Patents

Literature

203 results about "BASIC CUPRIC CARBONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basic copper carbonate is a chemical compound, more properly called copper(II) carbonate hydroxide. It is an ionic compound (a salt) consisting of the ions copper(II) Cu2+, carbonate CO2− 3, and hydroxide HO−. The name most commonly refers to the compound with formula Cu 2CO 3(OH).

Catalyst for production of 1,4-butynediol and preparation method of catalyst

ActiveCN102950014AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationBASIC CUPRIC CARBONATESlurry reactor

The invention discloses a catalyst for production of 1,4-butynediol and a preparation method of the catalyst, belongs to the field of catalyst research, more particularly relates to a load type catalyst for production of 1,4-butynediol in a slurry reactor and a preparation method of the catalyst. According to the method, nanosilicon dioxide which has a larger external specific surface is used as a carrier, copper and bismuth are attached to the carrier by adopting a settling and depositing method, the active components of the catalyst exist in a form of basic cupric carbonate, and the catalyst comprises the following components in percentage by mass: 20-50 percent of carrier, 35-70 percent of basic cupric carbonate and 2-15 percent of bismuth subcarbonate. The prepared catalyst has the characteristics of good activity and high selectivity and is easy to activate.

Owner:大连瑞克科技股份有限公司

Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

ActiveCN104437074AHigh mechanical strengthEvenly distributedDispersed particle separationCarbonyl sulfideAccelerant

The invention discloses a desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time. The desulfurizing agent is prepared through the following steps that S1, a compound containing zinc, a binder and an accelerant are mixed, kneaded and formed; S2, a mixture formed after mixing, kneading and forming in the S1 is dried, and then a dried desulfurizing carrier precursor is obtained; S3, the desulfurizing carrier precursor obtained in the S2 is calcinated, and then a desulfurizing agent carrier is obtained; S4, the desulfurizing agent carrier is impregnated in a first copper salt solution, and copper active components are loaded on the desulfurizing agent carrier, wherein the first copper salt solution is an ammonium hydroxide solution of basic cupric carbonate; S5, an impregnated sample obtained in the S4 is dried and calcinated, and then the desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time is obtained. The obtained desulfurizing agent is high in strength and not prone to pulverization, the impregnation effect of the active components is better, and hydrogen sulfide and carbonyl sulfide impurities in a high-temperature industrial gas source can be efficiently removed at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

Non-cyanide copper plating solution

Cyanogen-free preplated copper solution belongs to the technical field of surface treatment electroplating. The solution adopts a nontoxic organic phosphine compound to replace cyanide as a complexing agent for the preplated copper, and is particularly suitable for preplated copper used to electroplate steel, aluminum, magnesium, zinc, titanium and titanium alloy. The cyanogen-free preplated copper solution has the following main technical characteristic that the solution consists of (a) one sort of copper sulphate, basic cupric carbonate or copper nitrate with the volume concentration of between 30 and 60 g / L; (b) one sort or two sorts of compounds selected from methylene diphosphonic acid, 1-hydroxyethylidene 1.1 diphosphonic acid and 1-hydroxybutyleneidene 1.1 diphosphonic acid with the volume concentration of between 120 and 160 g / L; (c) one sort or two sorts of compounds selected from methylamino dimethylene diphosphonic acid, hexamethylene diamine tetramethylene phosphonic acid and ethylenediamine tetramethylene phosphonic acid with the volume concentration of between 2 and 5 g / L; (d) one sort of potassium citrate, amine citrate or seignette salt with the volume concentration of between 6 and 12 g / L, and (e) polyethyleneimine alkyl slat or aliphatic amine ethoxy sulfonated substance (AESS) with the volume concentration of between 0.02 and 0.05 g / L. The cyanogen-free preplated copper solution has the characteristics of stable service performance, simple solution compositions, convenient maintenance, high safety, environmental protection, reliable plating coat binding and the like.

