Method for continuously preparing high-purity low-chloride electroplating copper oxide

An electroplating grade copper oxide, high-purity technology, used in copper oxide/copper hydroxide and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

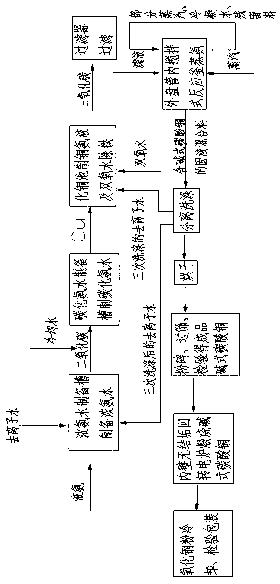

Method used

Image

Examples

Embodiment 1

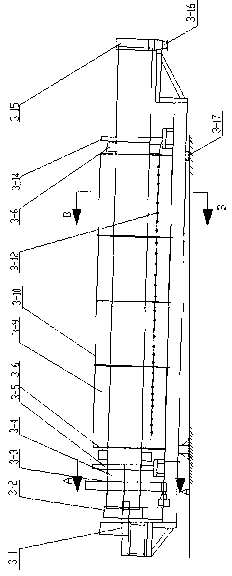

[0049] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity of ≥99.9% as raw materials, the production process using HZD-80 rotary electric furnace calcination is as follows:

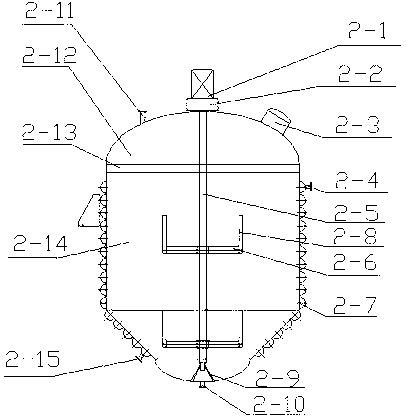

[0050] At 20m 3 Pump 15 meters into the concentrated ammonia preparation tank with cooling coil 3 Deionized water, open the liquid ammonia cylinder valve, make the liquid ammonia pressure into the preparation tank 0.2MPa, and pass ammonia gas for 6 hours to prepare a concentrated ammonia water with a concentration of 135g / L. Close the liquid ammonia cylinder valve; open the preparation tank The valve of the cooling water pipe, which is not connected to the concentrated ammonia water, is fed with cooling water whose temperature is less than 15℃, and then the carbon dioxide cylinder valve is opened to control the carbon dioxide pressure to 0.2MPa and the carbonization degree to 80% to produce carbonic acid. The carbonized ammonia water with the ammonium concentration of 3.18mol / L is...

Embodiment 2

[0055] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity of ≥99.9% as raw materials, the production process using HZD-80 rotary electric furnace calcination is as follows:

[0056] At 20m 3 Of concentrated ammonia preparation tank with cooling coil, pumped 15 meters 3 Deionized water, open the liquid ammonia cylinder valve, make the liquid ammonia pressure into the preparation tank 0.15MPa, and pass ammonia gas for 7 hours to prepare a concentrated ammonia water with a concentration of 120g / L. Close the liquid ammonia cylinder valve; open the preparation tank The valve of the cooling water pipe, which is not connected to the concentrated ammonia water, is fed with cooling water with a temperature of less than 15℃, and then the carbon dioxide cylinder valve is opened to control the pressure of the fed carbon dioxide at 0.15MPa and the degree of carbonization at 100% to produce ammonium carbonate. The carbonized ammonia water with the concentration of 3...

Embodiment 3

[0061] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity of ≥99.9% as raw materials, the production process using HZD-80 rotary electric furnace calcination is as follows:

[0062] At 20m 3 Of concentrated ammonia preparation tank with cooling coil, pumped 15 meters 3 Deionized water, open the liquid ammonia cylinder valve, make the liquid ammonia pressure into the preparation tank 0.1MPa, and pass ammonia gas for 7 hours to prepare a concentrated ammonia water with a concentration of 85g / L. Close the liquid ammonia cylinder valve; open the preparation tank The valve of the cooling water pipe, which is not connected to the concentrated ammonia water, is fed with cooling water with a temperature of less than 15℃, and then the carbon dioxide cylinder valve is opened to control the pressure of the carbon dioxide to be fed at 0.1MPa and the degree of carbonization at 140% to produce carbonic acid Carbonized ammonia water with a concentration of ammonium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com