Crankcase structure for engine of motorcycle

A technology for motorized two-wheeled vehicles and crankcases, which is applied to the lubrication of engines, machines/engines, motor vehicles, etc., to achieve the effect of simple structure and improved warm-up operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described with reference to embodiments of the present invention shown in the drawings.

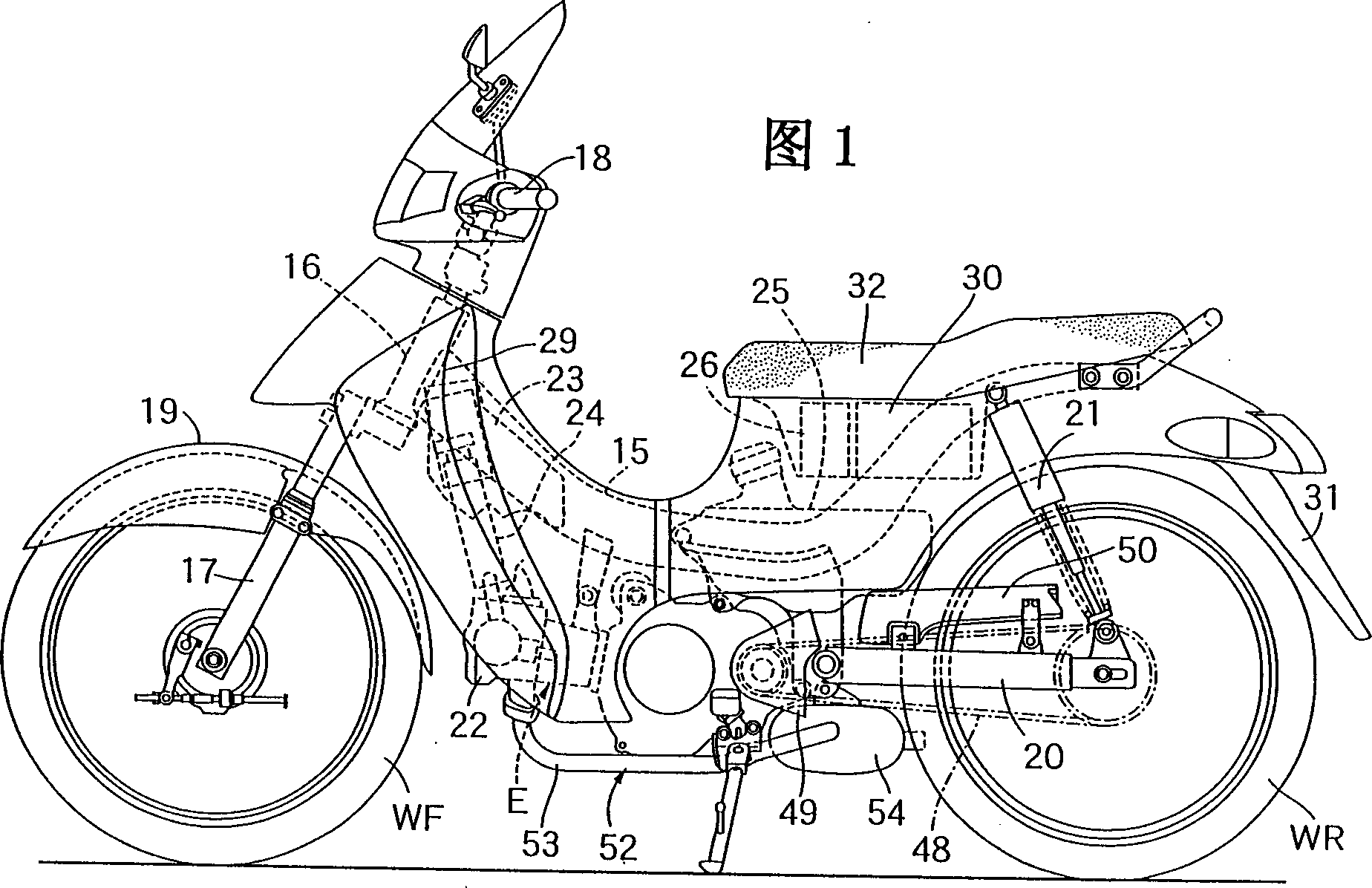

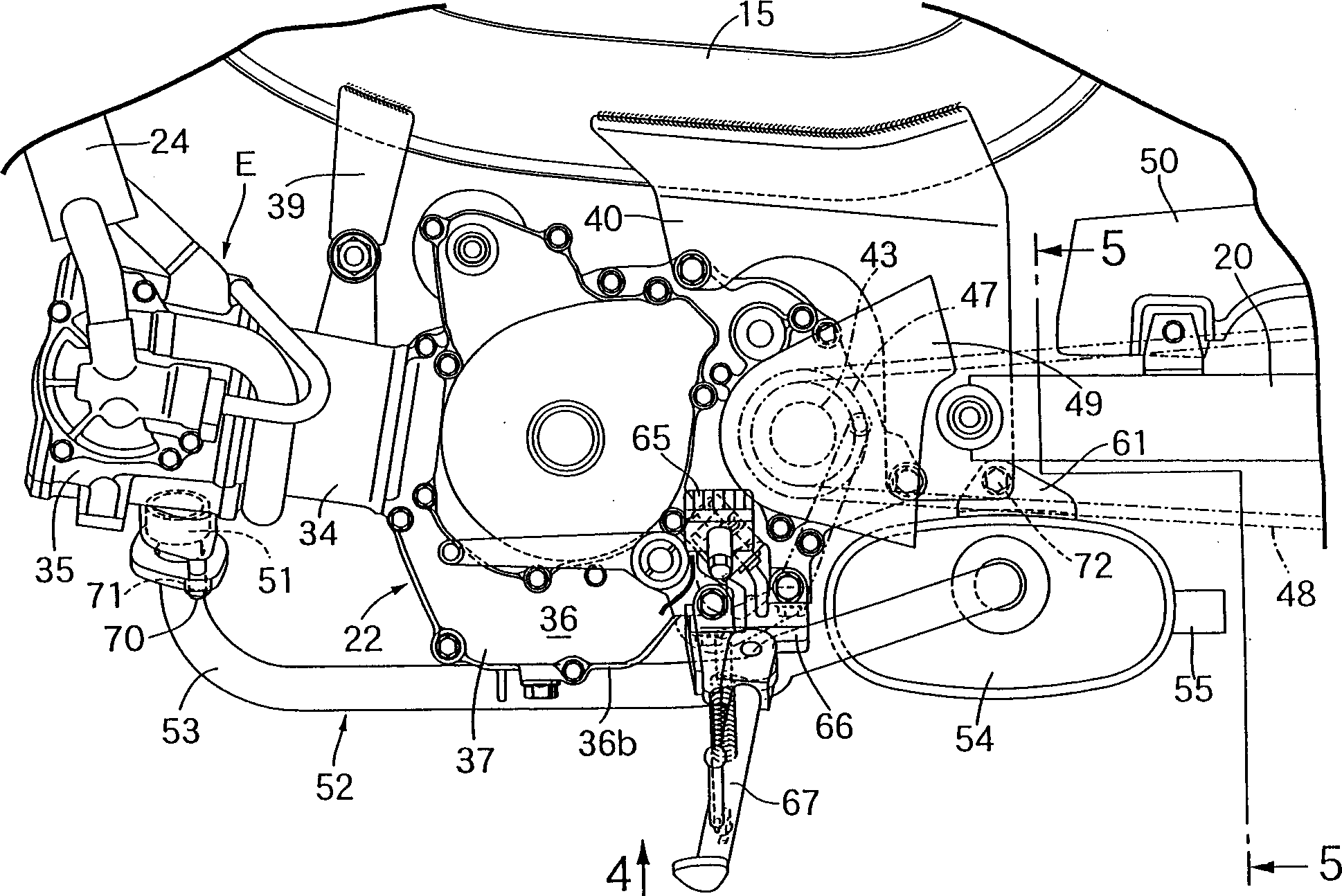