Owner:江南工业集团有限公司

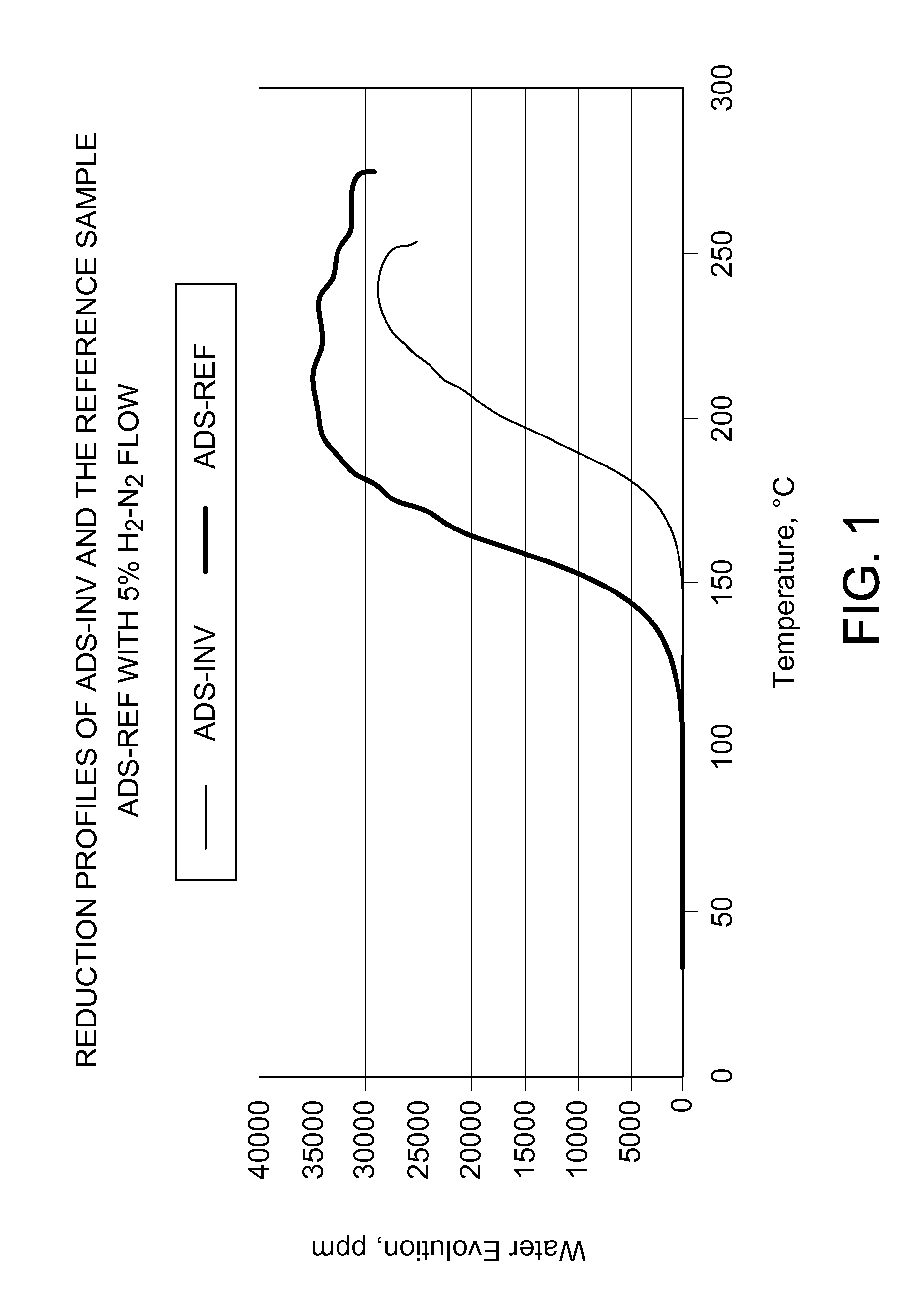

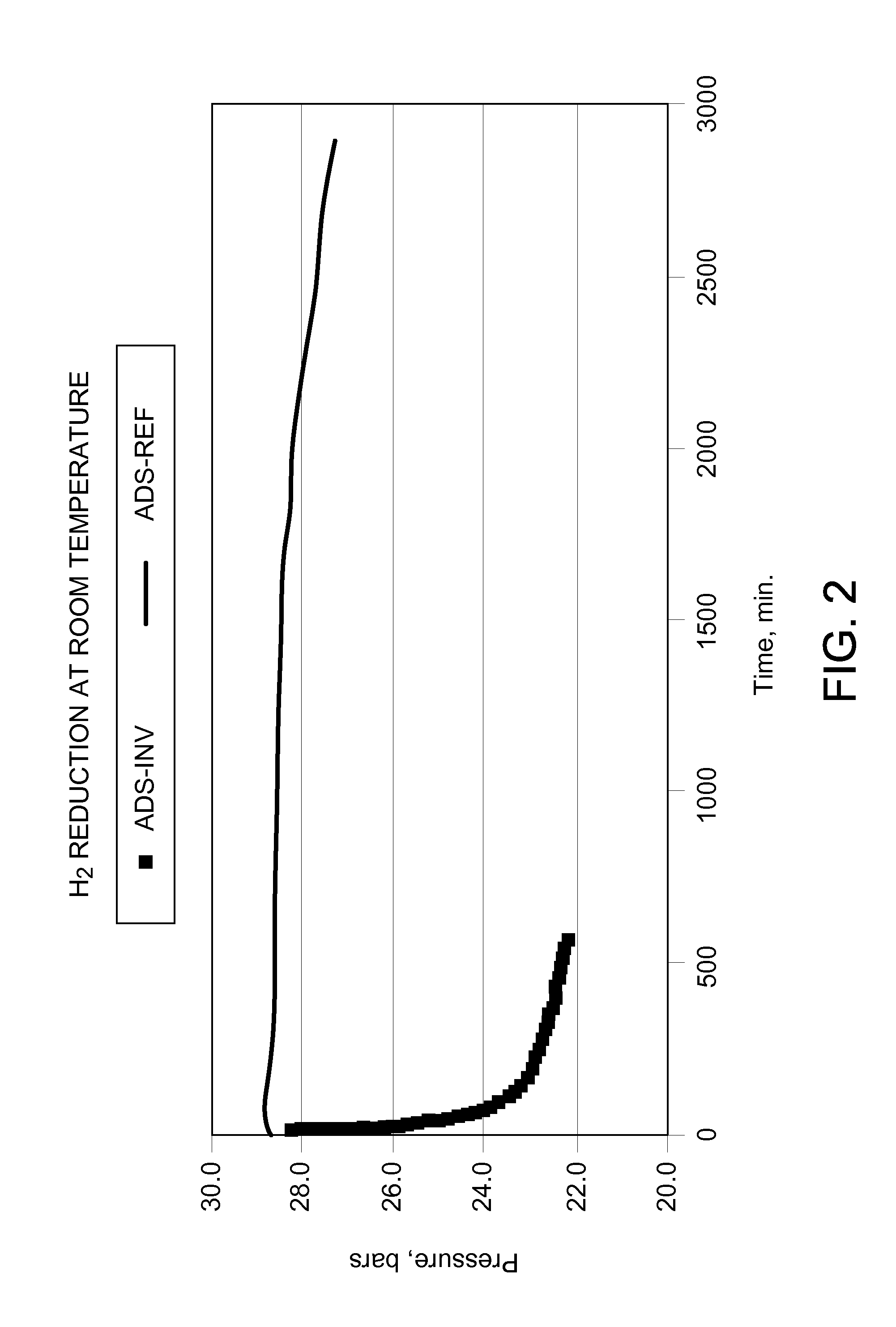

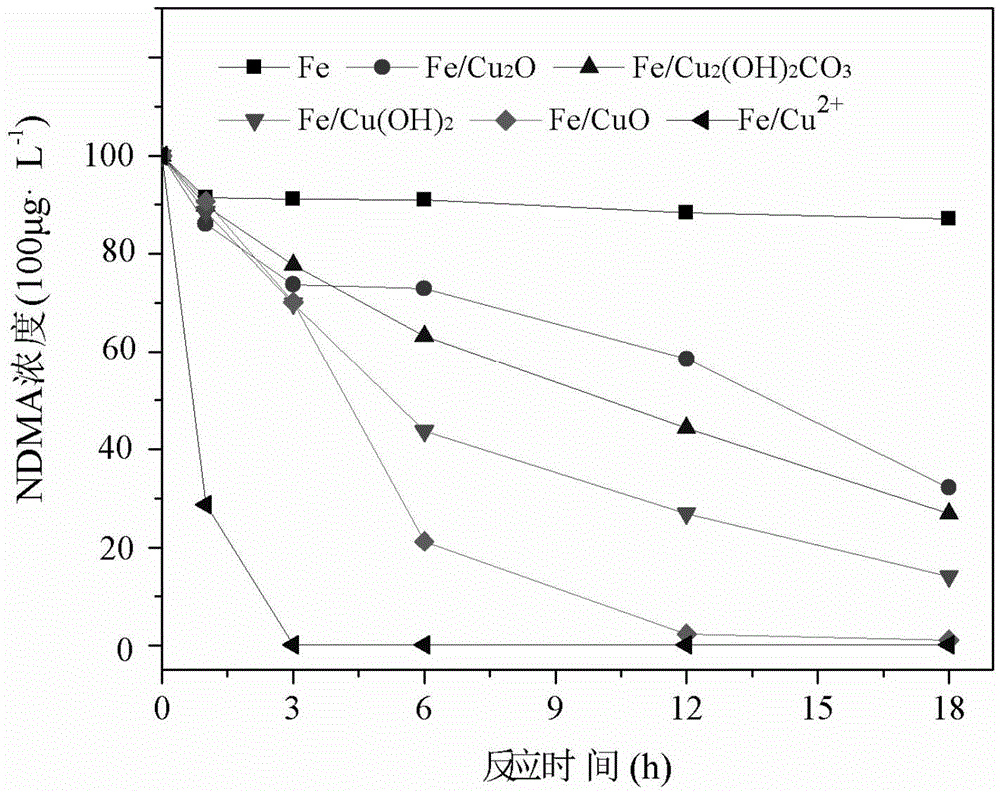

Synthesis gas purification by selective copper adsorbents

InactiveUS20130047850A1Reduce componentsImprove the immunityGas treatmentHydrogen separation using solid contactSorbentCopper oxide

Effective synthesis gas purification is achieved by applying copper adsorbents which are resistant to the reduction by the components of the synthesis gas H2 and CO at normal operation conditions. The novel adsorbents are produced by admixing small amounts of an inorganic halide, such as NaCl, to the basic copper carbonate precursor followed by calcination at a temperature sufficient to decompose the carbonate. The introduction of the halide can be also achieved during the forming stage of adsorbent preparation. These reduction resistant copper oxides can be in the form of composites with alumina and are especially useful for purification of synthesis gas or gas streams containing hydrogen carbon monoxide or other reducing agents.

Owner:UOP LLC

Active carbon desulfurizer and preparation method thereof

ActiveCN101664689AStrong water resistanceReduce manufacturing costOther chemical processesGas purification by catalytic conversionBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to an active carbon desulfurizer prepared by a kneading method and a preparation method thereof. The preparation method comprises the following steps: evenly mixing copper oxideor basic cupric carbonate and pulverized coal or charcoal powder with a certain quantity of water, then adding tar and rolling evenly, and then extruding bands to mold, drying and activating to prepare the active carbon desulfurizer for loading the copper oxide. Holes of the active carbon desulfurizer prepared by the kneading method are more than that of the active carbon desulfurizer prepared bya dipping method; the specific surface area of the active carbon desulfurizer is larger than 1,000<2> / g; the active carbon desulfurizer loading CuO and prepared by a kneading method is not only suitable for desulfuration in petrochemical industry, but also suitable for desulfuration of water gas; and when used for desulfuration of water gas, the active carbon desulfurizer not only has high activity, but also achieves over 30 percent of working sulfur capacity and has the advantages of regeneration, strong water resisting property, no argillization, low production cost and simple process.

Owner:一重集团大连工程建设有限公司

Gas generating composition

InactiveUS20120055593A1LoomsPedestrian/occupant safety arrangementBASIC CUPRIC CARBONATEBasic copper carbonate

The present invention is a gas generating composition including fuel and an oxidizing agent, which can be used for an inflator of a vehicle airbag apparatus, wherein the oxidizing agent includes basic copper carbonate, the gas generating composition having the content of the basic copper carbonate of more than 40% by mass and 60% by mass or lower, and satisfying the following requirements (a) to (c):(a) the burning rate is 7.0 mm / sec or above;(b) the gas output is 2.30 mol / 100 g or above; and(c) the calorific value per mol of generated gas is 100 kJ / mol or lower.

Owner:DAICEL CHEM IND LTD

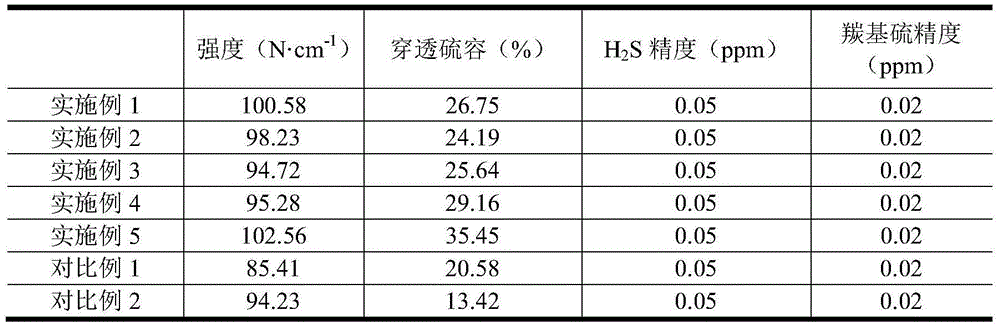

Desulfurizer

InactiveCN101961594AHigh precisionHigh sulfur capacityDispersed particle separationBASIC CUPRIC CARBONATEDecomposition

The invention discloses a desulfurizer which is composed of subcarbonate, silica and accessory ingredient. Based on the total weight of the desulfurizer, the desulfurizer comprises, in percentage by weight, 50-97 wt% of subcarbonate, 2.5-20 wt% of silica and 0.1-30 wt% of accessory ingredient, wherein the subcarbonate is at least one of basic cupric carbonate and basic zinc carbonate, and the accessory ingredient is at least one of alumina and attapulgite powder. The desulfurization (H2S) precision of the desulfurizer can be less than 0.05mg / M3, and sulphur content is about 20% (Wt / Wt). Because the raw material does not need high-temperature decomposition, energy consumption can be greatly lowered by more than 50%, thus obtaining the purpose of energy saving and emission reduction.

Owner:昆山市精细化工研究所有限公司

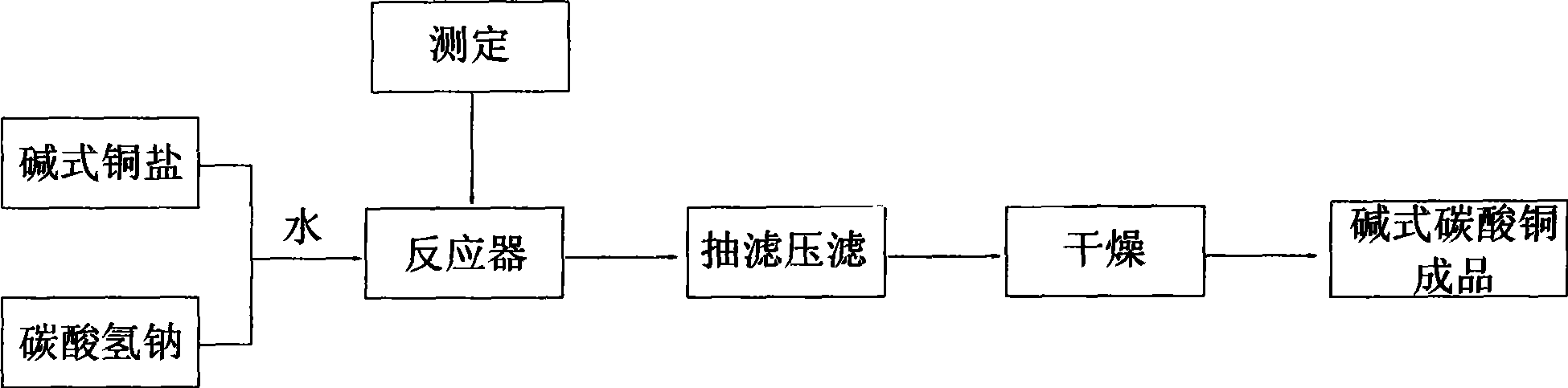

Process for producing basic copper carbonate

The invention discloses a preparation method of basic cupric carbonate, which comprises the following steps: step 1, stirring the solid basic cupric carbonate or cupric hydroxide and water into a paste shape in a reactor; step 2, adding solid sodium bicarbonate in the reactor to carry out solid state reaction and controlling the temperature to be between 20 DEG C and 140 DEG C; and step 3, after the completion of measurement and conversion, firstly preparing the wet basic cupric carbonate and then preparing the finished wet basic cupric carbonate after the wet basic cupric carbonate are subjected to solid-liquid separation, and washed and dried. The invention has the advantages of high purity, low cost and less amount of waste water produced.

