Patents

Literature

285results about How to "Avoid stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

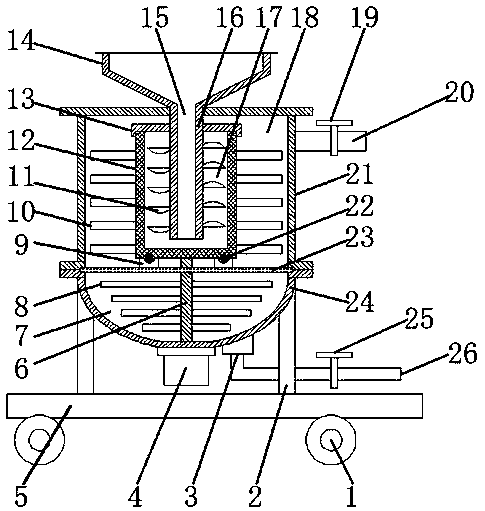

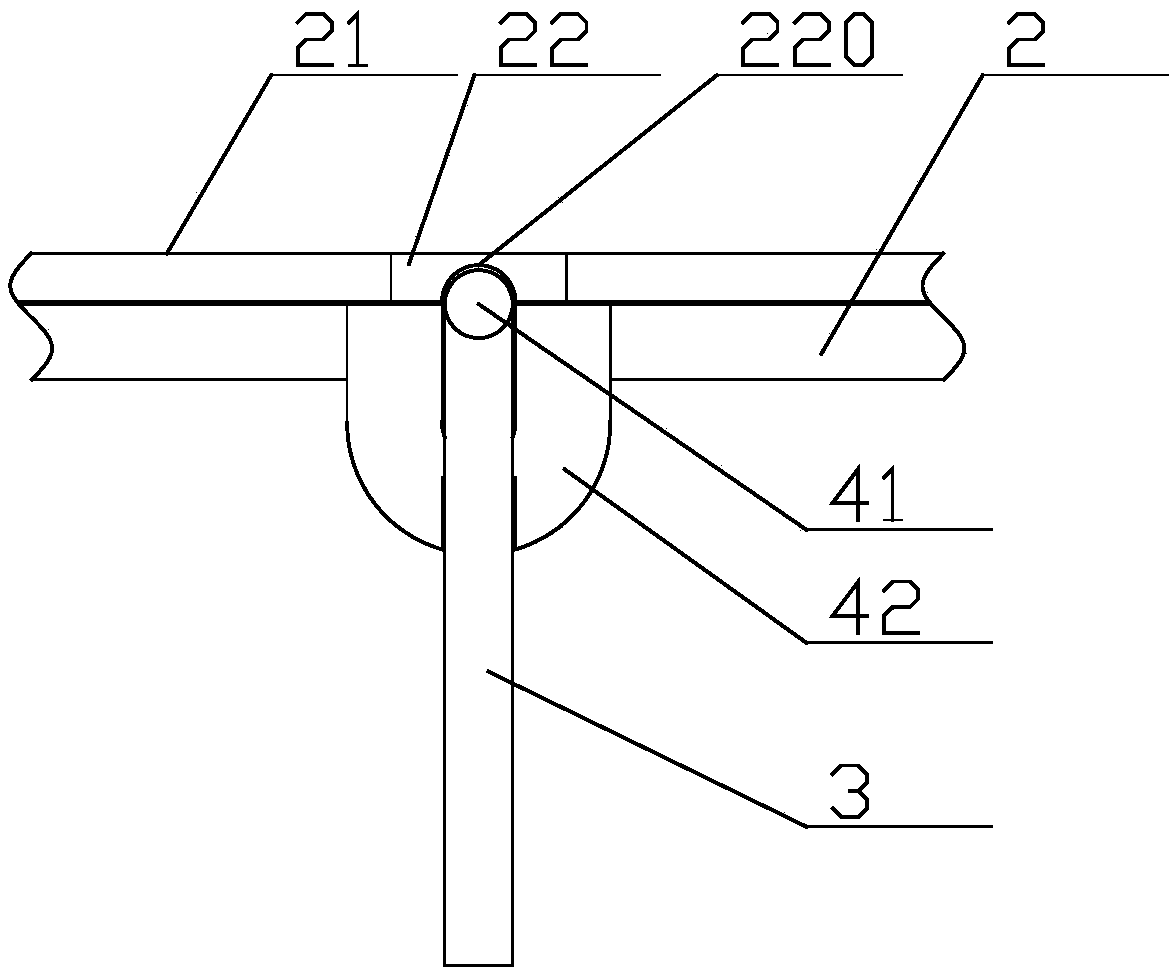

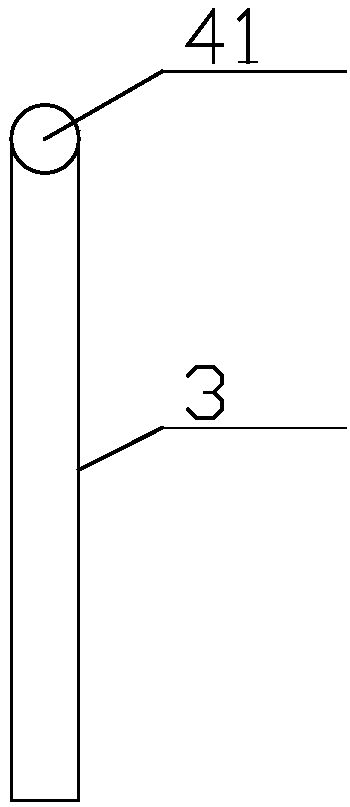

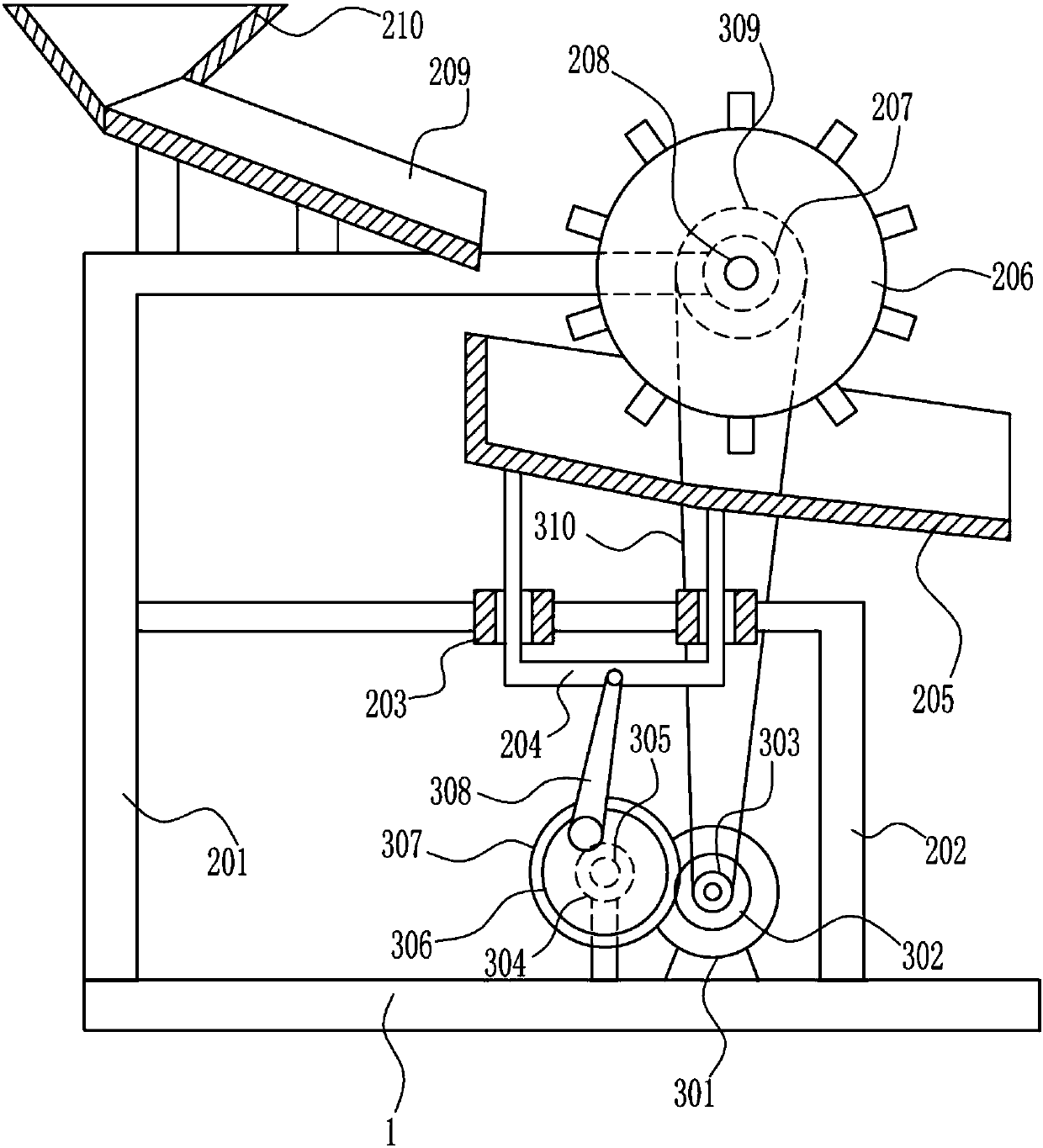

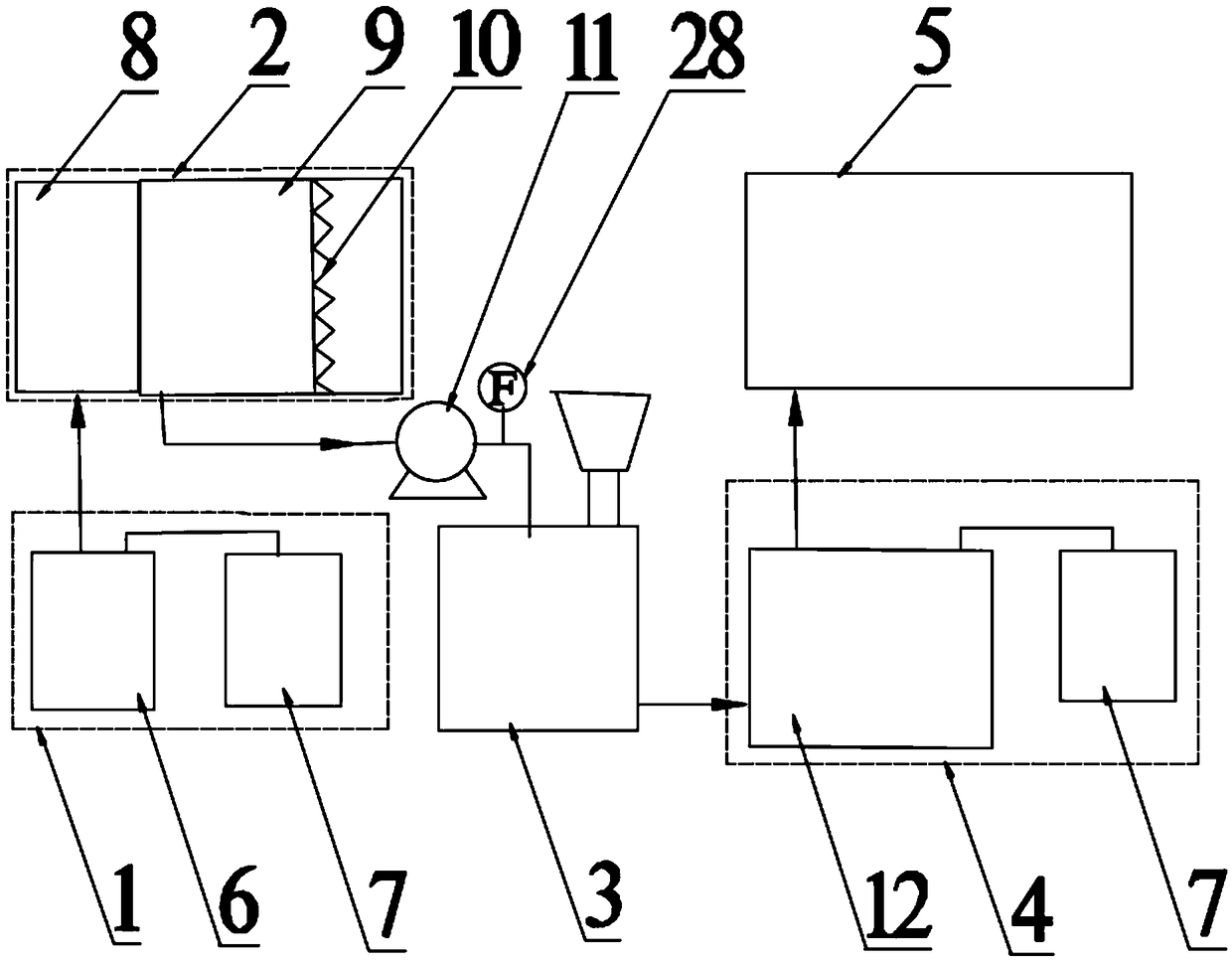

Drossing mud scraper

The invention relates to a drossing mud scraper, and relates to dual-purpose equipment for drossing and mud scraping. The invention provides a drossing mud scraper which reduces or prevents the stirring of mud scraping plates on sewage to a maximum degree in the non-operating state to improve a sedimentation effect. The drossing mud scraper is arranged in a sedimentation tank, and comprises a driving motor, a belt wheel I and a belt wheel II which are arranged at two ends of the position below a liquid level in the sedimentation tank, a belt wheel III and a belt wheel IV which are arranged attwo ends of the upper part of the bottom surface of the sedimentation tank, a pair of running belts and a plurality of mud scraping plates connected between the running belts, wherein the mud scraping plates are connected to the running belts by an opening and closing device; plate closing blocks are arranged at the front ends or rear ends of the belt wheel IV and the belt wheel II, are provided with an inclined plane I towards the running directions of the mud scraping plates and are fixedly connected to the tank wall of the sedimentation tank; and plate opening blocks are arranged at the front ends or rear ends of the belt wheel I and the belt wheel III and are fixedly connected to the tank wall of the sedimentation tank in an inclined mode. By the drossing mud scraper, the effect and quality of sewage treatment are improved.

Owner:扬州青青环保成套设备有限公司

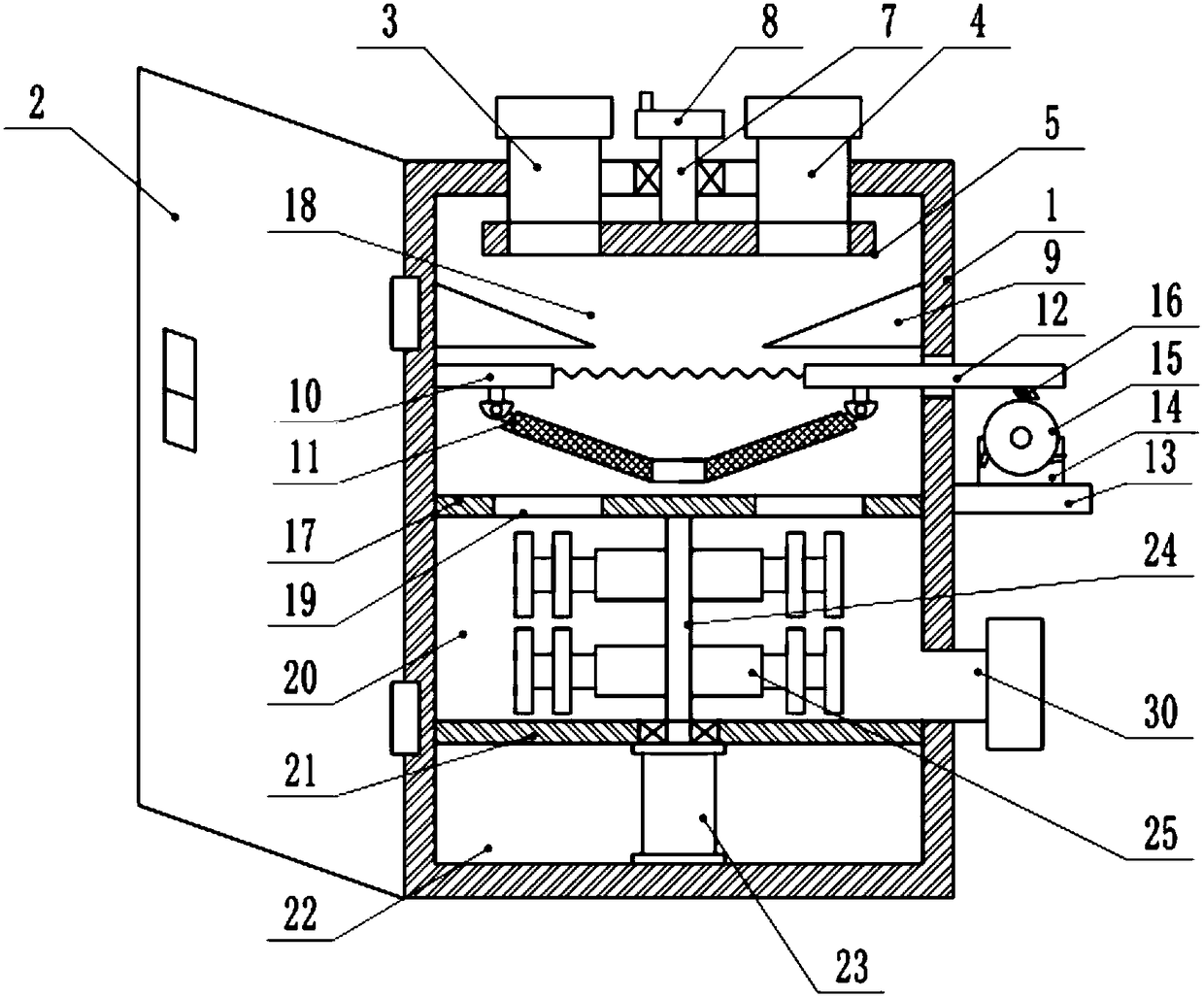

Vertical automatic wall tiling device for building construction

The invention discloses a vertical automatic wall tiling device for building construction. The vertical automatic wall tiling device for building construction comprises a base, wherein four first hydraulic machines are fixedly arranged at the top end of the base; one ends of first hydraulic rods of the four first hydraulic machines are fixedly connected to four corners at the bottom end of a shell; a groove is formed in the middle of the shell; and a first chute is formed in a bottom plate in the groove. According to the scheme, by arranging a tiling mechanism, a transport plate transports wall tiles into the groove. When the wall tiles are in contact with a contact sensor, a fifth electric telescopic rod stretches to limit and fix the wall tiles; a fourth electric telescopic rod stretchesto push the tiling mechanism out; a sixth electric telescopic rod stretches to push the wall tiles out of the groove; by arranging the first hydraulic machines and the first electric telescopic rod,the height and the transverse position of a slide barrel are adjusted; by arranging parts such as a wall tile placing groove and the transport plate, the wall tiles can move; by arranging a high precision distance sensor, the distance between the slide barrel and the wall can be detected.

Owner:江苏新龙兴建设集团有限公司

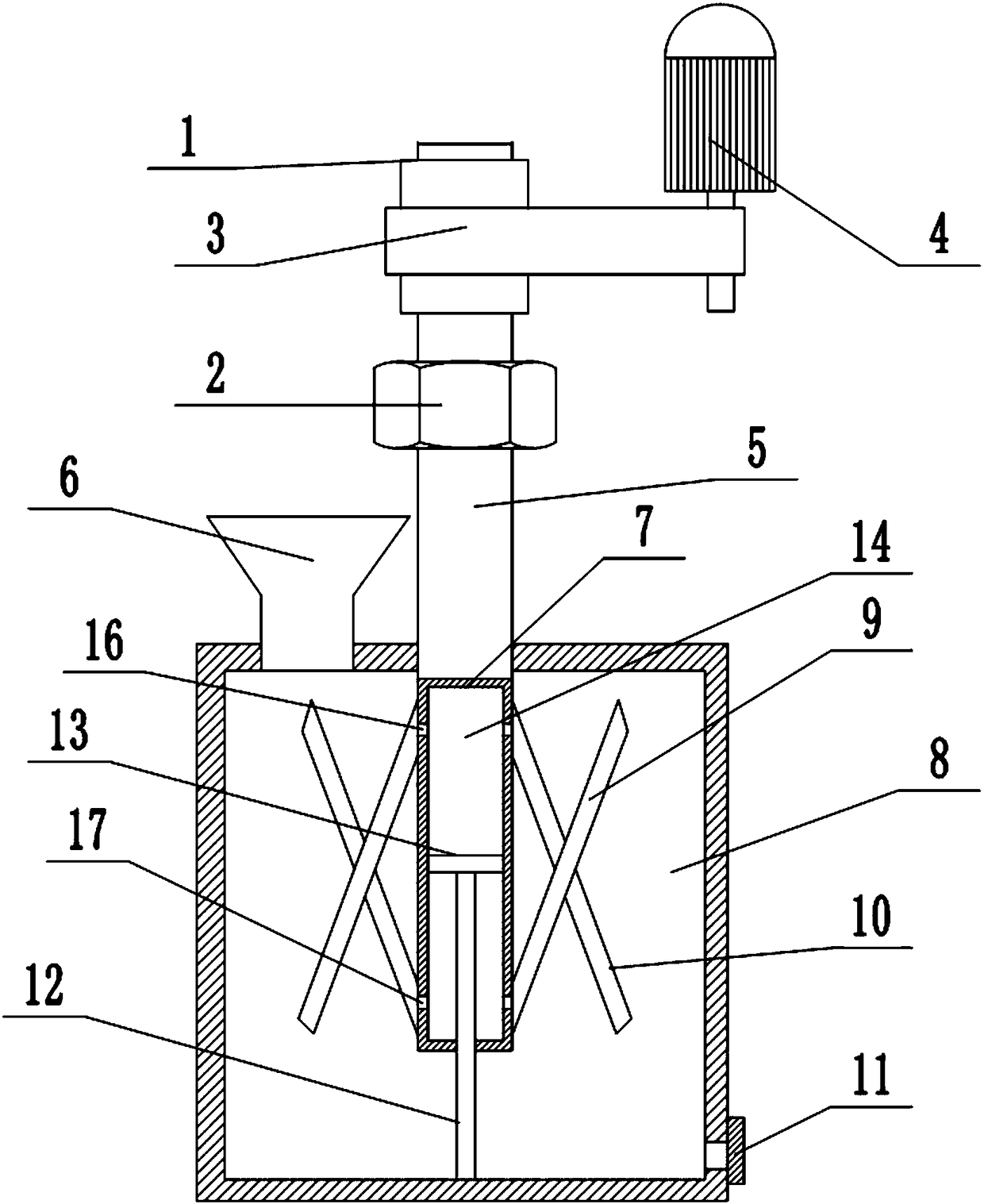

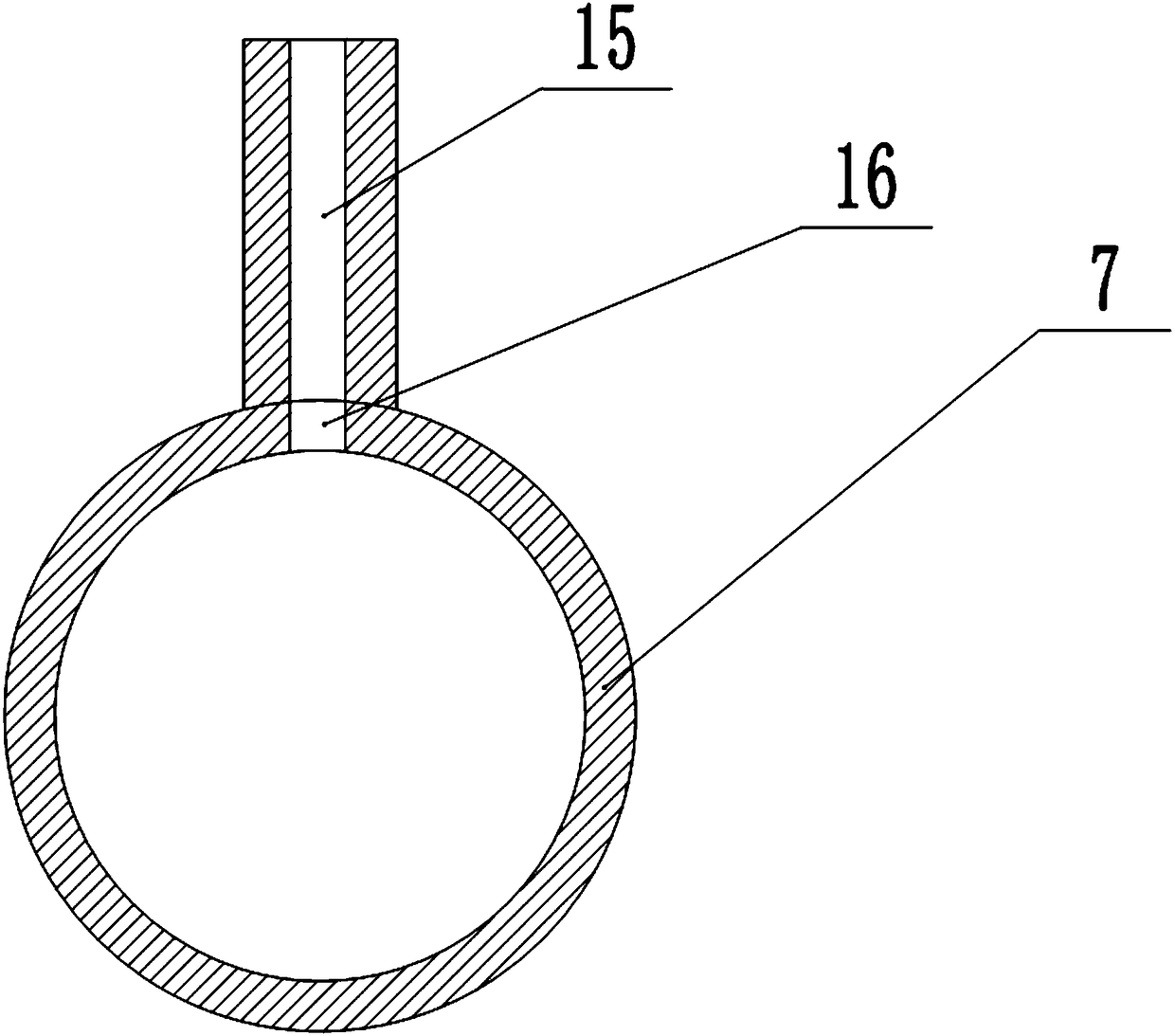

Decorative coating stirring device

ActiveCN108187525AUp and down velocity increasesStir wellFlow mixersTransportation and packagingEngineeringPiston rod

The invention belongs to the field of decoration engineering and particularly discloses a decorative coating stirring device. The decorative coating stirring device comprises a rack and a rotating shaft, wherein a stirring tank is arranged on the rack; the rotating shaft comprises a spline section, a thread section and stirring section, a splined sleeve is connected outside the spline section, anda nut is connected outside the thread section; a hollow cavity is formed in the stirring section, a piston is glidingly connected in the hollow cavity, a piston rod is fixed on the lower side of thepiston, first feed holes are formed in the upper part of the side wall of the stirring section in the circumferential direction, first discharge holes are formed between the adjacent first feed holes,and first stirring blades which are inclined downwards are connected to the first feed holes; second feed holes and second discharge holes are formed in the lower part of the side wall of the stirring section, second stirring blades which are inclined upwards are connected to the second feed holes, and hollow grooves are formed in centers of the first stirring blades and the second stirring blades respectively. With the adoption of the scheme, the stirring is more uniform and faster.

