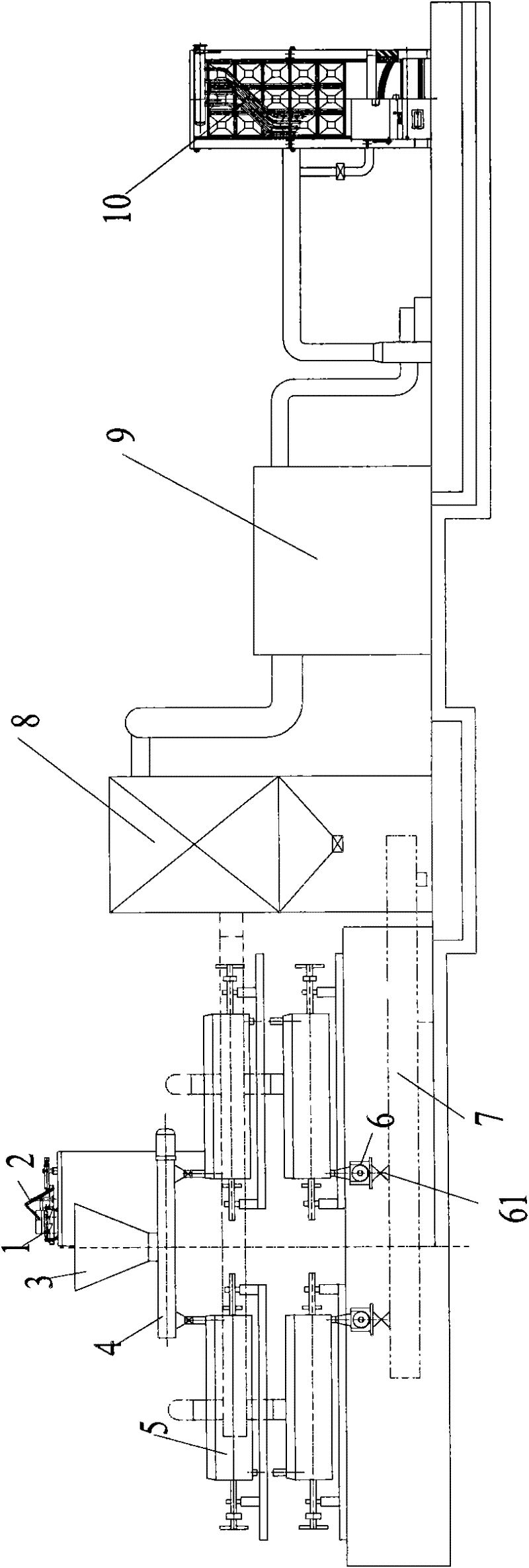

Lignitic coal modifying processing system and technology

A processing system and processing technology, which is applied in the field of lignite processing, can solve the problems of insufficiency of oxygen isolation, high lignite moisture, and high ash content, and achieve the effect of increasing value, high volatile content, and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Lignite to be processed: total water 28.4%, ash content 20.04%, volatile matter 29.06%, low calorific value 3224 kcal / kg.

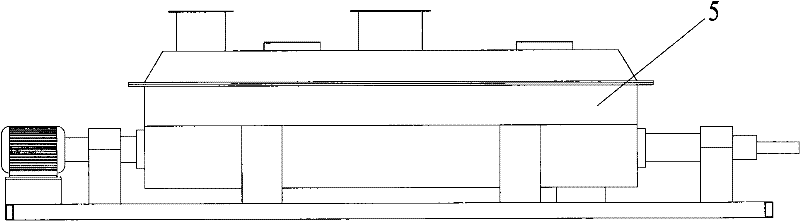

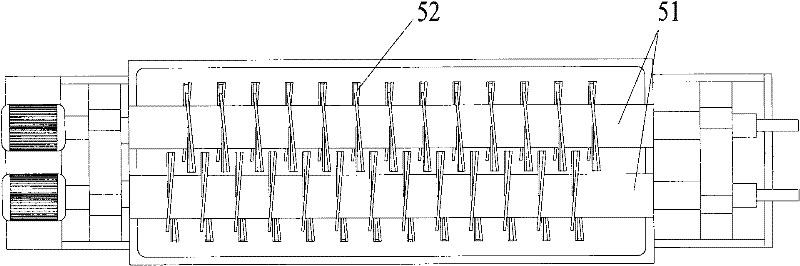

[0078] The lignite to be treated is crushed and ground to an average particle size of about 0.15mm, and then sent to a double-blade dryer, and the lignite is heated and dried by the heat transfer oil in the double-blade dryer, and the lignite is heated and dried at a temperature of 300°C. , Stirring treatment for 2 hours under the condition of pressure of 1.1Mpa, during the treatment process, the water vapor and escaping substances produced are discharged to the outside, and the external substances cannot enter the treatment system. After the treatment is completed, the lignite product is obtained.

[0079] Effect verification:

[0080] The lignite that the present embodiment is processed is sent to Guangdong Provincial Quality Supervision Coal Inspection Station (Guangzhou) for inspection, and the inspection results are as follows:

[0081] Inspe...

Embodiment 2

[0088] Lignite to be processed: total water 28.4%, ash content 20.04%, volatile matter 29.06%, low calorific value 3224 kcal / kg.

[0089] The lignite to be treated is crushed and ground to an average particle size of about 0.12mm, and then sent to a double-blade dryer, and the lignite is heated and dried by the heat-conducting oil in the double-blade dryer, and the lignite is heated and dried at a temperature of 400°C. 1. Under the condition of pressure of 0.9Mpa, the shearing treatment was carried out for 3 hours, and the water vapor and escaping substances produced during the treatment process were discharged to the outside, and the external substances could not enter the treatment system. After the treatment was completed, the lignite product was obtained. The lignite that the present embodiment is processed is delivered to the Guangdong Provincial Quality Supervision Coal Inspection Station (Guangzhou) for inspection, and the inspection basis is the same as embodiment one, ...

Embodiment 3

[0094] Lignite to be processed: total water 28.4%, ash content 20.04%, volatile matter 29.06%, low calorific value 3224 large / kg.

[0095] The lignite to be treated is crushed to an average particle size of about 2mm, and then sent to a double-blade dryer, and the heat-conducting oil in the double-blade dryer is used to heat and dry the lignite. Grinding treatment under the condition of 1.5Mpa for 5 hours, during the treatment process, the water vapor and escaping substances produced will be discharged to the outside world, and the outside substances will not enter the treatment system. The lignite product will be added with additives and then pressed into shape. The lignite that the present embodiment is processed is sent to Guangdong Provincial Quality Supervision Coal Inspection Station (Guangzhou) for inspection, and inspection basis is identical with that in embodiment one, and inspection result is as follows table 4:

[0096] Table 4

[0097] Test items

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com