Owner:沈祖达

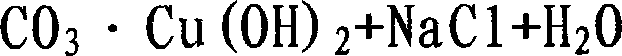

Preparation method for durable antibacterial cellulose fibres

ActiveCN109440450AImprove antibacterial propertiesHigh whiteness valueBiochemical fibre treatmentVegetal fibresSodium bicarbonateZinc hydroxide

The invention provides a preparation method for durable antibacterial cellulose fibres. The preparation method comprises the following steps: S1, removing impurities from cellulose fibres in a physical mechanical mode to obtain impurity-removed fibres; S2, performing pre-treatment on the impurity-removed fibres, and dewatering to obtain dewatered fibres, wherein the pre-treatment comprises a cleaning process and / or a refining and bleaching process; S3, performing antibacterial finishing on the dewatered fibres with an antibacterial working liquid to obtain durable antibacterial cellulose fibres, wherein the antibacterial working liquid comprises an antibacterial agent, an alkaline auxiliary agent and a penetrating agent; the antibacterial agent is one or more of magnesium carbonate, coppernitrate, copper chloride, copper hydroxide, copper carbonate, basic cupric carbonate, zinc chloride, zinc sulphate, zinc hydroxide and zinc carbonate; and the alkaline auxiliary agent is one or moreof sodium hydroxide, potassium hydroxide, sodium bicarbonate, ammonium carbonate, ammonia water, sodium phosphate and sodium carbonate. The prepared cellulose fibres have a durable antibacterial effect; and the whiteness value of the fibres is high.

Owner:山东欣悦健康科技有限公司 +1

Extraction method of theanine

ActiveCN105061249ASimple stepsIncrease the burdenCarboxylic acid amide separation/purificationUltrafiltrationTheanine

The invention provides an extraction method of theanine. The extraction method comprises the steps of ultrafiltration, precipitation, dissolution, electroosmosis, vacuum concentration, ethanol addition, sulfuric acid removal and the like. Specifically, the extraction method comprises the steps that after the ultrafiltration is performed on waste liquid to remove macromolecular substances, basic cupric carbonate reacts with theanine to generate theanine-basic cupric carbonate precipitation, then dilute sulphuric acid reacts with theanine-basic cupric carbonate to generate theanine-bluestone, then copper ions and sulfate ions in the theanine-bluestone are simultaneously removed through the electroosmosis, then moisture in a fresh water chamber is removed through vacuum concentration, and then sulfuric acid is separated from sulfuric acid-theanine by using absolute ethyl alcohol. The invention provides a simple method for extracting the theanine from the waste liquid after tea polyphenol is extracted from tea on the premise that substances such as sulfuretted hydrogen, barium hydroxide are not used, and the concentration of the theanine in theanine crude products reaches 70 to 90%.

Owner:CHANGSHA BOTANIX

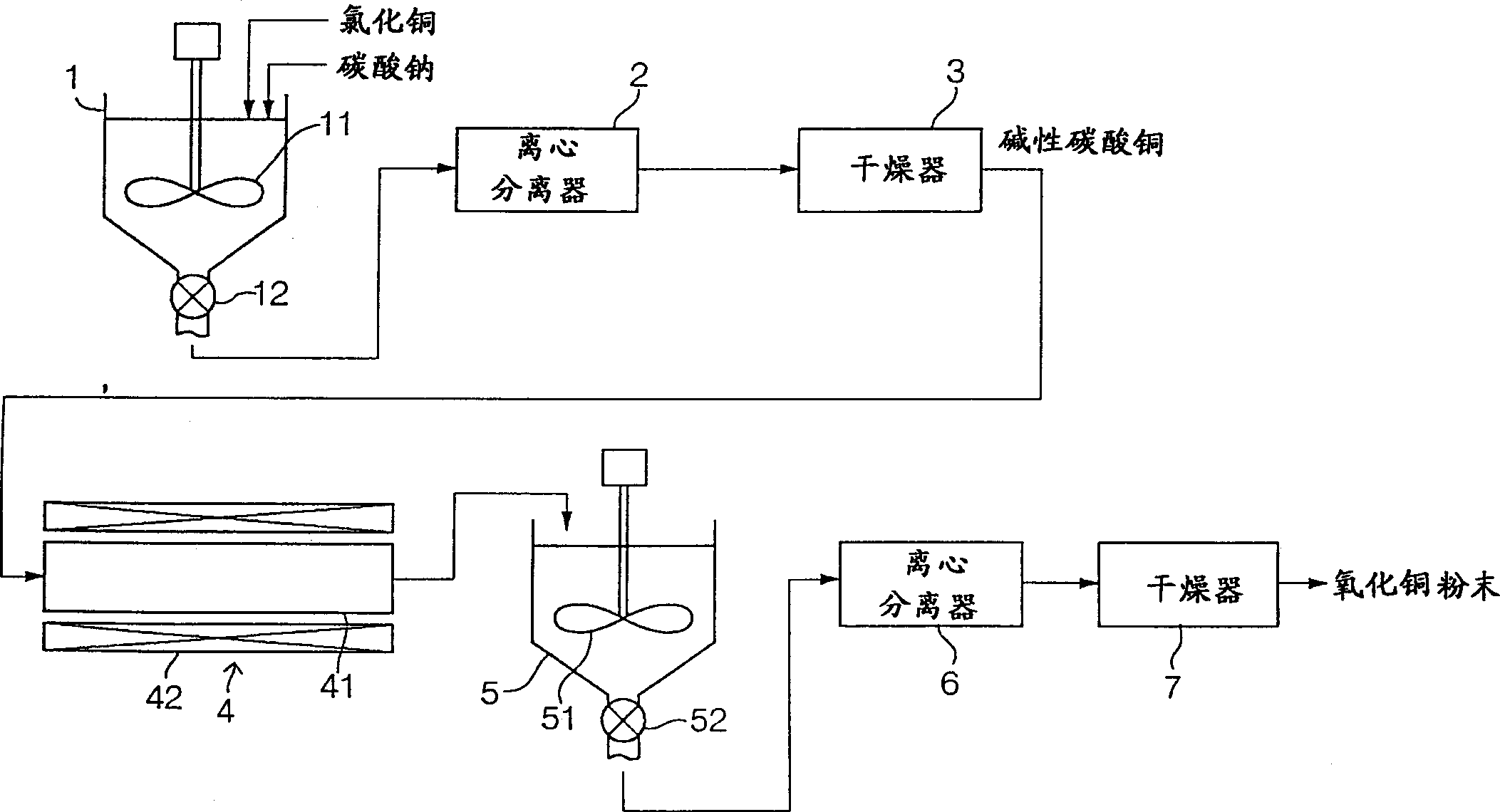

Method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate

InactiveCN103101958AGuaranteed purityOvercoming the disadvantages of static calcinationCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

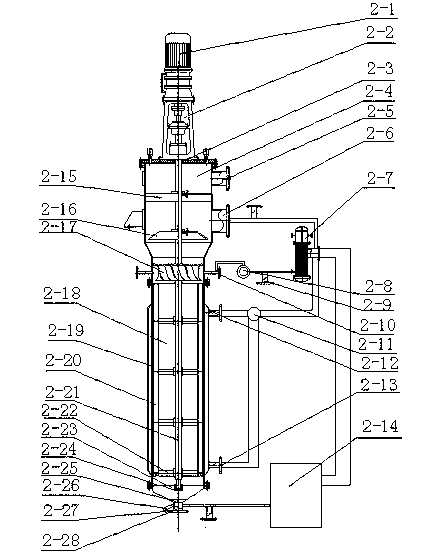

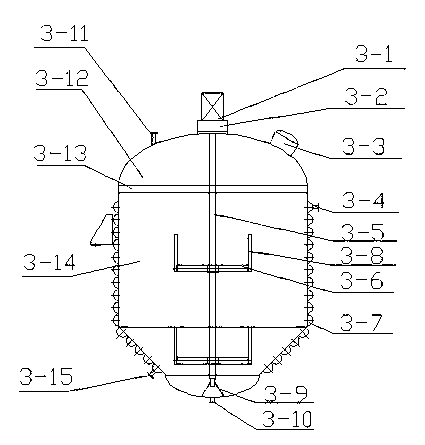

The invention discloses a method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate. According to the method, pure copper, liquid nitrogen and high-purity carbon dioxide are taken as materials to prepare the high-purity basic cupric carbonate through a centrifugal film evaporator or a scraper reaction kettle; the problem of impurities such as chlorine which may be caused by production of the basic cupric carbonate material by the traditional method is avoided; the purity of the basic cupric carbonate is improved; the high-purity low-chorine electroplating grade copper oxide is burnt from the high-purity basic cupric carbonate through a rotary kiln; the defects of inactivation, a plurality of impurities, large labor intensity, un-continuous production, long period, high energy consumption, large cost and the like due to the fact that the basic cupric carbonate at the low-temperature part is not burnt thoroughly and the content is not enough when a pushed slab kiln statically burns while copper oxide at the high-temperature part is burnt to death are overcome; the product activity is ensured; and the method is high in product quality, less in energy consumption, small in cost and more environment-friendly.

Owner:TAIXING SMELTING PLANT

Activated carbon capable of removing formaldehyde

InactiveCN104353417AEffective protectionLow costGas treatmentPhysical/chemical process catalystsBASIC CUPRIC CARBONATEActivated carbon

The invention relates to the technical field of activated carbon, and particularly relates to active carbon capable of removing formaldehyde. Coaly activated carbon acts as a carrier framework material, and 0.5wt%-3wt% of basic cupric carbonate, 0.5wt%-3wt% of manganous nitrate, 0.5wt%-3wt% of cerous nitrate, 0.01wt%-0.1wt% of silver nitrate and 40wt%-60wt% of adhesive (tar) are loaded on the carrier framework material. In the process of activated carbon preparation, chemical medicines and pulverized coal are mixed directly, and then the mixture is subjected to layering, carbonization and activation, so that the activated carbon for removing formaldehyde is prepared. Compared with other preparation methods, the production cost can be lowered greatly.

