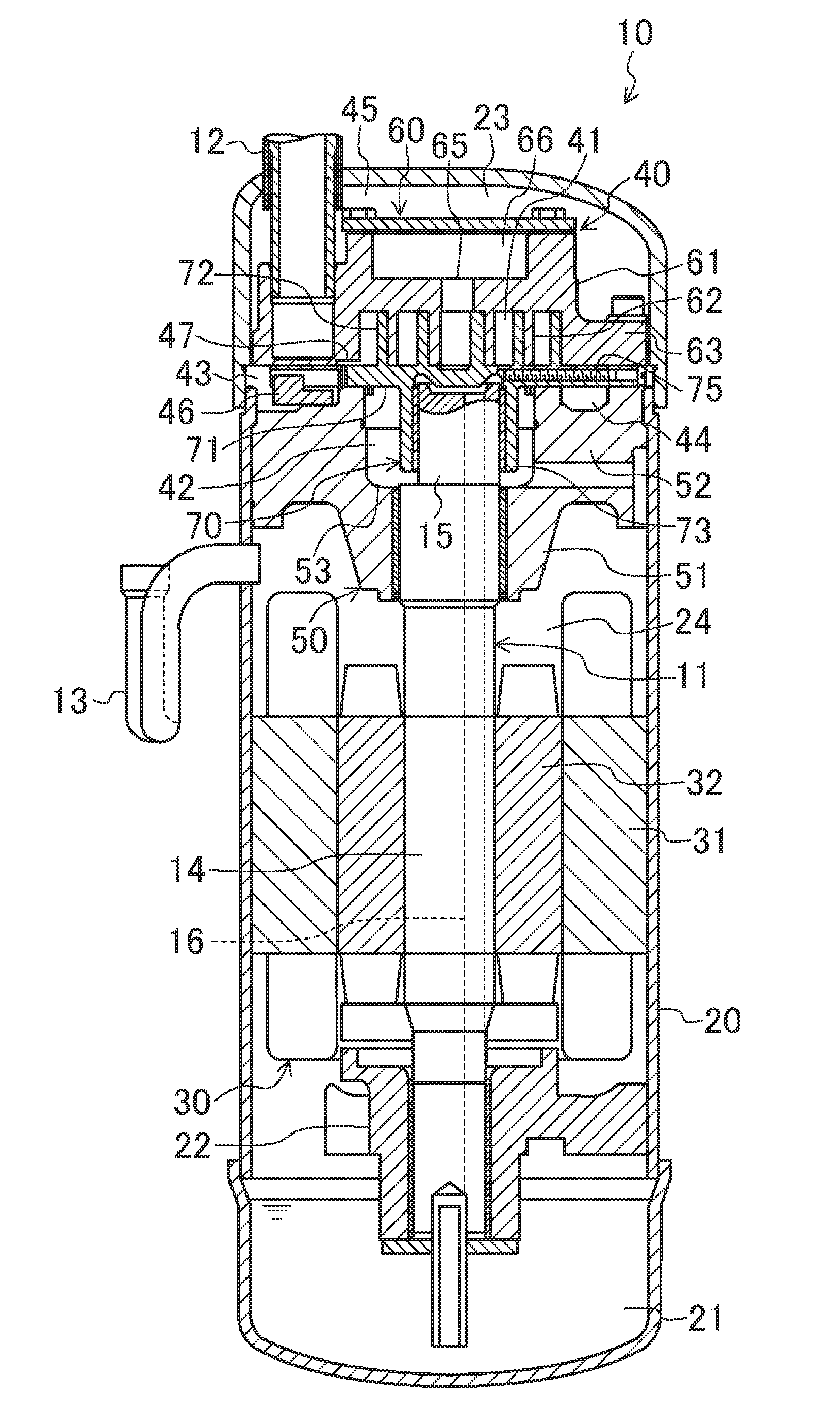

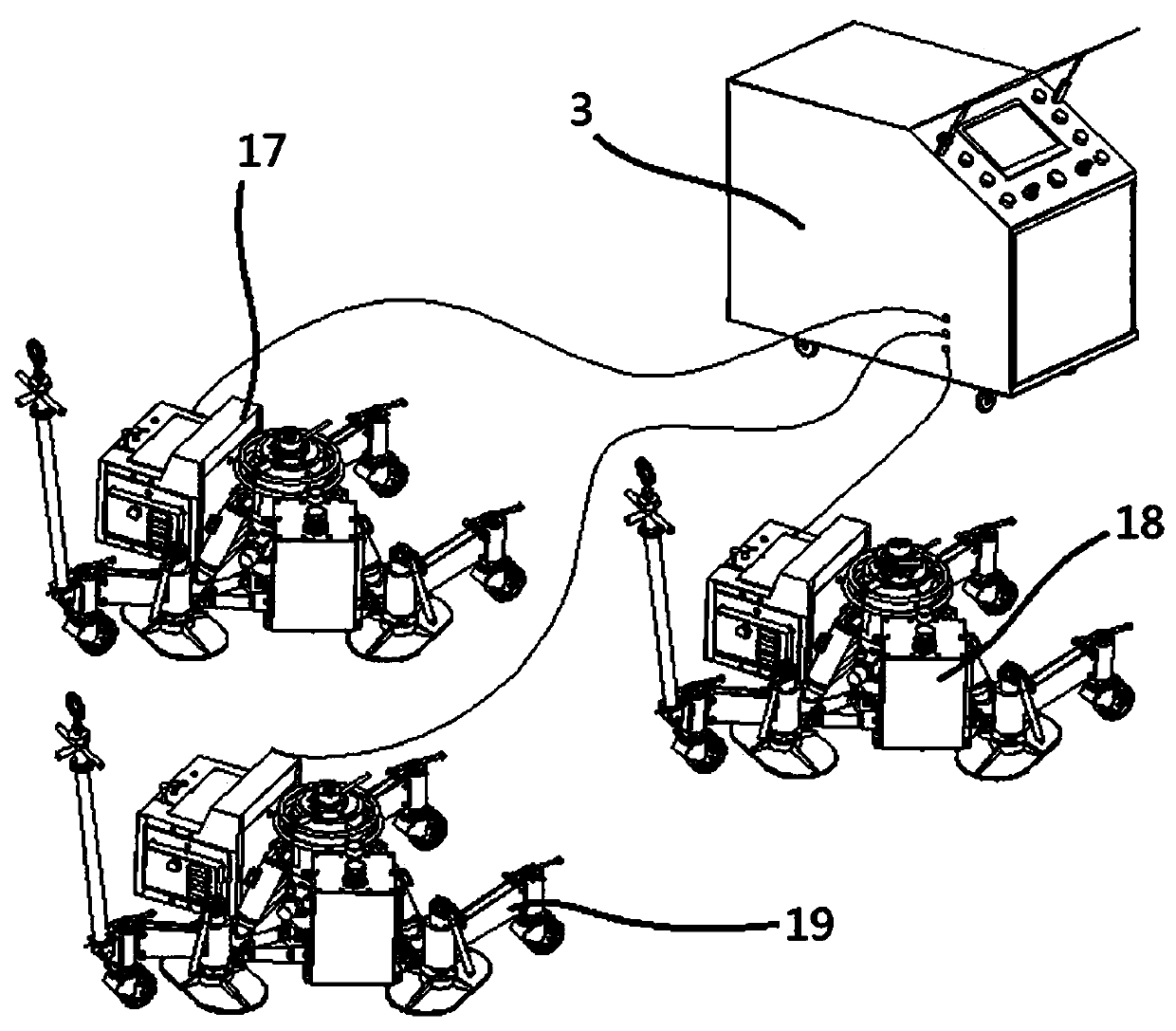

Aircraft actuator hydraulic system

ActiveUS20120001021A1Prevent backflowSuppressing increaseAircraft stabilisationWithout power ampliicationFlight vehicleHydraulic pump

When a loss or degradation in the function of one of a first aircraft central hydraulic power source and a second aircraft central hydraulic power source occurs, a controller performs a control so as to operate the other backup hydraulic pump, out of a first backup hydraulic pump and a second backup hydraulic pump, which is connected downstream of the other hydraulic power source, which is the other of the first and second aircraft central hydraulic power sources. Oil flowing through the other backup hydraulic pump is cooled by an oil cooler of the other hydraulic power source by operation of the other backup hydraulic pump in a state where the other hydraulic power source is being operated.