Owner:枣庄市鹏展木制品有限公司

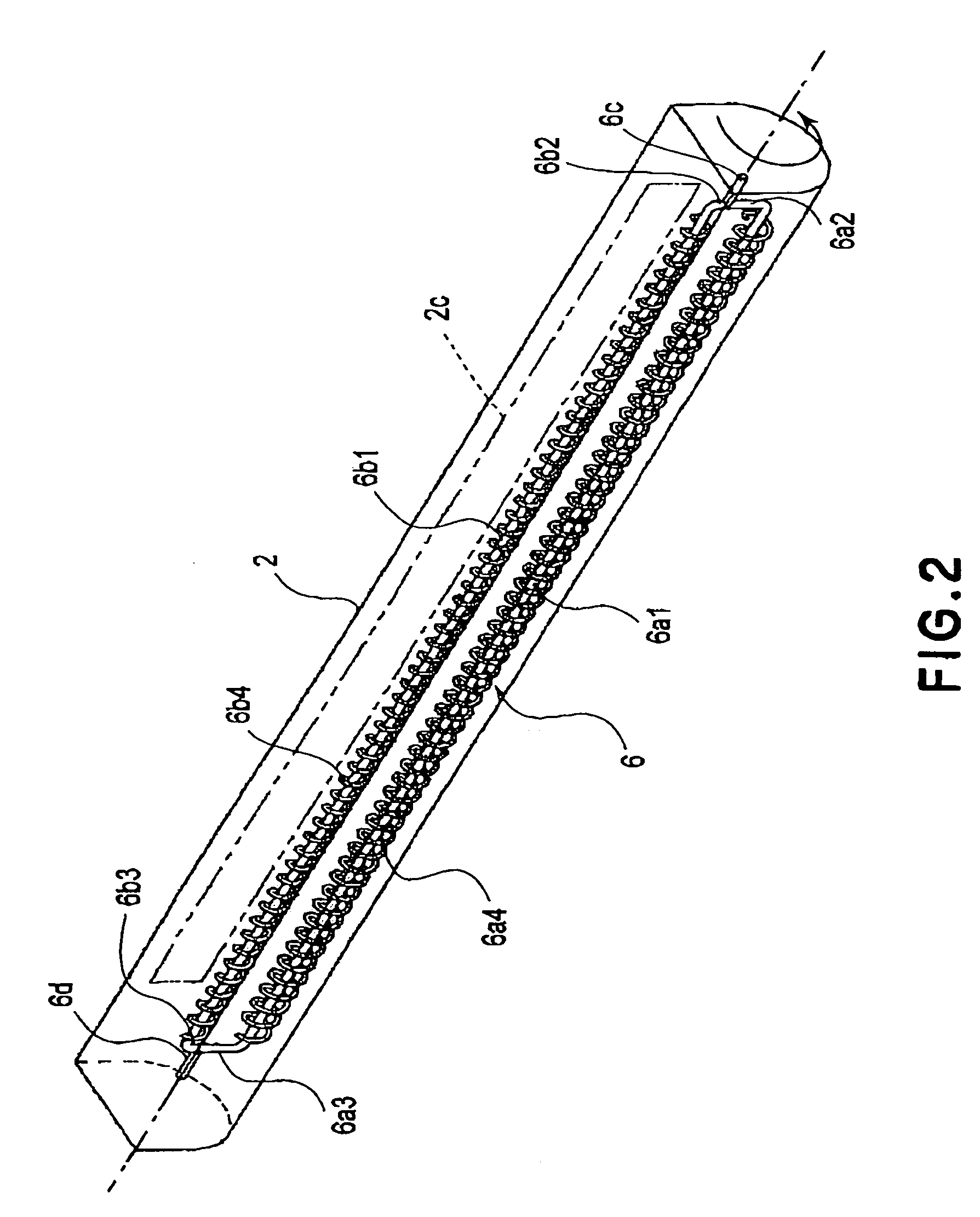

Developing apparatus

ActiveUS7257353B2Avoid problemsDeterioration of the developer in the developer container can be minimizedElectrographic process apparatusLatent imageEngineering

Owner:CANON KK

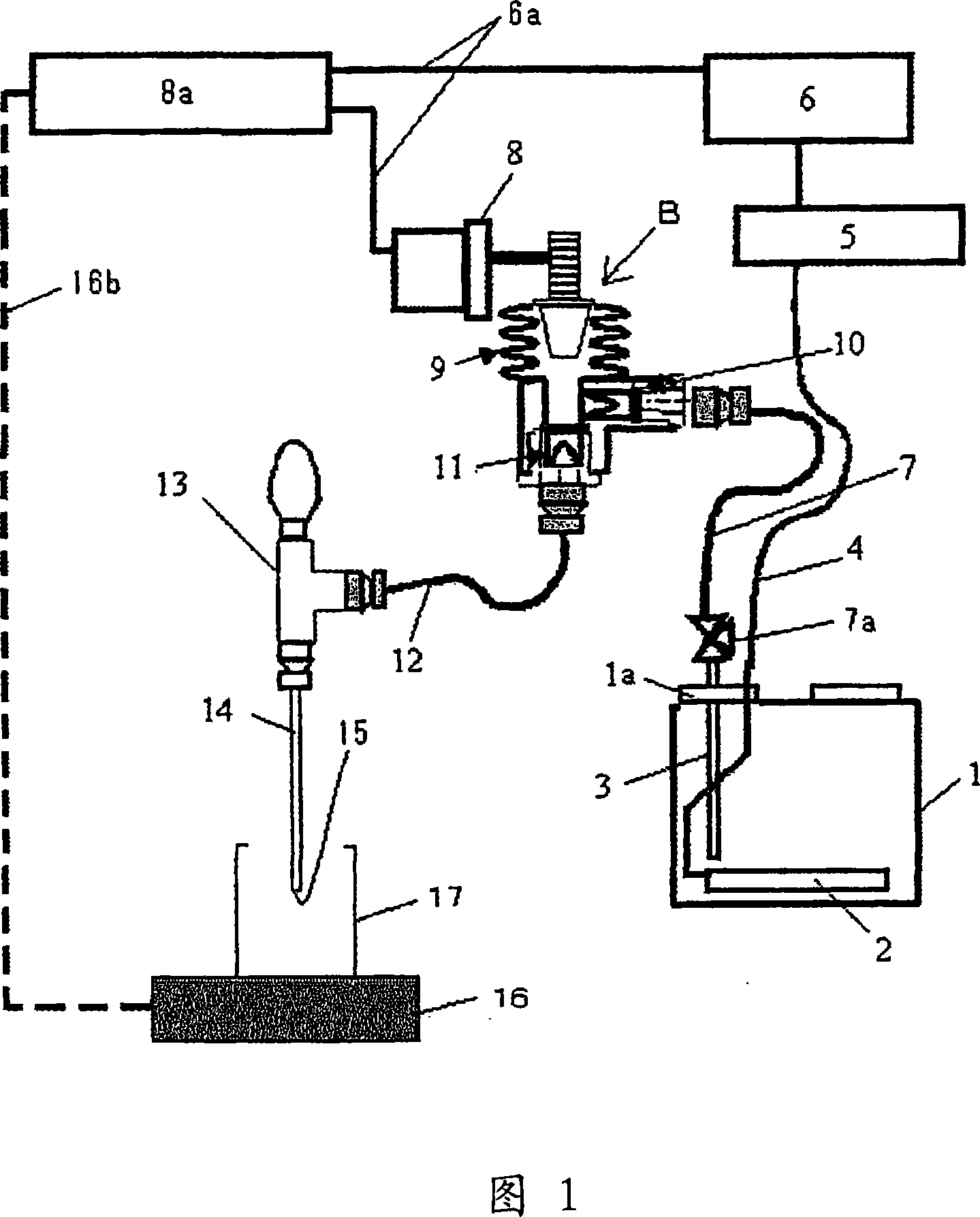

Transferring method of powder toner for electrophotograph and transferring apparatus thereof, and filling method of powder toner and the filling apparatus thereof

InactiveCN101103316AQuality assurancePrevent proliferationSolid materialElectrographic process apparatusEngineeringReciprocating motion

The present invention aims at providing a powder toner transferring method which fluidizes a powder toner with a gas supplied from an air supply means, sucks the fluidized powder toner with a suction means and transfers the powder toner by discharging the powder toner in a toner storage container, where the suction of the powder toner by means of the suction means is performed with a reciprocating-motion pump. The present invention also aims at providing a powder toner filling method that comprises the powder toner transferring process.

Owner:RICOH KK

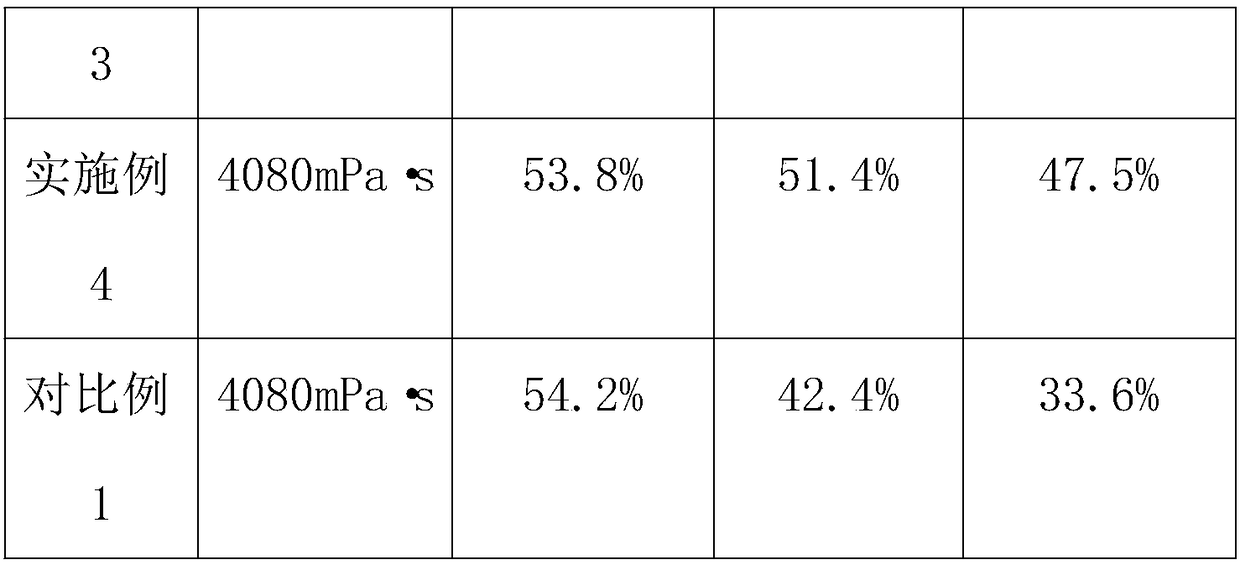

A slurrying method of a mixed cathode material

ActiveCN109119594AIncrease energy densityImprove dispersion uniformityCell electrodesDispersitySlurry

The present invention provides a slurrying method of a mixed cathode material, the mixed cathode material comprises a first active material having a first particle size, a second active material having a second particle size, and a third active material having a third particle size. The dispersity of different active materials is improved by slurrying different active materials under different conditions, and then the three kinds of slurry is mixed to obtain the slurry with high dispersity and stable performance.

Owner:江门市力源电子有限公司

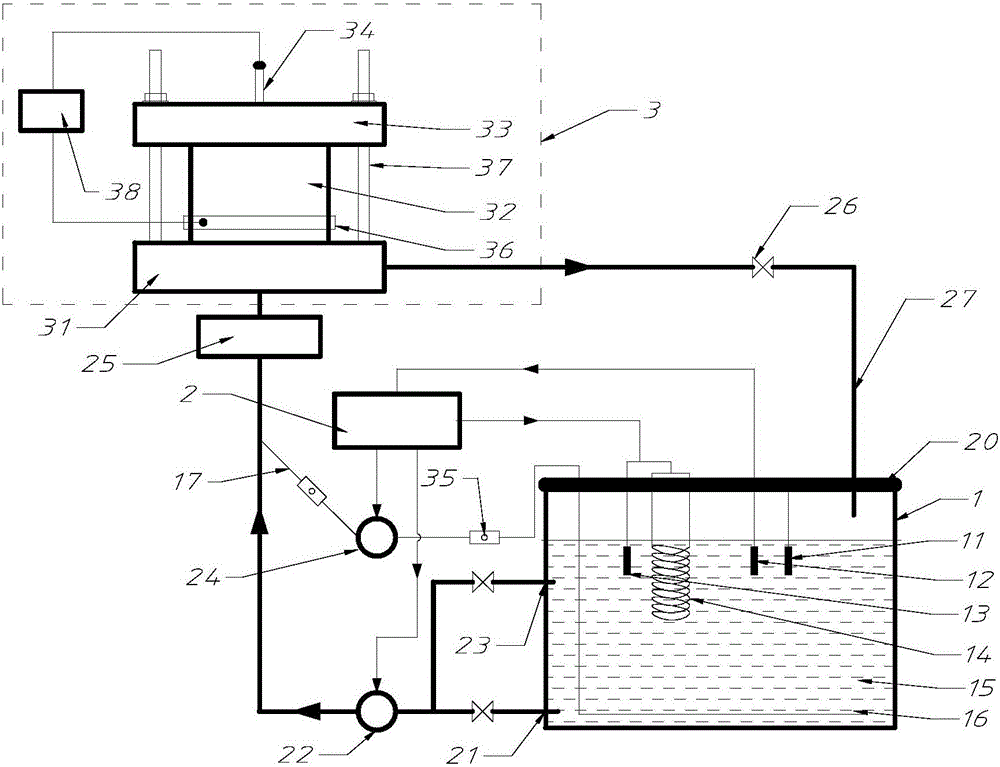

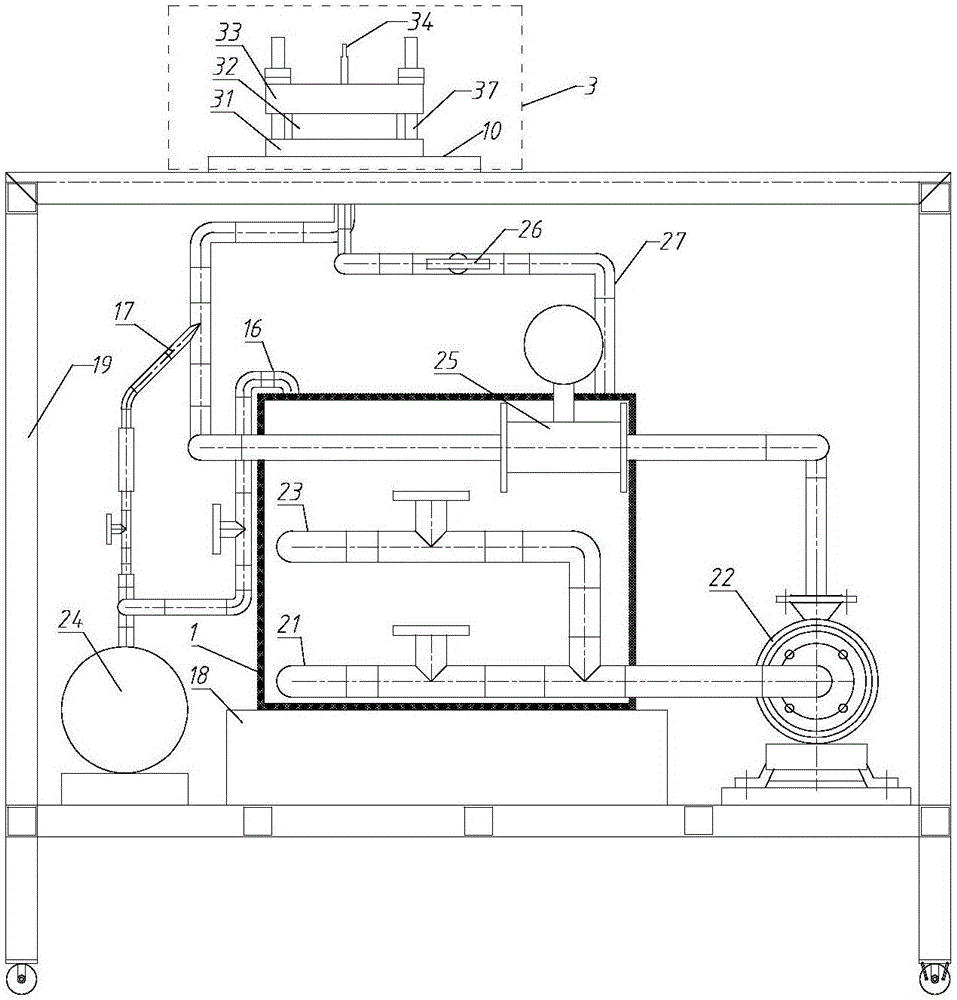

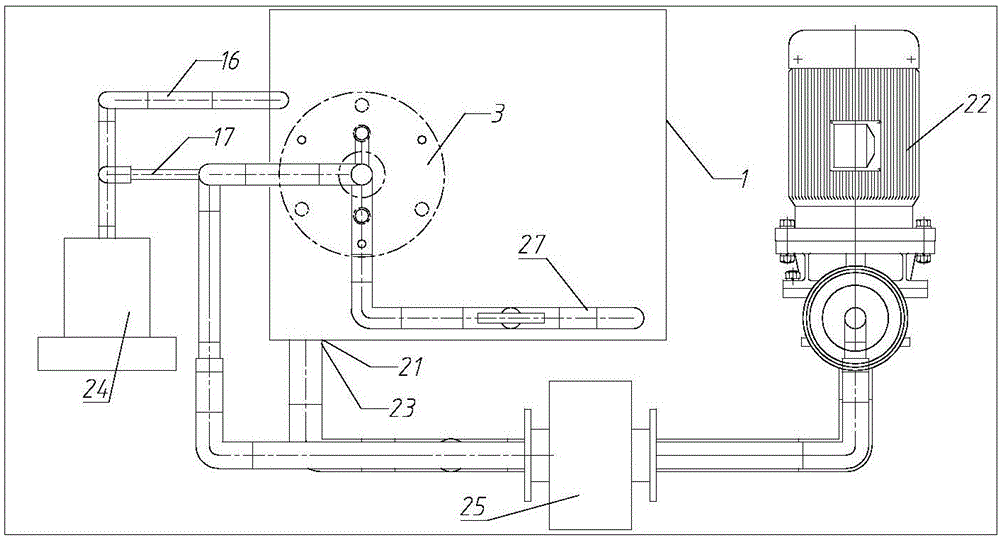

Device used for preparing Ni-SiC composite coating on inner surface of hollow workpiece

ActiveCN106283166AAvoid stirringReduce lossesElectrolysis componentsElectrolytic coatingsLiquid storage tankEngineering

The invention discloses a device for preparing a Ni-SiC composite coating on the inner surface of a hollow workpiece. A lower water outlet pipe and an upper water outlet pipe which are parallel and are arranged in an up-and-down manner are arranged in a liquid storage tank. After electroplating liquid flowing out of the upper water outlet pipe and electroplating liquid flowing out of the lower water outlet pipe are converged, the mixed electroplating liquid flows towards a sealed electroplating table under the drive force of an electroplating liquid circulation pump, and an electromagnetic flow meter is adjusted to control the volume flow rate of the electroplating liquid flowing towards the sealed electroplating table. After composite electroplating is completed in the sealed electroplating table, the electroplating liquid flows back into the liquid storage tank through a loop. One end of an air discharging pipe is connected with an outlet of a compressed air pump, and the other end of the air discharging pipe is connected in the liquid storage tank. The device is a the sealed and continuous-circulation electroplating device developed based on a traditional non-closed immersion type electroplating device and has the beneficial effects of being reasonable in structure, reliable in operation and convenient to use and operate, and the Ni-SiC composite coating with the good quality can be obtained on the inner surface of the hollow workpiece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

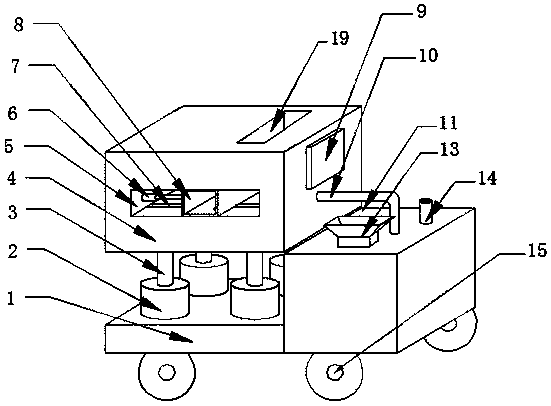

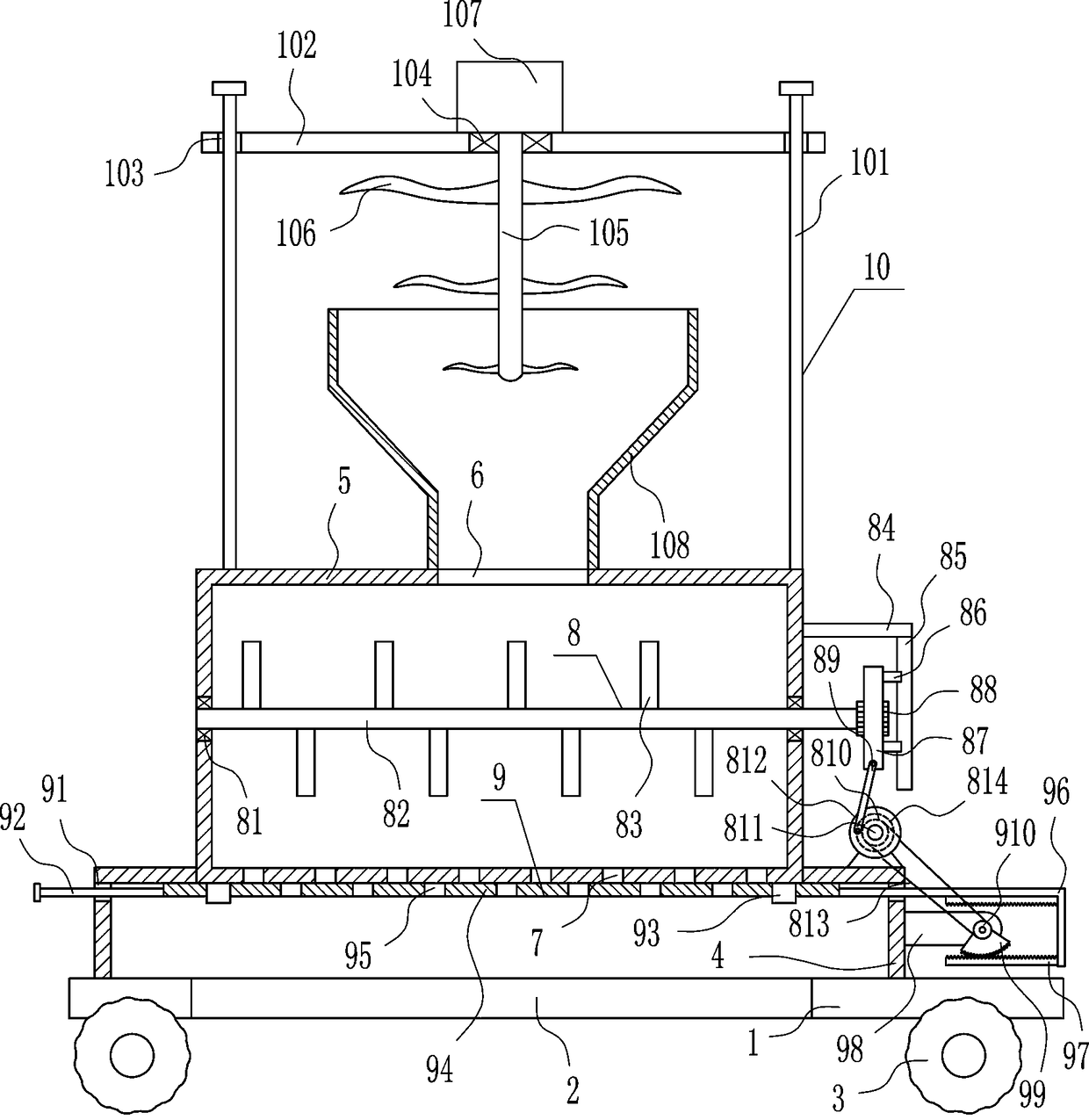

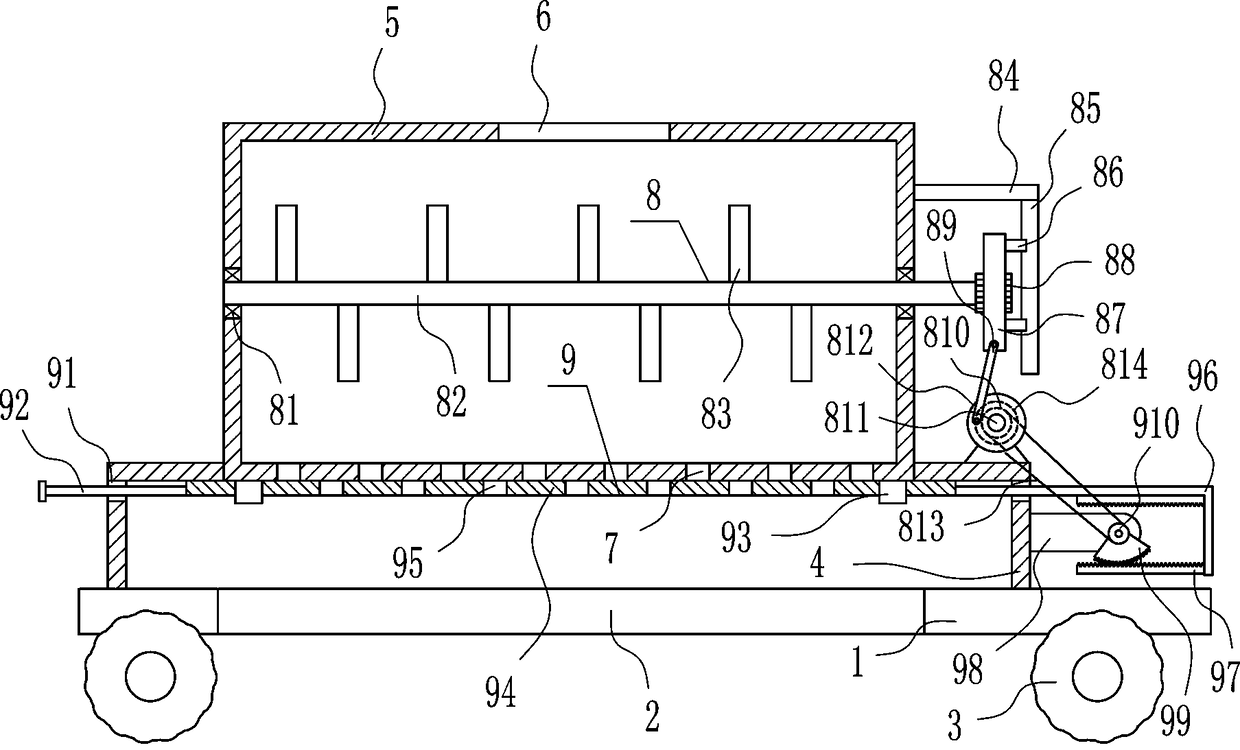

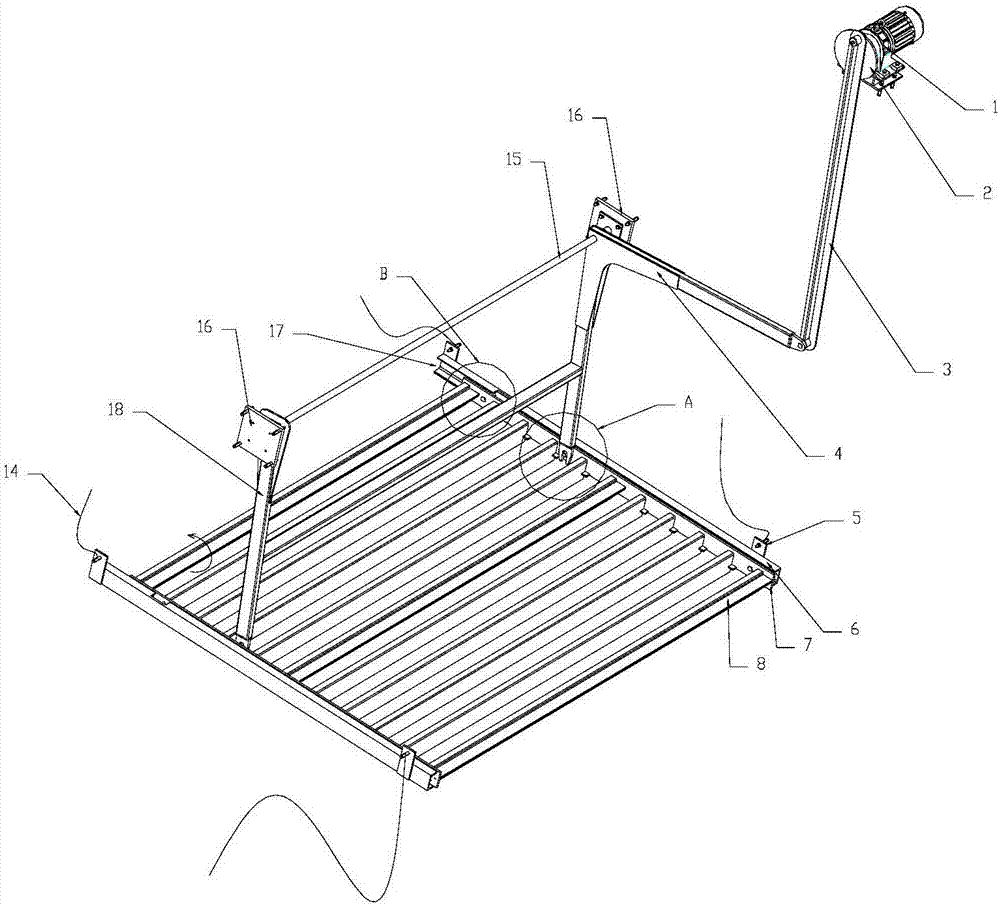

Agricultural soil even fertilizing equipment

InactiveCN108450106AEasy to useAvoid stirringWatering devicesFertiliser distributersAgricultural engineeringUltimate tensile strength

The invention relates to fertilizing equipment and relates to agricultural soil even fertilizing equipment. The invention aims at solving the technical problem of providing the agricultural soil evenfertilizing equipment which has the advantages of small labor intensity, evenness in fertilizing, ability in fertilizing after breaking caked fertilizers and better use. The agricultural soil even fertilizing equipment disclosed by the invention comprises a bottom plate and the like, wherein wheels are symmetrically arranged on the left side and the right side of the bottom of the bottom plate, anopening is formed in the left side of the bottom plate, supporting frames are arranged on the left side and the right side of the top of the bottom plate, a stirring box is arranged between the rightend of the left side supporting frame and the left end of the right side supporting frame, a feeding opening is formed in the middle of the top of the stirring box, and discharging openings are evenly formed at the bottom of the stirring box at intervals. According to the agricultural soil even fertilizing equipment disclosed by the invention, a breaking device is utilized to break the fertilizers at first, then the broken fertilizers fall on the ground to be applied, a water spraying device is utilized to spray water on the fertilizers, the fertilizer can be better infused into soil, and aneven fertilizing effect is achieved.