Owner:SHANXI XINHUA CHEM

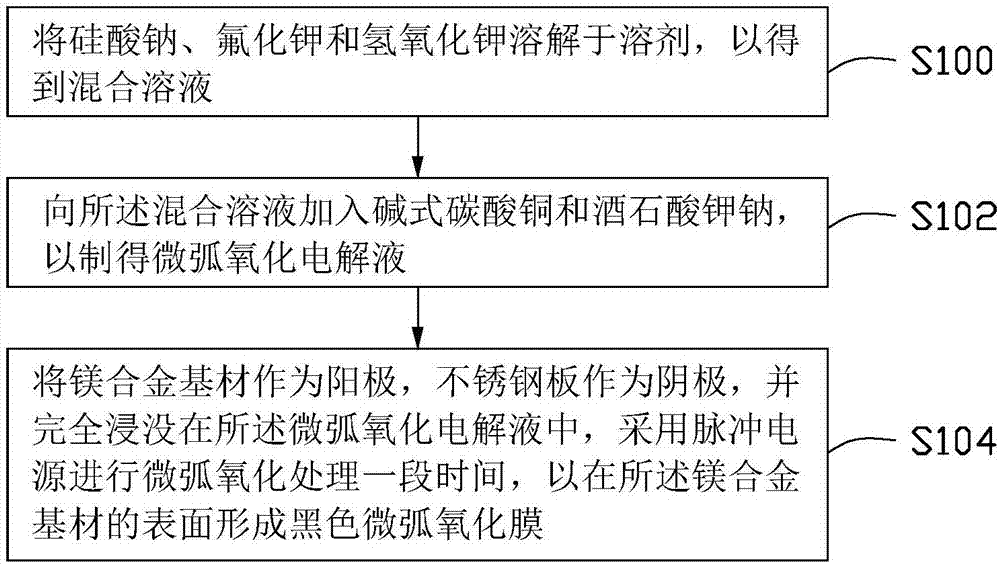

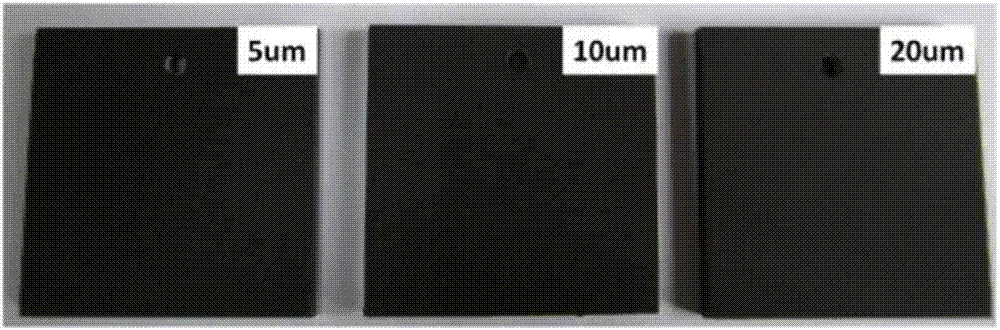

Preparing method for magnesium alloy black microarc oxidation film

InactiveCN107419315AImprove uniformityImprove compactnessAnodisationPlasma electrolytic oxidationMicro arc oxidation

Disclosed is a preparing method for a magnesium alloy black microarc oxidation film. The preparing method for the magnesium alloy black microarc oxidation film comprises the following steps that sodium silicate, potassium fluoride and potassium hydroxide are dissolved in a solvent, and a mixed solution is obtained; basic cupric carbonate and sodium potassium tartrate tetrahydrate are added into the mixed solution so as to prepare a microarc oxidation electrolyte solution, and the dosage of the basic cupric carbonate is 2-5 g / L; and a magnesium alloy base material is used as an anode, a stainless steel plate is used as a cathode, the magnesium alloy base material and the stainless steel plate are completely submerged in the microarc oxidation electrolyte solution, and microarc oxidation treatment is conducted for a period of time by using pulsed power supply, so that the black microarc oxidation film is formed on the surface of the magnesium alloy base material. According to the preparing method for the magnesium alloy black microarc oxidation film, the preparing technology is simple, the cost is low, and the black microarc oxidation film formed on the surface of the magnesium alloy base material is good in uniformity and compactness.

Owner:深圳市粤辉煌环保技术有限公司

Method for preparing analytically pure basic cupric carbonate

InactiveCN101885506AControl reaction temperatureControl reaction speedCopper compoundsSodium bicarbonateBASIC CUPRIC CARBONATE

The invention relates to a method for preparing analytically pure basic cupric carbonate. The method comprises the following steps of: (1) preparing sodium bicarbonate solution and copper sulfate solution; (2) synthesizing basic cupric carbonate, controlling pH values of the sodium bicarbonate solution and the copper sulfate solution to be between 8 and 8.05, and standing the solution for 4 to 5 hours after the reaction of the solution is finished to obtain sediment B; and (3) preparing the analytically pure basic cupric carbonate, namely pumping, washing and drying the sediment B prepared in the step (2) to obtain a finished product of the analytically pure basic cupric carbonate. The method prepares the analytically pure basic cupric carbonate by synthesizing sodium bicarbonate and copper sulfate and controlling the reaction temperature and synthetic feeding speed. The method can prepare the analytically pure basic cupric carbonate with high purity and low impurity content; and the method has the advantages of easy operation, simplicity and high production efficiency, and meets the market requirement.

Owner:TIANJIN CHEM REAGENT RES INST

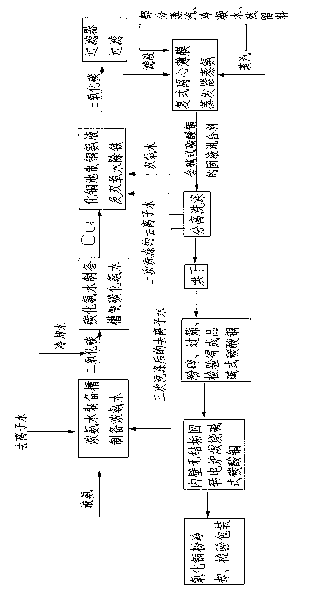

Comprehensive utilization method of waste liquor in production of basic cupric carbonate

ActiveCN103449501AAchieve reuseRealize recycling of resourcesCopper chloridesCopper nitratesSulfate radicalsIndustrial waste water

The invention discloses a comprehensive utilization method of waste liquor in the production of basic cupric carbonate and relates to the field of treatment methods of industrial wastewater. The invention aims at providing a comprehensive utilization method of waste liquor in the production of basic cupric carbonate, and in particular relates to a method for reusing sodium bicarbonate in the waste liquor. The waste liquor in the production of the basic cupric carbonate is the waste liquor generated after the basic cupric carbonate is produced by a reaction between an acidic copper chloride solution or an acidic copper sulfate solution and a sodium carbonate solution. The comprehensive utilization method of the waste liquor in the production of the basic cupric carbonate mainly comprises the following steps: adding a little distilled water into a reaction kettle as a base solution; when the reaction temperature rises to 35-90 DEG C, starting a stirring device, and adding the waste liquor containing sulfate radicals or chlorine and the acidic copper solution into the reaction kettle for reaction, wherein the pH value during the addition of the solutions is controlled to be 3-6; and filtering, washing, drying and sieving reaction products to obtain the basic copper salt. The method disclosed by the invention is simple to operate, easy to control reaction conditions, and widely applicable to the recycling and reusing of the waste liquor in the production of basic cupric carbonate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Preparation method of copper-based mercury removing agent

InactiveCN103521165AReduce manufacturing costImprove mercury removalOther chemical processesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention provides a preparation method of a copper-based mercury removing agent, belonging to the technical field of mercury removing agents. The preparation method comprises the following steps: (1) dissolving basic cupric carbonate into concentrated ammonia water or saturated ammonium bicarbonate solution or mixed solution of concentrated ammonia water and saturated ammonium bicarbonate, thus forming impregnation liquid; (2) impregnating a carrier in the impregnation liquid, taking out the saturated and impregnated carrier and draining or drying the carrier at 80-150 DEG C; (3) roasting the drained or dried carrier at 180-250 DEG C, thus obtaining a mercury removing agent precursor; (4) vulcanizing the mercury removing agent precursor, thus obtaining the copper-based mercury removing agent. The mercury removing agent prepared by the preparation method has the advantages of low production cost and high mercury removal accuracy.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