Owner:NABLESCO CORP

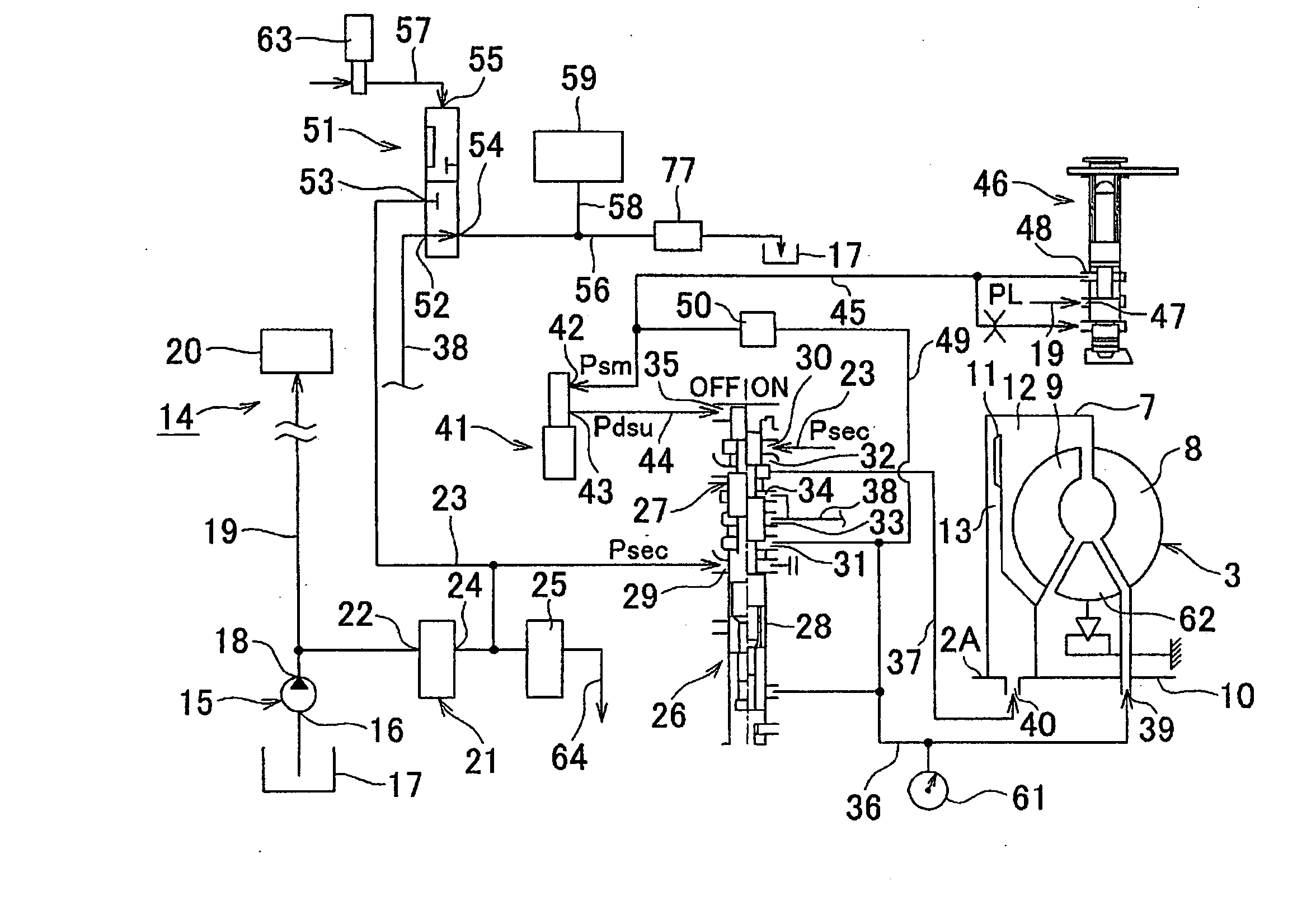

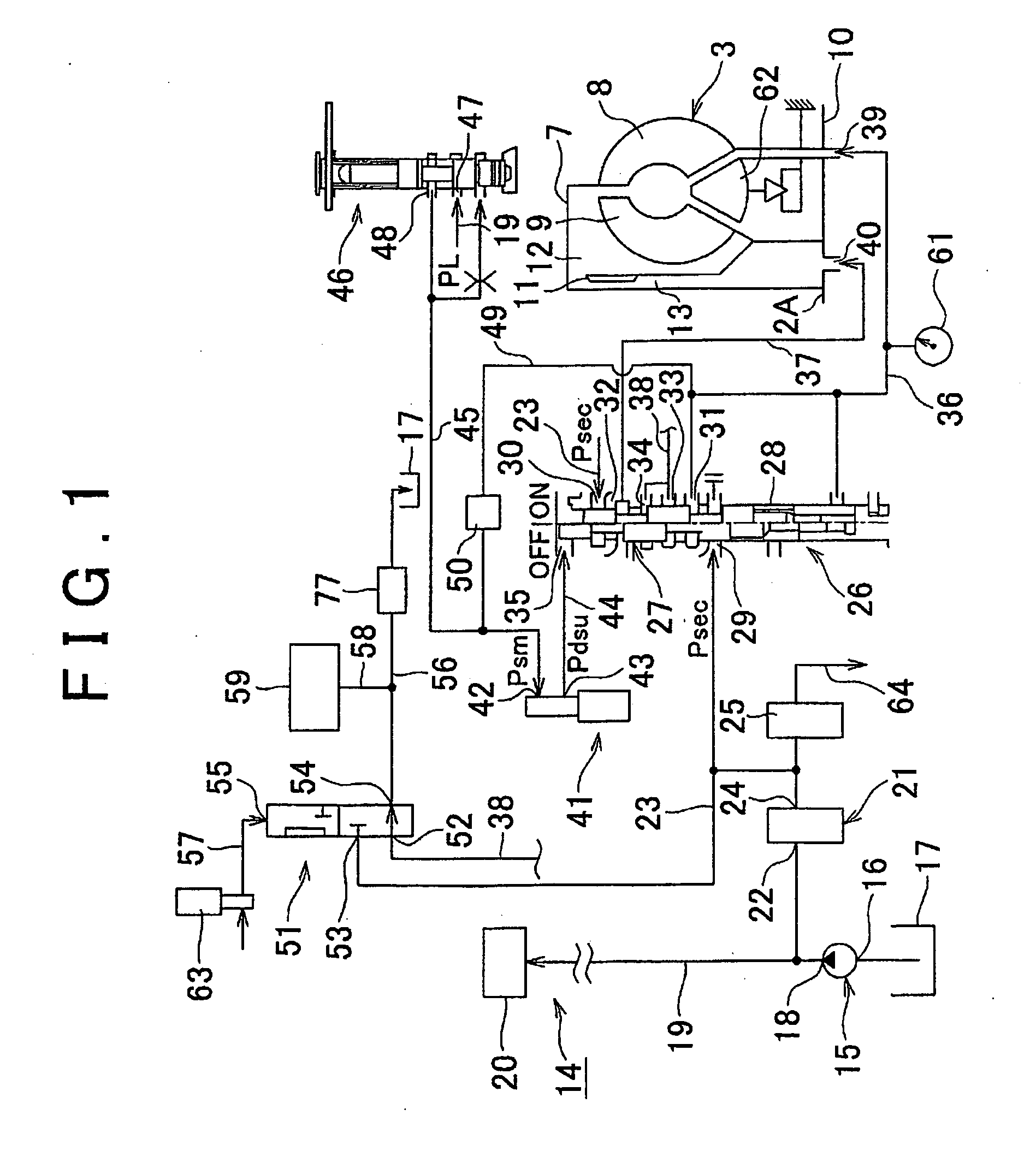

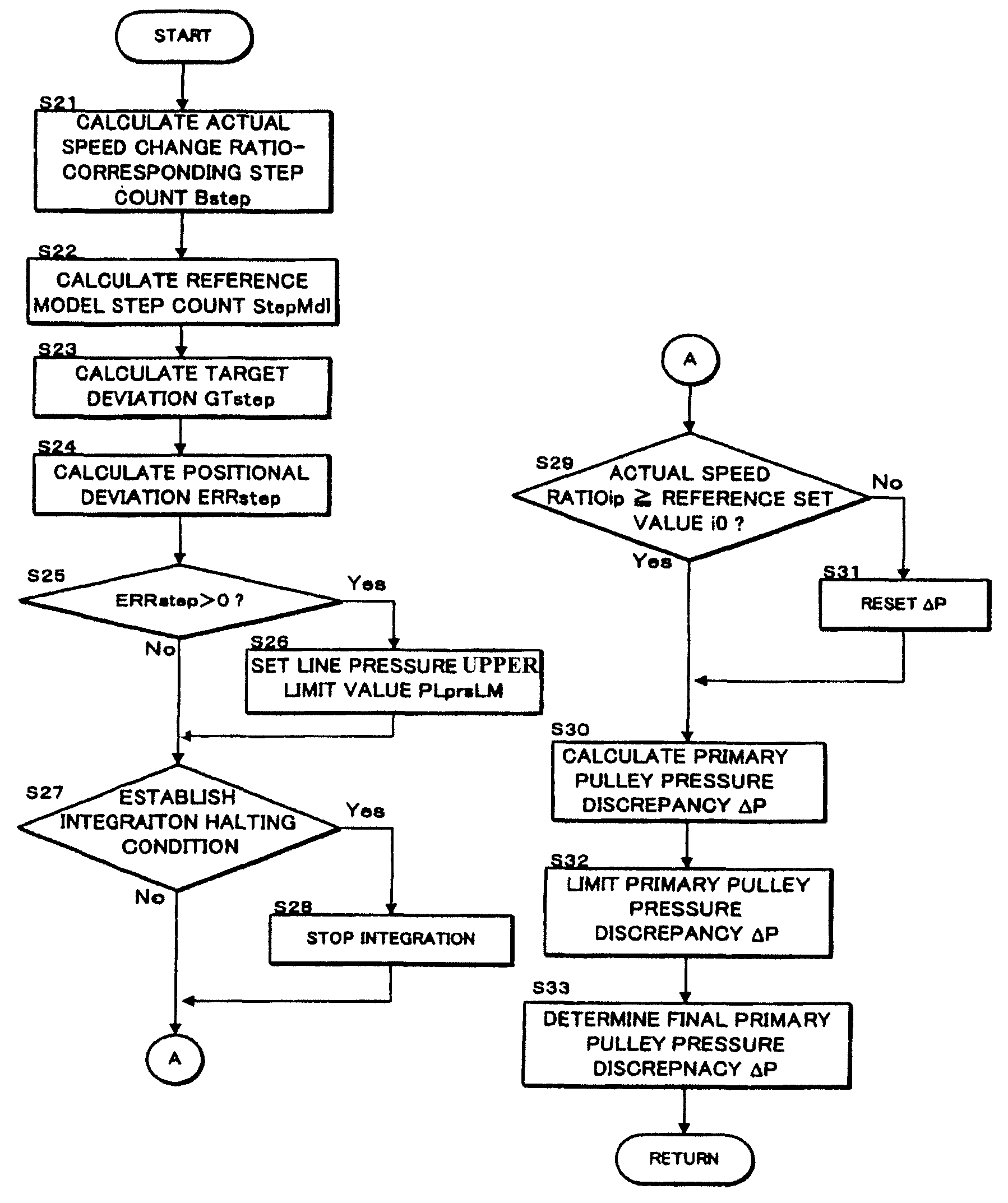

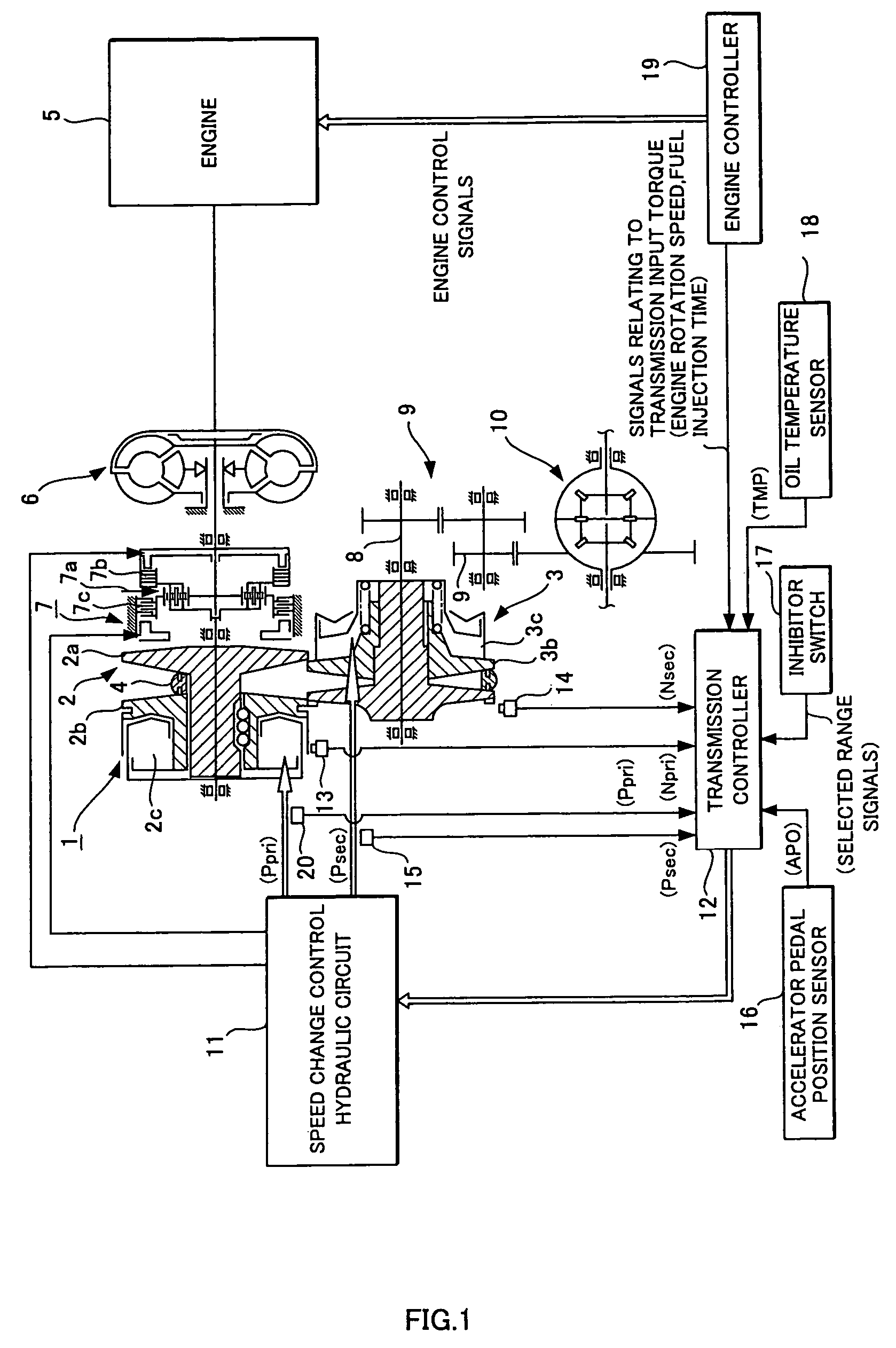

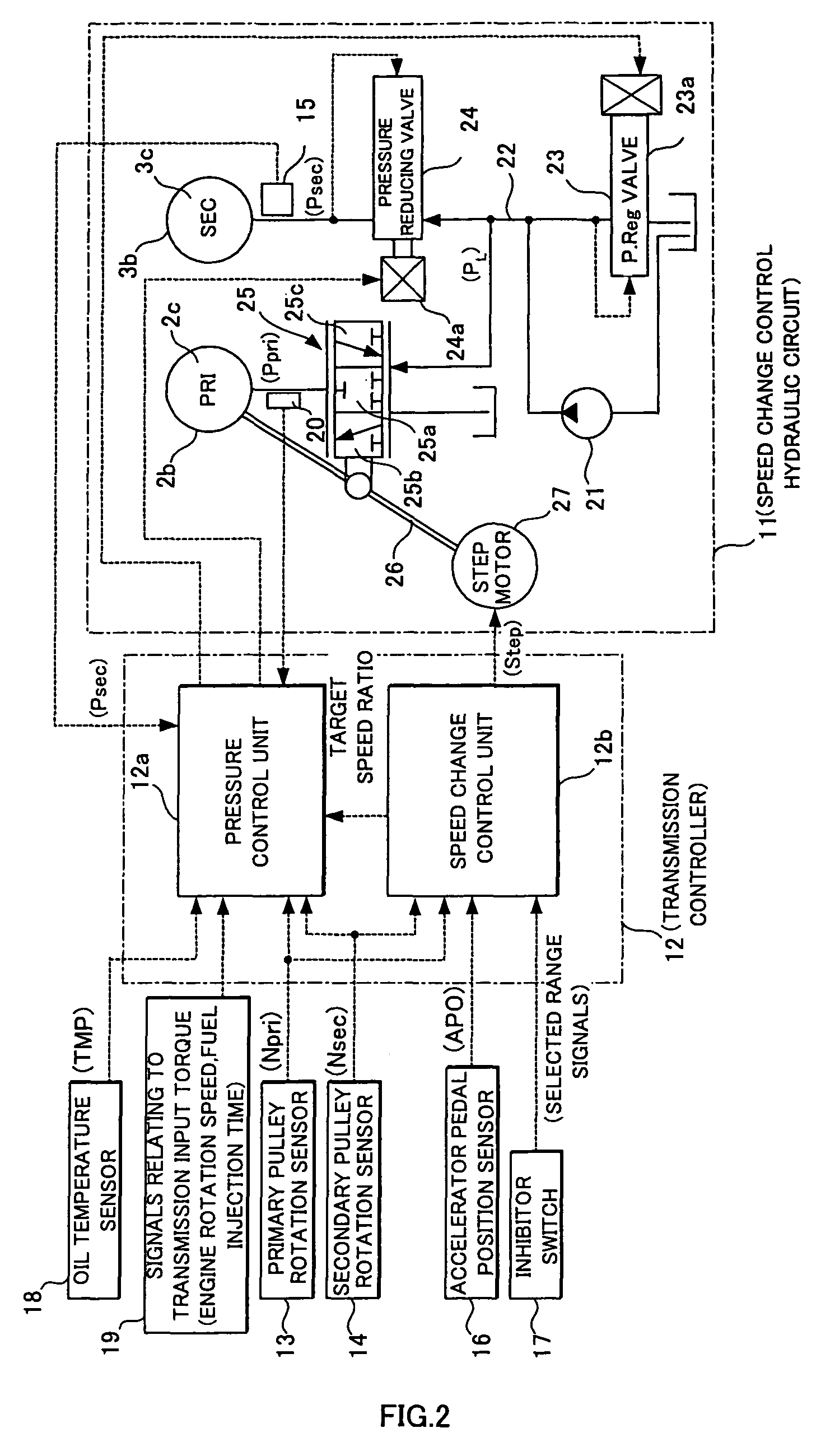

Continuously variable transmission and control method thereof

ActiveUS7806791B2Prevent excessive line pressureImprove fuel economyGearingGearing controlReference modelEngineering

A positional deviation ERRstep of a step motor 27 is calculated on the basis of a reference model step StepMdl, an actual speed ratio-corresponding step Bstep, and an added value obtained by adding together a target deviation GTstep, calculated in accordance with a transmission input torque Ti, and a starting learned value Gstep. When the transmission input torque Ti is large, the target deviation GTstep is increased in accordance with the transmission input torque Ti. A line pressure PL is then controlled on the basis of the positional deviation ERRstep obtained as a result.

Owner:JATCO LTD +1

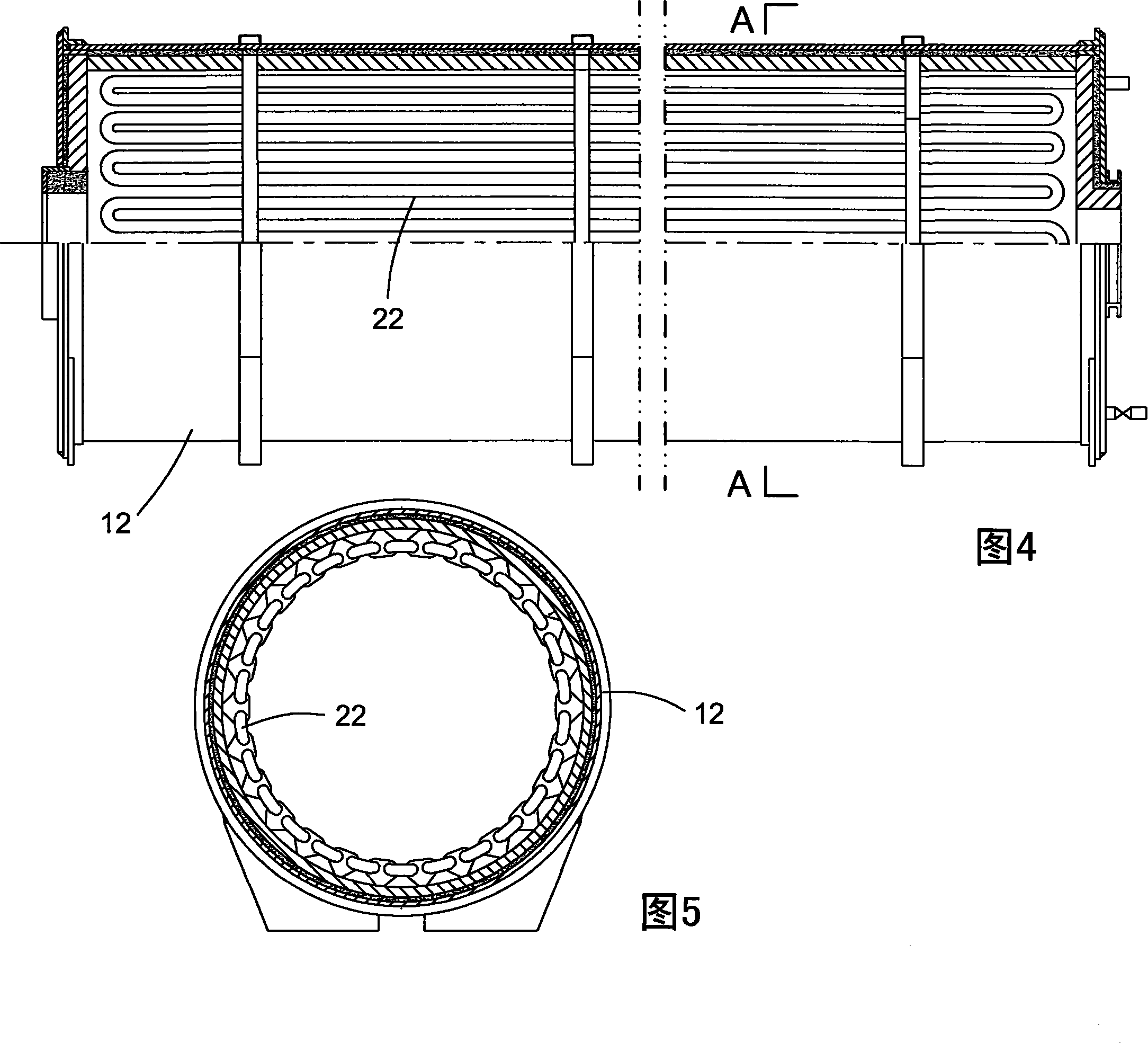

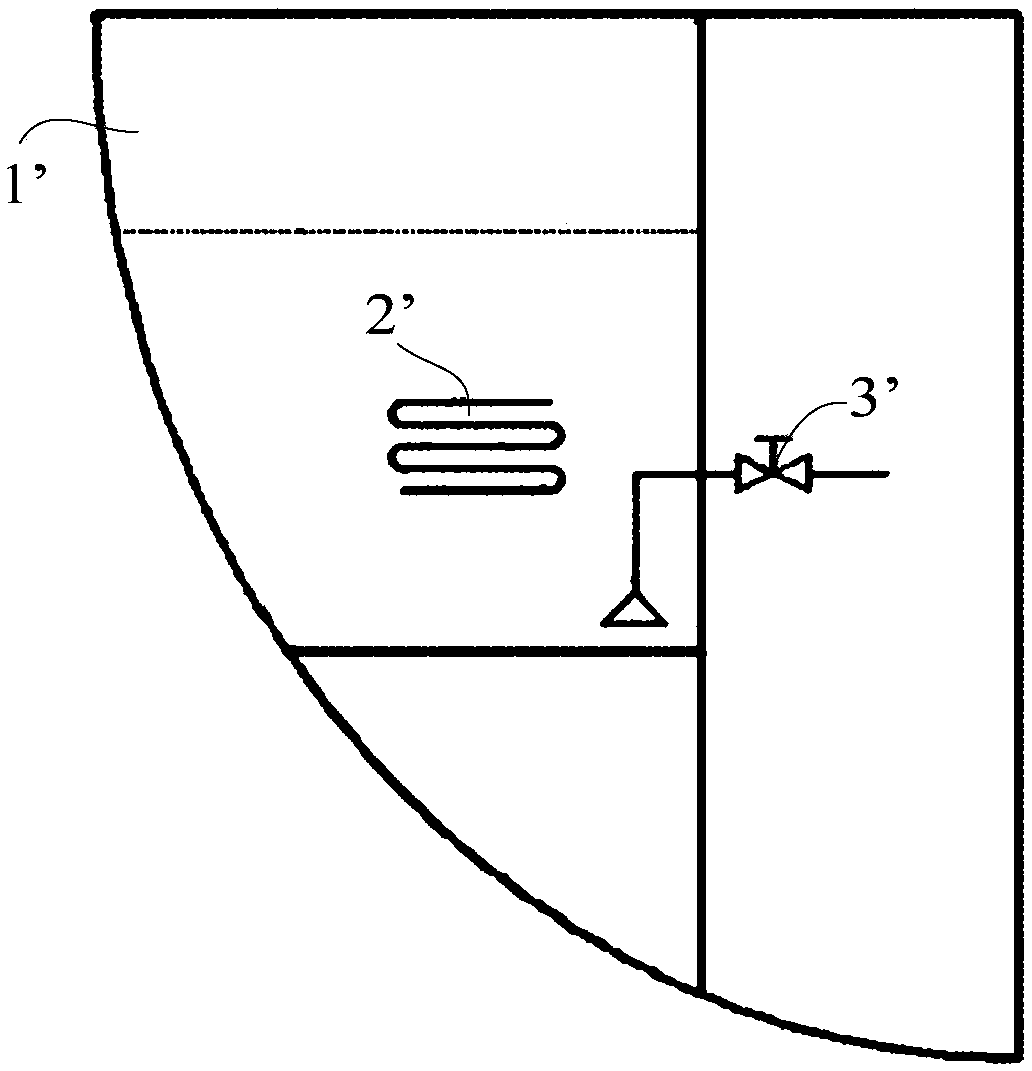

Subcritical pressure pouring boiler furnace

ActiveCN101140061AImprove drynessSimple and compact layoutBoiler water tubesSteam separation arrangementsBoiler furnaceLight pipe

The invention relates to a sub-critical pressure steam injection boiler, a steam pipeline system of which comprises a water pump, a water supply pipe, a steam discharge pipe, a radial pipe bundle, a convection pipe bundle, a steam separator and a feed water preheater; wherein the radial pipe bundle is formed by the connection of a plurality of rows of horizontal U-shaped straight pipes, the convection pipe bundle is formed by the connection of a plurality of rows of U-shaped light pipes and U-shaped finned pipes, the feed water preheater is composed of a shell and an internal sleeve pipe, the shell is provided with a shell side inlet and a shell side outlet, the two ends of the internal sleeve pipe are provided with a pipe side inlet and a pipe side outlet, the shell side inlet is communicated with the water supply pipe, the shell side outlet is communicated with the inlet of the convection pipe bundle, the outlet of the convection pipe bundle is communicated with the pipe side inlet, the pipe side outlet is communicated with the inlet of the radial pipe bundle, the outlet of the radial pipe bundle is communicated with a steam inlet pipe of the steam separator, and a steam outlet pipe of the steam separator is communicated with the steam discharge pipe. The steam injection boiler provided in the invention has the advantages of the concise and compact arrangement of the steam pipeline, the smooth operation, the safety and reliability and the high heat efficiency, and solves the problem of that the high-pressure deep-well block and the ultra thick oil block are difficult to be mined.

