Preparation method for nano-copper powders

A technology of nano-copper powder and nano-copper oxide, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to separate copper powder, easily blockage of reactors, and pollute the environment, and achieve low cost and high synthesis Simple process steps and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

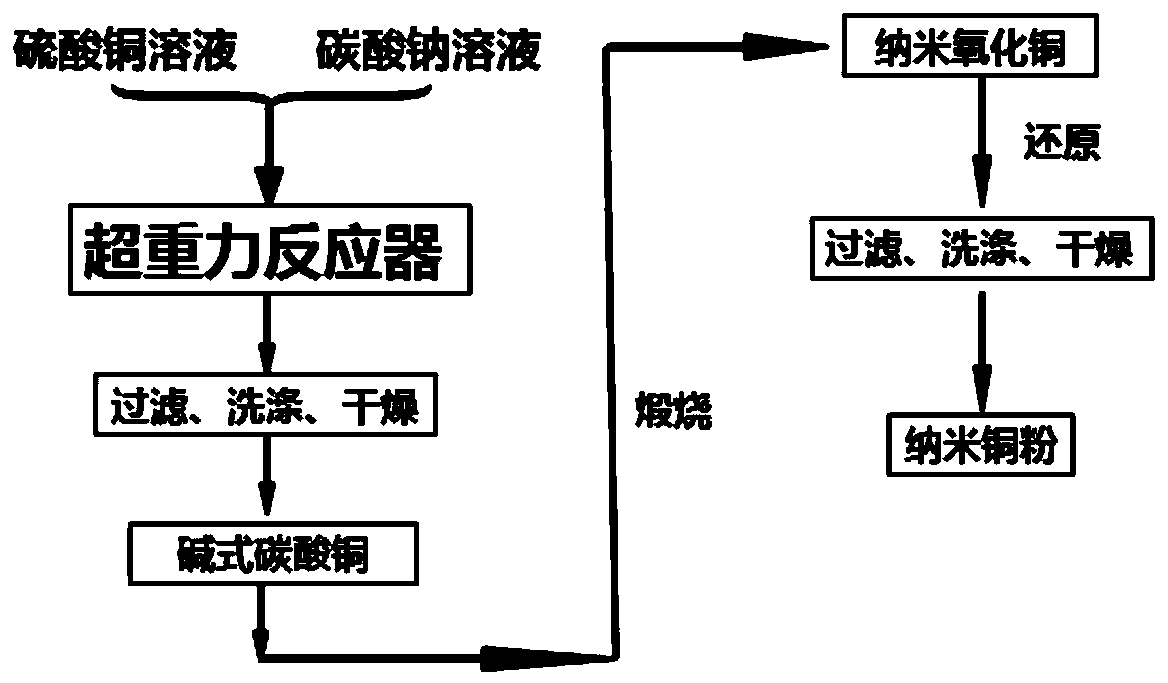

[0045] A preparation method of nano copper powder, comprising the following steps:

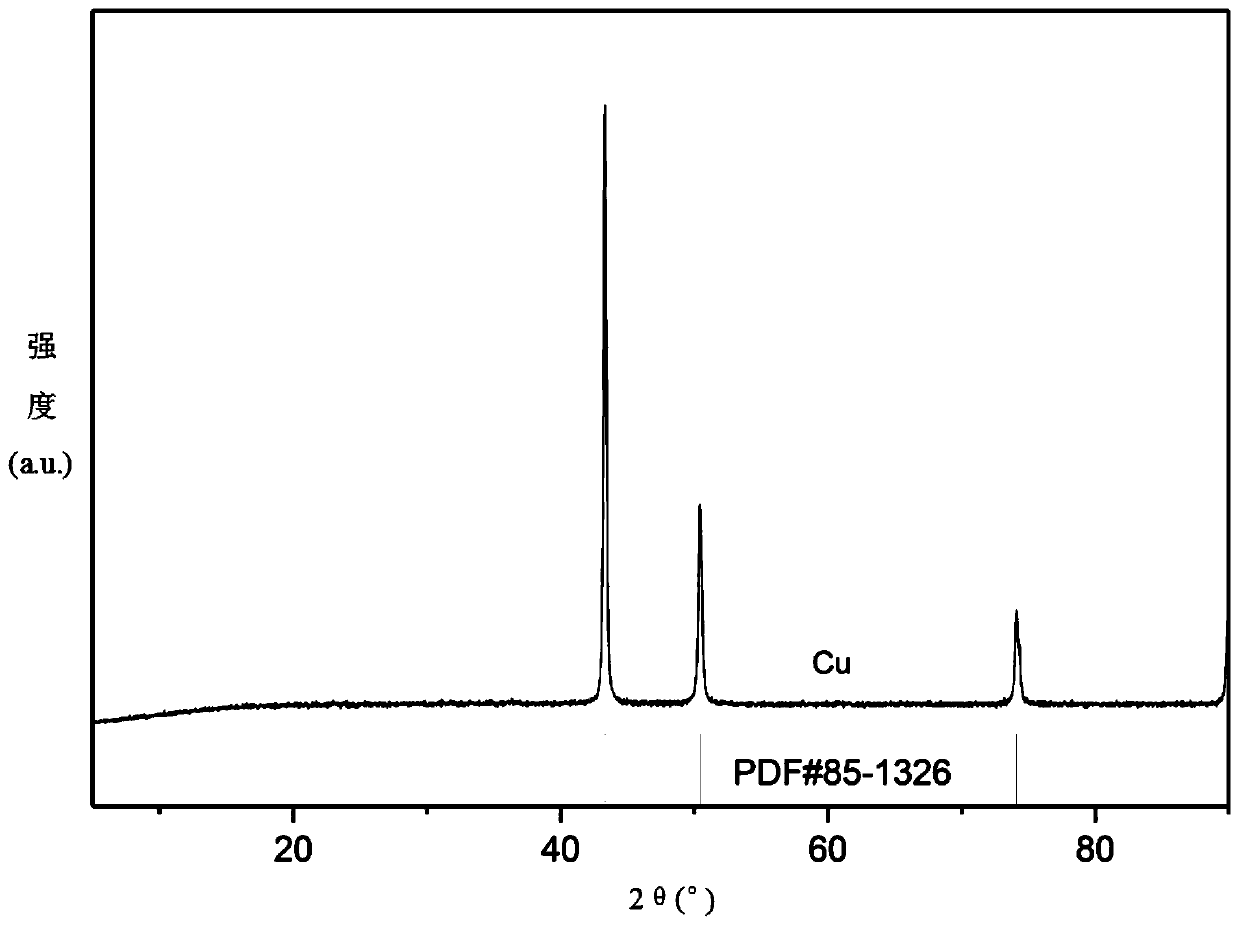

[0046] The first step is to prepare nano-scale basic copper carbonate by precipitation reaction. The specific preparation method is to configure 2L of copper sulfate solution with a concentration of 0.25mol / L, and then configure 2L of sodium carbonate solution with a concentration of 0.30mol / L; Bed supergravity reactor and keep the reactor speed at 1200rmp, then inject copper sulfate solution and sodium carbonate solution into the reactor at the same time at a flow rate of about 0.1L / min respectively, after the reaction solution is injected, and then inject the reaction solution The solution is injected into the reactor and circulated for a period of time. After the reaction, the reaction solution is filtered sequentially, washed 4 to 6 times, and the sodium sulfate is washed out, and then dried in a blast drying oven at 100°C for about 12 hours to obtain nano Grade granular basic copper carbo...

Embodiment 2

[0050] Same as Example 1, the difference is that 20% ethylene glycol is added as a dispersant (surfactant) in the reaction solution of the first step.

Embodiment 3

[0052] Same as Example 1, the difference is that 10% polyethylene glycol is added as a dispersant (surfactant) in the reaction solution of the first step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com