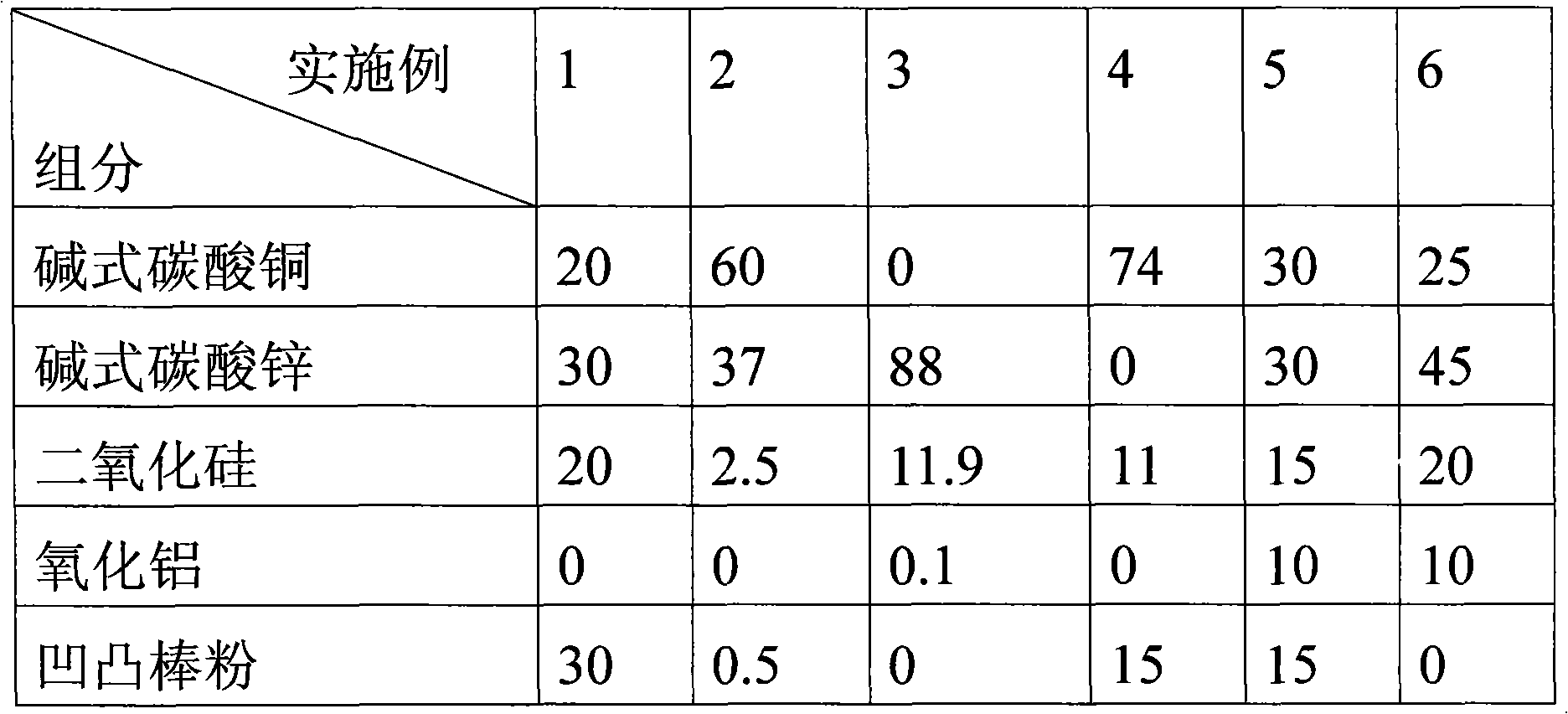

Method for preparing copper-based catalyst for catalyzing carbon dioxide hydrogenation reduction

InactiveCN106423175AWell mixedSmall sizeOrganic compound preparationHeterogenous catalyst chemical elementsAir atmosphereBASIC CUPRIC CARBONATE

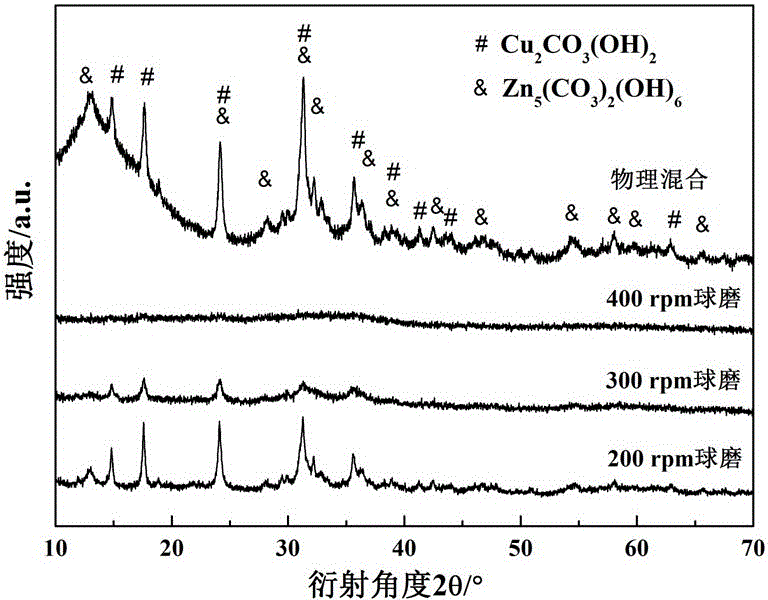

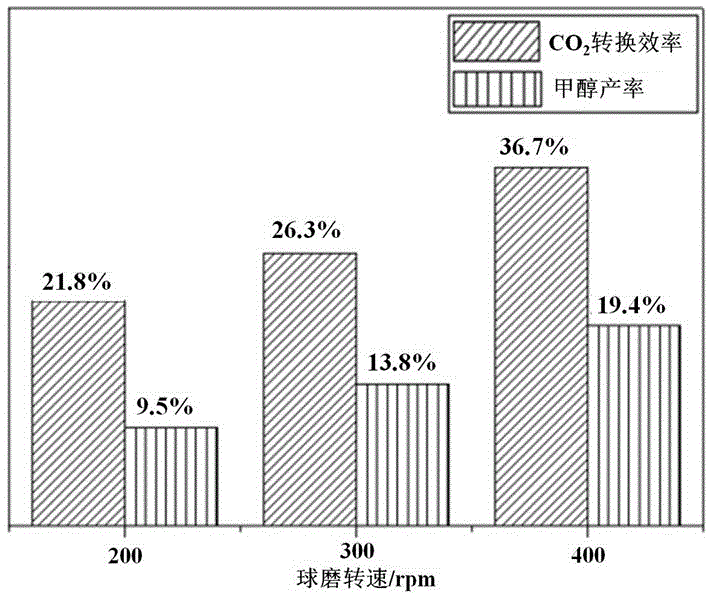

The invention belongs to the technical field of copper-based catalyst preparation and particularly relates to a method for preparing a copper-based catalyst for catalyzing carbon dioxide hydrogenation reduction. High energy generated through ball milling makes metal ions of different compounds substitute for one another, and accordingly the copper-based catalyst for catalyzing carbon dioxide hydrogenation reduction is prepared. Specifically, at the air atmosphere, basic cupric carbonate, basic zinc carbonate and basic carbonate or oxides of other catalyst carriers and auxiliaries are mixed, then ball milling is conducted, the product is forged and reduced, and the catalyst is obtained. The method has the advantages of being easy to prepare, high in yield and the like. The catalyst prepared through the ball milling method is excellent in catalytic performance, can catalyze carbon dioxide hydrogenation reduction at 240 DEG C and at 3 MPa, and has good conversion efficiency.

Owner:FUDAN UNIV

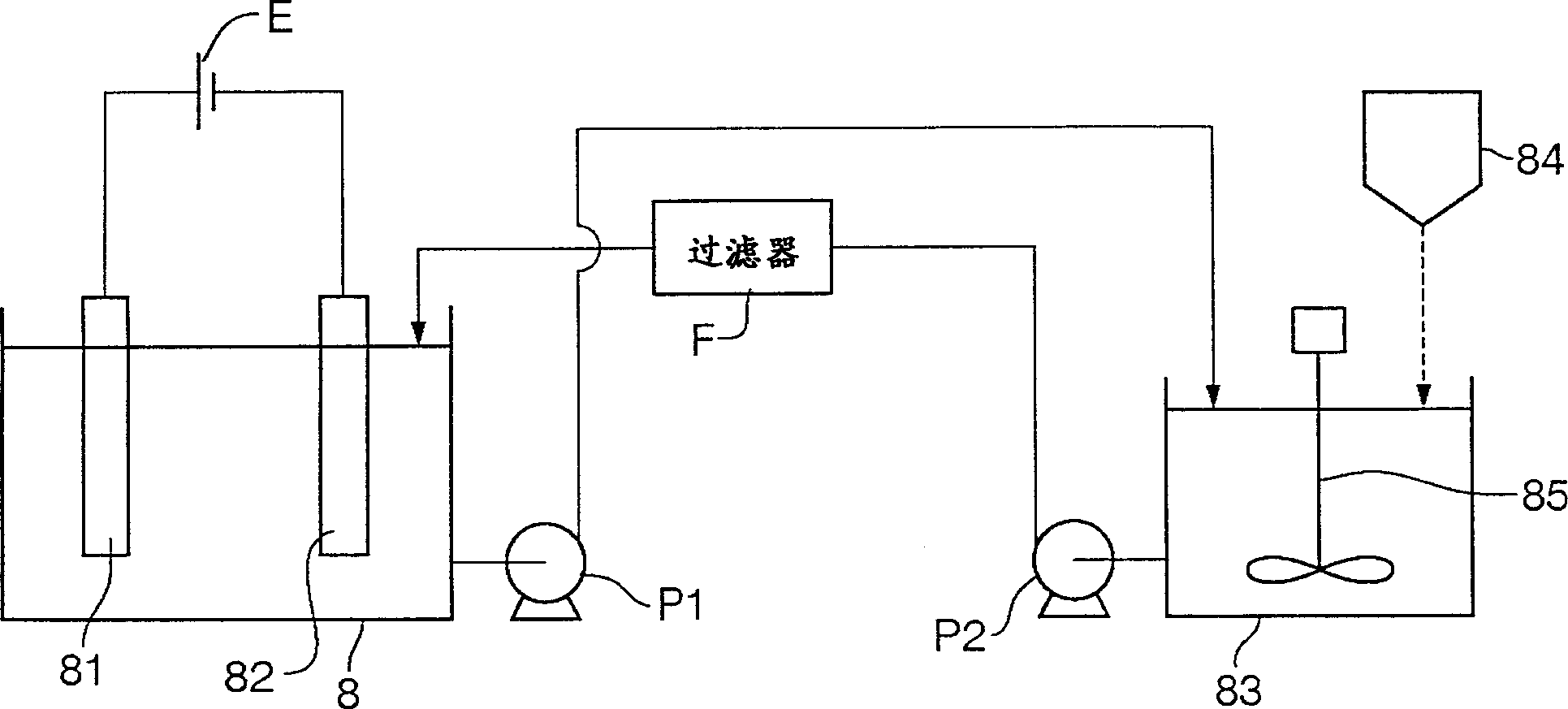

Preparing method of high-purity basic cupric carbonate

InactiveCN103991893AIncrease profitLow costCopper compoundsBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a preparing method of high-purity basic cupric carbonate. Electrolytic copper, aqueous ammonia and ammonium bicarbonate are adopted as raw materials. The high-purity basic cupric carbonate is obtained by steps of preparing the aqueous ammonia, leaching and synthesizing, filtering, performing thermolysis, centrifuging to remove water, rinsing, drying, smashing, packaging after the assay is approved, and the like, and by adoption of secondary oxidation. The preparing method has characteristics of no production of side products, no production of waste materials, high utilization rate of the raw materials, low cost and no pollution.