Owner:THE EIGHTH CONSTR COMPANY OF CNPC

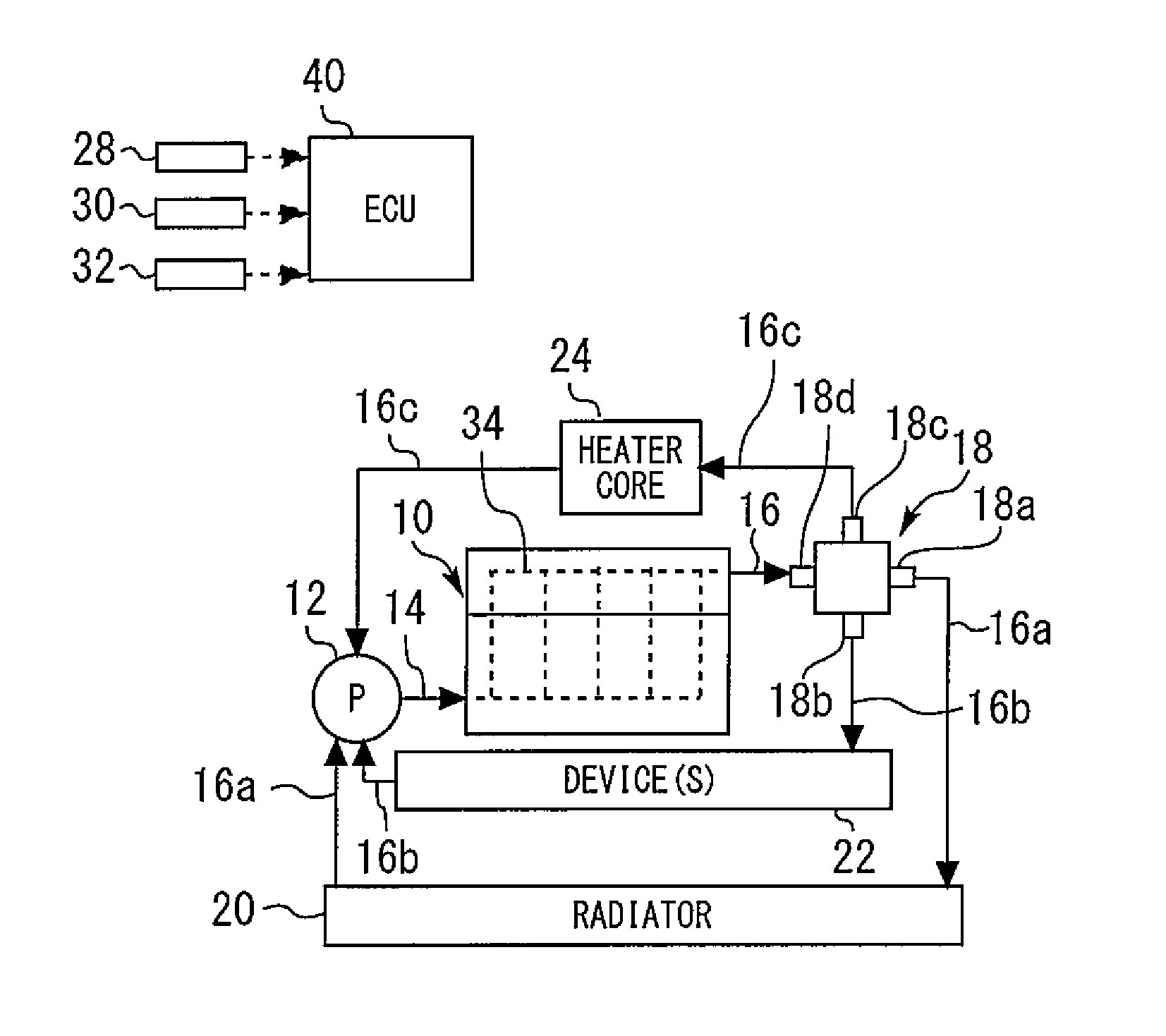

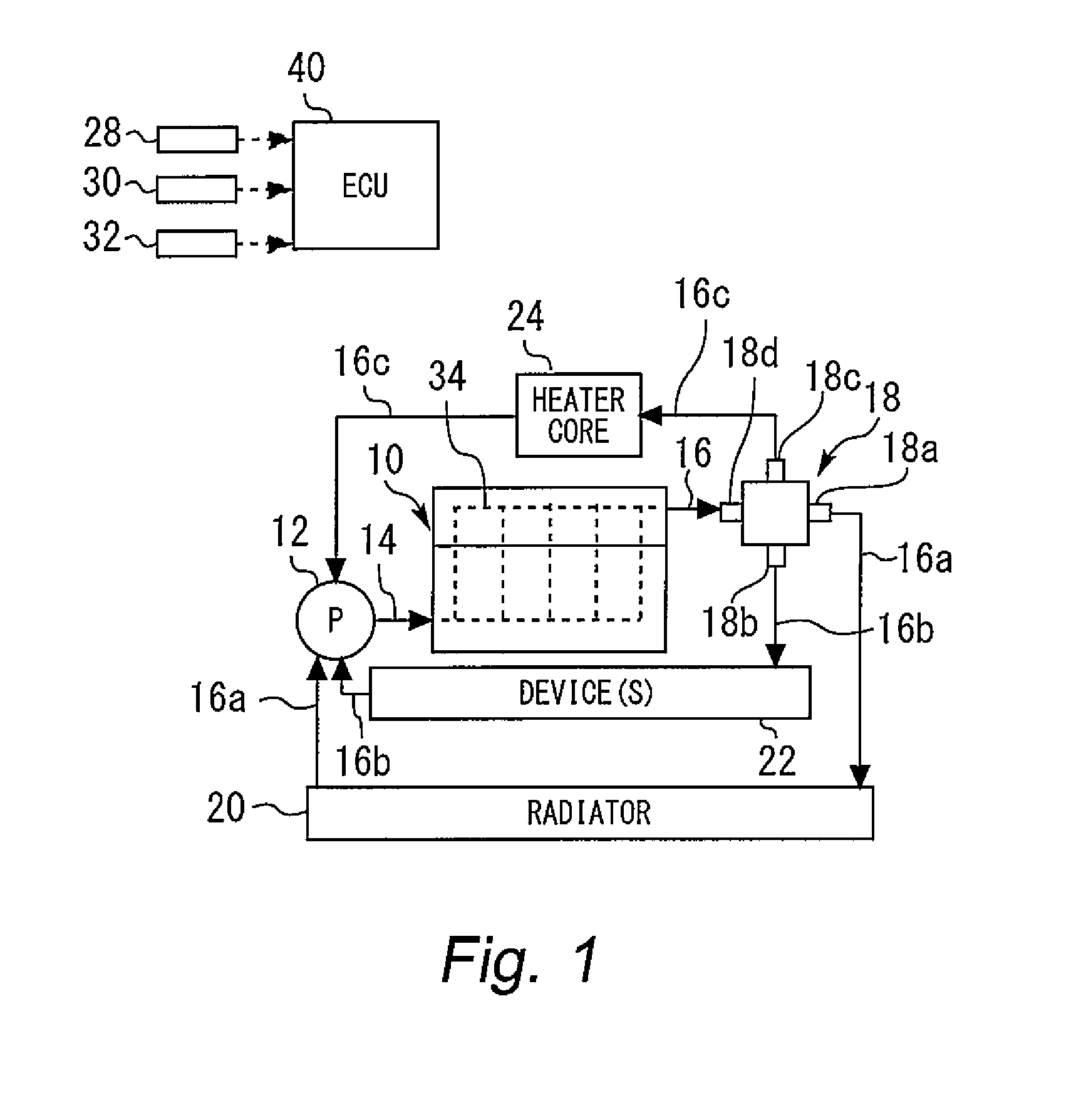

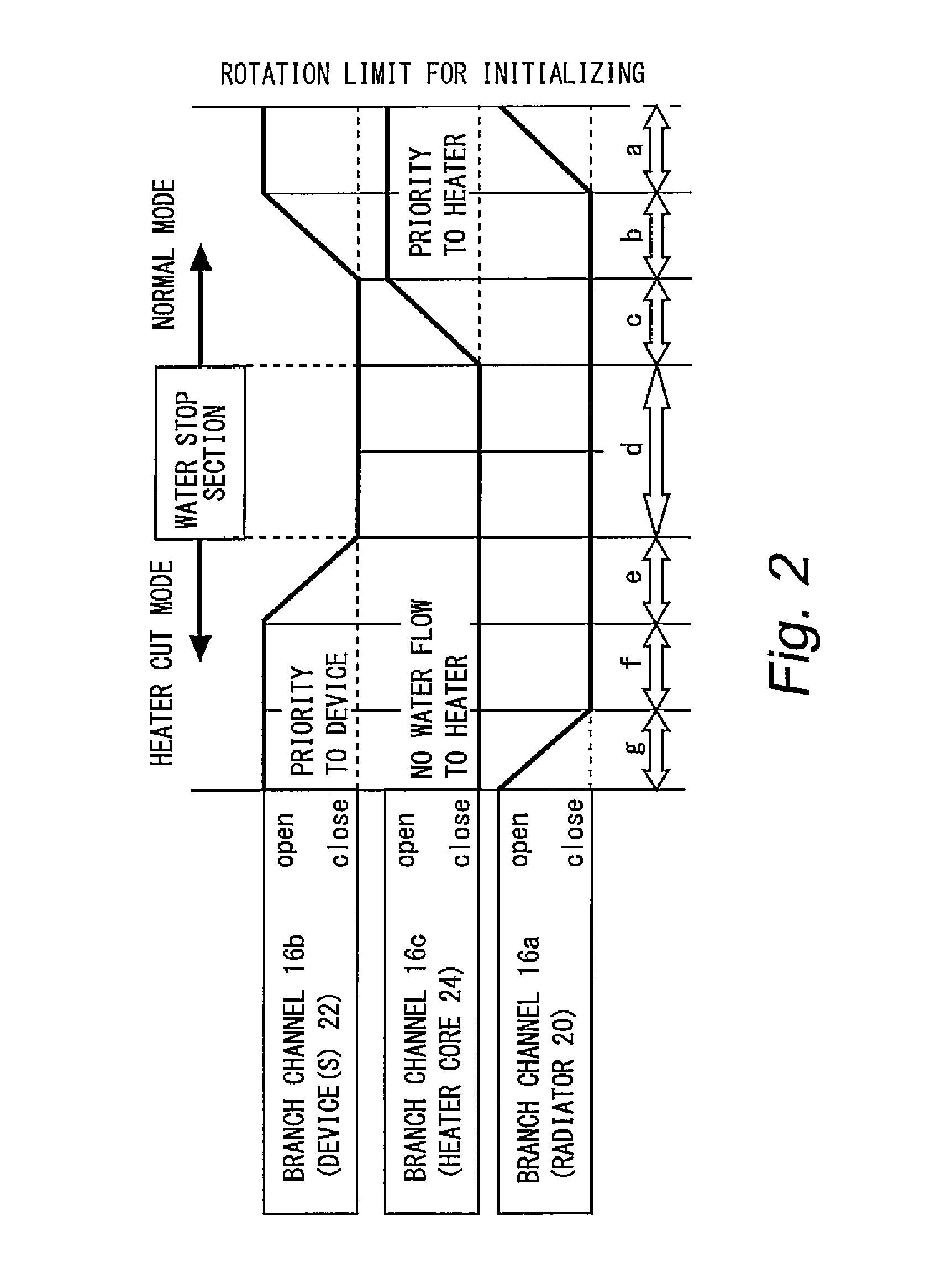

Cooling device for internal combustion engine

InactiveUS20170030251A1Limited output powerAvoid boilingLiquid coolingElectrical controlEngineeringExternal combustion engine

A cooling device includes a first cooling medium circuit for circulating a cooling medium that passes through a main body of an engine to a first heat exchanger, a second cooling medium circuit for circulating a cooling medium that passes through the main body to a second heat exchanger, a control valve that is commonly used in the first and second cooling medium circuits, and a control device. The control valve includes a rotatable rotor, and is configured such that a rotation range of the rotor includes a water stop section in which the circuits are both closed. The control device restricts output power of the engine in a period in which the rotation angle is in the water stop section, when the rotor rotates via the water stop section at an operating time of the control valve.

Owner:TOYOTA JIDOSHA KK

Aircraft actuator hydraulic system

ActiveUS8418956B2Small sizeIncrease in weightAircraft stabilisationWith power amplificationHydraulic pumpEngineering

When a loss or degradation in the function of one of a first aircraft central hydraulic power source and a second aircraft central hydraulic power source occurs, a controller performs a control so as to operate the other backup hydraulic pump, out of a first backup hydraulic pump and a second backup hydraulic pump, which is connected downstream of the other hydraulic power source, which is the other of the first and second aircraft central hydraulic power sources. Oil flowing through the other backup hydraulic pump is cooled by an oil cooler of the other hydraulic power source by operation of the other backup hydraulic pump in a state where the other hydraulic power source is being operated.