Owner:徐玺为

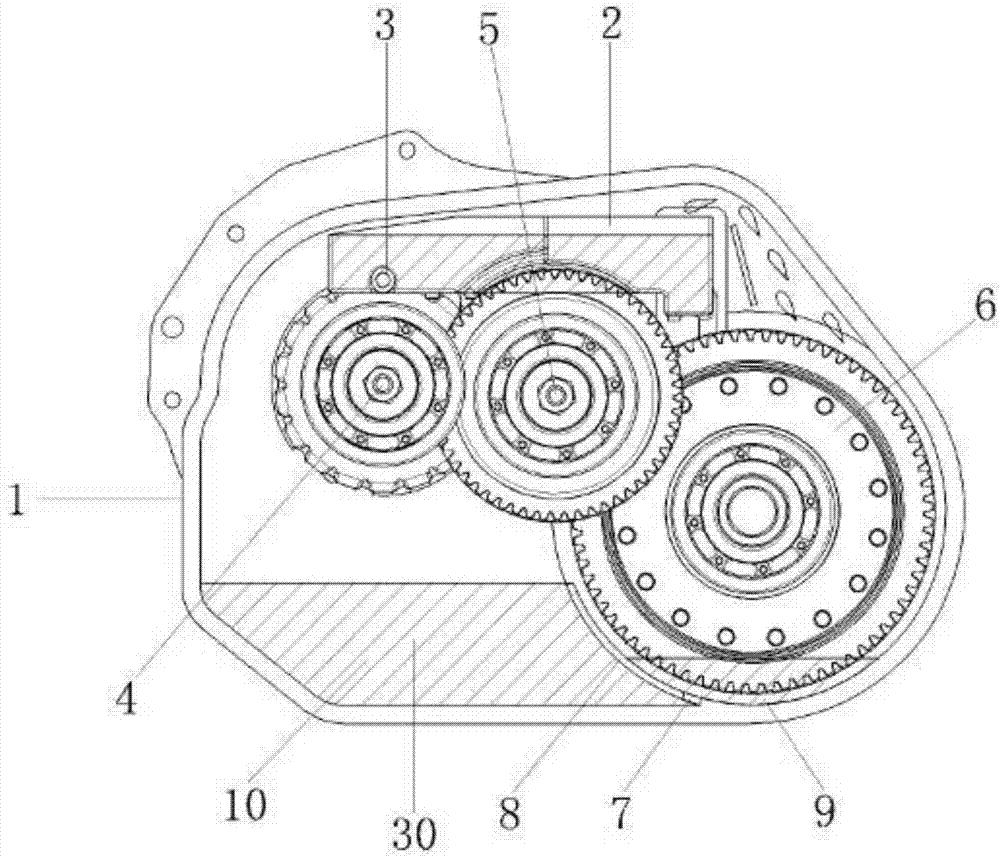

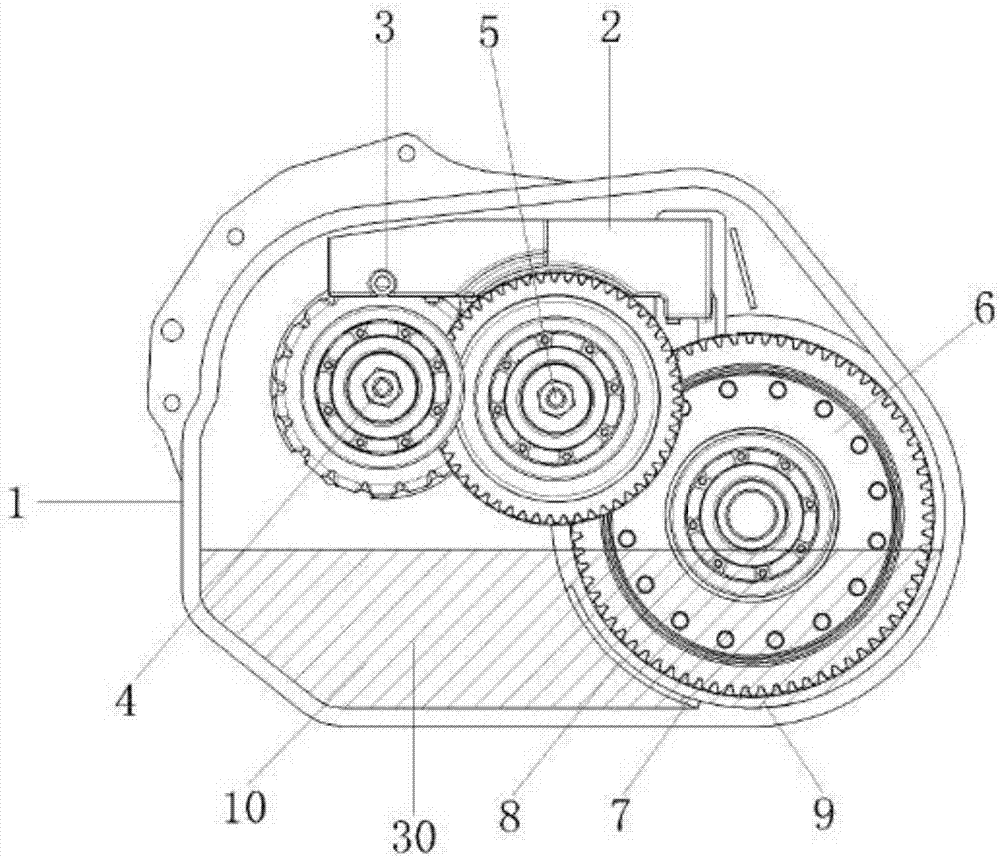

Blade electric vehicle transmission with novel lubrication structure

ActiveCN107314100AOutstanding and Beneficial Technical EffectsReduce dosageGear lubrication/coolingTransmission elementsCouplingGear wheel

The invention provides a blade electric vehicle transmission with a novel lubrication structure, and belongs to the technical field of transmissions. The problem that an existing structure lubrication manner is not effective enough is solved. The blade electric vehicle transmission comprises a transmission case. A temporary oil storage box is arranged on the top side in the transmission case, lubricating oil is stored on the bottom side in the transmission case, and the temporary oil storage box is provided with a plurality of lubricating oil dripping holes. A transmission input shaft and an intermediate coupling shaft which are connected through a gear are located on the lower side of the temporary oil storage box and above the lubricating oil face. An intermediate coupling shaft gear is connected with a differential mechanism gear. The lower side of the differential mechanism gear is immersed in lubricating oil. The differential mechanism gear rotates, so that the lubricating oil on the bottom side of the transmission case is splashed into the temporary oil storage box, and the lubricating oil lubricates various parts of the transmission through the lubricating oil dripping holes and then flows back to the bottom side of the transmission case to form a cycle. The blade electric vehicle transmission has the beneficial effects of being complete in lubrication, moderate in oil amount, capable of saving energy, environment-friendly and the like.

Owner:浙江鑫可传动科技有限公司

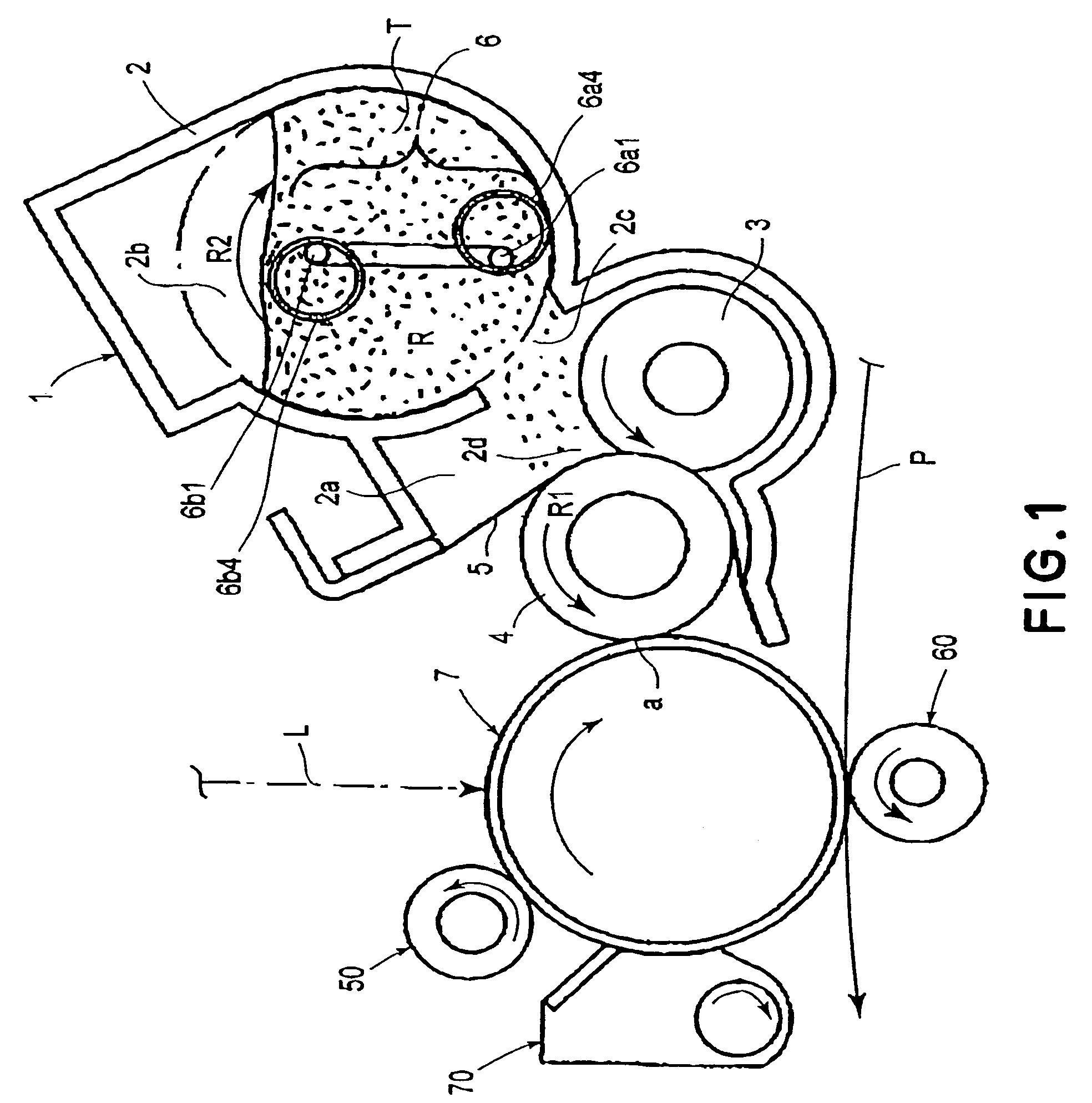

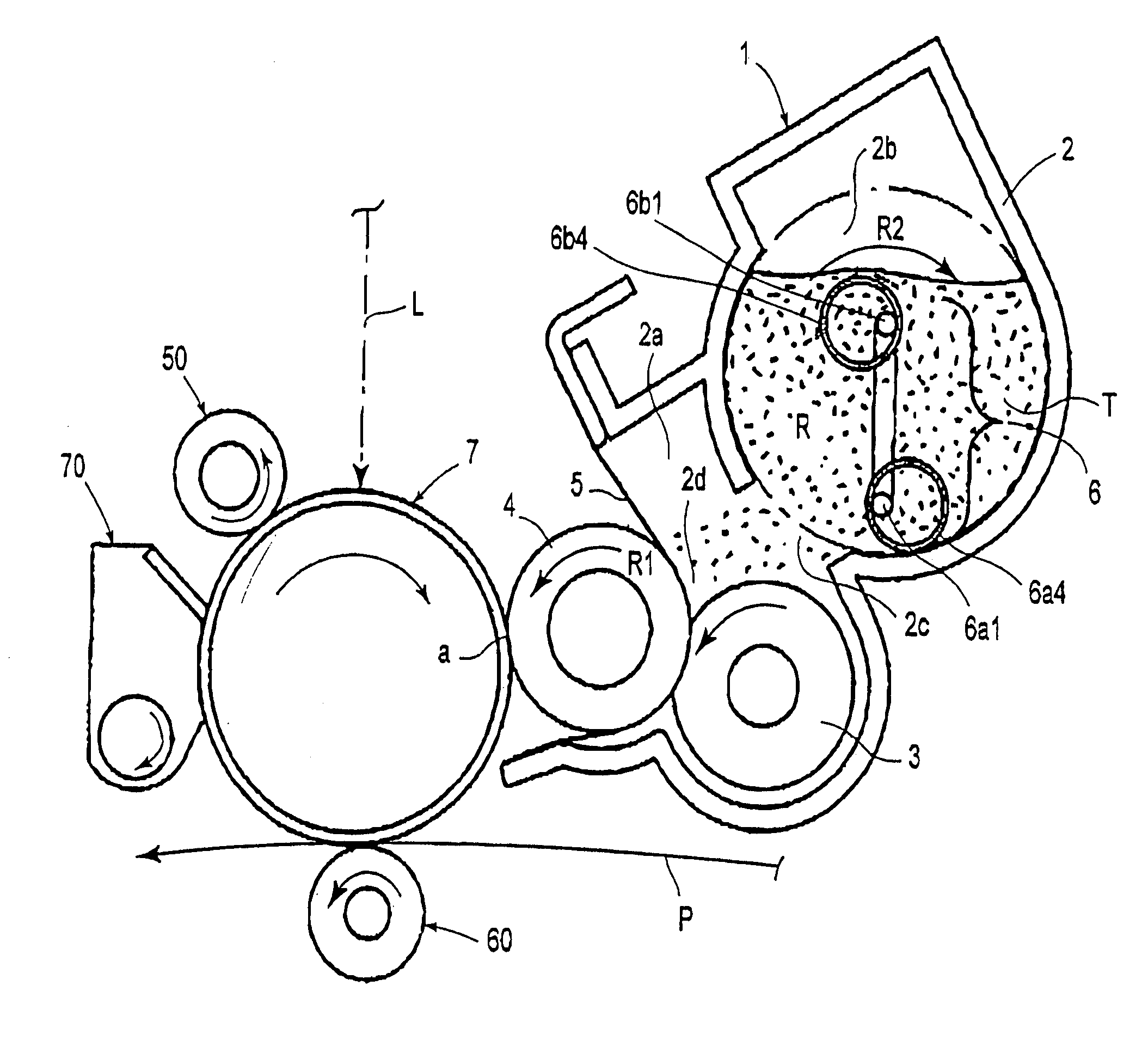

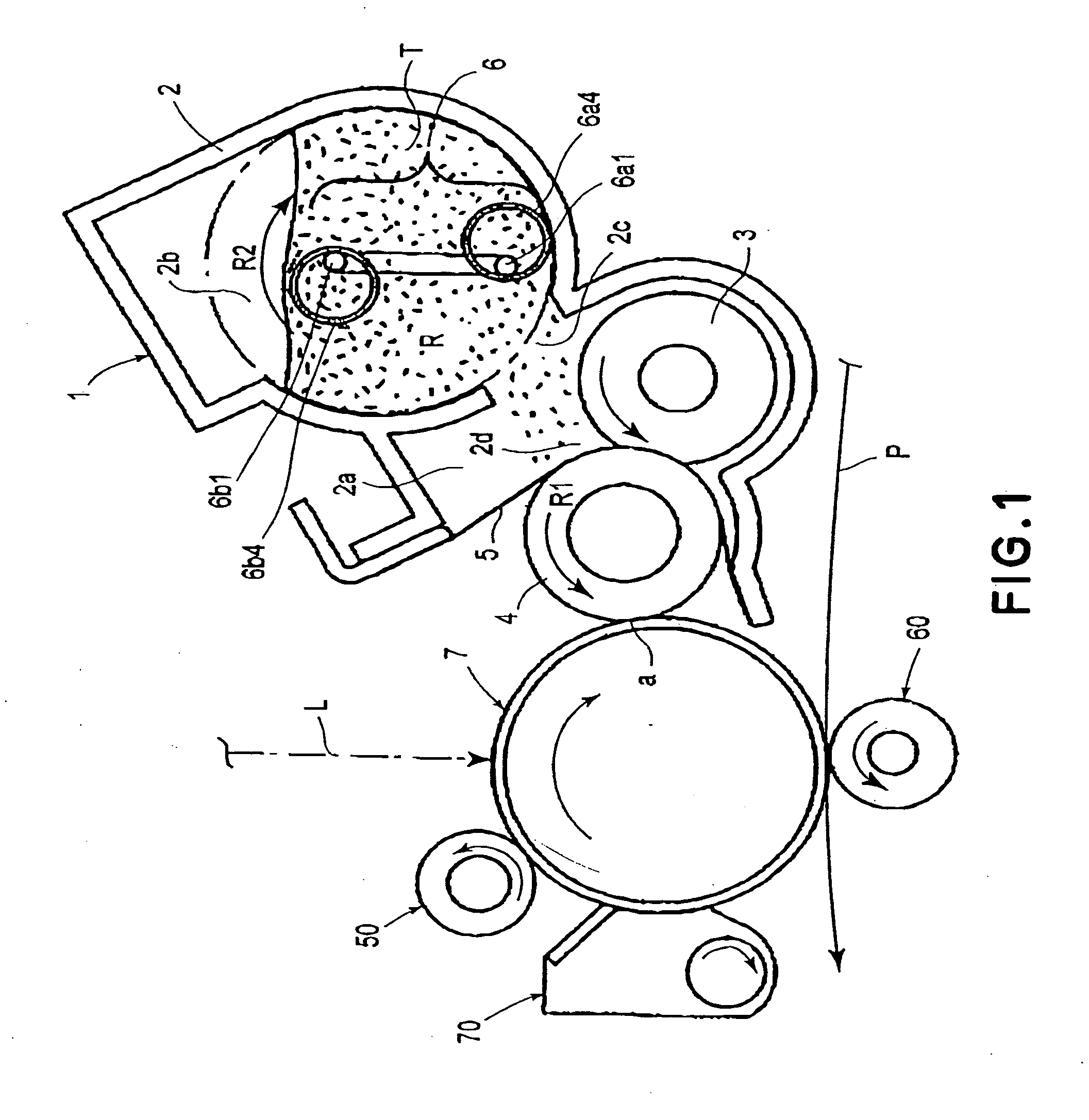

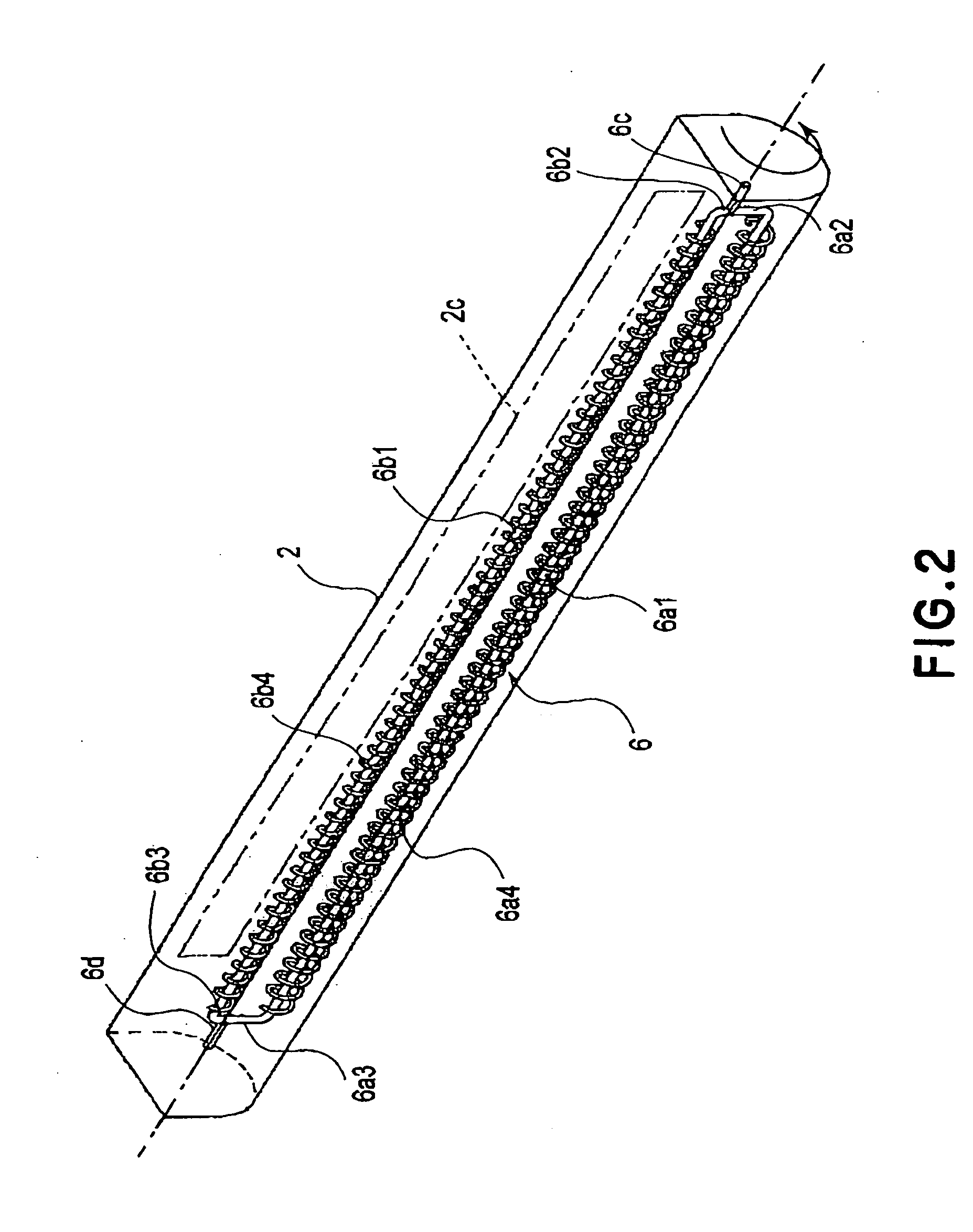

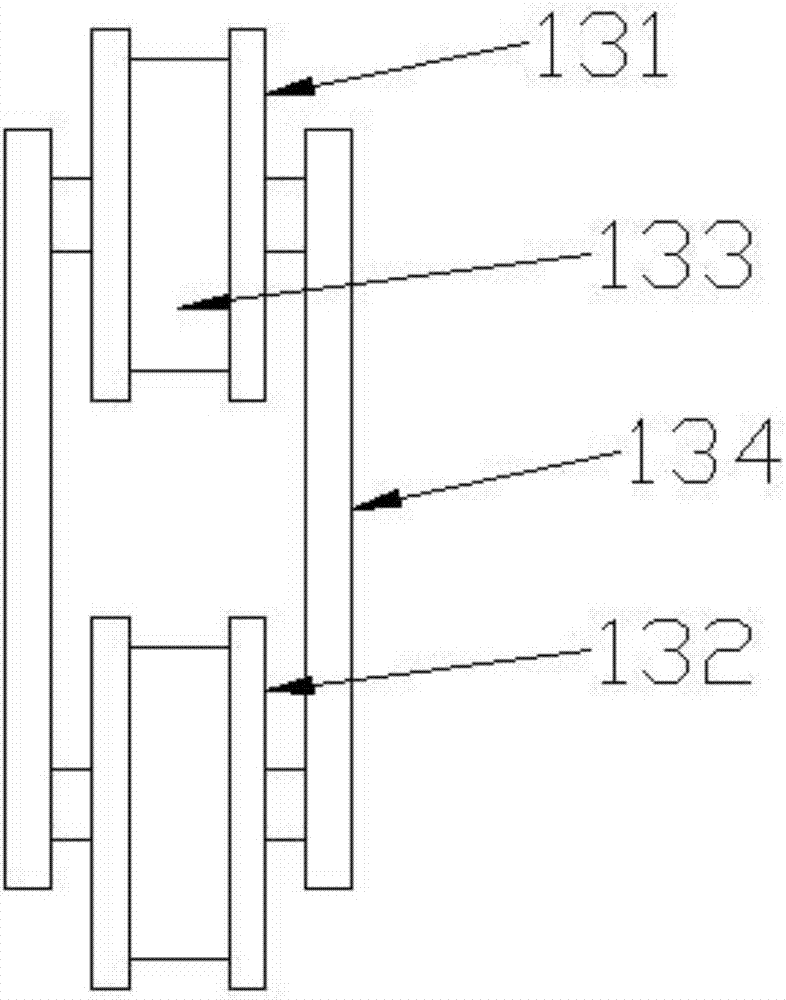

Developing apparatus

ActiveUS20060045574A1Developer deterioration occurs in specific portions of the developer container can be preventedDeterioration of the developer in the developer container can be minimizedElectrographic process apparatusLatent imageEngineering

A developing apparatus for developing an latent image formed on an electrophotographic photosensitive member with a developer in an electrophotographic image forming apparatus, the developing device includes a developer accommodating portion for accommodating the developer to be supplied to the developing member; a developer stirring member for stirring the developer in the developer accommodating portion, the developer stirring member including a rotatable member rotatably provided in the developer accommodating portion, a first stirring rotatable portion provided on the rotatable member, a first movable stirring portion movably provided on the first stirring rotatable portion, a second stirring rotatable portion provided on the rotatable member, and a second movable stirring portion movably provided on the second stirring rotatable portion, and wherein a radius of rotation of the first stirring rotatable portion and a radius of rotation of the second stirring rotatable portion are different from each other, and a part of a stirring region in which the first stirring rotatable portion and the first movable stirring portion stirs the developer and a part of a stirring region in which the second stirring rotatable portion and the second movable stirring portion stirs the developer, are overlapped.