Owner:JIANGSU TEHO METAL IND

Method for continuously preparing high-purity low-chloride electroplating copper oxide

InactiveCN103011251AHigh purityQuick responseCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:TAIXING SMELTING PLANT

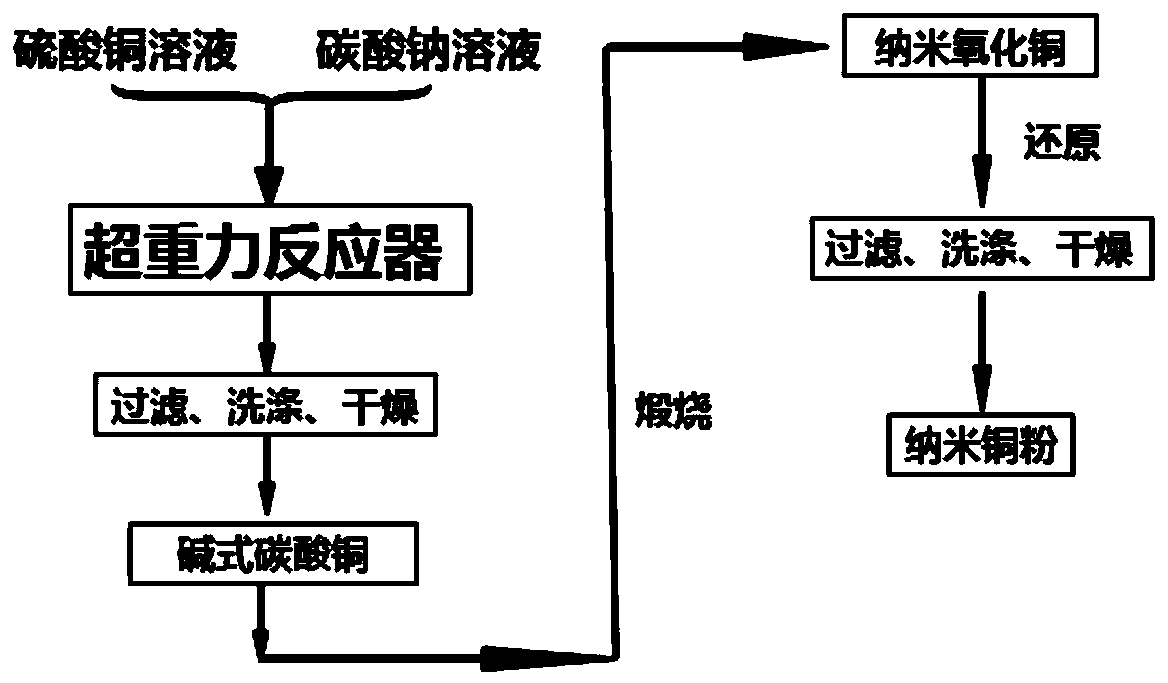

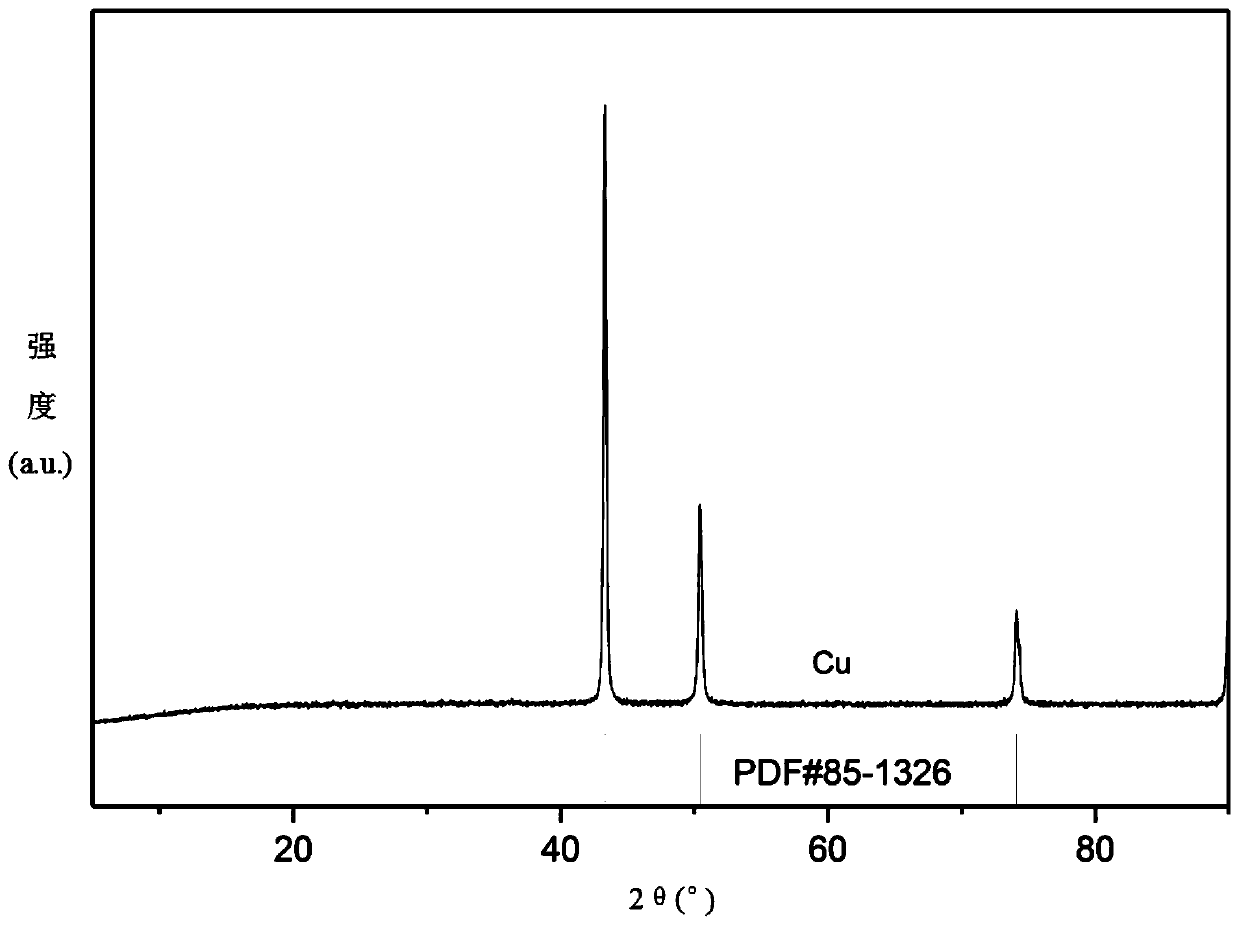

Preparation method for nano-copper powders

PendingCN110976901ALow costHigh purityMaterial nanotechnologyCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

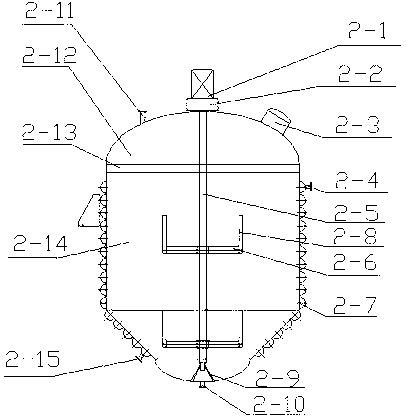

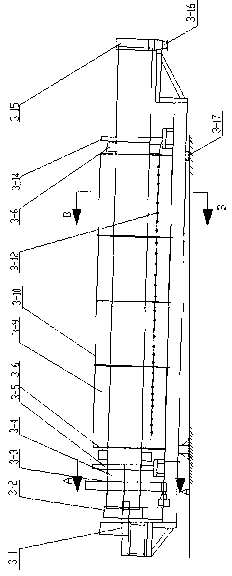

The invention relates to a preparation method for nano-copper powders. The preparation method comprises the following steps of: A: preparing nanoscale basic cupric carbonate by a method of precipitation: specifically, preparing a bivalent copper ion solution with certain concentration, then, preparing a precipitant solution with certain centration, starting a spiral channel type revolving bed hypergravity reactor, then, independently injecting two solutions into the reactor from different inlets according to a certain revolving speed to react to cause the two solutions to generate precipitation reaction, and after the reaction is finished, filtering, washing and drying a reaction liquid in sequence; B: carrying out calcination on a dried product to obtain a nanometer copper oxide; and C: reducing the nanometer copper oxide to obtain the nano-copper powders. The preparation method can stably produce the nano-copper powders with even particles on batch, and the produced nano-copper powders have a good application prospect on the aspects, including electric conduction, catalysis, lubrication and the like.