Owner:NABLESCO CORP

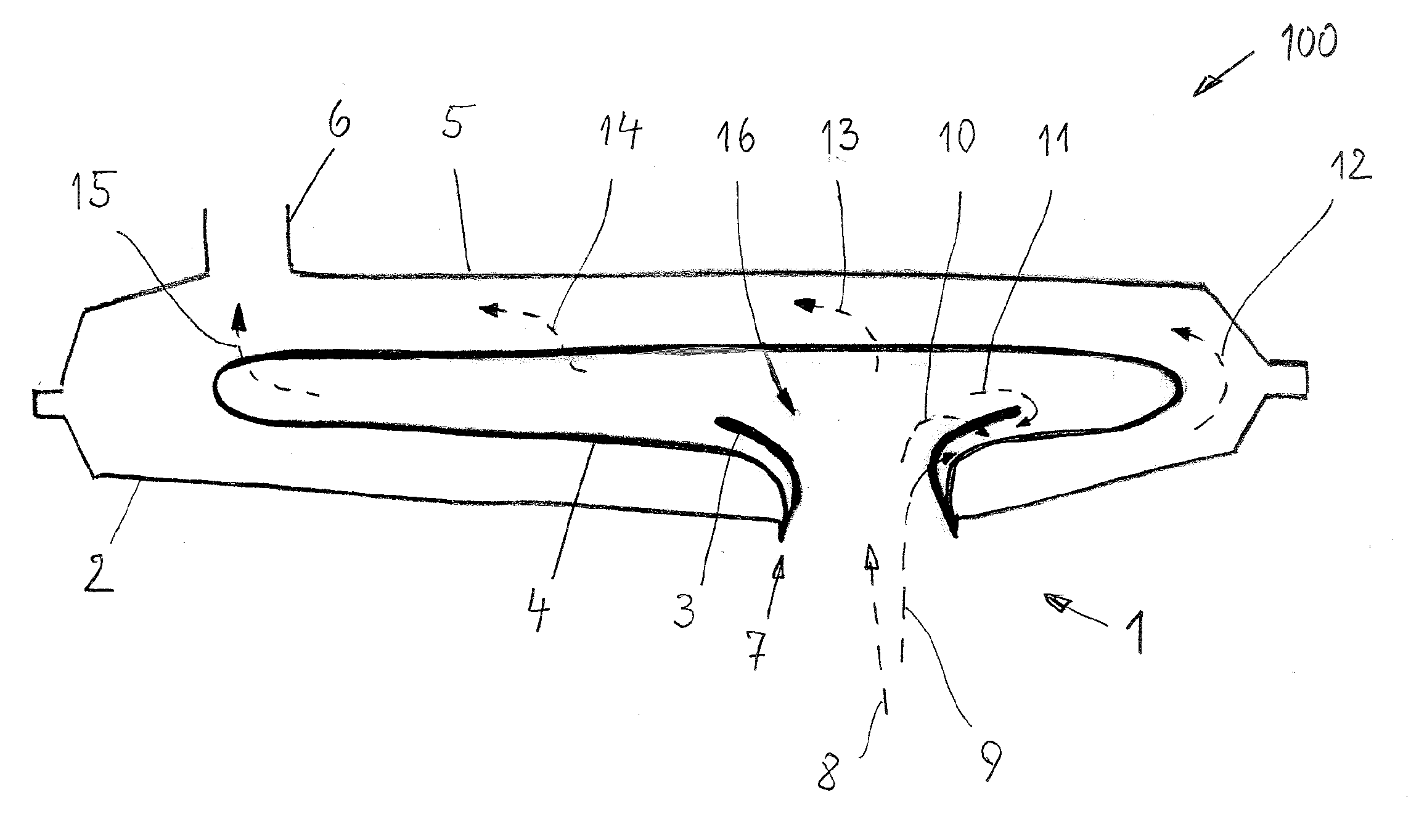

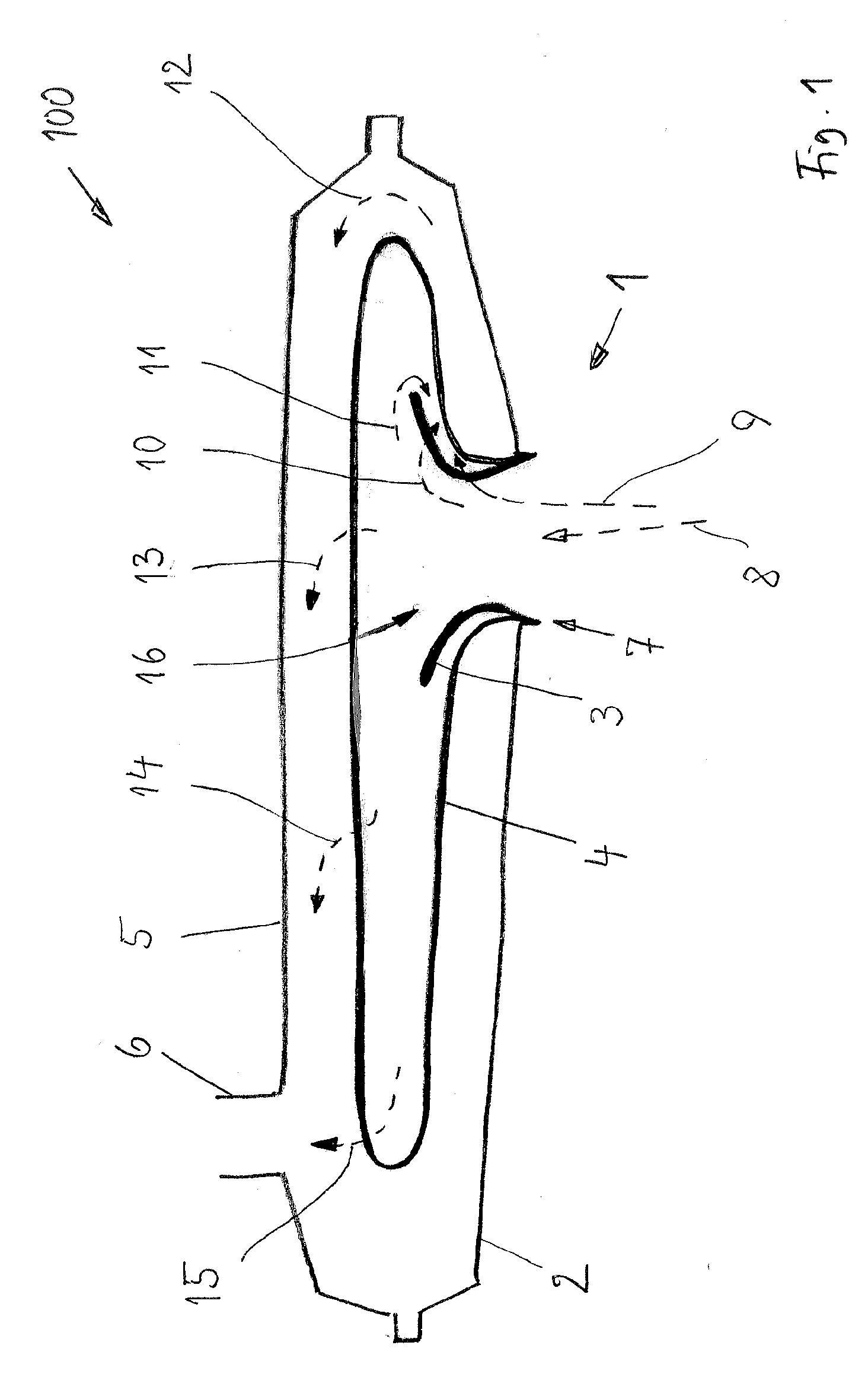

Screw compressor

ActiveUS20140010694A1Reduce leakageIncrease lubrication areaRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringHigh pressure

A scroll compressor includes a compression mechanism having a fixed scroll and an orbiting scroll. The fixed scroll includes a first end plate, an outer peripheral wall extending from an edge of first end plate, a first oil groove, and a first wrap inside of the outer peripheral wall. The orbiting scroll includes a second end plate in sliding contact with an end of the first wrap and an end of the outer peripheral wall, a second oil groove, and a second wrap. The first oil groove is disposed on a surface of the outer peripheral wall, extends along an inner periphery of the outer peripheral wall, and is configured to receive lubricating oil at a high pressure corresponding to a discharge pressure of the compression mechanism. The second oil groove is disposed on a surface of the second end plate, and is communicatable with the first oil groove.

