High-speed vertical and continuous wire-rewinding machine

A wire take-up machine and vertical technology, which is applied in the field of high-speed vertical continuous wire take-up machines, can solve the problems of low degree of automation and no guarantee of operator safety, and achieve the effect of high degree of automation, good wire take-up effect and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

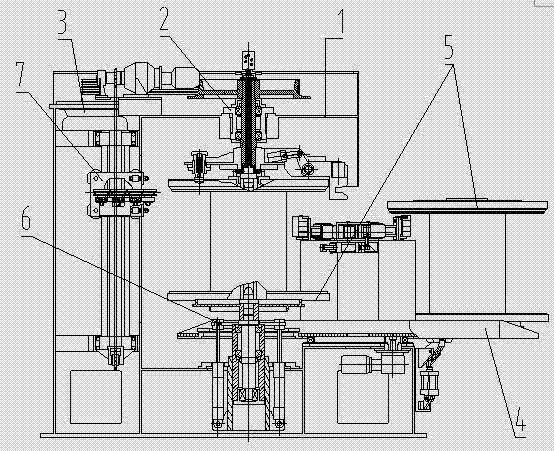

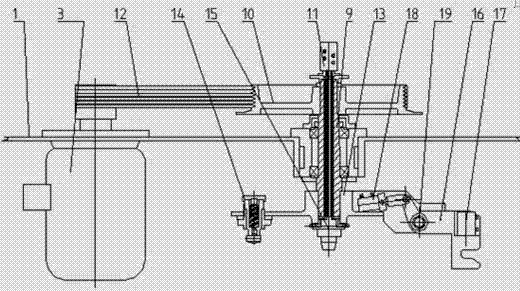

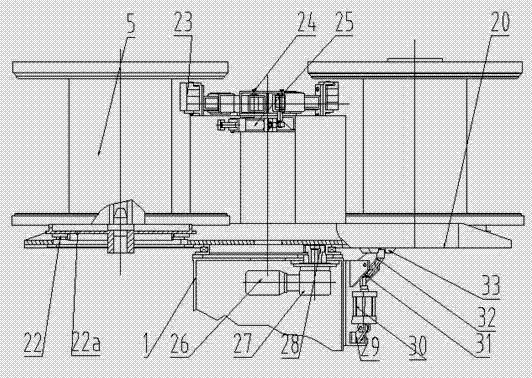

[0020] Examples of the present invention figure 1 As shown, the high-speed vertical continuous wire take-up machine mainly includes: the main body (1), the main shaft mechanism (2), the frequency conversion speed regulation motor (3), the rotary wire take-up mechanism (4), the I-shaped wheel (5) , holding up mechanism (6), wiring mechanism (7) and clamping and cutting device (8). The main shaft mechanism (2) runs through the fuselage through rolling bearings, and drives the main shaft mechanism to rotate at high speed with the frequency conversion speed regulating motor (3) fixed on the side of the fuselage (1) through a belt. The middle part of the fuselage is connected to the rotary take-up mechanism (4) through a slewing bearing, and the rotary take-up mechanism drives the rotation of the rotary take-up mechanism through the frequency conversion motor (26), gearbox (27) and gear (28) below, and the rotary Two spools (5) are placed above the take-up platform mechanism. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com