Owner:XIANGTAN UNIV

Copper plated material, its manufacturing method and method for copper plating

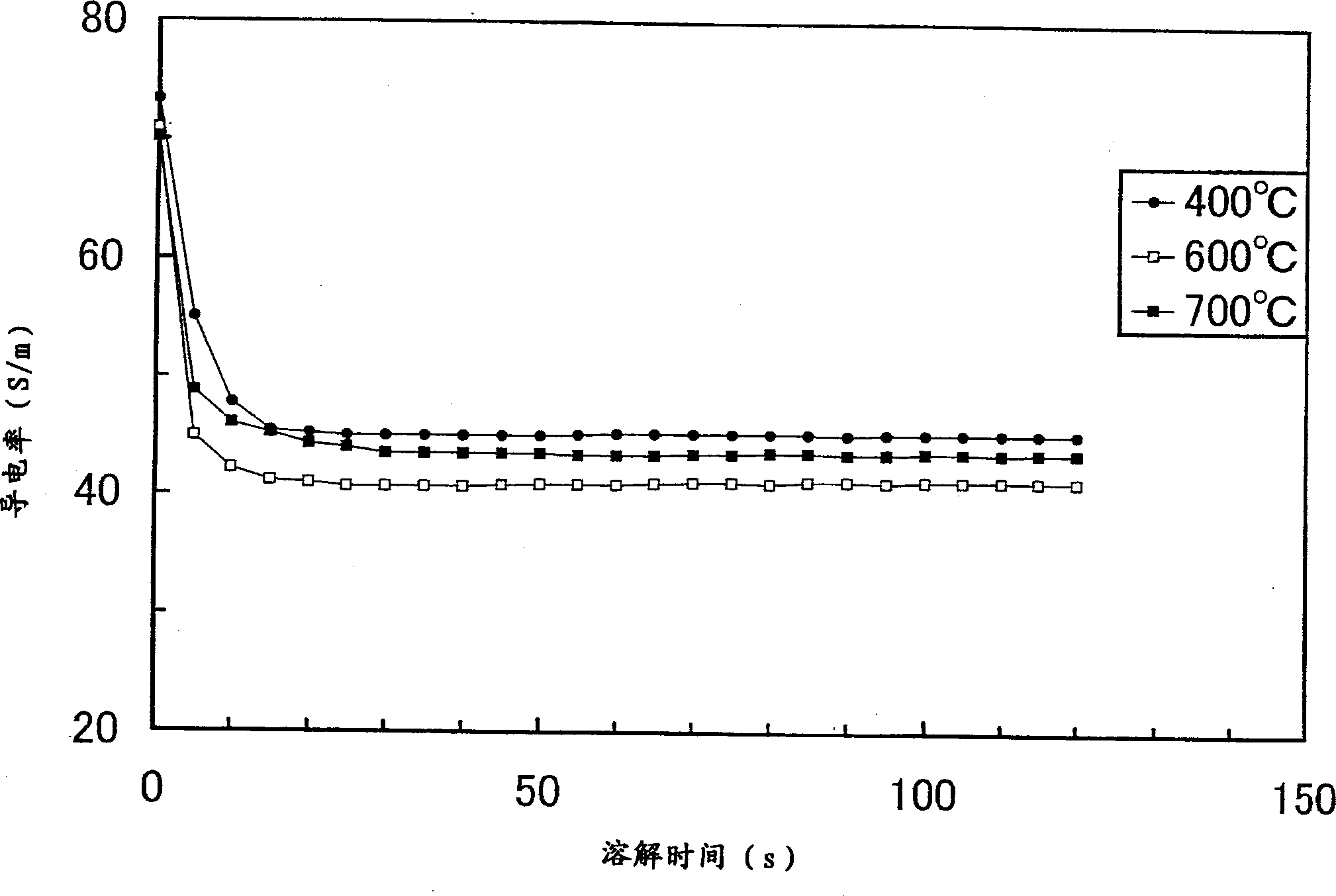

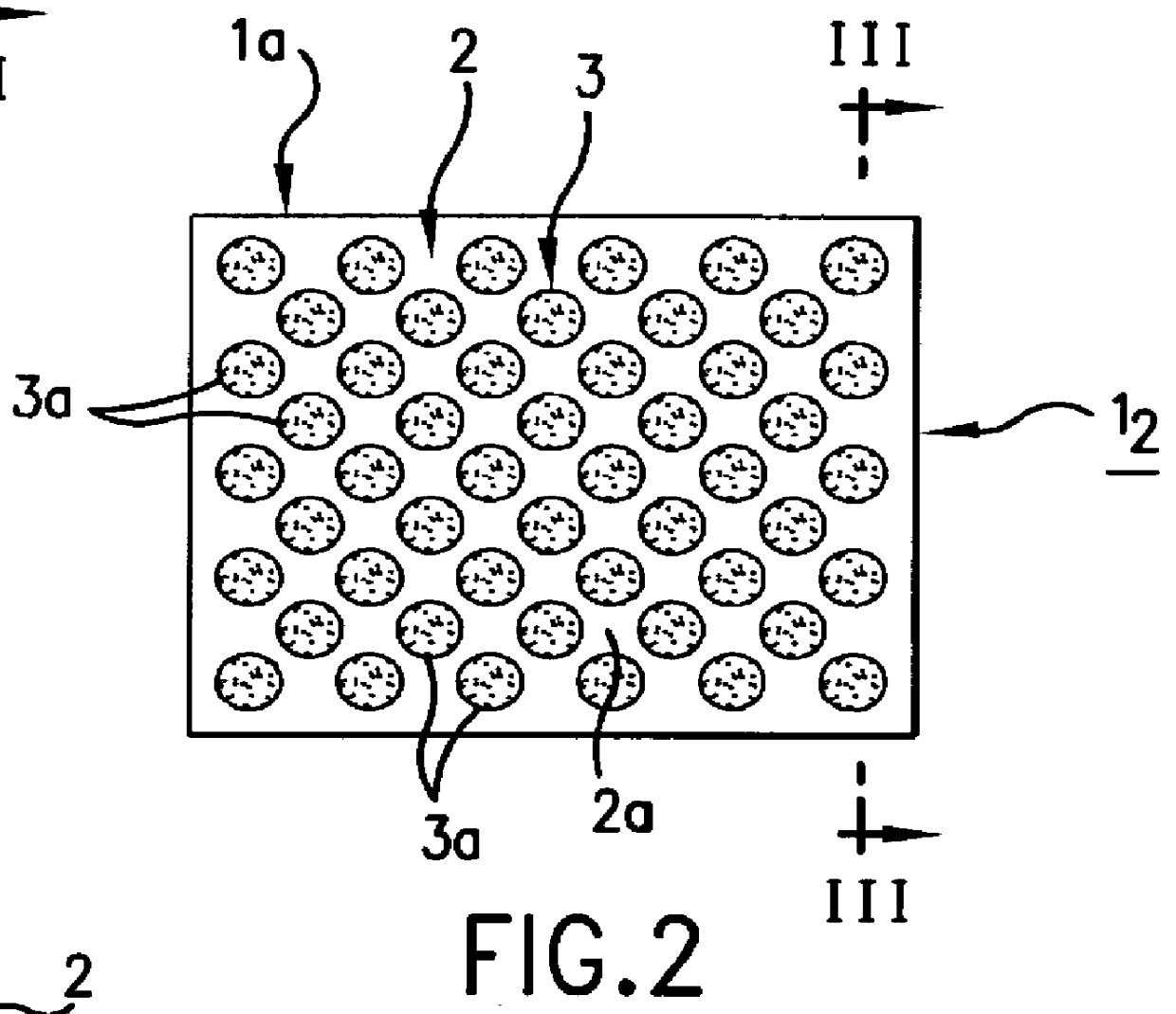

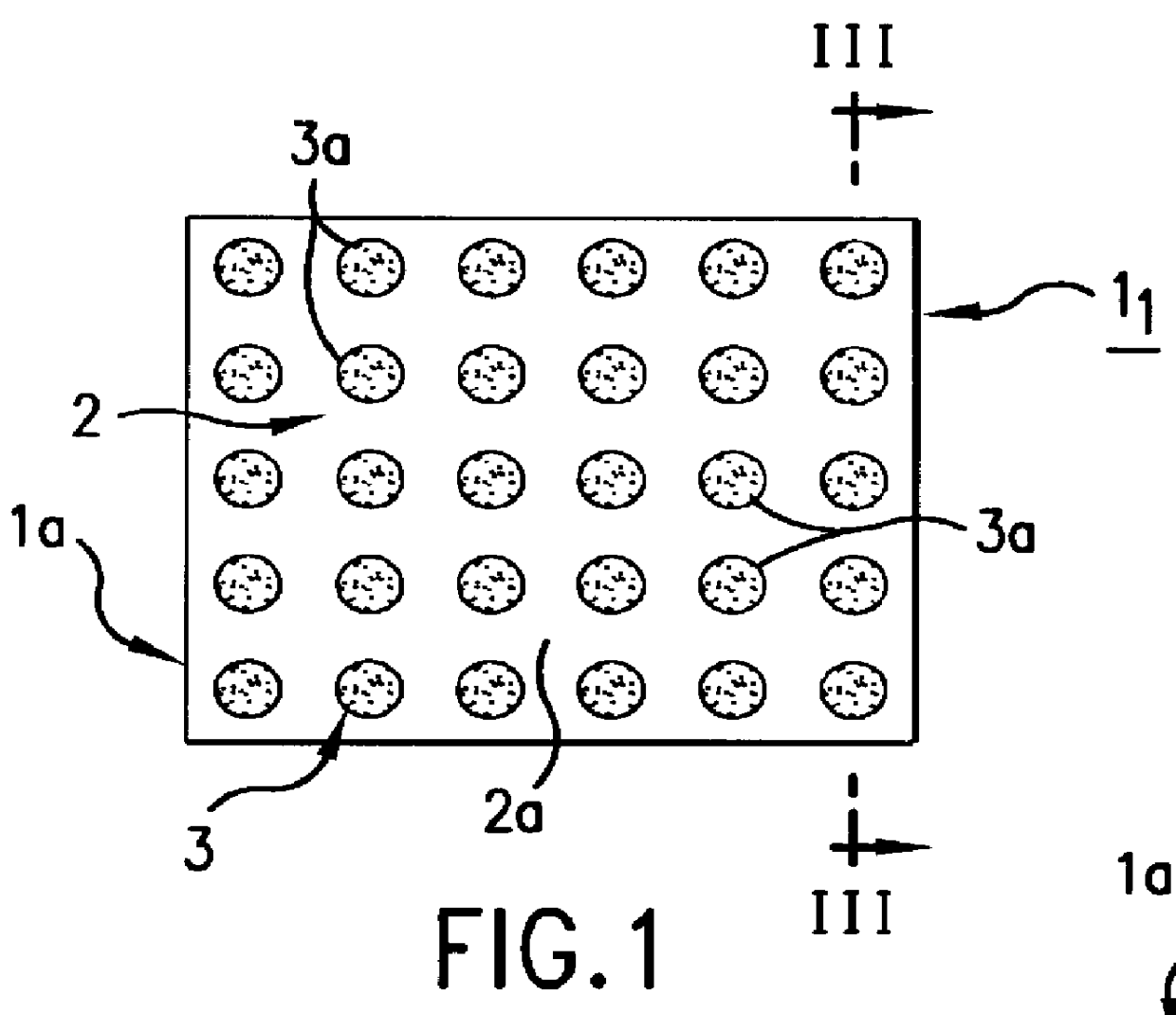

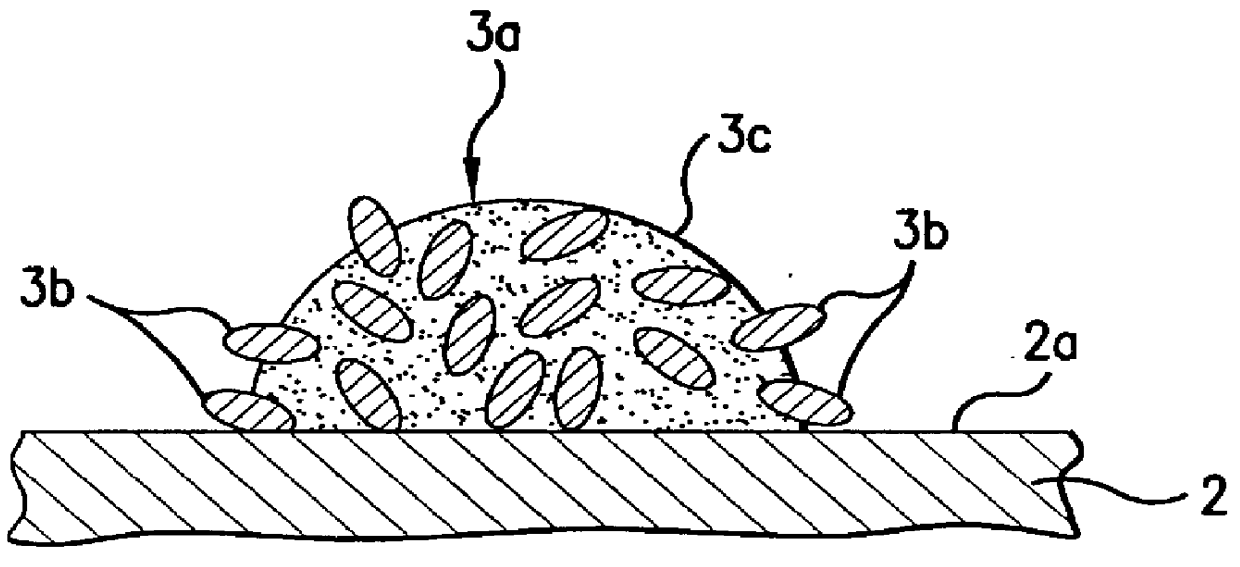

A copper electroplating material using as a copper supply source during preparation. Basic copper carbonate is formed in a reaction tank by deposition and heated to a temperature of between 250 DEG C. and 800 DEG C. in an atmosphere which does not form a reducing atmosphere which does not form a reducing atmosphere, to thereby be subjected to thermal decomposition, resulting in providing easily soluble copper oxide.

