Signal detection system and method for hydraulic force mechanical speed changing box

A technology for hydraulic machinery and signal detection, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc. Mechanical transmission torque converter, retarder use status detection and other problems, to avoid product life reduction, automatically adjust heat dissipation power, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

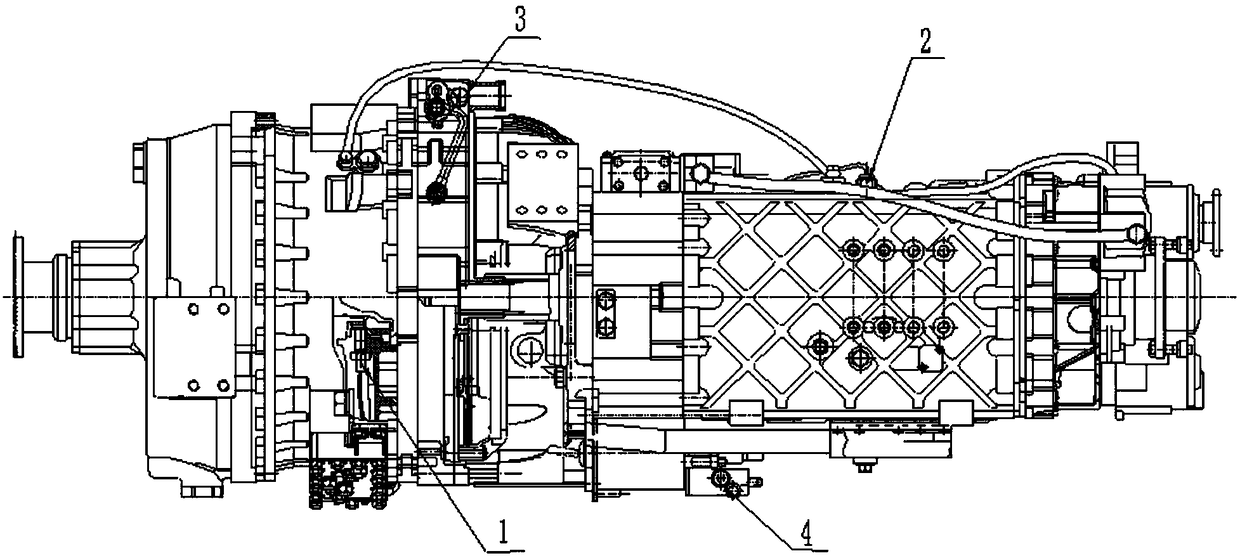

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

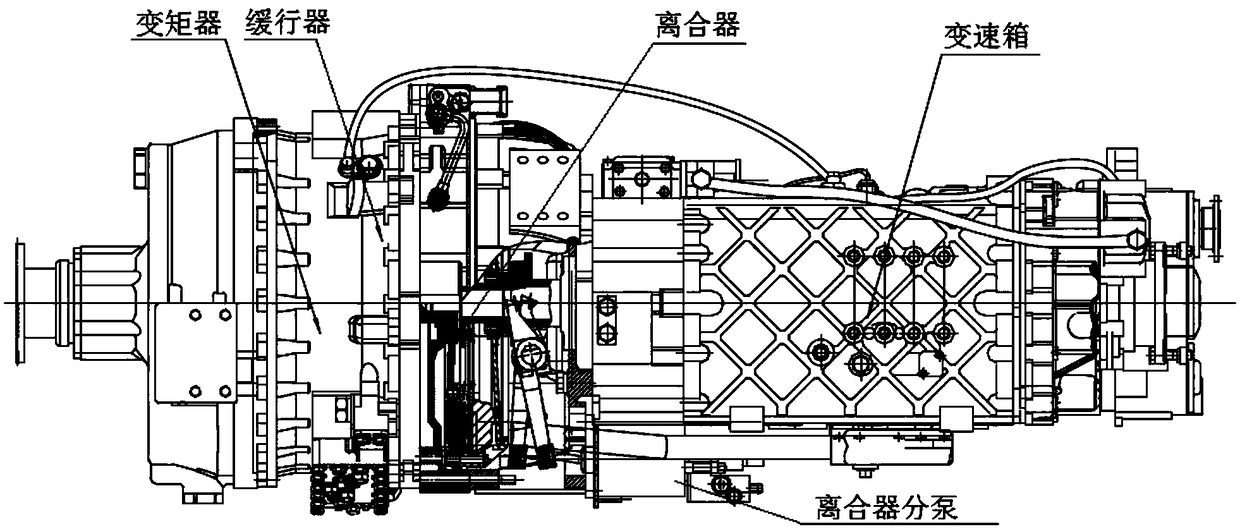

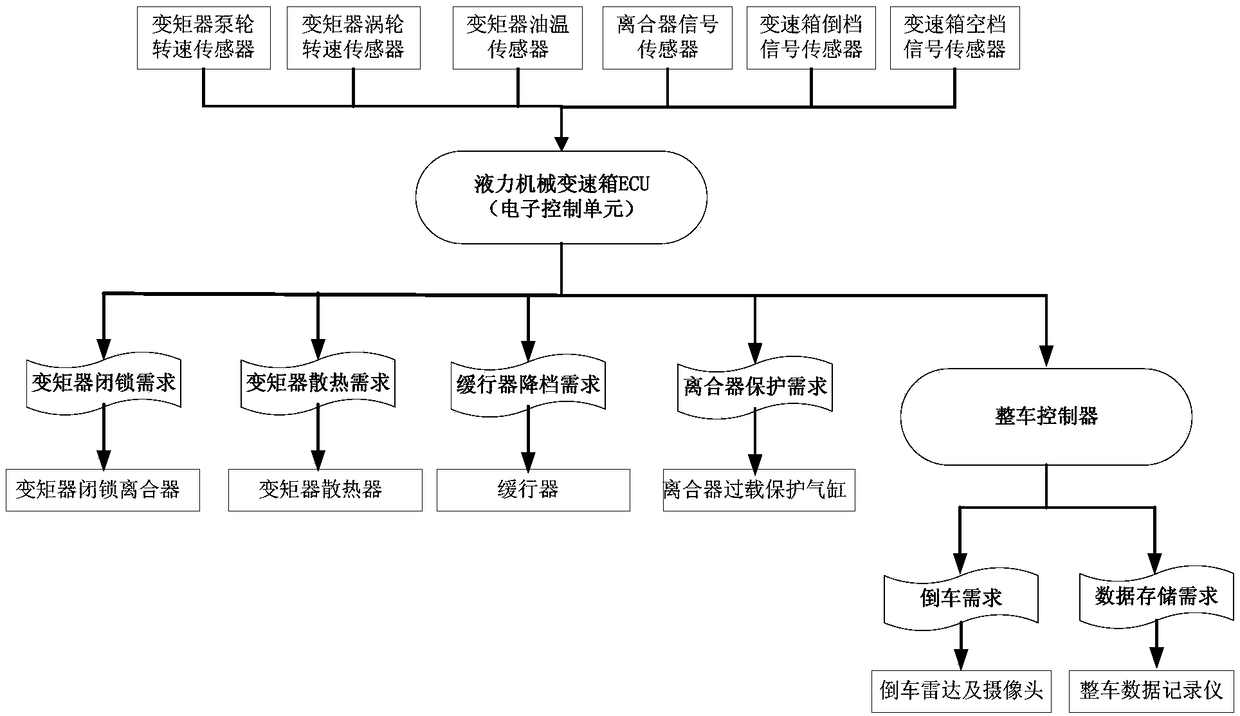

[0040] The present invention is a signal detection system and method for a hydraulic mechanical gearbox. The ECU control unit of the hydraulic mechanical gearbox is used as the central controller to realize the hydraulic detection by collecting the state of the built-in sensor and interacting with the vehicle controller. Action control and information storage of force mechanical gearbox. Specifically: the ECU control unit of the hydraulic mechanical transmission will realize the status signals of the detected torque converter pump wheel speed, turbine speed, oil temperature, clutch signal, transmission neutral gear, reverse gear signal, etc. The communication and information storage of the controller and memory provide data sources for the automatic adjustment of heat dissipation power of the radiator of the hydraulic mechanical trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com