Owner:CANON KK

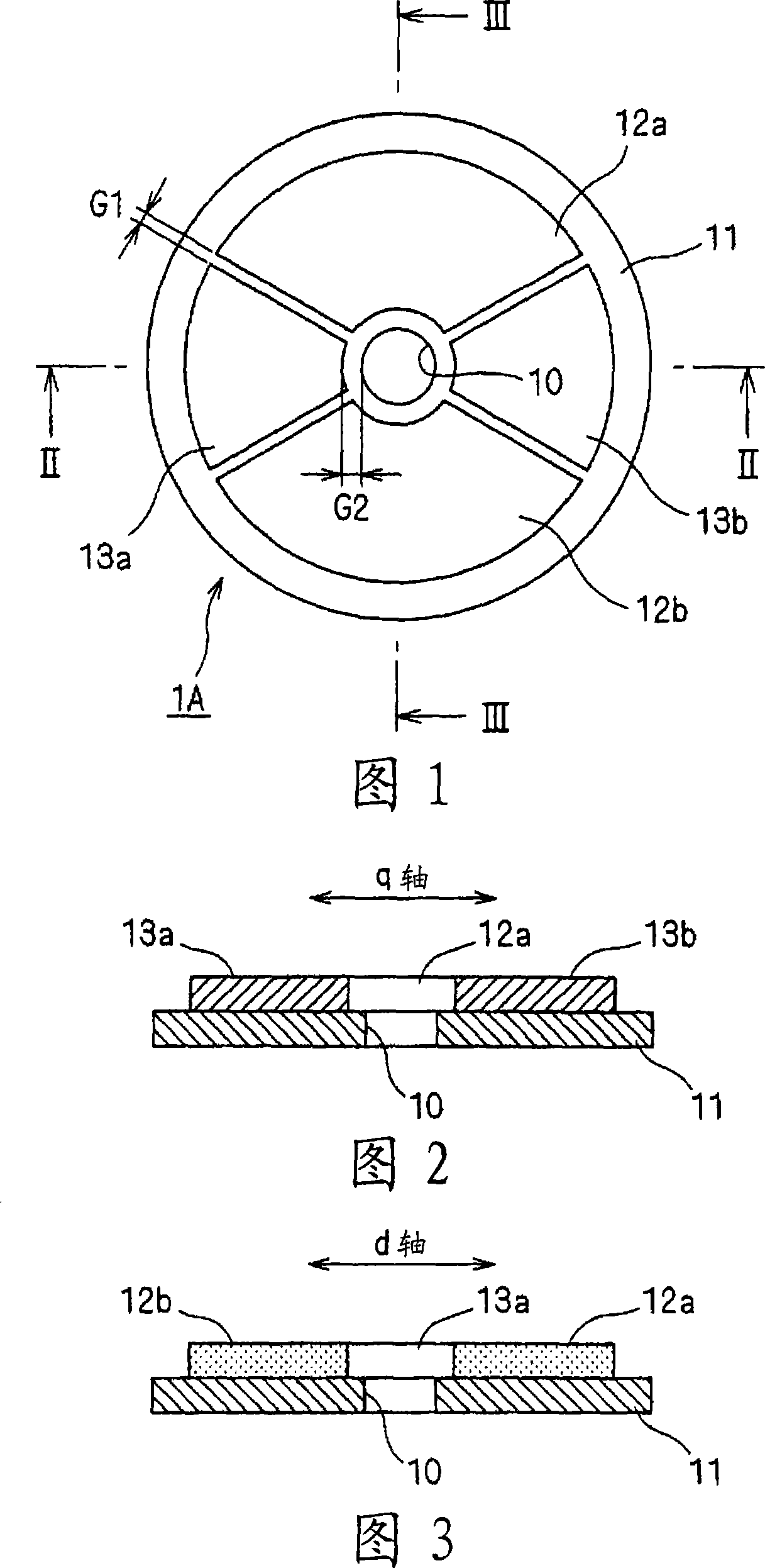

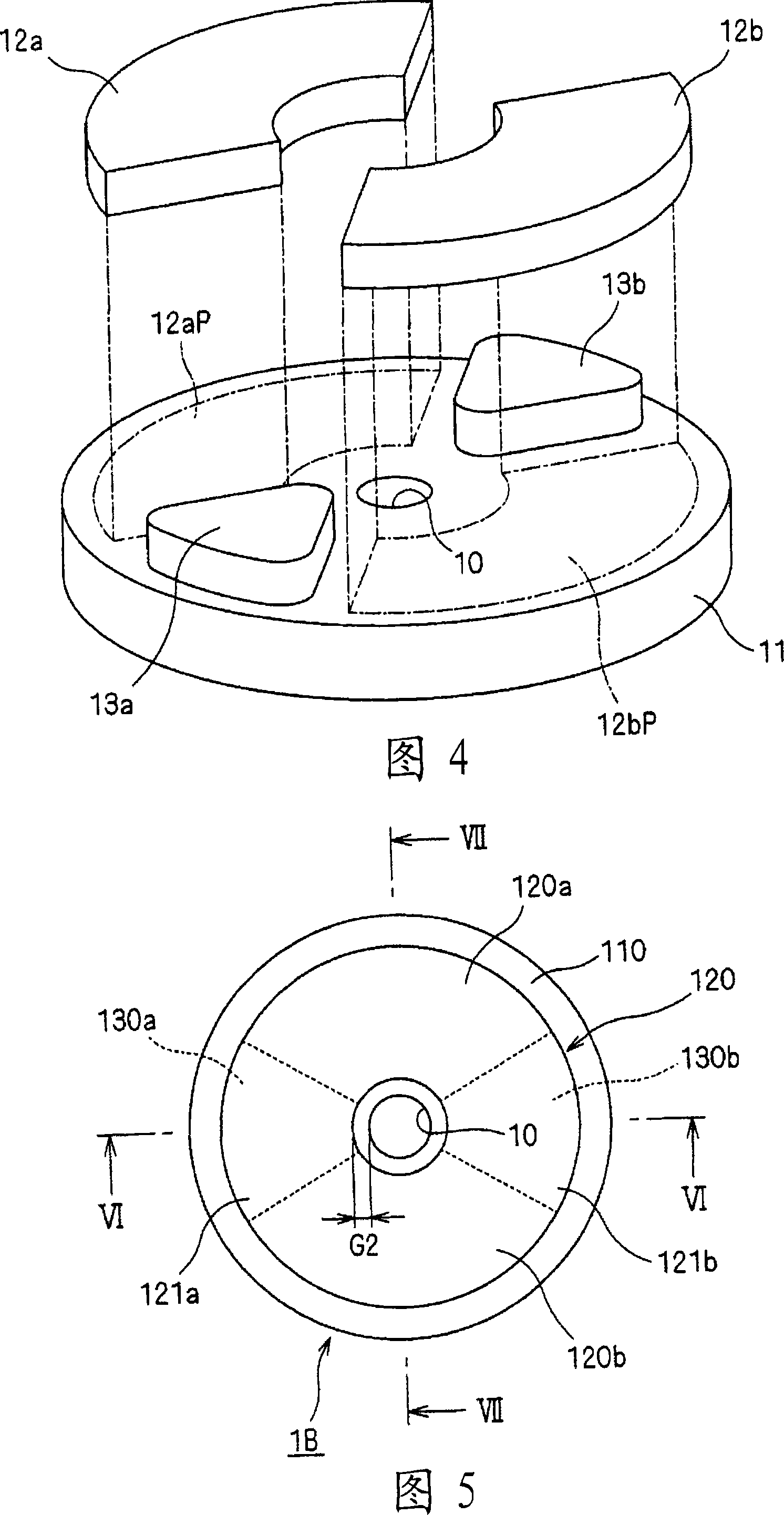

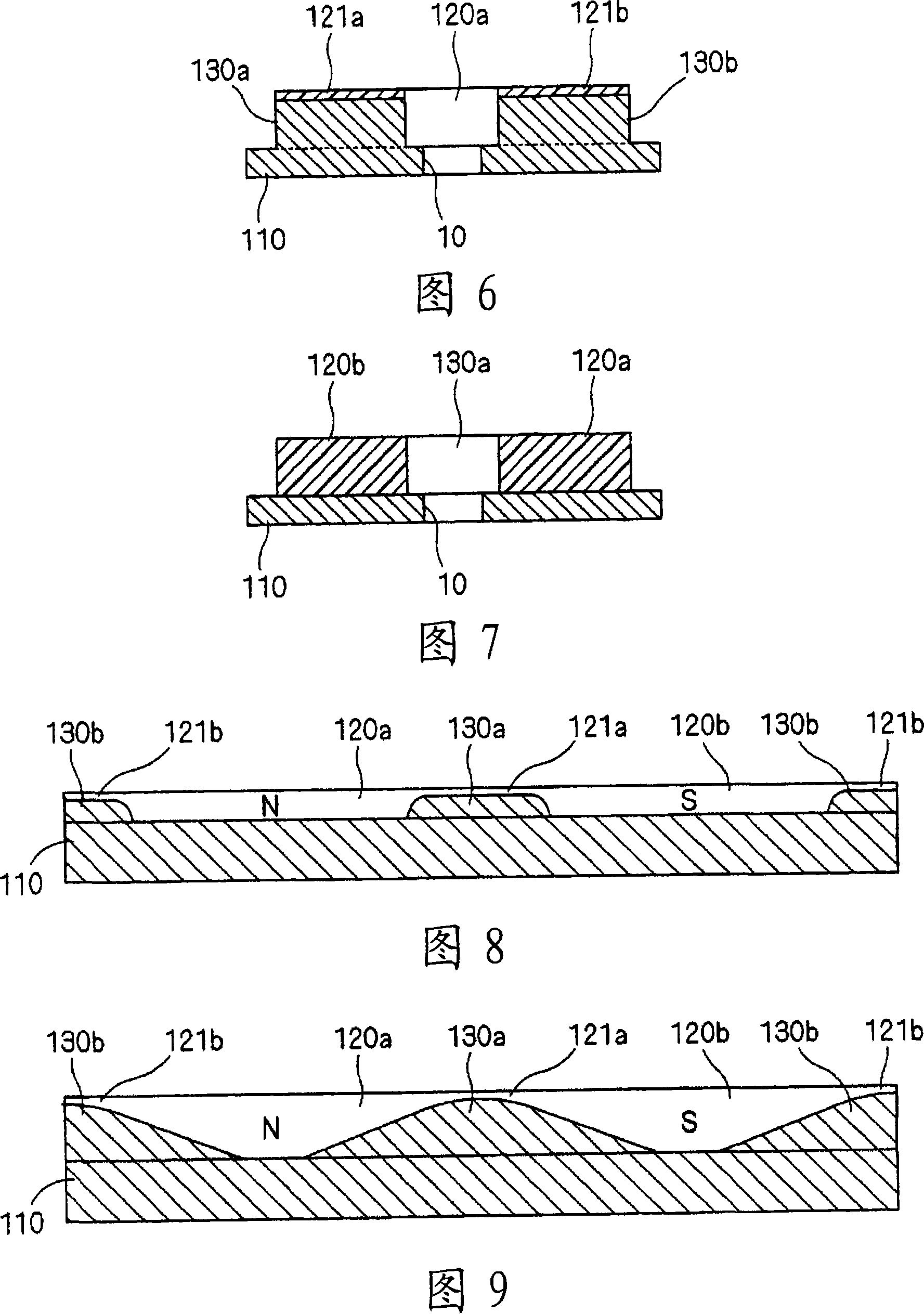

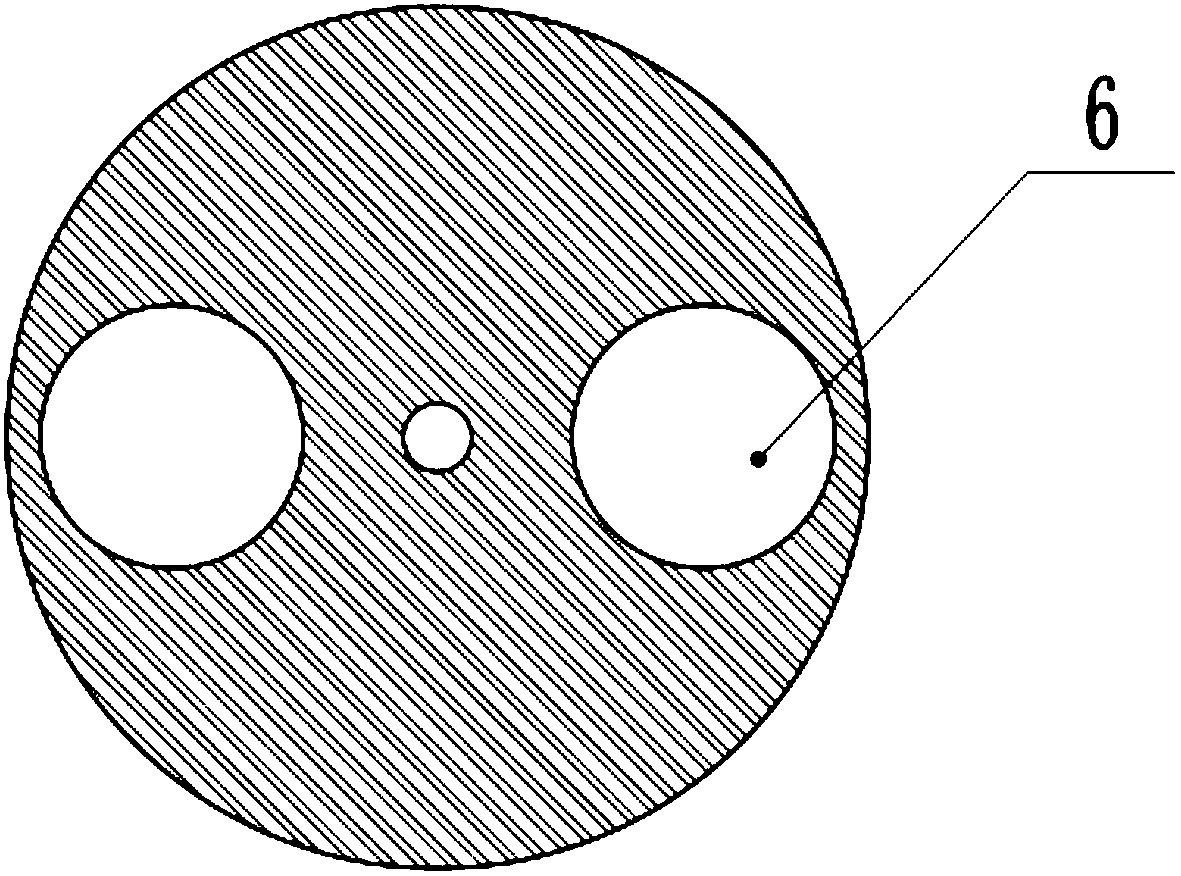

Rotor, axial gap type motor, driving method of motor, compressor

InactiveCN101107762ASmall torqueIncrease working pointMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveReverse salient

A rotor, an axial gap type motor comprising the rotor having reverse salient polarities and rotatable around a prescribed axis, a motor driving method, and a compressor. A plurality of magnets (12a, 12b) are annularly disposed on a substrate (11) with their polarities set symmetrical about a shaft hole (10). For example, the magnets (12a, 12b) present N-poles and S-poles on their stator side (toward you from paper surface). The plurality of magnetic substances (13a, 13b) are disposed vertically to the rotating axis direction, more specifically, extendedly between the magnets (12a, 12b).

Owner:DAIKIN IND LTD

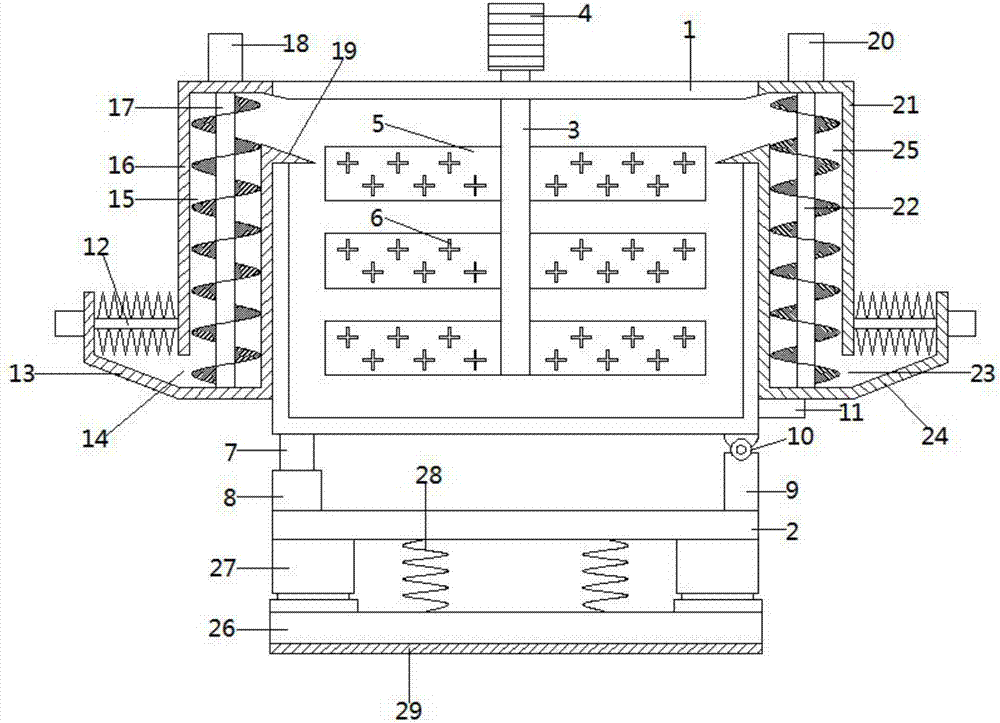

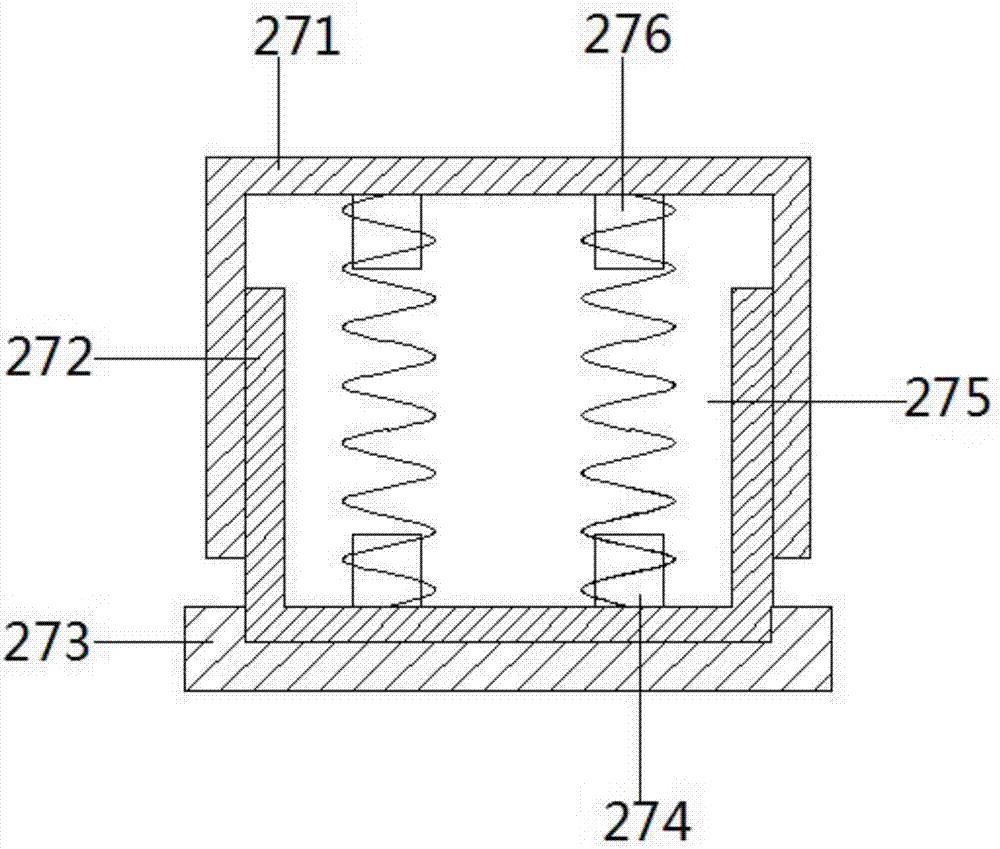

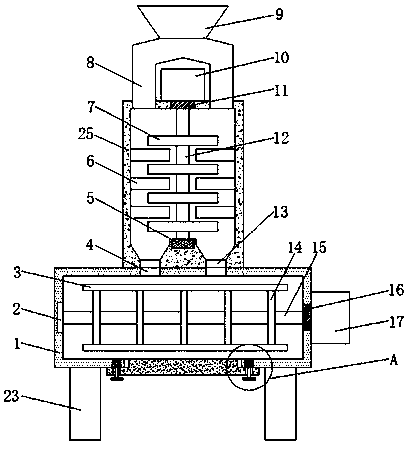

Self-feeding powder mixing device for constructional engineering

InactiveCN107224912AStir wellLarge thrustTransportation and packagingRotary stirring mixersWear resistantEngineering

The invention discloses a self-feeding powder mixing device for constructional engineering. The self-feeding powder mixing device for constructional engineering comprises a machine body; a supporting base is horizontally arranged on the lower side of the machine body; a wear-resistant concrete layer covers the outer wall of the machine body; a stirring rotating shaft is vertically arranged in the machine body; the top end of the stirring rotating shaft is connected with a driving motor; a plurality of stirring blades are arranged on the outer wall of the stirring rotating shaft; 12 stirring blades are divided into upper and lower three groups along the stirring rotating shaft circumferentially and uniformly. According to the self-feeding powder mixing device for constructional engineering, various materials can be input simultaneously, the materials do not need to be lifted to the top of the device by workers, feeding is conducted, time and labor are saved, the S-shaped stirring blades are adopted, and resistance-reducing holes are formed in the stirring blades, so the stirring uniformity is greatly improved, the left end of a stirring cylinder is jacked up to realize automatic discharging and the discharging blockage phenomenon is effectively avoided; in addition, the damping effect is good, and the noise is reduced while the stationarity is improved.

Owner:徐得强

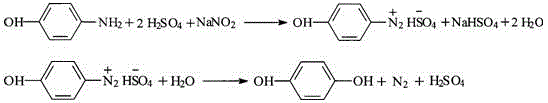

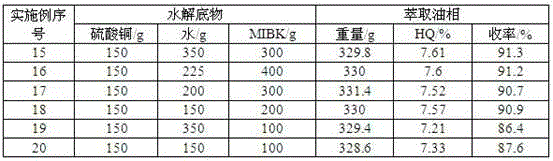

Hydrolysis process for hydroquinone

InactiveCN102746122AMake up for the disadvantage of high priceRealize cleaner productionOrganic chemistryOrganic compound preparationP-AminophenolReaction temperature

The invention discloses a hydrolysis process for hydroquinone and relates to a hydrolysis process during hydroquinone synthesis by subjecting p-aminophenol to diazotization and hydrolysis processes. The process includes: adding basic cupric carbonate, cupric sulfate and solvents into a hydrolysis reaction kettle, dropwise adding diazonium solution of 0+ / -0.5 DEG C obtained by subjecting sodium nitrite and dilute sulfuric acid to diazotization and performing hydrolysis reaction at a reaction temperature of 85 DEG C-88 DEG C. Raffinate phase does not generate waste acid, and the copper recovery rate reaches to more than 99.5%, so that a disadvantage of high copper price is made up; and sodium sulfate is obtained by means of concentration and crystallization of filtrate, concentrated water is used for preparing acid for diazo reaction, and crystallized mother solution of the sodium sulfate is used for preparing cupric sulfate solution for hydrolysis, so that clean production is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Beef packing machine

A beef packing machine comprises a support, a feeding mechanism and a bag making mechanism. The feeding mechanism and the bag making mechanism are disposed on the support, the feeding mechanism is connected with the bag making mechanism and consists of a hopper, a screw pushing device, a pressing cylinder and a metering cup, the screw pushing device is arranged below the hopper, the pressing cylinder is disposed at one end of the screw pushing device and positioned at the finish end of the pushing direction, and the metering cup is disposed below the pressing cylinder and connected with the bag making mechanism. Beef is quantitatively packed mechanically, manual packing is replaced, squeezing, smashing and stirring of the beef are avoided, moisture and freshness of the beef are guaranteed, the requirements of batch production are met, and the beef packing machine is high in quantitative precision, fast in packing speed and simple in structure and is quite practical.

Owner:SUZHOU HAODELAI FOOD

Equivalent filtering and mixing device for biomass liquid fuel

ActiveCN108079831AEqual feed realizationSpeed up filteringRotary stirring mixersTransportation and packagingLiquid fuelDrive motor

The invention discloses an equivalent filtering and mixing device for biomass liquid fuel. The equivalent filtering and mixing device comprises a tank, an equivalent feeding plate, a tank filter screen, a first drive motor, a second drive motor and stirring blades and is characterized in that the equivalent feeding plate is arranged at the lower ends of a fuel feeding pipe A and a fuel feeding pipe B, the filter screen is arranged below a fixed plate and a movable plate, each outer loop bar is of a hollow structure, a slider is slidably mounted inside each outer loop bar, a telescopic rod is welded to one side of each slider, and the stirring blades are welded to each telescopic rod. The equivalent filtering and mixing device has the advantages that by the equivalent feeding plate, fuel entering the tank in unit time can be identical in quantity, that is to say, equivalent feeding can be achieved, fuel measuring before mixing is not needed, and time and labor are saved; the telescopinglength of the telescopic rods can be changed according to centrifugal force during mixing so as to change the stirring range of the stirring blades, and accordingly the situation that fuel on two sides or in the middle of a stirring cavity cannot be stirred can be prevented, and the stirring and mixing effect can be increased greatly.

Owner:江西云顺新能源有限公司

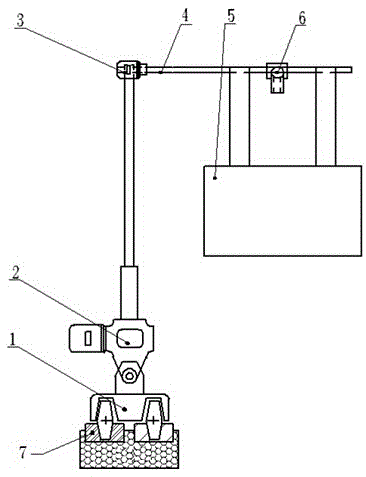

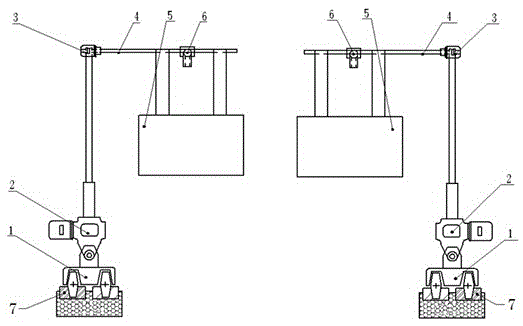

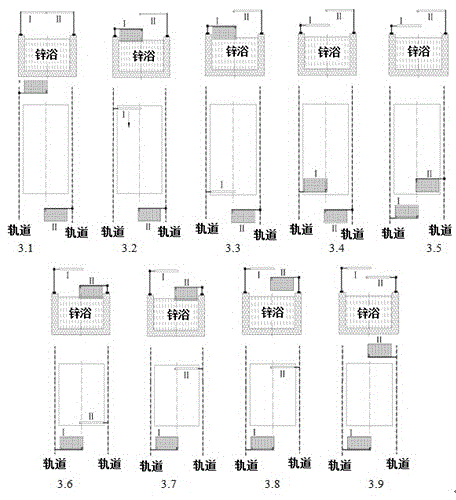

Ash scraping device for batched hot-dip galvanizing

ActiveCN105543751ARealize the mechanized operation of dust removalAchieve cleanupHot-dipping/immersion processesHot-dip galvanizationIr detector

The invention discloses an ash scraping device for batched hot-dip galvanizing, and belongs to the technical field of hot-dip galvanizing. The ash scraping device comprises an electric trolley, an electric push rod, a speed reduction motor and a rotating shaft, wherein one end of the electric push rod is fixed to the electric trolley, the other end of the electric push rod is connected to the speed reduction motor, the speed reduction motor is driven to be lifted vertically through extension of the electric push rod, and an output shaft of the speed reduction motor is connected to the rotating shaft; a scraper blade and an infrared detector are fixed to the rotating shaft, and the blade width of the scraper blade is greater than a half of the width of a zinc pot by 5-10 centimeters. Ash scraping devices are used in a paired mode when used for removing ash and are arranged on guide rails on the two sides in the length direction of the zinc pot respectively. The ash scraping device has the advantage that mechanical operation of removing the ash on the surface of a zinc bath in the batched hot-dip galvanizing process can be realized, and traditional ash removal can be replaced.

Owner:KUNMING UNIV OF SCI & TECH +1

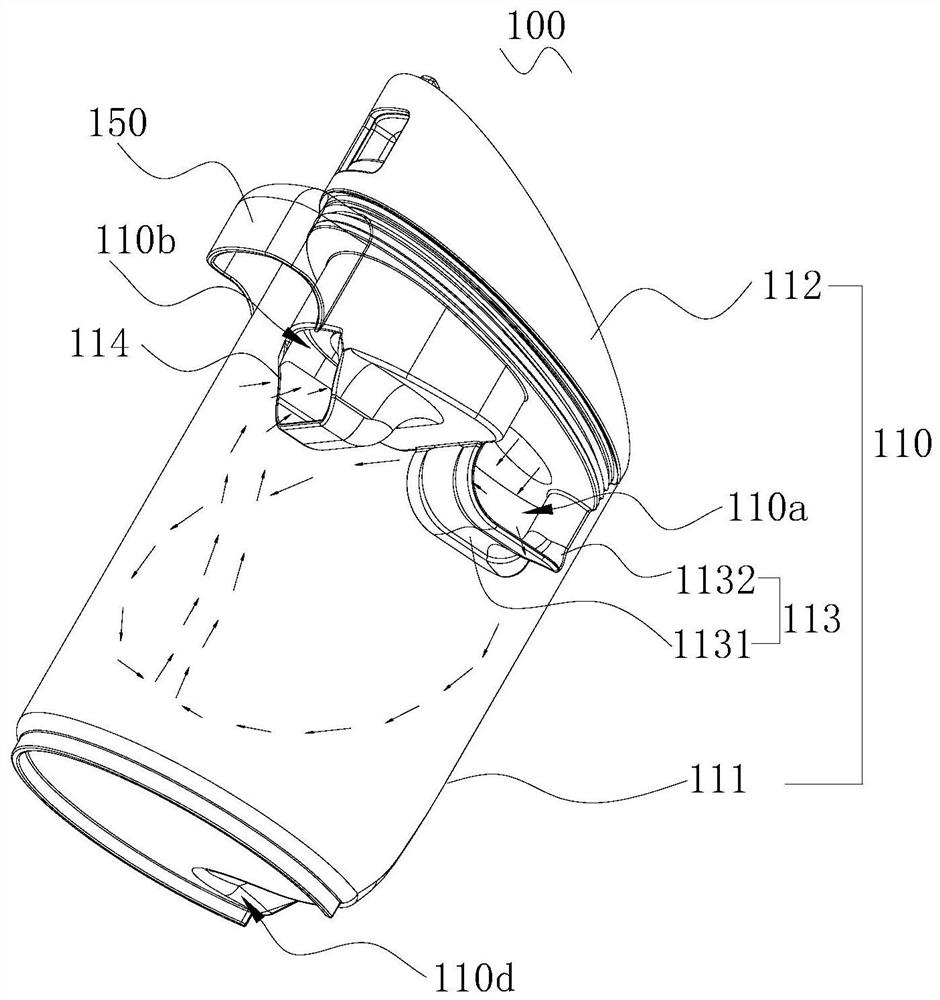

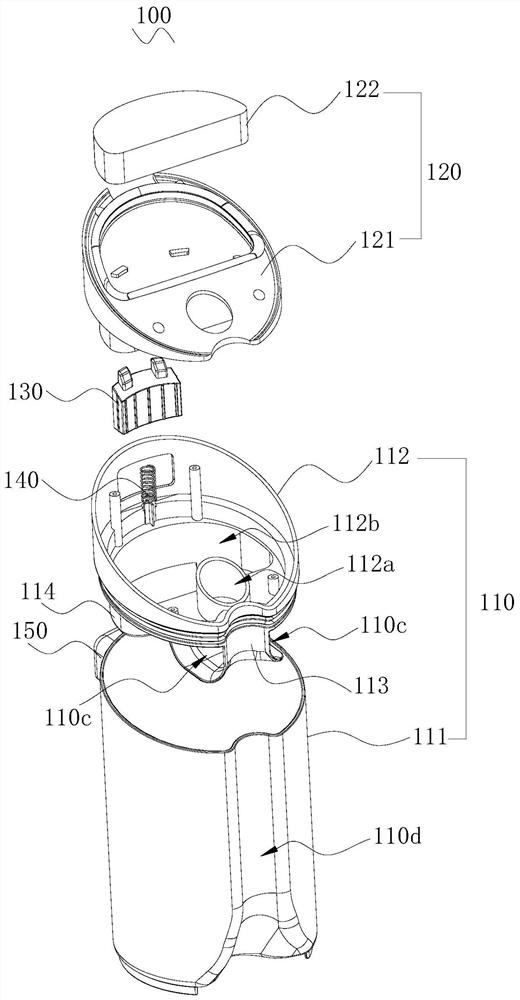

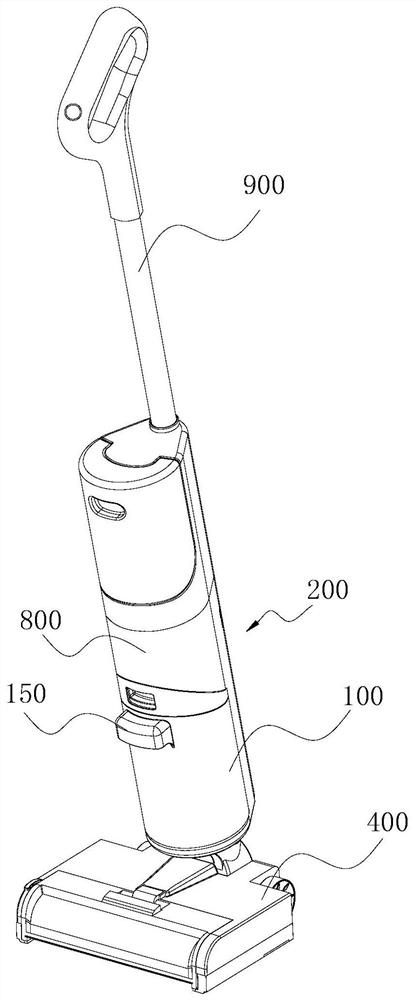

Sewage tank structure for cleaning equipment and cleaning equipment

PendingCN112773250AImprove space utilizationAvoid stirringSuction filtersCarpet cleanersSewageWater resource management

The invention relates to a sewage tank structure for cleaning equipment and the cleaning equipment. The sewage tank structure comprises a sewage tank, wherein the sewage tank is provided with a first flow channel and a second flow channel; the first flow channel is used for dividing fluid flowing into the sewage tank into a plurality of beams and enabling the plurality of beams of fluid to oppositely impact in the sewage tank; and the second flow channel is used for discharging gas in the sewage tank. After sewage garbage mixed with gas is divided into a plurality of bundles through the first flow channel, gas-liquid separation occurs in the process that each bundle of sewage garbage mixed with gas flows downwards into the sewage tank, and in the separation process, each bundle of sewage mixed with gas is subjected to opposite flushing in the sewage tank, so that the sewage garbage mixed with gas flows into the sewage tank; the kinetic energy of each beam of sewage mixed with gas is mutually reduced, counteracted or at least partially counteracted due to hedging, so that sewage garbage stably flows into the sewage tank, the separated gas and gas in other fluid beams are hedged in the sewage tank, the kinetic energy of the gas is reduced, and therefore, the suction generating device can more easily suck the separated gas through the second flow channel.