Owner:TOAGOSEI CO LTD

Artificially patinated copper material

InactiveUS6063480AGood molding effectAffect and impair appearanceNatural patternsSynthetic resin layered productsBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:SAMBO COPPER ALLOY

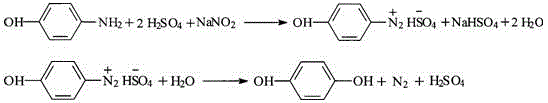

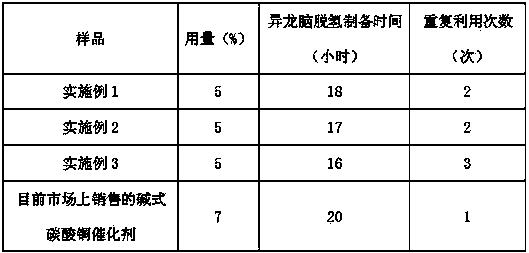

Hydrolysis process for hydroquinone

InactiveCN102746122AMake up for the disadvantage of high priceRealize cleaner productionOrganic chemistryOrganic compound preparationP-AminophenolReaction temperature

The invention discloses a hydrolysis process for hydroquinone and relates to a hydrolysis process during hydroquinone synthesis by subjecting p-aminophenol to diazotization and hydrolysis processes. The process includes: adding basic cupric carbonate, cupric sulfate and solvents into a hydrolysis reaction kettle, dropwise adding diazonium solution of 0+ / -0.5 DEG C obtained by subjecting sodium nitrite and dilute sulfuric acid to diazotization and performing hydrolysis reaction at a reaction temperature of 85 DEG C-88 DEG C. Raffinate phase does not generate waste acid, and the copper recovery rate reaches to more than 99.5%, so that a disadvantage of high copper price is made up; and sodium sulfate is obtained by means of concentration and crystallization of filtrate, concentrated water is used for preparing acid for diazo reaction, and crystallized mother solution of the sodium sulfate is used for preparing cupric sulfate solution for hydrolysis, so that clean production is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Automotive oil seal ring

The invention discloses an automotive oil seal ring, comprising, by weight, 100 to 125 parts of silicone rubber, 100 to 120 parts of butadiene rubber, 80 to 100 parts of nitrile-butadiene rubber, 80 to 100 parts of styrene butadiene rubber, 60 to 80 parts of butyl rubber, 60 to 80 parts of isoprene rubber, 5 to 8 parts of petroleum ether, 8 to 10 parts of diethylene glycol monobutyl ether, 5 to 8 parts of cyclopentadiene, 8 to 10 parts of dioctyl phthalate, 3 to 5 parts of coconut oil, 3 to 5 parts of rapeseed oil, 5 to 8 parts of realgar, 6 to 10 parts of ammonium hydrogen phosphate, 8 to 10 parts of basic cupric carbonate, 10 to 12 parts of silicon carbide powder, 6 to 8 parts of polyvinyl alcohol, 8 to 10 parts of nano-titanium dioxide, 8 to 10 parts of nano calcium carbonate, 8 to 12 parts of calcite powder, 6 to 8 parts of N-phenyl-alpha-benzenamine anti-aging agent, 8 to 10 parts of polypropylene glycol, 6 to 8 parts of diethylene glycol, and 8 to 10 parts of emulsified silicone oil. The automotive oil seal ring is low in cost, stable in performance, high in strength, low in compressive deformation, resistant to high and low temperatures, excellent in performance, and free of breakage and deformation in long-term operation.

Owner:陈新棠

Method for producing food-grade copper sulfate by smelting byproduct-copper sulfate

The invention discloses a method for producing food-grade copper sulfate by a smelting byproduct-copper sulfate. The method comprises the following steps of: dissolving the industrial smelting byproduct-copper sulfate in ultrapure water, heating to 70-80 DEG C, slowly dropwise adding acid for adjusting the pH value of a solution to be 1.00, stirring for dissolving, and slowly adding an oxidant; mixing polymeric ferric sulfate and basic cupric carbonate according to a mass ratio of 1:(2.0-5.0) to prepare a deposition complexing agent, slowly adding the deposition complexing agent which is 0.6-2.8% of the weight of the solution into the insulation solution, using basic cupric carbonate to adjust the pH value of the solution to be 3.0-4.0, slowly adding an adsorbing agent which is 1.0-2.5% of the weight of the solution, stirring and insulating for 6-8 hours, cooling to room temperature, and standing for a day; and carrying out vacuum filtration on the solution, filtering by using a microporous filter membrane of 0.2-0.3mu m, carrying out ultrasonic-assisted rotary evaporation and concentration on filter liquor for crystallization, and carrying out spray-drying to obtain the food-grade copper sulfate.

Owner:JIANGXI UNIV OF SCI & TECH

Biomass briquette fuel produced by performing anaerobic fermentation and modification on corn straws and production method thereof

InactiveCN105969467ALow costImprove mechanical durabilityBiofuelsSolid fuelsBULK ACTIVE INGREDIENTFermentation

The invention discloses a biomass briquette fuel produced by performing anaerobic fermentation and modification on corn straws. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, finally, biogas residue is dried and crushed, and then is composited with an anti-slagging agent and an oxidant and other active ingredients for compression moulding under condition of 6MPa. The preparation method has the advantages of fast moulding and less required pressure, and is helpful for reducing equipment wearing. In the invention, magnesium carbonate is taken as the anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, basic cupric carbonate and bleaching powder which are taken as an ignition-assisting agent are capable of reducing the burning-point of the biomass fuels and increasing the combustion efficiency and heat energy of the fuel, and the produced briquette fuel has the advantages of low cost, no slagging and low energy consumption.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG

Method for recycling copper and nickel in electroplating sludge

InactiveCN108611491ALess investmentMature technologyProcess efficiency improvementFerric hydroxideSludge

The invention provides a method for recycling copper and nickel in electroplating sludge. A separation method comprises the steps of 1, separation of copper, wherein a sodium carbonate solution is adopted for adjusting the pH of leachate called mother liquor to 5-5.5, and filtered sediments are mainly basic cupric carbonate and copper hydroxide; 2, separation of iron and nickel, wherein a sodium carbonate solution is utilized for adjusting the pH of the mother liquor to 8-9, sediments are nickel carbonate, ferric hydroxide and ferrous hydroxide, sulfuric acid and hydrogen peroxide are added tofully dissolve the sediments, afterwards, the pH is adjusted to 5 through alkaline liquor, and a sediment, namely ferric hydroxide, is filtered out; 3, purification and separation of a nickel product, wherein the filtered mother liquor is taken, the pH is adjusted by sulfuric acid to 2, hydrogen sulfide is introduced, copper in mixed liquor is turned into copper sulphide and separated out, at this moment, the mother liquor is nickel sulfate mother liquor, and nickel sulfate heptahydrate can be produced through a concentration and crystallization method. The method has the advantages that theinvestment is small, the technology is mature, the adaptability is high, and the automated degree is high.

Owner:TIANJIN RUISAIKE NEW MATERIAL TECH CO LTD

Sepiolite based biomass fuel and preparation method thereof

The invention discloses a sepiolite based biomass fuel, which comprises the following components by dry weight: 50-100 parts of agricultural and forestry waste, 50-100 parts of sawdust, 5-9 parts of pulverized coal, 10-20 parts of an anti-slagging agent, 20-40 parts of pine needle, 4-8 parts of potassium chlorate, 3-7 parts of gasoline, and 20-30 parts of a combustion supporting agent. The combustion supporting agent comprises the following components by weight: 60-80 parts of sepiolite powder, 40-60 parts of basic cupric carbonate, 30-50 parts of heavy calcium carbonate powder, 40-60 parts of sodium nitrate, and 10-16 parts of manganese oxide. The low cost and high temperature energy provided by the invention can meet the temperature requirements of most industrial heating and kiln fuels.

Owner:杨阳

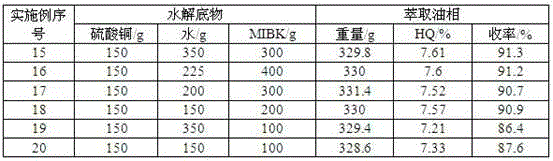

Method for preparing copper-based catalyst

InactiveCN104190419AHigh catalytic activityReduce dosageOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBASIC CUPRIC CARBONATESulfate radicals

The invention discloses a method for preparing a copper-based catalyst, belonging to the technical field of catalysts. The method comprises the following steps: dissolving copper sulfate in hot water, thereby obtaining a copper sulfate solution; adding a sodium carbonate solution into the copper sulfate solution, reacting, filtering, collecting a precipitate, and washing the precipitate with water until inspection with barium chloride proves that no sulfate radical exists in the precipitate solution; and adding zinc oxide into the aqueous solution of the precipitate, filtering, centrifugally separating the obtained filtrate, and drying. Compared with a commercially available basic cupric carbonate catalyst at present, the copper-based catalyst prepared by the invention has the advantages of smaller consumption, higher catalytic efficiency and higher repeated utilization frequency.

Owner:WUZHOU PINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com