Hydrolysis process for hydroquinone

A hydroquinone and process technology, which is applied in the field of hydroquinone hydrolysis process, can solve the problems of high sulfuric acid concentration, high corrosion, high material requirements, etc., and achieve the effect of clean and environmentally friendly process, increased production capacity, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

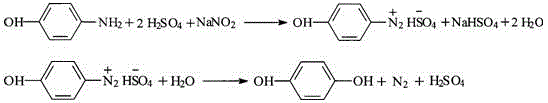

Method used

Image

Examples

Embodiment 1

[0026] 1. Diazotization reaction: Add 408g (0.625mol) of 15% sulfuric acid and 27.8g (0.25mol) of 98% p-aminophenol for industrial products into a 1000mL reactor, stir and cool down to -5~0°C, add 40% sulfuric acid dropwise Add 48g (0.275mol) of sodium nitrate aqueous solution, dropwise for 30-45min, keep warm for 0.5hr after dropping, add 1.5g of urea, stir for 15min, when the release of nitrogen is not obvious, add 1.5g of thiourea and stir for another 15min. The dropwise addition, heat preservation and feeding temperature were all kept at -5-5°C to obtain 470-480 g of dark brown diazonium liquid, which was stored at 0°C.

[0027] 2. Hydrolysis reaction: Add 42.5g (98%, 0.1875mol) of basic copper carbonate, 143.5g (98%, 0.5625mol) of copper sulfate pentahydrate, 314g of water and 200g of solvent n-butyl acetate or Methyl isobutyl ketone, heated to 85-88°C, then dropwise add the above diazonium solution at 0±0.5°C, dropwise for about 1 hr, and keep warm at 85-88°C for 1-1.5 h...

Embodiment 2 to 7

[0031] The preparation method is the same as in Example 1, except that the sulfuric acid concentration of the diazonium reaction is different. (All copper in hydrolysis is calculated as copper sulfate)

[0032]

[0033] The yield of diazoic acid is stable from 9 to 25%, and the yield is stable at 90 to 91%. When the acid concentration is reduced and increased, the yield shows a clear downward trend.

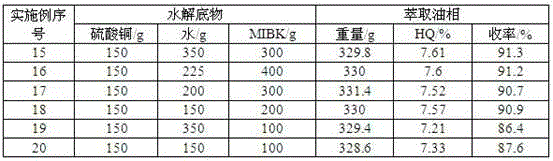

Embodiment 8 to 14

[0035] The preparation method is the same as in Example 1, except that the concentration of copper sulfate in the hydrolysis is changed. (All copper in hydrolysis is calculated as copper sulfate)

[0036]

[0037] The concentration of the hydrolyzed copper sulfate aqueous solution is higher than 30%, and the yield is 90-91%, and the yield shows an obvious downward trend when it drops to 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com