Owner:KEEWOO ROBOTICS TECH CO LTD

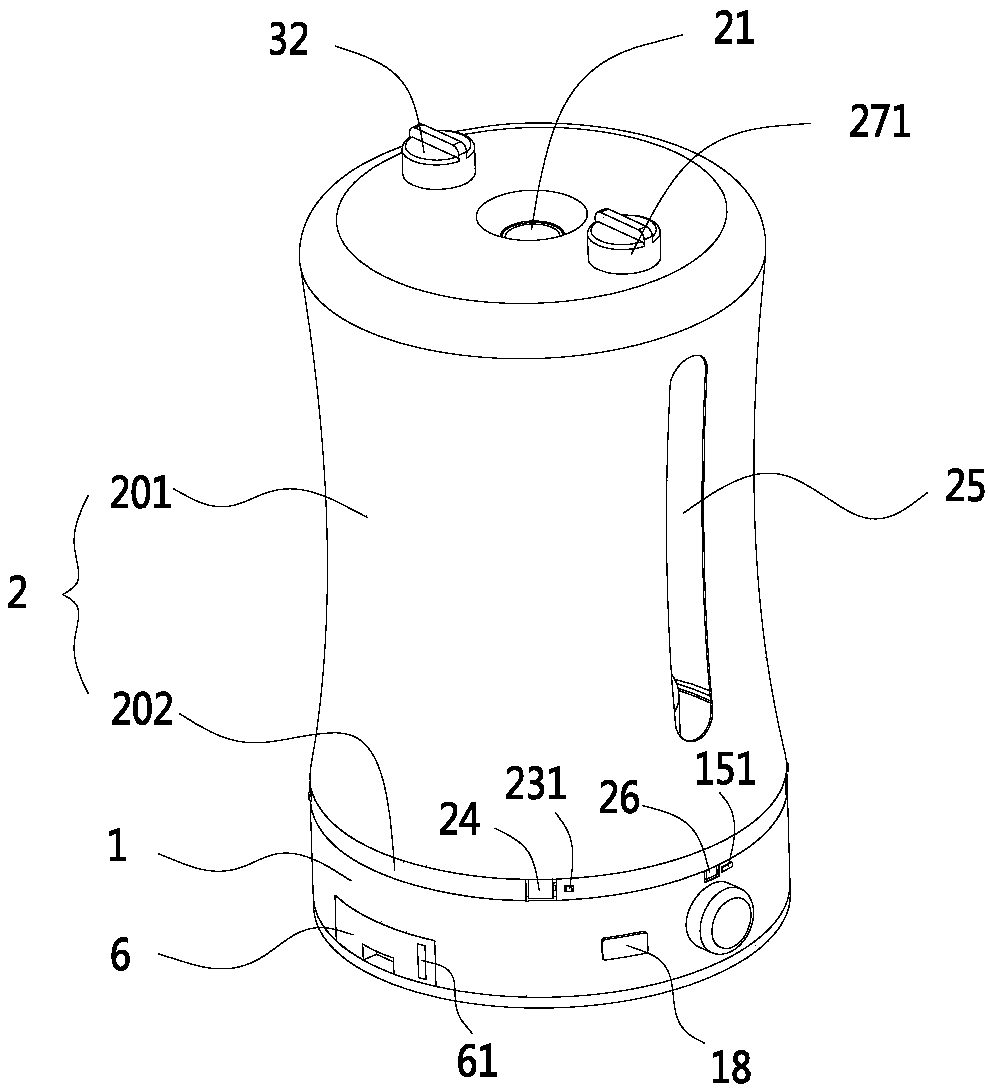

Multifunctional humidifier and control method thereof

InactiveCN108361900AFunctional changeRealize timed injection effectLighting and heating apparatusGaseous substancesWater storageEngineering

The invention discloses a multifunctional humidifier, and belongs to the technical field of intelligent home. The multifunctional humidifier comprises a base; a water storage groove is formed in the base; a moisture generator is arranged in the water storage groove; a water tank is arranged on the base; a moisture channel is formed in the water tank; water in the water storage groove, under the action of the moisture generator, is emitted out of the moisture channel; the water tank comprises a water storage inner cavity; an additive box in which an additive is placed is arranged on the water tank; the additive box communicates with the water storage inner cavity; and an ejector for ejecting the additive in the additive box to the water storage inner cavity is arranged on the additive box.In addition, the invention further discloses a control method of the multifunctional humidifier. The multifunctional humidifier and the control method of the multifunctional humidifier have the advantages that functions of the humidifier are diversified.

Owner:HANGZHOU SIWENKE TECH CO LTD

Variable-diameter mixing machine for coating processing

PendingCN106943928AImprove mixing effectImprove mixing efficiencyFlow mixersRotary stirring mixersCirculating pumpRaw material

The invention discloses a variable-diameter mixing machine for coating processing. The machine comprises a mixing tank, a horizontal conveying tank and a circulating tank, wherein a speed reducer is connected to the lower end of an output shaft of a first motor; two groups of stirring components are arranged on a stirring rod; each stirring component comprises a fixed sleeve, a movable sleeve, a support rod, an elastic stirring fin and a balancing weight; the bottom part of a lower hopper is communicated with the horizontal conveying tank; the circulating tank is communicated to the upper side of the right end of the horizontal conveying tank; a plastic hose is communicated to one end of a circulating pump, and winds on an adjusting mechanism; the adjusting mechanism is formed by an upper guide wheel, a lower guide wheel, a pipe trough and an installation plate. According to the variable-diameter mixing machine for coating processing provided by the invention, the arranged stirring components are used for mixing raw materials in a stirring barrel, the stirring speed of a stirring shaft is adjusted through the speed reducer during a stirring process, and the degrees of outwards stretching the elastic stirring fins through the balancing weights are different according to different rotary speeds, so that the stirring radius is changed, stirring are carried out at different positions, and the stirring effect is improved.

Owner:李姗姗

Metal powder and adhesive mixing device

ActiveCN108554210AAvoid stirringHigh purityTransportation and packagingMetal-working apparatusAdhesiveSlide plate

The invention relates to the technical field of mixing equipment in powder metallurgy, and particularly discloses a metal powder and adhesive mixing device. The metal powder and adhesive mixing devicecomprises a machine frame and a mixing tank, wherein a partition board is fixedly connected to the interior of the mixing tank; an opening is formed in the partition board; a screen is horizontally connected to the opening in a sliding manner; a material storage chamber is fixedly mounted on the side wall of the mixing tank; the material storage chamber is communicated with a discharge pipe; a fixing block is mounted on the discharge pipe; the fixing block is connected with a sliding plate in a sliding manner; a through hole is formed in the sliding plate; in the sliding process of the sliding plate, the through hole can be intermittently communicated with the discharge pipe; a second spring is connected between the sliding plate and the partition board; a motor and a cylinder are fixedlymounted on the machine frame; the motor is used for driving the screen and the sliding plate to slide so as to achieve feeding; the cylinder is connected with an elastic gasbag for storing gas. The metal powder and adhesive mixing device can fully contact a metal powder with an adhesive, so that the mixing uniformity of the two is improved and the mixing efficiency of the two is improved, therefore, the production quality of hard alloy is guaranteed and the market competitiveness of an enterprise is improved.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

Fertilizing irrigator for agriculture

InactiveCN107593074AStable structureEasy to moveRotary stirring mixersPressurised distribution of liquid fertiliserAgricultural irrigationAgricultural engineering

The invention discloses a fertilizing irrigator for agriculture. The fertilizing irrigator comprises a filter cylinder, a fertilizer adding pipe, a fertilizer mixing tank body and a liquid storage tank body, wherein the upper end of the liquid storage tank body is connected with the fertilizer mixing tank body; and the filter cylinder is arranged inside the fertilizer mixing tank body, a fertilizer dissolving cavity is formed inside the filter cylinder, the top of the filter cylinder is covered with a filter cylinder cover, the filter cylinder cover is soldered on the outer wall of the fertilizer adding pipe, and a plurality of ejecting blades are soldered on the outer wall of the fertilizer adding pipe under the filter cylinder cover. According to the fertilizing irrigator, the fertilizerefficiency can be increased; fertilizer is prevented from directly depositing to the bottom of the fertilizer mixing tank body, the fertilizer dissolving sufficiency can be increased, large-grain fertilizer or large-grain foreign substances in the fertilizer can be prevented from falling into the fertilizer mixing cavity, feed liquid in the fertilizer mixing cavity can be further filtered by thefertilizer filter screen, the clean degree of fertilizer liquid flowing into the fertilizer liquid storage cavity can be improved, grains are prevented from blocking an irrigating pipe, and the quality and effect of agricultural irrigation can be improved.

Owner:蒋炳坤

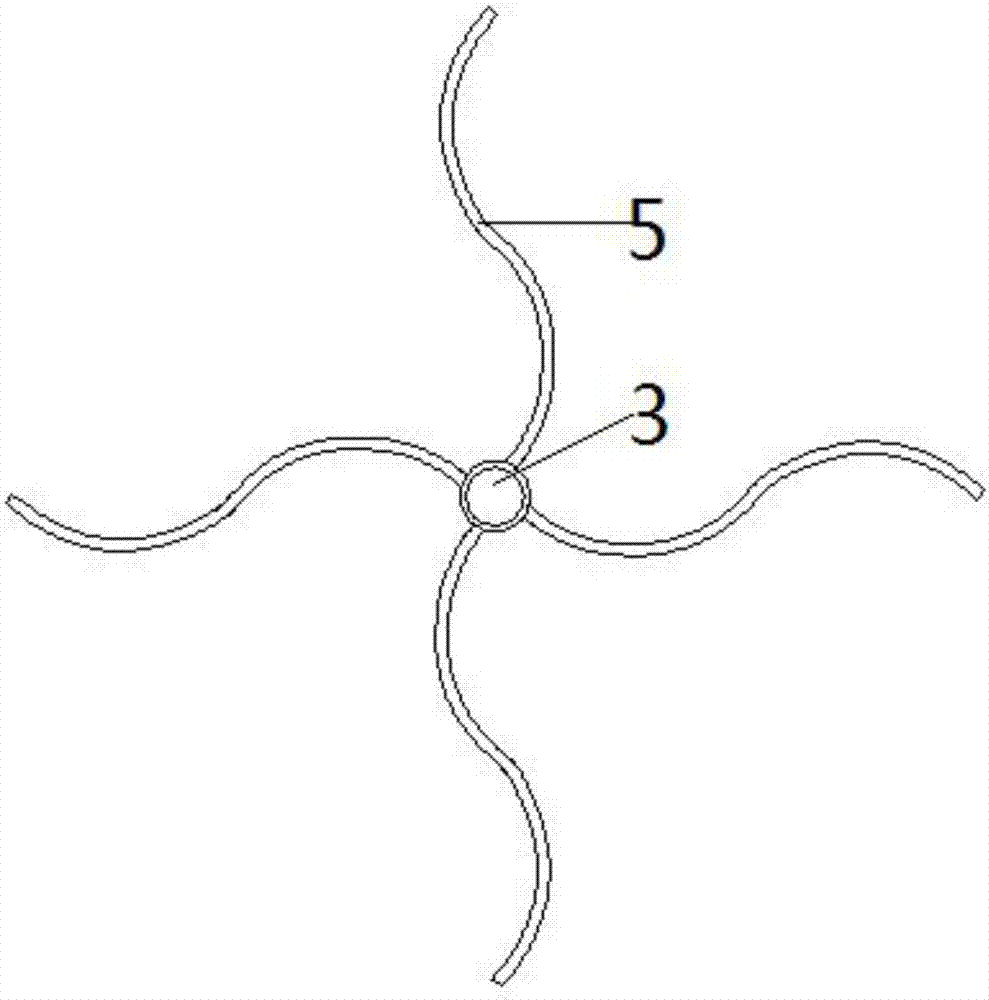

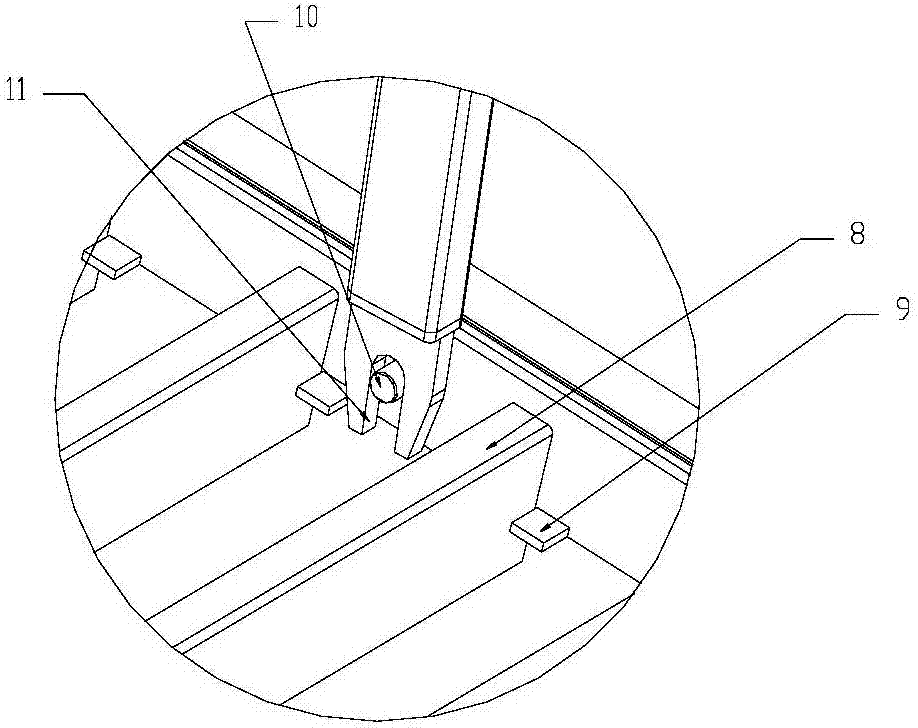

Sludge scraping assembly

The invention discloses a sludge scraping assembly, and belongs to the technical field of sewage treatment. The sludge scraping assembly comprises a sludge scraping module used for scraping sludge at the bottom of a precipitation tank and a driving module for driving the sludge scraping module to reciprocate back and forth; the sludge scraping module comprises sludge scraping plates and slide plates arranged at two ends of the sludge scraping plates, two ends of the sludge scraping plates are respectively connected to the slide plates in a single-degree-of-freedom rotating manner, the slide plates are provided with spacing members for spacing the sludge scraping plates being in a sludge scraping state, and the driving module comprises a connecting lever and a driving mechanism for driving the connecting lever to swing back and forth; and the lower end of the connecting lever is hinged to one of the slide plates in a sliding manner. The sludge scraping module always reciprocate on the horizontal plane determined by the bottom of the precipitation tank without up-and-down elevation motion, so the strong stirring of the sludge scraping module to precipitated sludge is effectively avoided, and natural precipitation is facilitated.