Owner:DAIKIN IND LTD

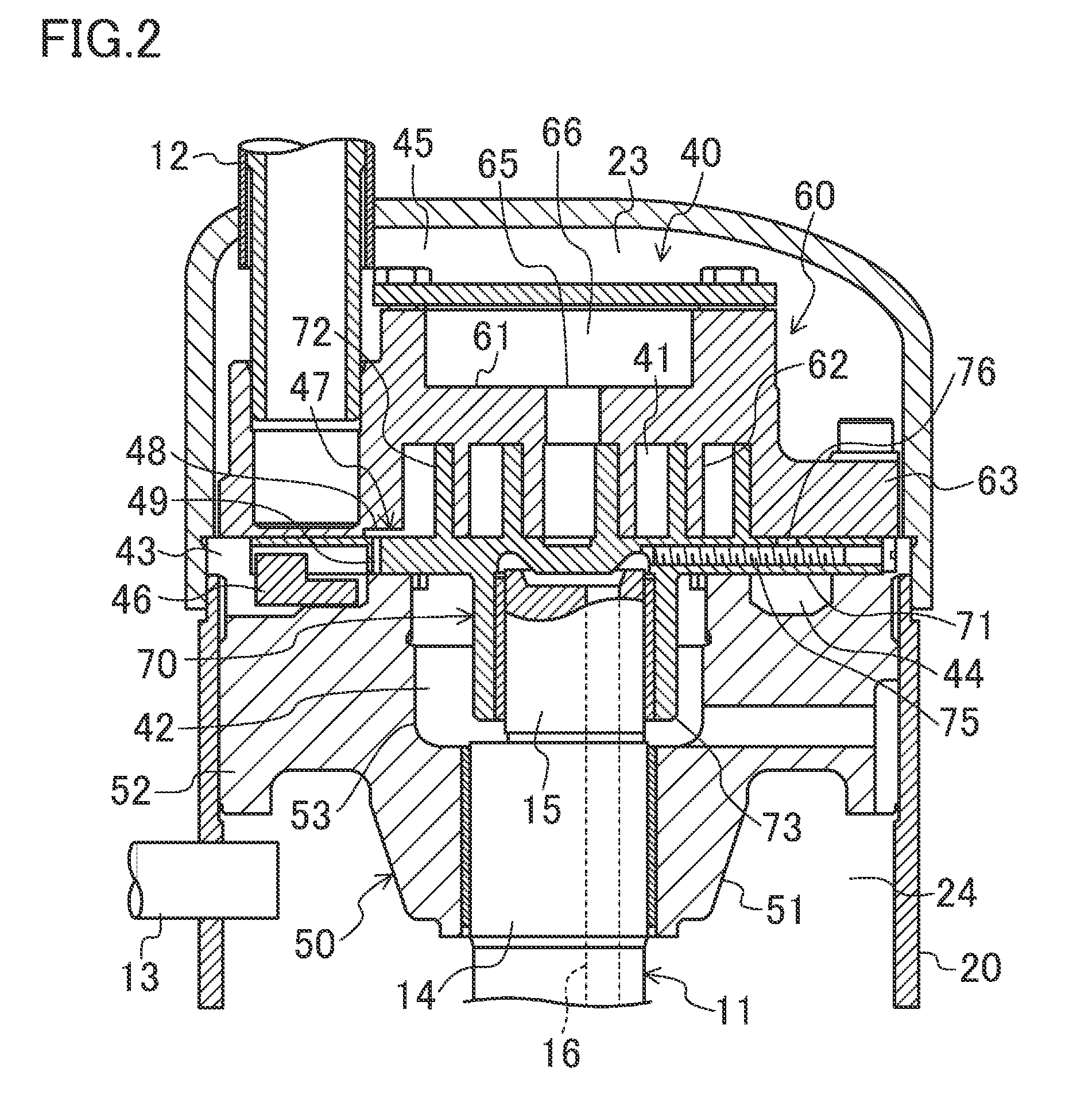

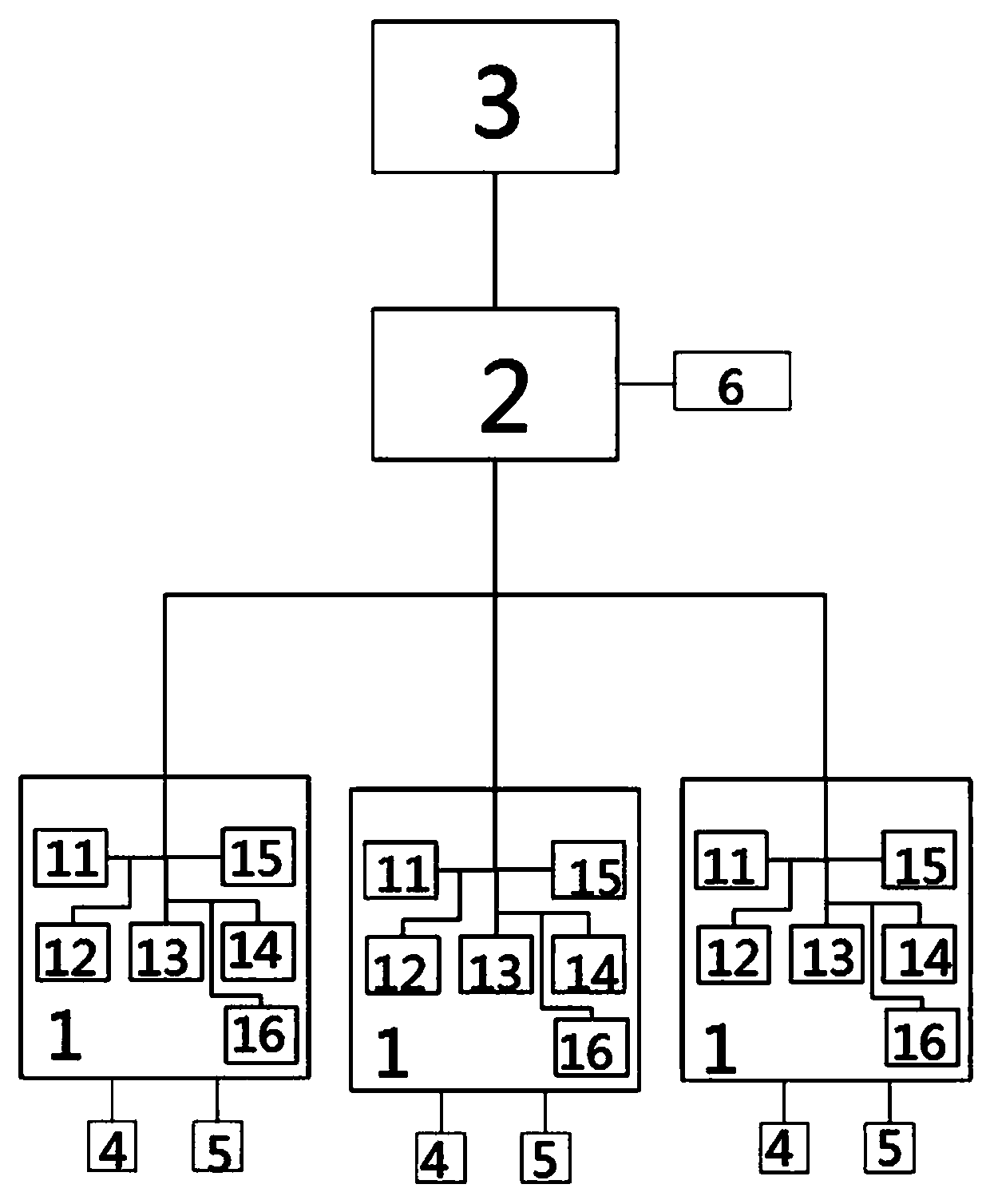

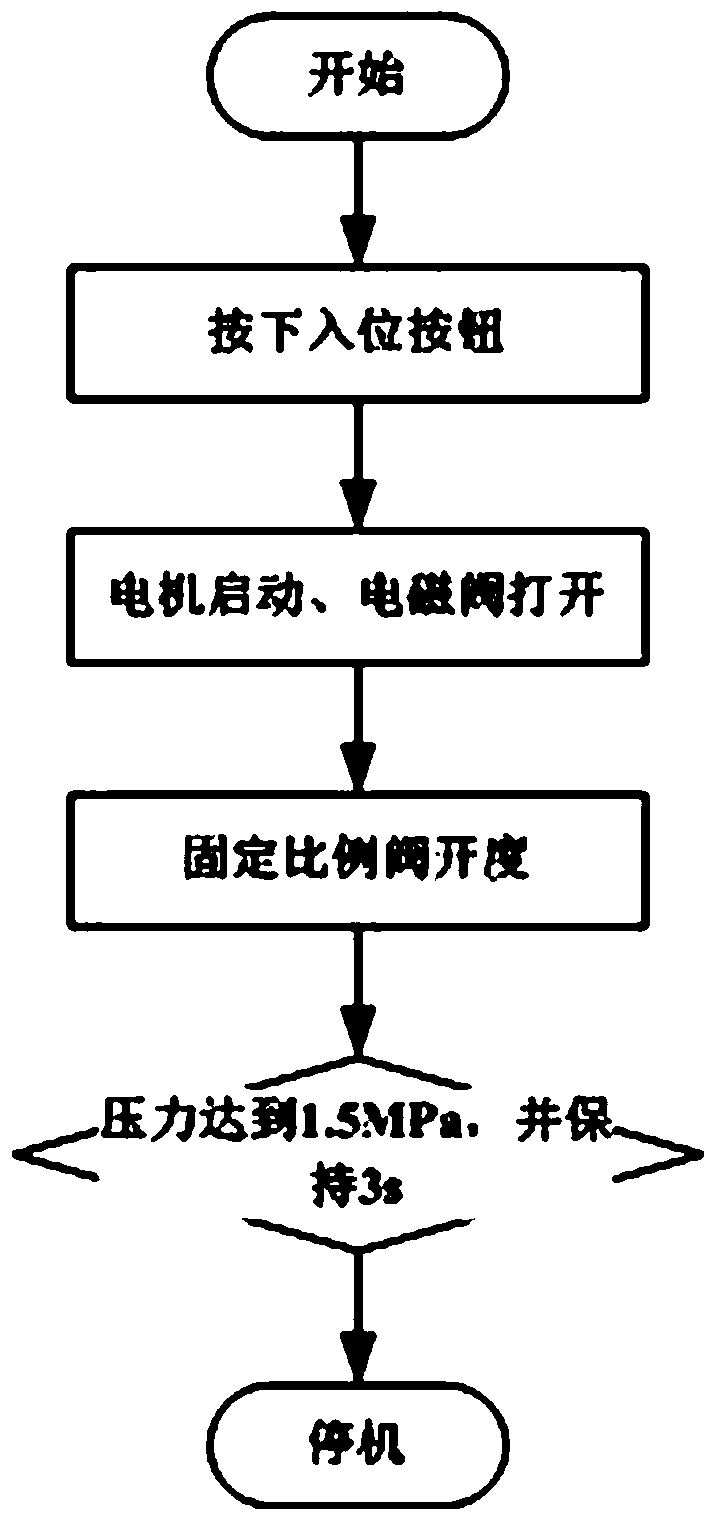

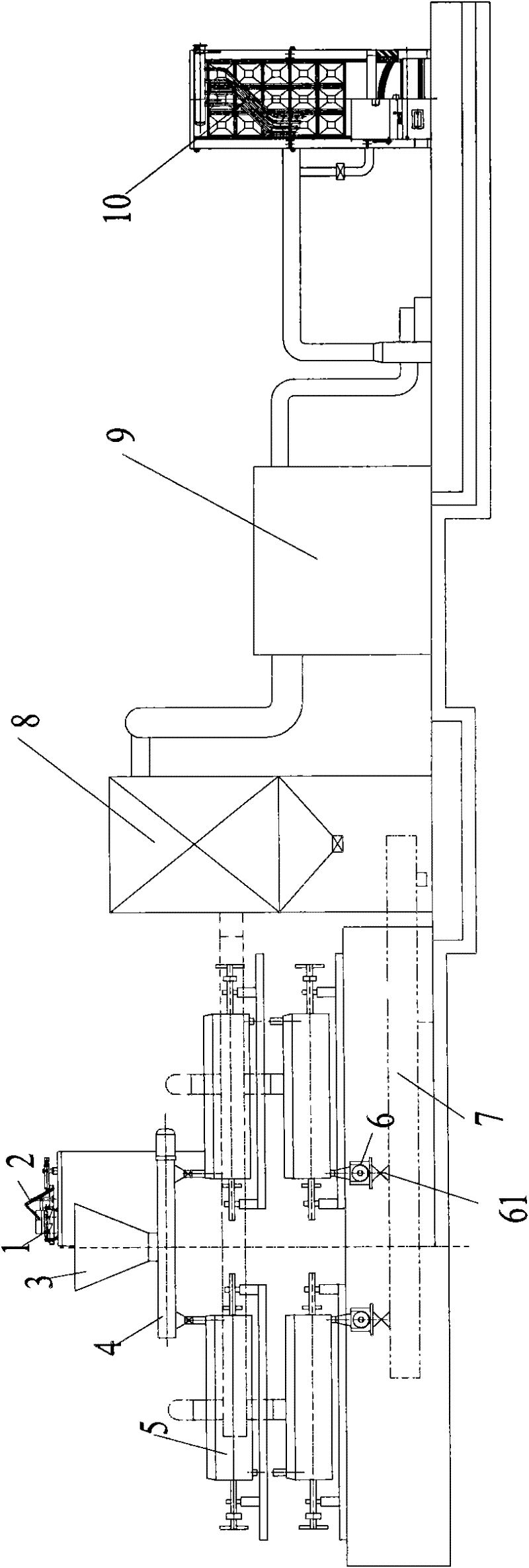

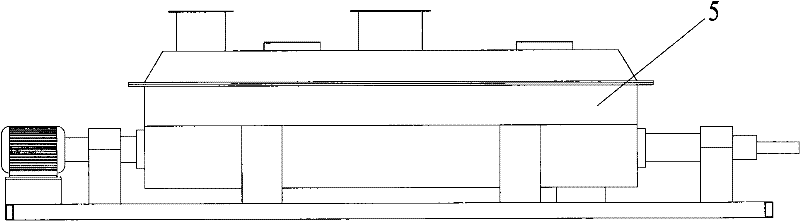

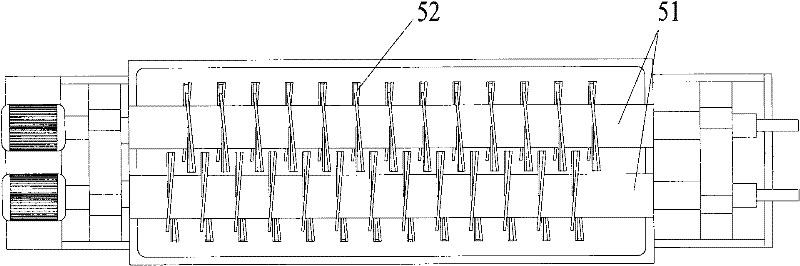

Accurate control system and method for synchronous jack-up main jacks for aircraft

PendingCN108681306AReduce labor intensityShorten maintenance preparation timeLifting devicesProgramme control in sequence/logic controllersElectricityElectric machine

The invention discloses an accurate control system and method for synchronous jack-up main jacks for an aircraft. The control system comprises at least three main jacks and further comprises a PLC controller electrically connected with each main jack, and a control end electrically connected with the PLC controller, wherein each main jack is equipped with a servo driver, the servo drivers are electrically connected with servo motors of the main jacks, a pipeline on which the servo motors are communicated with main jack acting cylinders is further provided with a proportion valve and an electromagnetic valve, pull wire sensors are further connected between supporting heads of the main jack acting cylinders and the main jack acting cylinders, and the servo drivers, the proportion valve, theelectromagnetic valve and the pull wire sensors are electrically connected with the PLC controller. The accurate control system is advantaged in that an automatic full-machine synchronous jack-up modeis employed, labor intensity of the aircraft staff is greatly reduced, the preparation time for military aircraft maintenance is shortened, and economic benefits of civil aircrafts are improved.

Owner:西安飞豹科技有限公司

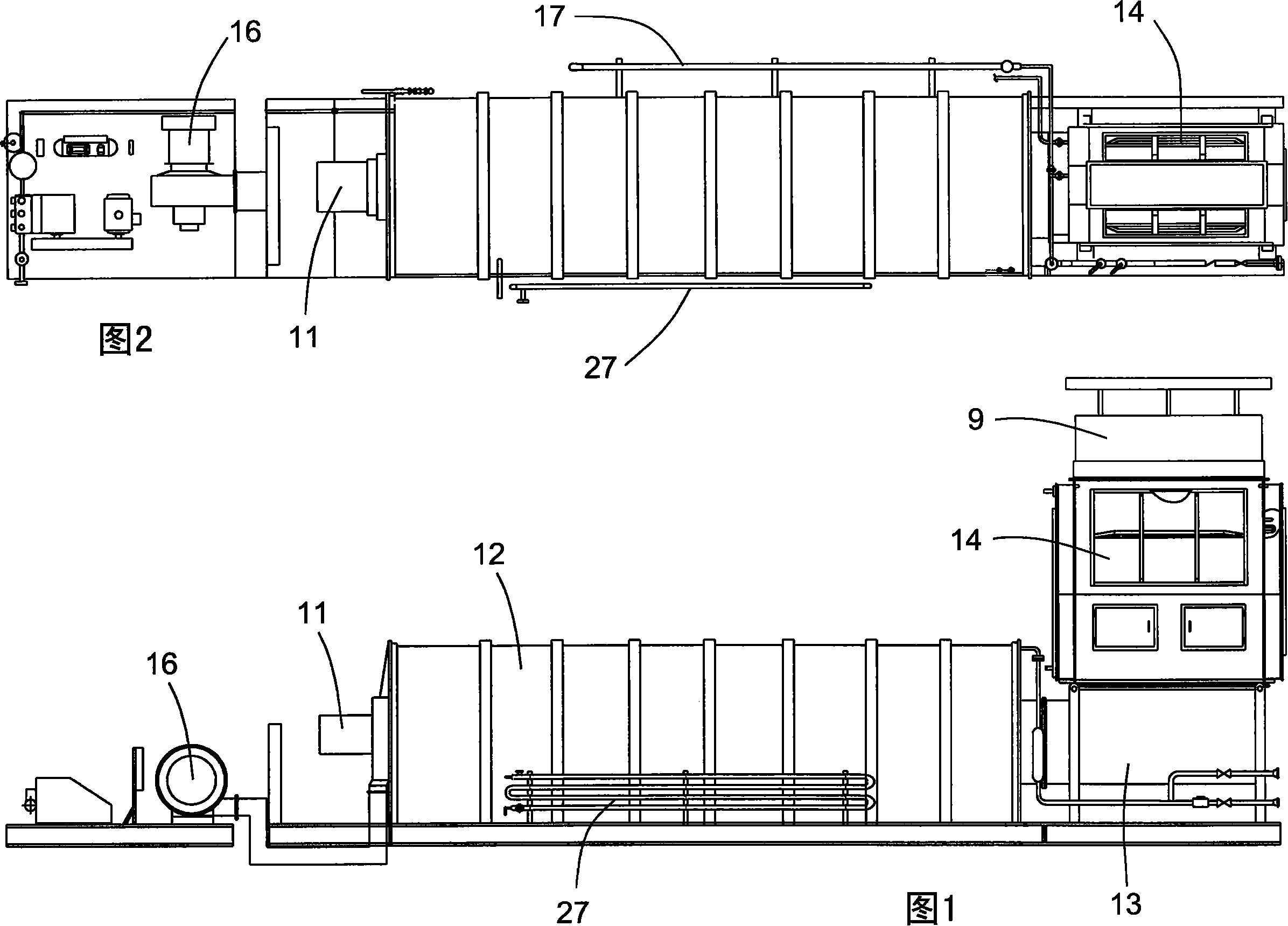

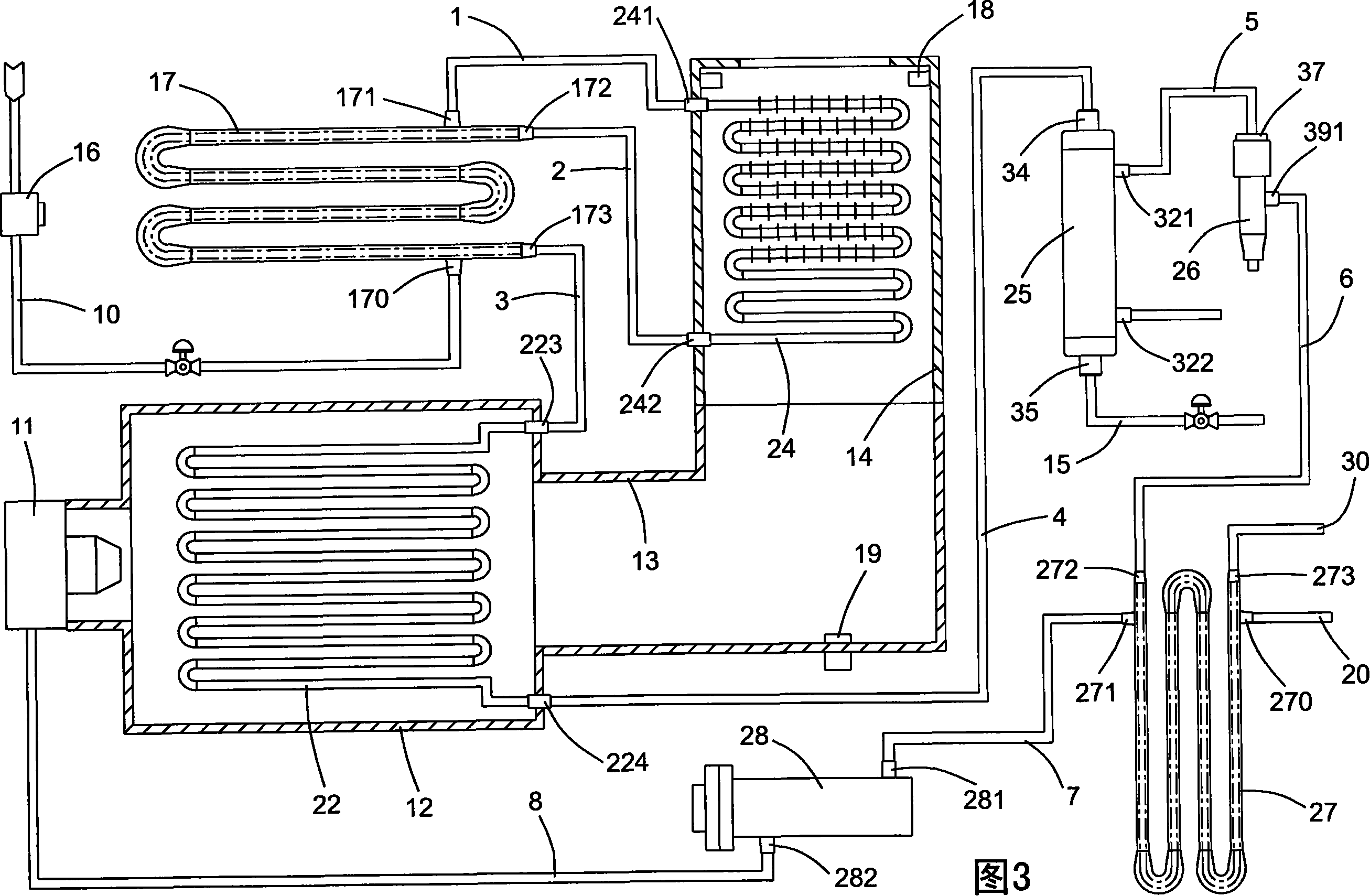

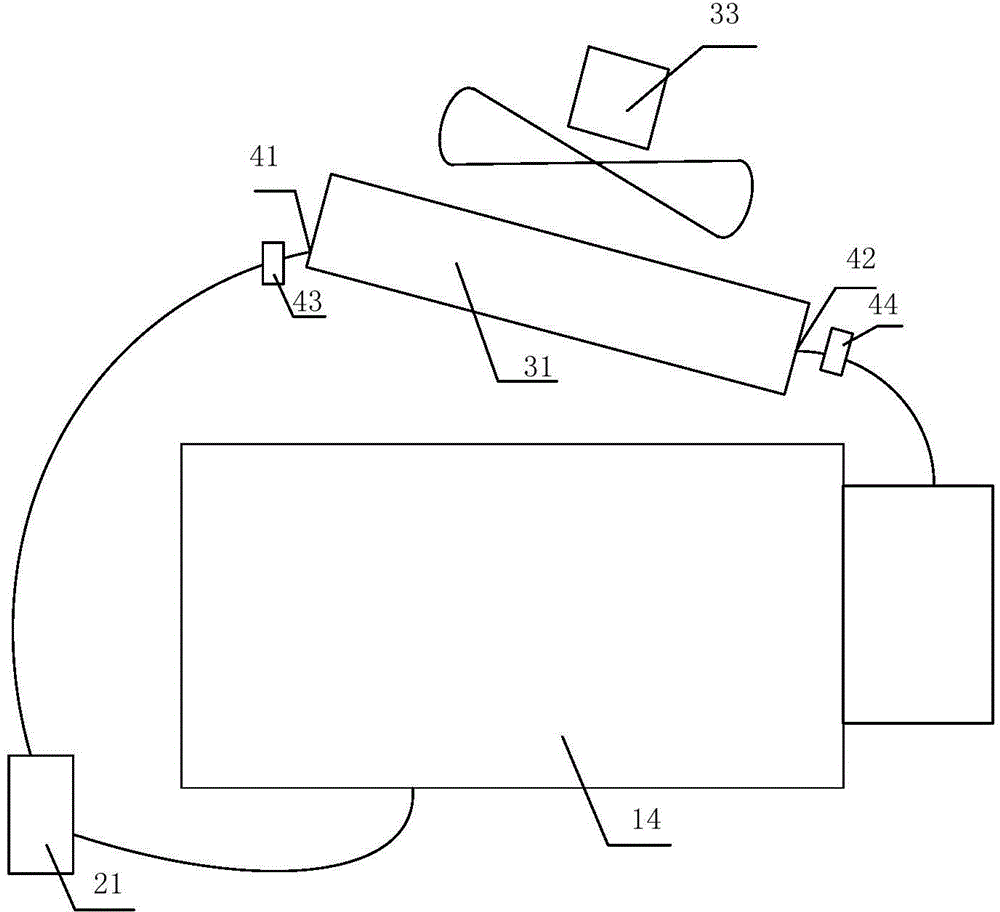

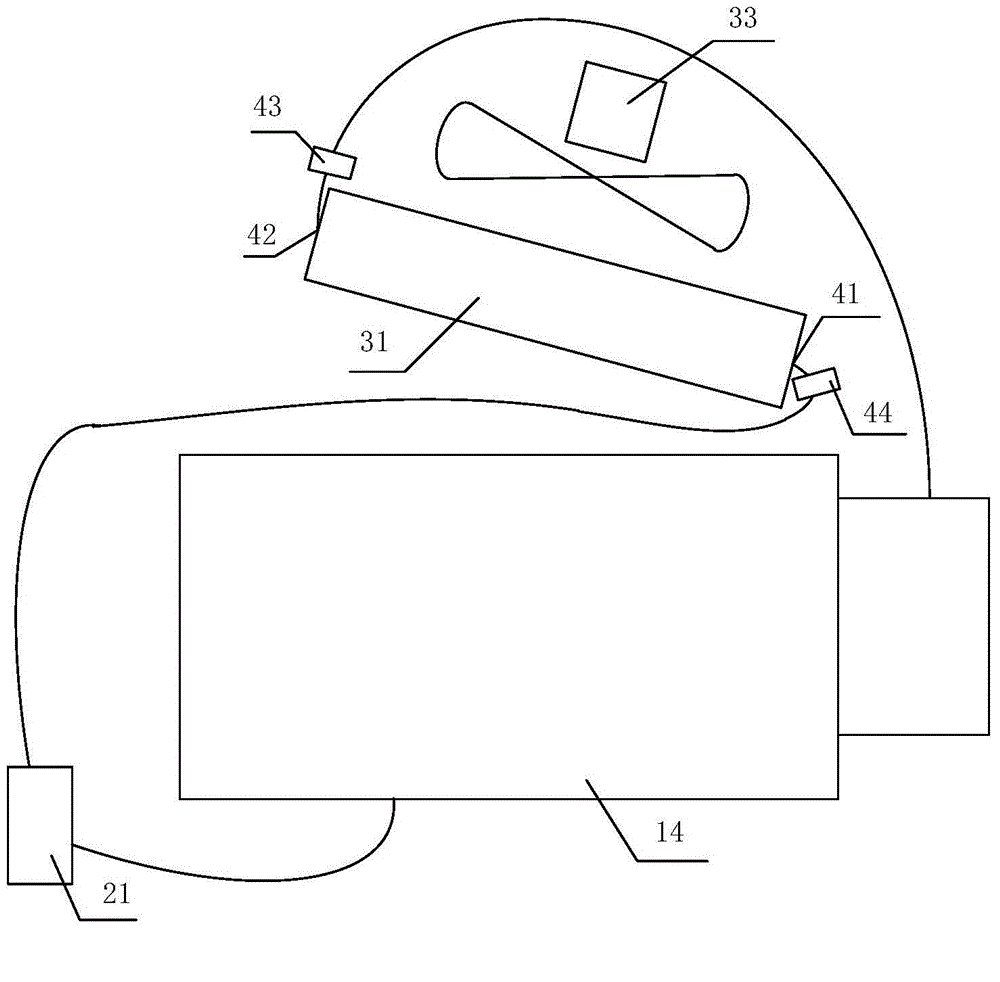

Lignitic coal modifying processing system and technology

InactiveCN102175074AIncrease oil temperatureIncrease valueSolid fuelsDrying solid materialsCombustionHeat conducting