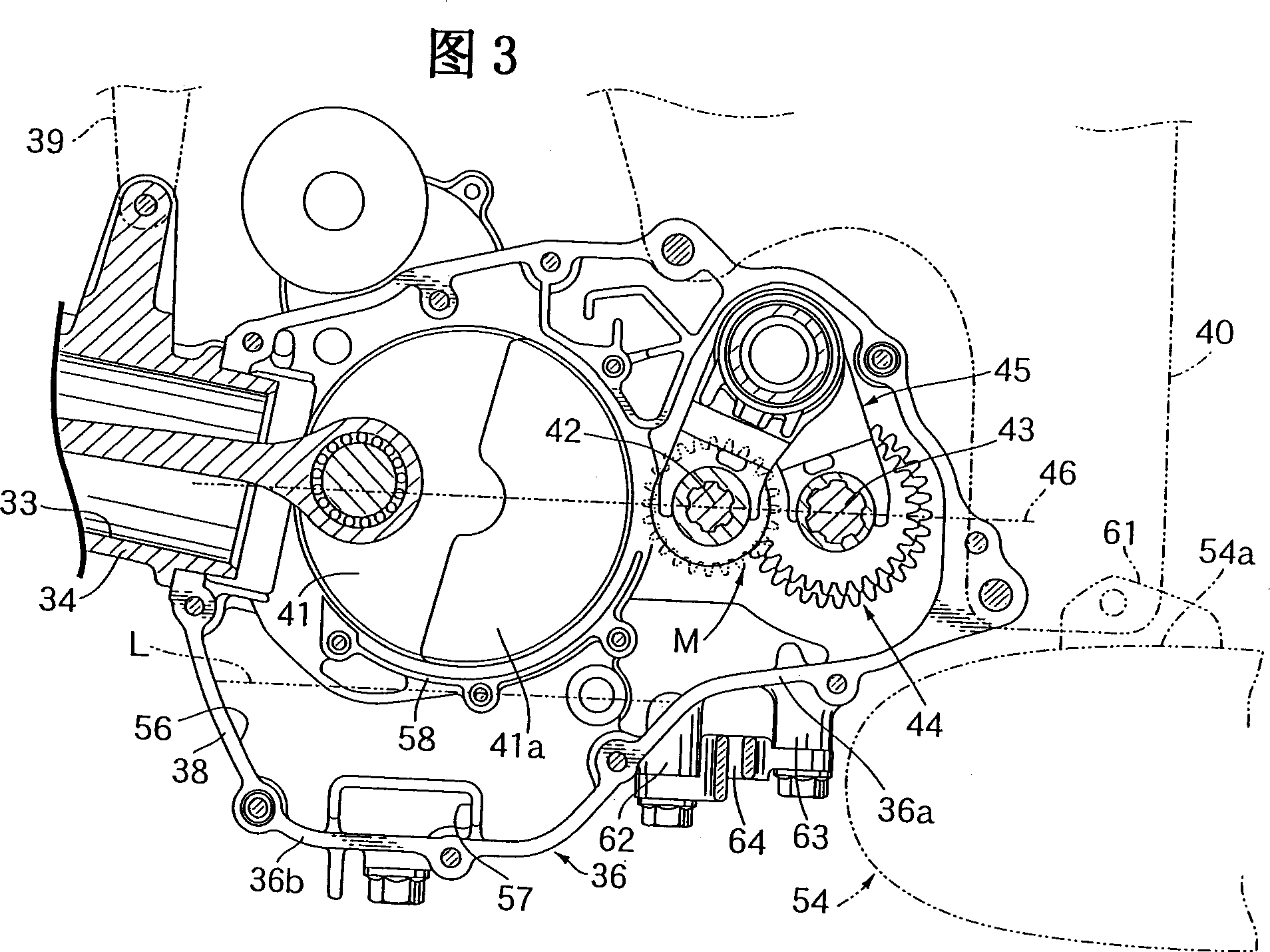

[0018] figure 1- Figure 5 Representing the first embodiment of the present invention, Fig. 1 is a side view of a motorized two-wheeled vehicle, figure 2 It is a partially enlarged view of FIG. 1, FIG. 3 is a longitudinal sectional side view showing the interior of the crankcase, and FIG. 4 is a figure 2 Bottom view of middle arrow 4, Figure 5 is along figure 2 Cross-sectional view of line 5-5.

[0019] First, in FIG. 1, a front fork 17 that supports a front wheel WF is pivotally supported steerably on a head pipe 16 provided on a front end of a frame 15 of a motorcycle. The lever 18 is connected to the upper end of the front fork 17 , and the front fender 19 covering the upper side of the front wheel WF is supported by the front fork 17 . In addition, the rear fork 20 supporting the rear wheel WR is pivotally supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com