Owner:河南中成环保科技股份有限公司

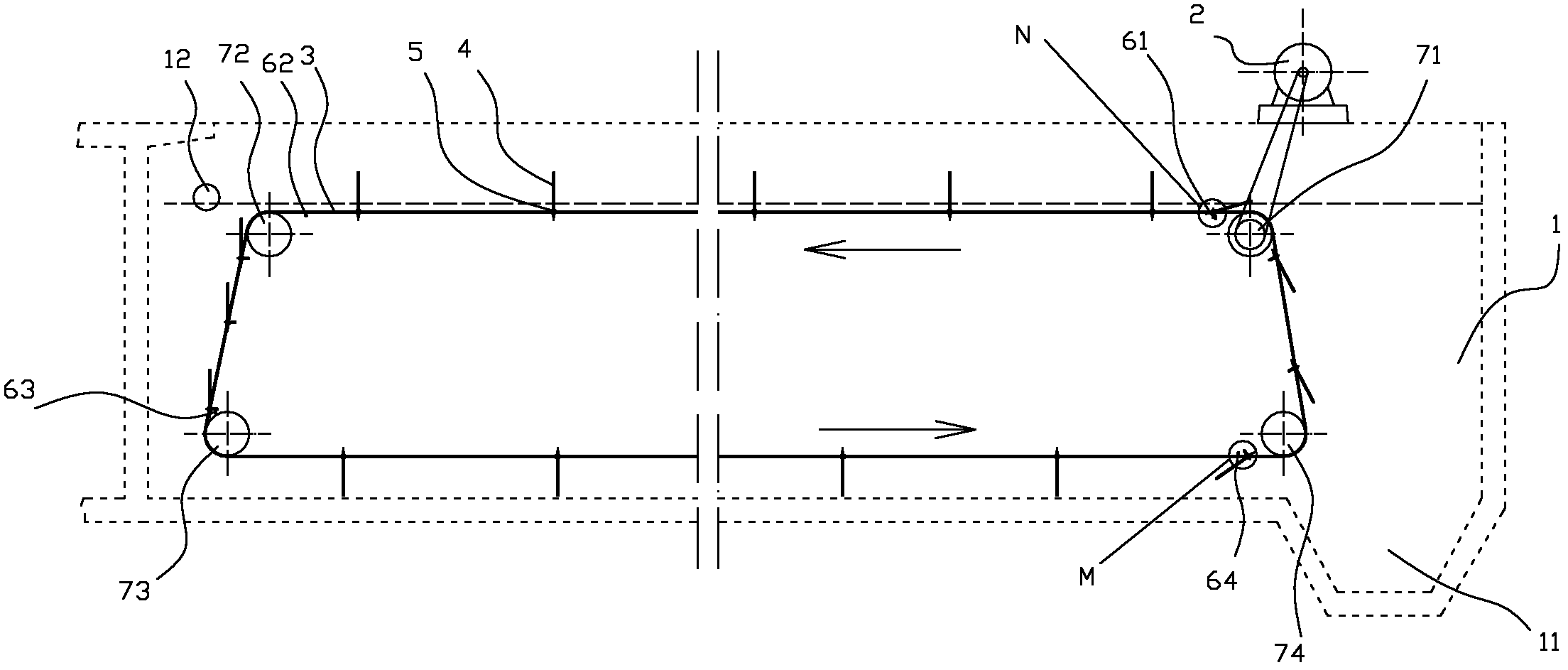

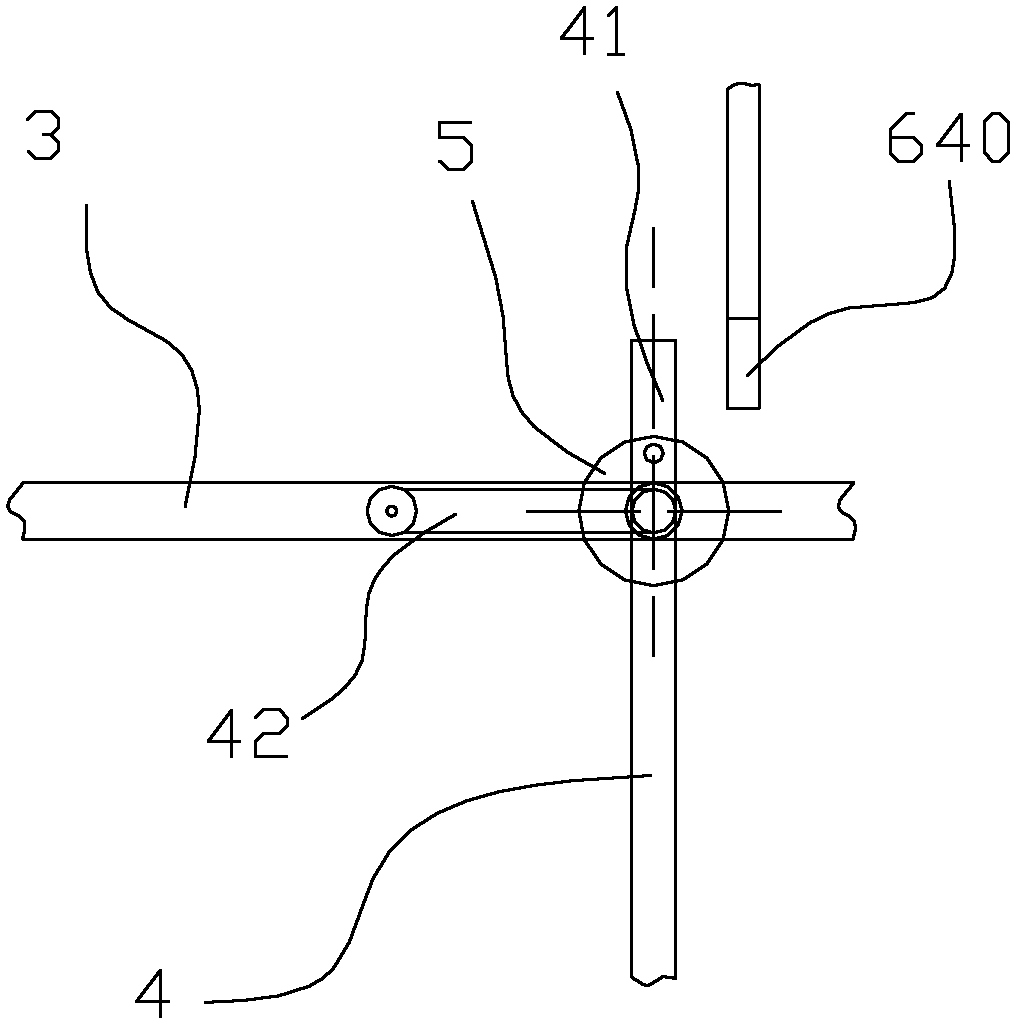

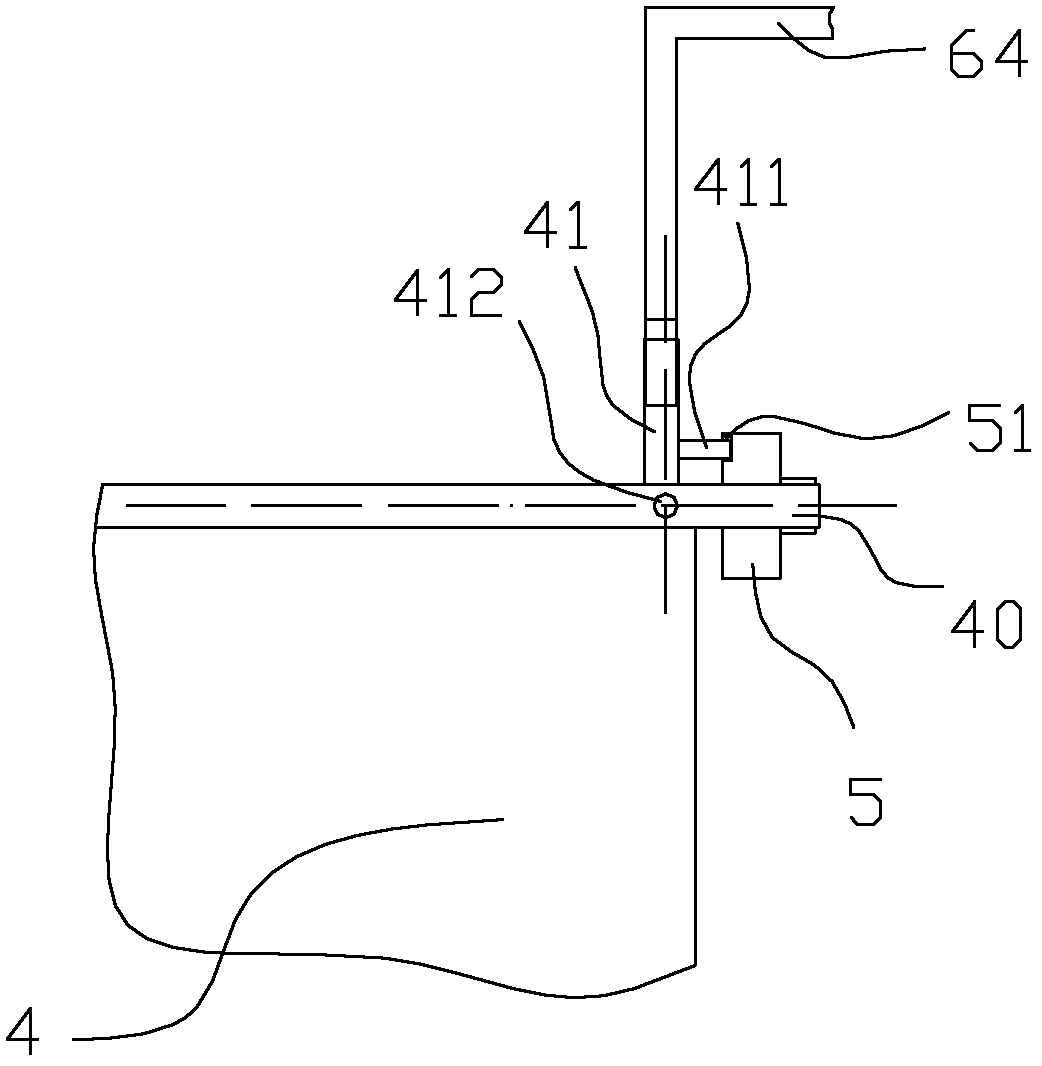

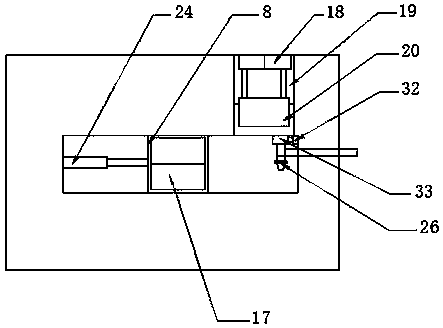

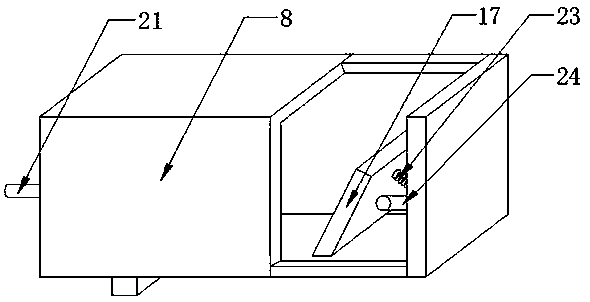

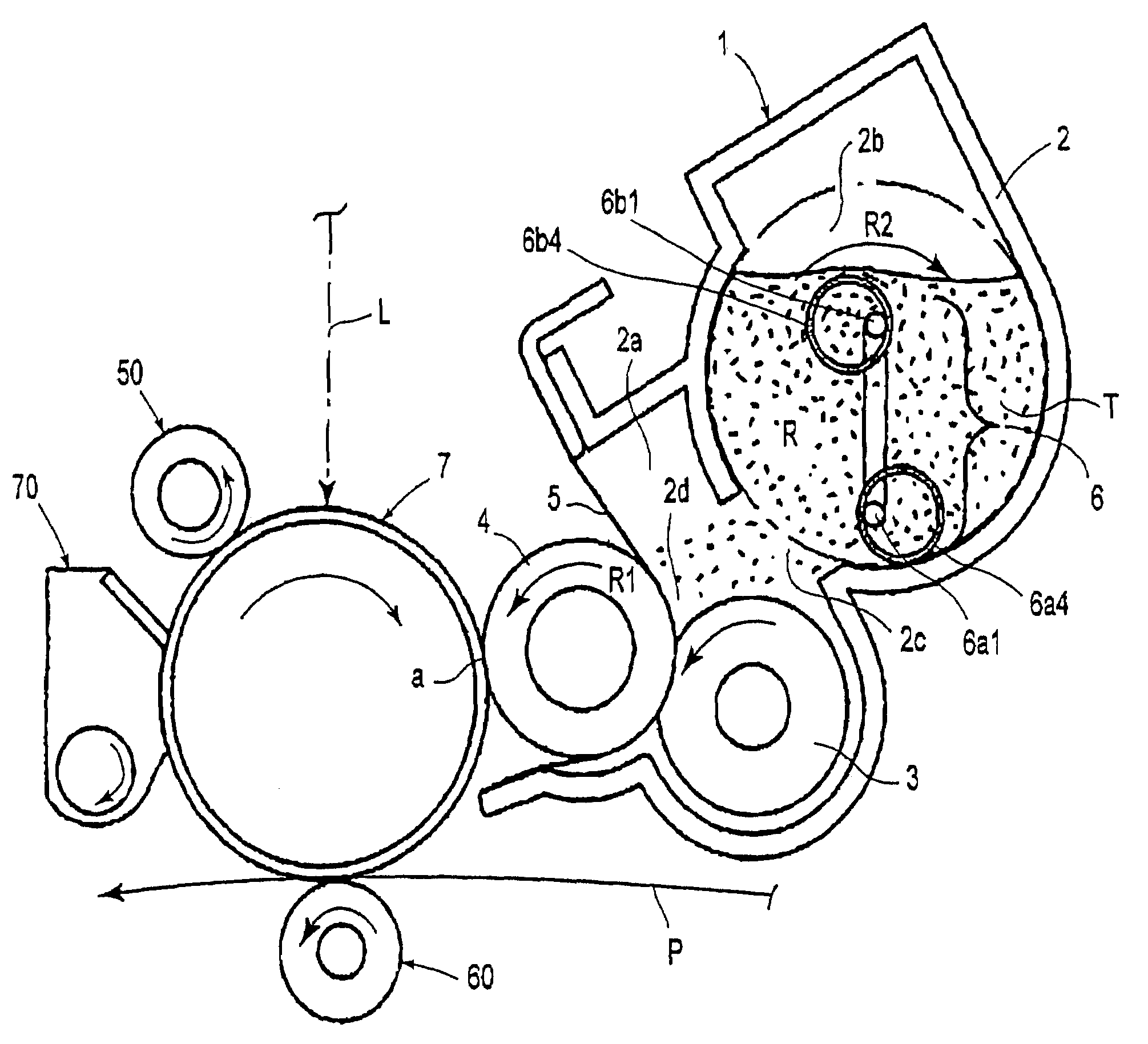

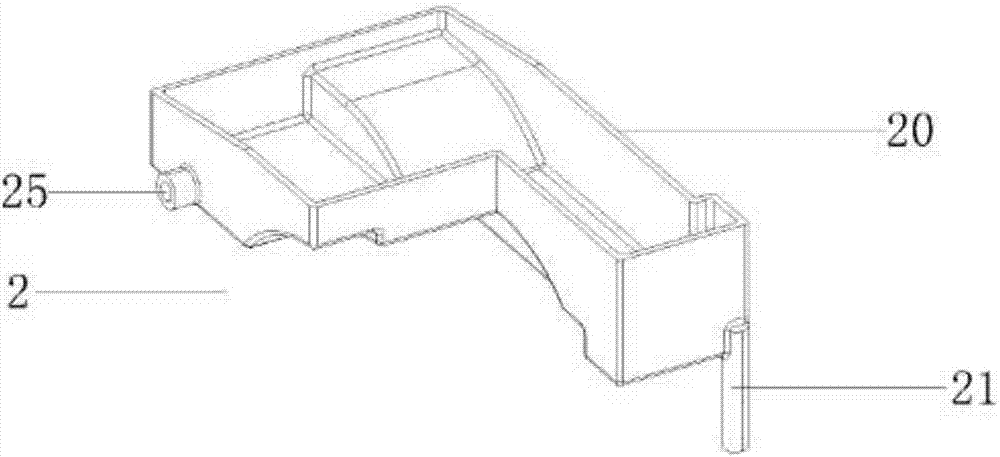

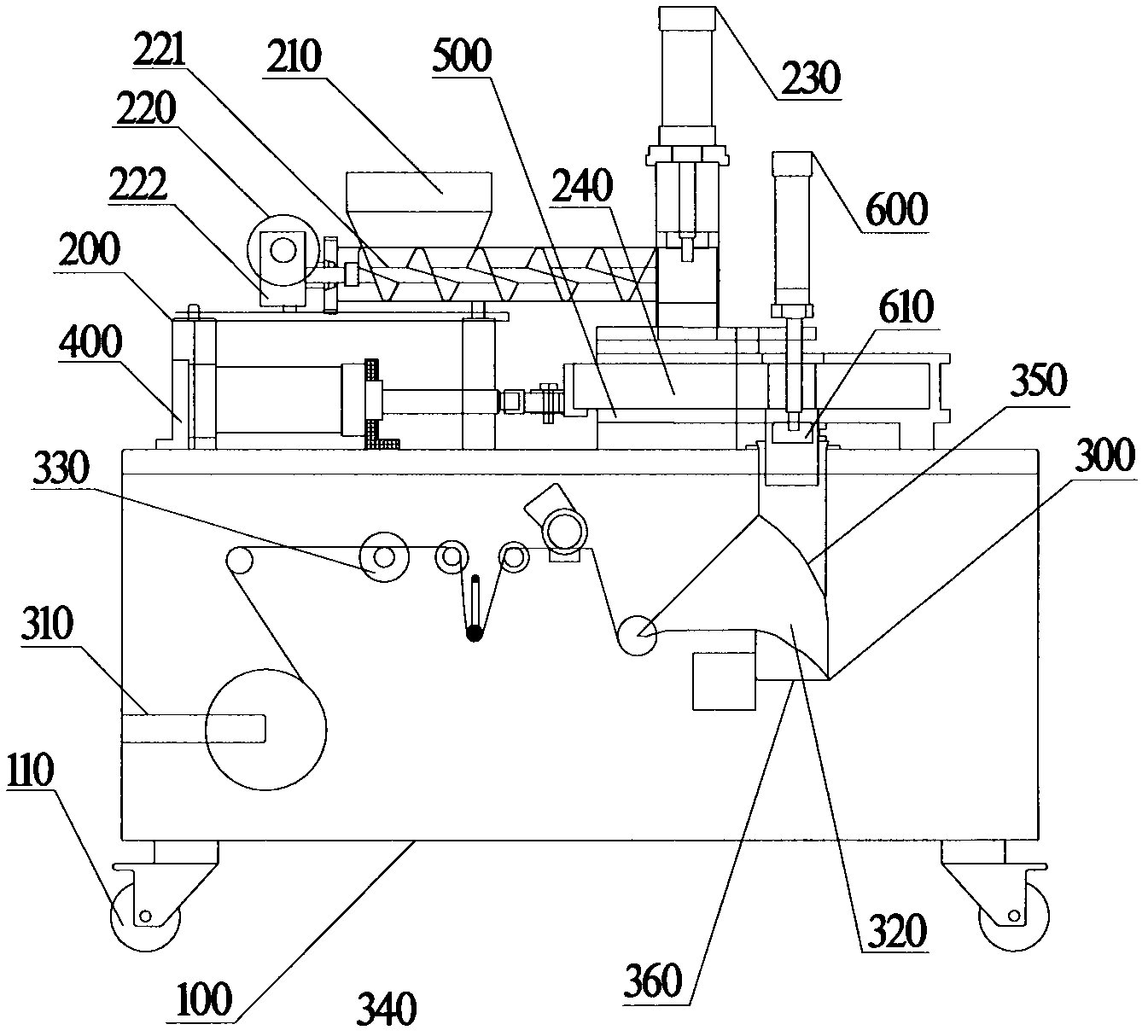

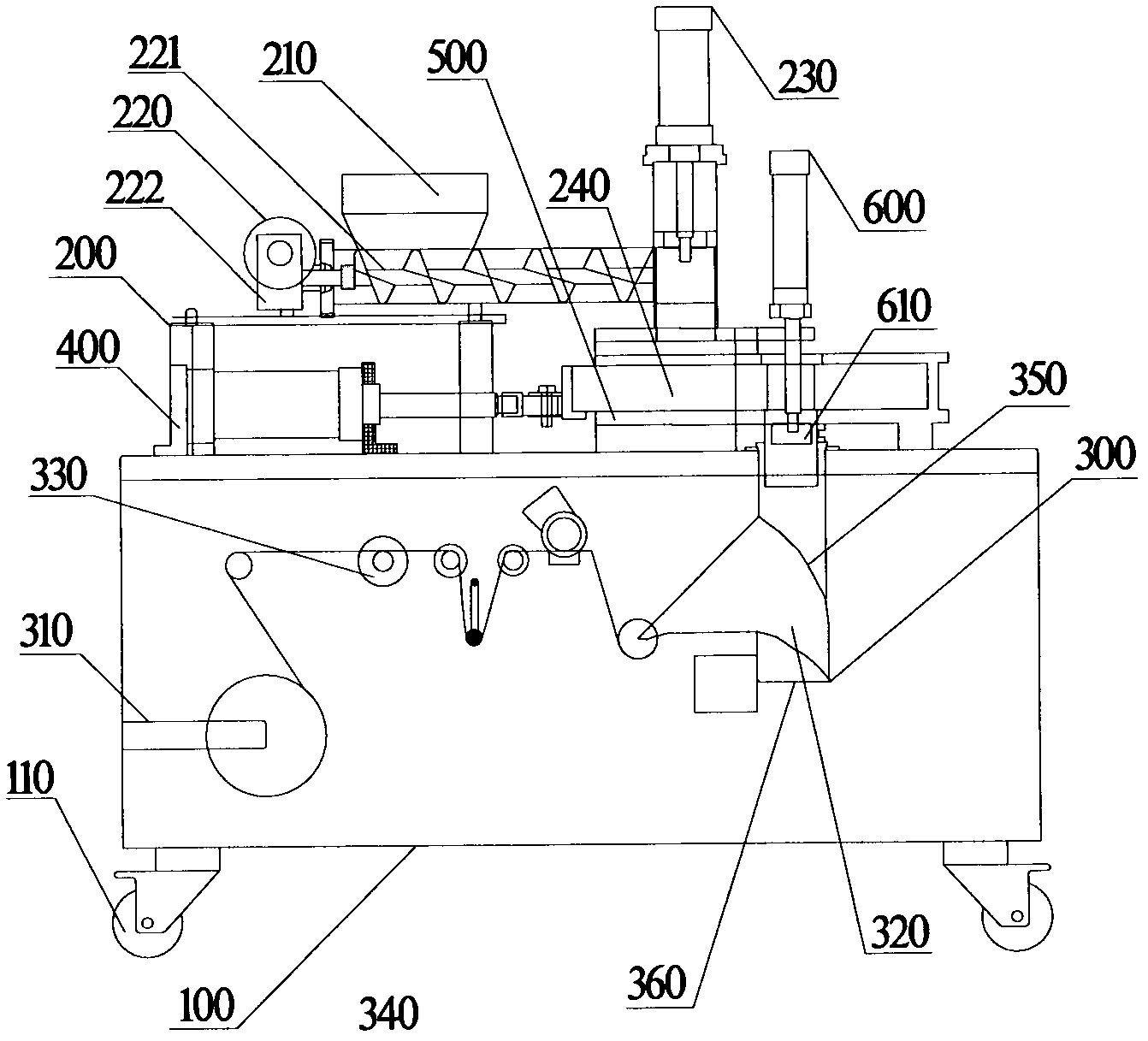

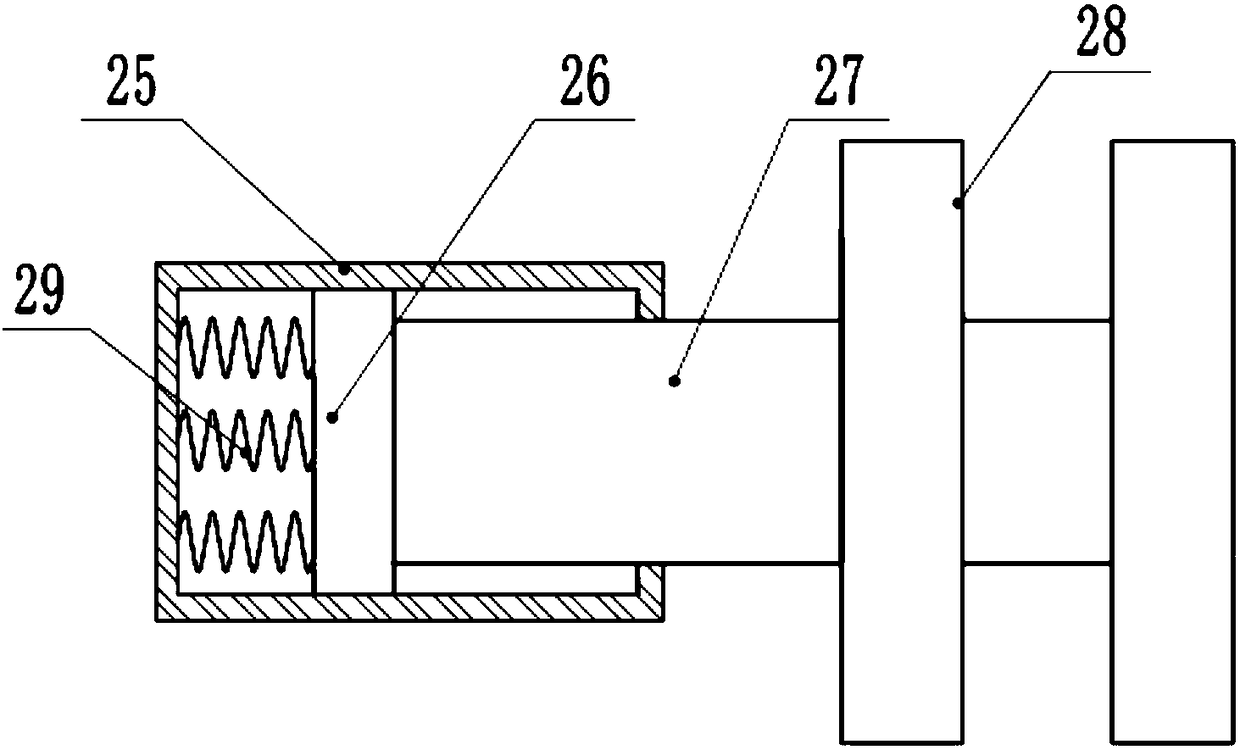

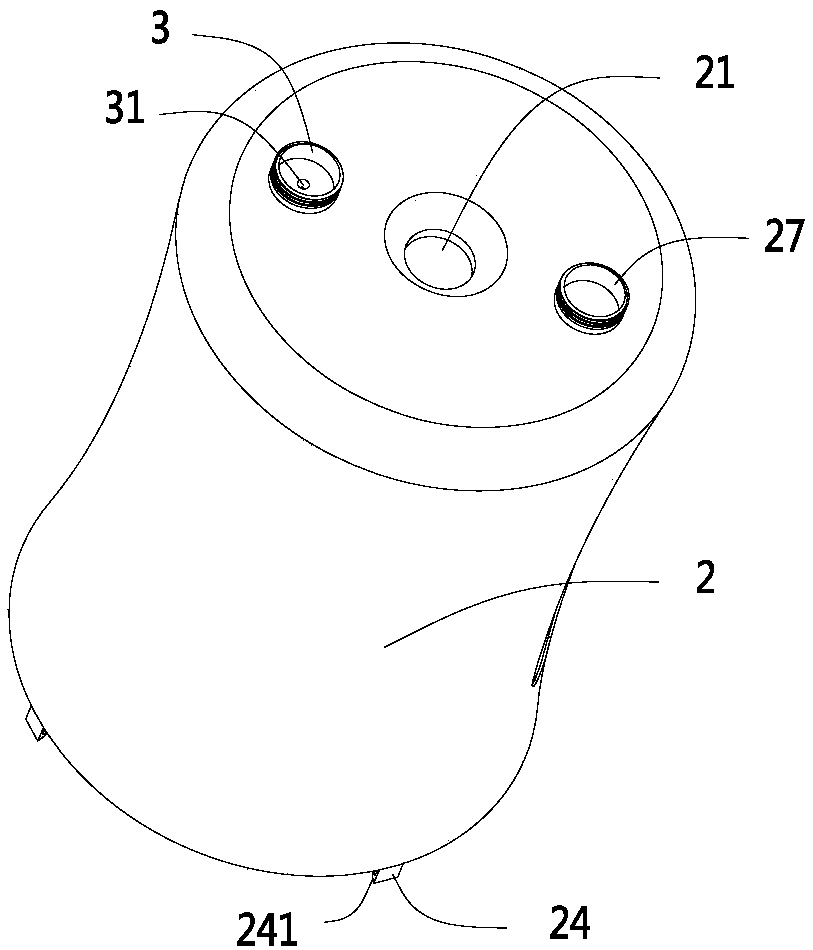

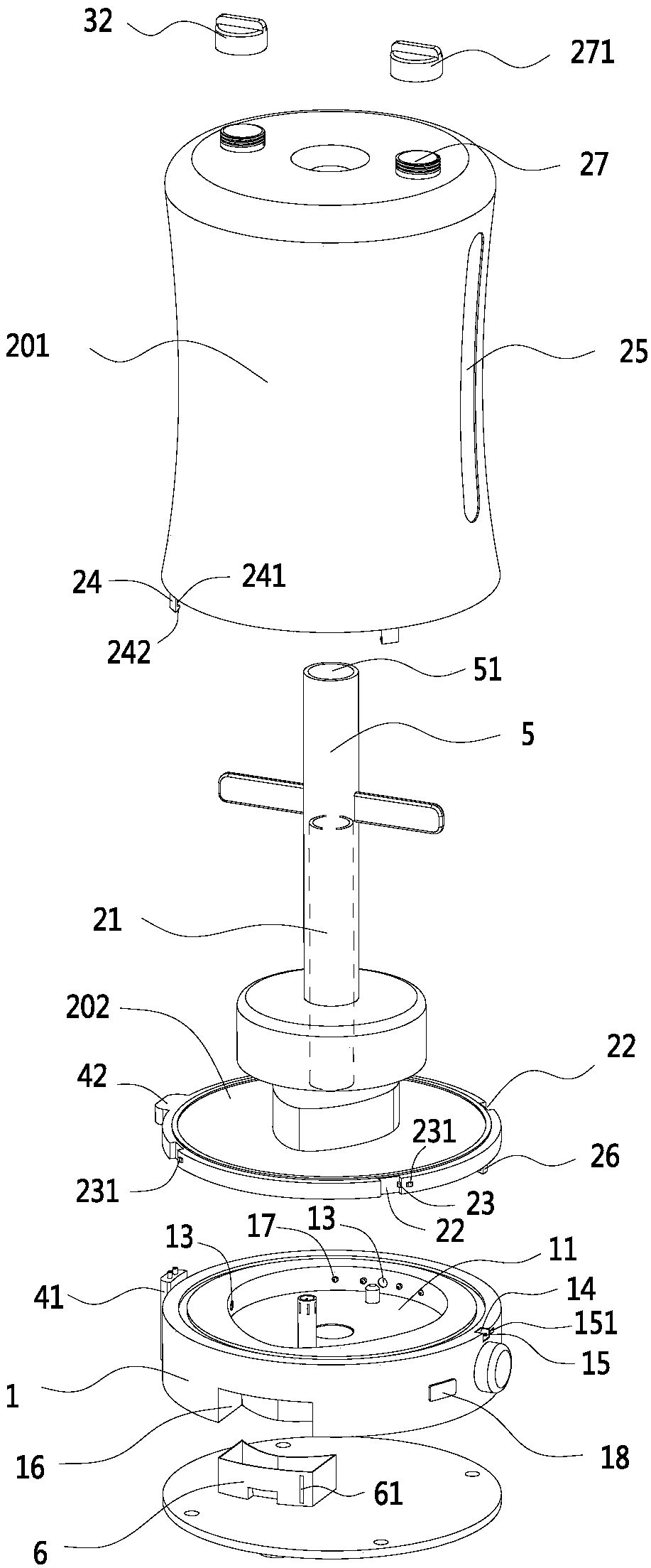

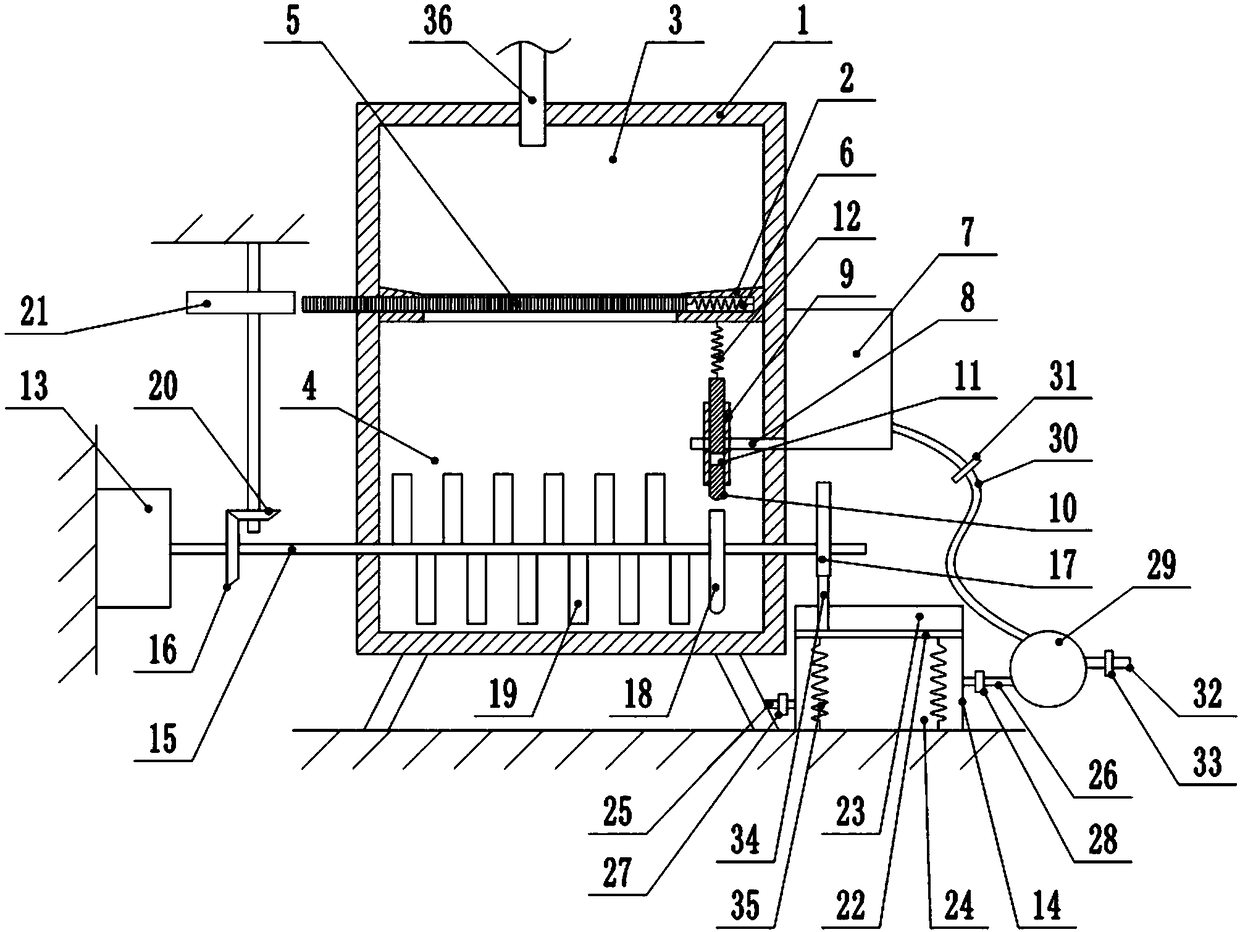

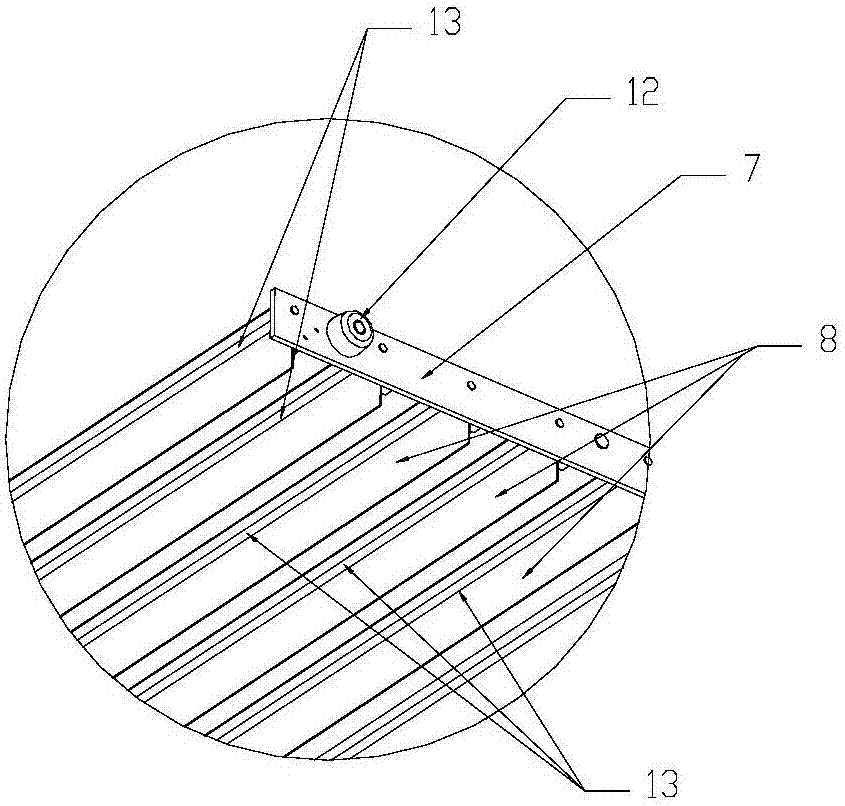

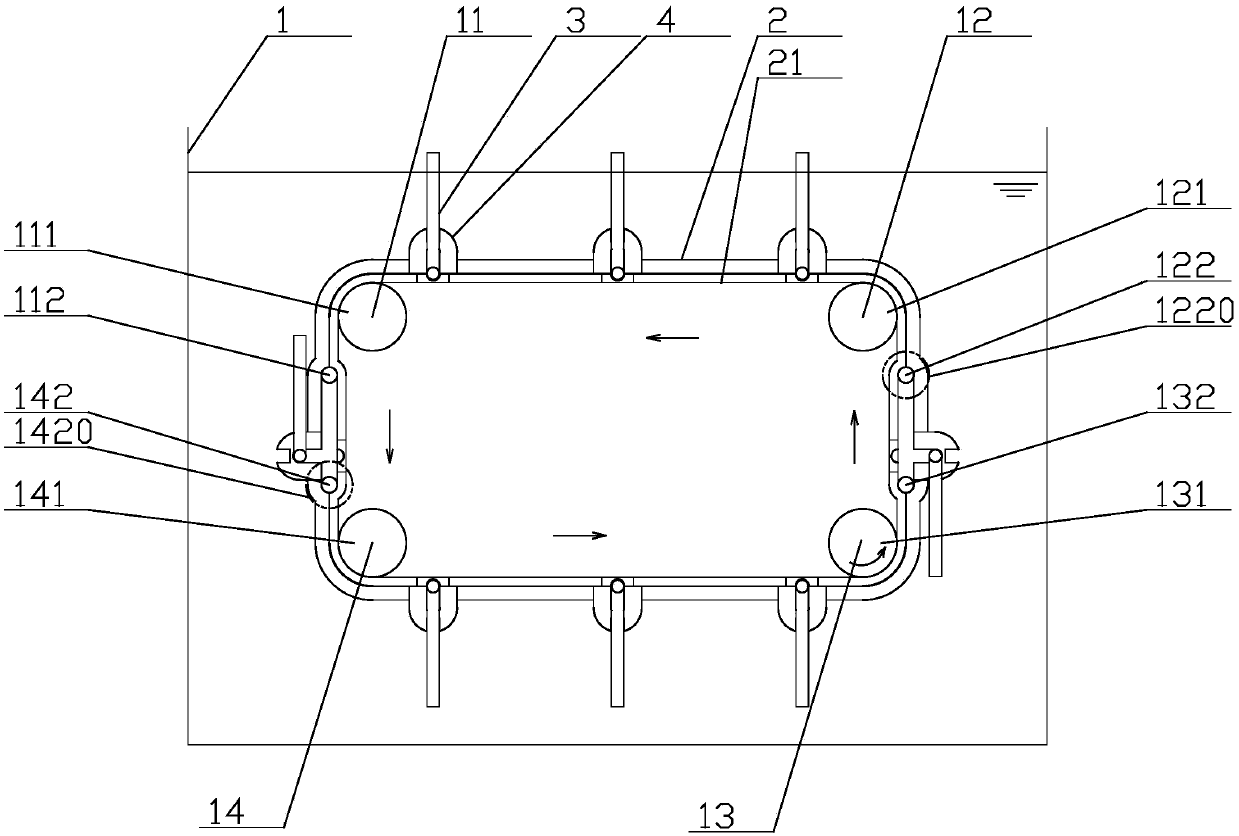

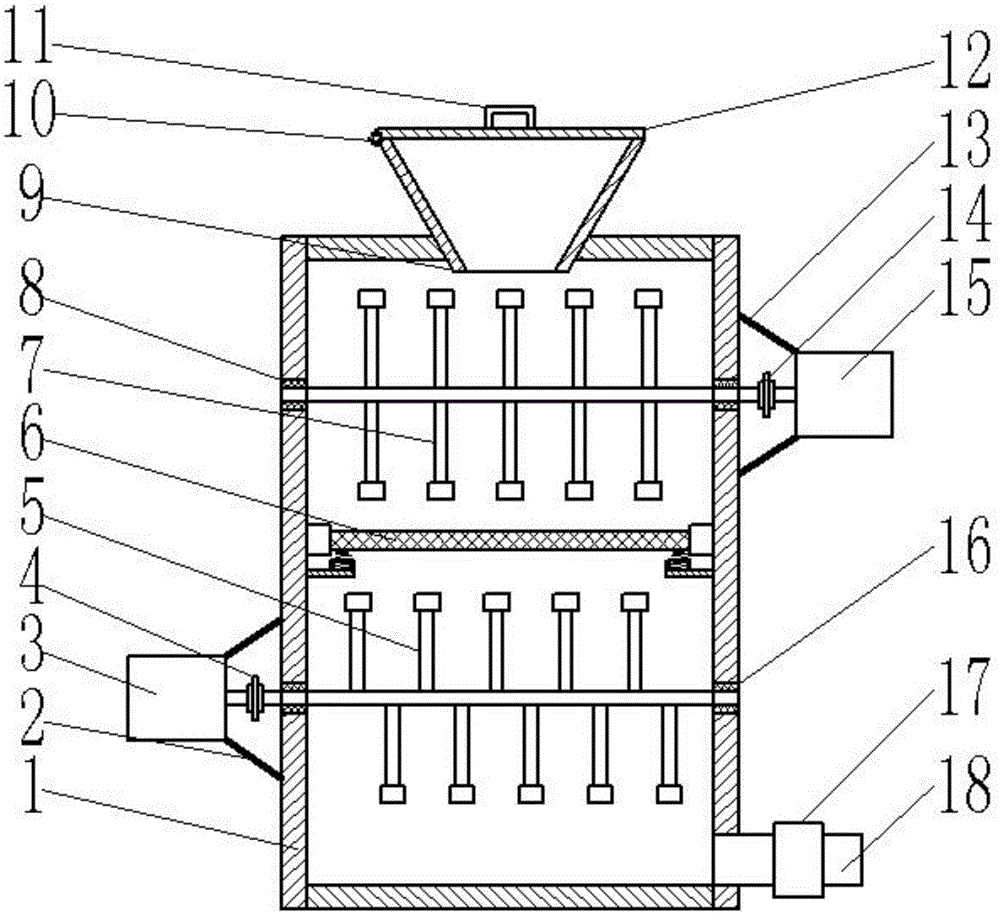

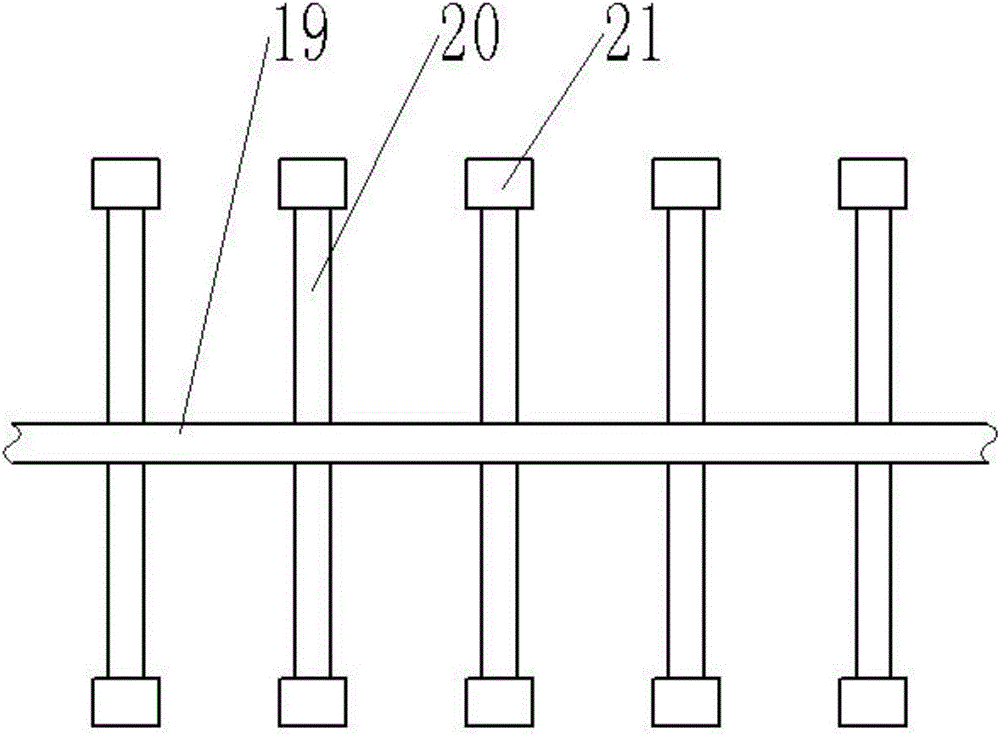

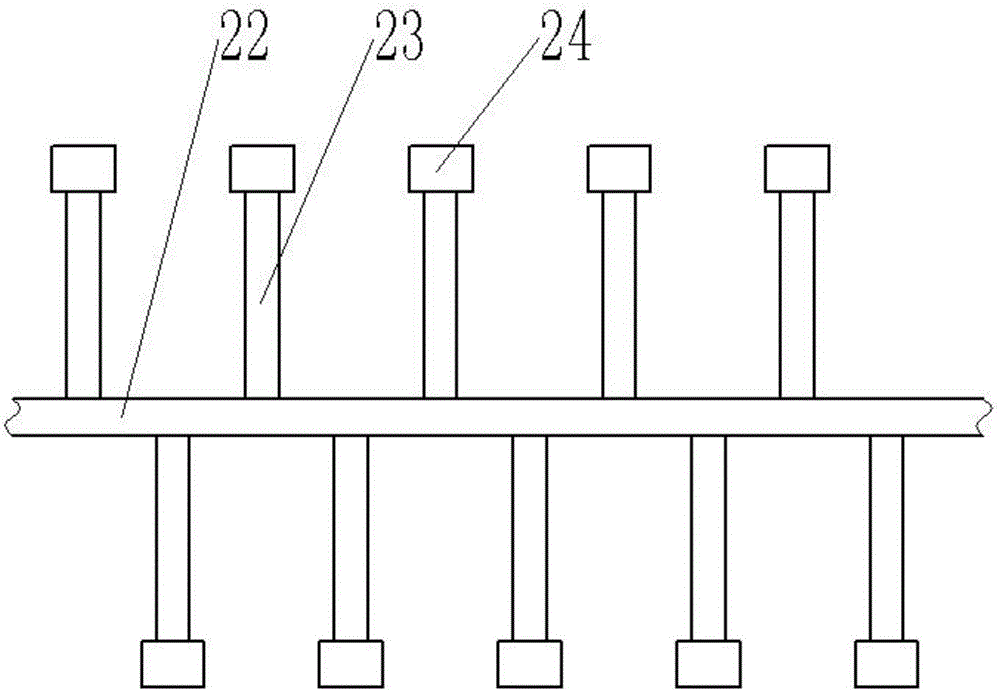

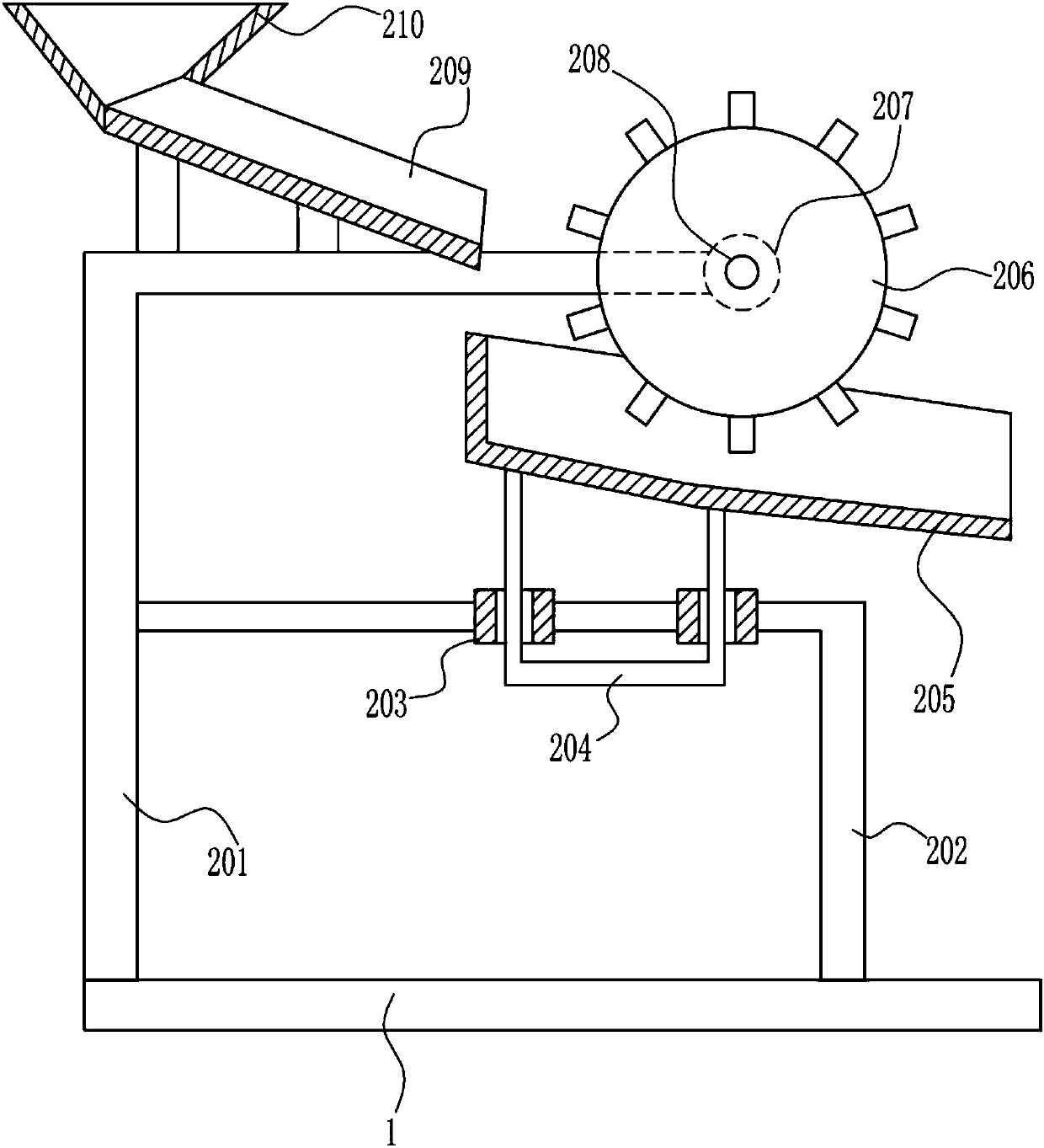

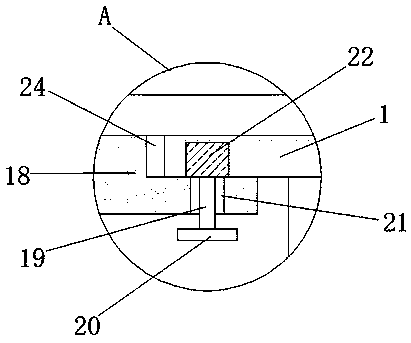

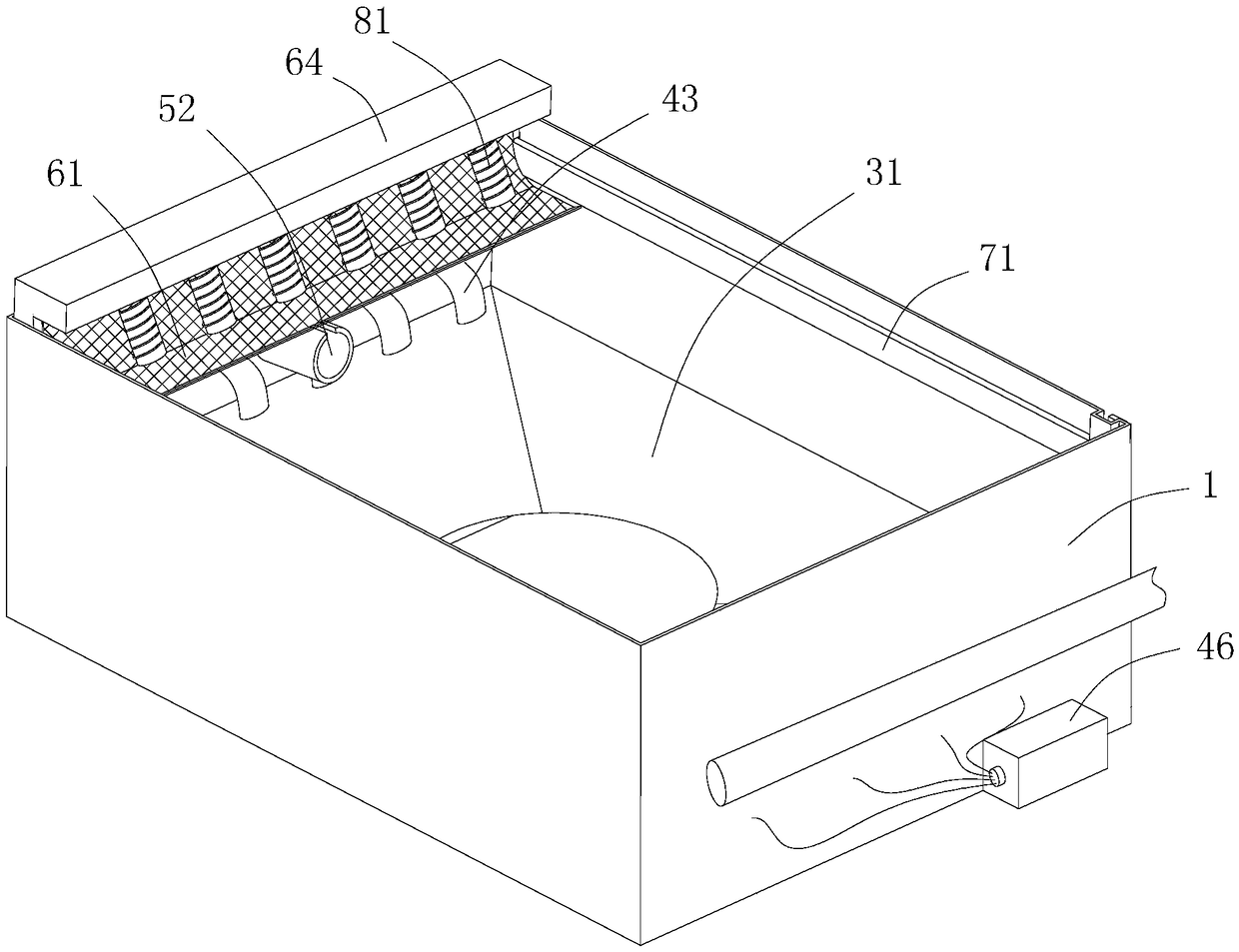

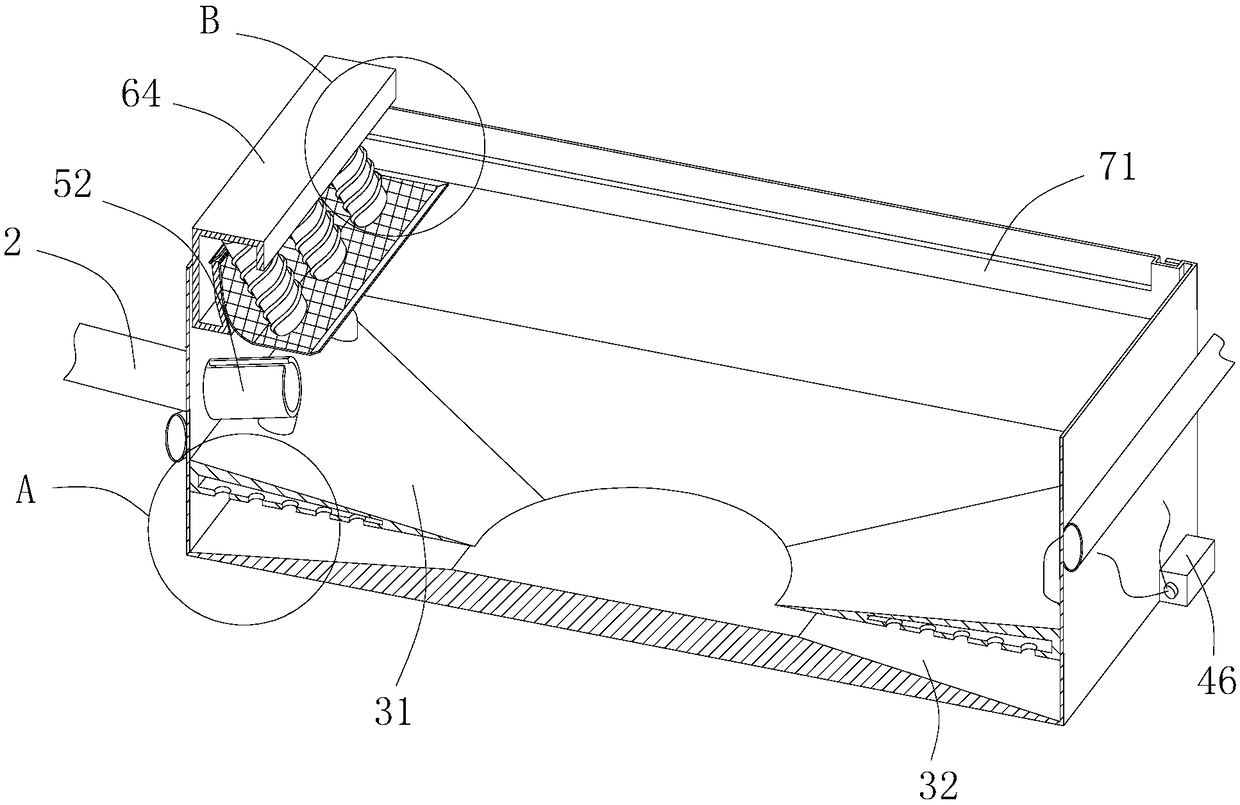

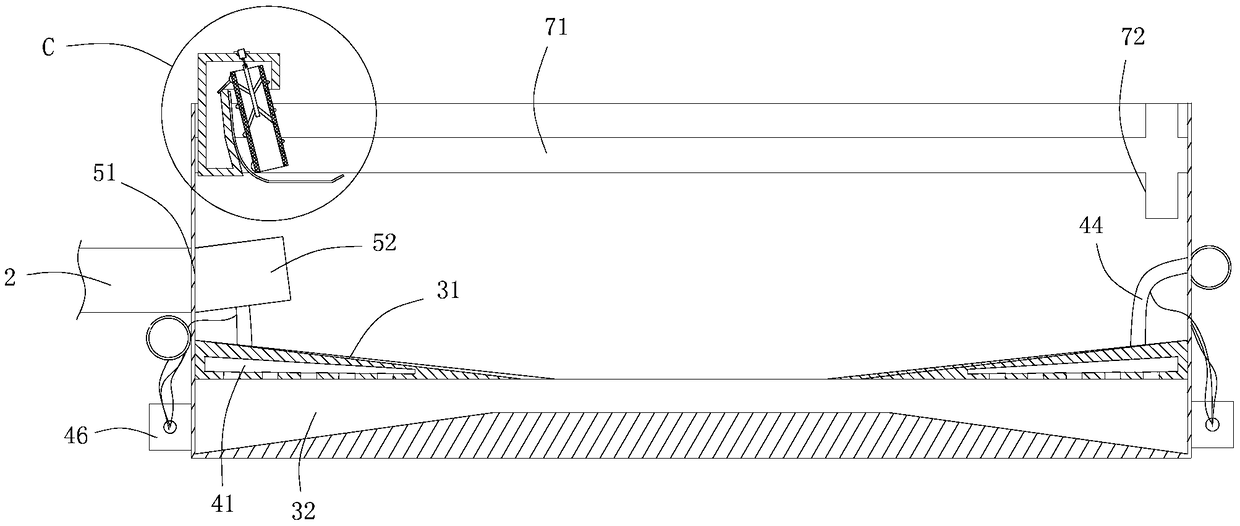

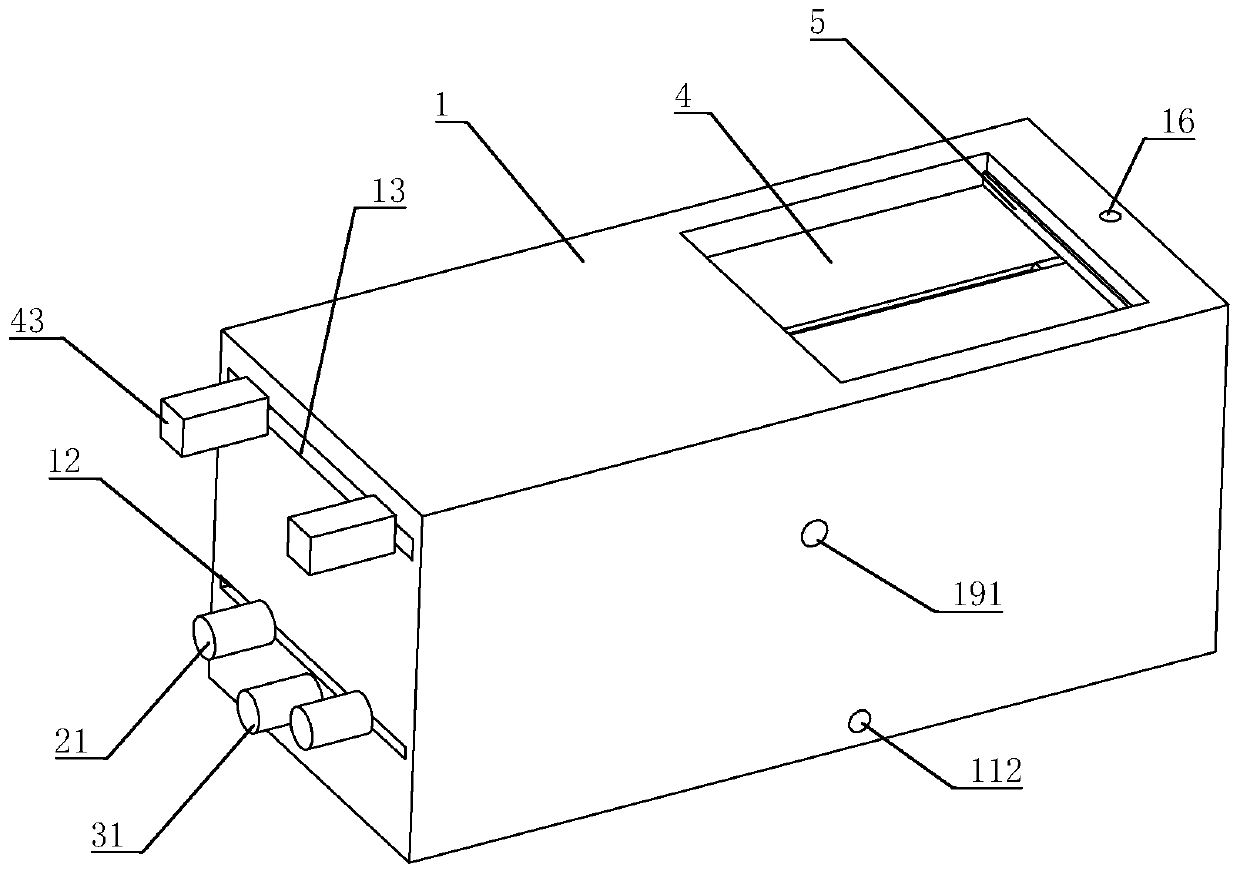

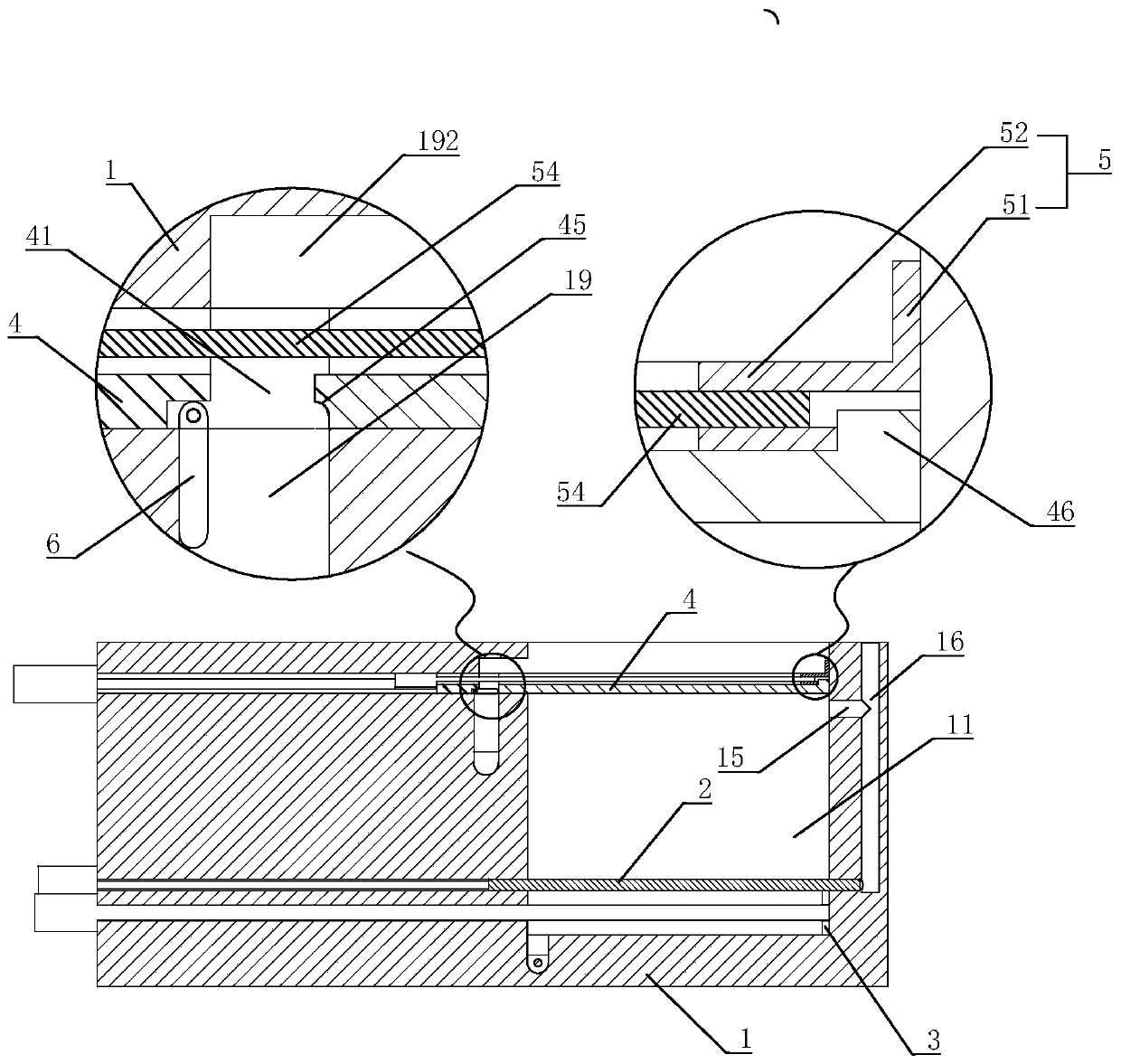

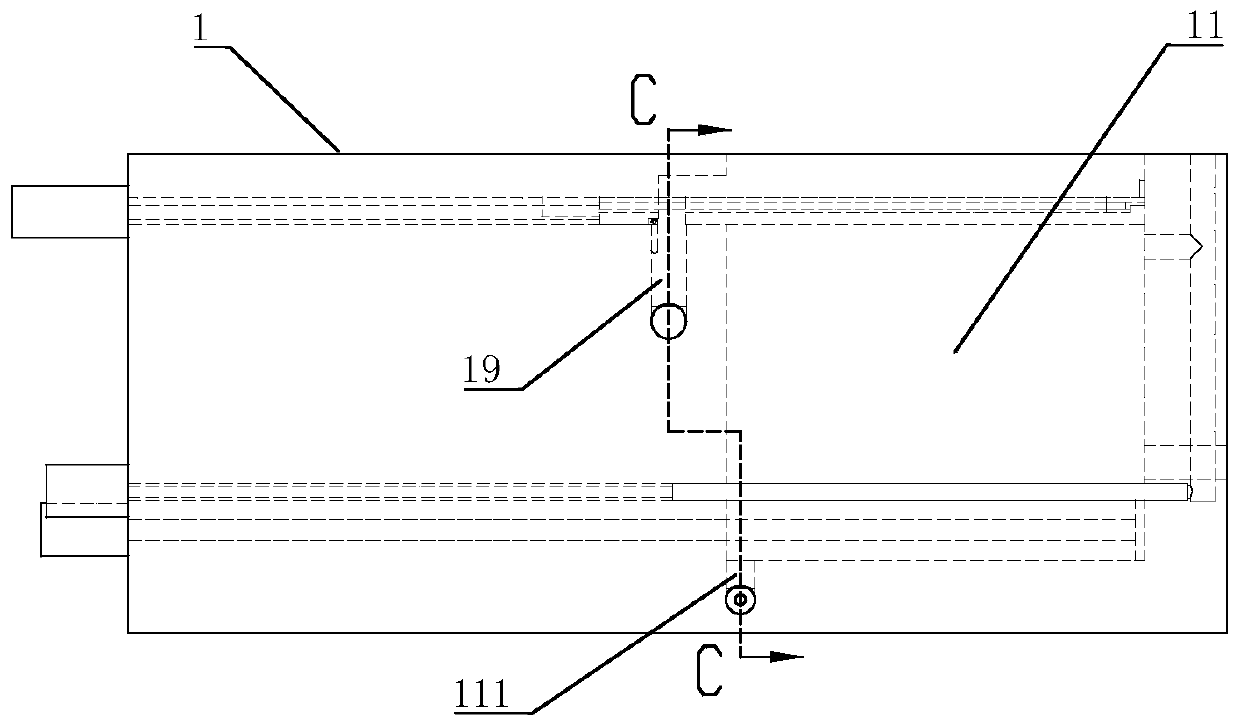

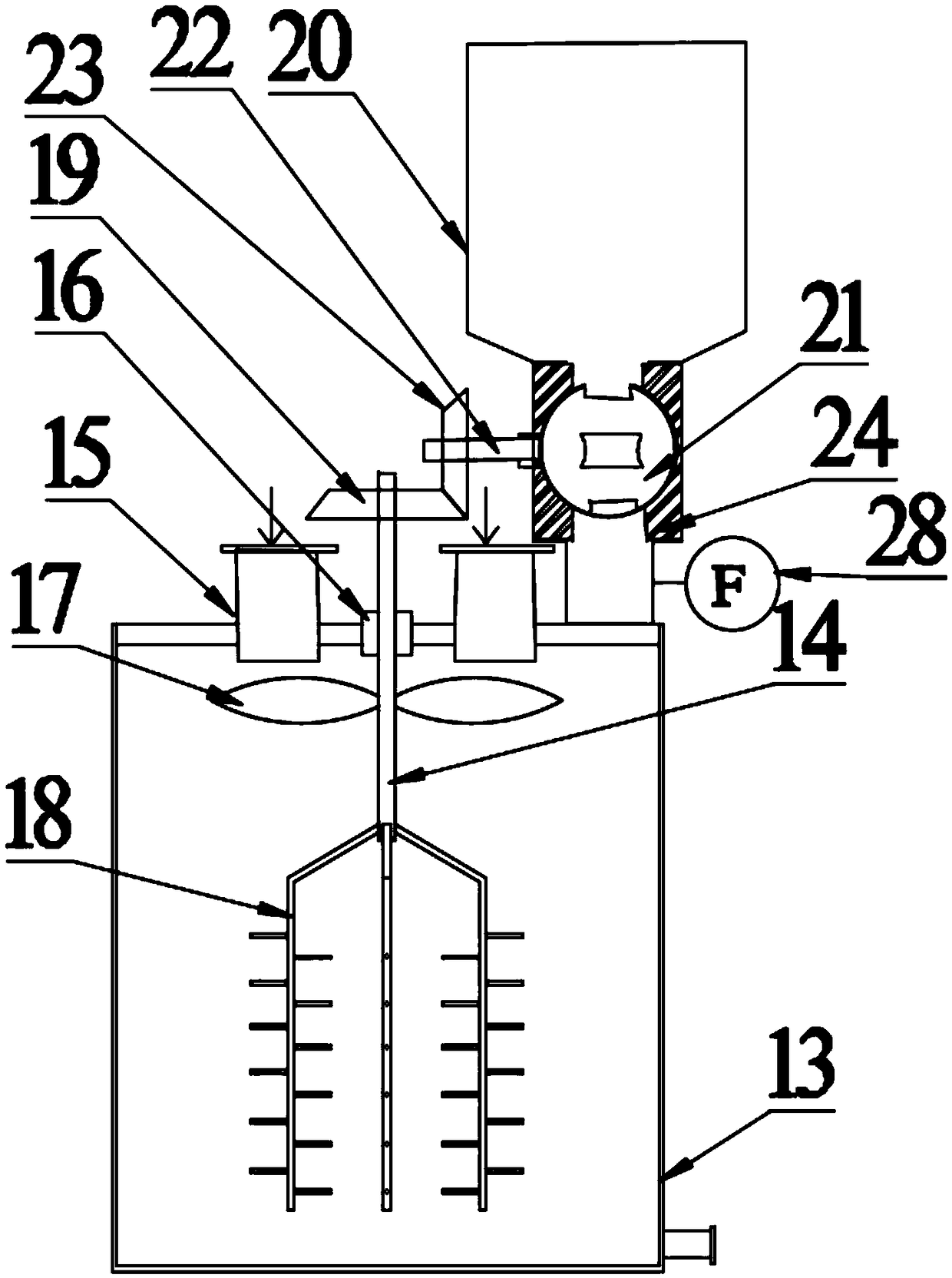

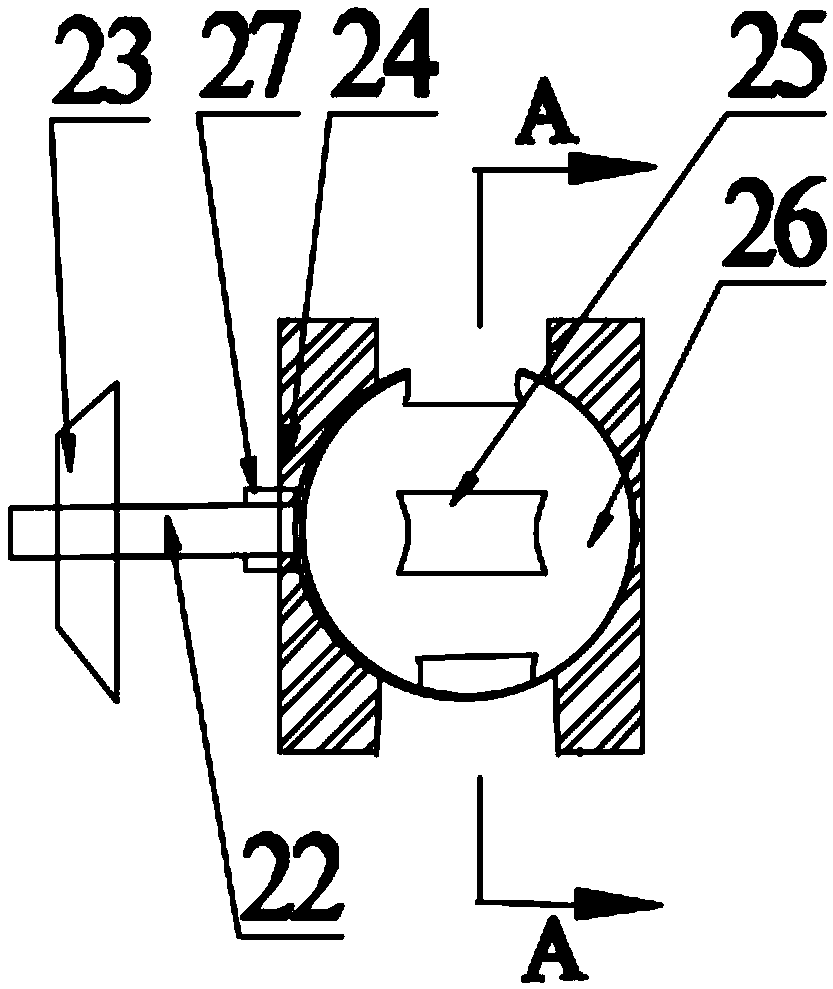

Skimming and mud scraping device

ActiveCN107670346AAvoid stirringHigh precipitation efficiencySedimentation settling tanksEngineeringSewage treatment

The invention discloses a skimming and mud scraping device, relates to the field of sewage treatment equipment, and particularly relates to improvement on skimming and mud scraping machines. The skimming and mud scraping device is exquisite in structure, good in stability and high in reliability and is good in structural strength during mud scraping and skimming, and false triggering can be prevented. The skimming and mud scraping device is arranged in a settling pond and comprises a first belt pulley, a second belt pulley, a third belt pulley, a fourth belt pulley, a conveyor belt, a plurality of scraping plates and a plurality of connecting assemblies. The first belt pulley and the second belt pulley are arranged at two ends of a location which is positioned below the internal liquid level of the settling pond, the third belt pulley and the fourth belt pulley are arranged at two ends of the upper portion of the bottom surface of the settling pond, and the conveyor belt is annularly sequentially wound on the first belt pulley, the second belt pulley, the third belt pulley and the fourth belt pulley. The skimming and mud scraping device integrally has the advantages that the skimming and mud scraping device is exquisite in structure, good in stability and high in reliability and is good in structural strength during mud scraping and skimming, the false triggering can be prevented, and the stirring degree of pond water can be lowered to a great extent.

Owner:扬州青青环保成套设备有限公司

Feed premixing device capable of filtering

InactiveCN106732139AEasy to premixPremix preventionFeeding-stuffRotary stirring mixersLow speedCoupling

The invention provides a feed premixing device capable of filtering. The feed premixing device capable of filtering comprises a box body, a cutting device, a filtering device and a stirring device; the lower right part is provided with a discharging pipe, the lower left part of the box body is provided with a low speed motor, the upper right part of the box body is provided with a high speed motor, and the top of the box body is provided with a filler cabin; a main shaft of the low speed motor is connected to the stirring device through a first coupling; a main shaft of the high speed motor is connected to the cutting device; the cutting device is composed of a first rotating shaft, a knife handle and a cutting knife; the filter screen is arranged at the lower portion of the cutting device, and the filtering device is composed of a vibrator, a spring, a limiting sleeve, a support plate and a filter screen; the stirring device is composed of a second rotating shaft, a stirring rod and a stirring blade. The feed premixing device capable of filtering can cut feed, further reduces the volume of the feed, and facilitate premixing; the feed which is not cut is prevented from being mixed; the feed is prevented from not being fully mixed due to the large volume, and the premixing efficiency and premixing quality are improved.

Owner:郑州吉音动漫科技有限公司

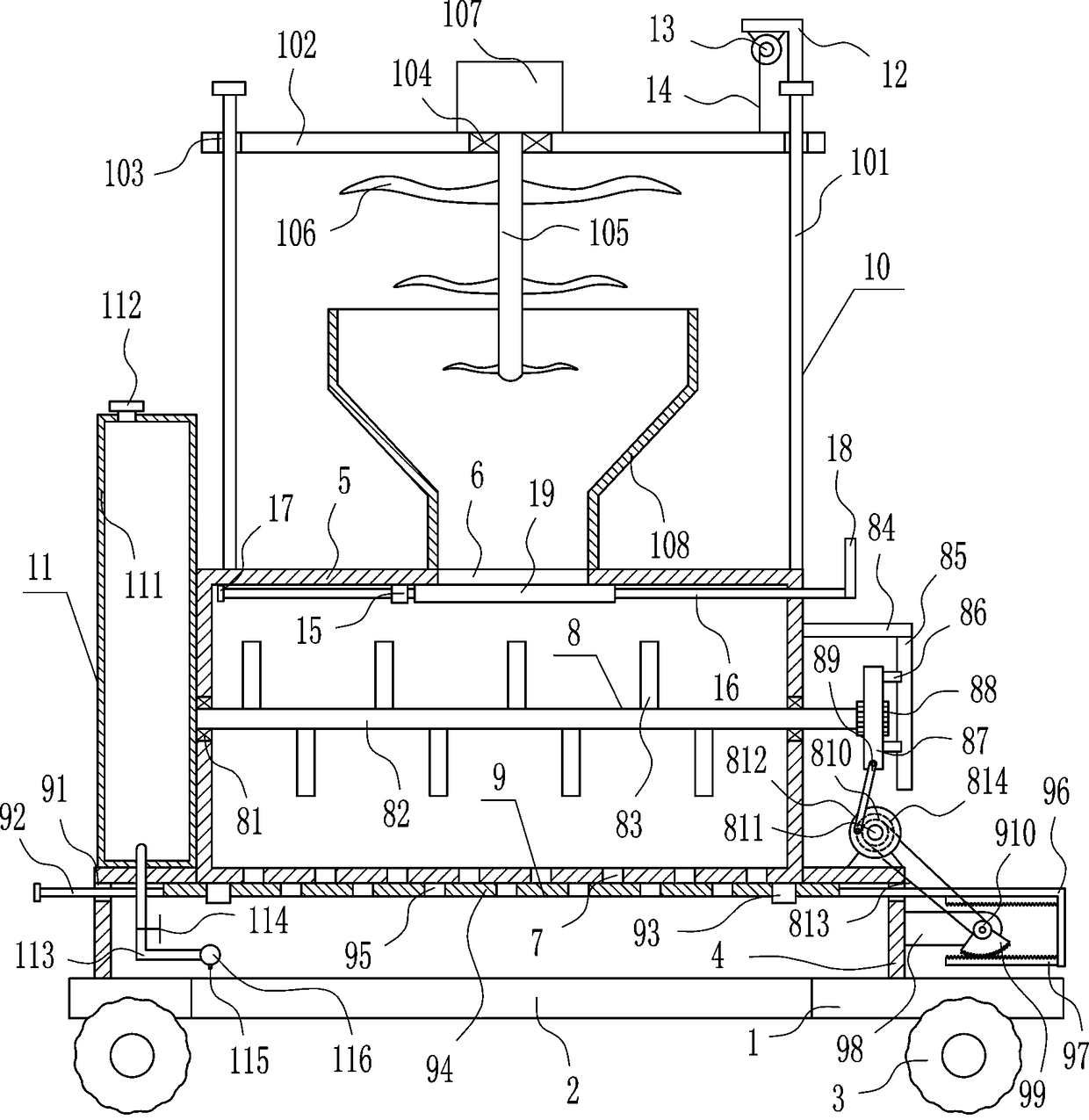

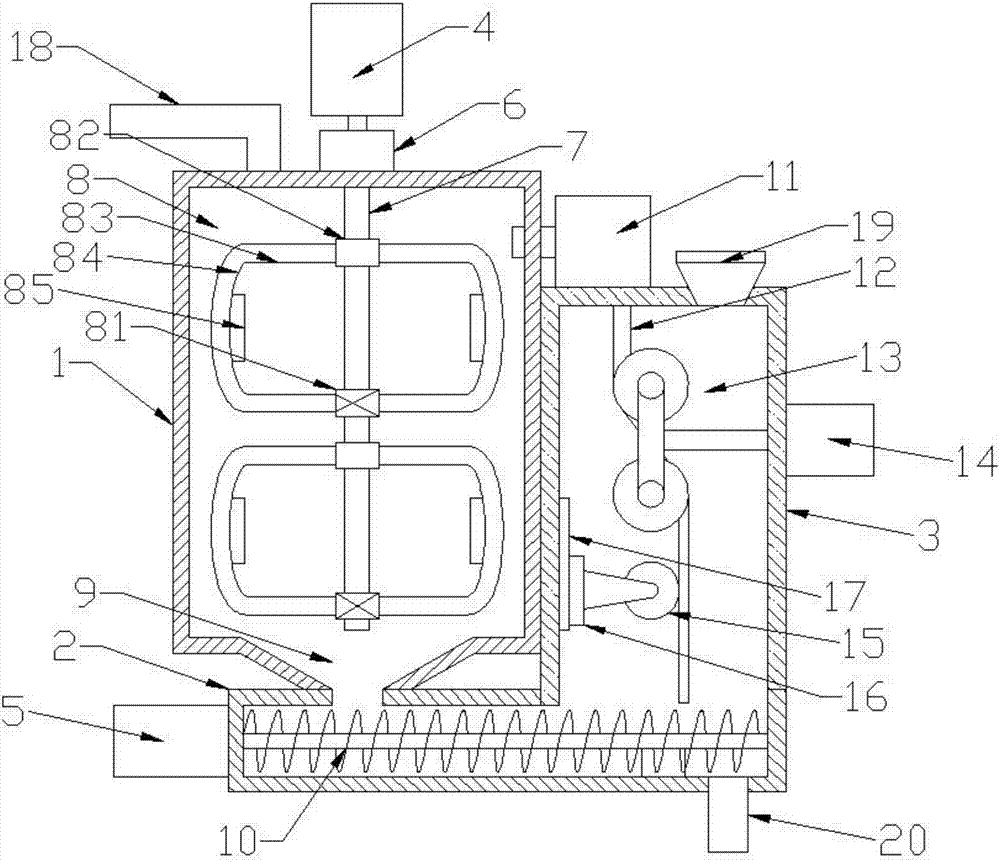

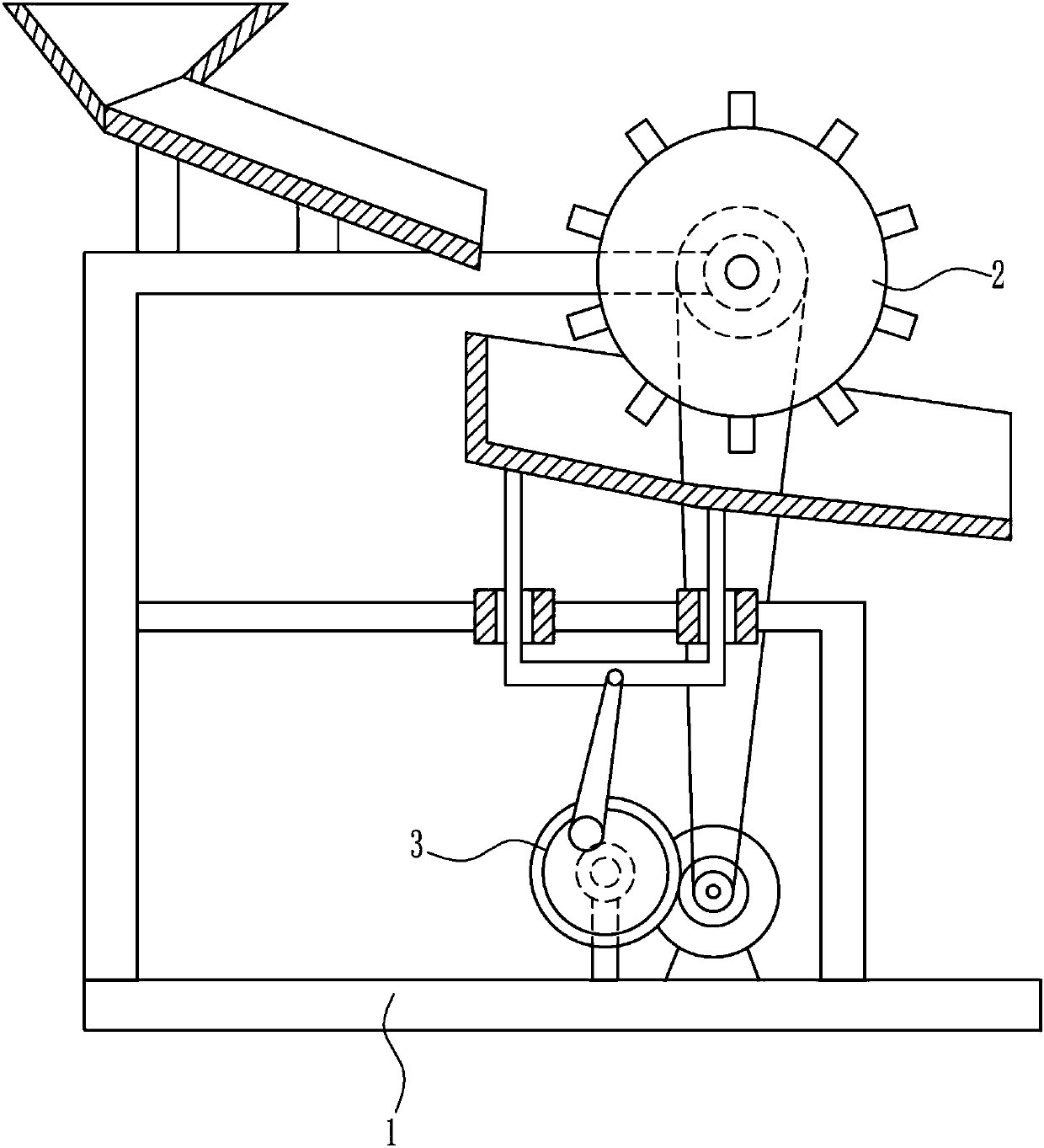

Agitation device for concrete for bridge construction