The invention discloses a lignitic coal modifying processing system which comprises a raw material delivery device, a drying device and a heat conducting oil furnace, wherein the drying device is respectively connected with the raw material delivery device and the heat conducting oil furnace; the raw material delivery device delivers the lignitic coal raw material to the drying device; the heat conducting oil furnace delivers the heat conducting oil to the drying device; and the lignitic coal is modified by the drying devices through the heat conduction of the heat conducting oil under the environment of isolating external materials. According to the lignitic coal modifying processing system provided by the invention, because the lignitic coal is subjected to heat conduction by utilizing the high-temperature heat conducting oil, simultaneously the lignitic coal is dried by isolating the influence of the external materials, not only can the heat value of the lignitic coal be improved, but also the volatile can be improved, and the moisture of the lignitic coal is reduced, thus the lignitic coal is dried fully, the moisture of the obtained lignitic coal product is obviously reduced, the heating productivity is improved greatly, the self-combustion of the coal can be prevented and the coal is convenient to transport and store, the system is good for the use of power generation, gas making, chemical engineering, and the like.

Owner:QIANQIU ENERGY SHANGHAI

Oil filter device

ActiveUS8673141B2Simply producibleLow effortWater/sewage treatmentMachines/enginesFilter mediaOil filter

The present invention provides a suction oil filter device for an engine or a transmission that has an oil inlet and an oil outlet on the filter housing, a suction oil pump connectable to the oil outlet, using which a partial vacuum may be generated between oil inlet and oil outlet, a fine filter medium and an ultrafine filter medium, which are situated between the oil inlet and the oil outlet. The fine filter medium is attached to the oil inlet or to the oil outlet, and the ultrafine filter medium is situated before the fine filter medium in the flow direction and in a secondary flow area of the filter housing. A high filtration performance may thus be achieved at low production outlay.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

Lubrication and cooling system for gear case

ActiveCN104565327AControl running torqueSmooth startGear lubrication/coolingFrequency changerProportion integration differentiation

The invention discloses a lubrication and cooling system for a gear case. The lubrication and cooling system comprises an oil pump, an oil pump motor, a cooler fan, a fan motor and a cooler; the oil inlet of the oil pump is connected with the oil outlet of the gear case; the oil pump motor and the fan motor are respectively connected with a frequency changer; speed control is performed on the oil pump motor and the fan motor by the frequency changer; the control mode of the frequency changer is a PID (proportion integration differentiation) control mode; a temperature used for detecting the temperature of an oil groove of the gear case is arranged in the oil groove of the gear case. According to the lubrication and cooling system disclosed by the invention, on the basis of temperature information fed back by the temperature sensor arranged in the oil groove of the gear case, PID automatic control is performed on the running frequency of the oil pump motor and the running frequency of the fan motor, so that the control of the running speed of the fan and the running torque of the oil pump motor is realized by the frequency changer; in the start-up process and the running process of the oil pump motor, according to the conditions of the temperature and the viscosity of lubricating oil, the oil pump motor is smoothly started, and the goal that the energy is saved under the high temperature condition is achieved.

Owner:DALIAN SHINERGY SCI & TECH DEV

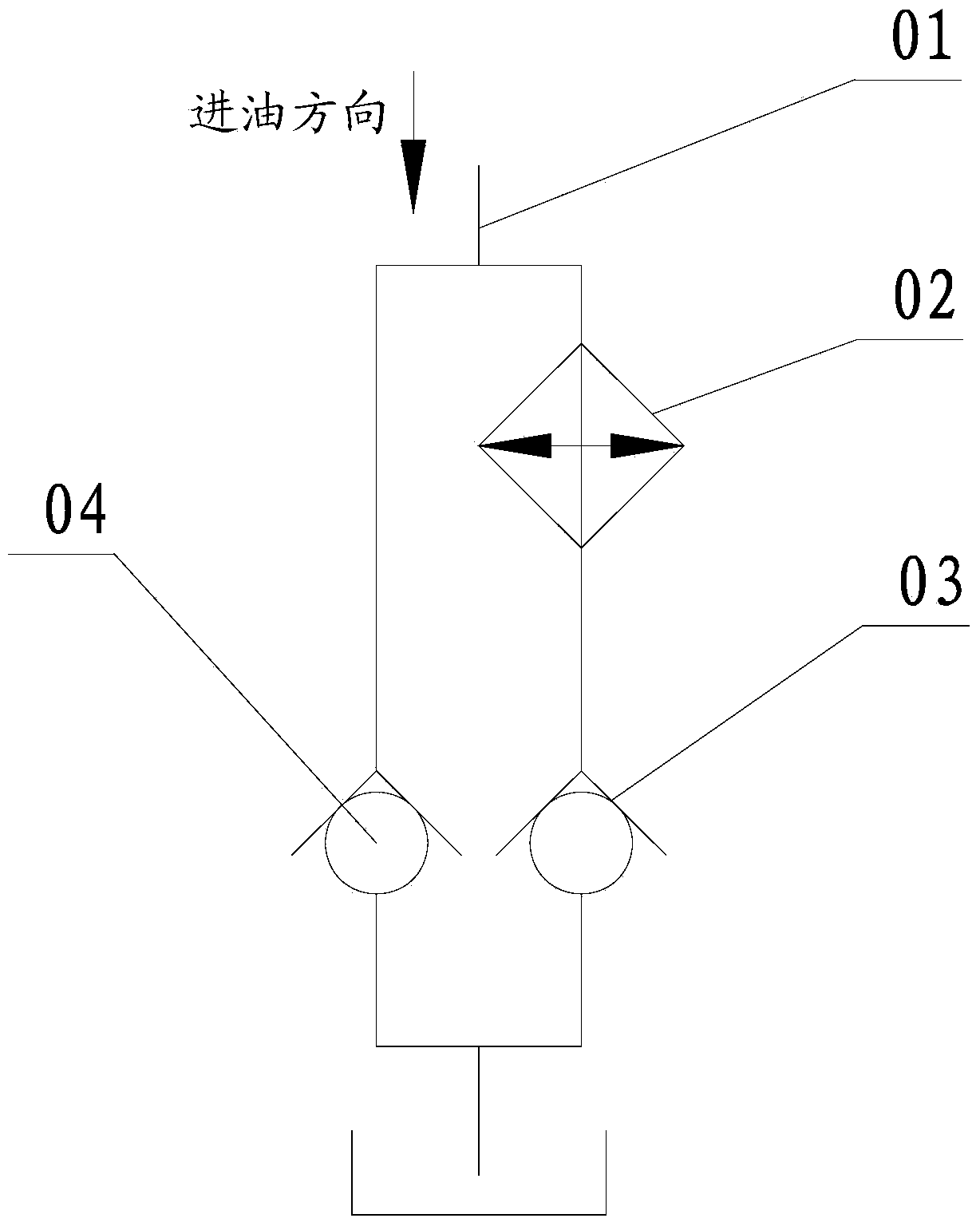

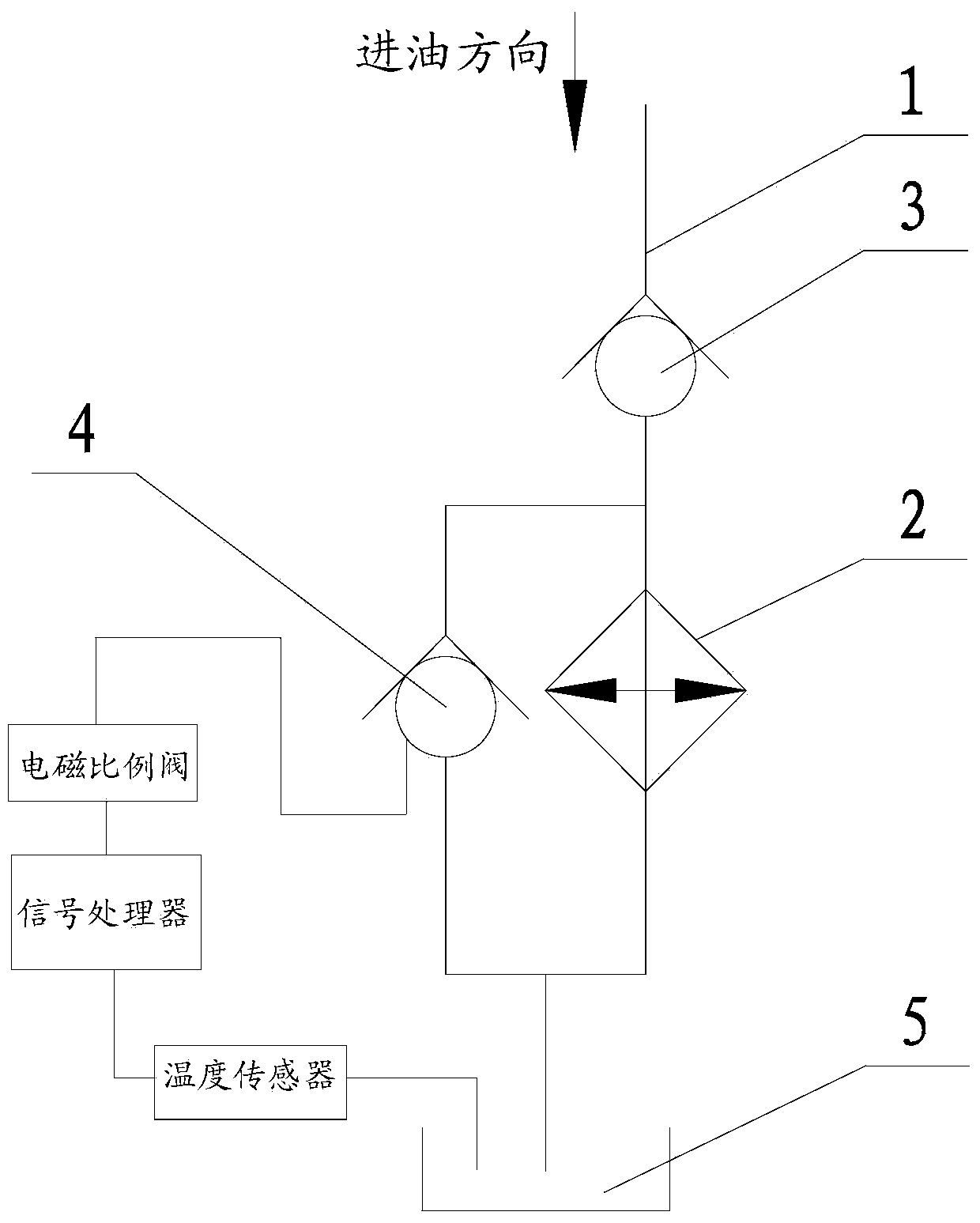

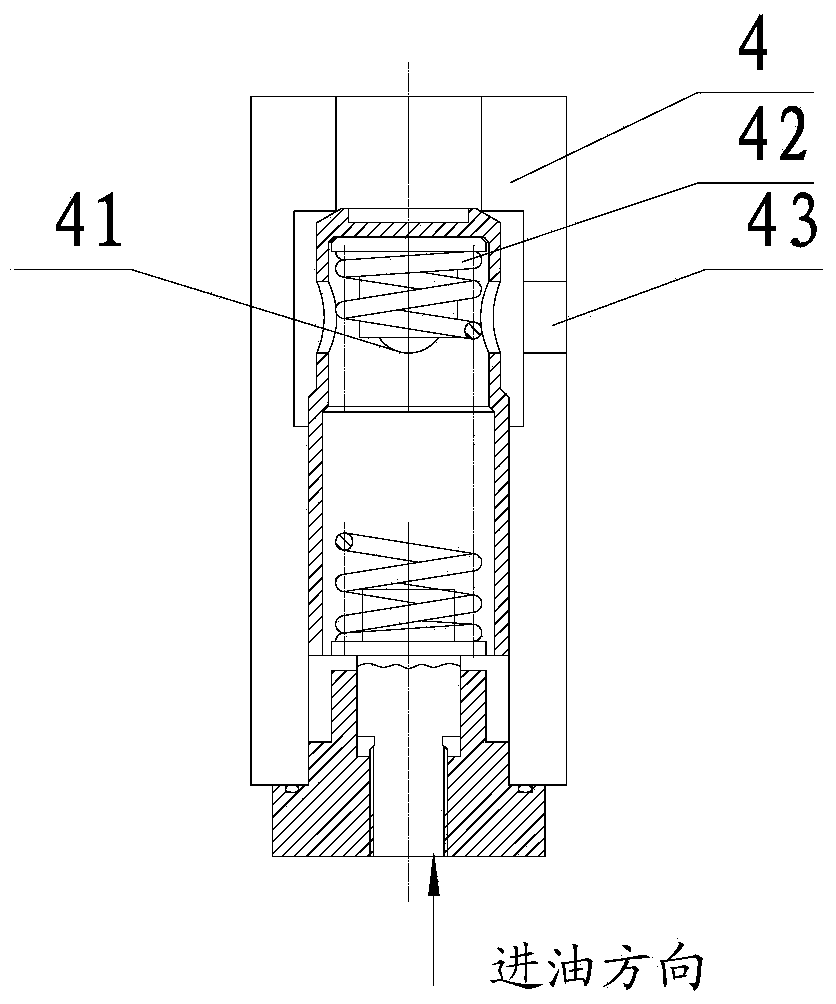

Hydraulic oil-return device, hydraulic system and excavator

InactiveCN103470574AImprove practicalityIncrease oil temperatureServomotor componentsFluid-pressure actuator componentsTemperature controlExcavator

The invention relates to a hydraulic oil-return device, a hydraulic system and an excavator. The hydraulic oil-return device is characterized in that an oil-taking check valve is arranged on an oil-return oil circuit connected with a main valve, and an oil outlet of the oil-taking check valve is connected with a bypass check valve and a radiator which are in parallel connection, so that oil flowing out from the main valve is firstly decompressed via the oil-taking check valve to reduce oil-taking pressure of the radiator to have the same protected; in addition, the hydraulic oil-return device is further characterized by being provided with an oil-temperature control device, opening pressure of the bypass check valve is regulated according to oil temperature, when the oil temperature is higher, larger opening pressure can be set so as to allow the hydraulic oil to pass through the radiator as much as possible to have the oil temperature of an oil-return oil tank lowered and radiating effect improved; similarly, when the oil temperature is lower, the bypass check valve is controlled to be opened at the lower oil pressure so as to allow the hydraulic oil to pass through the bypass check valve as much as possible to improve use efficiency of the radiator, prolong the service life thereof, and improve practicability of the hydraulic oil-return device.

