Copper plated material, its manufacturing method and method for copper plating

A copper-plating material and a copper-plating technology are applied in the fields of copper-plating materials, their manufacturing and copper-plating, and can solve the problems of rising cost of workpieces to be plated, increased electroplating costs, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

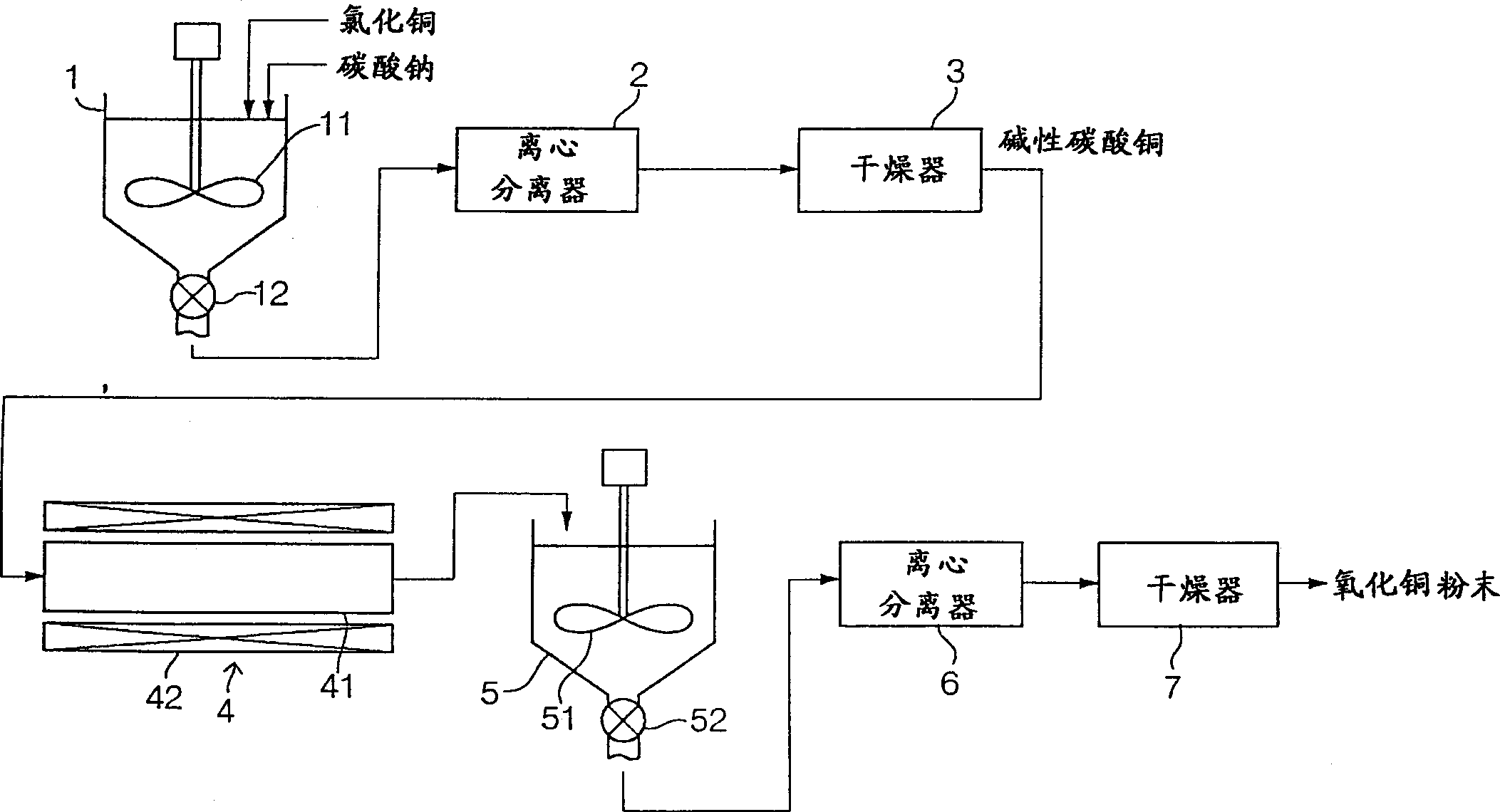

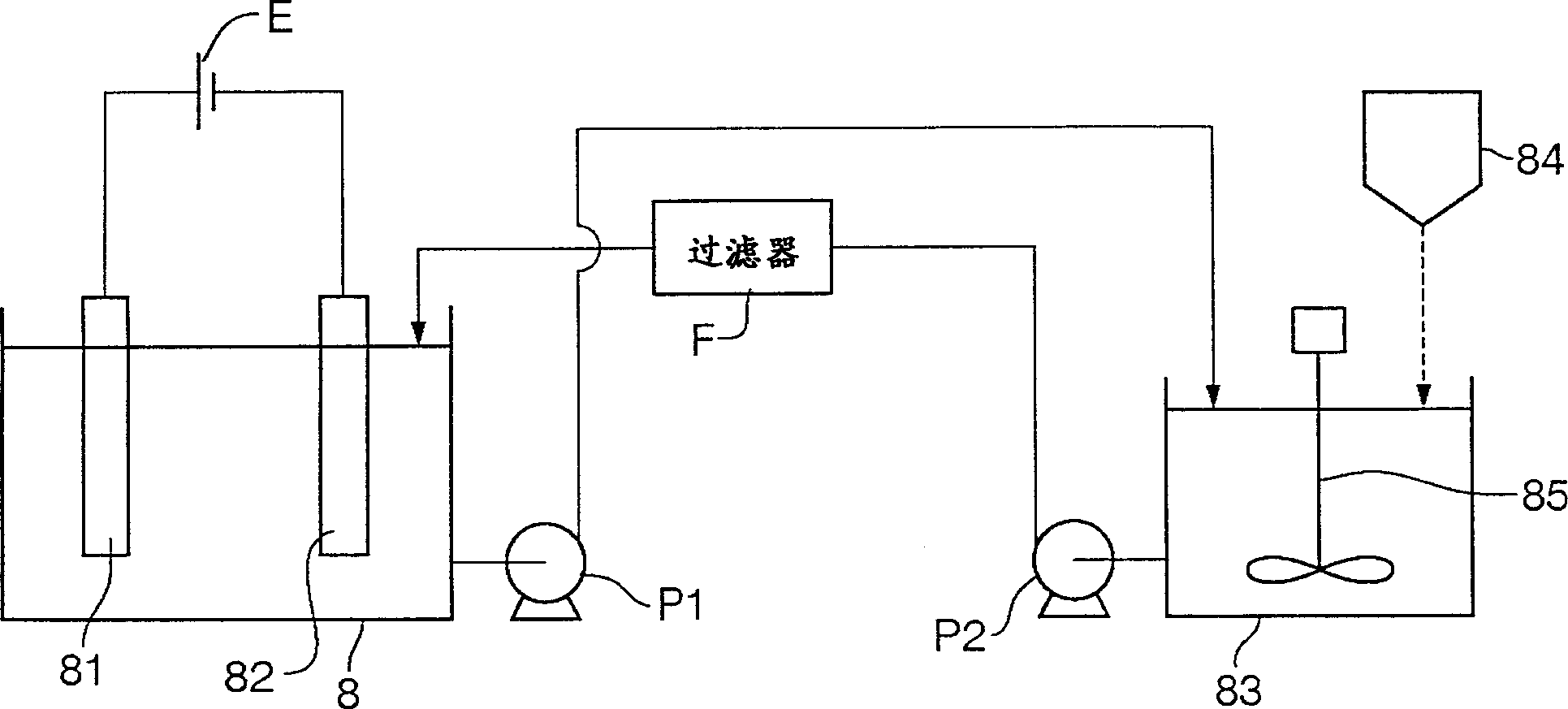

Method used

Image

Examples

example 1-5

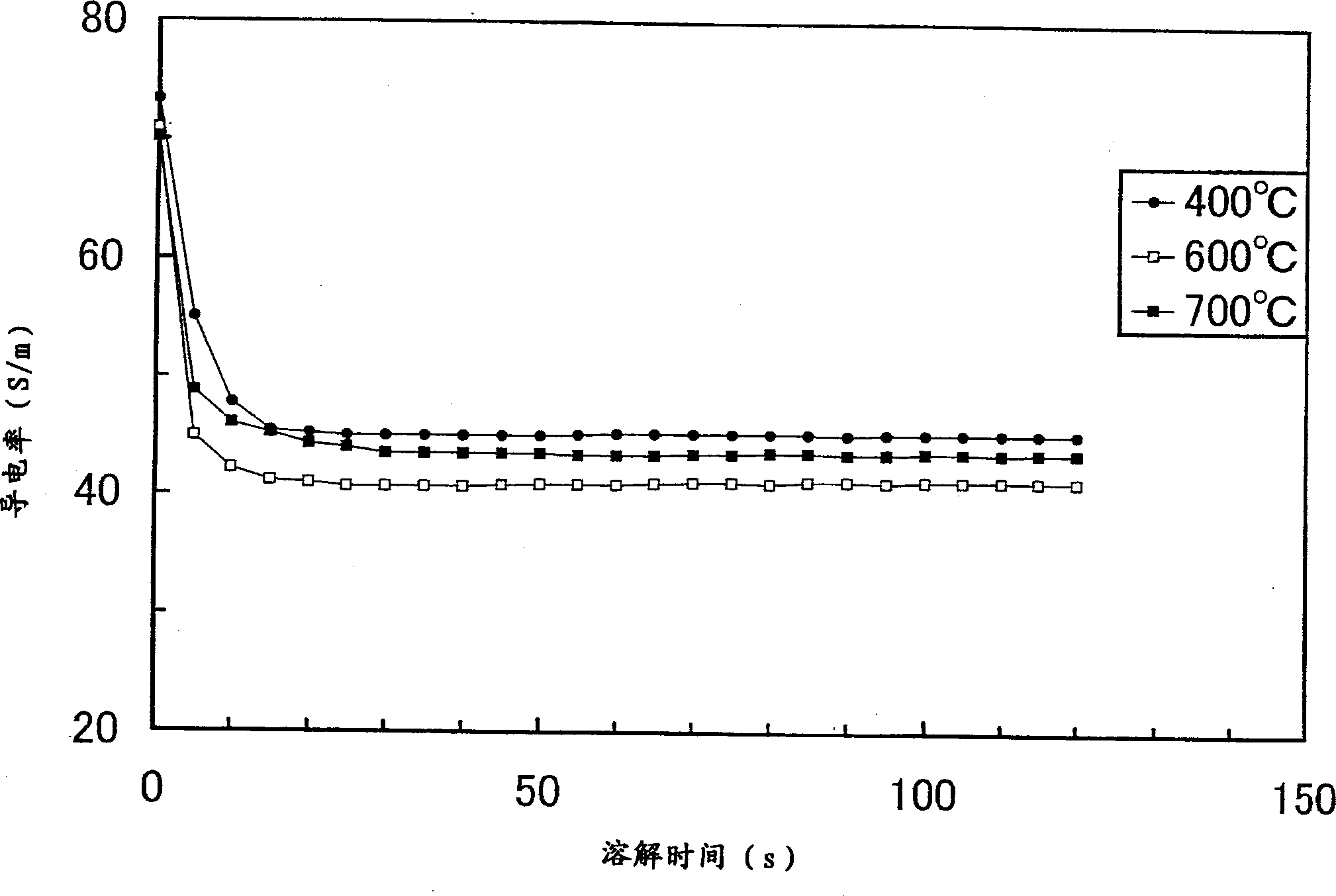

[0057] According to the embodiment described above, the basic copper carbonate is thermally decomposed at 800° C. for about 60 minutes to obtain copper oxide. (comparative example 1)

example 2

[0063] Copper oxide was obtained by thermally decomposing basic copper carbonate at 400° C. for about 60 minutes according to the above embodiment. (Comparative example 2-1)

Embodiment 3

[0070] Washing conditions: add 500g of copper oxide powder to 4500g of water, stir for 10 minutes, filter and wash with water. 500 g of copper oxide powders were washed with 5000 g of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com