ActiveCN107662286AStir wellAvoid stirringDischarging apparatusCement mixing apparatusRaw materialBuilding construction

The invention relates to an agitation device, and particularly relates to an agitation device for concrete for bridge construction. The invention aims at solving the technical problem of providing anagitation device for the concrete for the bridge construction, in which not only can an agitation rod be rotated but also an agitation box can be rotated and by which the discharging and the agitationcan be further carried out at the same time. In order to solve the technical problem, the invention provides such an agitation device for the concrete for the bridge construction. The agitation device comprises a base and the like, wherein the top of the base is connected with an agitation mechanism; the top of the base is connected with a driving mechanism; the agitation mechanism is connected with the driving mechanism. The invention designs the agitation device for the concrete for the bridge construction; the agitation box can be also powerfully moved up and down while arranged pinion andgearwheel are used for enabling an agitation wheel to agitate the concrete in the agitation box, so that a concrete raw material in the agitation box can be more uniformly agitated and the effects that not only can the agitation rod be rotated and the agitation box can be also rotated but also the discharging and the agitation can be carried out at the same time are realized.

Owner:顾凯华 +1

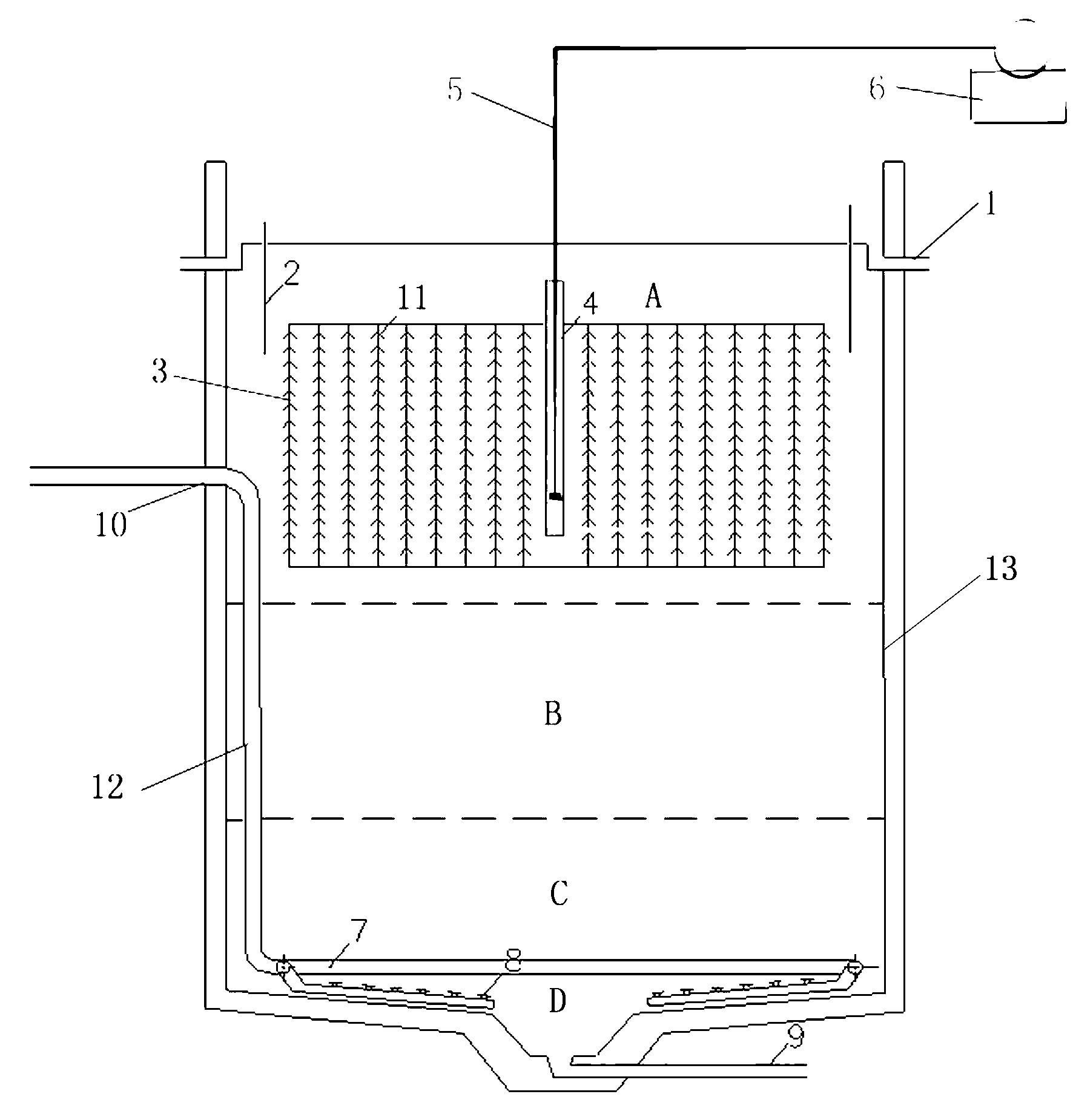

Biochemical treatment device for sewage and treatment method thereof

ActiveCN103183412APromote denitrificationReduce energy consumptionTreatment with aerobic and anaerobic processesSludgeBiochemical engineering

The invention relates to a biochemical treatment device for sewage, which comprises an air supply pipe, a biochemical pool body, and a water outlet and a sewage inlet both formed in the biochemical pool body; an inverted-cone-shaped separation rotational flow mud collecting pit is formed at the bottom of the biochemical pool body; a mud discharging port is formed in the mud collecting pit; a horizontal water pipe connected with the sewage inlet, as well as tangential water jetting heads, is distributed above the mud collecting pit; the sewage inlet is arranged above the horizontal water pipe and the tangential water jetting heads; at least one riser tube is vertically arranged above the biochemical pool body; the air outlet end of the air supply pipe extends into the lower part of the riser tube, and the air inlet end extends out of the biochemical pool body; the biochemical pool body is sequentially divided into an aerobiotic zone, an oxygen-poor zone, and an anaerobic zone from the top down; the water outlet is arranged at the upper part of the aerobiotic zone; a baffle is arranged in the biochemical pool body close to the water outlet; and the top of the baffle is higher than the water outlet on the pool body. The invention further relates to a treatment method adopting the treatment device. The biochemical treatment device for sewage and the treatment method thereof have the characteristics of simple technology, low cost and energy conservation.

Owner:江苏绿境生态环境科技股份有限公司

Mixing device for production of bubble bricks

InactiveCN109895254ASmooth rotationAvoid CatonMixing operation control apparatusCement mixing apparatusBrickMixed materials

The invention discloses a mixing device for production of bubble bricks. The mixing device comprises a mixing box, a first motor is fixedly connected to the middle of the right side face of the mixingbox, a first sealed bearing is fixedly inlaid in the middle of the right side face of the mixing box, a stirring shaft is fixedly connected to the output end of the first motor, and the end, away from the first motor, of the stirring shaft penetrates through the first sealed bearing and extends into the mixing box. According to the mixing device for production of the bubble bricks, materials needing to be mixed can be guided into a crushing box, the guided-in materials can be crushed, the situation that large blocks of materials exist in the mixed materials, and consequently the production quality is affected is avoided, rotation jamming of a transmission rod in the using process can be avoided, the crushed materials are guided into the mixing box to be mixed and stirred, the problem thatthe materials on a bottom layer cannot be stirred is avoided, the stirring and mixing effects of the mixing device are improved, and the mixing box can be sealed and discharges the materials better.