Owner:SANY HEAVY MACHINERY

Hydraulic system and wind turbine generator provided therewith

InactiveUS9169829B2StartabilityIncrease oil temperaturePropellersWind motor controlLine tubingFuel tank

Owner:MITSUBISHI HEAVY IND LTD

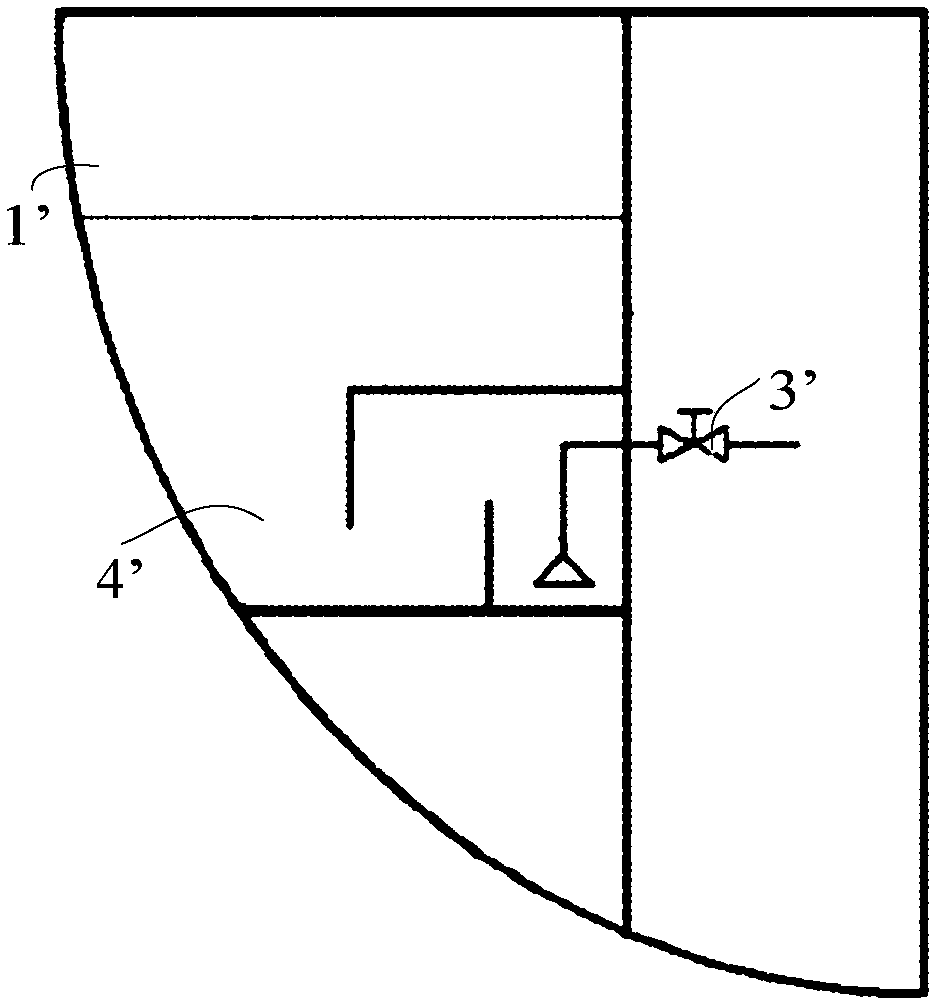

Cabin cabinet energy-saving system heat exchange box and ship fuel oil preheating system

ActiveCN109436280ALittle resistance lossReduce operating loadAuxillariesVessel ventillation/heating/coolingOperational costsFuel oil

The invention relates to the technical field of ship fuel oil preheating, and particularly relates to a cabin cabinet energy-saving system heat exchange box and a ship fuel oil preheating system, andthe problem that the oil temperature nearby a suction port is too low and the cold starting and pumping of the delivery pump are difficult existing in the existing 'small isolation cabin' form ship fuel oil preheating system are relieved. The cabin cabinet energy-saving system heat exchange box comprises an oil injection pipe and an oil pumping pipe; at least part of the input end of the oil injection pipe is positioned in the suction end of the oil pumping pipe; and a heating coil sleeves the input end of the oil injection pipe. According to the cabin cabinet energy-saving system heat exchange box and ship fuel oil preheating system, the viscosity of the fuel oil near the oil injection pipe is reduced, the conveying resistance of the oil pumping pipe is reduced, a conveying system can normally work when the conveying system is started, the phenomenon that the initial moment resistance of the starting of the delivery pump is too large and the work load of the delivery pump is too largeto start the delivery pump due to too low fuel oil temperature in the oil injection pipe is avoided, the heat exchange efficiency is improved, and the operation cost is reduced.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

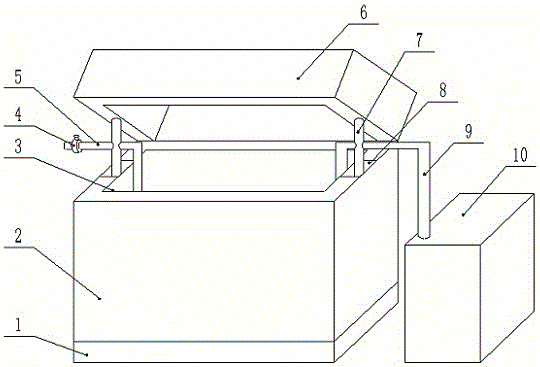

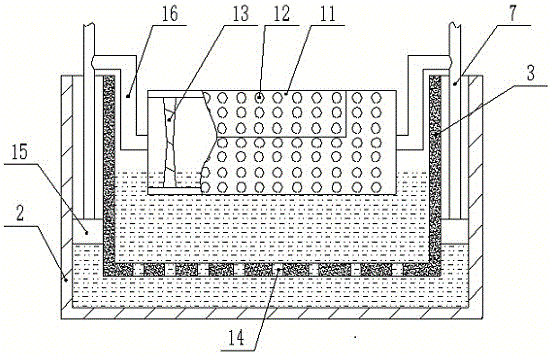

Odd taste broad bean deep-frying device

InactiveCN106797977ALow boiling pointIncrease oil temperatureOven air-treatment devicesOil/fat bakingDeep fryingEngineering

The invention relates to the technical field of food production and processing, in particular to an odd taste broad bean deep-frying device. The device comprises a heater and a vacuum pump, wherein a heating tank is arranged in the heater, a sealing cap is installed on the heating tank, a liner is installed in the heating tank, a cavity is reserved between the liner and heating tank, and a plurality of oil holes are formed in the liner; the two sides of the heating tank are both provided with a piston cylinder communicated with the cavity, pistons are installed in the piston cylinders, the pistons are connected to hollow piston rods in a hinged mode, the piston rods hinged to the sealing cover and one piston rod is communicated with an air inlet pipe provided with a relief valve, and the other piston rod is communicated with an air intake pipe; the open end of the air intake pipe is connected to the vacuum pump, a deep-frying drum is installed in the liner, fan blades are installed inside the deep-frying drum, oil-immersion holes are formed in the deep-frying drum, the two ends of the deep-frying drum are connected to tube shafts respectively, and the tube shafts are communicated with the piston rods respectively. According to the scheme, flowing air is guaranteed in the device in the vacuumizing process, accordingly the temperature of the colza oil is lowered, and oil fume generated in the device is brought away by the flowing air.

Owner:CHONGQING XINTAIFA FOOD

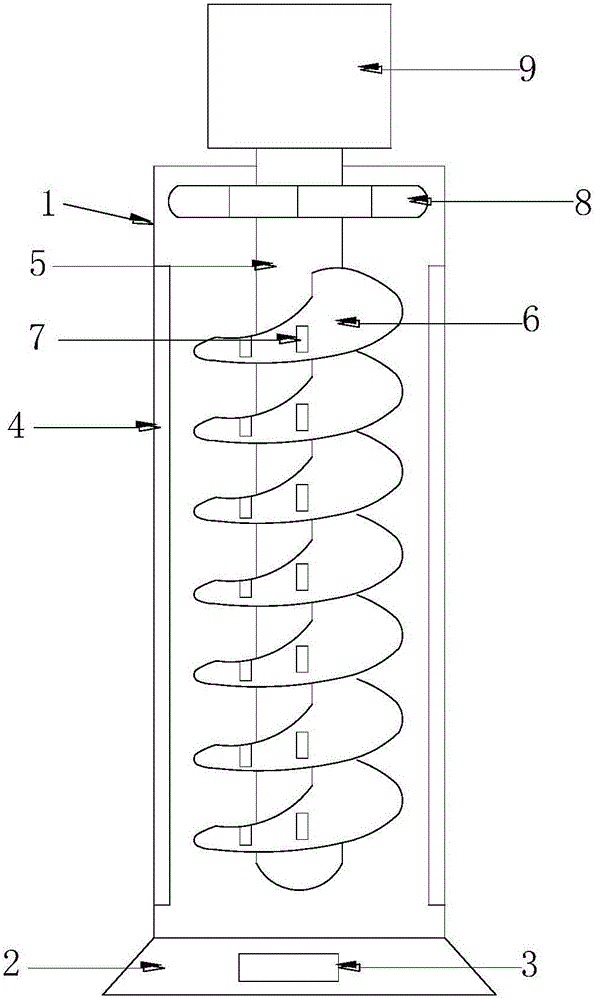

Screw type efficient oil pumping device

Owner:XI'AN PETROLEUM UNIVERSITY

Output control apparatus of engine

ActiveUS20130261906A1Increase temperatureIncrease torqueElectrical controlDigital data processing detailsAutomatic transmissionEngineering

Engine output control apparatus has shift range detecting section detecting shift range of automatic transmission; vehicle speed detecting section detecting vehicle speed; engine output state detecting section detecting engine output state; and controller. The controller performs (a) judgment control judging that torque converter is in a stall state if following judgment conditions (i) to (iii) are satisfied, (i) shift range is drive range, (ii) vehicle speed is equal to or less than predetermined vehicle speed, (iii) engine is in a high output state, (b) cumulation control cumulating a period of agreement of the judgment conditions if the judgment conditions are satisfied, and (c) output suppression control suppressing output of the engine if a control start condition is satisfied by cumulation of the agreement period. The control start condition is set so that as the vehicle speed becomes higher, start of the output suppression control is more delayed.

Owner:JATCO LTD

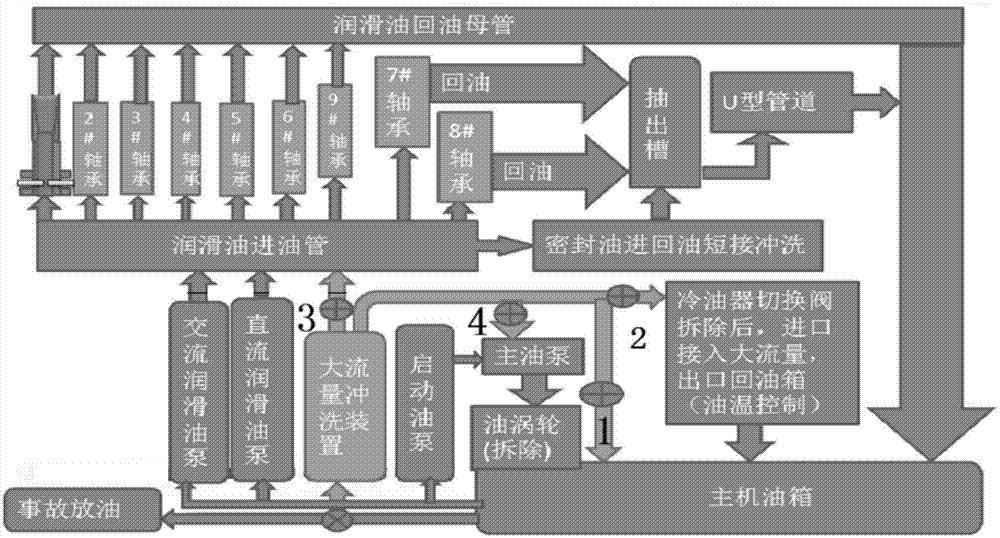

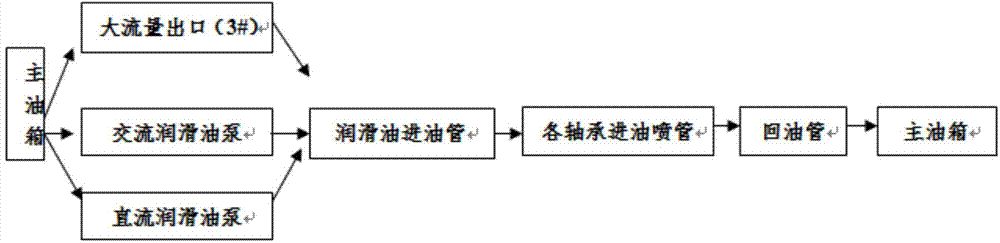

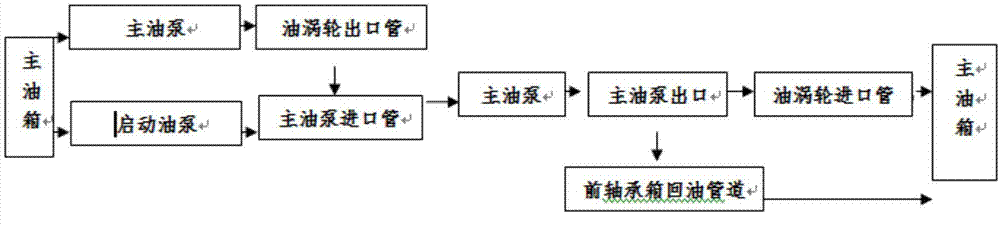

Turbine generator set oil pipeline half-outside oil circulation system

A turbine generator set oil pipeline half-outside oil circulation system comprises a main engine oil tank, an engine oil conveying part connected with the main engine oil tank, and a lubricating part connected with the engine oil conveying part; the lubricating part comprises a lubricating oil inlet pipe, components to be lubricated and a lubricating oil return mother pipe, wherein the components to be lubricated are connected with the lubricating oil inlet pipe, the lubricating oil return mother pipe is connected with the components to be lubricated, and the lubricating oil return mother pipe is connected with the main engine oil tank; the engine oil conveying part comprises four temporary engine oil conveying oil circuits and a high-flow flushing device. The turbine generator set oil pipeline half-outside oil circulation system has the advantages that the high-flow flushing device is used in the system flow unified distribution state, the flushing mode of paralleling operation of a pumping set of the system and a high-flow pumping set can be realized, and the requirement of a lubricating oil system for high-flow flushing is well met.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

