Scraped car recycled part cleaning system

A technology for cleaning systems and scrapped cars, applied in liquid cleaning methods, cleaning methods and utensils, water/sludge/sewage treatment, etc., can solve low work efficiency, waste of water resources, long drainage and water injection time, etc. problems, to achieve the effect of improving cleanliness, reducing water waste, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

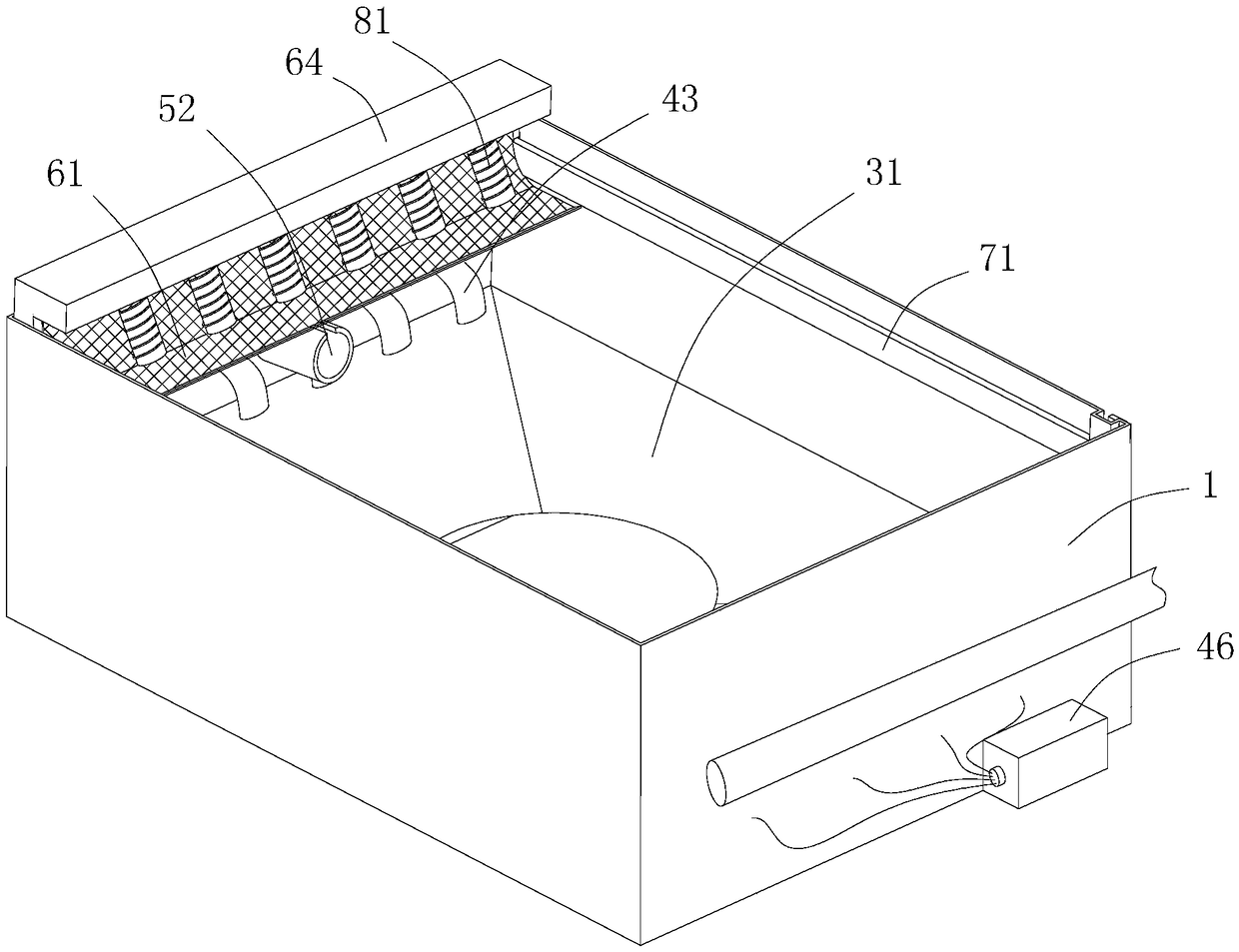

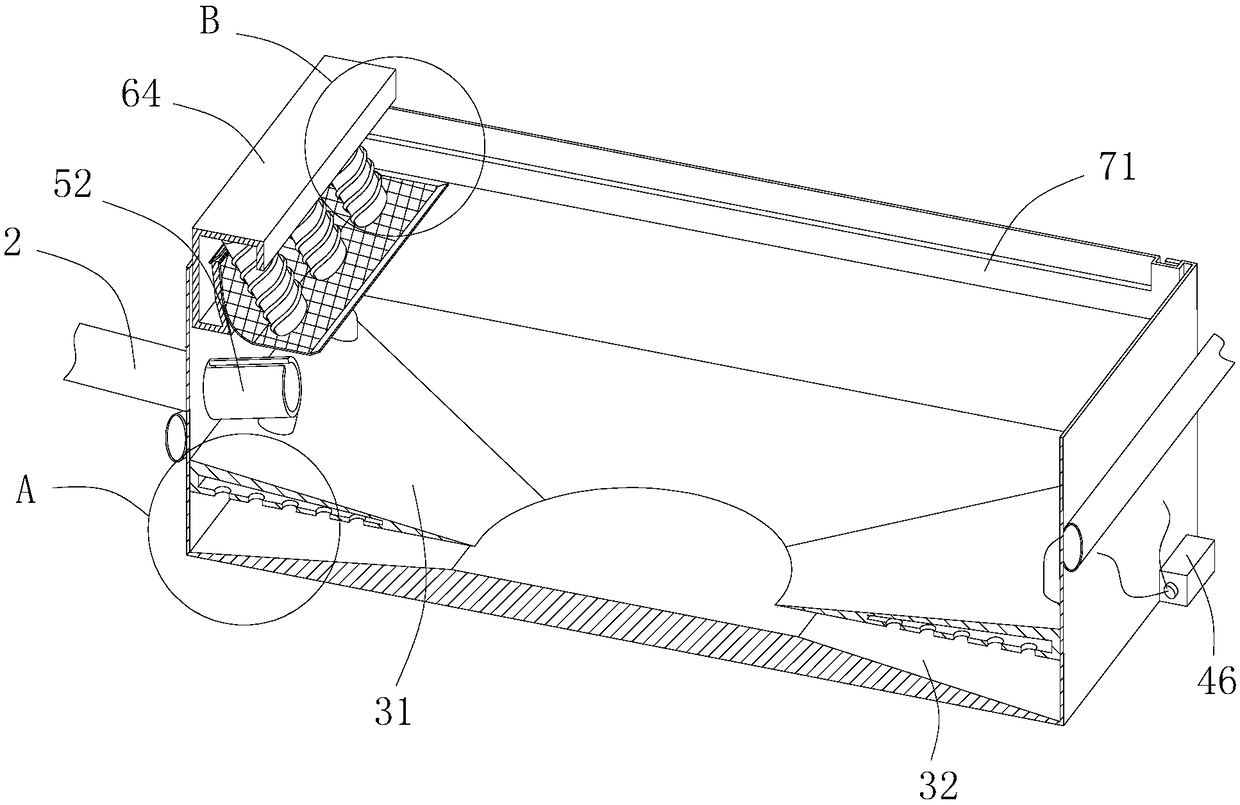

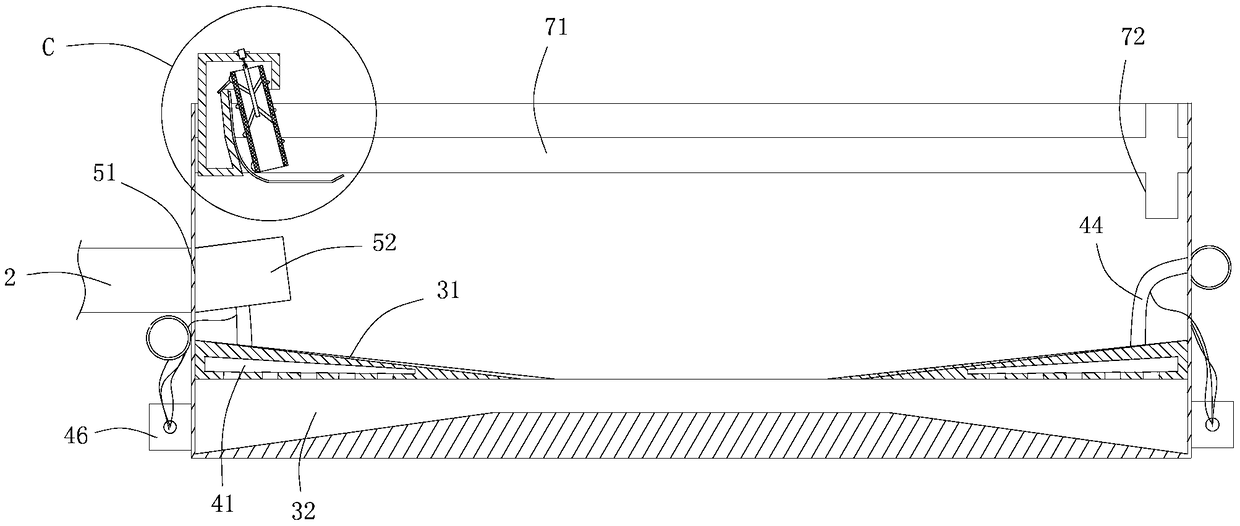

[0031] Such as Figure 1-9As shown, a cleaning system for reused parts of scrapped automobiles includes a cleaning tank 1, an ultrasonic cleaning device, a water inlet pipe 2, a sediment cleaning device and an oil cleaning device, and the cleaning tank 1 can be a cuboid made of stainless steel The pool body can also be a pool body processed by cement or reinforced concrete. The pool body is relatively large and not the size of a conventional machine. The specific size is determined by actual needs and is not specifically limited here; The water body of the component, the water body can be clear water or other cleaning preparations, etc., and is not limited to the body; the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com