Owner:扬州慕星新材料有限公司

Scraped car recycled part cleaning system

InactiveCN109174802AShorten the timeReduce replenishmentFatty/oily/floating substances removal devicesTreatment involving filtrationResource utilizationWater resources

The invention discloses a scraped car recycled part cleaning system. The scraped car recycled part cleaning system comprises a cleaning pool, an ultrasonic cleaning device, a water inlet pipeline, a sediment cleaning device and an oil stain cleaning device. The cleaning pool is internally provided with a water body for cleaning parts. The ultrasonic cleaning device is used for performing ultrasonic cleaning on the parts placed in the cleaning pool. The water inlet pipeline is disposed at the middle position of the side wall of the cleaning pool, and is used for conveying clean water into the cleaning pool. The sediment cleaning device is used for discharging outward sediments deposited at the bottom of the cleaning pool to the outside of the cleaning pool. The oil stain cleaning device isused for removing oil stains floating on the upper layer of liquid in the cleaning pool. The scraped car recycled part cleaning system is provided with the sediment cleaning device and the oil stain cleaning device so that the sediment and oil stain cleaning operation and the water injection operation can be simultaneously performed, the time required for water change of the cleaning pool is effectively shortened, and the working efficiency is improved; and secondly, the filling quantity of the clean water can be reduced, the waste of water resources is reduced, and the resource utilization rate is improved.

Owner:陈守昌

Settling water-purification device

InactiveCN110270141AEasy to cleanGuaranteed effectSettling tanks feed/dischargeSedimentation settling tanksEngineeringMechanical engineering

The invention discloses a settling water-purification device. The device comprises a box body, an accommodating space with an upper opening is formed in the box body and is in a cuboid shape, and a first water-stop plate is slidably installed at the lower end of the left side wall of the accommodating space horizontally, can slidably extend into the accommodating space and partition the accommodating space, and is connected with a first driving mechanism capable of driving the first water-stop plate to slide; a sludge outlet extending to the outside is formed in the bottom surface of the accommodating space, and a first scraper blade fits the front and back side walls of the accommodating space and is connected with a second driving mechanism capable of driving the first scraper blade to slide. According to the design, a water pool is cleaned conveniently, it is also avoided that when water is discharged from a water outlet, sludge at the bottom is stirred, and the settling purification effect is effectively ensured.

Owner:TAIZHOU CHUANGXING ENVIRONMENTAL PROTECTION SCI & TECH

Energy-saving type chemical adding and stirring device for sludge and sludge treatment system

PendingCN109095752AAvoid stirringAvoid the trouble of asynchronous dosingWater treatment parameter controlSludge treatment by de-watering/drying/thickeningFiltrationAir compressor

The invention provides an energy-saving type chemical adding and stirring device for sludge and a sludge treatment system. In the energy-saving type chemical adding device, sludge enters a stirring tank from sludge inlets to drive blades and a stirring rod to rotate, the stirring rod drives a stirring paddle to perform stirring, and besides, a gear drives a rotating shaft of a rotating switch in achemical adding tank to rotate. According to the chemical adding and stirring device, the stirring and chemical adding device is driven to rotate through energy produced during sludge conveying, electric energy is saved, and synchronous chemical adding is facilitated. The sludge treatment system sequentially performs sieving, impurity removal, water removal, concentration, chemical adding and stirring, aeration for removal of organic matter and dewatering and filter pressing for blocking on the sludge. Heating is not required in the treatment process, the filtration speed and the process of aeration for removal of organic matter are increased through an air compressor, the treatment method is simple, equipment input is low, energy is saved, the content of sludge impurities, organic matterand water after treatment can be greatly reduced, and the device and the system can be used for building materials.

Owner:湖北中瑞世家建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com