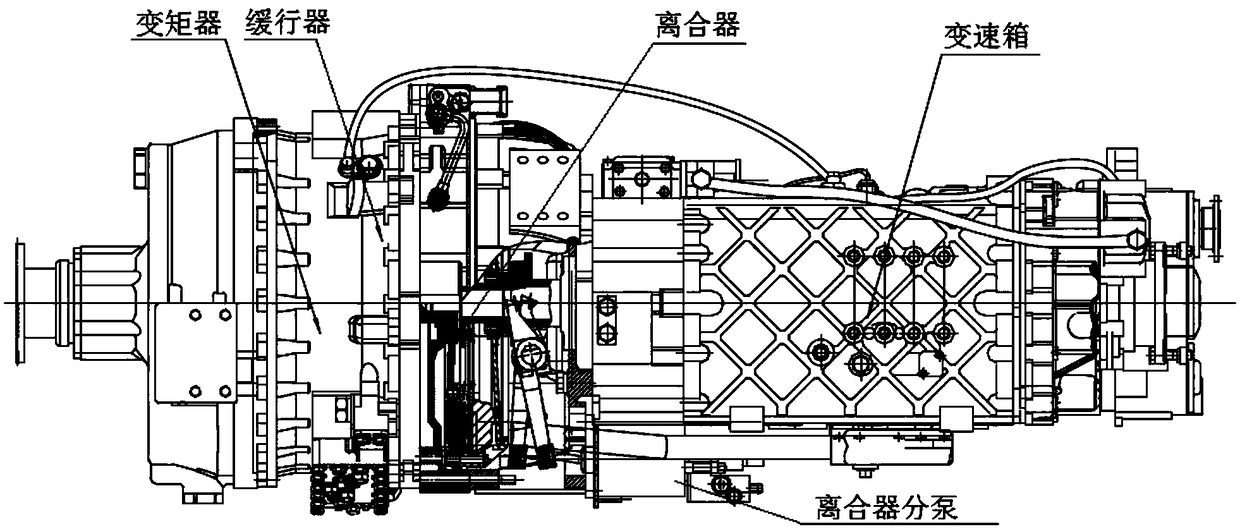

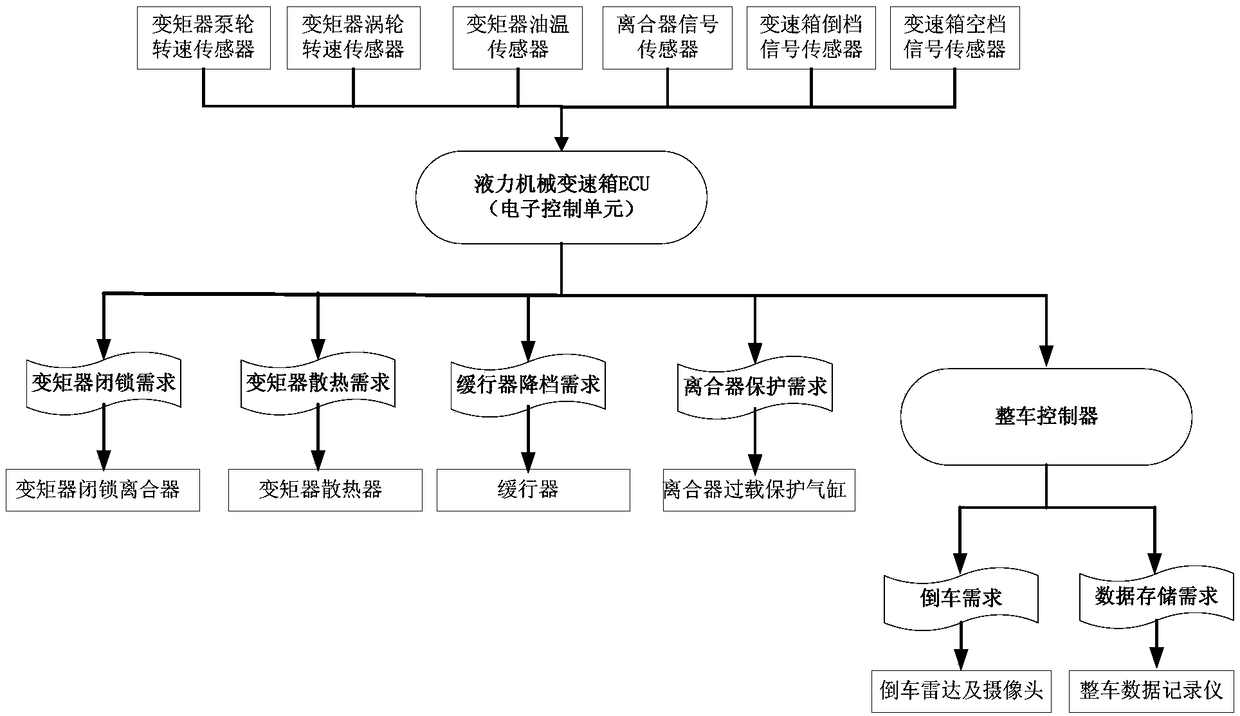

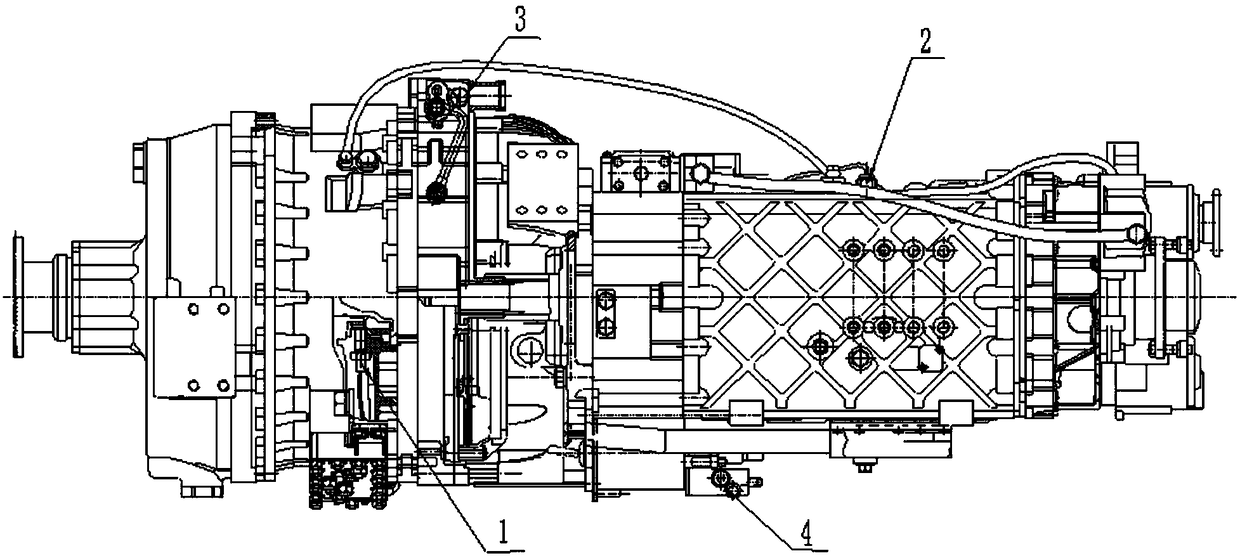

Signal detection system and method for hydraulic force mechanical speed changing box

The invention provides a signal detection system and method for a hydraulic force mechanical speed changing box. A hydraulic force mechanical speed changing box ECU control unit is used as a central controller, movement control and information storage of the hydraulic force mechanical speed changing box are realized through two ways of collection built-in sensor state and vehicle control unit interaction. Specifically that the rotate speed of a torque converter pump wheel, turbine rotate speed, oil temperature, a clutch signal, speed changing box neutral position, reverse gear and other statussignals obtained by detection realize communication and information storage with the vehicle control unit and a storage through CAN bus, the hydraulic force mechanical speed changing box ECU controlunit provides data sources for automatic adjustment heat dissipation power of a hydraulic force mechanical speed changing box radiator, the overload protection of a clutch, a reversing radar, an amblecaution and fault diagnosis, the problem that the hydraulic force mechanical speed changing box is damaged caused by the amble high temperature and the clutch high temperature is avoided, and meanwhile functions such as reversing radar reminding and the fault diagnosis are provided for users.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

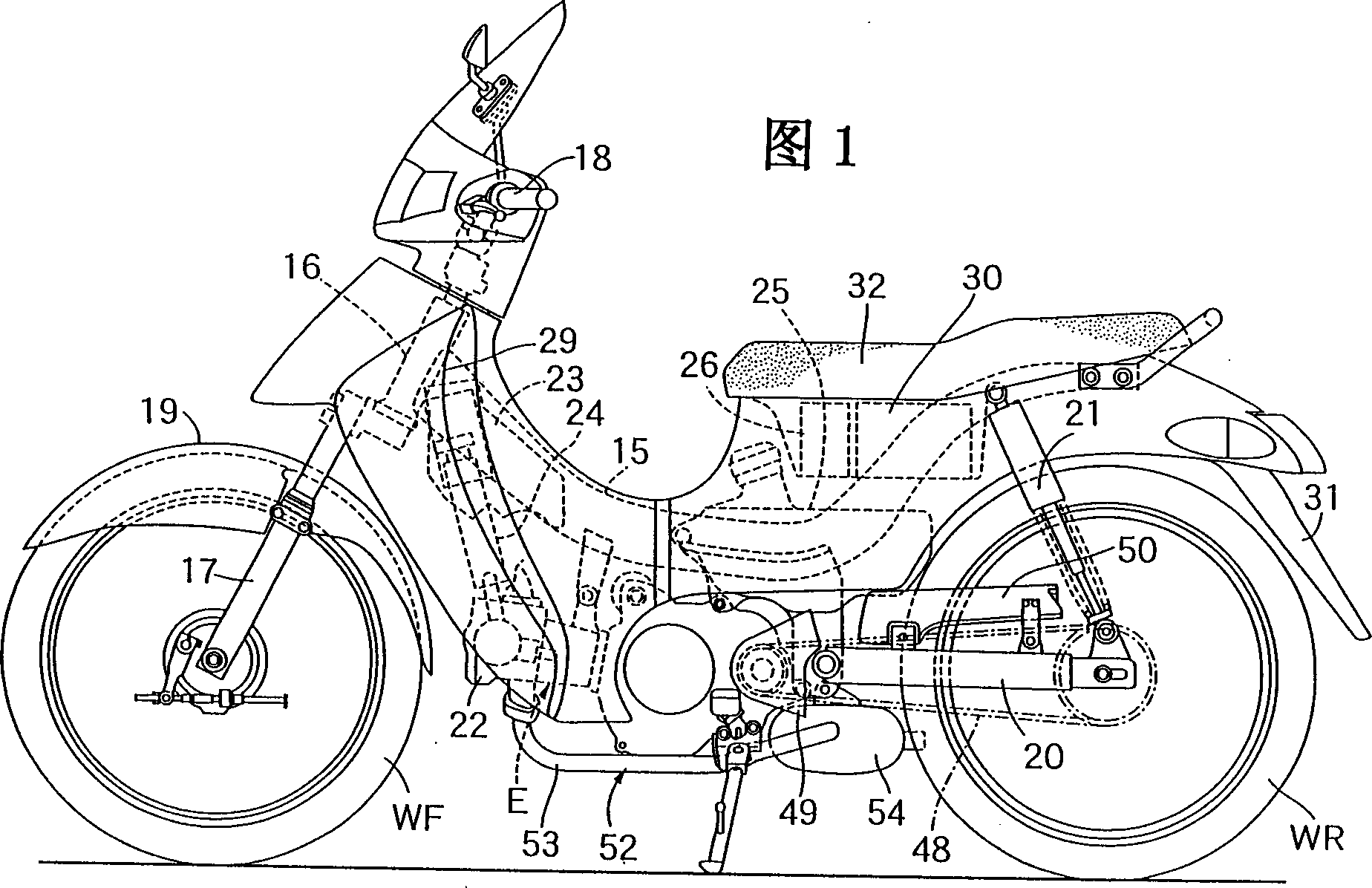

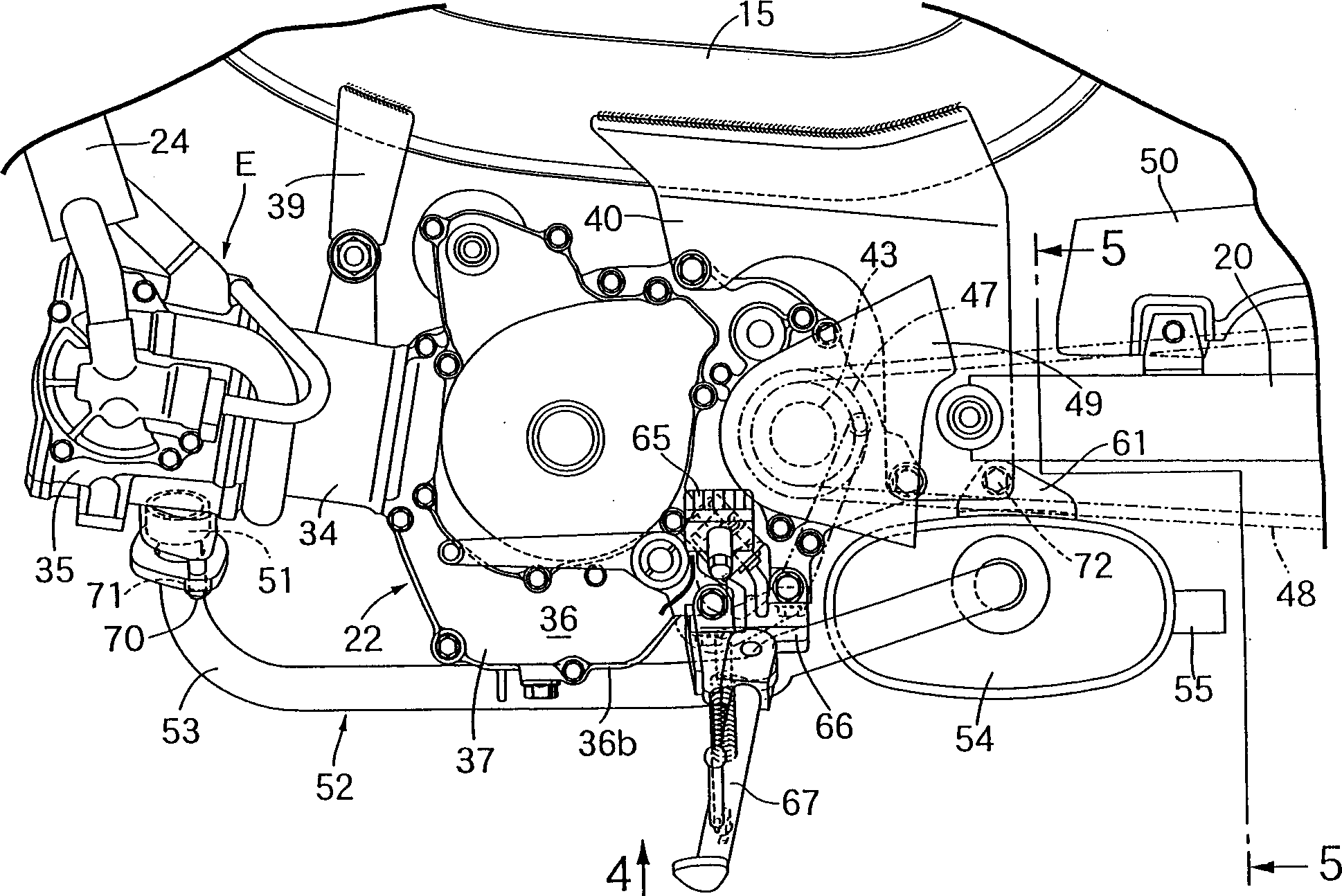

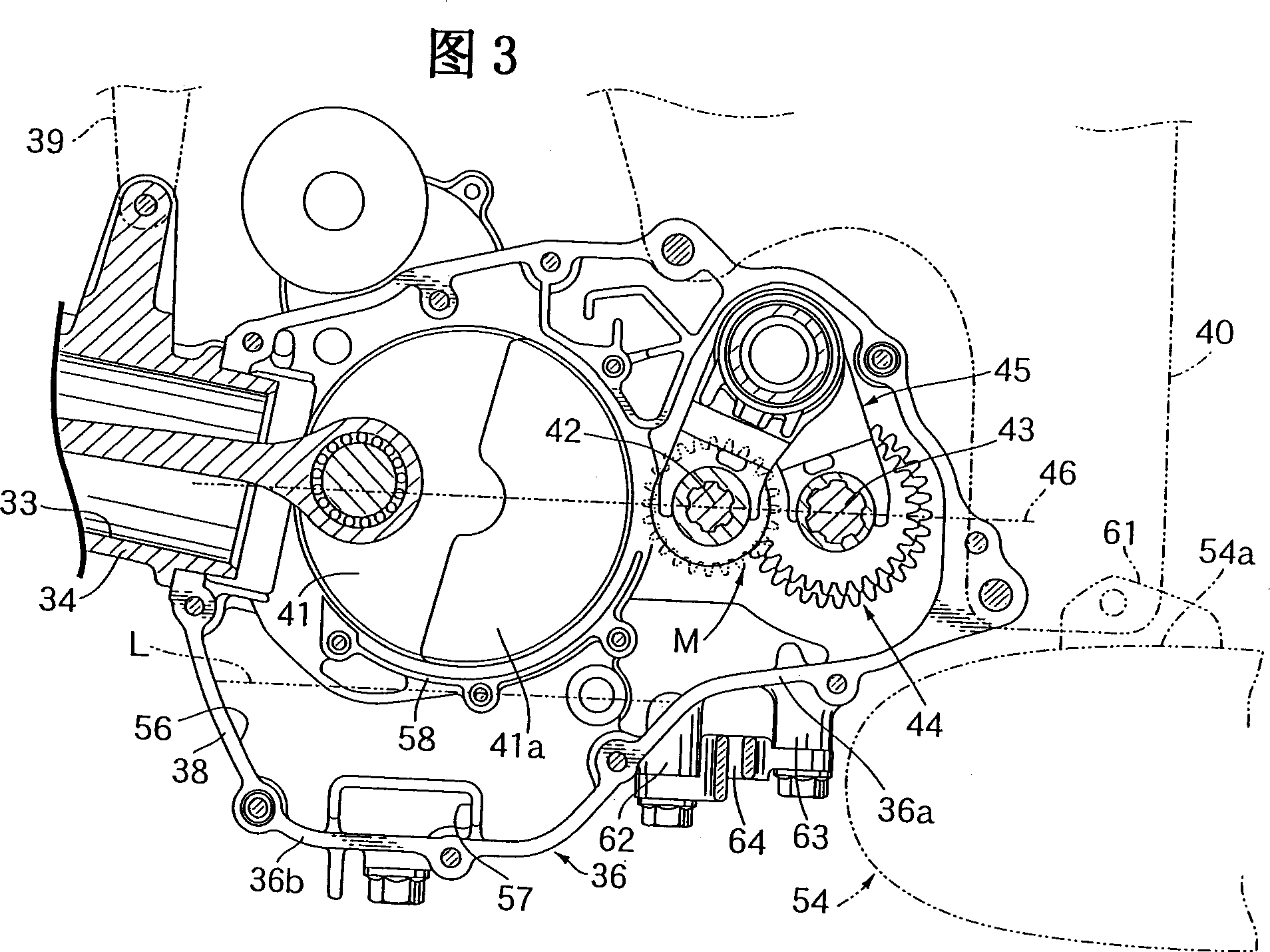

Crankcase structure for engine of motorcycle

A bottom wall rear part 36a of the crankcase 36 corresponding to the transmission shafts 42 and 43 can secure a space for arranging at least a part of an exhaust muffler 54 under the bottom wall rear part 36a, and is formed higher than a bottom wall front part 36b of the crankcase 36 corresponding to the crankshaft 41. To efficiently pump up oil with a simple pumping-up structure, and to improve warming-up performance while reducing an oil quantity stored in a crankcase in an engine for a motorcycle or a motor-tricycle for rotatably supporting transmission shafts for orthogonally arranging the axis on an almost horizontal straight line extending in the longitudinal direction by passing through the axis of a crankshaft on the rear side more than the crankshaft in the crankcase.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com